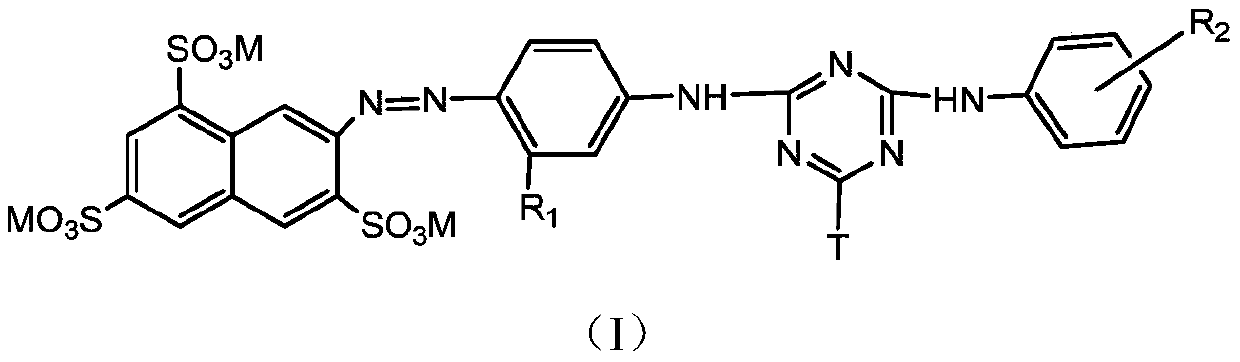

Reactive yellow dye for ink jet printing and preparation method and application thereof

A technology of reactive yellow and dyes, which is applied in reactive dyes, dyeing methods, azo dyes, etc., can solve the problems that the solubility cannot meet the requirements of inkjet printing, the actual utilization rate is not high, and the water consumption of dyeing is high, so as to reduce hydrolysis Side effects, increase hydrophilicity, good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

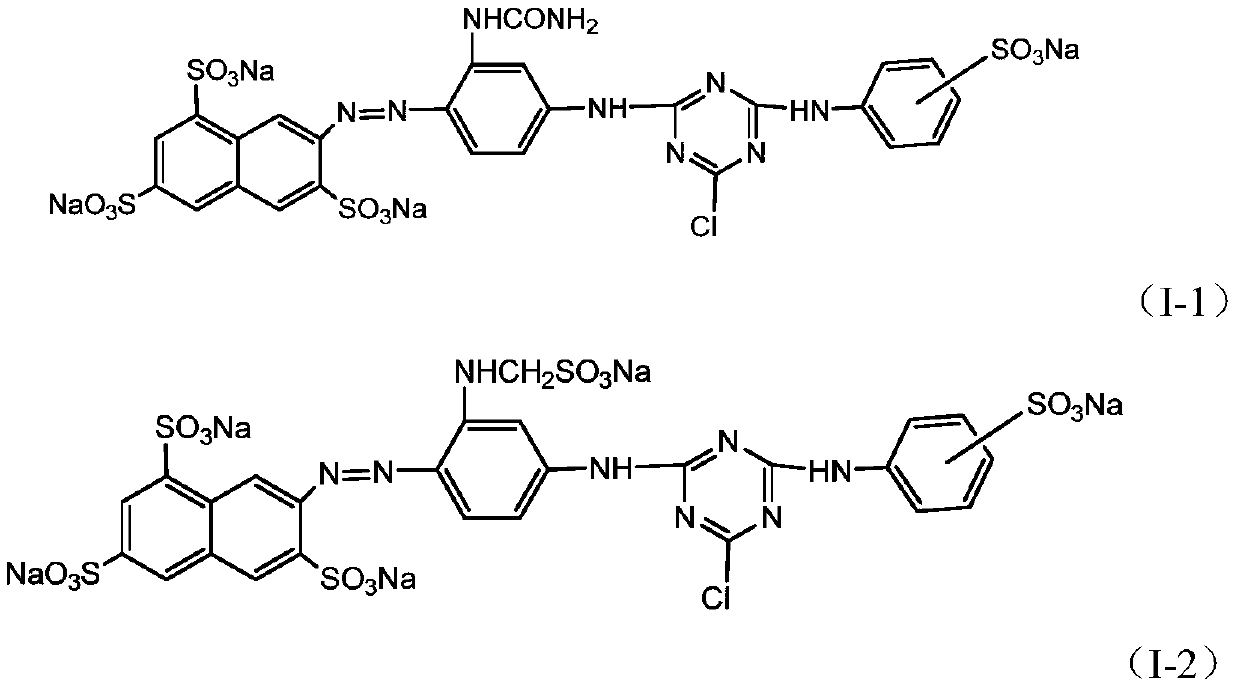

[0065] Embodiment 1 prepares compound (I-1)

[0066] (1) Preparation of Intermediate 1:

[0067] In a 150ml beaker, add 90g of water, 10.8g of m-phenylenediamine and beat for 20 minutes, raise the temperature to 20-25°C, slowly add 73g of 30% dilute hydrochloric acid, dissolve the m-phenylenediamine, add 8.45g of sodium cyanate to the dissolved m-phenylenediamine In the diamine solution, the temperature is always controlled at 8-20°C, and the pH is adjusted to 3-3.5 with a 10% soda ash aqueous solution, and reacted for 1 hour. After the reaction is completed, a sample is taken for analysis, and the pH is adjusted to 7 after passing the test.

[0068] (2) Diazo coupling reaction:

[0069] In a 250ml beaker, add 20g of ice, 38.3g of 2-naphthylamine-3,6,8-trisulfonic acid, grind on ice for 30 minutes, slowly add 6.97g of sodium nitrite to form diazonium salt, and use Congo red test paper during the diazonium process The acidity test shows dark blue, if it does not show dark blu...

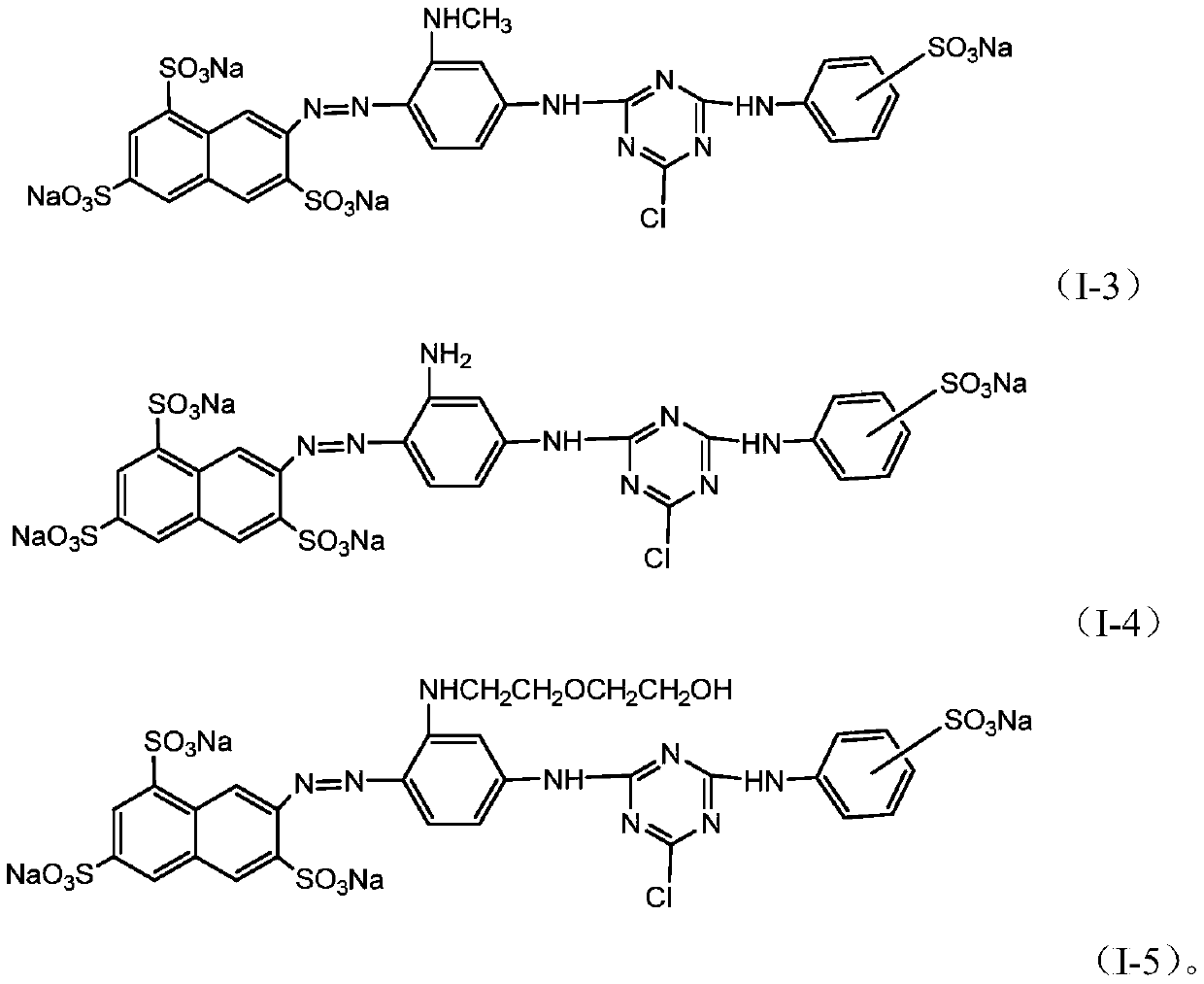

Embodiment 2

[0074] Embodiment 2 prepares compound (I-2)

[0075] (1) Preparation of intermediate 2:

[0076] In a 150ml beaker, add 90g of water, 10.8g of m-phenylenediamine and beat for 20 minutes, raise the temperature to 20-25°C, slowly add 73g of 30% dilute hydrochloric acid to dissolve the m-phenylenediamine, add 8g of sodium pyrosulfite to the dissolved m-phenylenediamine In the solution, always control the temperature at 30-35°C, stir for 20 minutes, then slowly add 33g of formaldehyde, raise the temperature to 40-45°C after the addition, and react for 4 hours. After the reaction, take samples for analysis, adjust the pH to 7 after passing the test, and set aside.

[0077] (2) Diazo coupling reaction:

[0078] In a 250ml beaker, add 20g of ice, 38.3g of 2-naphthylamine-3,6,8-trisulfonic acid, grind on ice for 30 minutes, slowly add 6.97g of sodium nitrite to form diazonium salt, and use Congo red test paper during the diazonium process The acidity test shows dark blue, if it does...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com