Full-automatic workpiece assembling system

An assembly system, fully automatic technology, applied in the direction of metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult assembly, large production space, lack of flexibility, etc., to ensure processing stability, improve production efficiency, and reasonable The effect of using space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to facilitate those skilled in the art to understand, the present invention will be described in further detail below in conjunction with embodiment:

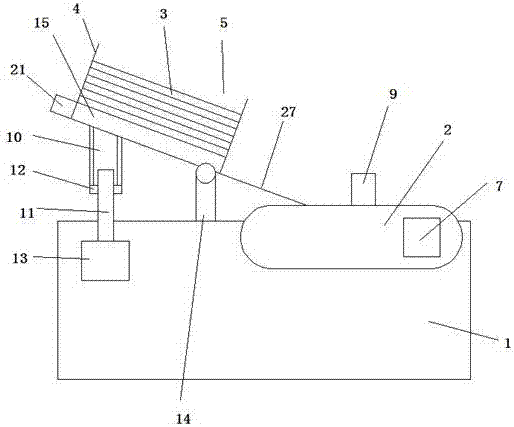

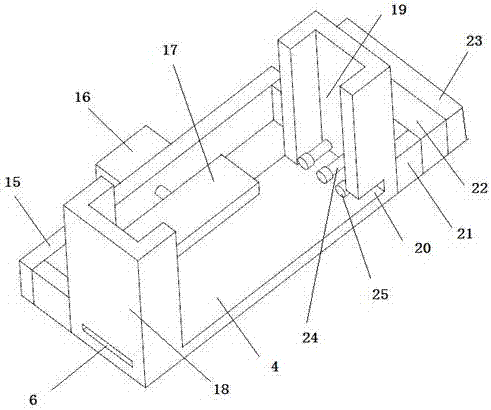

[0041] This embodiment provides a fully automatic workpiece assembly system, such as Figure 1-Figure 9As shown, it includes a feeding part and an assembly part arranged at the rear end of the feeding part. The feeding part includes a frame 1 and a feeding mechanism arranged at the front end of the frame 1 and a conveyor belt 2 arranged at the rear end of the frame 1. The feeding mechanism includes a storage strip 3 for accommodating the material tape, and the feeding mechanism also includes a material rack 4, and the material rack 4 is provided with a material cavity 5 for accommodating a plurality of storage strips 3, behind the material cavity 5 The end is provided with a discharge port 6 that allows the bottom material belt to pass through. The material rack 4 is placed obliquely backward and downward. As a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com