Medical waste bag and manufacturing method thereof

A garbage bag and bag body technology, which is applied in the field of medical garbage bags and their preparation, can solve the problems of inconvenient access and use, and achieve the effects of convenient operation, simple processing and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

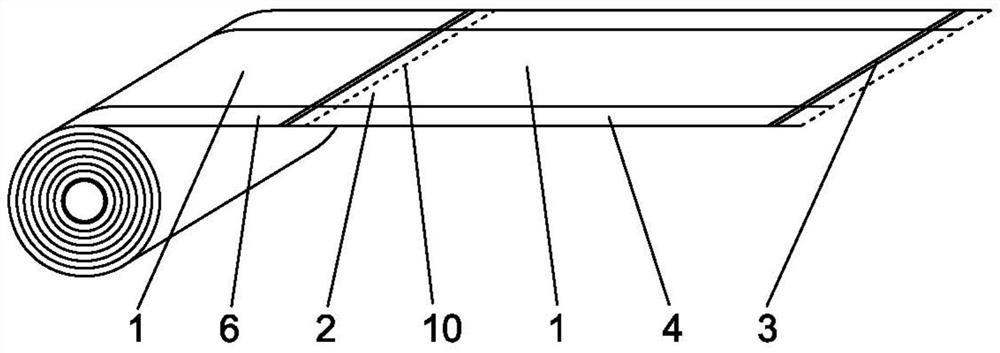

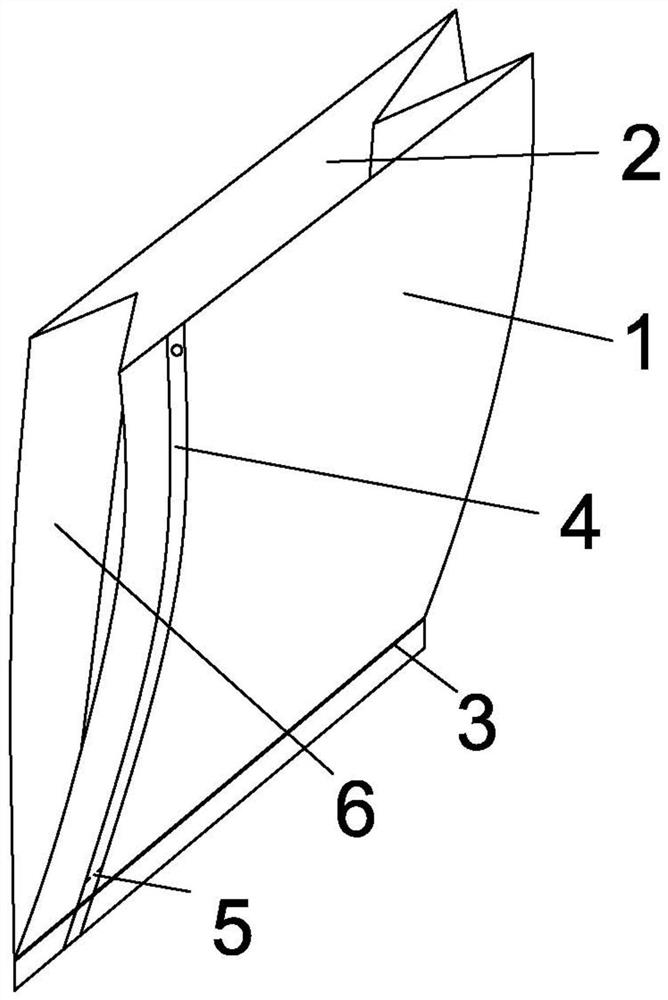

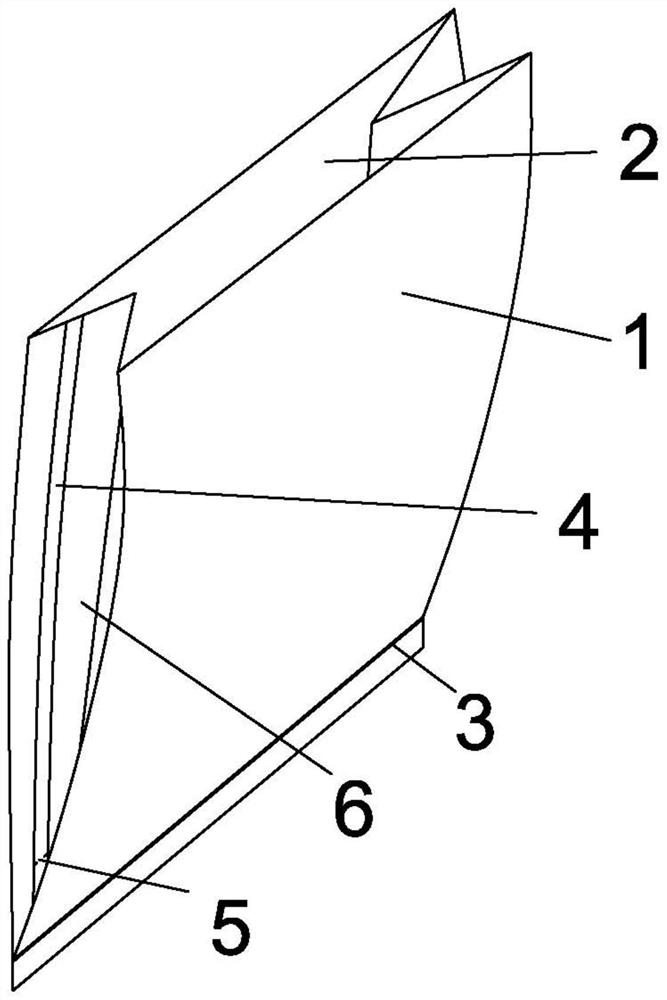

[0053] like Figure 1-2 As shown, the present invention discloses a medical garbage bag, comprising a plurality of bags 1; one end of each bag 1 is an open end 2, and the other end is a sealed end 3; the open end 2 of each bag 1 is adjacent to The sealed end 3 of the bag body 1 can be tearably connected, and the sealed end 3 can be tearably connected with the open end 2 of another adjacent bag body 1; a plurality of bag bodies 1 are connected and wound into a roll; each The opening end 2 of the bag body 1 is fixed and hot-pressed with a cable tie 4 . The medical garbage bag connected in roll shape according to the invention is convenient to take and store.

[0054] One end of the cable tie 4 is fixed and heat-pressed to the opening end 2 of the bag body, and the other end is heat-pressed and fixed to the sealing end 3 of the bag body 1; the side of the cable tie 4 near the sealing end 3 is provided with a tearable Cable tie point breaks 5. The cable tie 4 added by the prese...

Embodiment 2

[0059] Based on Example 1, such as Figure 4-6 As shown, the open end 2 of the bag body 1 of the present invention is provided with a handle 7 facing away from the sealed end 3 . The handle 7 can facilitate the medical waste bag of the present invention to be taken out from the trash can or other containers.

[0060] One end of the cable tie 4 is fixed to the handle 7, and the connection position between the cable tie 4 and the bag body 1 is combined with the connection position of the handle 7, so that the preparation process can be saved.

[0061] The handle 7 is made integrally with the bag body 1, which can save the processing steps of the garbage bag and improve the production efficiency.

Embodiment 3

[0063] Based on Example 1, this example discloses a method for preparing a medical garbage bag, including S1 preparation of cable ties, S2 stacking of plastic film and cable ties, S3 connection of plastic film and cable ties, and S4 preparation of garbage bags.

[0064] S1 cable tie preparation, the continuous cable tie 4 is provided by the cable tie feeding device, the cable tie is driven on the production line by the cable tie traction device, and the cable tie point breakage is made equidistantly on the cable tie 4 by using the easy-to-tear thread cutter 5; The distance between the broken line 5 of adjacent cable tie points is equal to the length of the bag body 1 .

[0065] S2 The plastic film and the cable tie are stacked, the plastic film feeding device provides a continuous roll of plastic film, the plastic film traction device is used to make the plastic film advance on the production line, and the cable tie 4 processed in step S1 is stacked on the plastic film.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com