High-efficiency purifying device and process for fluorine

A purification device and fluorine gas technology, applied in the direction of fluorine/hydrogen fluoride, specific gas purification/separation, fluorine, etc., can solve the problems of easily blocking the gas flow channel of the adsorption device and affecting the normal production process, etc., and achieve rapid and thorough adsorption reaction and prolong The effect of life and simplification of operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

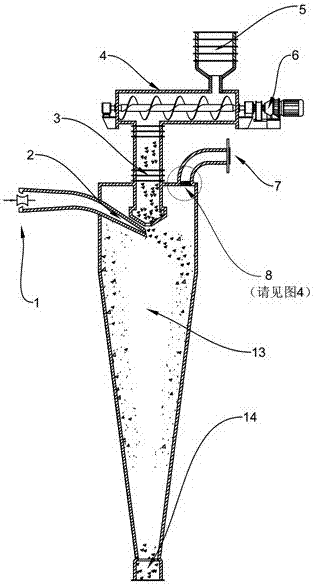

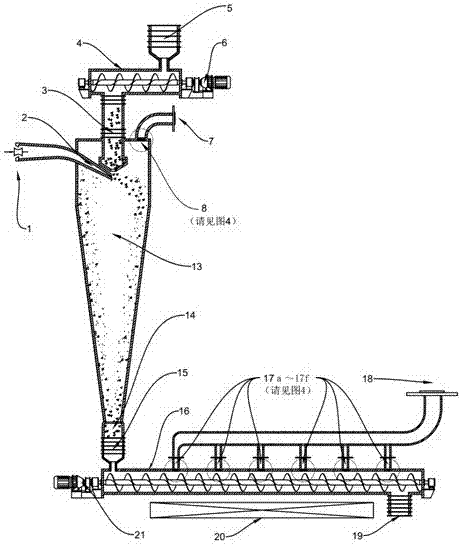

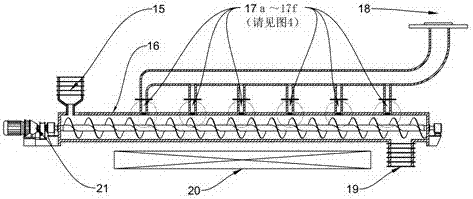

[0064] A high-efficiency purification device and process for fluorine gas, comprising the following steps.

[0065] Put the sodium fluoride whose quality meets the first grade index of YS / T 517-2009 into the feeding bin (5) of the screw feeder with a volume of 300L through the powder conveyor belt, and start the screw feeder (4) with a power of 1.0KW The variable frequency speed regulating motor (6) sends the sodium fluoride powder to the discharge bin (3) at a uniform speed under the condition that the set delivery rate is 0.5kg / min.

[0066] The fluorine gas to be purified is introduced into the fluorine gas booster pump (1), pressurized to 0.12Mpa, and the fluorine gas flow rate is set at 1.0kg / min, and connected to the fluorine gas nozzle (2) with an aperture of 0.1mm.

[0067] In a conical reactor (14) with a volume of 1000L, a bottom surface diameter ratio of 1:3, and a bottom height ratio of 1:10, a high-speed fluorine gas flow is injected from the fluorine gas nozzle (...

Embodiment 2

[0085] A high-efficiency purification device and process for fluorine gas, comprising the following steps.

[0086] Sodium fluoride whose quality is required to meet the first-class index of YS / T 517-2009 is put into the feeding bin (5) of the screw feeder with a volume of 500L through the airtight pipeline, and the screw feeder (4) with a power of 2.0KW is started. The variable frequency speed regulating motor (6) transports the sodium fluoride powder to the discharge bin (3) under the condition that the set delivery rate is 1.5kg / min.

[0087] Introduce the fluorine gas produced by medium-temperature fluorine production into the fluorine gas booster pump (1), pressurize to 0.15Mpa, set the fluorine gas flow rate at 2.0kg / min, and connect the fluorine gas nozzle with an aperture of 0.12mm (2 )middle.

[0088] In a conical reactor (14) with a volume of 2000L, a bottom surface diameter ratio of 1:3, and a bottom height ratio of 1:11, a high-speed fluorine gas flow is ejected f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com