Release film for printed circuit board molding, and making method thereof

A technology of printed circuit board and release film, applied in the field of plastic film, can solve the problems of affecting welding performance, insufficient softness, high price, etc., and achieve the effect of ensuring deformation followability, reducing cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

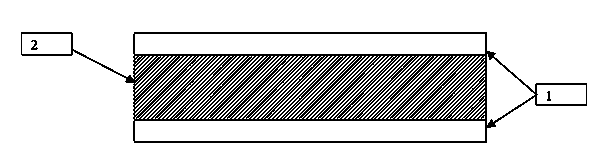

Image

Examples

Embodiment 1

[0032] Embodiment 1, sample film preparation

[0033] The No.1-9 films listed in Table 1 were prepared by a three-layer co-extrusion method, and the thicknesses were all 120 microns.

[0034] A film with a thickness of 80 microns and containing 70% PETG and 30% nylon 6 was prepared by single-layer extrusion, and a 20 micron PET film was laminated on both sides to make sample 10.

[0035] A high temperature resistant PP film (sample A) and a TPX film (sample B) with a thickness of 120 microns were prepared by a single-layer extrusion method for comparison of release properties.

[0036] Table 1 Sample number and composition list

[0037] Sample serial number 1 2 3 Core composition PETG70: PP30 PETG85: PP25 PET75: Nylon 6 25 Surface composition PET PET PET

[0038] Sample serial number 4 5 6 Core composition PETG75: PP25 PET75: PP25 PET75: PP25 Surface composition PET PBT PTT

[0039] Samp...

Embodiment 2

[0040] Embodiment 2, release effect comparison

[0041] Attach the above samples to both sides of the circuit board, conduct a hot pressing test, and use the release property and shape followability to determine whether it can be used as a release film.

[0042] Table 2 Comparison table of release effect of each sample

[0043] sample Release shape following Comprehensive judgment 1 qualified qualified qualified 2 qualified qualified qualified 3 qualified qualified qualified 4 qualified qualified qualified 5 qualified qualified qualified 6 qualified qualified qualified 7 qualified qualified qualified 8 qualified qualified qualified 9 qualified qualified qualified 10 qualified qualified qualified A very poor qualified unqualified B qualified unqualified unqualified

[0044]Release and shape followability are two major indicators for evaluat...

Embodiment 3

[0045] Embodiment 3, pollution comparison

[0046] The circuit board samples that passed the above pressing test and the circuit boards laminated with release paper containing silicon release layer were analyzed by fluorescent X-ray for the silicon element on the solder joints. The solder joints of the pressed circuit board contain silicon element, which will cause virtual soldering and desoldering; while the above solder joints of the circuit board pressed with the release film of the present invention do not contain silicon element, and the pollution test is qualified.

[0047] In the present invention, the film structure of the core layer is replaced by the film structure of the surface layer of polyester resin with high melting point and high crystallization and the blend of low melting point resin as the main component, which not only ensures the release of the integrated circuit board after stamping at high temperature It also guarantees the deformation followability of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| crystallization time | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com