Spraying structure for hydraulic machining

A hydraulic and spray head technology, applied in the field of hydraulic processing, can solve problems such as uncompact combination of components, small adjustable nozzle angle, scratches on the workpiece surface, etc., so as to prevent the loss of components and the difficulty of replacing accessories, and increase the front and rear Mobility, powerful spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

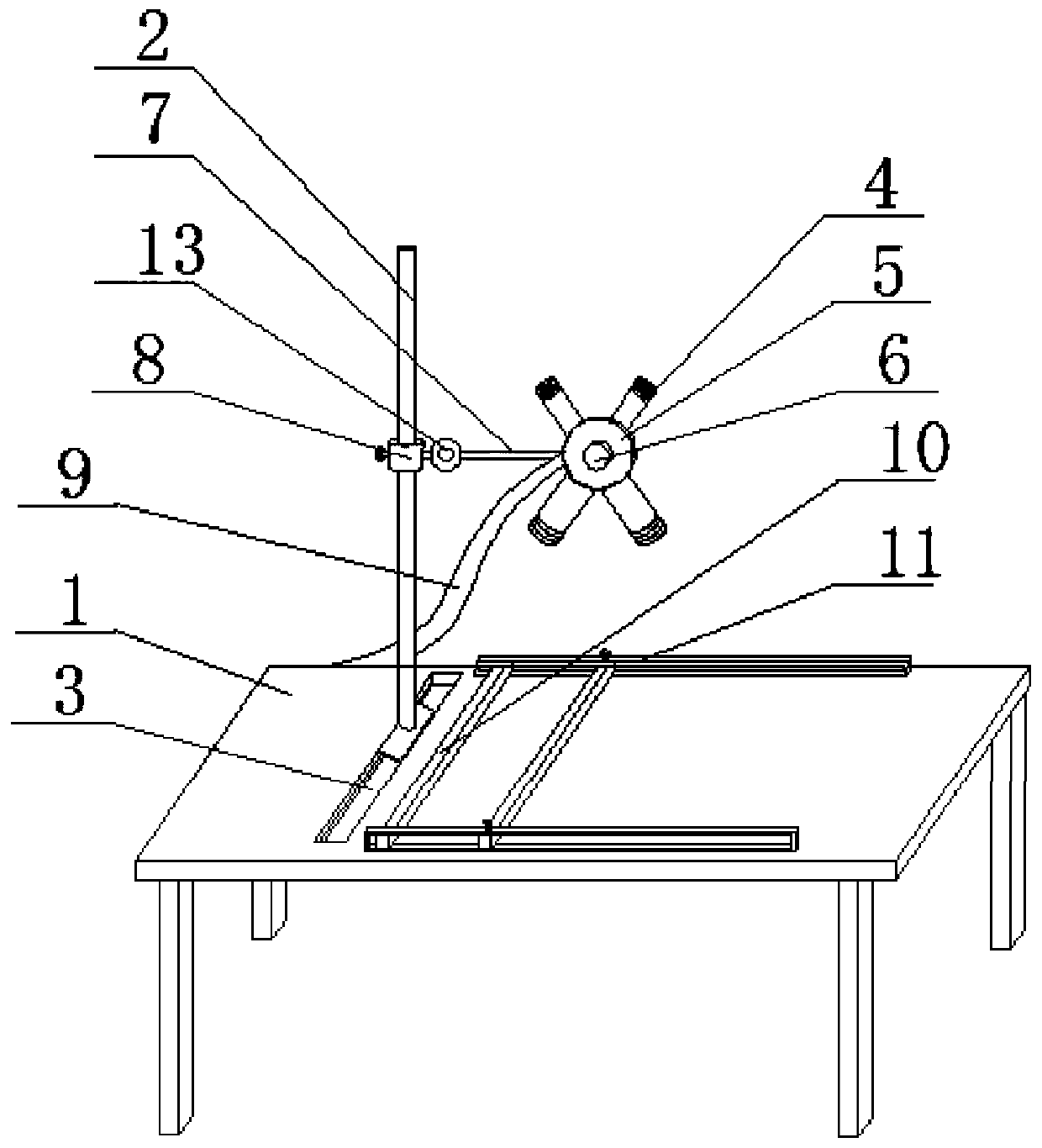

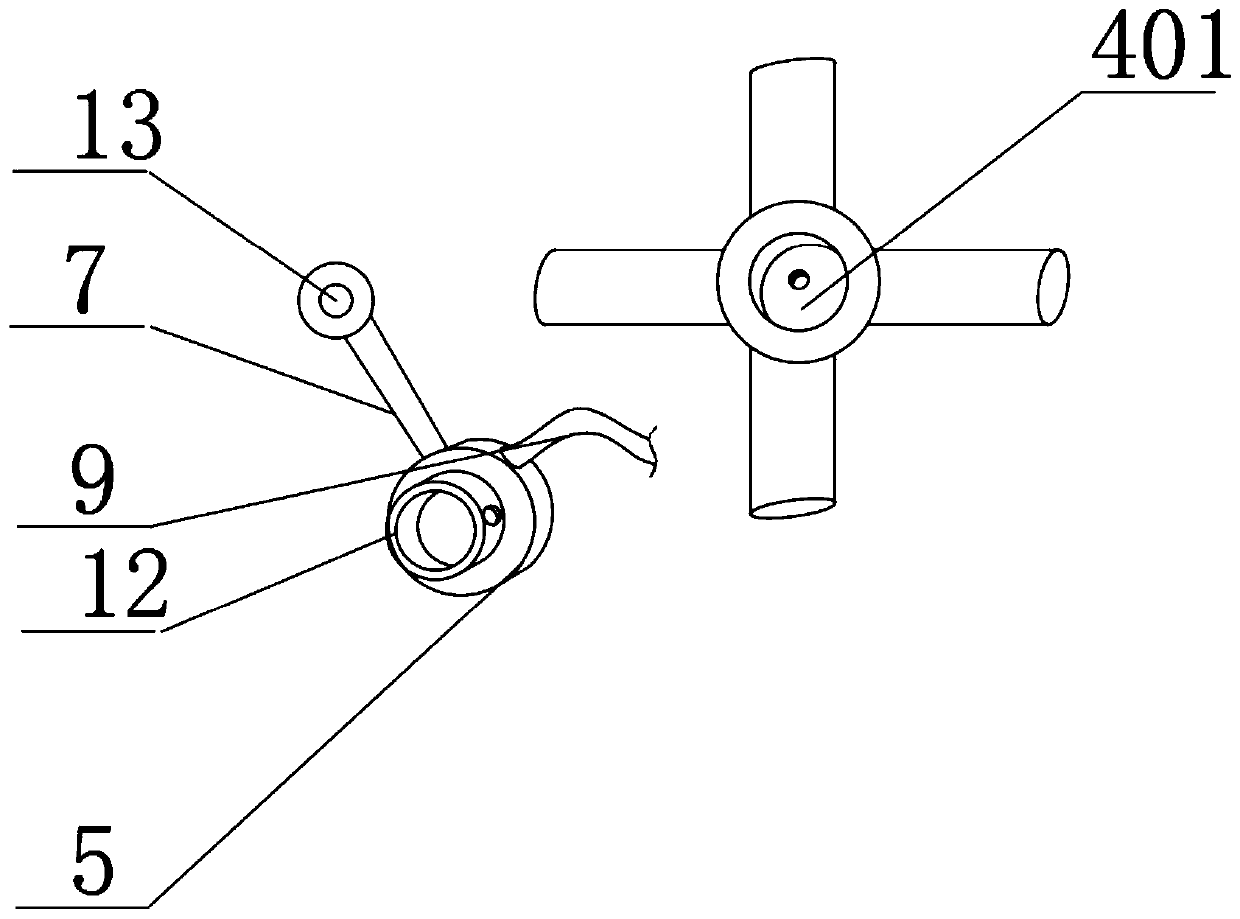

[0031] see Figure 1~4 , in an embodiment of the present invention, an injection structure for hydraulic machining, including an operation table 1, a pressure chamber 5 and an injection head 4, wherein the pressure chamber 5 is arranged on the operation table 1 so as to be movable laterally, and The pressure chamber 5 can be adjusted up and down in the vertical direction, and the pressure chamber 5 is a disc-shaped structure, which is characterized in that,

[0032] The replaceable connection on the pressure chamber 5 is provided with a plurality of spray heads 4, and each spray head 4 is arranged at intervals along the circumference of the pressure chamber 5; the diameter of the spray hole in each of the spray heads 4 is different;

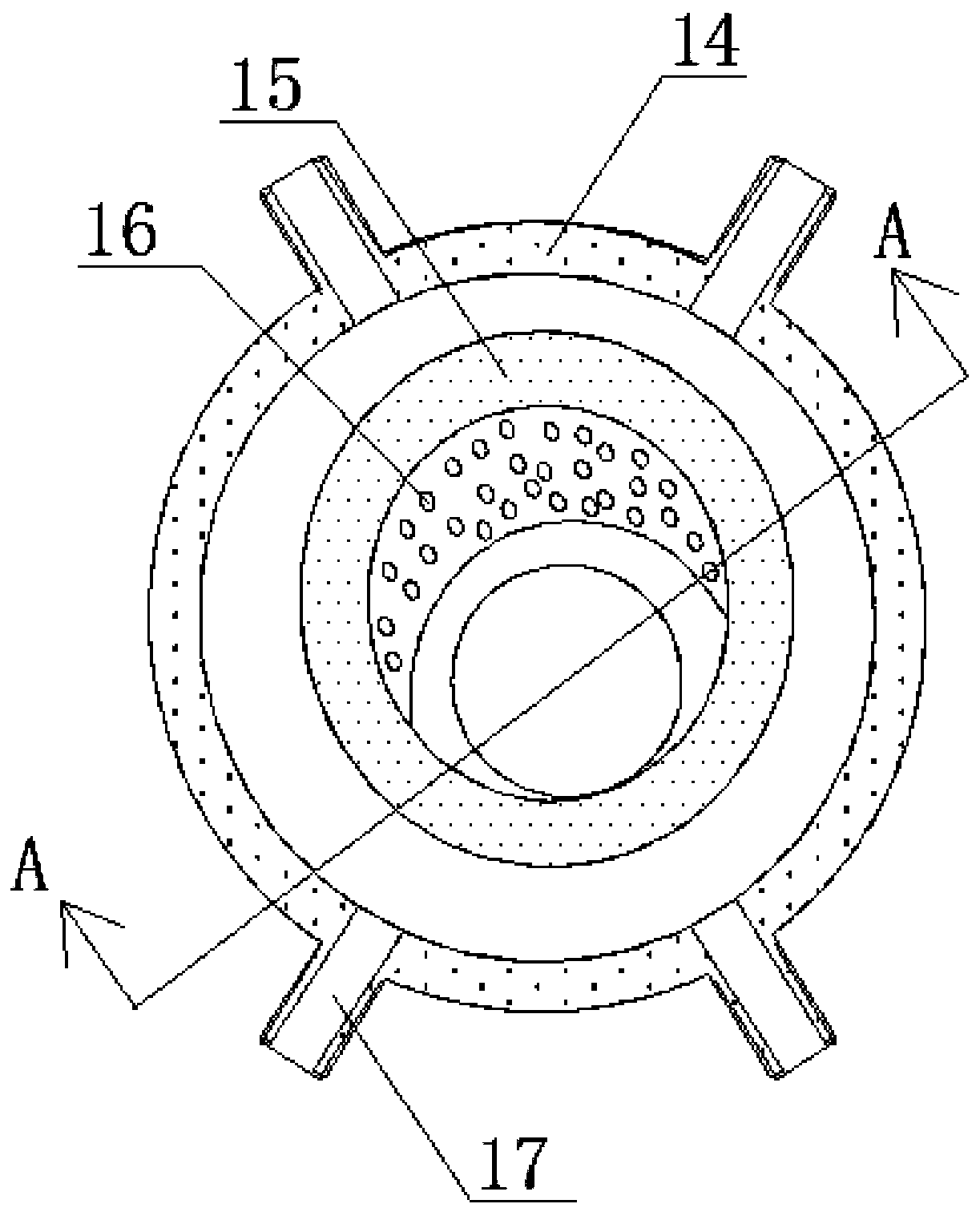

[0033] The inside of the pressure chamber 5 is coaxially provided with an outer water jacket 14, and the inside of the outer water jacket is eccentrically provided with an air hole sleeve 15, between the inner wall of the outer water jacket 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com