Micro-nano automatic chip mounter

An automatic placement machine, micro-nano technology, applied in the directions of micro-needles, hypodermic injection devices, needles, etc., can solve the problems of low processing efficiency and processing quality, and substandard hygiene of patch products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with specific examples. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

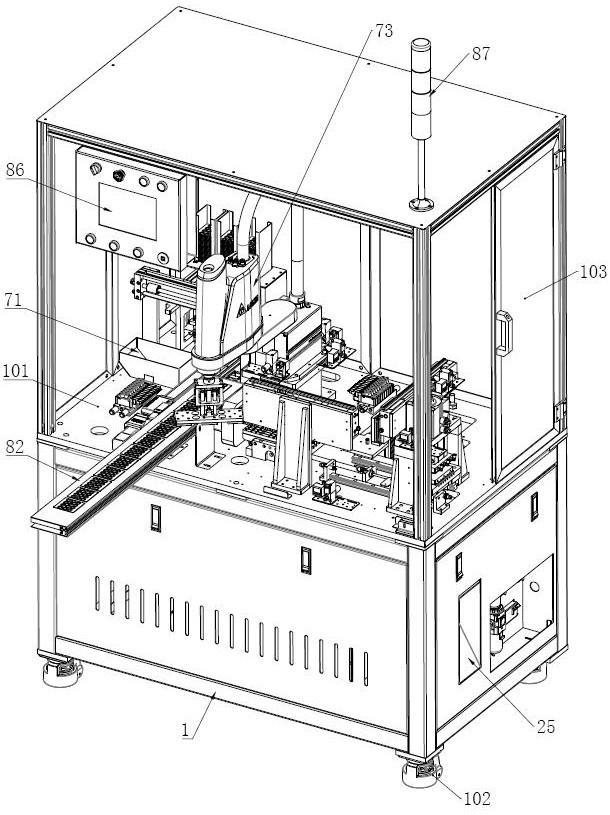

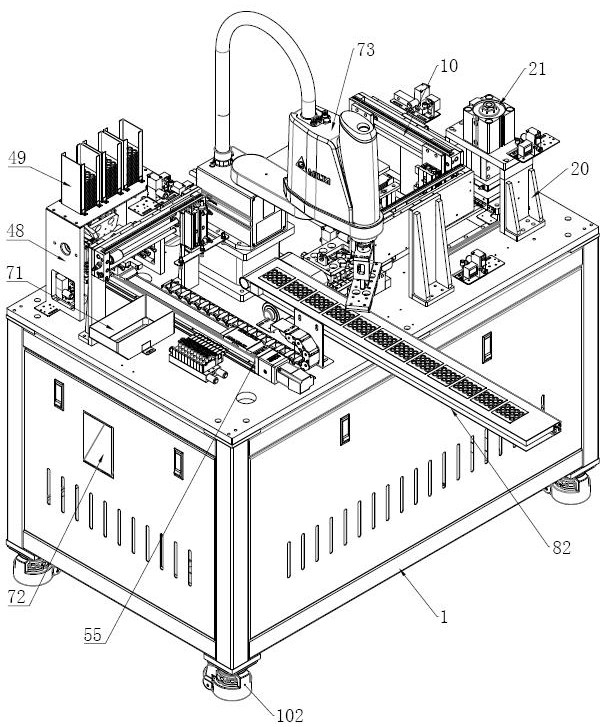

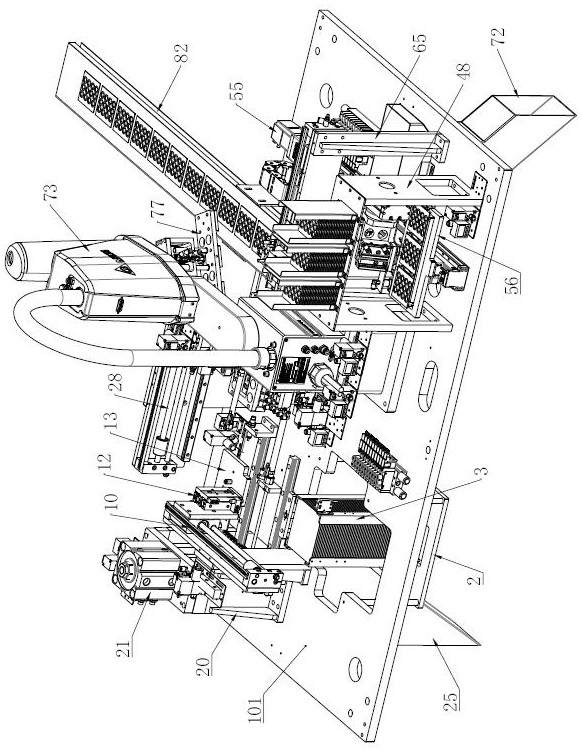

[0072] Such as Figure 1 to Figure 4 , Figure 18 Commonly shown, the present embodiment provides a micro-nano automatic placement machine, including a frame 1, and the workbench 101 of the frame 1 is provided with an original sheet feeding mechanism, an original sheet retrieving mechanism, an original sheet cutting mechanism, The material take-up torque-changing mechanism and the material-piece torque-changing placement table, the original sheet retrieving mechanism is located between the original sheet feeding mechanism and the original sheet cutting mechanism, and the two ends of the original sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com