Patents

Literature

108results about "Fluorine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High dose implantation strip (HDIS) in h2 base chemistry

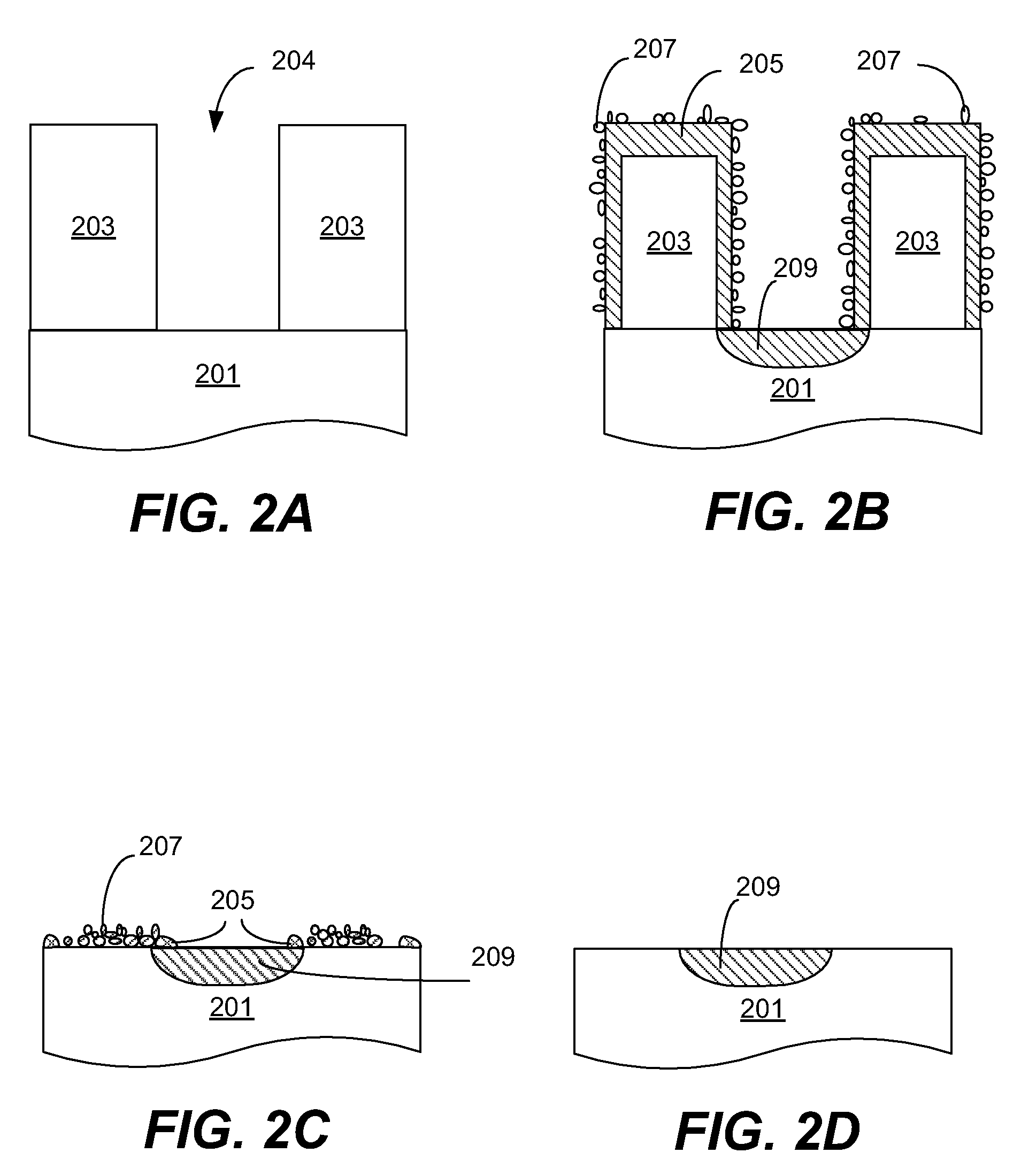

Plasma is generated using elemental hydrogen, a weak oxidizing agent, and a fluorine containing gas. An inert gas is introduced to the plasma downstream of the plasma source and upstream of a showerhead that directs gas mixture into the reaction chamber where the mixture reacts with the high-dose implant resist. The process removes both the crust and bulk resist layers at a high strip rate, and leaves the work piece surface substantially residue free with low silicon loss.

Owner:NOVELLUS SYSTEMS

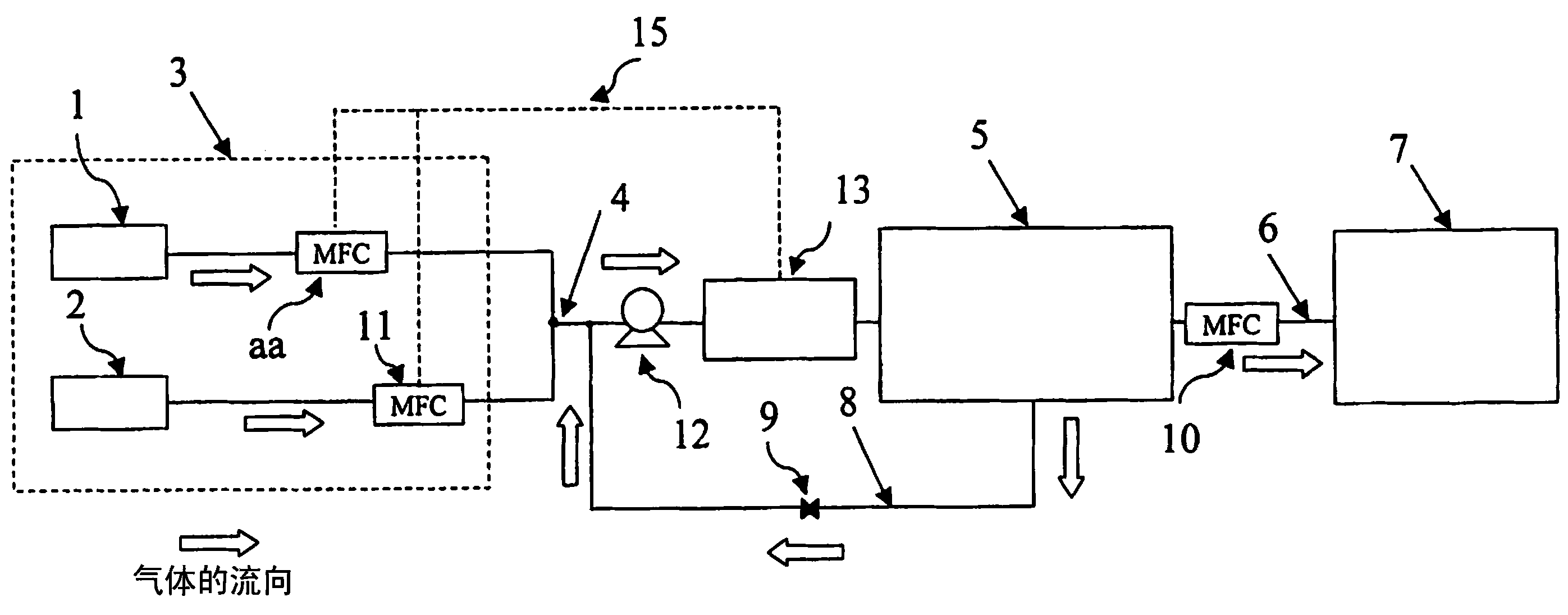

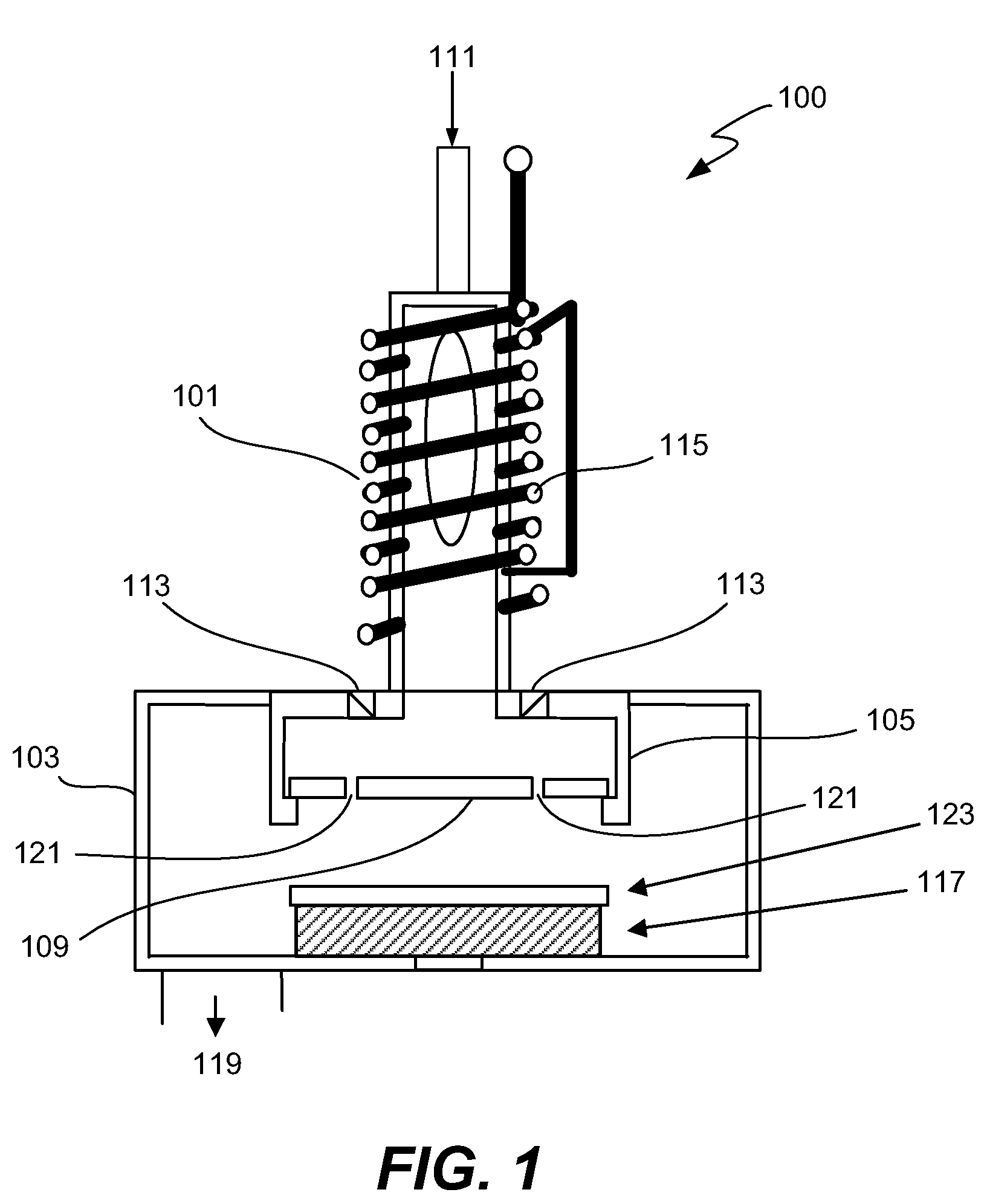

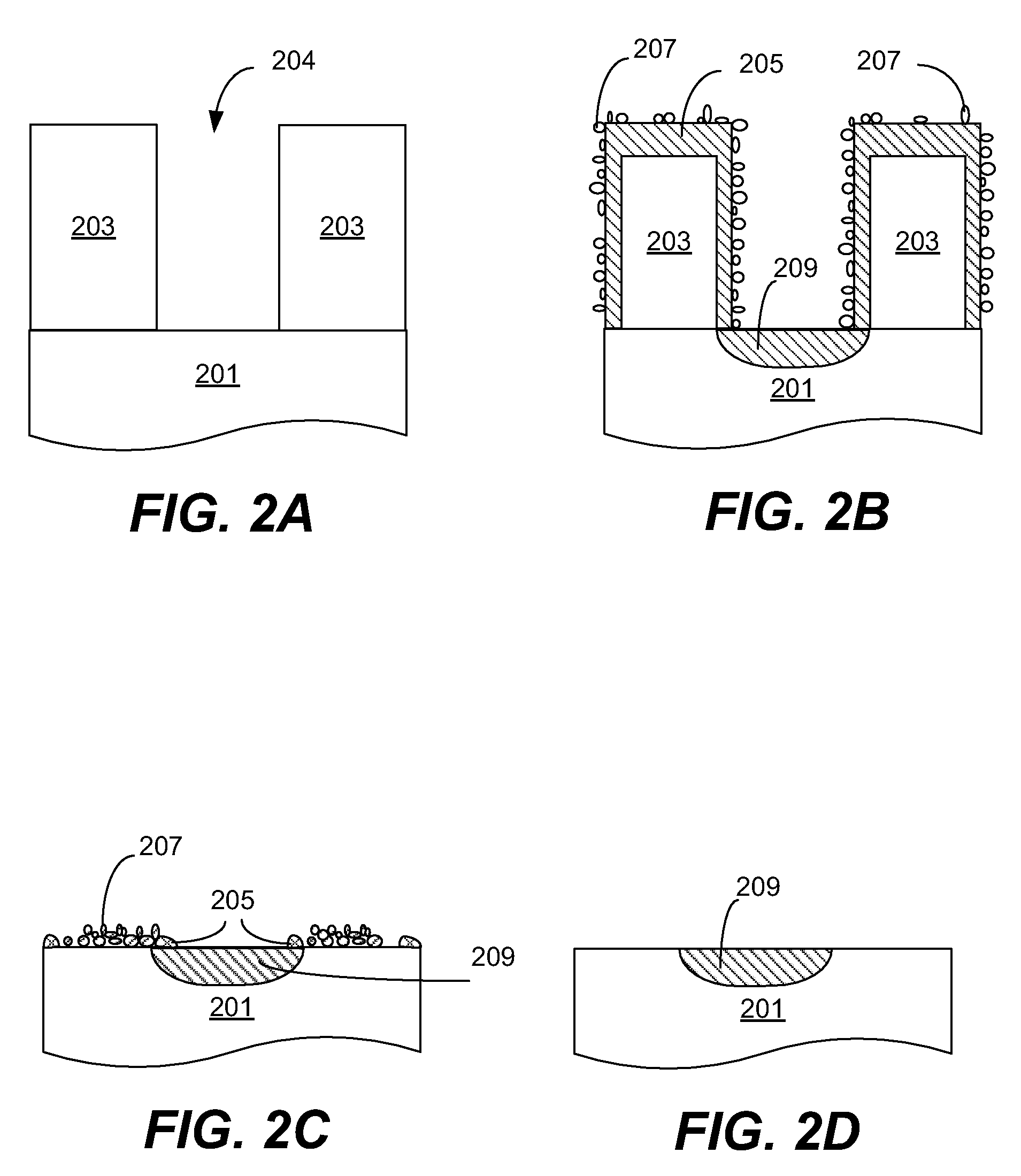

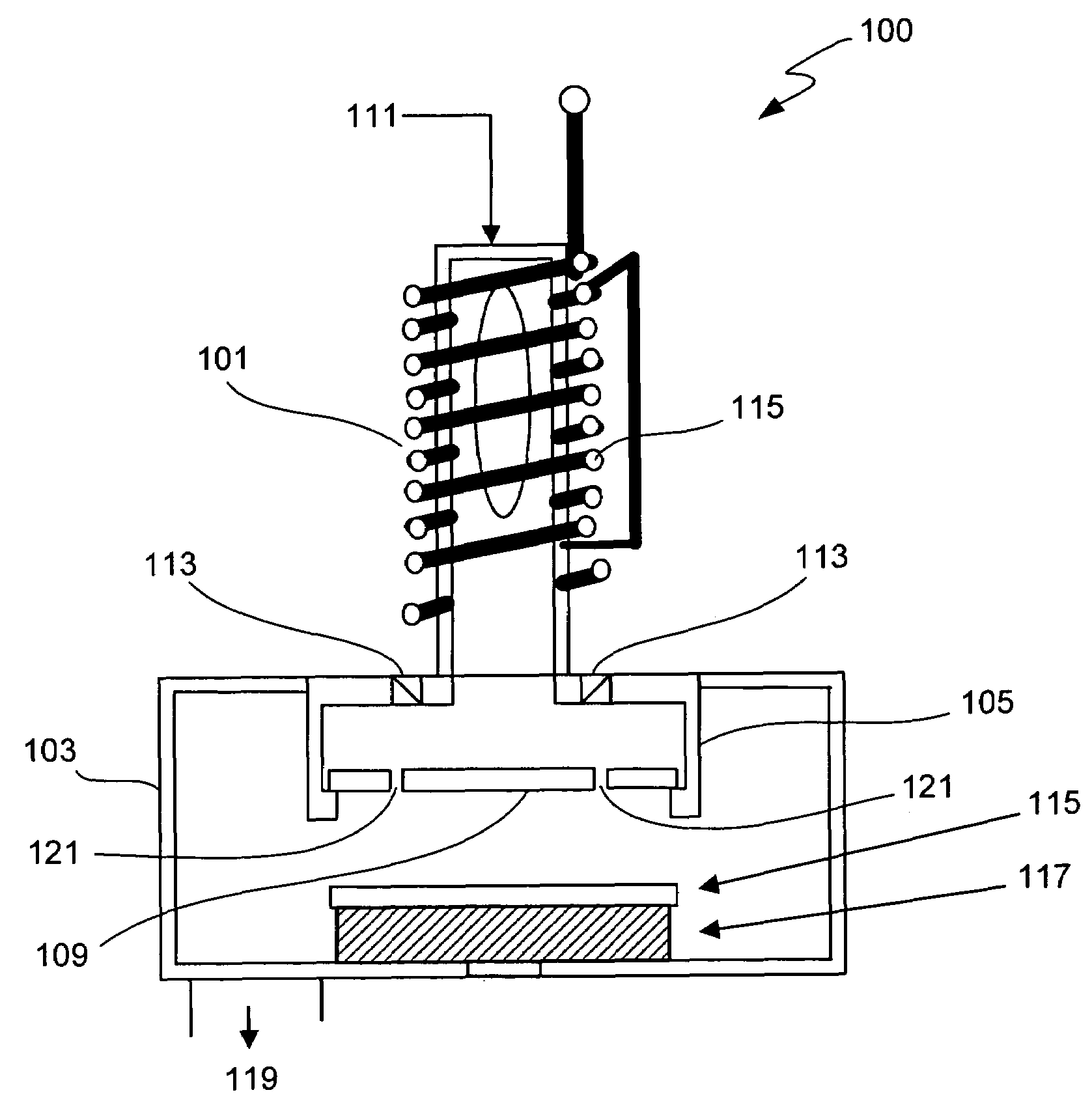

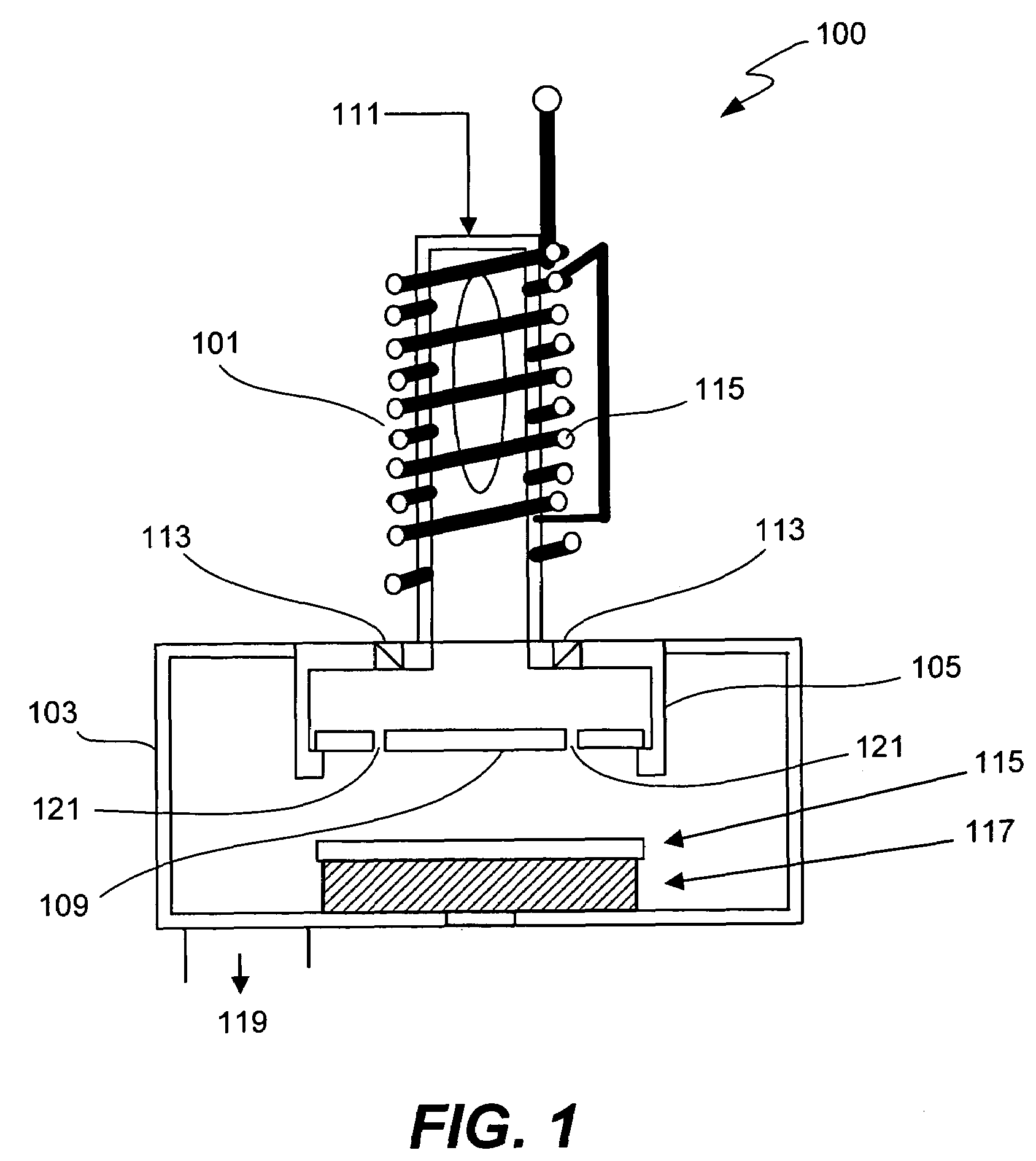

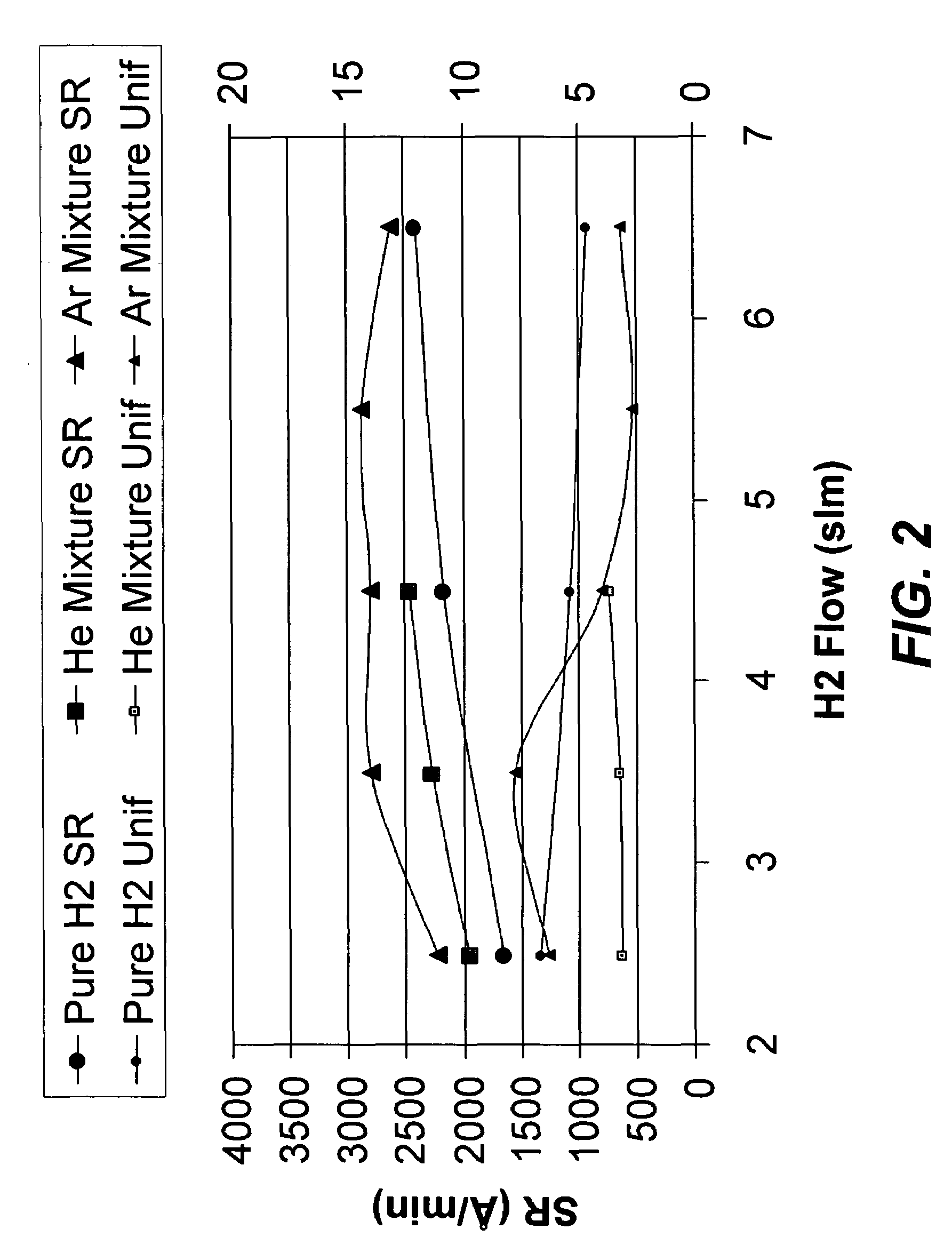

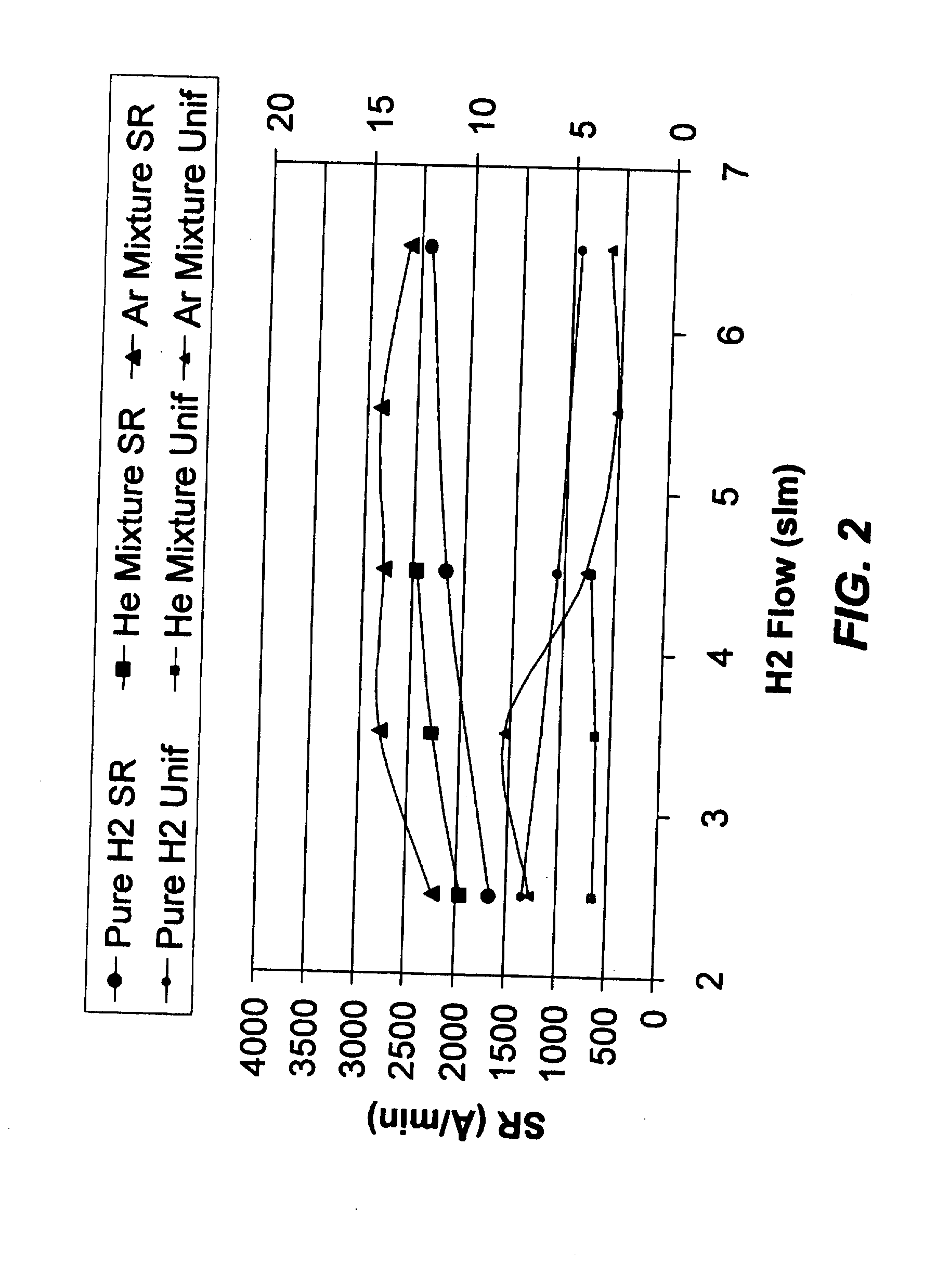

Enhanced stripping of low-k films using downstream gas mixing

ActiveUS7202176B1Reducing required hydrogen flow rateImprove stripping rateHydrogenElectric discharge tubesResistHydrogen

The present invention pertains to methods for removing unwanted material from a work piece. More specifically, the invention pertains to stripping photo-resist material and removing etch-related residues from a semiconductor wafer during semiconductor manufacturing. Methods involve implementing a hydrogen plasma operation with downstream mixing with an inert gas. The invention is effective at stripping photo-resist and removing residues from low-k dielectric material used in Damascene devices.

Owner:NOVELLUS SYSTEMS

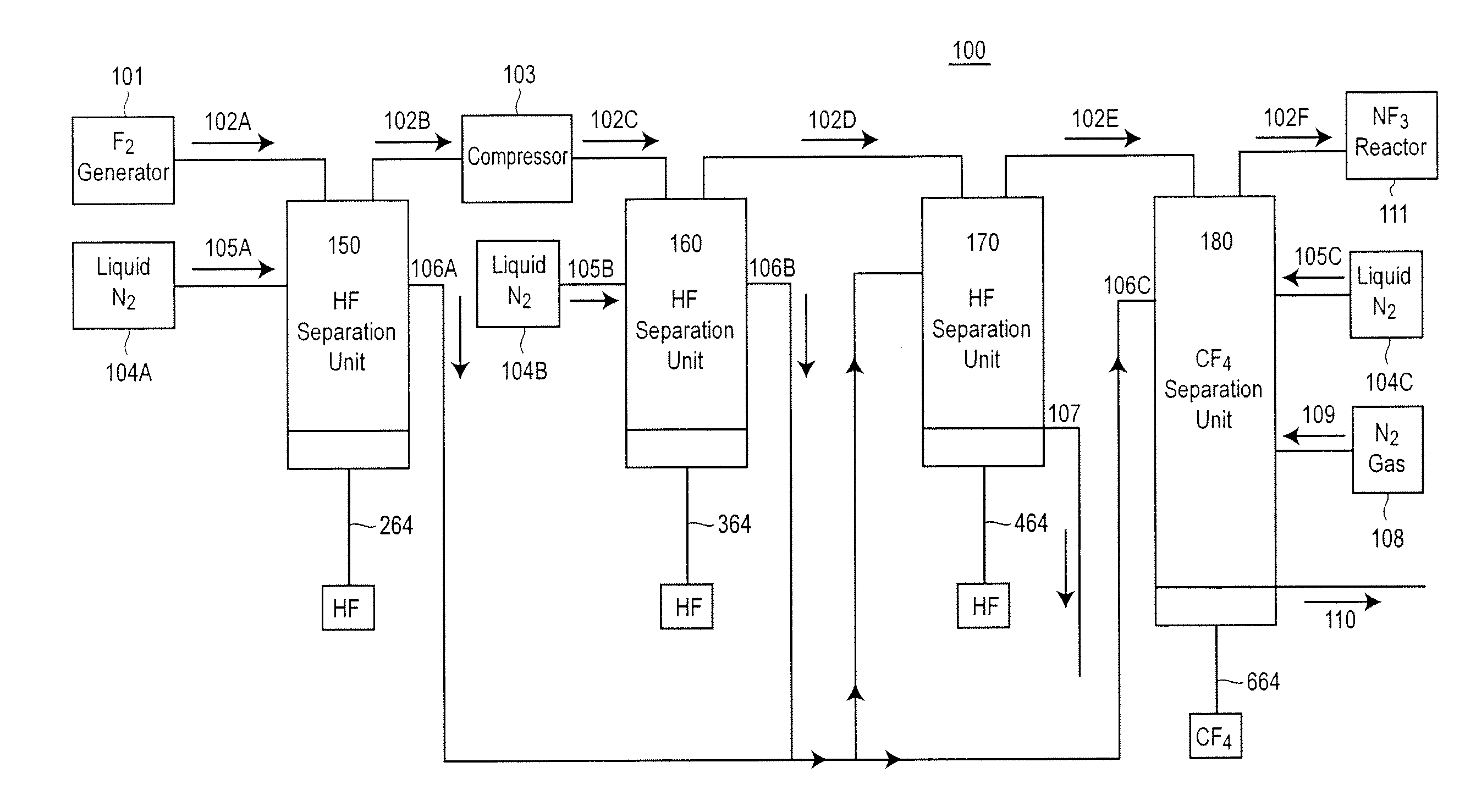

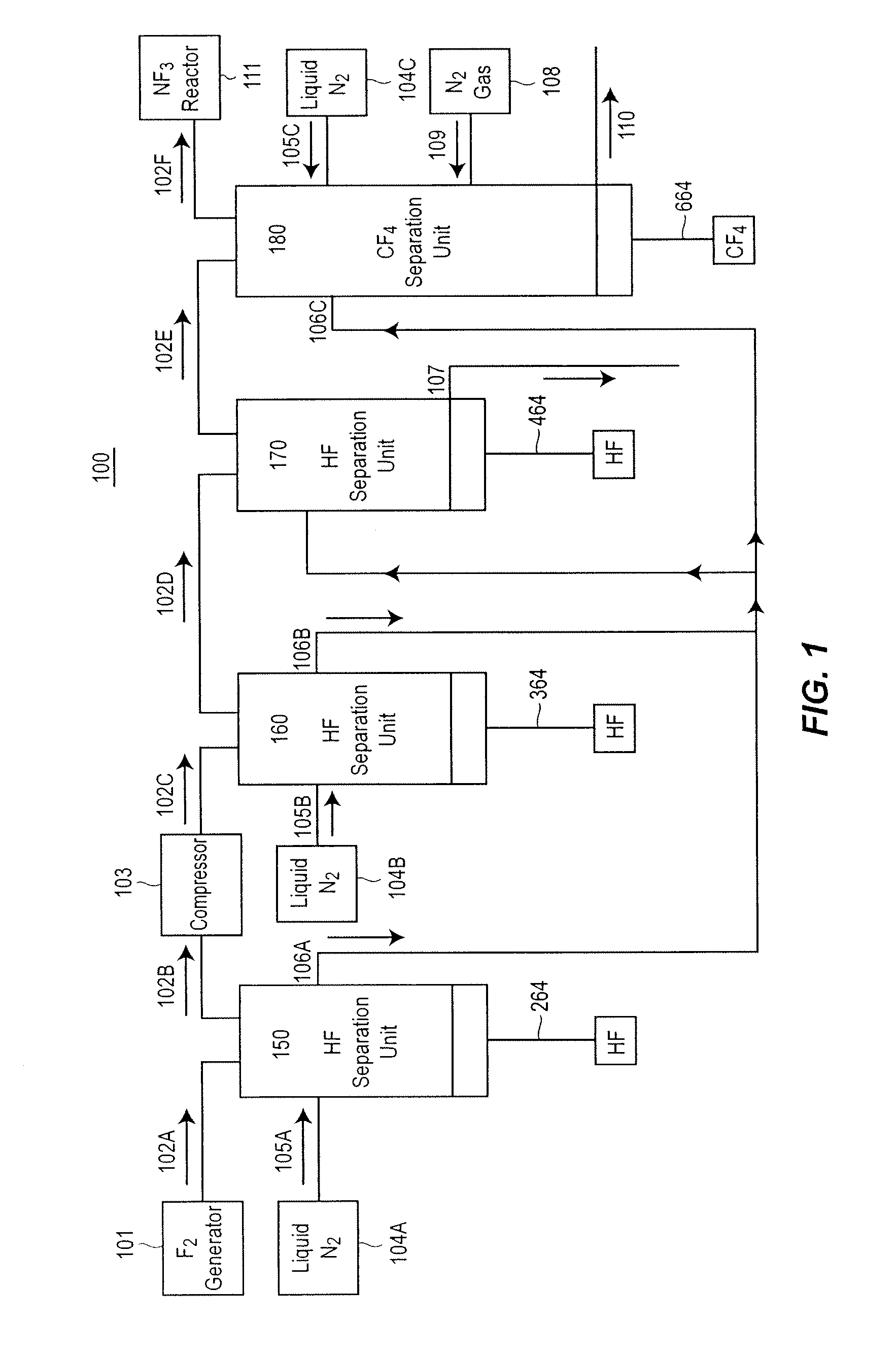

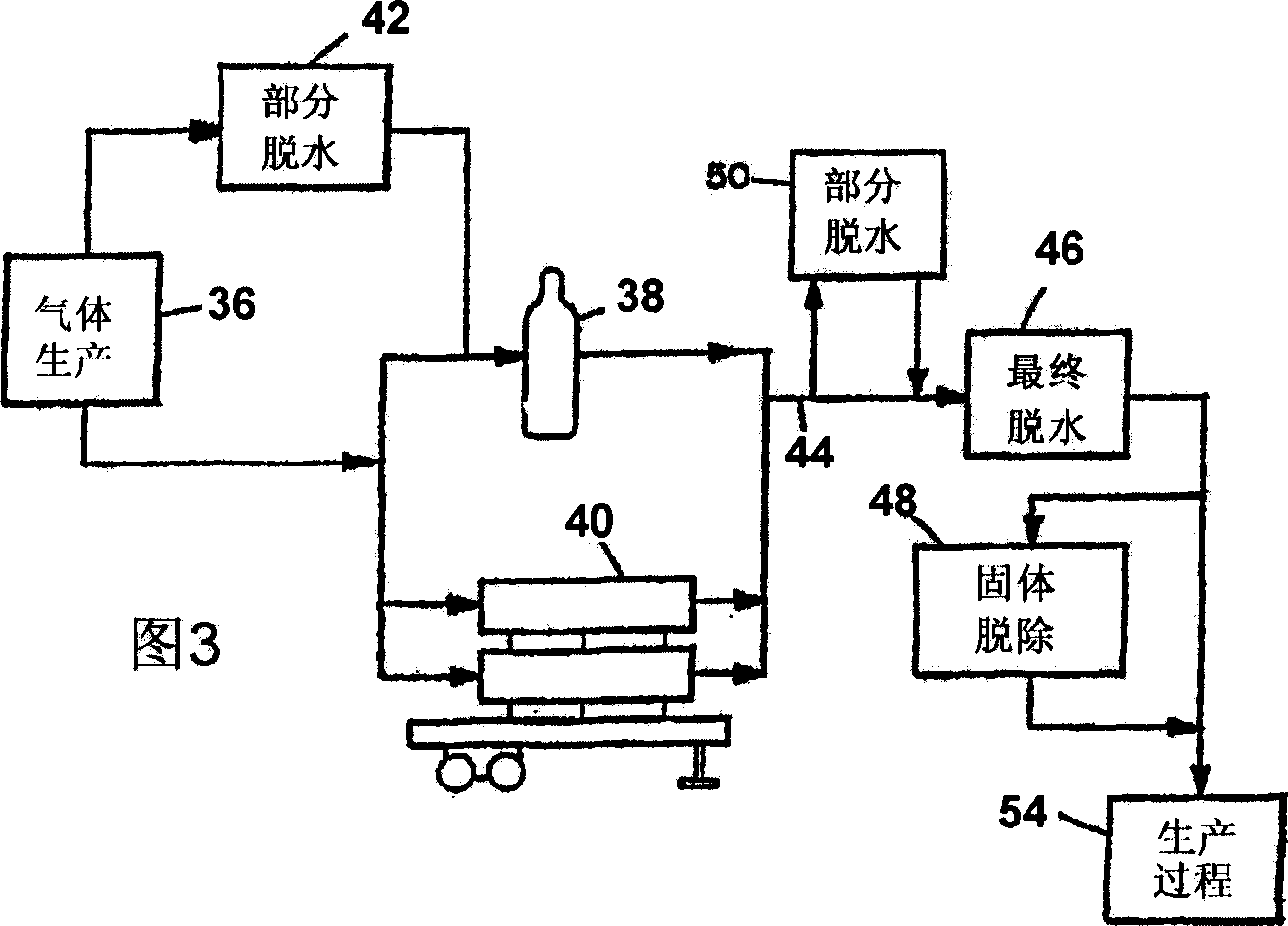

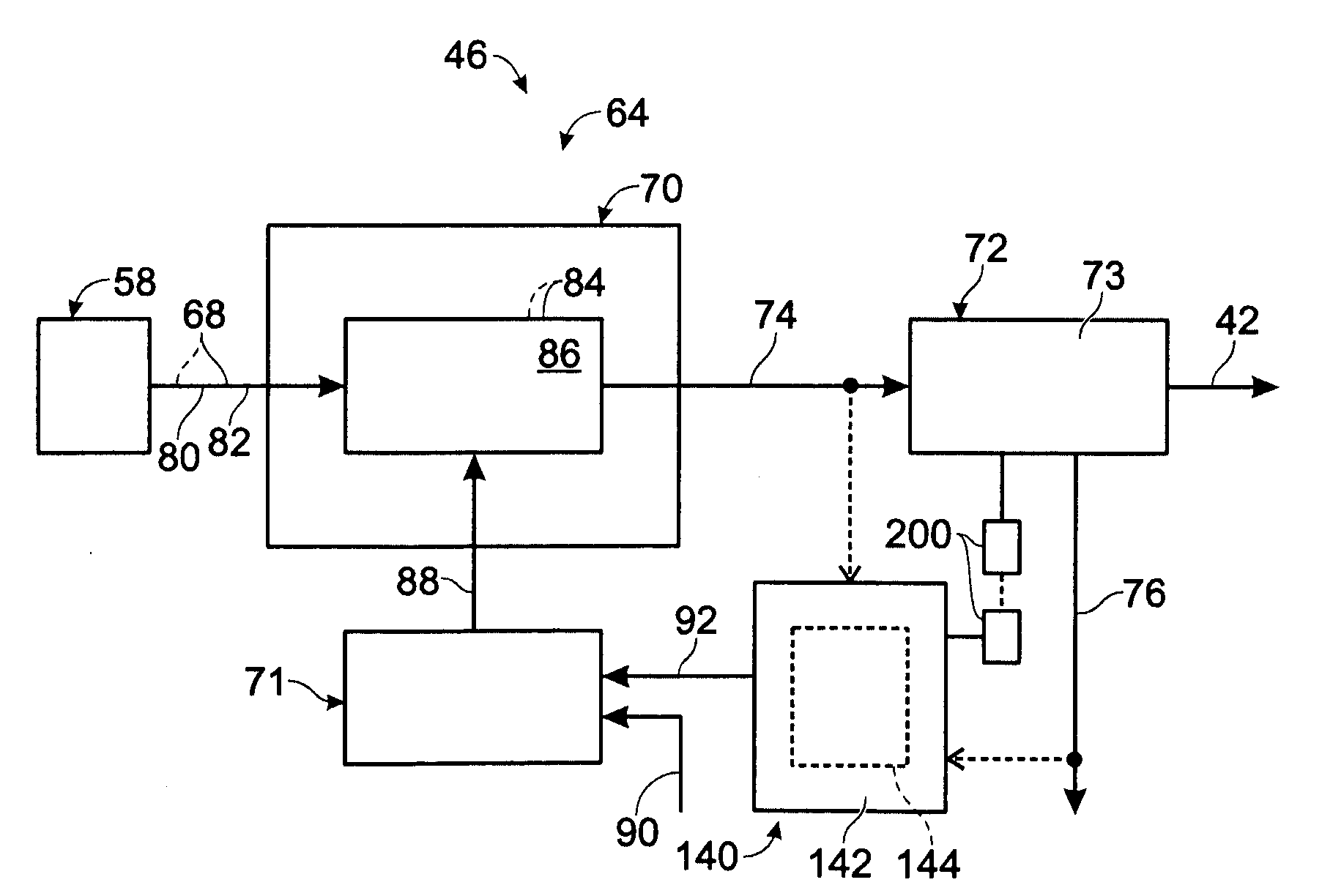

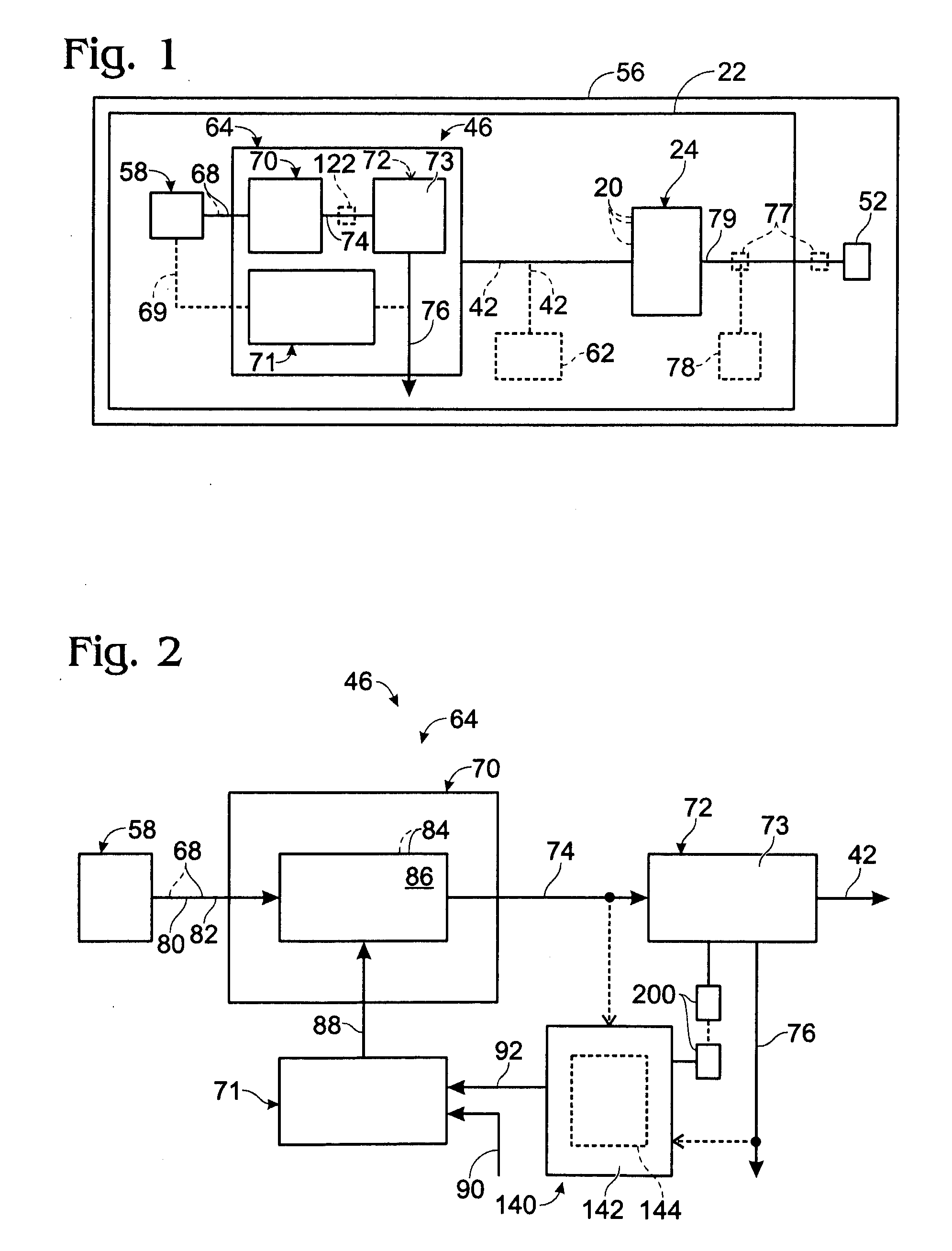

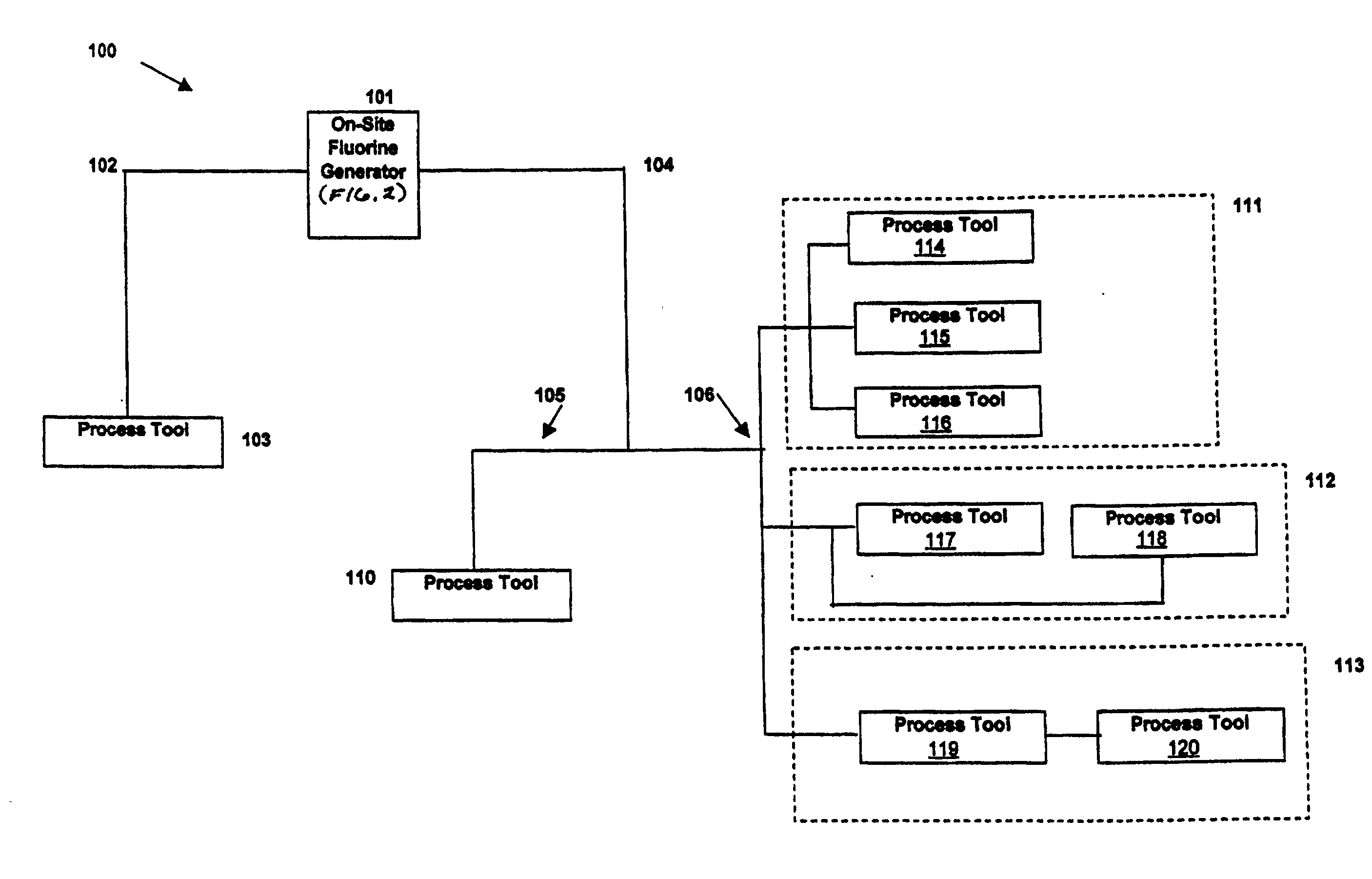

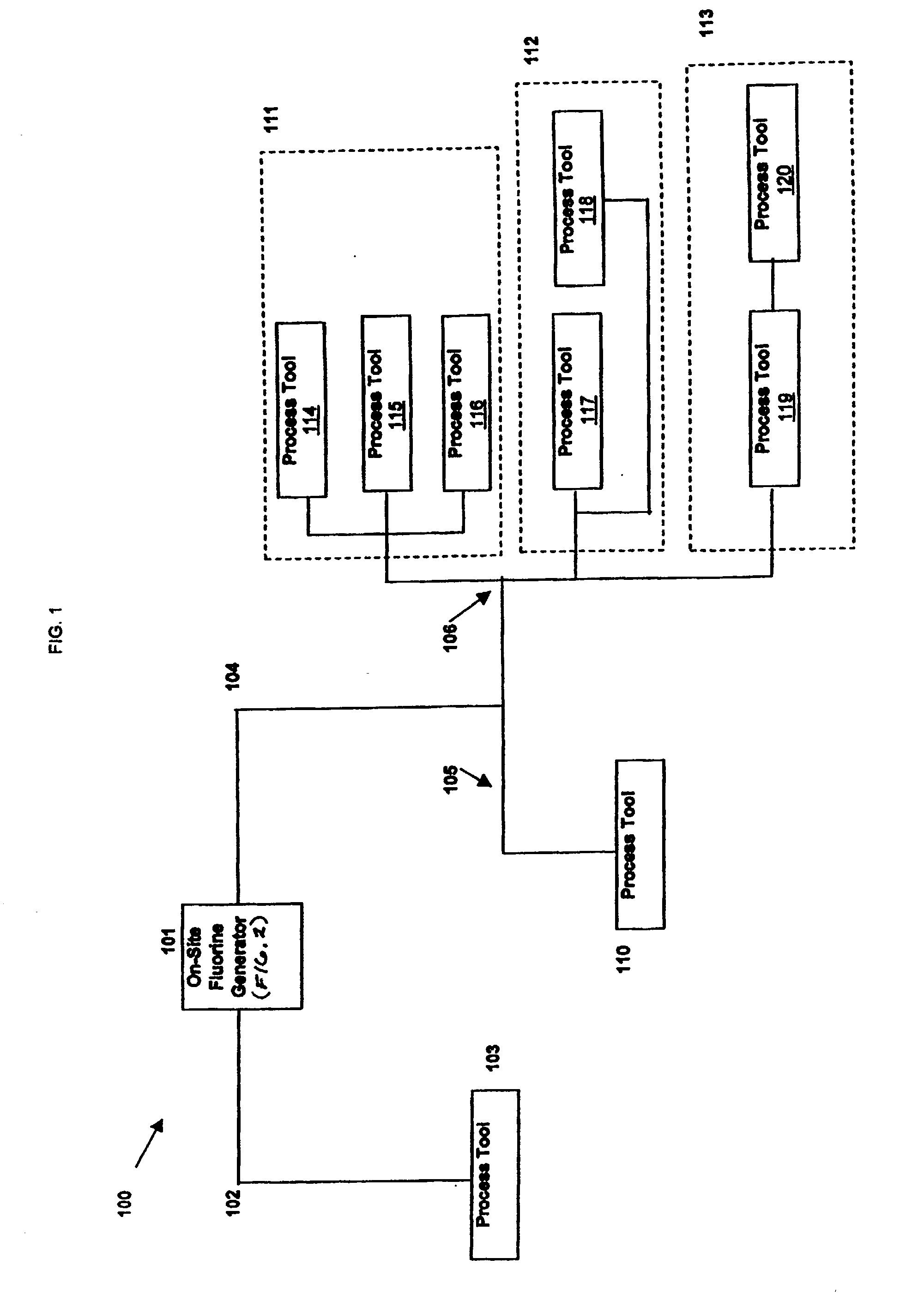

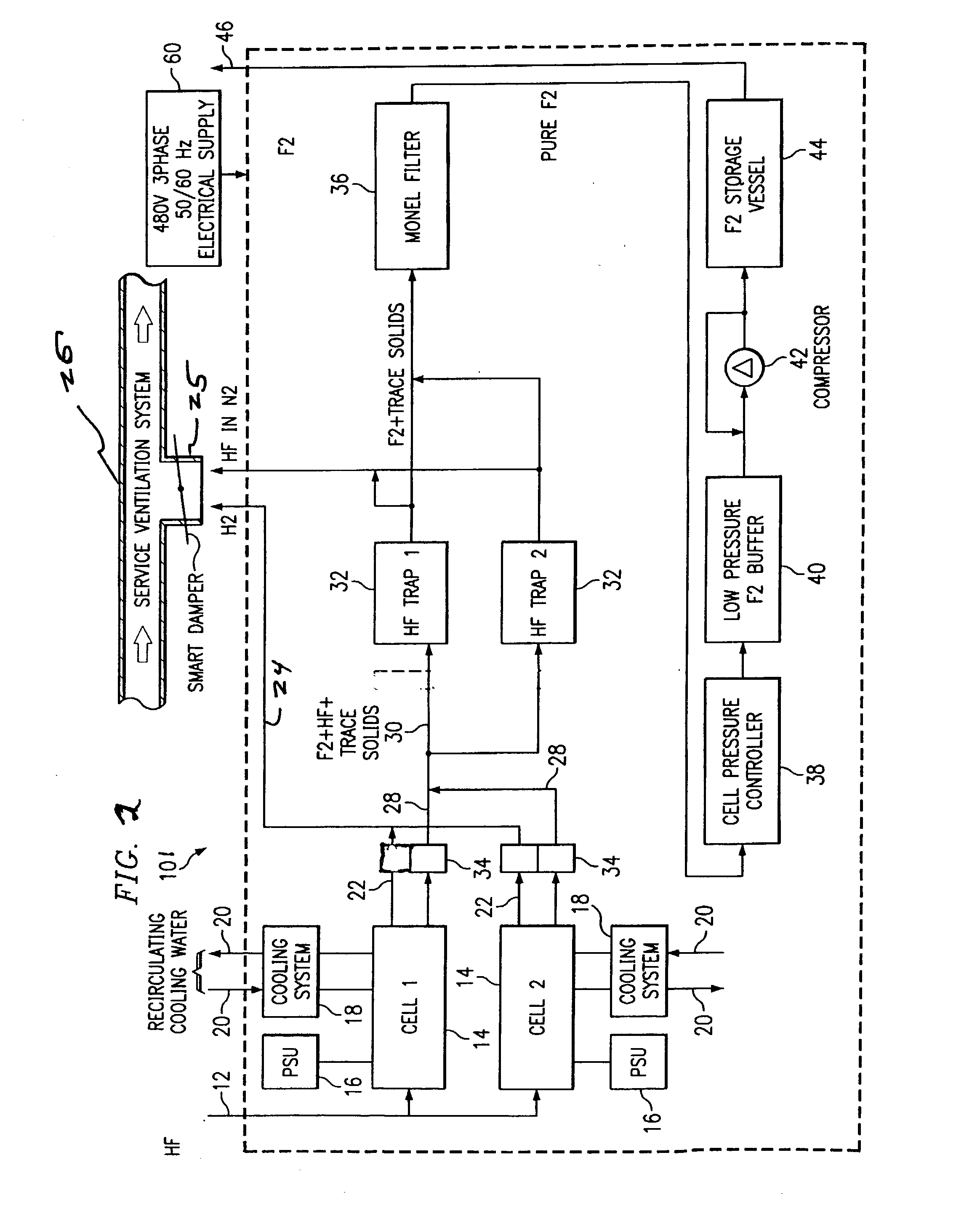

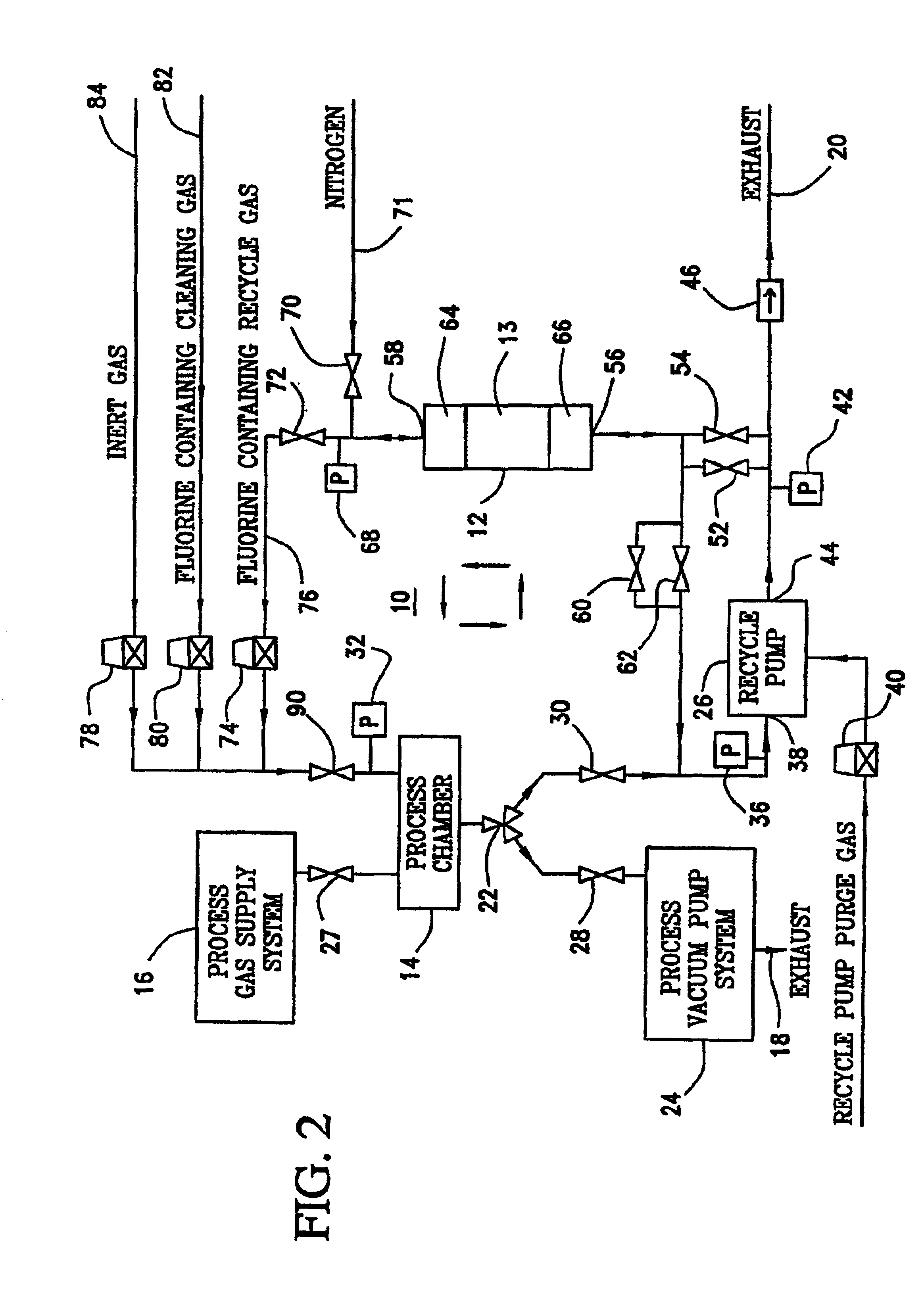

Generation and distribution of molecular fluorine within a fabrication facility

Molecular fluorine may be generated and distributed on-site at a fabrication facility. A molecular fluorine generator may come in a variety of sizes to fit better the needs of the particular fabrication facility. The generator may service one process tool, a plurality of process tool along a process bay, the entire fabrication facility, or nearly any other configuration within the facility. The process can obviate the need and inherent risks with transporting or handling gas cylinders. The process can be used in conjunction with a cleaning or fabrication operation used in the electronics fabrication industry.

Owner:FLUORINE ON CALL

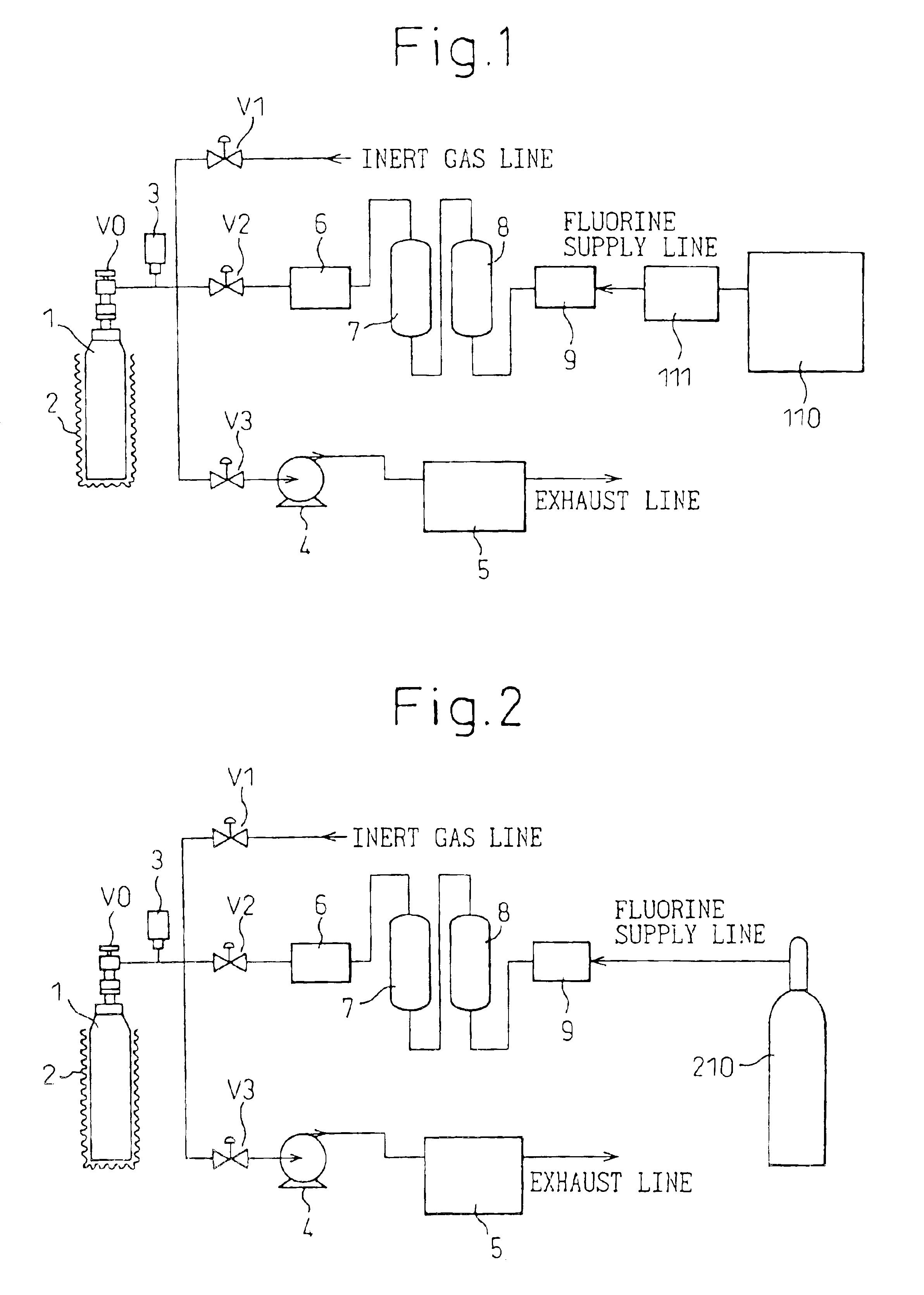

High-purity fluorine gas, production and use thereof, and method for analyzing trace impurities in high-purity fluorine gas

InactiveUS20040028600A1Reduced corrosion resistanceAvoid pollutionLaser detailsComponent separationHydrogen fluorideInternal pressure

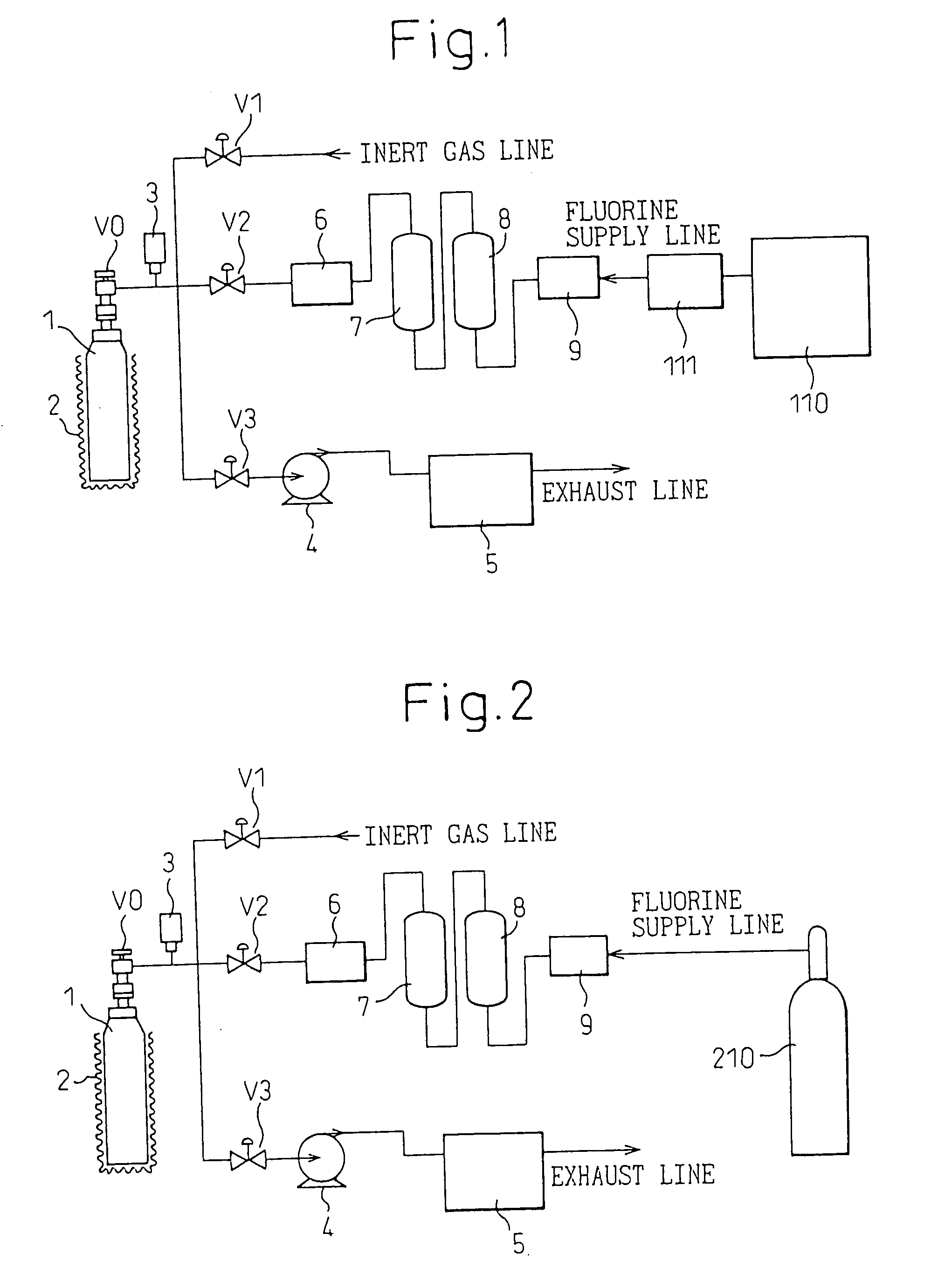

A step (1) of heating a fluoronickel compound to release a fluorine gas, a step (2) of allowing a fluorine gas to be occluded into a fluorinated compound, and a step (3) of heating the fluoronickel compound and reducing an inner pressure are conducted in a container, respectively, at least once, and thereafter a high-purity fluorine gas is obtained in the step (1). Also, a step (5) of heating a fluoronickel compound and reducing an inner pressure and a step (6) of allowing a fluorine gas reduced in a hydrogen fluoride content to be occluded into the fluoronickel compound are conducted in a container having a fluorinated layer formed on its surface, respectively, at least once, the step (5) is further conducted, and thereafter a fluorine gas containing impurity gases is contacted with the fluoronickel compound to fix and remove the fluorine gas, and the impurities are analyzed by gas chromatography.

Owner:SHOWA DENKO KK

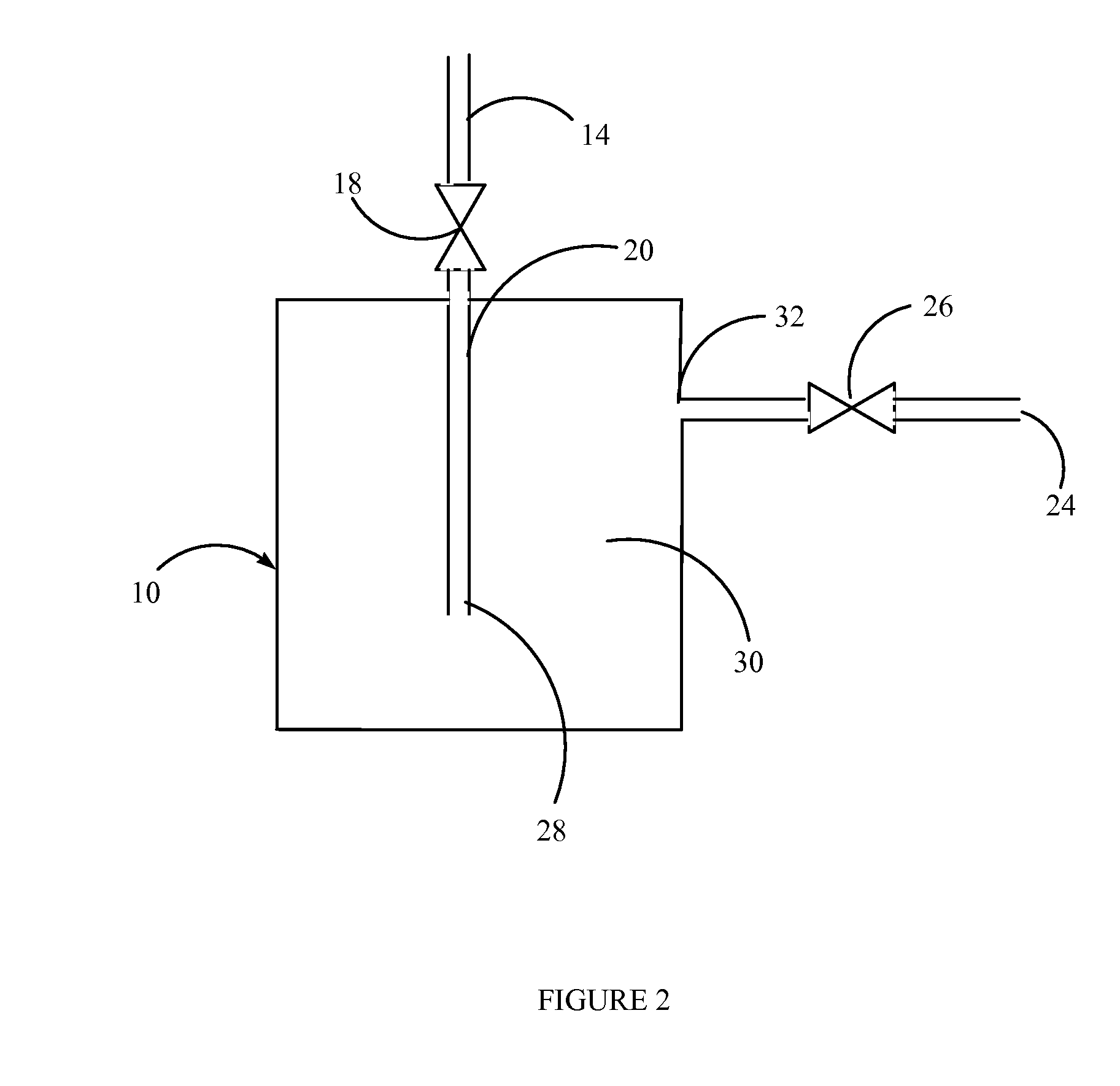

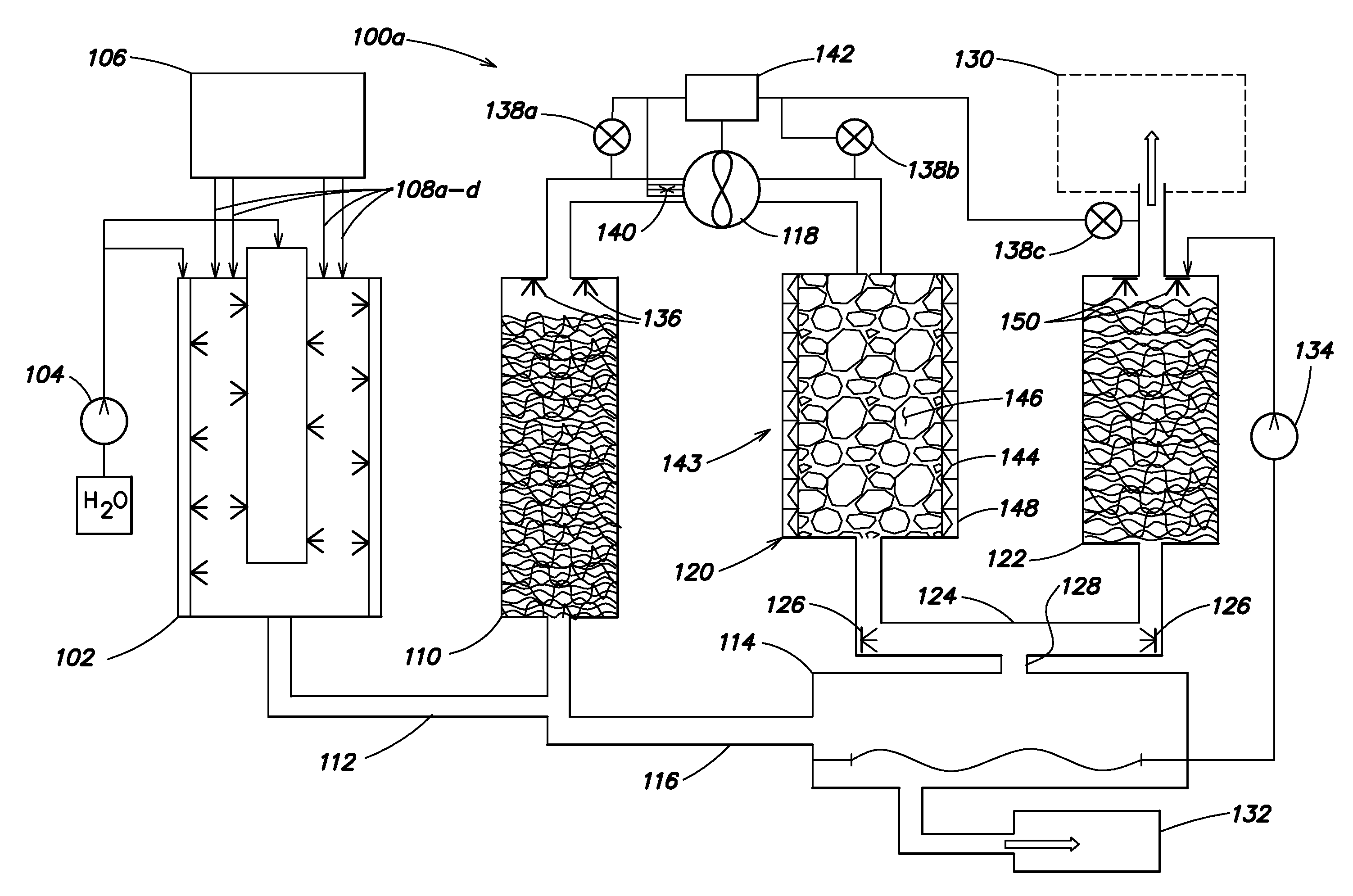

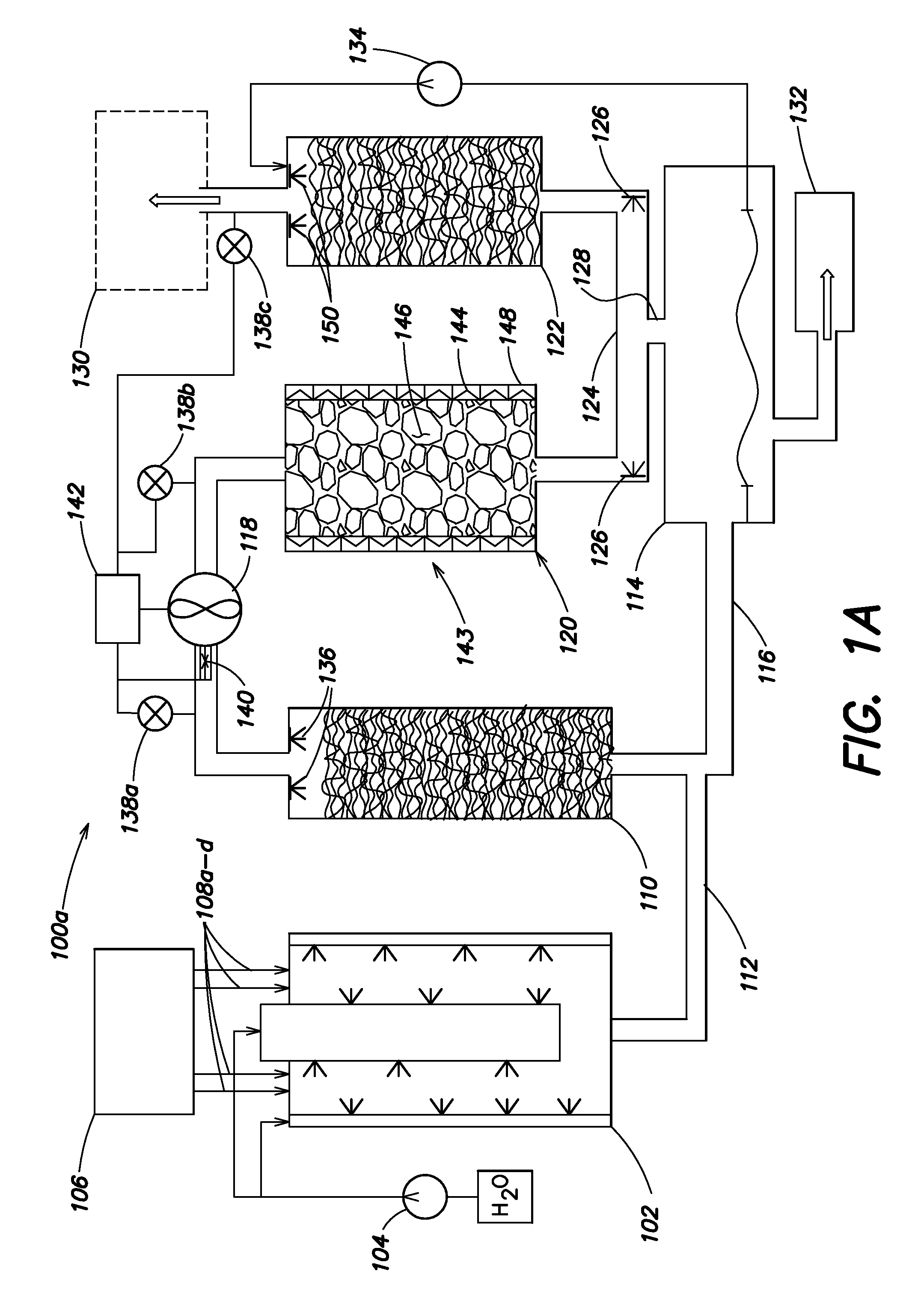

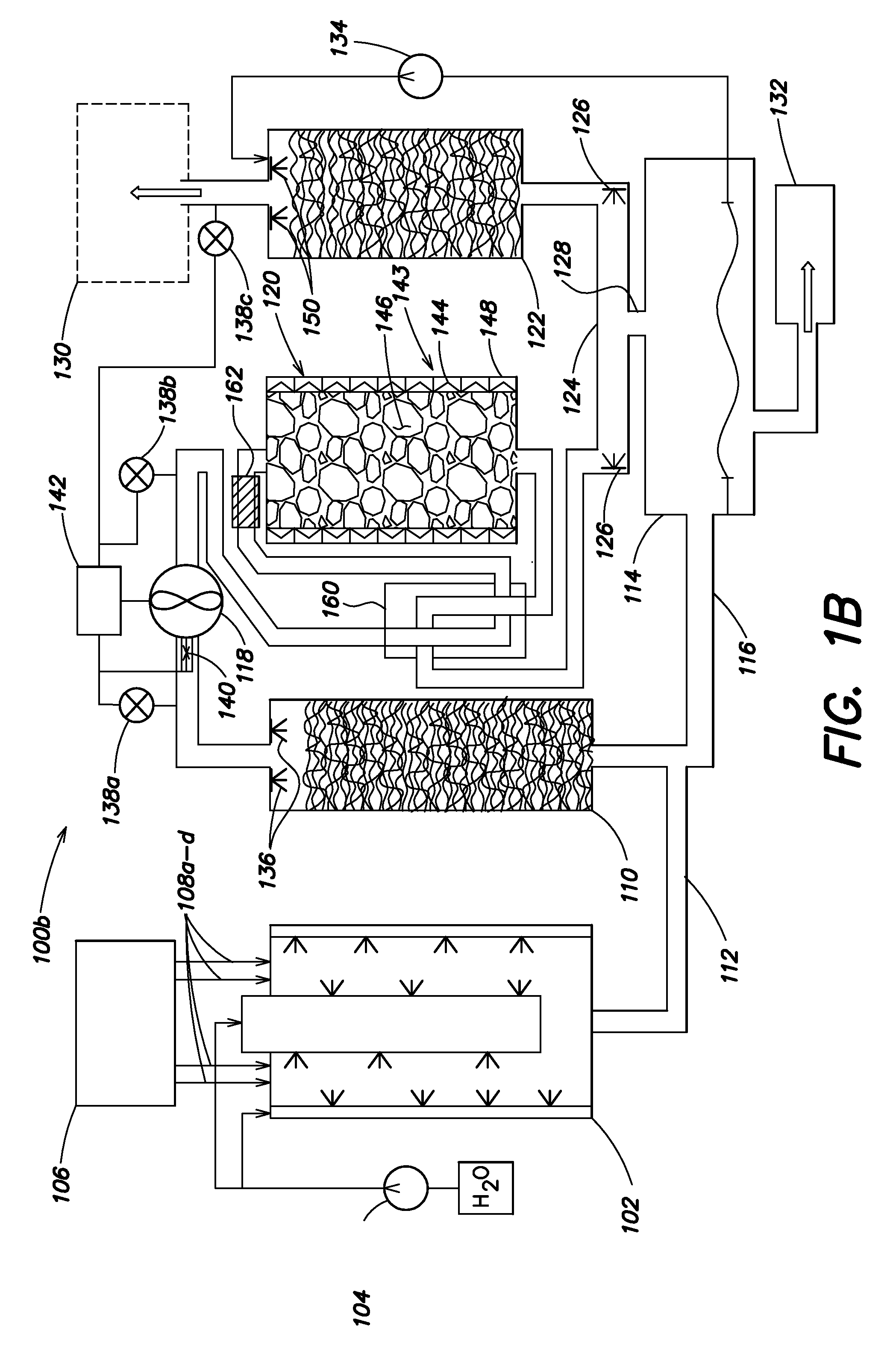

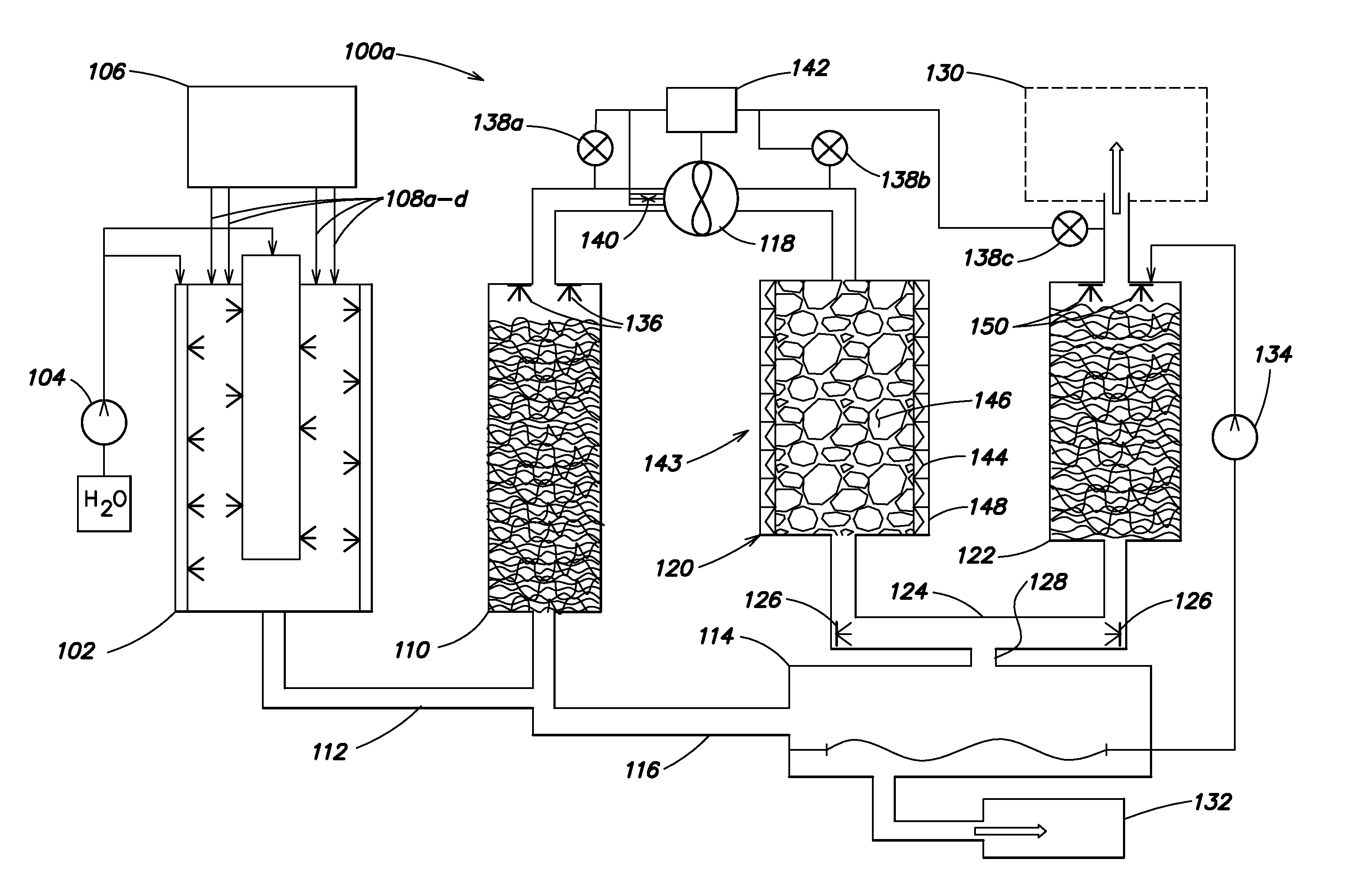

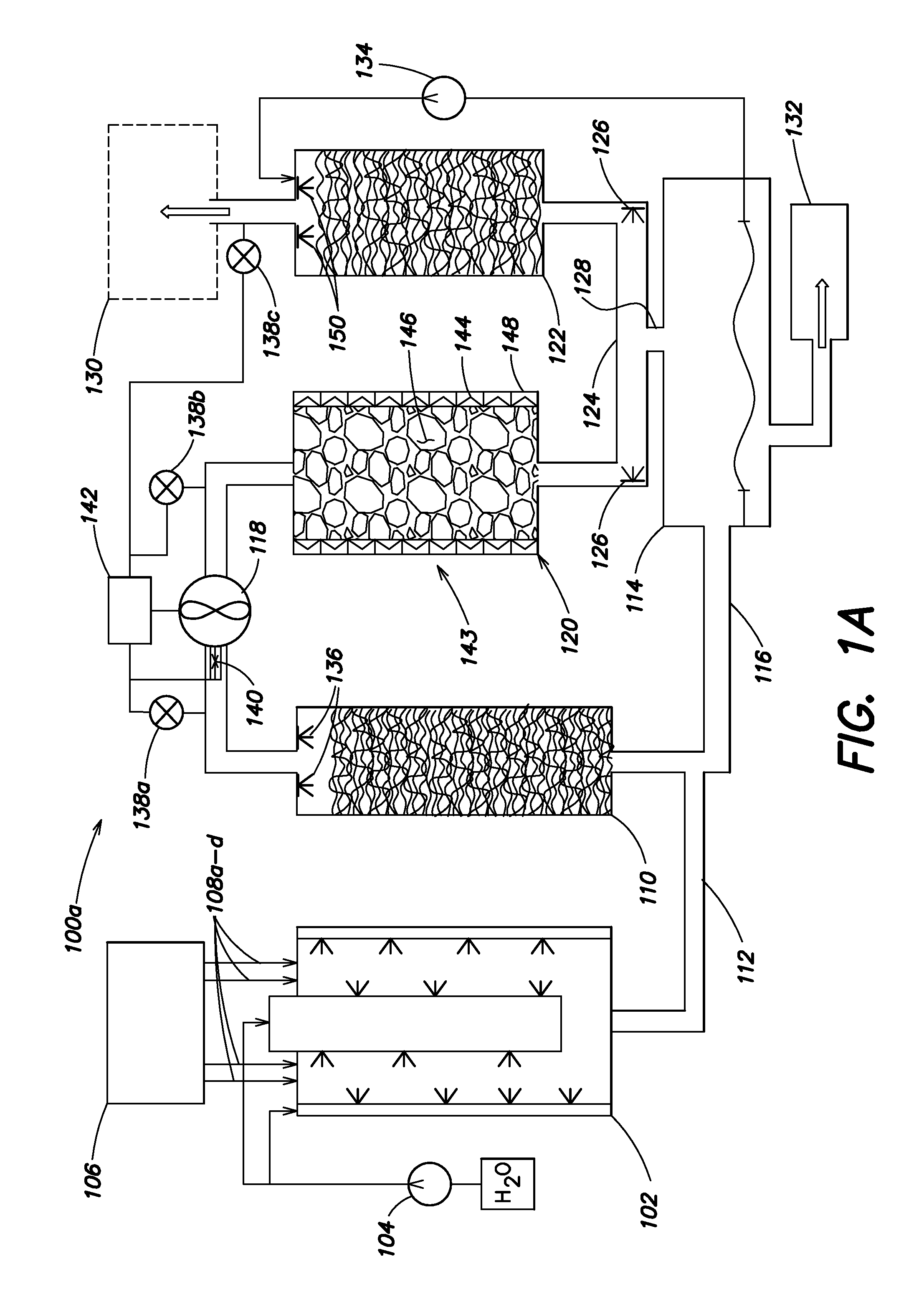

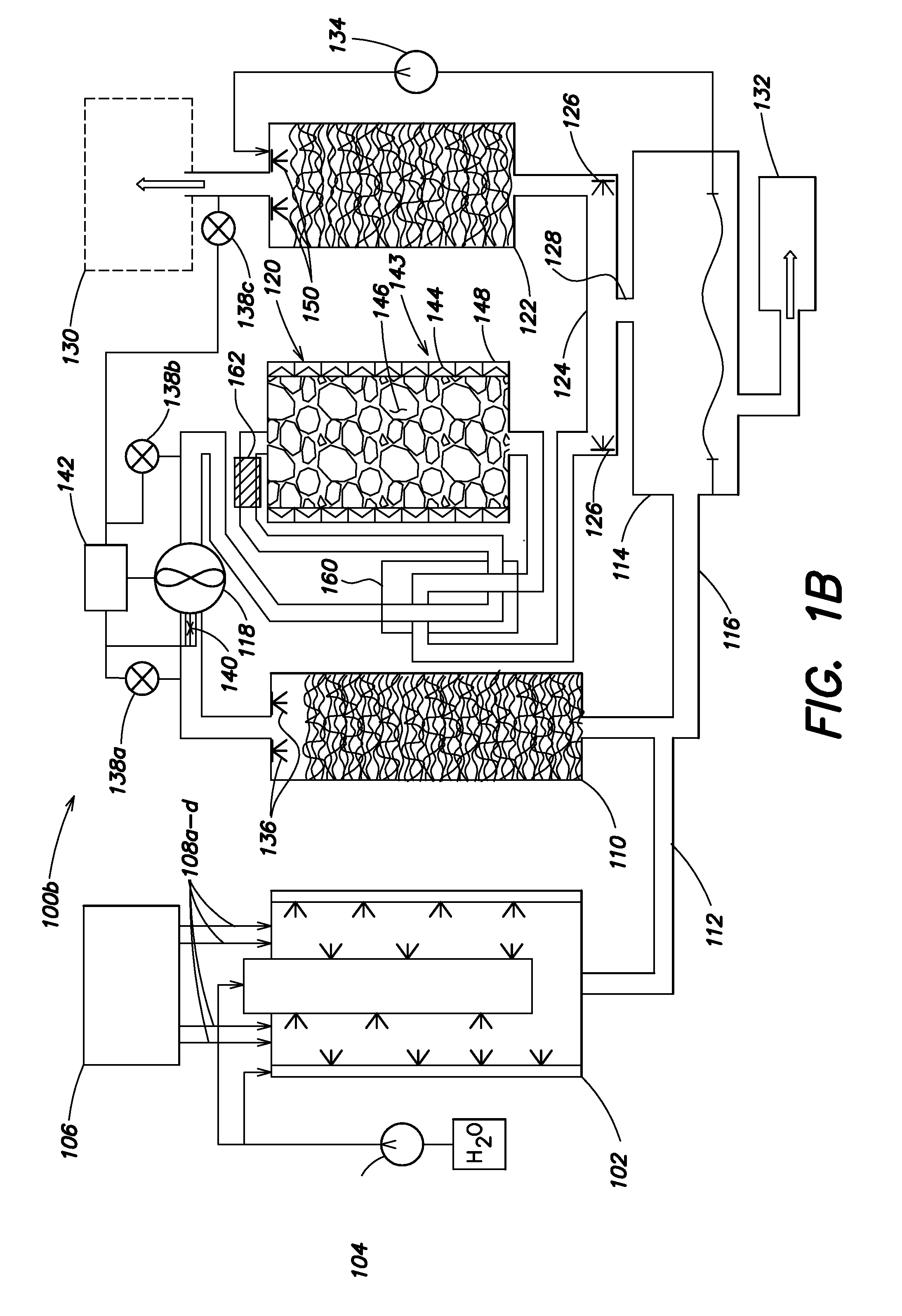

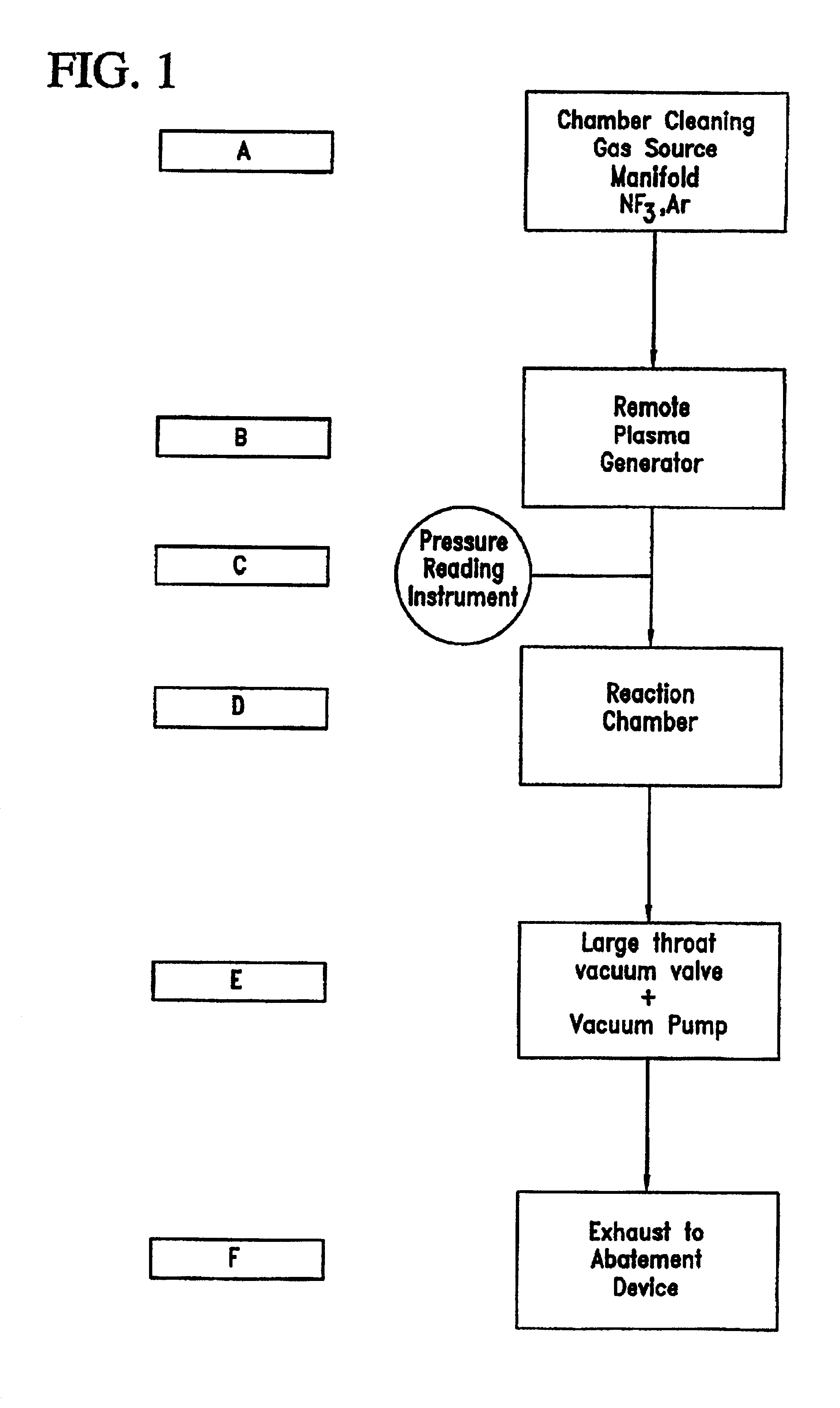

Method of recycling fluorine using an adsorption purification process

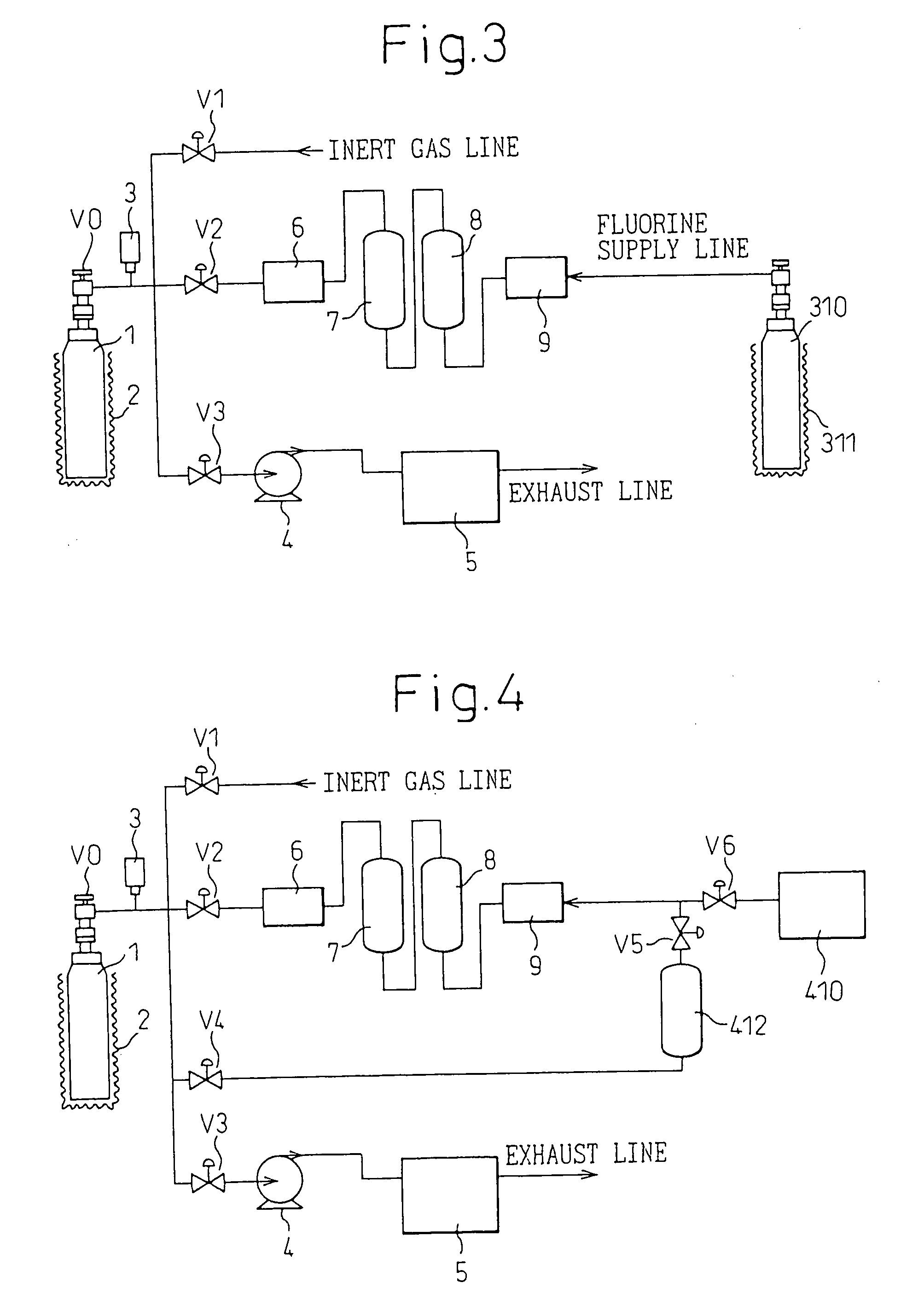

InactiveUS6955707B2Final product manufactureSemiconductor/solid-state device manufacturingSorbentImpurity

A method and apparatus is disclosed for producing fluorine by providing a contained fluorine precursor source located proximate to or remotely from an adsorbent bed, optionally in a replaceable unit that may be a replaceable module comprising both the fluorine source and the adsorbent bed. Fluorine derived preferably from a nitrogen trifluoride source and used to remove deposited silicon-containing impurities in reaction chambers is reclaimed from an adsorbent bed, and made available to the reaction chamber as a supplemental fluorine source to reduce the total required amount of nitrogen trifluoride source gas. The separation column adsorbent is regenerated in cyclical intervals using a reverse flow of inert gas.

Owner:BOC GRP INC

Enhanced stripping of low-K films using downstream gas mixing

The present invention pertains to methods for removing unwanted material from a work piece. More specifically, the invention pertains to stripping photo-resist material and removing etch-related residues from a semiconductor wafer during semiconductor manufacturing. Methods involve implementing a hydrogen plasma operation with downstream mixing with an inert gas. The invention is effective at stripping photo-resist and removing residues from low-k dielectric material used in Damascene devices.

Owner:NOVELLUS SYSTEMS

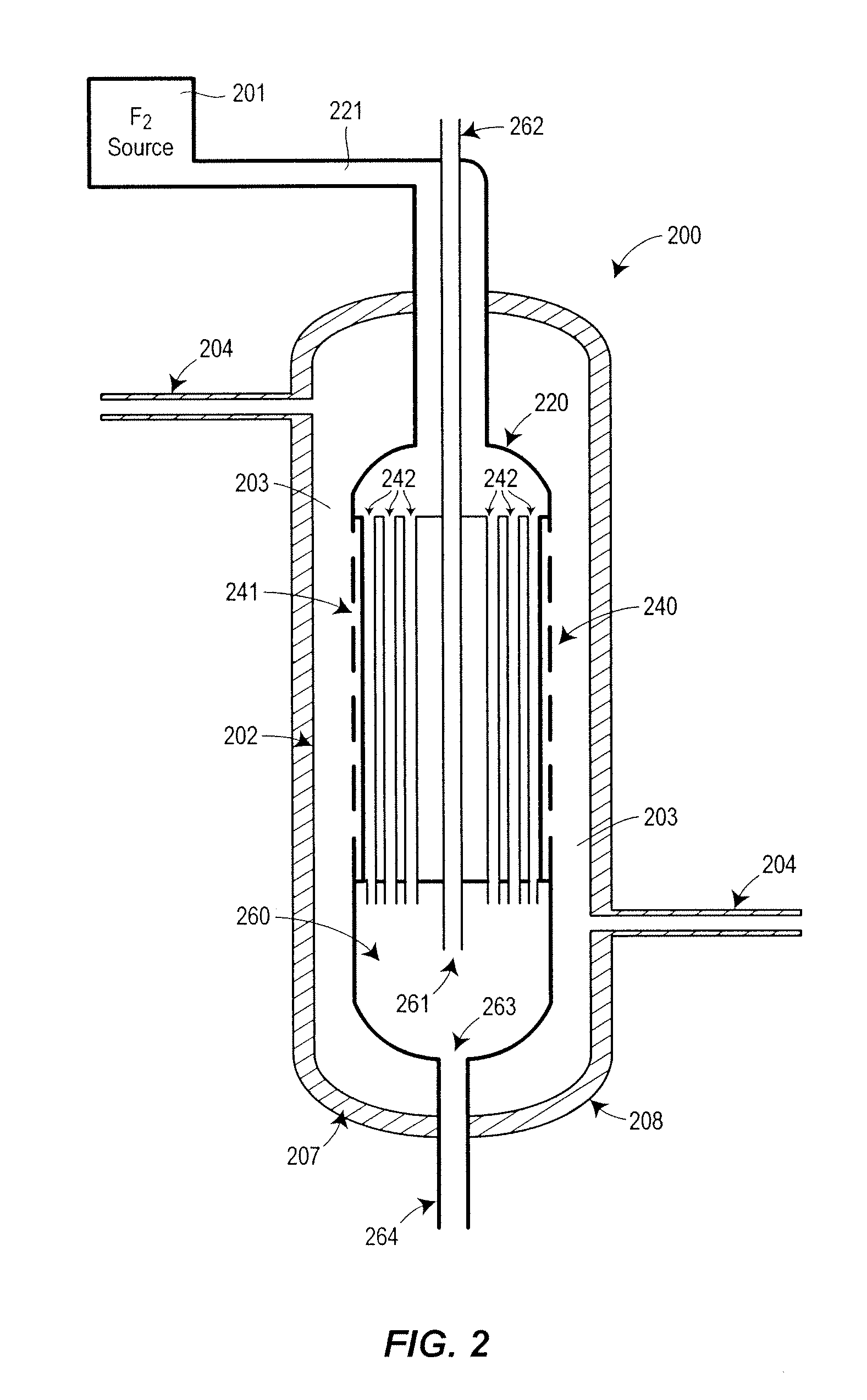

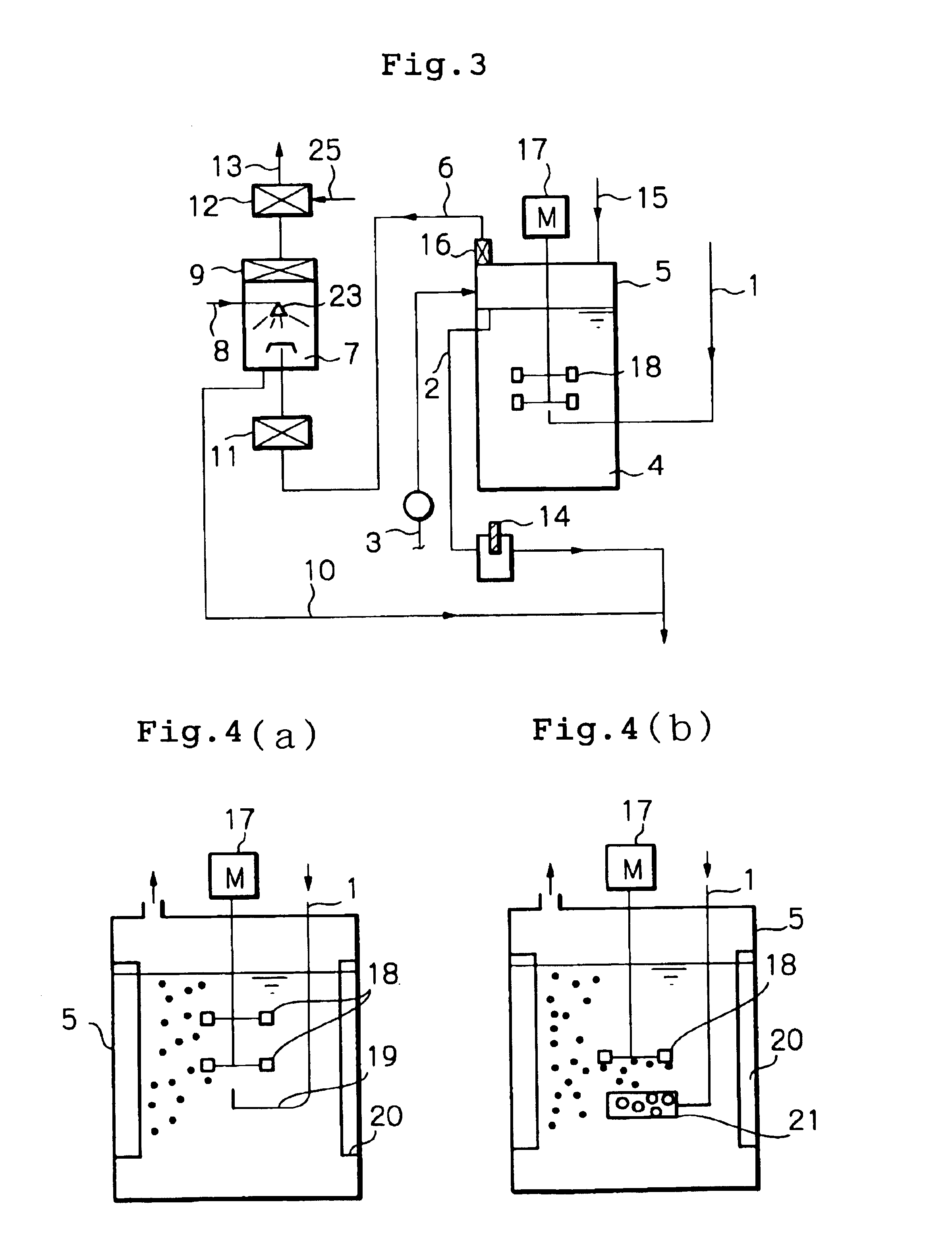

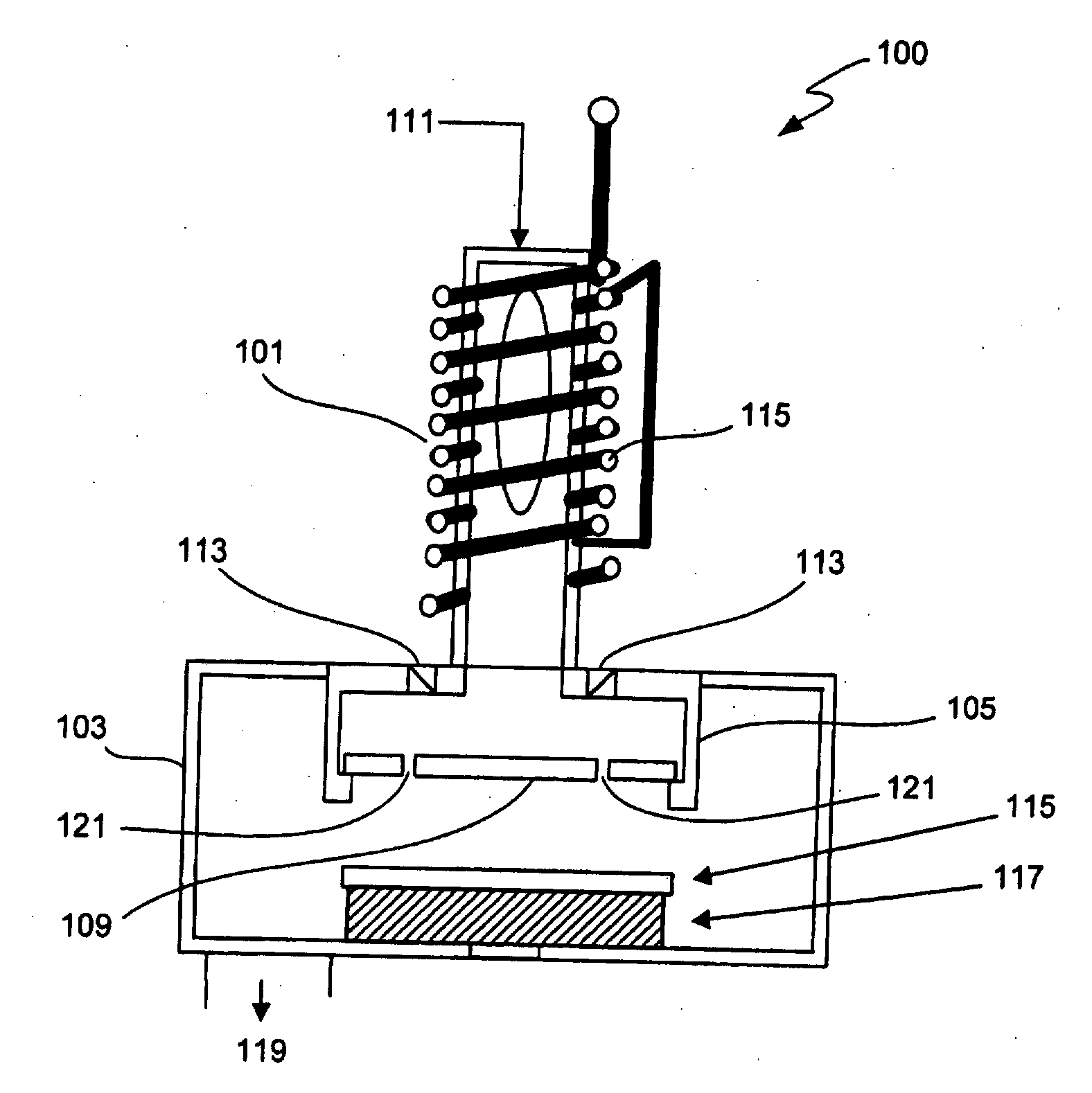

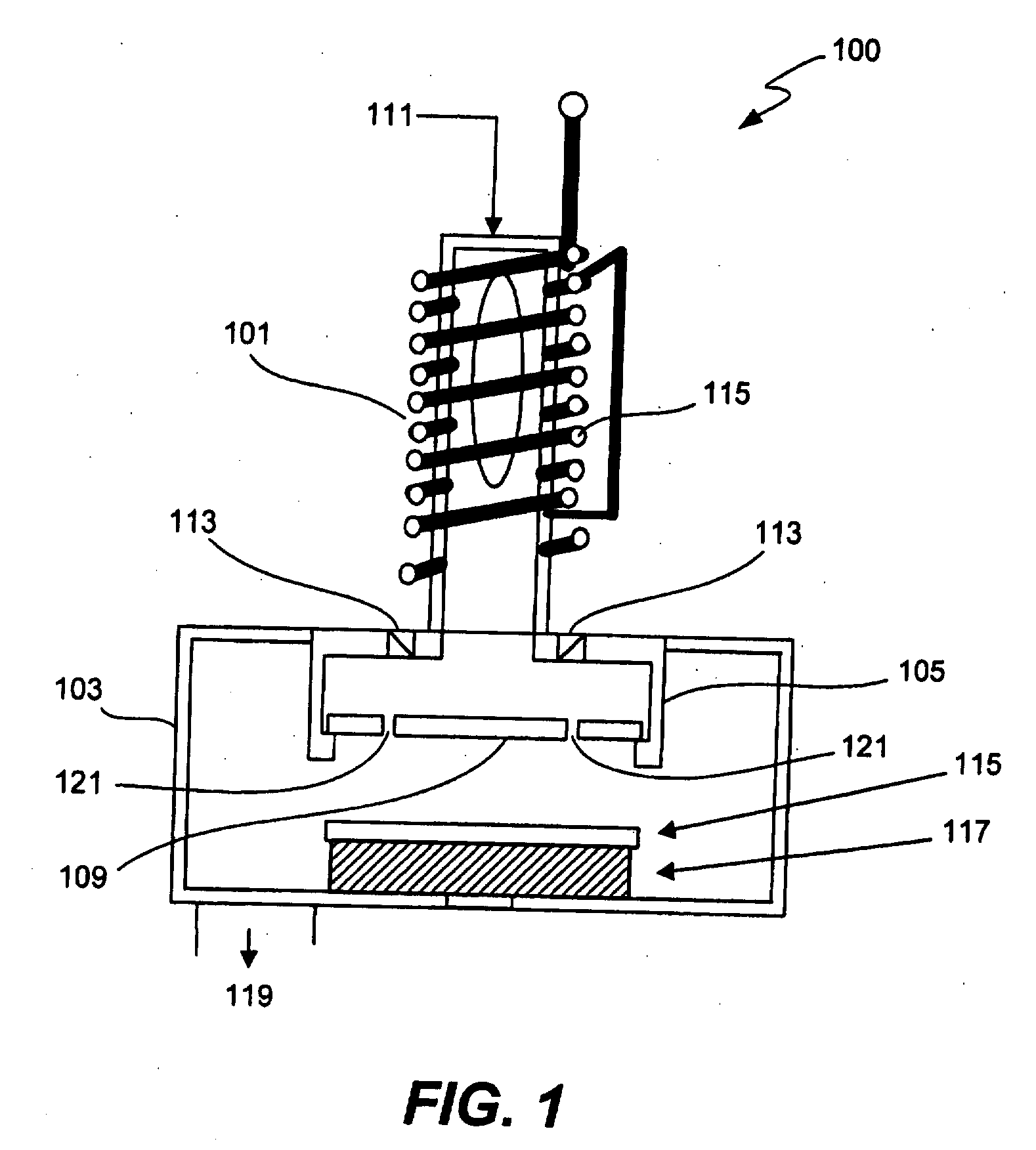

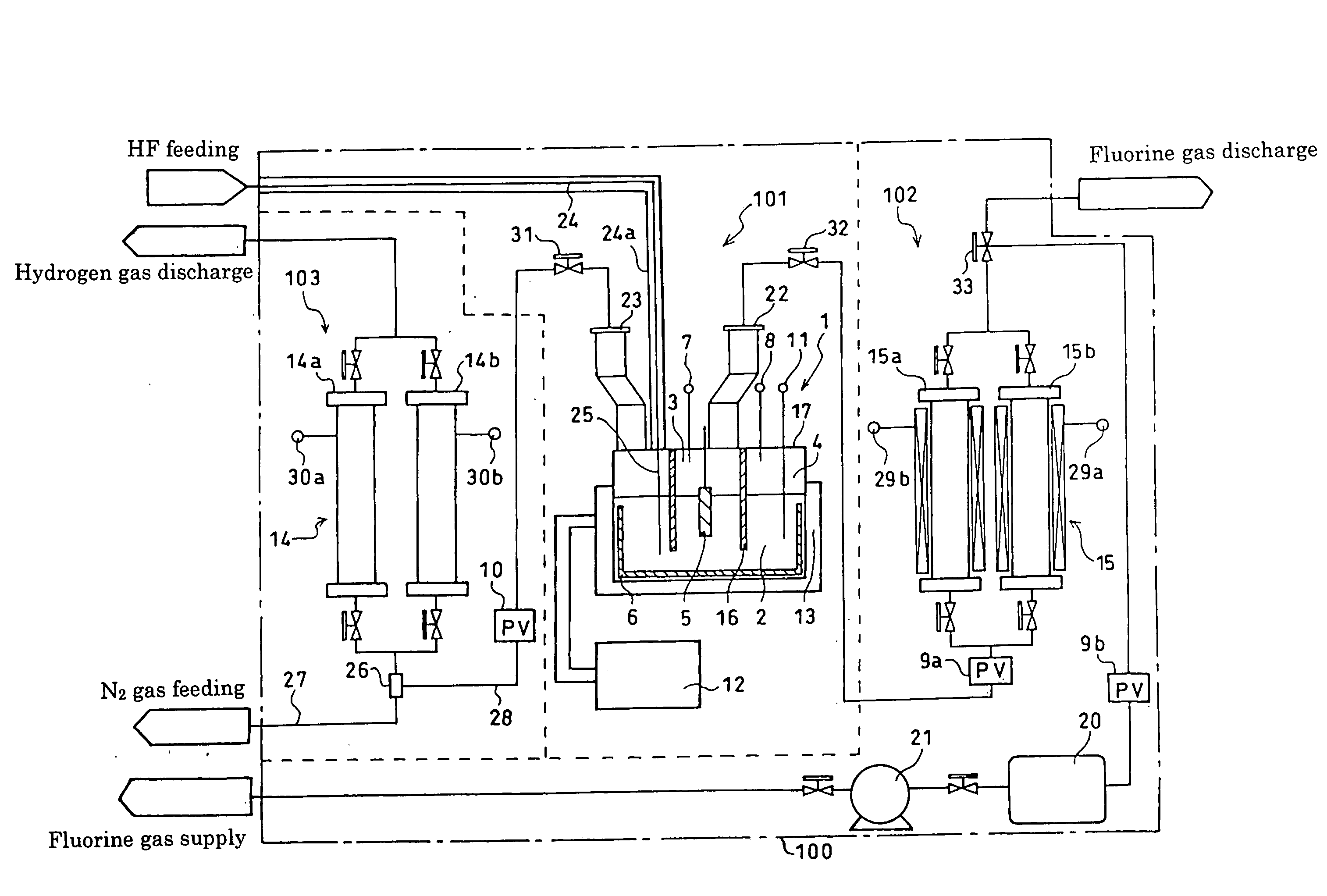

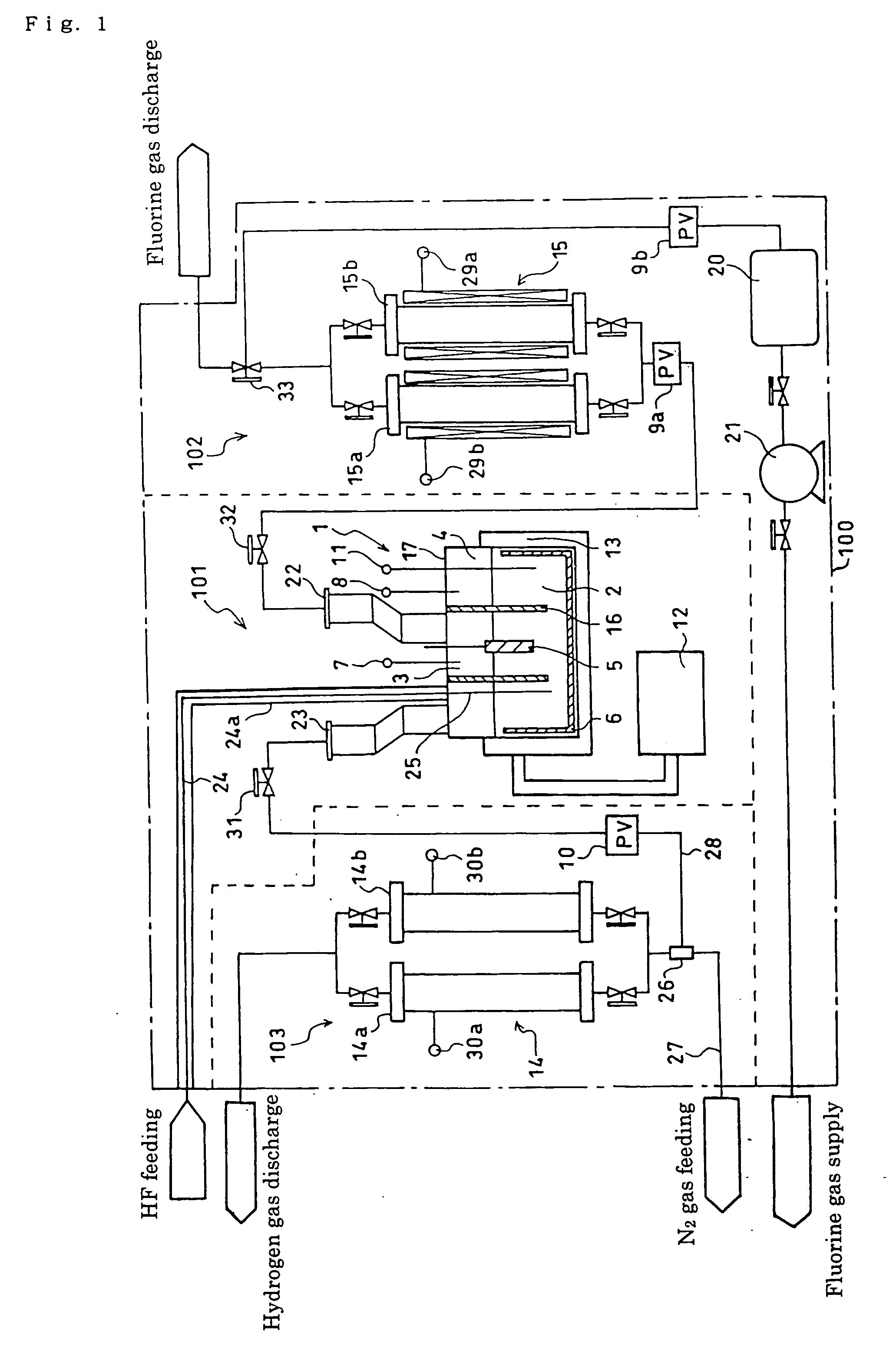

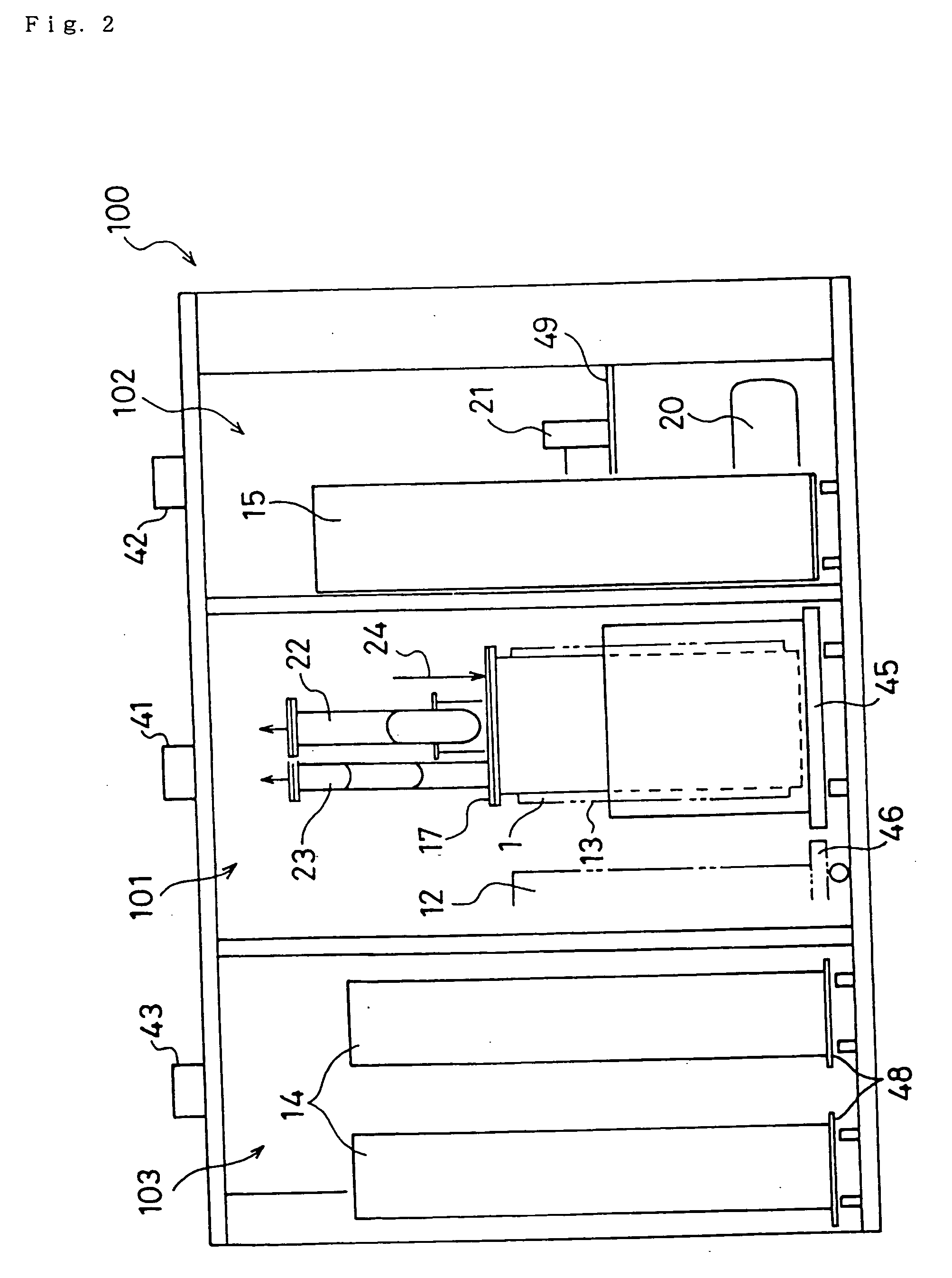

Fluorine gas generator

InactiveUS20040055874A1Exchange be easeEasy maintenanceCellsPhotography auxillary processesProduct gasEngineering

A fluorine gas generator is provided with which the gases used and / or generated, in case of leakage thereof, can be prevented from mixing together as far as possible and, even in case of gas leakage into the outside of the generator system, the leakage gas can be treated safely and in which the maintenance, exchange and other operations are easy to carry out. The generator comprises a box-shaped body containing an electrolyzer for fluorine gas generation, and the box-shaped body is divided into two or more compartments, including a compartment containing the electrolyzer.

Owner:TOYO TANSO KK

Method for preparing [F-18-]fluoride ion

InactiveUS6190637B1Improve efficiencyImprove collection efficiencyCation exchanger materialsIn-vivo radioactive preparationsProtonFluoride

The present invention provides a method for preparing [F-18]-fluoride ion which comprises the step of bringing [O-18]-enriched water containing [F-18]-fluoride ion formed by proton irradiation of [O-18]-enriched water into contact with a strongly acidic cation exchange resin to remove impurity cations, the step of then bringing the [O-18]-enriched water containing [F-18]-fluoride ion treated above into contact with a weakly basic anion exchange resin to make [F-18]-fluoride ion adsorbed to the resin and, along therewith, to recover the [O-18]-enriched water which has passed through the resin, and the step of eluting and collecting the [F-18]-fluoride ion adsorbed to the weakly basic anion exchange resin. According to the method for preparing [F-18]-fluoride ion of the present invention, [F-18]-fluoride ion can be collected at a high collection efficiency even from a larger amount (about 2 ml or more) of [O-18]-enriched water containing [F-18]-fluoride ion than the amount in prior method, and moreover expensive [O-18]-enriched water can be recovered and reused in the preparation of [F-18]-fluoride ion.

Owner:NIHON MEDI PHYSICS CO LTD

High-purity fluorine gas, production and use thereof, and method for analyzing trace impurities in high-purity fluorine gas

InactiveUS6955801B2Avoid pollutionComponent separationActive medium materialHydrogen fluorideInternal pressure

A step (1) of heating a fluoronickel compound to release a fluorine gas, a step (2) of allowing a fluorine gas to be occluded into a fluorinated compound, and a step (3) of heating the fluoronickel compound and reducing an inner pressure are conducted in a container, respectively, at least once, and thereafter a high-purity fluorine gas is obtained in the step (1). Also, a step (5) of heating a fluoronickel compound and reducing an inner pressure and a step (6) of allowing a fluorine gas reduced in a hydrogen fluoride content to be occluded into the fluoronickel compound are conducted in a container having a fluorinated layer formed on its surface, respectively, at least once, the step (5) is further conducted, and thereafter a fluorine gas containing impurity gases is contacted with the fluoronickel compound to fix and remove the fluorine gas, and the impurities are analyzed by gas chromatography.

Owner:SHOWA DENKO KK

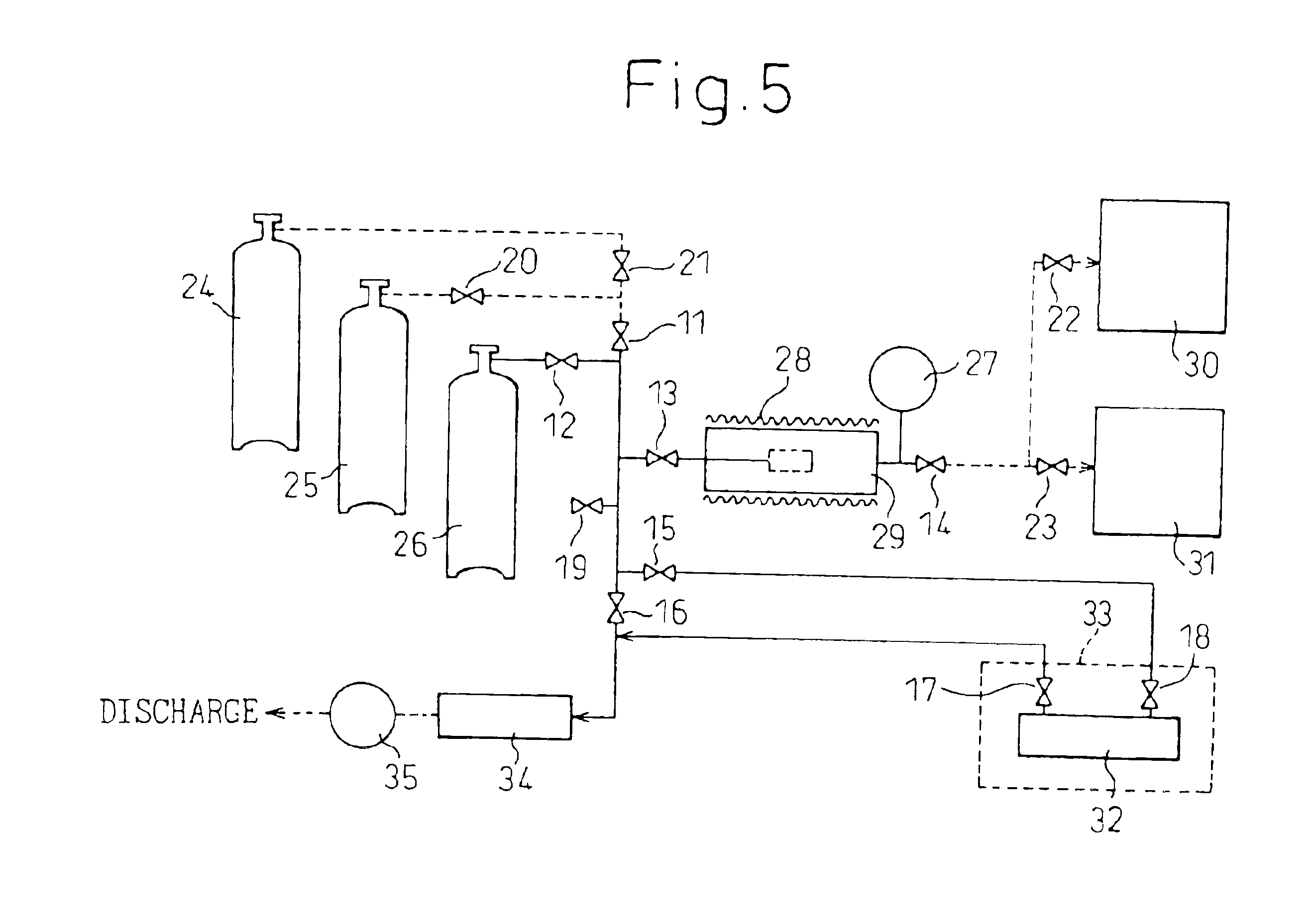

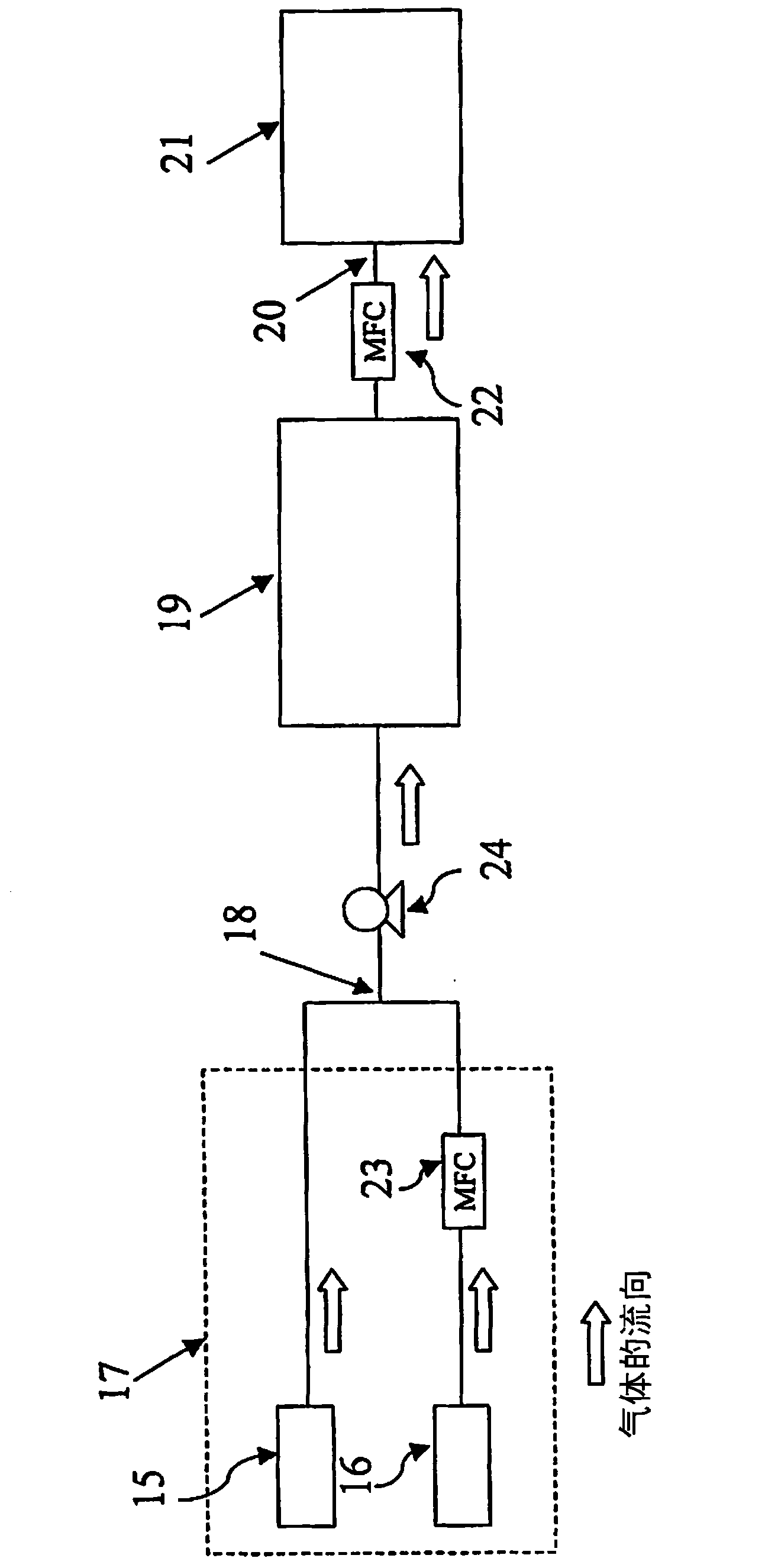

System for in-situ mixing and diluting fluorine gas

InactiveCN102369591AStable supplyTransportation and packagingSemiconductor/solid-state device manufacturingBuffer tankProcess engineering

It is a task to provide a fluorine gas supply system which can stably supply fluorine gas generated by a fluorine gas generation device to a semiconductor processing device in a large quantity and in a precise concentration. In the fluorine gas supply system, a mixed gas stored in a buffer tank is introduced into a gas introducing piping before the mixed gas is adjusted in the buffer tank to circulate the mixed gas and a monitoring device is disposed which measures a fluorine gas concentration within the mixed gas so that, in response to the obtained fluorine gas concentration, a flow quantity of inert gas supply source can be adjusted.

Owner:CENT GLASS CO LTD

High dose implantation strip (HDIS) in H2 base chemistry

Plasma is generated using elemental hydrogen, a weak oxidizing agent, and a fluorine containing gas. An inert gas is introduced to the plasma downstream of the plasma source and upstream of a showerhead that directs gas mixture into the reaction chamber where the mixture reacts with the high-dose implant resist. The process removes both the crust and bulk resist layers at a high strip rate, and leaves the work piece surface substantially residue free with low silicon loss.

Owner:NOVELLUS SYSTEMS

Fluorine purification

Owner:FLUOROMER

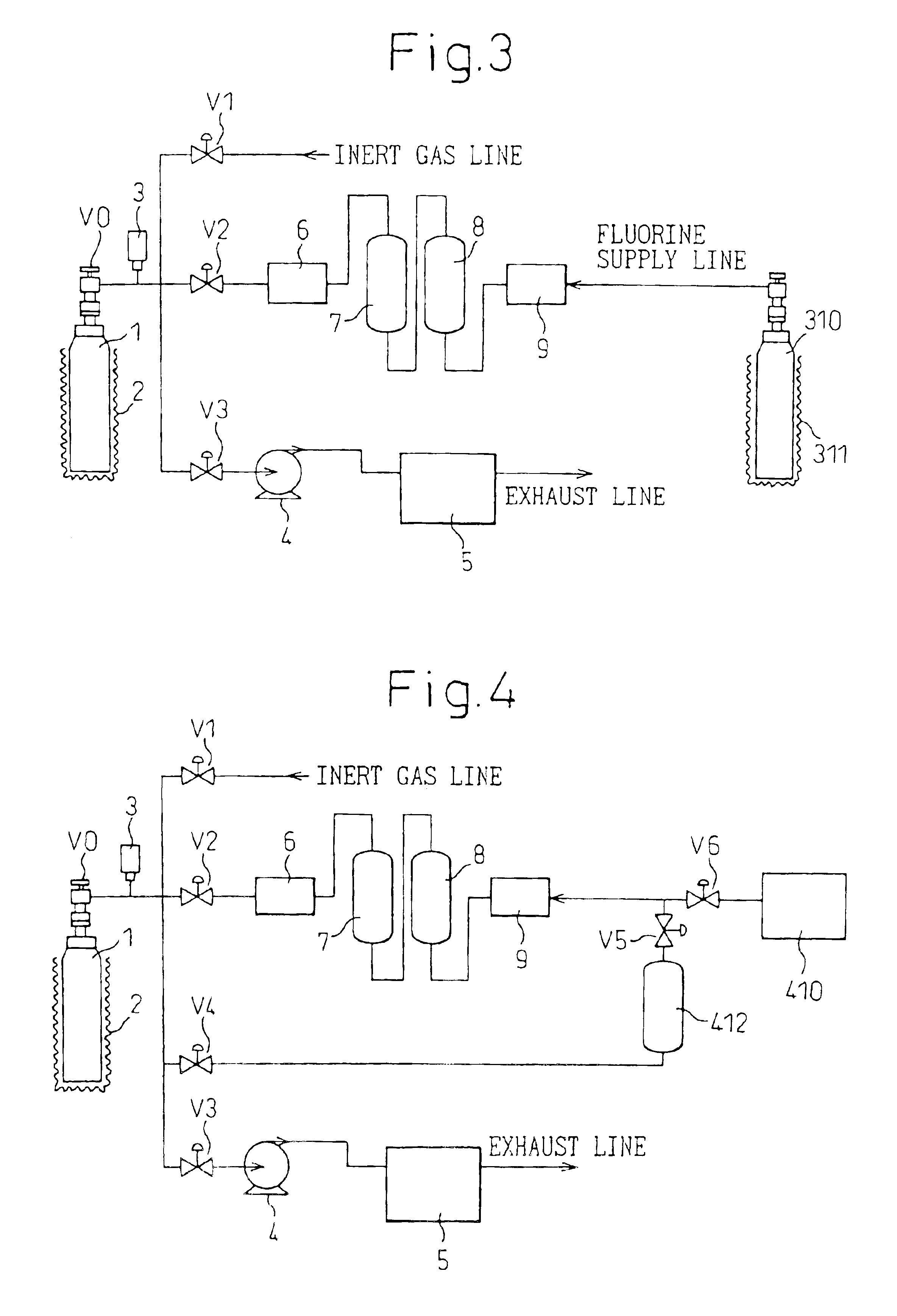

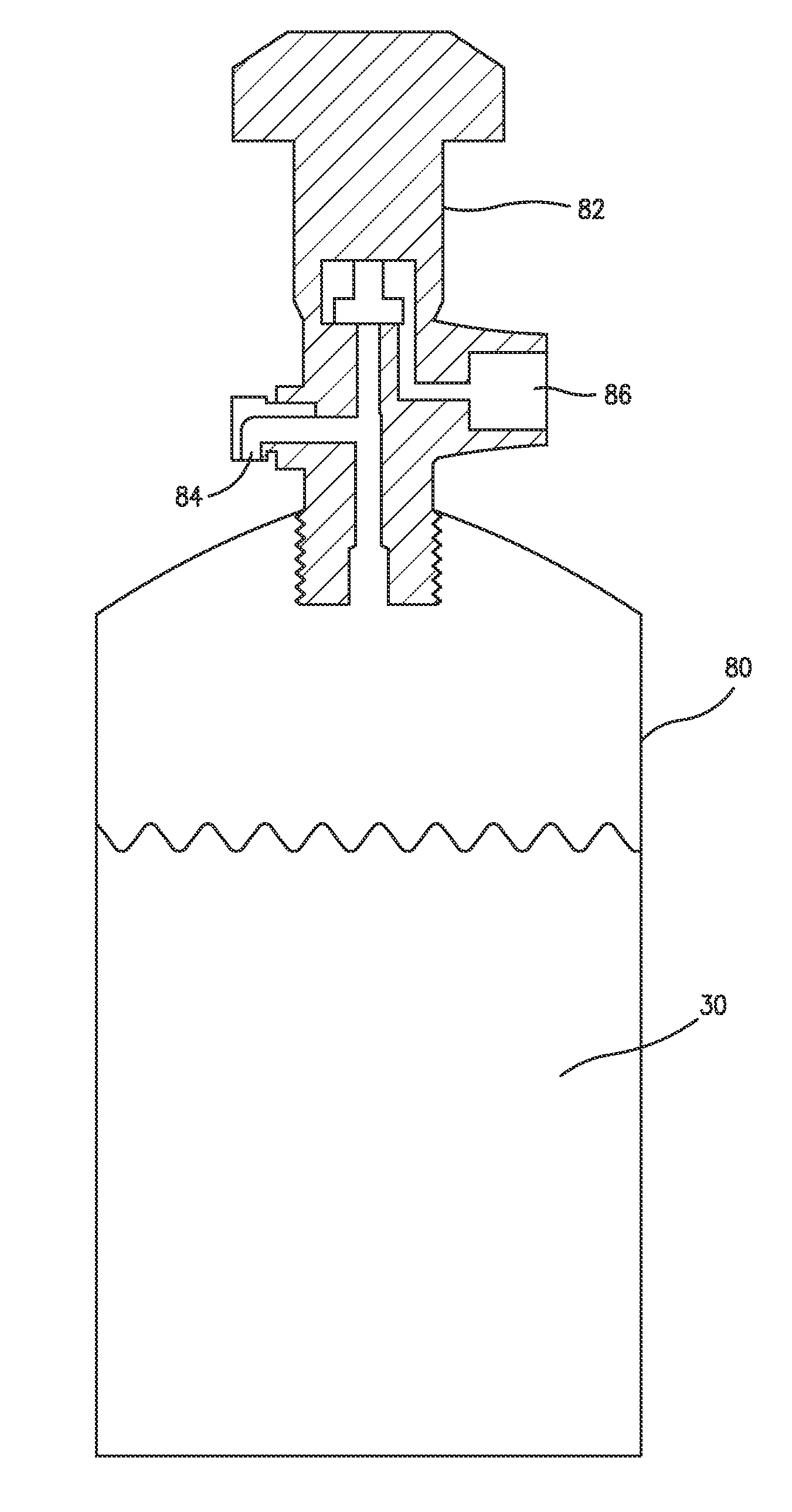

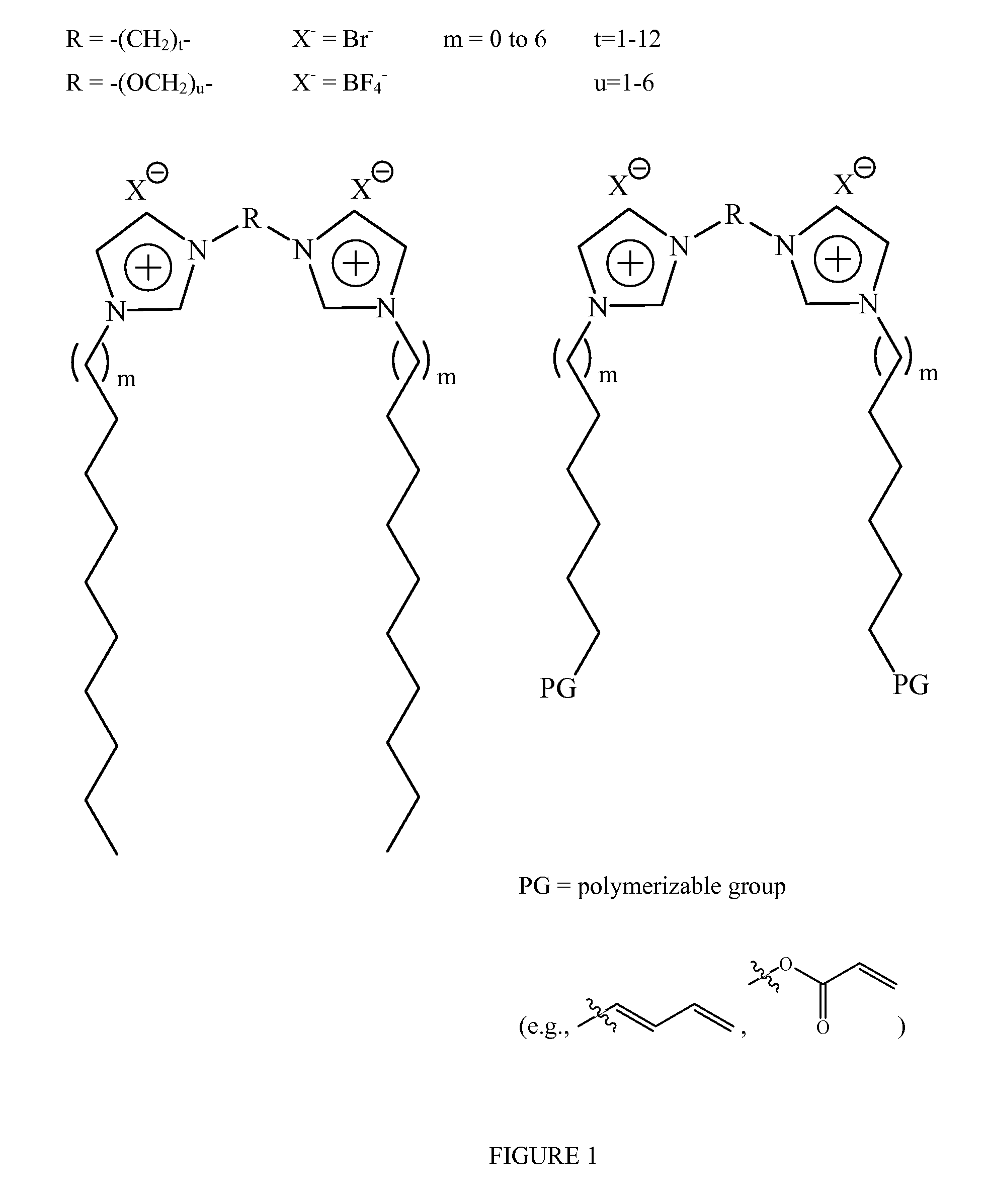

Fluid storage and dispensing methods and apparatus

InactiveUS20080319202A1Chlorine/hydrogen-chlorideOxygen/ozone/oxide/hydroxideSolventSURFACTANT BLEND

A method and device for storing and dispensing a fluid includes providing a vessel configured for selective dispensing of the fluid therefrom. Provided within a vessel is a nanocomposite material comprising an imidazolium surfactant and an integral solvent that is essential to the formation of the nanocomposite material. The fluid is contacted with the nanocomposite material for take-up of the fluid by the polymerized nanocomposite material. The fluid is released from the nanocomposite material and dispensed from the vessel.

Owner:UNIV OF COLORADO THE REGENTS OF

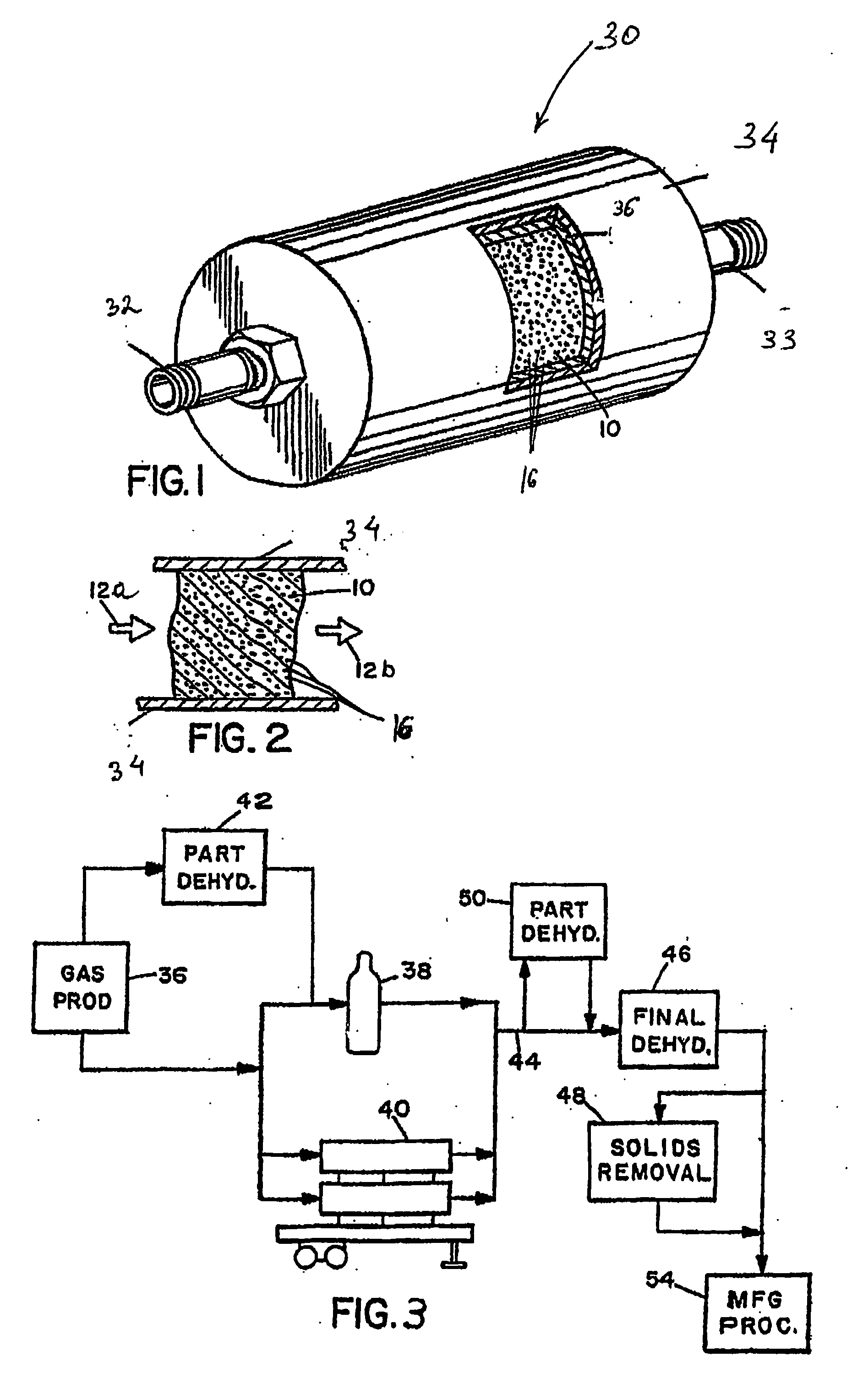

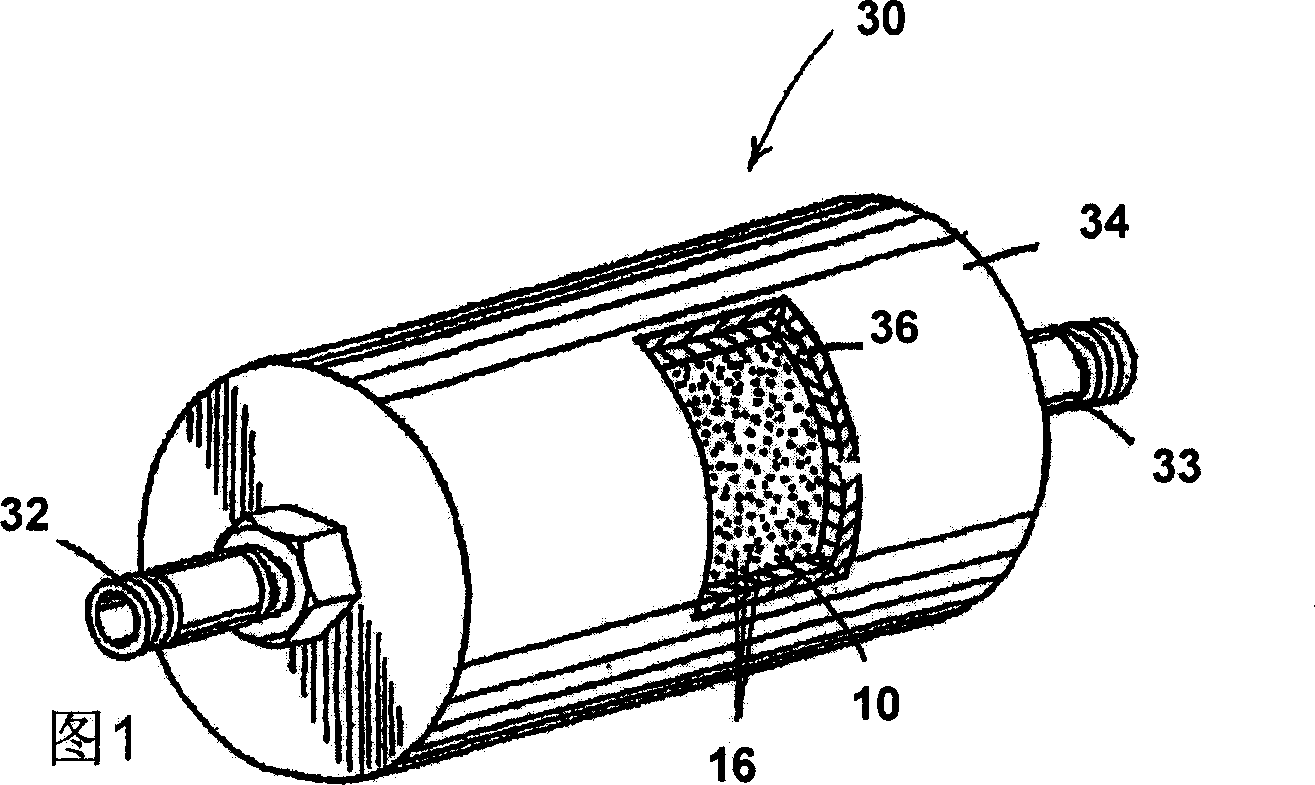

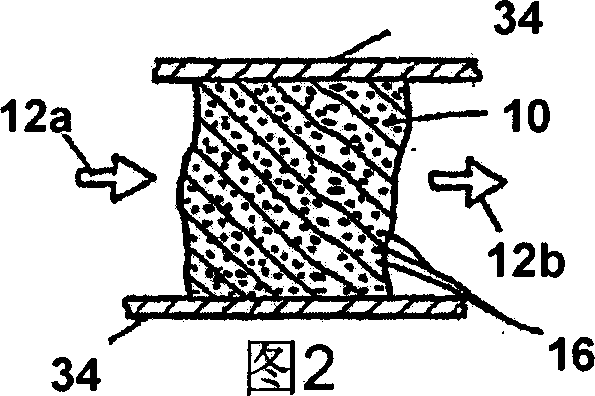

Apparatus and method for purification of corrosive gas streams

InactiveUS20070031321A1Reduce moistureWater contentMagnesium fluoridesHydrogen bromideParticulatesHalogen

A process, composition and apparatus for the removal of impurities from corrosive gases, particularly halogen-containing gases, down to about 100 ppb concentration are described. The critical component is zirconia (ZrO2), which in a variety of physical forms is capable of dehydrating such gases. The zirconia can be in the form of a coating on a substrate, as a granular bulk material, or deposited within the pores of a porous body. The zirconia is retained in a simple container which is easily installed in a gas supply line, such as to a gas- or vapor-deposition manufacturing unit. The purification process can be operated for long periods of time in the presence of these gases. The invention provides final purification to gas streams intended for gas- or vapor-deposition formation of high purity electronic, prosthetic or similar products, and can be used in combination with a preliminary dehydration process or a solid particulate removal unit upstream.

Owner:MYKROLIS CORP +1

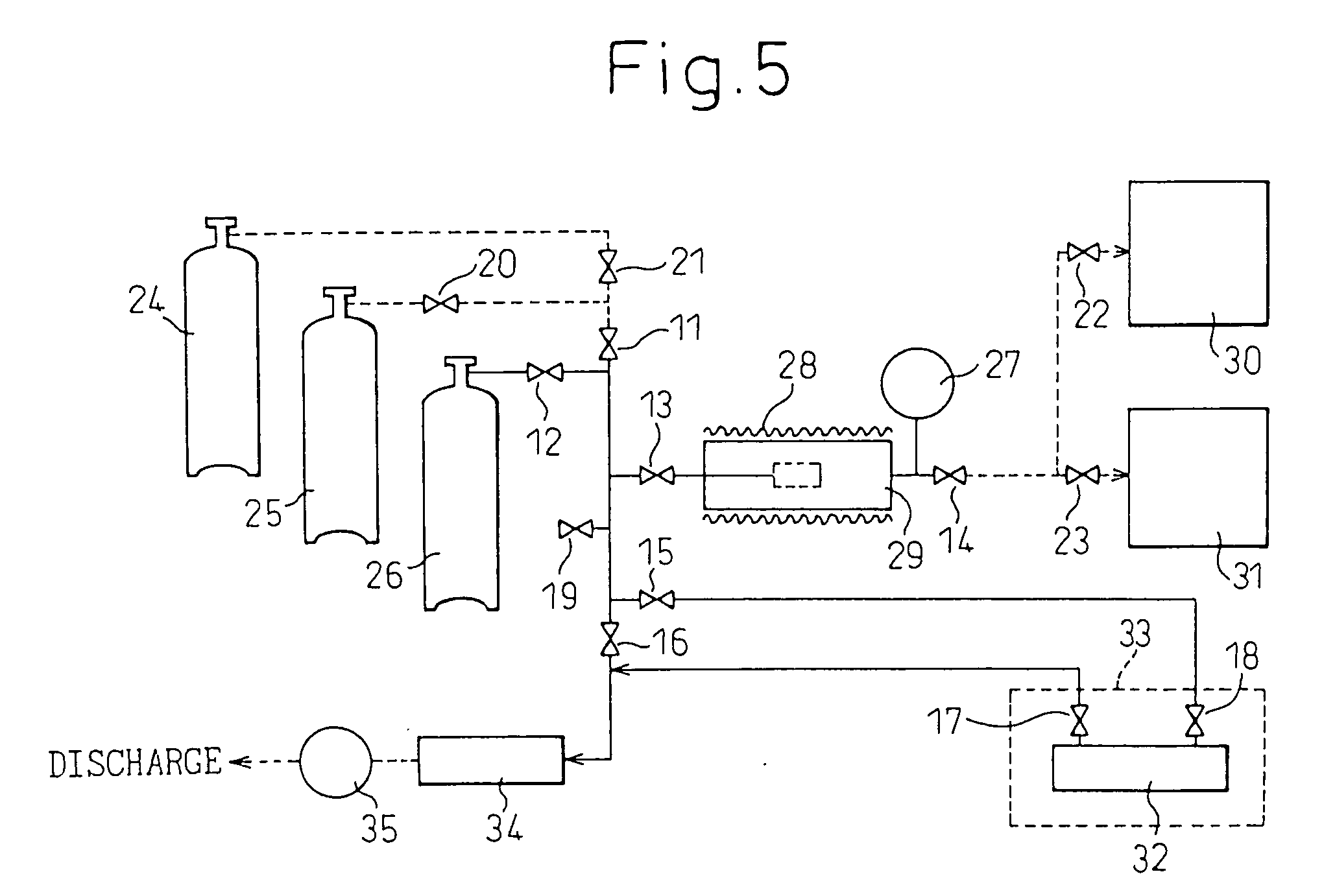

Methods and apparatus for PFC abatement using a CDO chamber

In some aspects, an apparatus is provided for abating perfluorocarbons (PFCs) in a controlled decomposition oxidation (CDO) thermal reaction chamber. The apparatus includes (1) a cartridge insertable into the thermal reaction chamber having gas-permeable first and second ends and including a catalyst material; and (2) thermally-conductive fixtures positioned within the cartridge. Numerous other aspects are provided.

Owner:APPLIED MATERIALS INC

Apparatus and method for purification of corrosive gas streams

InactiveCN1809412ALess susceptible to corrosionReduce moisture contentHydrogen bromideBromineHalogenPhysical chemistry

A process, composition and apparatus for the removal of impurities from corrosive gases, particularly halogen-containing gases, down to about 100 ppb concentration are described. The critical component is zirconia (ZrO2), which in a variety of physical forms is capable of dehydrating such gases. The zirconia can be in the form of a coating on a substrate, as a granular bulk material, or deposited within the pores of a porous body. The zirconia is retained in a simple container which is easily installed in a gas supply line, such as to a gas- or vapor-deposition manufacturing unit. The purification process can be operated for long periods of time in the presence of these gases. The invention provides final purification to gas streams intended for gas- or vapor-deposition formation of high purity electronic, prosthetic or similar products, and can be used in combination with a preliminary dehydration process or a solid particulate removal unit upstream.

Owner:ENTEGRIS INC

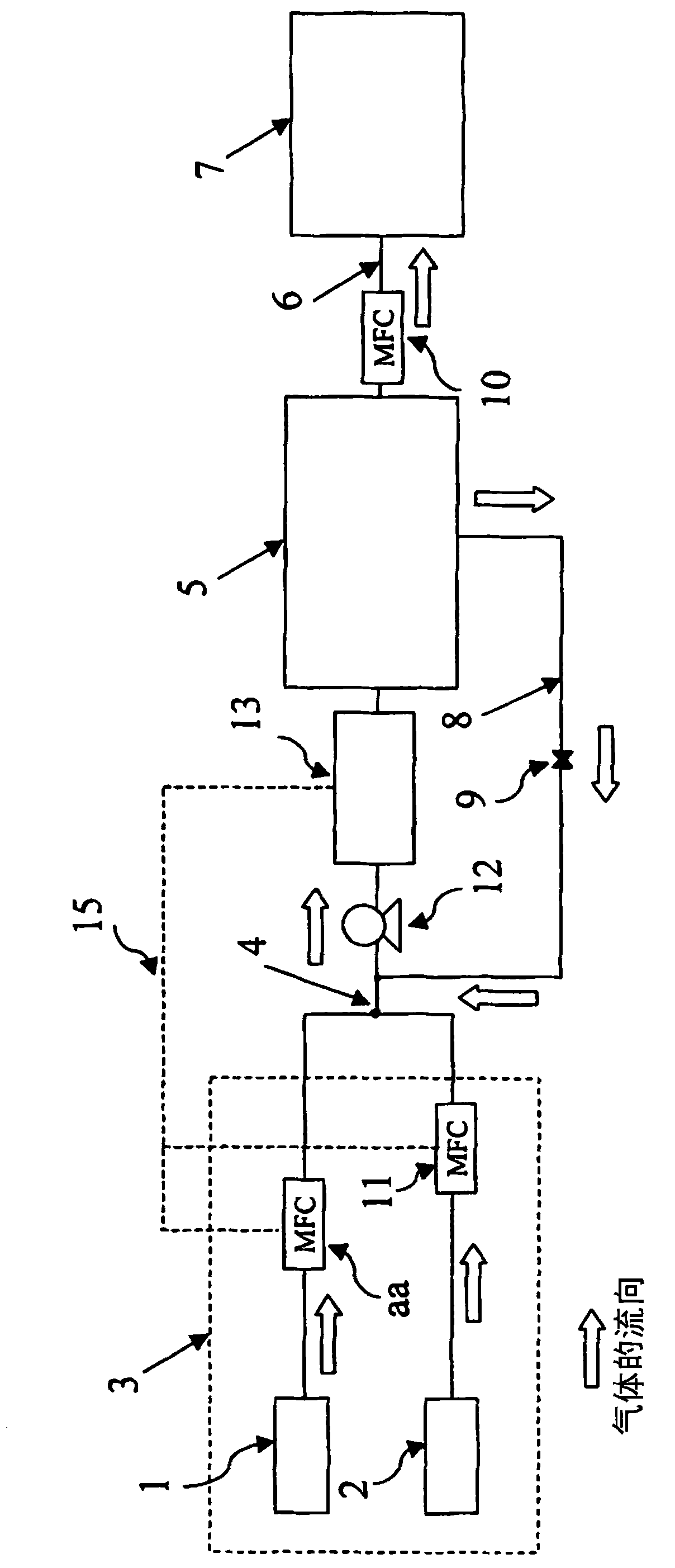

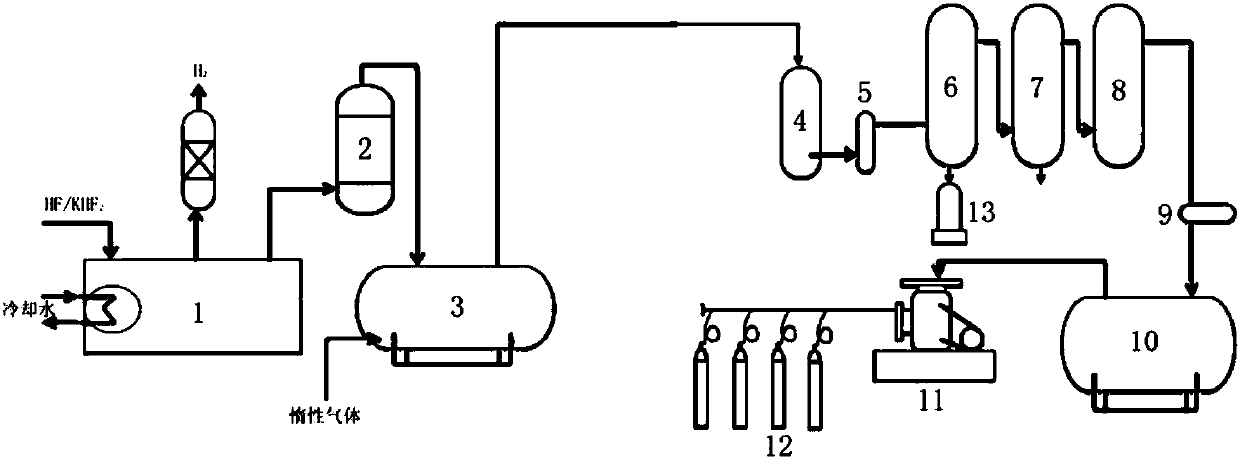

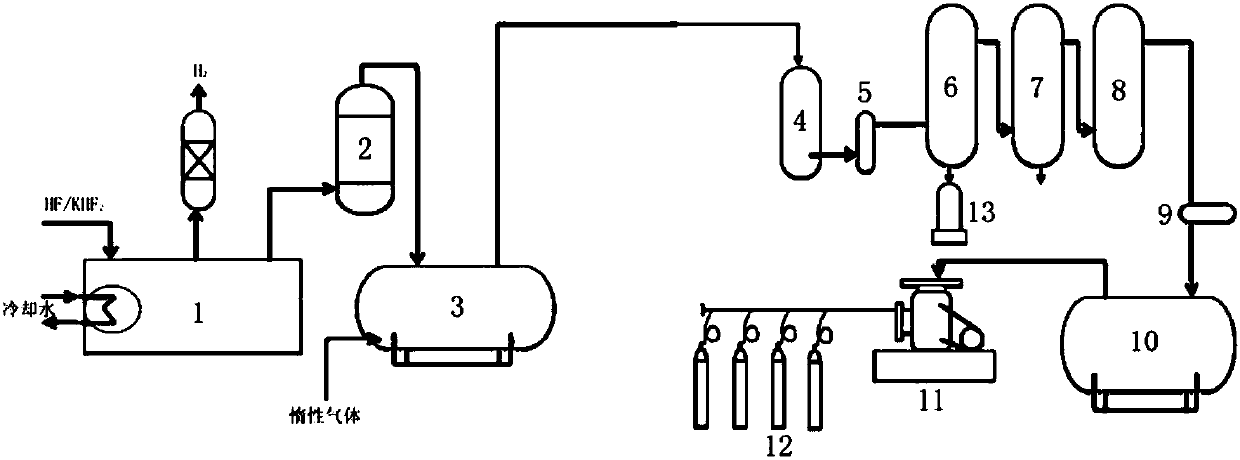

Method and device for preparing high-purity fluorine gas or high-purity fluorine-containing mixed gas

ActiveCN106698352AQuality improvementMeet the requirements of fluorine gas for productionCombination devicesGas treatmentElectrolysisPositive pressure

The invention relates to a method and device for preparing high-purity fluorine gas or high-purity fluorine-containing mixed gas and belongs to the technical field of fluorine chemicals. The method comprises the following steps: pressurizing fluorine gas made by electrolysis or fluorine-containing mixed gas blended by the fluorine gas made by electrolysis to positive pressure, filtering, and sequentially performing primary condensation and secondary condensation, wherein the temperature of the primary condensation is 60-100 DEG C below zero, and the temperature of the secondary condensation is 120-180 DEG C below zero. The purity of the fluorine gas product obtained by the method is 99.9% or higher, and the fluorine gas requirements for production in the existing electron industry and fine chemical engineering are met; the purity of the obtained fluorine-containing mixed gas is 99.9% or higher, and the production requirements of fluorine-containing special gases are met; and the quality of the fluorine gas product is wholly improved, the application market is expanded, the reject ratio of downstream finished products caused by low purity of the fluorine gas or fluorine-containing mixed gas in the production process is reduced, and the method has high economic values and wide application prospects.

Owner:DO FLUORIDE CHEM CO LTD

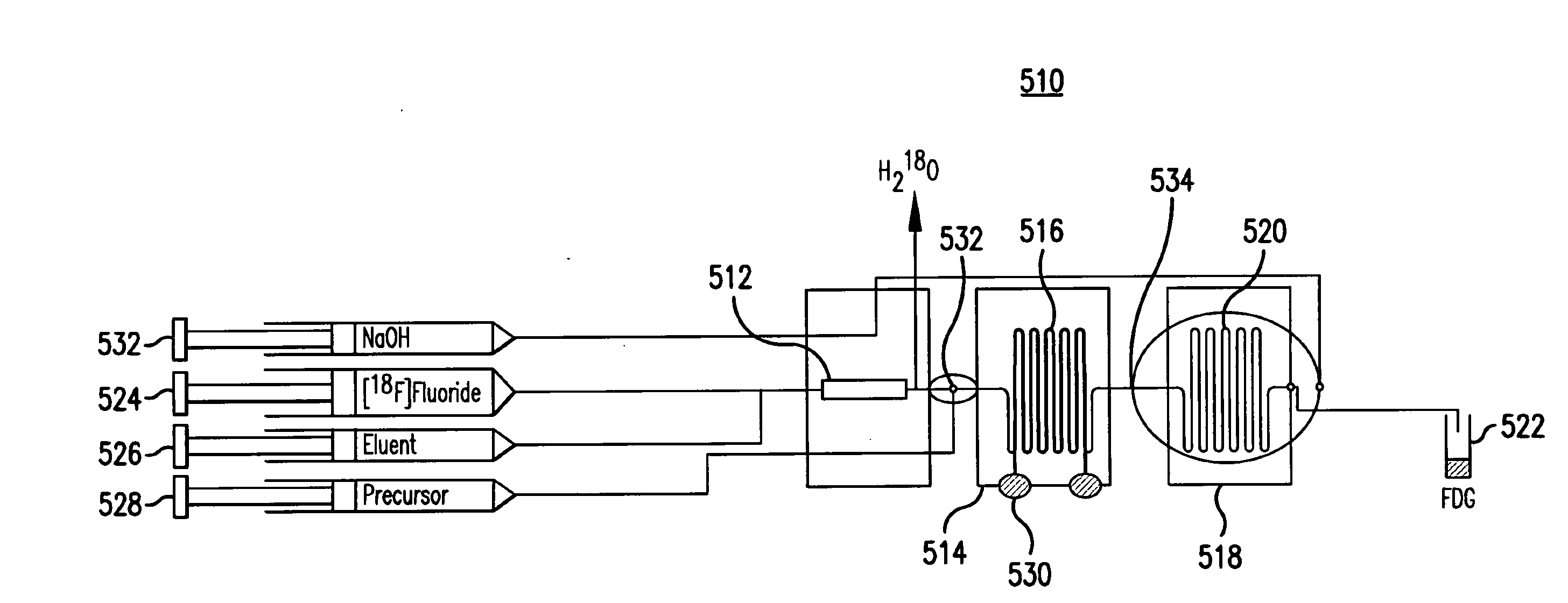

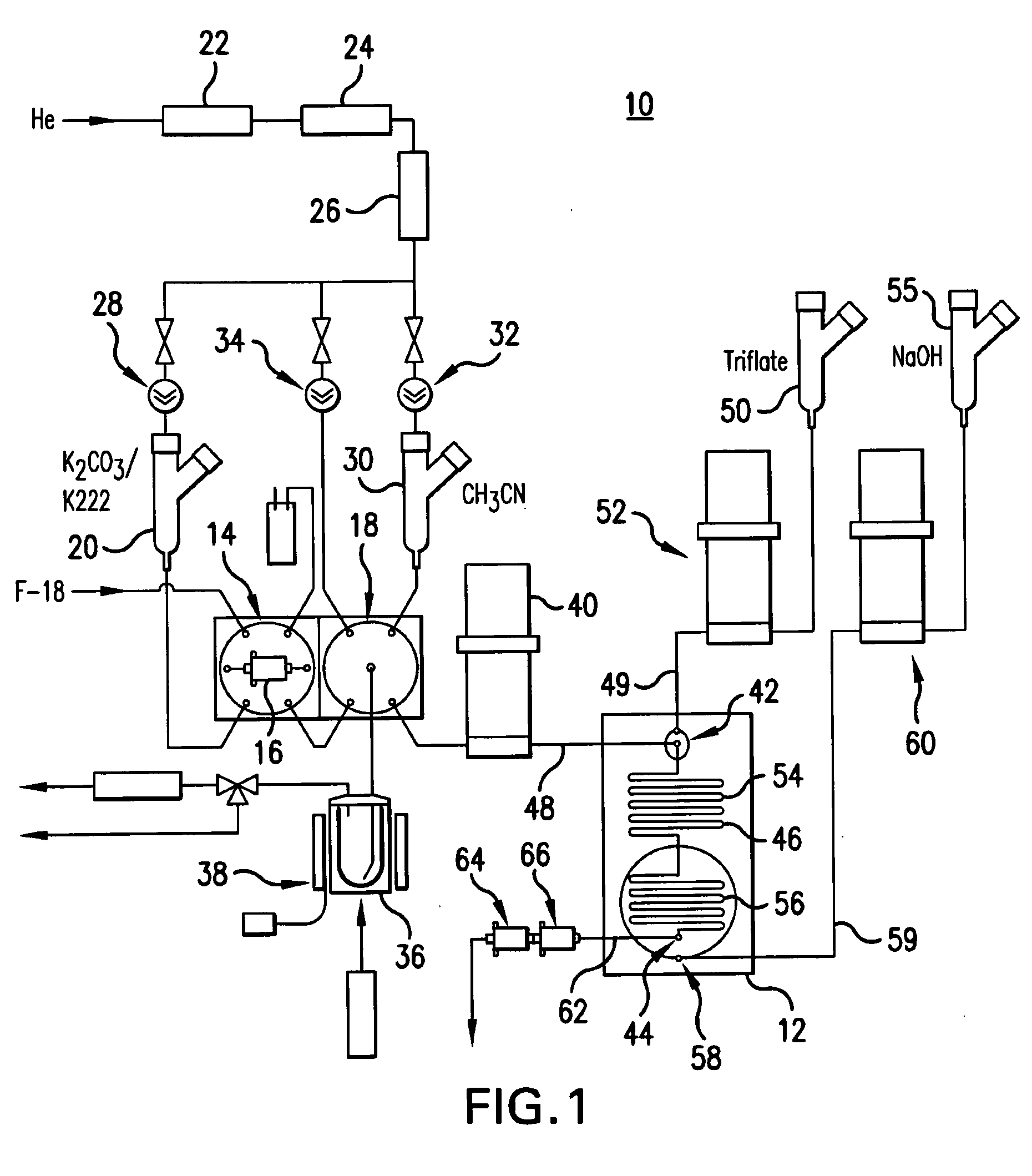

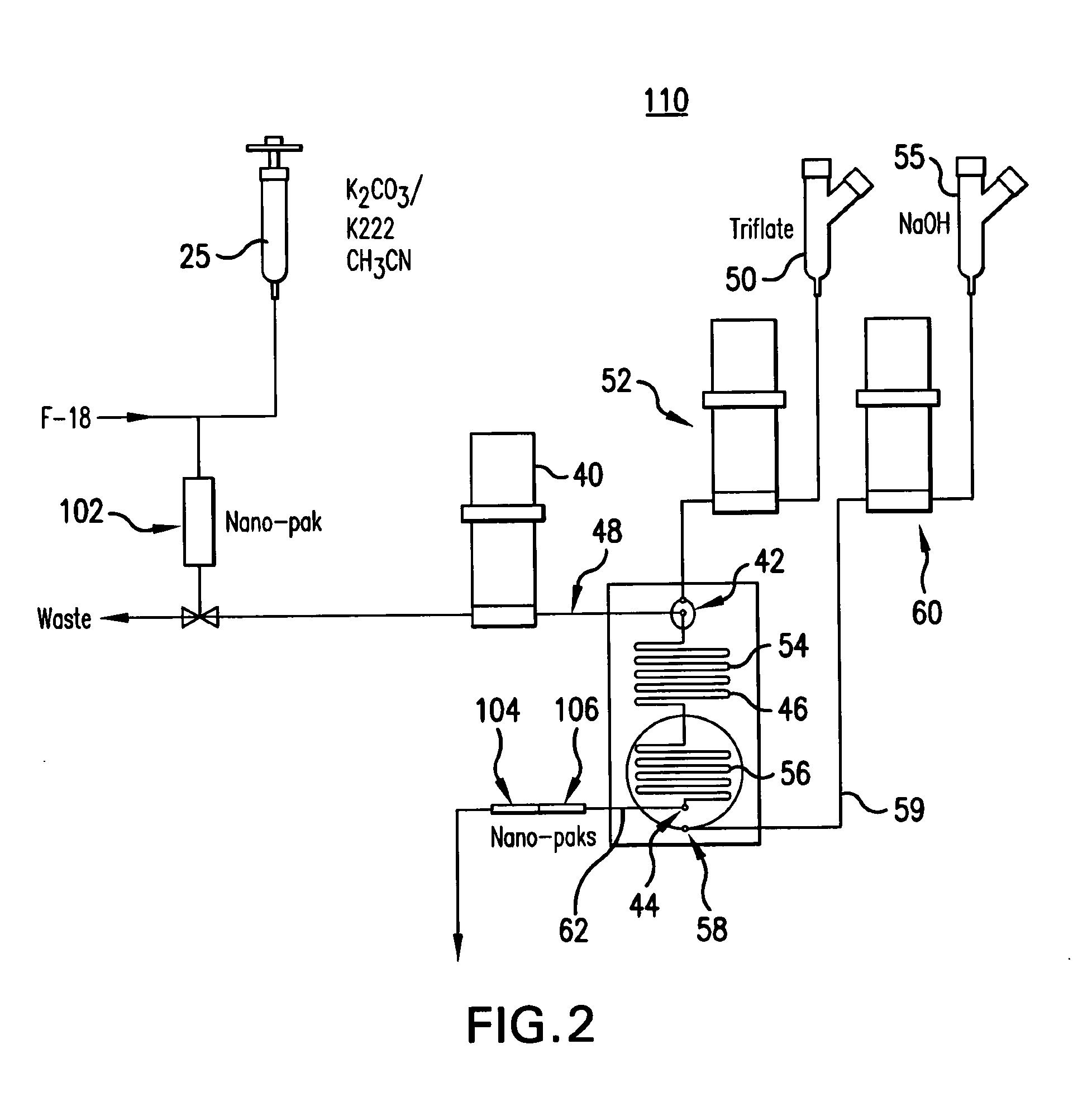

Nucleophilic radiofluorination using microfabricated devices

InactiveUS20090311157A1Simple designTransuranic element compoundsChemical/physical/physico-chemical microreactorsFluorideRadiosynthesis

A microscale solution for conducting [18F]fluoride phase transfer and subsequent radiosynthesis of 2-[18F]FDG that eliminates the azeotropic drying process. [18F]fluoride phase transfer is performed using an inexpensive disposable microchip. Additionally, each subsequent each step may be performed on the same single microchip.

Owner:STEEL COLIN +3

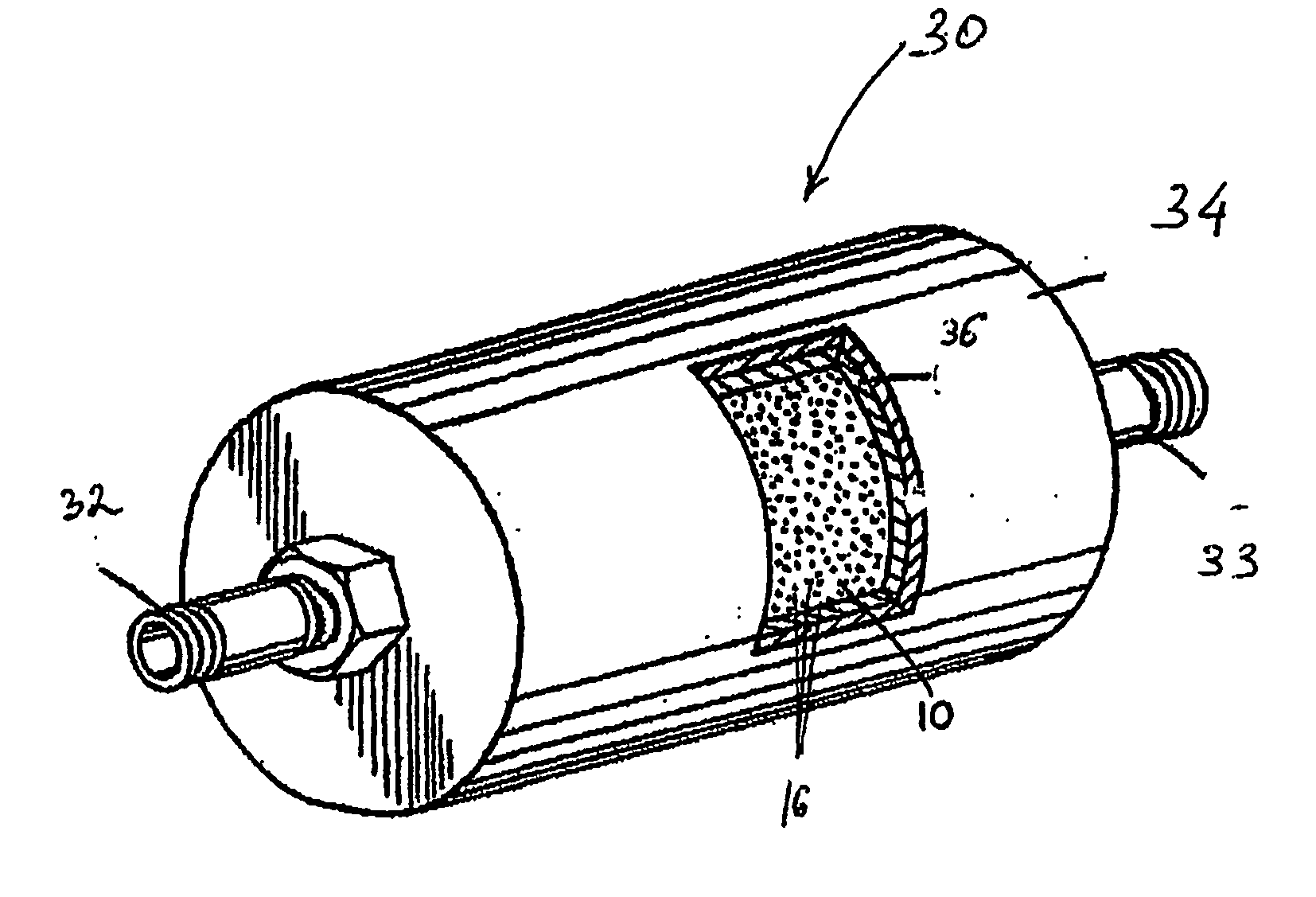

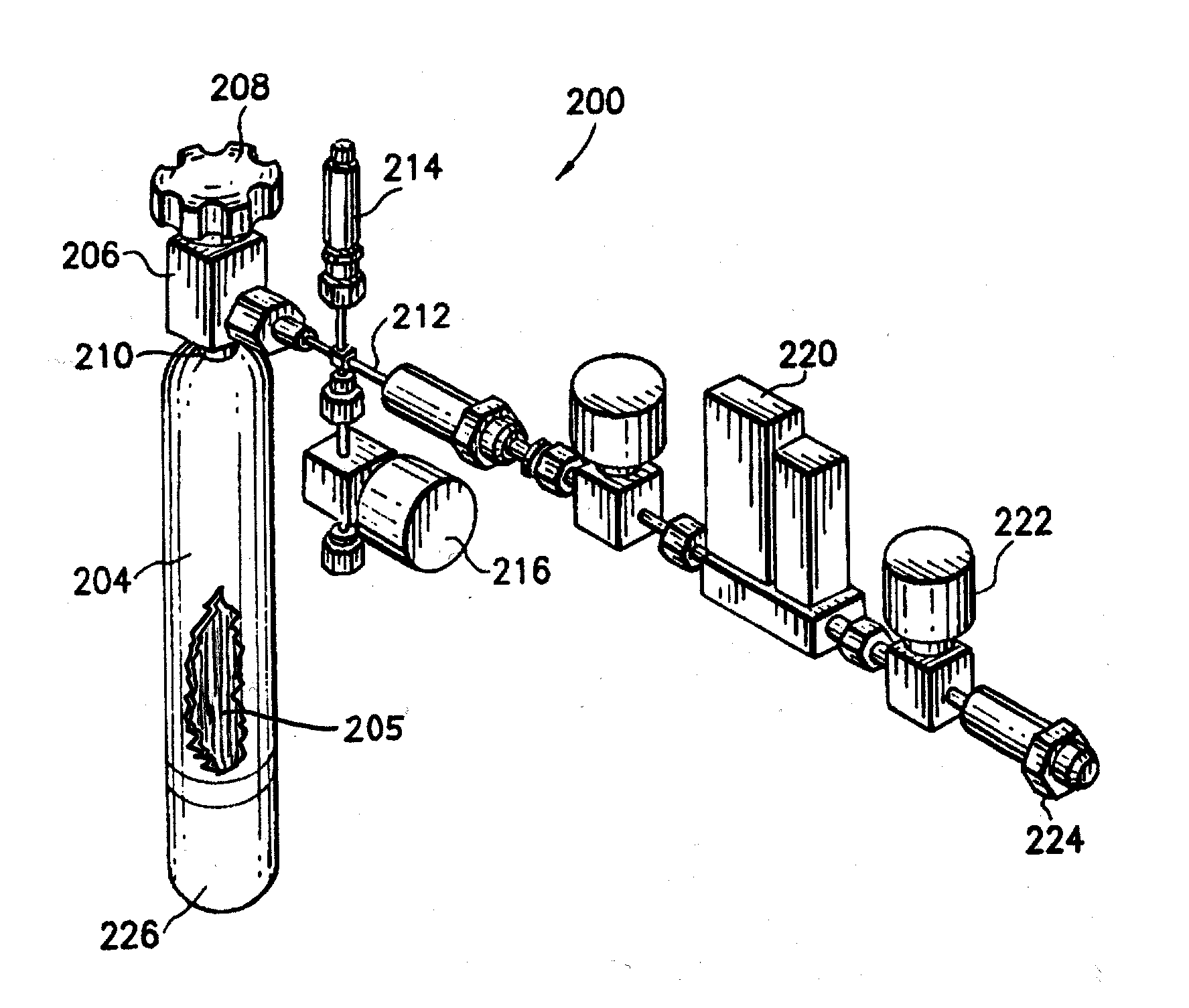

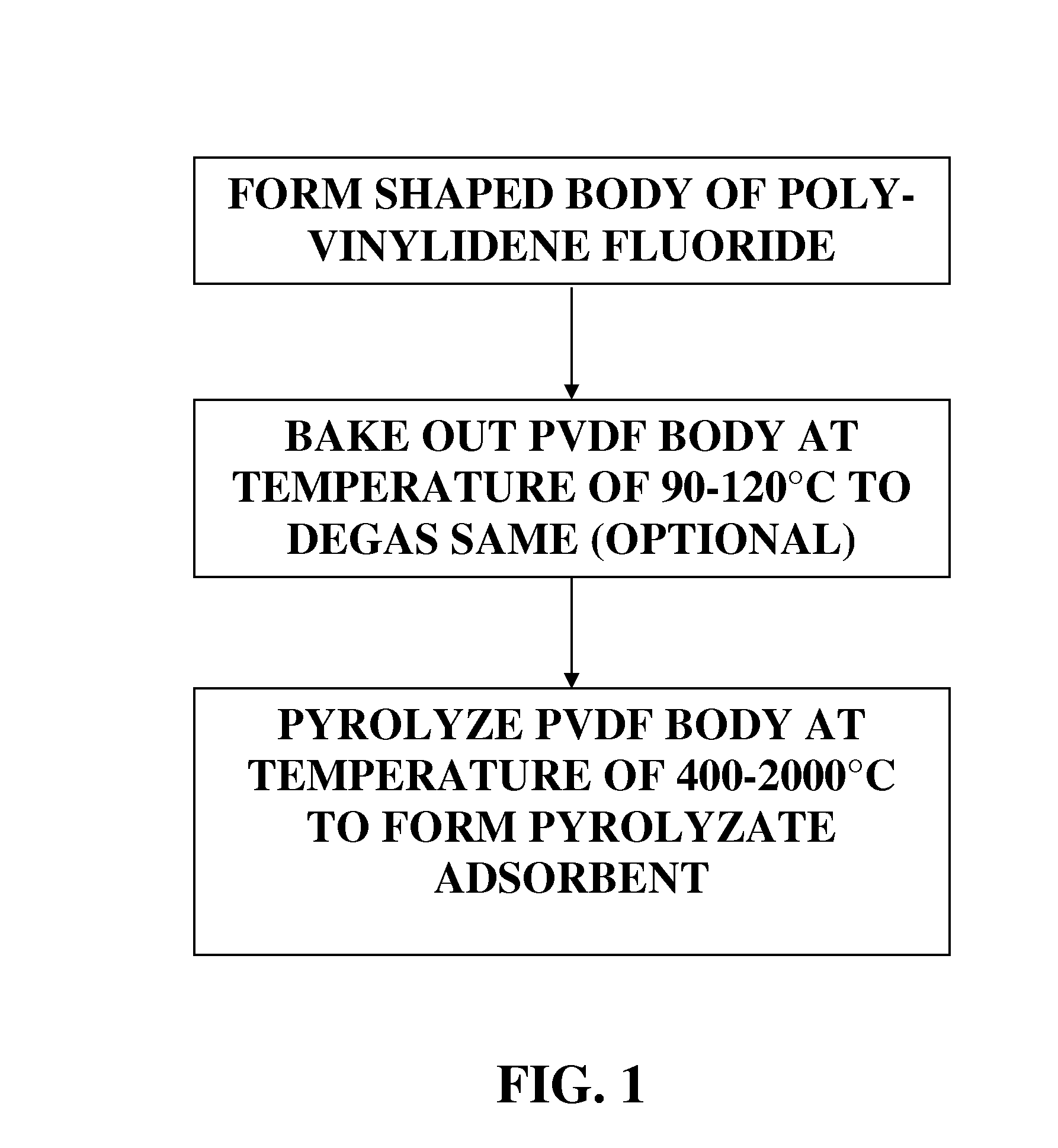

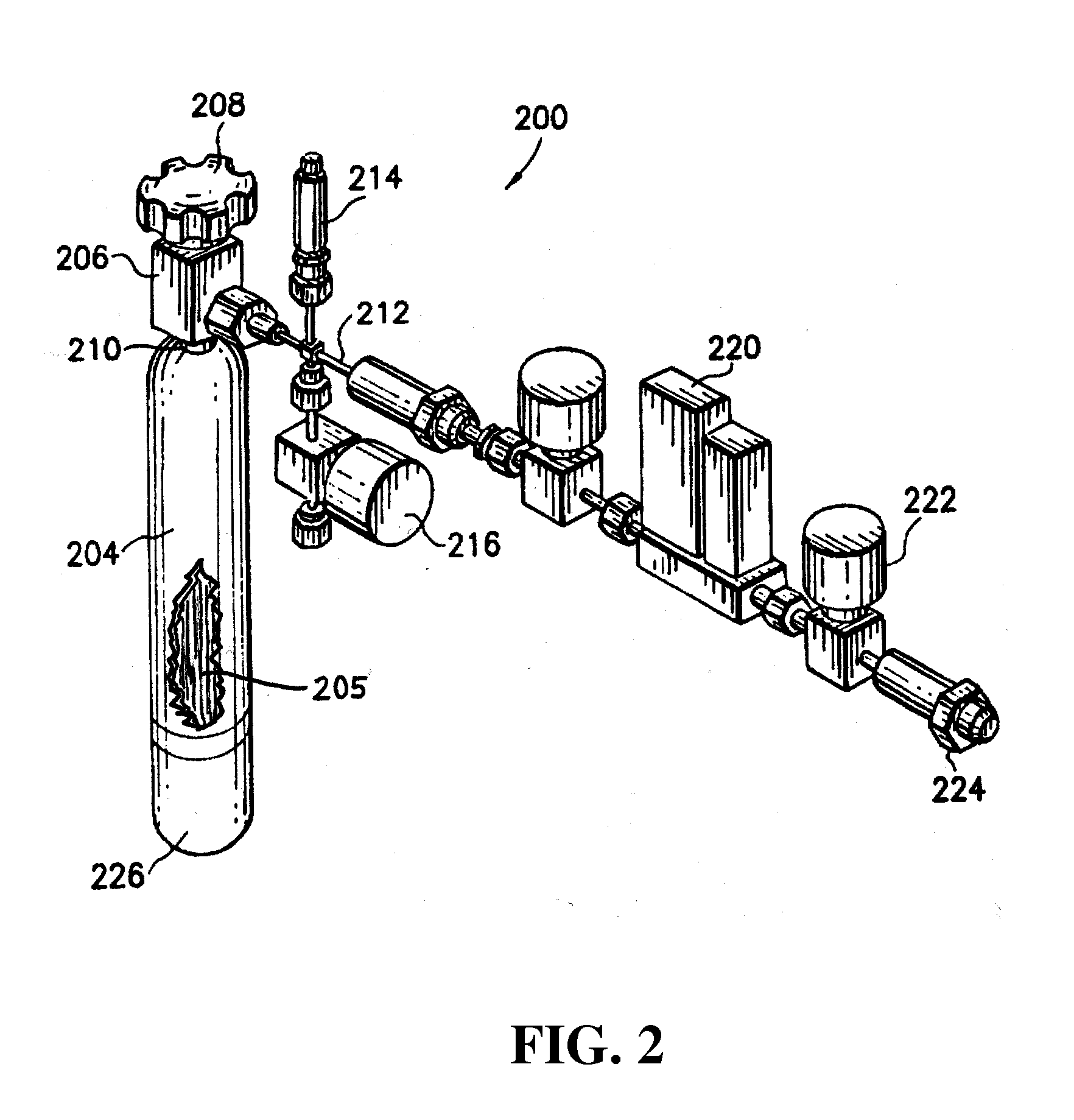

Pvdf pyrolyzate adsorbent and gas storage and dispensing system utilizing same

A polyvinylidene fluoride (PVDF) pyrolyzate adsorbent is described, having utility for storing gases in an adsorbed state, and from which adsorbed gas may be desorbed to supply same for use. The PVDF pyrolyzate adsorbent can be of monolithic unitary form, or in a bead, powder, film, particulate or other finely divided form. The adsorbent is particularly suited for storage and supply of fluorine-containing gases, such as fluorine gas, nitrogen trifluoride, carbo-fluoride gases, and the like. The adsorbent may be utilized in a gas storage and dispensing system, in which the adsorbent is contained in a supply vessel, from which sorbate gas can be selectively dispensed.

Owner:ENTEGRIS INC

Methods and apparatus for PFC abatement using a CDO chamber

In certain aspects, a system is provided for abating perfluorocarbons (PFCs) from a gaseous waste stream that includes (1) a wet scrubber adapted to scrub a gaseous waste stream and having an outlet adapted to discharge a scrubbed gaseous waste stream; and (2) a controlled decomposition oxidation (CDO) system. The CDO system includes a CDO thermal reaction chamber that includes (a) an inlet coupled to the outlet of the wet scrubber; (b) a catalyst bed adapted to abate PFCs within the CDO thermal reaction chamber; and (c) an outlet. Numerous other aspects are provided.

Owner:APPLIED MATERIALS INC

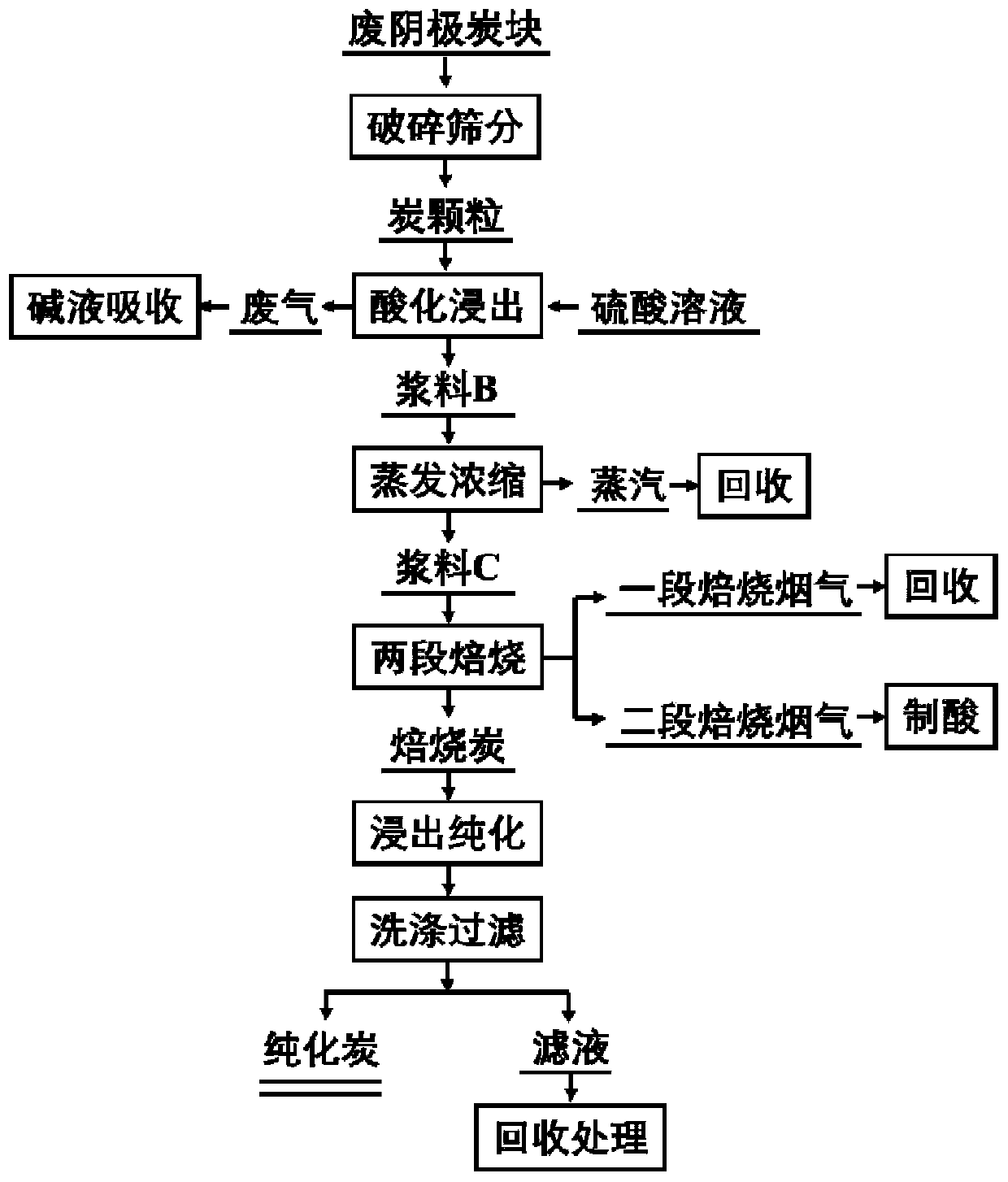

Recovery method of aluminum electrolysis waste cathode carbon block

ActiveCN111232947AAchieve recyclingAchieve cycleSulfate/bisulfate preparationFluorineAluminium electrolysisFlue gas

The invention discloses a recovery method of an aluminum electrolysis waste cathode carbon block. The method comprises the following steps: (1) crushing and screening waste cathode carbon blocks to obtain carbon particles, (2) mixing the carbon particles with a sulfuric acid solution to obtain slurry A, and then performing pressure leaching to obtain slurry B, (3) evaporating and concentrating theslurry B until the mass percent of water is lower than 8% to obtain slurry C, (4) adding concentrated sulfuric acid into the slurry C to obtain slurry D, roasting at 150-300 DEG C for 0.5-10 hours, and roasting at 300-600 DEG C for 0.5-8 hours to obtain roasted carbon, and (5) mixing and leaching the roasted carbon and a leaching agent, and filtering and washing to obtain purified carbon. In thetreatment process, high-temperature fluorine-containing flue gas and fluorine-containing wastewater are not generated, and fluorine, aluminum and carbon materials can be recycled, so that comprehensive recycling and cleaning treatment on the aluminum electrolysis waste cathode carbon block are realized.

Owner:CENT SOUTH UNIV

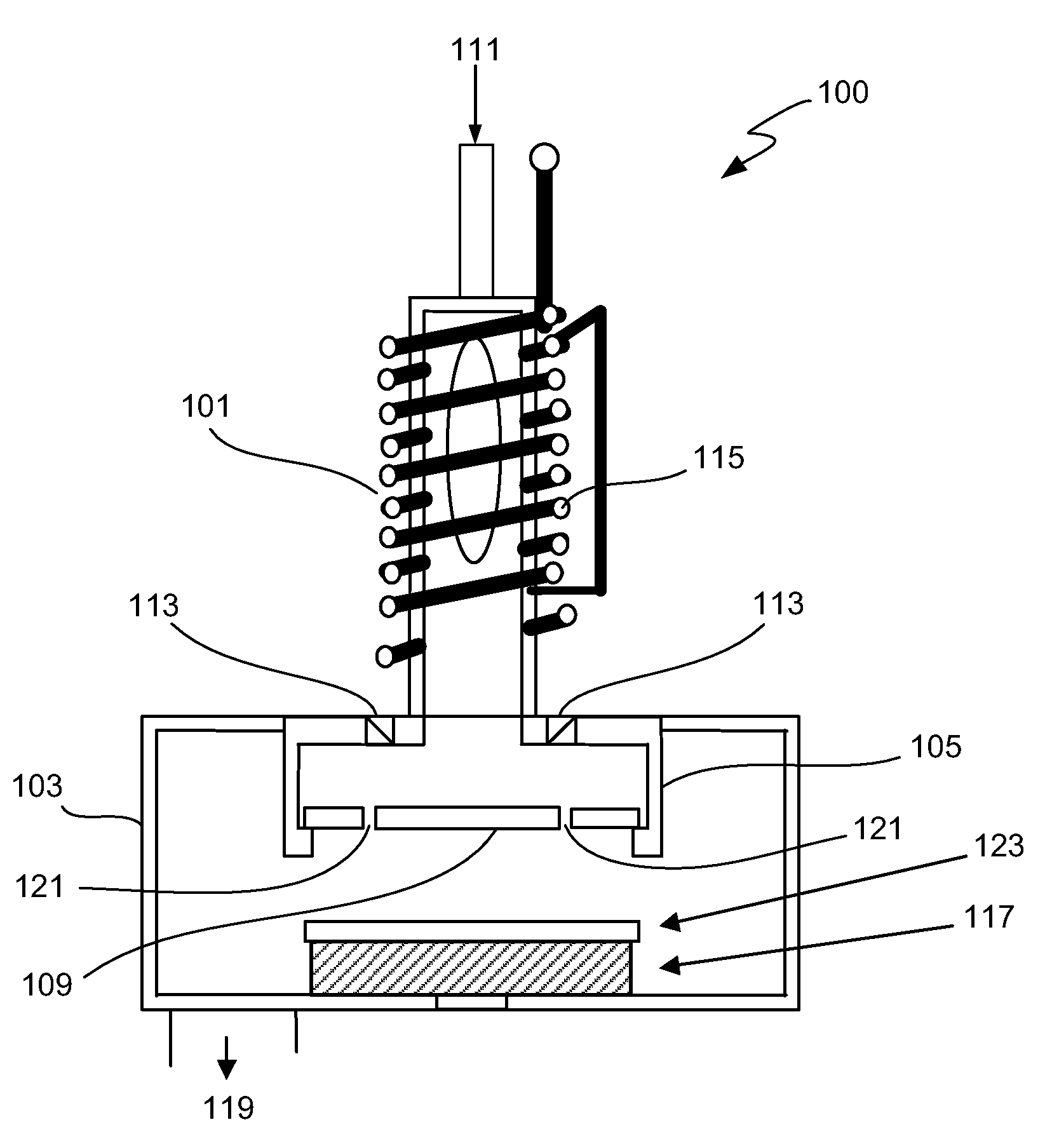

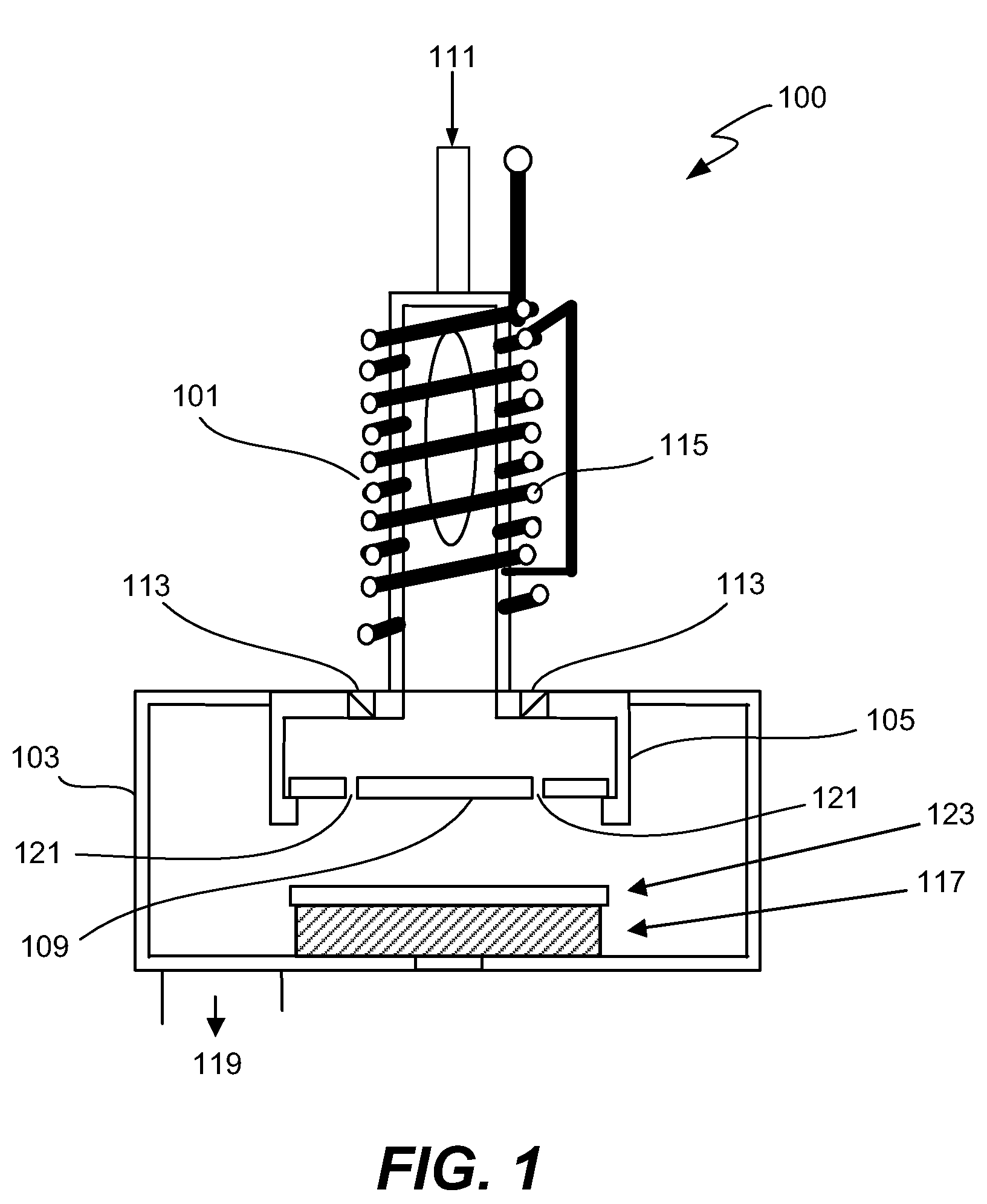

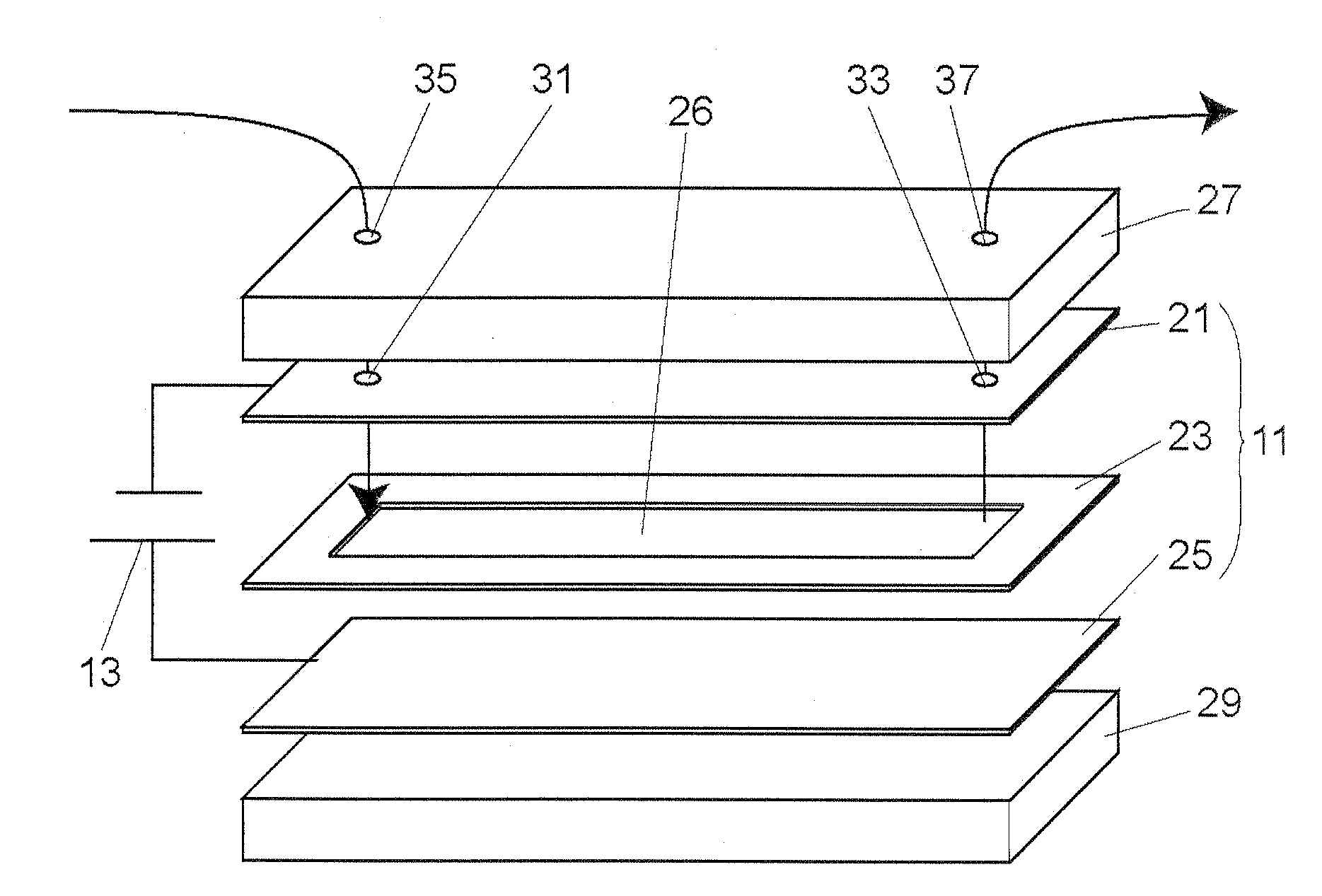

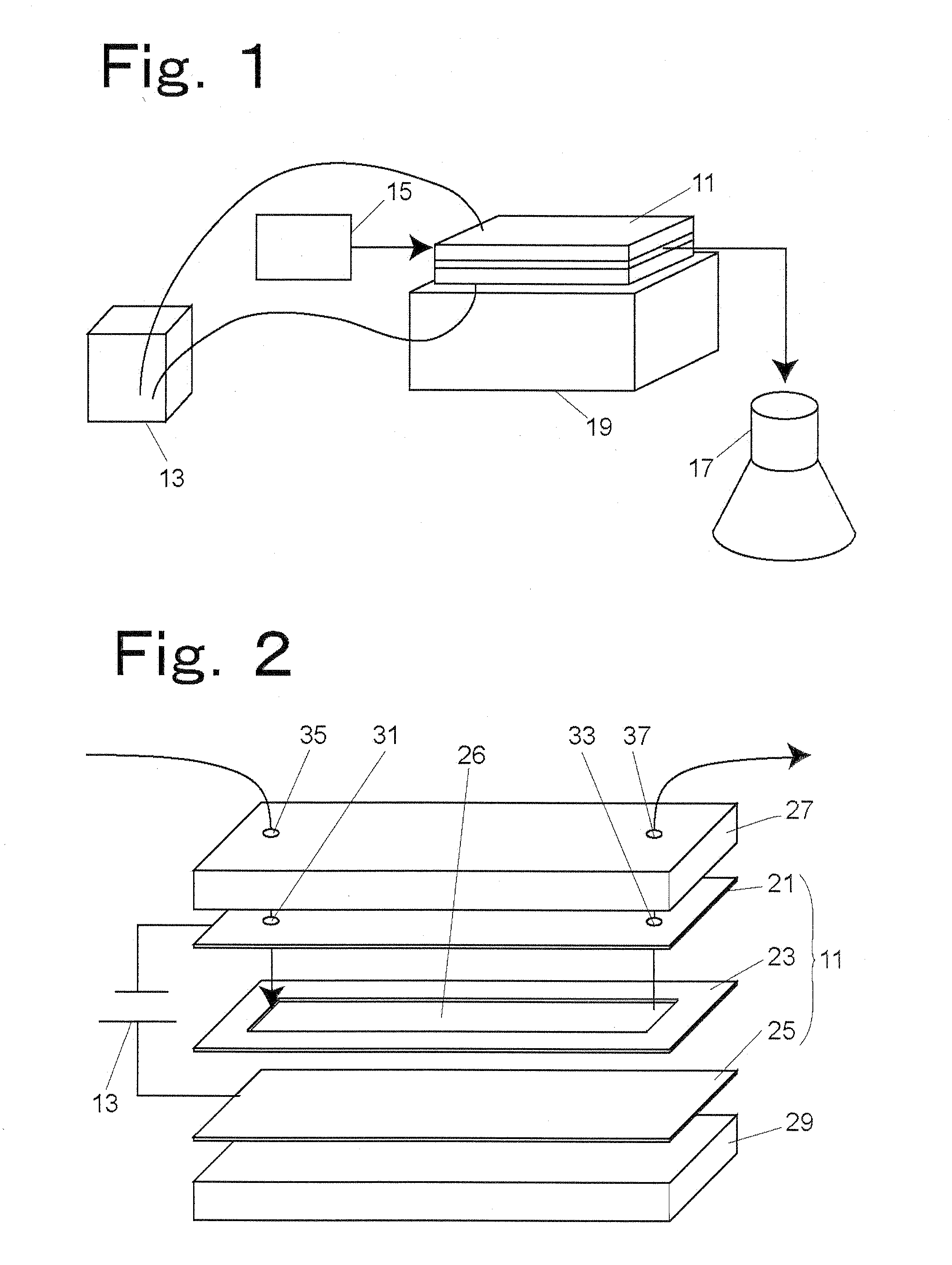

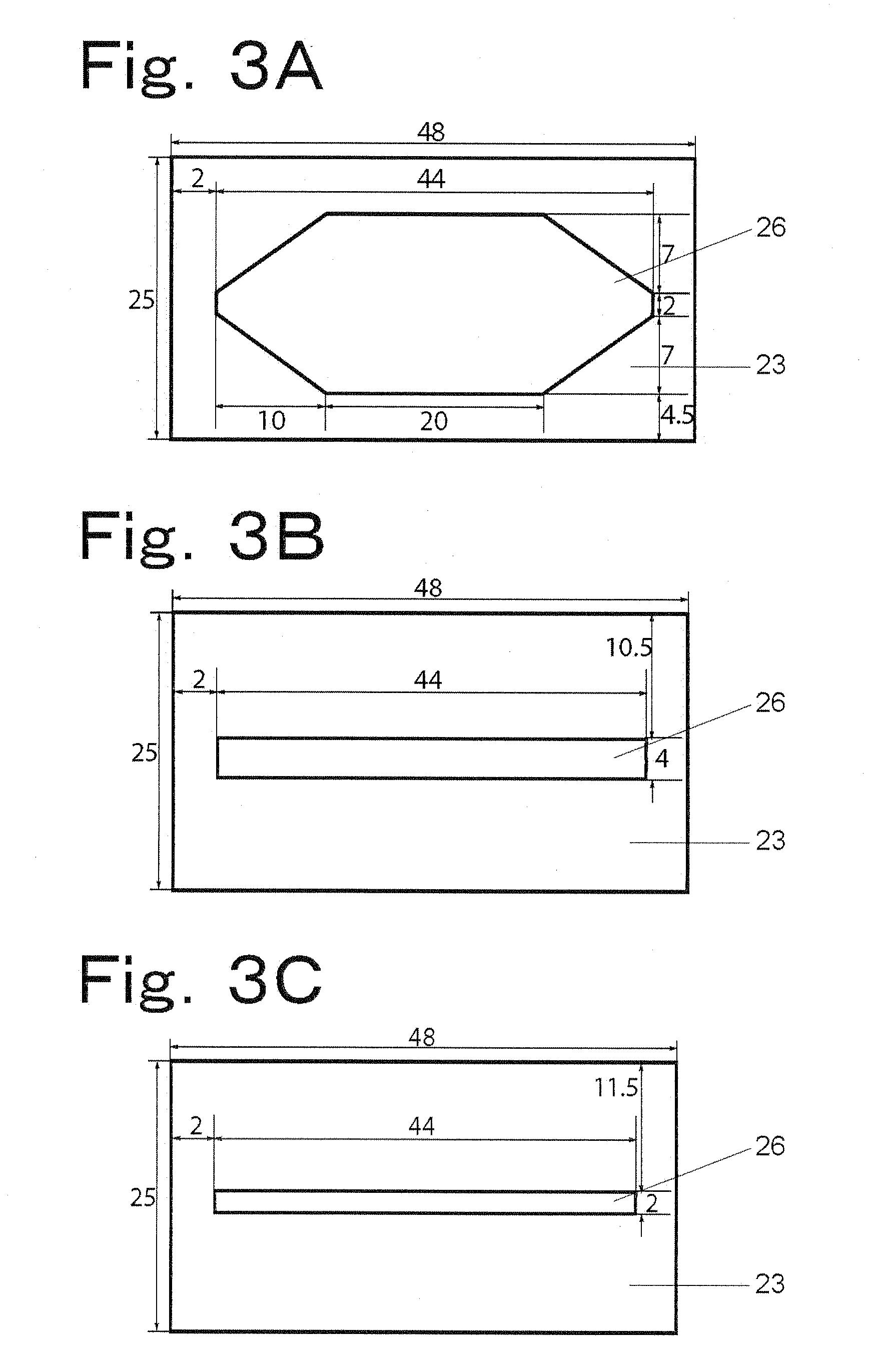

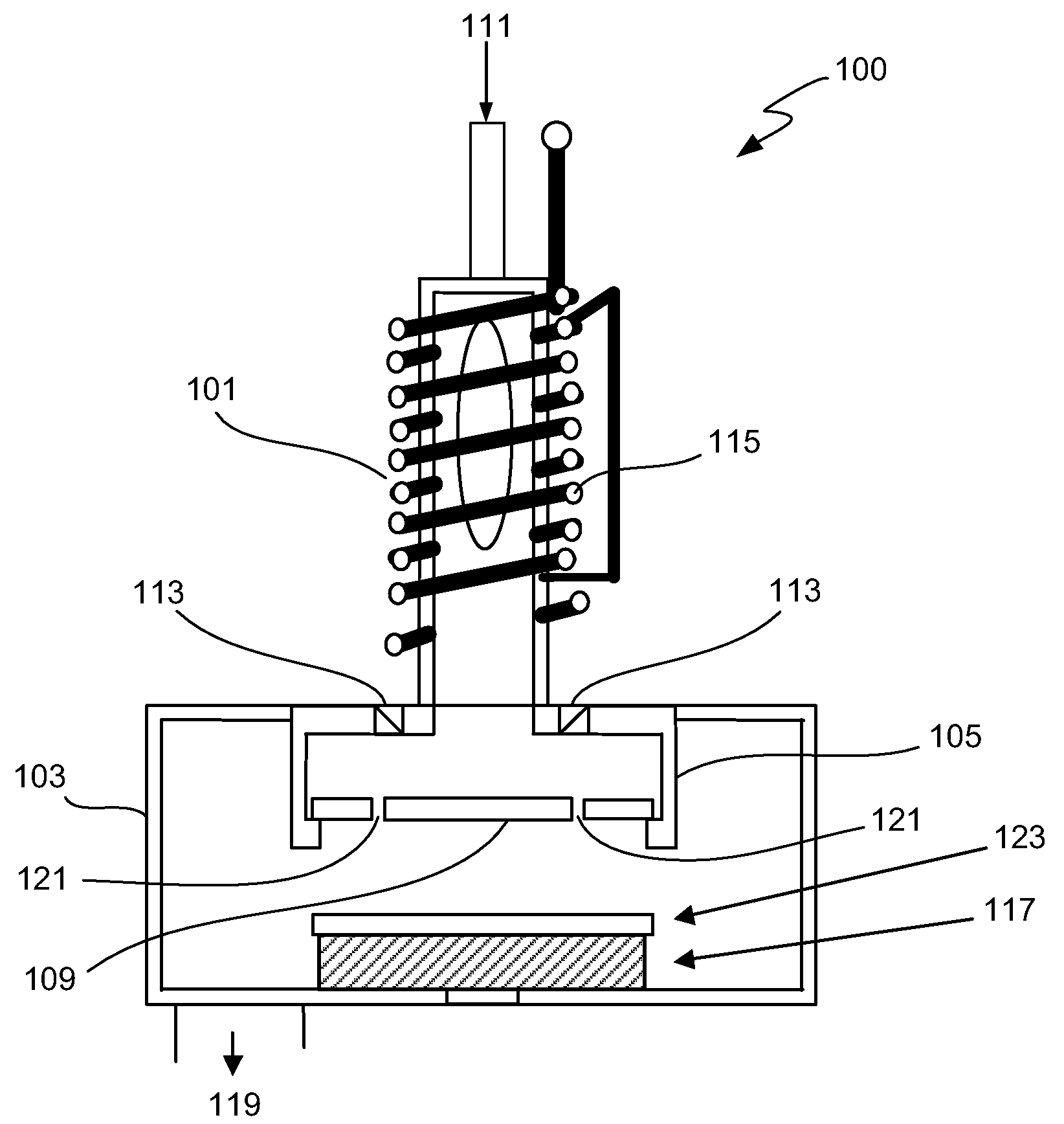

Radioactive fluorine anion concentrating device and method

InactiveUS20100101943A1Large specific surface areaLower the volumeSpecific isotope recoveryCellsMetallic materialsFluoride

A radioactive fluoride anion concentrating device capable of concentrating 18F− ions speedily and efficiently. A flow cell (11) is composed of a metal plate electrode (21), an insulating sheet (23) and a carbon plate electrode (25) located so that the sides of electrodes may be opposed to each other with the insulating sheet (23) inserted between them. An example of the plate metal plate electrode (21) is obtained by forming a film of metallic material on an insulation plate, and an example of the insulating sheet (23) is a PDMS from which a groove being a channel (26) having a thickness of ≦500 μm is cut out. The thickness of the sheet is desirably about 100 μm. The upper and lower sides of the flow cell (11) are fixed by fixing jigs (27) and (29).

Owner:SHIMADZU CORP +1

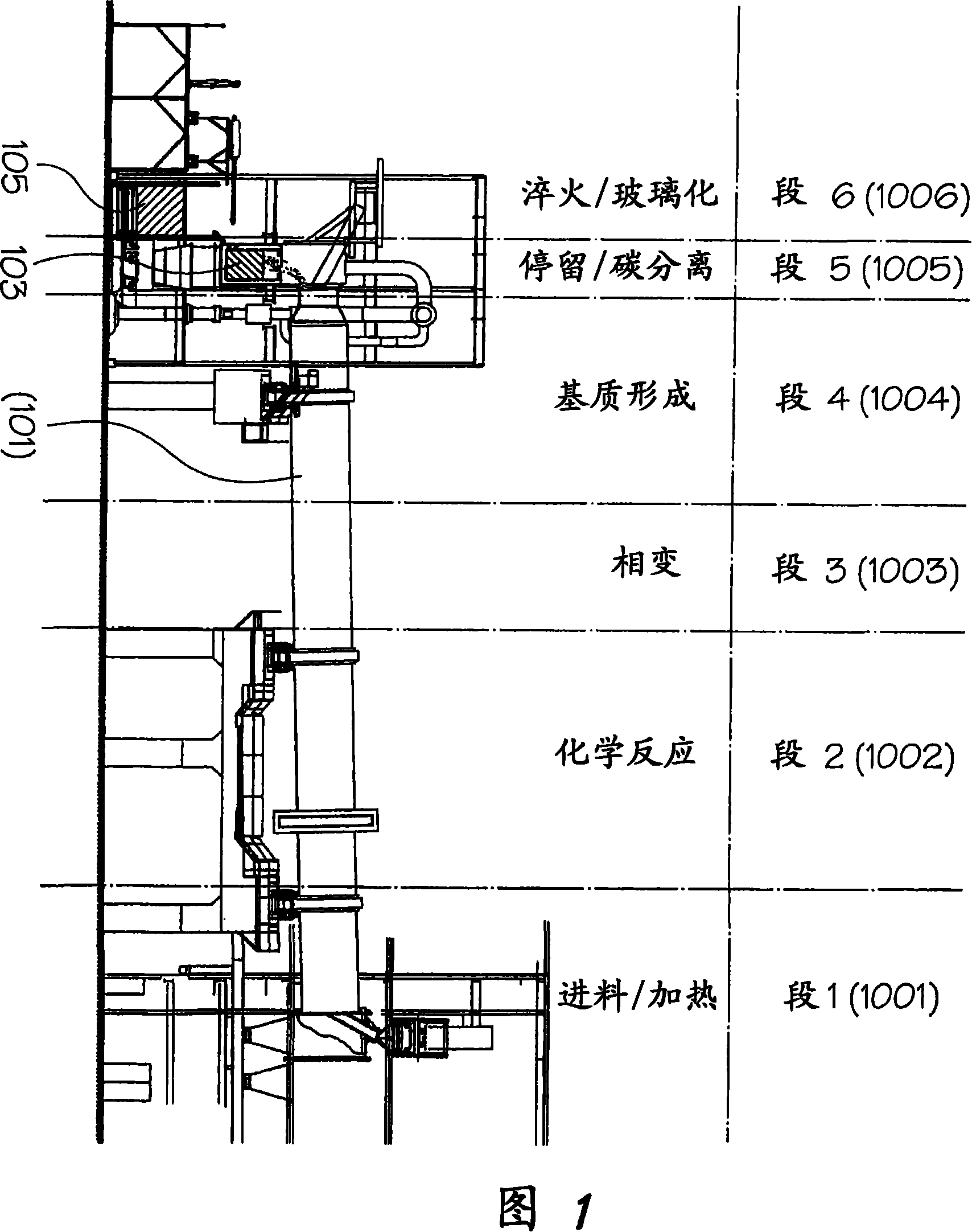

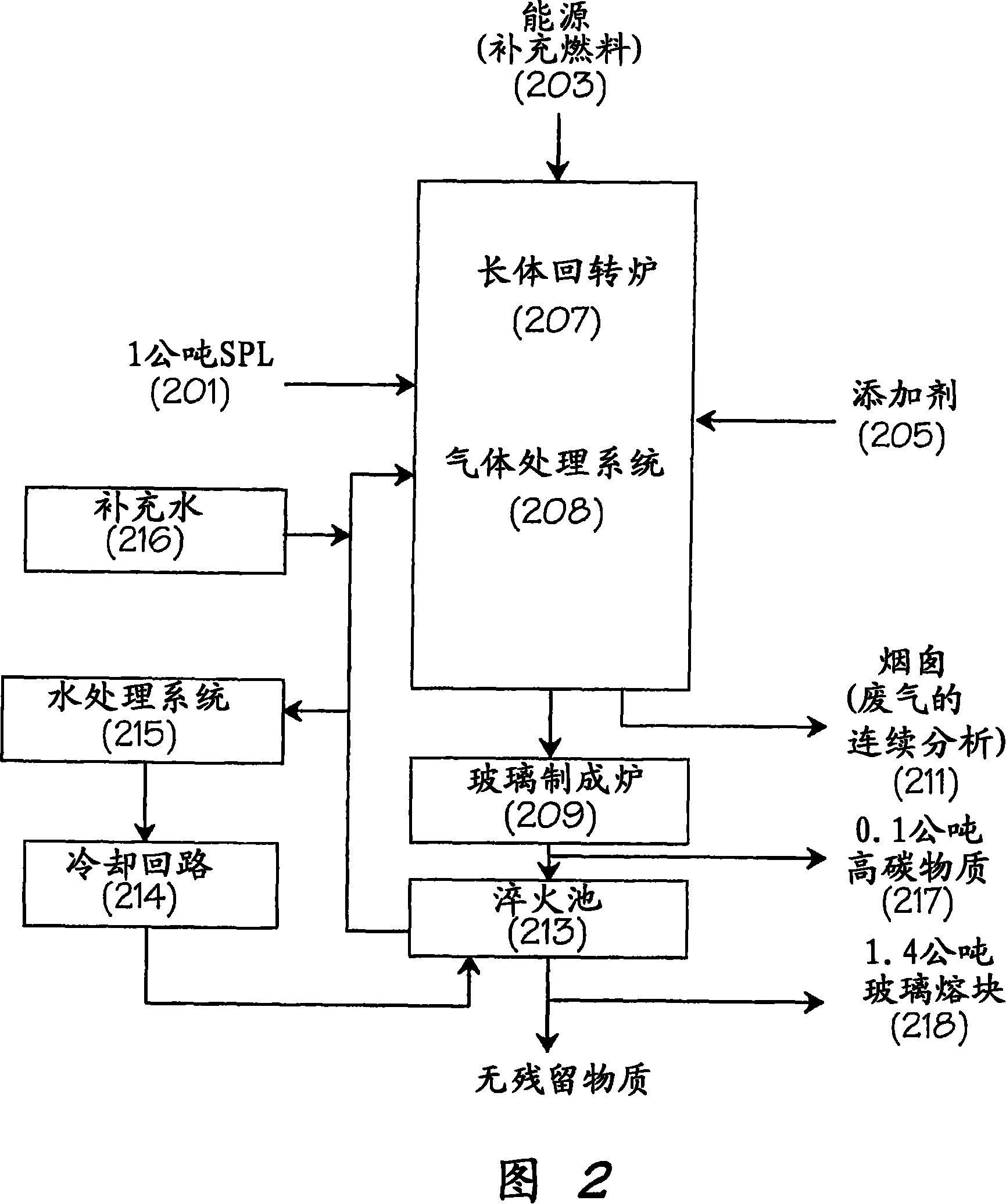

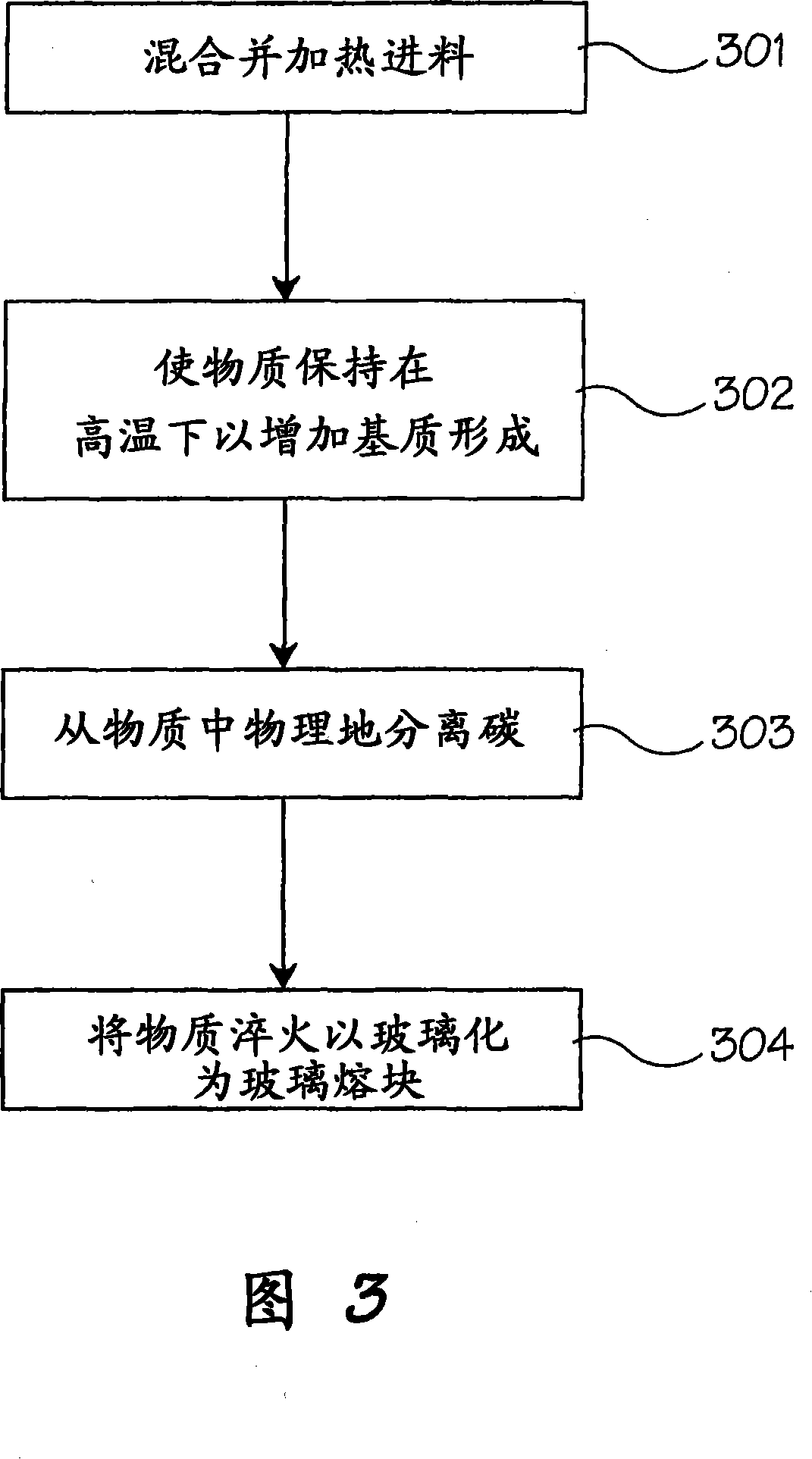

Process and apparatus for converting spent potliners into a glass frit, and resulting products

The present invention relates to a fire metallurgy method for converting the waste slot liner or other harmful material from the aluminum production industry to the glass clinker clew of amorphous fluorine-bearing sodium aluminosilicate and amorphous fluorine-bearing aluminum calcium silicate and converting to the high-carbon material and the device. The raw materials of waste slot liner, silicon dioxide or siliceous material and calcium oxide are added to the non-burner end of the counterflow rotary burner. The material is heated to destroy the cyanide, the salt fluoride is converted to calcium fluoride and forms a homogeneous liquid material. Then the carbon is physically separated from the material. Afterwards the material is glassed to generate the valuable glass clinker clew and high-carbon material.

Owner:NUOVOFORD INT

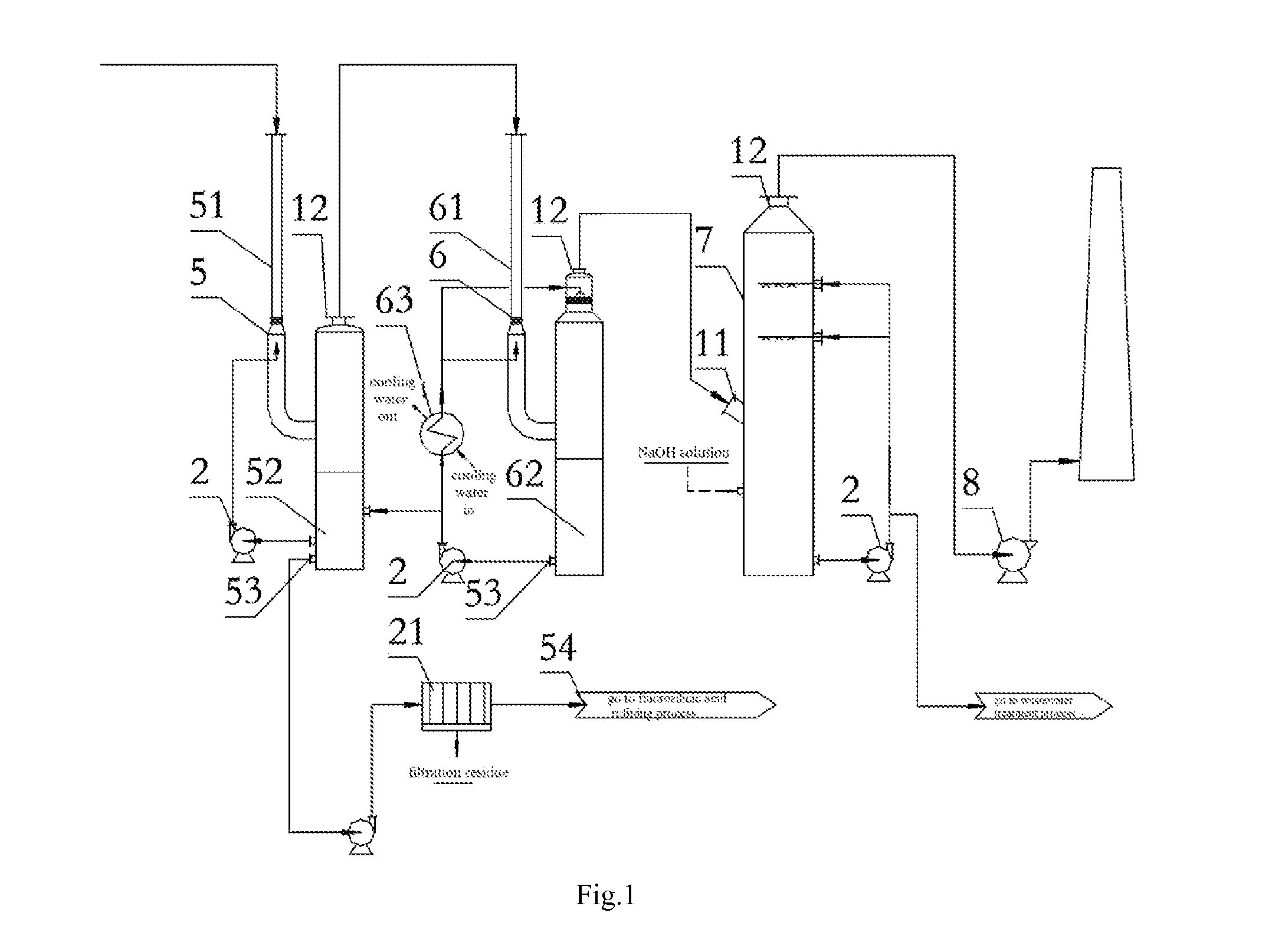

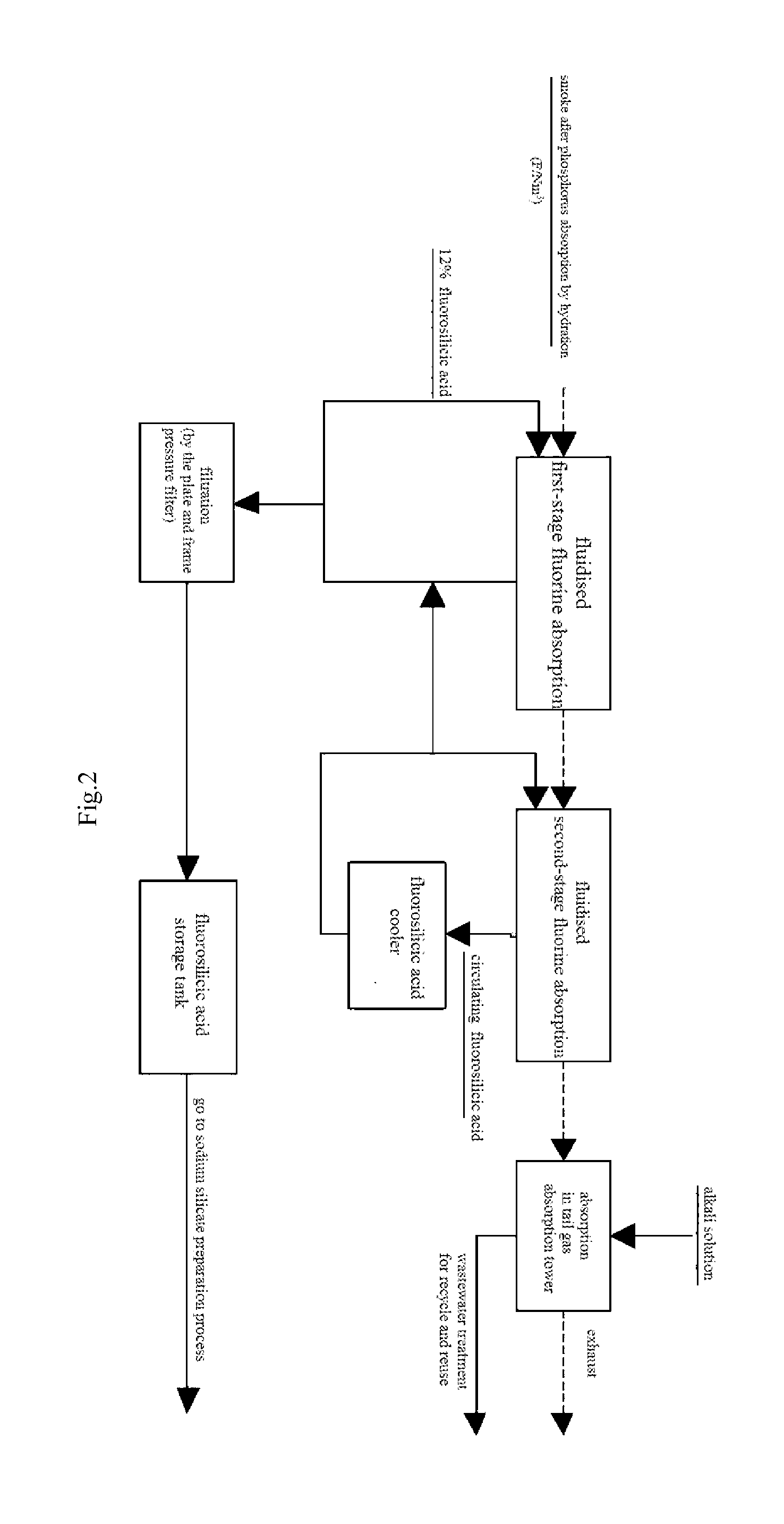

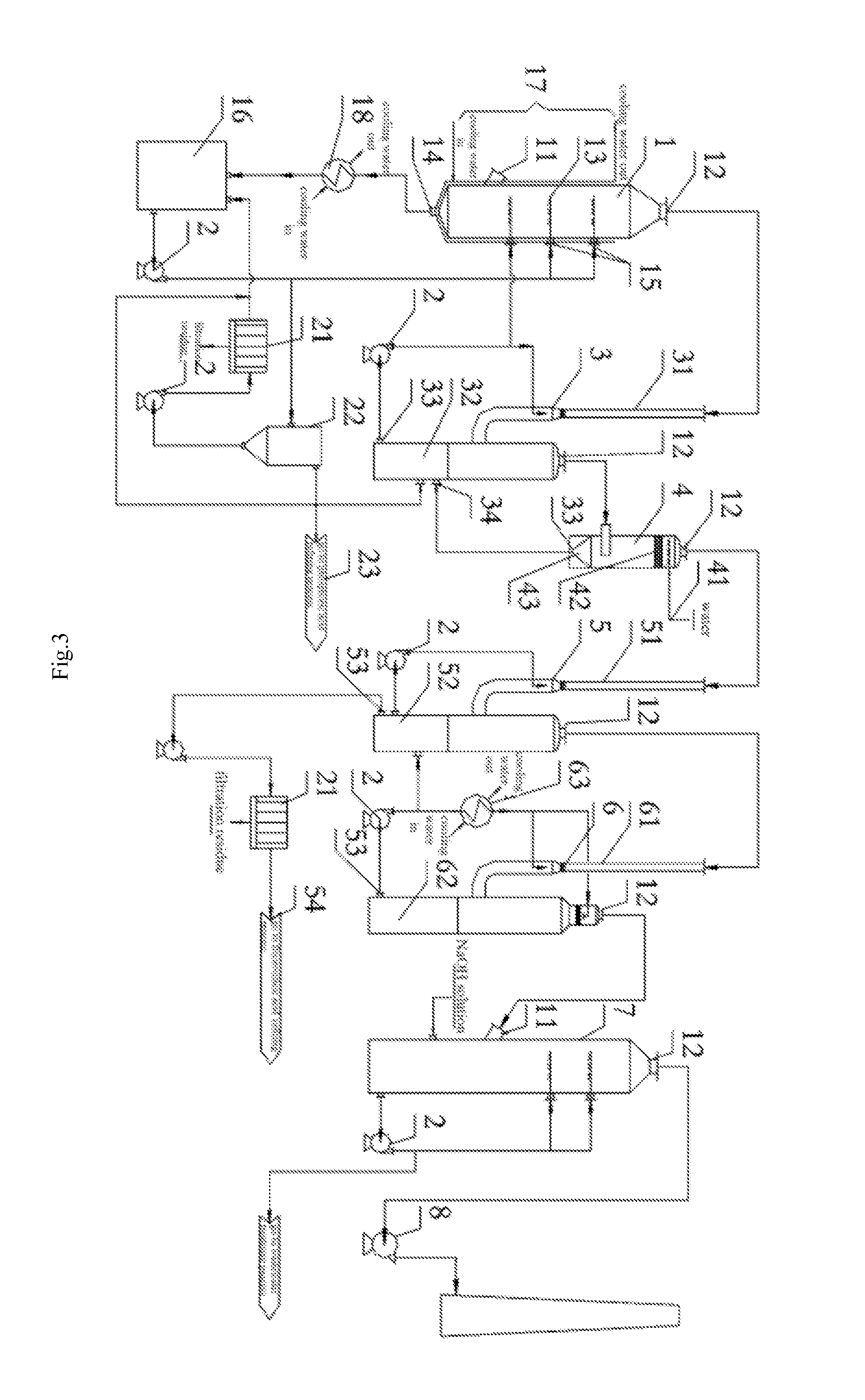

Device and process for fluorine recovery from smoke after phosphorus absorption by hydration in kiln process for production of phosphoric acid

A device and process for fluorine recovery from smoke after phosphorus absorption by hydration in KPA, wherein the device comprises a first-stage and second-stage fluorine absorption tower, which are both fluidised counter-current washing towers. The device according to the present invention has simple structure, low investment cost, high raw material utilization rate, and good fluorine recovery effects.

Owner:SICHUAN JIUCHANG SCI & TECH

Method for purifying fluorine gas

The invention provides a method for purifying fluorine gas, wherein the fluorine gas is obtained by electrolyzing fuse salt in an electrolyzer, and the fluorine gas to be purified, obtained through electrolysis, is introduced into a heat exchange device having the operation pressure being 0-0.5MPa and the internal temperature being minus 10 DEG C to minus 100 DEG C, and is then adsorbed by a fluoride. According to the method provided by the invention, the pressure of the heat exchange device and the pressure of an electrolytic bath are the same, so that the system is convenient to control; the equipment is simple in structure, and conventional heat exchanger and adsorption column can be used without increasing the reforming cost; and with the adoption of the method disclosed by the invention, the fluorine gas without HF can be obtained after fluorine preparation based on electrolysis, and HF can be recovered at the same time.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

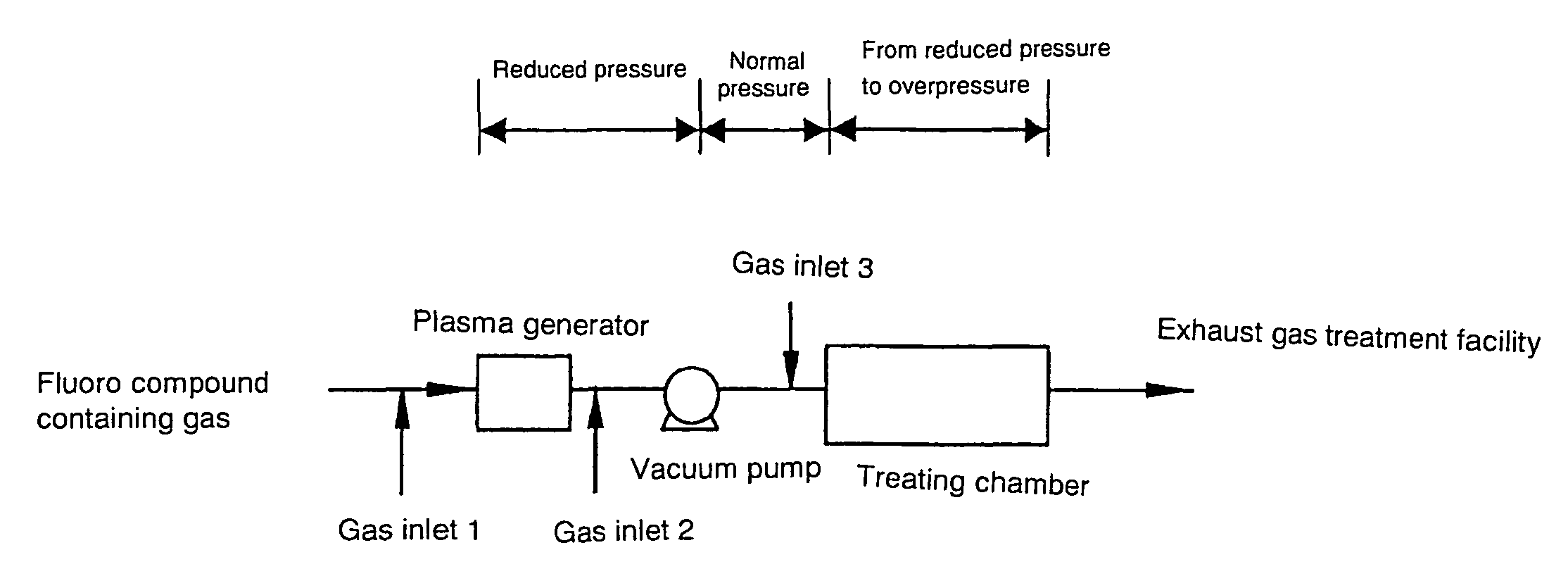

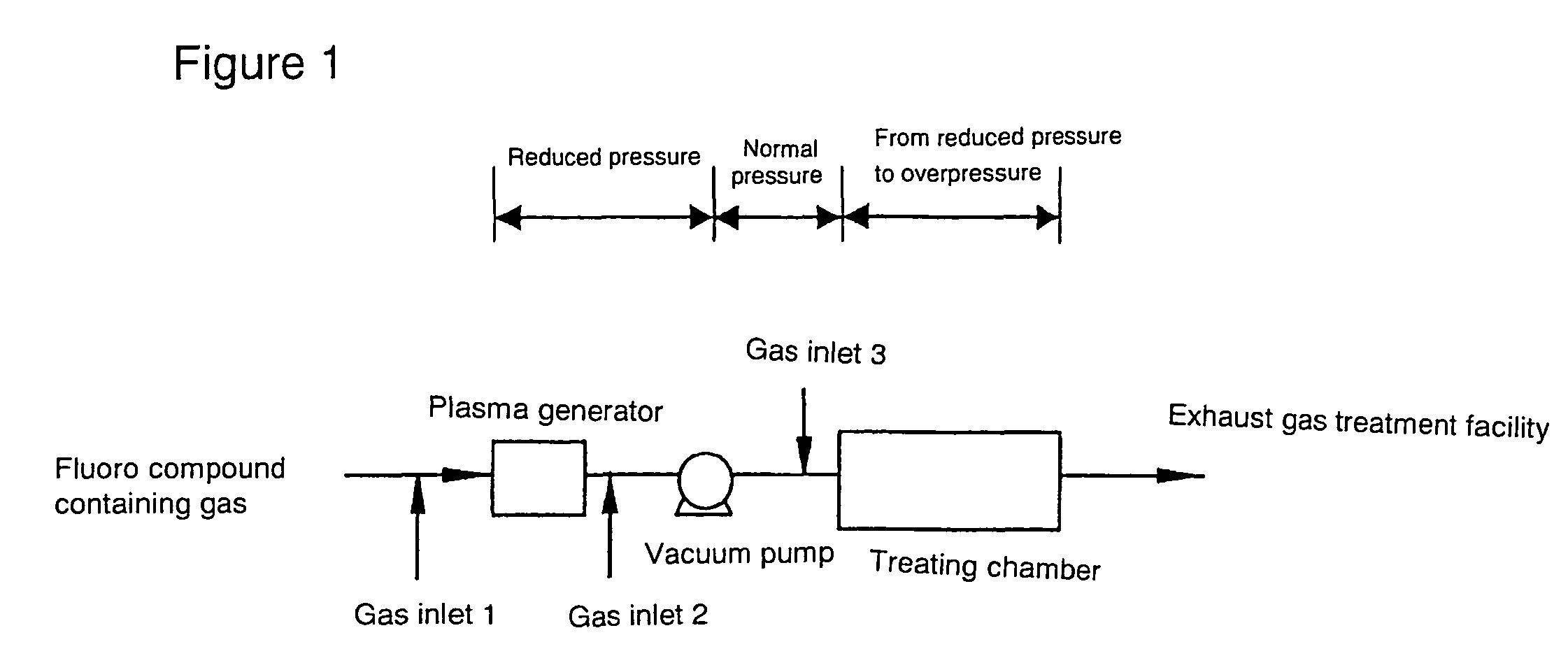

Processes and equipments for preparing F2-containing gases, as well as process and equipments for modifying the surfaces of articles

ActiveUS7919141B2Semiconductor/solid-state device manufacturingSolid state diffusion coatingTM compoundSurface modification

The present invention provides processes and equipments for safely and easily preparing an F2-containing gas, as well as processes and equipments for surface modification using the F2-containing gas prepared.According to the present invention, a gas containing a fluoro compound that is easier to handle than F2 is supplied and the fluoro compound is excited and decomposed to convert it into F2 gas before surface modification and then used for surface modification. According to the present invention, there is no necessity of providing, storing and transporting a large amount of F2 gas in advance because a necessary amount of F2 gas is obtained immediately before surface modification.A process for preparing an F2-containing gas comprises the steps of exciting at least one fluoro compound in a fluoro compound-containing gas by conferring energy on the fluoro compound-containing gas under reduced pressure; and partially or completely converting the excited fluoro compound-containing gas containing the excited fluoro compound into F2 under normal pressure or overpressure.

Owner:KANTO DENKA IND CO LTD

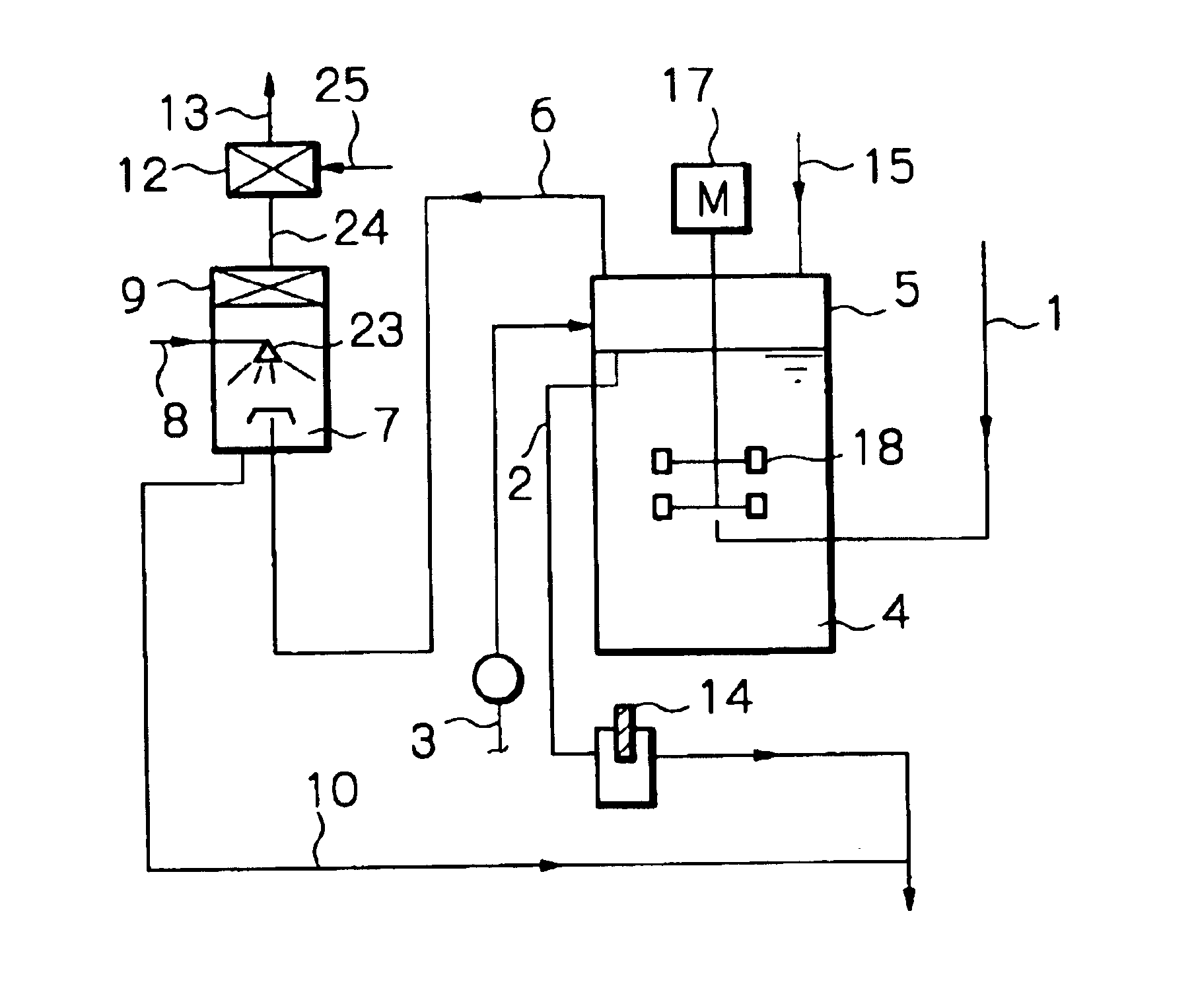

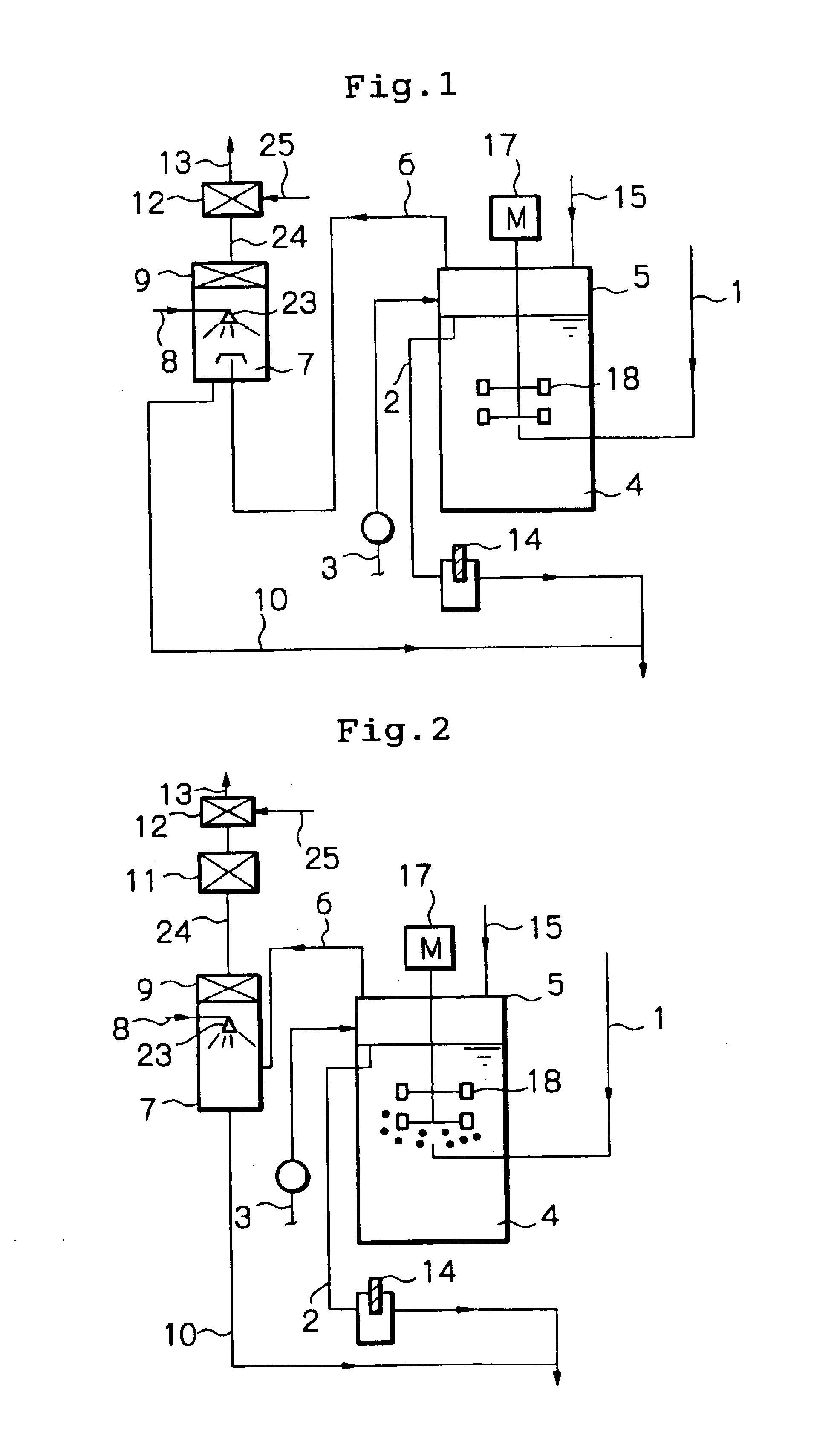

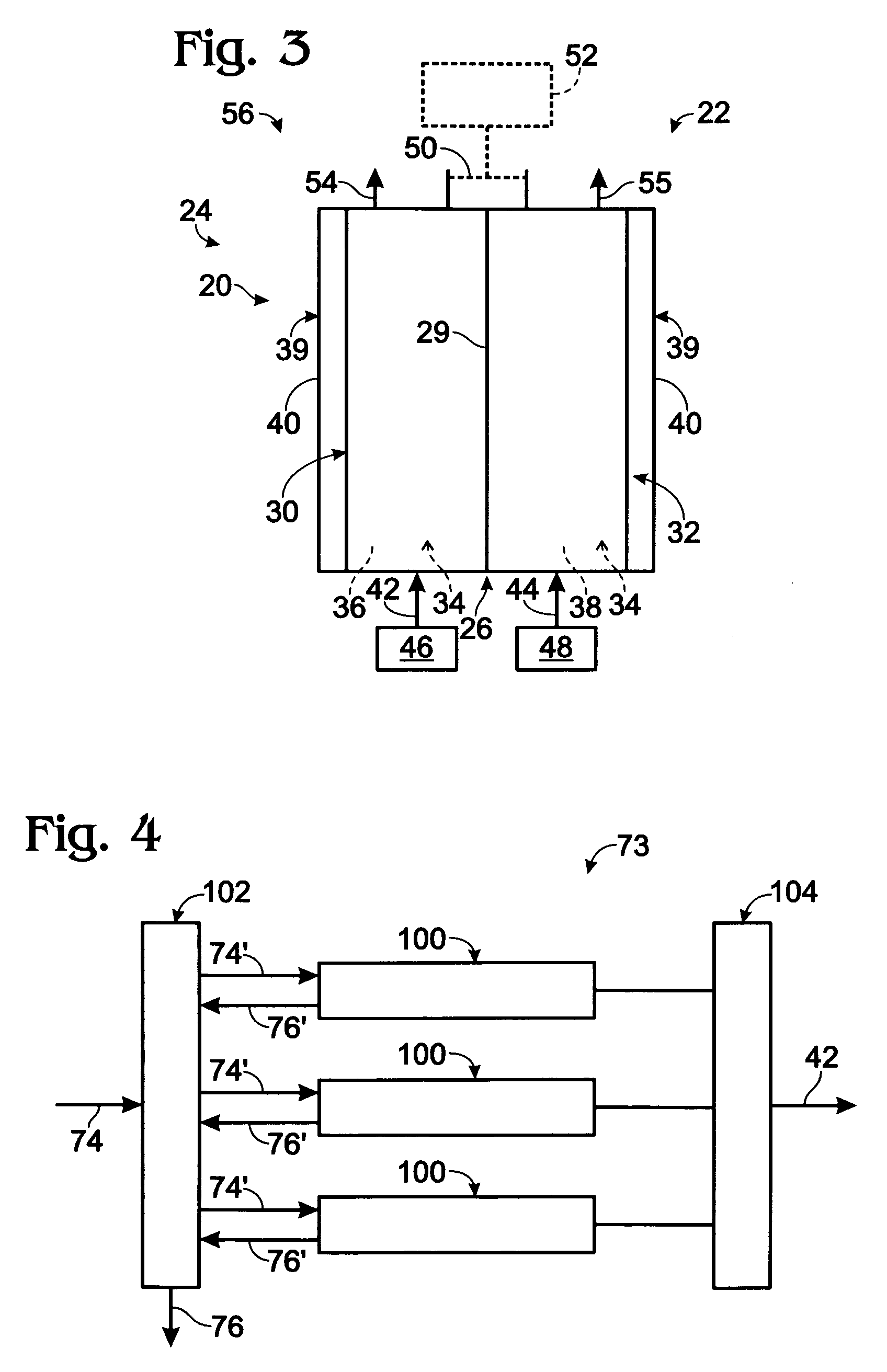

Process and apparatus for treating semiconductor production exhaust gases

InactiveUS6953557B1High removal rateLow running costChlorine/hydrogen-chlorideCombination devicesHalogenPolysilicon halides

A process and an apparatus for treating exhaust gases, comprising an aeration stirring tank (5) employing an aqueous alkaline liquid, and, as a posterior stage, a gas-liquid contact device (7) and / or a packed column (11). The apparatus can remove at the posterior stage harmful gases that the aeration stirring tank fails to remove, for example, water-soluble organic compounds such as ethanol, halogenated silicon compounds such as SiCl4, and halogen gases such as F2 and Cl2. The process and apparatus are particularly suitable for purifying exhaust gases discharged from a semiconductor production device.

Owner:EBARA CORP

Fluorine gas purifying filler and preparation method and application thereof

ActiveCN107337180AHigh porosityWidely used valueDispersed particle separationFluorineHydrofluoric acidPorosity

Owner:洛阳森蓝化工材料科技有限公司

Systems and methods for supplying auxiliary fuel streams during intermittent byproduct discharge from pressure swing adsorption assemblies

Combustion fuel stream supply systems for use with pressure swing adsorption (PSA) assemblies, and hydrogen-generation assemblies and / or fuel cell systems containing the same. The PSA assemblies are operated according to a PSA cycle to receive a mixed gas stream and, while producing a product hydrogen stream therefrom, intermittently discharge a byproduct stream. The byproduct stream, when available, may be delivered as a fuel stream to a heating assembly, which may heat the hydrogen-producing region that produces the mixed gas stream. A combustion fuel stream supply system selectively supplies an auxiliary fuel stream when a byproduct stream is not discharged or otherwise does not have a predetermined combustion fuel value sufficient, when combusted, to maintain the hydrogen-producing region within a desired temperature range. The one or more streams supplied to the heating assembly have a combined combustion fuel value at least as great as the predetermined threshold value.

Owner:DCNS SA

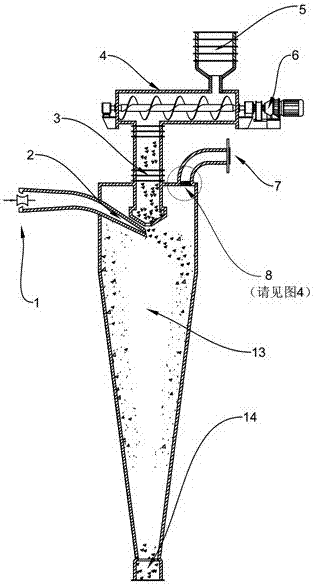

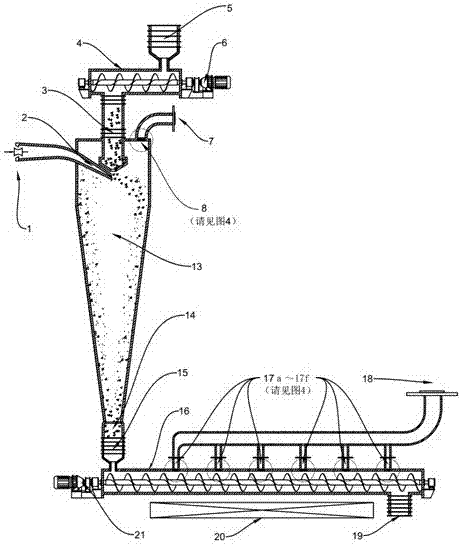

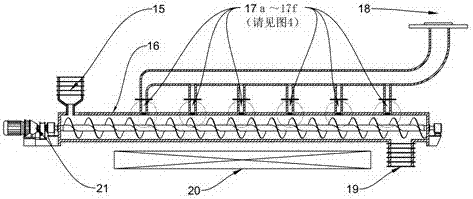

High-efficiency purifying device and process for fluorine

InactiveCN107441883AThe adsorption reaction is rapid and thoroughEfficient continuous productionGas treatmentDispersed particle filtrationHydrogen fluorideSorbent

The invention discloses a high-efficiency purifying device and a high-efficiency purifying process for fluorine. The high-efficiency purifying device for the fluorine comprises a feeding cabin, a spiral feeder, a fluorine pressurizing pump, a fluorine jet head, a conical reactor, filters and a spiral regenerative reactor, and is characterized in that after being pressurized,the fluorine is jetted to entrain a powder adsorbent through the jet head; the fluorine and the powder adsorbent form a gas / solid turbulent cluster; and the powder adsorbent adsorbs hydrogen fluoride entrained in the fluorine. A pure product is obtained after dust in purified fluorine is filtered through the filters. The adsorbent sinks to the bottom of the reactor, and enters the spiral regenerative reactor for heating and regenerating through an airtight material cabin. The hydrogen fluoride is desorbed from the adsorbent, is attracted through an external negative pressure device, is filtered and gathered through a plurality of gas branch pipe filters, and flows out from the spiral regenerative reactor. The regenerated adsorbent is transmitted through an external device and is returned to the material cabin for recycling. The high-efficiency purifying device and the high-efficiency purifying process for the fluorine realize high-efficiency purifying of industrial fluorine, and have the advantages of reliable process, stable product quality and the like.

Owner:广东金光高科股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing [F-18-]fluoride ion Method for preparing [F-18-]fluoride ion](https://images-eureka.patsnap.com/patent_img/63103ae1-86ae-4e4f-a790-e6d5768e00ff/US06190637-20010220-C00001.png)

![Method for preparing [F-18-]fluoride ion Method for preparing [F-18-]fluoride ion](https://images-eureka.patsnap.com/patent_img/63103ae1-86ae-4e4f-a790-e6d5768e00ff/US06190637-20010220-C00002.png)

![Method for preparing [F-18-]fluoride ion Method for preparing [F-18-]fluoride ion](https://images-eureka.patsnap.com/patent_img/63103ae1-86ae-4e4f-a790-e6d5768e00ff/US06190637-20010220-C00003.png)