Patents

Literature

37results about How to "Extended spin time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

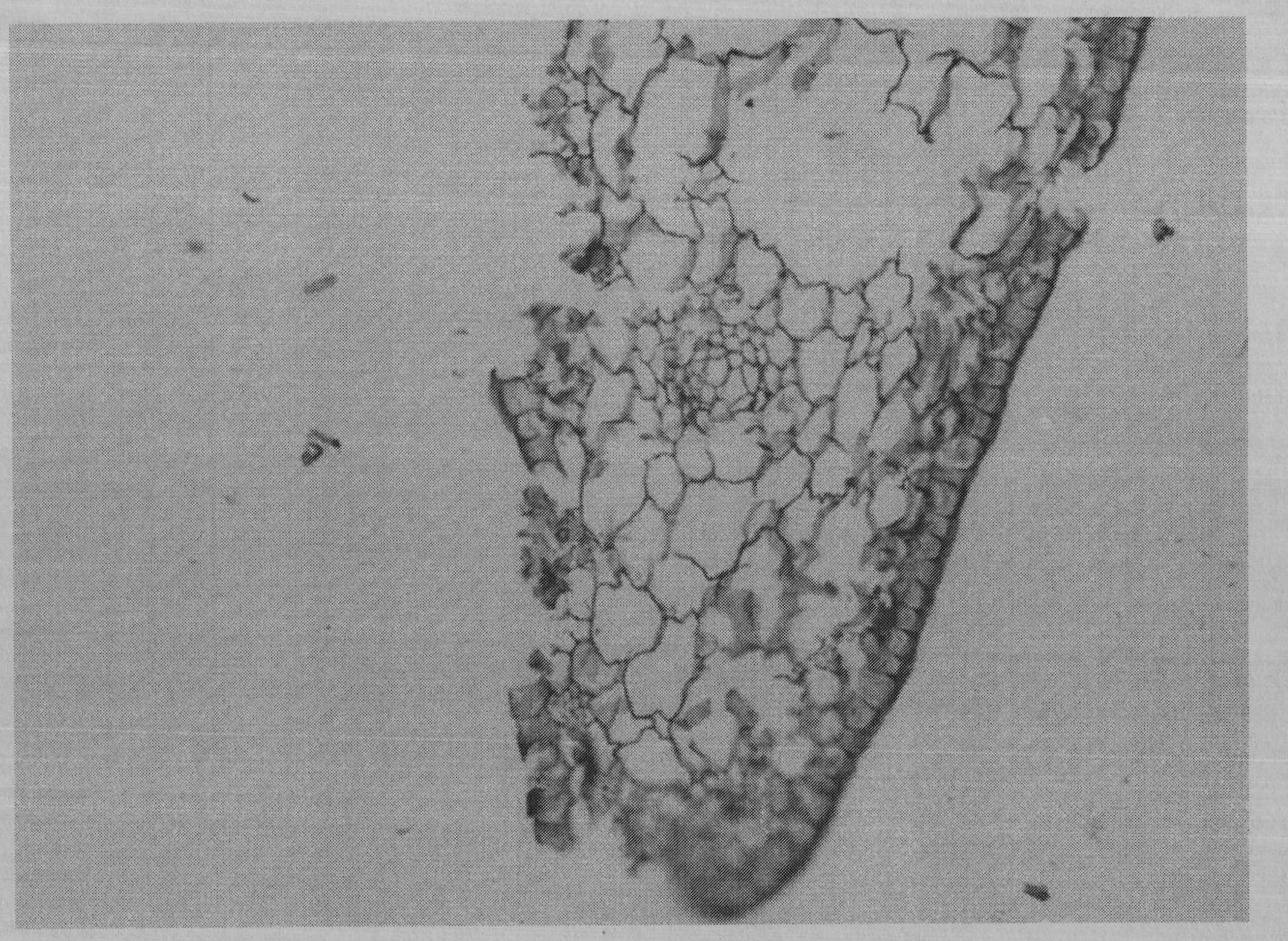

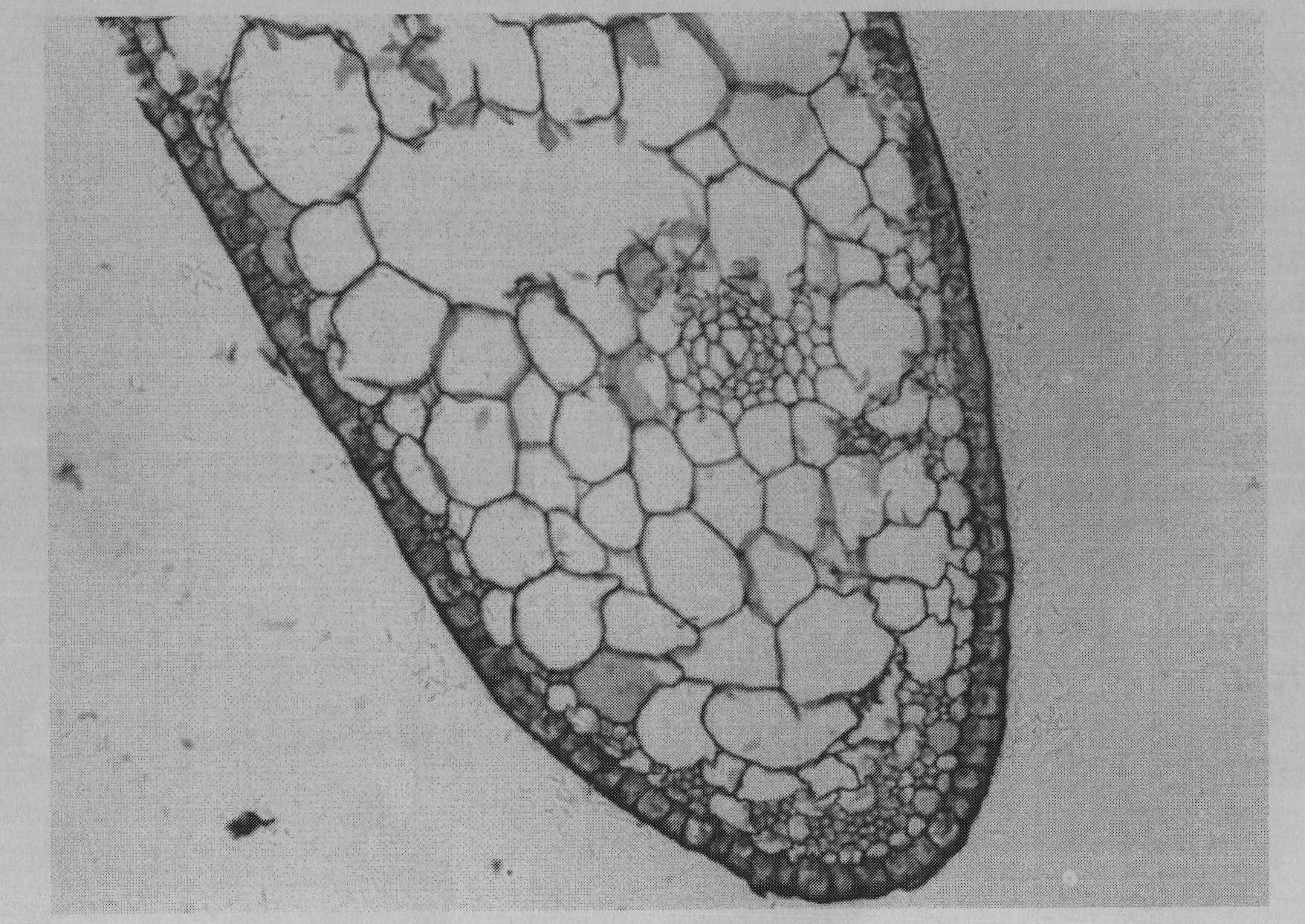

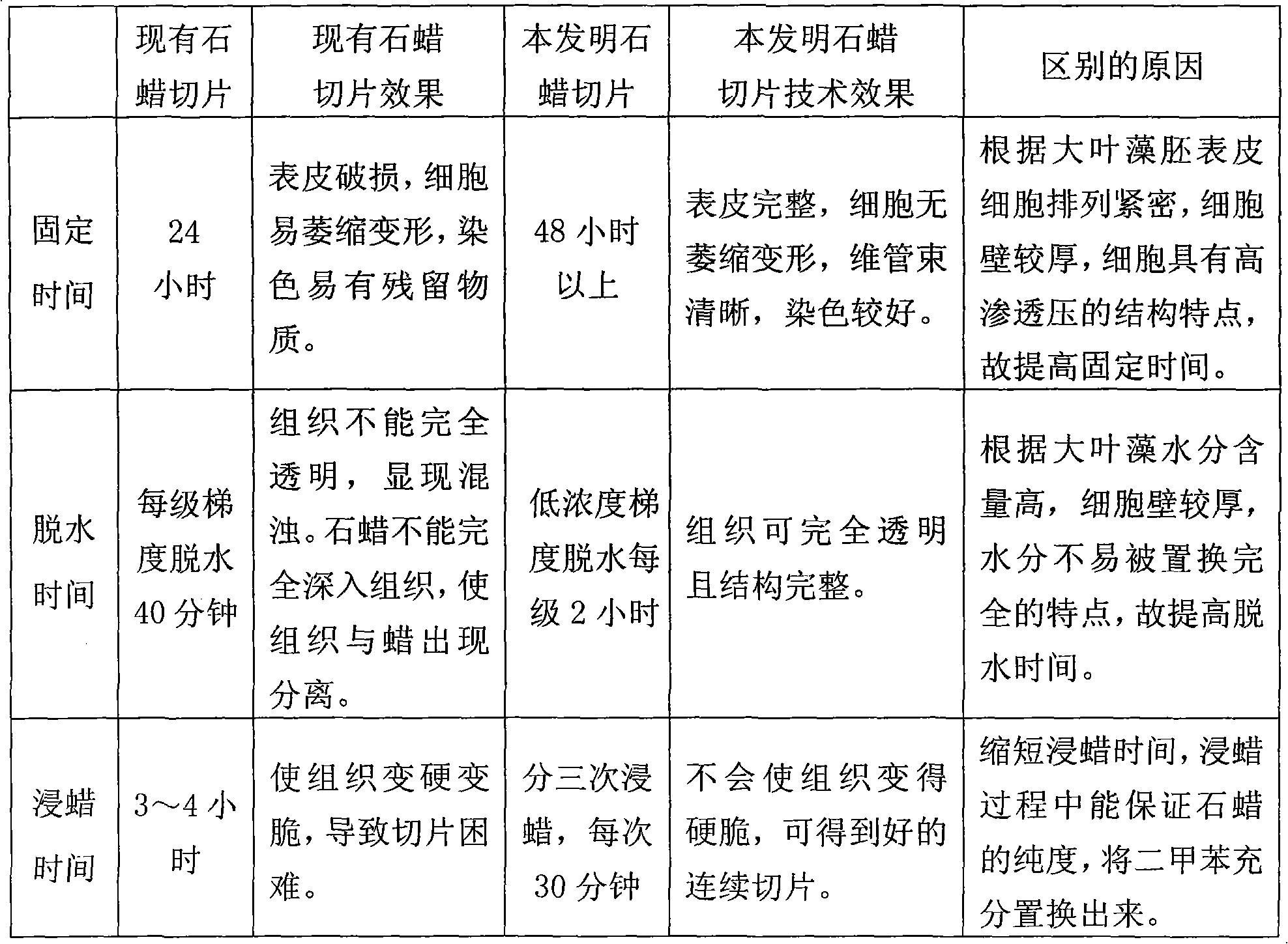

Manufacturing method of paraffin sections of zostera marina embryo

ActiveCN102116711AAvoid deformationModerate hardnessWithdrawing sample devicesPreparing sample for investigationParaffin waxEmbryo

The invention discloses a manufacturing method of paraffin sections of zostera marina embryo, comprising the following steps: (1) material drawing and fixation: zostera marina seeds are taken and the fruit skin is stripped, and after endosperm is removed, an integral zostera marina embryo is soaked in FAA (free amino acids) fixing solution and is fixed for more than 48 hours; (2) dehydration: the zostera marina embryo is taken out from the fixing solution and is soaked in alcohol for dehydration; (3) waxing and embedding: paraffin is added gradually in a vessel containing the zostera marina embryo and dimethylbenzene, and conventional paraffin embedding is carried out to obtain the wax blocks containing the zostera marina embryo; (4) slicing, spreading and drying: the wax blocks coated with the zostera marina embryo is fixed on a wheel rotation type slicing machine for carrying out continuous slicing of the paraffin, so as to obtain wax bands and enable the wax bands to be attached to an object slide; (5) dewaxing, rehydration and dyeing of hematoxylin dye solution; (6) slicing, dehydration and dyeing of eosin and alcohol; and (7) transparence and mounting are carried out to manufacture a permanent section. In the manufacturing method disclosed by the invention, the paraffin sections of the zostera marina embryo, which have clear dyeing and an integral texture structure, can be obtained.

Owner:SHANDONG ORIENTAL OCEAN SCI TECH

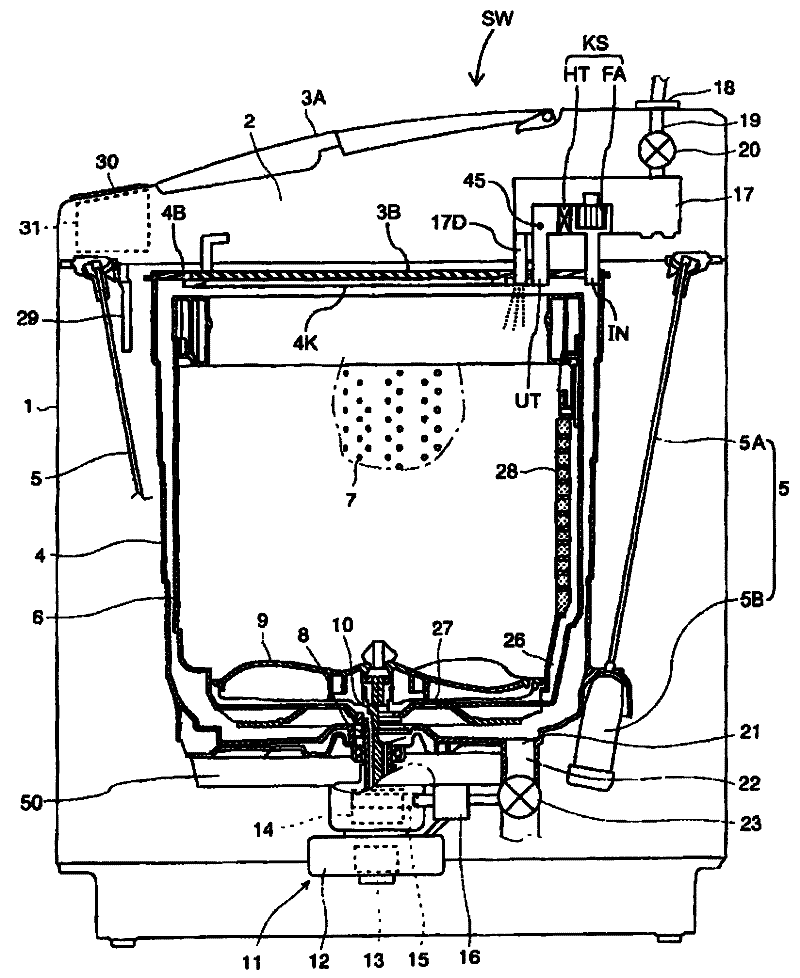

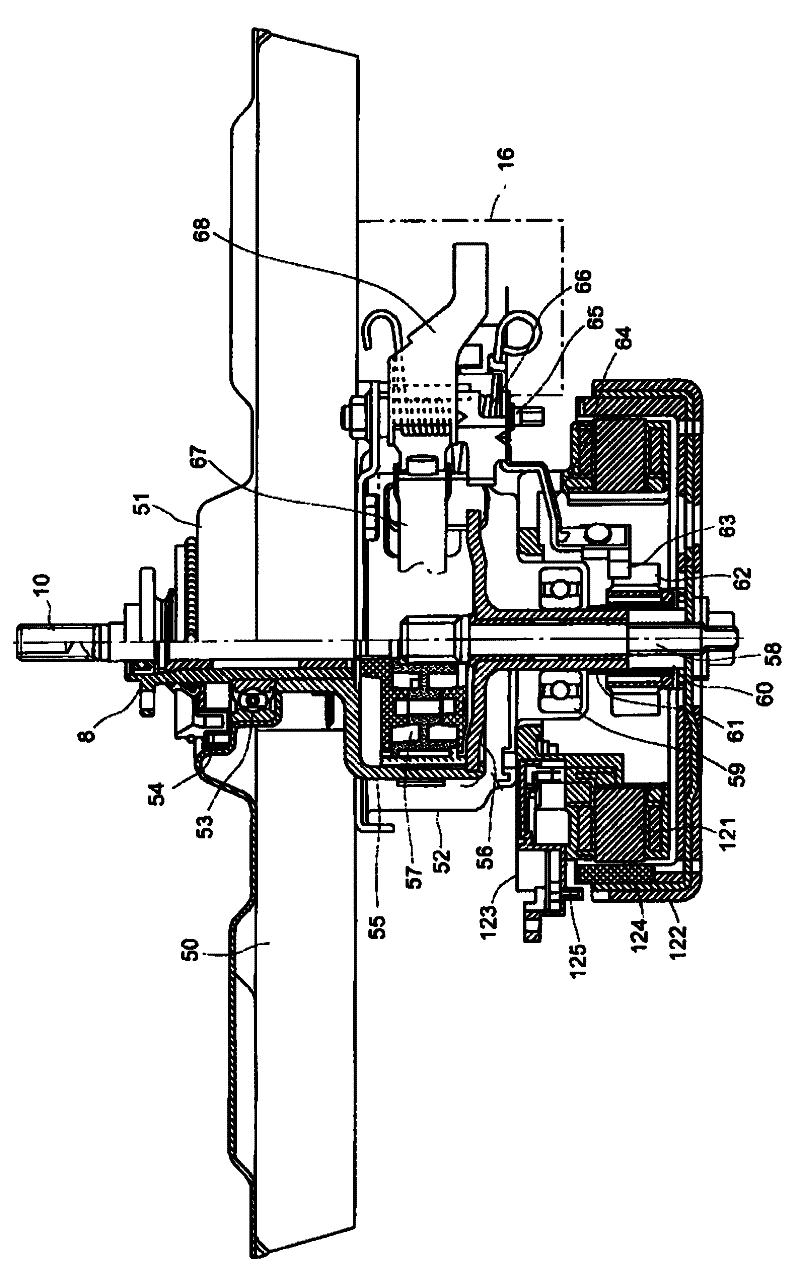

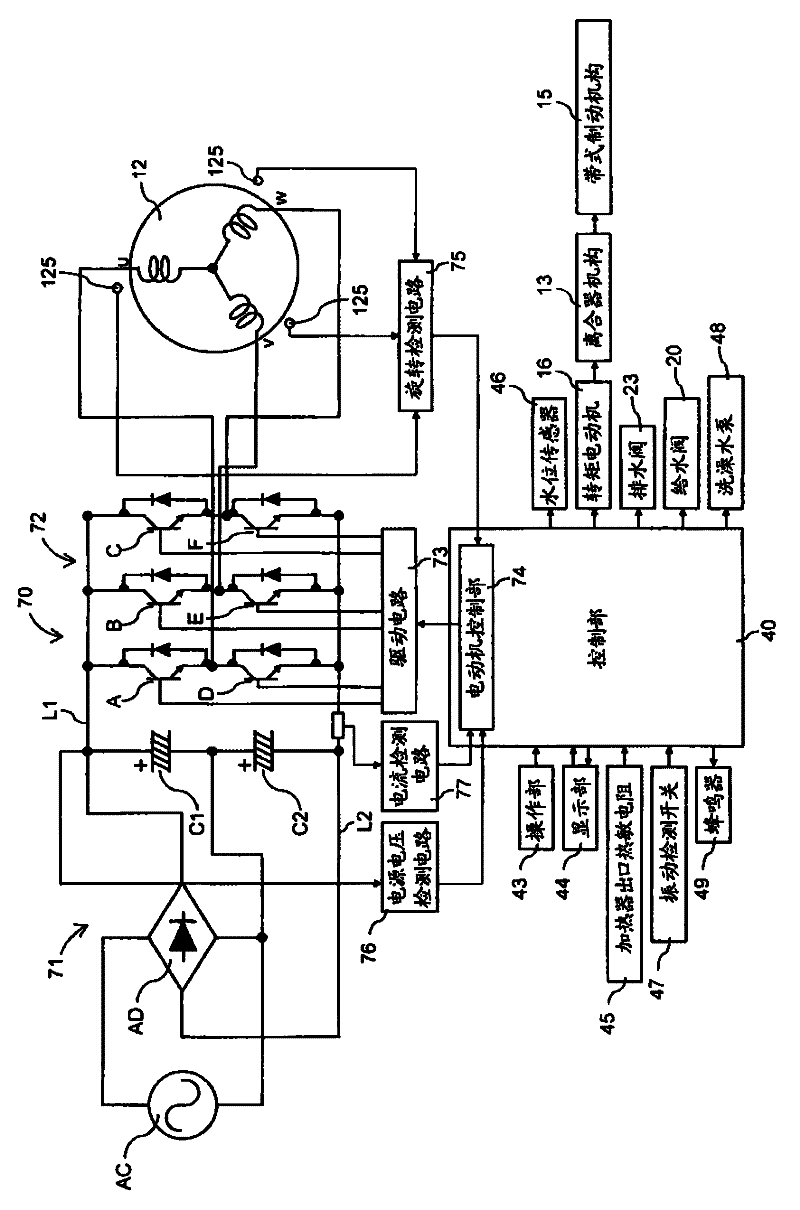

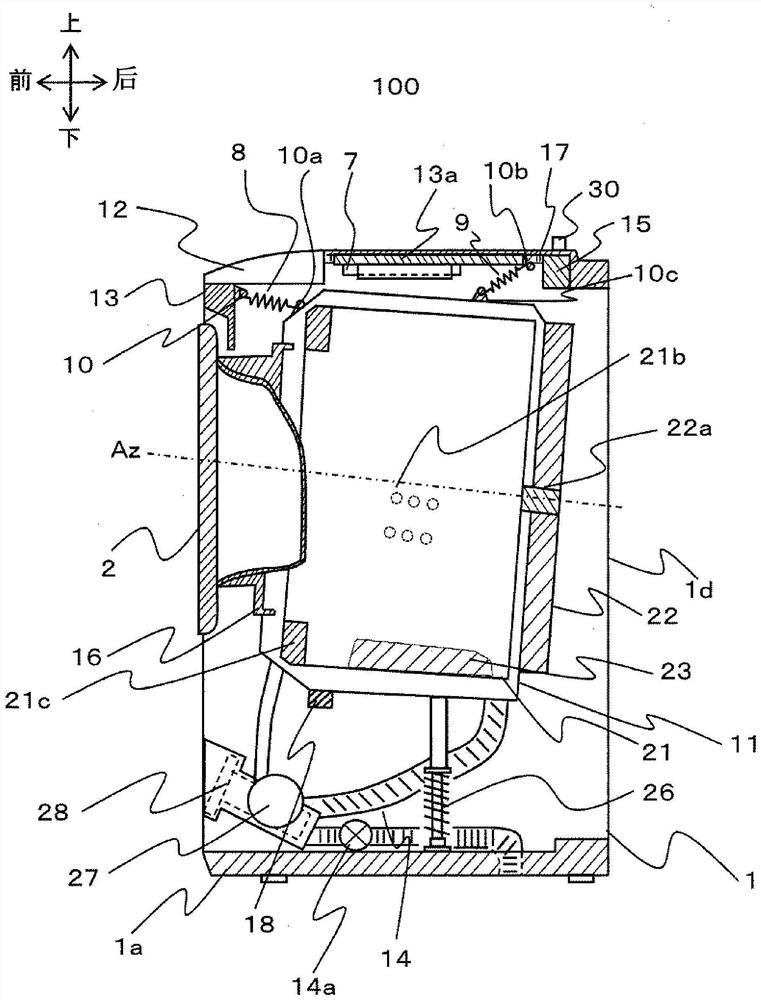

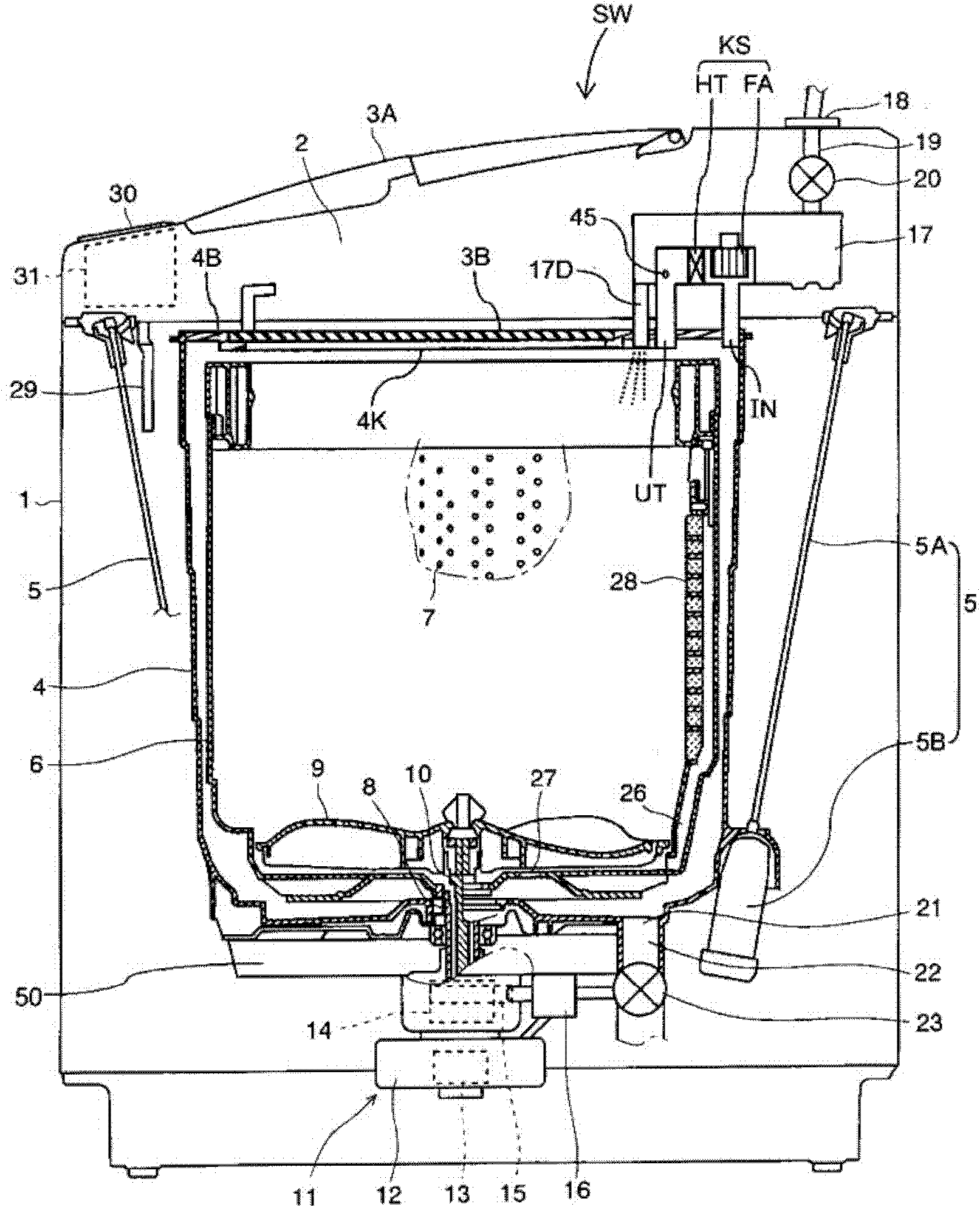

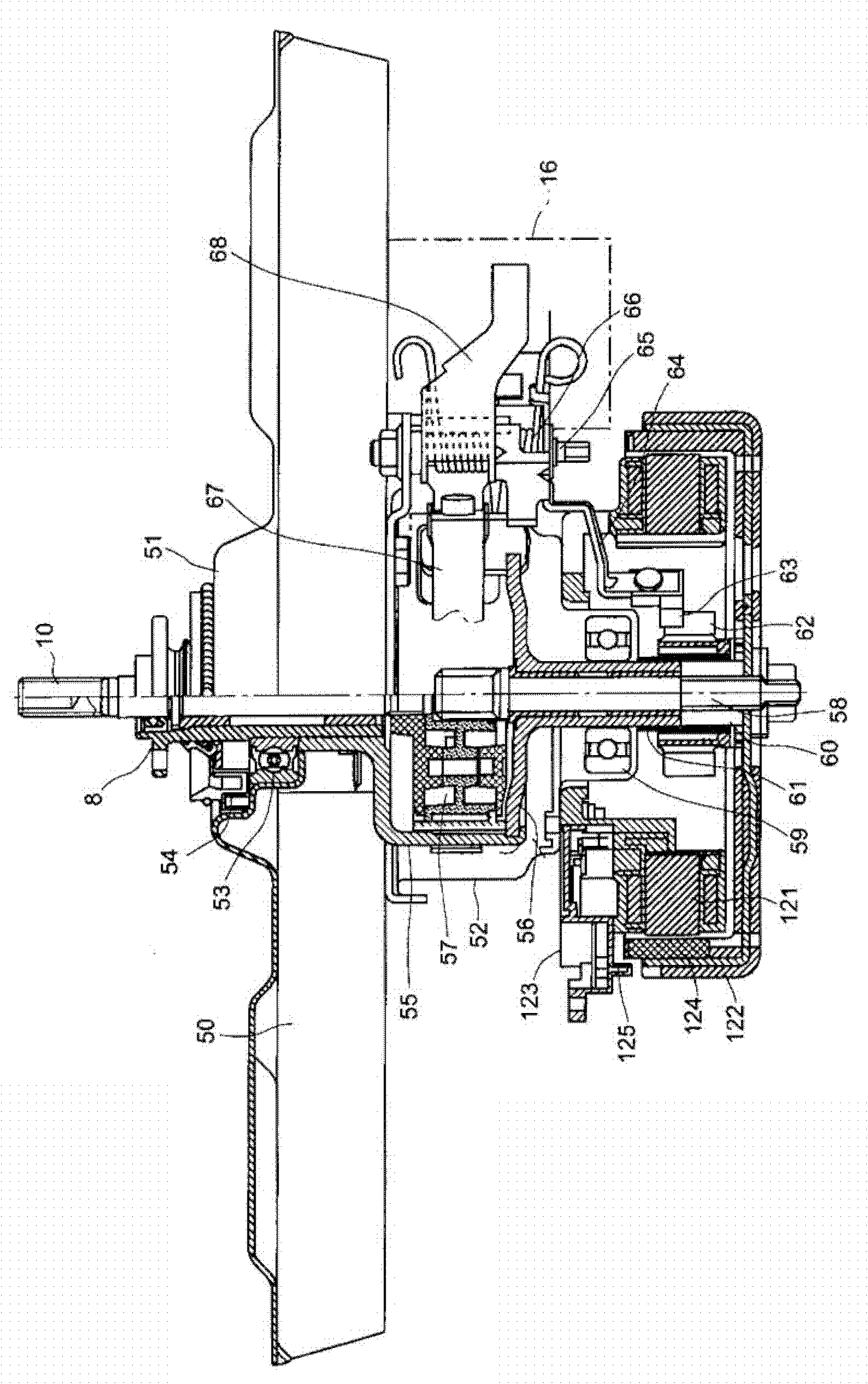

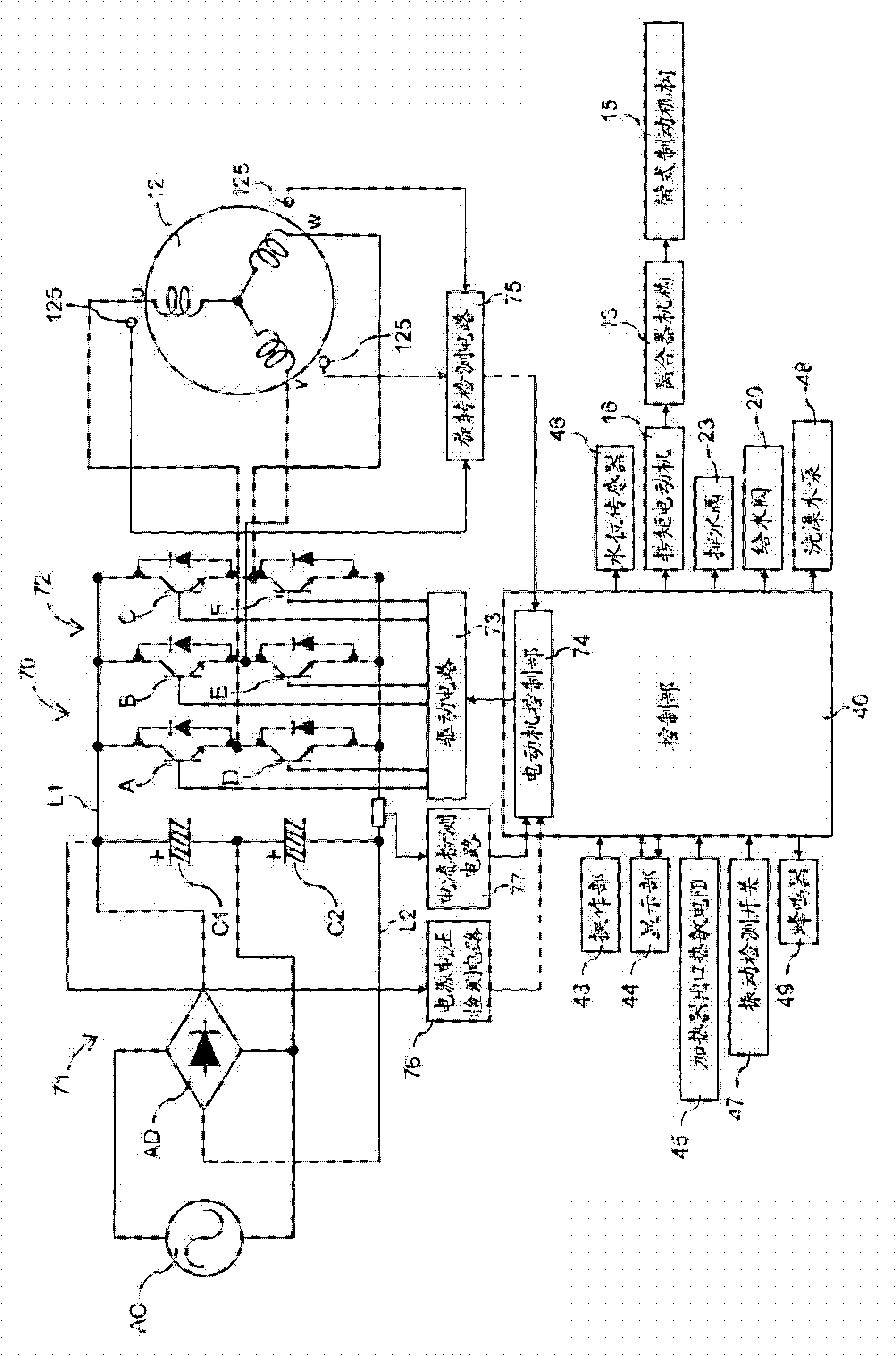

Washing machine

ActiveCN102251367AAvoid abnormal vibrationReduce speedControl devices for washing apparatusWashing machine with receptaclesElectrical controlEngineering

The invention provides a washing machine, wherein a washing dehydration tank and a pulsator integrally formed in an outer groove is rotated at a high speed so as to perform the dehydration of laundry. Meanwhile, a mechanism is provided to restrain the vibration of the washing dehydration tank via the electrical control. When the outer groove is made of synthetic resin, the intrinsic value of the outer groove (inherent resonance point) varies with the temperature. When the temperature of the outer groove rises, the rotation speed of the washing dehydration tank is lowered so as to be away fromthe inherent value of the outer groove and prevent the abnormal vibration. In addition, the temperature of the outer groove can also be directly or indirectly determined. If the temperature rises, the dehydration speed is lowered. If the temperature decreases, the dehydration speed is increased. Meanwhile, by utilizing a washing machine with drying function, wherein the circulation of the washingdehydration tank is realized by the heating of a heater, if the temperature at the outlet of the heater rises, the dehydration speed is lowered. If the temperature decreases, the dehydration speed isimproved.

Owner:HAIER GRP CORP +1

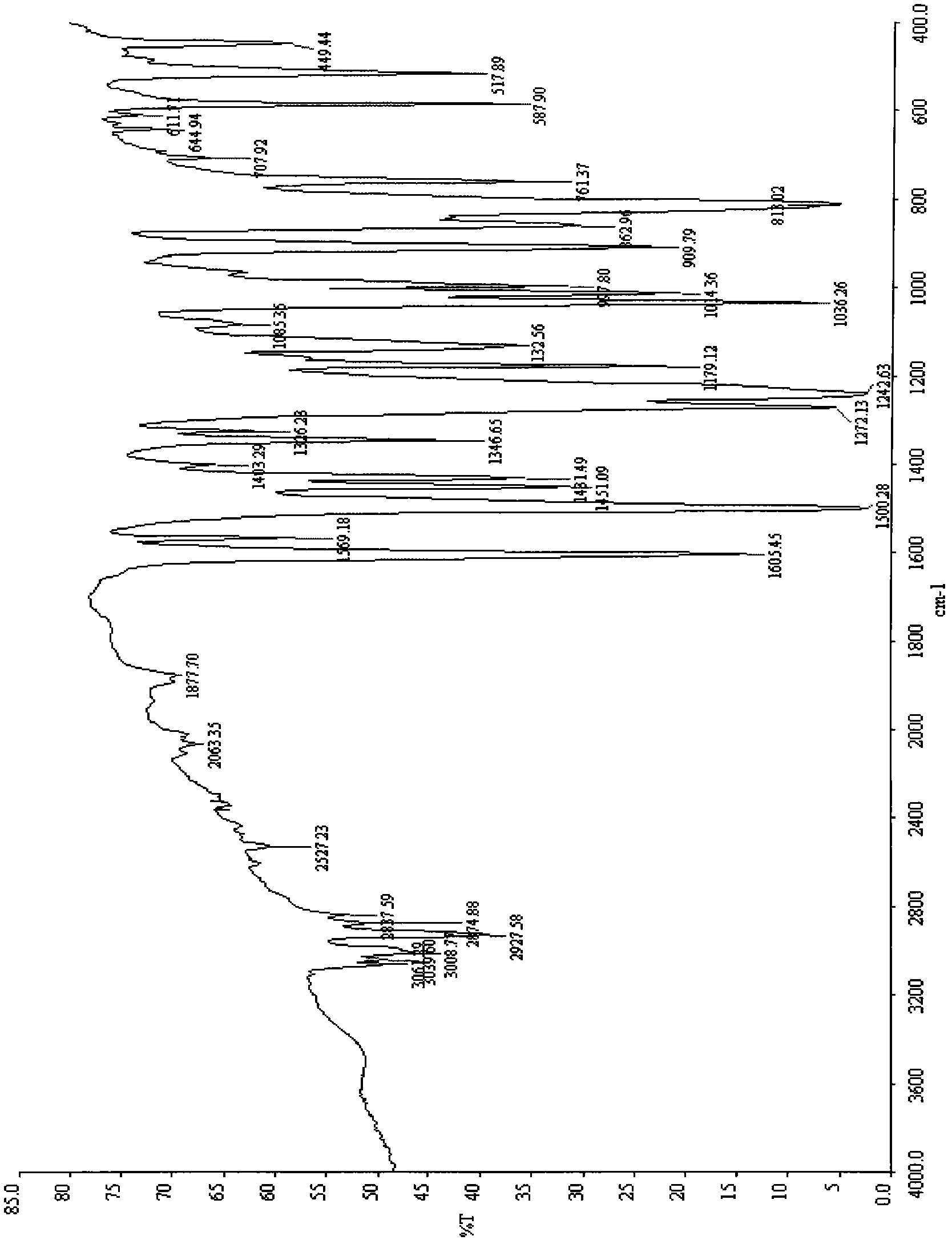

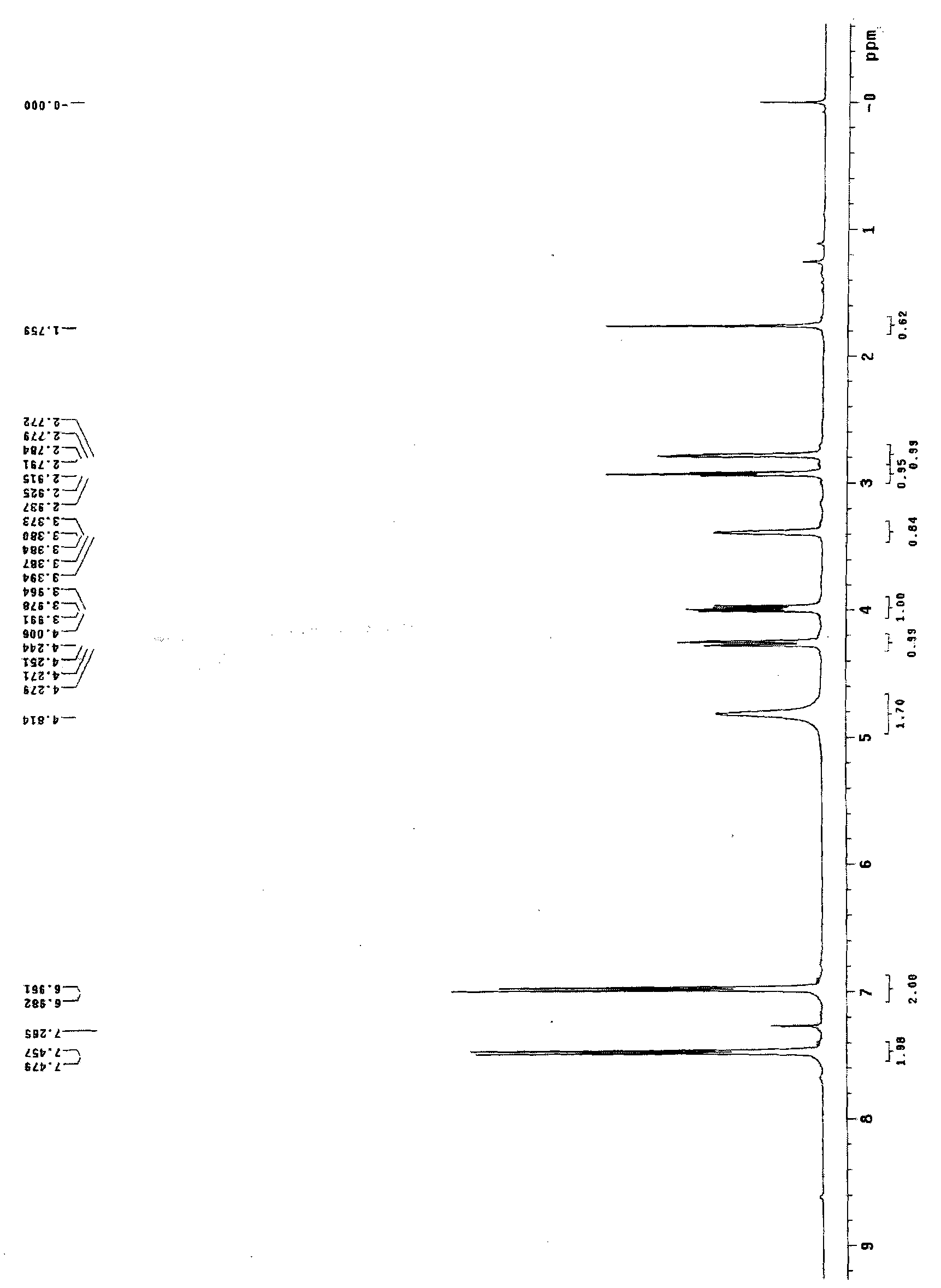

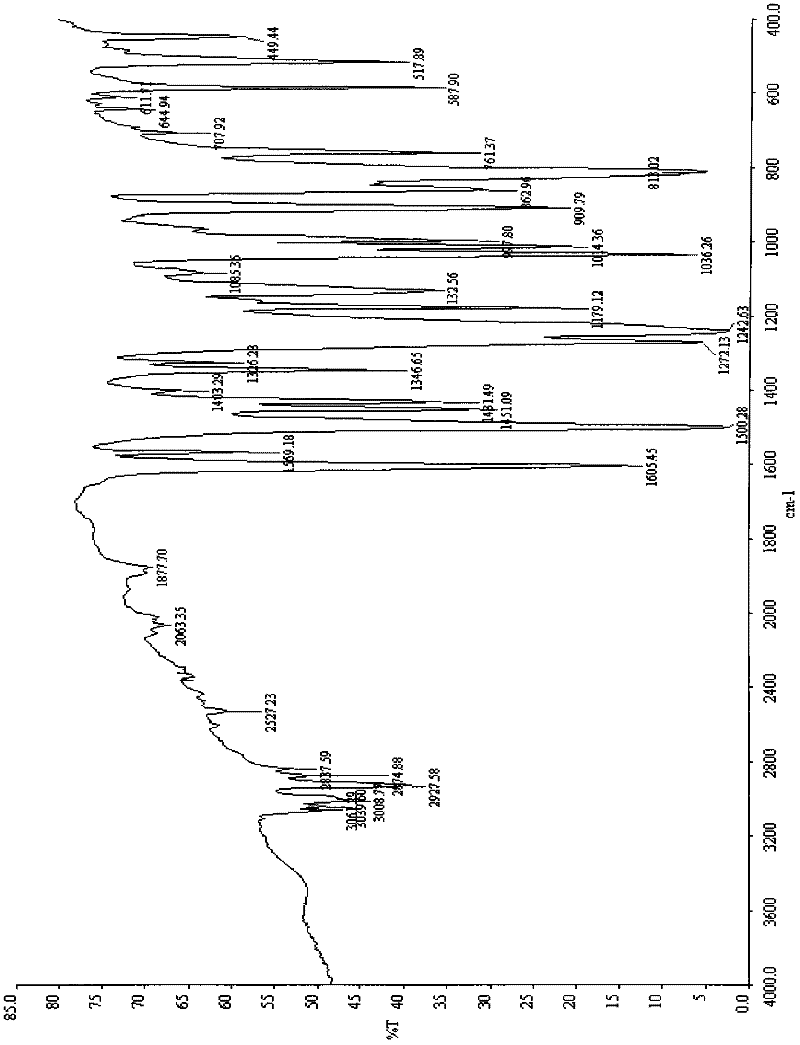

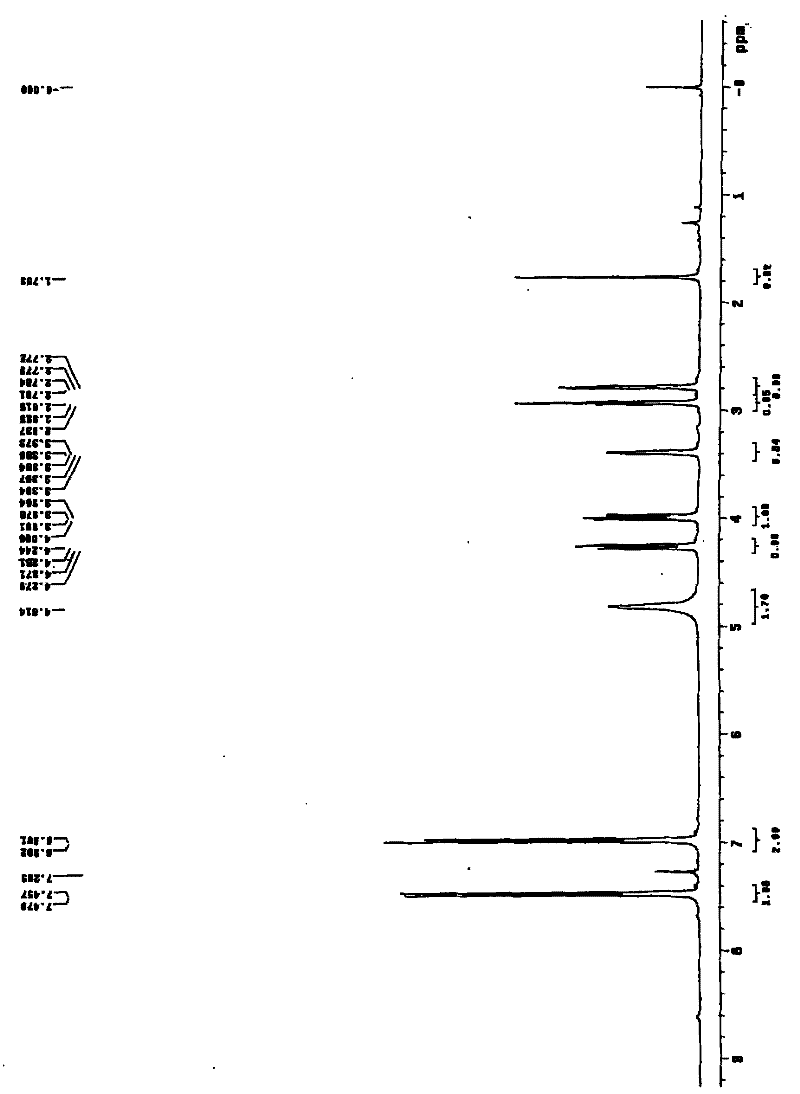

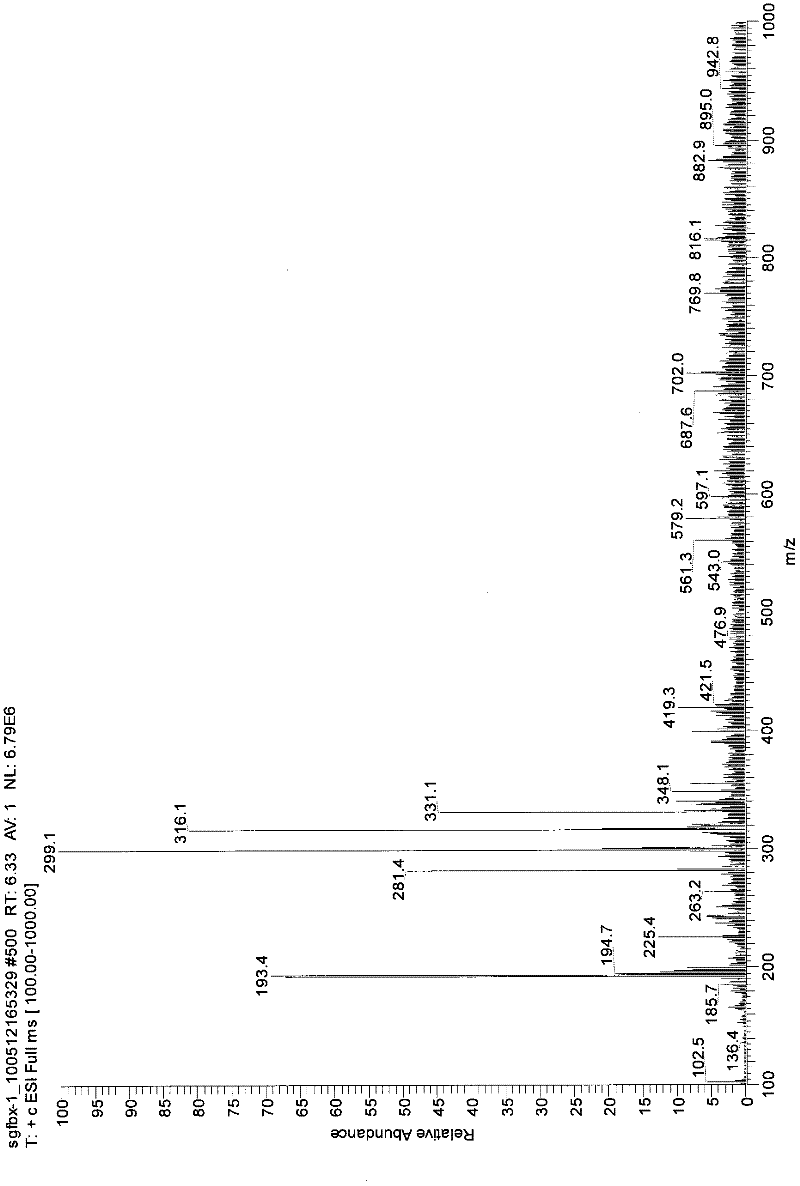

Preparation method of 4,4'-biphenol diglycidyl ether

ActiveCN102030726AReduce hydrolysis side reactionsHigh yieldOrganic chemistryTwo stepEpichlorohydrin

The invention discloses a preparation method of 4,4'-biphenol diglycidyl ether. In the preparation method provided by the invention, 4,4'-biphenol and epichlorohydrin are used as raw materials to be synthesized by a two-step method under the effect of a heterogeneous catalyst. The preparation method comprises the following steps: firstly, carrying out a ring-opening etherifying reaction, then carrying out a ring-closing reaction, and in the alkalizing process, separating out water generated in the reaction by a water-separating technique, so that the reaction shifts to the right at equilibrium, and various hydrolysis secondary reactions in the system can be controlled. The product obtained by the technique has high epoxide equivalent and high yield, the technique has simple reaction steps and is convenient for posttreatment, and experimental results show that the epoxide number is 0.65-0.67, and the melting range is 159.1-160.4 DEG C.

Owner:兰州精细化工有限责任公司

Improved processing method of plant insulating oil

ActiveCN104987949AShorten the timeImprove processing efficiencyFatty-oils/fats refiningVacuum mixingImpurity

The invention discloses an improved processing method of plant insulating oil. The method includes the first step of coalescence dewatering, the second step of vacuum dewatering and the third step of vacuum mixing and refined filtering so that plant insulating oil can be obtained. The water content of the plant insulating oil processed through the improved processing method is smaller than 50 mg / kg, and 100 ml oil contains 2000 or less of impurity particles with diameter larger than 5 microns.

Owner:GUANGZHOU POWER SUPPLY CO LTD +1

Treatment method for reducing dielectric loss of vegetable insulating oil

InactiveCN104987950AImprove adsorption capacityChemically stableFatty-oils/fats refiningDielectric lossFiltration

The invention discloses a treatment method for reducing the dielectric loss of vegetable insulating oil. The treatment method comprises the following steps: 1, raising the temperature of the vegetable insulating oil to 45 DEG C to 65 DEG C, adding activated clay, and conducting stirring and mixing for 40-80 minutes, wherein the additive amount of the activated clay takes up 2-4% of the weight of the vegetable insulating oil; 2, lowering the temperature below 45 DEG C under the stirring condition, and then conducting cycling filtration on a mixture obtained in step 1; 3, placing the vegetable insulating oil obtained in step 2 into a dehydration pot, raising the temperature, and conducting the cycling dehydration for 4-6 hours till the content of water in the vegetable insulating oil is not greater than 30 mg / kg. By means of the treatment method, the dielectric loss of the vegetable insulating oil can be reduced to 0.3%.

Owner:GUANGZHOU POWER SUPPLY CO LTD +1

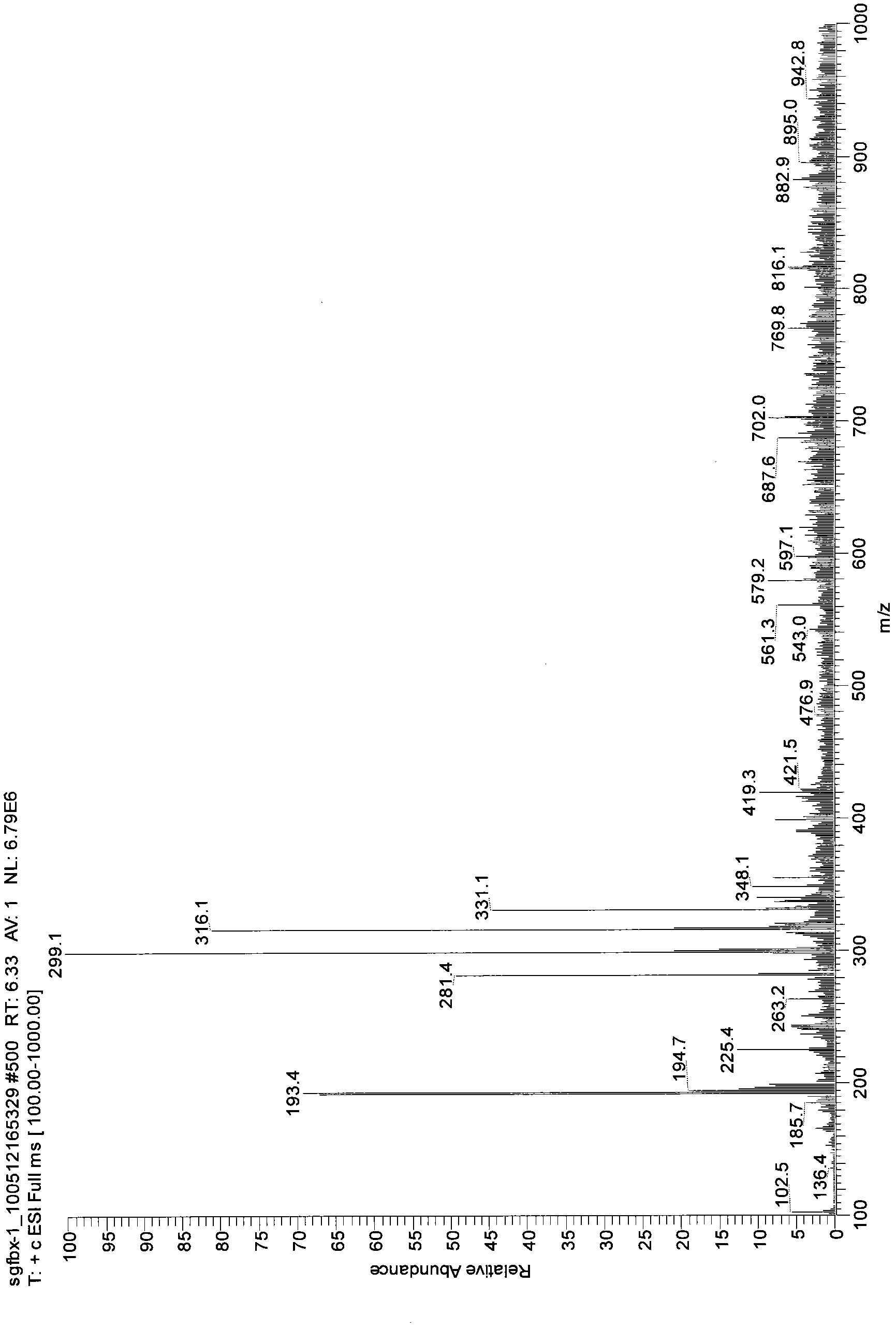

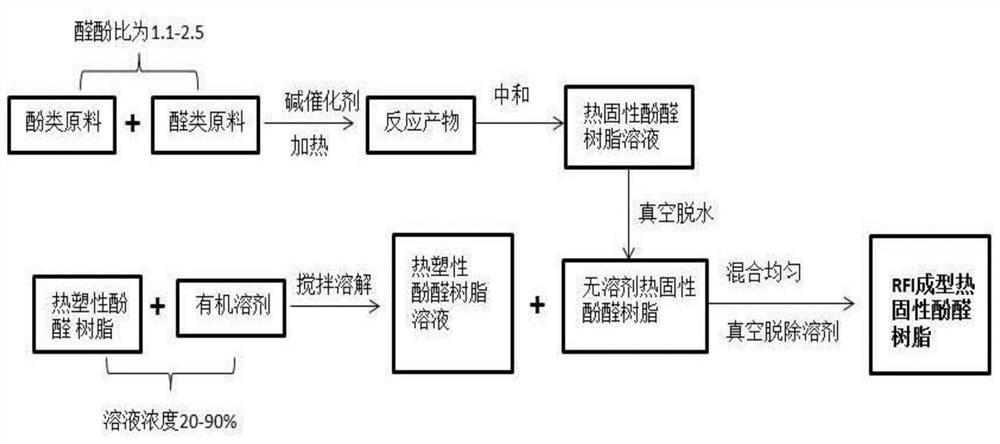

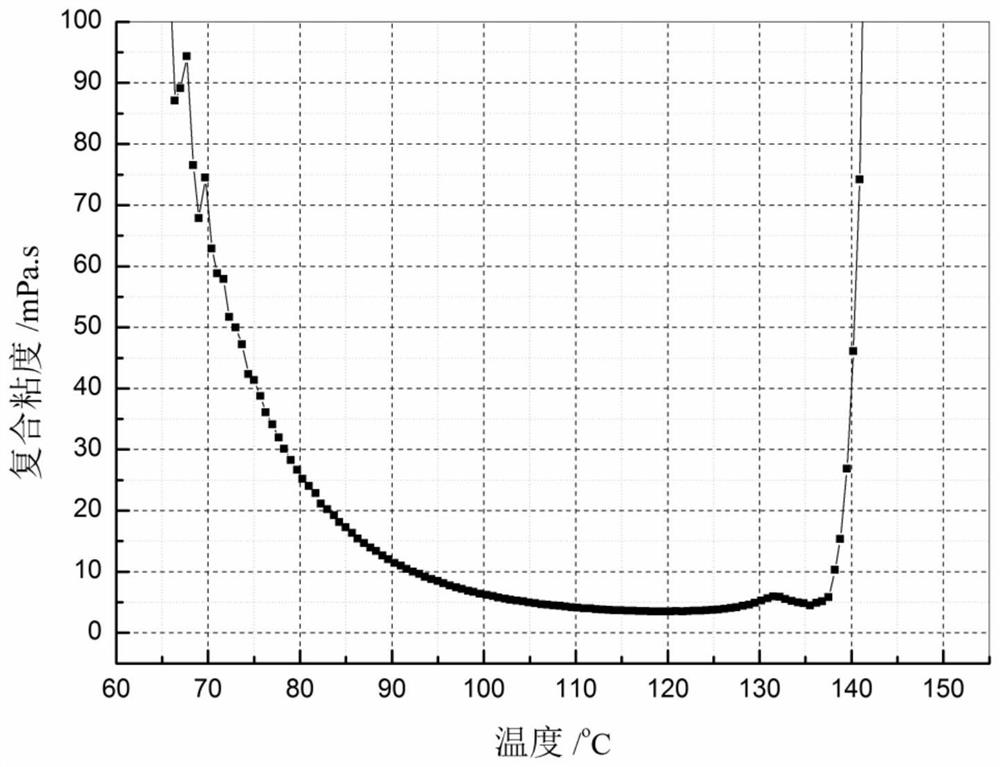

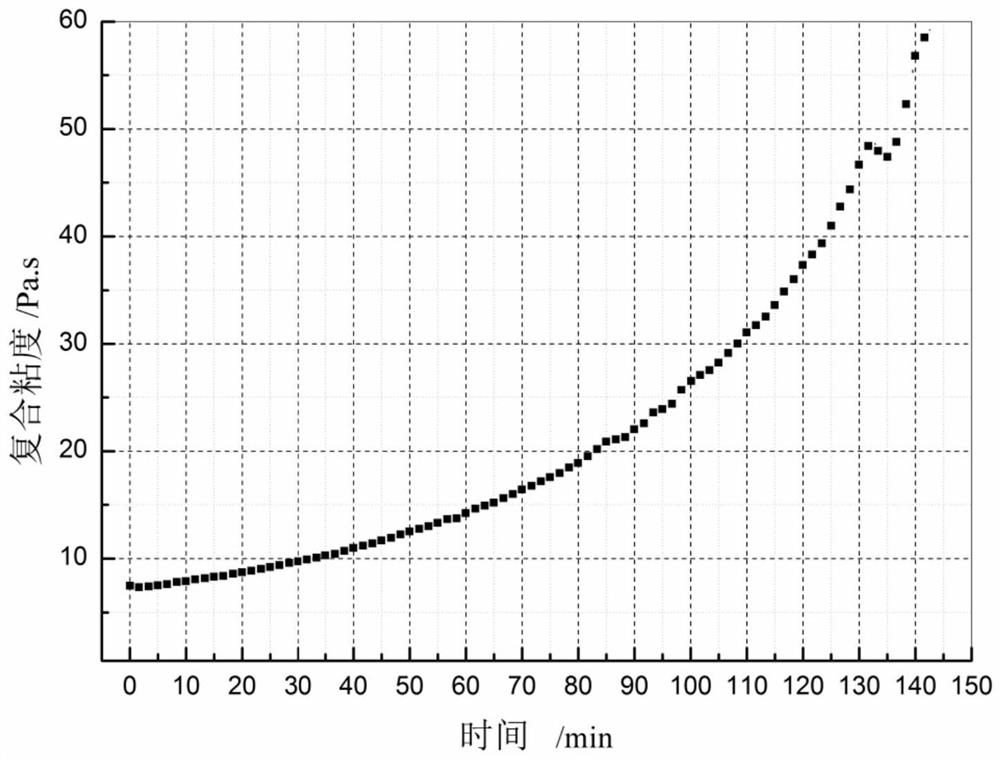

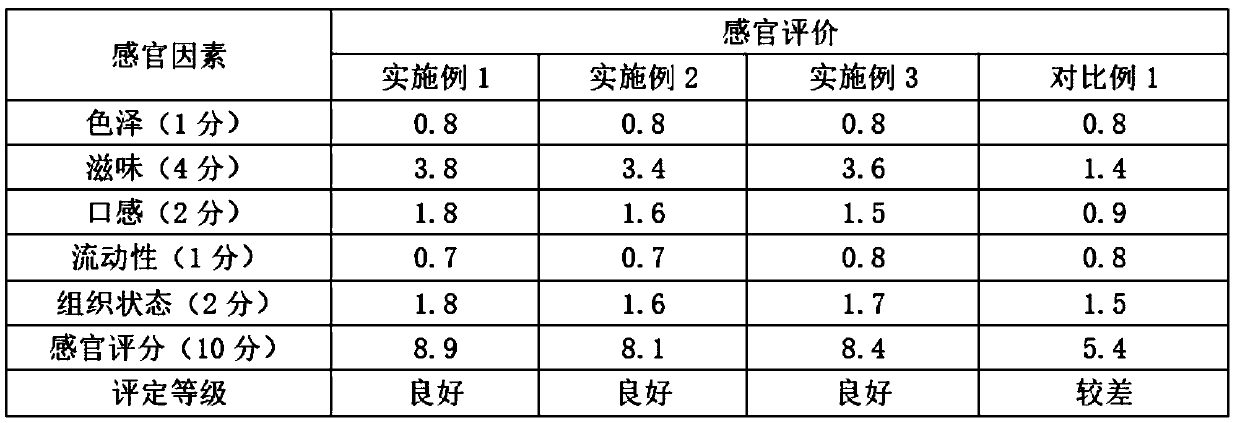

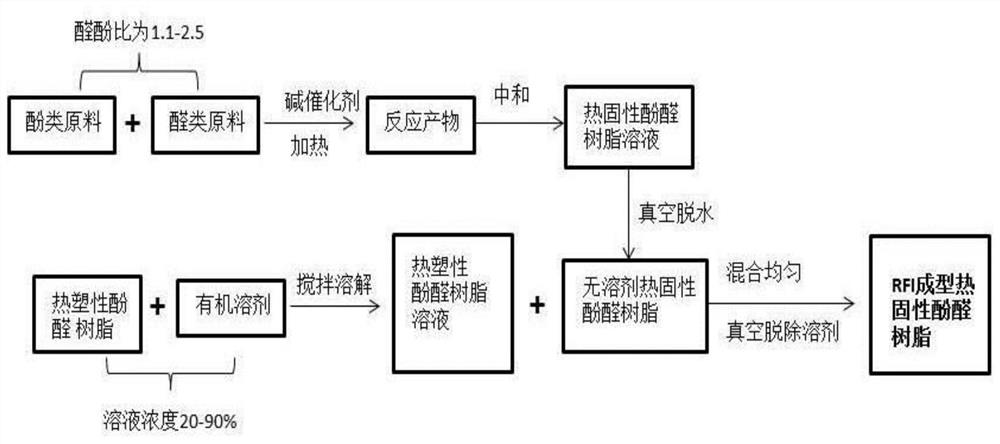

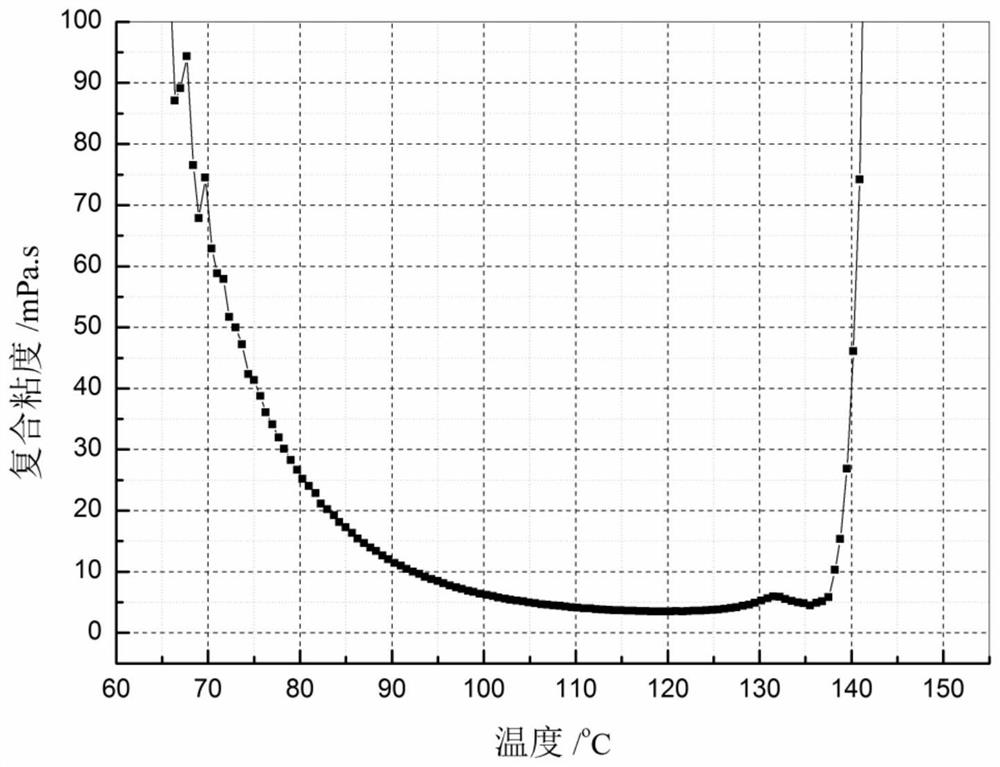

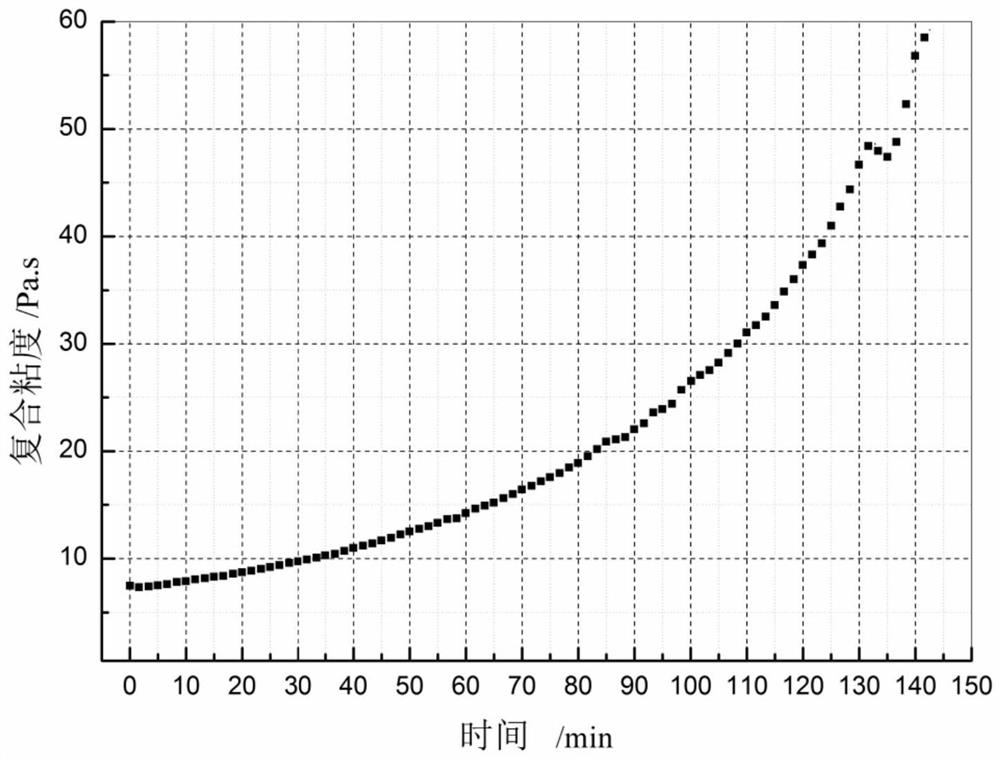

Modified phenolic resin as well as preparation method and application thereof

The invention relates to thermosetting phenolic resin as well as a preparation method and application thereof. The phenolic resin is prepared by reaction of thermosetting phenolic resin and thermoplastic phenolic resin, the contradiction between high viscosity of traditional phenolic resin and a narrow process window is solved, and the advantages of good heat resistance and high carbon residue rate of phenolic resin are maintained. The thermosetting phenolic resin suitable for a resin film infiltration process (RFI) provided by the invention is low in cost, simple in preparation method, high in operability and convenient for large-scale preparation. The phenolic resin has excellent forming and curing process performance, heat resistance and carbon residue performance, is good high-performance composite material matrix resin, has a good application prospect in the high-tech fields of thermal protection and the like, can be used for preparing phenolic resin flame-retardant prepreg clothby a dry method, and has a great application potential in the fields of flame-retardant and fireproof interior materials of large airplanes and high-speed trains and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

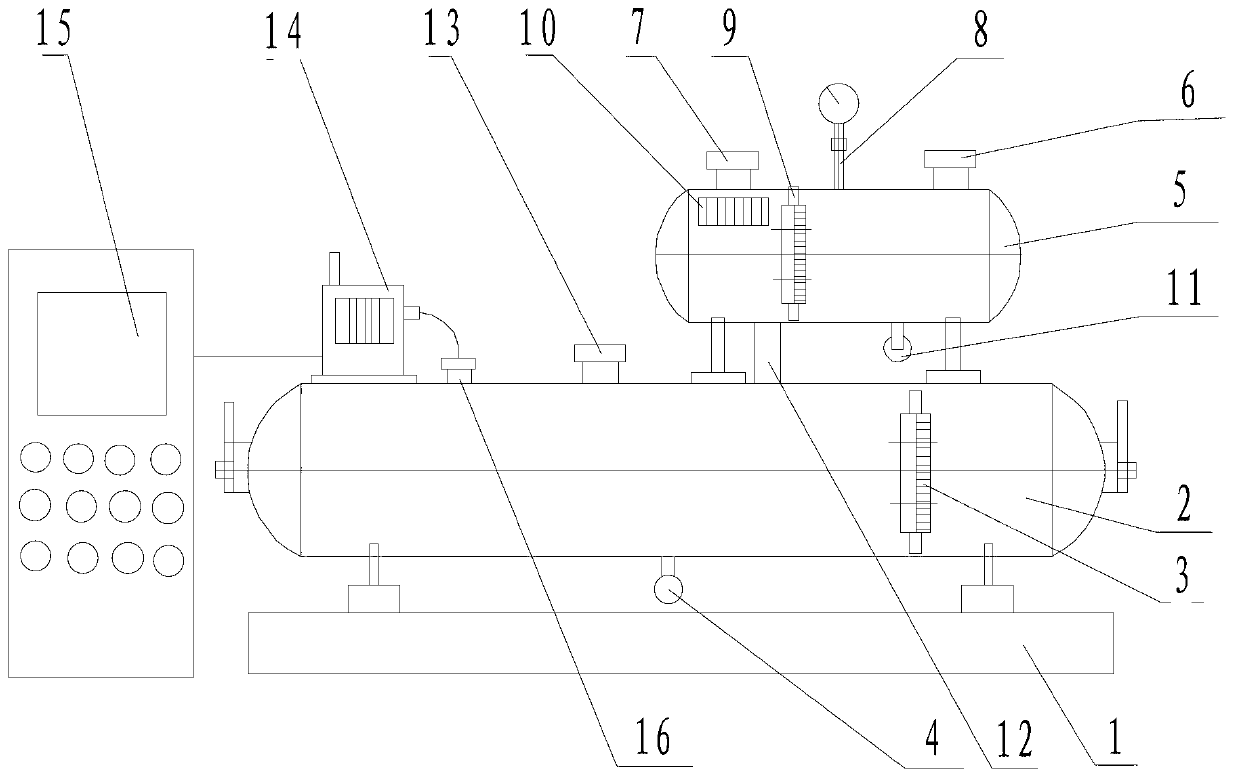

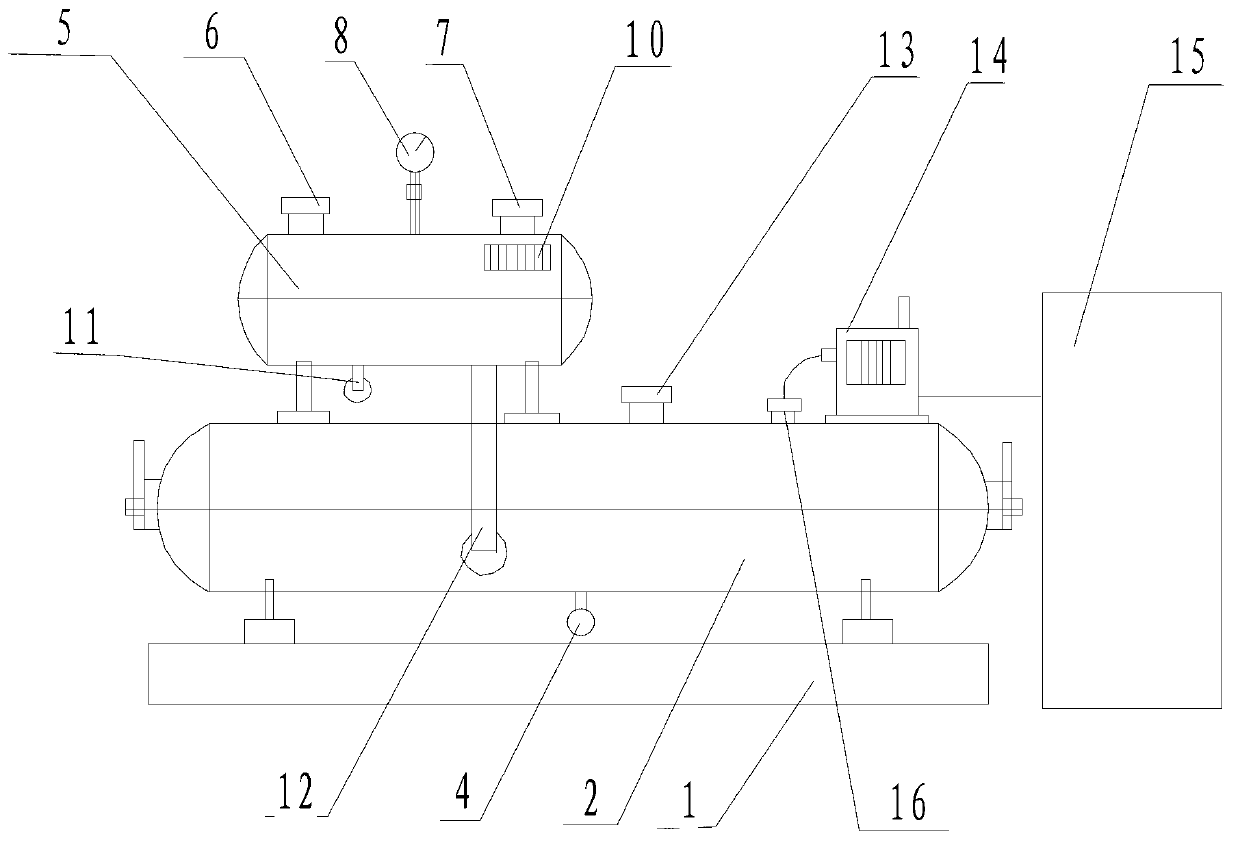

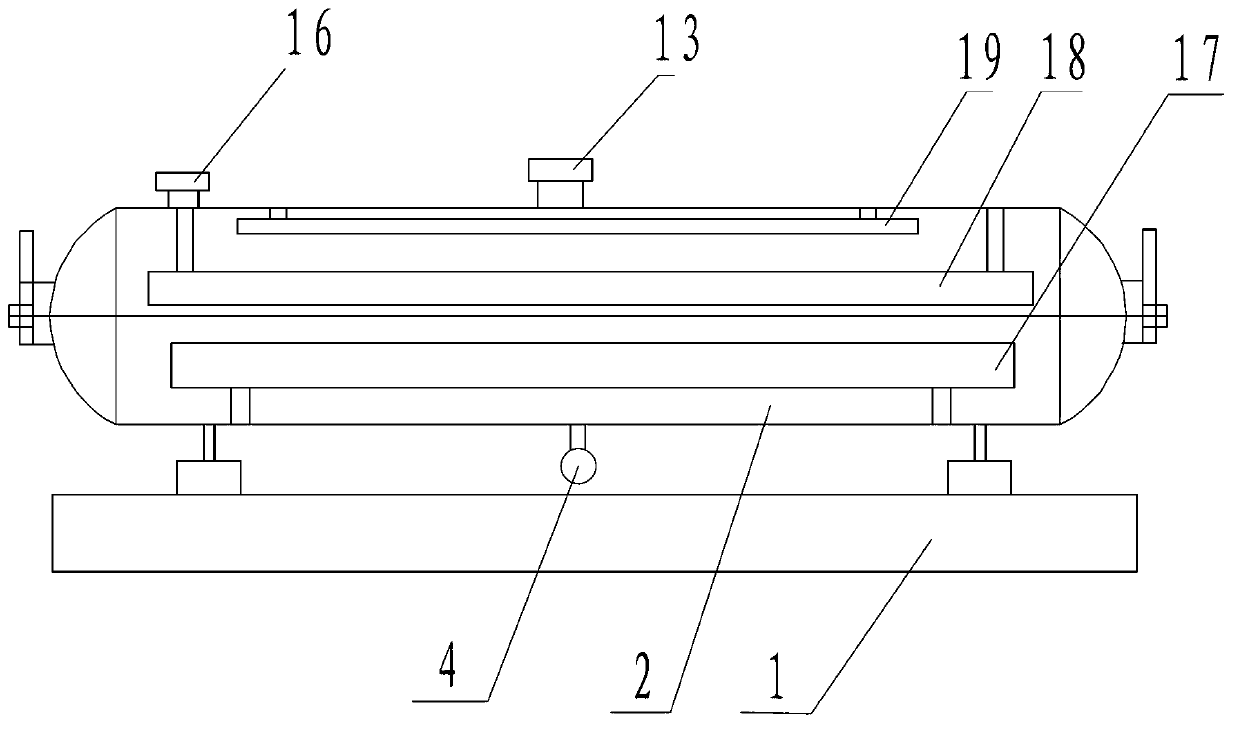

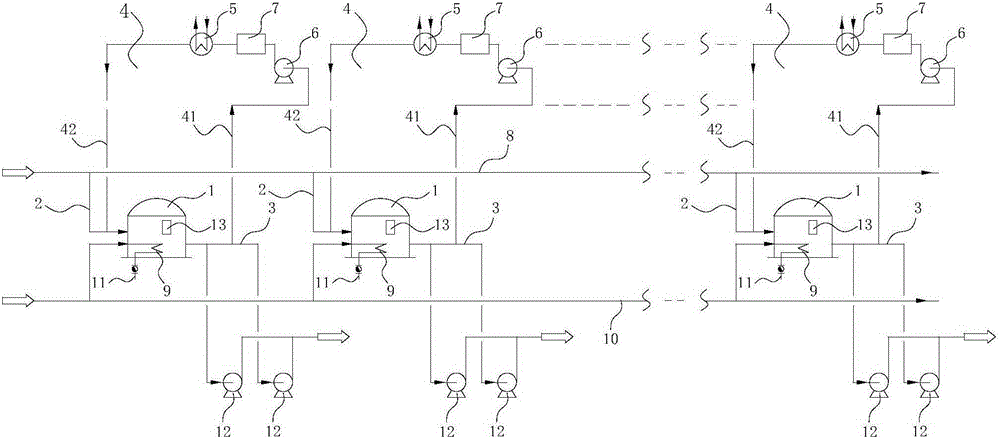

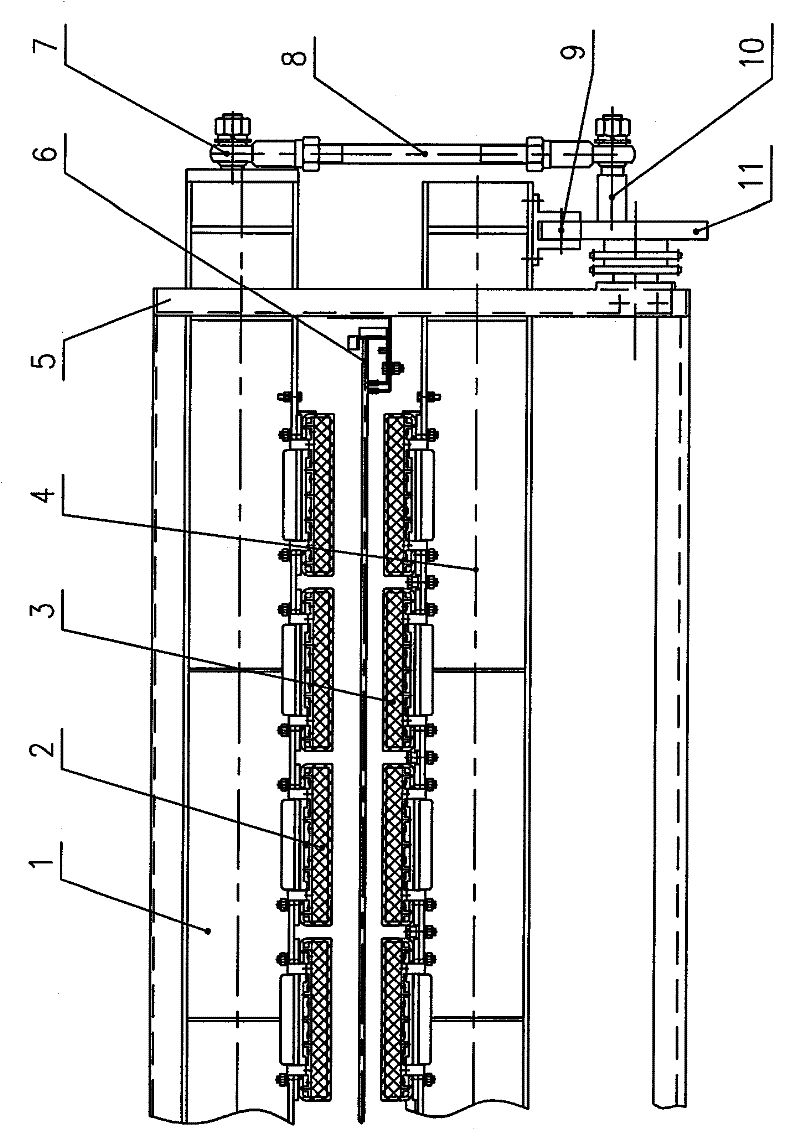

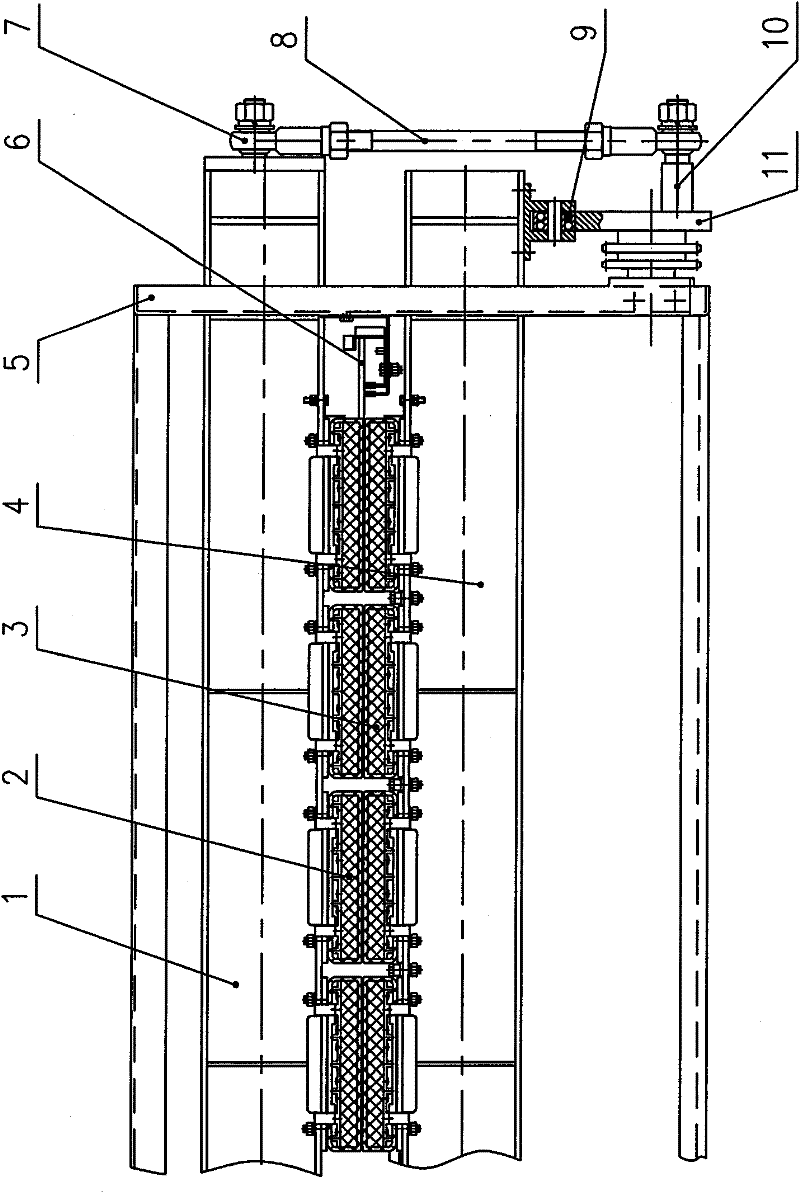

Quick electrostatic agglomerate separating device and process

ActiveCN103343017ASolve low dehydration rateSolve the problem of oily drainageDewatering/demulsification with electric/magnetic meansHigh energyTransformer

The invention provides a quick electrostatic agglomerate separating device and a quick electrostatic agglomerate separating process. The quick electrostatic agglomerate separating device is composed of a pry seat, an oil-water separation tank, an oil-water interface instrument, a water outlet, a gas-liquid separation tank, a liquid inlet, a gas outlet, a pressure gauge, a gas-liquid interface instrument, an adsorption plate, a water outlet, an oil / water transmission pipe, an oil outlet, a transformer, a transformer, a control cabinet, a high pressure introduction hole, a feed oil distributor, an electrostatic coalescence electrode and a discharged oil collecting pipe; a high water cut well liquid enters the gas-liquid separation tank via the liquid inlet; a combustible gas is discharged from the gas outlet and enters the oil-water separation tank; oil and water are separated from each other under the action of gravity, and further separated in an electric field generated by the electrostatic coalescence electrode; and crude oil is output from the oil outlet. Therefore, the problems of low crude oil dehydration rate, high oil content in drainage and high energy consumption are solved, the electric field space is extended and the dehydration time of crude oil in the electric field is prolonged; and as the result, the dehydration efficiency is effectively improved, the electricity consumption in operation is reduced and the production cost is reduced.

Owner:LUOYANG ZHENGYUAN PETROCHEM

Melt/solid state polycondensation preparation method for polylactic acid

The invention relates to a melt / solid state polycondensation preparation method for polylactic acid, which mainly solves the problems of long reaction time, difficult continuous production or high cost in the prior art. The method comprises the following steps of: 1) performing a dehydration oligomerization reaction of lactic acid at the temperature of between 100 and 160 DEG C under the absolute pressure of between 6,000 and 25,000 Pa and under the action of a catalyst A for 0.5 to 5 hours first, and continuing the ehydration oligomerization reaction at the temperature of between of 120 and 180 DEG C under the absolute pressure of between 200 and 1,500 Pa and under the action of the catalyst A for 0.5 to 5 hours to generate a product I; 2) performing a melt polycondensation reaction of the product I at the reaction temperature of between 150 and 200 DEG C under the absolute pressure of between 30 and 600 Pa and under the action of a catalyst B for 0.5 to 15 hours to generate a polylactic acid prepolymer and lactide serving as a by-product, and refluxing the lactide to a reaction mixture at the reflux temperature of between 70 and 95 DEG C; 3) pelletizing the polylactic acid prepolymer obtained in the step 2), and crystallizing in an inertia airflow at the temperature of between 50 and 130 DEG C for 0.5 to 10 hours; and 4) performing a solid state polycondensation reaction of the polylactic acid prepolymer processed in the step 3) in the inertia airflow at the temperature of between 120 and 170 DEG C for 5 to 40 hours to obtain the polylactic acid. The technical scheme of the invention better solves the problem, and can be used for the industrial production of the polylactic acid.

Owner:CHINA PETROLEUM & CHEM CORP +2

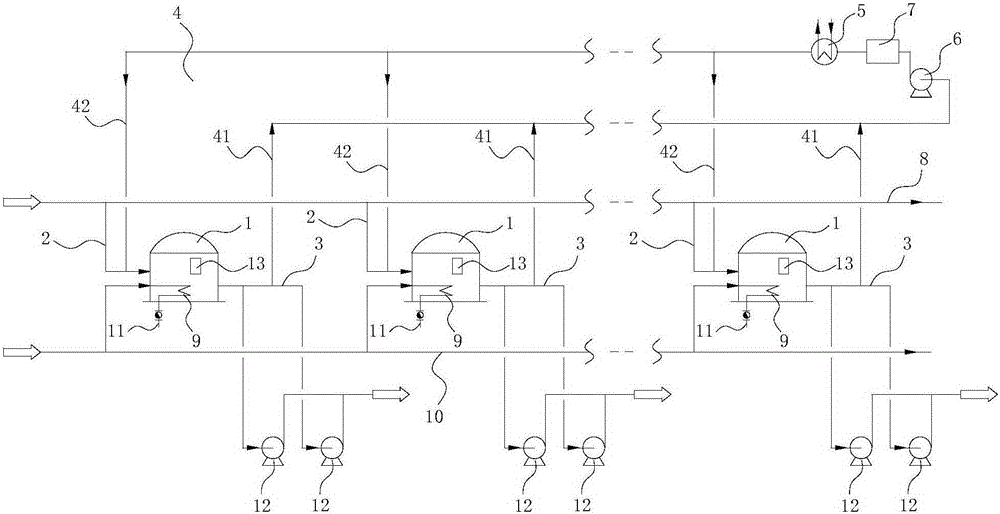

Tank field temperature maintaining and rising system

InactiveCN105329568AReduce energy consumption and production costsSpeed up dehydration timeLarge containersTank wagonsEngineeringEnergy consumption

The invention discloses a tank field temperature maintaining and rising system which comprises at least one storage tank, wherein the storage tank is connected with a material inlet pipeline and a material outlet pipeline respectively; a temperature maintaining pipeline is connected onto the material outlet pipeline; a heat exchanger is connected onto the temperature maintaining pipeline; part of material flows into the temperature maintaining pipeline via the material outlet pipeline and then flows into the material outlet pipeline via the temperature maintaining pipeline after heat exchange and temperature rise by the heat exchanger. According to the invention, the temperature maintaining pipeline and the heat exchanger arranged outside the storage tank can heat part of the material and mixes part of the material with the unheated material in the storage tank to further realize temperature maintenance and rise of the material in the storage tank and replace the original heating and temperature maintenance manner through steam; in addition, hot water (technological waste heat) is adopted to maintain the temperature of the storage tank and heat the storage tank, so that the steam use level is decreased, and the production cost and energy consumption are reduced; through filling a demulsifier, the material dehydration time is shortened, and the dehydration effect is improved; the heating manner outside the storage tank is adopted to reduce the maintenance cost when the existing heating coil in the storage tank leaks.

Owner:GUANGZHOU YOUHUA PROCESS TECH

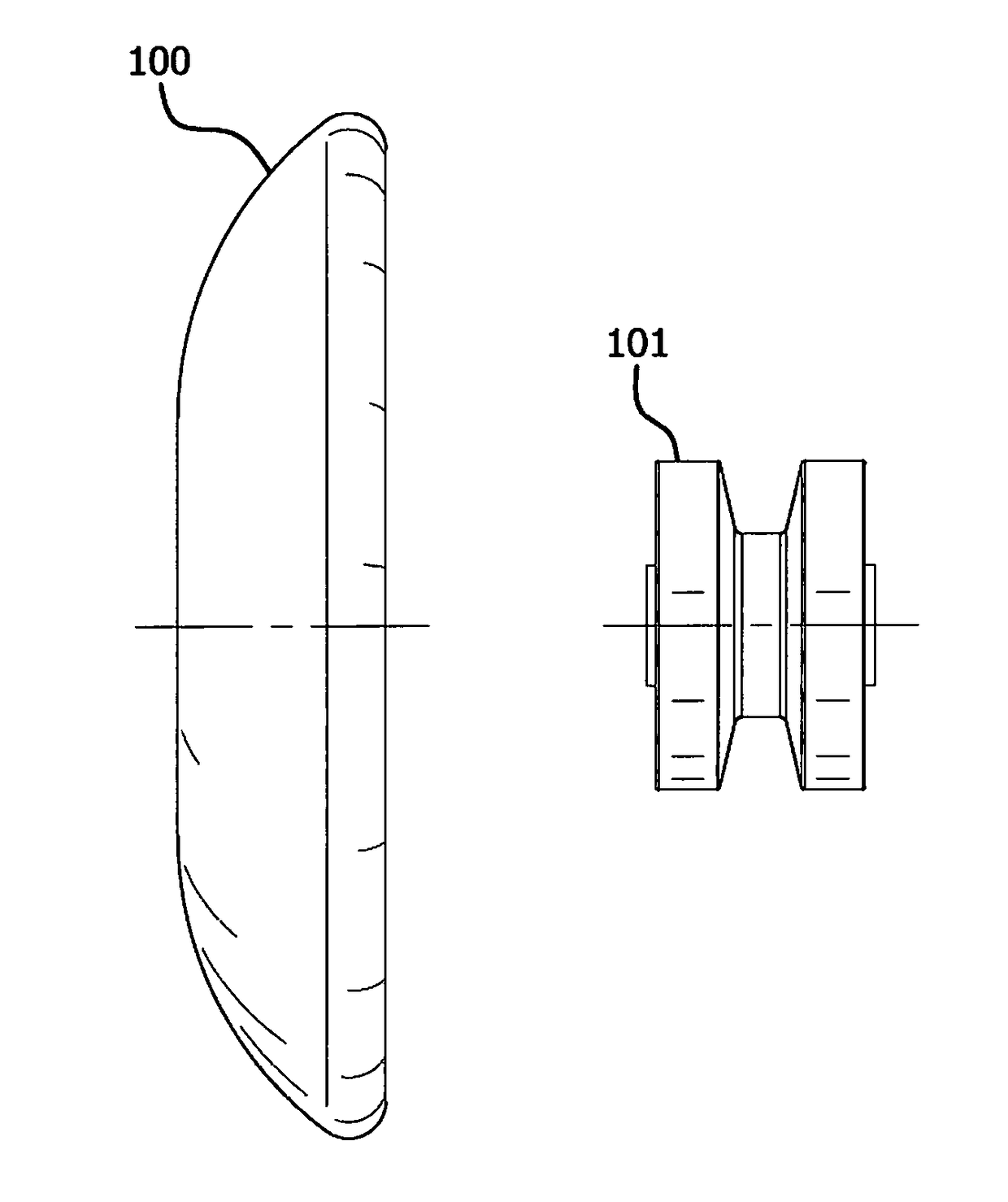

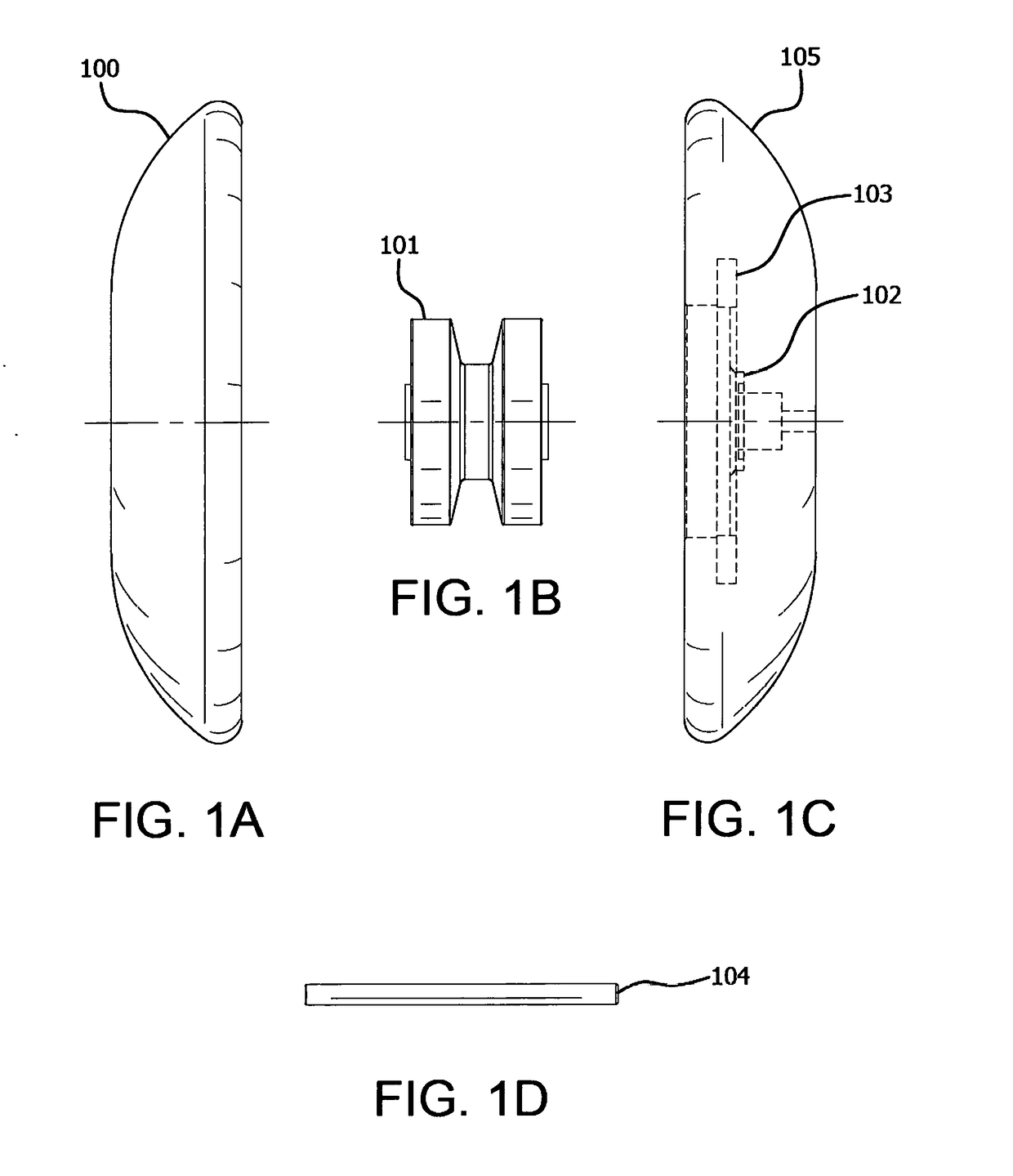

Yo-yo having a magnetically supported bearing yoke integrated with the axle

Owner:THEINER THOMAS FREDERICK

Improved Processing Method of Vegetable Insulating Oil

ActiveCN104987949BShorten the timeImprove processing efficiencyFatty-oils/fats refiningVacuum mixingImpurity

Owner:GUANGZHOU POWER SUPPLY CO LTD +1

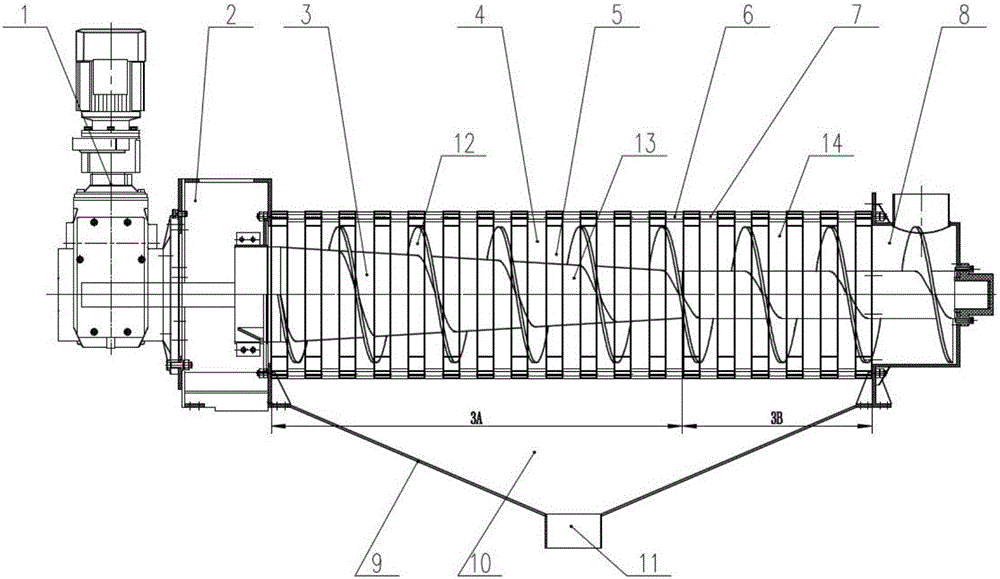

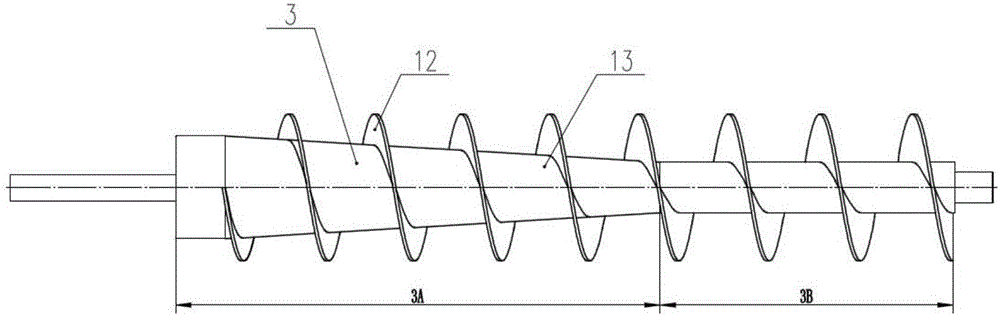

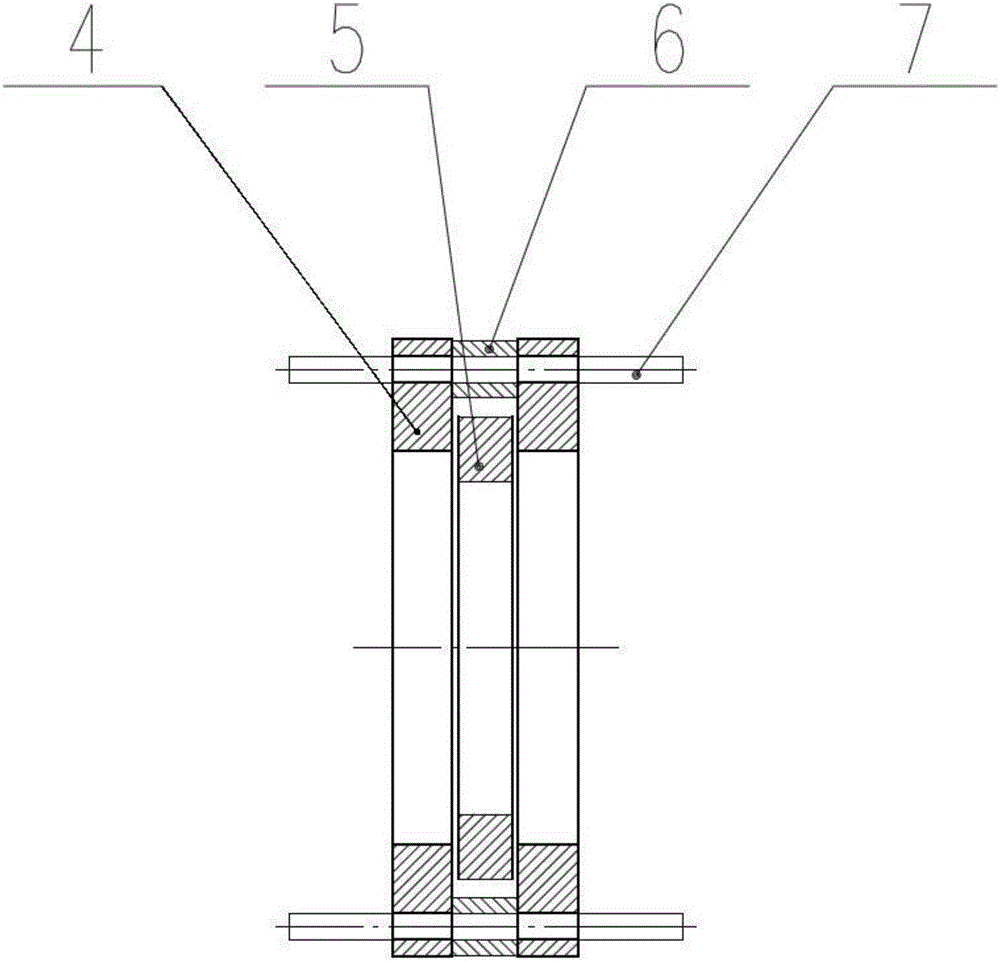

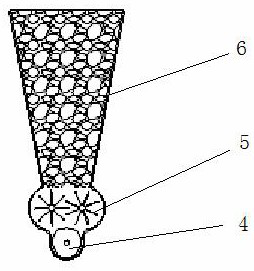

Pectin dedicated volute sludge dehydrator and screw shaft thereof

InactiveCN105712608ALong dehydration residence timeReduce moisture contentSludge treatment by de-watering/drying/thickeningWaste water treatment from food industryRetention timeSludge

The invention discloses a pectin dedicated volute sludge dehydrator and a screw shaft thereof. A reducing variable pitch screw shaft is adopted, a pitch of a screw panel is gradually reduced along a sludge outlet tank; the diameter of the screw shaft is gradually increased along a sludge outlet tank direction from the 1 / 3 position of the shaft length; and the length of the back 2 / 3 section of the screw shaft, namely the dehydration section, is increased by 10-15%. Aiming at the features that the pectin is high in sludge organic content, soft in mud, light in proportion, and hard to dehydrate, the pectin dedicated volute screw shaft is innovated and designed; and through special design of the screw shaft, the pressure in a dehydration cavity is higher, the compression ratio of a mud inlet end to a mud outlet end can achieve 3.5: 1, the dehydration time is longer, and the dehydration effect is better. The pectin dedicated volute sludge dehydrator has the characteristics of being larger in cavity pressure, hard to stick the shaft, longer in sludge dehydration retention time and high in dehydration efficiency; and the sludge dehydration effect can be effectively improved while guaranteeing that the processing efficiency of unit time cannot be reduced.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

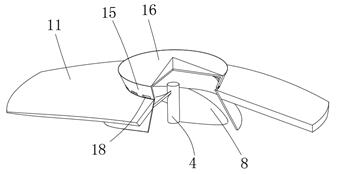

Taro powder making device

InactiveCN112544927ASave milling processReduce processSievingScreeningAgricultural engineeringStructural engineering

The invention belongs to the technical field of agricultural product processing, and particularly relates to a taro powder making device. In order to solve the problems in the prior art, the followingscheme is provided: the taro powder making device comprises an outer cylinder body, wherein a feeding hopper is arranged on the outer wall of the top of the outer cylinder body, and a feeding cover covers the outer wall of the top of the feeding hopper; a material distributing plate is fixedly connected to the inner wall of the side surface of the outer cylinder body through a connecting rod, anda conical shell is fixedly connected to the inner wall of the side surface of the material distributing plate; a material extruding shell is fixedly connected to the outer wall of the top of the material distributing plate, and material extruding openings which are annularly and uniformly distributed are formed in the bottom of the outer wall of the side surface of the material extruding shell; and a screen is fixedly connected to the inner wall of the bottom of the outer cylinder body. According to the taro powder making device disclosed by the invention, the working procedure of making taropowder can be omitted, the efficiency of making the taro powder is improved, the temperature in the outer cylinder body can be reduced, pasty taros are prevented from being adhered to the inner wallof the outer cylinder body and a cutter strip, the circumstance that the pasty taros on the screen are accumulated, and falling of the taro powder is influenced can be avoided, the dehydrating time ofthe pasty taros on the material distributing plate is prolonged, and the dehydrating efficiency is improved.

Owner:贲伟

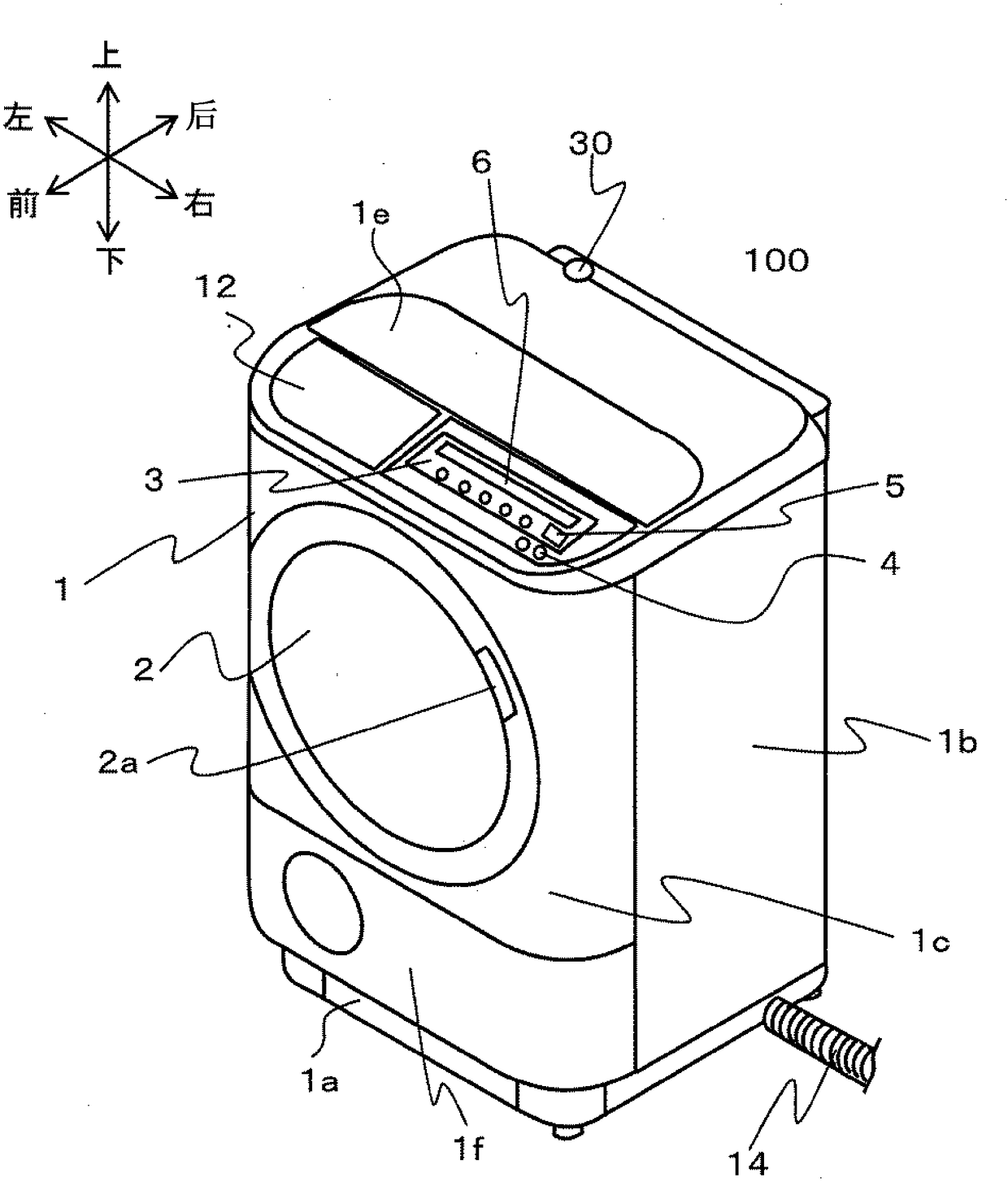

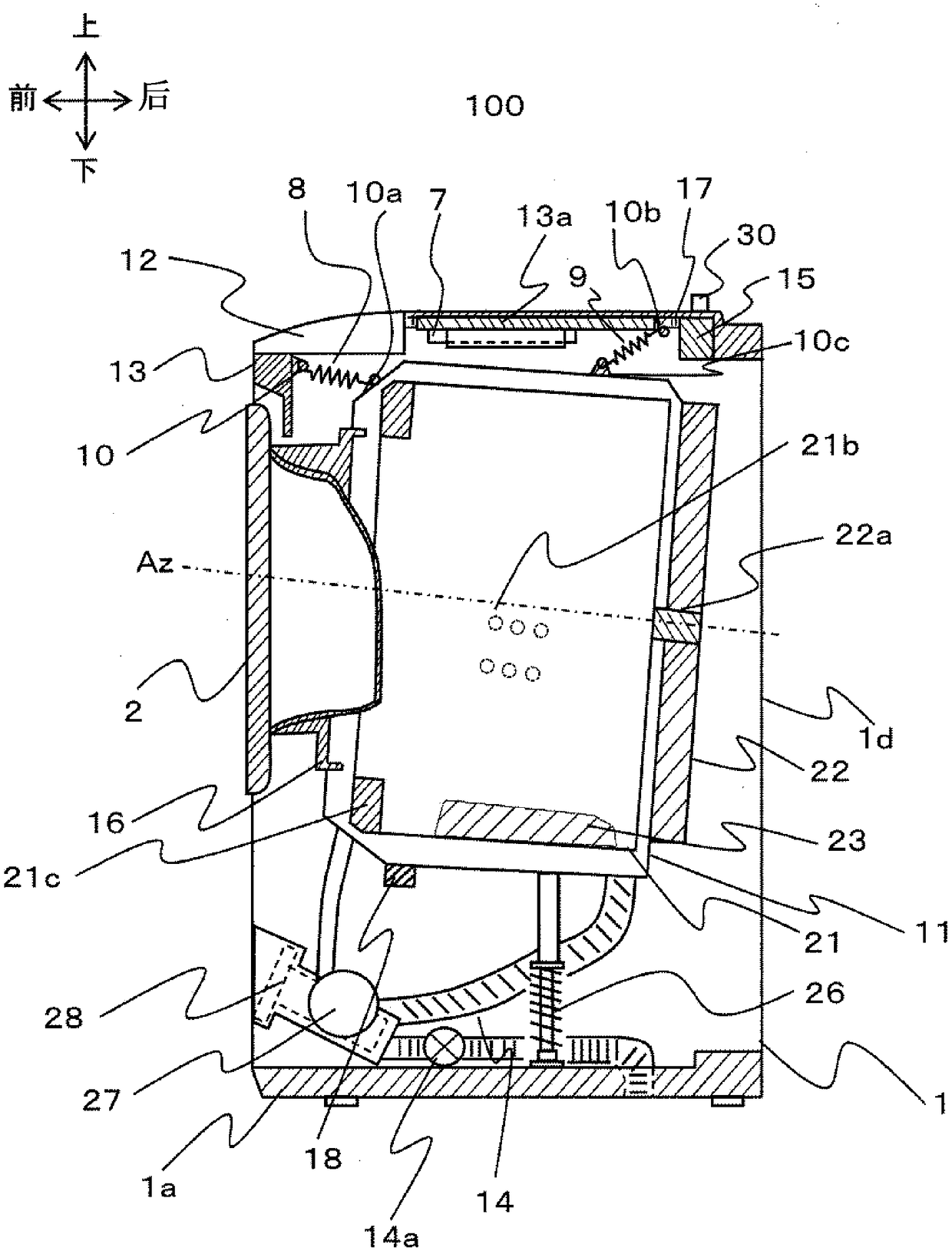

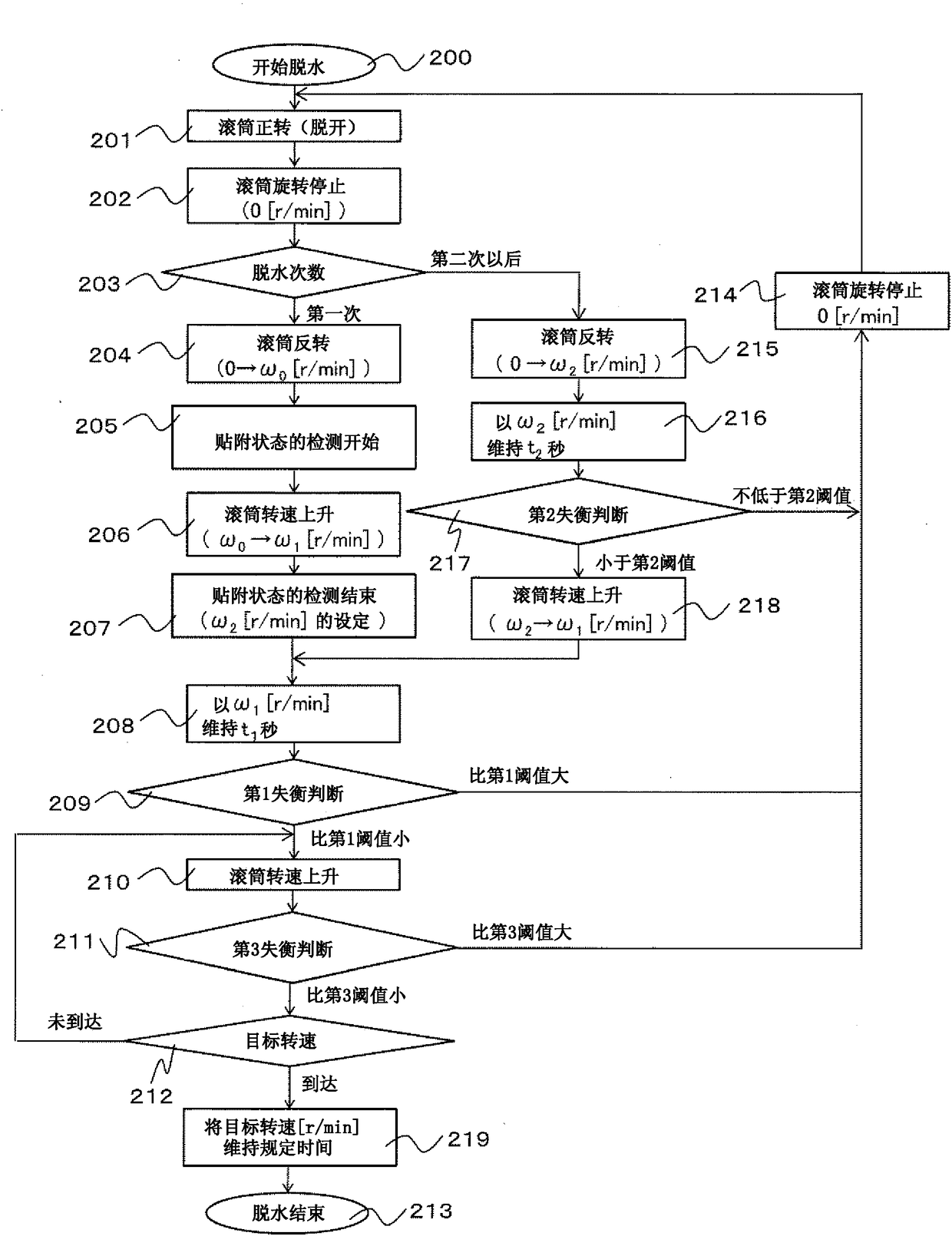

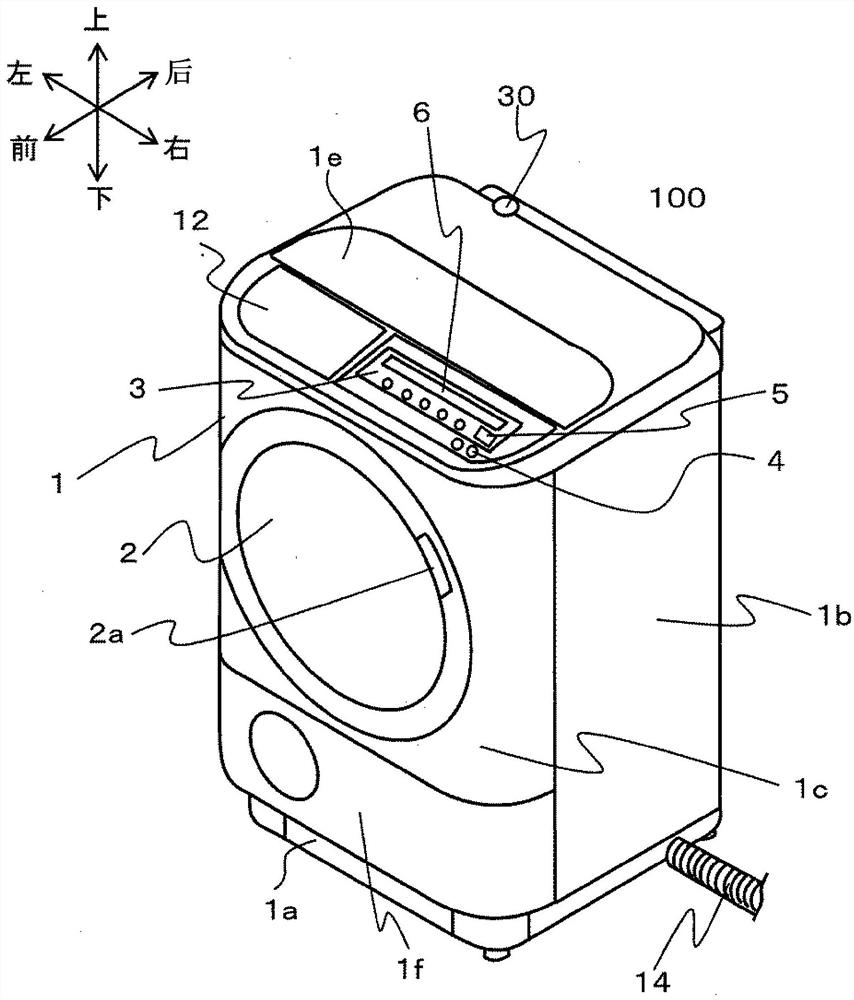

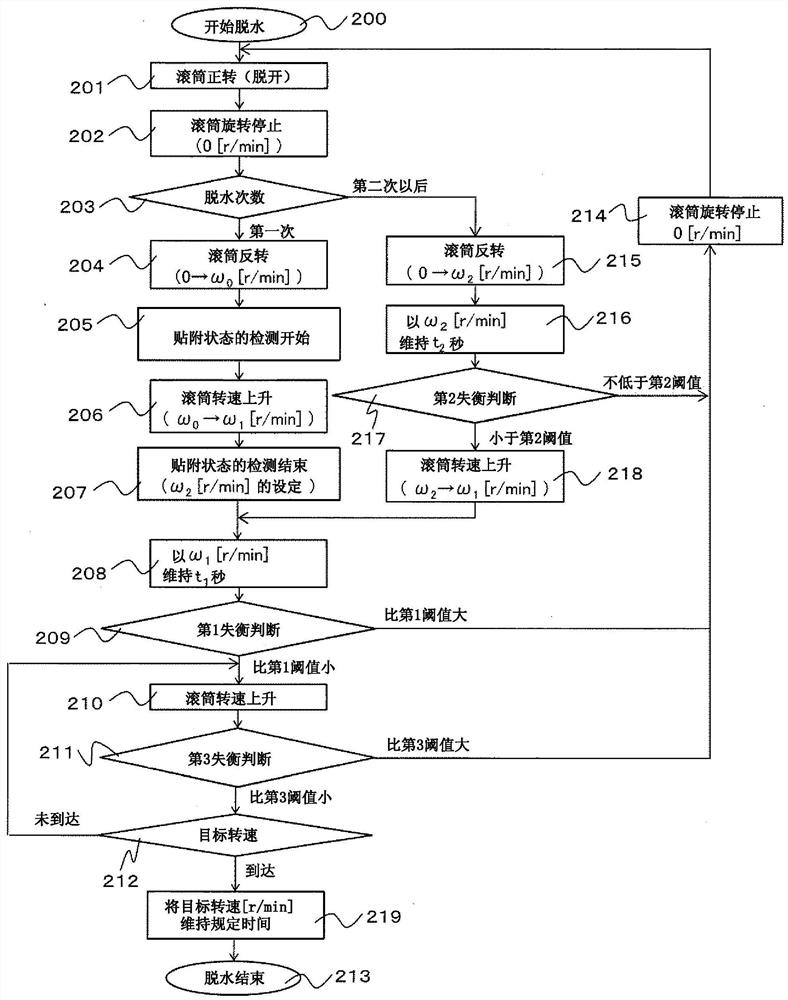

Drum type washing machine and drum type washing and drying machine

ActiveCN108729116AExtended spin timeIncrease power consumptionOther washing machinesControl devices for washing apparatusSpinsEngineering

By attaching the laundry to the unbalanced side in the low-speed rotation region of the spin-drying process, it is possible to shorten the correction time of the imbalance when large-sized clothes such as a carpet and a felt having different combinations are combined, and to provide a drum type washing machine and a drum type washing and drying machine that suppress the increase in the dehydrationtime and the amount of power consumption. The drum type washing machine comprises: a rotatable drum which is horizontally inclined or inclined in a manner that the depth side is downward; an outer tub which encloses the drum and is used for storing washing water; a casing which encloses the outer tub; a judging means and an imbalance determining means which judge the attaching state of the laundry in the rotatable drum ad the imbalance determination of the laundry in the first dehydrating operation. The first dehydrating operation is performed when the imbalance is greater than the thresholdof the imbalance determining means during the determination of the attachment state of the laundry. The rotation control of the dehydration operation after the second dehydration is started again, andthe rotation control of the second and subsequent dehydration operations is different from the dehydration operation.

Owner:HITACHI APPLIANCES INC

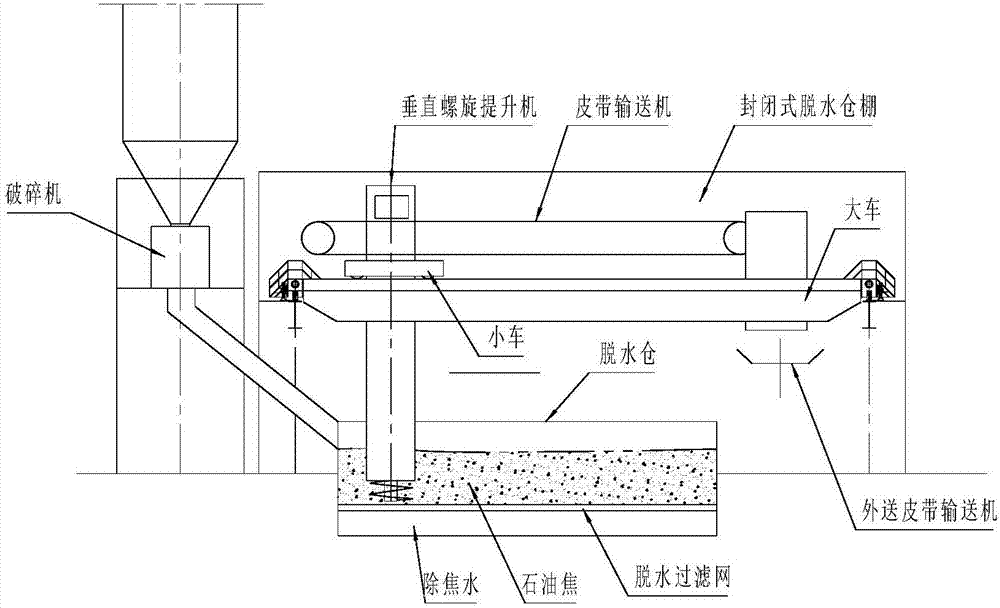

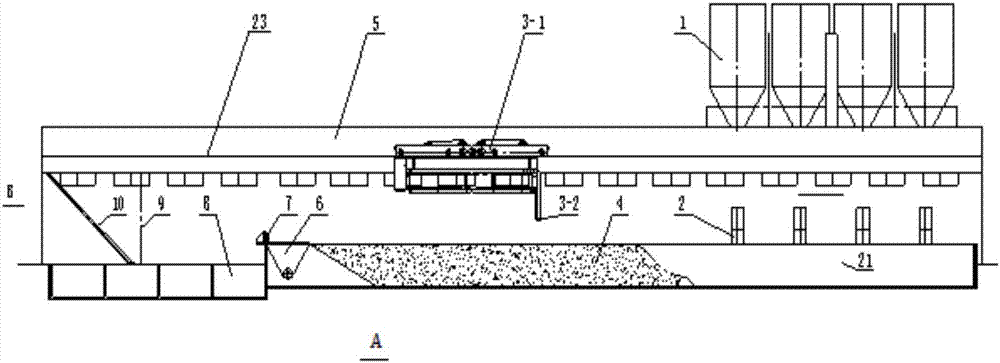

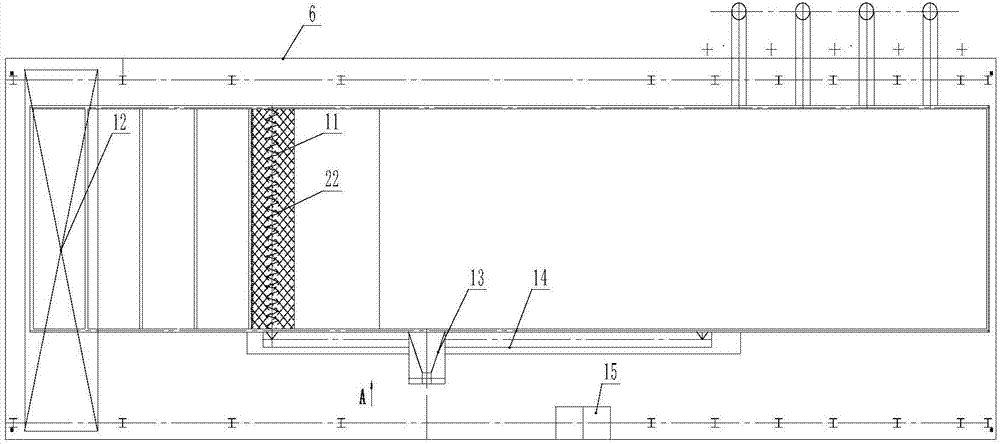

Closed petroleum coke dewatering-storage-transport facility

InactiveCN108003900AExtended spin timeEasy to handleCoking carbonaceous materialsFiltration circuitsTowerPetroleum

The invention relates to a closed petroleum coke dewatering-storage-transport facility. According to the technical scheme, the facility comprises coke towers, inclined chutes, a closed shed, a bridge-type material pushing crushing machine, a push plate, petroleum coke, a material bin, metal needles, a sedimentation pond, a crane track column, an inclined support, a spiral material pushing machine,a grabbing crane, a buffer hopper, a spiral drain pipe, an external-transport operation chamber, an inclined spiral elevator, a flat gate valve, a coke removal water inlet, a coke removal water outlet, a tail gas output port, a coke storage pond, a grid and a crane track. The problems are emphatically solved that when petroleum coke is prepared into coke, oil gas volatilization is large, harmfulgas pollutes the environment, coke powder is blown by wind and flies everywhere in the outdoor storage process of the petroleum coke, the water content of the petroleum coke cannot be guaranteed on rainy days, and the coke powder is scattered everywhere when the bridge-type grabbing crane loads and transports the coke powder during external transport.

Owner:樊东升

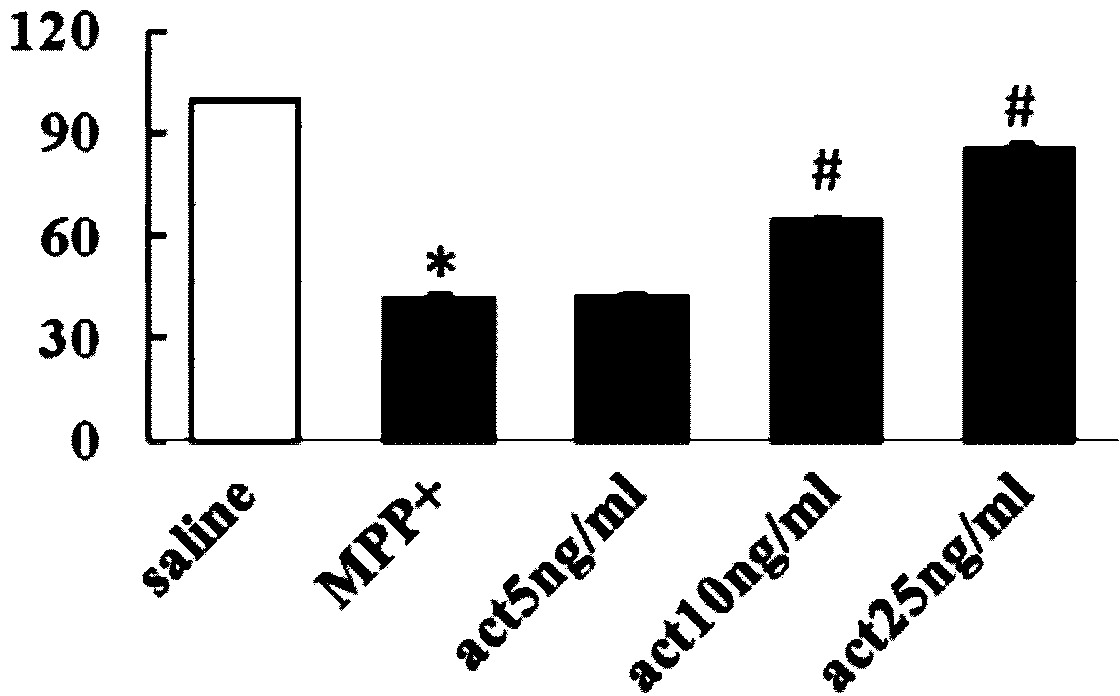

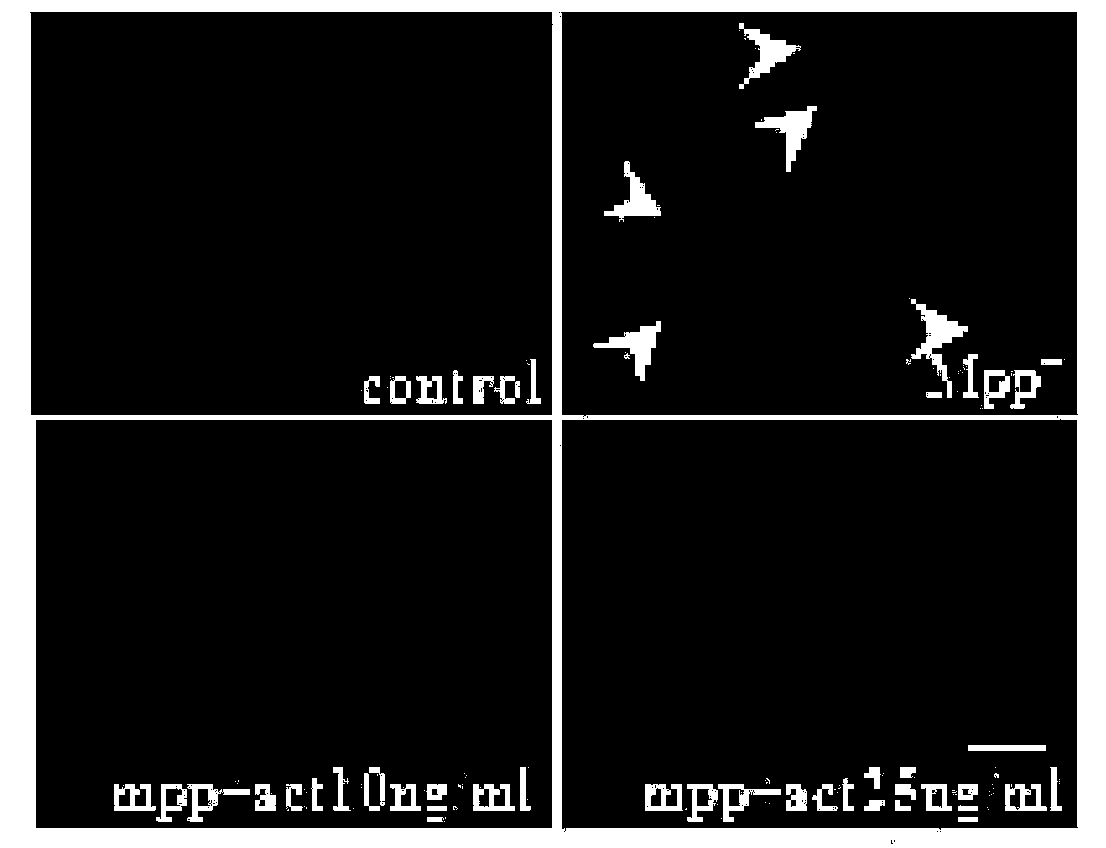

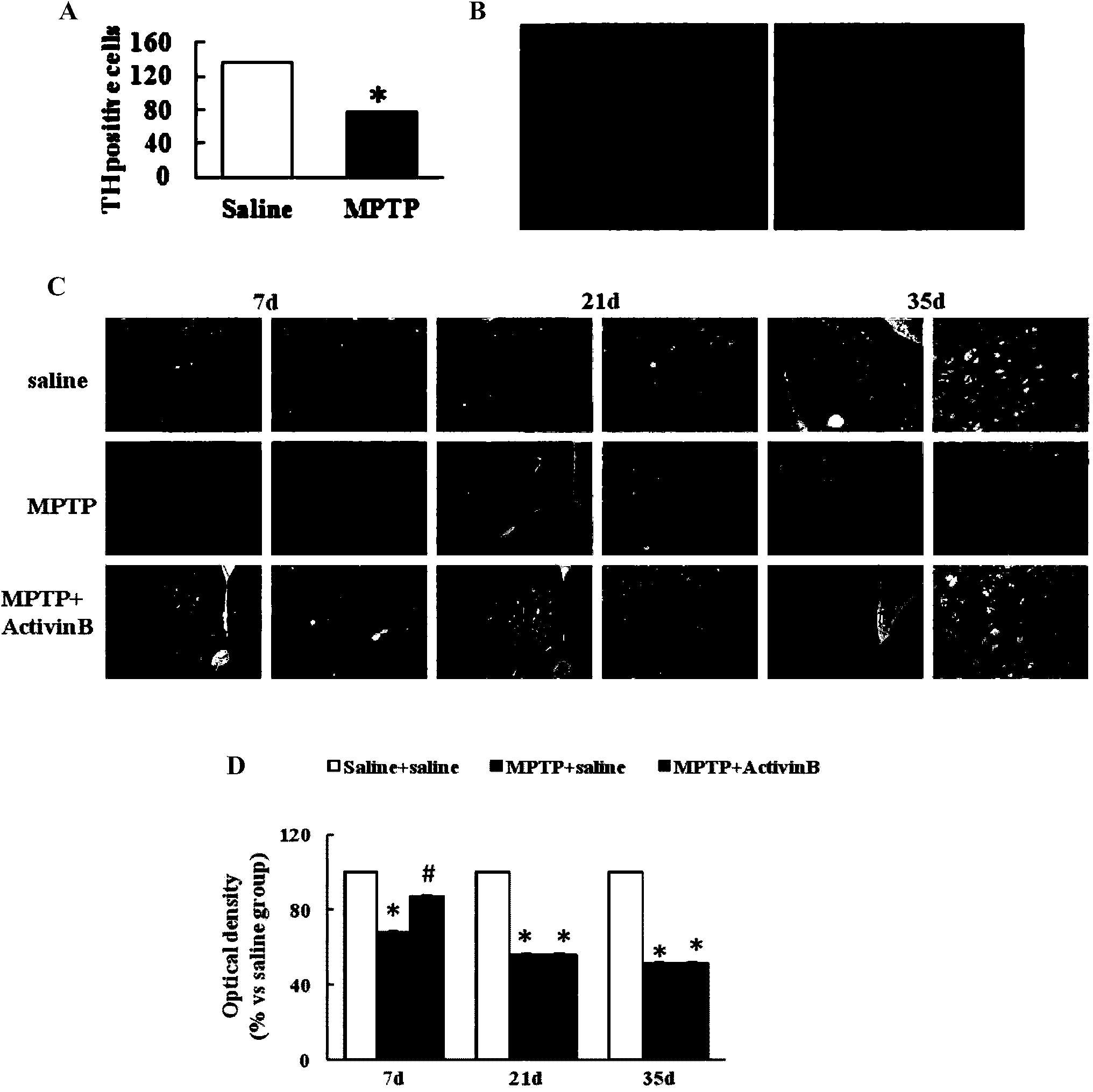

Application of Activin B in preparation of medicine for treating neurodegeneration diseases

InactiveCN104353060AReduce neuronal apoptosisIncrease nerve fiber densityNervous disorderPeptide/protein ingredientsSide effectNeurodegeneration

The invention discloses an application of Activin B in preparation of medicine for treating neurodegeneration diseases. In vivo and in vitro experimental research shows that Activin B can be used in treatment of the neurodegeneration diseases, can effectively reduce nerve cell apoptosis, increase TH immunoreactive nerve fiber density in a corpus striatum region, reduce the inflammatory response and remarkably increase the rotarod time of a mouse with the Parkinson's disease, the field movement distance and speed; and further, Activin B is basically free of toxic and side effects, is novel medicine which has development prospect and is used for treating the neurodegeneration diseases, and particularly is expected to be developed into novel medicine for treating Parkinson's disease.

Owner:SOUTHERN MEDICAL UNIVERSITY

Freeze preparation method of aloe powder

InactiveCN110731440AHygroscopicMoisturizingCosmetic preparationsSugar food ingredientsBiotechnologyFreeze-drying

The invention relates to the field of freeze preparation methods, in particular to a freeze preparation method of aloe powder. The disclosed freeze preparation method of aloe powder includes the following steps: step 1, preparing an aloe extract from fresh aloe by using an enzyme-assisted method, step 2, performing treatment on the aloe extract and a neodiosmin system through a molecular embeddingmethod so as to prepare a bitter-removed aloe solution, and step 3, performing drying dehydration on the bitter-removed aloe solution by using a heat pump method, and then performing drying dehydration by using a freeze method. The problems that in the prior art, after aloe powder is prepared through freeze drying of aloe, the aloe powder is brewed so as to obtain a drink, but the produced aloe powder has bad taste due to bitter taste and fishy smell are solved. The aloe powder prepared by using the preparation method has no bitter taste and no fishy smell, has good taste and easy solubilityin water, and has guide significance to preparation of aloe drinks and beauty products.

Owner:HAINAN ZHONGCHEN BIOLOGIC ENG

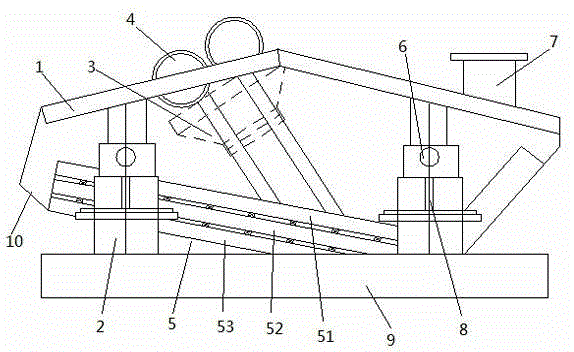

Vibrating-dewatering screen

InactiveCN106178657AThoroughly dehydratedExtended spin timeMoving filtering element filtersEngineeringMechanical engineering

The invention discloses a vibrating-dewatering screen. The vibrating-dewatering screen comprises a fixing base and a machine frame, wherein a spring shock absorption device is arranged on the fixing base; the machine frame is mounted on the fixing base through the spring shock absorption device; the spring shock absorption device comprises a shock absorption support and springs, wherein the springs are mounted on the shock absorption support, and a discharge opening is formed in the front end of the machine frame; a feeding hopper is arranged at the upper part of the rear section of the machine frame; and a liner is mounted at the top of the machine frame through a fixing shaft. Two vibrating motors arranged on the machine frame drive a screen mesh group to vibrate horizontally and vertically so as to dehydrate materials, the screen mesh group consists of three layers of screen clothes, meshes of the first screen cloth on the top layer are the biggest, materials of different specifications are vibrated to dehydrate on the different screen clothes, so that working procedures for subsequent working namely screening the materials are simplified, the processing time is shortened, and the production efficiency is improved. The screen mesh groups are obliquely placed, so that the dehydration time of the materials is prolonged, and more thorough dehydration is guaranteed.

Owner:LAIAN COUNTY XINYUAN MECHANICAL & ELECTRICAL EQUIP

A kind of modified phenolic resin and its preparation method and application

Owner:INST OF CHEM CHINESE ACAD OF SCI

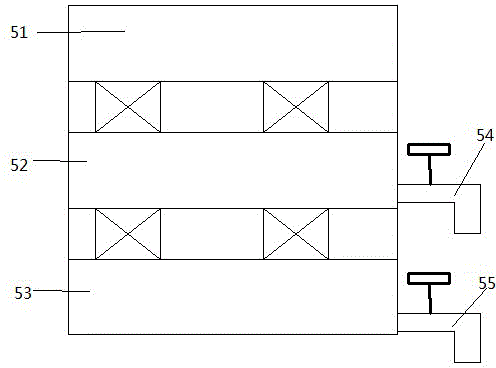

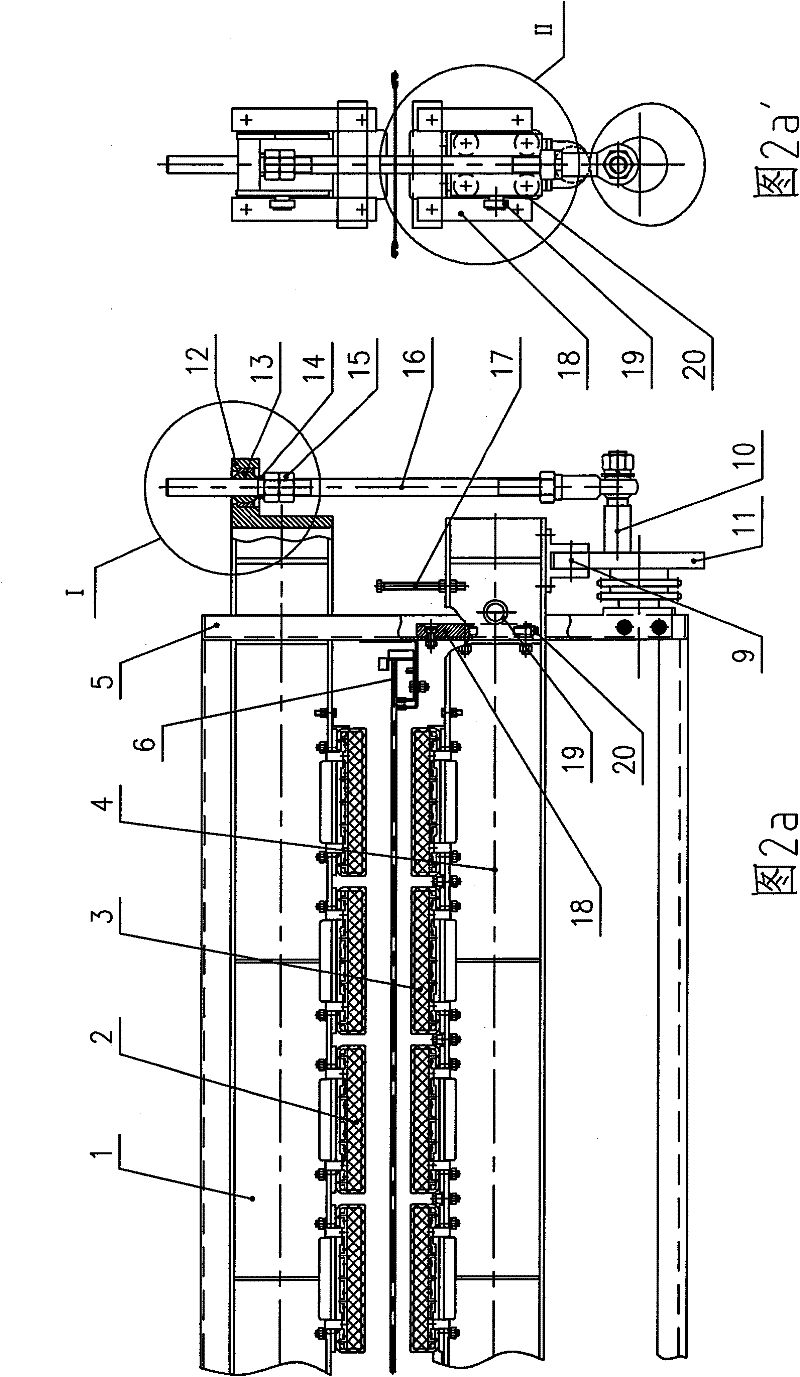

Deadweight flattening-type dehydrator for dehydration section of laver one-step processing unit

InactiveCN101715803BReduce resistance to movementShorten drying timeFruits/vegetable preservation by dehydrationFood treatmentEngineeringDehydration

The invention provides a deadweight flattening-type dehydrator which comprises an upper dehydration beam, a lower dehydration beam and a transmission mechanism, wherein the transmission mechanism is used for driving the upper dehydration beam and the lower dehydration beam to move in the same direction or opposite directions; the transmission mechanism comprises a post rod; the dehydrator also comprises a bracket, a locking regulating component and an upper dehydration beam spacing component; the bracket is arranged on the end part of the upper dehydration beam and provided with a through hole; the first end of the post rod pass through the through hole of the bracket and extends and can move in the through hole of the bracket within a certain range; and the locking regulating component is installed on the post rod. The deadweight flattening-type dehydrator can prolong the dehydration time, remove the water in the process of making vegetable cakes to the maximum and shorten the dryingtime of the vegetable cakes, thereby realizing the technical effect of energy conservation and consumption reduction.

Owner:LIANYUNGANG FUAN LAVER MACHINE

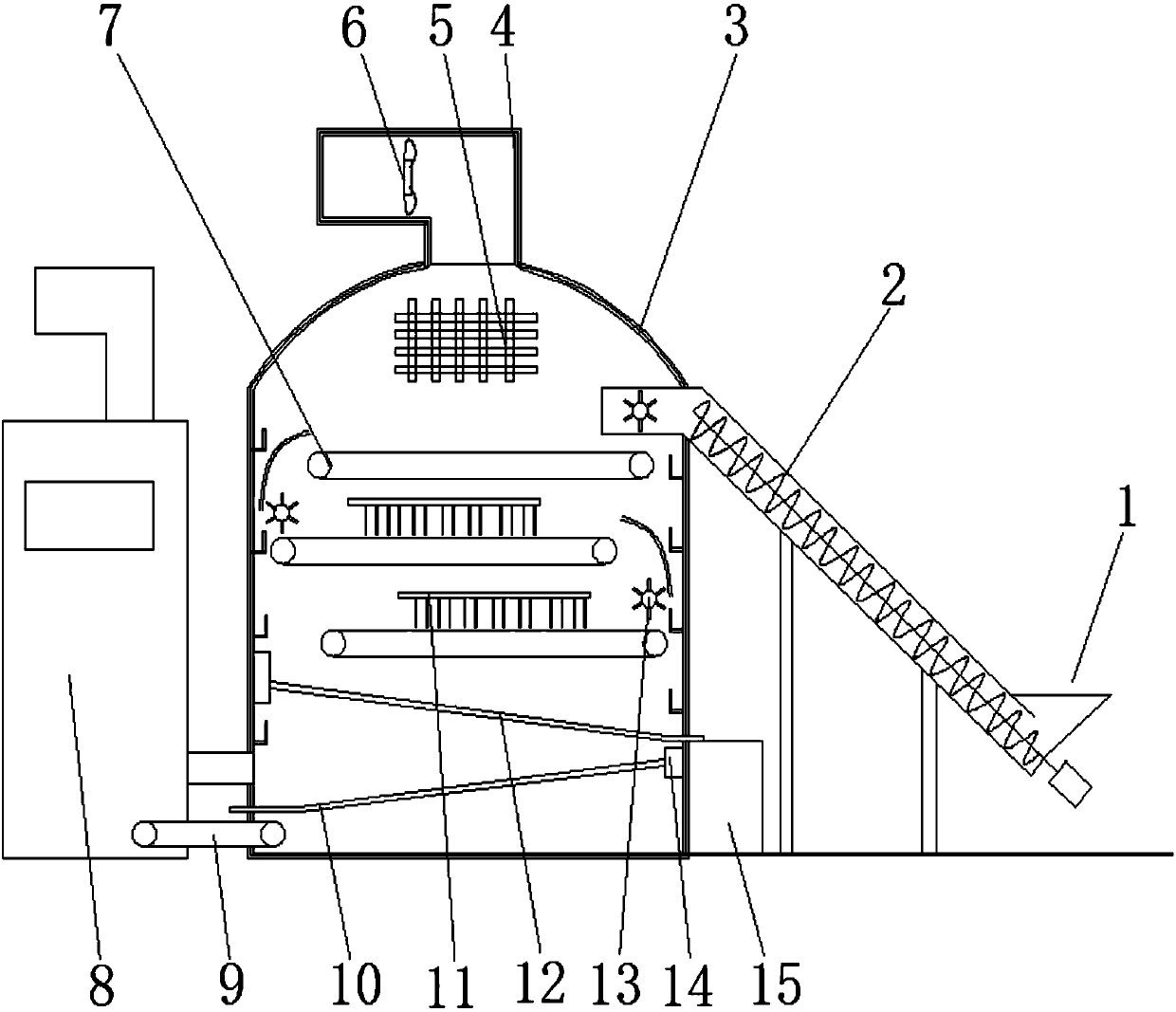

Intelligent tea dehydrating machine

InactiveCN109900098AExtended spin timeImprove qualitySievingPre-extraction tea treatmentSmall footprintDewatering

The invention discloses an intelligent tea dehydrating machine. The intelligent tea dehydrating machine comprises a dewatering chamber, wherein the top of the dewatering chamber is connected with an output port of a conveying pipeline, a rolling wheel is arranged in an output port of the conveying pipeline, and a feeding port is formed in the bottom of the conveying pipeline; a dewatering area composed of a plurality of conveying belts arranged in a staggered mode is arranged in the dewatering chamber, a dewatering frame is arranged between every two adjacent conveying belts, and rolling wheels are arranged at the joints of the adjacent conveying belts; an inclined filtering net is arranged below the dewatering area, a collecting bucket is arranged at the lowest end of the filtering net, and a shaking device is connected to the highest end of the filtering net. The plurality of conveying belts can increase the dewatering time of the tea in the dewatering chamber, the occupied area of the dewatering chamber is small, the structure is compact, the cost is low, the tea can be dehydrated more thoroughly due to the intelligent operation and control, according to the intelligent tea dehydrating machine, the tea can be dehydrated intelligently within a short time, so that the damage to the tea is reduced.

Owner:吴西萍

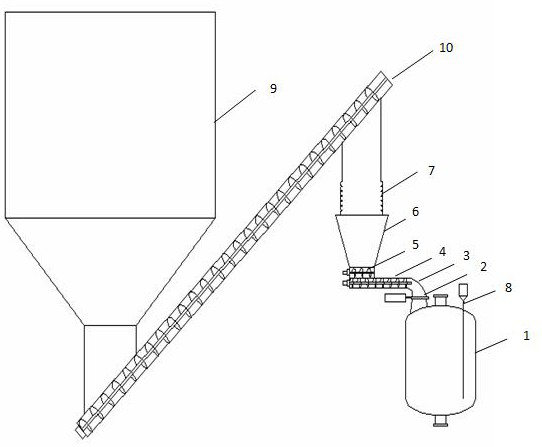

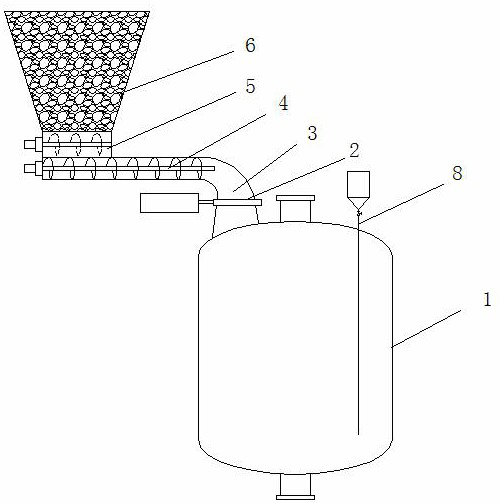

An industrial pure pu foam alcoholysis recovery method and special recovery feeding device

ActiveCN109320764BLow hydroxyl valueMass ratio is stablePlastic recyclingChemical recyclingPolyolPtru catalyst

The invention discloses an industrial pure PU foam alcoholysis recovery method and a special recycling feeding device, which is characterized in that the recycling feeding device includes a reaction kettle, a pneumatic gate valve, a feeding variable diameter elbow, and a main feeding screw conveying Machine, auxiliary feeding double-screw feeding conveyor, feeding hopper, soft connection and catalyst, hexamethylenetetramine and hydrogen peroxide and other small material feeding devices; the alcoholysis recovery method includes feeding, alcoholysis and recovery steps; The invention has the advantages of fast feeding speed and accurate feeding, which ensures that the quality of the pure PU foam feed and the mass ratio of the added main recovery alcoholysis agent are stable, and ensures that the catalyst, hexamethylenetetramine and hydrogen peroxide can be added in time according to the process requirements. In the reaction system, the control indicators of each batch of recycled polyols are guaranteed to be stable. The pure PU foam feeding method is combined with the recycling process to produce recycled polyols with stable performance, moisture content, and relatively low VOC indicators.

Owner:YANTAI ZHENGHAI HIGH TECH

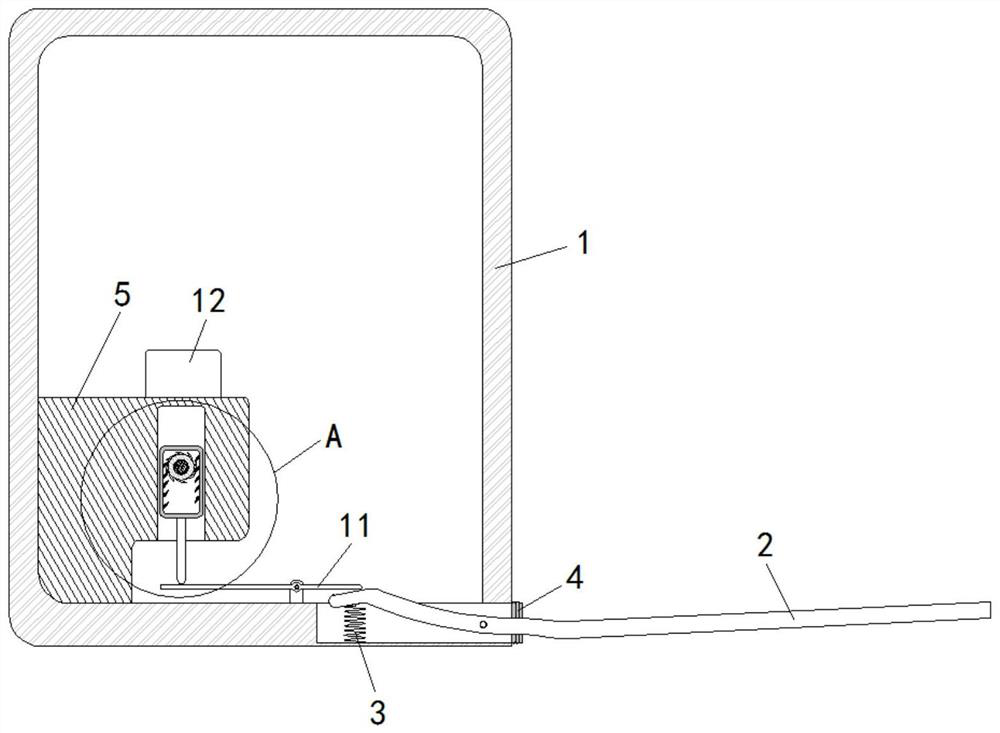

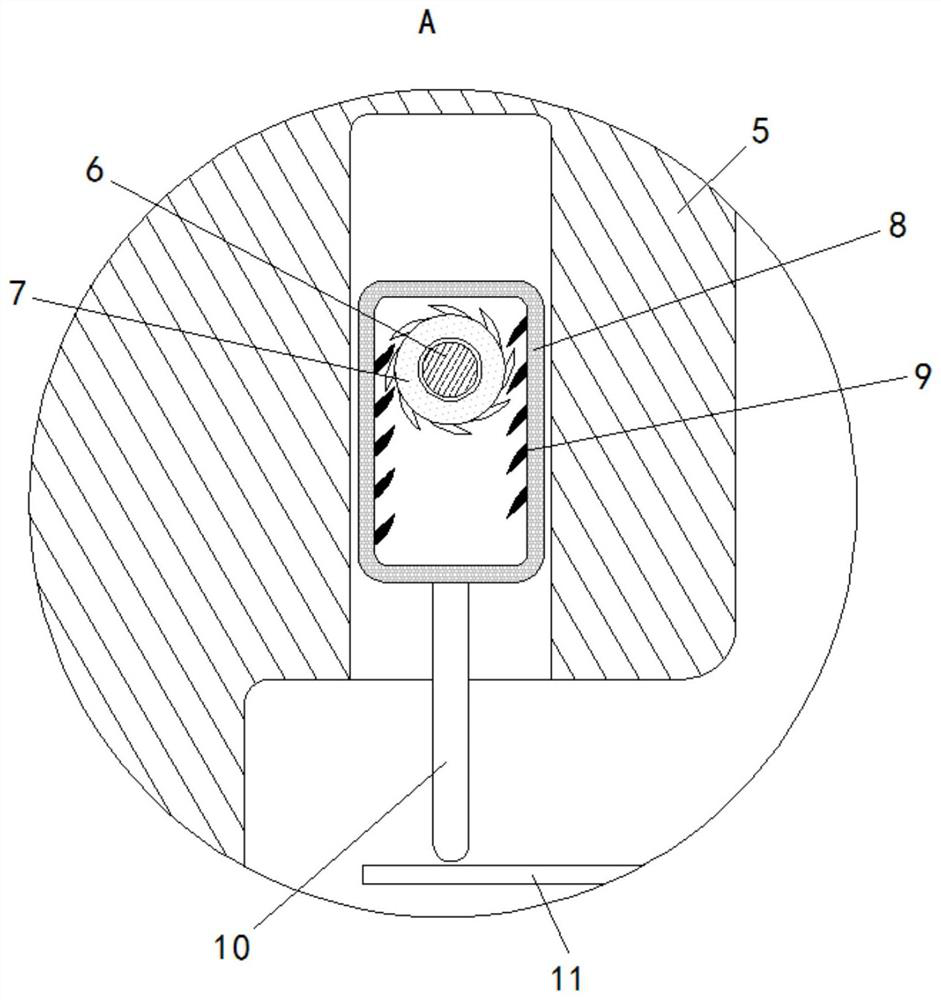

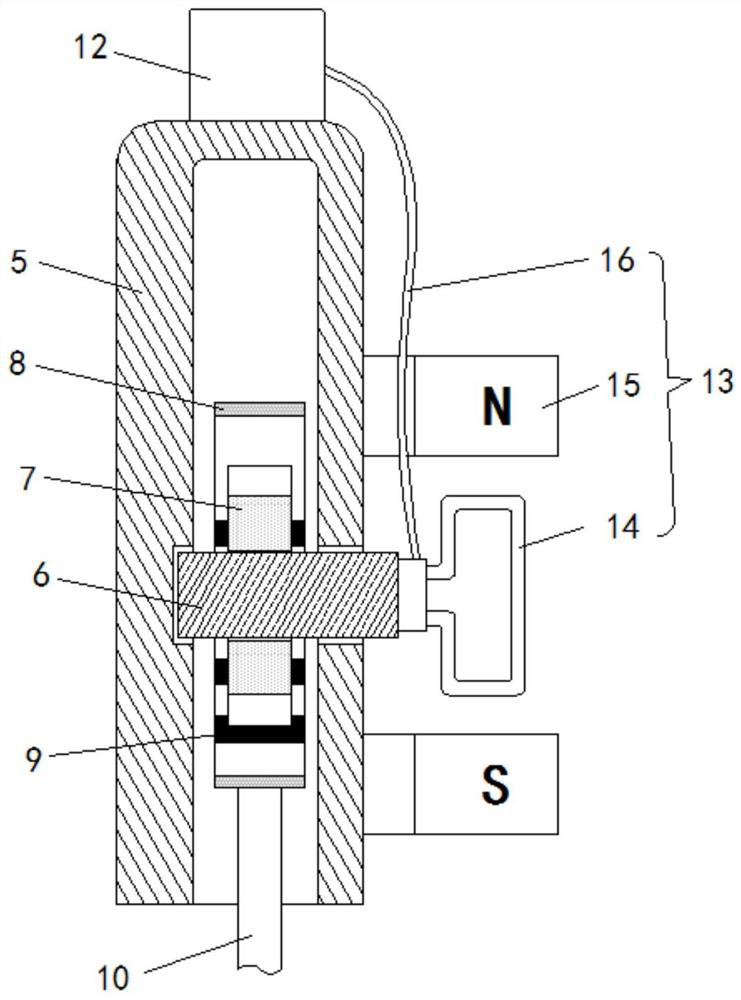

Encryption case standby device based on human body activity charging

InactiveCN111614204AGuaranteed storage capacityExtended spin timeBatteries circuit arrangementsElectric powerPower storageHuman body

The invention provides an encryption case standby device based on human body activity charging. The device comprises a box body, and a treading plate is rotationally connected to the inner bottom wallof the box body; the outer side of the rotating shaft is fixedly sleeved with a bevel gear, the inner wall of the lifting base is provided with a rack corresponding to the bevel gear, the top of thelifting base is fixedly connected with a vertical plate, a lever plate is movably installed in the box body and located between the treading plate and the vertical plate, and a charging assembly corresponding to the storage battery is fixedly installed on the back face of the rotating shaft. When a user works, the treading plate is continuously treaded, deflection of the treading plate is continuously generated, the treading plate drives the vertical plate and the lifting base to move up and down through the lever plate; the lifting base drives the bevel gear and the one-way rotation through the rack, and the rotating shaft drives the conductor to rotate, so that magnetic induction lines between the magnet assemblies are cut, an induced current is generated, the storage battery is charged,the power storage capacity of the storage battery can be effectively ensured, and the left side work of the case is further ensured.

Owner:杭州雅凇科技有限公司

Preparation method of 4,4'-biphenol diglycidyl ether

The invention discloses a preparation method of 4,4'-biphenol diglycidyl ether. In the preparation method provided by the invention, 4,4'-biphenol and epichlorohydrin are used as raw materials to be synthesized by a two-step method under the effect of a heterogeneous catalyst. The preparation method comprises the following steps: firstly, carrying out a ring-opening etherifying reaction, then carrying out a ring-closing reaction, and in the alkalizing process, separating out water generated in the reaction by a water-separating technique, so that the reaction shifts to the right at equilibrium, and various hydrolysis secondary reactions in the system can be controlled. The product obtained by the technique has high epoxide equivalent and high yield, the technique has simple reaction stepsand is convenient for posttreatment, and experimental results show that the epoxide number is 0.65-0.67, and the melting range is 159.1-160.4 DEG C.

Owner:兰州精细化工有限责任公司

Front-loading washing machines and front-loading washer-dryers

ActiveCN108729116BExtended spin timeShort correction timeOther washing machinesControl devices for washing apparatusLaundry washing machineProcess engineering

Owner:HITACHI GLOBAL LIFE SOLUTIONS INC

Melt/solid state polycondensation preparation method for polylactic acid

The invention relates to a melt / solid state polycondensation preparation method for polylactic acid, which mainly solves the problems of long reaction time, difficult continuous production or high cost in the prior art. The method comprises the following steps of: 1) performing a dehydration oligomerization reaction of lactic acid at the temperature of between 100 and 160 DEG C under the absolutepressure of between 6,000 and 25,000 Pa and under the action of a catalyst A for 0.5 to 5 hours first, and continuing the ehydration oligomerization reaction at the temperature of between of 120 and 180 DEG C under the absolute pressure of between 200 and 1,500 Pa and under the action of the catalyst A for 0.5 to 5 hours to generate a product I; 2) performing a melt polycondensation reaction of the product I at the reaction temperature of between 150 and 200 DEG C under the absolute pressure of between 30 and 600 Pa and under the action of a catalyst B for 0.5 to 15 hours to generate a polylactic acid prepolymer and lactide serving as a by-product, and refluxing the lactide to a reaction mixture at the reflux temperature of between 70 and 95 DEG C; 3) pelletizing the polylactic acid prepolymer obtained in the step 2), and crystallizing in an inertia airflow at the temperature of between 50 and 130 DEG C for 0.5 to 10 hours; and 4) performing a solid state polycondensation reaction of the polylactic acid prepolymer processed in the step 3) in the inertia airflow at the temperature of between 120 and 170 DEG C for 5 to 40 hours to obtain the polylactic acid. The technical scheme of the invention better solves the problem, and can be used for the industrial production of the polylactic acid.

Owner:CHINA PETROLEUM & CHEM CORP +2

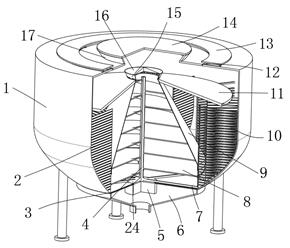

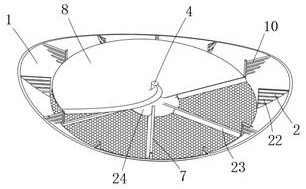

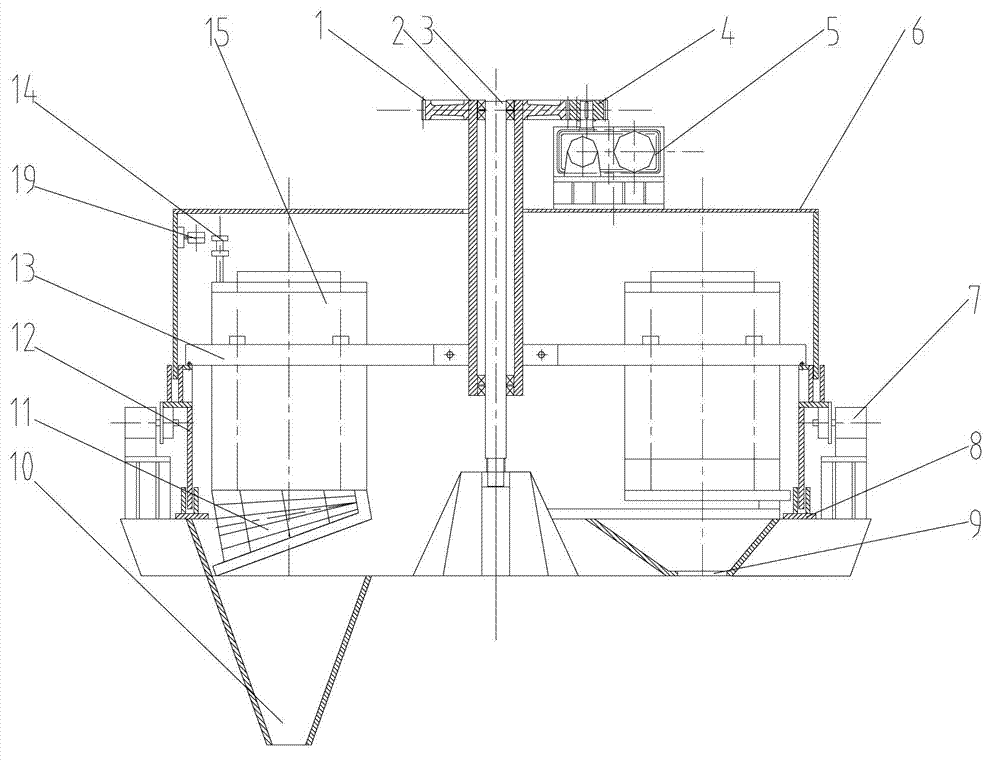

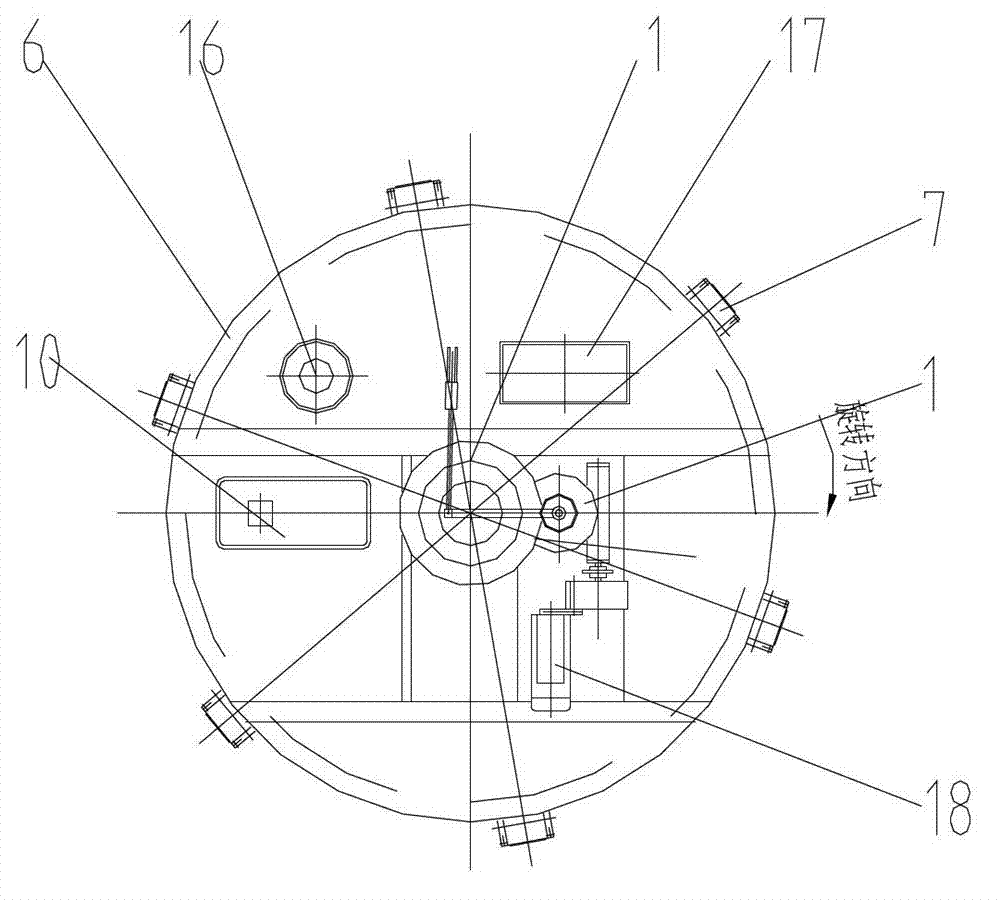

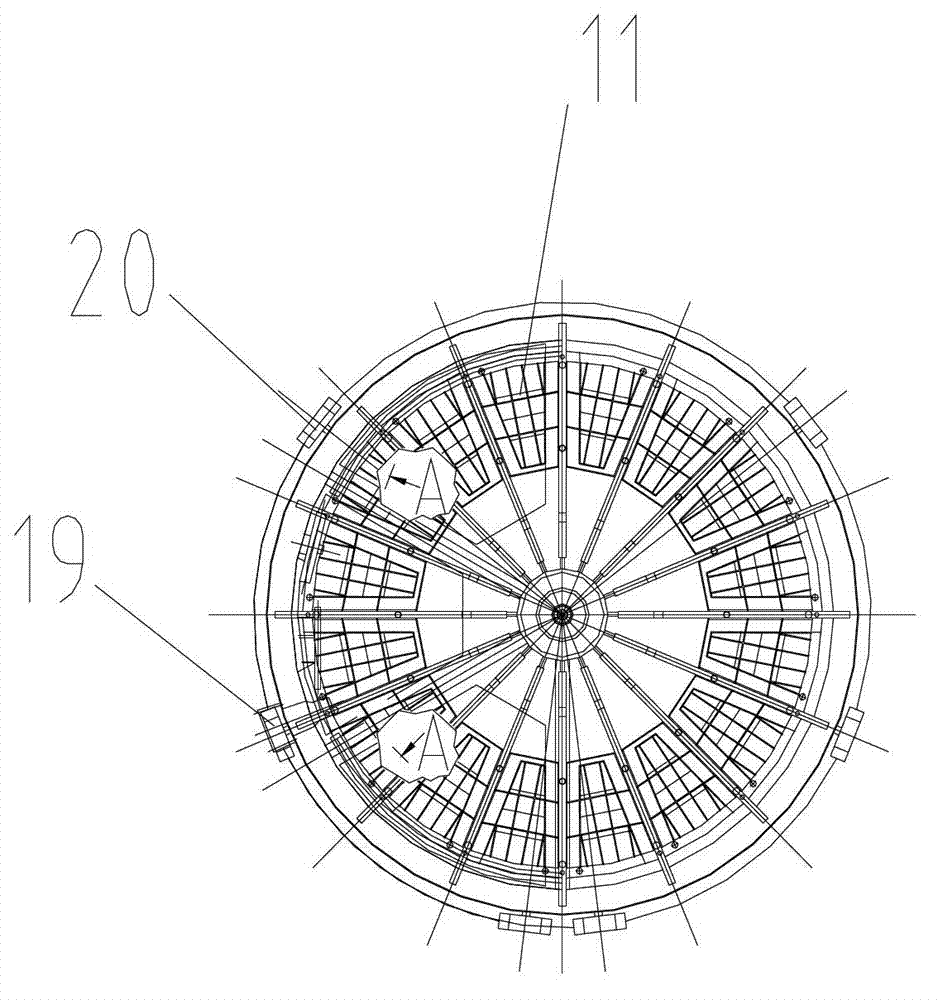

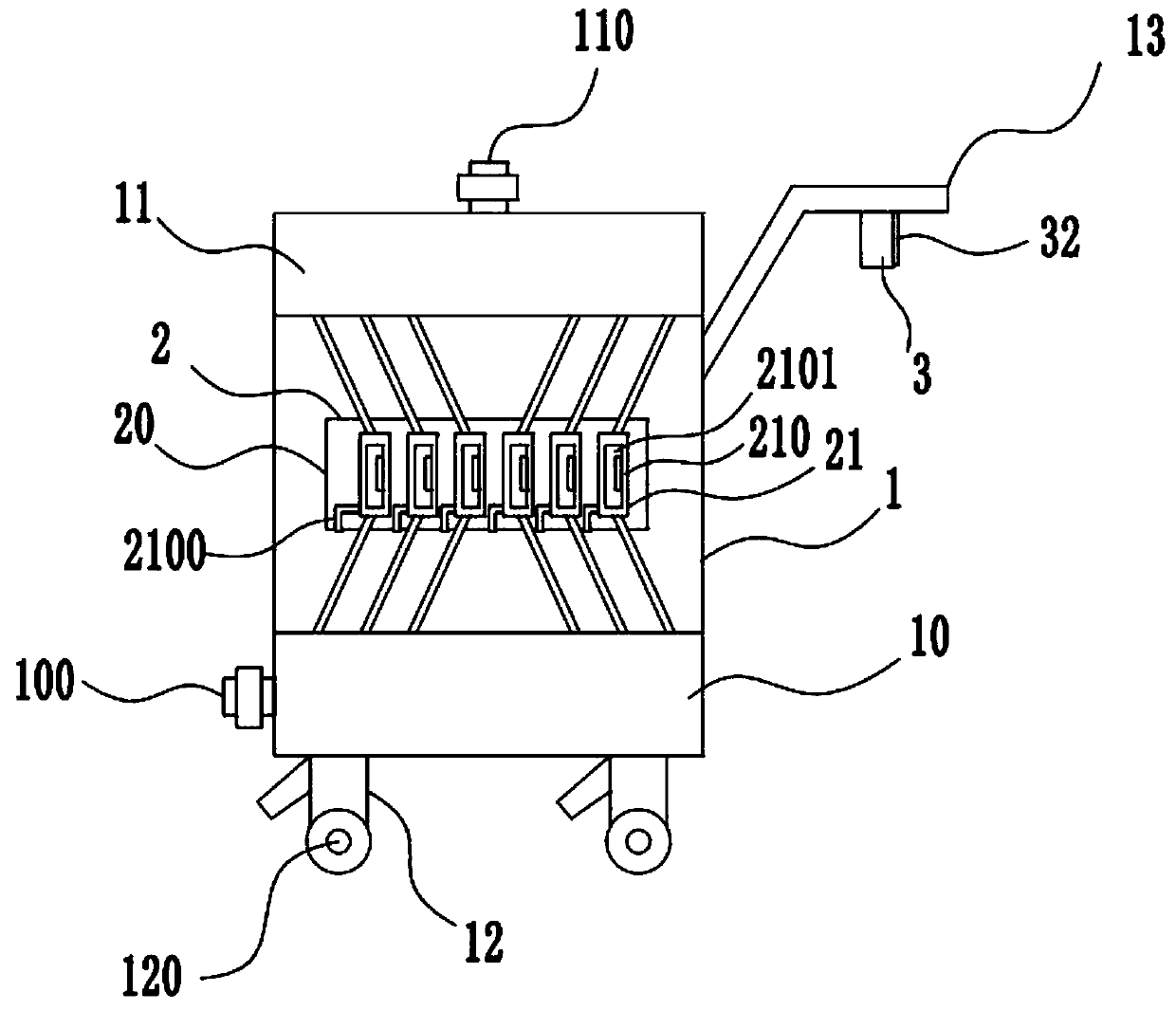

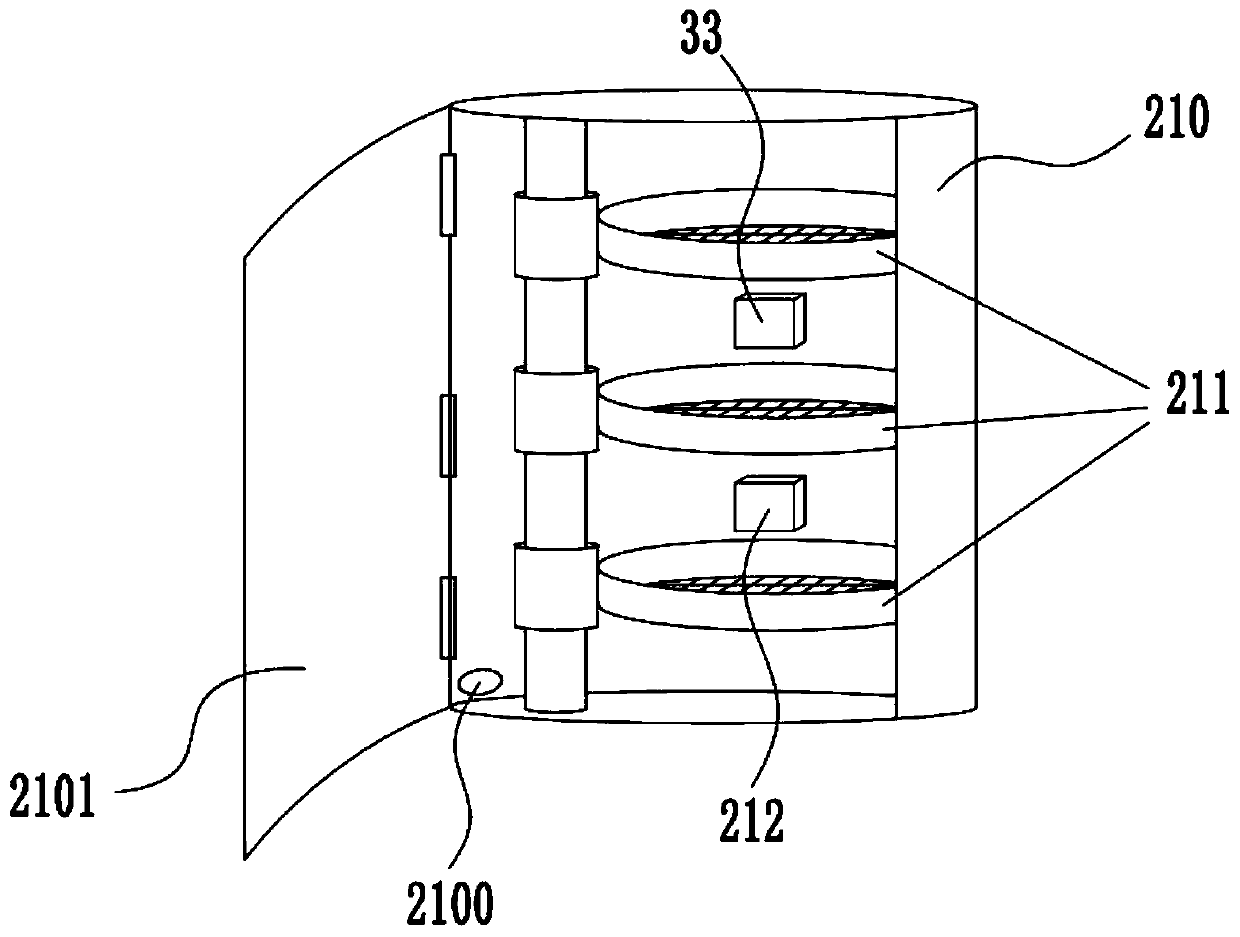

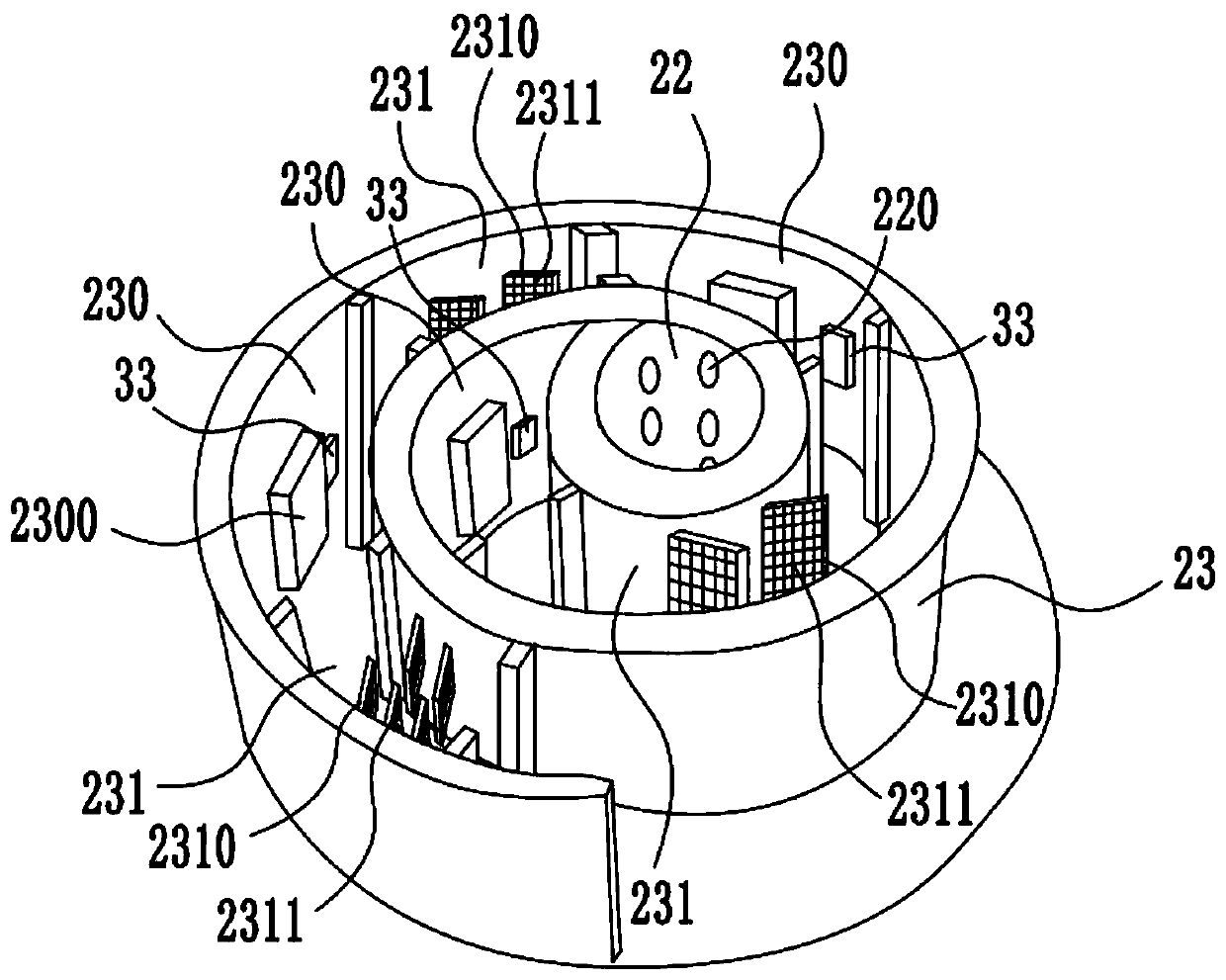

Disc dehydration unit

The invention discloses a disc dehydration unit which comprises a central column (3) and a rotating cylinder (12) which rotates around the central column (3), wherein a plurality of sieve hoppers (15) are arranged in the rotating cylinder (12) and a sieve plate (11) which can automatically close and open is connected to the bottom of each of the sieve hoppers (15). According to the disc dehydration unit, the design is reasonable, the structure is simple, the failure rate is low, the overhaul is convenient, and the service life is long. Water slag dehydration time is long, the moisture content of product slag is low, and the unit is applicable to various blast furnaces, no sewage is discharged, and the unit is environment-friendly.

Owner:BERIS ENG & RES CORP

Vertical dehydration device for biogas purification

InactiveCN110846095AExtended spin timeAvoid structureGaseous fuelsCondensation temperatureProcess engineering

The invention discloses a vertical dehydration device for biogas purification, and belongs to the technical field of biogas purification. The device mainly comprises a vertical frame body, biogas purification and dehydration elements, an intelligent control element and a power supply, the biogas purification and dehydration elements of three different structures are arranged to dehydrate biogas, each structure can dehydrate the biogas in multiple layers, the defects that a traditional biogas dehydration treatment device is single in structure, poor in dehydration effect and poor in practicability are overcome, the number of collisions between the biogas and the biogas purification and dehydration elements is increased, so that moisture in the biogas can be better and completely removed, and the dehydration effect is increased; by controlling the gradient of the condensation temperature of the biogas purification and dehydration elements to reduce, the moisture in the biogas can be completely condensed and desulfurized, so that the dehydration effect is ensured, and the use requirement is met; The vertical dehydration device has the advantages of good dehydration effect, high reliability and strong practicability, and is suitable for mass promotion.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Washing machine

ActiveCN102251367BReduce speedAvoid abnormal vibrationControl devices for washing apparatusWashing machine with receptaclesElectrical controlEngineering

The invention provides a washing machine, wherein a washing dehydration tank and a pulsator integrally formed in an outer groove is rotated at a high speed so as to perform the dehydration of laundry. Meanwhile, a mechanism is provided to restrain the vibration of the washing dehydration tank via the electrical control. When the outer groove is made of synthetic resin, the intrinsic value of the outer groove (inherent resonance point) varies with the temperature. When the temperature of the outer groove rises, the rotation speed of the washing dehydration tank is lowered so as to be away fromthe inherent value of the outer groove and prevent the abnormal vibration. In addition, the temperature of the outer groove can also be directly or indirectly determined. If the temperature rises, the dehydration speed is lowered. If the temperature decreases, the dehydration speed is increased. Meanwhile, by utilizing a washing machine with drying function, wherein the circulation of the washingdehydration tank is realized by the heating of a heater, if the temperature at the outlet of the heater rises, the dehydration speed is lowered. If the temperature decreases, the dehydration speed isimproved.

Owner:HAIER GRP CORP +1

Method of extracting krill oil by supercritical CO2

InactiveCN105199829AExtended spin timeHigh energy consumptionFatty-oils/fats productionChemistryHeating time

The invention provides a method of extracting krill oil by supercritical CO2. The method comprising the steps of carefully selecting 100 to 300 parts of high quality krill meat; putting the well-selected high quality drill meat into water for heating, wherein the heating temperature is 55 to 85 DEG C, and the heating time is 5 to 15min; performing drying treatment on the heated krill meat, the drying temperature is 55 to 75 DEG C, and the drying time is 10 to 20min; smashing the dried krill meat into krill powder; putting the smashed krill powder into an extraction kettle, taking the supercritical CO2 as an extraction agent and taking methyl alcohol and ethyl alcohol as an entrainer, performing extraction, and the krill oil is obtained after extracting for 1 to 3 hours; the reaction of the supercritical CO2 and the krill powder is more perfect, the adding proportion of the methyl alcohol and the ethyl alcohol of the entrainer is 2 to 1 and the extraction rate is increased, the solubility and the selectivity of the supercritical CO2 are improved, the work efficiency is improved, and the method of extracting krill oil by the supercritical CO2 is suitable for large-scale industrialized production, simple in extraction method and extraction process step, easy to operate, low in component, and the extracted krill oil can meet the requirements of manufacturers.

Owner:JIANGSU JIANGDAYUAN ECOLOGICAL BIOLOGICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com