Cotton filling device for toy production

A cotton and equipment technology, which is applied in the field of cotton plug equipment for toy production, can solve the problems of uneven filling, difficult operation, and easy sticking of cotton.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

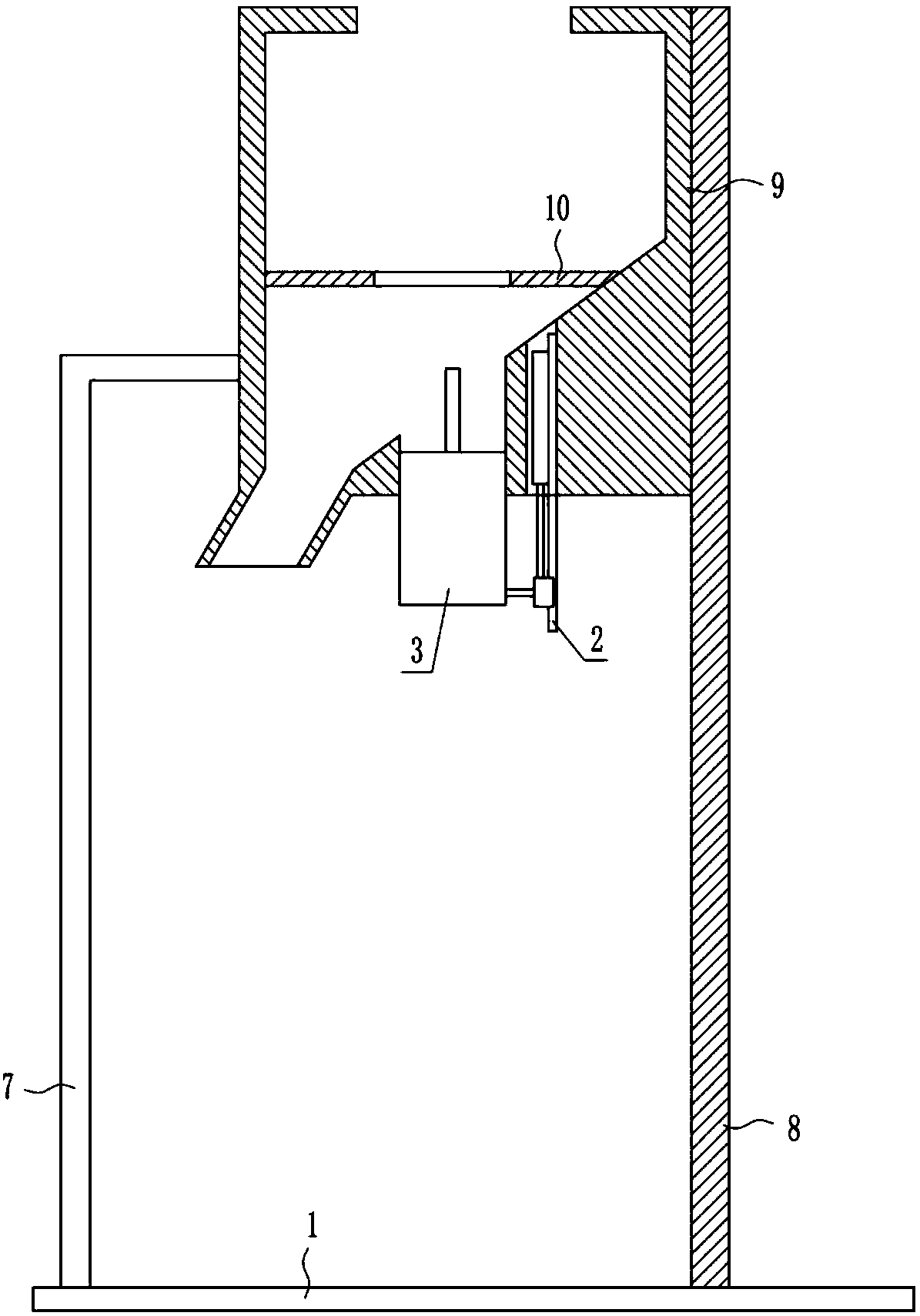

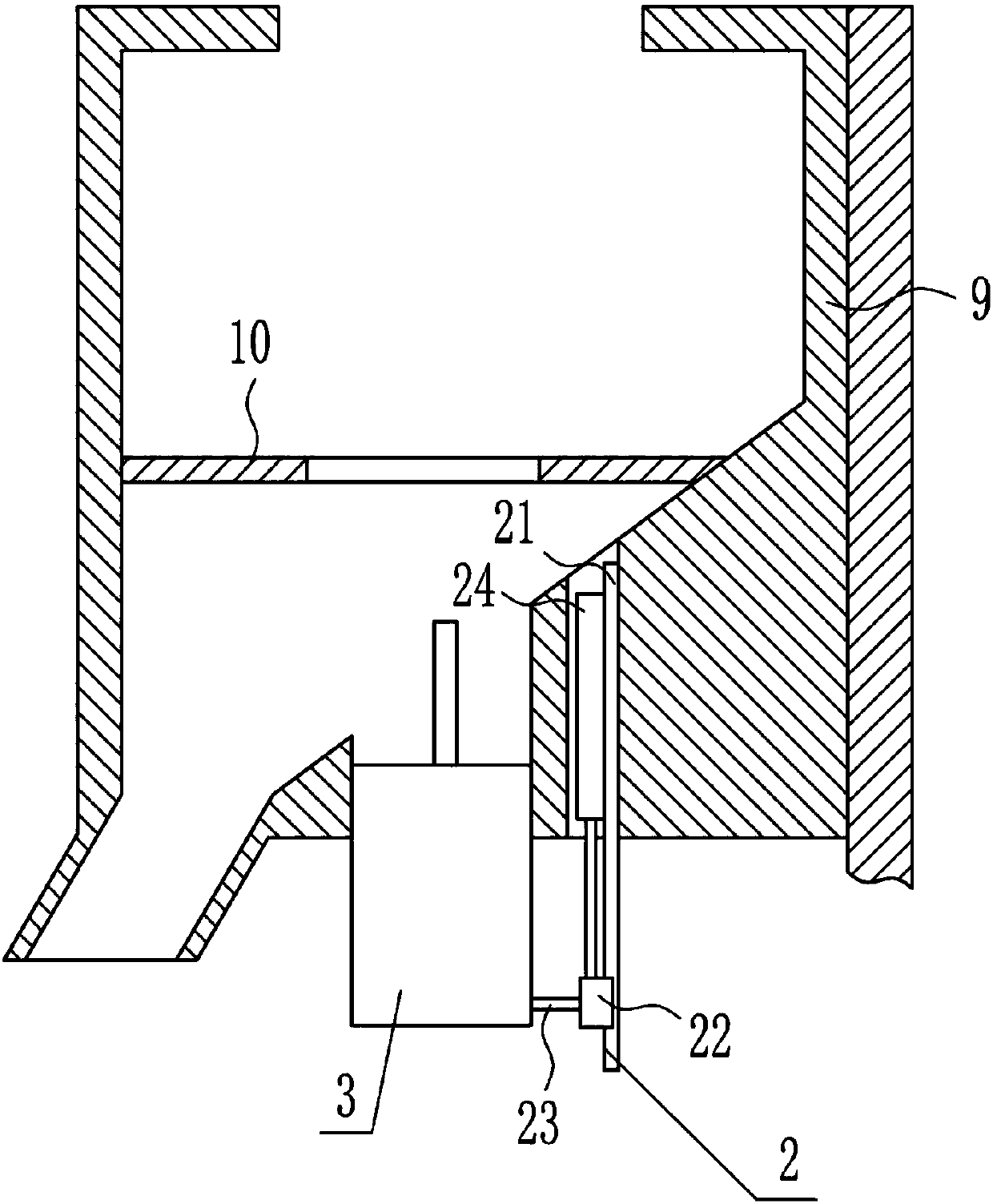

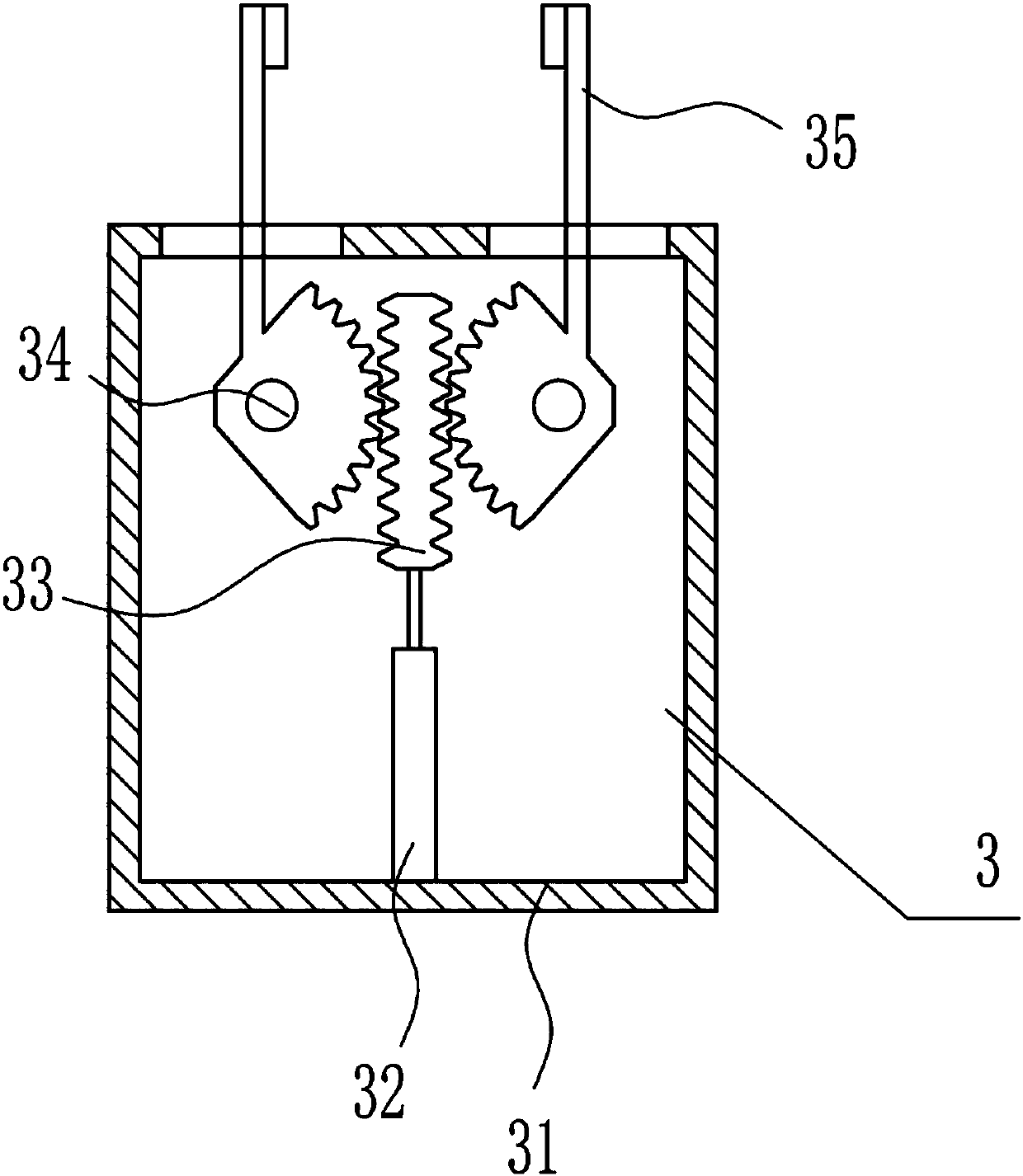

[0041] A kind of stuffing cotton equipment for toy production, such as Figure 1-9 As shown, it includes a bottom plate 1, a left frame 7, a right frame 8, a placement box 9, a placement plate 10, an up and down moving device 2 and a clamping device 3, and the left and right sides of the top of the bottom plate 1 are connected with a left frame 7 and a right frame 8. Left frame 7 is positioned at the left side of right frame 8, is connected with placing box 9 between left frame 7 and right frame 8, is connected with placing plate 10 in placing box 9, has the first feeding opening on placing plate 10, and placing box The left side of the bottom of 9 is provided with a second feeding opening, the middle of the top of the storage box 9 has a third feeding opening, the middle of the bottom of the storage box 9 has a second opening, and the storage box 9 on the right side of the second opening has a groove , an up and down moving device 2 is installed in the groove, and a clamping ...

Embodiment 2

[0043] A kind of stuffing cotton equipment for toy production, such as Figure 1-9 As shown, it includes a bottom plate 1, a left frame 7, a right frame 8, a placement box 9, a placement plate 10, an up and down moving device 2 and a clamping device 3, and the left and right sides of the top of the bottom plate 1 are connected with a left frame 7 and a right frame 8. Left frame 7 is positioned at the left side of right frame 8, is connected with placing box 9 between left frame 7 and right frame 8, is connected with placing plate 10 in placing box 9, has the first feeding opening on placing plate 10, and placing box The left side of the bottom of 9 is provided with a second feeding opening, the middle of the top of the storage box 9 has a third feeding opening, the middle of the bottom of the storage box 9 has a second opening, and the storage box 9 on the right side of the second opening has a groove , an up and down moving device 2 is installed in the groove, and a clamping ...

Embodiment 3

[0046] A kind of stuffing cotton equipment for toy production, such as Figure 1-9 As shown, it includes a bottom plate 1, a left frame 7, a right frame 8, a placement box 9, a placement plate 10, an up and down moving device 2 and a clamping device 3, and the left and right sides of the top of the bottom plate 1 are connected with a left frame 7 and a right frame 8. Left frame 7 is positioned at the left side of right frame 8, is connected with placing box 9 between left frame 7 and right frame 8, is connected with placing plate 10 in placing box 9, has the first feeding opening on placing plate 10, and placing box The left side of the bottom of 9 is provided with a second feeding opening, the middle of the top of the storage box 9 has a third feeding opening, the middle of the bottom of the storage box 9 has a second opening, and the storage box 9 on the right side of the second opening has a groove , an up and down moving device 2 is installed in the groove, and a clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com