Method and device for preparing high-purity fluorine gas or high-purity fluorine-containing mixed gas

A mixed gas and high-purity technology, which is applied in the direction of combined devices, separation methods, fluorine/hydrogen fluoride, etc., can solve the problems that cannot meet the requirements of fine chemical industry and high-end electronics industry, low purity of fluorine gas, and great difference between high-purity fluorine gas and other problems , to achieve good economic value, improve the purity, and expand the effect of the application market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

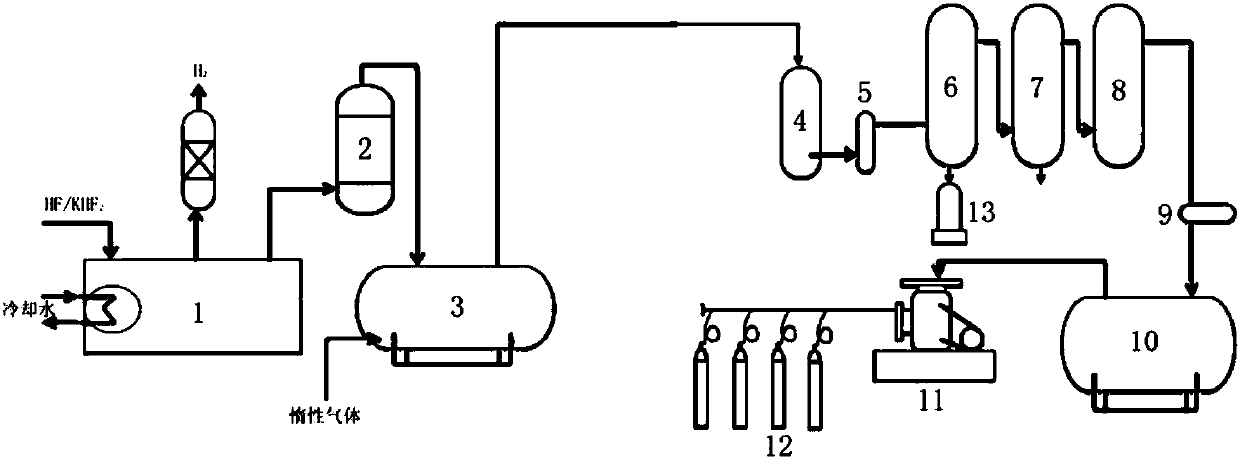

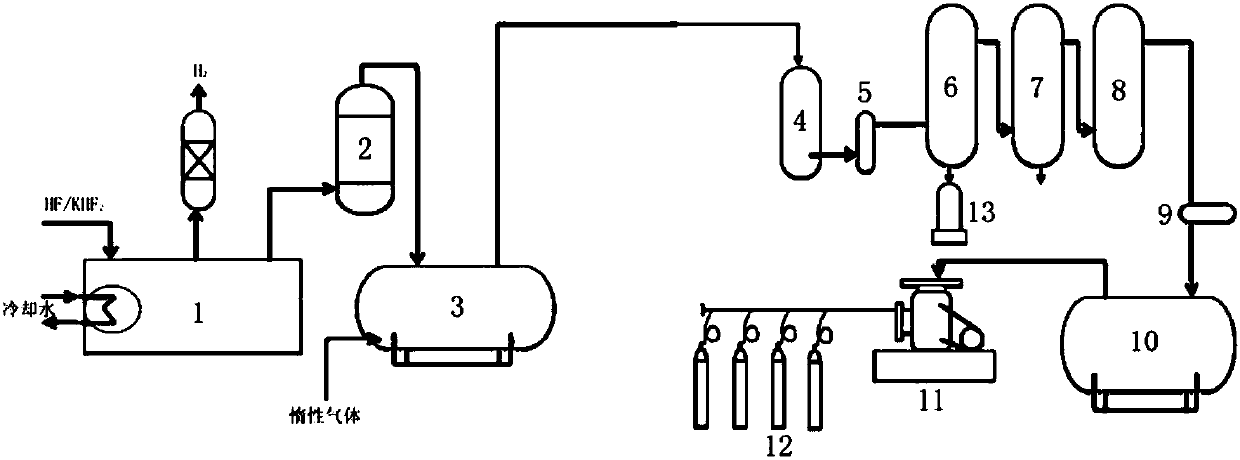

[0041] The device for preparing high-purity fluorine gas or high-purity fluorine-containing mixed gas in this embodiment, such as figure 1As shown, it includes an electrolysis device and a primary filter 5 connected in series, a primary condenser 6 with a condensation temperature of -60 to -100°C, and a secondary condenser 7 with a condensation temperature of -120 to -180°C; In the flow direction, the upstream of the primary filter 5 is connected with a gas booster device 4, which is used to mix the fluorine gas prepared by electrolysis or the fluorine gas prepared by electrolysis in the upstream. Gas pressurization; the refrigerant used in the primary condenser 6 and secondary condenser 7 is liquid nitrogen; the bottom of the primary condenser 6 is connected with a liquid collection device 13 for collecting condensed liquid HF;

[0042] After the gas pressurization device 4 (before the primary filter 5), a gas flow meter is installed to adjust the gas flow;

[0043] The elec...

Embodiment 2

[0049] The method for preparing high-purity fluorine gas in this embodiment adopts the device described in Embodiment 1, specifically:

[0050] Pressurize 1500g of purified fluorine gas produced by medium-temperature electrolysis KF·2HF to a pressure of 0.15MPa, and adjust the flow rate to 0.2m 3 / min, after being filtered through a primary filter with a pore size of 5 μm, the primary condensation and secondary condensation are performed in sequence; the temperature of the primary condensation is controlled at -75°C, and the temperature of the secondary condensation is controlled at -140°C ;

[0051] After the secondary condensed gas is purified, it is filtered through a secondary filter with a pore size of 0.2 μm, and then enters the finished product storage tank, which is high-purity fluorine gas.

[0052] 300 g of gas samples in the storage tank of the finished product are tested by a gas chromatograph, and the purity of the obtained high-purity fluorine gas is 99.9%.

Embodiment 3

[0054] The method for preparing high-purity fluorine-containing mixed gas (fluorine-nitrogen mixed gas) in this embodiment adopts the device described in Example 1, specifically:

[0055] Prepare 2000g of fluorine-nitrogen mixed gas (in the fluorine-nitrogen mixed gas, the mass percentage of fluorine gas is 20%) from the purified fluorine gas produced by medium-temperature electrolysis KF·2HF, pressurize to a pressure of 0.20MPa, and adjust the flow rate to 0.4m 3 / min, after being filtered through a primary filter with a pore size of 10 μm, the primary condensation and secondary condensation are performed in sequence; the temperature of the primary condensation is controlled at -80°C, and the temperature of the secondary condensation is controlled at -130°C ;

[0056] After the secondary condensed gas is purified, it is filtered through a secondary filter with a pore size of 1.0 μm, and then enters the finished product storage tank, which is a high-purity fluorine-nitrogen m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com