Preparation method of 4,4'-biphenol diglycidyl ether

A technology of diglycidyl ether and biphenol, which is applied in 4 fields, can solve the problems of cumbersome processing, and achieve the effects of simple reaction steps, avoiding growth, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

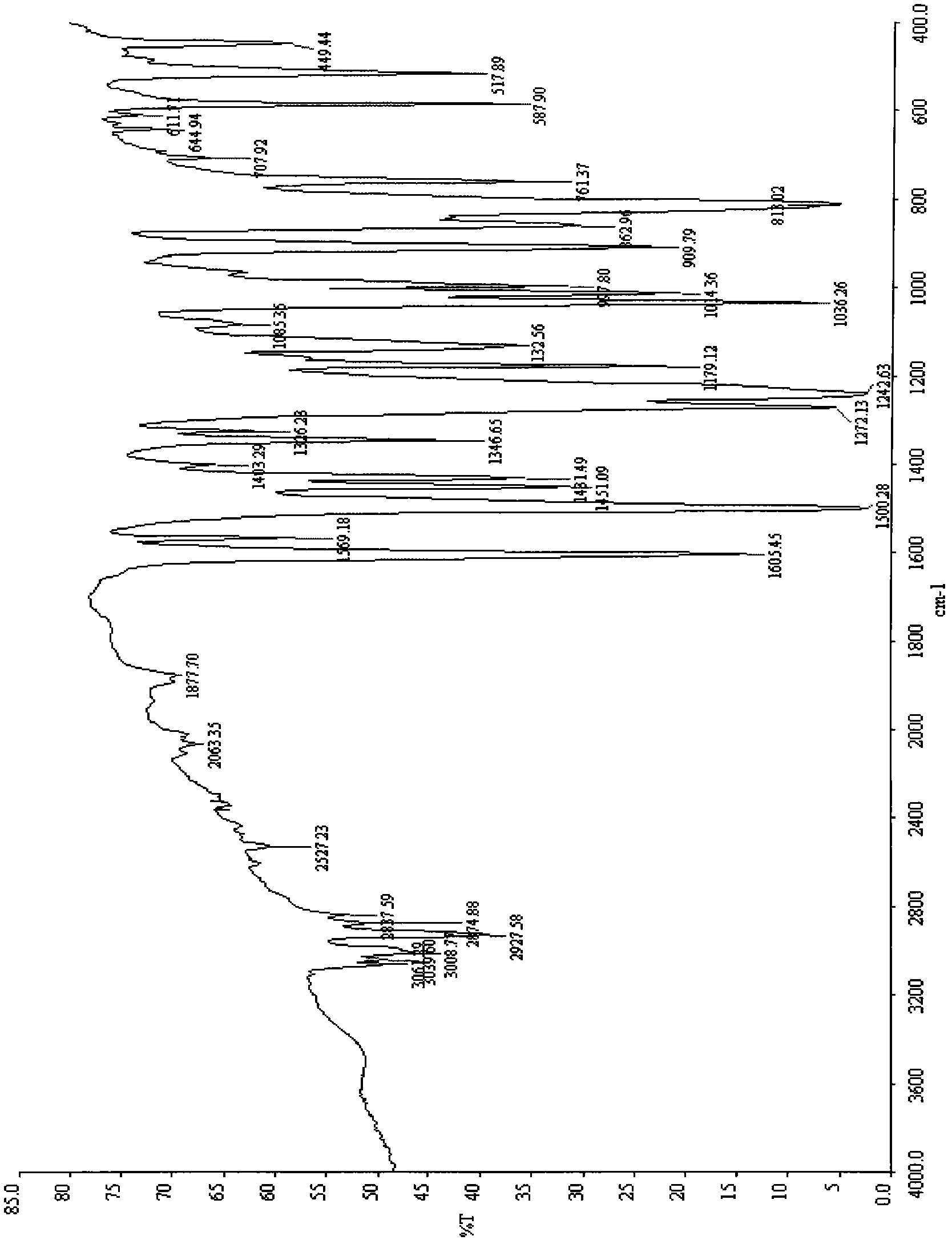

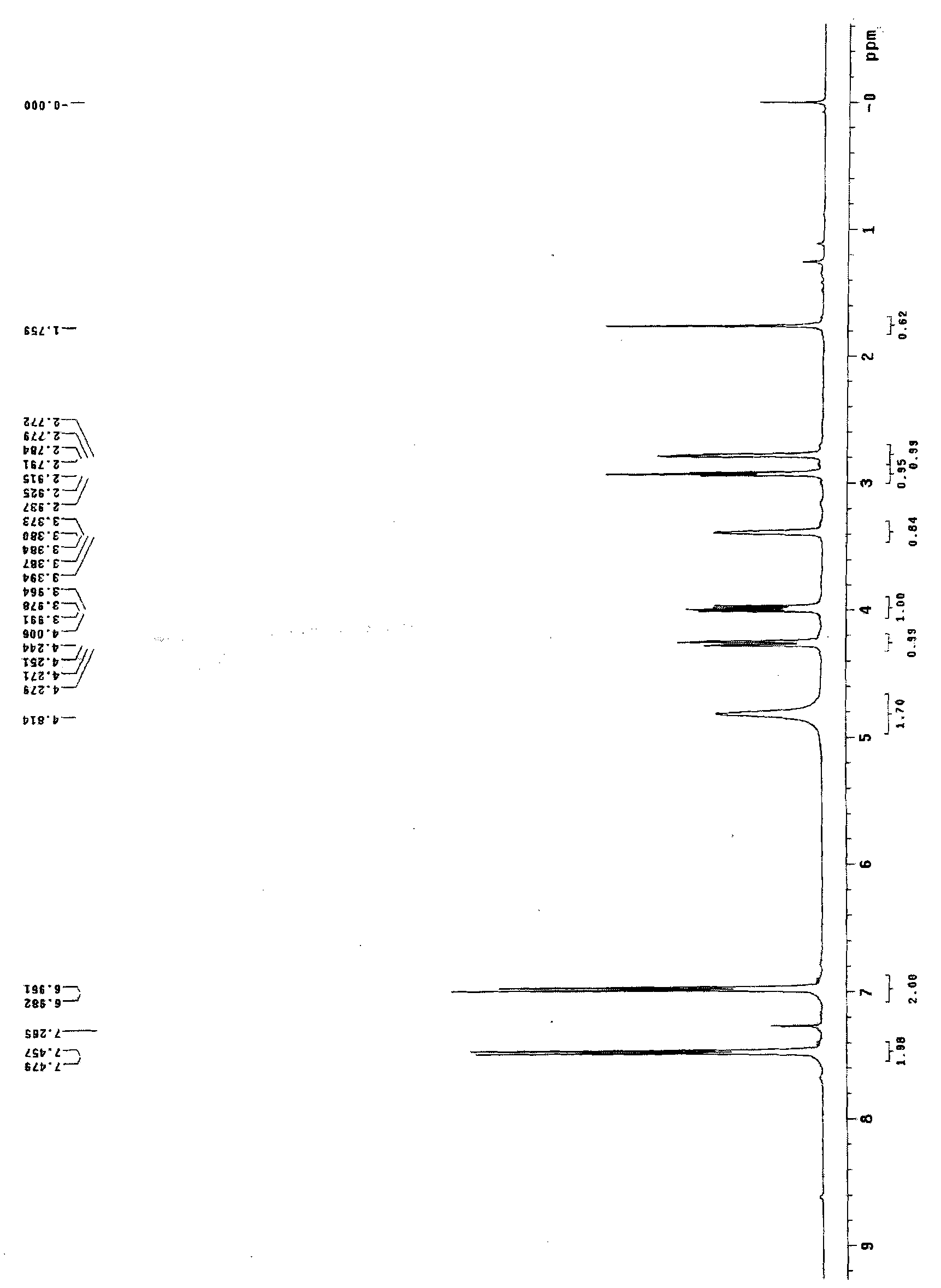

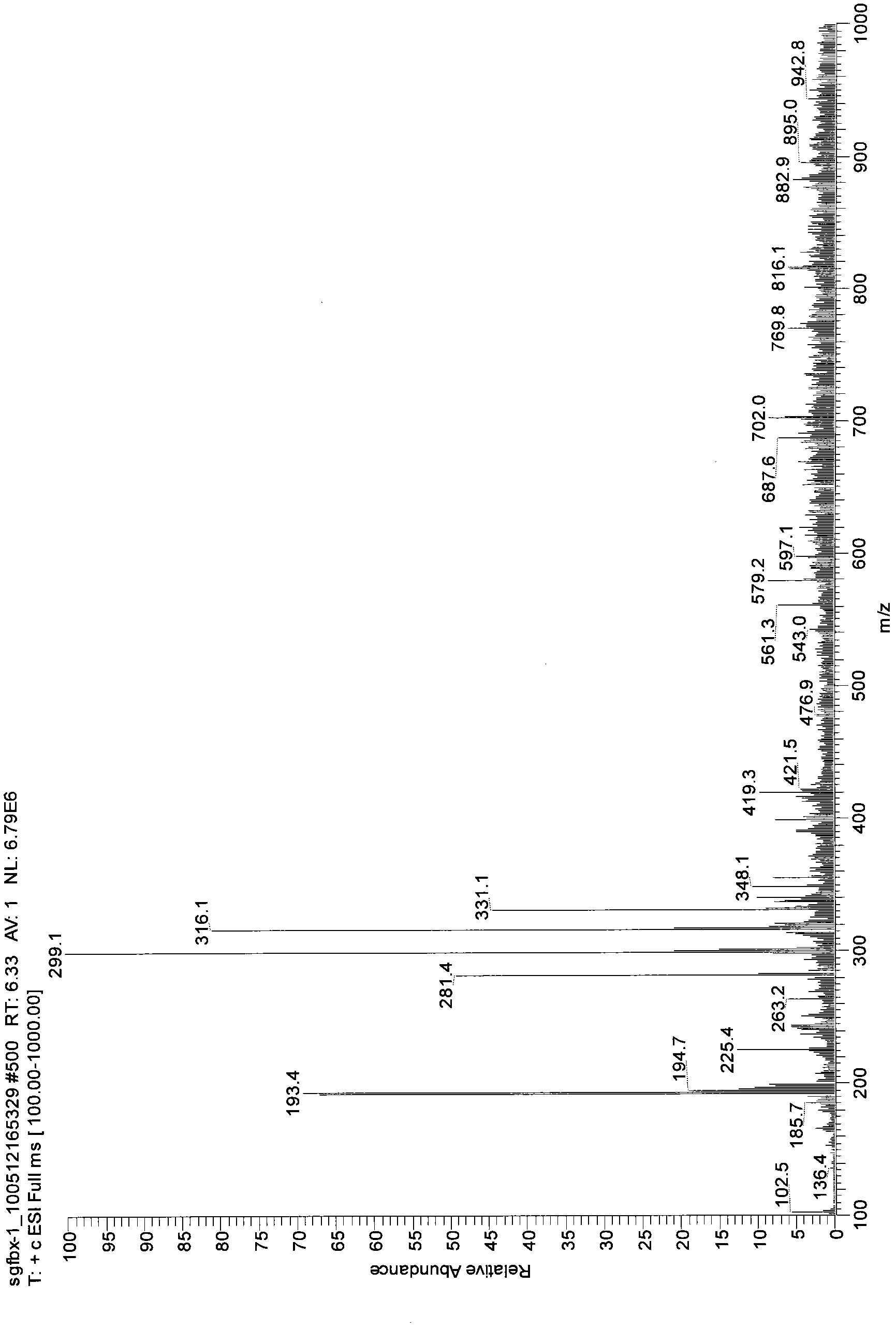

Image

Examples

Embodiment 1

[0060] Ring-opening etherification reaction process: Add 20 grams of 4,4'-biphenol, 320 grams of epichlorohydrin, and 0.2 grams of phase transfer catalyst benzyltriethylammonium chloride into a three-necked flask with a water separator , nitrogen protection, heating up at 80°C, reacting for 5.0 hours, using high performance liquid chromatography to detect the reaction raw material 4,4'-diphenol content is less than 0.5% (mass percentage), start vacuum distillation epichlorohydrin, and finally The distillation temperature reaches 100°C and the vacuum degree is 0.075MPa.

[0061] Ring-closing reaction process: Then add 400 grams of toluene to the system, and then add 13 grams of NaOH in three times. After reacting at 80°C for 1 hour, raise the temperature to 110°C to let the toluene reflux under normal pressure, and use the lower water separator to separate continuously. The water generated by the reaction in the system is detected by high performance liquid chromatography after...

Embodiment 2

[0063] Ring-opening etherification reaction process: Add 20 grams of 4,4'-biphenol, 400 grams of epichlorohydrin, and 0.2 grams of phase transfer catalyst benzyltriethylammonium chloride into a three-necked flask with a water separator , nitrogen protection, heating up at 100°C, reacting for 3.0 hours, using high performance liquid chromatography to detect the reaction raw material 4,4'-diphenol content is less than 0.5% (mass percentage), start vacuum distillation epichlorohydrin, and finally The distillation temperature reaches 100°C and the vacuum degree is 0.075MPa.

[0064] Ring-closing reaction process: Then add 400 grams of toluene and 13 grams of NaOH to the system, react at 80°C for 1 hour, raise the temperature at 110°C to let the toluene reflux, and use the lower water separator to continuously separate the water generated by the reaction in the system. After 8 hours, it was detected by high-performance liquid chromatography, and the content of 4,4-biphenol diglycid...

Embodiment 3

[0066] Ring-opening etherification reaction process: Add 20 grams of 4,4'-biphenol, 400 grams of epichlorohydrin, and 0.2 grams of phase transfer catalyst benzyltriethylammonium chloride into a three-necked flask with a water separator , nitrogen protection, heating up at 90°C, reacting for 4.0 hours, using high performance liquid chromatography to detect the reaction raw material 4,4'-diphenol content is less than 0.5% (mass percentage), start vacuum distillation epichlorohydrin, and finally The distillation temperature reaches 115°C and the vacuum degree is 0.075MPa.

[0067] Ring-closing reaction process: Then add 400 grams of toluene and 13 grams of NaOH to the system, react at 80 ° C for 1 hour, raise the temperature at 110 ° C to let the toluene reflux and use the lower water separator to continuously separate the water generated by the reaction in the system, reaction 8 After one hour, it was detected by high-performance liquid chromatography, and the content of 4,4-bip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com