A kind of release material with hole and preparation method thereof

A release material with a hole technology, which is applied in the field of plastic film, can solve the problems of coil and mold damage, coil cannot be removed from the mold, and main insulation is impregnated, etc., to achieve enhanced impregnation performance, not easy to break, and short degradation cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

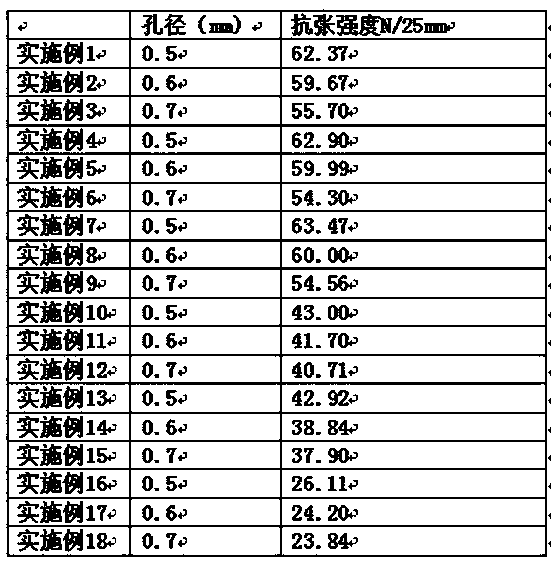

Embodiment 1

[0016] A release material with holes, comprising the following raw materials in parts by weight: 20 parts of polyethylene terephthalate, 20 parts of PVC paste resin, 15 parts of polyvinyl chloride, 10 parts of epoxy resin, 25 parts of polypropylene resin Parts, 1 part of fumed silica, 10 parts of polypropylene cellulose, 5 parts of pullulan, 1 part of cedar oil, 7 parts of 2-(2′-hydroxy-5′-methylphenyl) benzotriazole, 1 part of plasticizer, 1 part of light stabilizer, 4 parts of silane coupling agent;

[0017] A method for preparing a release material with holes, comprising the following steps, (1) polyethylene terephthalate, PVC paste resin, polyvinyl chloride, epoxy resin 1, polypropylene resin, gas phase dioxide Add silicon, polypropylene cellulose, pullulan, cedar oil and 2-(2'-hydroxy-5'-methylphenyl)benzotriazole into the hopper for one heating, the temperature of the first heating is 120°C, and the first heating The time is 40 minutes to obtain the mixture A; (2) Put t...

Embodiment 2

[0024] The other preparation methods are exactly the same as in Example 1 except that the diameter of each hole is 0.6 mm.

Embodiment 3

[0026] The other preparation methods are exactly the same as in Example 1 except that the diameter of each hole is 0.7 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com