Quick electrostatic agglomerate separating device and process

An electrostatic coalescence and separation device technology, applied in the direction of electricity/magnetic dehydration/emulsification, can solve the problems of increased operation and maintenance costs, large power consumption, and large floor space, so as to reduce sewage treatment costs and The effect of environmental protection pressure, reducing the number of equipment stages and equipment, and improving the stability of equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

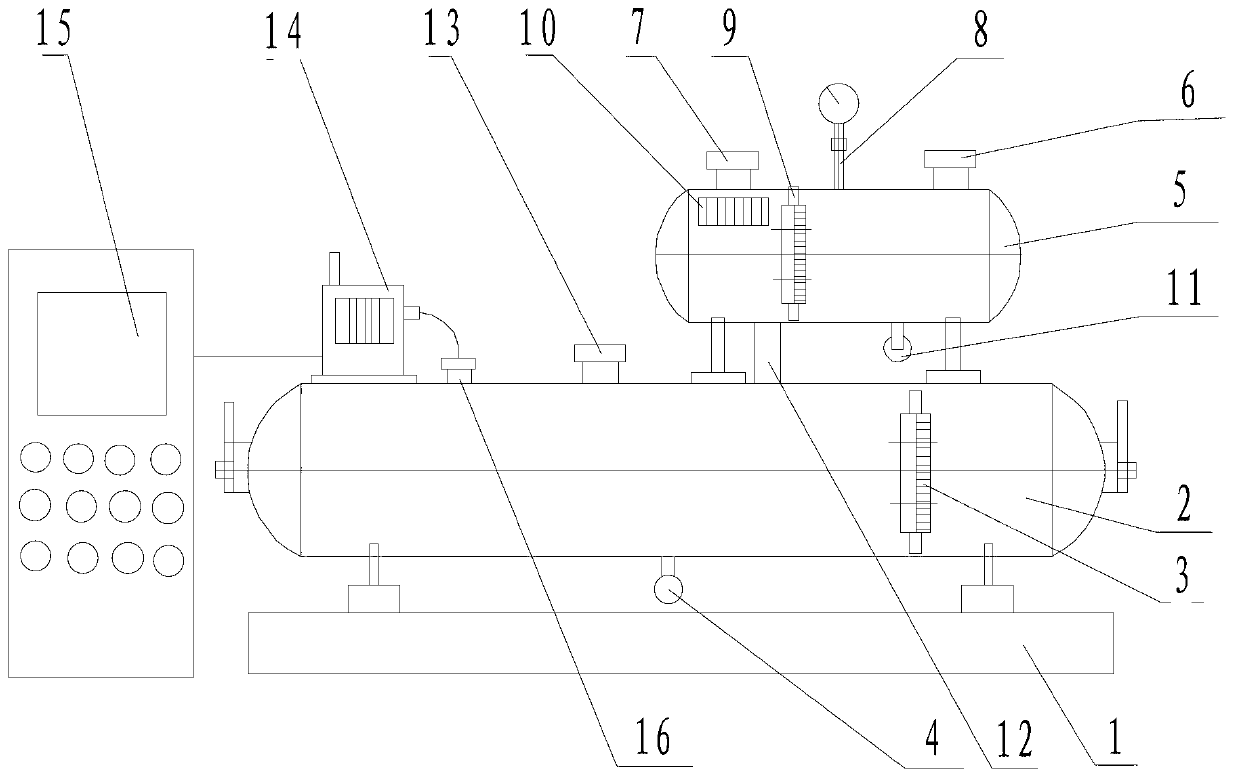

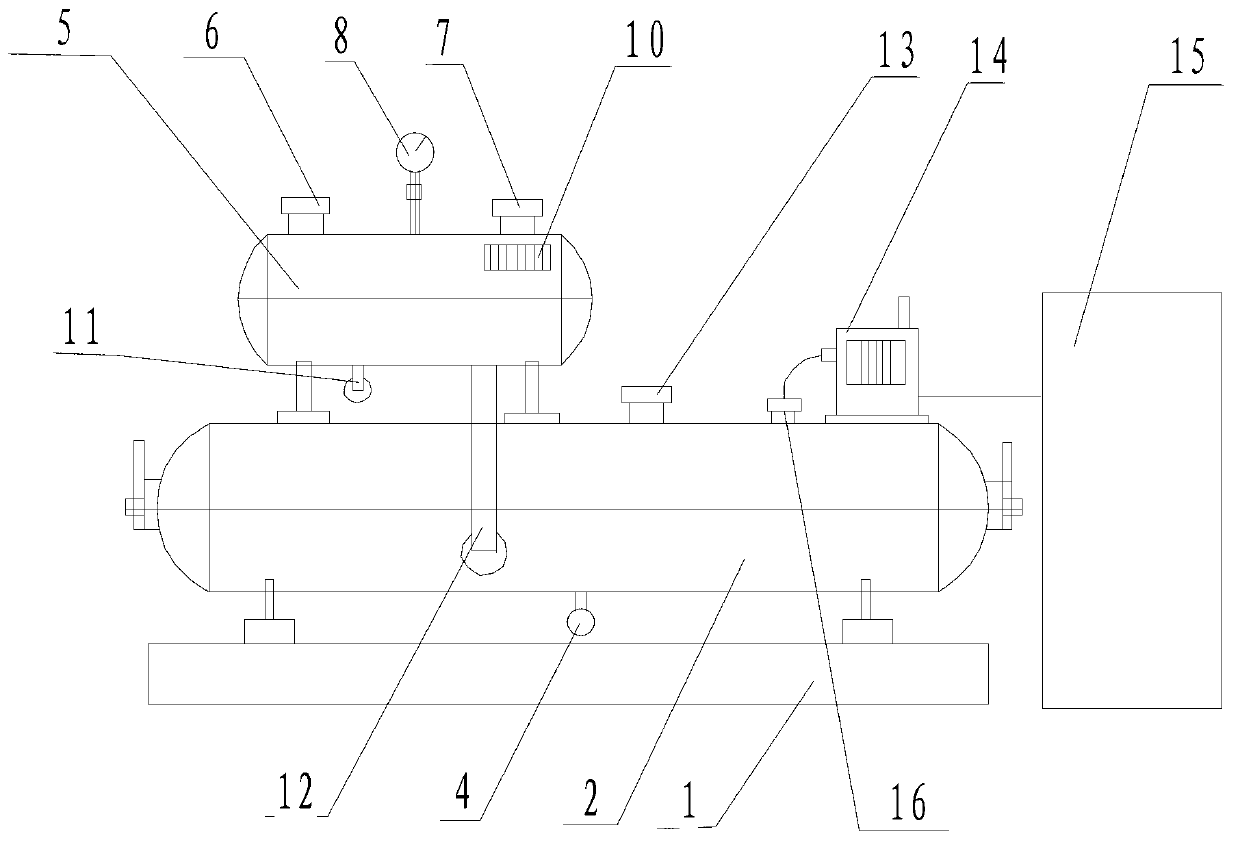

[0026] The oil-water separation tank 2 is fixed on the skid base 1, the bottom of the oil-water separation tank 2 is provided with a water outlet 4, the side of the oil-water separation tank 2 is provided with a control cabinet 15, the upper middle part of the oil-water separation tank 2 is provided with an oil outlet 13, and the side of the oil-water separation tank 2 is provided with a transformer 14. A gas-liquid separation tank 5 is set on the other side, a liquid inlet 6 is set on one side above the gas-liquid separation tank 5, a gas outlet 7 is set on the other side, a water outlet 11 is set on one side of the bottom of the gas-liquid separation tank 5, and a water outlet 11 is set on the other side An oil delivery water pipe 12 is arranged, and the bottom of the oil delivery water pipe 12 is arranged correspondingly to the oil-water separation tank 2 .

Embodiment 2

[0028] The well fluid with high water content enters the gas-liquid separation tank 5 from the liquid inlet 6, the gas-liquid boundary gauge 9 displays the liquid level position of the high water content well fluid in the gas-liquid separation tank 5, and the pressure gauge 8 displays the pressure in the gas-liquid separation tank 5 , the pressure in the gas-liquid separation tank 5 is lower than the pressure in the well fluid pipeline. Under the action of pressure, the combustible gas in the well fluid overflows, and after being adsorbed by the adsorption plate 10, it enters the torch for combustion through the gas outlet 7; The water-containing crude oil is naturally separated by gravity in the gas-liquid separation tank 5, and the sewage settled at the bottom is discharged through the water outlet 11.

Embodiment 3

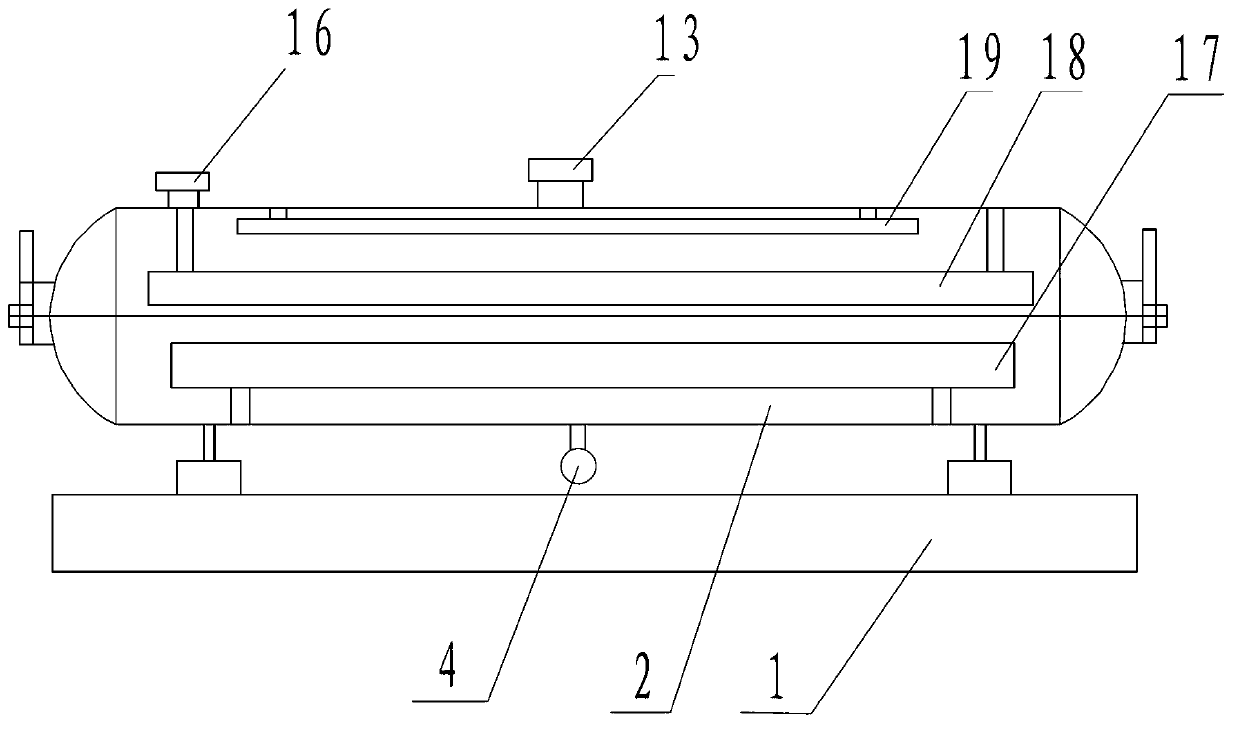

[0030] The water-containing crude oil enters the oil inlet distributor 17 in the oil-water separation tank 2 through the oil delivery pipe 12, and multi-group distribution holes are arranged around the oil inlet distributor 17, and the water-containing crude oil enters the oil-water separation tank 2 through the distribution holes. During the ascent of crude oil, oil and water are naturally separated by gravity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com