Vertical dehydration device for biogas purification

A dehydration device, biogas technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of corrosion and desulfurization equipment, water can not be completely condensed and separated, and not have it, so as to increase the number of collisions, facilitate the maintenance of equipment, and avoid structural problems. single effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

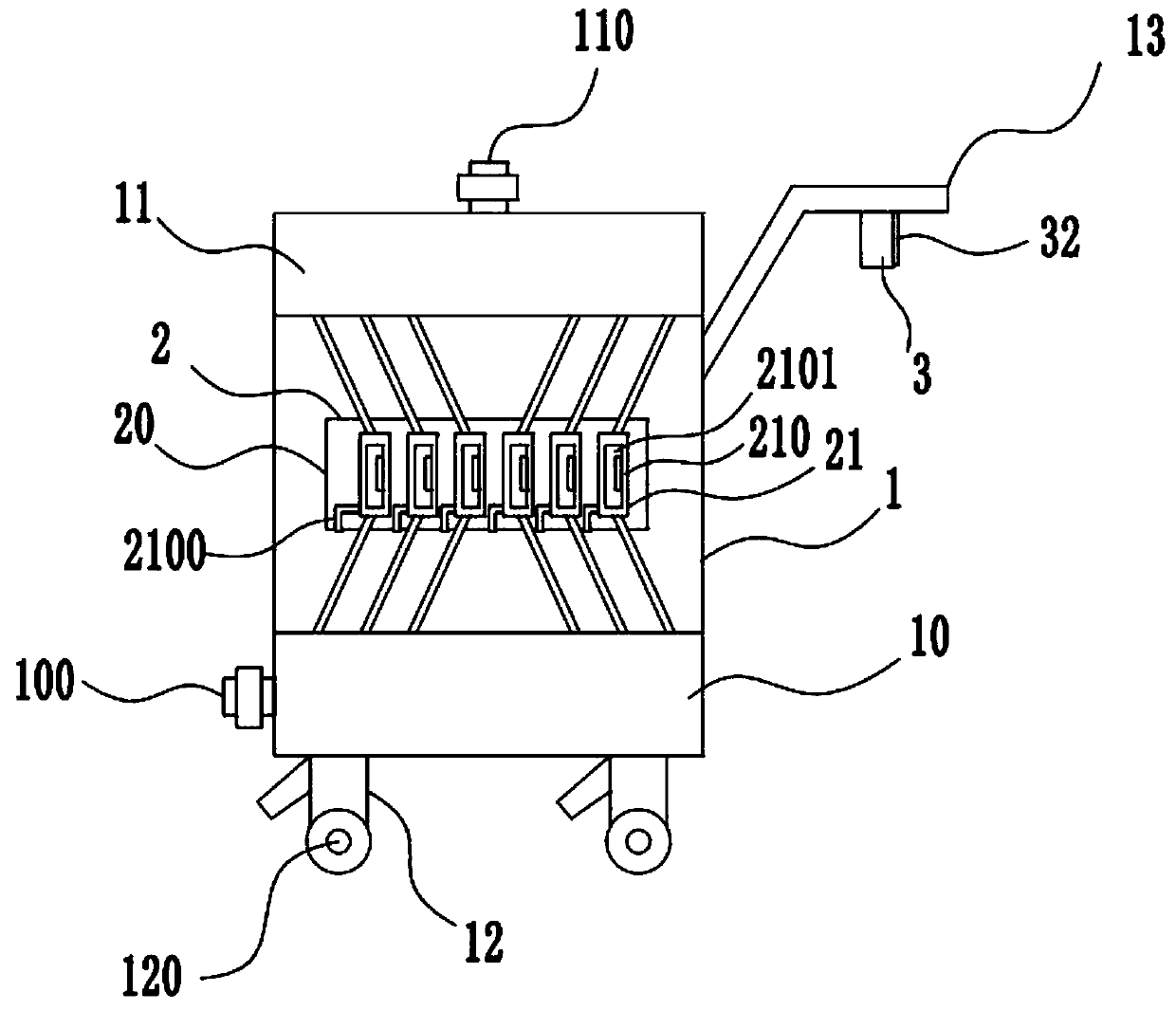

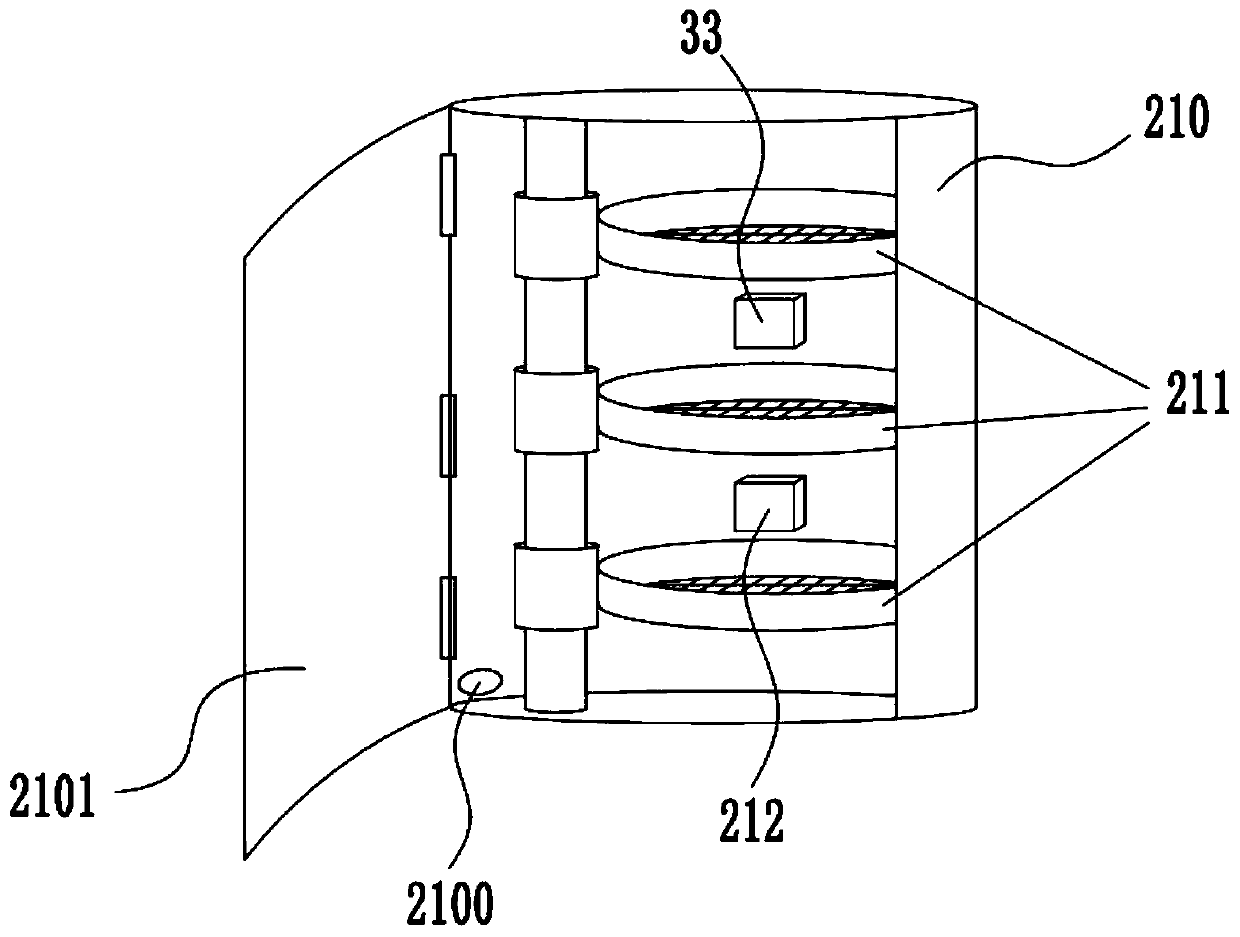

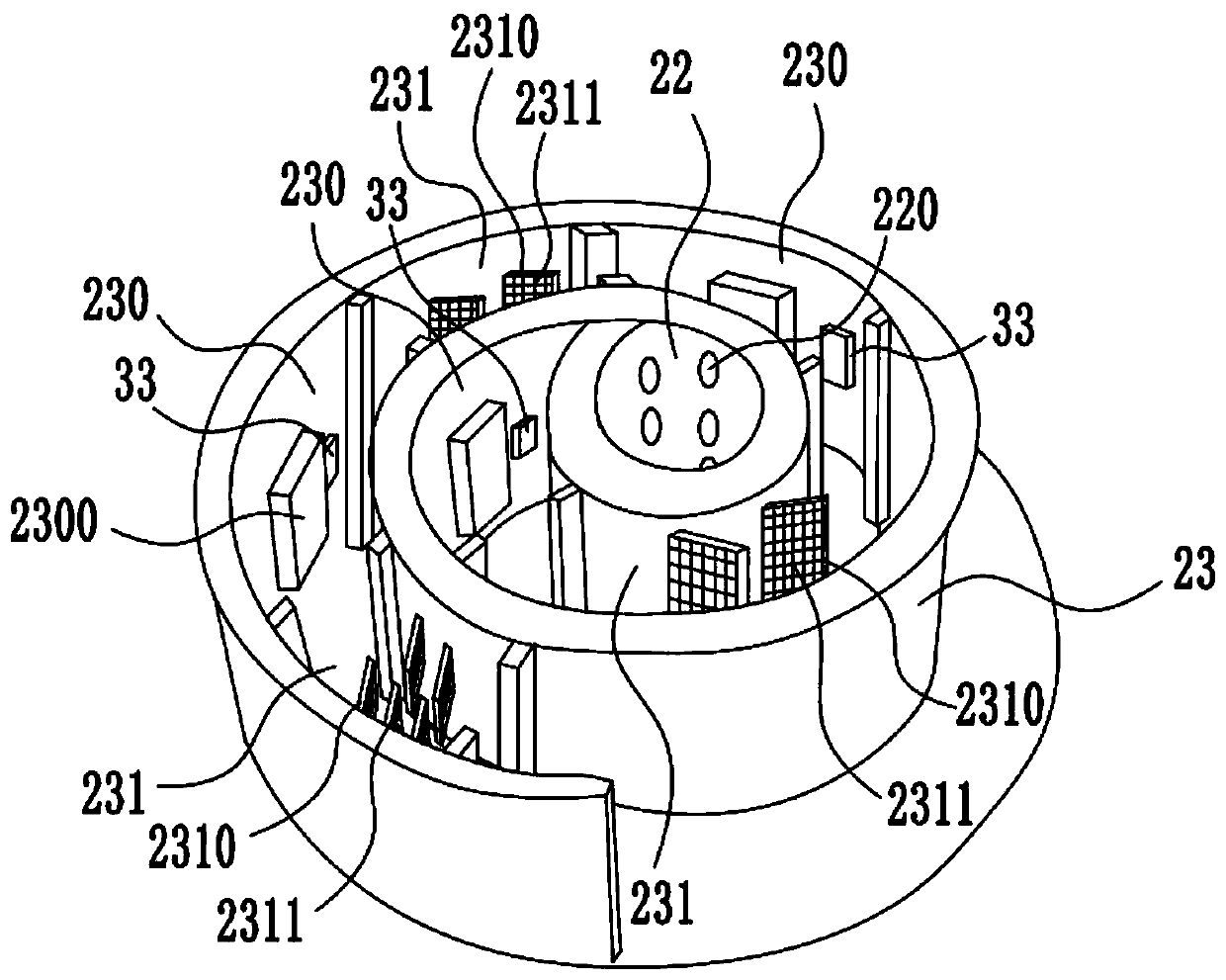

[0029] Such as figure 1 The shown vertical dehydration device for biogas purification and purification mainly includes a vertical frame body 1 with a biogas splitter box 10 at the bottom end and a biogas temporary storage box 11 at the upper end, and is arranged in the middle of the vertical frame body 1 and A biogas purification and dehydration element 2 for dehydrating biogas, an intelligent control element 3, and a power supply; a biogas inlet 100 is provided on the side wall of the biogas distribution box 10, and a biogas outlet 110 is provided at the upper end of the biogas temporary storage box 11, and the biogas inlet 100 and the biogas outlet Electromagnetic valves are provided at 110 places, and there are legs 12 at the bottom end of the vertical frame body 1. The bottom end of the legs 12 is provided with a moving wheel 120, and the moving wheel 120 is provided with a brake element. One side of the vertical frame body 1 is provided with a push handle 13, Through the ...

Embodiment 2

[0037] Such as figure 1 The shown vertical dehydration device for biogas purification and purification mainly includes a vertical frame body 1 with a biogas splitter box 10 at the bottom end and a biogas temporary storage box 11 at the upper end, and is arranged in the middle of the vertical frame body 1 and A biogas purification and dehydration element 2 for dehydrating biogas, an intelligent control element 3, and a power supply; a biogas inlet 100 is provided on the side wall of the biogas distribution box 10, and a biogas outlet 110 is provided at the upper end of the biogas temporary storage box 11, and the biogas inlet 100 and the biogas outlet Electromagnetic valves are provided at 110 places, and there are legs 12 at the bottom end of the vertical frame body 1. The bottom end of the legs 12 is provided with a moving wheel 120, and the moving wheel 120 is provided with a brake element. One side of the vertical frame body 1 is provided with a push handle 13, Through the ...

Embodiment 3

[0045] Such as figure 1 The shown vertical dehydration device for biogas purification and purification mainly includes a vertical frame body 1 with a biogas splitter box 10 at the bottom end and a biogas temporary storage box 11 at the upper end, and is arranged in the middle of the vertical frame body 1 and A biogas purification and dehydration element 2 for dehydrating biogas, an intelligent control element 3, and a power supply; a biogas inlet 100 is provided on the side wall of the biogas distribution box 10, and a biogas outlet 110 is provided at the upper end of the biogas temporary storage box 11, and the biogas inlet 100 and the biogas outlet Electromagnetic valves are provided at 110 places, and there are legs 12 at the bottom end of the vertical frame body 1. The bottom end of the legs 12 is provided with a moving wheel 120, and the moving wheel 120 is provided with a brake element. One side of the vertical frame body 1 is provided with a push handle 13, Through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com