Patents

Literature

80results about How to "Orderly processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

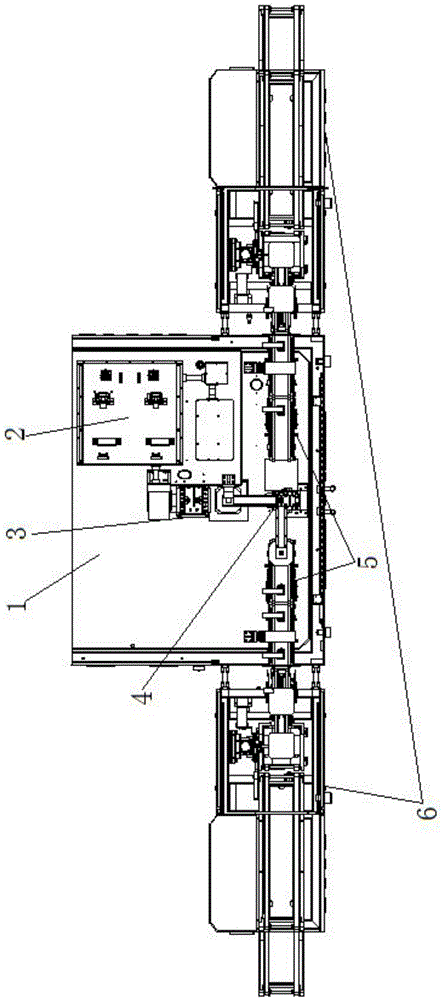

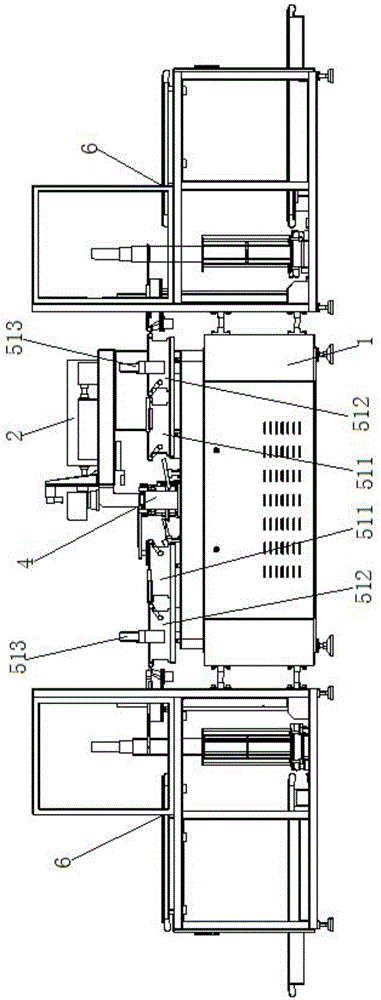

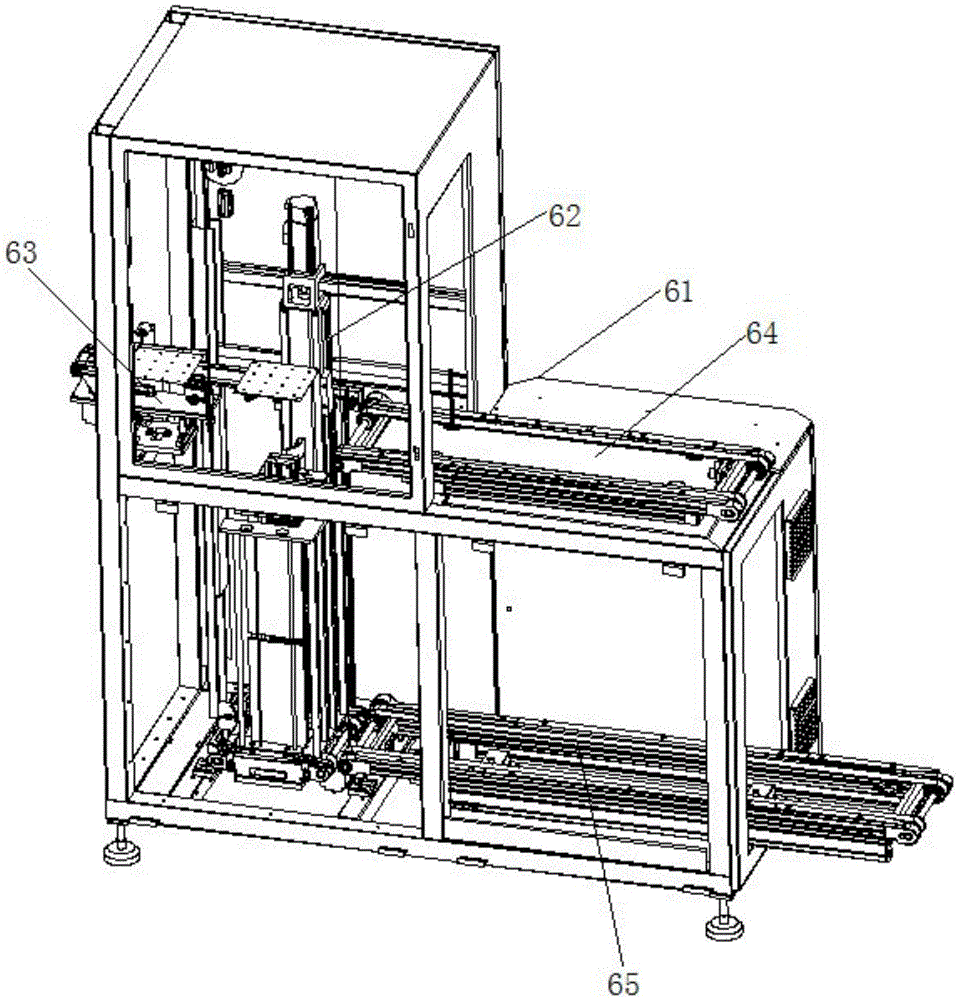

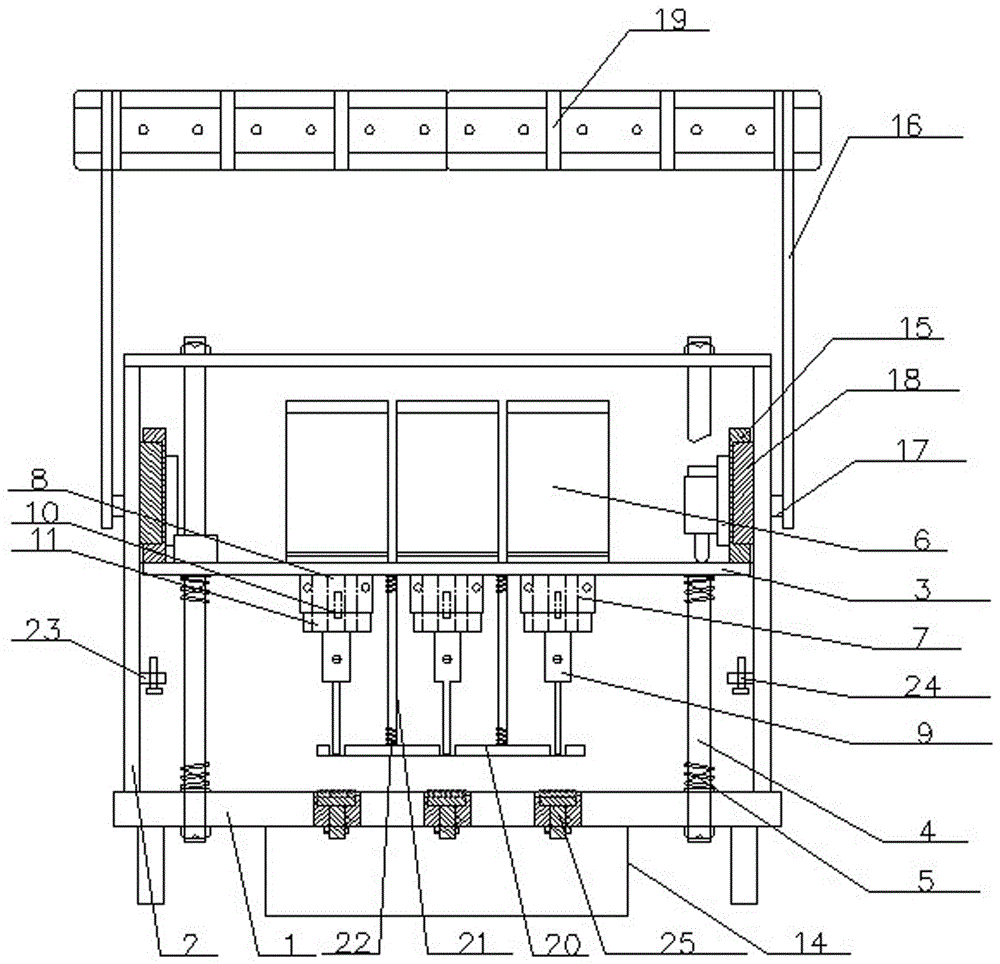

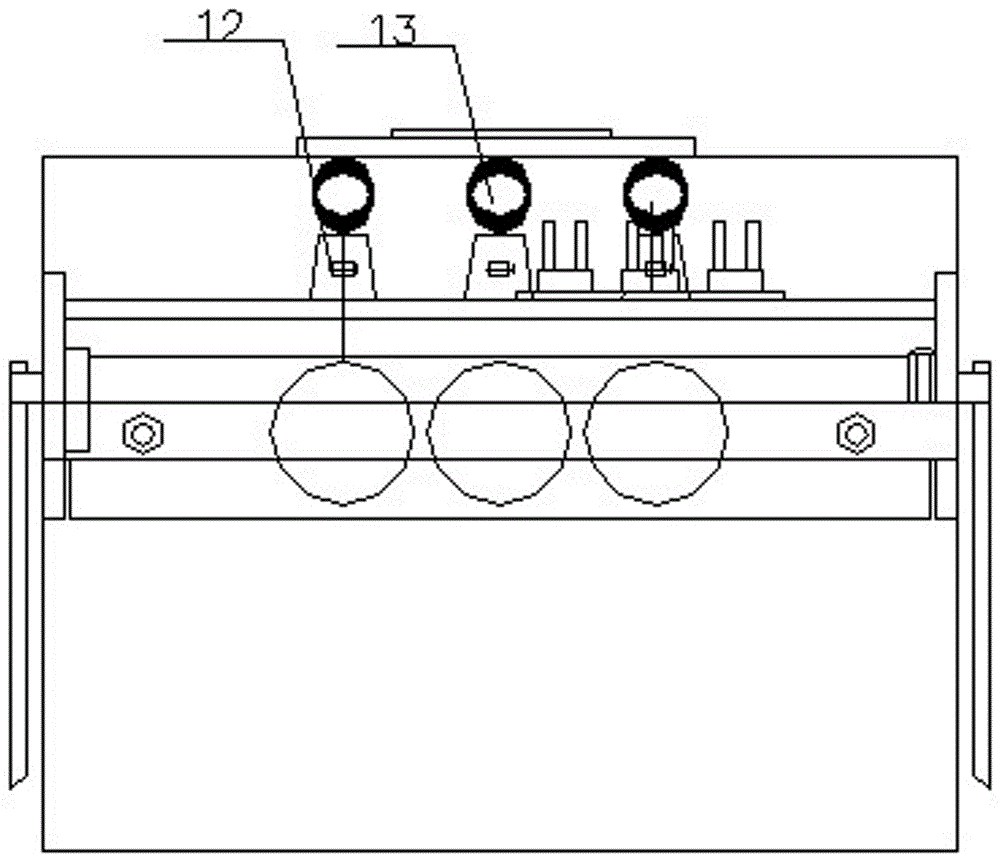

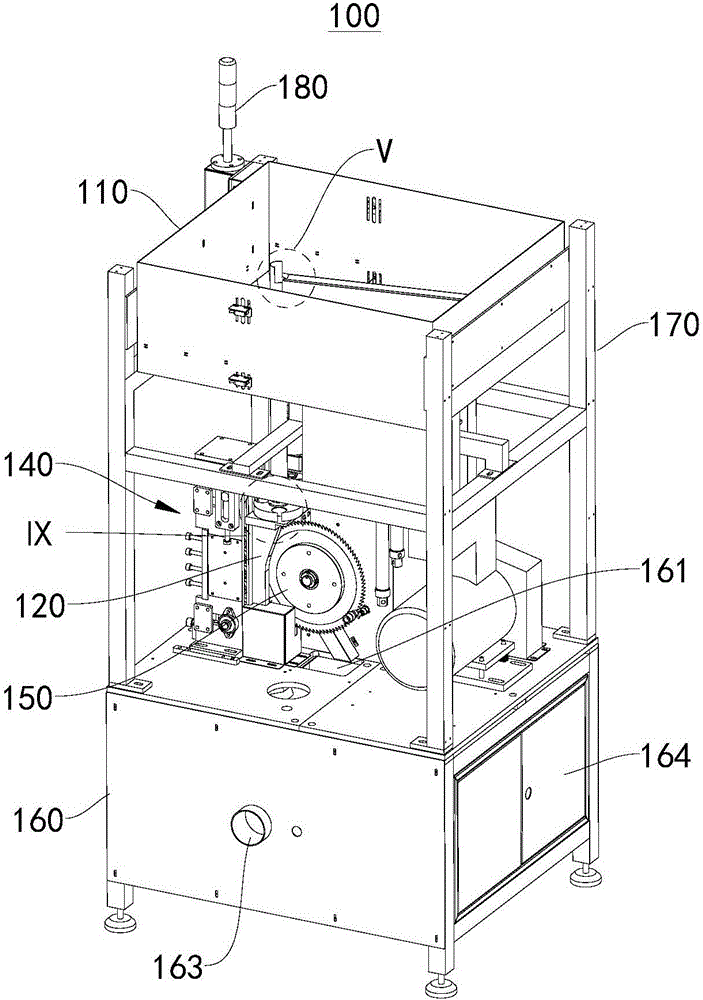

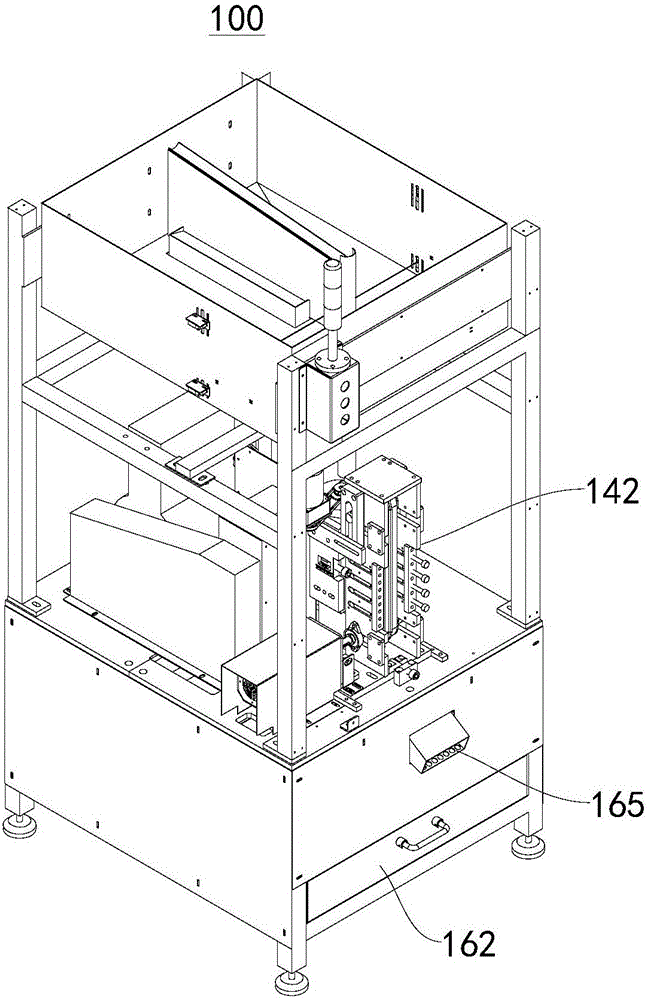

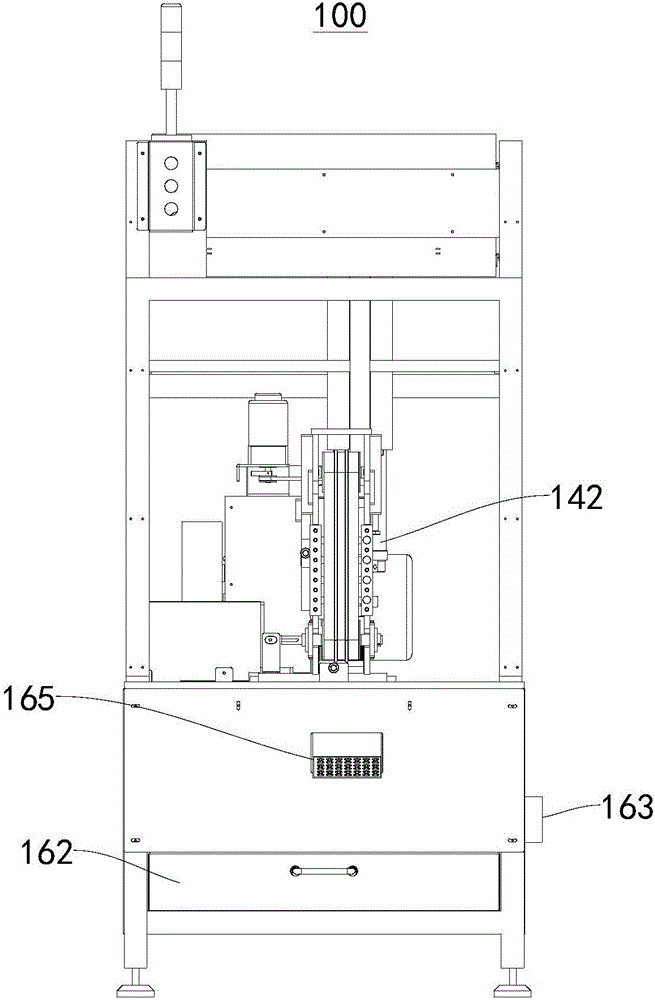

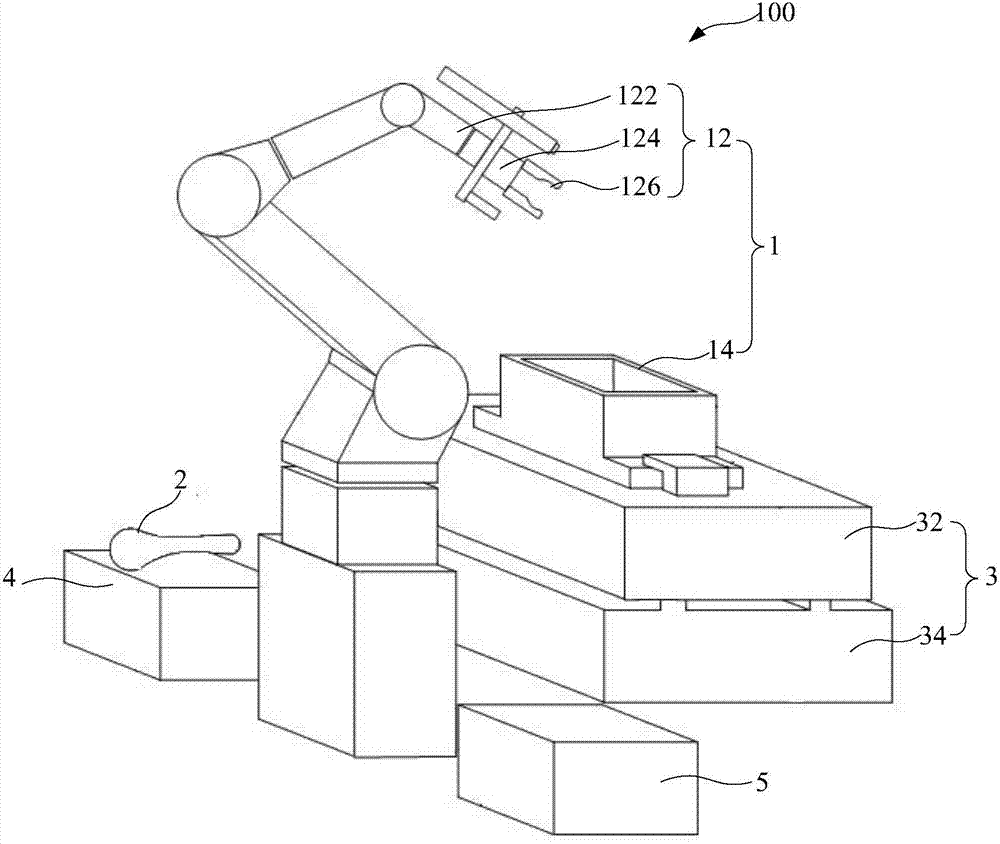

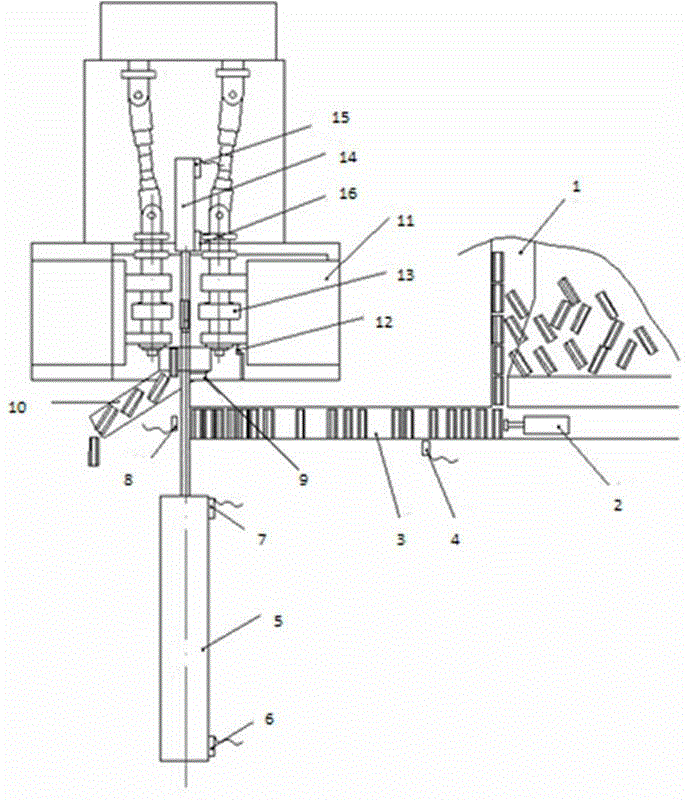

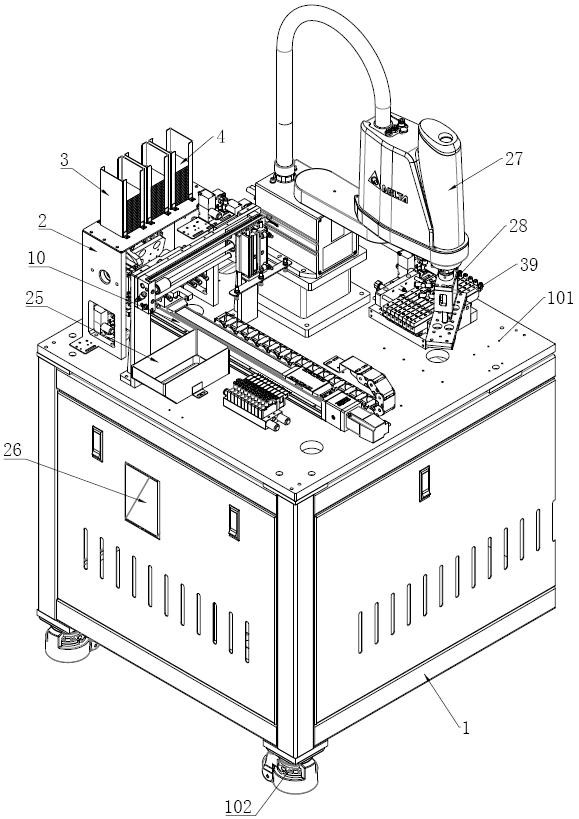

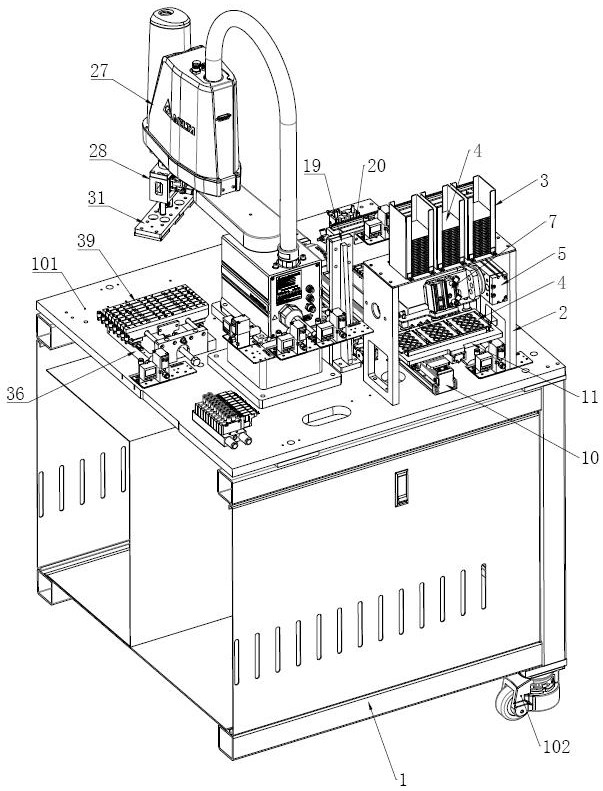

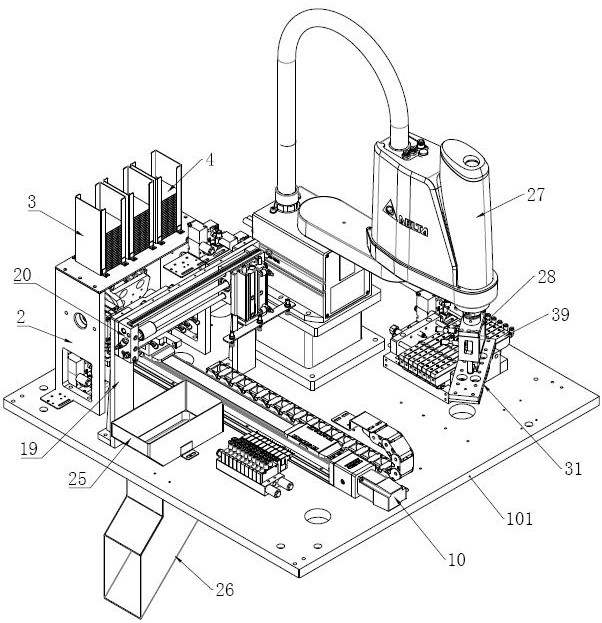

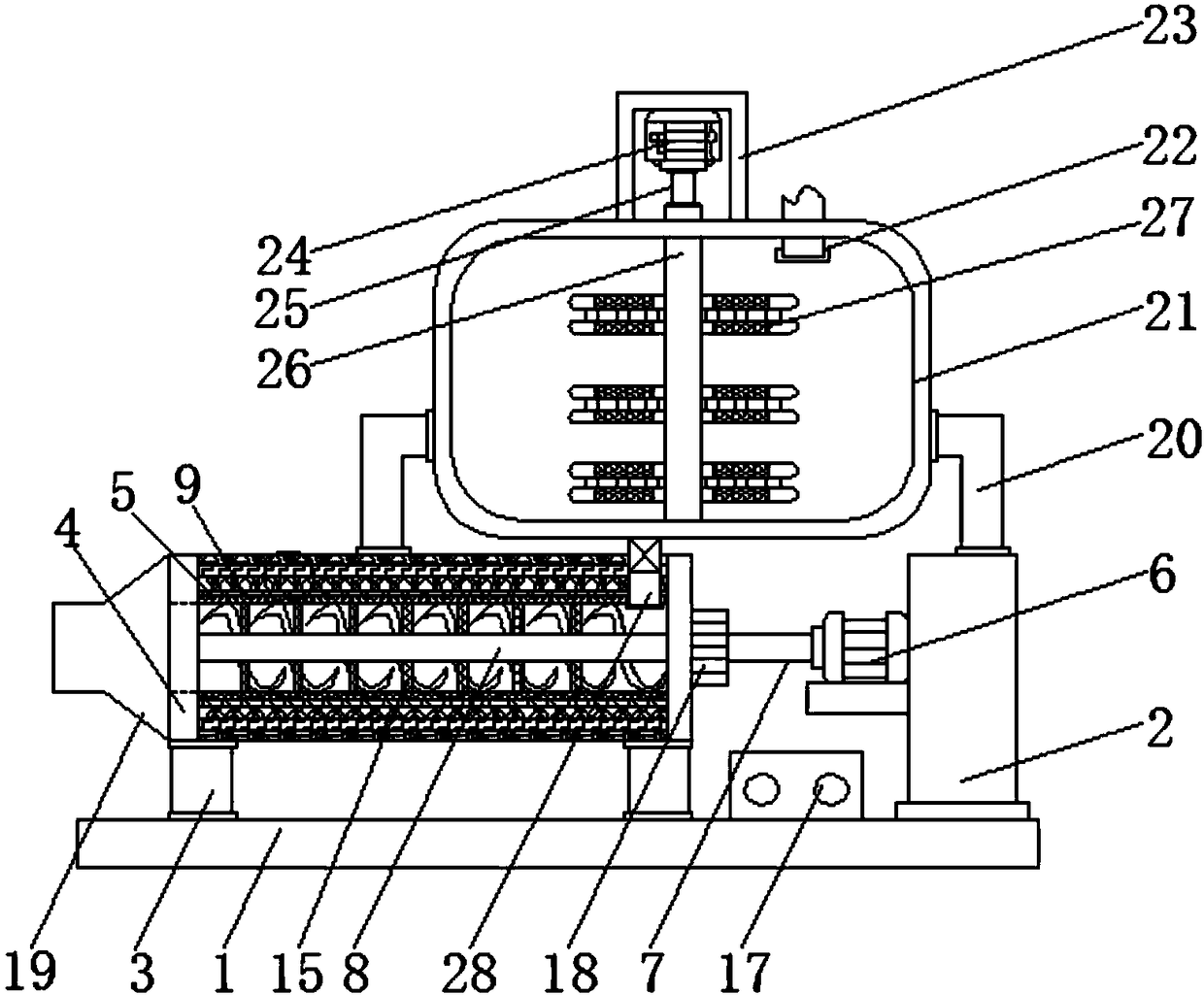

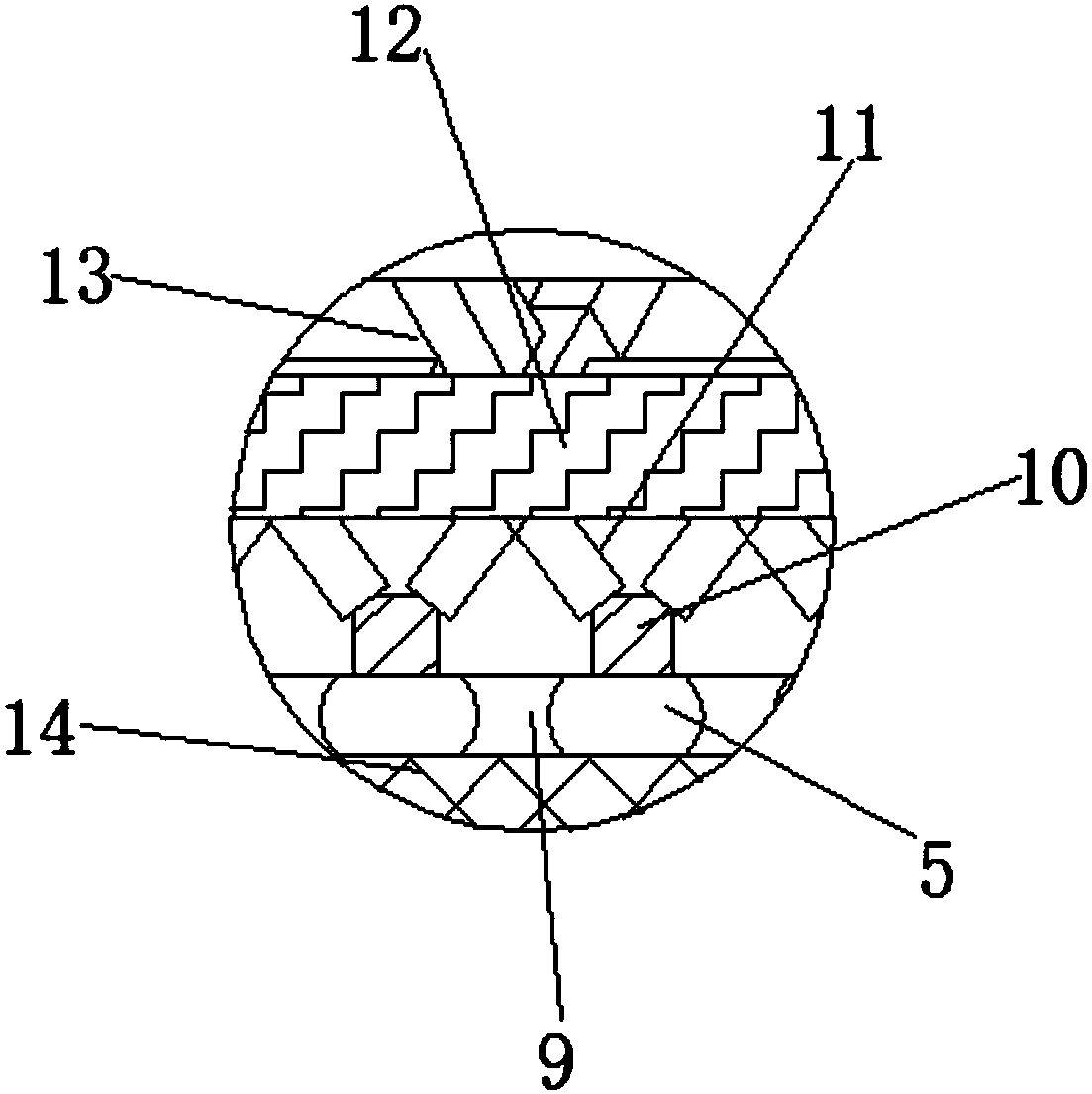

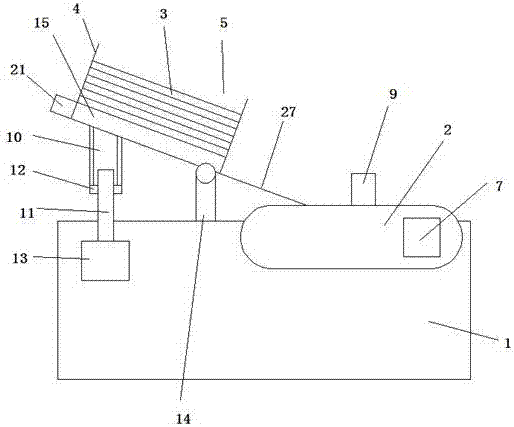

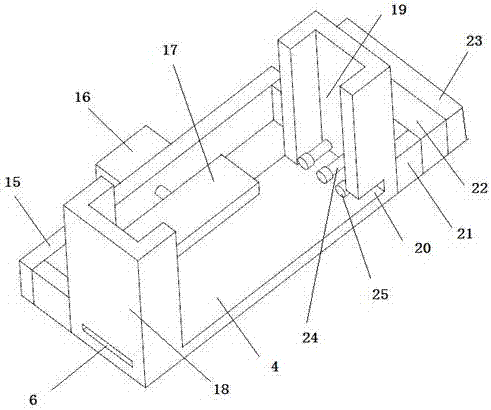

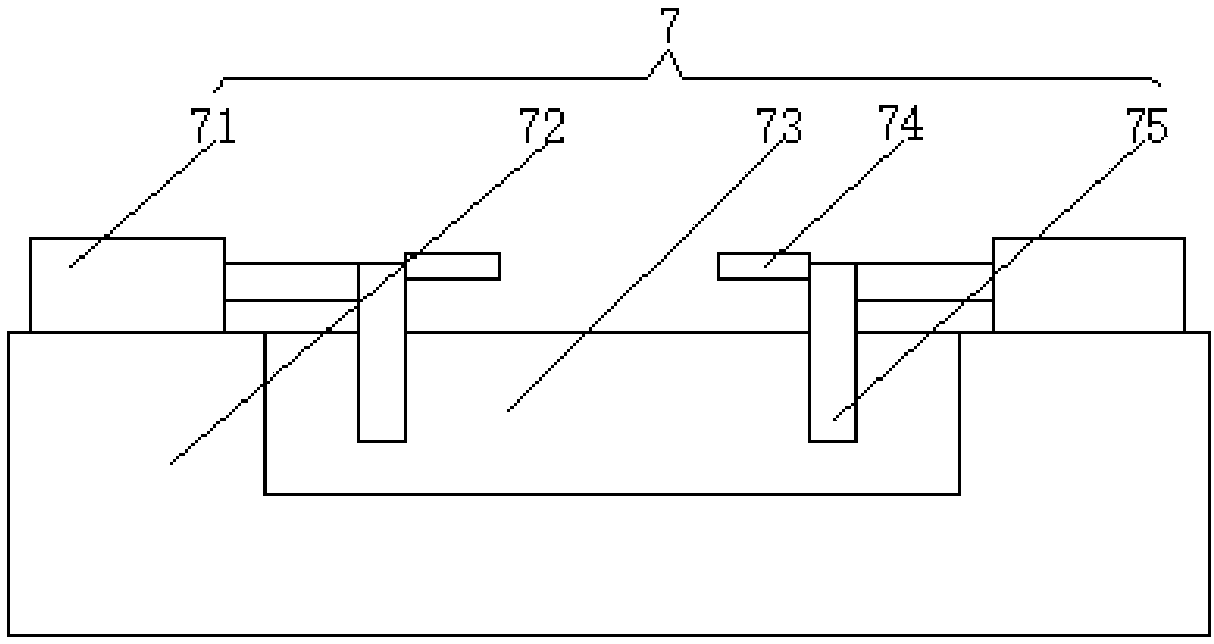

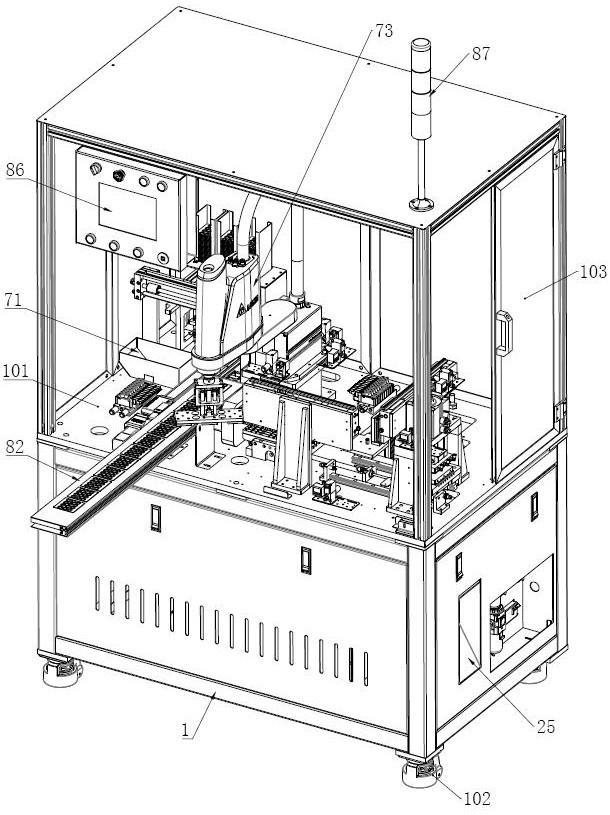

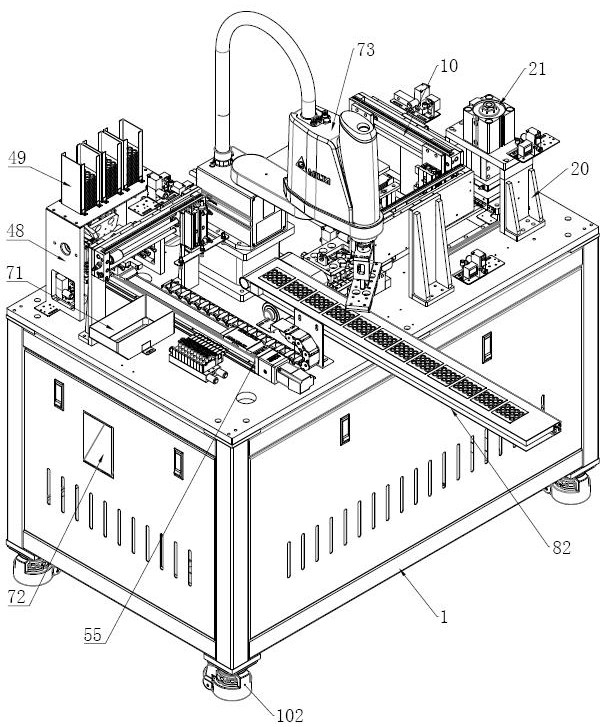

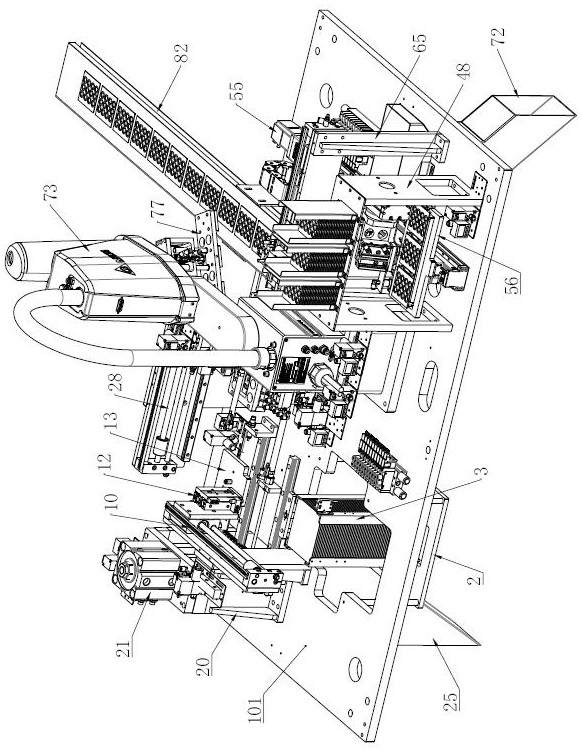

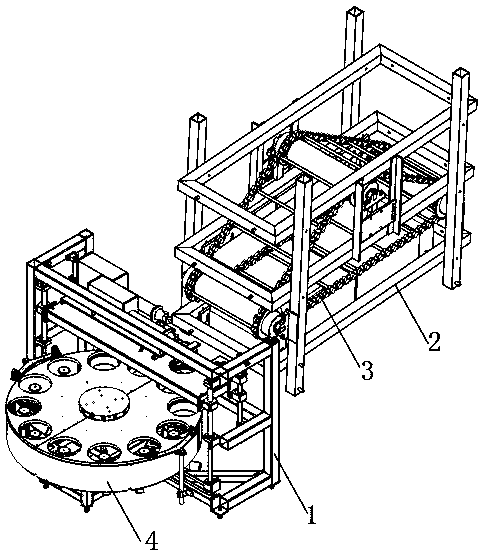

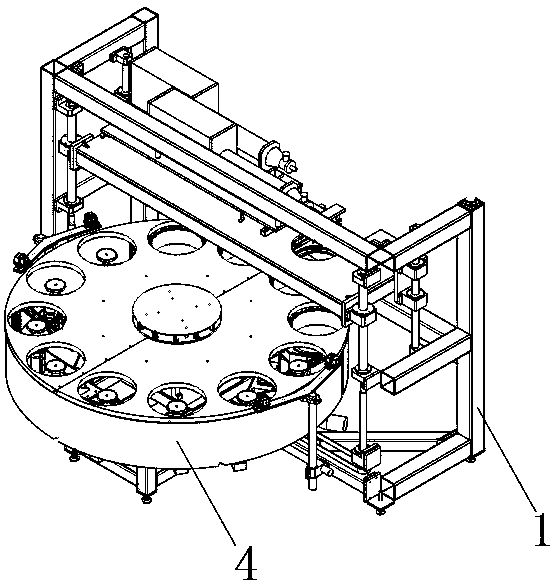

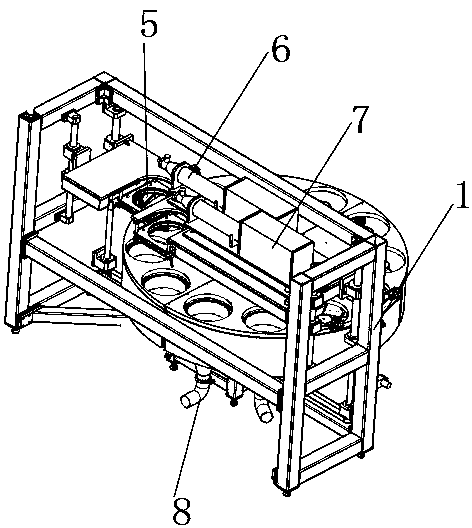

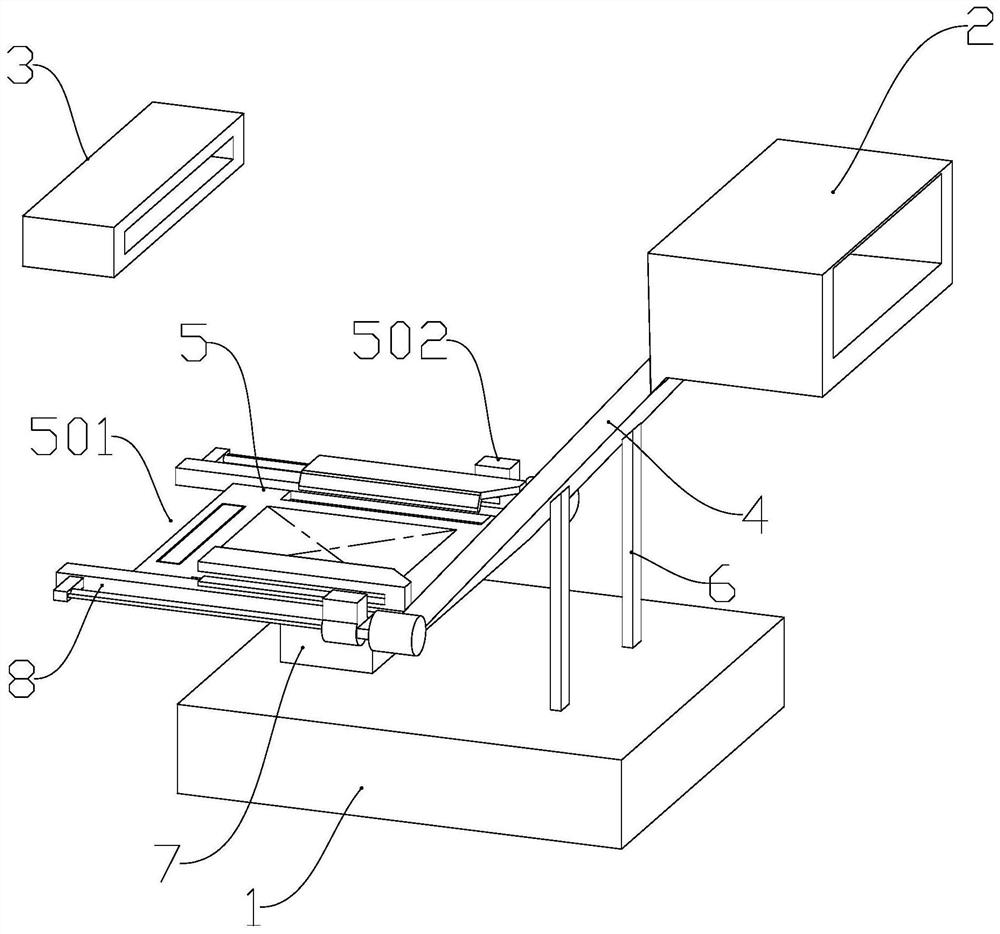

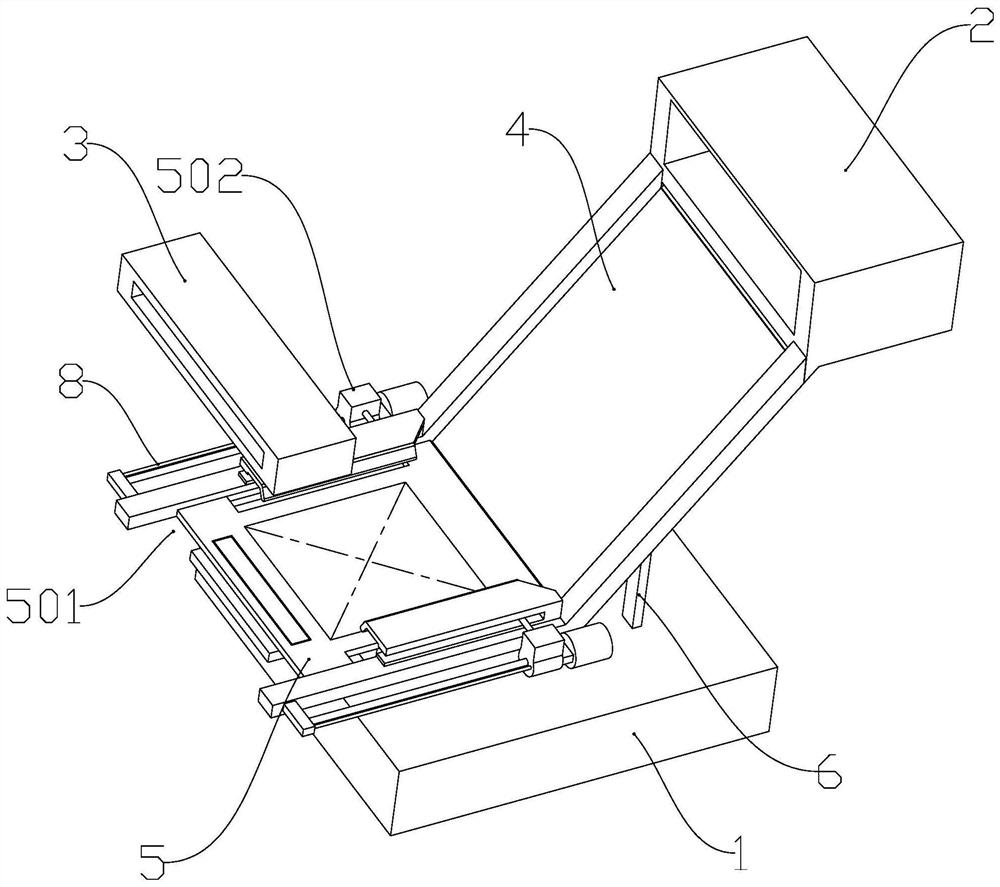

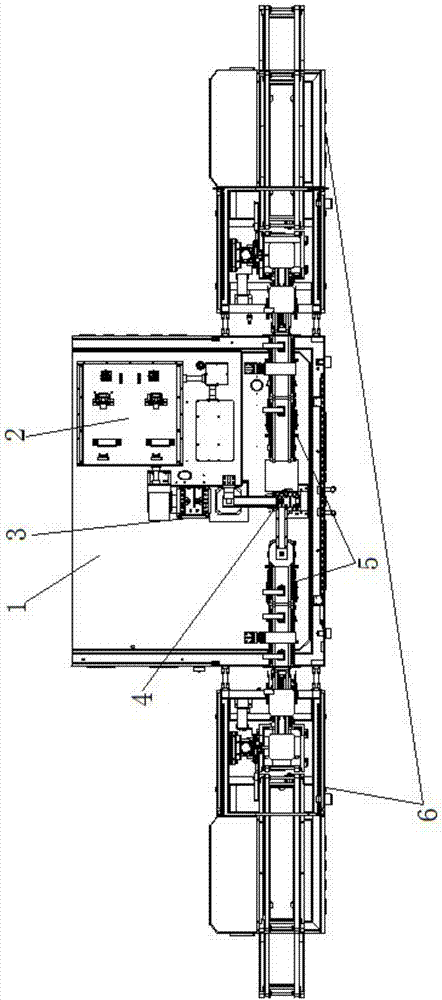

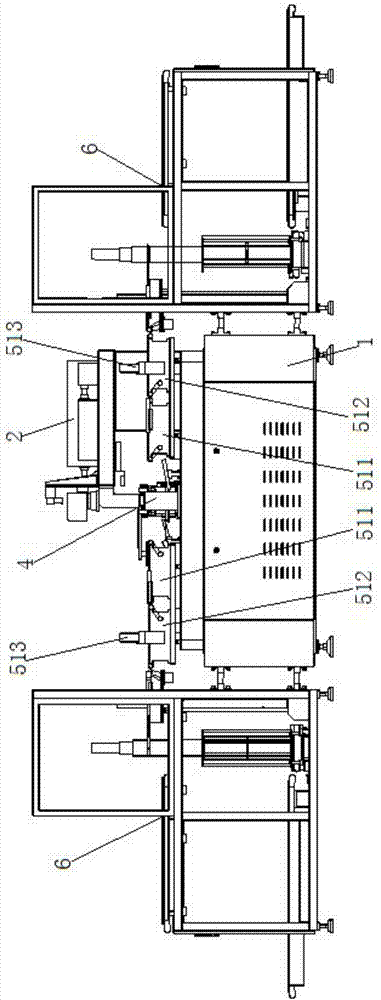

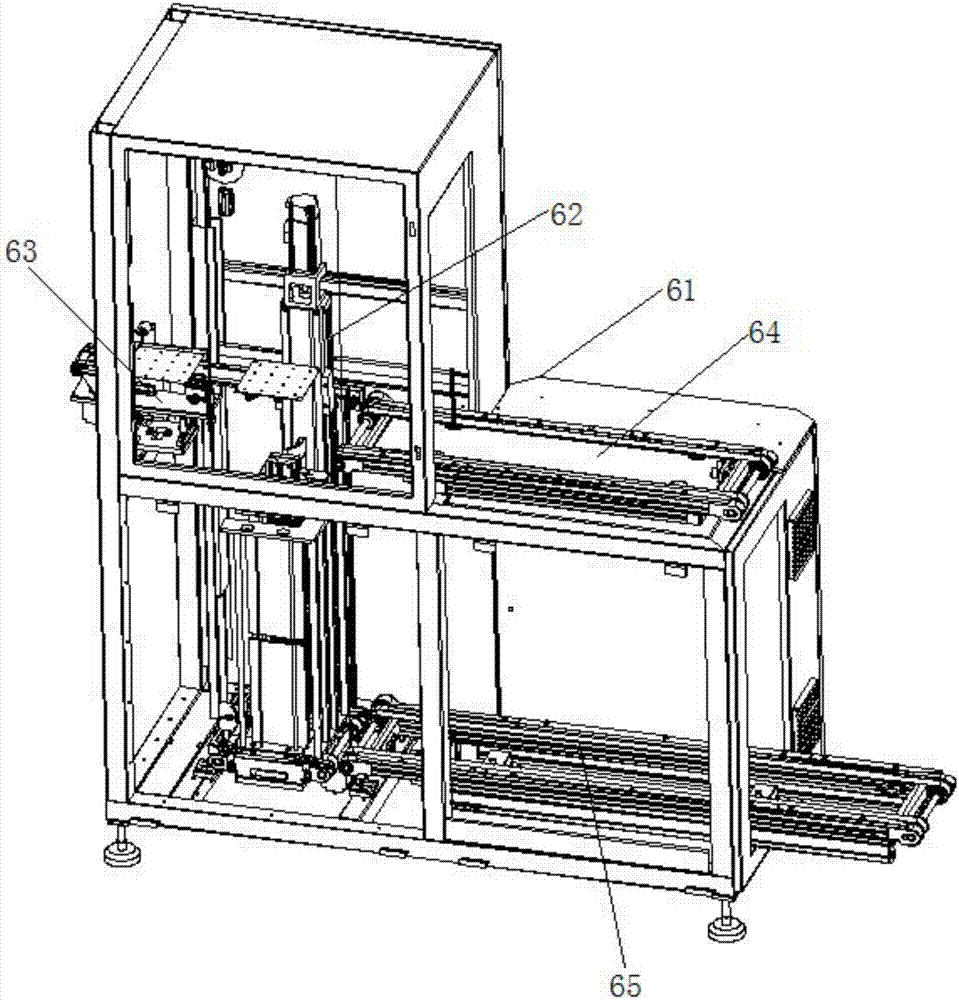

Laser processing equipment for full-automatic solar battery piece

ActiveCN105618934ASimple structureEasy to useManipulatorLaser beam welding apparatusLaser processingEngineering

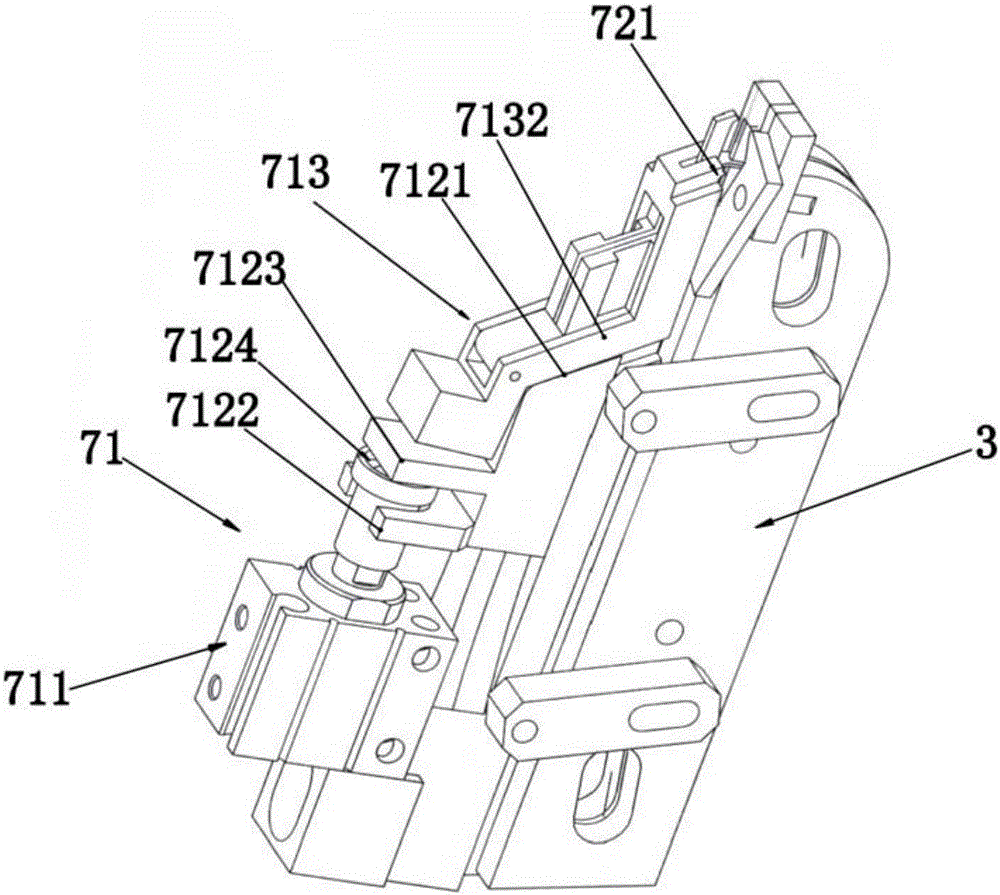

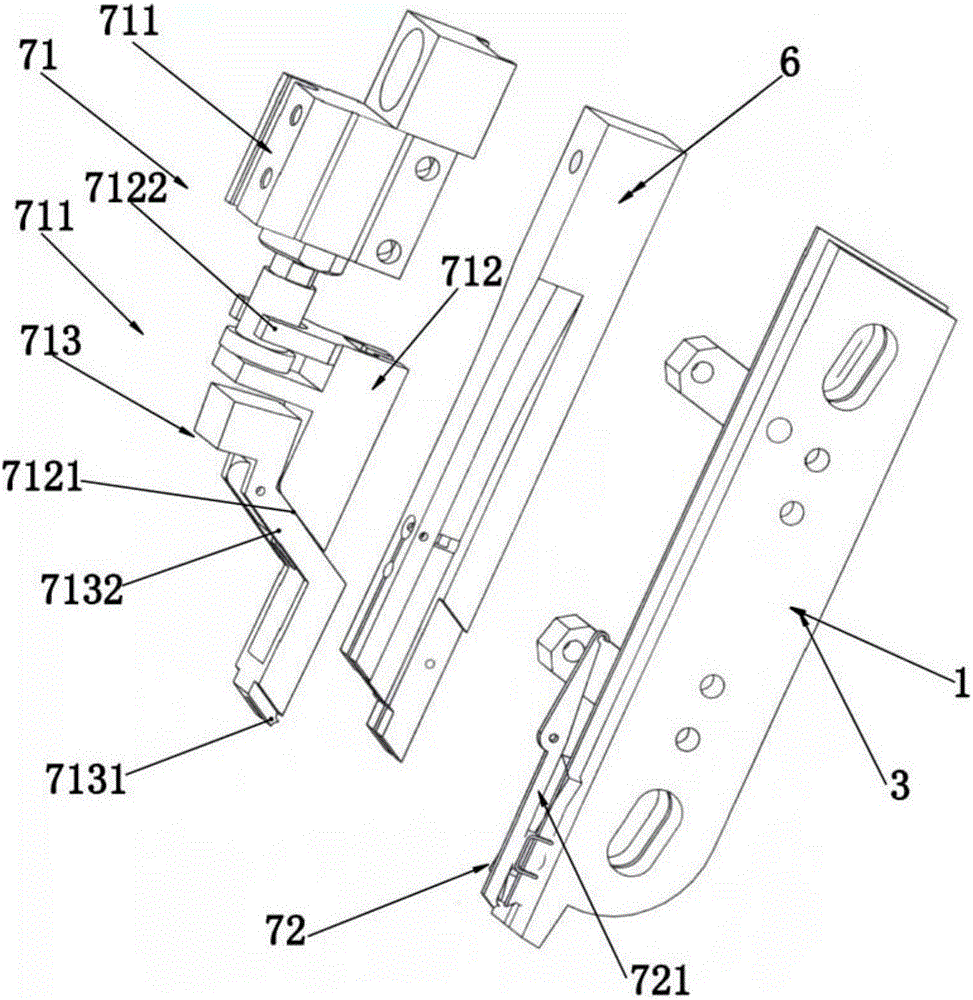

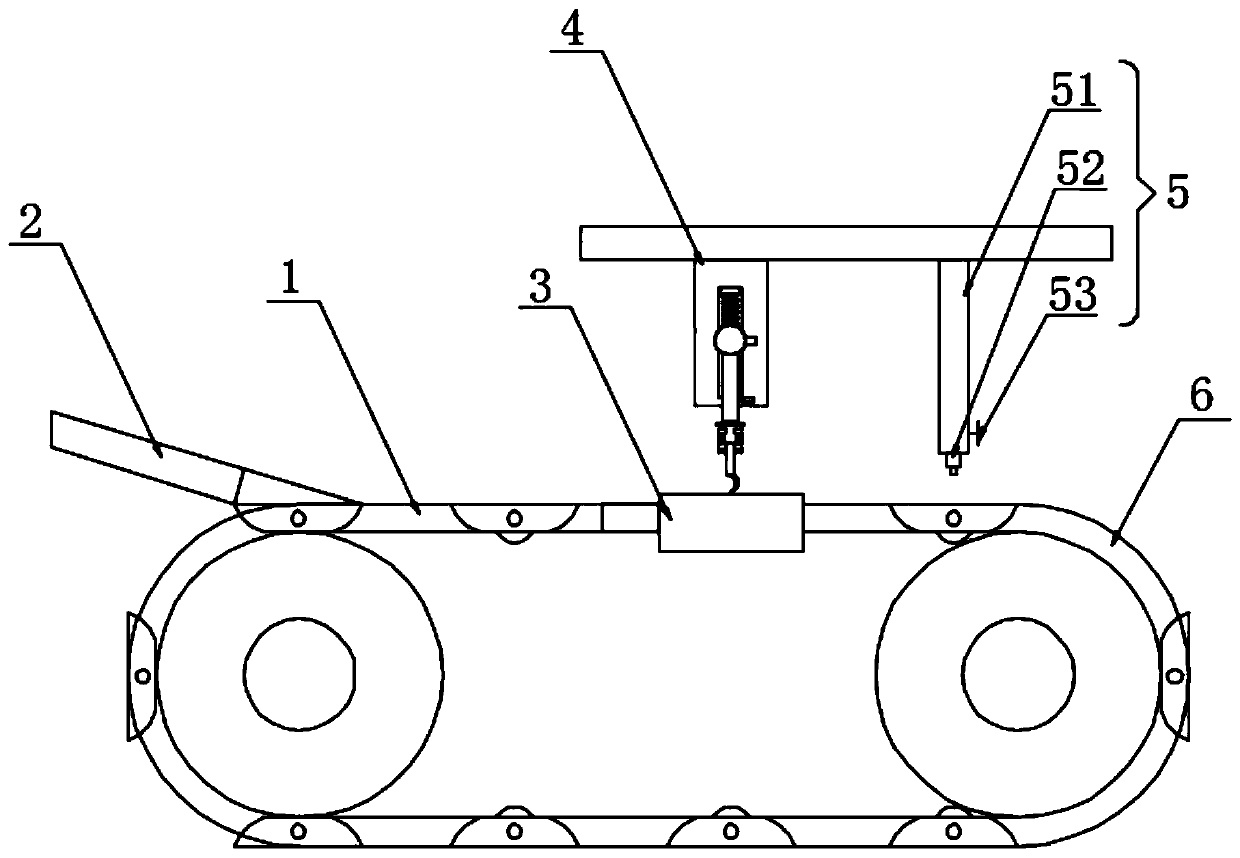

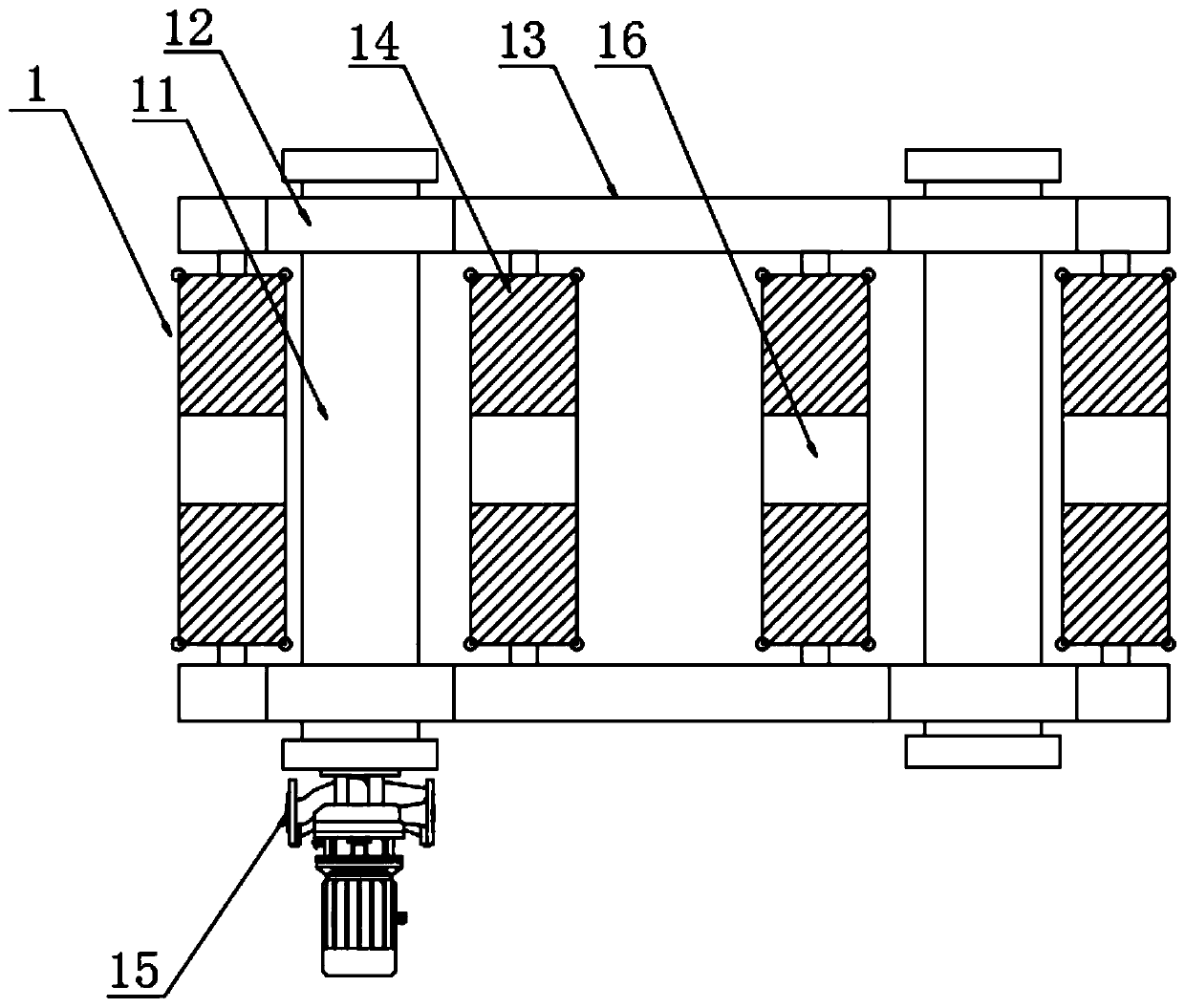

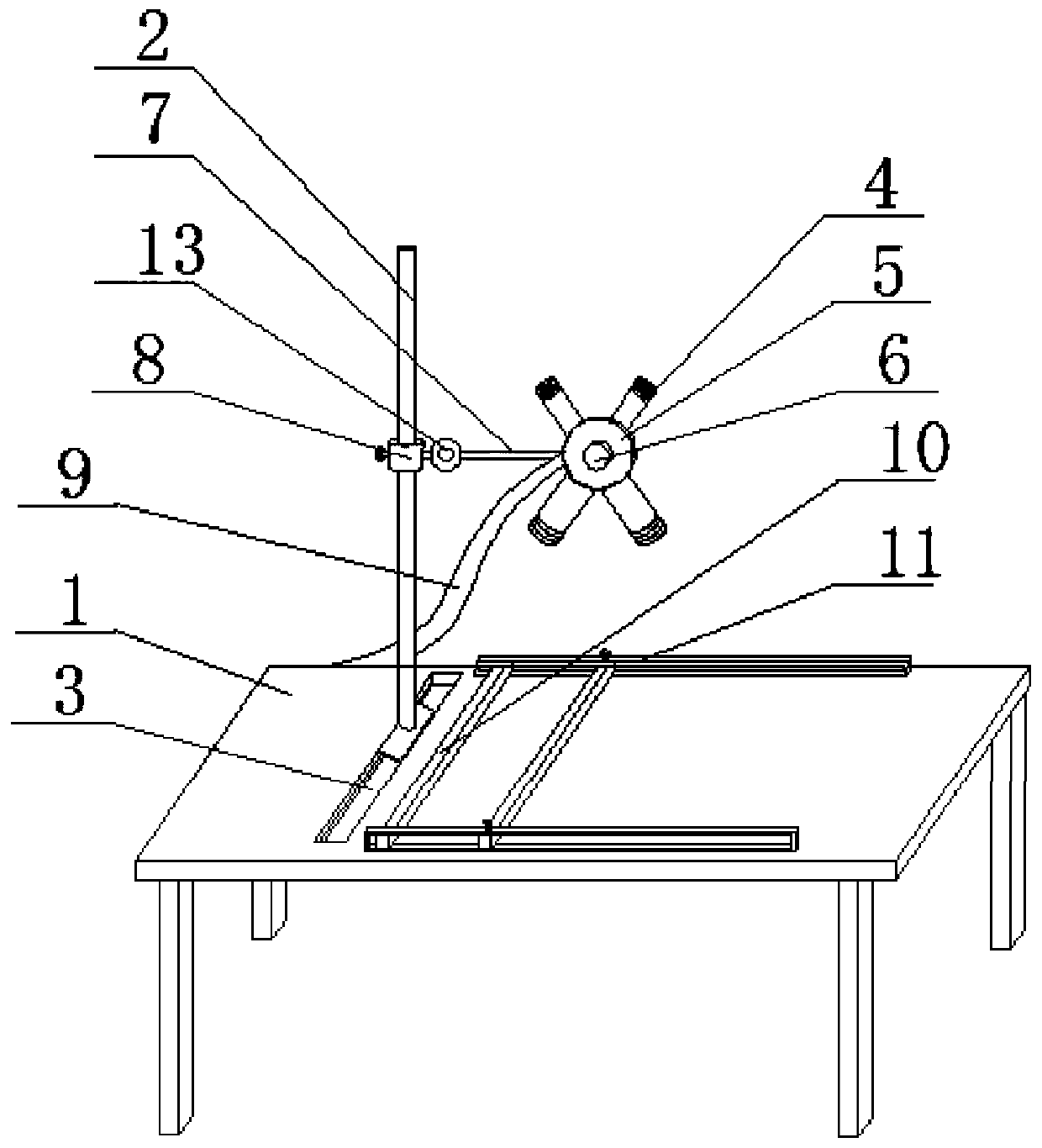

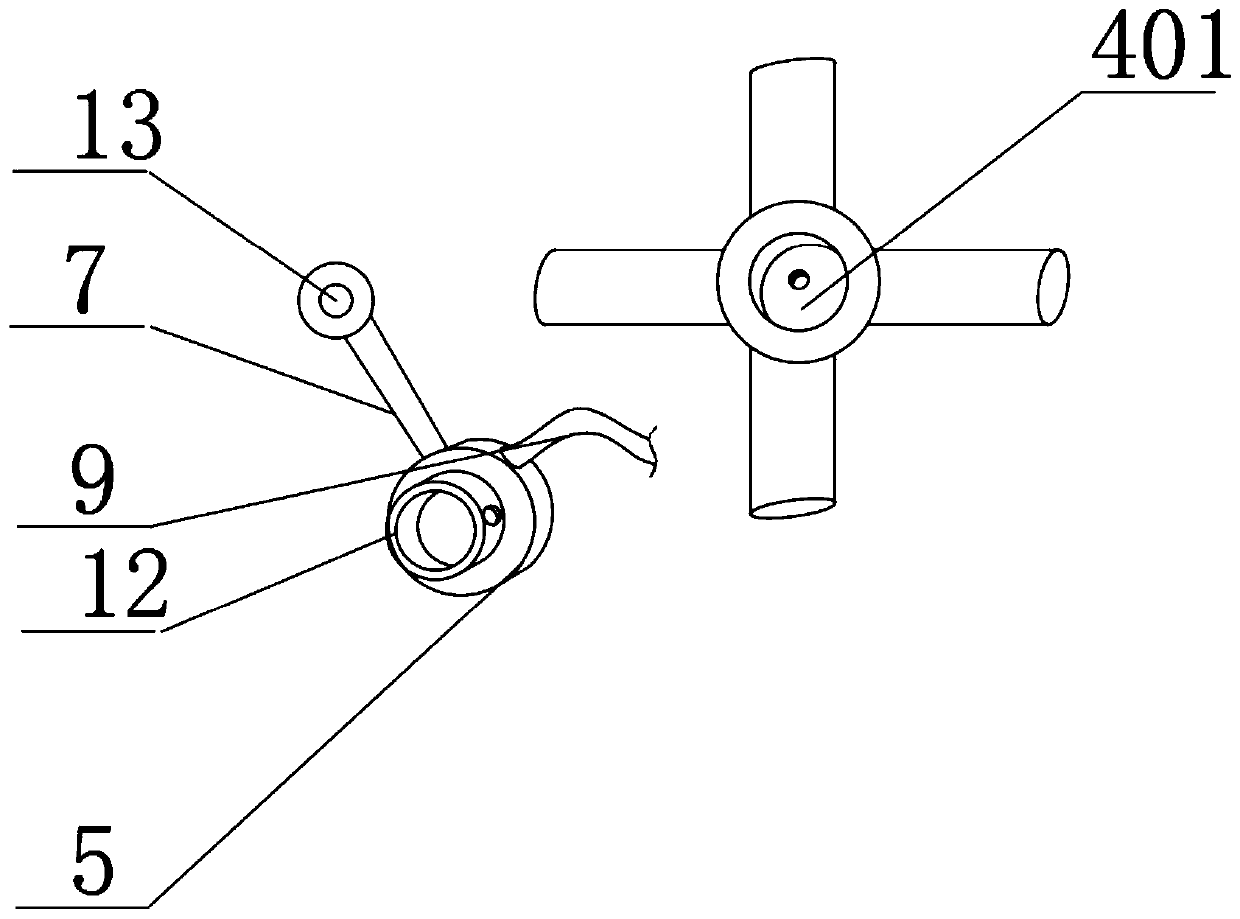

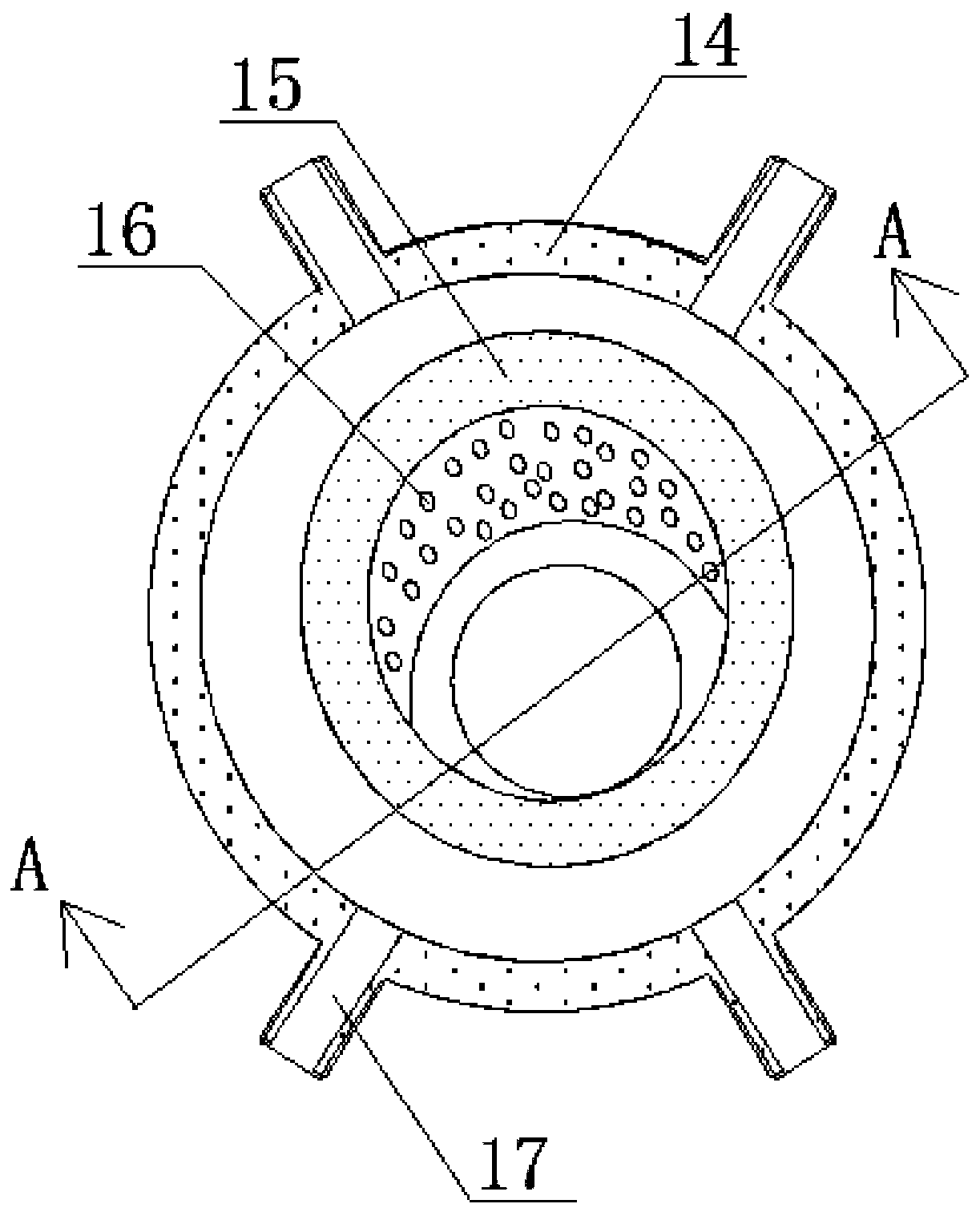

The invention relates to laser processing equipment for a full-automatic solar battery piece. The laser processing equipment comprises a workbench, a laser processing host, a battery piece processing table, a rotary mechanical arm assembly, left and right battery piece caching and transferring components and left and right battery piece connection assemblies, wherein the laser processing host and the battery piece processing table are both installed on the workbench; the battery piece processing table is arranged below a laser processing head of the laser processing host; the rotary mechanical arm assembly is installed on the workbench on one side of the battery piece processing table; the left and right battery piece caching and transferring components are installed on the workbench on the two sides of the rotary mechanical arm assembly; in the rotation process of the rotary mechanical arm assembly, the free end of the rotary mechanical arm assembly can rotate to the positions above the battery piece processing table and above the left and right battery piece caching and transferring components on the two sides of the rotary mechanical arm assembly respectively; and the left and right battery piece connection assemblies are installed on the two sides of the workbench. The laser processing equipment has the advantages of simple structure, convenience in use, high production efficiency and strong processing stability.

Owner:WUHAN DR LASER TECH CORP LTD

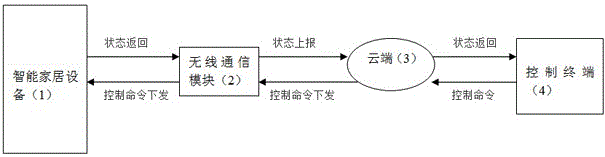

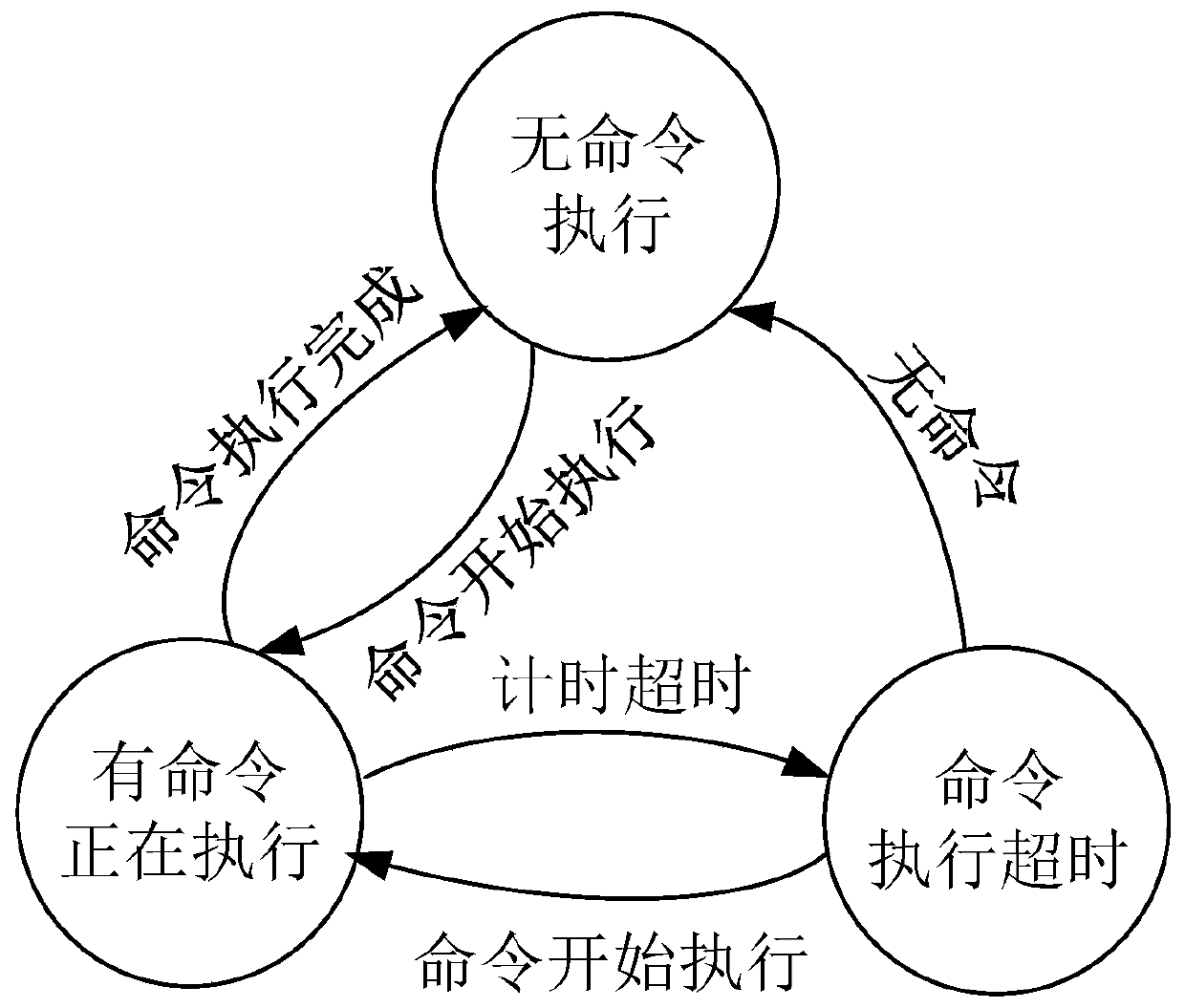

Control method of smart home device

InactiveCN106027341AEasy to handleOrderly processingData switching by path configurationWireless commuication servicesEmbedded systemCurrent time

The invention discloses a control method of a smart home device. The method comprises the steps that a wireless communication module receives control commands sent by a control terminal of the smart home device and caches the control commands to a cache queue, wherein the control commands in the cache queue are issued to the smart home device in sequence; before the control command at the head of the cache queue is issued to the smart home device, the wireless communication module judges the time interval between the time of receiving the control command and current time, if the time interval is lower than a set value T, the wireless communication module issues the control command to the smart home device in a delayed mode; and when there are more than two same control commands in the cache queue, the received earliest control command is reserved, and the other same control commands are deleted. According to the method, the received control commands can be effectively and orderly processed; the same control commands are not performed repeatedly; the processing efficiency is improved; and the response timeout is avoided.

Owner:HANGZHOU BROADLINK ELECTRONICS TECH

High-efficiency production method of safety braid

ActiveCN104674567AEasy to operateHigh yarn stabilization efficiencySafety beltsAuxillary apparatusYarnAfter treatment

The invention discloses a high-efficiency production method of a safety braid. The high-efficiency production method comprises the following steps: (1) receiving and inspecting raw materials; (2) pre-treating the raw materials; (3) stabilizing yarns; (4) threading the yarns; (5) changing the yarns, and braiding; (6) preparing a dyeing solution; (7) carrying out dyeing pretreatment; (8) carrying out dyeing and color fixation; (9) carrying out dyeing after-treatment; (10) detecting a finished product braid; (11) cutting the braid; and (12) packaging the braid, and warehousing the packaged braid. The high-efficiency production method has beneficial effects that the operability is high, the yarn stabilizing efficiency is high, the yarn stabilizing effect is good, the accuracy and the intelligence in positioning are realized, the orderliness in processing and production is realized, the fault rate of machines is reduced, the dyeing effect is improved, the relatively high dyeing degree and the relatively attractive appearance are guaranteed, and the service life of the safety braid is prolonged.

Owner:LANGXI FEIMA IND FABRICS

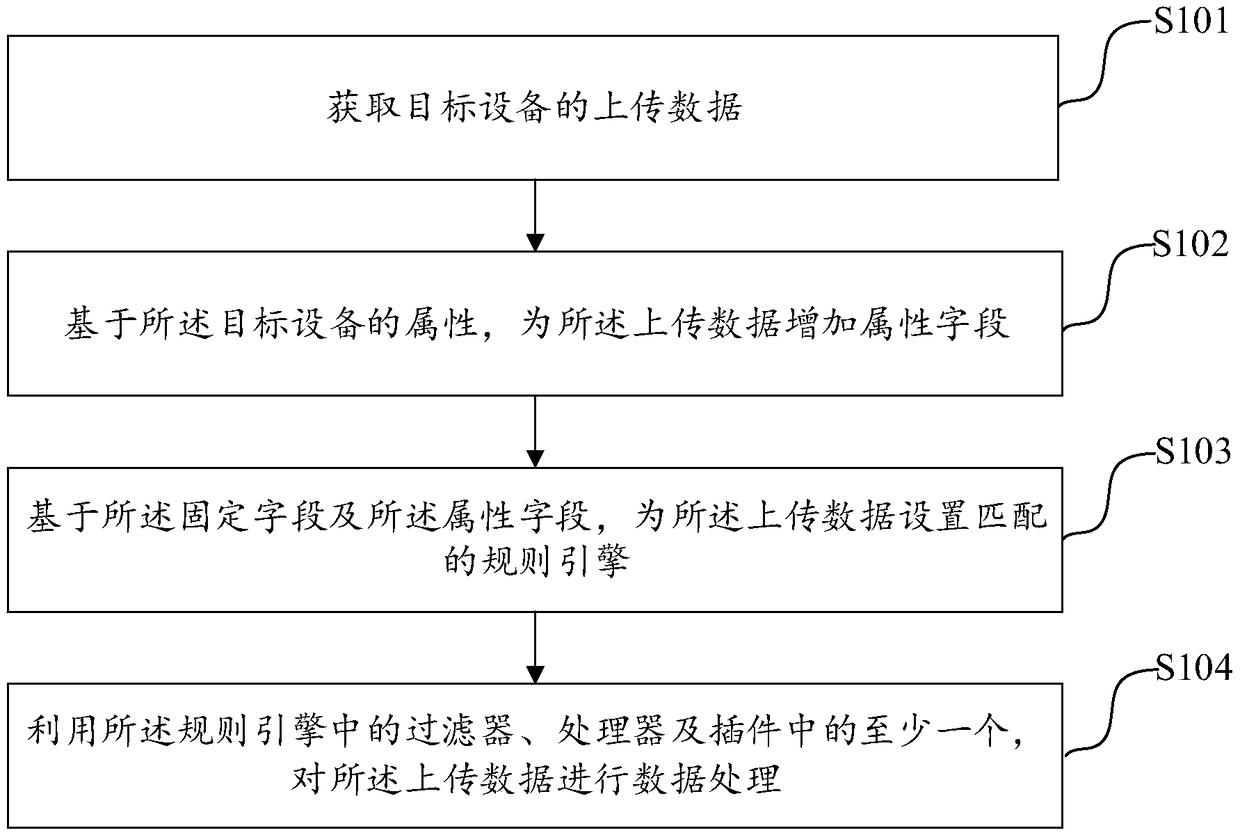

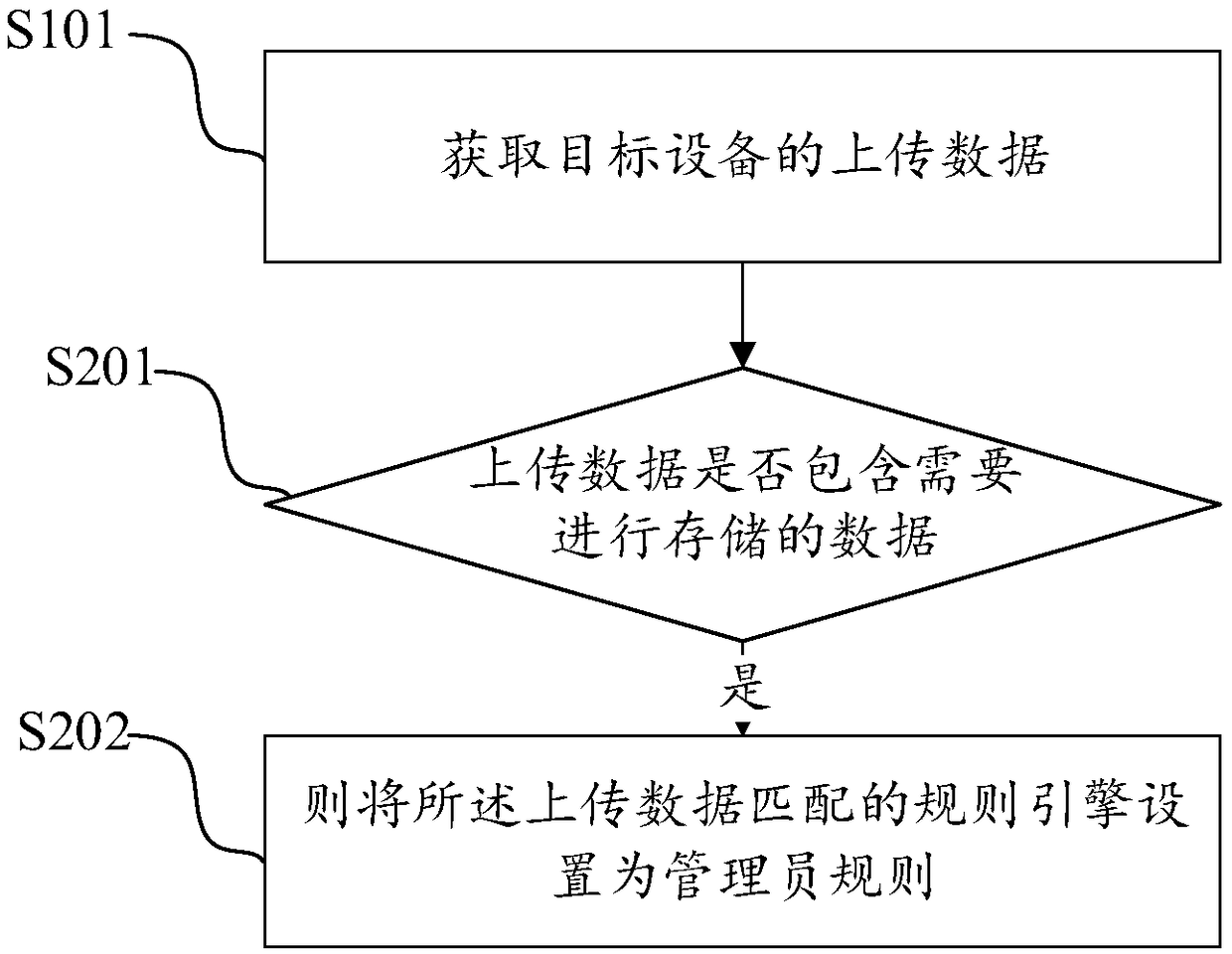

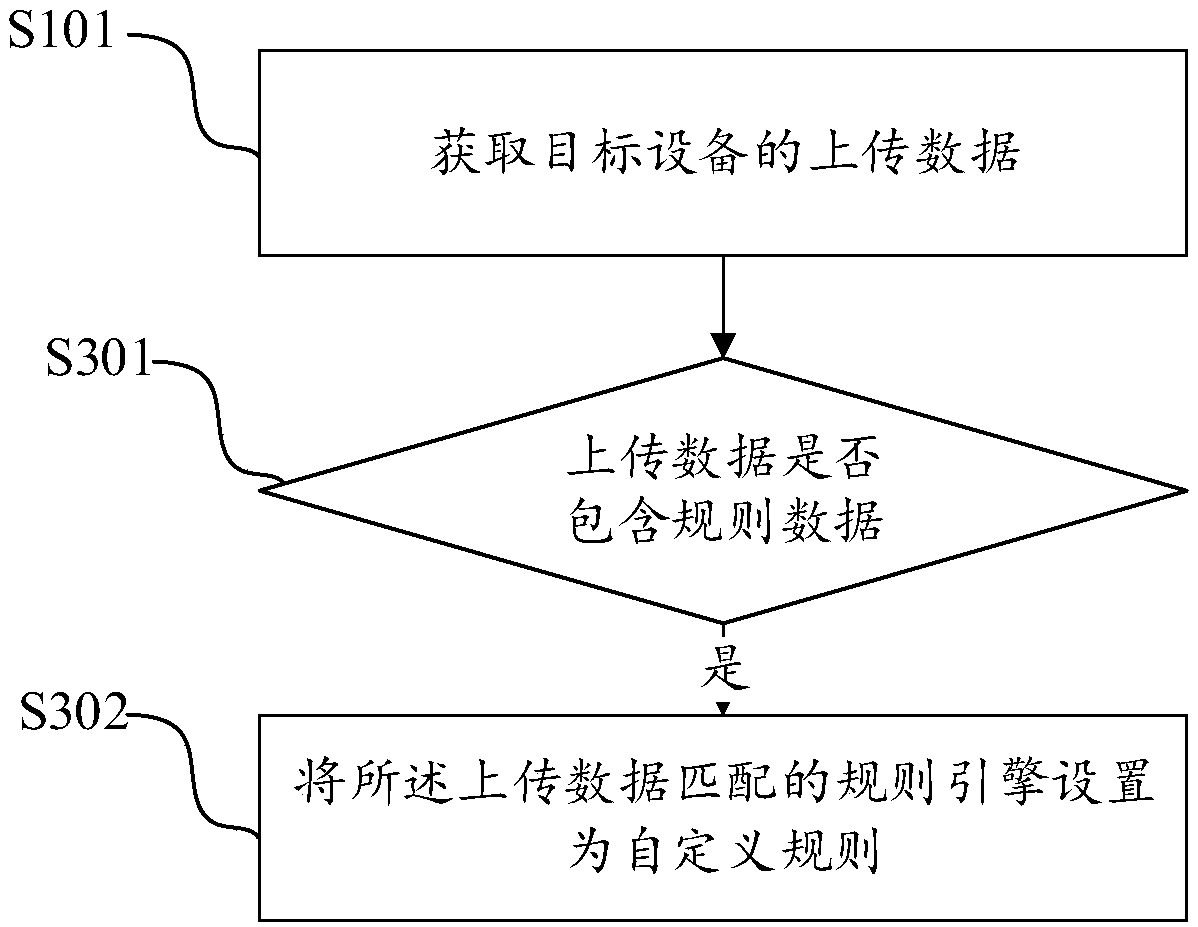

Data processing method and device based on rule engine, and electronic equipment

InactiveCN108833154AIncrease flexibilityEasy to analyze dataData switching networksFixed fieldData processing

Embodiments of the invention disclose a data processing method and a data processing device based on a rule engine, and electronic equipment, belonging to the technical field of data processing. The method comprises: acquiring upload data of the target equipment, wherein the upload data comprises one or more fixed fields; adding an attribute field to the upload data based on the attribute of the target equipment; setting a matching rule engine for the upload data based on the fixed fields and the attribute field; and processing the upload data by using at least one of the filter, the processorand the plug-in in the rule engine. Through the solution provided by the application, the efficiency of data processing is improved.

Owner:THUNDERSOFT

Three-hole electric bookbinding machine with scrap removal device

The invention relates to a three-hole electric bookbinding machine with a scrap removal device. A hollow drill spindle and a drill sleeve are adopted to throw paper scraps to a connecting sleeve by means of centrifugal force; the paper scraps in the connecting sleeve enters a scrap accumulating disk through a reed pipe from a scrap guiding opening. Orderly treatment of paper scraps is realized; files are pressed by means of a press foot plate; the files are fixed and then drilled so as to avoid offset during the process of drilling. By means of the combination of a position switch and a spacing block, the process is restricted; an adjusting screw on the spacing block can regulate strokes and the three-hole electric bookbinding machine with scrap removal device has good applicability.

Owner:泰兴市现代办公用品厂

Shell opening device and nut processing system

ActiveCN106360751ANo chance of clogging the deviceImprove processing qualityHuskingHullingEngineeringLeather belt

The invention provides a shell opening device and a nut processing system and belongs to the field of food processing. The shell opening device comprises a feeding hopper, a profiling mold and a saw blade, wherein the profiling mold is arranged under the feeding hopper and used for receiving a fruit material from the feeding hopper, the profiling mold comprises a saw blade gap for containing the saw blade and a guiding groove for controlling a walking track of the fruit material, the saw blade gap is communicated with the guiding groove formed in the profiling mold, the saw blade is embedded into the guiding groove through the saw blade gap, a belt conveying assembly is next to the profiling mold, and a belt of the belt conveying assembly is kept in the guiding groove to drive the fruit material in the guiding groove to roll downwards. The nut processing system comprises a material frying device and the shell opening device. The cutting efficiency can be improved, the broken fruit material can be decreased, an obtained opening angle ranges from 180 degrees to 360 degrees, nuts are easy to eat, flavorings can fully penetrate into pulp in the making process and is fully in contact with the pulp, and pulp taste is improved.

Owner:杭州淘道科技有限公司

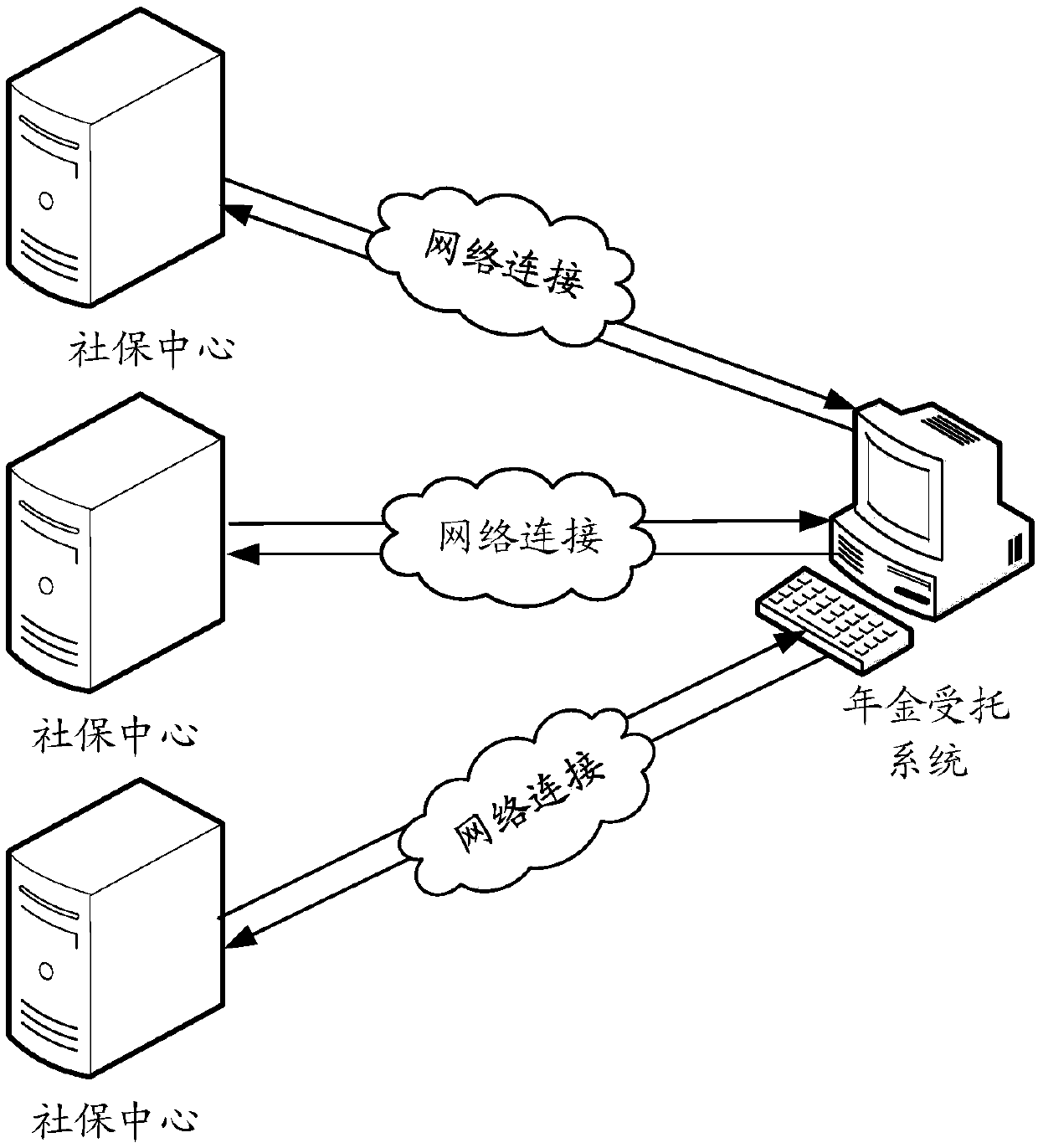

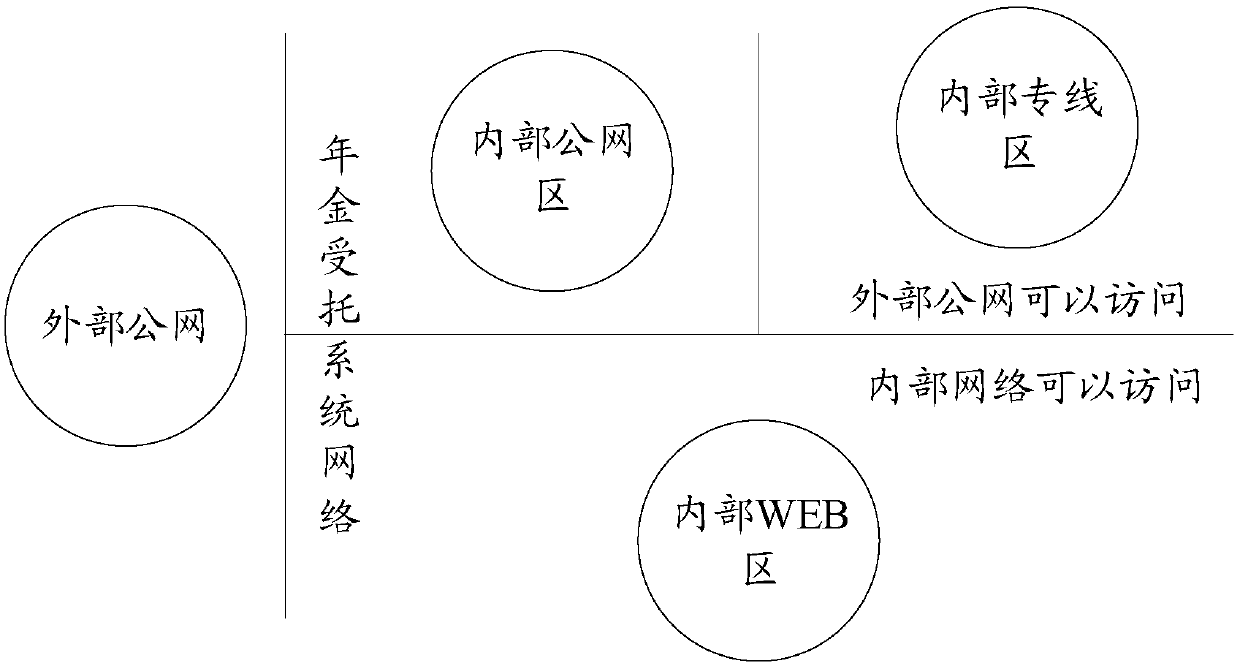

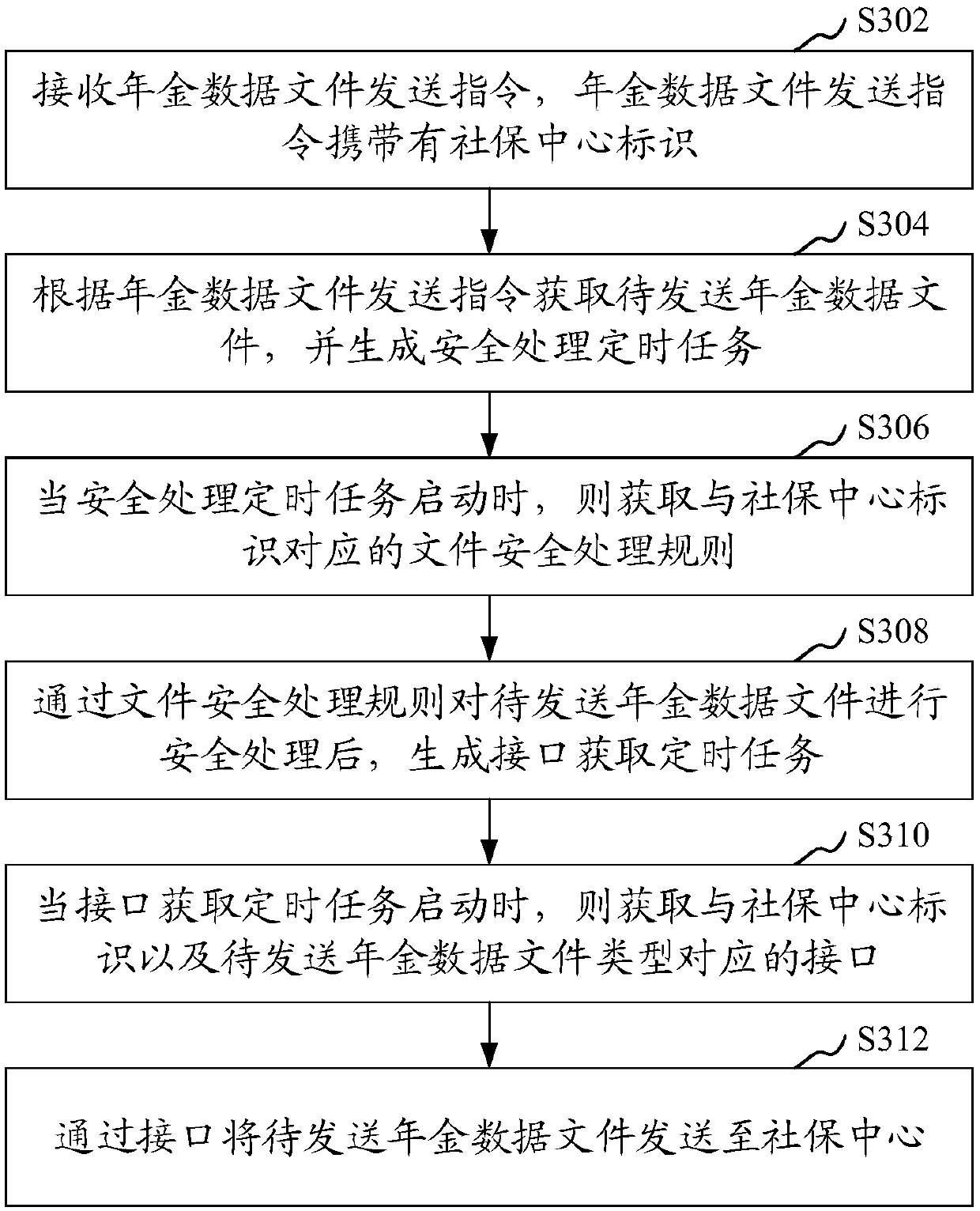

Annuity data file sending method and device, computer equipment and storage medium

The invention relates to an annuity data file sending method and device, computer equipment and a storage medium. The method includes: receiving an annuity data file sending instruction, wherein an annuity data file sending instruction carries a social-security center identifier; acquiring a to-be-sent annuity data file according to an annuity data file sending instruction, and generating a safety-processing timing task; acquiring a file safety-processing rule, which corresponds to the social-security center identifier, when the safety-processing timing task is started; carrying out safety processing on the to-be-sent annuity data file through the file safety-processing rule, and then generating an interface-acquiring timing task; acquiring an interface, which corresponds to the social-security center identifier and the type of the to-be-sent annuity data file, when the interface-acquiring timing task is started; and sending the to-be-sent annuity data file to a social-security centerthrough the interface. According to the above-mentioned annuity data file sending method and device, the above-mentioned computer equipment and the above-mentioned storage medium, files can be sent toa plurality of social-security centers simply by one annuity entrusted-system, and thus costs are reduced.

Owner:PING AN PENSION INSURANCE

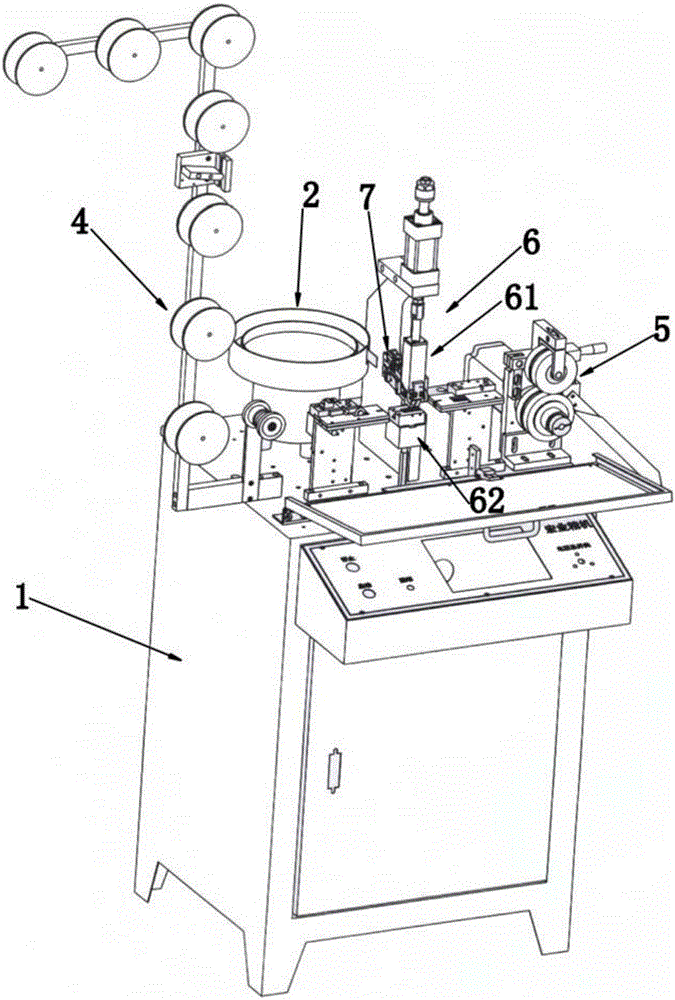

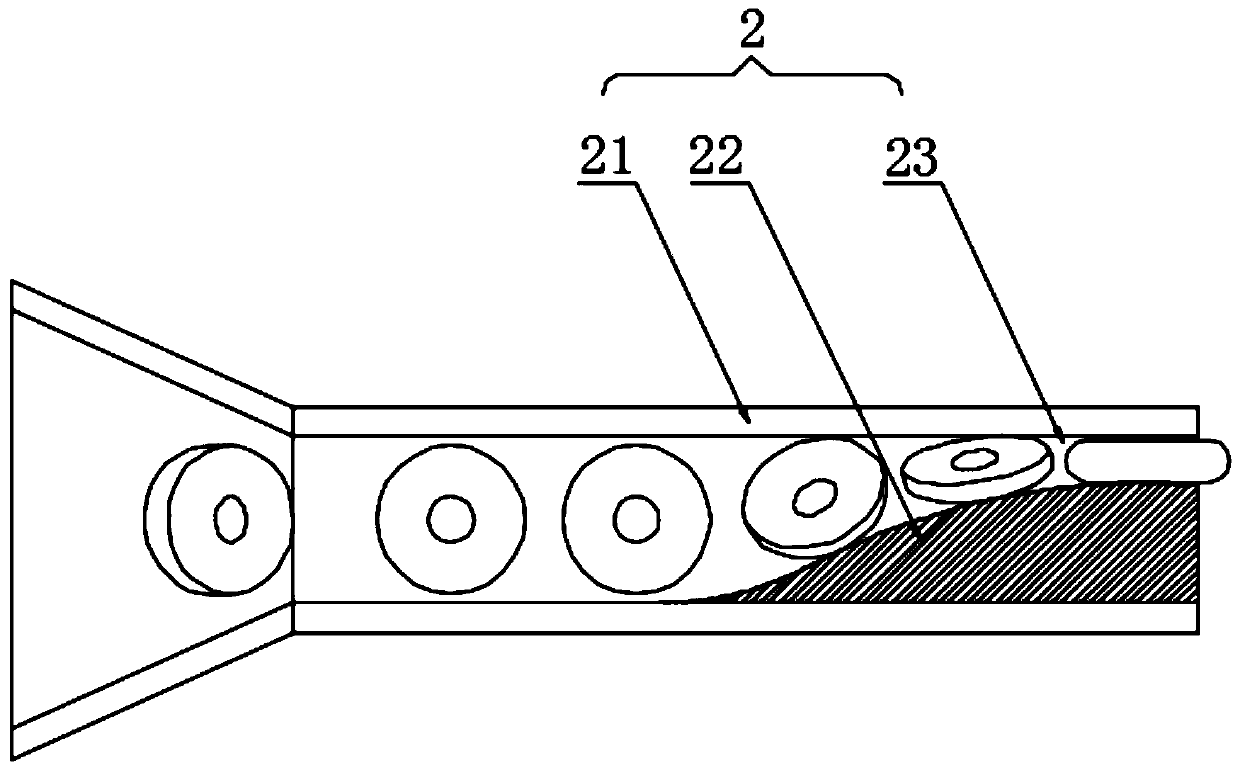

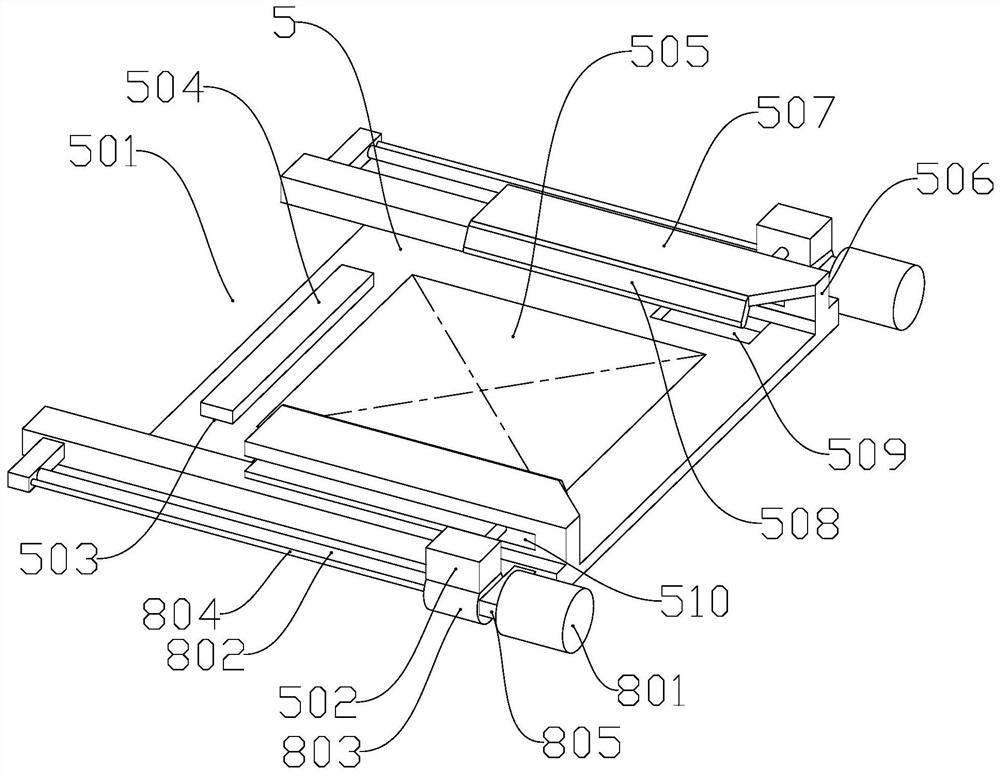

Full-automatic conceal zipper movable code loading equipment

The invention relates to zipper code loading equipment, in particular to full-automatic conceal zipper movable code loading equipment. According to the technical scheme, the full-automatic conceal zipper movable code loading equipment comprises a machine body, a vibration tray, a limiting code conveying rail, a zipper belt conveying mechanism, a zipper belt traction mechanism and a punching code loading mold; a limiting code conveying assembly is arranged between the limiting code conveying rail and the punching code loading mold, and includes a limiting code one-by-one feeding and positioning device and a limiting code limiting device; the limiting code limiting device includes a clamping bar erected on the limiting code conveying rail and suffered from external force to swing on the limiting code conveying rail; and the limiting code one-by-one feeding and positioning device includes a driving source erected above the limiting code conveying rail, a slide base and a clamping arm hinged with the slide base. By means of the technical scheme, the full-automatic conceal zipper movable code loading equipment urges limiting codes to enter the mold one by one in sequence, and is simple in structure and high in sensitivity.

Owner:WENZHOU HONGYE PRECISE MACHINERY

Persimmon peeling device

ActiveCN110693047ARealize steppingEasy peeling workClimate change adaptationVegetable peelingGear wheelElectric machinery

The invention discloses a persimmon peeling device and particularly relates to the field of persimmon processing equipment. The persimmon peeling device comprises a conveying mechanism, a placing mechanism, a fixing mechanism, a peeling mechanism and a sprinkling mechanism and is characterized in that the placing mechanism is obliquely arranged on one side of the top of the conveying mechanism, the fixing mechanism is arranged at the top of the conveying mechanism, the peeling mechanism is arranged above the fixing mechanism, and the sprinkling mechanism is arranged on one side of the peelingmechanism; the conveying mechanism comprises rotary shafts, gears, chains, conveying plates and a drive motor. The persimmon peeling device has the advantages that the conveying mechanism is in linkage with the fixing mechanism through a linkage mechanism, and stepping conveying of the conveying plates and clamping of the fixing mechanism can be achieved by the coordination of a U-shaped frame anda motor self-reset switch; by the coordination of an upper pressing plate and a self-reset switch, when a pull rod drives a cutting head to move downwards, persimmon rotary cutting and sprinkling oxidation prevention of peeled persimmons can be achieved at the same time, high persimmon processing efficiency is achieved, and the whole device is convenient and safe to operate.

Owner:泰安岱创科技咨询有限公司

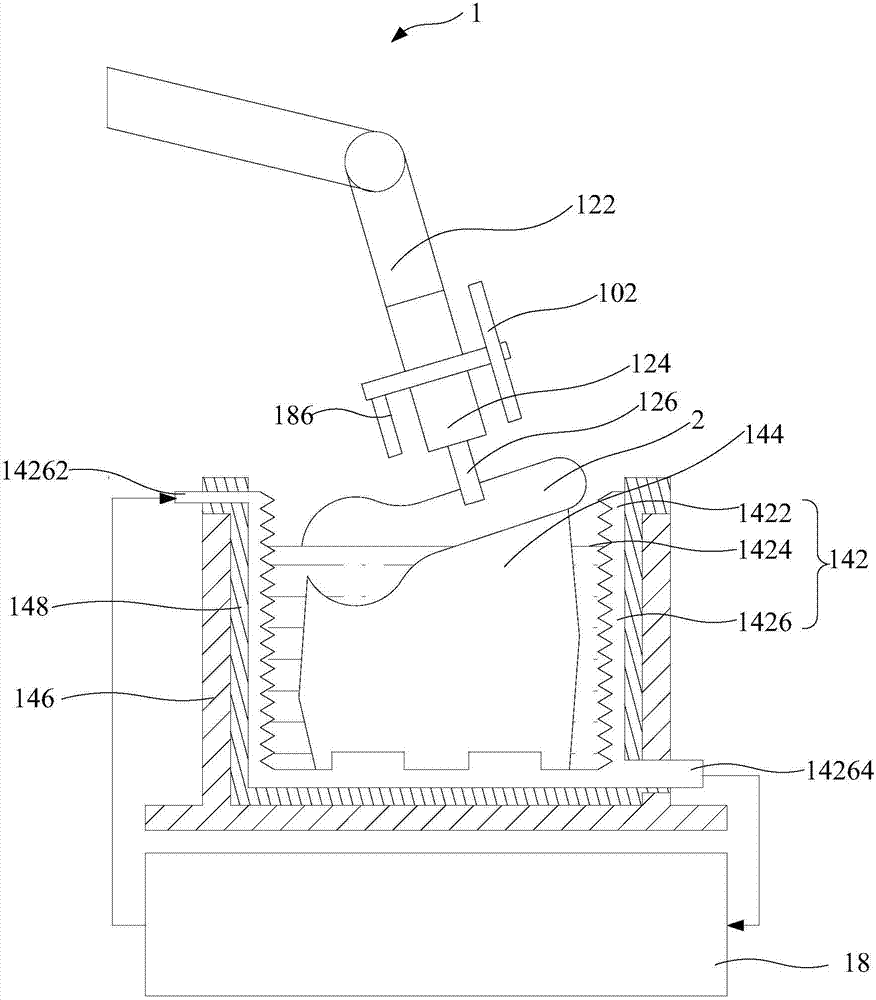

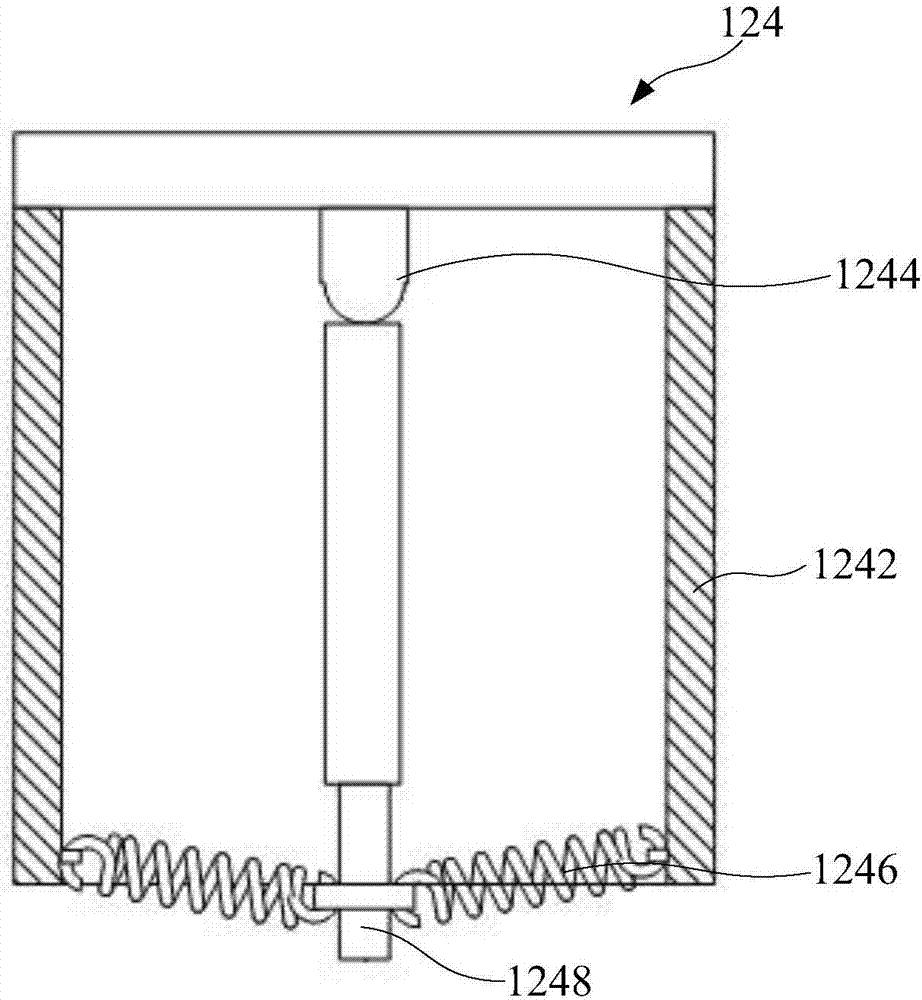

Clamp, machining assembly and application method of machining assembly

ActiveCN106862959AInfluence positioningImprove accuracyPositioning apparatusMetal-working holdersEngineeringUltimate tensile strength

The invention provides a clamp, a machining assembly and an application method of the machining assembly. The clamp is matched with a machine tool for use and comprises a clamping mechanism and a fixing assembly. The clamping mechanism is arranged on the machine tool and comprises a mechanical arm, an elastic supporting assembly and a chuck. The elastic supporting assembly is connected with the mechanical arm and the chuck. The chuck is used for clamping a special-shaped part. The fixing assembly is installed on a workbench and comprises a container with the top being provided with an opening and a supporting piece. The container is used for containing a phase-change material, and the supporting piece is installed inside the container. When the chuck is used for clamping the special-shaped part, the special-shaped part can abut against the supporting piece through the opening position of the container according to the machining positioning requirements, and the special-shaped part, the supporting piece and the container are cured and fixedly connected together through the phase-change material. According to the clamp provided by the invention, the problem of posture uncertainty of the special-shaped part in the positioning process is avoided, the clamp with high fixing strength and rigidity and good machining datum repeatability is provided for finish machining, and the degree of using satisfaction by users is increased.

Owner:ZHEJIANG WANGLIYANG TRANMISSION CO LTD

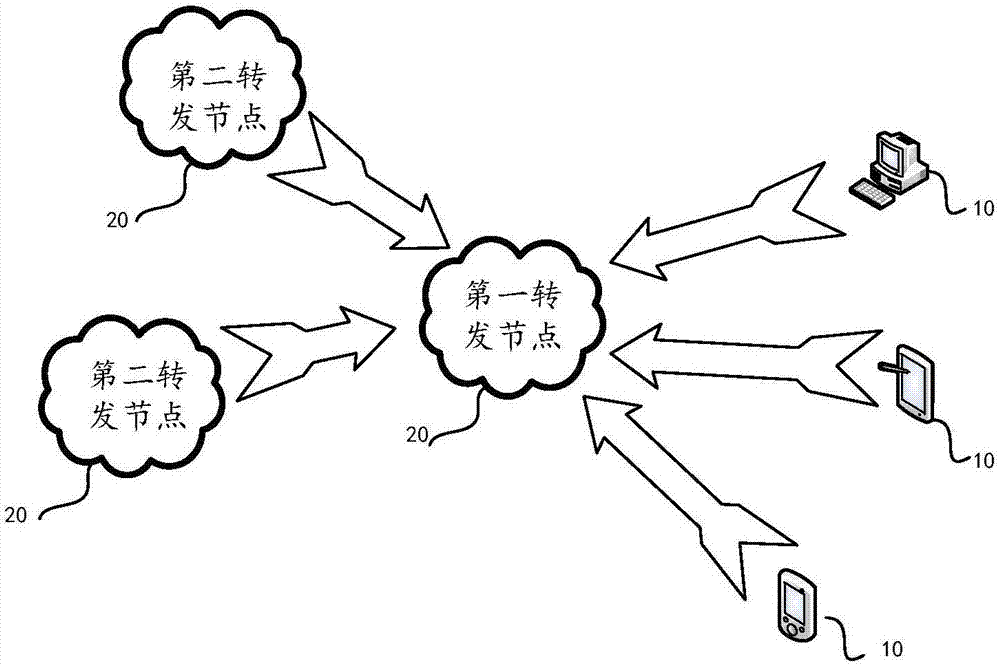

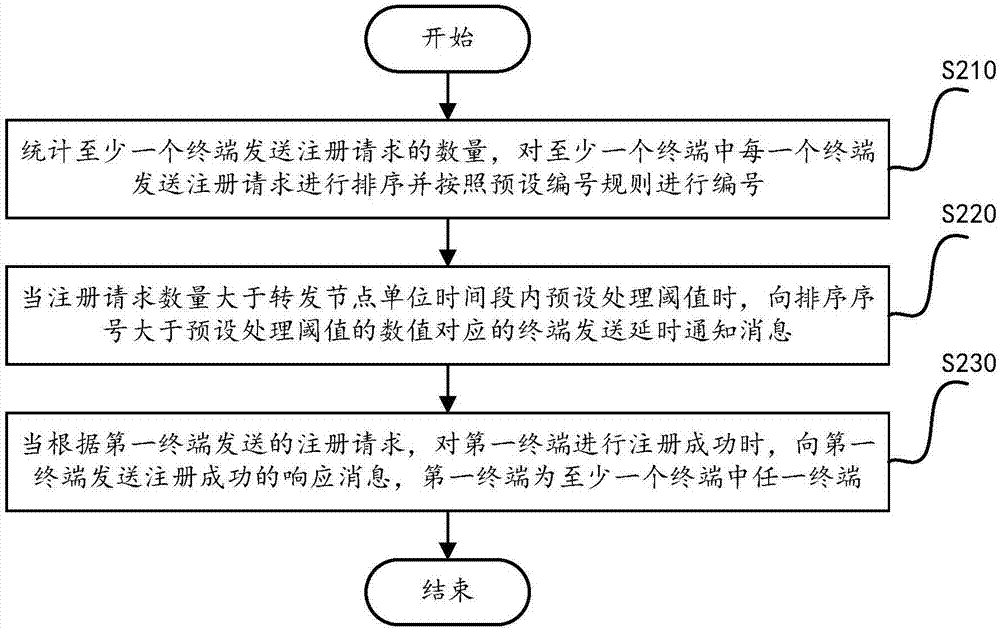

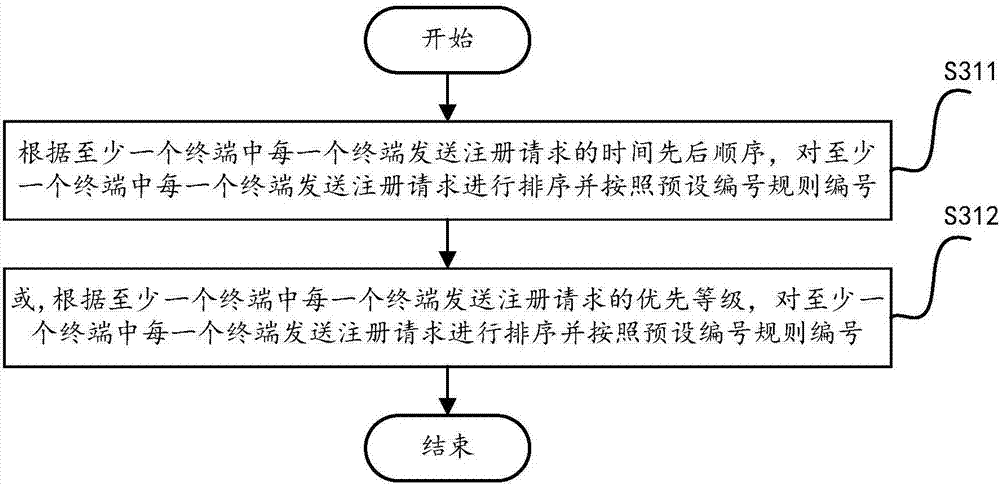

Method and system for networking between terminal and forwarding node

ActiveCN107483310AReduce stressOptimize layoutNetworks interconnectionWireless communicationDistributed computingComputer terminal

The invention relates to a method and system for networking between a terminal and a forwarding node. The method includes counting the number of registration requests sent by at least one terminal, sending a registration request to each of the at least one terminal and sorting, and performing numbering according to a preset numbering rule; sending a delay notification message to the terminal corresponding to the value whose sequence number is greater than a preset processing threshold when the number of registration requests is greater than the preset processing threshold within the unit time period of the forwarding node; and sending a response message of successful registration to the first terminal when the first terminal is registered successfully according to the registration request sent by the first terminal, wherein the first terminal is any one terminal of the at least one terminal. The method and system provided reduce the pressure of the forwarding node, improve the networking efficiency, timely process the registration request sent first and the registration request with high priority, can effectively reduce the pressure on the forwarding node, and improve the networking efficiency.

Owner:SHENZHEN SHENGLU IOT COMM TECH CO LTD

Full-automatic steel pipe knurling system

ActiveCN104148877AReasonable designOrderly processingMetal working apparatusKnurlingLinear vibration

The invention provides a full-automatic steel pipe knurling system which comprises a linear vibration feed machine, a first material sending cylinder, a material passageway, a first magnetic cylinder, a material thumbing block, a material receiving box, a thread rolling machine, a thread rolling wheel travel switch, thread rolling wheels and a second magnetic cylinder. The full-automatic steel pipe knurling system is characterized in that the two thread rolling wheels are arranged in the middle of the top of the thread rolling machine. According to the technical scheme, design is reasonable; materials to be machined are arrayed in sequence through the linear vibration feed machine so that machining can be orderly; no manual operation needs to directly participate in knurling due to cooperation of sensors, the cylinders and the thread rolling machine, production safety is ensured, and quality and consistency of products are effectively ensured through devices such as the sensors and the cylinders.

Owner:GUANGZHOU KOIDE KOKAN

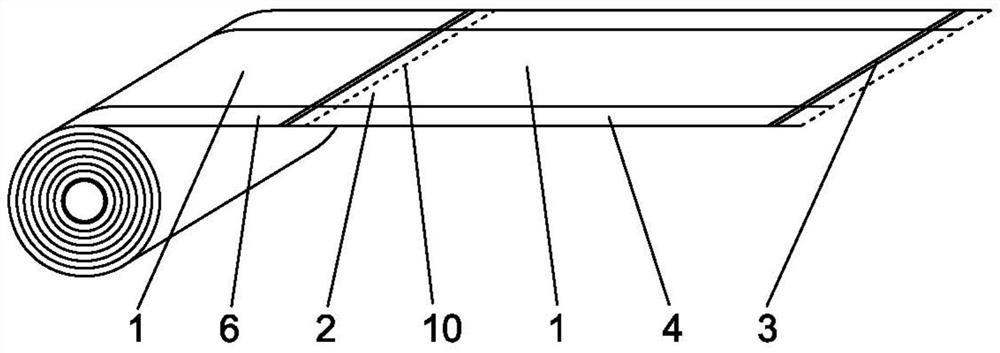

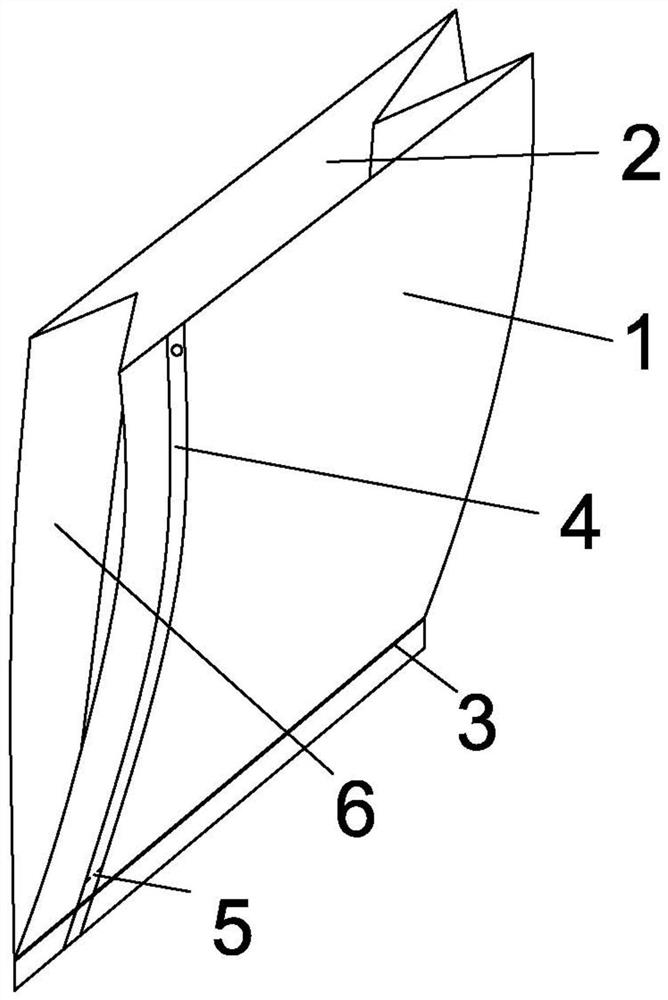

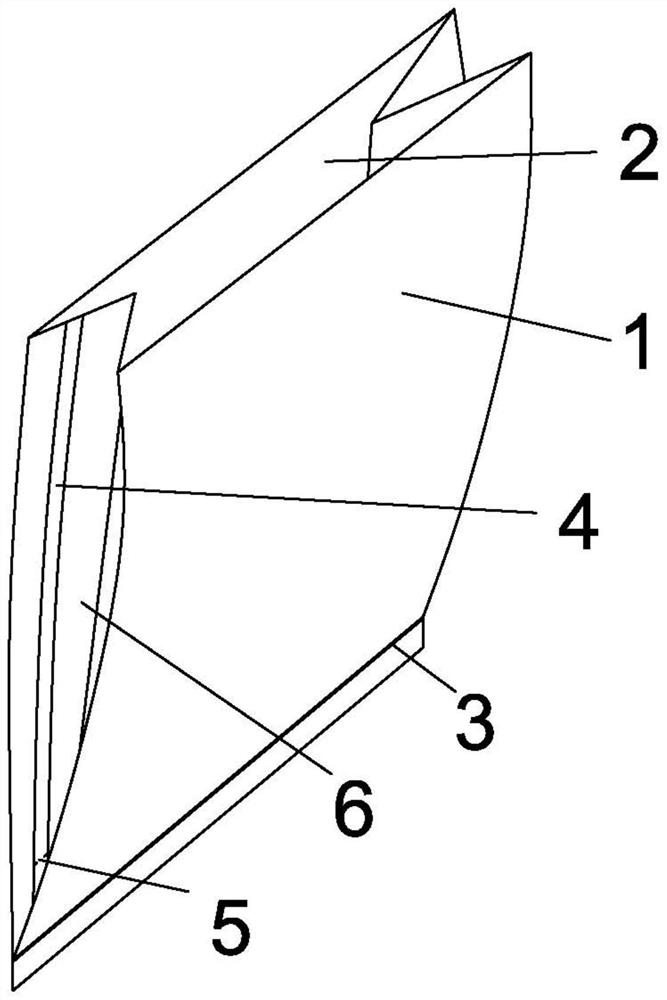

Medical waste bag and manufacturing method thereof

PendingCN111703765AEasy to processOrderly processingBag making operationsPaper-makingProcess engineeringWaste recovery

The invention belongs to the technical field of waste recovery, and particularly relates to a medical waste bag and a manufacturing method thereof. The medical waste bag comprises a plurality of bag bodies. One end of each bag body is an open end, and the other end of each bag body is a sealed end. The open end of each bag body is connected with the sealed end of the adjacent bag body in a tearingmode, and the sealed end of each bag body is connected with the open end of another adjustment bag body in a tearing mode. The bag bodies are connected and wound into a cylinder. A ribbon is fixed tothe open end of each bag body through hot-pressing. The medical waste bag connected and wound into the cylinder is convenient to use and store. The waste bag can be closed through the additionally-arranged ribbons. The preparation method of the medical waste bag is simple and high in production efficiency.

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV

Automatic hydrogel slide feeding and patching device

The invention belongs to the technical field of micro-nano patching, and provides an automatic hydrogel slide feeding and patching device. The automatic hydrogel slide feeding and patching device comprises a machine frame, wherein a slide placing frame driven by an electric cylinder is arranged on a workbench of the machine frame, a slide positioning mechanism is arranged on the slide placing frame, and a slide bin and a film tearing mechanism are sequentially arranged on a workbench in the sliding direction of the slide placing frame; a slide feeding mechanism is correspondingly arranged below the slide bin; and a patching mechanical arm and a material sheet placing table are further arranged on the workbench, the material sheet placing table is located on one side of the patching end ofthe electric cylinder, the patching mechanical arm is located between the electric cylinder and the material sheet placing table, and a material taking and placing mechanism used for taking and placing material sheets is arranged at the end of a working shaft of the patching mechanical arm. According to the invention, automatic processing of hydrogel slide feeding, release film tearing and lamination of the material sheets on the hydrogel slide can be realized, so that the patching efficiency and the patching quality are greatly improved, the sanitation of the material sheets is not influencedin the processing course, and the produced patching product is ensured to meet the production requirement of sanitation standard.

Owner:SHANDONG NOVOSHINE OPTOELECTRONICS CO LTD

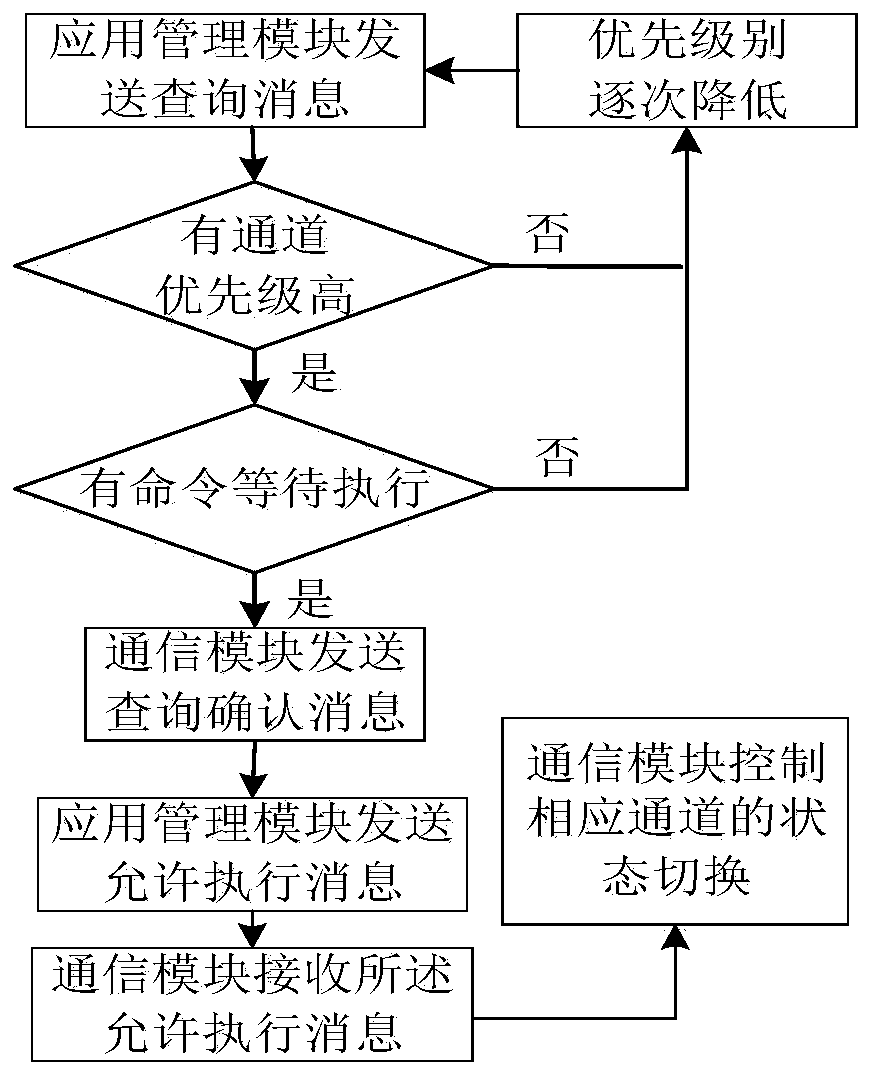

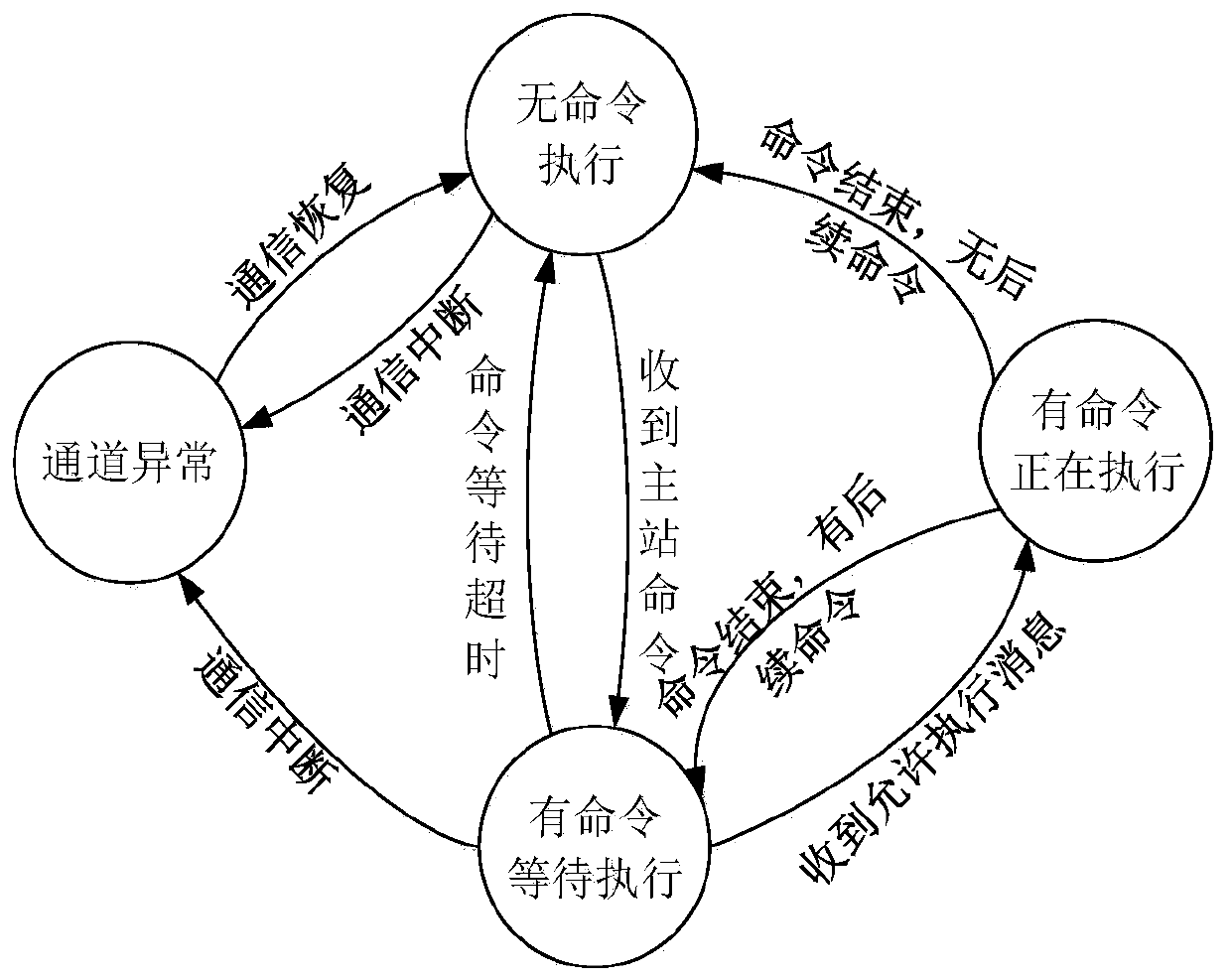

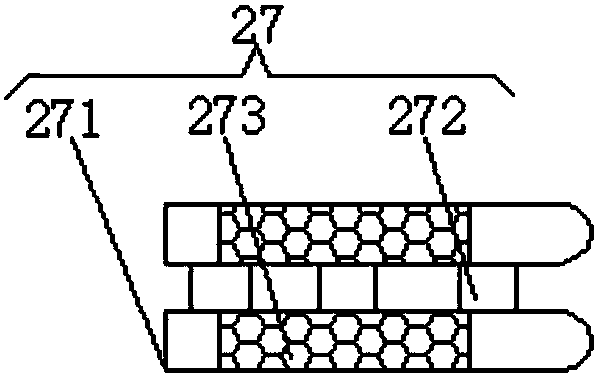

Information protection substation and priority response method thereof for master station command

ActiveCN111092419AProcessing rulesOrderly processingEmergency protective circuit arrangementsInformation technology support systemStationMaster station

The invention relates to an information protection substation and a priority response method thereof for a master station command. The application management module sends a channel state query message, and the communication module receives the channel state query message, a channel number, a channel state and a channel priority corresponding to a channel are written into a query confirmation message and the query confirmation message is returned if the priority level is not lower than the priority level and the channel state is a channel with a command to wait for execution; otherwise, the query confirmation message is not returned; if receiving the query confirmation message, the application management module sends an execution permission message; the communication module receives the execution permission message and controls the state of the corresponding channel to be switched to a state that a command is being executed; and if the query confirmation message is not received, the priority level is reduced step by step, and the channel state query message is resent, so as to solve the problem in the prior art that how to process the command according to different priority levels in the master station and the sub-station does not exist.

Owner:XUJI GRP +2

Discharging device for preparing plastic product

The invention discloses a discharging device for preparing a plastic product. The discharging device comprises a fixed base, wherein a fixed block is fixedly connected to the right side of the top ofthe fixed base, connecting columns are fixedly connected to the two sides of the top of the fixed base respectively, and the connecting columns are located on the left side of the fixed block; protective shells are fixedly connected to the top ends of the connecting columns respectively, and an injection barrel is fixedly connected between the opposite sides of the protective shells; and one sideof the fixed block is fixedly connected with a first motor through a base, and an output shaft of the first motor is fixedly connected with a rotating shaft. The invention relates to the technical field of plastic preparation equipment. According to the discharging device for preparing the plastic product, the problems that an existing discharging device is not capable of well controlling the temperature in the discharging process, and materials cannot be kept in a liquid state in the discharging process all the time are solved, the raw materials in a discharging cylinder can be uniformly heated, the temperature is kept constant, and the working efficiency of the plastic product preparation is improved.

Owner:俞云飞

Full-automatic workpiece assembling system

PendingCN106925989AGood slide outStable processingMetal working apparatusMotor driveTransmission belt

The invention discloses a full-automatic workpiece assembling system. The full-automatic workpiece assembling system comprises a feeding part and an assembling part arranged at the rear end of the feeding part. The feeding part comprises a rack, a feeding mechanism arranged at the front end of the rack, and a conveying belt arranged at the rear end of the rack, and the conveying belt is connected with a driving motor used for driving the conveying belt to operate. The assembling part comprises a case and a turntable rotatably arranged on the case. A stepping motor driving the turntable to rotate is arranged in the case. A plurality of mounting bases are annularly arranged on the turntable at equal angles. A nut feeding mechanism used for embedding nuts into the mounting bases, a taking mechanism used for taking material strips to the mounting bases, a safety braking mechanism used for embedding accessories into the mounting bases manually, a screw locking mechanism used for locking screws to corresponding positions, and a discharging mechanism used for discharging assembled pieces out of the mounting bases are arranged on the case around the turntable.

Owner:HUIZHOU ZHONGBANG ELECTRONICS

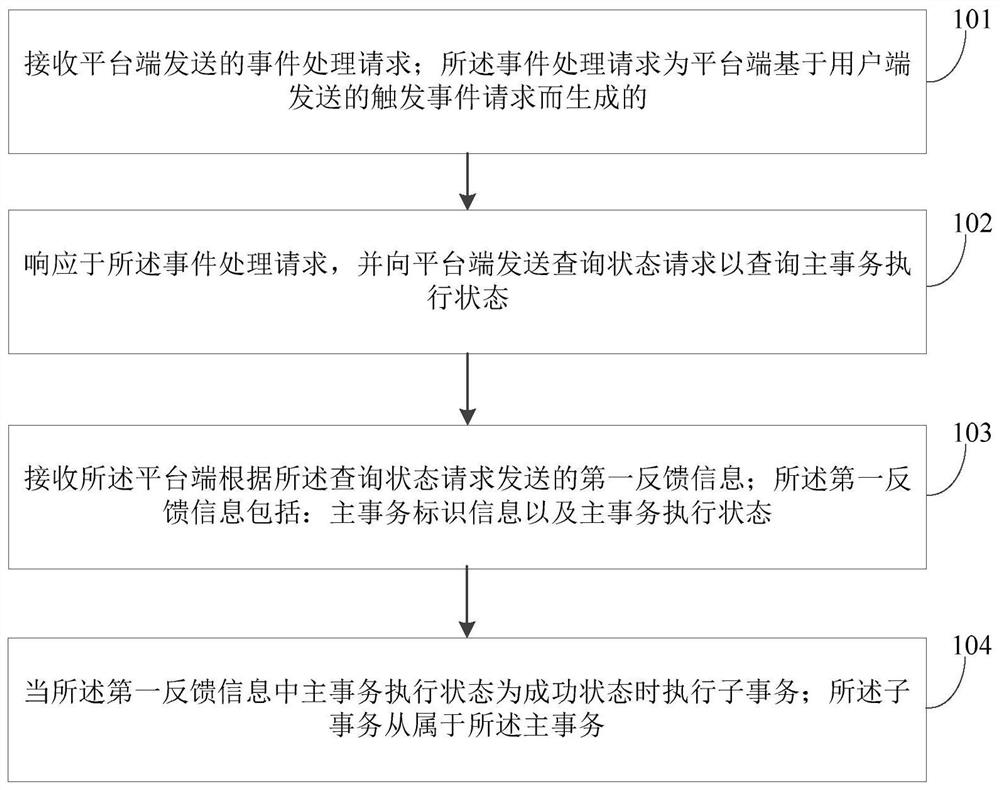

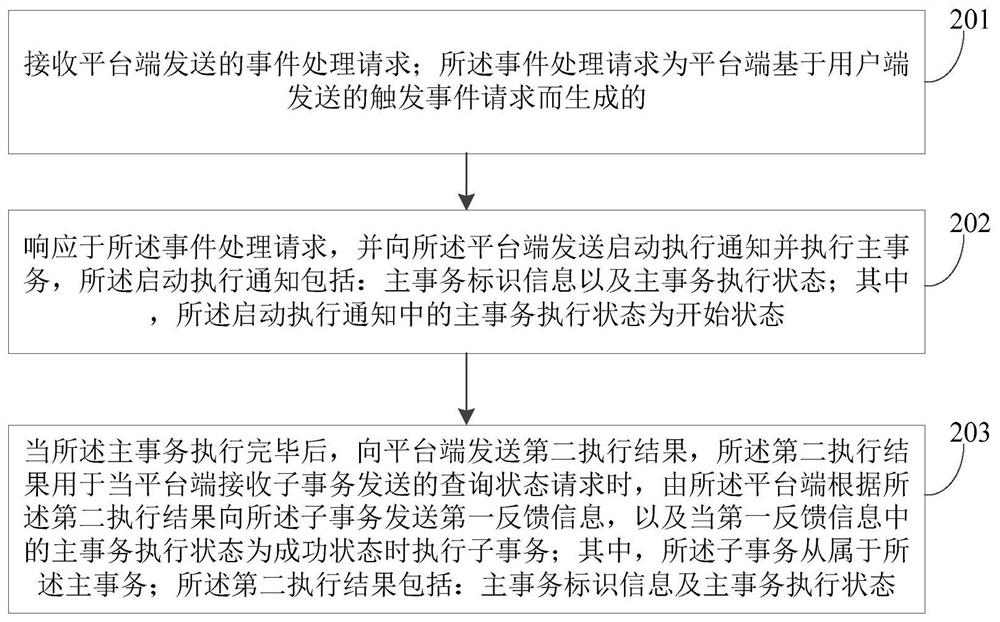

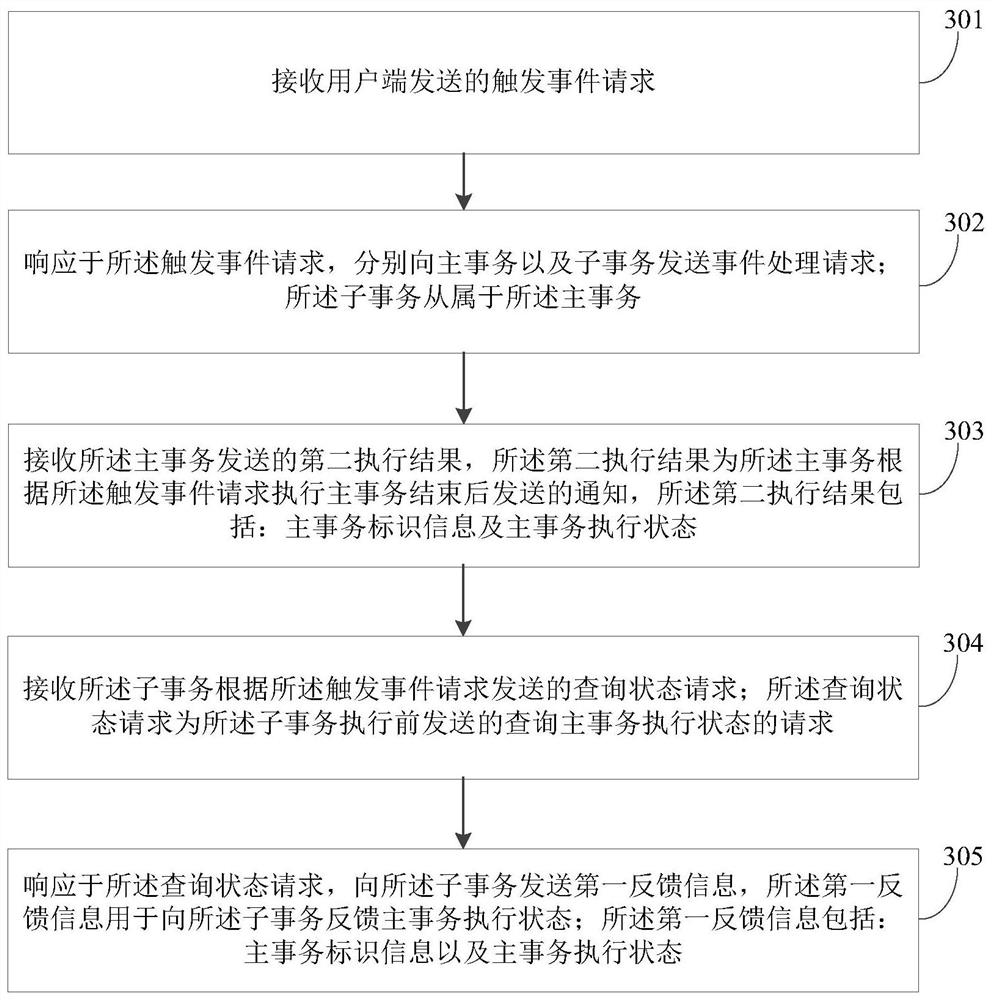

Distributed transaction processing method and device based on service-free architecture

PendingCN113051044AOrderly processingLow implementation costDatabase updatingSpecial data processing applicationsEngineeringTransaction processing

The invention provides a distributed transaction processing method and device based on a service-free architecture. The method comprises the following steps: receiving an event processing request sent by a platform end, wherein the event processing request is generated by the platform end based on a trigger event request sent by a user end; responding to the event processing request, and sending a query state request to a platform end to query a main transaction execution state; receiving first feedback information sent by the platform end according to the query state request, wherein the first feedback information comprises main transaction identification information and a main transaction execution state; and when the execution state of the main transaction in the first feedback information is a successful state, executing the sub-transaction, wherein the sub-transaction is subordinate to the main transaction. According to the method disclosed by the embodiment of the invention, the subordinate differentiation is carried out on the transactions in the event according to the logic, and the orderly processing of the data in the event is ensured through a sequential execution transmission method, so that the method is low in implementation cost, and the problem of data consistency can be effectively solved.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

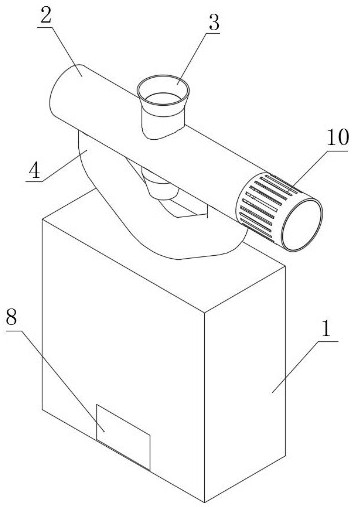

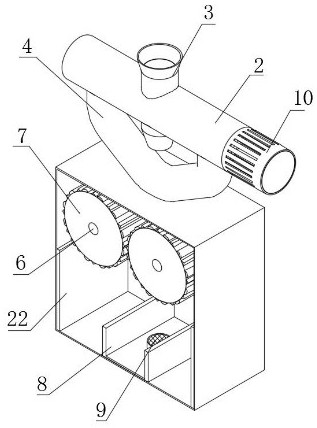

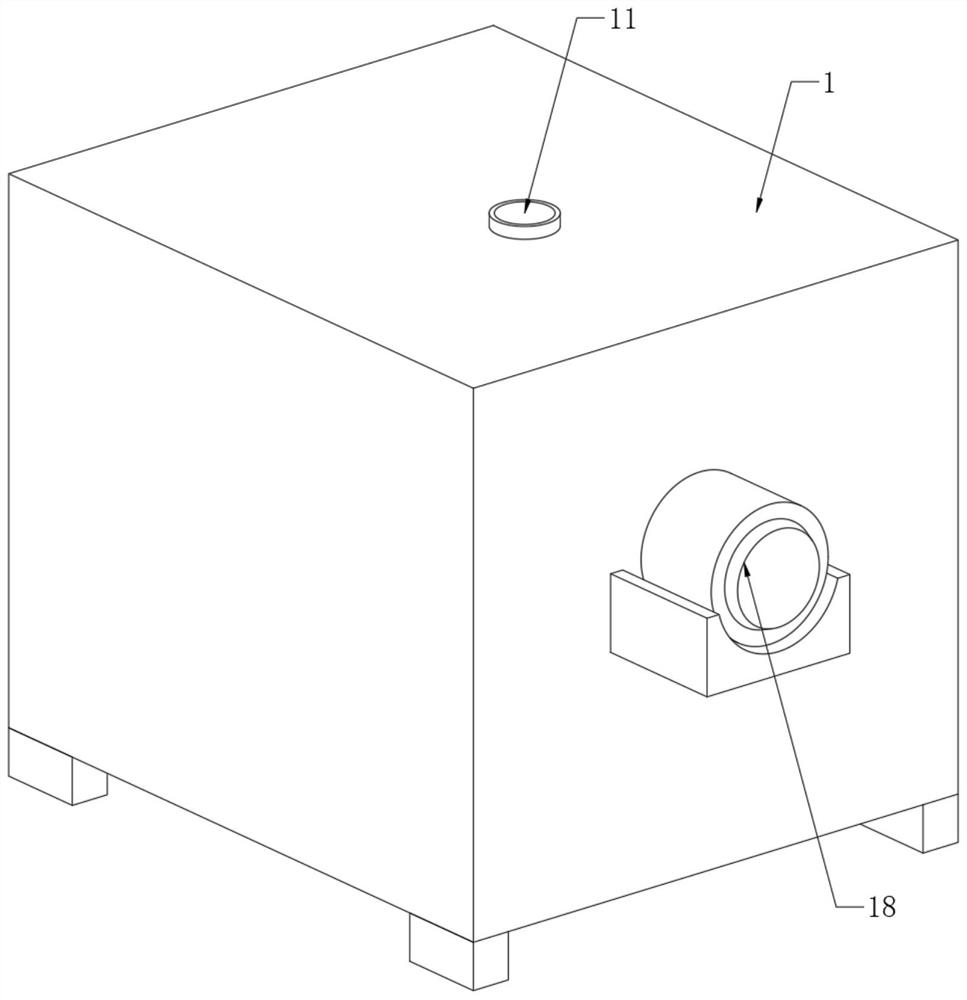

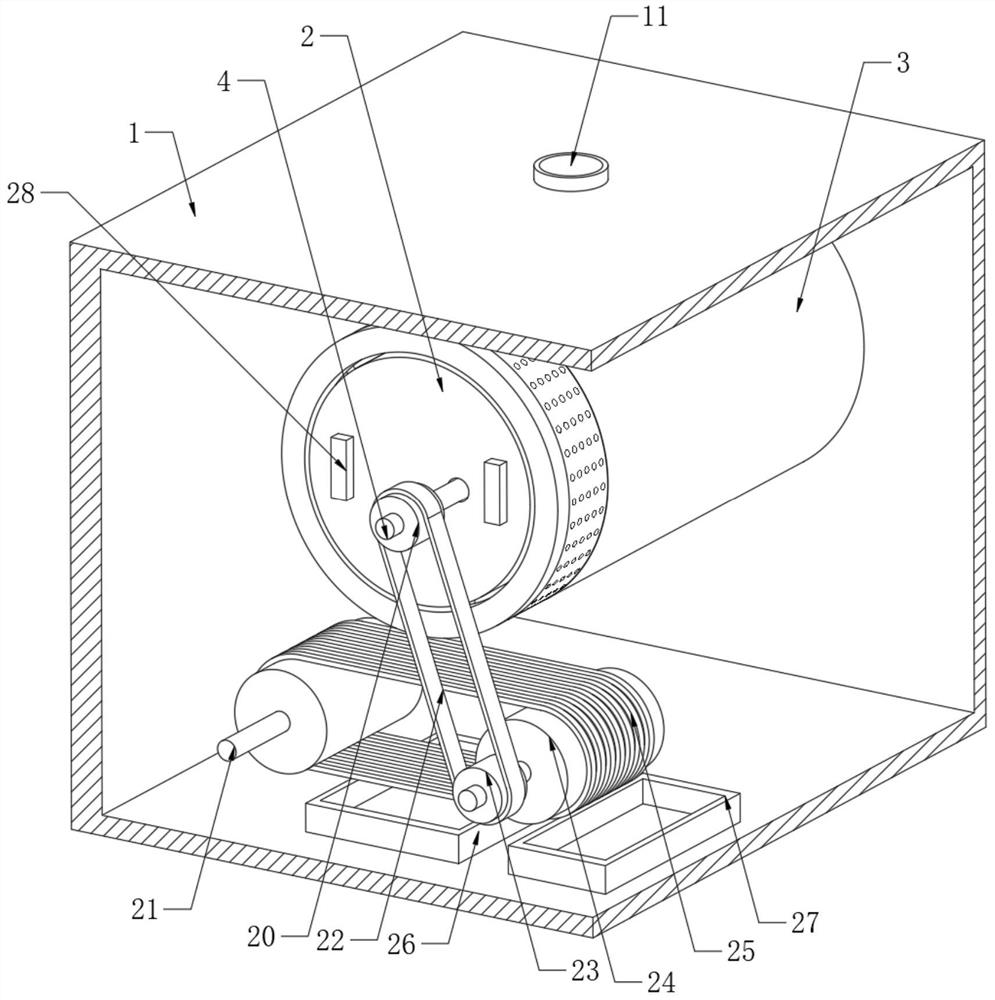

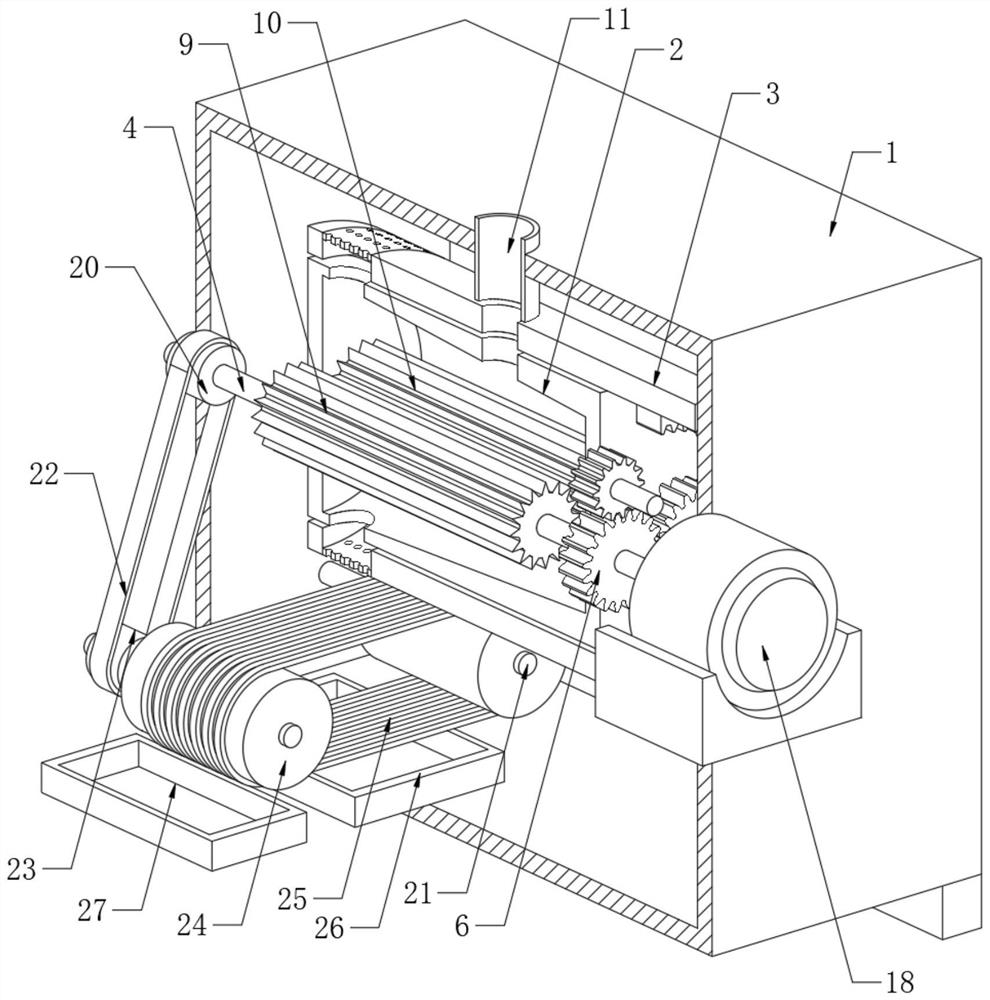

Ordered waste textile smashing equipment

ActiveCN113680435AReduce cloggingOrderly processingGrain treatmentsMetal impuritiesProcess engineering

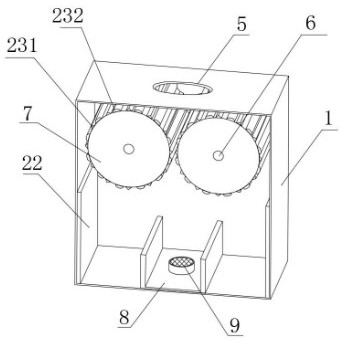

The invention discloses ordered waste textile smashing equipment. The ordered waste textile smashing equipment comprises a shell and an electric control assembly, a feeding port is formed in the top of the shell, the feeding port is connected with a feeding pipe in a sealed mode, two openings are symmetrically formed in the end, away from the feeding port, of the feeding pipe, the two openings are jointly connected with a material distributing barrel in a sealed mode, a feeding hopper is arranged in the center of the top of the material distributing barrel in a communicating mode, a uniform material distributing structure is arranged in the material distributing barrel, and a smashing and collecting structure is arranged in the shell. The ordered waste textile smashing equipment has the advantages that waste textiles uniformly fall and are smashed in batches, so that the probability of blockage in the transportation process is greatly reduced, an ordered processing process is kept, metal impurities are separated under the action of electrostatic attraction, the falling speed of products is slowed down under the action of wind power, and the separation effect is improved.

Owner:南通吉利新纺织有限公司

A kind of high-efficiency manufacturing method of safety webbing

ActiveCN104674567BEasy to operateHigh yarn stabilization efficiencySafety beltsAuxillary apparatusYarnAfter treatment

The invention discloses a high-efficiency production method of a safety braid. The high-efficiency production method comprises the following steps: (1) receiving and inspecting raw materials; (2) pre-treating the raw materials; (3) stabilizing yarns; (4) threading the yarns; (5) changing the yarns, and braiding; (6) preparing a dyeing solution; (7) carrying out dyeing pretreatment; (8) carrying out dyeing and color fixation; (9) carrying out dyeing after-treatment; (10) detecting a finished product braid; (11) cutting the braid; and (12) packaging the braid, and warehousing the packaged braid. The high-efficiency production method has beneficial effects that the operability is high, the yarn stabilizing efficiency is high, the yarn stabilizing effect is good, the accuracy and the intelligence in positioning are realized, the orderliness in processing and production is realized, the fault rate of machines is reduced, the dyeing effect is improved, the relatively high dyeing degree and the relatively attractive appearance are guaranteed, and the service life of the safety braid is prolonged.

Owner:LANGXI FEIMA IND FABRICS

Task processing method and device, computer equipment and storage medium

PendingCN114595457AAvoid system crashOrderly processingInterprogram communicationPlatform integrity maintainanceCloud computingVulnerability detection

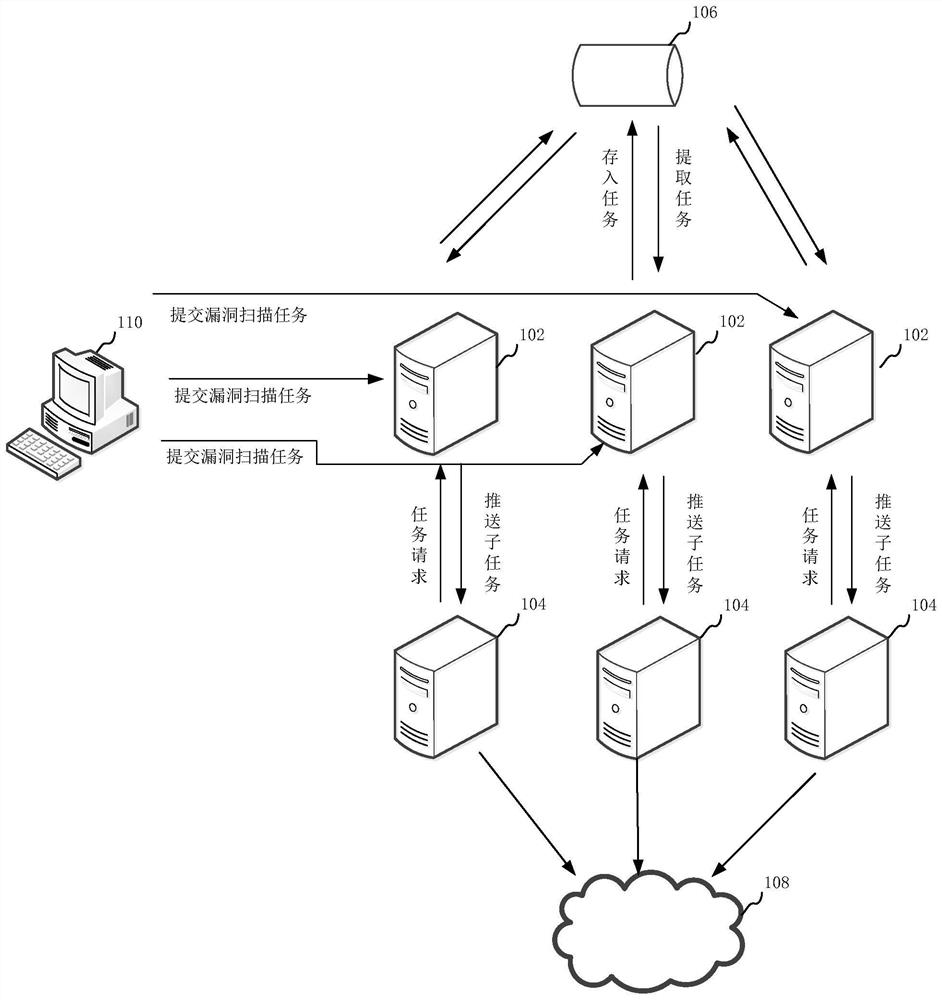

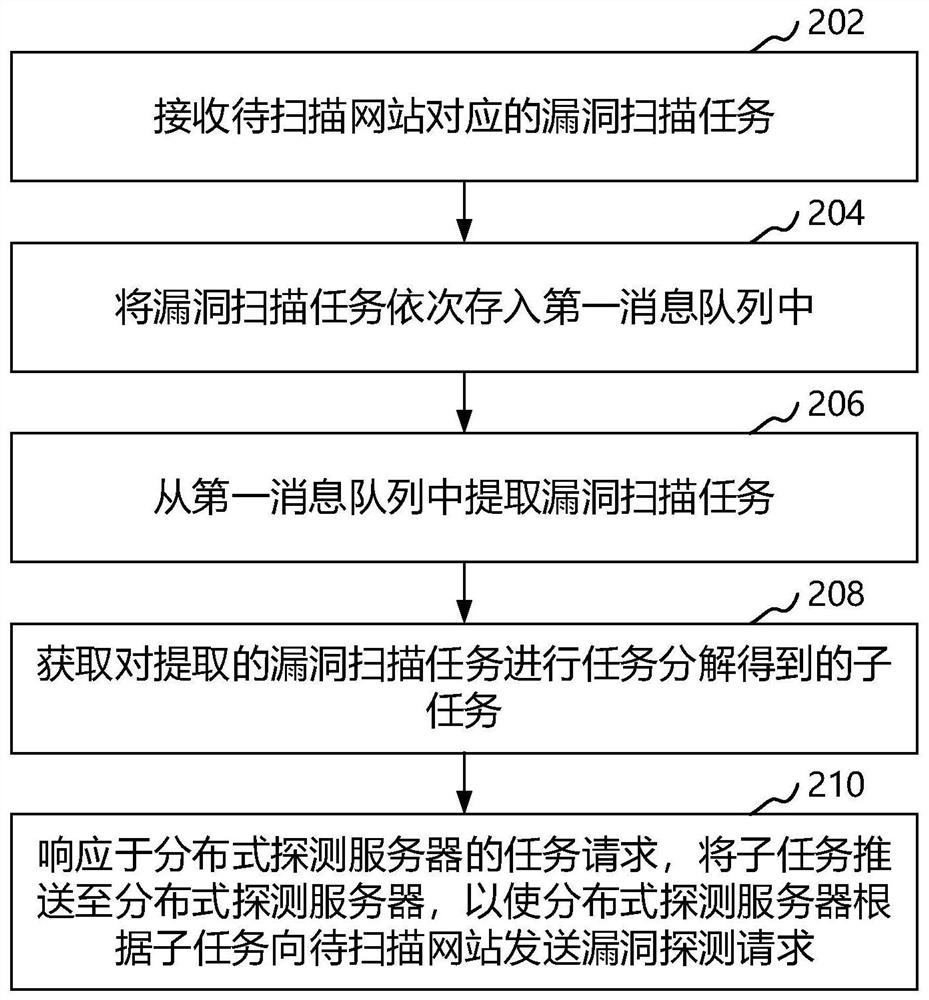

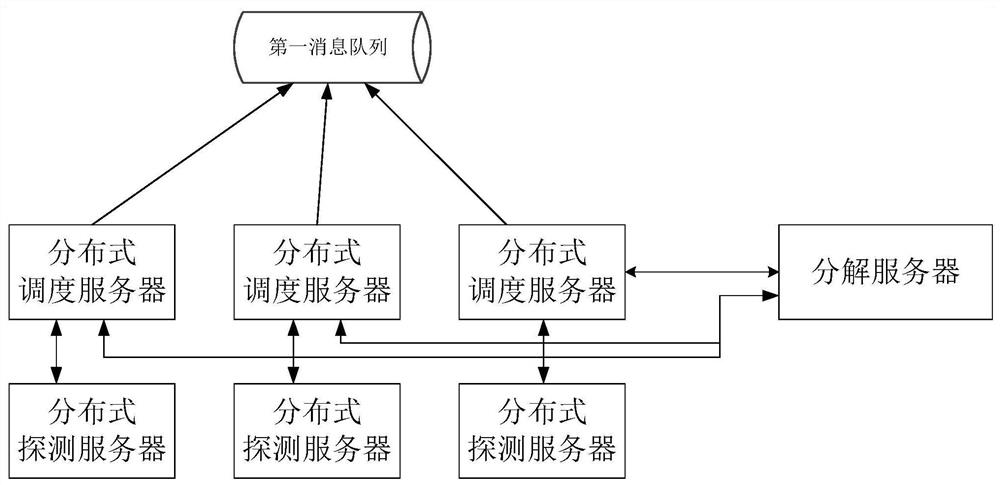

The invention relates to a task processing method and device, computer equipment and a storage medium. The method relates to cloud computing and cloud security technologies. The method comprises the following steps: receiving a vulnerability scanning task corresponding to a website to be scanned; storing the vulnerability scanning tasks in a first message queue in sequence; extracting a vulnerability scanning task from the first message queue; obtaining subtasks obtained by performing task decomposition on the extracted vulnerability scanning task; and in response to a task request of the distributed detection server, pushing the sub-task to the distributed detection server, so that the distributed detection server sends a vulnerability detection request to the to-be-scanned website according to the sub-task. By adopting the method, the vulnerability scanning efficiency can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Spraying structure for hydraulic machining

InactiveCN109910106AImprove processing efficiencyGuaranteed smoothnessMetal working apparatusMachined surfaceEngineering

The invention discloses a spraying structure for hydraulic machining. The spraying structure is used for cutting in a manner of mixing bubbles with water, the bubbles are attached to water before being sprayed, when the water is impacted on the surface of a workpiece, the bubbles are instantly broken, and the efficiency of workpiece machining is improved; due to the bubbles flow in the water, thesurface quality and smoothness of the machined surface are ensured, and the machining quality is improved meanwhile the machining efficiency is ensured; an air hole sleeve is eccentrically arranged inan outer water jacket, through the eccentric arrangement, air flow and liquid flow in the outer water jacket can automatically flow towards each other due to the fact that the eccentric inner space is not uniform, so that the combination performance of the air bubbles and water is improved; through the conical design of the air hole sleeve and the sleeve connection structure of the outer water jacket, the stability and the mixing effect of machining can be effectively ensured, and the spraying machining efficiency is ensured; and moreover, a plurality of spraying heads are arranged, and the spraying heads with spraying holes of different diameter can be used for machining, so that the structure is convenient and simple.

Owner:东莞市中帆新材料科技有限公司

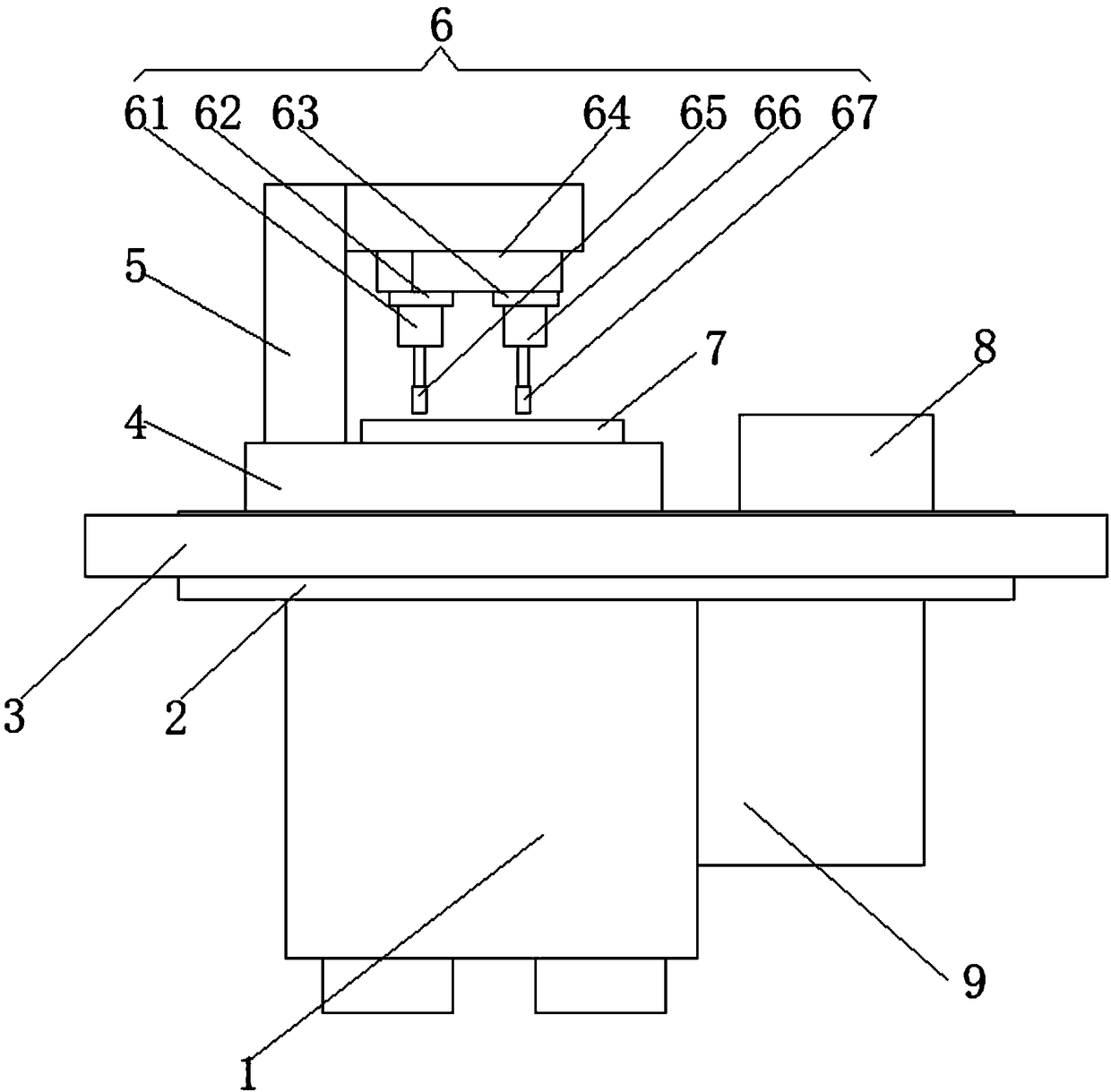

Drilling machine tool for mold machining

InactiveCN108436139AReduce spillageAvoid blockingMaintainance and safety accessoriesBoring/drilling machinesEngineeringMachine tool

The invention provides a drilling machine tool for mold machining and relates to the field of mold machining. The drilling machine tool for mold machining comprises a base; a damping sizing block is fixedly connected to the bottom of the base; the top of the base is fixedly connected with a support board; the left side of the top of the support board is fixedly connected with a workbench; the topof the workbench is fixedly connected with a support; the inner side of the support is fixedly connected with a drilling part; the drilling part comprises an inclined connection board; and the bottomof the inclined connection board is fixedly connected with a first mounting base. According to the drilling machine tool for mold machining, through arrangement of the support board and a pull rod, abaffle forms a collection blocking body for chippings of mold machining and can reduce splashing of the chippings, a surrounding semicircular collection groove can collect the splashed and falling chippings, a guide groove formed in the middle of a collection board guides the chippings to fall off and shortens the chipping clearing stroke, cleaning is facilitated, a control board is pulled out through guide of a guide wheel, and the falling chippings are collected in a unified mode.

Owner:桂峰

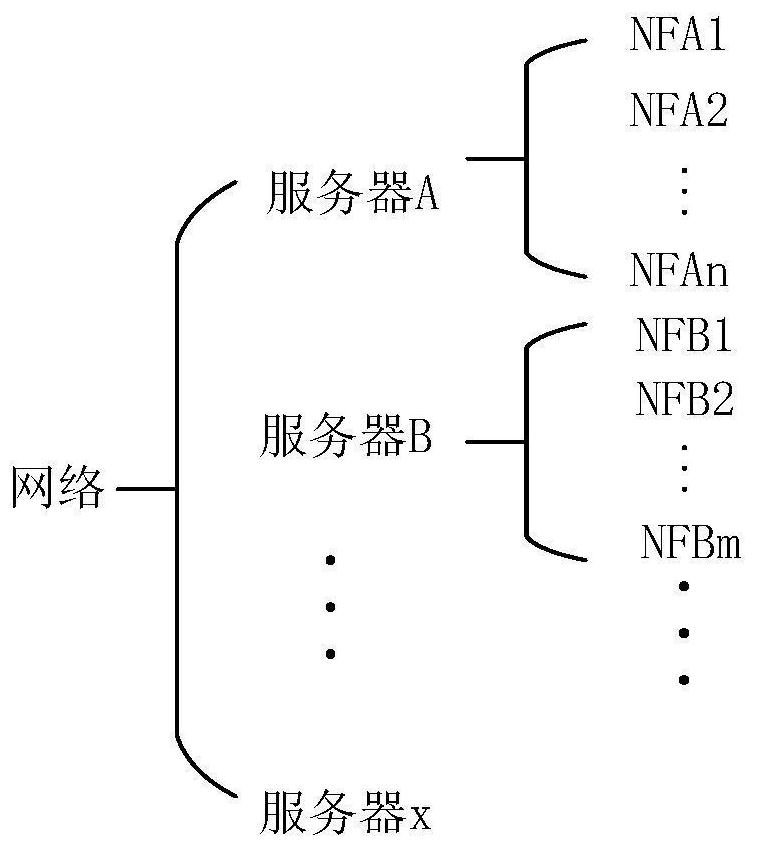

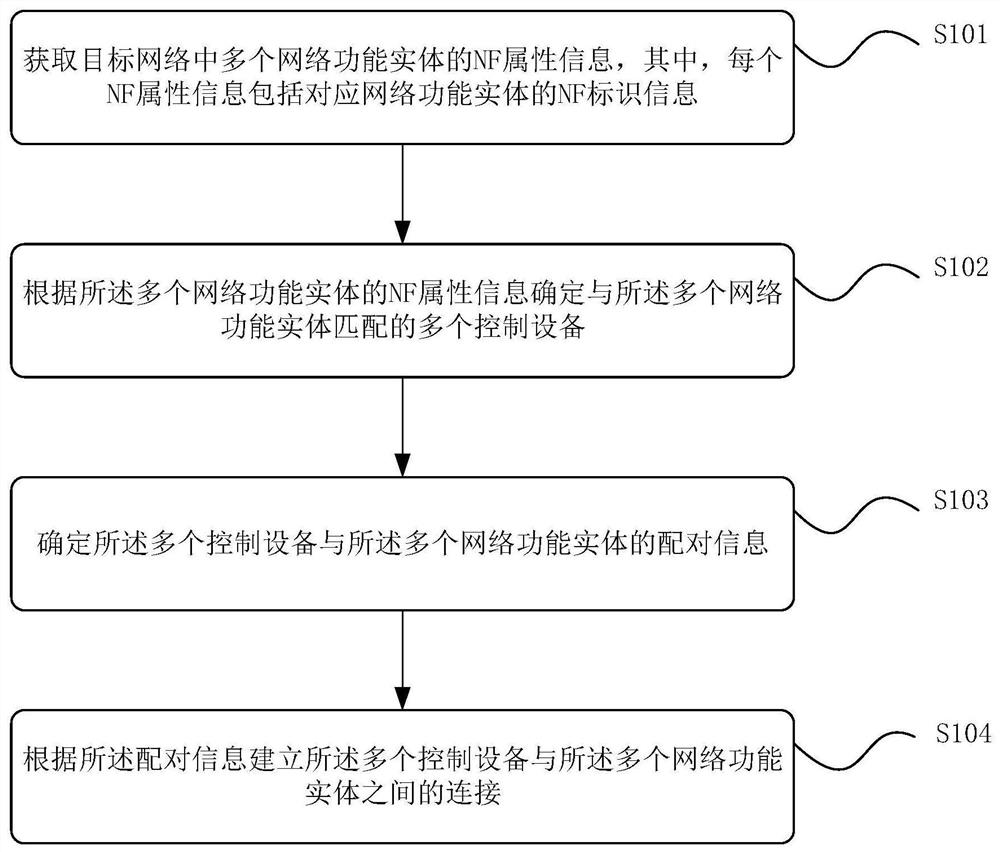

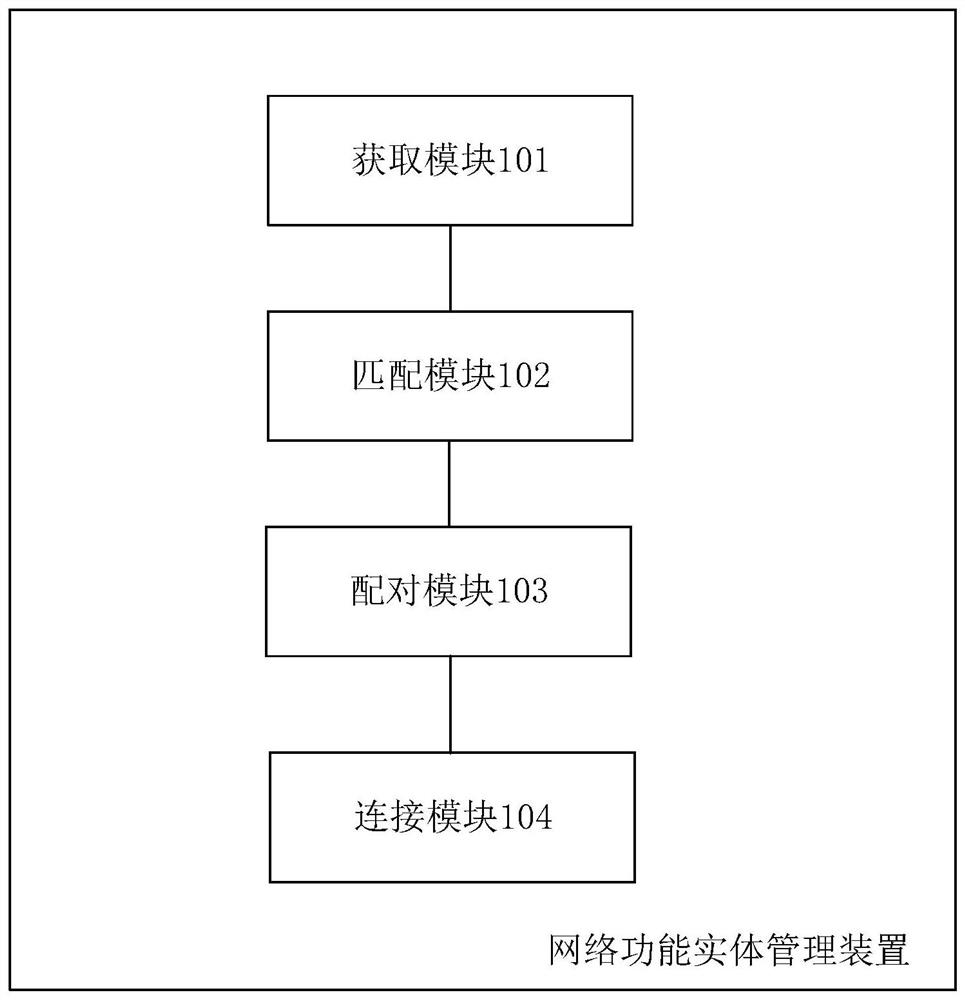

Method, device and equipment for managing network function entity and storage medium

InactiveCN112350859AImprove throughputEasy to handleData switching networksComputer networkInternet traffic

The invention provides a method and device for managing network function entities, computer equipment and a storage medium, and the method specifically comprises the steps: obtaining the NF attributeinformation of a plurality of network function entities in a target network, and enabling each piece of NF attribute information to comprise the NF identification information of the corresponding network function entity; determining a plurality of control devices matched with the plurality of network function entities according to the NF attribute information of the plurality of network function entities; determining pairing information of the plurality of control devices and the plurality of network function entities; and establishing connection between the plurality of control devices and the plurality of network function entities according to the pairing information. According to the method, a large number of network function entities can be managed, so that the network flow processingprocess becomes more efficient and orderly, meanwhile, each network function entity can be quickly and effectively controlled, the resource utilization rate is improved, and the throughput of the network is increased.

Owner:WUHAN GREENET INFORMATION SERVICE

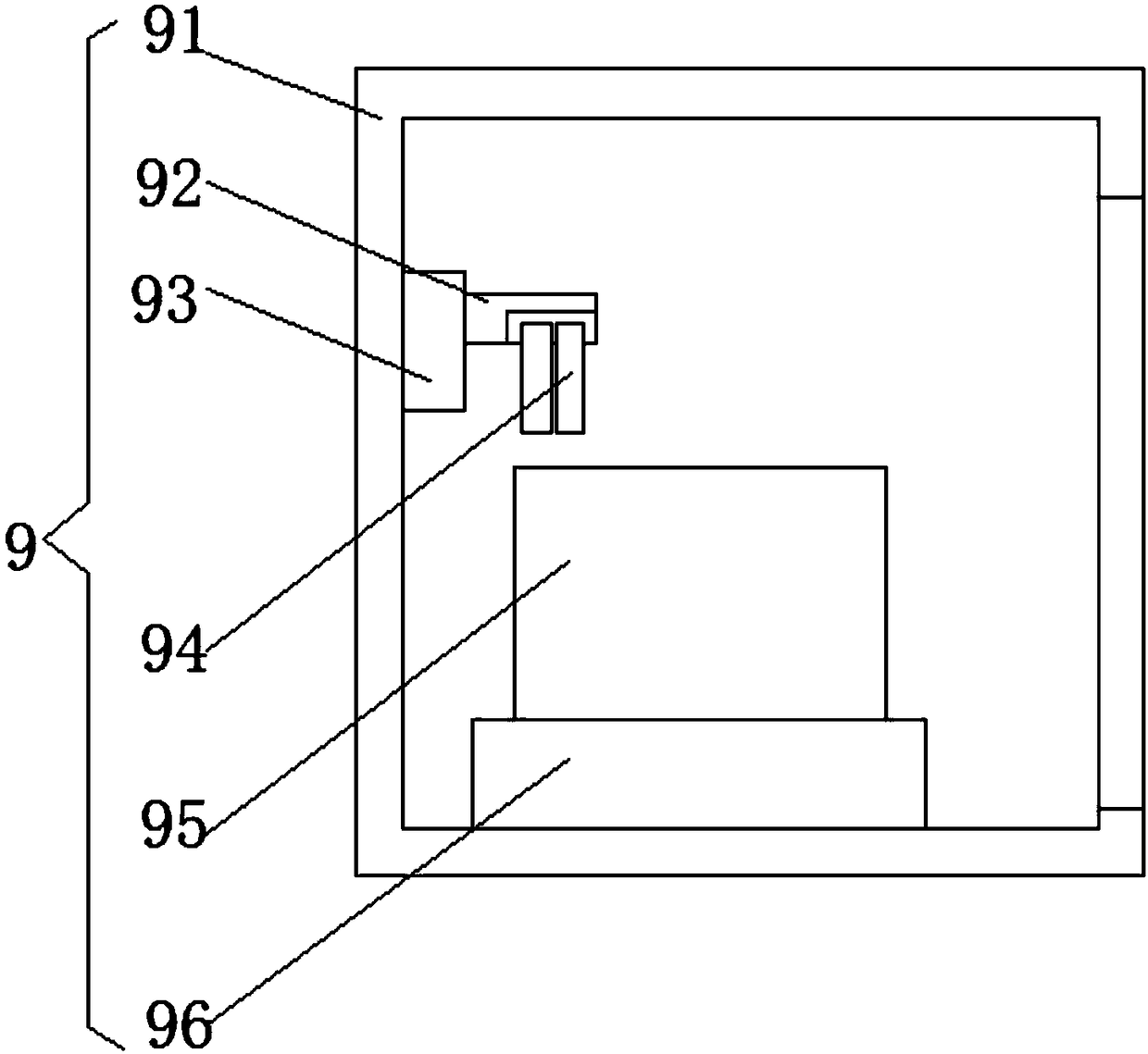

Micro-nano automatic chip mounter

ActiveCN112516453ACompact structureRealize feedingMicroneedlesMedical devicesMicro nanoAutomatic processing

The invention belongs to the technical field of micro-nano chip mounting, and provides a micro-nano automatic chip mounter. The micro-nano automatic chip mounter comprises a rack, wherein a raw chip feeding mechanism, a raw chip taking mechanism, a raw chip cutting mechanism, a material chip taking and torque converting mechanism and a material chip torque converting placement table are arranged on a workbench of the rack; a chip carrying placement rack driven by an electric cylinder is further arranged on the workbench; a chip carrying positioning mechanism is arranged on the chip carrying placement rack; a chip carrying bin and a film tearing mechanism are sequentially arranged on the workbench in the sliding direction of the chip carrying placement rack; the chip carrying feeding mechanism is correspondingly arranged below the chip carrying bin; a chip mounting mechanical arm and a conveying belt are arranged between the material chip torque converting placement table and the electric cylinder; and a material chip taking and placing mechanism is arranged at the end part of a working shaft of the chip mounting mechanical arm. According to the micro-nano automatic chip mounter, integrated automatic processing of soluble microneedle raw chip cutting, material chip torque converting feeding, hydrogel chip carrying feeding, release film tearing and material chip mounting can be realized, the processing efficiency and the chip mounting quality are greatly improved, and the produced chip mounting product is ensured to meet the production requirement of sanitation standard.

Owner:SHANDONG NOVOSHINE OPTOELECTRONICS CO LTD

Multi-layer paint spraying device for rotating disk in robot and application method thereof

ActiveCN110355038AWon't sprayImprove efficiencyPretreated surfacesLiquid spraying apparatusEngineeringMechanical engineering

The invention discloses a multi-layer paint spraying device for a rotating disk in a robot. The multi-layer paint spraying device comprises a first frame and a second frame, wherein the second frame is installed on one side of the middle of the first frame; the other side of the bottom of the first frame is connected with a circular base, and the edge of the base is connected with a plurality of paint spraying heads; the middle end of the top of the base is vertically and rotationally connected with a rotating shaft; the upper part of the base is horizontally and rotationally provided with a mounting plate; the top of the rotating shaft is connected with the middle end of bottom of the mounting plate; a plurality of loading holes are formed in the edge of the mounting plate in a penetrating mode; and annular edge plates are connected inside the loading holes in a threaded mode. Each paint spraying head can spray paint on the bottom of the rotating disk, each paint spraying head can spray a kind of paint, and the bottom of the rotating disk can be painted for many times, so that the efficiency of paint spraying is improved; and the rotating disk is convenient to take and place through intermittent rotation, and meanwhile, paint spraying pipes and the paint spraying heads can accurately spray paint to the rotating disk, so that the paint is not wasted.

Owner:徐州福凯欣智能科技有限公司

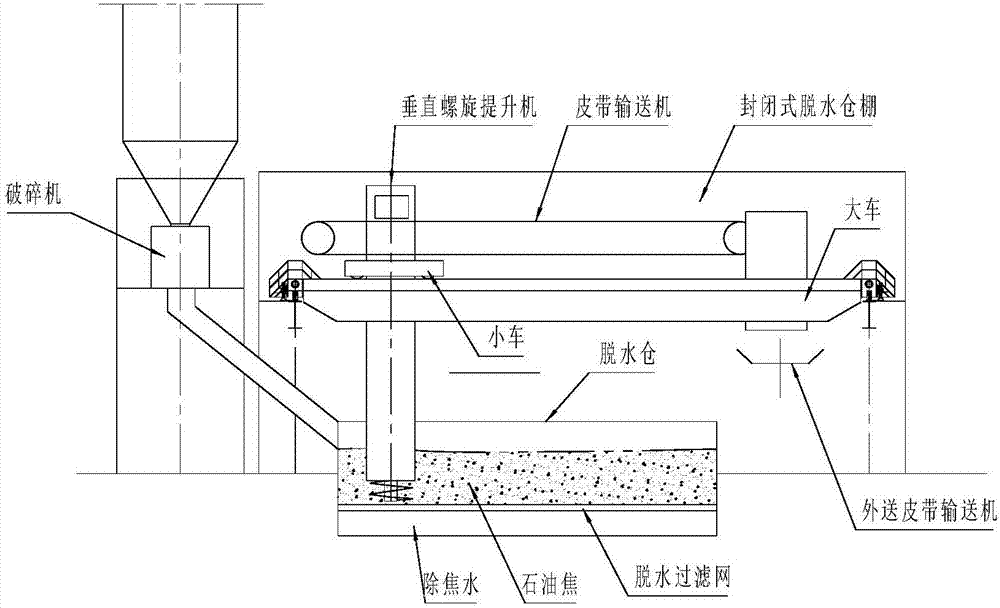

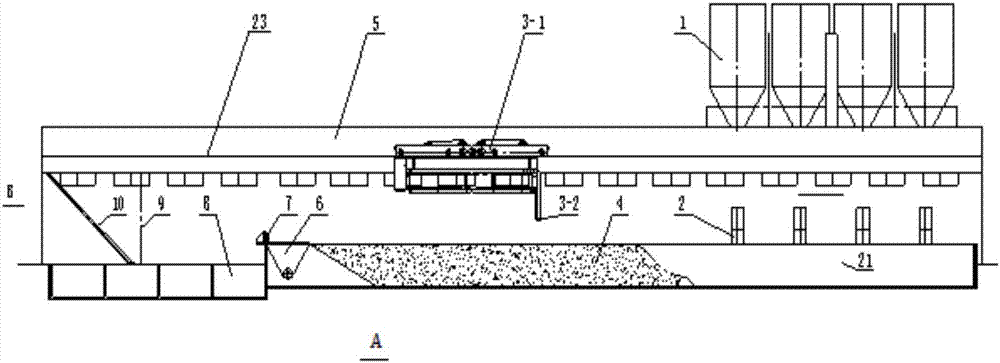

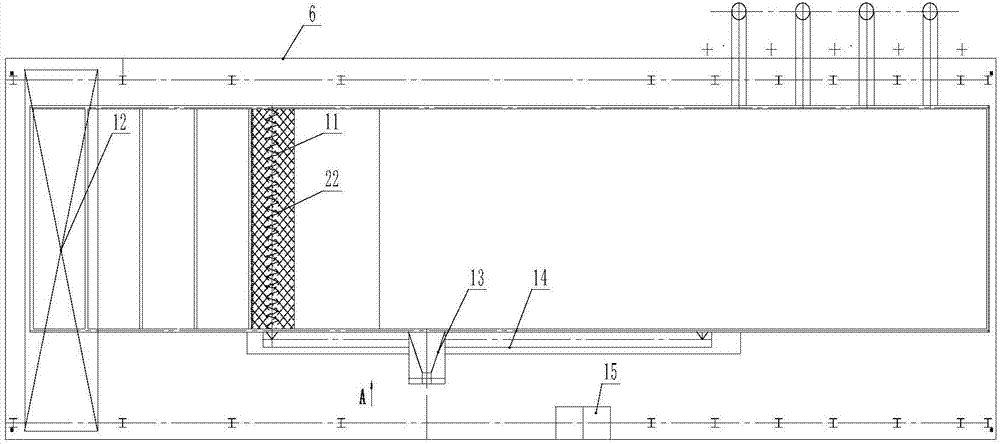

Closed petroleum coke dewatering-storage-transport facility

InactiveCN108003900AExtended spin timeEasy to handleCoking carbonaceous materialsFiltration circuitsTowerPetroleum

The invention relates to a closed petroleum coke dewatering-storage-transport facility. According to the technical scheme, the facility comprises coke towers, inclined chutes, a closed shed, a bridge-type material pushing crushing machine, a push plate, petroleum coke, a material bin, metal needles, a sedimentation pond, a crane track column, an inclined support, a spiral material pushing machine,a grabbing crane, a buffer hopper, a spiral drain pipe, an external-transport operation chamber, an inclined spiral elevator, a flat gate valve, a coke removal water inlet, a coke removal water outlet, a tail gas output port, a coke storage pond, a grid and a crane track. The problems are emphatically solved that when petroleum coke is prepared into coke, oil gas volatilization is large, harmfulgas pollutes the environment, coke powder is blown by wind and flies everywhere in the outdoor storage process of the petroleum coke, the water content of the petroleum coke cannot be guaranteed on rainy days, and the coke powder is scattered everywhere when the bridge-type grabbing crane loads and transports the coke powder during external transport.

Owner:樊东升

Material transfer conveying device for constructing automatic production line

InactiveCN111776684APrevent slippingWhen sliding to the transfer table, the limit table is in the sliding position of the material to avoidConveyorsControl devices for conveyorsProduction lineDrive shaft

The invention relates to a material transfer conveying device for constructing automatic production line. The material transfer conveying device comprises a base, a front leading port, a rear leadingport, a guiding plate and a transfer table, wherein a lifting drive device is arranged at the top of the base, a drive shaft of the lifting drive device is connected with the bottom of the transfer table, and a butt joint notch is formed in the left end of the transfer table; and an adjusting air cylinder and an electric screw rod assembly are arranged on each of two sides of the transfer table, and a clamp part is detachably connected onto an air cylinder shaft of each adjusting air cylinder. According to the material transfer conveying device, the guiding plate guides a material of front equipment to reach the transfer table, the material is subjected to position adjusting and correcting on the transfer table, then the transfer table is lifted to correspond to the rear leading port, thematerial is transferred to rear equipment in a fixed state, accurate and order processing for the material is conveniently performed in the rear equipment, meanwhile, automatic circulation of the material is realized, and production efficiency and production quality of the automatic production line are effectively improved.

Owner:CHENGDU HENGLIDA TECH

Waste textile crushing, sorting and recycling equipment

PendingCN114733602AImprove crushing efficiencyReduce cloggingSievingScreeningMechanical engineeringIndustrial engineering

The waste textile crushing, sorting and recycling equipment comprises a box body, the inner wall of the box body is horizontally and fixedly connected with a cylindrical fixed roller through a plurality of connecting plates, the fixed roller is coaxially and rotationally sleeved with a rotating ring, and the inner wall of the rotating ring is slidably connected with the peripheral wall of the fixed roller; the end, away from the connecting plate, of the rotating ring is rotationally connected with the inner wall of the box body, and a first rotating shaft and a second rotating shaft are symmetrically, horizontally and rotationally installed on the side face, away from the connecting plate, of the fixed roller. According to the waste textile crushing device, through cooperation of a feeding pipe, a first through hole and a second through hole, waste textiles can be periodically and automatically discharged and crushed in batches while the waste textiles are crushed, the probability of blockage in the transportation process is greatly reduced, the ordered processing process is kept, and the waste textile crushing efficiency is improved. And therefore, the crushing efficiency of the waste textiles is improved.

Owner:南通夕颜纺织品有限公司

A fully automatic solar cell laser processing equipment

ActiveCN105618934BSimple structureEasy to useManipulatorLaser beam welding apparatusLaser processingEngineering

The invention relates to laser processing equipment for a full-automatic solar battery piece. The laser processing equipment comprises a workbench, a laser processing host, a battery piece processing table, a rotary mechanical arm assembly, left and right battery piece caching and transferring components and left and right battery piece connection assemblies, wherein the laser processing host and the battery piece processing table are both installed on the workbench; the battery piece processing table is arranged below a laser processing head of the laser processing host; the rotary mechanical arm assembly is installed on the workbench on one side of the battery piece processing table; the left and right battery piece caching and transferring components are installed on the workbench on the two sides of the rotary mechanical arm assembly; in the rotation process of the rotary mechanical arm assembly, the free end of the rotary mechanical arm assembly can rotate to the positions above the battery piece processing table and above the left and right battery piece caching and transferring components on the two sides of the rotary mechanical arm assembly respectively; and the left and right battery piece connection assemblies are installed on the two sides of the workbench. The laser processing equipment has the advantages of simple structure, convenience in use, high production efficiency and strong processing stability.

Owner:WUHAN DR LASER TECH CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com