Patents

Literature

34results about How to "Shorten dipping time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

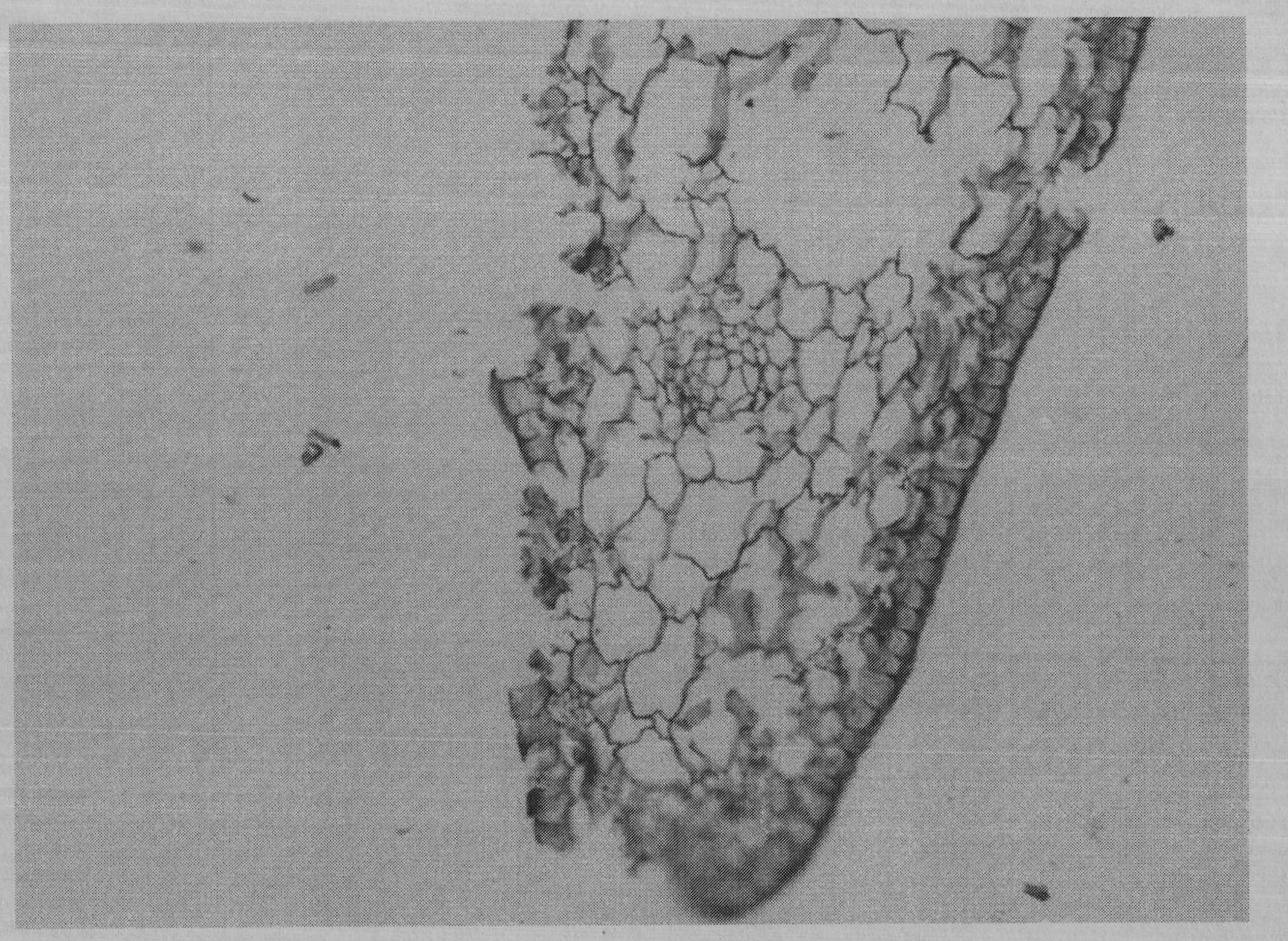

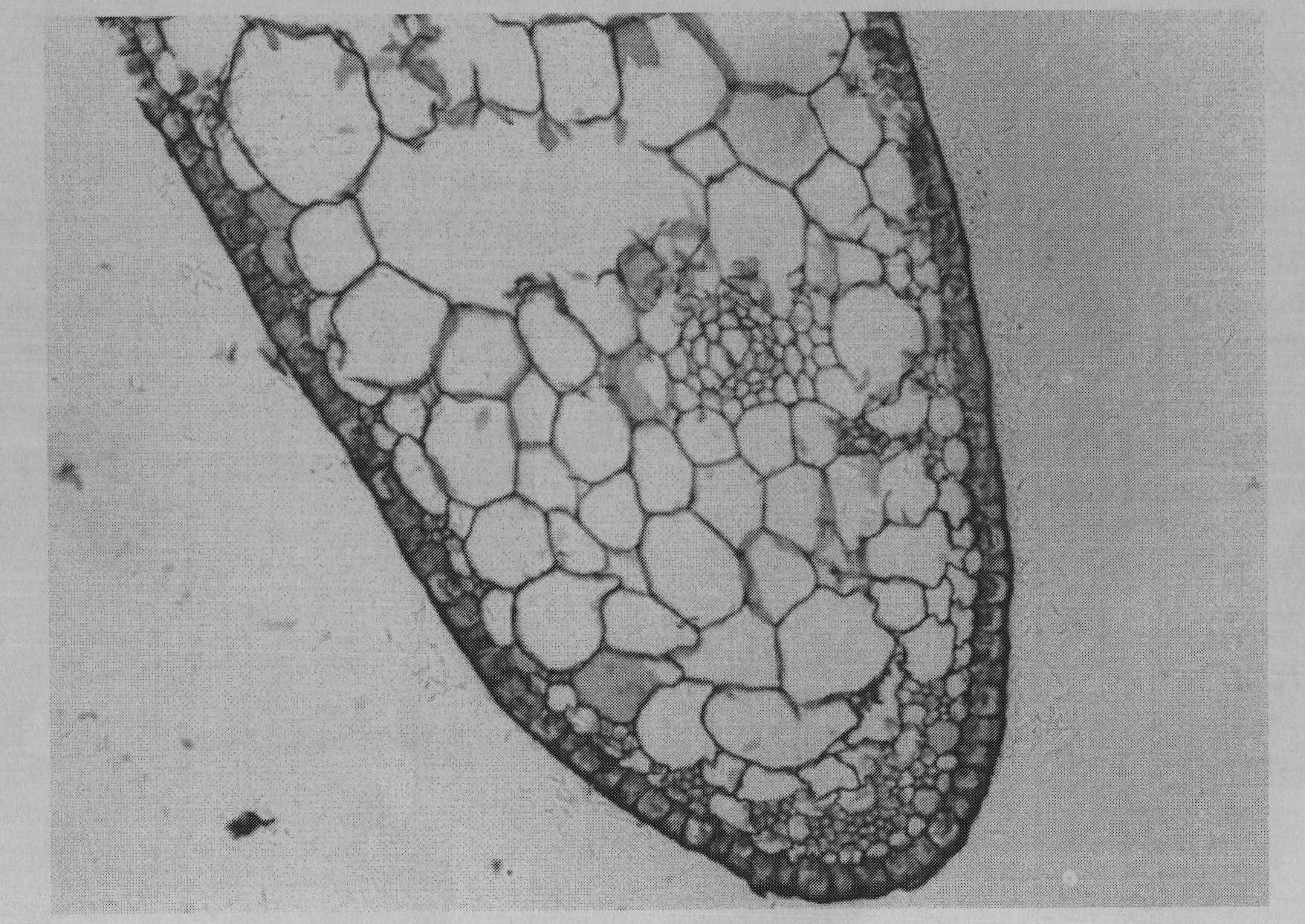

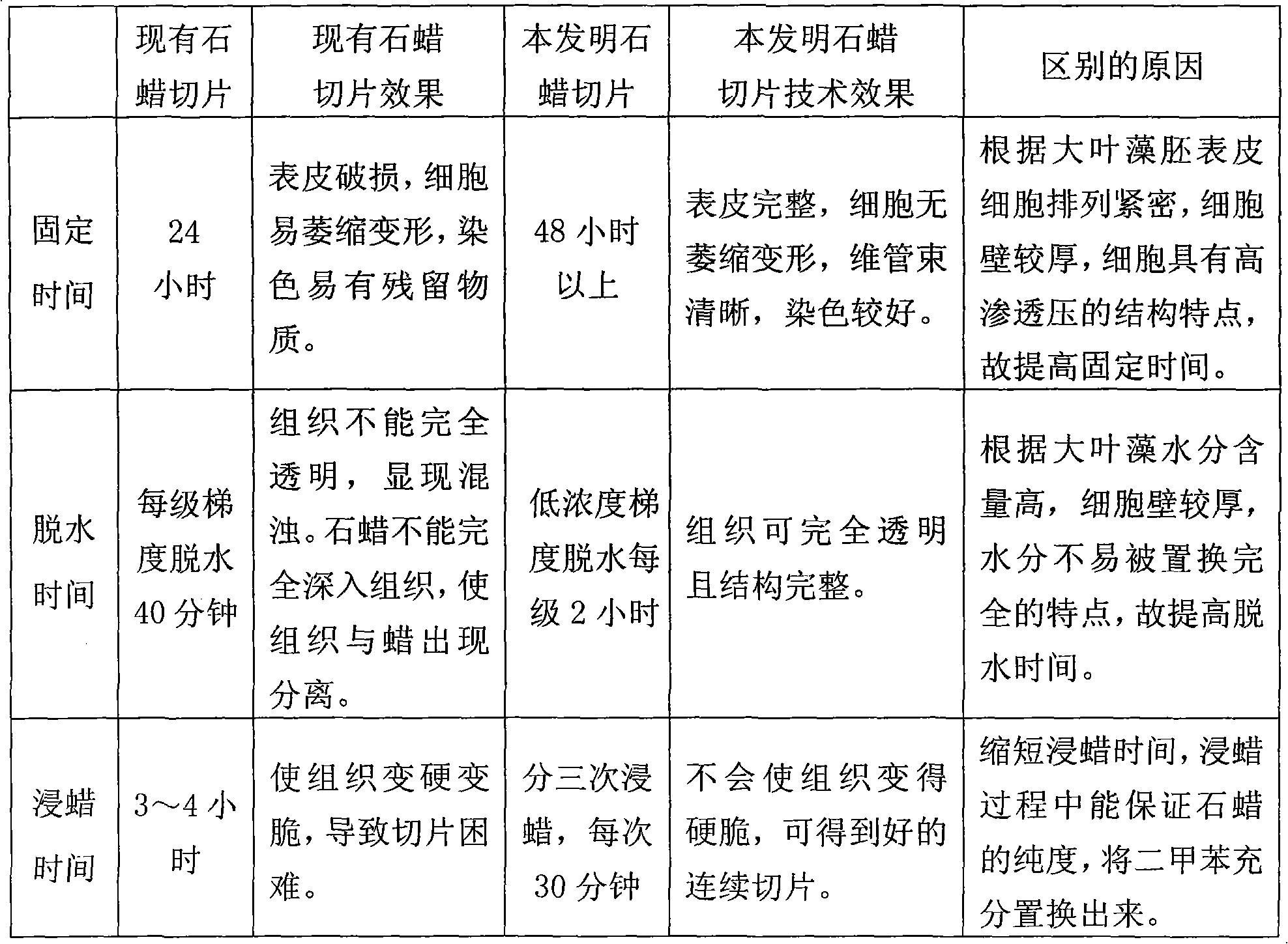

Manufacturing method of paraffin sections of zostera marina embryo

ActiveCN102116711AAvoid deformationModerate hardnessWithdrawing sample devicesPreparing sample for investigationParaffin waxEmbryo

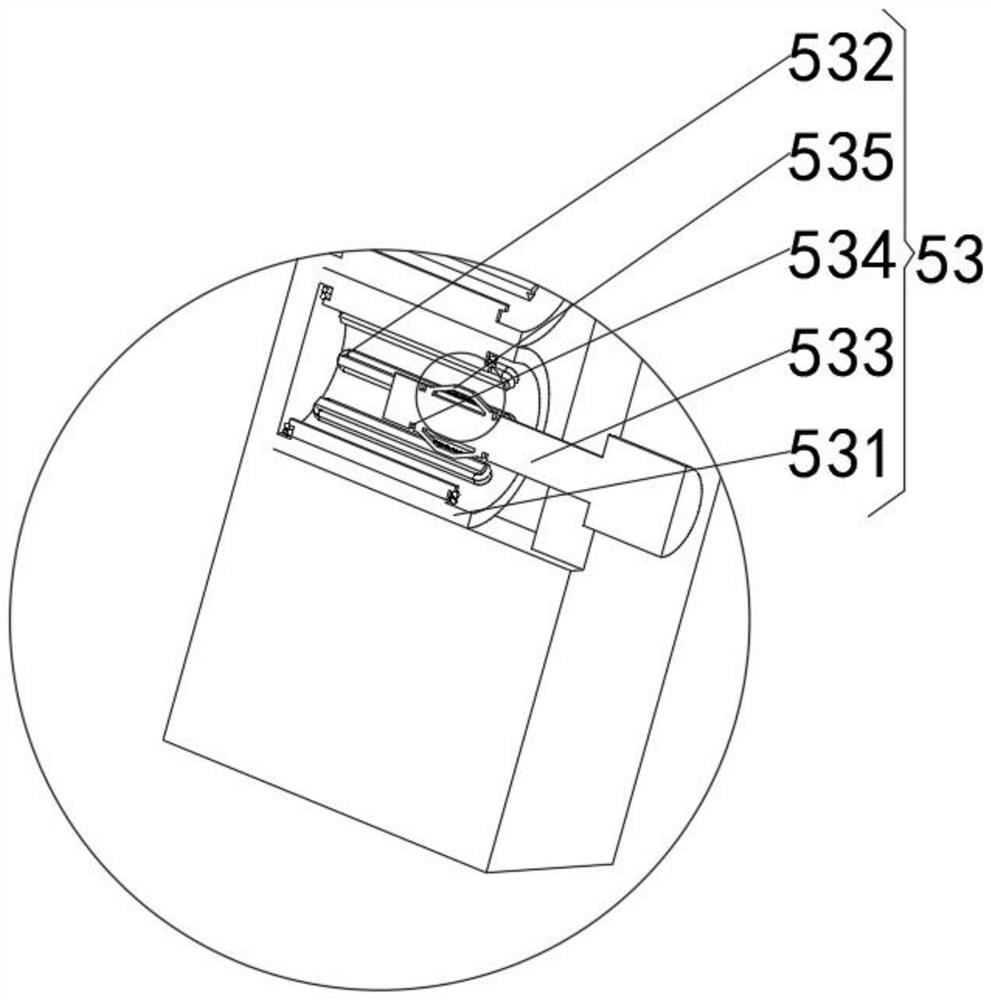

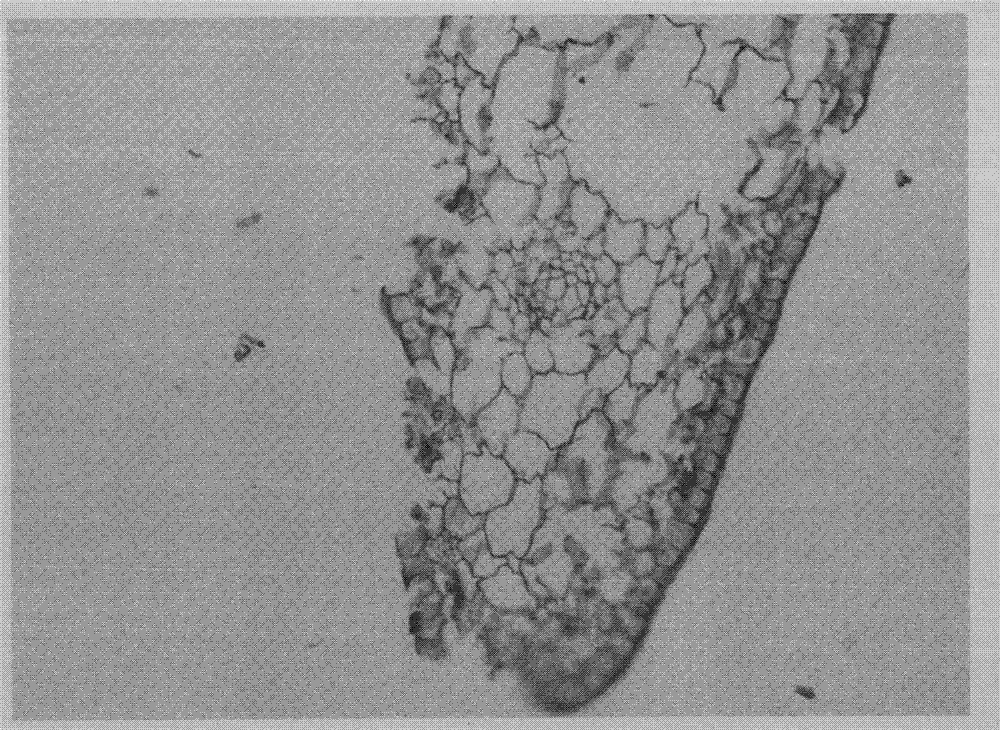

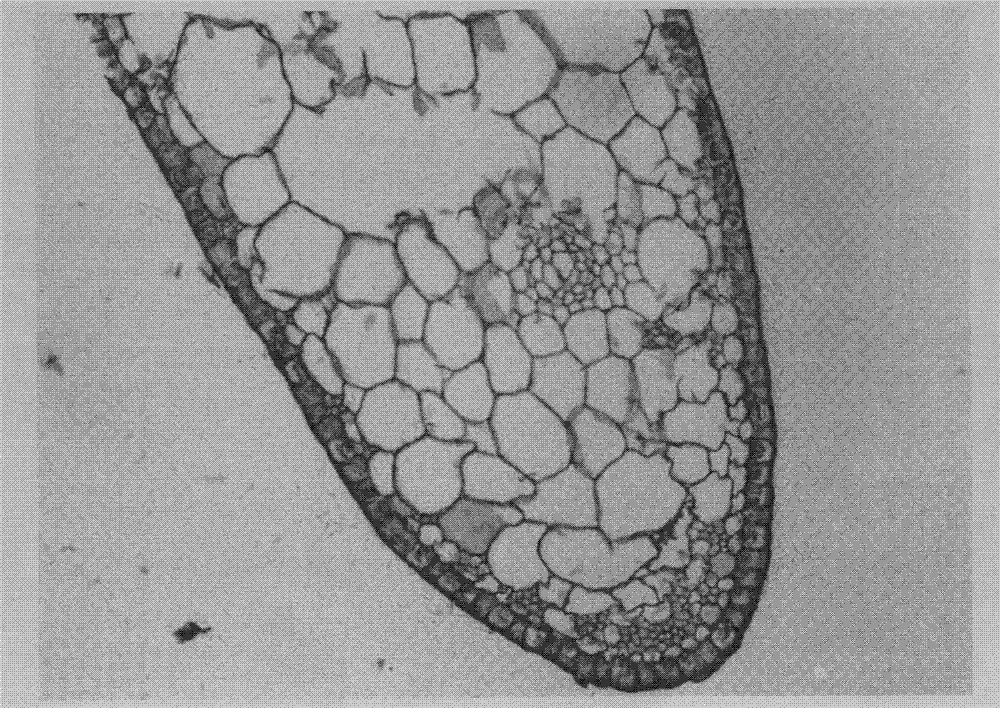

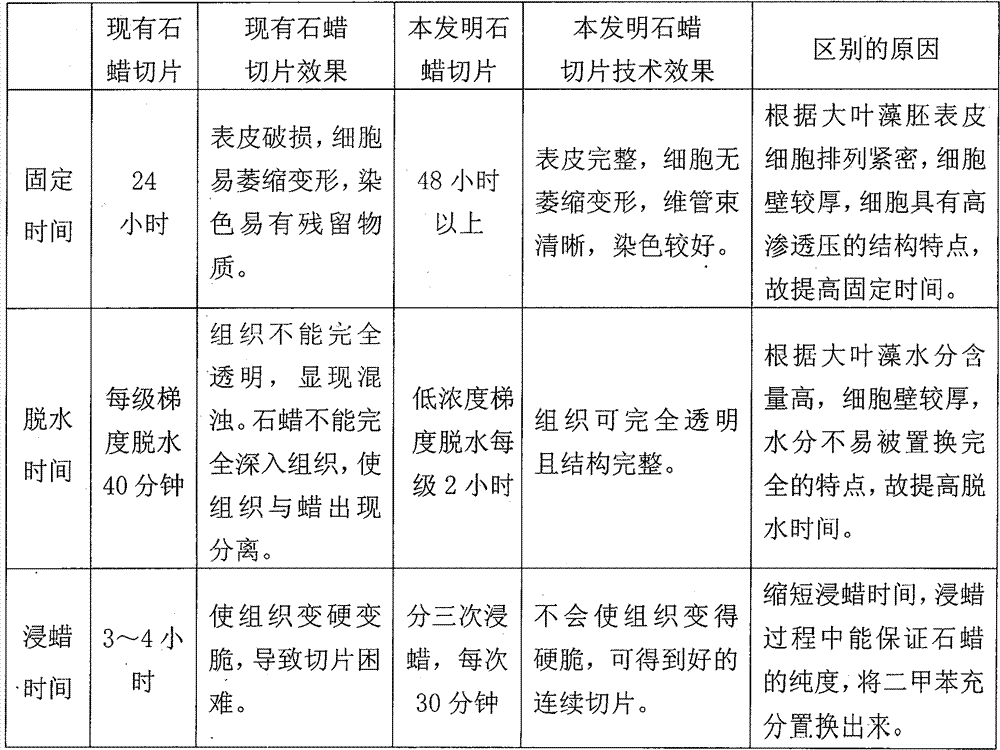

The invention discloses a manufacturing method of paraffin sections of zostera marina embryo, comprising the following steps: (1) material drawing and fixation: zostera marina seeds are taken and the fruit skin is stripped, and after endosperm is removed, an integral zostera marina embryo is soaked in FAA (free amino acids) fixing solution and is fixed for more than 48 hours; (2) dehydration: the zostera marina embryo is taken out from the fixing solution and is soaked in alcohol for dehydration; (3) waxing and embedding: paraffin is added gradually in a vessel containing the zostera marina embryo and dimethylbenzene, and conventional paraffin embedding is carried out to obtain the wax blocks containing the zostera marina embryo; (4) slicing, spreading and drying: the wax blocks coated with the zostera marina embryo is fixed on a wheel rotation type slicing machine for carrying out continuous slicing of the paraffin, so as to obtain wax bands and enable the wax bands to be attached to an object slide; (5) dewaxing, rehydration and dyeing of hematoxylin dye solution; (6) slicing, dehydration and dyeing of eosin and alcohol; and (7) transparence and mounting are carried out to manufacture a permanent section. In the manufacturing method disclosed by the invention, the paraffin sections of the zostera marina embryo, which have clear dyeing and an integral texture structure, can be obtained.

Owner:SHANDONG ORIENTAL OCEAN SCI TECH

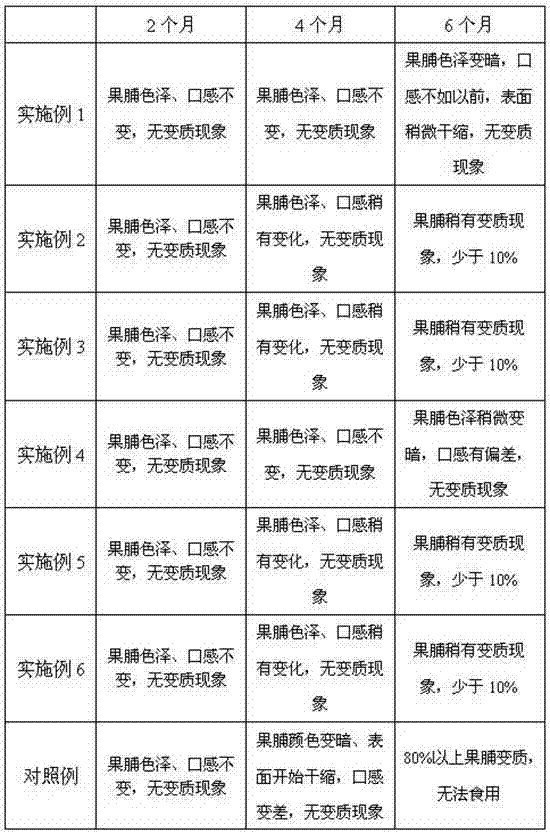

Low-sugar preserved jerusalem artichoke and preparation method thereof

InactiveCN102894170AGreat tasteIncrease osmotic pressureConfectionerySweetmeatsBiotechnologyVitamin C

The invention discloses low-sugar preserved jerusalem artichoke and a preparation method thereof. The method comprises the following steps of: selecting materials, washing, removing skin, slicing, protecting color, hardening, blanching, infusing sugar, impregnating sugar and drying. The sugar solution used for infusion and impregnation comprises the following components in percentage by weight: 30 to 40% of high fructose corn syrup, 10 to 20% of green tea extract, 0.2 to 0.8% of citric acid, 0.02 to 0.1% of vitamin C and the balance of water. The composition of the sugar solution for infusion and impregnation is changed, which changes the flavor and appearance of the preserved jerusalem artichoke, prolongs the quality guarantee period, offers the preserved jerusalem artichoke a good mouthfeel and makes the preserved jerusalem artichoke easy to store.

Owner:SHANDONG JIANZHU UNIV

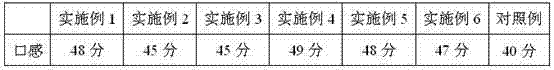

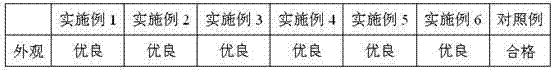

Dried fruit food with red aeterio and production thereof

InactiveCN1817165AComplete fruitBright red uniform colorConfectionerySweetmeatsMangroveAdditive ingredient

A health-care preserved mangrove raspberry fruit for removing free radicals from human body, delaying sanility and preventing and treating cancers is prepared through collecting mangrove raspberry fruits, quick freezing, deactivating enzyme, vacuum preserving in sugar, water washing, vacuum drying, treating with isolating agent, baking, examining and packing.

Owner:LIAONING TODAY AGRI

Production and processing method of candied blueberries

The invention relates to a production and processing method of candied blueberries. The production and processing method comprises the following steps of performing selection of raw materials, performing cleaning, performing scalding, performing color protection, performing hardening, performing high-temperature sugar dipping, performing draining and performing drying. The candied blueberries processed and made by the production and processing method disclosed by the invention are uniform in sugar dipping, the sugar content is as low as 40%-50%, and the candied blueberries are plump in granules, supple, good in mouth feel and moderate in sour and sweet degrees, and have the fruity flavor of natural blueberries. The candied blueberries are good in degree of perfection, the color of the candied blueberries maintains the original blue of the blueberries, the candied blueberries are high in surface gloss, and few of nutrient components run off. The candied blueberries are long in quality guarantee period, and are easy to store.

Owner:MAJIANG QIANYONG BLUEBERRIES

Staining fluid for zirconia pre-burned false tooth

The invention relates to staining fluid for a zirconia pre-burned false tooth. The staining fluid consists of the following raw materials in parts by weight: 1000 parts of deionized water, 9.6 to 57 parts of iron chloride, 4.2 to 46.2 parts of erbium nitrate and 0.6 to 24 parts of praseodymium nitrate. The staining fluid has excellent permeation rate, the staining fluid can permeate for 0.8mm in 5 seconds in a single direction, for 1.2mm in 10 seconds in a single direction and for 1.5mm in 20 seconds in a single direction, the permeation speed is high, the stained pre-burned false tooth is integrally uniform in color; moreover, the light transmittance is similar to that of a natural color. Besides, the satisfaction on the requirement of vita 16 colors, four effect colors of A5, B5, C5 and G1 (gingival porcelain color) can also be achieved by the staining color, the production demand of a technician is satisfied, and the blank of the effect color in the industry can be filled. The staining fluid has the characteristics of short time, good staining effect and low cost, and is capable of completing the staining in ten seconds and suitable for the production of false tooth companies.

Owner:QINHUANGDAO ZEKENI CERAMIC TECH CO LTD

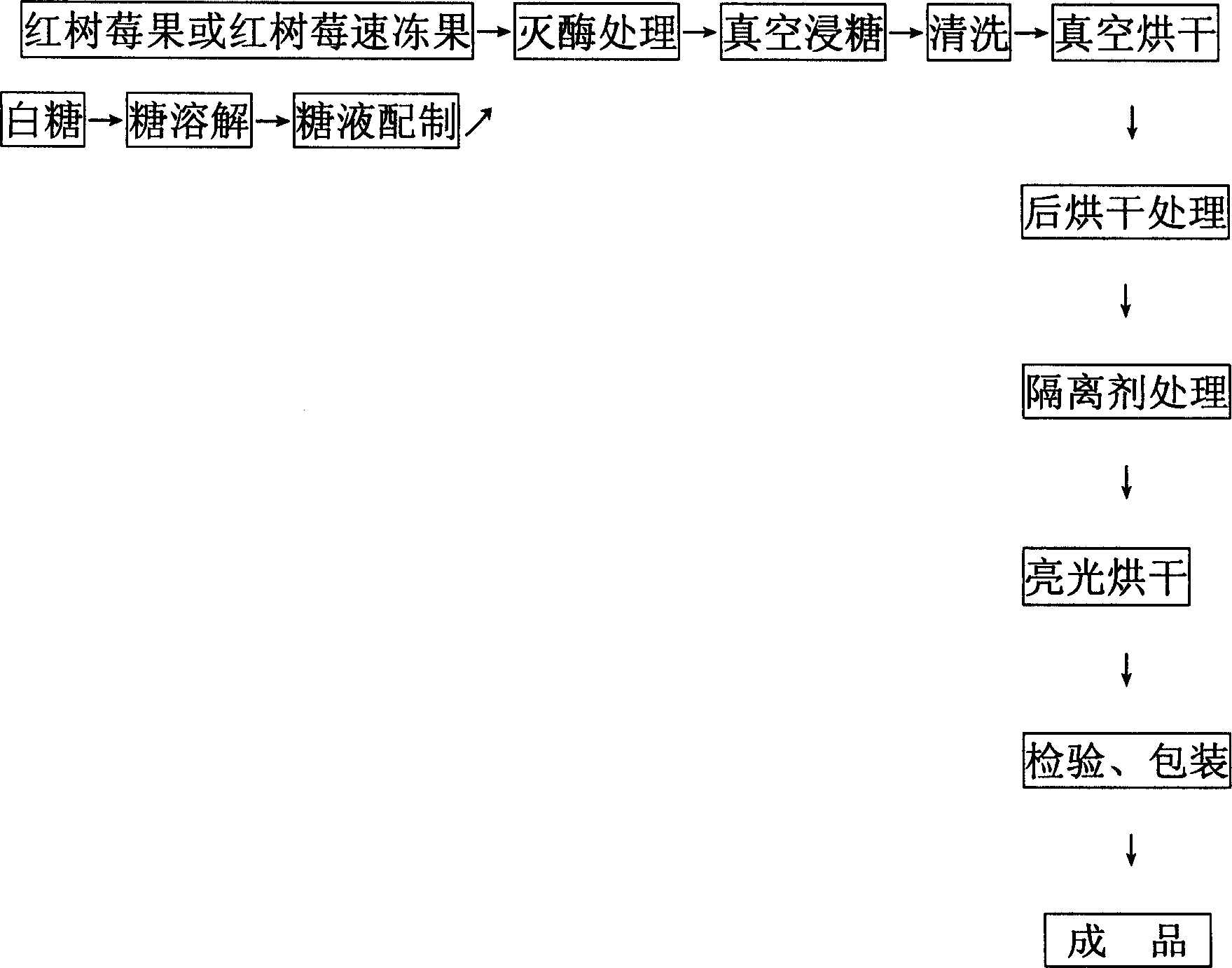

Low-sugar candied jack fruit strips and making method thereof

ActiveCN105124100ASolve the waste of resourcesIncrease added valueConfectionerySweetmeatsBiotechnologySucrose

The invention discloses low-sugar candied jack fruit strips and a making method thereof. The low-sugar candied jack fruit strips are prepared by using jack fruit strips as raw materials, and are specifically prepared through the following working procedures: using the jack fruit strips as the raw materials, cleaning the jack fruit strips, processing the cleaned jack fruit strips with hot water, pickling the processed jack fruit strips, rinsing the pickled jack fruit strips, desalinating the rinsed jack fruit strips, hardening the desalinated jack fruit strips, rinsing the hardened jack fruit strips, drying the rinsed jack fruit strips, sugaring the dried jack fruit strips in a vacuum manner, sugar boiling the sugared jack fruit strips, drying the sugar-boiled jack fruit strips, and packaging the dried jack fruit strips. According to the low-sugar candied jack fruit strips and the making method thereof, disclosed by the invention, by-products, namely the jack fruit strips obtained by processing the jack fruits are firstly used for making low-sugar candied fruits, the processing method is novel in conception, unique in technology, simple to operate, and easy to implement. The purposes of reducing the consumption of cane sugar and improving the flavor of the candied fruits are realized, and the problems that high-sugar candied fruits are easy to generate the situation that sugars flow off and granulated sugar is easy to form are solved. The sugar-soaking time is greatly shortened, the low-sugar candied jack fruit strips are uniform in sugar soaking, the plumpness of finished products is good, the production efficiency is high, and the low-sugar candied jack fruit strips and the making method thereof open up a new way for the reprocessing and the utilization of edible jack fruit strips in the by-products obtained by processing the jack fruits, and develop a novel leisure candied fruit, so that the added value of the jack fruits is greatly increased.

Owner:SOUTH CHINA AGRI UNIV

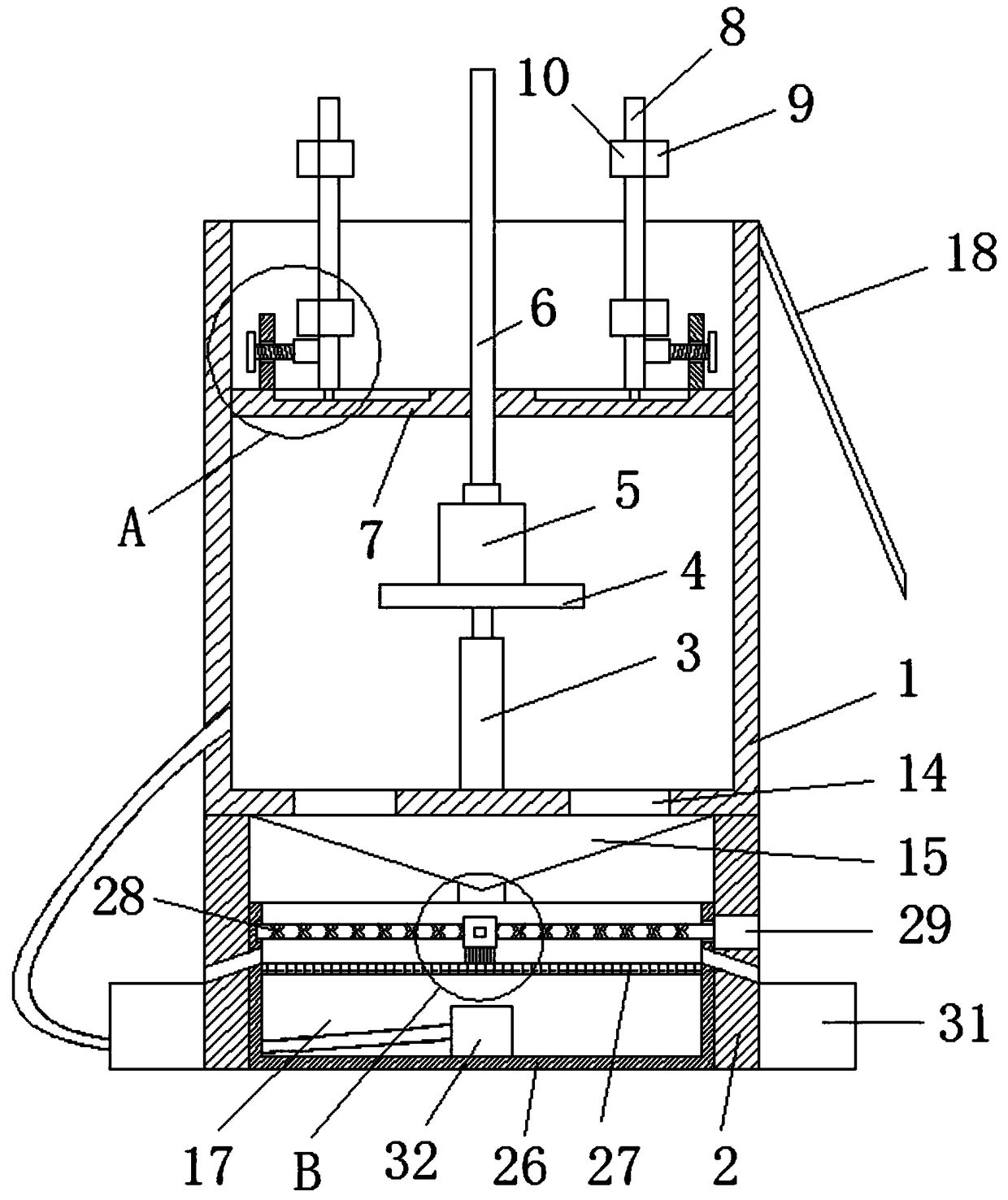

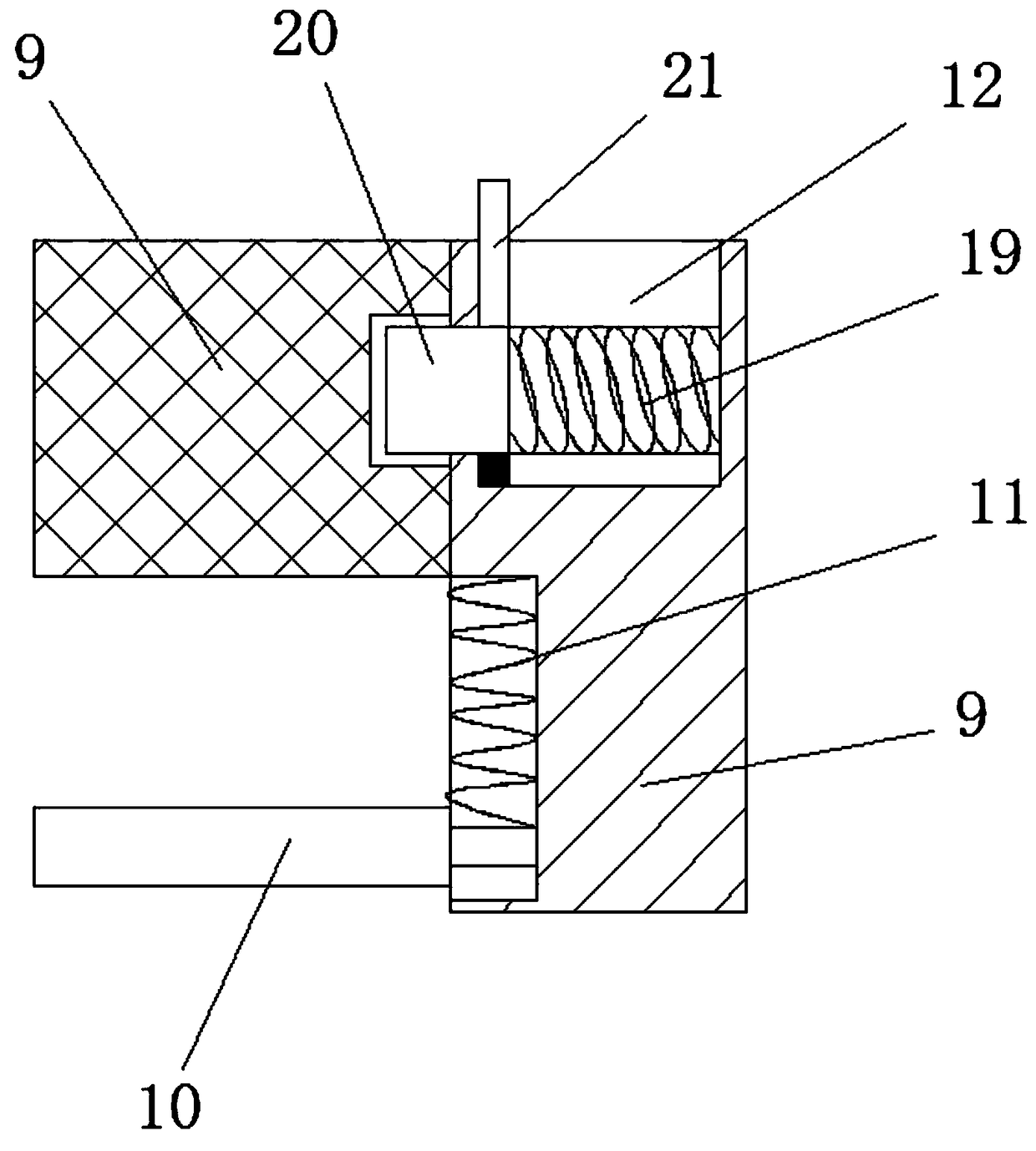

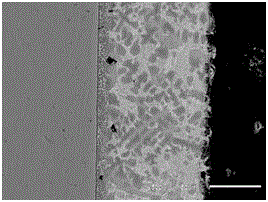

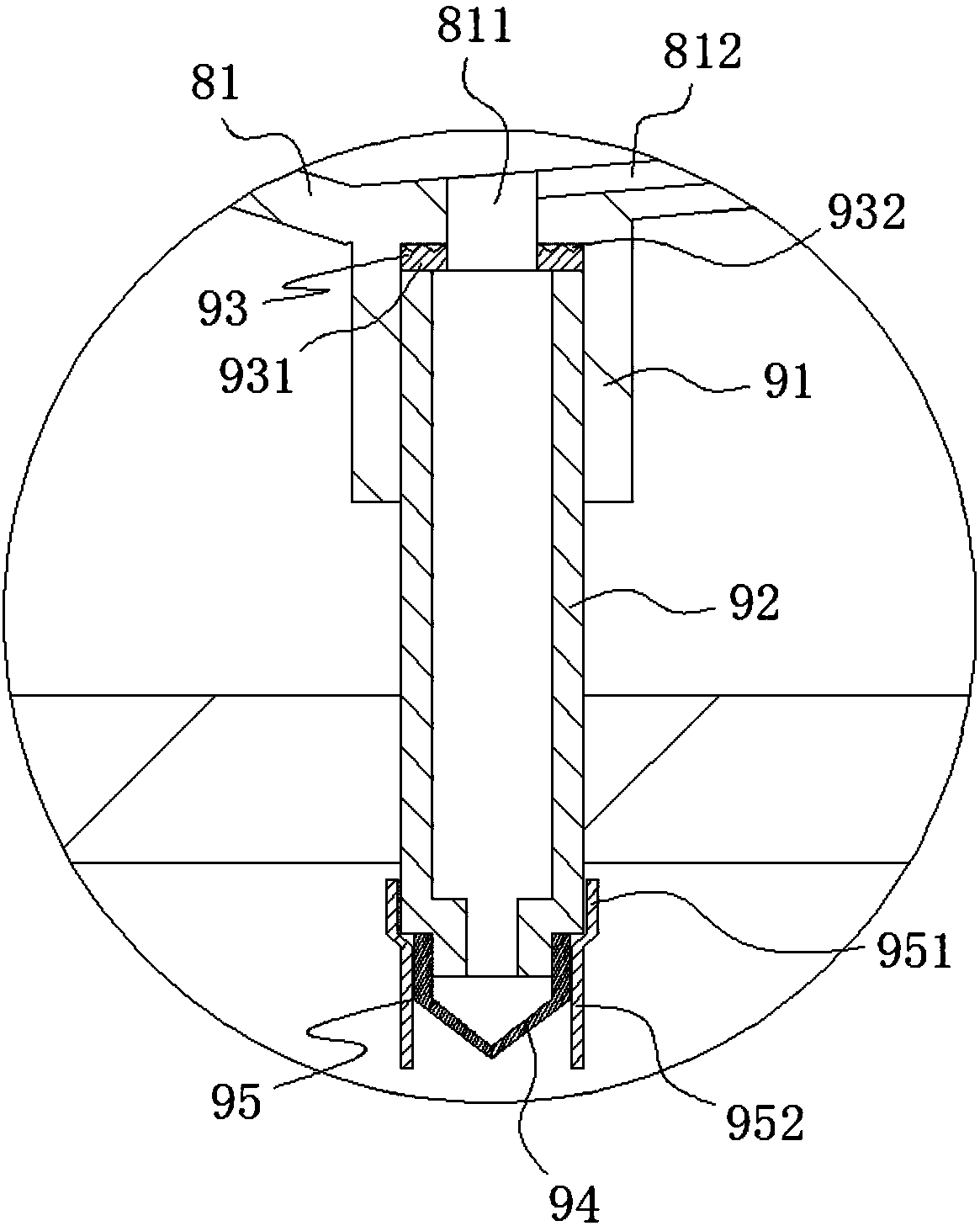

Textile dye vat

InactiveCN108893914ADip dyed evenlyShorten dipping timeTextile treatment containersTextile treatment machine arrangementsElectric machineryEngineering

The invention relates to the technical field of textile, and discloses a textile dye vat. The textile dye vat comprises a dye vat body, wherein four corners of the bottom of the dye vat body are separately fixedly connected with supporting legs; the inner wall of the bottom of the dye vat body is fixedly connected with an electric push rod; the top of the electric push rod is fixedly connected with a first supporting plate; the top of the first supporting plate is fixedly connected with a first rotating motor; the output end of the first rotating motor is fixedly connected with a rotating rod;a second supporting plate is fixedly arranged on the outer wall of the rotating rod in a sleeving manner; first supporting rods are separately arranged on the left side and the right side of the rotating rod; the bottom of each first supporting rod is fixedly connected with a first slider; and a first chute which is connected with the first slider in a matched manner is formed in the upper surface of the second supporting plate. By the textile dye vat, dip dyeing time of broken cloth pieces can be shortened, dip dyeing of the broken cloth pieces can be uniform, meanwhile, the broken cloth pieces in different sizes can be clamped conveniently, and impurities in a dyeing agent can be filtered conveniently.

Owner:JIAXING YUNYUN TEXTILE

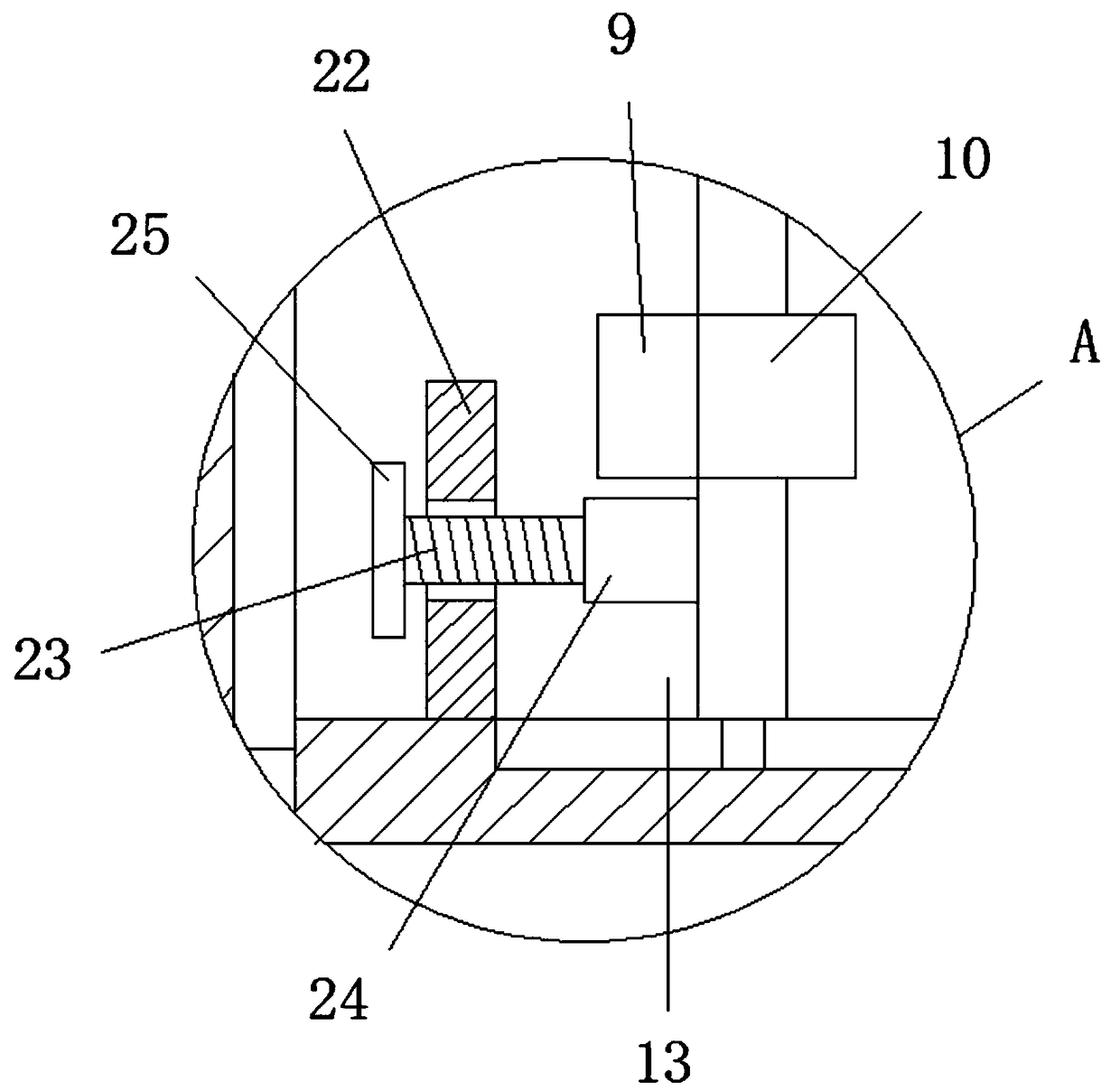

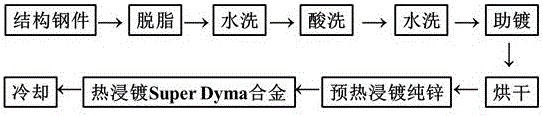

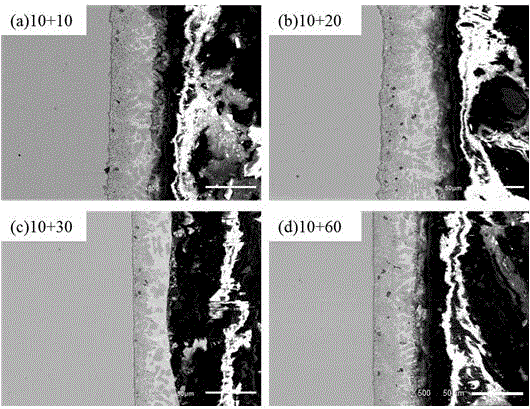

Two-step SuperDyma alloy hot dipping technology for structural steel

InactiveCN106521385AThickness is easy to controlImprove surface qualityHot-dipping/immersion processesAlloy coatingTwo step

The invention belongs to the technical field of hot dipping and relates to a two-step SuperDyma alloy hot dipping technology for structural steel. The technology sequentially comprises degreasing, water washing, acid pickling, water washing, dipping assisting, drying, pure zinc preheating and dipping, SuperDyma alloy hot dipping and cooling. After being pretreated by a common massive hot galvanizing method, a workpiece is dipped in a 430-470DEG C pure zinc bath for 2-30s and then dipped in a 430-470DEG C SuperDyma alloy bath which is arranged with the pure zinc bath side by side for 5-120s. The surface of an obtained alloy coating is great in quality, even in thickness and great in mechanical performance, the corrosion resistance of the alloy coating is more than 10 times of a common pure zinc coating, and the service life is long. The problems that silicon reacts when the structural steel is hot-dipped with pure zinc and the surface quality of a coating only coated with SuperDyma alloy is poor are overcome, and the use of an unstable dipping assistant is avoided. Under the condition of obtaining the same workpiece service life, the thickness of the coating can be reduced, hop dipping time is shortened, and the production cost is reduced. The technology is stable, and the quality of the coating is easy to control.

Owner:CHANGZHOU UNIV

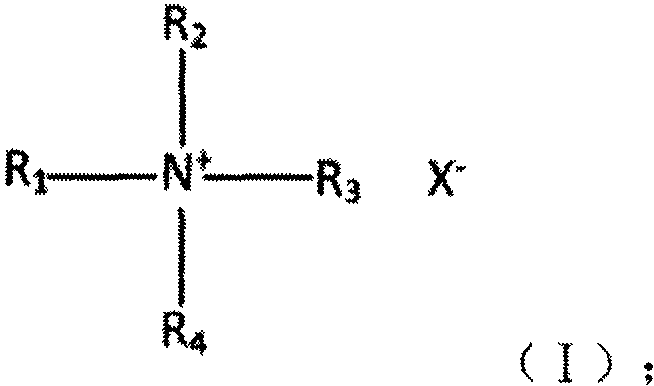

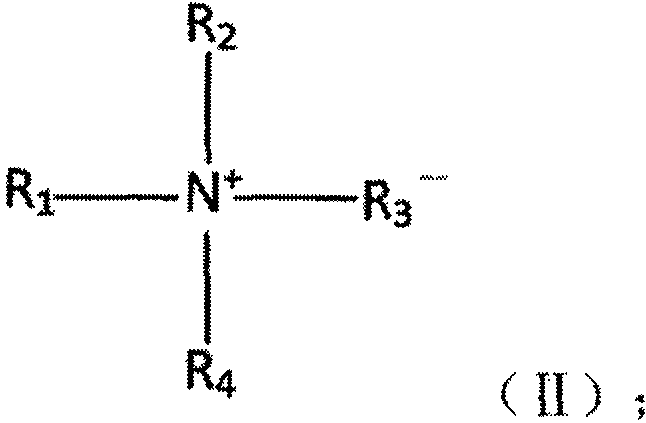

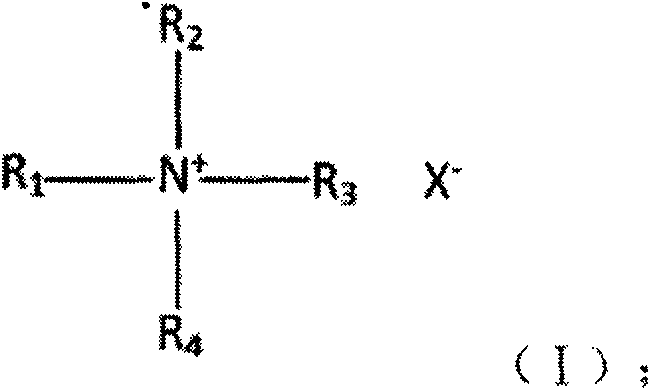

Additive for plating assisting, plating assisting solution and hot-dip plating method

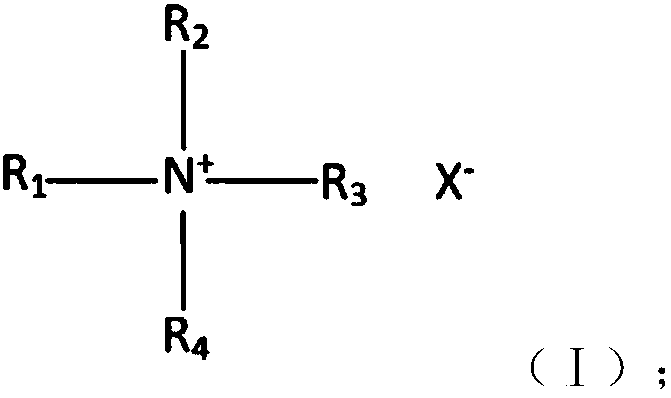

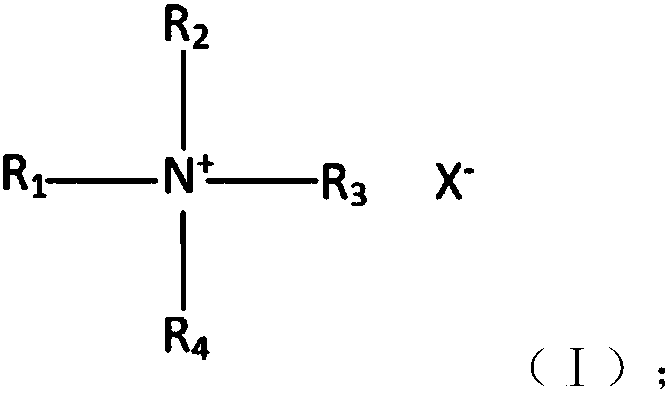

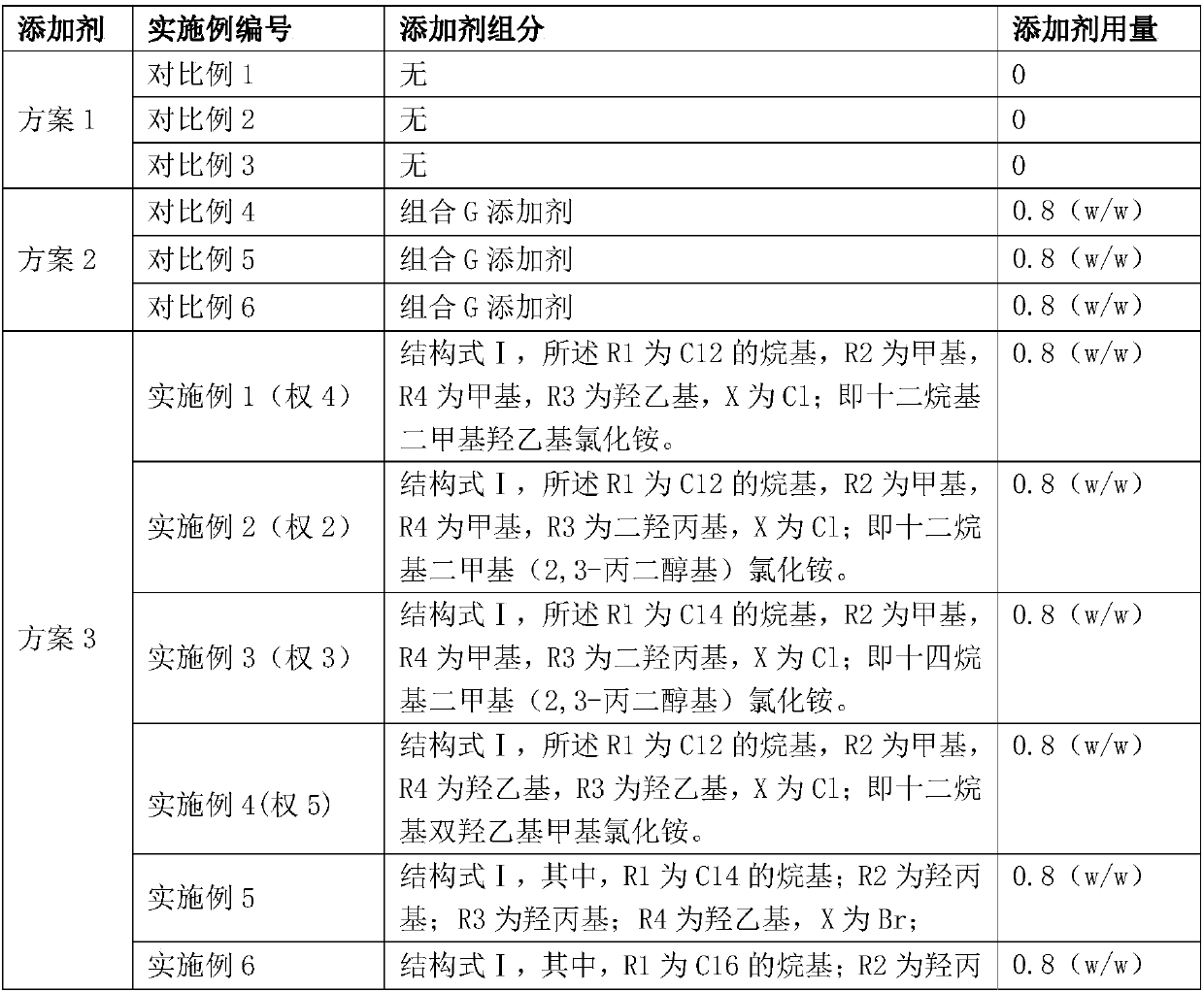

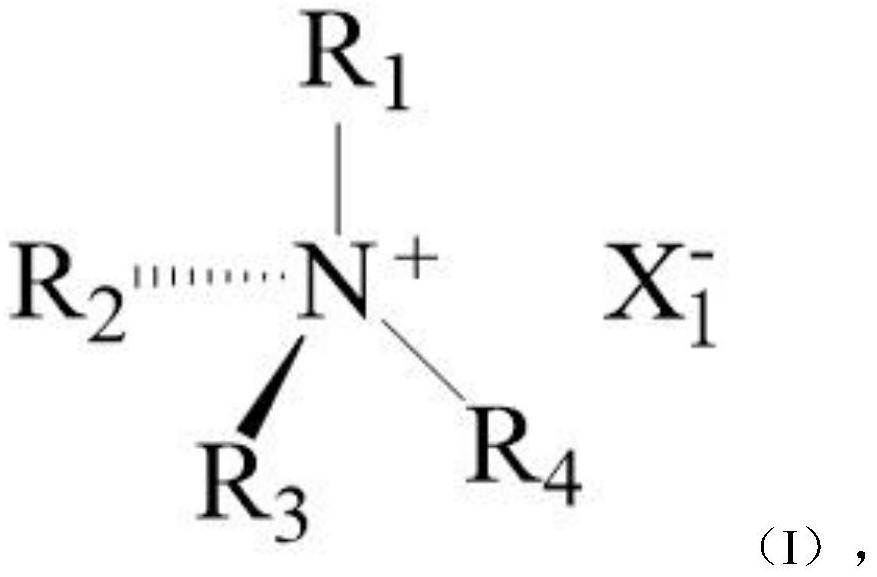

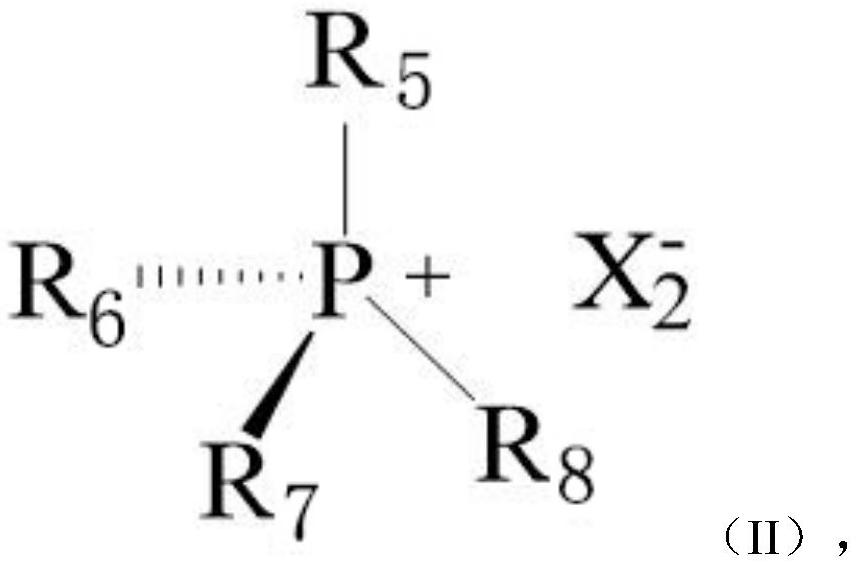

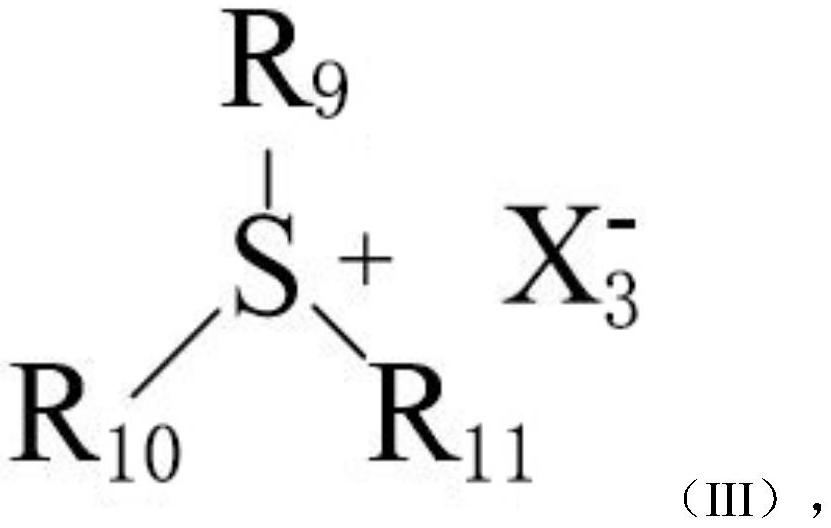

ActiveCN107699833AReduce the amount of adhesionGood interface wettabilityHot-dipping/immersion processesOrganic chemistryMaterial consumptionMethyl group

The invention relates to an additive for plating assisting, a plating assisting solution and a hot-dip plating method in the technical field of chemical engineering. The additive for plating assistingcomprises a chemical compound which is as shown in the formula I (Please see the formula I in the specification.), wherein R1 represents C12-16 alkyl radical, R2 represents methyl or hydroxypropyl, R3 represents one of hydroxyethyl, hydroxypropyl and dihydroxy propyl, R4 represents one of methyl, hydroxyethyl and dihydroxy propyl, and X represents one of Cl, Br and I. According to the additive, better interface wettability between molten coated metal and workpieces can be achieved, and skip plating is prevented; and meanwhile, the adhesion amount of a plating assisting agent is reduced, the drying process is accelerated, the risk of accidents such as scalds is reduced, the dip plating time is shortened, and material consumption is reduced.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

Method for manufacturing clothes hanger with wood chips as raw material

InactiveCN107914331AIncrease added valueImprove adsorption capacityWood working apparatusDomestic articlesCompression moldingDaily living

The invention belongs to the technical field of daily living articles and specially discloses a method for manufacturing a clothes hanger with wood chips as the raw material. The method for manufacturing the clothes hanger with the wood chips as the raw material comprises the following steps of (1) processing the wood chips, wherein the dried wood chips are processed through an amphoteric surfactant BS-12 aqueous solution, then primarily-modified wood chips are obtained, pyrolysis is conducted on the primarily-modified wood chips, and then re-modified wood chips are obtained; (2) mixing raw materials, wherein by weight, a certain parts of the primarily-modified wood chips, the re-modified wood chips and an adhesive are weighed and evenly mixed; (3) conducting compression molding; (4) spraying finishing paint. According to the method for manufacturing the clothes hanger with the wood chips as the raw material, the wood chips are used as the raw material, the wood chips are modified, then the wood chips, the adhesive and the like are mixed and placed in a mold to be pressed to form the clothes hanger, in this way, the application range of the wood chips is expanded, the additional value of wood chip machining is increased, and the manufactured clothes hanger has good mechanical performance.

Owner:荔浦庆祥竹木有限公司

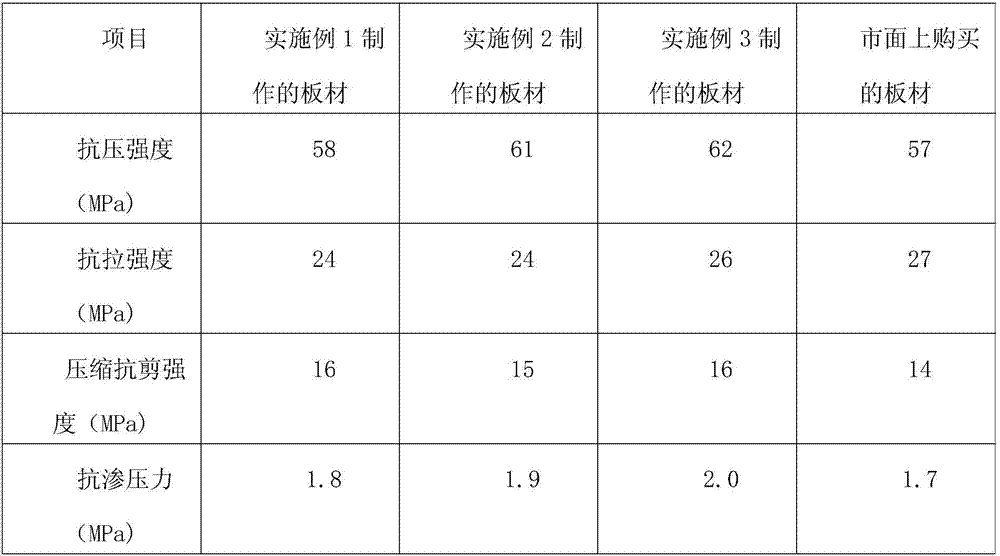

Method for manufacturing board by using saw dust

InactiveCN107972156AIncrease added valueImprove mechanical propertiesWood treatment detailsThermal wood treatmentCompression moldingMetallurgy

The invention belongs to the technical field of furniture material products, and particularly discloses a method for manufacturing a board by using saw dust. The method for manufacturing the board byusing the saw dust comprises the steps of (1), raw material pretreatment, (2), raw material mixing, (3), compression molding, and (4), post treatment. According to the method, the saw dust is used asa raw material, is subjected to modification treatment and then is mixed with an adhesive and the like to be put into a die to be pressed and to be made into the board, so that the application range of the saw dust is enlarged, the additional value of saw dust processing is improved, and the produced board has good mechanical properties.

Owner:广西桂林林博士家具有限公司

Method for processing preserved apricot

InactiveCN101946848BPrevent browningEliminate hardening processConfectionerySweetmeatsLiquid ratioBrix

The invention discloses a method for processing preserved apricot, which belongs to the technical field of fruit and vegetable processing. The method is characterized by comprising the following steps of: cleaning and dissecting apricots and removing cores to obtain apricot bowls; performing superheated steam jet impact blanching for 30 to 180 seconds under the conditions that the airflow temperature is 100 to 150 DEG C, the air speed is 6 to 20m / s and the relative humidity is 10 to 90 percent; soaking the apricot bowls into 45 to 70-degree sugar solution of Brix in a material-liquid ratio of1:3-1:10, soaking sugar in a vacuum pulsation pressure device, and performing pulsation in a pulsation ratio of 1-15min: 1-15min when the vacuum degree of a pulsation pressure chamber is between 0.080-0.098MPa and 0MPa, wherein the sugar soaking temperature is room temperature and the time is 1 to 6 hours; and drying the apricot bowls in a gas jet impact drying oven for 8 to 20 hours at the temperature of between 50 and 70 DEG C and the air speed of between 3 and 20m / s to obtain the preserved apricot. Because the superheated steam blanching technology is adopted, sulfur is not fumigated during processing, and any additive is not used; and because the vacuum pulsation pressure low-temperature quick osmosis technology is adopted, nutrition loss caused by repeated high-temperature hot boiling is avoided, and sugar osmosis can be greatly quickened.

Owner:CHINA AGRI UNIV

High-carbon preservative bamboo wallboard and production method

ActiveCN106808550AImprove anti-corrosion performanceDoes not affect glossConstruction materialDomestic articlesHigh carbonPreservative

The invention discloses a high-carbon preservative bamboo wallboard production method, which comprises the steps of (1) removing tabasheer from a fresh bamboo and rolling the bamboo to obtain a silky bamboo splint; (2) drying the bamboo splint until the water content is lower than 6-9%; (3) carbonizing the bamboo splint that meets the water content requirement in a carbonization chamber at normal pressure, and selecting qualified and removing the unqualified bamboo splint after carbonization; (4) processing the qualified carbonized bamboo splint by impregnation, and drying the bamboo splint until the water content is between 13-17% after processing; and (5) processing the bamboo splint for health preserving and balancing in a health preserving room; (6) performing hot pressing moulding to obtain a bamboo sheet; (7) processing the bamboo sheet to obtain the bamboo wallboard. The invention also relates to a bamboo wallboard obtained by the above method. The bamboo preservative performance of the bamboo wallboard can be greatly improved by carbonization; the production period is short; the operation is simple; the appearance quality is high; and advantages like safety and environmental protection are provided.

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

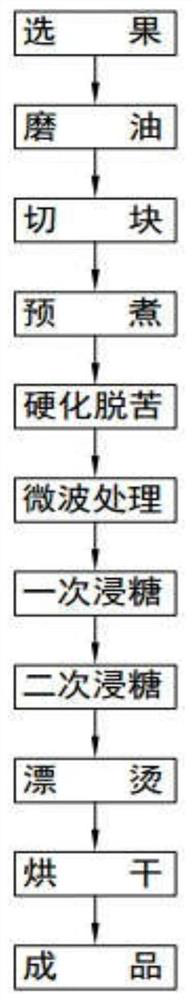

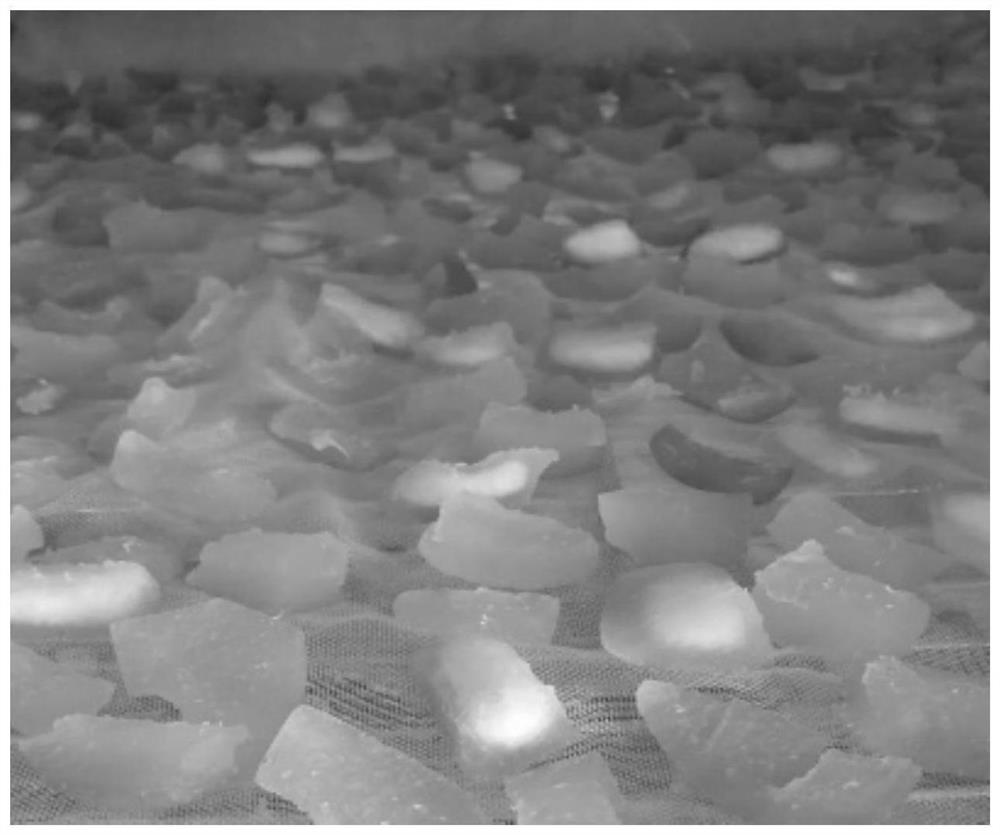

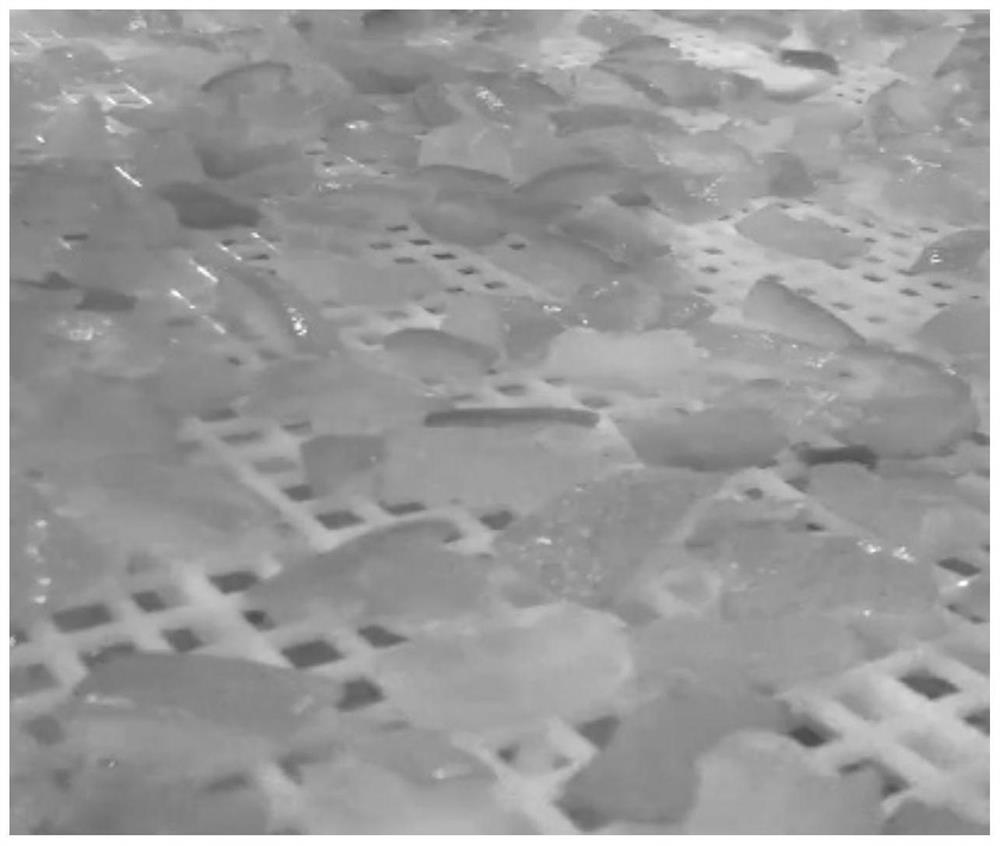

Method for preparing low-sugar orange preserved fruits through enzymatic hardening intermittent vacuum sugar soaking

ActiveCN113712107AMaintain nutrientsKeep the flavorFruit and vegetables preservationConfectioneryBiotechnologyFruit development

The invention discloses a method for preparing low-sugar orange preserved fruits through enzymatic hardening intermittent vacuum sugar soaking. The method comprises the following steps of cleaning orange fruits and grinding peels; peeling and dicing the orange fruits or hardening the whole orange fruits with pectinesterase and calcium ions; after hardening, blanching and boiling with hot water to remove bitterness; after debitterizing, carrying out intermittent vacuum sugar soaking according to a certain sugar liquid and material ratio; and soaking in sugar and drying. According to the method, the processes of mechanical oil grinding, enzymatic hardening, intermittent vacuum sugar soaking and the like are innovatively adopted, so that the orange peel essential oil is recycled, a traditional hardening method of chemical reagents such as lime water, sodium pyrosulfite, calcium chloride and alum is avoided, the sugar soaking process is accelerated, the sugar soaking time is shortened, the production efficiency is greatly improved, the sugar content of a product is reduced, the method maximally maintains the nutritional ingredients and flavor of raw materials, improves the product appearance, conforms to current preserved fruit development trend, has the characteristics of high resource utilization rate, environmental protection, short processing time, high production efficiency, good product quality and the like.

Owner:SOUTHWEST UNIVERSITY +2

Hot dip galvanizing processing technology

InactiveCN107937854AImprove adhesionReduce generationHot-dipping/immersion processesWater flowMoisture

The invention discloses a hot dip galvanizing processing technology. The hot dip galvanizing processing technology comprises the following steps that 1, a workpiece is degreased; 2, the workpiece is washed by using a hydrochloric acid solution for 35-40 minutes, and then is washed by using clear water; 3, after the water flow for washing the workpiece in the step 2 flows into a neutralization tankto perform neutralization reaction, the water flow is discharged into the outside; 4, plating assistance is carried out, wherein the workpiece is placed in a plating assistance solution with the temperature of 60-80 DEG C for 10-12 seconds; 5, drying is carried out, wherein the workpiece is dried in a drying chamber with the temperature of 130-140 DEG C for 1-2 minutes, and moisture on the surface of the workpiece is removed; 6, hot dip plating is carried out; and 7, cooling is carried out. According to the hot dip galvanizing processing technology, Al and Ni are added into a plating solution, so that the product quality is effectively improved, and the hot dipping efficiency is high; and then, before hot dip plating, the workpiece firstly reacts with the plating assistance solution, so that the surface of the workpiece is activated, the adhesive force of a zinc layer is increased, the quality of the workpiece is improved, and the production efficiency is improved.

Owner:浙江金盛钢管塔有限公司

High-efficiency penetrant for composite material

PendingCN113248899ARapid Wetting and PenetrationUniform wetting and penetrationPolymer scienceAlcohol ethyl

The invention discloses an efficient penetrant for a composite material. The penetrant is prepared from the following raw materials in parts by weight: 1 to 40 parts of fatty alcohol-polyoxyethylene ether, 1 to 40 parts of isomeric alcohol polyoxyethylene ether, 0.1 to 1 part of urea, 0.1 to 1 part of triethanolamine, 2 to 15 parts of ethanol and 40 to 70 parts of water. Compared with the prior art, the high-efficiency penetrant for the composite material provided by the invention has the advantages that resin can be quickly and uniformly wetted and permeated in a fiber base material, penetration time is only 40-50 seconds, and gum dipping time is shortened.

Owner:中复(常州)新材料有限公司

Additive for flux plating, flux solution and hot-dip plating method

ActiveCN107699833BReduce the amount of adhesionGood interface wettabilityHot-dipping/immersion processesOrganic chemistryMetallurgyPhysical chemistry

The present invention relates to an additive for plating flux, a plating flux solution and a hot-dip plating method in the field of chemical industry. The additive for plating flux contains a compound of the following formula I: (I); wherein R1 is C12- 16 alkyl; R2 is methyl or hydroxypropyl; R3 is one of hydroxyethyl, hydroxypropyl, and dihydroxypropyl; R4 is one of methyl, hydroxyethyl, and dihydroxypropyl , X is one of Cl, Br, I. The additive of the present invention can make the interface wettability better between the molten coating metal and the workpiece, reduce the amount of plating flux adhesion while preventing the occurrence of missing plating, accelerate the drying process, reduce the risk of accidents such as burns, and shorten the immersion plating time , reduce material consumption.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

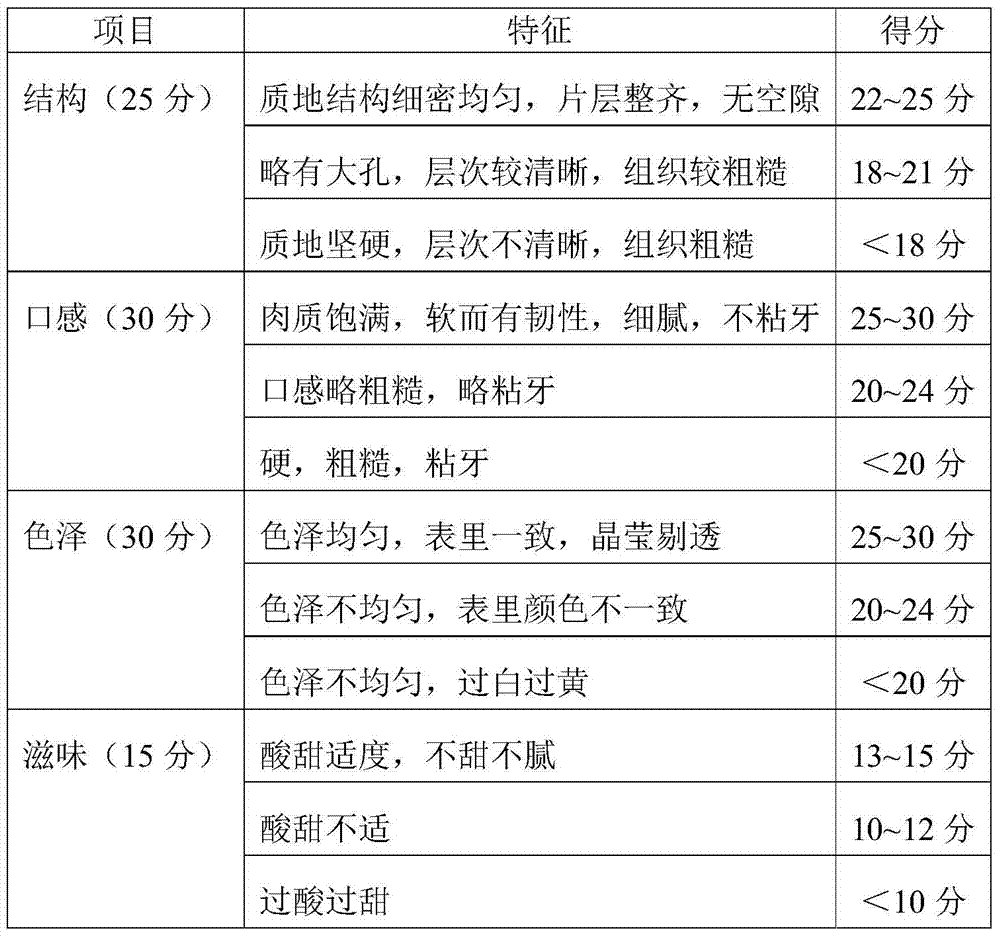

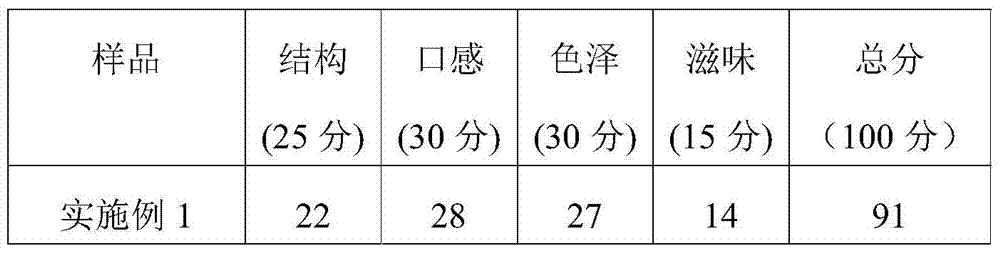

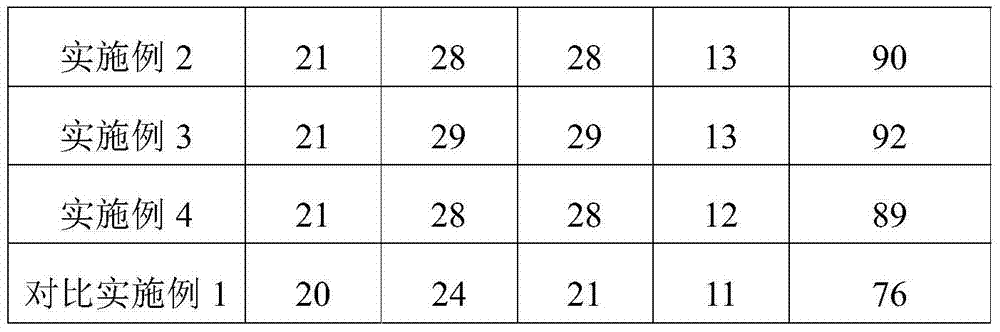

A kind of mushroom candied fruit and preparation method thereof

The invention discloses a candied mushroom and a preparation method thereof. The invention provides a preparation method of preserved shiitake mushrooms, which comprises the following steps: (1) putting shiitake mushrooms into citric acid aqueous solution for blanching, taking them out, and draining to obtain blanched shiitake mushrooms; (2) blanching shiitake mushrooms in step (1) Pour the blanched shiitake mushrooms described in into the sugar solution for the first dipping in sugar for the first time, take it out, drain, and get the shiitake mushrooms once soaked in sugar; (3) soak the mushrooms described in step (2) once Pour the sugared shiitake mushrooms into the sugar solution for the second sugar dipping for the second time, take out, drain, and get the second sugar dipping mushrooms; (4) pour the second sugar dipping mushrooms described in step (3) Carry out sugar dipping for the third time in the sugar solution of dipping sugar for the third time, get three times sugar dipping mushrooms; Soft, mixed with powder for the second time, that is to say. The preparation method has high production efficiency, and the prepared candied mushrooms have good taste, good color and long shelf life.

Owner:上海大山合菌物科技股份有限公司

Multifunctional plating assistant additive for hot-dip metal plating and preparation method thereof

ActiveCN112430795AGood explosion-proof functionImprove wettabilityHot-dipping/immersion processesMetallic materialsAlclad

The invention discloses a multifunctional plating assistant additive for hot-dip metal plating and a preparation method thereof, which belongs to the technical field of corrosion prevention of metal materials, and aims to improve the wettability between liquid metal and a workpiece, improve plating assistant adhesion uniformity and continuity, and reduce drying time by by adding explosion-proof factors into traditional raw materials. By adding a ampholytic surfactant and a nonionic surfactant, liquid metal splashing can be effectively prevented, immersion plating time can be shortened, raw materials can be saved, the residue form can be improved, ash content can be reduced, ash discharge speed can be increased, air can be isolated, oxidation can be completely eradicated, and residual dirtcan be expelled. The multifunctional plating assistant additive is suitable for various processes such as hot galvanizing, hot galvanizing of aluminum alloy and hot aluminizing.

Owner:南通昇润新材料有限公司

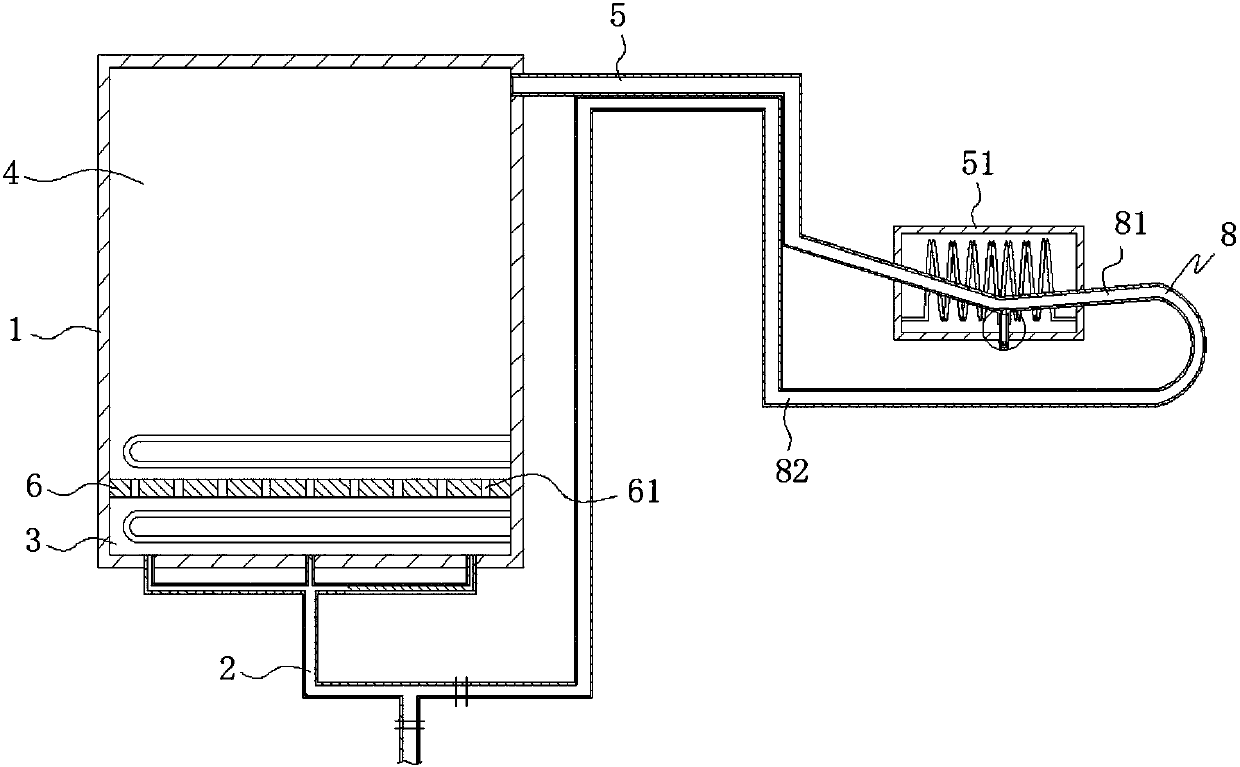

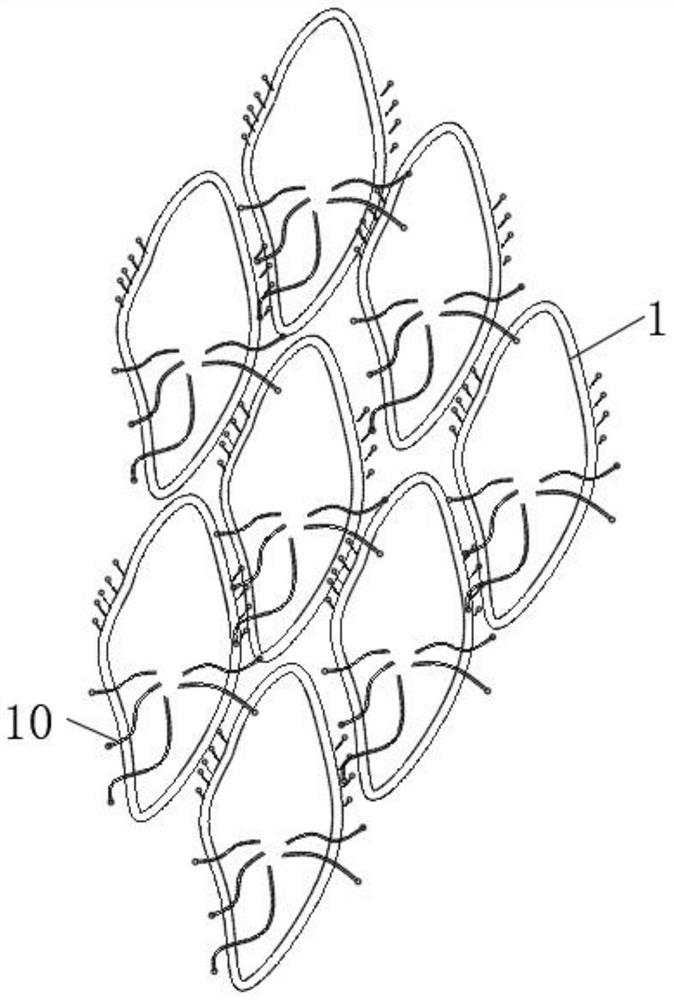

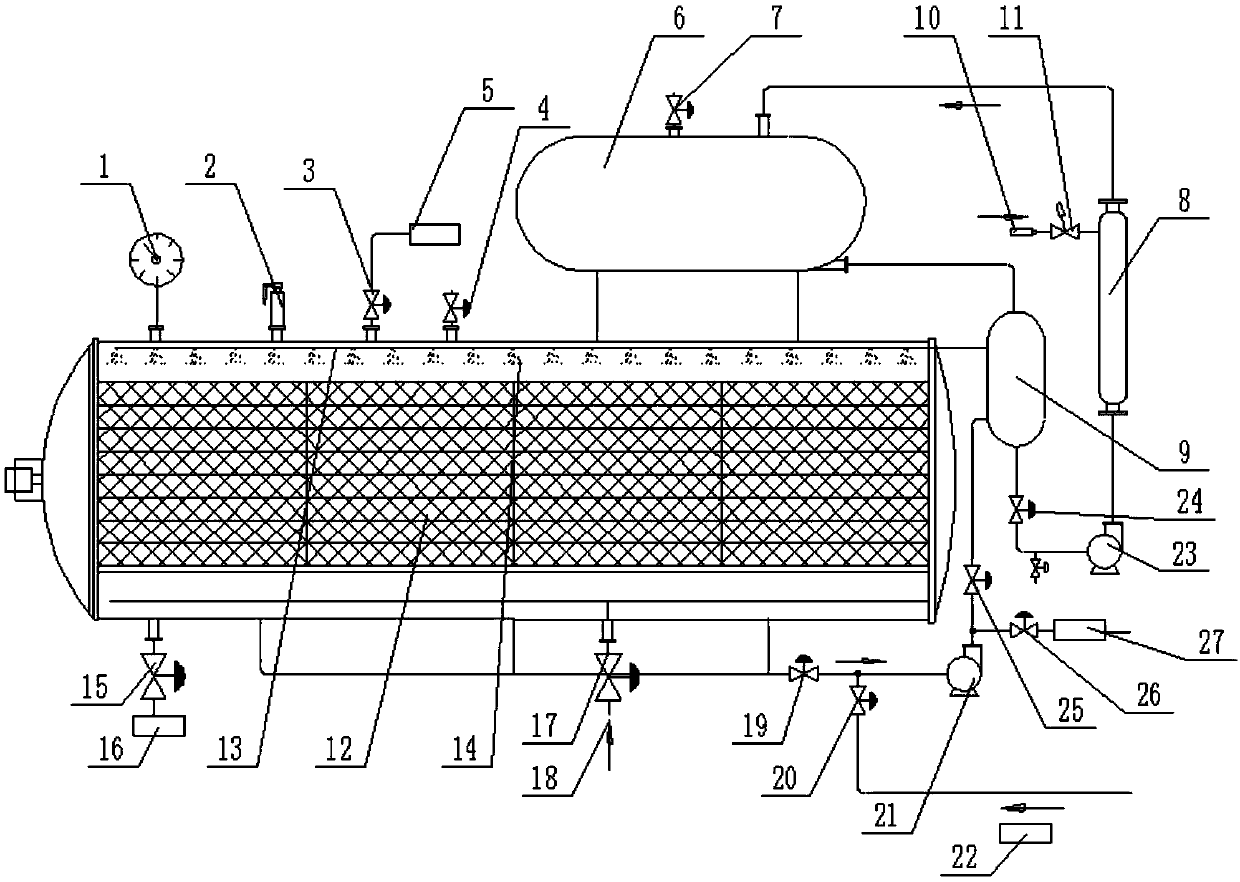

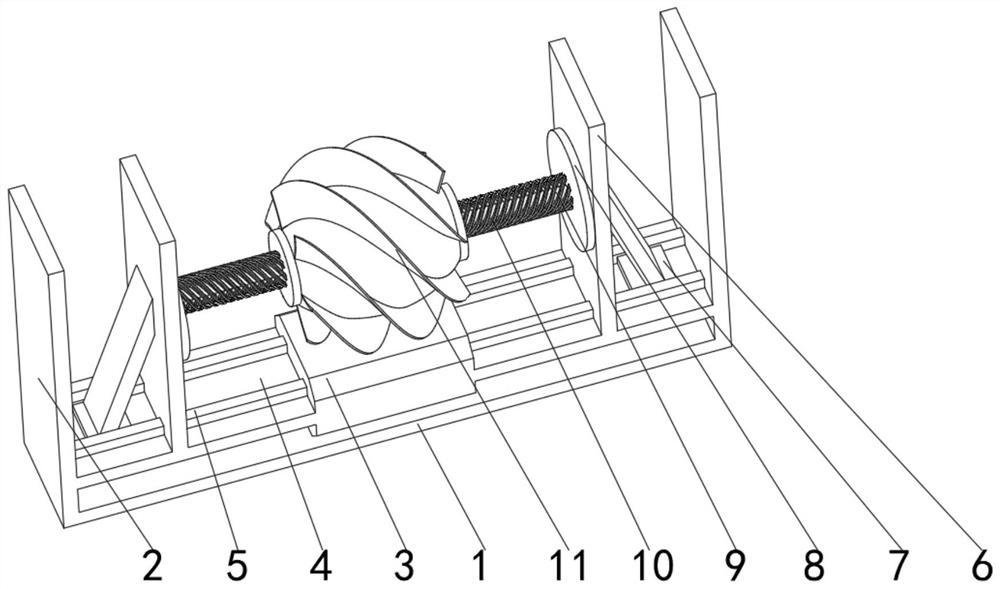

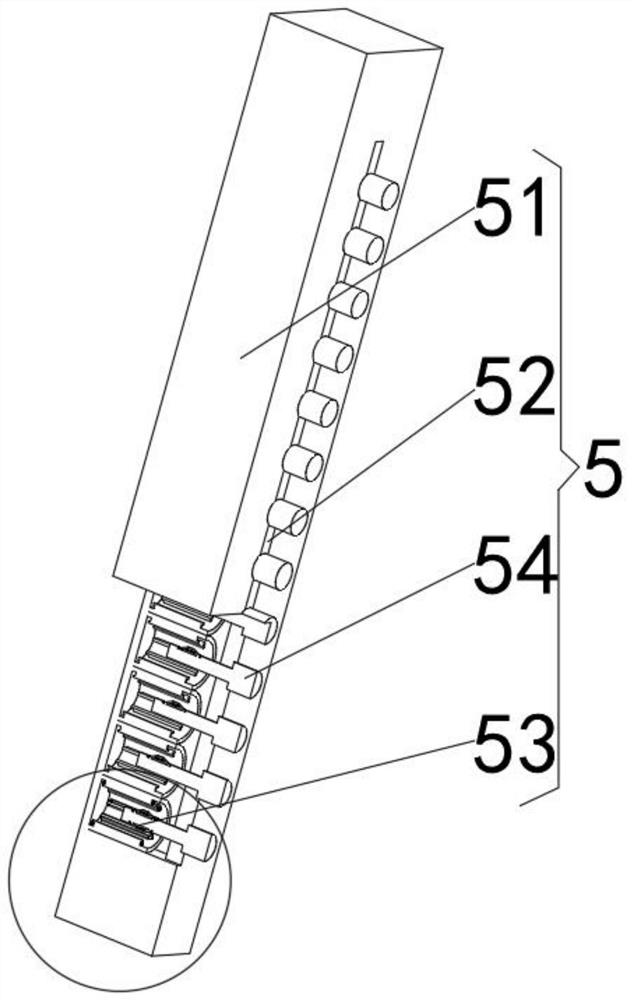

Preserved fruit circular spraying vacuum sugar-soaking equipment

InactiveCN109511765AShorten dipping timeQuick feeding and unloadingConfectionerySweetmeatsPulp and paper industrySugar

The invention relates to preserved fruit circular spraying vacuum sugar-soaking equipment and belongs to the technical field of preserved fruit processing. The equipment comprises a sugar soaking tank, a heater exchanger and a hot water tank. The hot water tank is arranged at the upper end of the sugar soaking tank, the heat exchanger is arranged on the right side of the sugar soaking tank, a spray pipe is fixed to the top end in the sugar soaking tank, the right end of the spray pipe is connected to the heat exchanger, the lower left end of the heat exchanger is connected to a sugar liquid circulating pump, the upper end of the heat exchanger is connected to the hot water tank, the lower end of the heat exchanger is connected to a hot water circulating pump, and a steam tank is arranged between the hot water circulating pump and the hot water tank. The preserved fruit circular spraying vacuum sugar-soaking equipment has the beneficial effects that the sugar soaking time can be shortened greatly by way of vacuum sugar soaking; the horizontal tank is near the ground, so that materials are input and taken quickly, and the equipment is convenient and rapid; the syrup can be at constant temperature by means of the heat exchange, so that the whole sugar soaking process is carried out in a closed environment, and therefore, all external pollution is avoided and the equipment is safeand sanitary.

Owner:烟台鲁顺食品股份有限公司

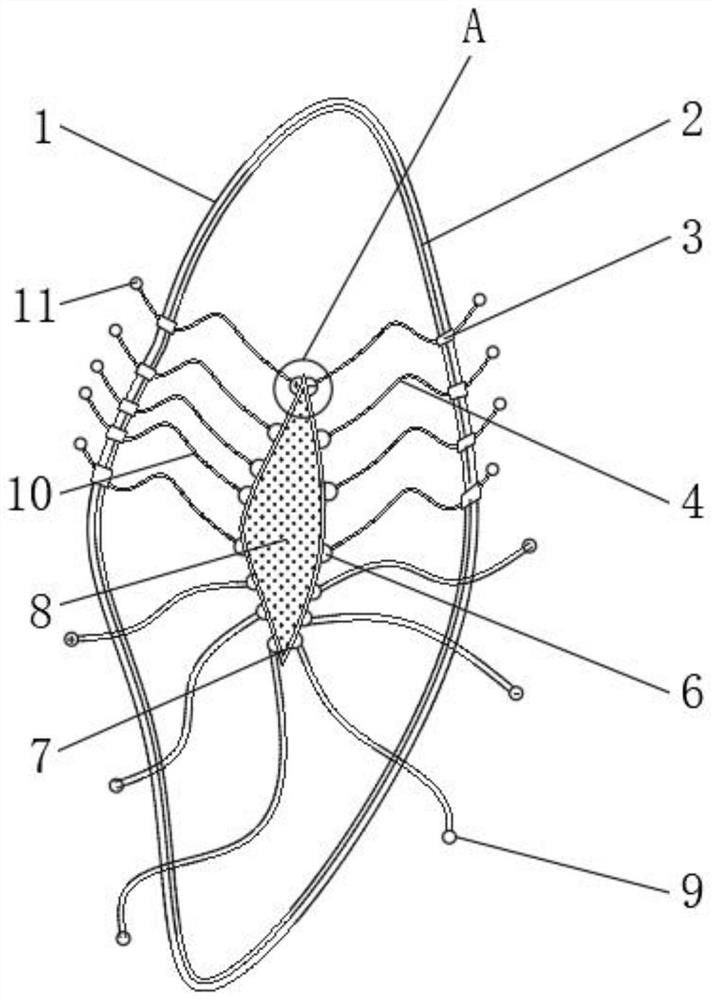

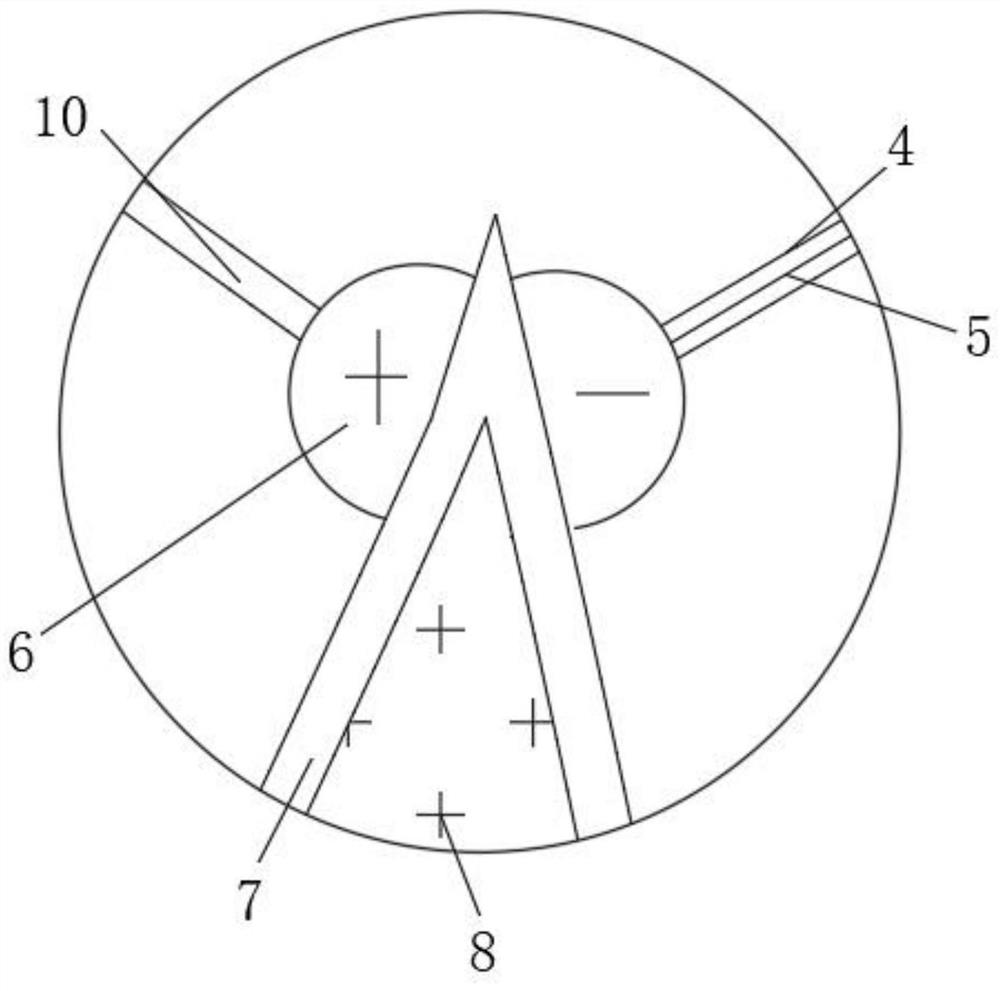

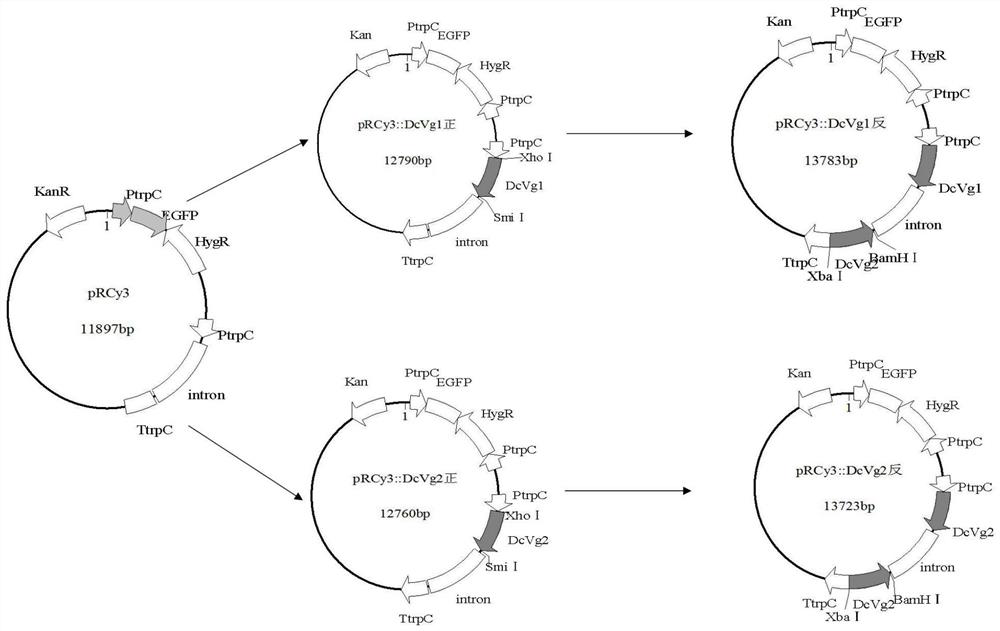

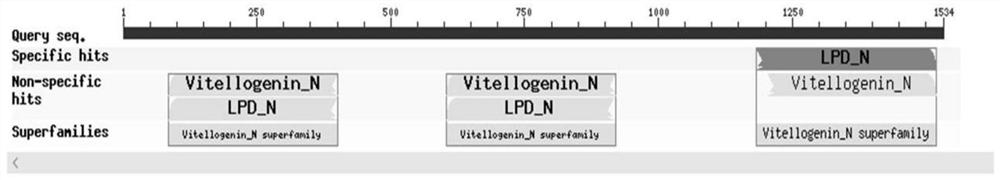

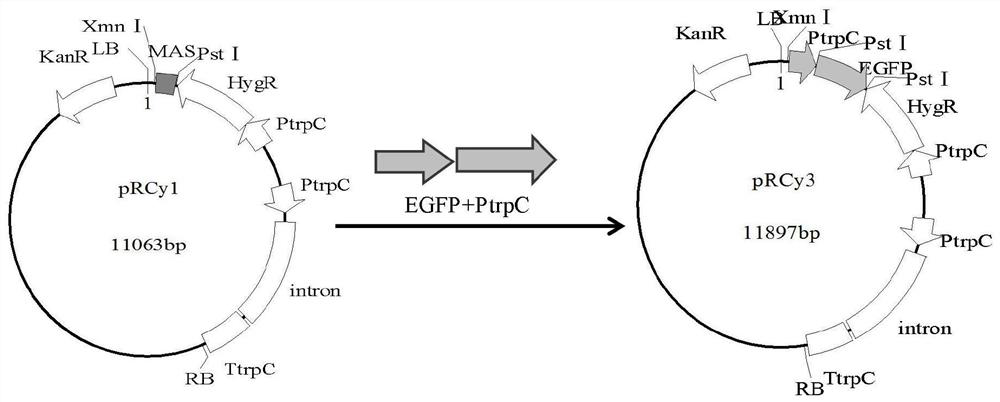

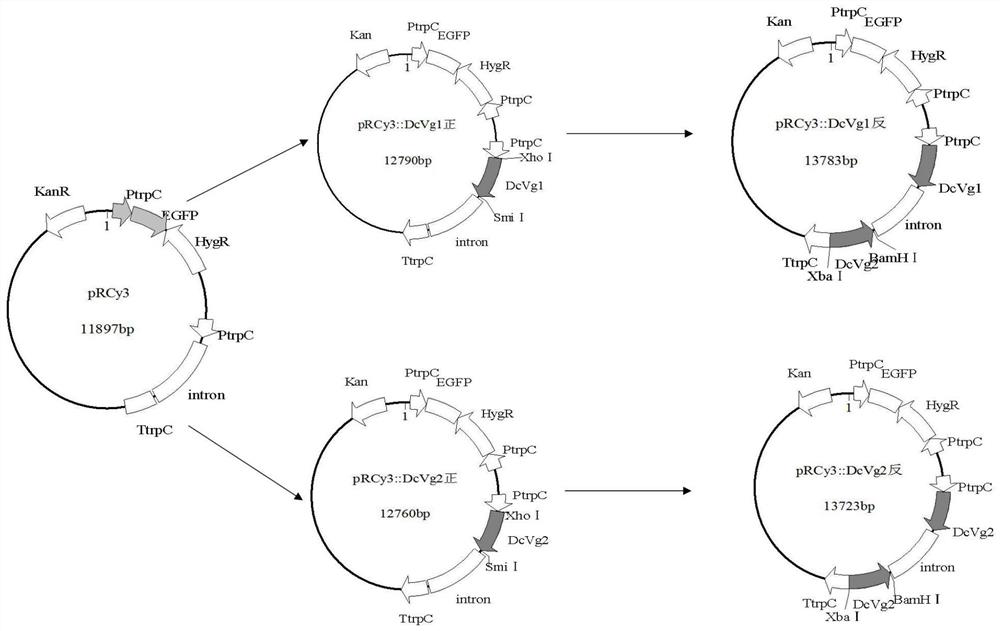

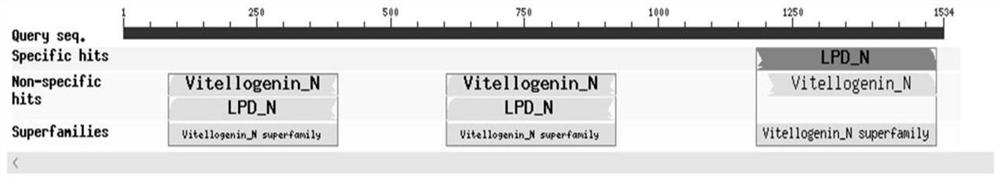

Transgenic biocontrol fungus interfering with citrus psyllid vitellogenin gene expression and its preparation method and application

The invention discloses a citrus psyllid vitellogenin gene RNAi carrier and its preparation method and application. The RNAi carrier includes a backbone carrier and a hairpin structure, and the hairpin structure is an ihpRNA expression cassette. The structure is PtrpC promoter+forward target gene segment+intron+reverse target gene segment+TtrpC terminator structure, the target gene segment is the conserved sequence DcVg1a or DcVg1b of the citrus psyllid vitellogenin gene; the backbone vector is filamentous Fungal expression vector. Also disclosed is a transgenic biocontrol fungus and its preparation method and application. The transgenic biocontrol fungus is obtained by using the RNAi vector to transform the biocontrol fungus. Experiments have confirmed that the obtained transgenic Lecanococcus attenuata can effectively improve its virulence to citrus psyllids and shorten the time of infecting psyllids.

Owner:SOUTHWEST UNIV

Deep eutectic solvent type hot galvanizing additive and preparation method and application thereof

ActiveCN113088856APrevent splashStop splashHot-dipping/immersion processesInorganic saltsActive agent

The invention belongs to the technical field of plating assistant additives, and discloses a deep eutectic solvent type hot galvanizing additive and a preparation method and application thereof. The deep eutectic solvent type hot galvanizing additive is prepared by heating a deep eutectic solvent, a nonionic surfactant, inorganic salt and deionized water according to the weight ratio of (30-70): (1-20): (3-8): (1-10), mixing the materials uniformly and standing the mixture. The additive is suitable for being directly added into a plating assistant and applied to a hot galvanizing process, molten zinc splashing in the galvanizing process can be effectively prevented, molten zinc loss is reduced, the galvanizing speed is increased, the yield is increased, consumption of ammonium zinc chloride in the plating assistant is reduced, and the carrying amount of iron ions can be remarkably reduced; and the drying time of a plating agent is shortened, the production efficiency is improved, residual oil stains on the surface of a plated part are effectively removed, air is isolated, secondary rusting caused by oxidation is relieved, skip plating is obviously reduced, the molten zinc splashing strength is weakened, the risk of accidents such as scalding is reduced, and meanwhile smoke reduction and environmental protection are achieved.

Owner:JIANGXI SCI & TECH NORMAL UNIV

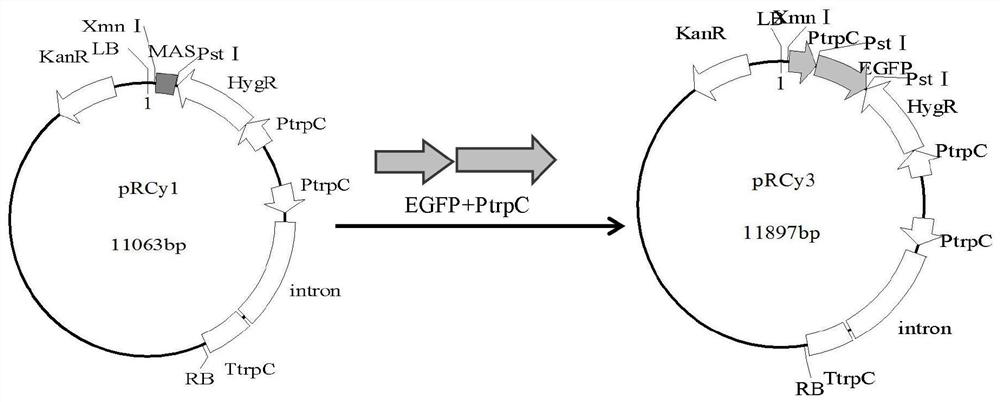

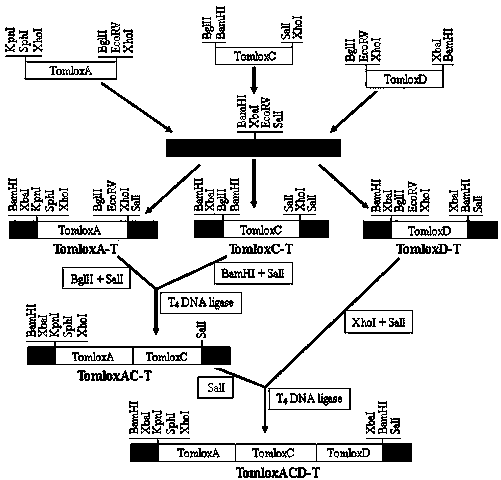

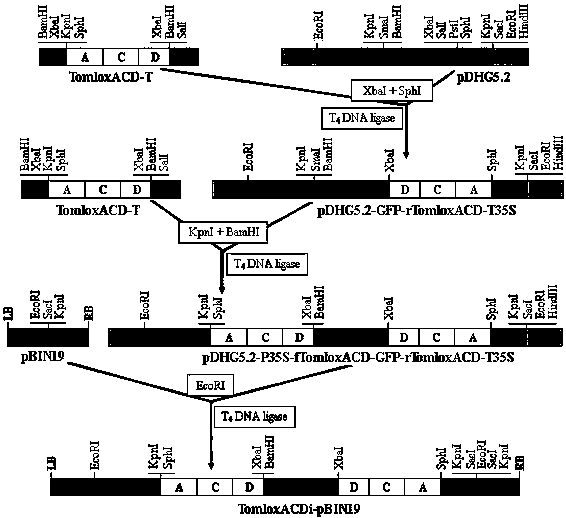

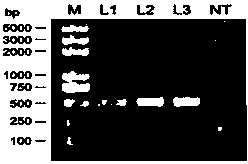

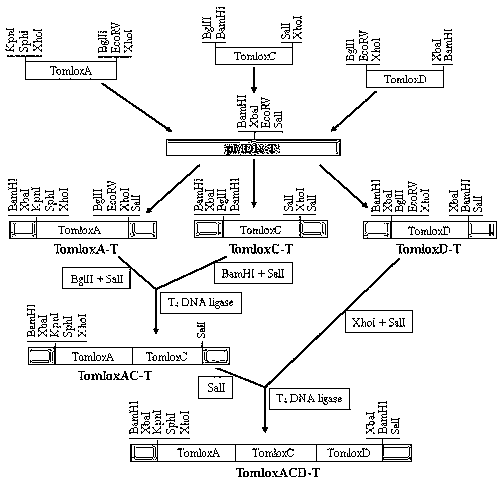

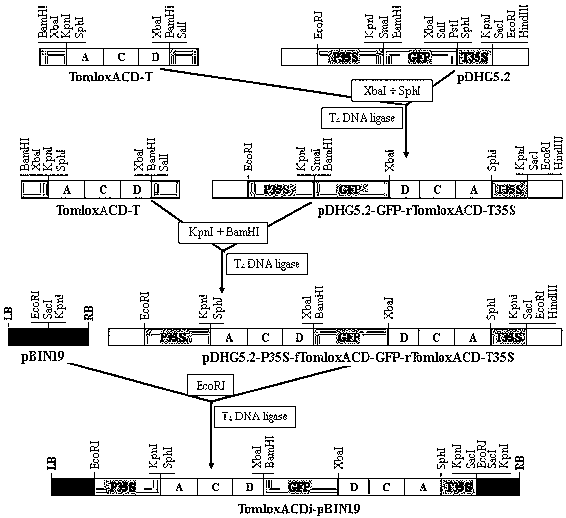

Tomato lipoxygenase family silent expression vector, and construction method and application thereof

The invention discloses a tomato lipoxygenase family silent expression vector and its construction method and application. The silent expression vector contains a double-stranded RNA expression unit, including a promoter, a forward segment of the TomloxACD splicing gene, and a reverse segment of the TomloxACD splicing gene and terminator, the TomloxACD splicing gene is spliced by the TomloxA gene fragment (SEQIDNo.1), the TomloxC gene fragment (SEQIDNo.2) and the TomloxD gene fragment (SEQIDNo.3); the silencing expression vector is transferred into by Agrobacterium-mediated The contents of α-linolenic acid and linoleic acid in the fruits of transgenic positive plants obtained from wild-type tomato were significantly higher than those of non-transgenic plants, indicating that the silencing expression vector can be used for breeding tomato plants with high unsaturated fatty acid fruit. It has a good application prospect in improving the fruit quality and improving the nutritional value of tomato fruit.

Owner:CHONGQING UNIV

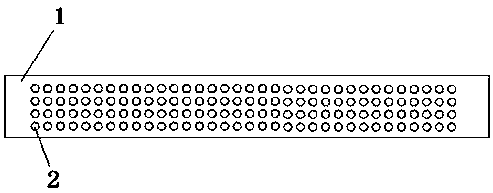

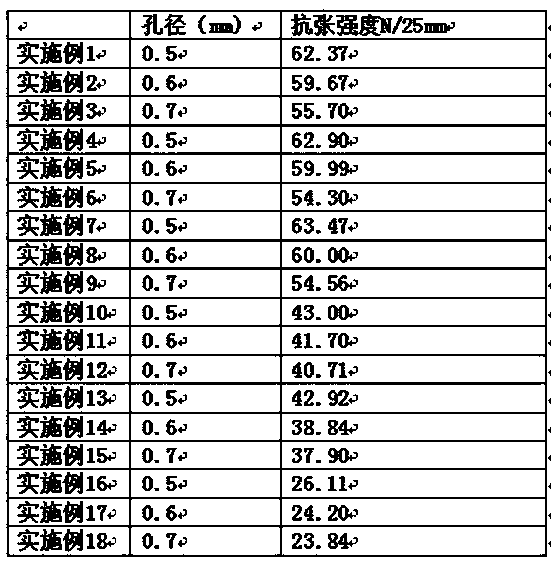

A kind of release material with hole and preparation method thereof

ActiveCN107151388BImprove wear resistanceHigh tensile strengthLaser beam welding apparatusBreakage probabilityEpoxy

Owner:SHANDONG QILU ELECTRIC MOTOR MFG

Textile dip dyeing equipment

InactiveCN112411080APrevent sinkingImprove processing qualityLiquid/gas/vapor treatment machines driving mechanismsTextile treatment containersTextile technologyStructural engineering

The invention discloses textile dip dyeing equipment, and relates to the technical field of textile. The textile dip dyeing equipment comprises a base plate, protective baffles are fixedly connected to the symmetrical positions of the two sides of the top of the base plate, a magnetic electromagnet is fixedly connected to the middle position of the top of the base plate, and rail plates are fixedly connected to the middle positions of the outer walls of the two sides of the magnetic electromagnet. Power generation rails are fixedly connected to the front faces and the back faces of the tops ofthe rail plates, friction supports are fixedly connected to the middle positions of the sides, away from each other, of force application plates, and modulation rods are fixedly connected to the middle positions of the sides, away from the friction supports, of mounting discs. A traction rope is fixedly connected to the side, away from the friction supports, of the mounting discs, and a dip dyeing box is fixedly connected to the end, away from the mounting discs, of the traction rope. Power is applied through airflow flowing, textiles and dip dyeing liquid move mutually, the dip dyeing progress is promoted, the dip dyeing time is shortened, and the quality of the textiles is protected.

Owner:邓苗苗

Manufacturing method of paraffin sections of zostera marina embryo

ActiveCN102116711BAvoid deformationModerate hardnessWithdrawing sample devicesPreparing sample for investigationParaffin waxEmbryo

The invention discloses a manufacturing method of paraffin sections of zostera marina embryo, comprising the following steps: (1) material drawing and fixation: zostera marina seeds are taken and the fruit skin is stripped, and after endosperm is removed, an integral zostera marina embryo is soaked in FAA (free amino acids) fixing solution and is fixed for more than 48 hours; (2) dehydration: thezostera marina embryo is taken out from the fixing solution and is soaked in alcohol for dehydration; (3) waxing and embedding: paraffin is added gradually in a vessel containing the zostera marina embryo and dimethylbenzene, and conventional paraffin embedding is carried out to obtain the wax blocks containing the zostera marina embryo; (4) slicing, spreading and drying: the wax blocks coated with the zostera marina embryo is fixed on a wheel rotation type slicing machine for carrying out continuous slicing of the paraffin, so as to obtain wax bands and enable the wax bands to be attached toan object slide; (5) dewaxing, rehydration and dyeing of hematoxylin dye solution; (6) slicing, dehydration and dyeing of eosin and alcohol; and (7) transparence and mounting are carried out to manufacture a permanent section. In the manufacturing method disclosed by the invention, the paraffin sections of the zostera marina embryo, which have clear dyeing and an integral texture structure, can be obtained.

Owner:SHANDONG ORIENTAL OCEAN SCI TECH

Tomato lipoxygenase family silent expression vector, and construction method and application thereof

The invention discloses a tomato lipoxygenase family silent expression vector, and a construction method and application thereof. The silent expression vector contains a double-chain RNA (ribonucleic acid) expression unit, and comprises a promoter, a TomloxACD spliced gene forward segment, a TomloxACD spliced gene reverse segment and a terminator, wherein the TomloxACD spliced gene is spliced from TomloxA gene segment (SEQ ID No.1), TomloxC gene segment (SEQ ID No.2) and TomloxD gene segment (SEQ ID No.3). The silent expression vector is transformed into wild type tomato under the mediation of agrobacterium to obtain the transgenic positive plant; and the alpha-linolenic acid and linoleic acid content in the fruit is obviously increased as compared with that in the non-transgenic plant, which indicates that the silent expression vector can be used for breeding high-unsaturated-fatty-acid fruit tomato plants and has favorable application prospects in the aspects of improving the tomato fruit quality and enhancing the nutritive value of the tomato fruit.

Owner:CHONGQING UNIV

Transgenic biocontrol fungus for interfering expression of diaphorina citri kuwayama vitellogenin gene as well as preparation method and application of transgenic biocontrol fungus

Owner:SOUTHWEST UNIVERSITY

A kind of high-carbon anti-corrosion bamboo wallboard and production method thereof

ActiveCN106808550BImprove anti-corrosion performanceDoes not affect glossConstruction materialFlat articlesPreservativeHigh carbon

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

A kind of high-carbon anti-corrosion bamboo floor and production method thereof

ActiveCN106808547BImprove anti-corrosion performanceDoes not affect glossWood charring/burningHigh carbonCarbonization

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com