Closed petroleum coke dewatering-storage-transport facility

A petroleum coke, closed technology, applied in the petroleum industry, coke oven, transportation and packaging, etc., can solve the problems of coke powder scattering, gas pollution environment, large oil and gas volatilization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

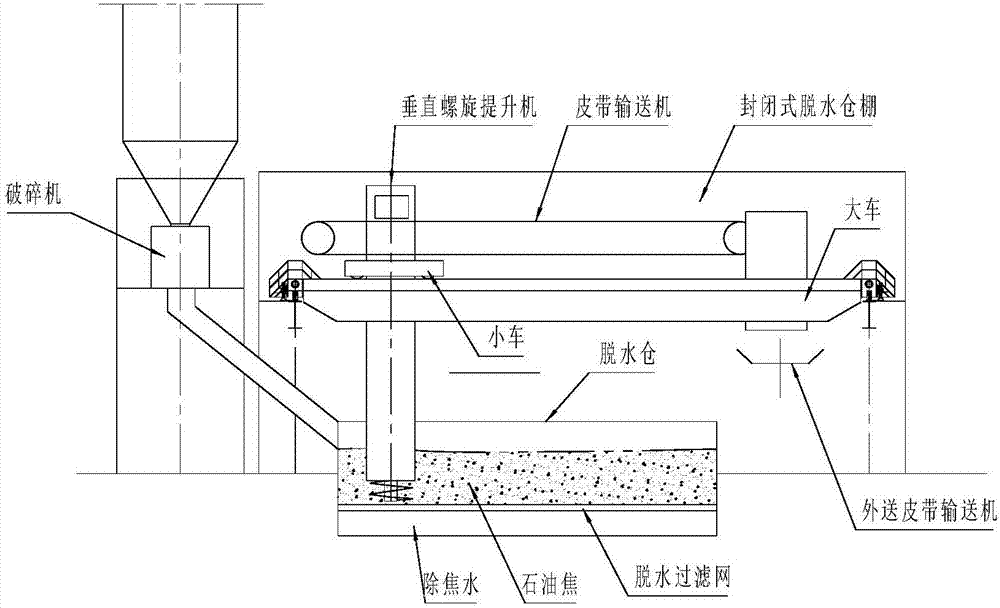

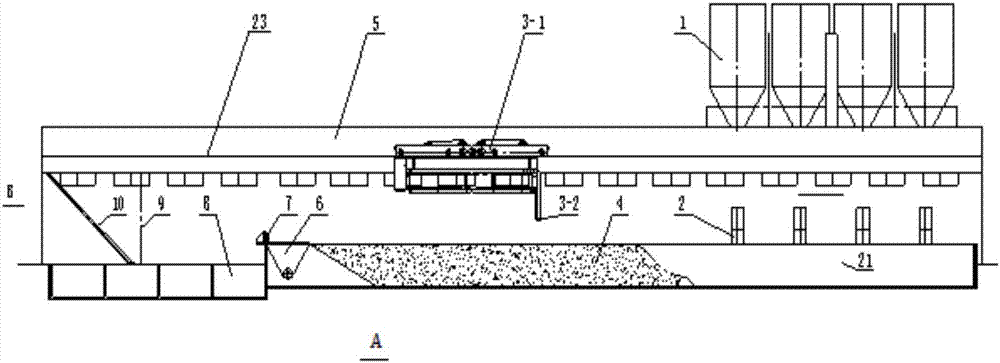

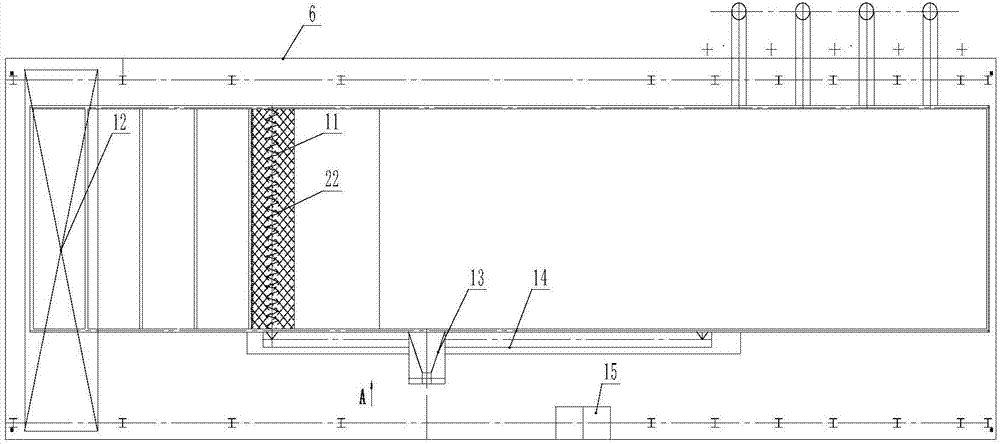

[0029] Such as figure 2 , image 3 , Figure 4 , Figure 5As shown, a closed petroleum coke dehydration, storage and transportation facility according to the present invention includes a coke tower 1, an inclined chute 2, and a closed shed 5. The bottom is connected in a fully enclosed form, and also includes bridge type pusher crusher 3-1, push plate 3-2, petroleum coke 4, silo 6, metal needle 7, sedimentation tank 8, crane rail column 9, diagonal brace 10 , screw pusher 11, grab crane 12, buffer hopper 13, spiral drain pipe 14, outbound operation room 15, inclined screw elevator 16, flat gate valve 17, decoking water inlet 18, decoking water outlet 19, Exhaust gas outlet 20, coke storage tank 21, grille 22, crane track 23, wherein the lower part of the inclined chute 2 is connected to the coke storage tank 21, the coke coming out directly enters the coke storage tank 21, and the crane track 23 is installed above the inside of the closed shed 5 , the bridge pusher 3-1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com