Front-loading washing machines and front-loading washer-dryers

A technology for washing machines and drums, which is applied to other washing machines, washing machine control devices, washing devices, etc., to achieve the effects of suppressing increase, dehydration time and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

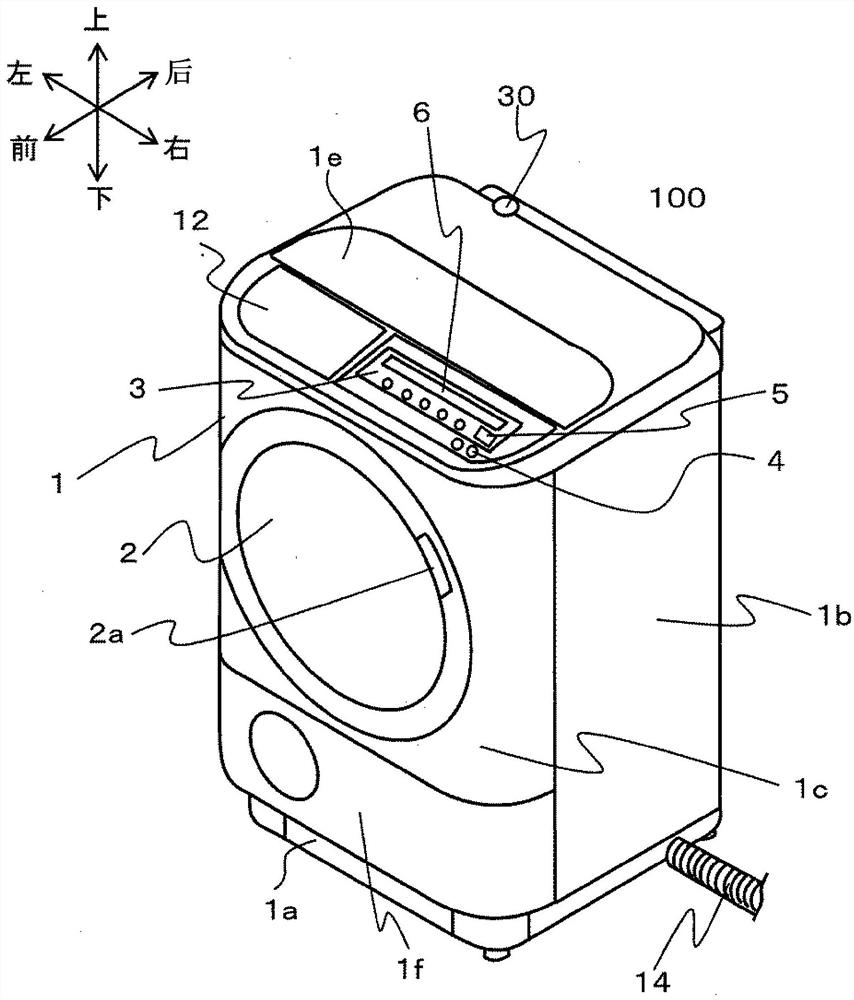

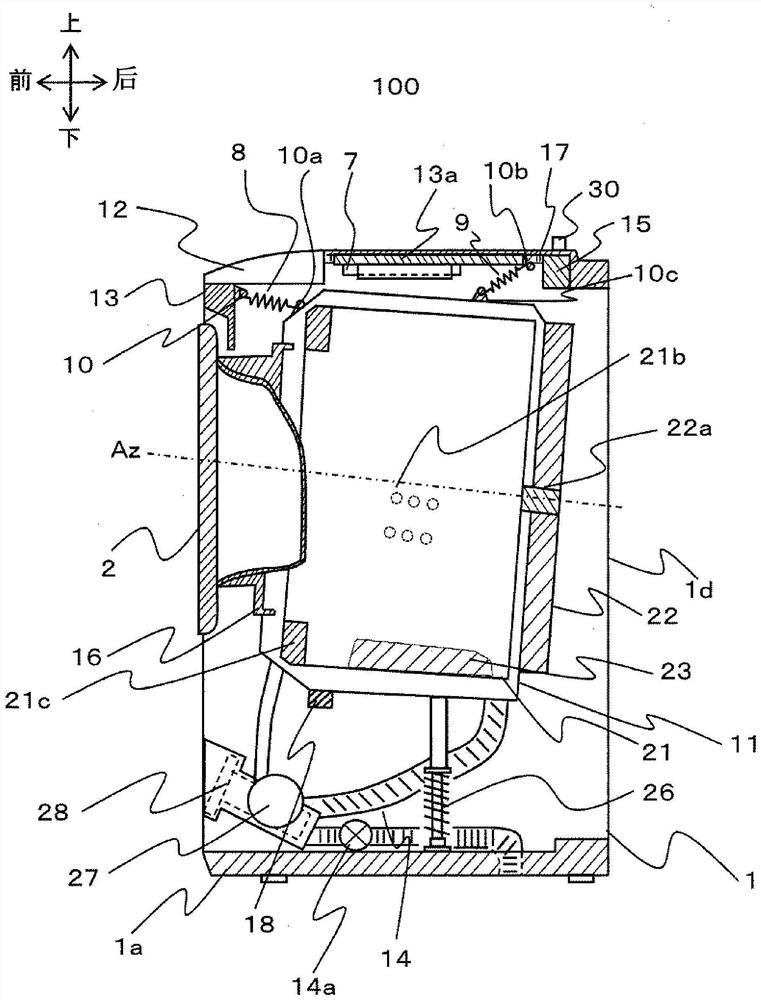

[0033] figure 1 is a perspective view of the drum type washing machine 100 of the present invention, figure 2 It is a side view showing the internal structure of the front-loading washing machine 100 . use figure 1 and figure 2 , the structure and operation of the front-loading washing machine 100 will be described.

[0034] constitute figure 1 The shell 1 of the outline of the drum type washing machine 100 shown is installed on the base 1a, and the left and right side plates 1b ( figure 1 Only the right side panel is shown in the figure), front cover 1c, rear cover 1d (refer to figure 2 ), top cover 1e, and lower front cover 1f constitute. The upper cover 1e is provided with a water supply hose connection port 30 for supplying water from a water tap to the front-loading washing machine 100 . The casing 1 includes a box-shaped outer frame with a base 1a, and has sufficient strength as an outer frame.

[0035] The door 2 is a member for closing an inlet (not shown) p...

Embodiment 2

[0069] Then refer to Figure 6 Example 2 will be described in detail.

[0070] In addition, since front-loading-type washing machine 100 has basically the same structure as that of Embodiment 1, different parts will be described below.

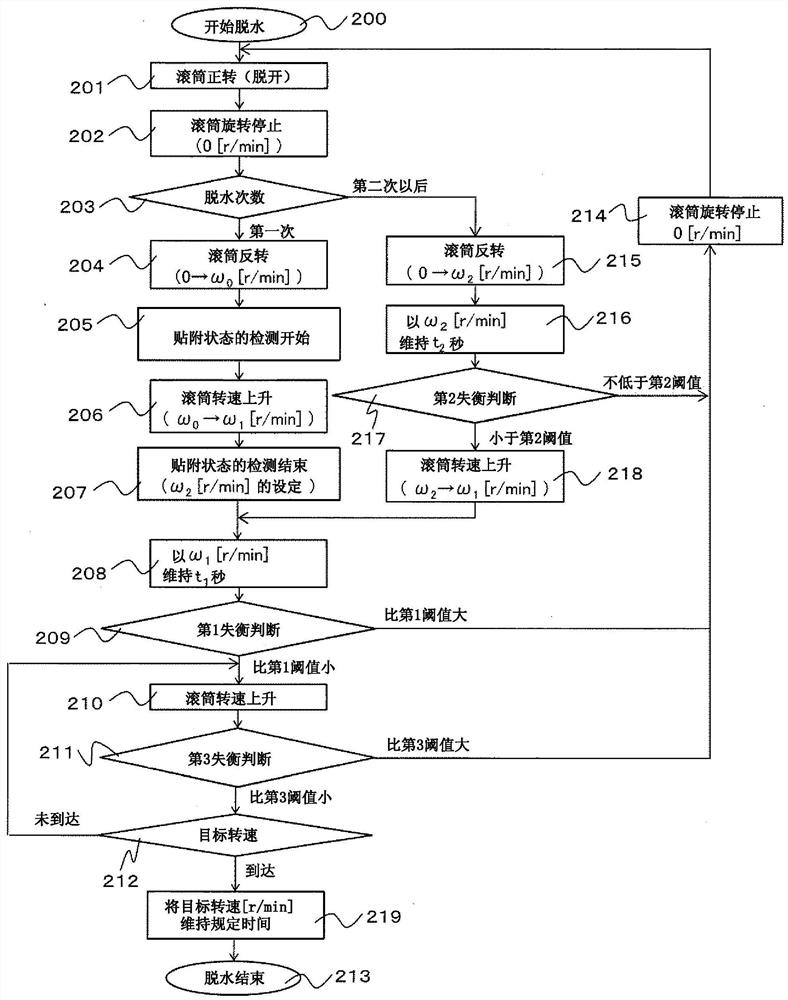

[0071] Figure 6 A flowchart showing the dehydration step of the second embodiment. In addition, the spin-drying operation after the first unbalance determination ( 209 ) and before the rotation up of the drum 21 ( 210 ) is the same as that of the first embodiment, and the same reference numerals are used to omit description.

[0072] In Embodiment 2, when the imbalance in the high-speed rotation speed region is greater than the threshold value of the vibration sensor 18 in the third imbalance judgment (211), the rotation speed of the drum 21 is temporarily stopped (300), and the attachment state setting according to the first dehydration is cleared. fixed ω 2 settings (301). Afterwards, disengage action (302), the rotation of drum 21 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com