Patents

Literature

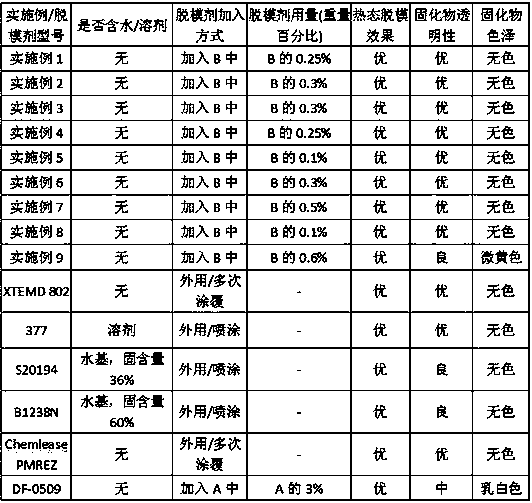

69results about How to "Guaranteed release effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

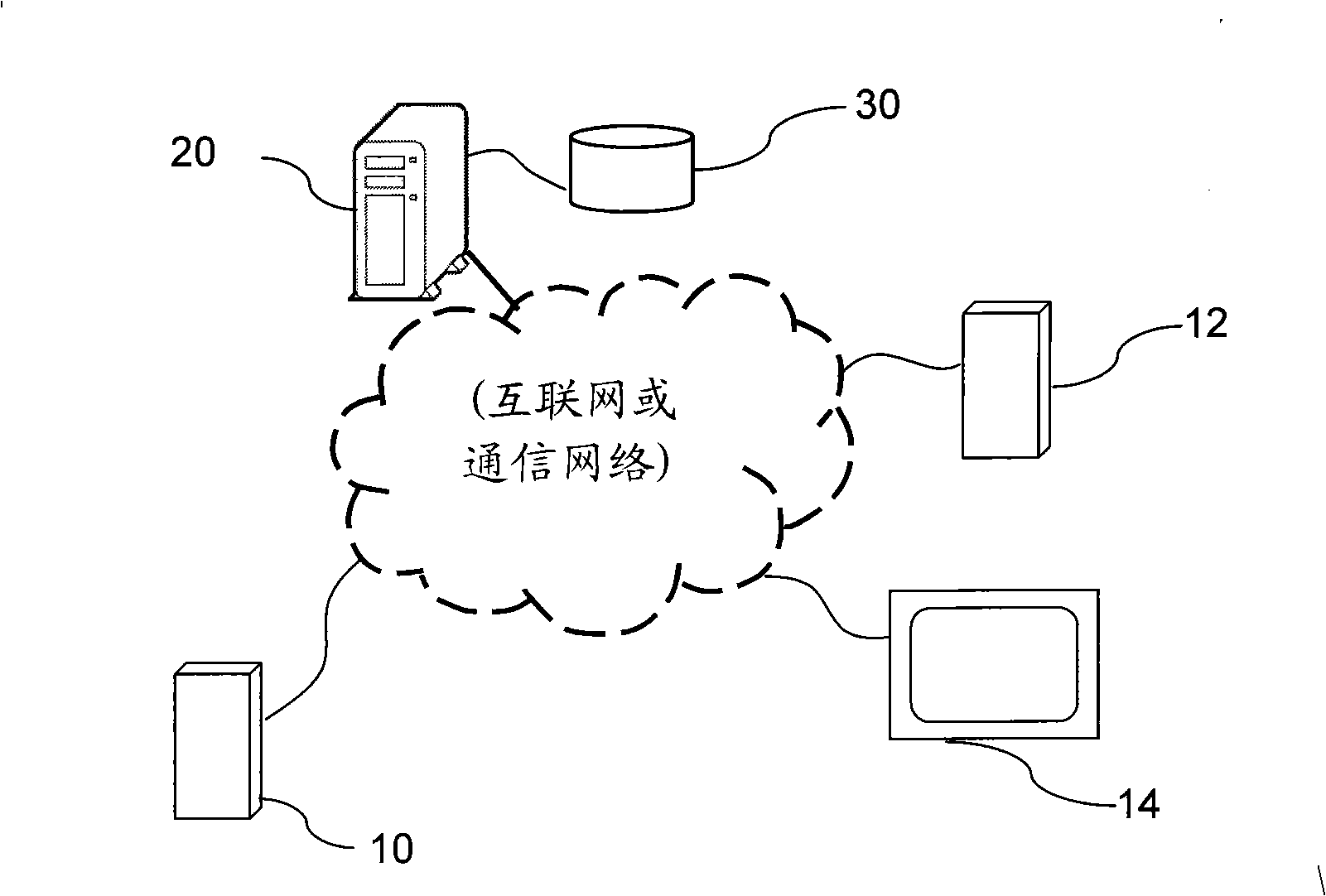

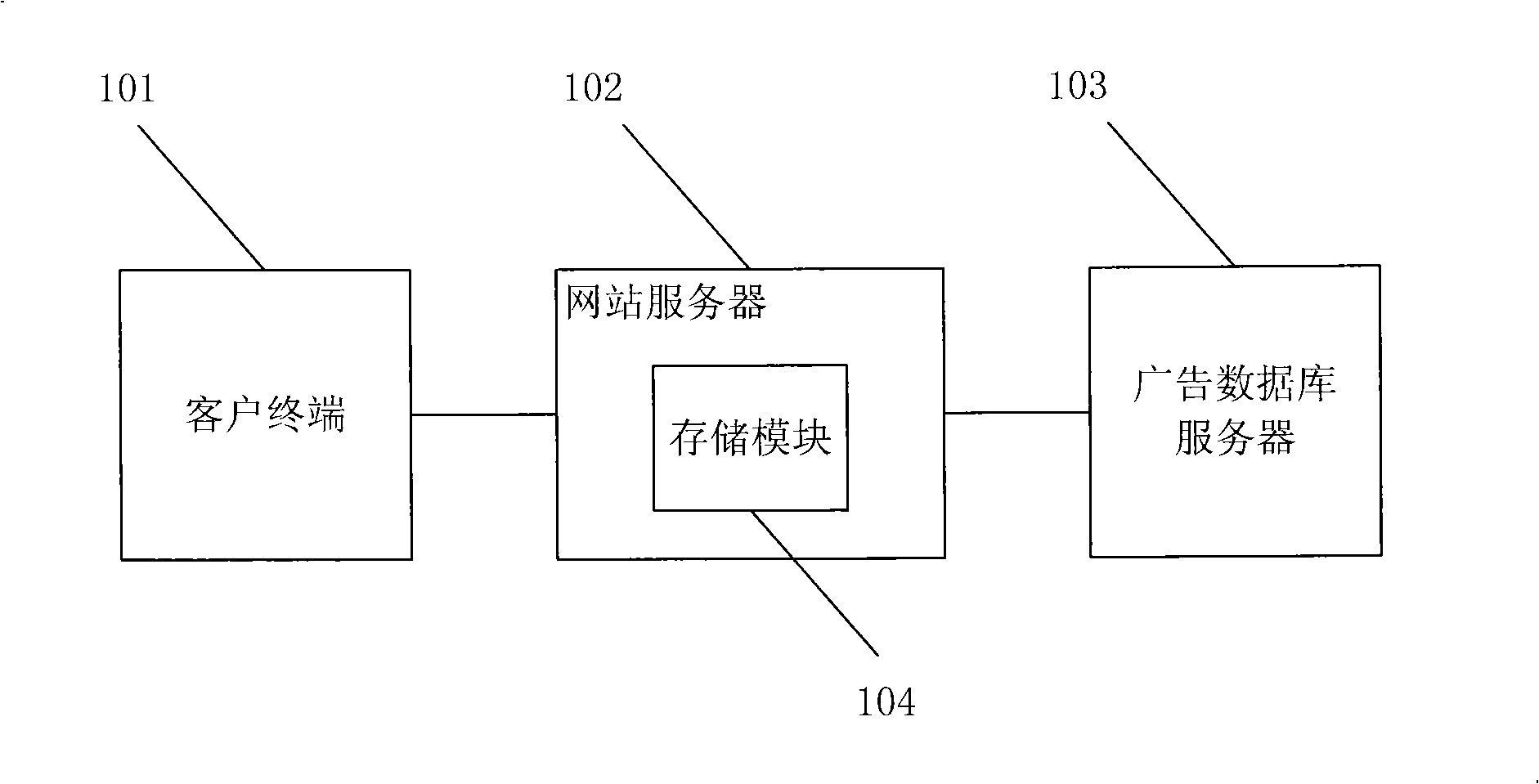

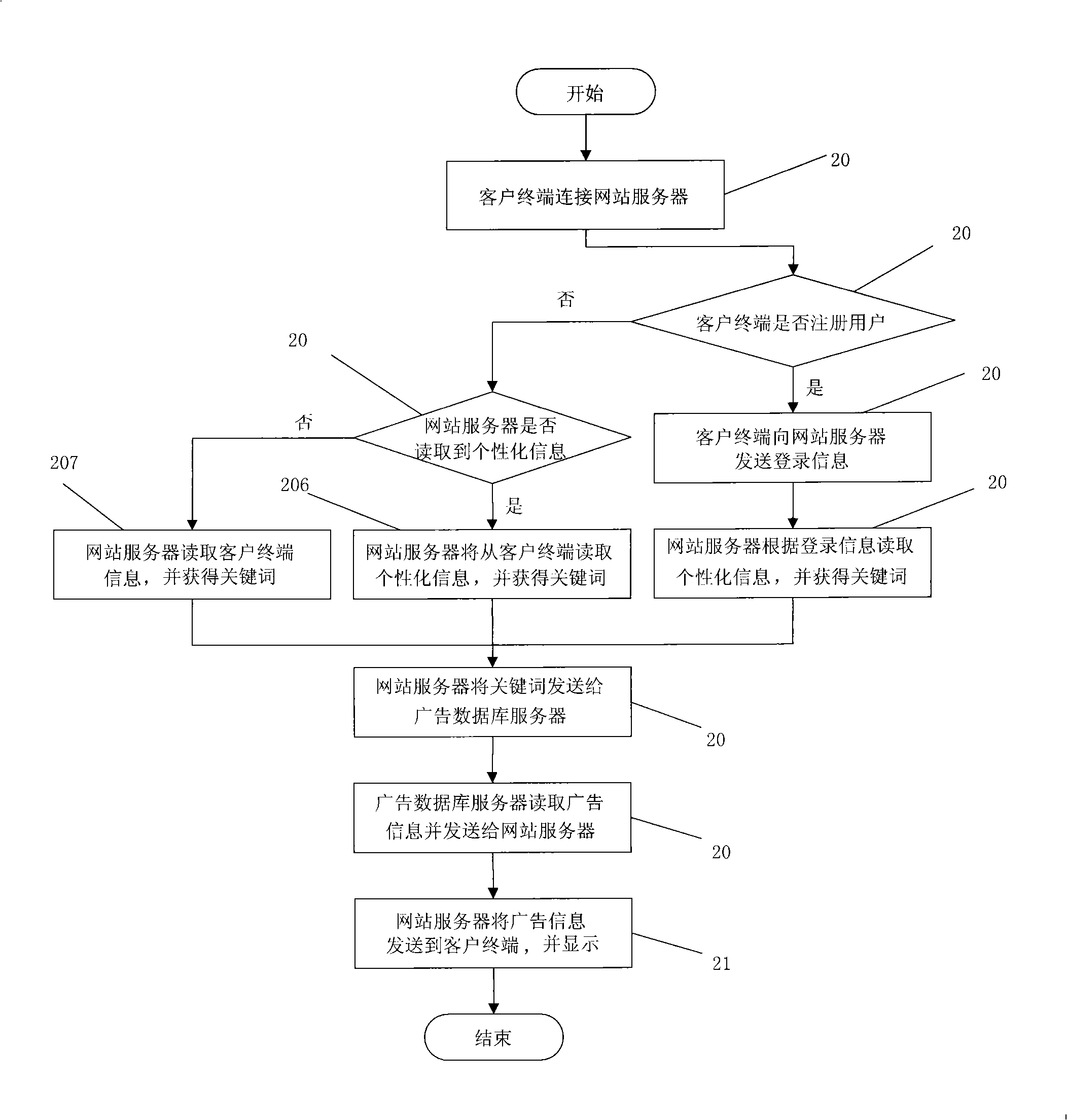

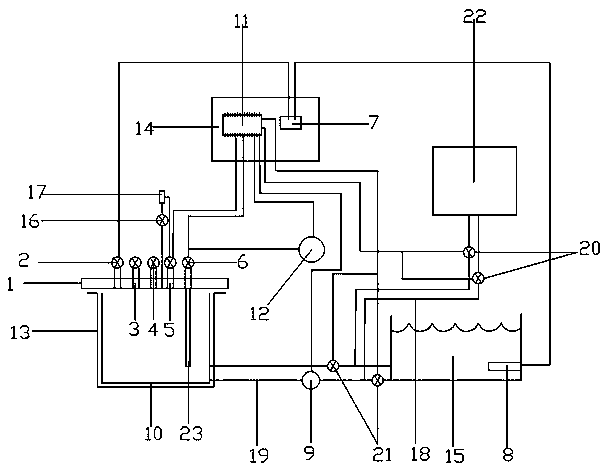

Method and system for publishing network advertisement

InactiveCN101350092AGuaranteed release effectCommerceSpecial data processing applicationsPersonalizationWeb site

The invention discloses a method for publishing network advertisement and a system, wherein a client is connected with a website server through a client terminal, login information is sent to the website server by the client, the website server reads personalized information of the corresponding client according to the login information and obtains key words according to the personalized information, the key words are sent to an advertise database server by the website server, the advertise database server reads corresponding advertise information according to the key words and sends the corresponding advertise information to the website server, and the advertise information is sent to the client terminal by the website server and is displayed. Using the technical scheme of the invention, related advertise content is published according to different situation of different users, thereby guaranteeing the publishing effects of network advertisement.

Owner:BEIJING XIEYOU JUXIN INFORMATION TECH

Masking tape containing printing layer and preparation method thereof

ActiveCN103725222AOvercome affinityProduction process is environmentally friendlyNon-fibrous pulp additionFilm/foil adhesivesWater basedEmulsion

The invention discloses a masking tape containing a printing layer and a preparation method thereof. The masking tape comprises a substrate, wherein one side of the substrate is provided with an adhesive layer, and the other side of the substrate is sequentially provided with a printing layer and a release layer; the substrate is masking tape base paper impregnated by a hydroxy butadiene-styrene emulsion; the printing layer is a water-based ink; the adhesive layer is a water-based acrylate pressure-sensitive adhesive; and the release layer is a water-based release agent. All the raw materials are water-based materials, and thus, the production technique is environment-friendly; and the product has the advantages of stable performance, long shelf life, low production cost and high added value.

Owner:广州市白云区麒胜装饰材料厂有限公司

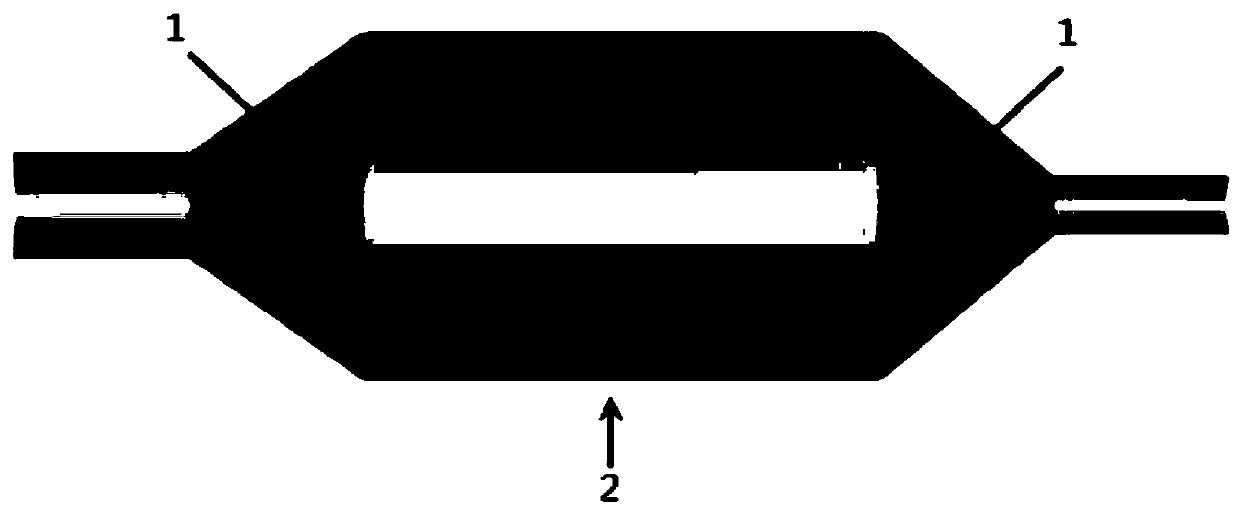

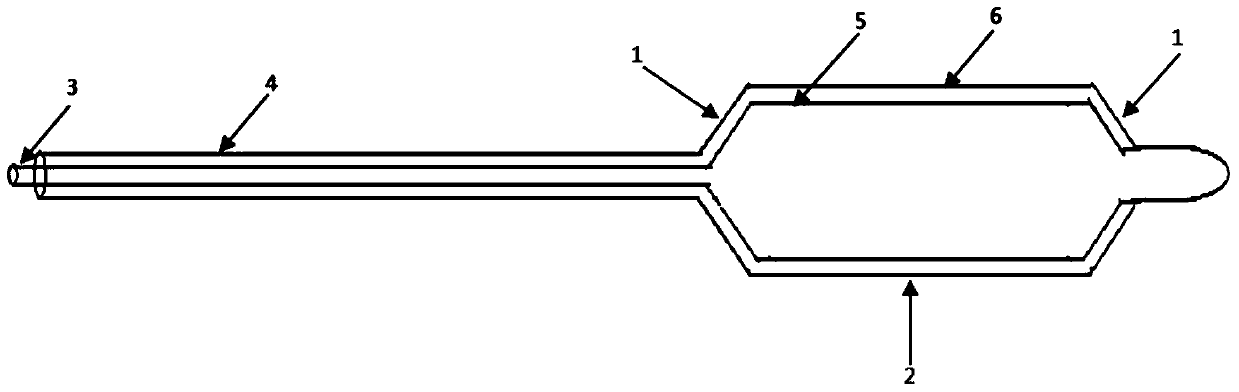

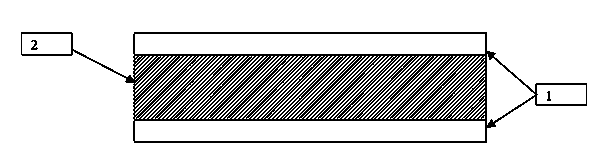

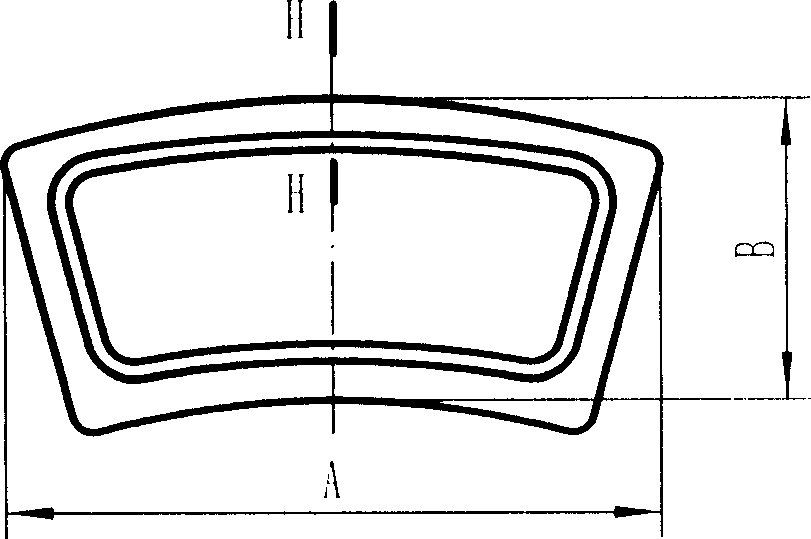

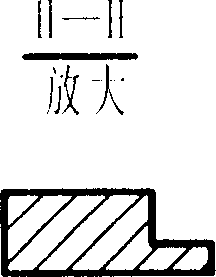

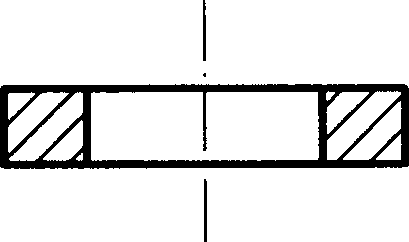

Drug delivery balloon dilating catheter

ActiveCN103623497ASatisfied with repeated expansionMeet shrinking needsSurgeryDilatorsPorosityBalloon dilatation catheter

The invention provides a drug delivery balloon dilating catheter of a double-layer balloon structure. The drug delivery balloon dilating catheter comprises a pressurizing hole-free inner balloon body and an outer balloon body with a drug-permeable micro-hole permeable membrane. Compared with the prior art, the hole diameter of the drug delivery balloon dilating catheter is even, and the high porosity and the high mechanical strength are achieved. The invention further discloses a manufacturing method of the drug delivery balloon dilating catheter of the double-layer balloon structure, the drug delivery balloon dilating catheter is made of materials such as polyethylene or nylon 12, the micro-hole permeable membrane is manufactured with a thermally induced phase separation method, and the drug delivery balloon dilating catheter has the advantages of being simple in manufacturing process, suitable for large-scale production, low in manufacturing cost and the like.

Owner:SHENZHEN SALUBRIS BIOMEDICAL ENG CO LTD

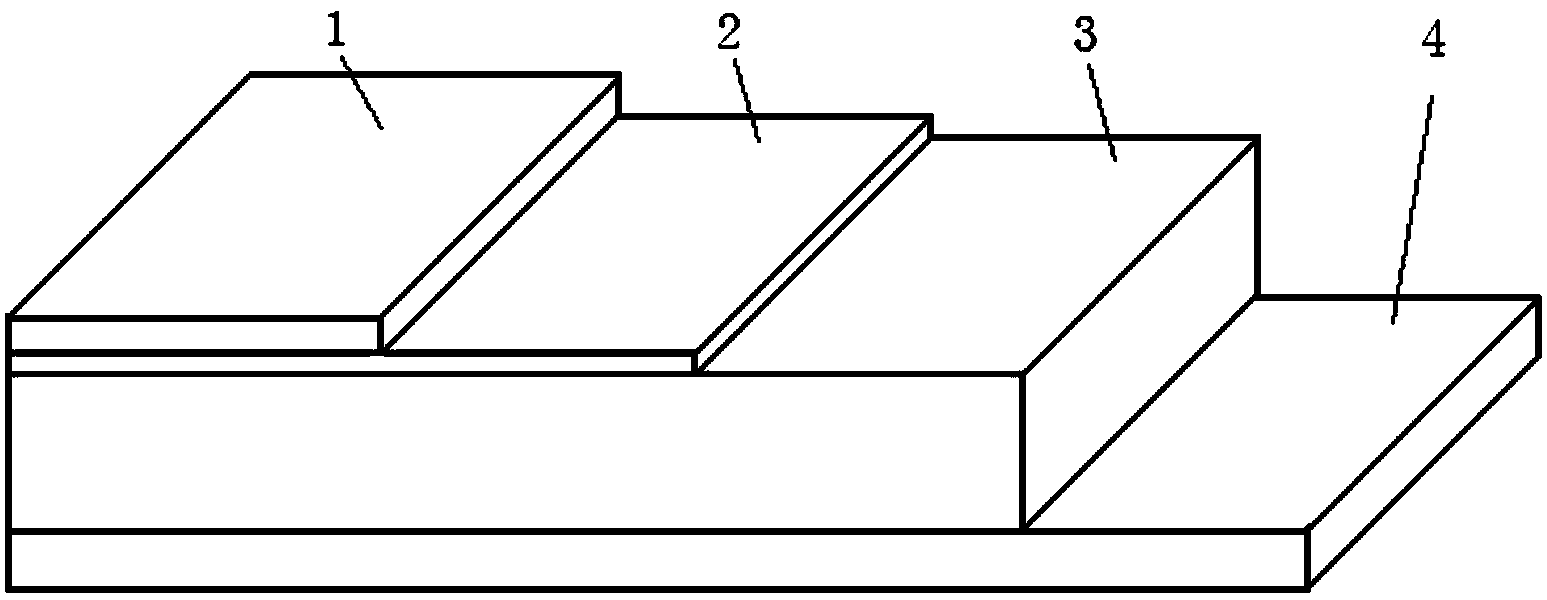

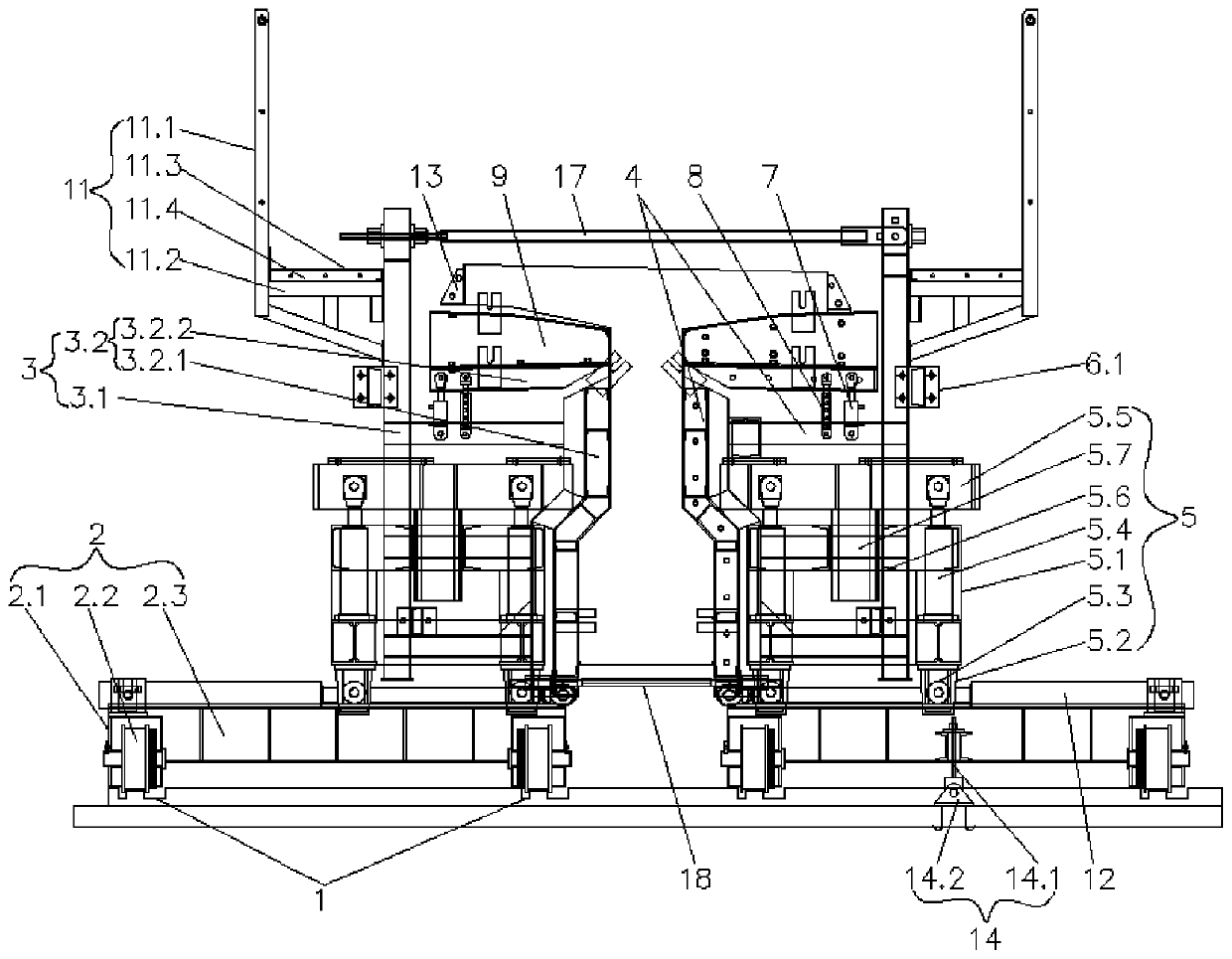

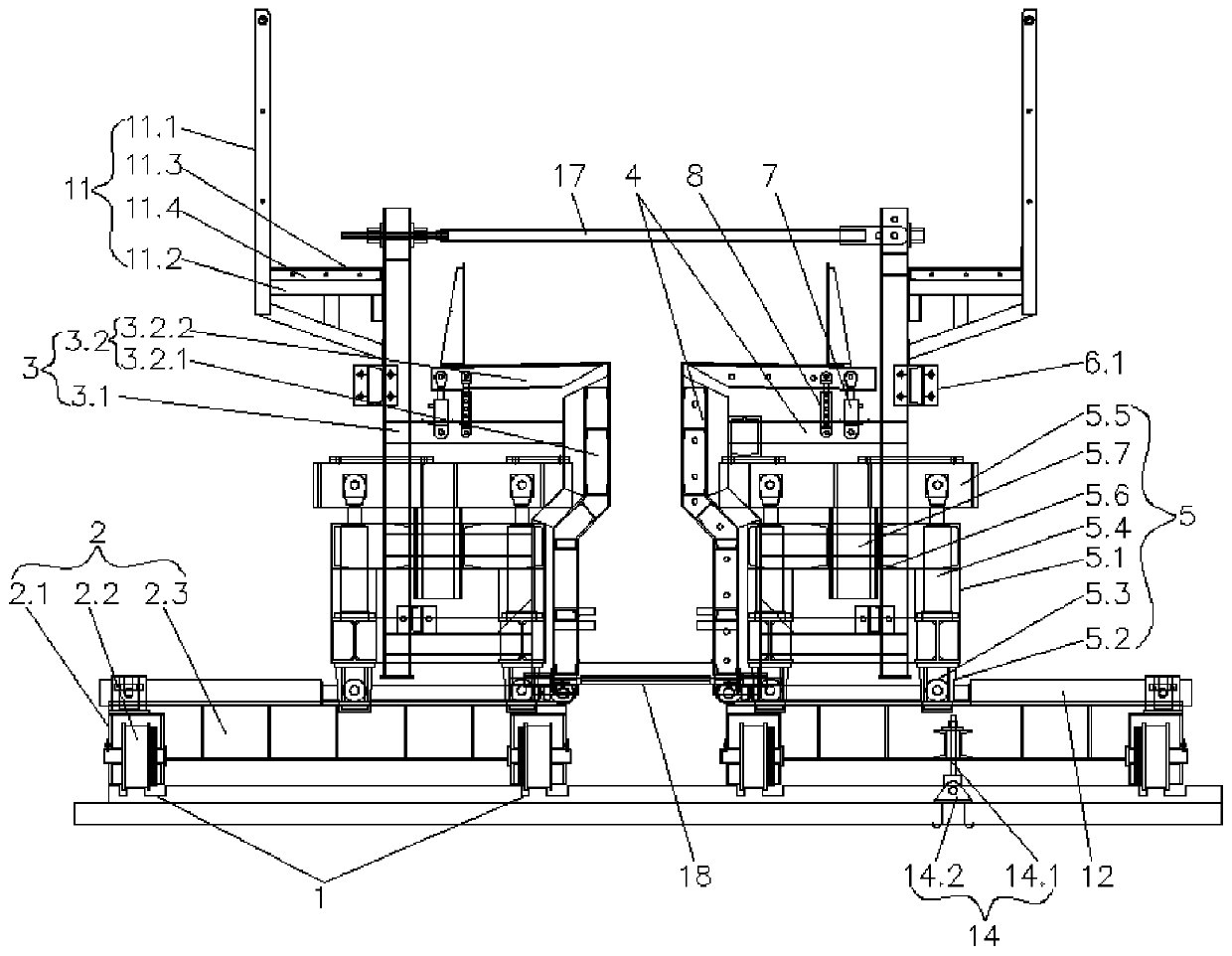

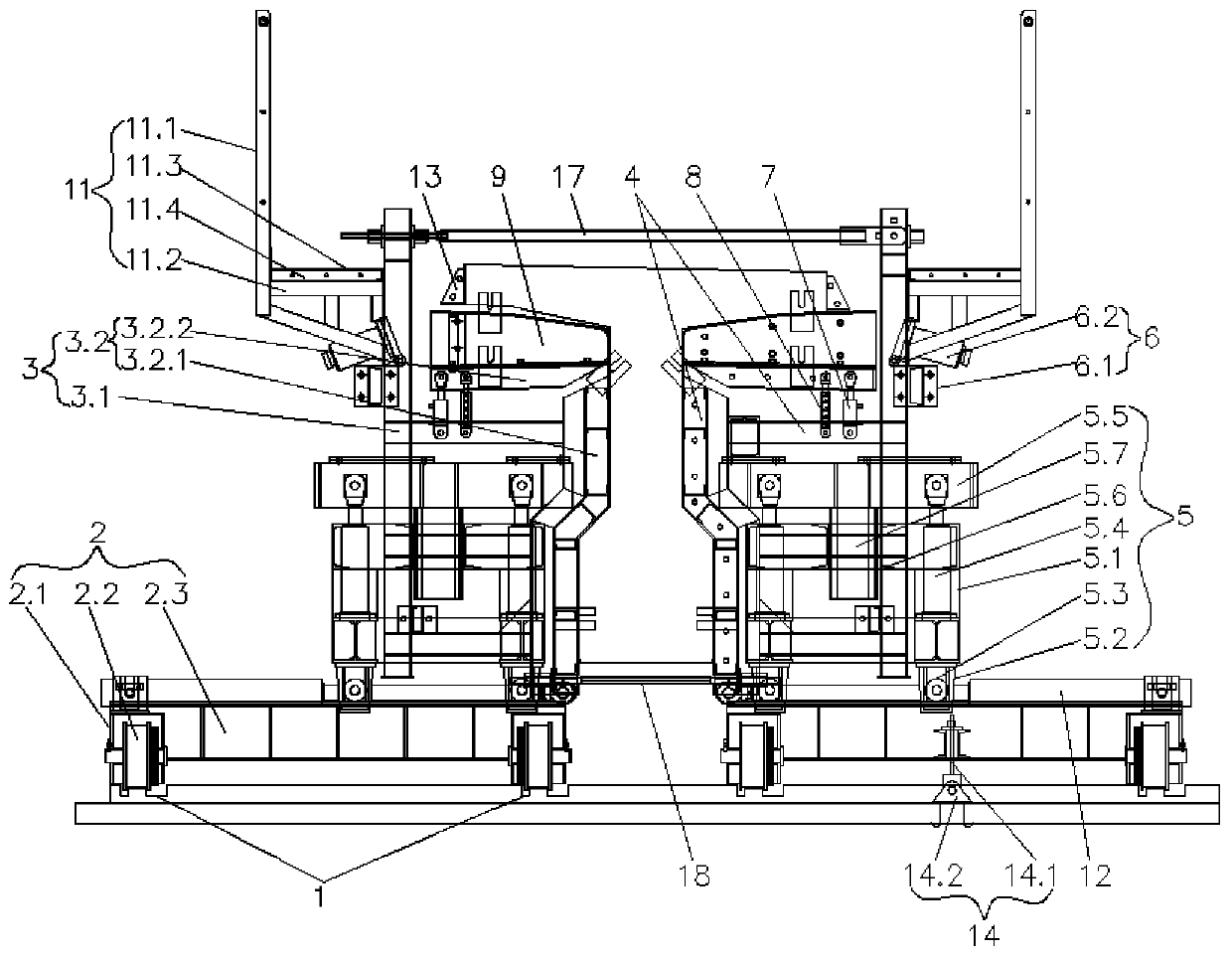

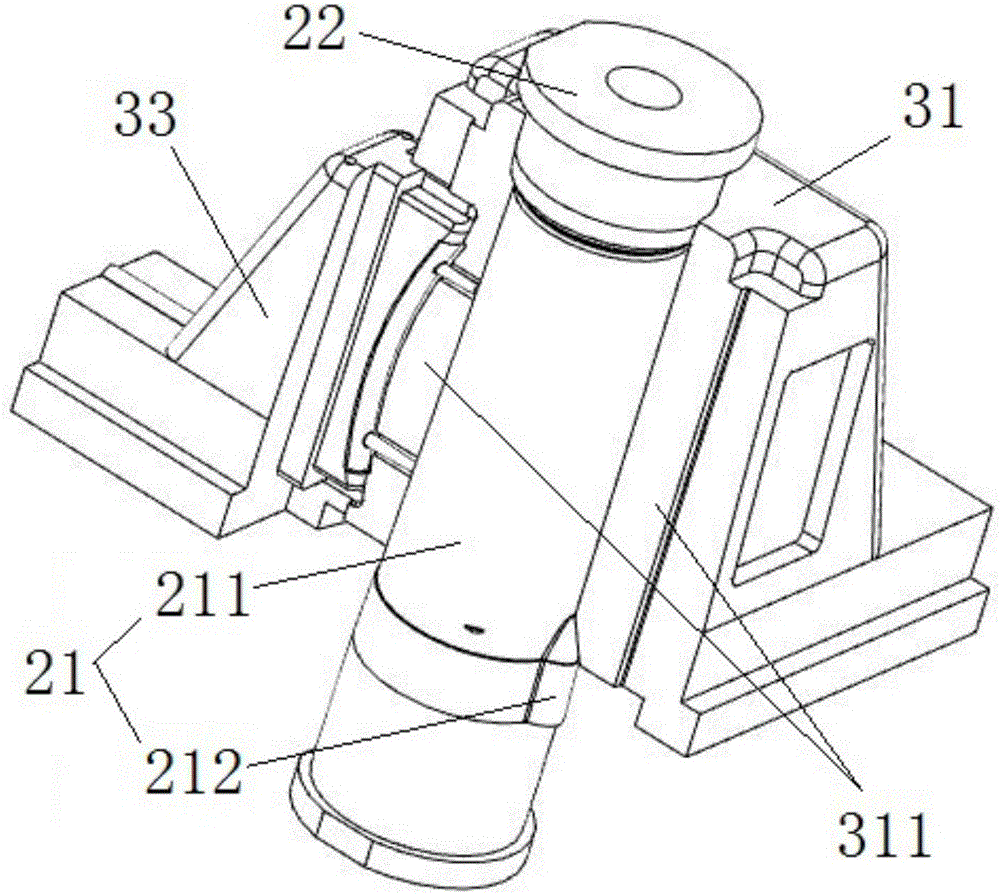

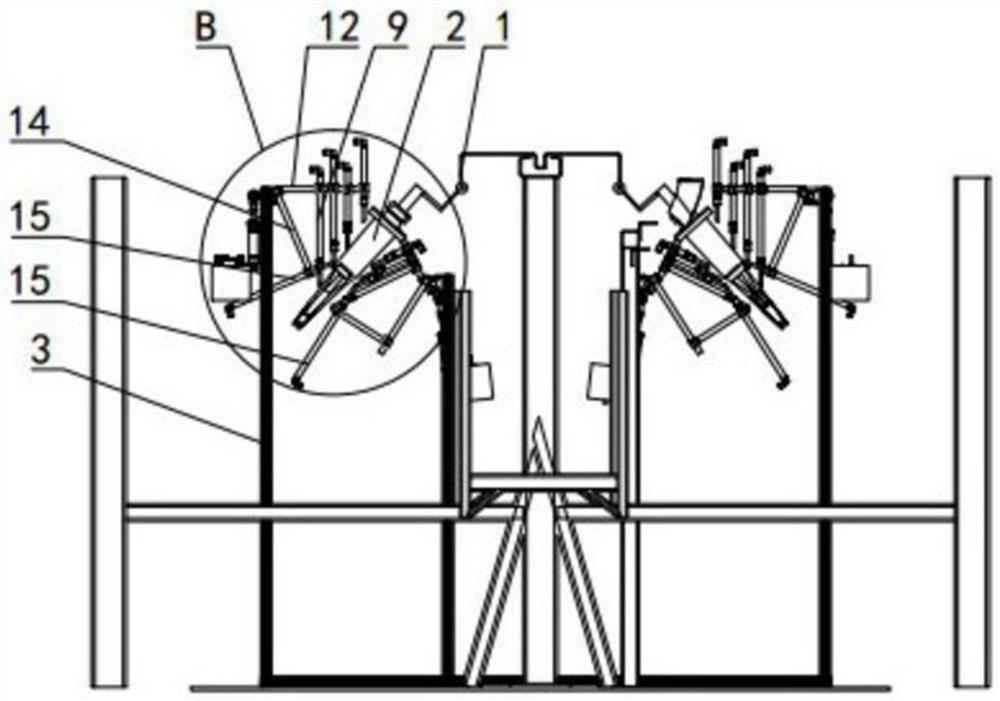

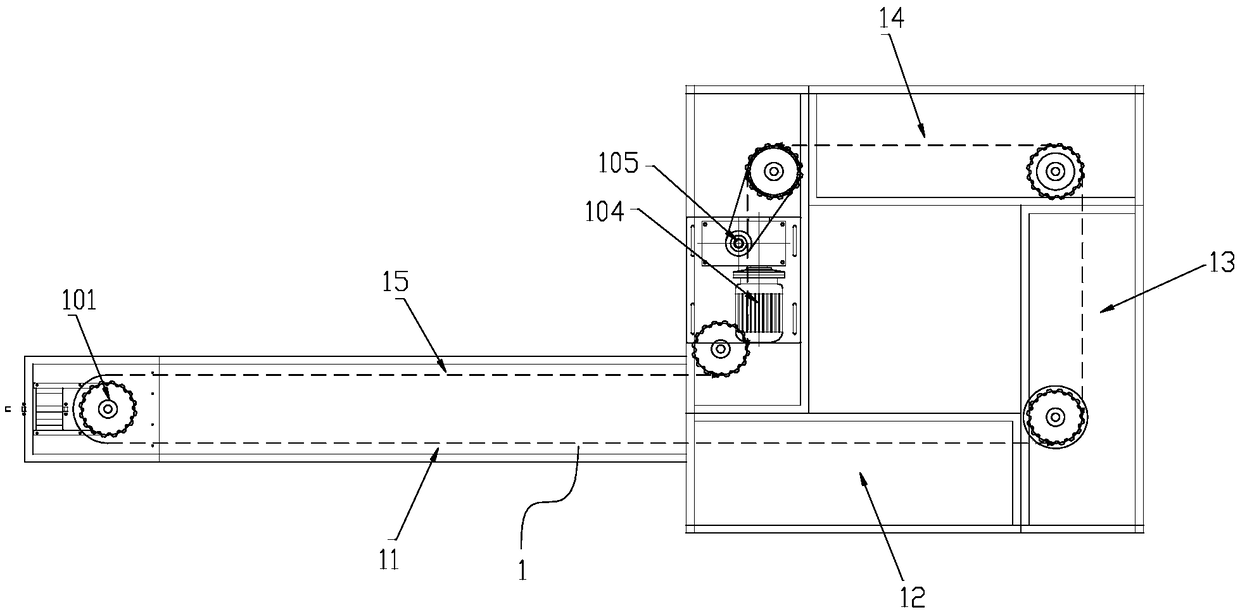

T-shaped beam casting special mold and using method thereof

PendingCN109968499AQuality improvementHigh quality, high market application prospectsDischarging arrangementMouldsShaped beamT-beam

The invention discloses a T-shaped beam casting special mold and a using method thereof, and relates to the technical field of T-shaped beam manufacturing. The T-shaped beam casting special die comprises a guide rail, wherein a walking trolley is arranged on the sliding rail in a sliding mode, a left mold and a right mold are symmetrically arranged on the walking trolley, the left mold comprises frames and panels connected to the inner side of the frames, the walking trolley is provided with mold guide devices which are positioned at the outer side ends of the two frames and provided with high-stroke spaces, the outer side ends of the two frames are provided with overturning type demolding mechanisms, an automatic slope adjusting mechanism and a locking mechanism are arranged on each frame, the tops of the automatic slope adjusting mechanisms and the tops of the locking mechanisms are hinged to the bottom of rotatable parts of the panels, combined adjusting mechanisms for adjusting theheight of the left mold and the bottom of the right mold are arranged at the bottom of the left mold and the bottom of the right mold, and supporting columns which are convenient to assemble and disassemble are arranged on the outer sides of the tops of the two frames, and during use, the supporting columns are subjected to mold closing and grouting, demoulding. The T-shaped beam casting specialmold has the advantages of being complete in function and good in T-shaped beam forming quality.

Owner:SICHUAN EAST SPRING MACHINERY EQUIP MFG CO LTD

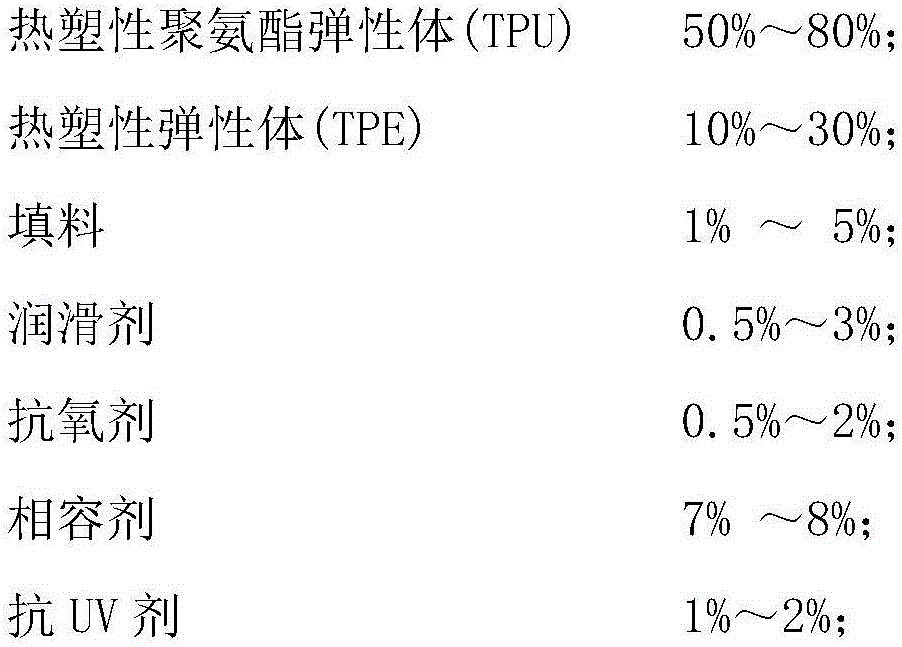

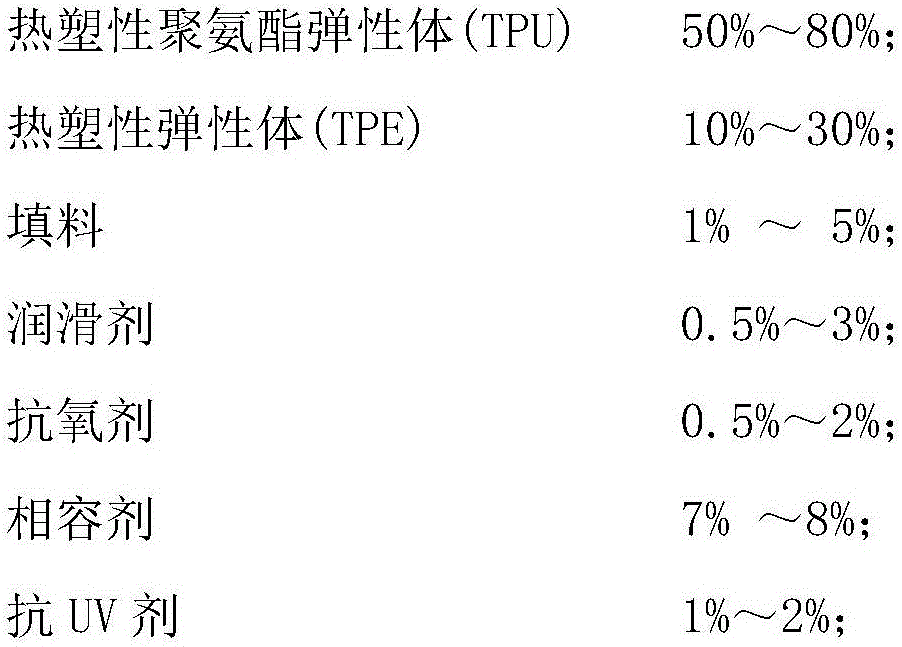

Modified thermoplastic polyurethane elastomer and preparation method thereof

InactiveCN106280391ASimple structureChange the melt viscosityWeather resistanceThermoplastic elastomer

The invention relates to a modified thermoplastic polyurethane elastomer and a preparation method thereof. The elastomer is characterized by being prepared from, by weight, thermoplastic polyurethane elastomer (TPU) 50%-80%, thermoplastic elastomer (TPE) 10%-30%, filler 1%-5%; lubricant 0.5%-3%, antioxidant 0.5%-2%, compatilizer 7%-8% and UV-resistant agent 1%-2%, wherein the thermoplastic elastomer (TPE) is the TPE with the hardness of 75-85 A and the melt index of 20-50 g / 10 min at the melting temperature of 190 DEG C in the state of 5 kg load. The compatilizer is an MAH graft with SEBS, PP or PE as a base material. The problems of poor forming performance and poor weather resistance of an existing thermoplastic polyurethane elastomer (TPU) are solved, the forming performance is good, the liquidity and demolding performance of the product in the production process are ensured, the product quality is remarkably improved, and the production cost is obviously reduced.

Owner:锦州希尔达汽车零部件有限公司

Polyurethane waxy release agent and application thereof

The invention discloses a polyurethane waxy release agent, which is characterized by comprising the following ingredients by weight: 20% of a demoulding wax, 10-20% of paraffin, 5-10% of microcrystalline wax, 0.5-1% of a foam stabilizer and 49-64.5% of a solvent. The invention has the beneficial effects that (1) good demoulding effect; (2) no pollution or corrosivity to mould surface; (3) repetitious usage for one time coating; and (4) especially suitable for demoulding of polyurethane high resilience foam.

Owner:上海力太化学有限公司

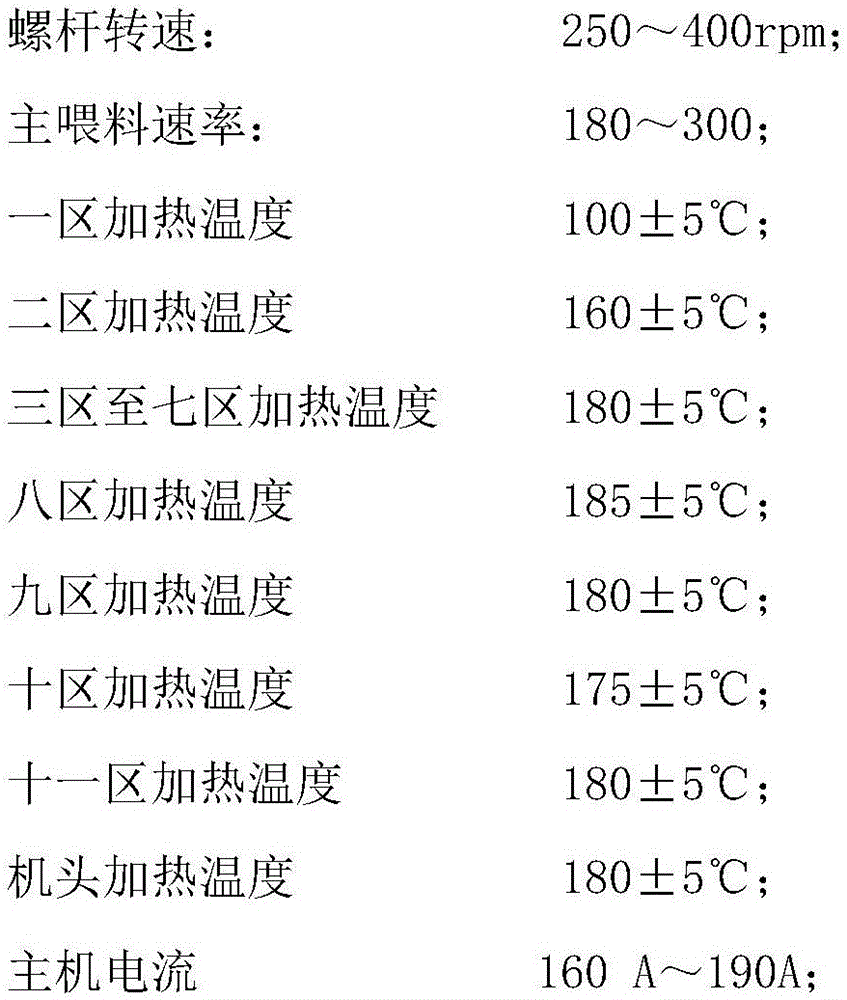

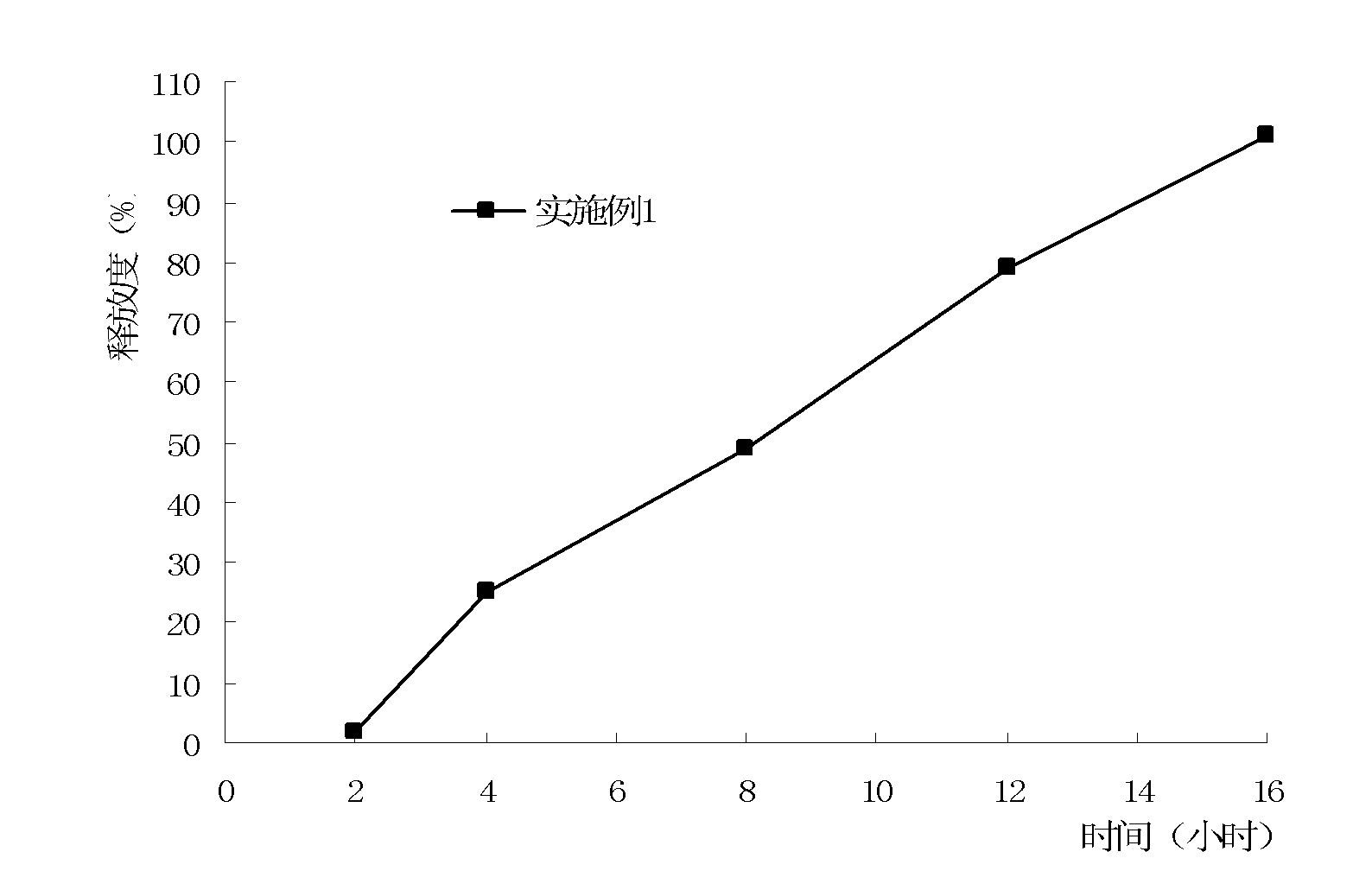

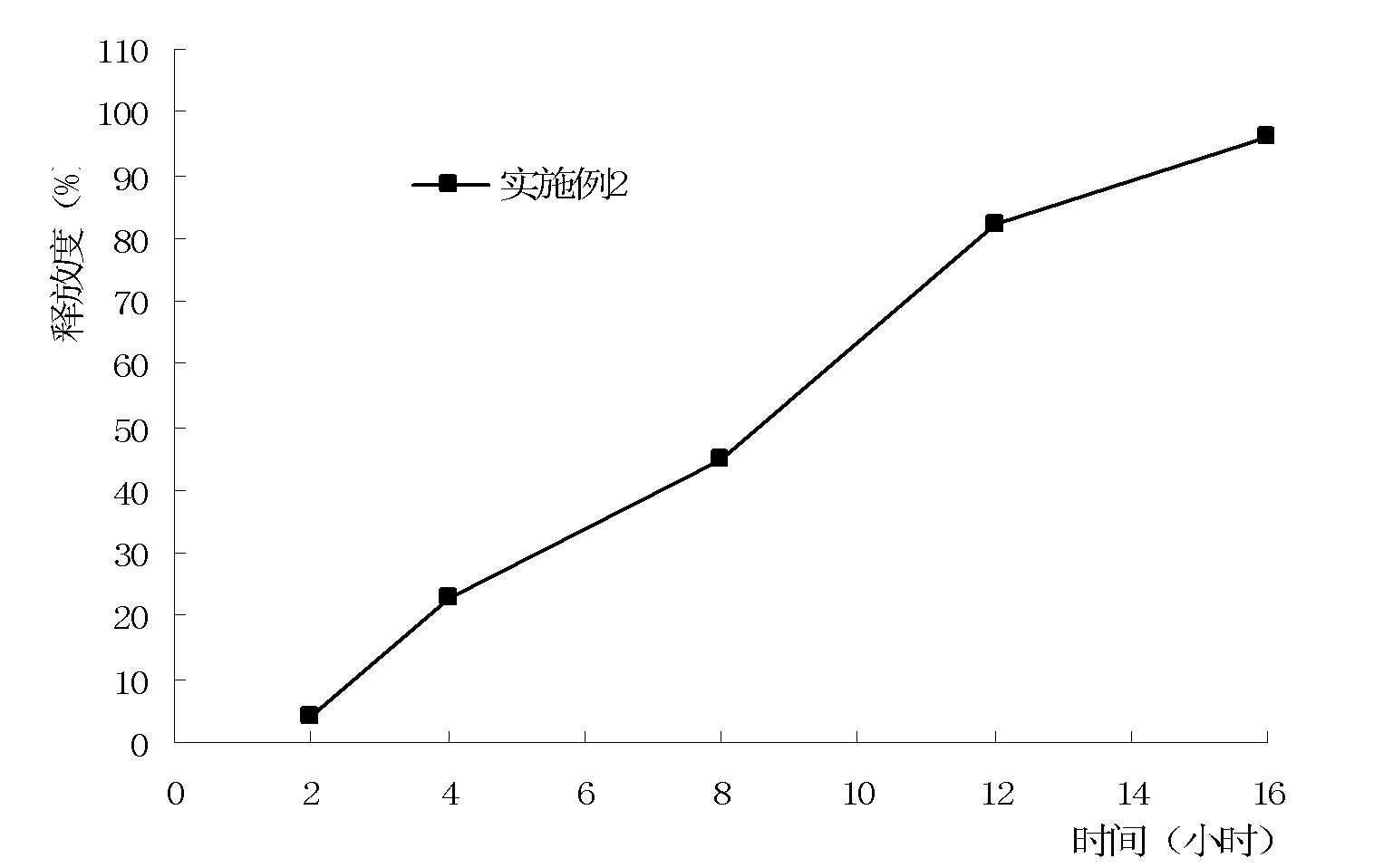

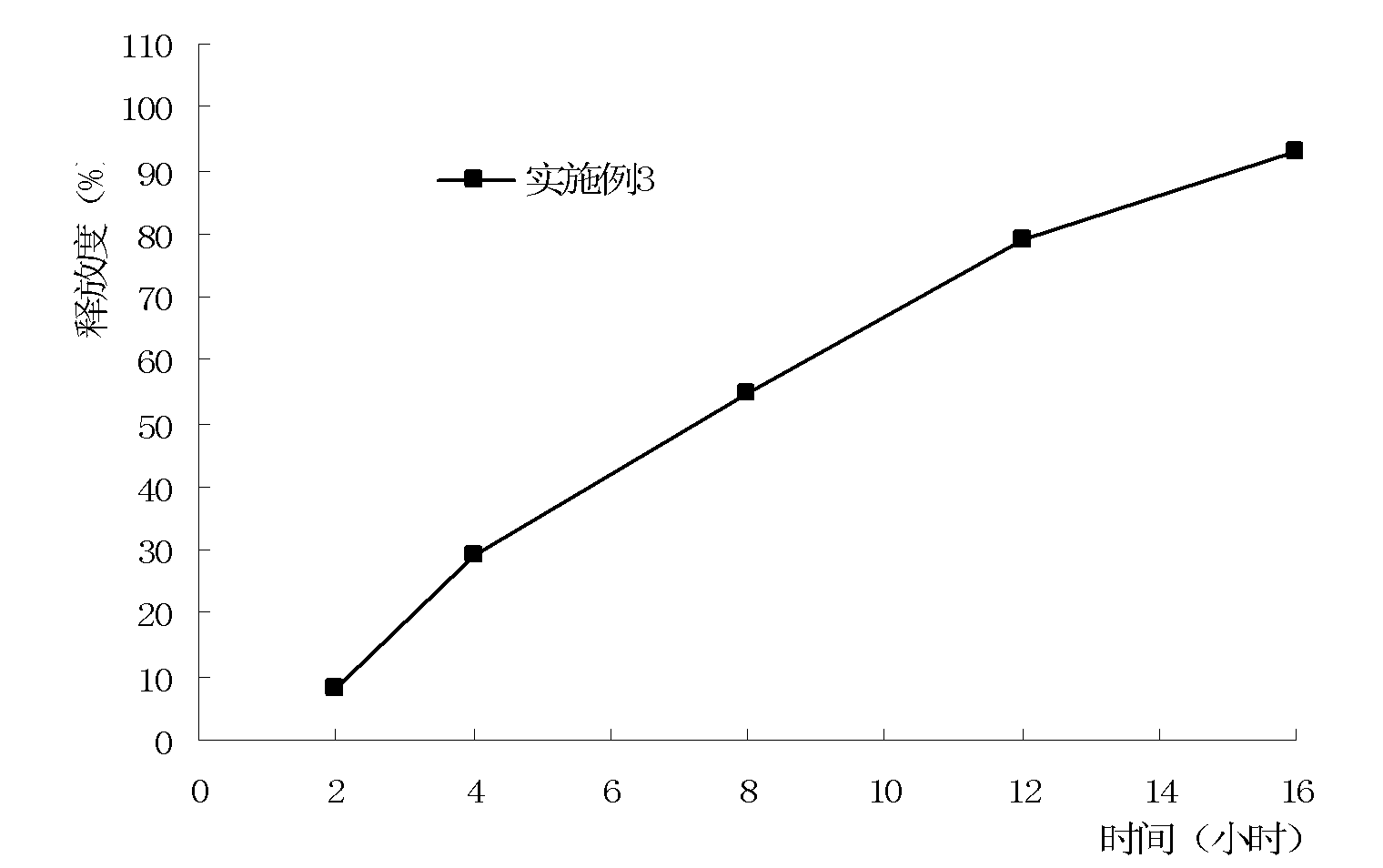

Preparation method of melbinum osmotic pump controlled release tablets

ActiveCN102133204AHigh dissolution rateIntrinsic quality is stableOrganic active ingredientsMetabolism disorderIrritationControlled Release Tablet

The invention relates to a preparation method of melbinum osmotic pump controlled release tablets for treating type 2 diabetes. The preparation method comprises the steps of preparing tablet cores, coating semi-permeable membrane layers, perforating, drying and coating damp-proof layers, characterized in that when the tablet cores are prepared, a medicinal salt of melbinum and a nonionic surfactant are added, and the nonionic surfactant accounts for 2-20wt.% of the medicinal salt of melbinum. The medicament disclosed by the invention has stable release, no irritation on intestinal tracts and few times of administration, is acceptable by patients, and greatly improves the compliance of patients.

Owner:SHANDONG XINHUA PHARMA CO LTD

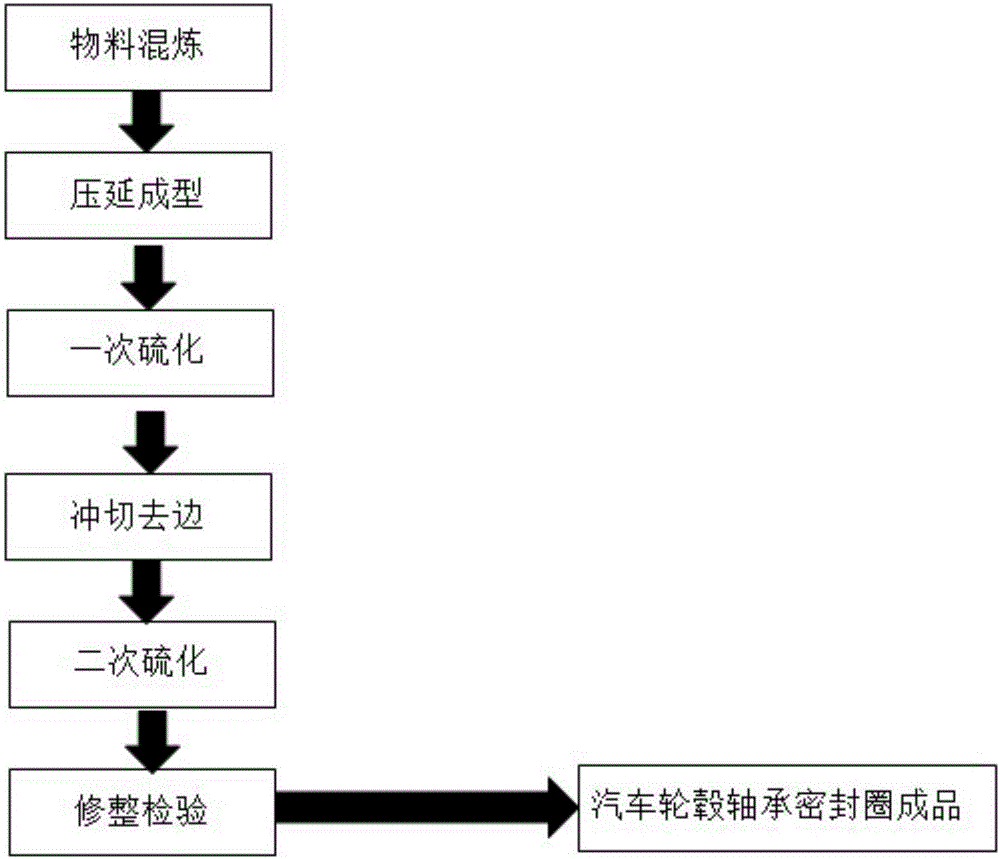

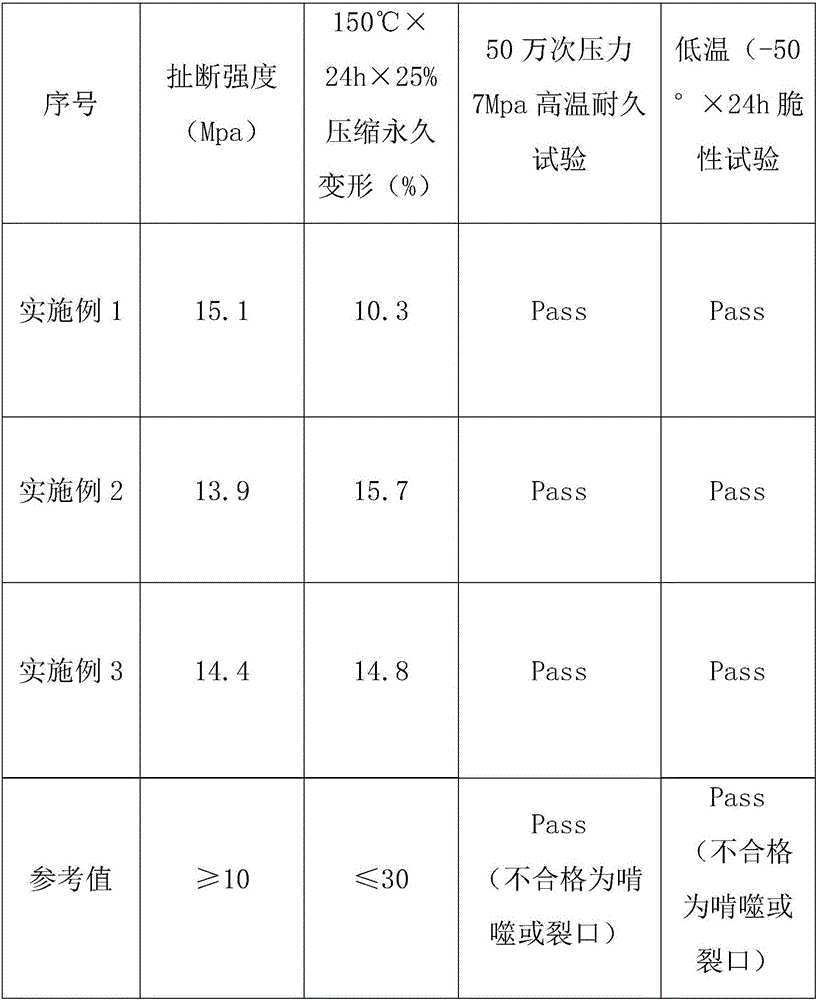

Automobile hub bearing sealing ring and preparation method thereof

Relating to the field of processing of auto parts, the invention discloses an automobile hub bearing sealing ring and a preparation method thereof. The automobile hub bearing sealing ring comprises: hydrogenated nitrile butadiene rubber, sulfur, an anti-aging agent, an activating agent, stearic acid, a lubricant, alumina powder, dibutyl phthalate, silica, a vulcanization accelerator, an acid-base balance agent, inorganic filler and other components. The finished product is obtained by the steps of material mixing, calendaring molding, first vulcanization, punching and edge removing, second vulcanization, finishing and inspection. The raw material formula has reasonable design, and the prepared sealing ring has excellent oil resistance, heat resistance, cold resistance, corrosion resistance, tensile resistance, tear resistance and compressibility, and long service life.

Owner:ANHUI YUETIAN SPECIAL AXLE

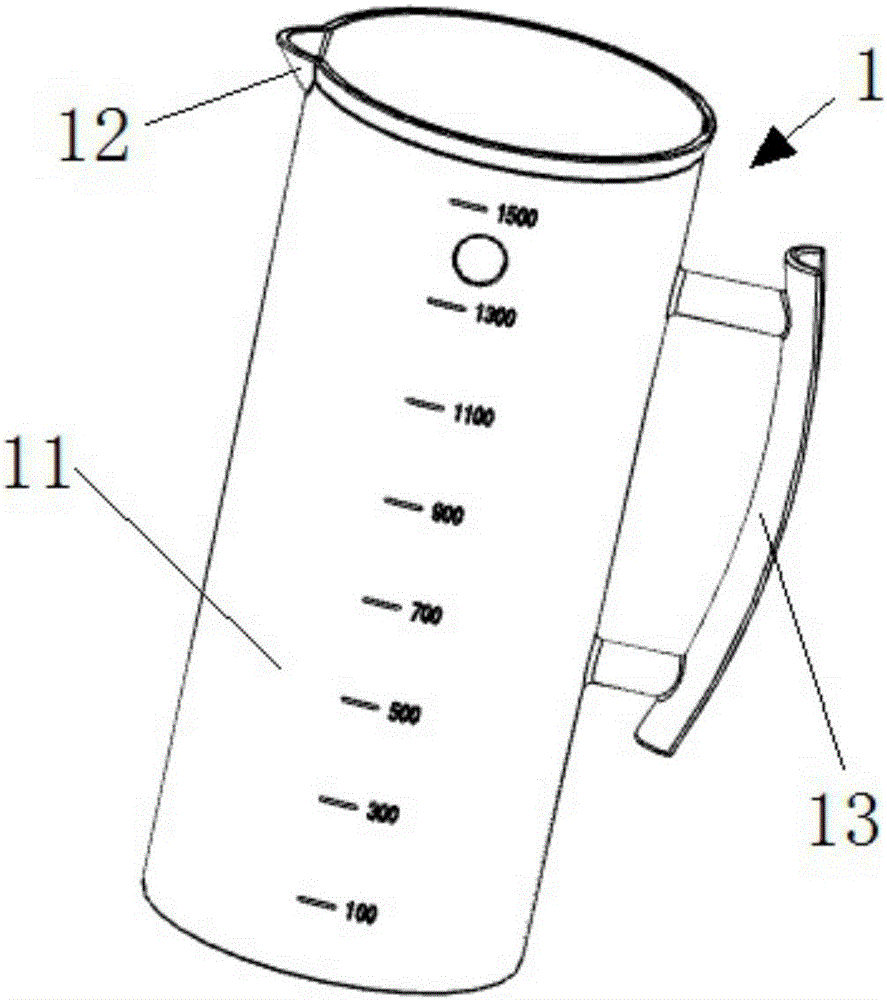

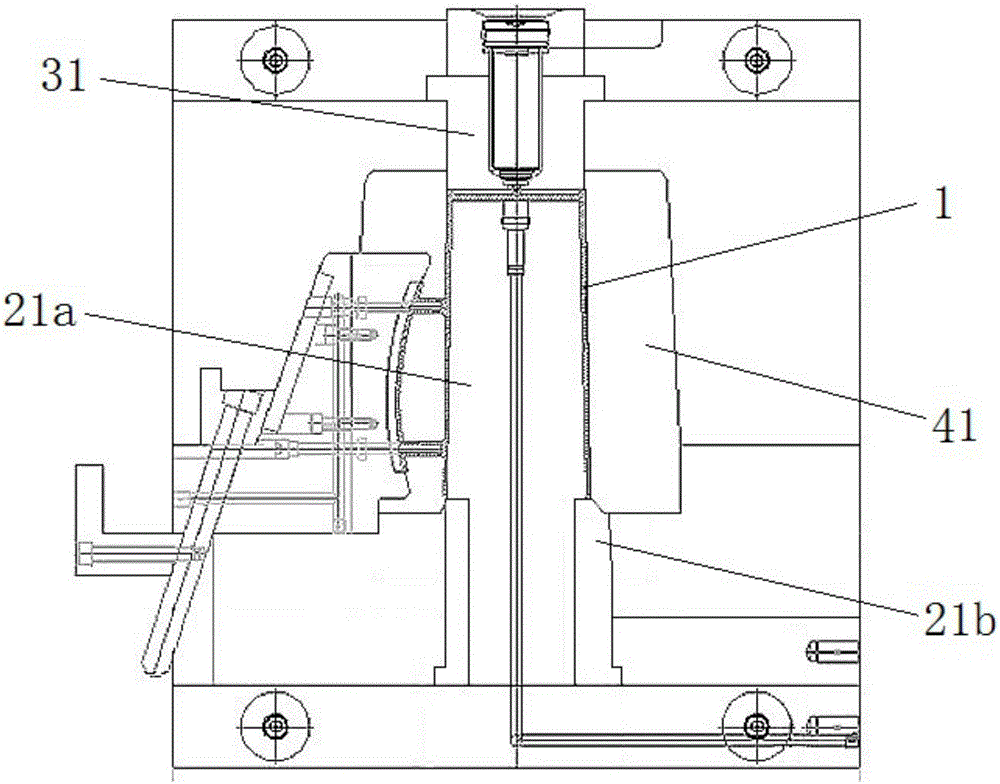

Kettle forming mold

InactiveCN106313450AQuality assuranceGuaranteed release effectDomestic articlesTemperature differenceWater bottle

The invention belongs to the technical field of injection molds and relates to a kettle forming mold. The kettle forming mold is used for forming a kettle with a spout and comprises a male mold insert, a female mold insert and a plurality of sliders, wherein the male mold insert and the female mold insert are opposite to each other up and down; a plurality of sliders are spliced around the male mold insert and the female mold insert; the male mold insert comprises a body shaped like a cone frustum; the body is provided with a fine end and a thick end; the fine end is close to the female mold insert; the thick end is far from the female mold insert; a spout formed body is integrally formed at the side of the thick end of the body. The kettle forming mold has the beneficial effects that as the spout formed body and the body are integrally formed, the body and the spout of the kettle can be connected in a seamless manner and the heat from the spout formed body and the body is directly conducted, thus avoiding generating gas marks in the transition region of the body and the spout of the kettle due to surface temperature difference and then ensuring the product quality and the demolding effects.

Owner:SUZHOU BAIANSI HOUSEWARES

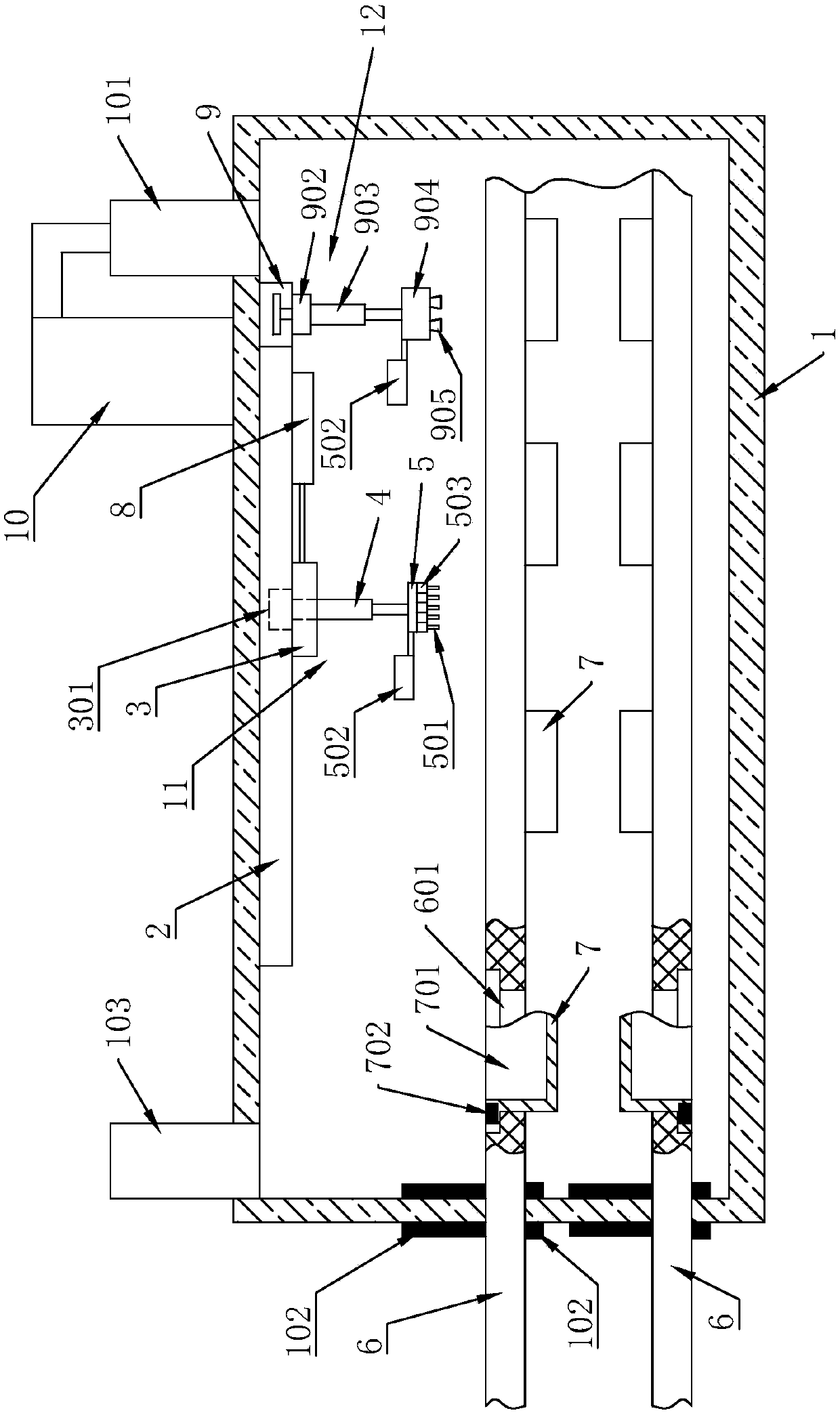

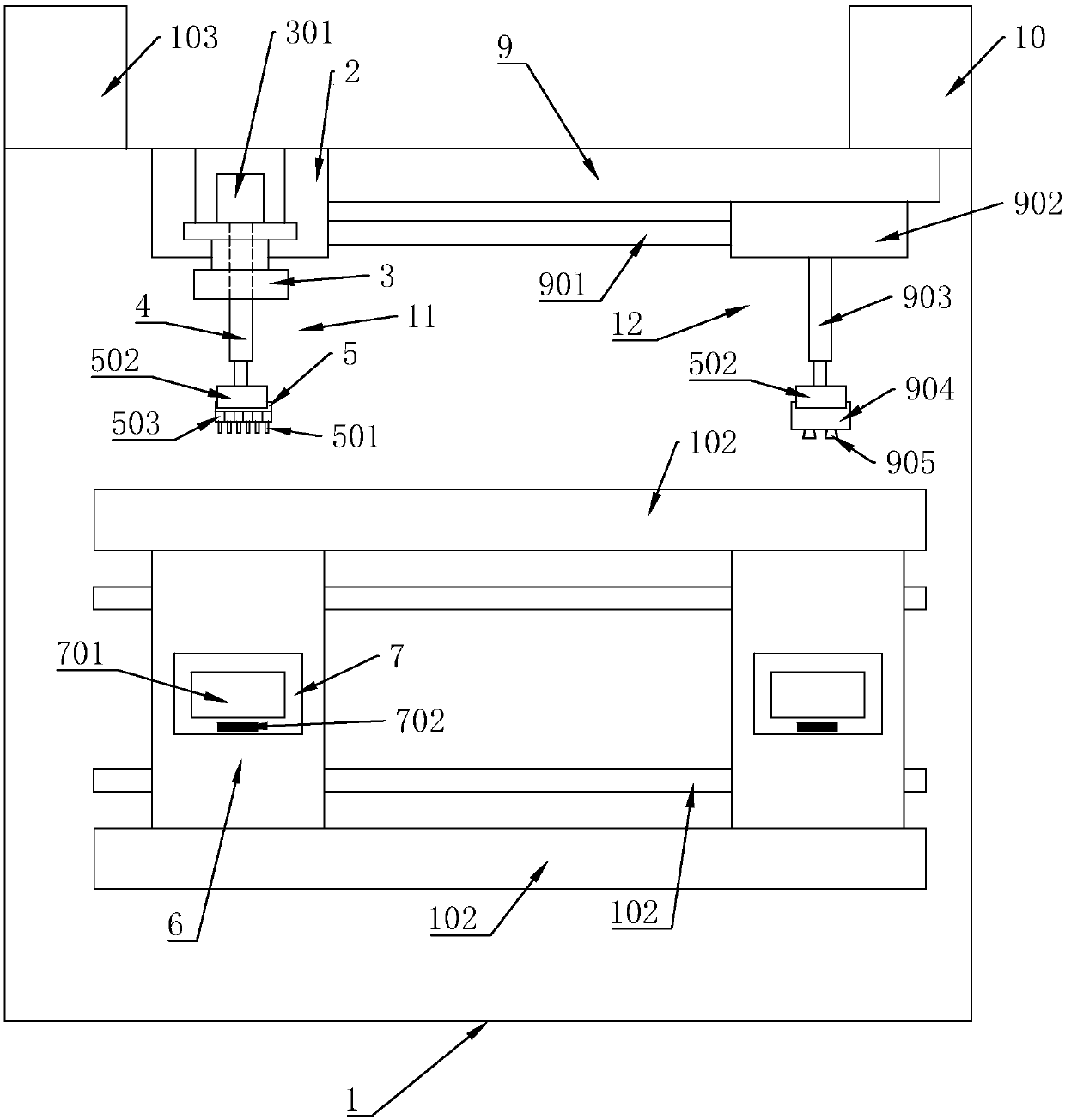

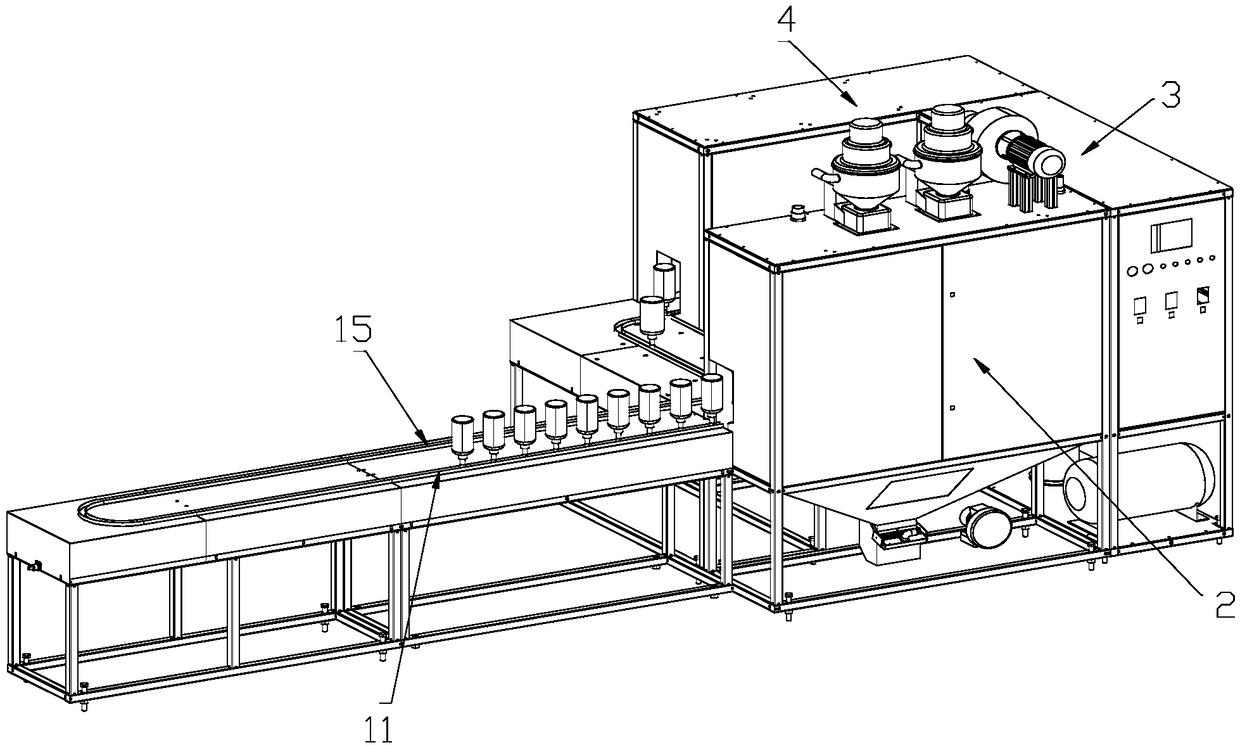

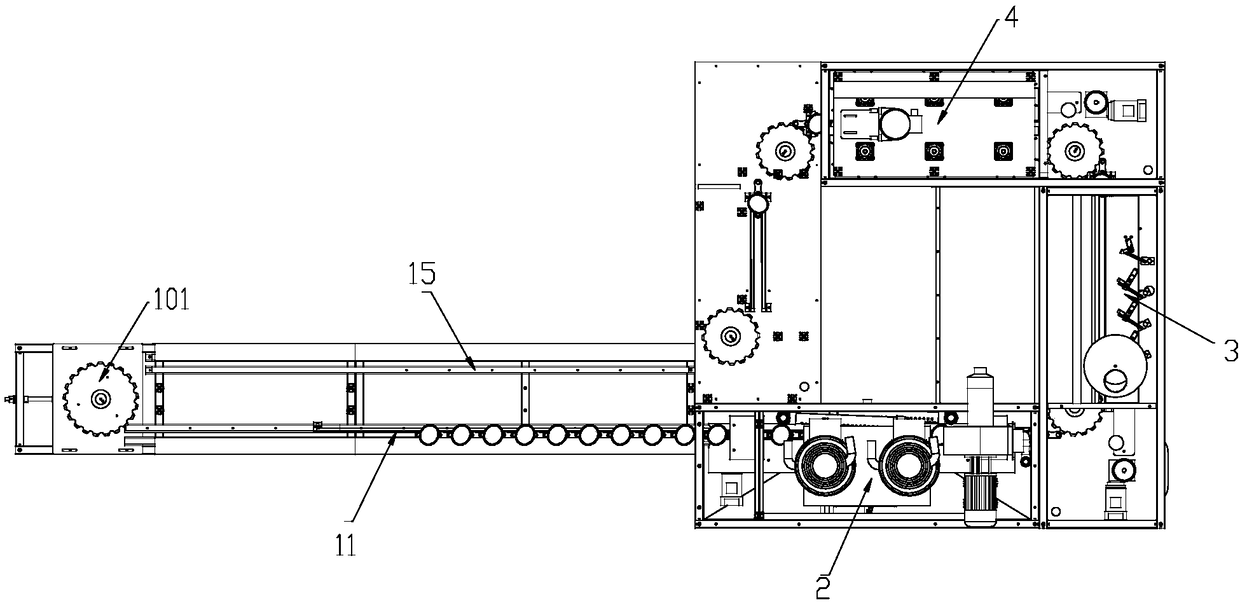

Automatic elastic gluing and transferring device

The invention discloses an automatic elastic gluing and a transferring device. The device comprise a sealed gluing chamber, wherein the top of the sealed gluing chamber is provided with a gluing mechanism and a transferring mechanism; a plurality of spray heads are arranged on the gluing mechanism in an elastic mode; the device further comprises two conveying belts which are arranged in parallel and are opposite in running direction, and the same ends of the two conveying belts extend to the outside of the sealed gluing chamber, and the other ends of the two conveying belts are located in thesealed gluing chamber; each conveying belt is provided with a plurality of mounting holes; templates are arranged on the portions, located in the mounting holes, of the conveying belts; grooves are formed in the templates; and the sealed gluing chamber is further communicated with an air inlet pipe and an exhaust pipe, and the exhaust pipe is communicated with a peculiar smell treatment device. According to the automatic elastic gluing and the transferring device, mechanical glue spraying work is realized, the labor intensity of workers is reduced, the labor amount and the labor cost are reduced, the working efficiency is improved, the working environment is improved, and the problem that the peculiar smell pollutes the environment and harms the health of the body is solved.

Owner:青岛创高世纪信息科技有限公司

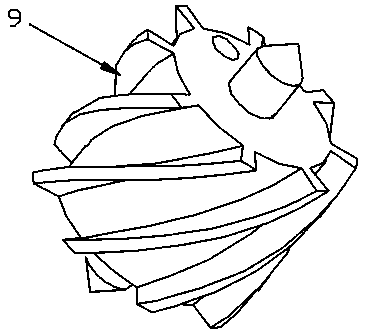

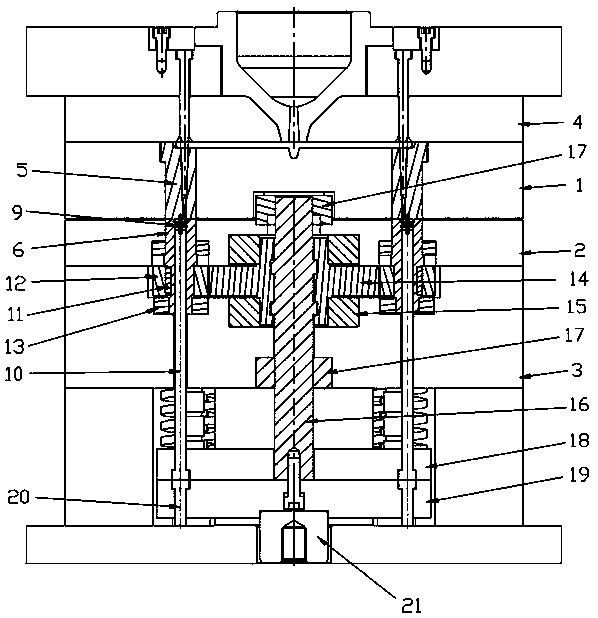

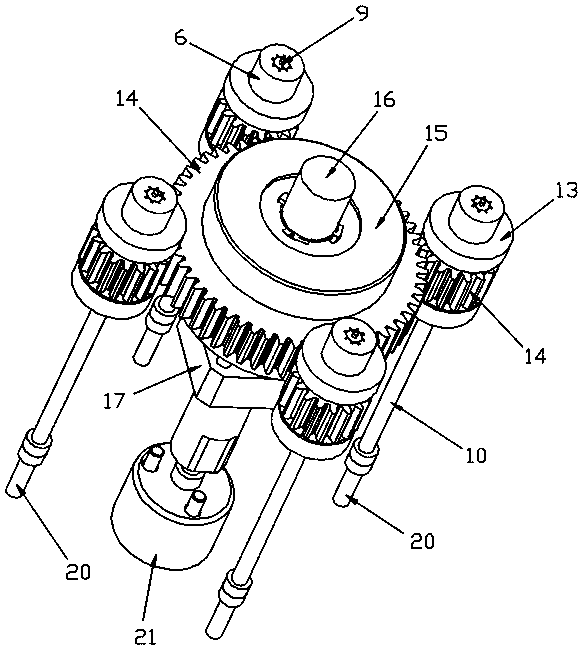

Forming and die releasing device for injection molding die gear and injection molding device thereof

The invention discloses a forming and die releasing device for an injection molding die gear and an injection molding device thereof. The forming and die releasing device for the injection molding diegear comprises an injection molding assembly, a forming chamber assembly and a rotating push-out mechanism, wherein the forming chamber assembly comprises a mold cavity which is arranged on a fixed die plate and is connected to the injection molding assembly, and a mold core which fits the mold cavity and is arranged on a movable die plate; and the rotating push-out mechanism comprises a rotatingdriving assembly for driving the mold core to rotate, and a push-out driving assembly which is used for pushing out a product from the mold core while the mold core rotates. According to the formingand die releasing device for the injection molding die gear, the product is pushed out while the mold core rotates so as to realize die releasing, and thus a product with a large oblique tooth helicalangle on the side surface applies, and the product forming and die releasing effects can be ensured.

Owner:SHENZHEN SKYWORTH PRECISION TECH

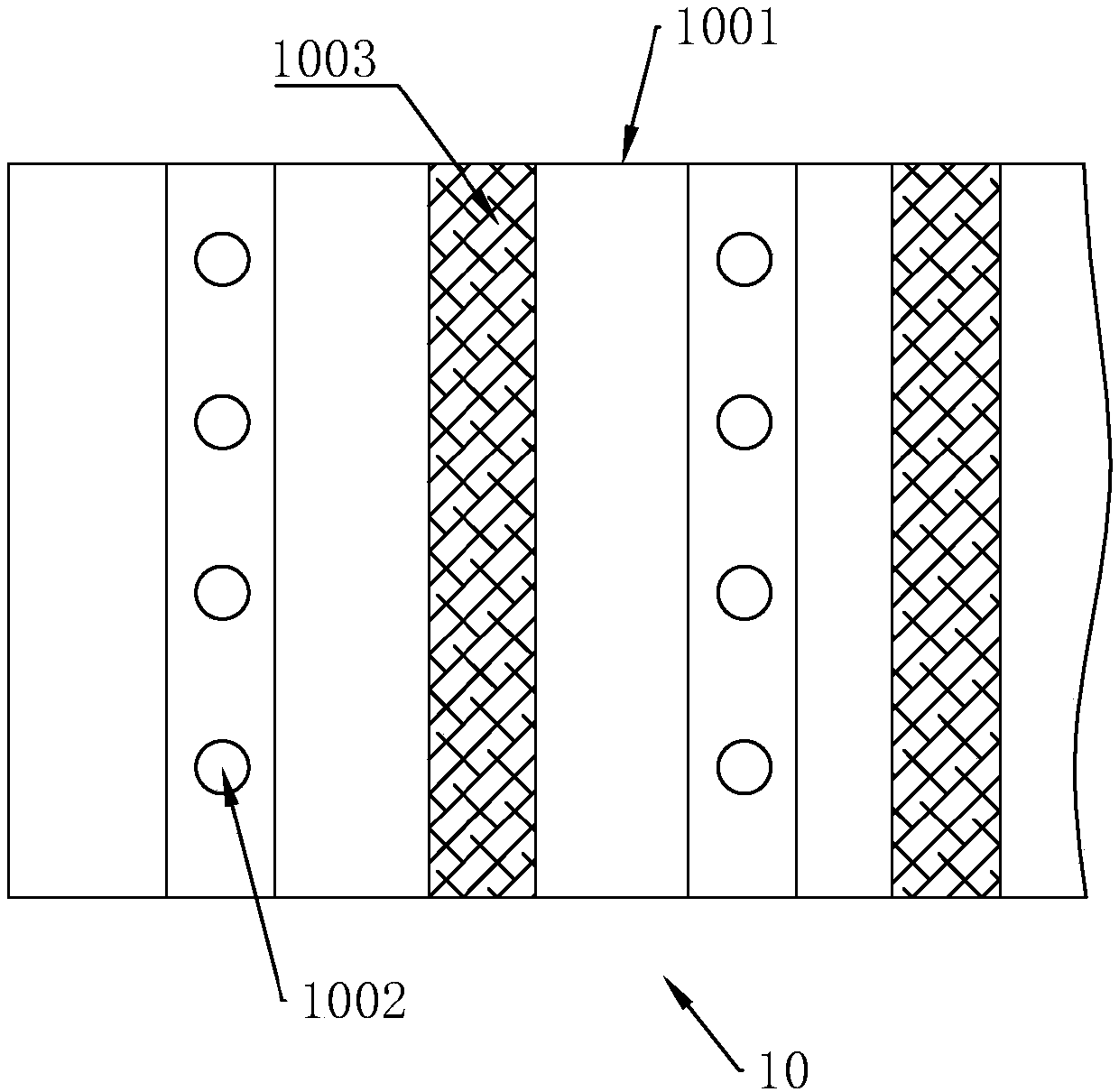

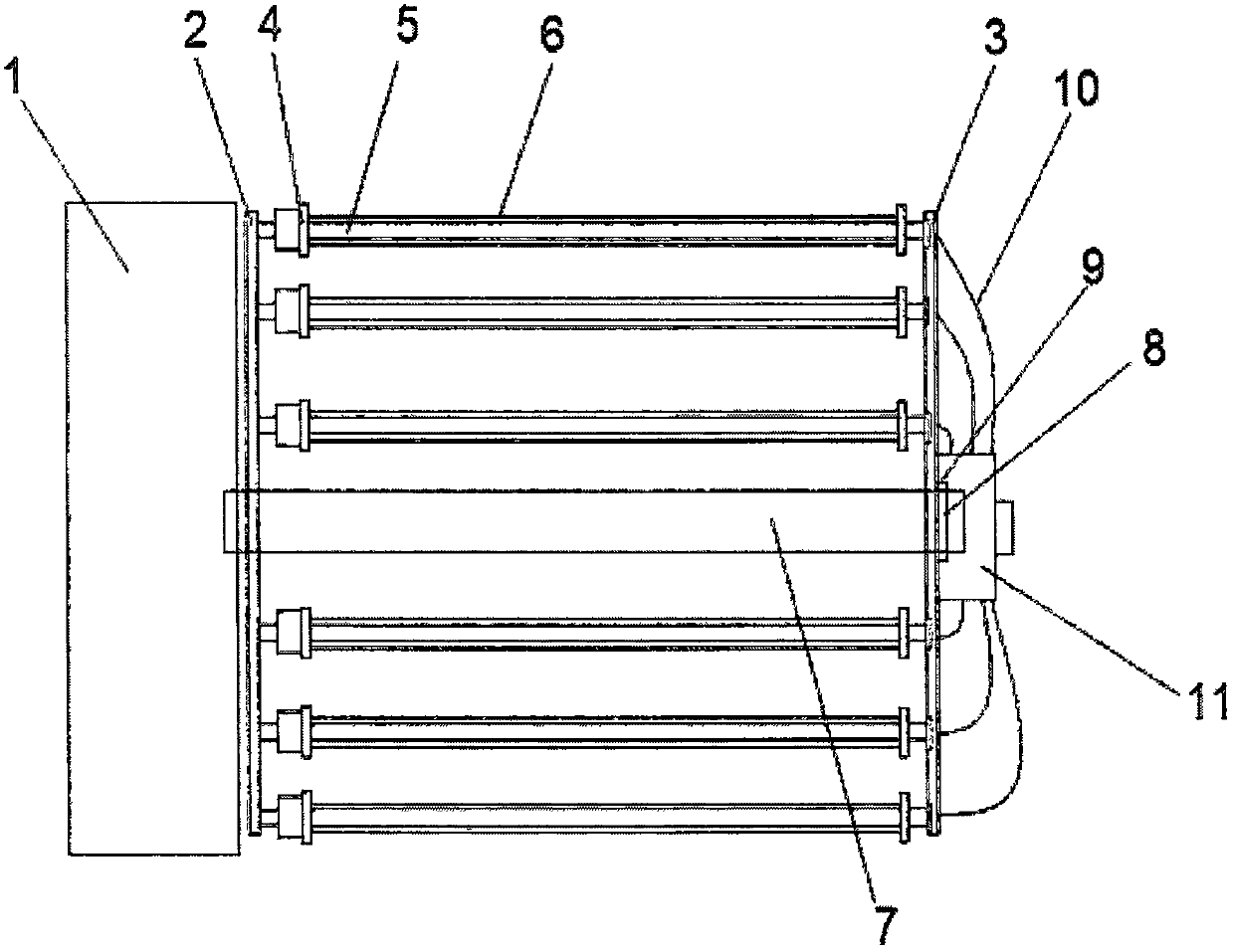

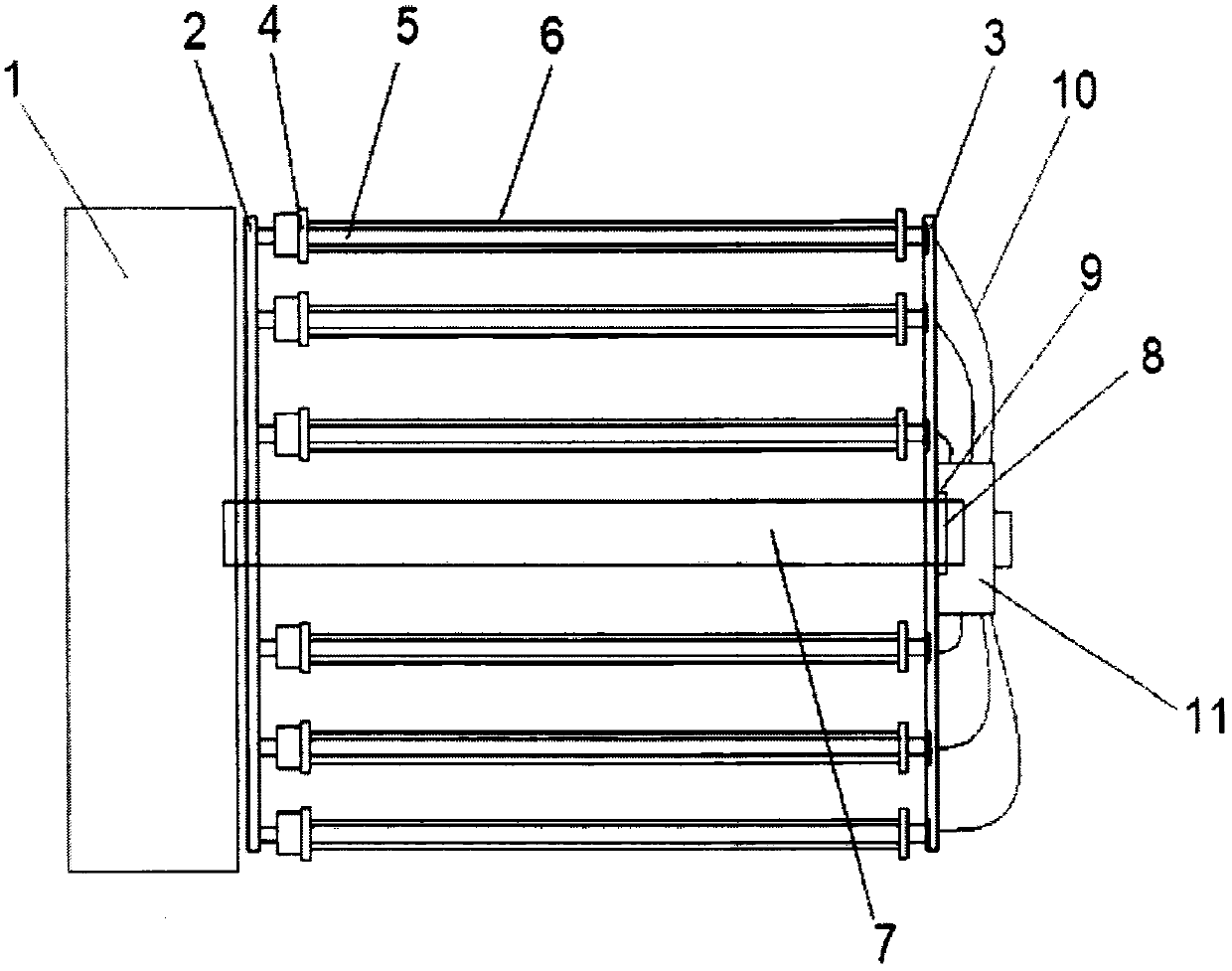

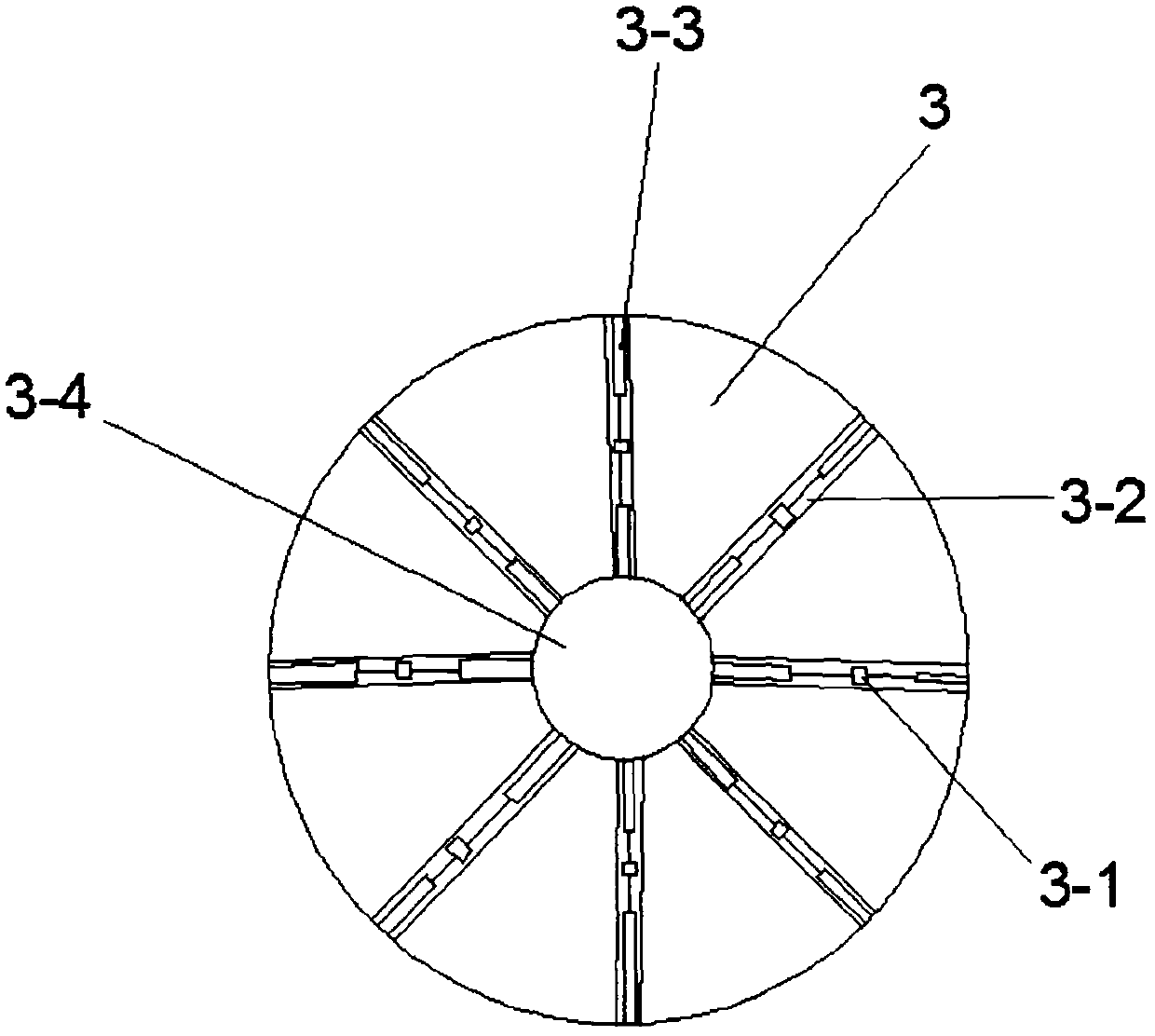

Large-diameter steel strip winding pipe die and winding method thereof

ActiveCN107790557AGuaranteed release effectImprove molding qualityShaping toolsData acquisitionEngineering

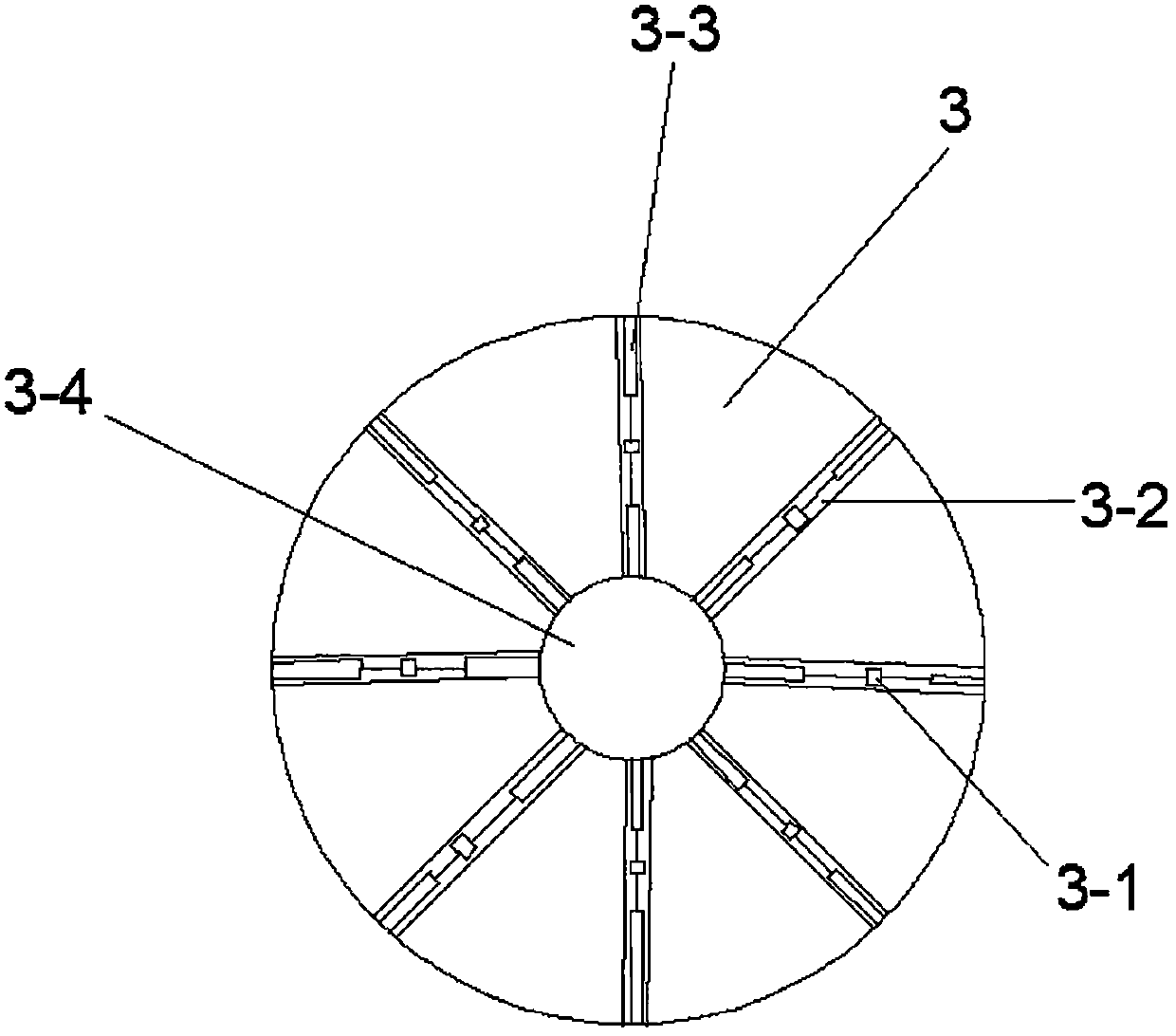

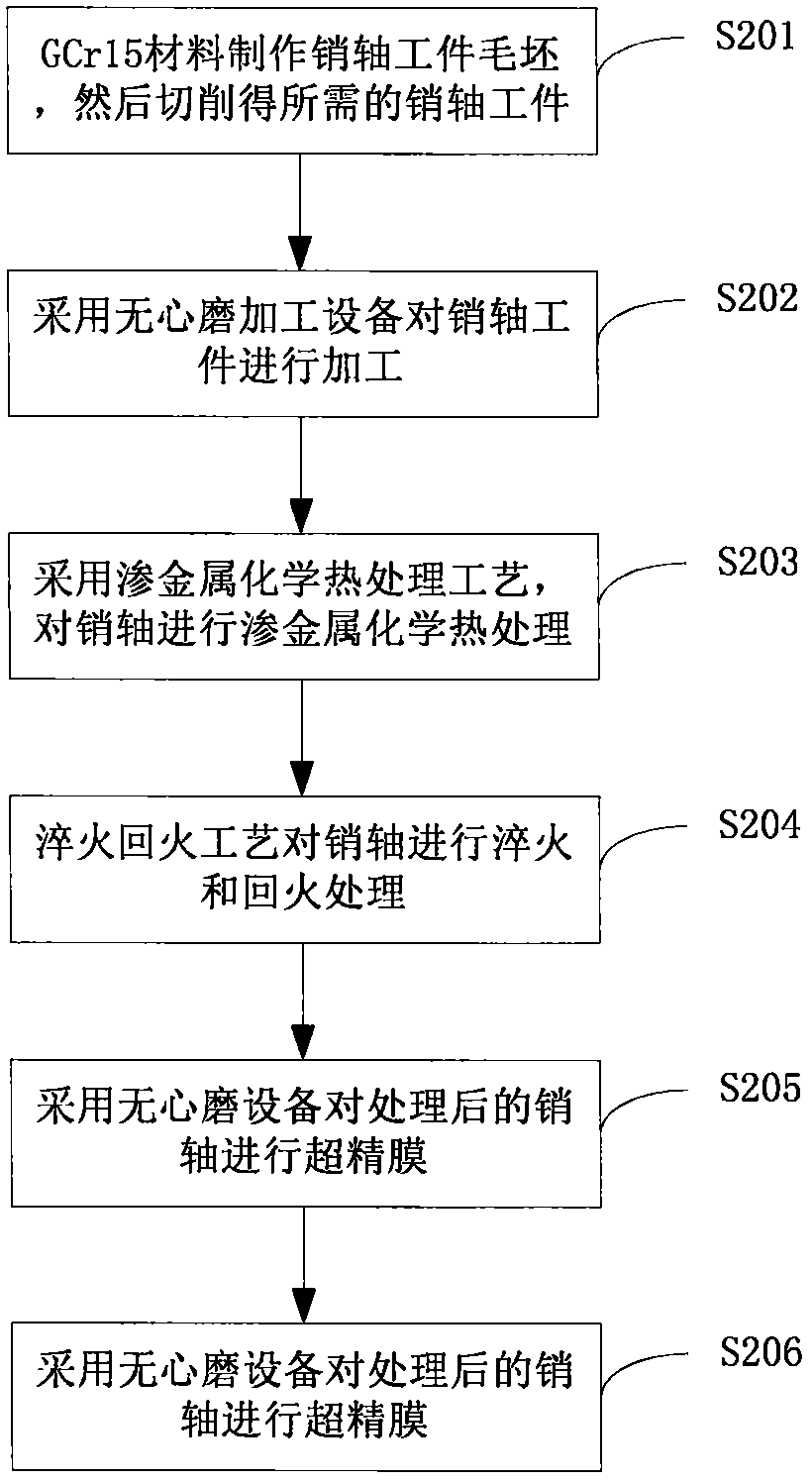

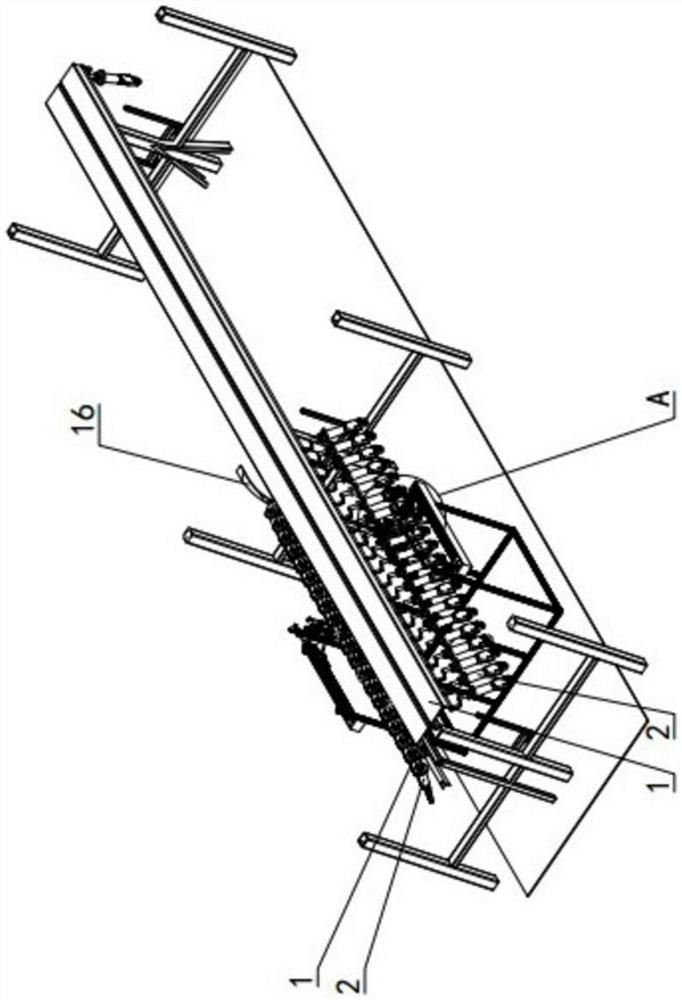

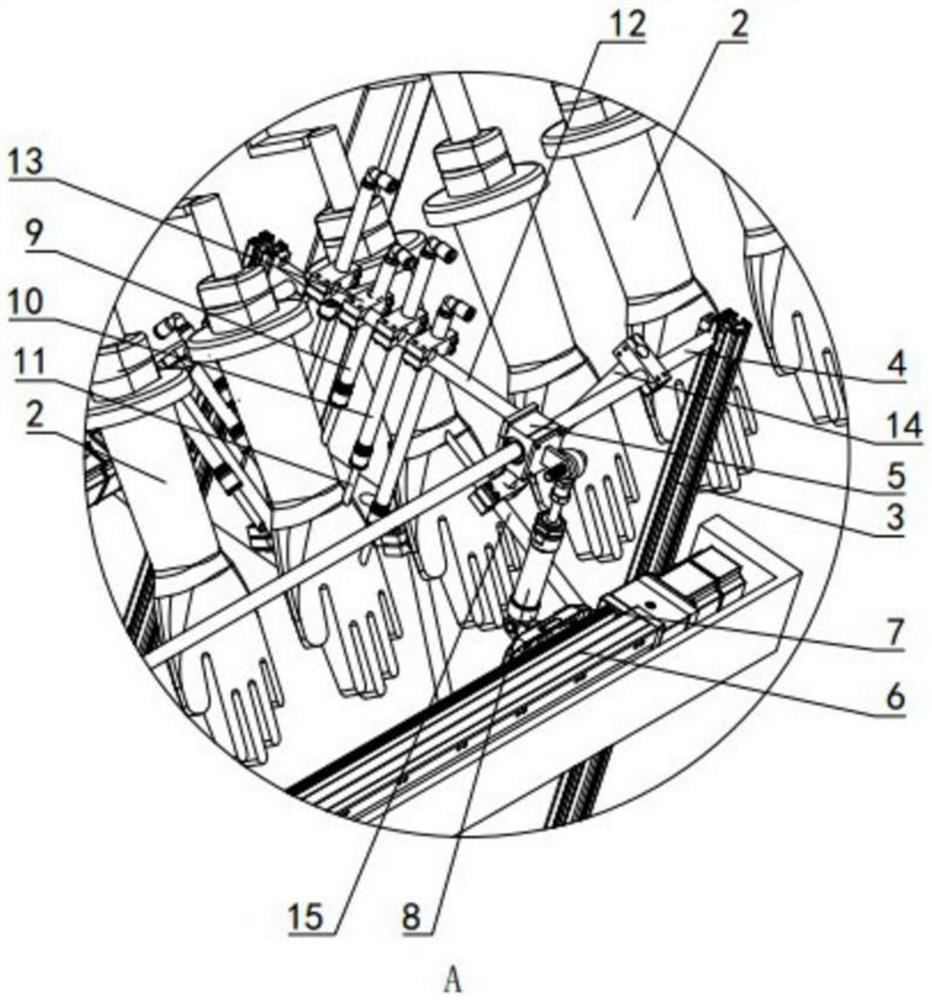

The invention discloses a large-diameter steel strip winding pipe die and a winding method of the large-diameter steel strip winding pipe die. A first supporting disc is arranged on a unit spindle, aplurality of gear discs are arranged on the first supporting disc, rollers are installed on the gear discs, and rolling shafts are installed in the rollers. The tail ends of the rollers are installedon a second supporting disc, and the two ends of each roller are connected with the two gear discs arranged on the corresponding rolling shaft correspondingly. A mandrel is arranged in the middle of the first supporting disc and the middle of the second supporting disc in a penetrating mode, a pin hole is formed in the end, penetrating out of the second supporting disc, of the mandrel, and a hingepin is inserted into the pin hole. The winding method comprises the steps that sampling is conducted through a high-frequency data acquisition card; the step length voltage value is calculated; the step length voltage value is converted into pressure data, and detection information is sent; the speed of a motor is adjusted according to the detection information, and a hydraulic rod is adjusted tocontrol the appearance structure of the die at the same time. By the adoption of the large-diameter steel strip winding pipe die and the winding method, the forming quality of pipelines is improved,the formed pipelines are closely attached to the surface of the die and easily fall off, the production efficiency and the product quality are improved, and the large-diameter steel strip winding pipedie and the winding method can be used for producing straight pipes and taper pipes.

Owner:胜利油田兴达高祥新材料有限责任公司

Unreleased glove picking device stable in work, visual detection system and detection method

ActiveCN113334664AImprove extraction efficiencyEasy to separateDomestic articlesCoatingsMechanical engineeringVisual perception

The invention provides an unreleased glove picking device stable in work, and belongs to the technical field of glove picking equipment. Two sets of picking pipes are arranged on the two sides of a hand mold, each set of picking pipes is installed on a translation device and reciprocates along with the translation device in the direction parallel to the hand mold, and air nozzles of the picking pipes face the fingertip end of the hand mold, so that compressed air blows gloves on the hand mold to slide downwards; two reverse blowing pipes are arranged on the two sides of the hand mold, air nozzles of the reverse blowing pipes are arranged upwards. The invention further provides unreleased glove visual detection system. The system comprises the unreleased glove picking device and further comprises a demolding station camera, an outer guiding device, a shape arranging device, a reinspection camera, a removing unit and a last position detection camera. The separation of gloves and hand molds is achieved, the separation effect is good, and the picking efficiency is high; and meanwhile, the gloves can be stretched and arranged, the detection is carried out through various cameras, unqualified products are removed, and therefore the detection precision of the completeness of the gloves is improved.

Owner:海特锐(天津)科技有限公司

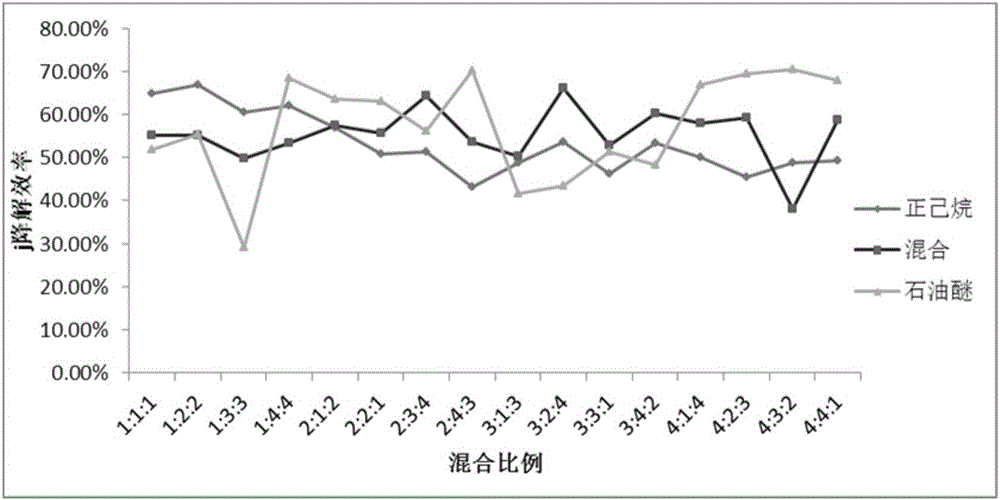

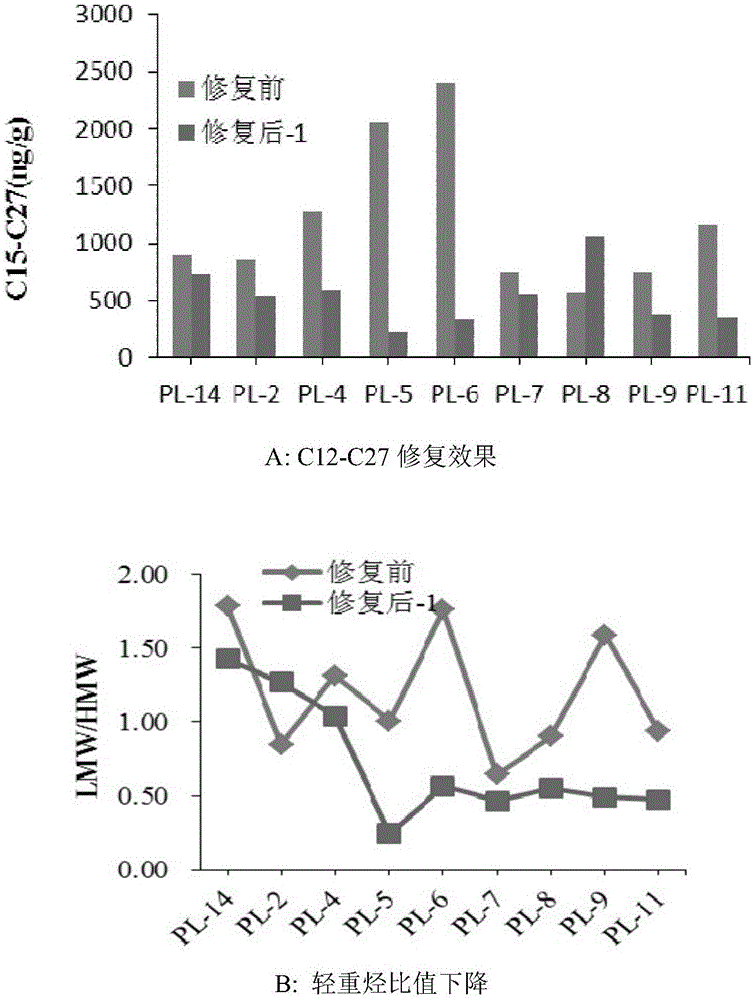

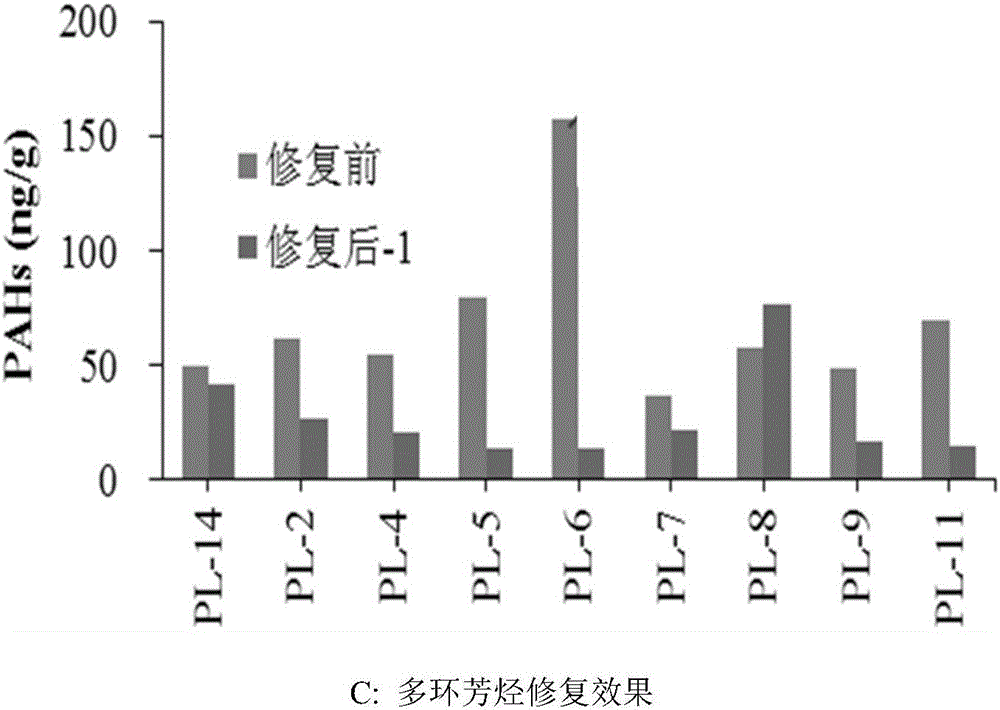

Method for repairing sediment pollution in open sea area

ActiveCN106698672AGuaranteed repair effectGuaranteed delivery effectWater treatment compoundsSeawater treatmentRiver mouthFresh water organism

The invention relates to the field of water environment treatment conducted by microorganisms, in particular to a method for repairing sediment pollution in an open sea area or a deep freshwater area, a river mouth and the like. The method comprises the steps: loading a bacterial strain with zeolite, coating with a flocculating agent and putting the coated bacterial agent into a to-be-treated water area so as to repair sediment petroleum and organic pollutants in the water area. The method mainly aims at the seawater / freshwater area with the water depth being 2 to 50 meters and has a good effect of repairing the sediment petroleum pollution and other organic pollution. The method is integral in system and simple in operating method, has the remarkable effect of repairing the sediment, no secondary pollution and high offshore construction safety, and is particularly suitable the special-function sea areas such as a petroleum exploitation area and an aquaculture area, and can guide implementation of sea sediment pollution repair engineering.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

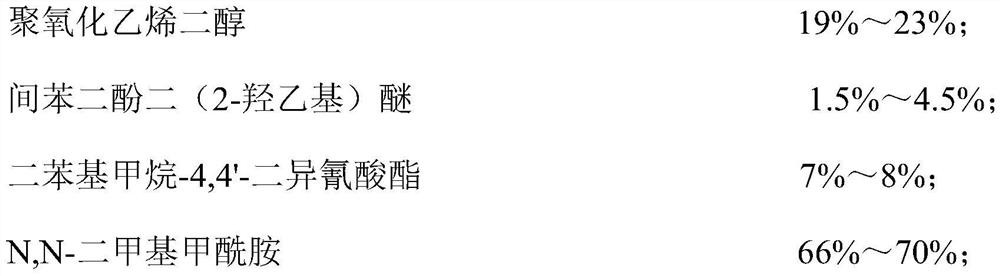

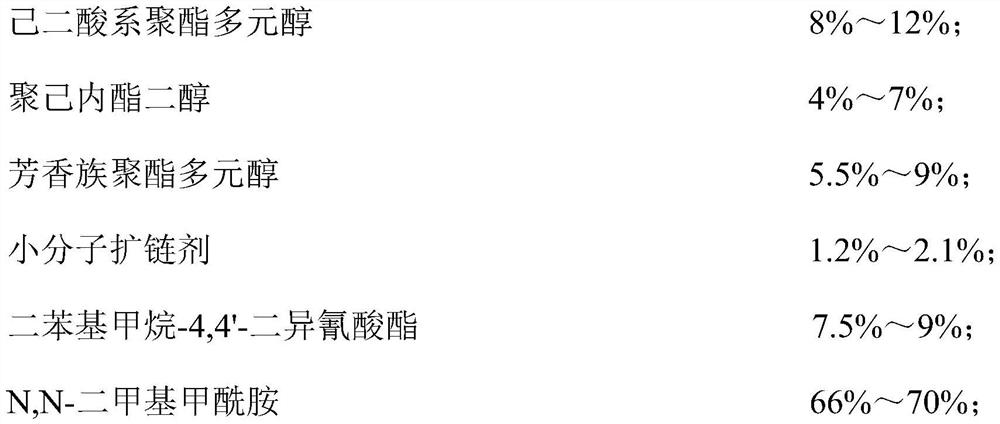

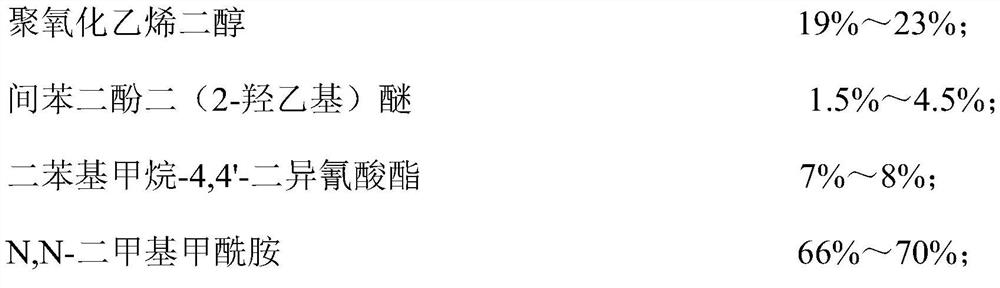

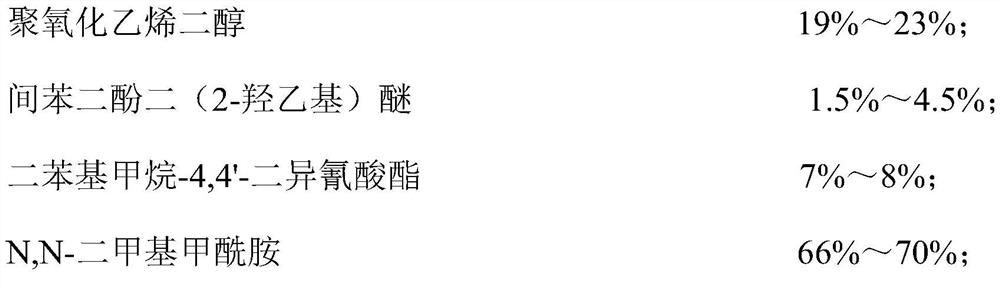

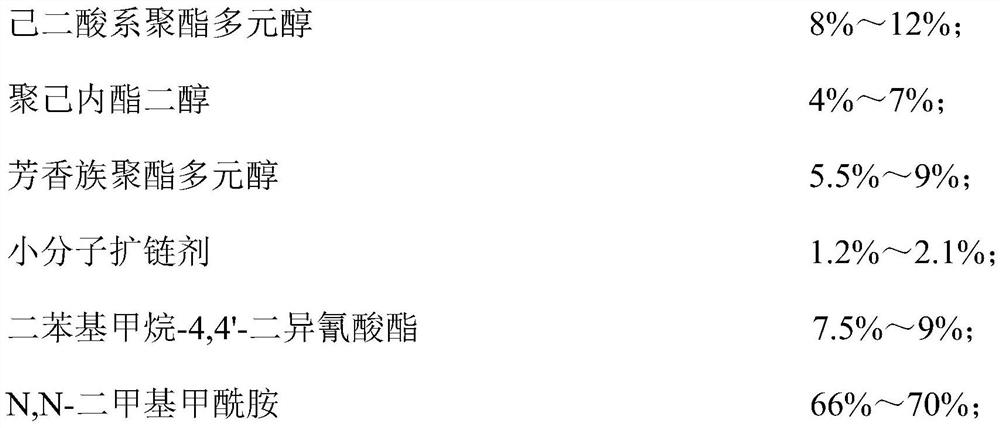

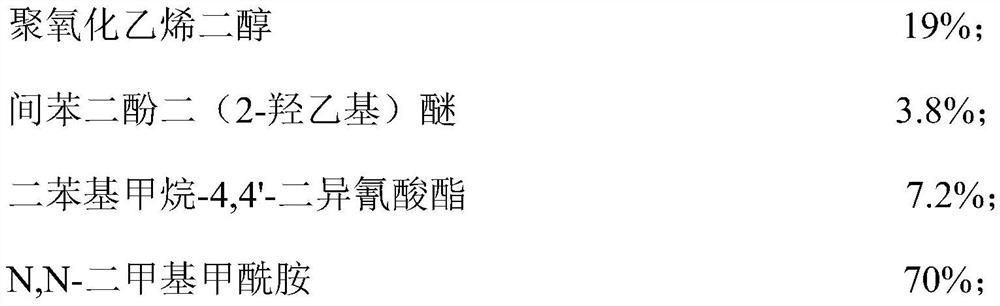

Wet-process polyurethane resin as well as preparation method and application thereof

The invention provides wet-process polyurethane resin as well as a preparation method and application thereof. The wet-process polyurethane resin comprises a component A, a component B and a component C. The component A is prepared from the following raw materials: polyoxyethylene glycol, resorcinol bis(2-hydroxyethyl) ether, diphenylmethane-4,4'-diisocyanate and N,N-dimethylformamide. The component B is prepared from the following raw materials: adipic acid-series polyester polyol, polycaprolactone glycol, aromatic polyester polyol, a small-molecular chain extender, diphenylmethane-4,4'-diisocyanate and N,N-dimethylformamide. The component C is composed of cellulose acetate butyrate and SAN resin in a weight ratio of 1: 2 to 1: 1. Labor protection gloves made of the wet-process polyurethane resin have the advantages of good demolding performance, good rebound resilience and favorable abrasion resistance and are good in air permeability and wearing comfort.

Owner:SHANGHAI HUIDE TECH CO LTD

Preparation method of antistatic release agent

InactiveCN109777212AReduce the use temperatureImprove high temperature resistancePolyurea/polyurethane coatingsPolyether coatingsAntistatic agentSilicone oil

The invention relates to the technical field of preparation of a release agent, in particular to a preparation method of an antistatic release agent. The antistatic release agent mainly comprises 100to 120 parts of reaction medium, 6 to 10 parts of resin powder, 1 to 2 parts of a coupling agent, 1 to 3 parts of an initiator, 5 to 8 parts of silicone oil, 3 to 5 parts of an antistatic agent, 3 to6 parts of starch and 1 to 2 parts of a flatting agent. The release agent prepared by the method is low in use temperature, can be used under the condition of normal temperature, has high high-temperature resistance and avoids deformation and property reduction at high temperature; in addition, the release agent can effectively reduce the adhesion ability of a release film and guarantee the release effect of the release film; meanwhile, the release film has antistatic effect and can be applied in the special technical field.

Owner:苏州市奥贝新材料科技有限公司

Forming method of soft paraffin wax and microcrystalline wax

The invention relates to a forming method of a soft paraffin wax and a microcrystalline wax. The forming method comprises the special steps of: adopting a method that circulating hot water is introduced into a plate frame, controlling the temperature of the circulating hot water to be higher than a melting point by 5-6 DEG C, then, filling a wax solution the temperature of which is higher than the melting point by 8-10 DEG C, fusing the wax solution and the plate frame into a whole, and naturally cooling the wax when the circulating hot water keeps to be higher than the melting point by 1-2 DEG C; when the wax on the middle part of the plate frame is basically cooled, stopping heating the circulating hot water, and unceasingly circulating; when the wax in the plate frame is fully solidified, changing the circulating hot water into cold water, further cooling the wax, when the temperature of the wax drops to be below 40 DEG C, and stopping cooling; and forming a wax block, loosening an extrusion plate of a plate frame forming machine, so as to enable the wax block to fall down from the plate frame. The forming method provided by the invention has the advantages that the technological problems puzzled for multiple years are solved, the soft waxes and the microcrystalline waxes with high additional values and different brands are manufactured again, and the large economic benefits are created.

Owner:NO 2 OIL PRODION PLANT HENAN OIL FIELD BRANCHCORP SINOPEC

Release film for printed circuit board molding, and making method thereof

ActiveCN103434231ACreate pollutionLow costSynthetic resin layered productsLaminationEnvironmental resistanceHalogen

The invention provides a release film for printed circuit board molding. The release film for printed circuit board molding comprises at least two surface layers and one core layer; each of the surface layers is composed of a high-crystallization polyester resin having a melting point of above 200DEG C, or the high-crystallization polyester resin and low-melting-point olefin, or a polyformaldehyde high-crystallization resin; and the core layer is composed of a low-crystallization or non-crystalline polyester resin and the low-melting-point olefin or polar-group-containing flexible resin blend. The release film guarantees the release of a stamped integrated circuit board at a high temperature, also guarantees the deformation tracing ability of the film during processing, has a good stitching property, does not pollute the environment during waste because of the zero content of halogen elements, and has the advantages of excellent quality, low cost and environmental protection.

Owner:胡宇翔

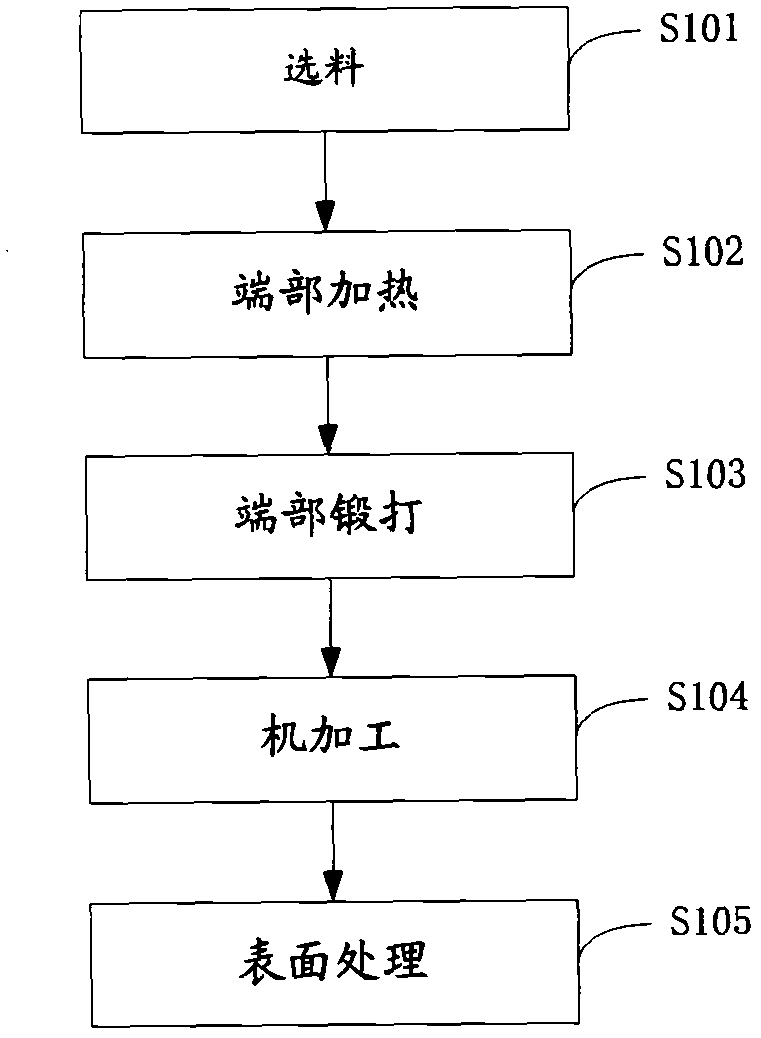

Method for forming fan-shape polygon frame forge piece

InactiveCN1111103CEnsure fair distributionGuaranteed liquidityEngine componentsEngineeringSuperalloy

The forging process includes the following steps: forging hole-enlarged ring which is a ring basically, marking on end face of the hole-enlarged ring according to the position ratio of sectorial polygonal frame corners, single-side lengthening according to the size of every side of sectorial polygonal frame and ensuring that marked place possesses a certain wall thick range and its height can not be allowed to becomse small exceeding its requirement and symmetricall hot angle pressing at marked place according to the corner form. Said process is stable and reliable, low in cost, short in production period, and specially is applicable to fine working process of polygonal frame structural member blanks of high-temp. alloy and structural steel, etc with multiple corners.

Owner:沈阳黎明航空发动机集团公司

Lens film stripping equipment

InactiveCN109174780ASolve the problem of irreparable useReduce in quantityCleaning using liquidsTemperature controlEconomic benefits

The invention discloses a lens film stripping device. The device comprises a reaction kettle body, an electric box and a PLC; and a kettle cover of a reaction kettle is connected to a temperature sensing probe, an automatic pressure relief anti-explosion valve, a pressure gauge, a manual air release valve, an air release electromagnetic valve and an air inlet electromagnetic valve. According to the lens film stripping equipment, the structure is simple and reasonable, the effect of film stripping can be effectively guaranteed, and the operation safety can be improved through the automatic pressure relief anti-explosion valve; meanwhile automatic temperature control and coil pipe type heating mode are adopted, the PLC is used for programmable control, the automation level is improved, and an extremely good condition is created for batch production; and the processing of a coating film product after stripping is promoted, the efficiency is improved, and the economic benefits of optical lens processing are improved.

Owner:孟凡清

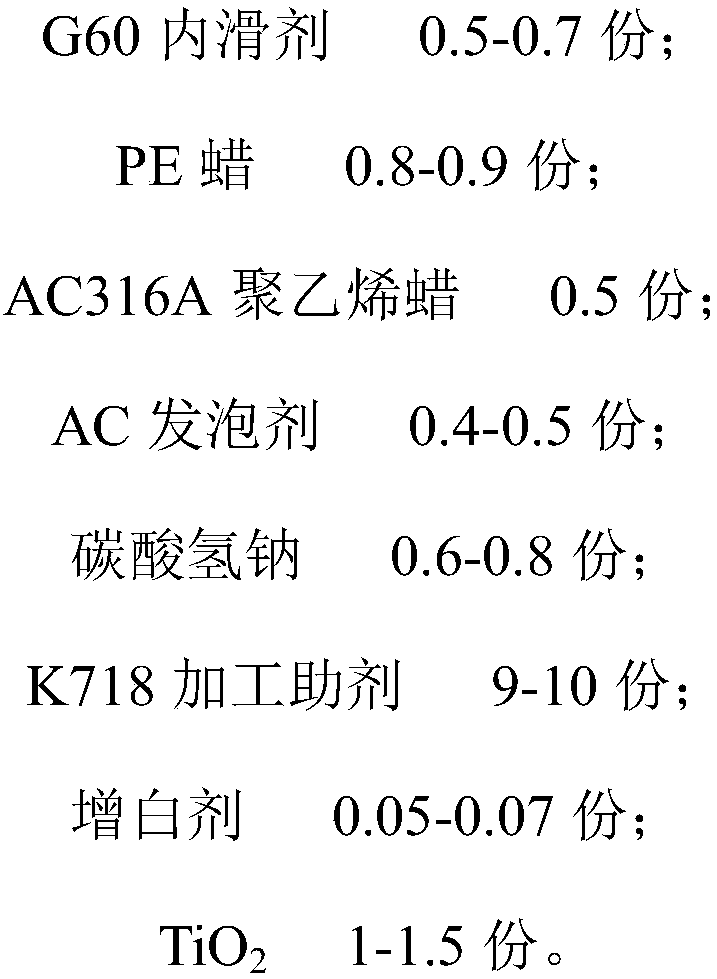

Internal demolding agent for epoxy resin LED packaging material, and preparation method thereof

The invention relates to an internal demolding agent for an epoxy resin LED packaging material, and a preparation method of the internal demolding agent. The demolding agent is prepared by carrying out an addition reaction on the following raw materials in parts by weight: 100-15 parts of low-hydrogen silicone oil, 100-200 parts of an olefin compound and a platinum catalyst based on Pt, wherein the dosage of the platinum catalyst is 5-20 ppm of the total amount of the low-hydrogen silicone oil and the olefin compound. According to the invention, the demolding agent can be directly added into acuring agent of an epoxy resin LED packaging material as an additive and is kept stable, has good compatibility and transparency with the epoxy resin curing agent, can ensure the demolding effect between the epoxy resin curing product and the mold, and especially has the characteristics of convenient use, easy removal of the packaging material, good integrity and the like when being used as the internal demolding agent of the epoxy resin LED packaging material.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

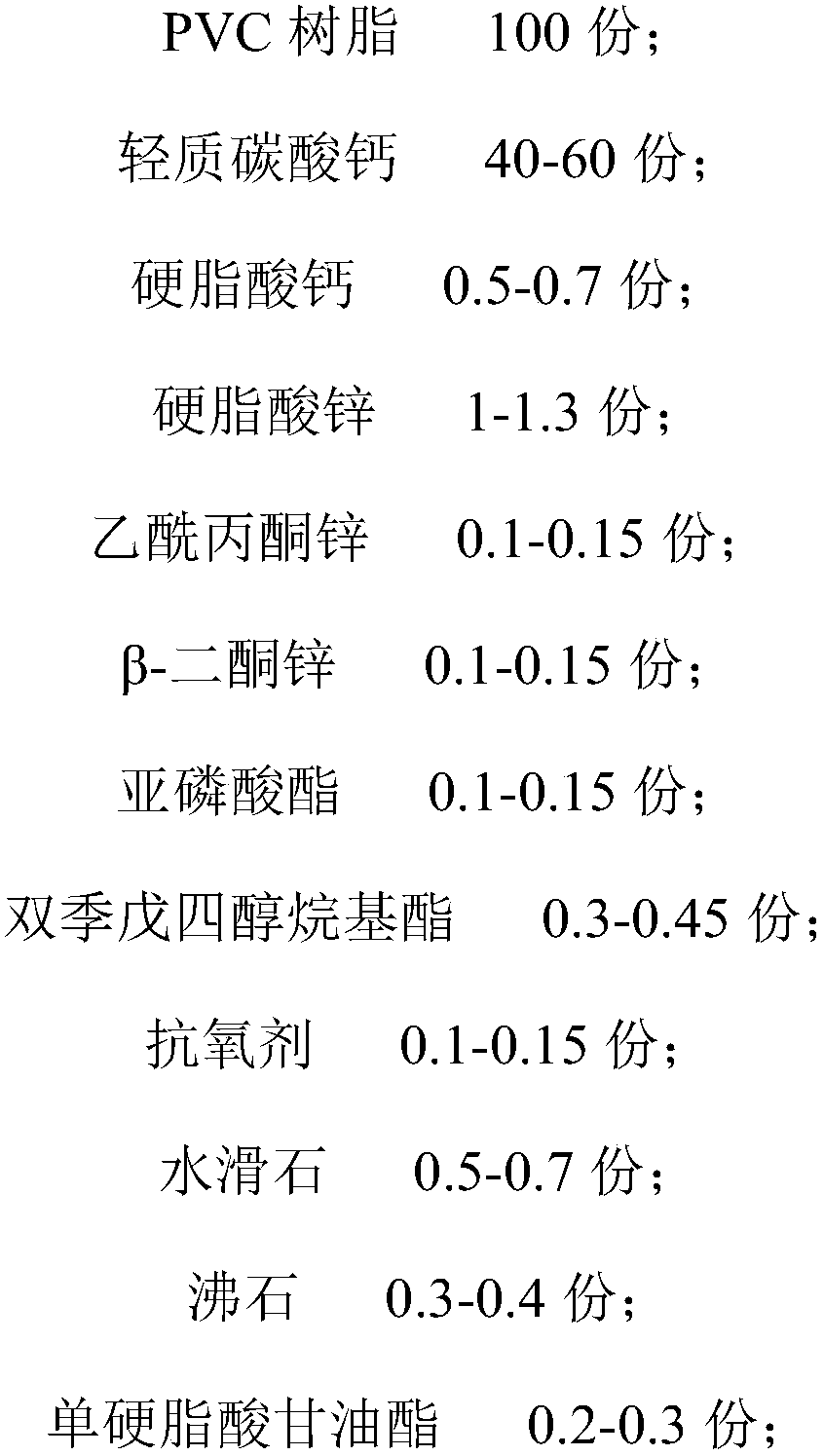

PVC furniture board and preparation method thereof

InactiveCN108586975AImprove plasticizing effectSolve the initial colorabilitySodium bicarbonateWhitening Agents

The invention discloses a PVC furniture board and a preparation method thereof. The PVC furniture board comprises the following raw materials by weight: PVC resin, light calcium carbonate, calcium stearate, zinc stearate, zinc acetylacetonate, zinc beta-diketone, phosphite ester, dipentaerythritol alkyl ester, an antioxidant, hydrotalcite, zeolite, glyceryl monostearate, an internal lubricant G60,PE wax, polyethylene wax AC316A, a foaming agent AC, sodium bicarbonate, a processing auxiliary agent K718, a whitening agent and TiO2. The PVC furniture board obtained by using the method provided by the invention is environmentally-friendly and safe, has good thermal stability, is uniform to foam, and has Shore hardness of no less than 70 D, tensile strength of no less than 12 Mpa, elongation at break of no less than 10% and a bending elastic modulus of no less than 1780 MPa.

Owner:WUHU CONCH NEW MATERIAL

Full-automatic glass bottle decoration firing and film removal machine

PendingCN109264130AHigh degree of automationGood membrane breaking effectArticle unpackingEngineeringTime cost

The invention relates to the technical field of film removal machines, in particular to a full-automatic glass bottle decoration firing and film removal machine. The full-automatic glass bottle decoration firing and film removal machine comprises a film removal line, a film breaking mechanism, a film blowing mechanism and a cleaning mechanism, and the film breaking mechanism, the film blowing mechanism and the cleaning mechanism are sequentially erected on the film removal line. The film breaking mechanism comprises a high-pressure sand blast gun, the film blowing mechanism comprises a high-pressure air gun, and the cleaning mechanism comprises a brush. Glass bottles sequentially pass through the film breaking mechanism, the film blowing mechanism and the cleaning mechanism to complete film removal along the film removal line. Rubber particles are jetted to surfaces of the glass bottles by the high-pressure sand blast gun, so that small pores in different sizes are formed in films on the surfaces of the glass bottles subjected to decoration firing; then the films are instantaneously blown off by instantaneous jetting of the high-pressure air gun, so that a film removal effect is achieved; by the brush for cleaning the glass bottles, film residues on the glass bottles can be thoroughly cleared. The full-automatic glass bottle decoration firing and film removal machine has advantages of great film removal effects, reasonable and compact structure, high automation degree, efficiency improvement and reduction of labor cost and time cost.

Owner:深圳市晶盛自动化设备有限公司

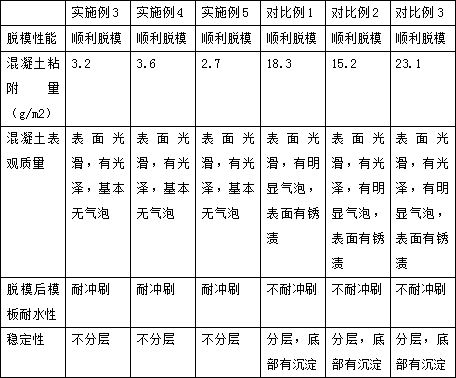

Novel water-based aluminum formwork concrete release agent and preparation method thereof

InactiveCN112538396AStrong wall hangingGuaranteed release effectCeramic shaping apparatusLubricant compositionPlant GumsBase oil

The invention provides a novel water-based aluminum formwork concrete release agent and a preparation method thereof. The novel water-based aluminum formwork concrete release agent comprises the following components in parts by weight: 20-35 parts of lubricating oil base oil; 2-4 parts of OP-7; 1-2 parts of Span-80; 1.0-1.5 parts of a plant colloid component; and 57.5-76 parts of deionized water.The plant colloid component is a composition of xanthan gum and guar gum, and the mass ratio of xanthan gum to guar gum is 4:1. According to the water-based aluminum formwork concrete release agent with the wall-hanging property, through a mixture of the release isolation components and the plant colloid and due to the suspension property and viscosity of the plant colloid, the wall-hanging property is provided for the release agent on a mold of a vertical wall body.

Owner:惠州市麒麟环保材料有限公司

Low-viscosity hollow capsule release agent and preparation method thereof

The invention discloses a low-viscosity hollow capsule release agent and a preparation method thereof. The release agent comprises the following components of, in parts by weight, 500-510 parts of purified water, 1-2 parts of lauryl sodium sulfate, 35-40 parts of pulullan, 80-86 parts of liquid paraffin, 5-12 parts of dendrobium officinale leach liquor and 1-3 part of castor oil; the liquid paraffin and the castor oil are mixed, the mixture is poured into a reaction kettle, after stirring and mixing are conducted, and the temperature is heated to 85-90 DEG C, after heat preservation is conducted for 10-25 minutes, a mixture A is obtained; the pullulan and the dendrobium officinale extracting solution are mixed, the mixture is put into a reaction kettle, the temperature is heated to 30-45 DEG C, and a mixture B is obtained; and when the mixture A is cooled to 30-40 DEG C, the mixture B is added, then the lauryl sodium sulfate and the purified water are added, after emulsion reaction is carried out, and filtering is conducted to obtain the release agent. The release agent is simple in component and small in friction coefficient, a used mold is easy to wash, and the release agent has good application prospect.

Owner:JIANGSU LEFAN CAPSULE

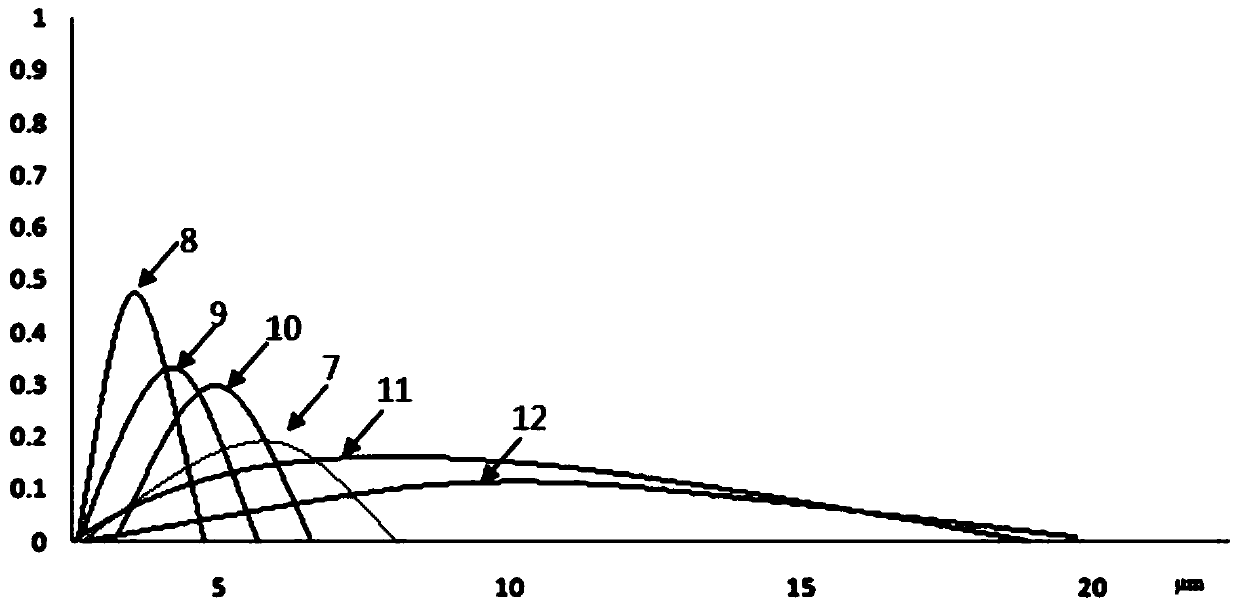

Slow-release humic acid and urea compound fertilizer and preparation method thereof

InactiveCN103073350AQuality improvementAchieving a breakthrough in secondary controlled releaseFertilizer mixturesControl releaseResin coating

The invention discloses a slow-release humic acid and urea compound fertilizer and a preparation method thereof. The preparation method of the slow-release humic acid and urea compound fertilizer is characterized in that, water and a part of steam condensate, which are generated during reaction of humic acid and urea, are taken as a liquid phase and rolled into granules under the participation of a balling agent, wherein in the granulating process, the humic acid and the urea form balls through the balling agent and are tightly jointed together; when the granules grow to a certain grain diameter, the granules are thrown out under the action of a centrifugal force of a disc to enter a drying machine through a belt; the granules are dried till the moisture content is less than or equal to 2.5%, and the granules are sieved to obtain the granular fertilizer with the grain diameter of 2-4.75mm; and a layer of slow-release agent is coated on the surfaces of the granules to form secondary controlled release. By increasing or decreasing the use amount of a resin coating agent and the proportion of the humic acid, different slow-release humic acid and urea compound fertilizers with the grain diameters of 50-400 can be produced, so that the problems that the conventional nitrogen fertilizer resource has more constraints and the utilization ratio is relatively low are solved; the slow-release humic acid and urea compound fertilizer has the advantages of improving soil and improving the efficacy of the nitrogen fertilizer; and the preparation method is applicable to production of slow-release humic acid urea.

Owner:SHANXI CHANGXIN BIOLOGICAL AGRI TECH

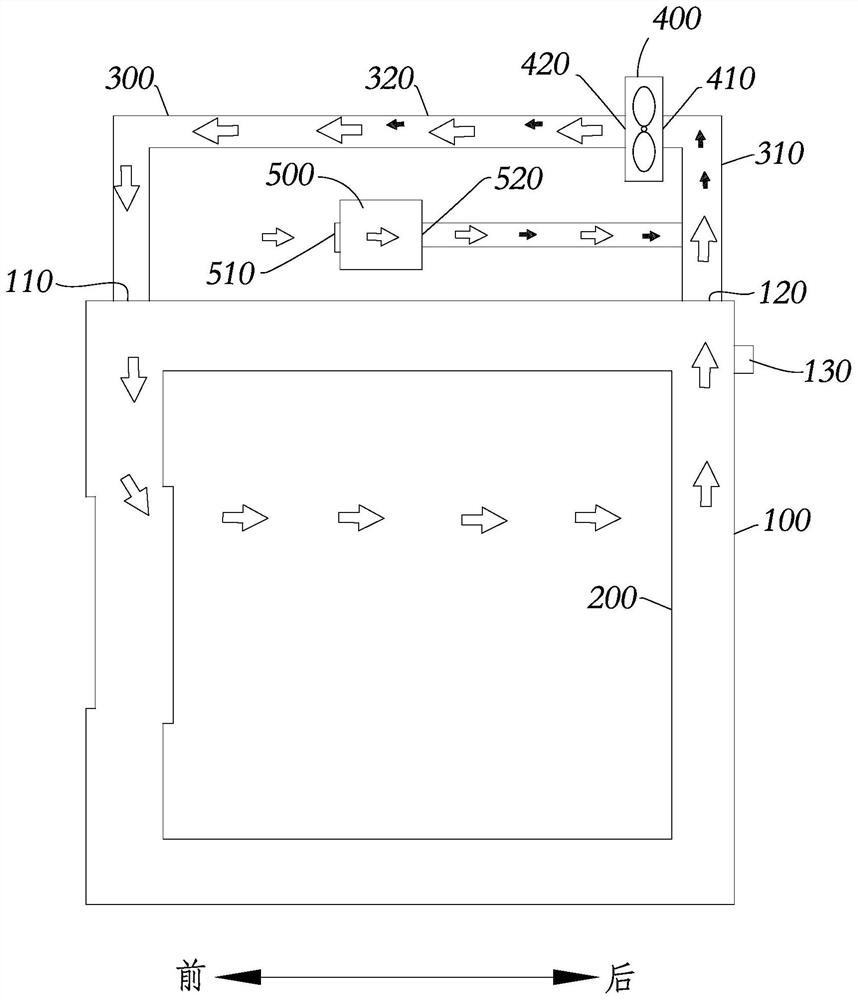

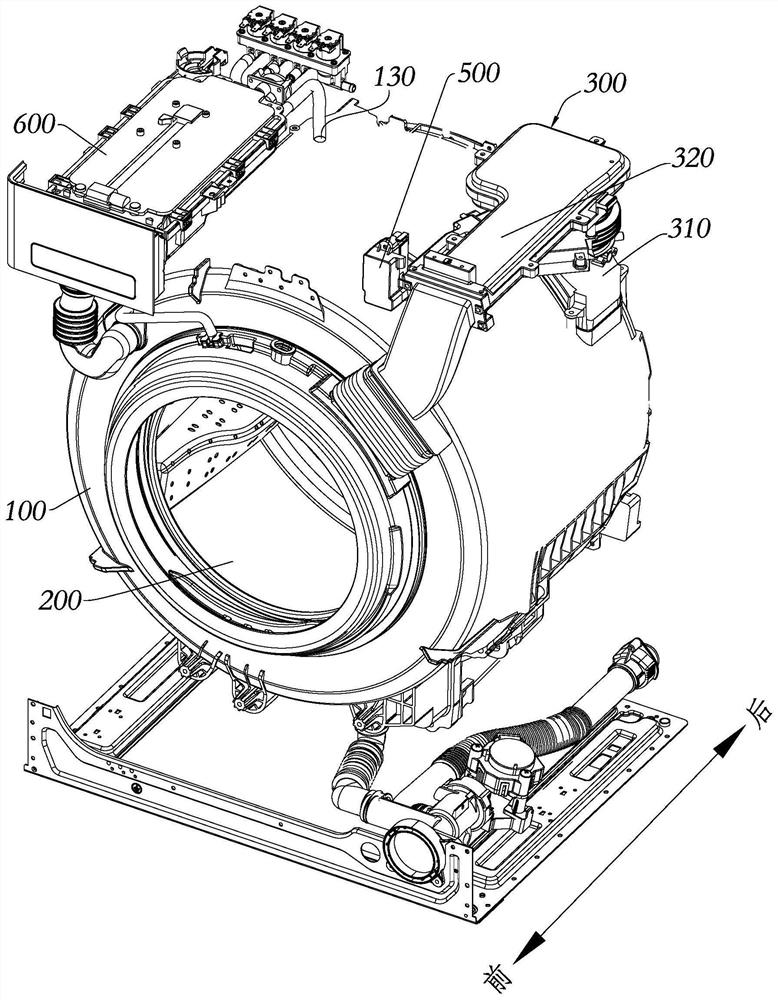

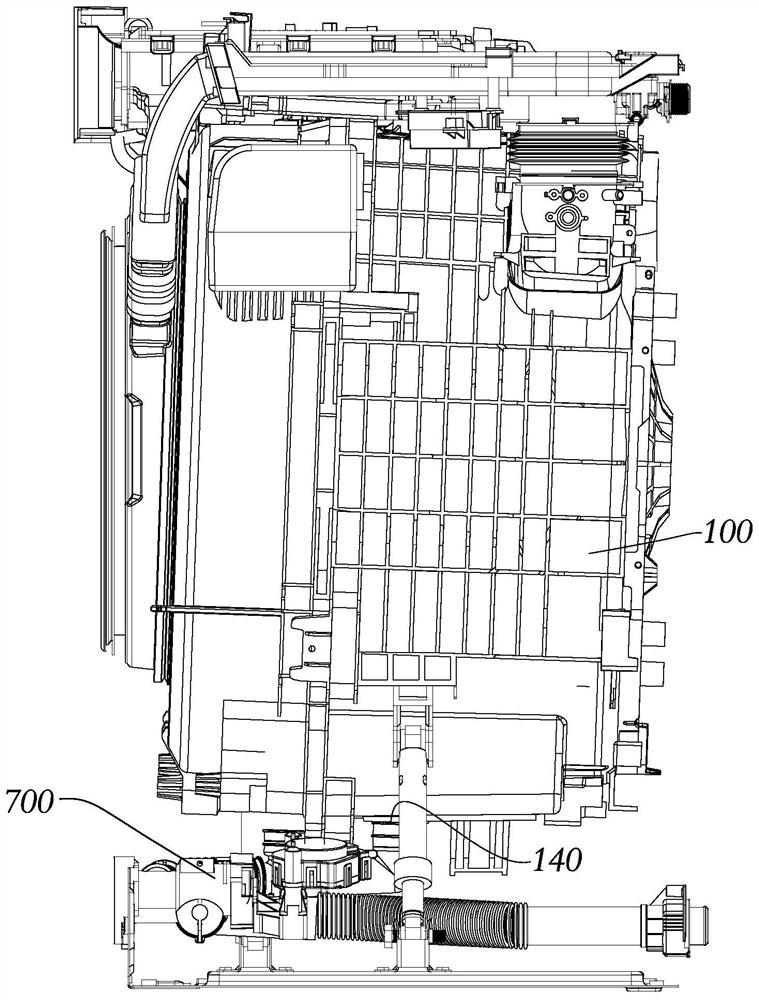

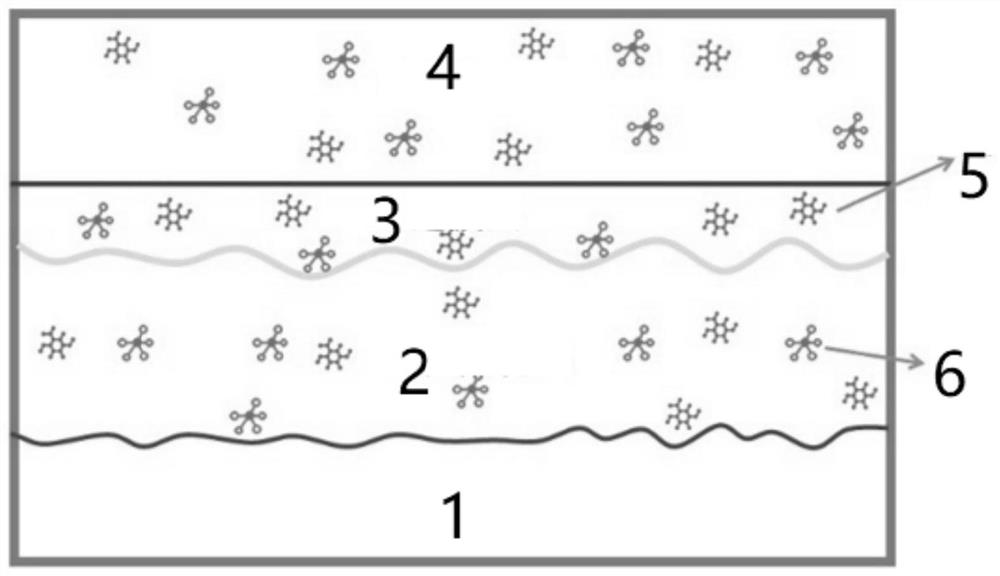

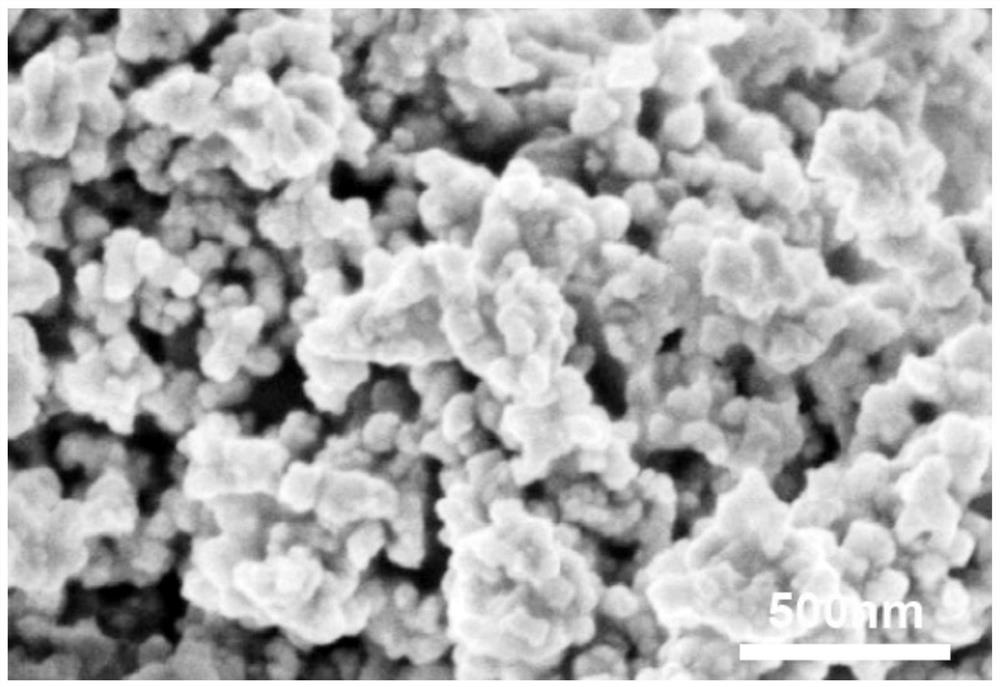

Clothes treatment equipment

PendingCN113605062AUniform adhesionGuaranteed release effectTextiles and paperLaundry driersProcess engineeringMechanical engineering

The invention discloses clothes treatment equipment, and belongs to the technical field of household appliances. The clothes treatment equipment comprises a water containing barrel, an air pipe, an electrostatic atomization device and an exhaust channel, wherein a washing barrel communicating with the water containing barrel and capable of rotating is arranged in the water containing barrel; the two ends of the air pipe with a fan are connected to the water containing barrel, and the fan acts to enable circulating airflow to be formed in the washing barrel and the air pipe; the electrostatic atomization device capable of generating atomized particles is provided with an air inlet communicated with the outside space and an air outlet communicated with the air pipe, and the atomized particles generated by the electrostatic atomization device are fed into the air pipe by means of airflow sucked by the outside and enter the water containing barrel and the washing barrel along with the circulating airflow; and the exhaust channel is used for communicating the water containing barrel to the outside space in the care process. In the care process, part of air in the water containing barrel can be released to the outside through the exhaust channel, the air pipe can continuously suck outside air from the air inlet of the electrostatic atomization device, and the atomized particles generated in the electrostatic atomization device are blown into the air pipe, so that the release effect of the electrostatic atomization device is guaranteed.

Owner:PANASONIC APPLIANCES CHINA CO LTD +1

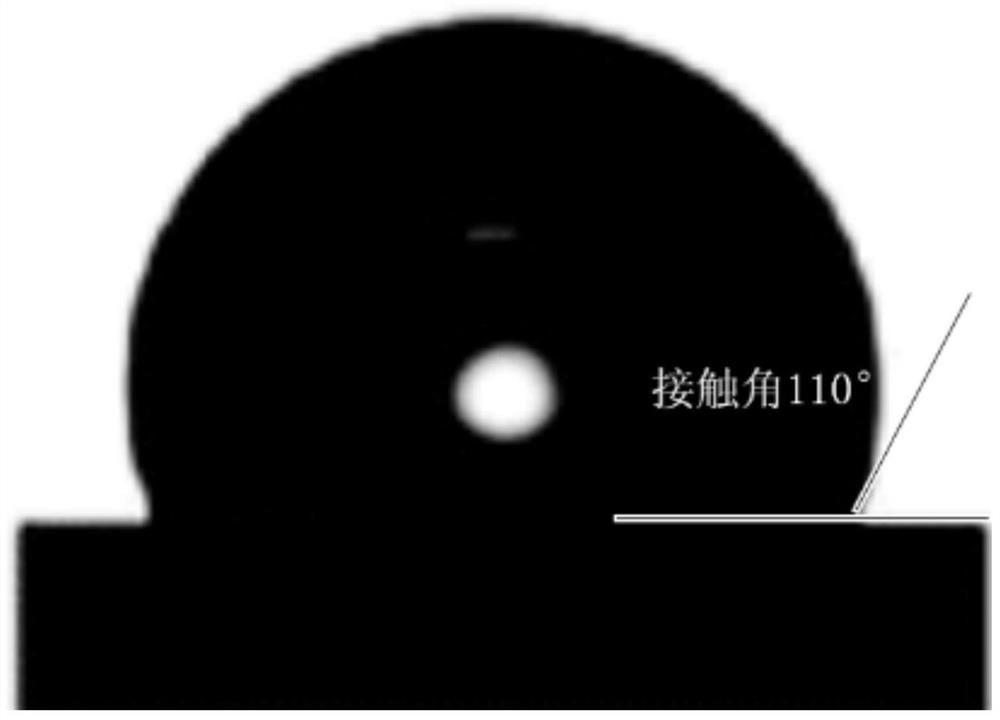

Double fluorine treatment solution, preparation method and surface treatment method of magnesium alloy building formwork

ActiveCN112251088BReduce pollutionEasy disposalLiquid surface applicatorsAntifouling/underwater paintsNano siliconEmulsion

Owner:重庆建谊祥科技有限公司

A large-caliber steel strip winding pipe die and winding method thereof

ActiveCN107790557BGuaranteed release effectImprove molding qualityShaping toolsData acquisitionEngineering

The invention discloses a large-diameter steel strip winding pipe die and a winding method of the large-diameter steel strip winding pipe die. A first supporting disc is arranged on a unit spindle, aplurality of gear discs are arranged on the first supporting disc, rollers are installed on the gear discs, and rolling shafts are installed in the rollers. The tail ends of the rollers are installedon a second supporting disc, and the two ends of each roller are connected with the two gear discs arranged on the corresponding rolling shaft correspondingly. A mandrel is arranged in the middle of the first supporting disc and the middle of the second supporting disc in a penetrating mode, a pin hole is formed in the end, penetrating out of the second supporting disc, of the mandrel, and a hingepin is inserted into the pin hole. The winding method comprises the steps that sampling is conducted through a high-frequency data acquisition card; the step length voltage value is calculated; the step length voltage value is converted into pressure data, and detection information is sent; the speed of a motor is adjusted according to the detection information, and a hydraulic rod is adjusted tocontrol the appearance structure of the die at the same time. By the adoption of the large-diameter steel strip winding pipe die and the winding method, the forming quality of pipelines is improved,the formed pipelines are closely attached to the surface of the die and easily fall off, the production efficiency and the product quality are improved, and the large-diameter steel strip winding pipedie and the winding method can be used for producing straight pipes and taper pipes.

Owner:胜利油田兴达高祥新材料有限责任公司

A kind of wet process polyurethane resin and its preparation method and application

The invention provides a wet-process polyurethane resin and a preparation method and application thereof. The wet-process polyurethane resin includes three components, A, B and C, and the preparation raw materials of the A component include the following components: polyethylene oxide di Alcohol, resorcinol bis(2-hydroxyethyl) ether, diphenylmethane-4,4'-diisocyanate and N,N-dimethylformamide; the preparation raw materials of the B component include the following groups Divided into: adipic acid-based polyester polyol, polycaprolactone diol, aromatic polyester polyol, small molecule chain extender, diphenylmethane-4,4'-diisocyanate and N,N-dimethylene Formamide; the C component is composed of cellulose acetate butyrate and SAN resin in a weight ratio of 1:2 to 1:1. The labor protection gloves made of the wet-process polyurethane resin of the present invention have the advantages of good mold release, good resilience and good wear resistance, as well as good air permeability and good wearing comfort.

Owner:SHANGHAI HUIDE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com