Full-automatic conceal zipper movable code loading equipment

A technology of invisible zipper and movable code, which is applied in the direction of transportation, packaging, conveyors, etc., and can solve the problems that the mold cannot complete the processing, the limit code is broken, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

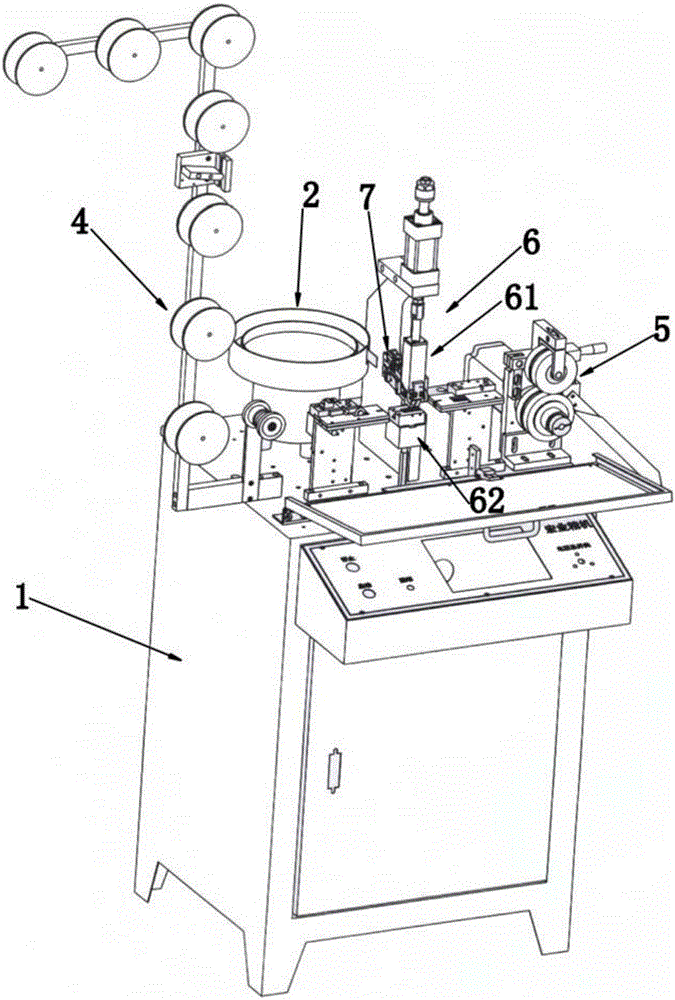

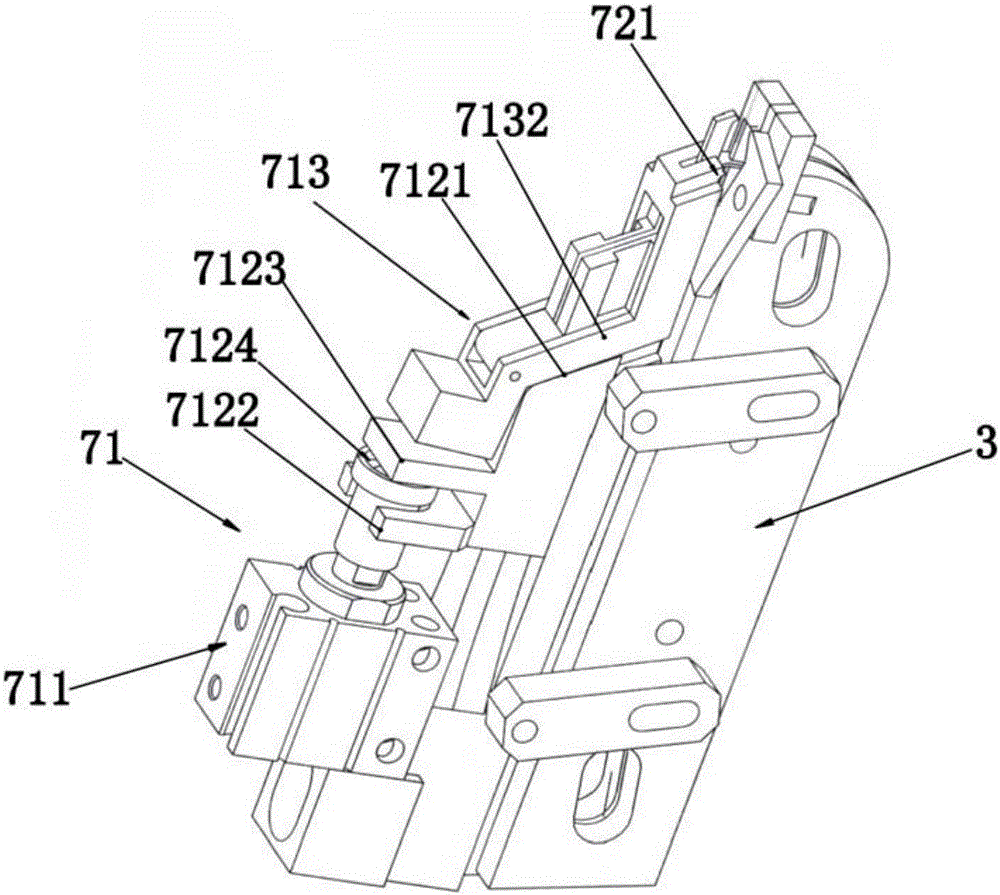

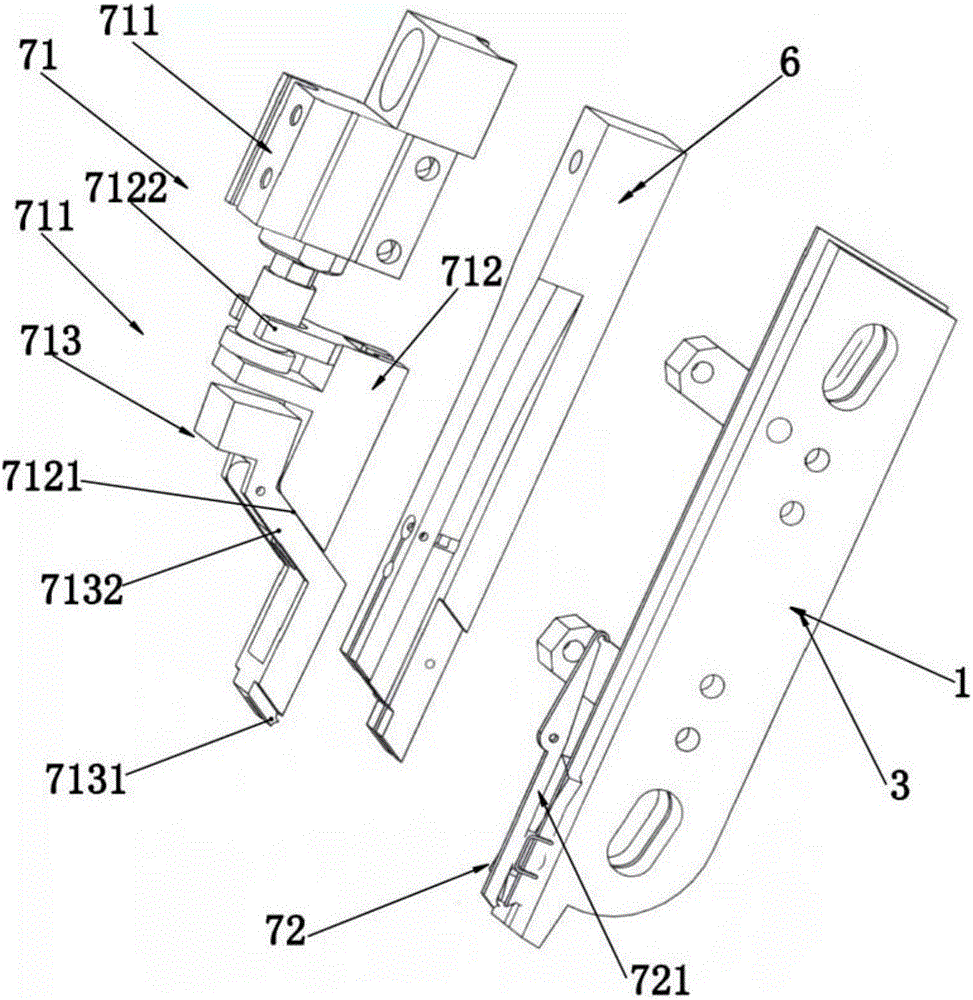

[0028] like figure 1 — Figure 7A fully automatic movable code device on invisible zippers shown includes a body 1, a vibrating tray 2 arranged on the body 1, a limit code conveying track 3 connected with the vibrating tray 2, a zipper belt conveying mechanism 4, a zipper The belt traction mechanism 5 and the stamping upper code mold 6 located between the zipper belt conveying mechanism 4 and the zipper belt traction mechanism 5, the limit code conveying assembly 7 is arranged between the limit code conveying track 3 and the stamping upper code mold 6, The limit code conveying assembly 7 includes a limit code one by one feed positioning device 71 and a limit code limit device 72. The clamping bar 721 that swings on the bit code conveying track 3, one axial end of the clamping bar 721 is a clamping limit end 7211, and the other end is an elastic tension end 7212, between the clamping limit end 7211 and the elastic tension end 7212 Between is the hinged end 7213 that is hinged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com