Patents

Literature

85 results about "Desoldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In electronics, desoldering is the removal of solder and components from a circuit board for troubleshooting, repair, replacement, and salvage.

Soldering or desoldering iron

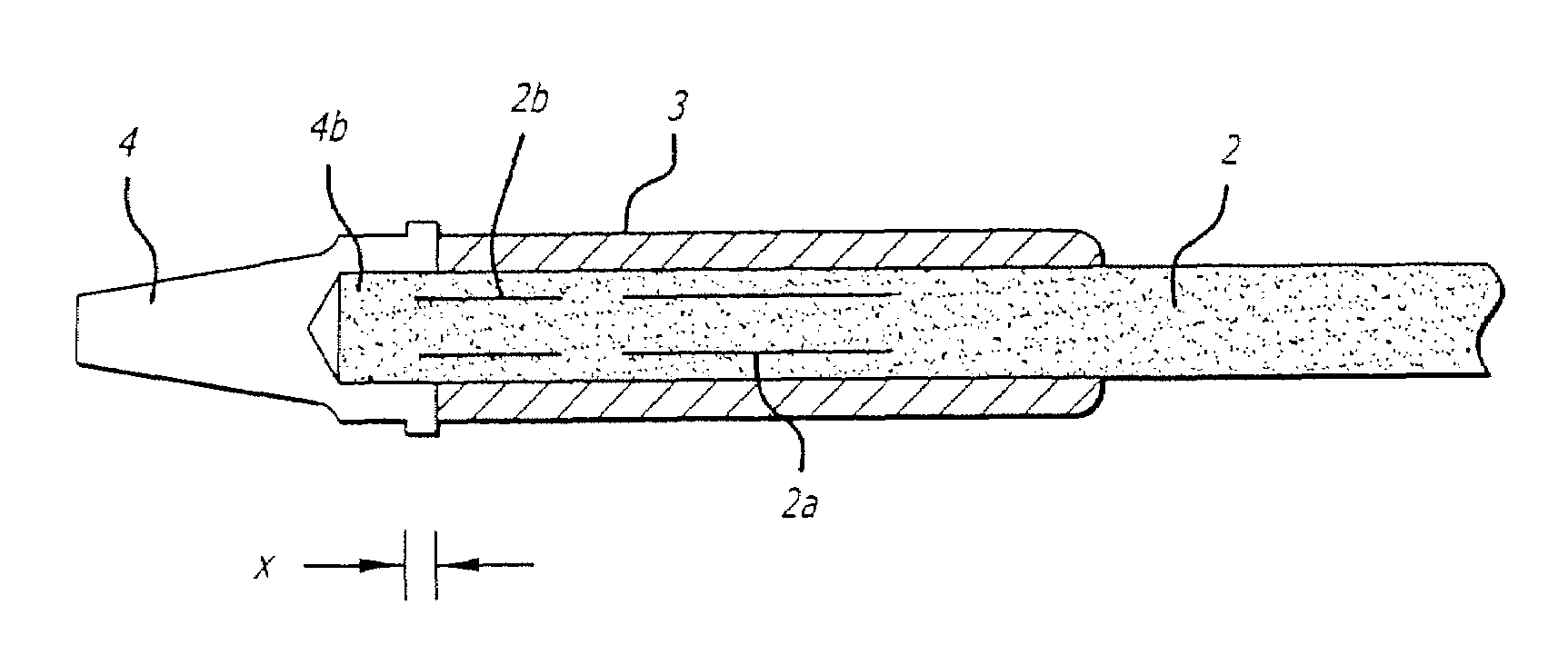

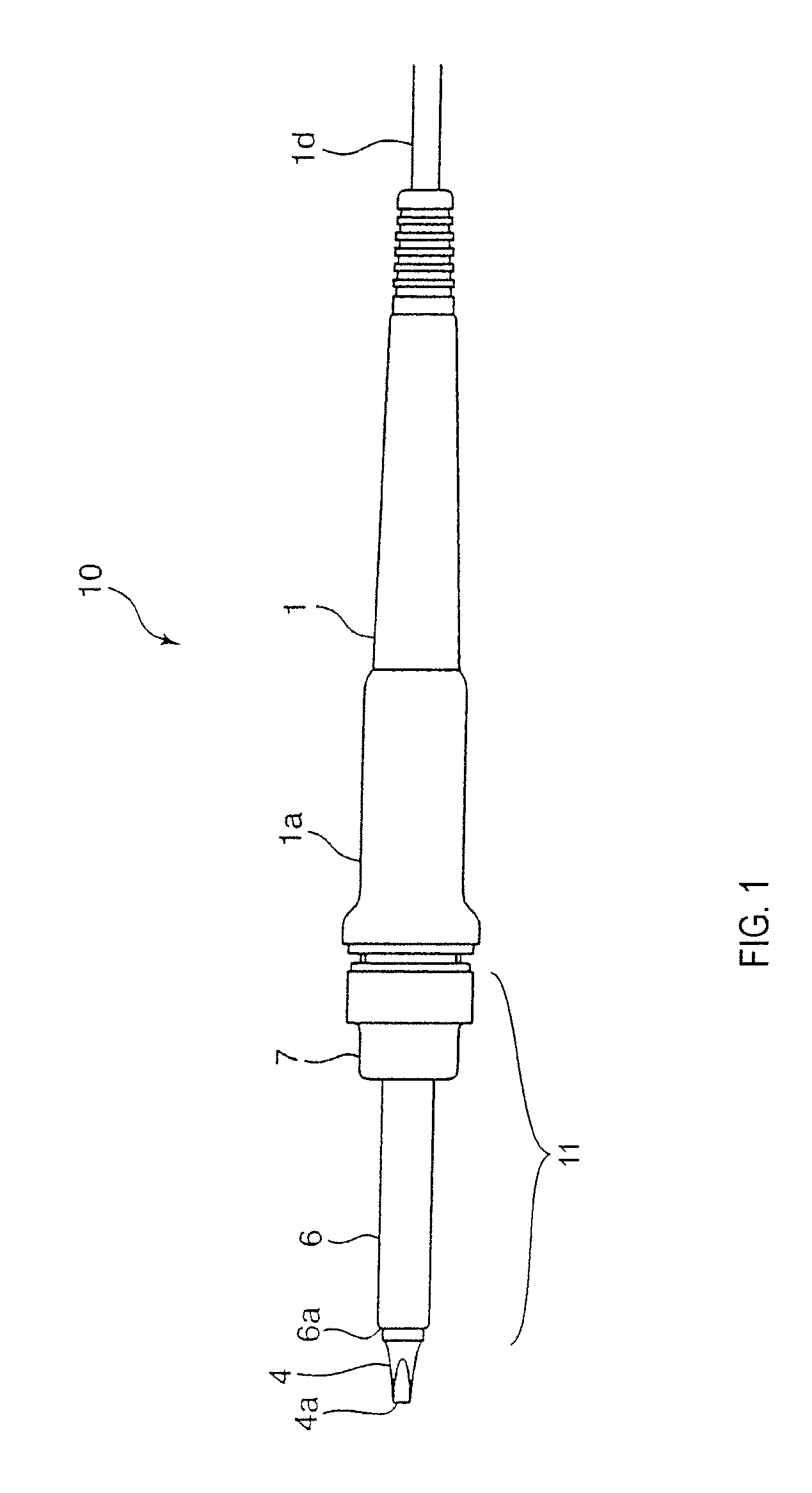

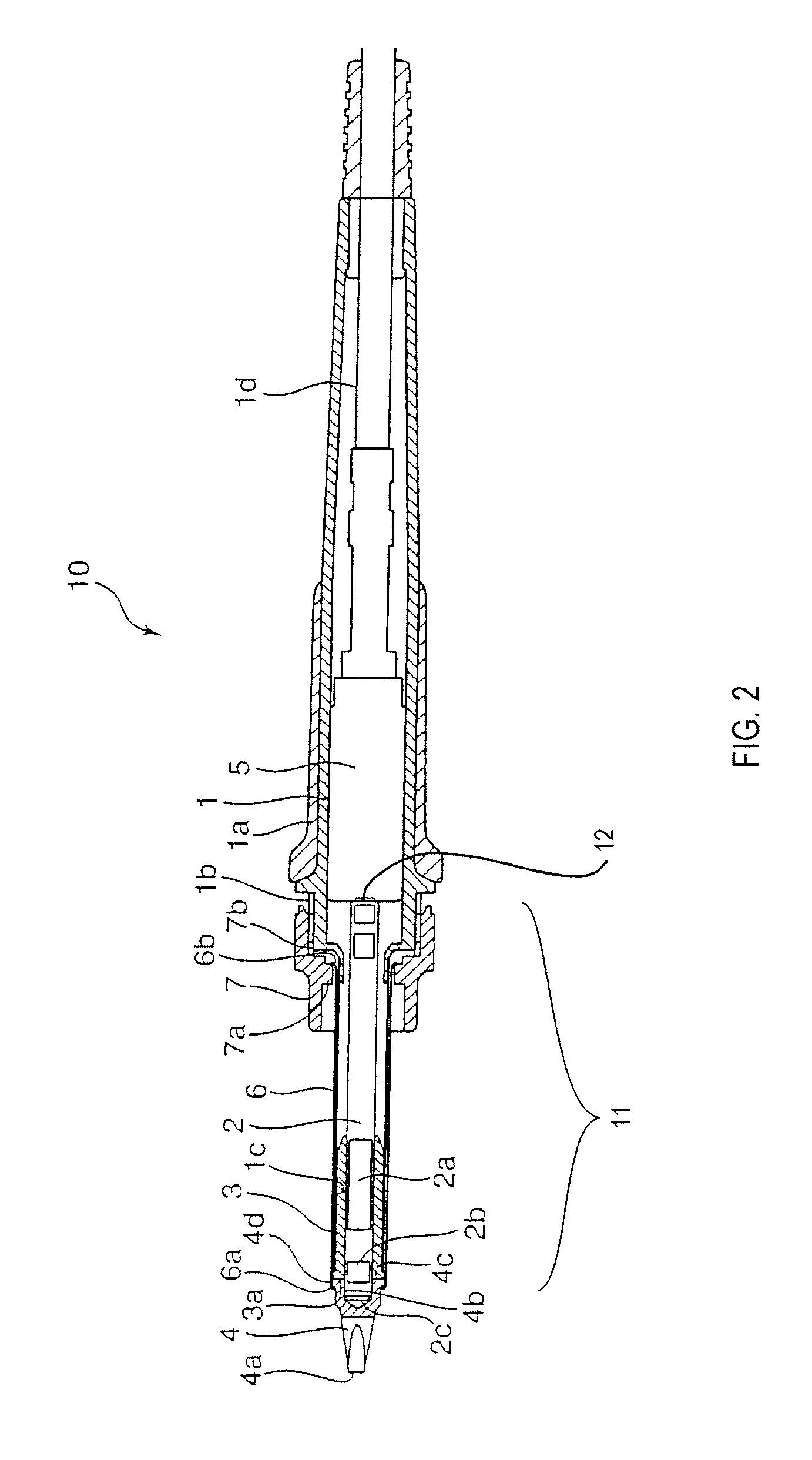

ActiveUS7679032B2Low costSecurely holdHeating element shapesHeating appliancesSolderingBiomedical engineering

Owner:HAKKO CO LTD

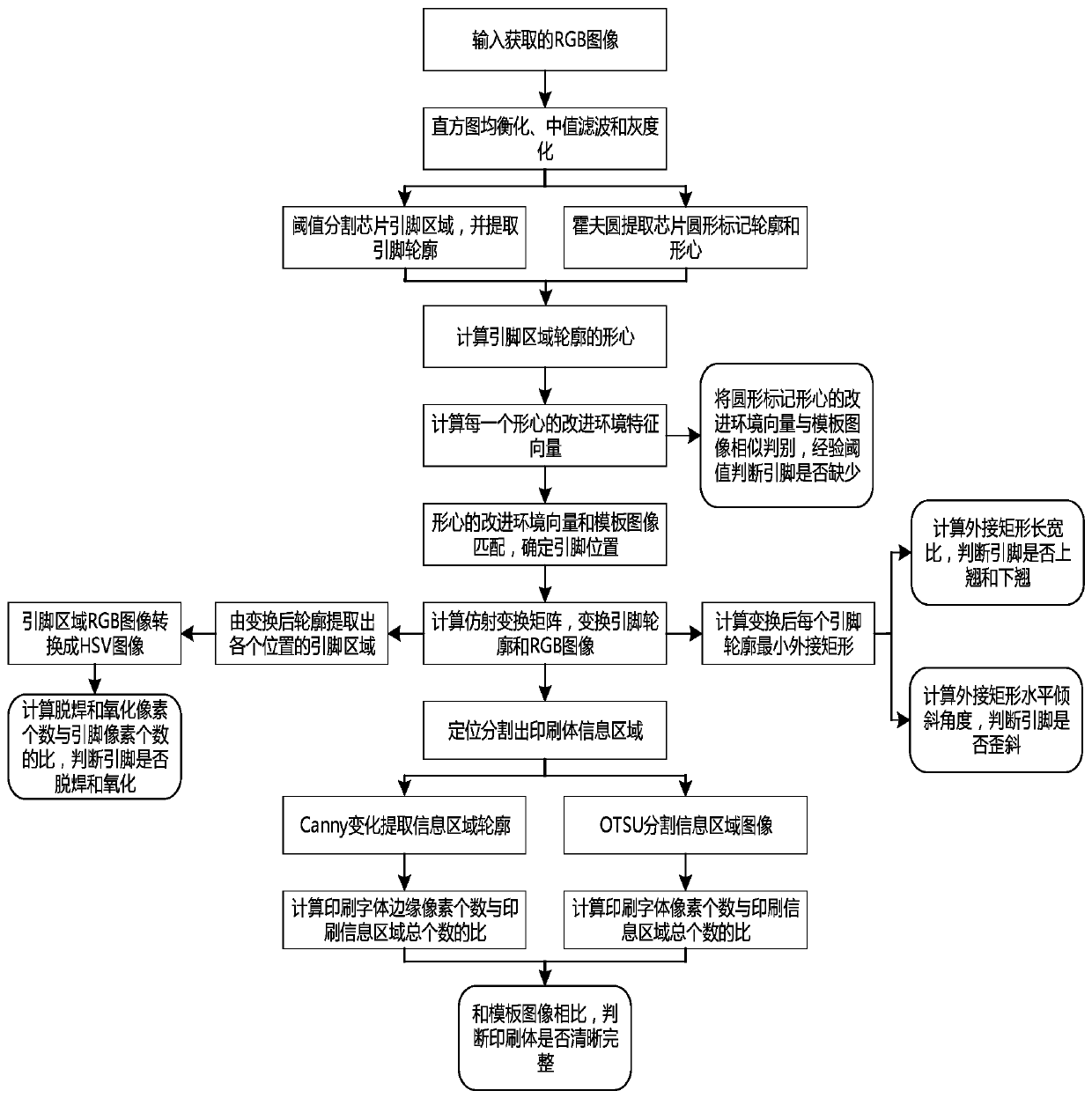

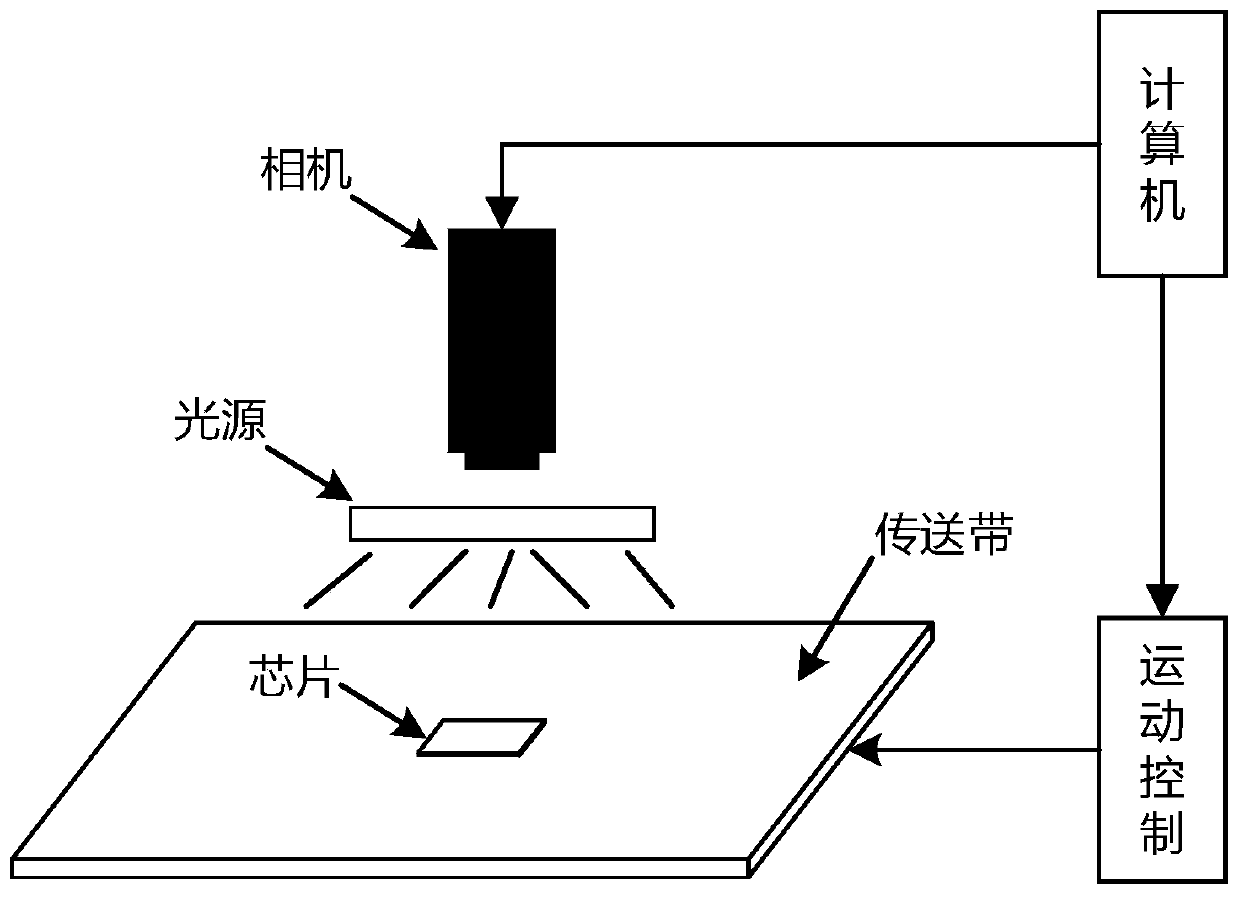

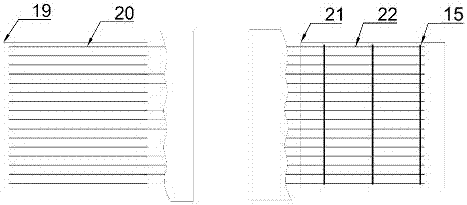

Chip apparent defect detection method

The invention discloses a chip apparent defect detection method. The method comprises: an SOP chip image is shot by using a color CCD camera; extracting the circular mark of the chip and the contour and the centroid of the pin through a series of pretreatment; calculating improved environment feature vectors of the circular mark and each centroid of the pin; matching and positioning with a template image are carried out; calculating an affine transformation matrix; carrying out affine transformation on the image to obtain a template image coordinate system; and finally, judging whether the pins are lacked or not according to the improved environment vector of the circular mark. printing pixels are extracted from the printing area, the edge of the printing area is used for judging whether printing information is defective or not, a minimum circumscribed rectangle is calculated for the outline of each pin to judge whether the pins are warped upwards, warped downwards and skewed or not, and oxidation and desoldering pixels are extracted from the pin area to judge whether the pins are oxidized or desoldered or not. The method can automatically, quickly, conveniently and accurately judge the problems of lack, upwarp, downwarp, skew, desoldering and oxidation of the SOP chip pins, can also judge whether a printing information area is clear and complete or not, can effectively detectthe appearance of an SOP chip product, and reduces the labor intensity of workers.

Owner:HUNAN UNIV

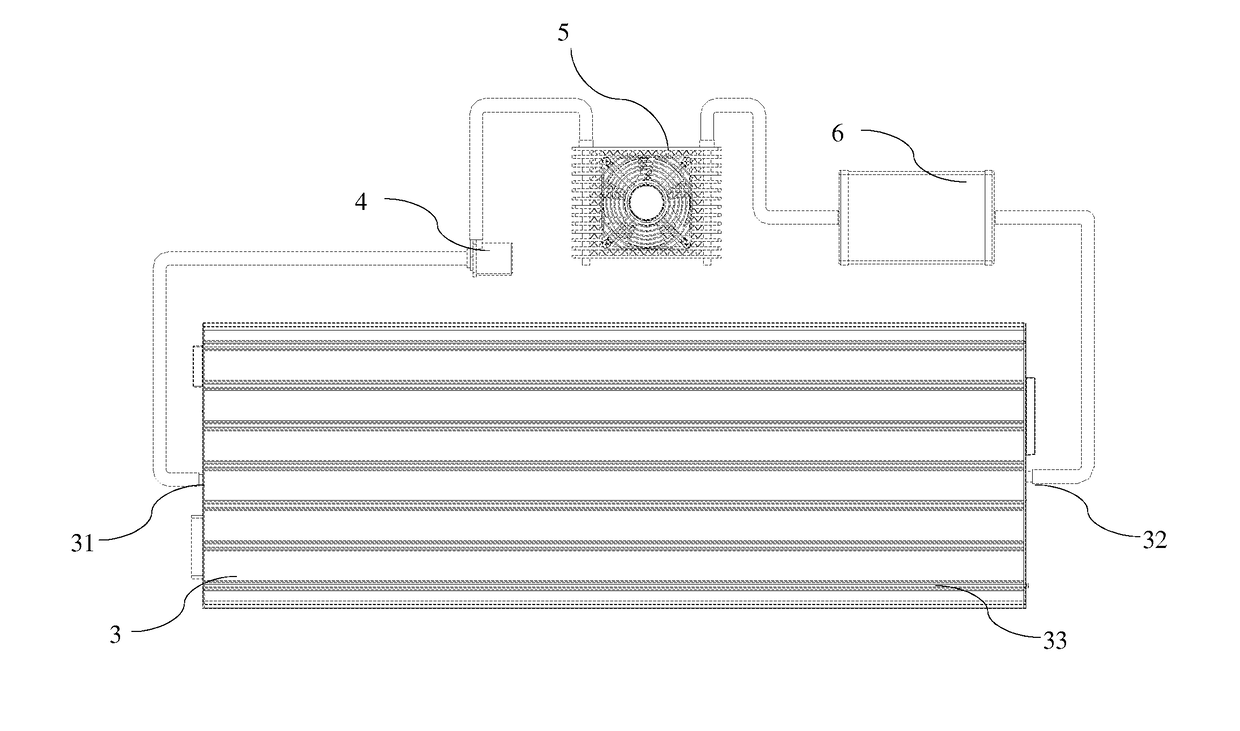

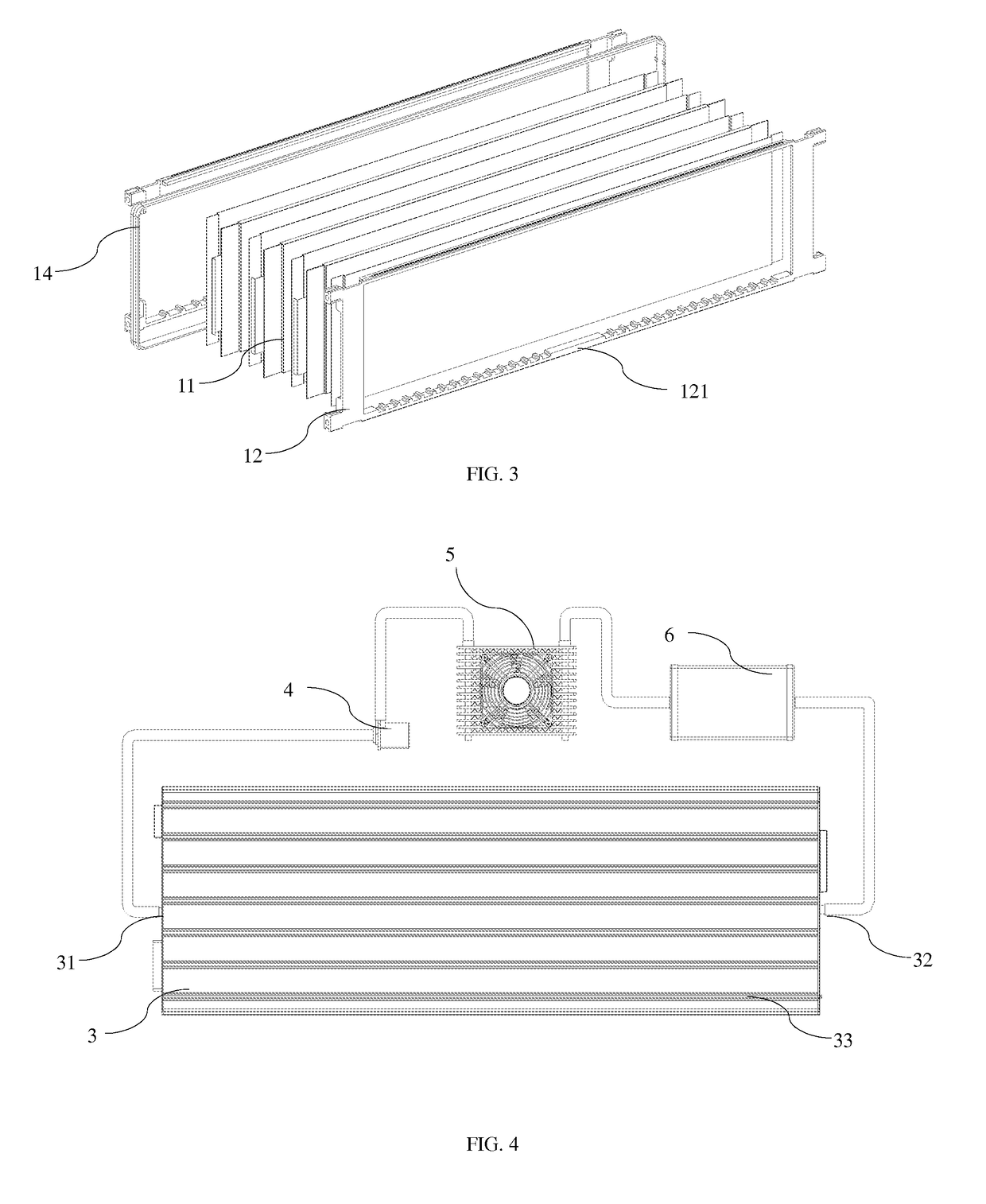

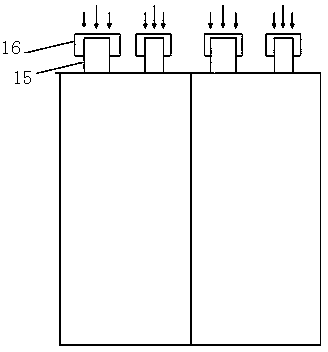

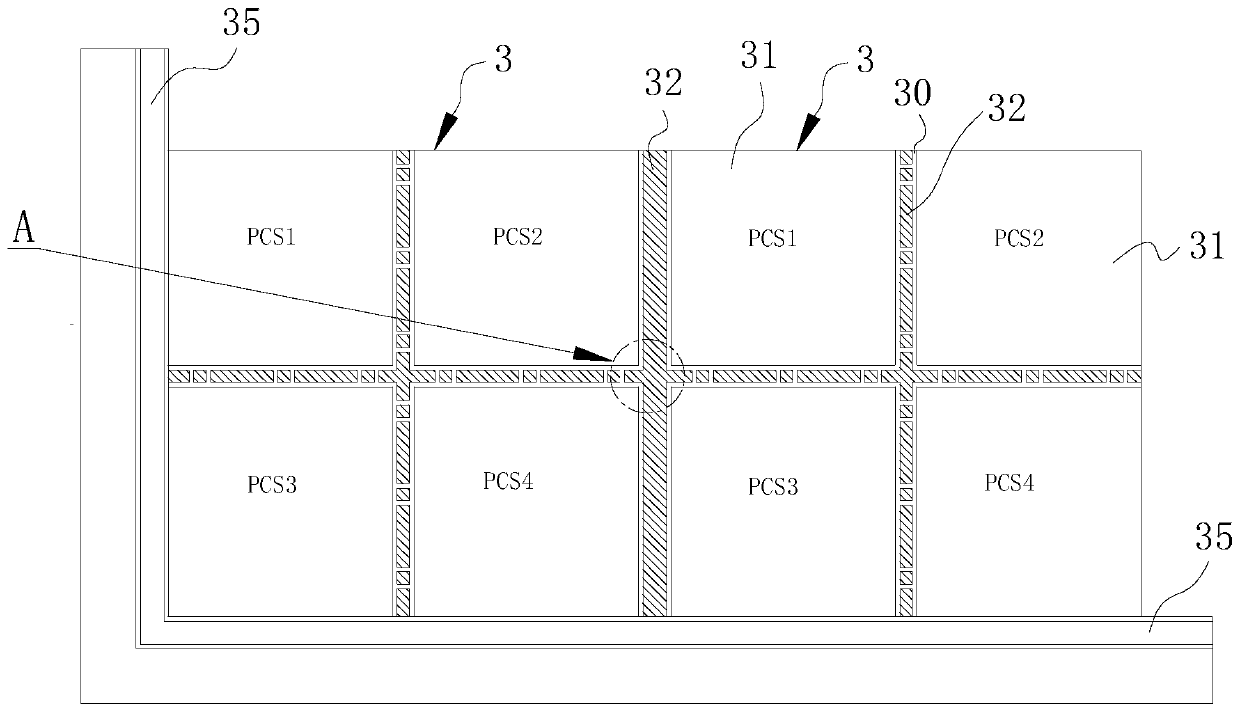

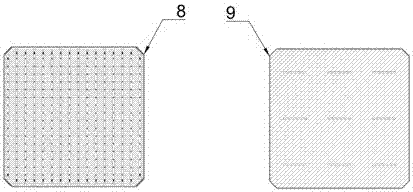

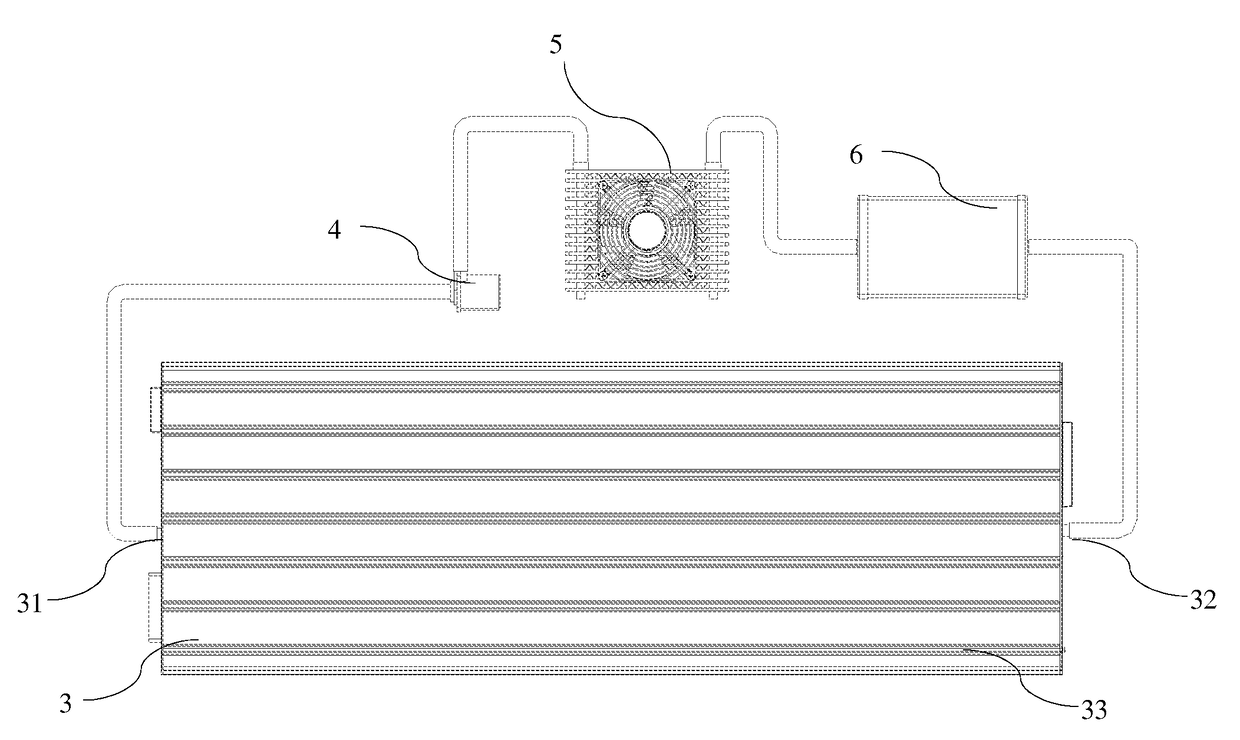

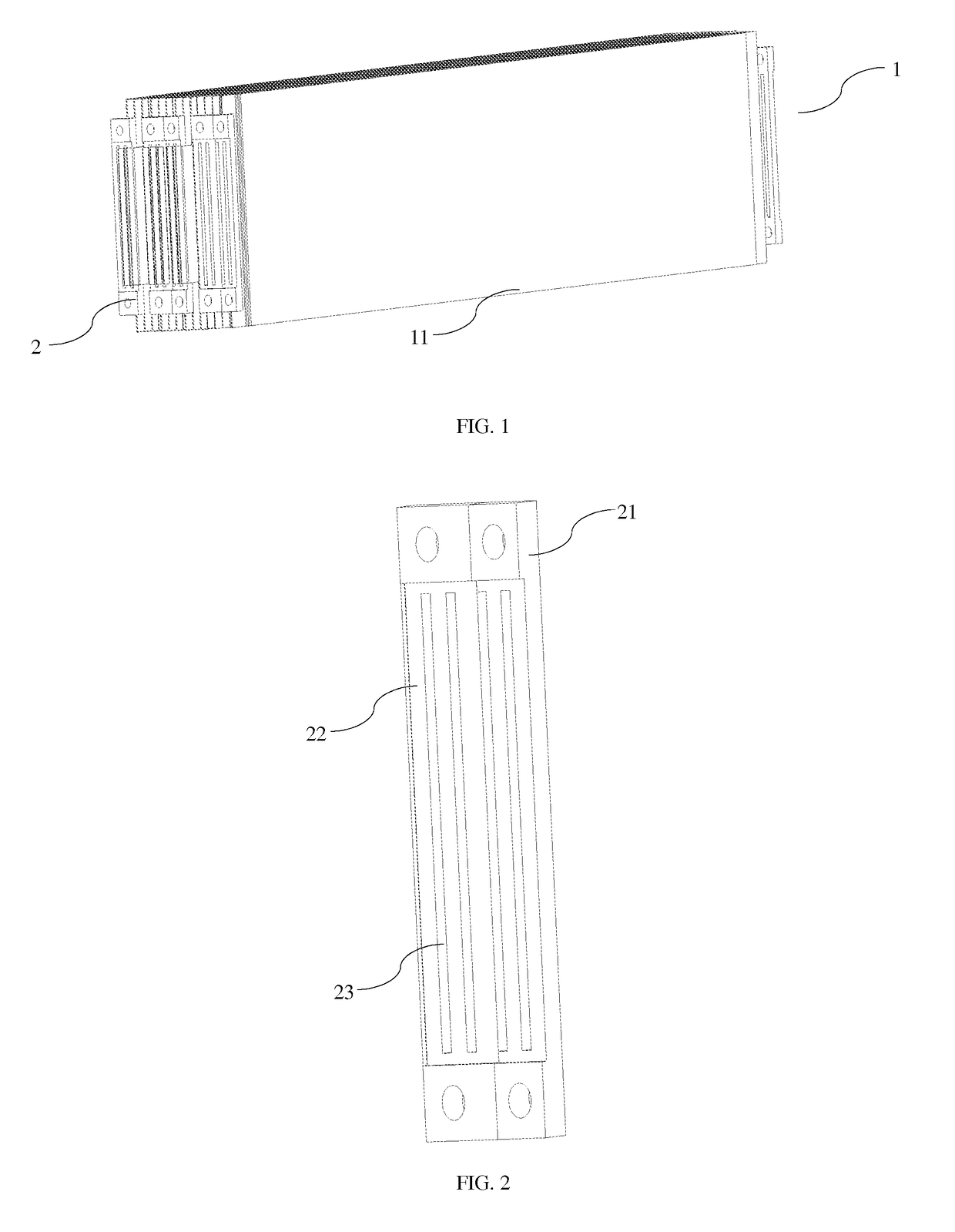

Liquid-cooled battery pack system

ActiveUS20170162923A1Improve securityIncrease energy densitySecondary cellsCell component detailsEngineeringDesoldering

The present invention provides a battery module and a liquid-cooled battery system that uses it, a battery cell and a current collector sheet, on the premise that the materials like the electrode and separator and so on are completely the same, energy density of the battery pack is greatly increased; the cell and the current collector sheet are fully welded connections, the joints are fewer and it is not prone to produce desoldering, also ensuring the stability of the of the cell tab and high current carrying capacity, and when putting the parallel battery module in series, the use of wires are avoided, thus reduces the volume of the battery pack; the innovative design for the liquid-cooled battery pack system, improves the thermal balance between the cells, and the heat-dissipation in battery pack distributes more evenly, the insulation property of the battery package is highly improved, controlling the heat-dissipation capacity of the system by adjusting the flow rate of the circulating pump, not only the unnecessary energy consumption can be avoided, but also have a better impact resistance.

Owner:MICROVAST

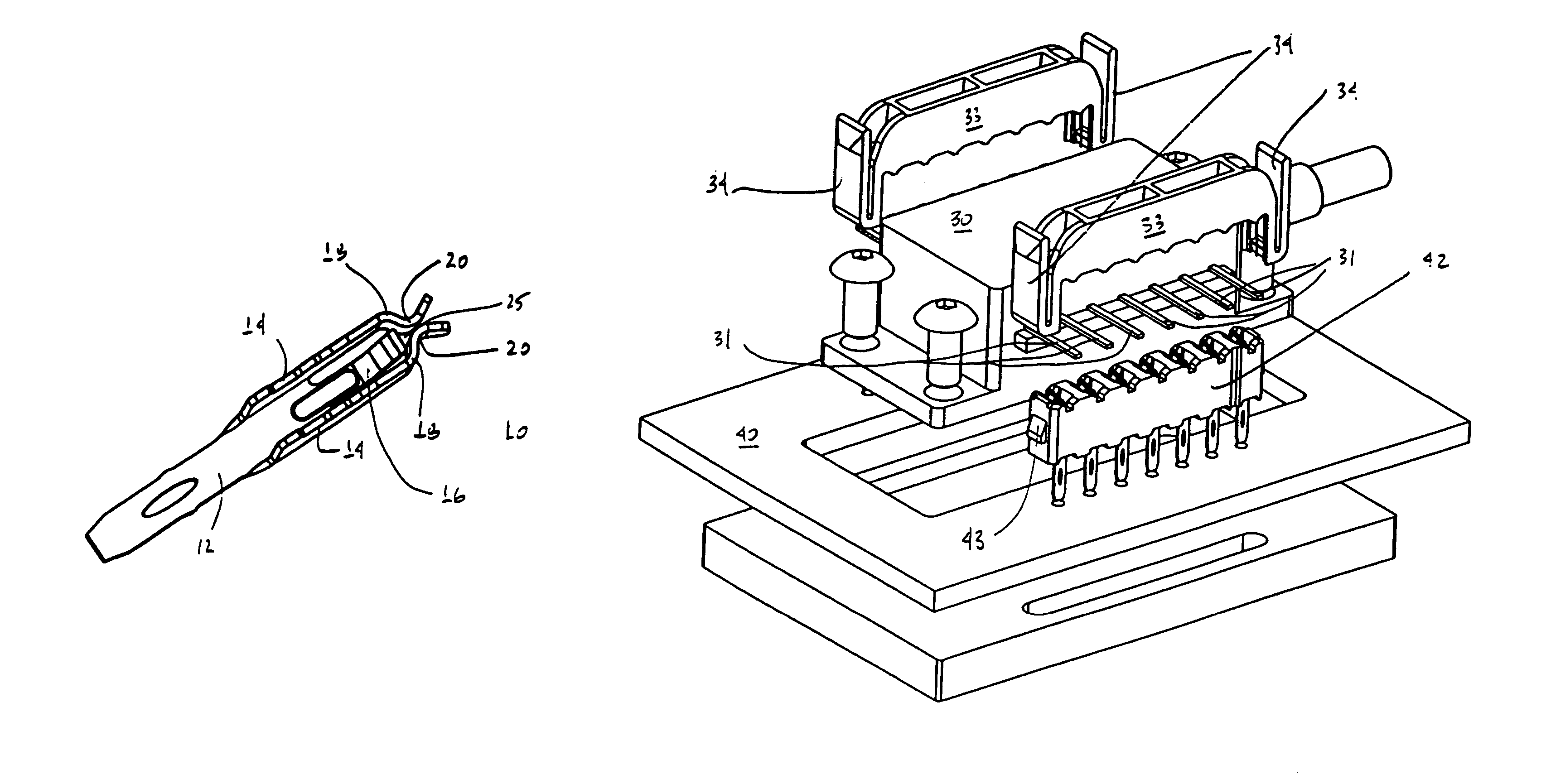

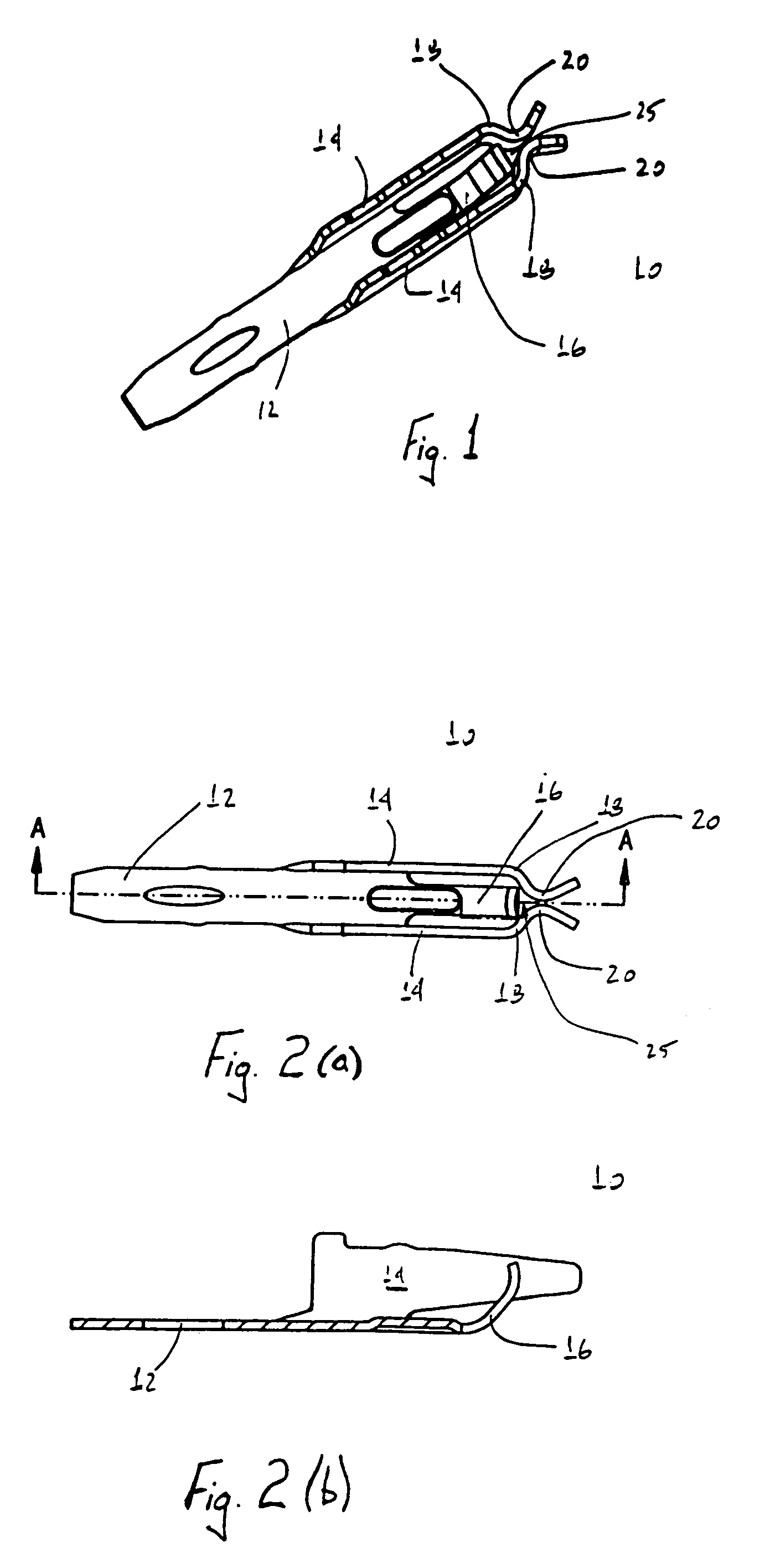

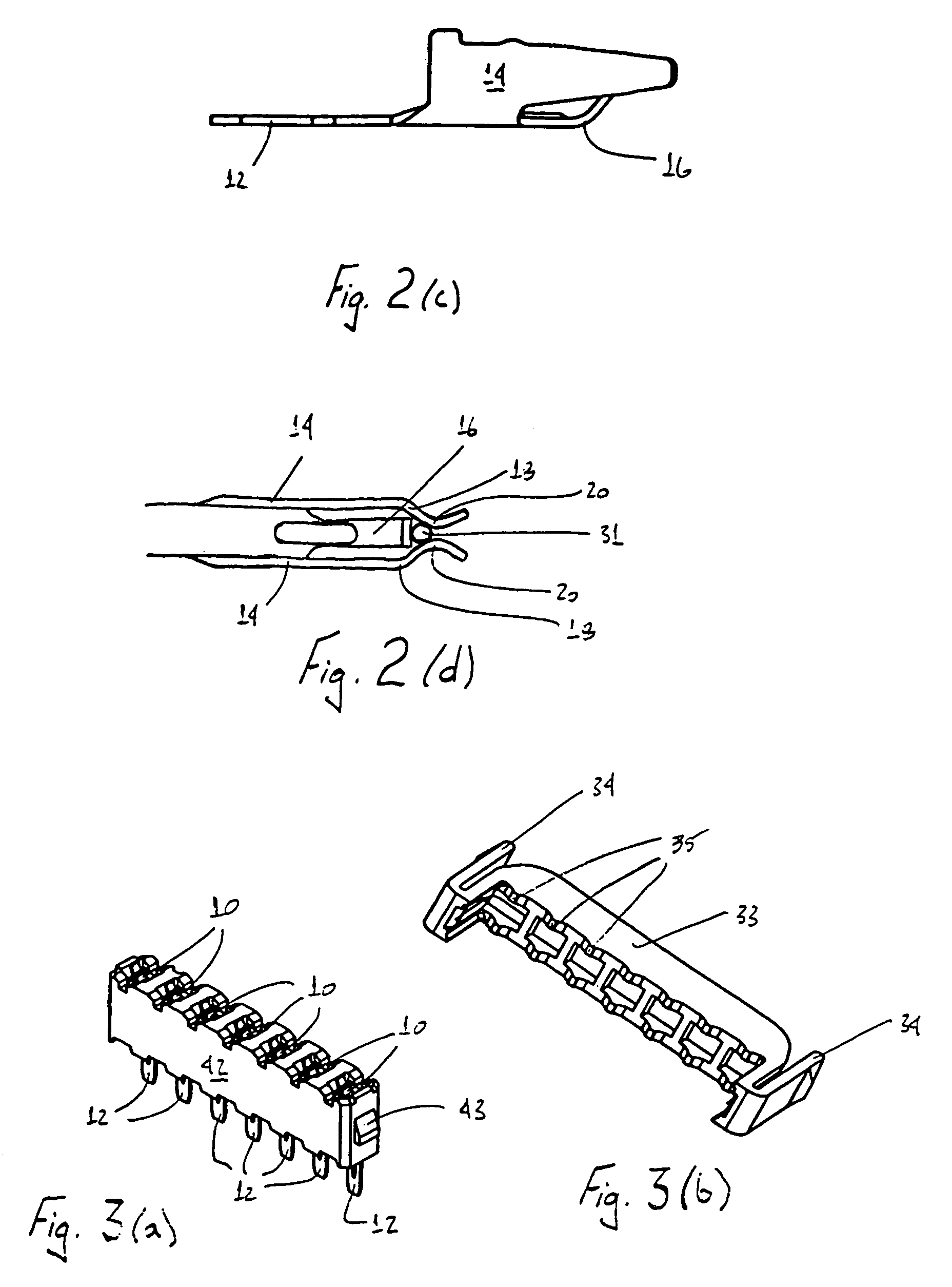

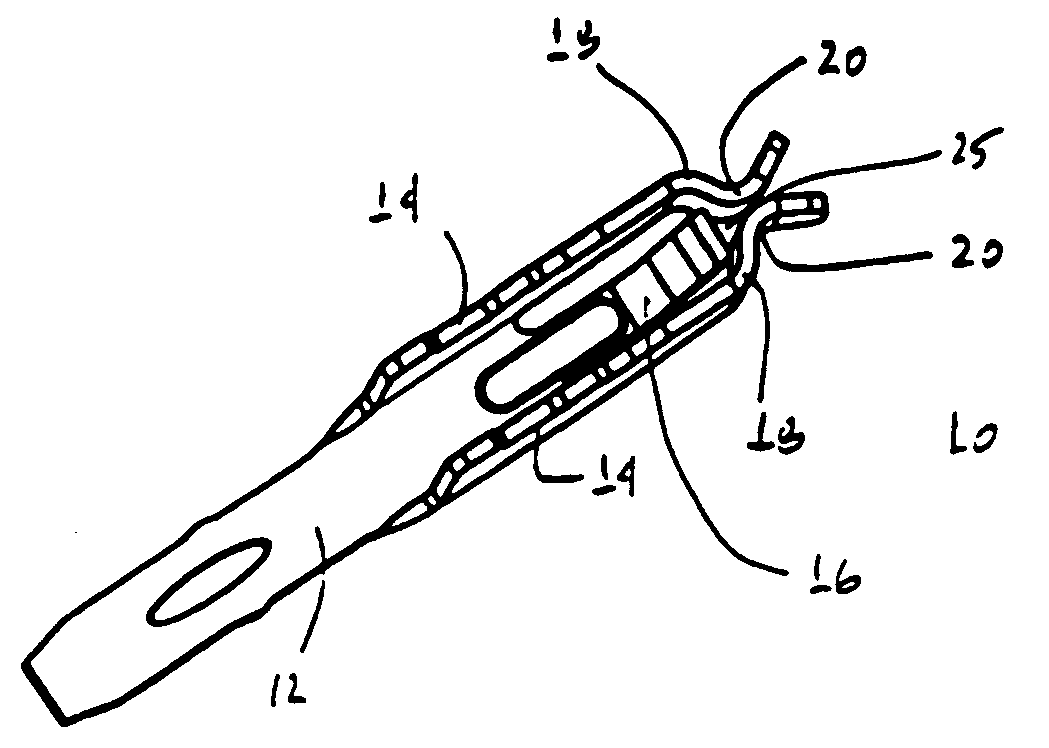

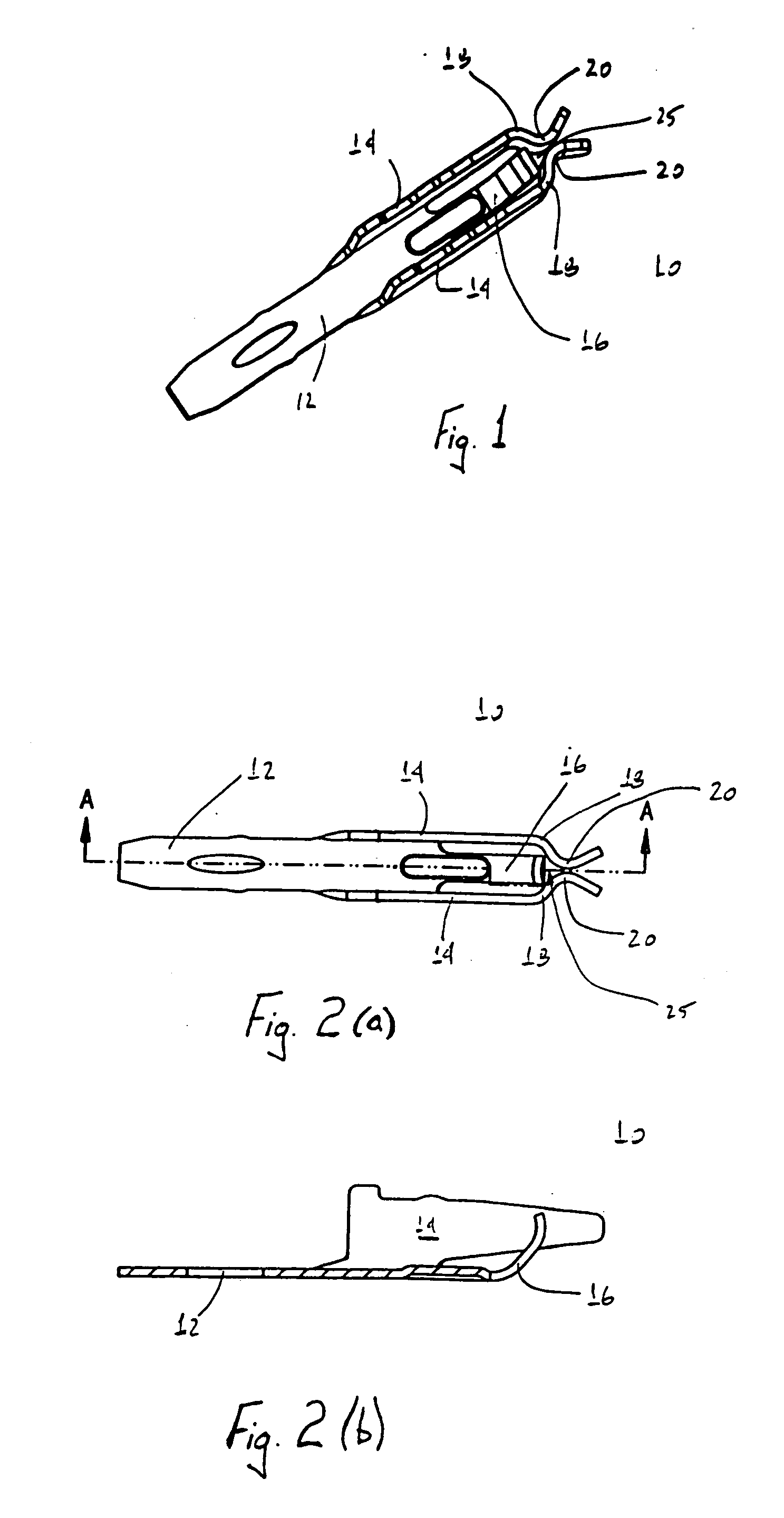

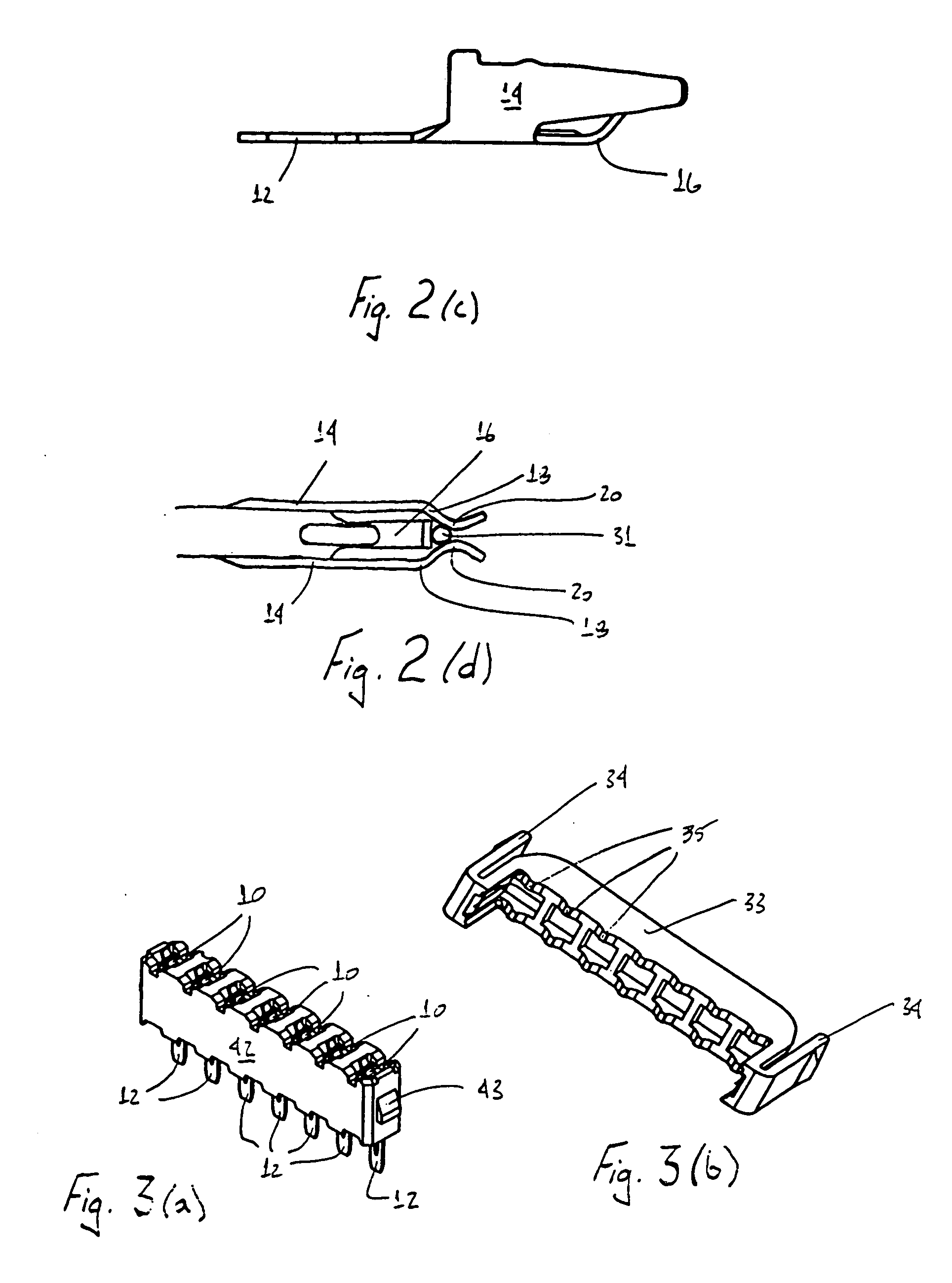

Spring contact for connectors

InactiveUS6991498B2Quick installationEasy to removeCoupling contact membersElectric connection basesElectrical connectionEngineering

A spring contact design used to connect varied electrical components to circuit boards such that the components may be installed onto the board and thereafter removed without soldering and desoldering of the component leads is disclosed. The inventive contacts use integral flexible elements and appropriate contact element shaping to ensure solid multiple electrical connection points between the contact and the electrical component lead. With the use of the inventive spring contacts, components may be easily installed onto a circuit board and tested to ensure functional performance and, if necessary, may be removed or replaced without the need for time consuming soldering and desoldering of the component leads to the board contacts. The inventive contacts are designed to ensure sound electrical connection with component leads of different cross sections, shapes and sizes. Use of the inventive contacts in housings sized and shaped for different electrical components are also disclosed.

Owner:TE CONNECTIVITY CORP

Intelligent automatic resistance spot-welding device

ActiveCN103737167AAvoid scrappingAvoid wastingMetal working apparatusResistance welding apparatusAutomatic controlBiochemical engineering

The invention discloses an intelligent automatic resistance spot-welding device which comprises a rack. A cell clamp is arranged on the rack, a shifting mechanism is arranged at the lower end of the cell clamp, a switch is arranged on the rack, a fixing support is arranged on the rack, a servo motor is arranged at one end of the fixing support and fixed on a horizontally-arranged guide rail, a fixing plate is further arranged on the guide rail, one side of the fixing plate is connected with the guide rail, an air cylinder is arranged on the other side of the fixing plate, a resistance welding machine is arranged on the other side of the air cylinder, a supporting support is arranged on the rack, and a camera for photographing a cell is fixedly arranged on the supporting support. According to the intelligent automatic resistance spot-welding device, according to the cell actual condition, namely relative position parameters of a tab and a bonding pad, the best welding point position can be judged, and desoldering can be avoided; if the positions of the tab and the bonding pad do not meet the welding condition, badness can be prompted, a cell can be retreated automatically, cell scrapping and resource waste caused by welding position errors are avoided, the economic cost is saved, intelligent automatic control is achieved, and the working efficiency is improved.

Owner:HUIZHOU DESAY BATTERY

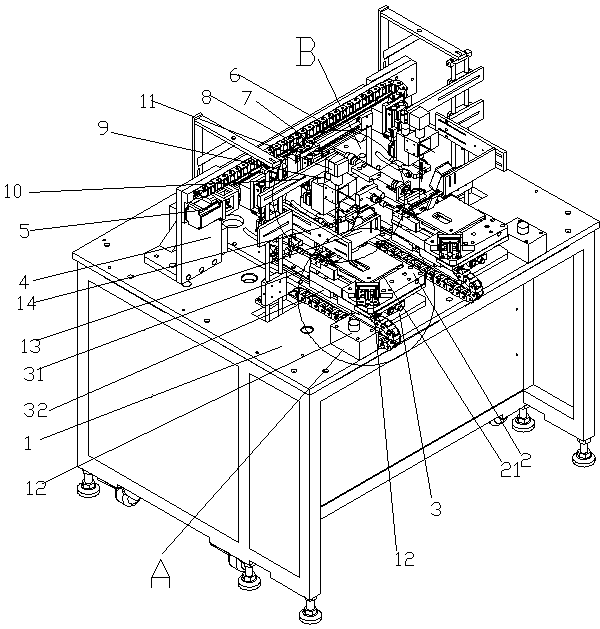

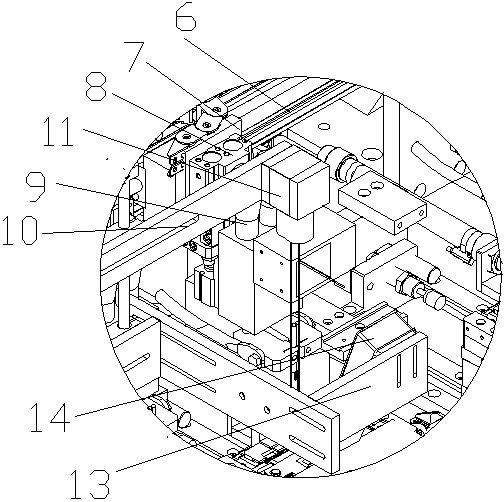

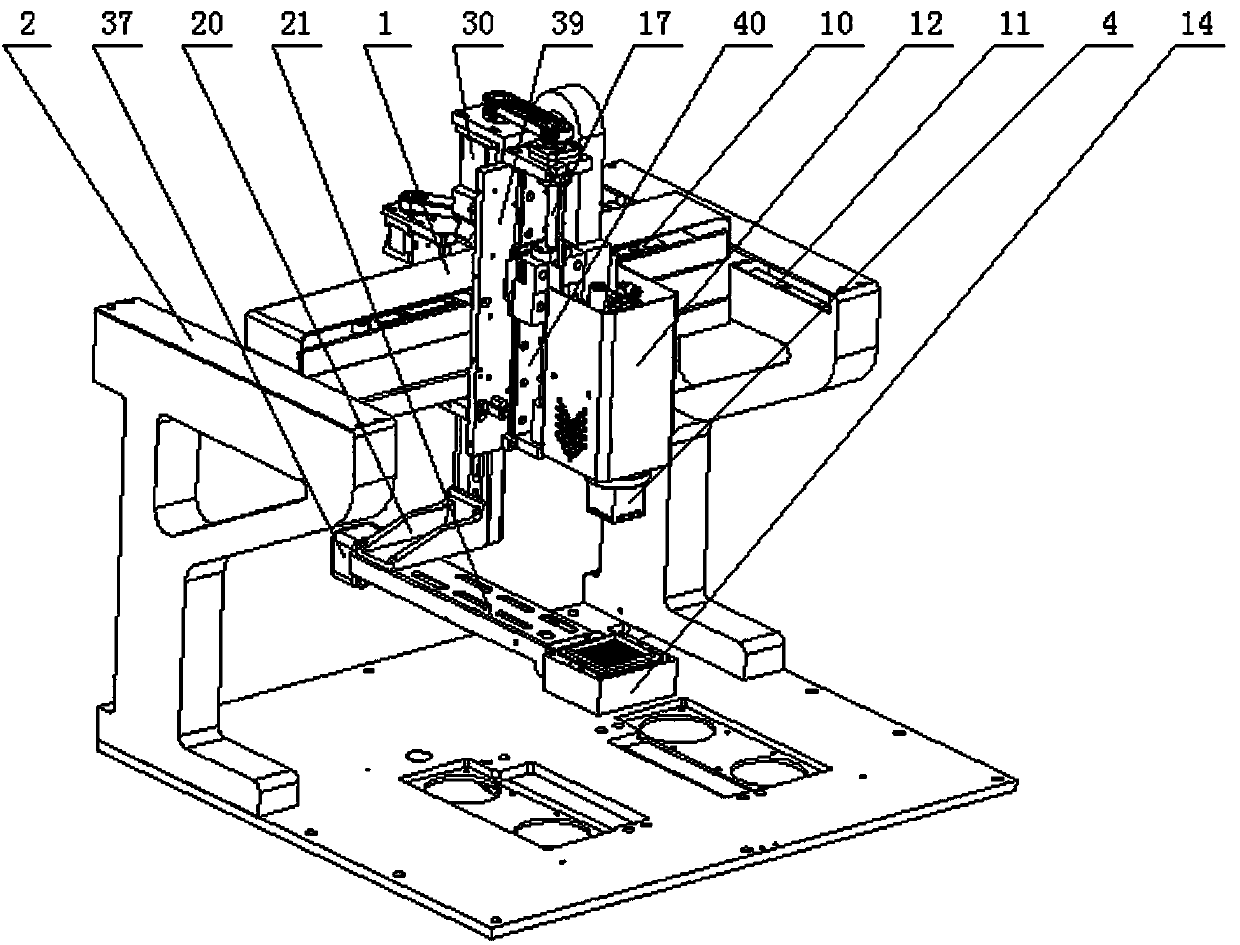

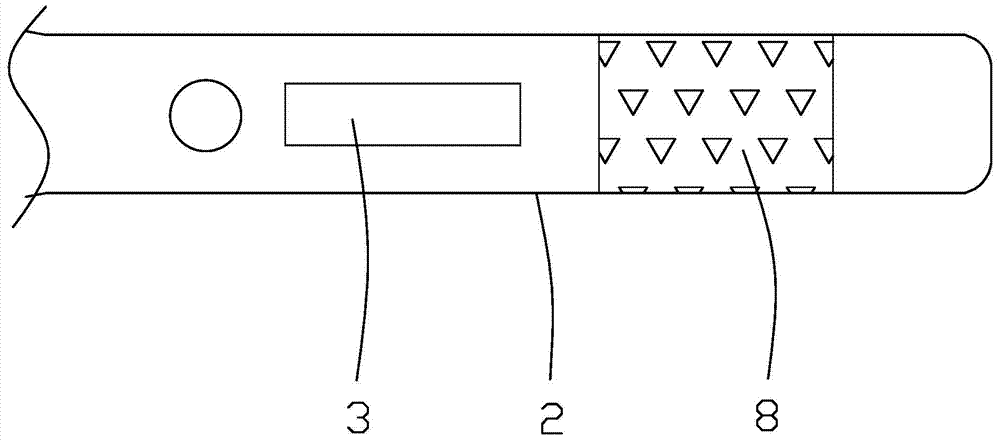

Automatic desoldering and detinning equipment

PendingCN106695045ASo as not to damageReduce damage rateSoldering apparatusMetal working apparatusEngineeringTemperature difference

The invention relates to automatic desoldering and detinning equipment. The automatic desoldering and detinning equipment comprises a main frame; the main frame is provided with a horizontal workbench; a workpiece fixing jig and a workpiece preheating table are installed on the horizontal workbench; a portal frame is further erected on the horizontal workbench and provided with an x-direction sliding seat and a z-direction sliding seat; a desoldering assembly and a detinning assembly are installed on the two side edges of the surface of the z-direction sliding seat correspondingly; and a connection plate is further arranged on the outer side of a third servo motor located on a first longitudinal installation plate, a CCD industrial camera is fixed to the upper portion of the connection plate, and the lower portion of the connection is located between the desoldering assembly and the detinning assembly and provided with an LED light source matched with the CCD industrial camera. According to the automatic desoldering and detinning equipment, before being subjected to desoldering and detinning processes, workpieces are all preheated through the workpiece preheating table under the workpieces, the situation that a circuit board is damaged due to the fact that the temperature difference between the upper portion and the lower portion is too large and dilatation coefficients are different can be avoided, the fault rate and scrape rate of the circuit board are substantially decreased, and environment protecting is facilitated.

Owner:东莞市崴泰电子有限公司

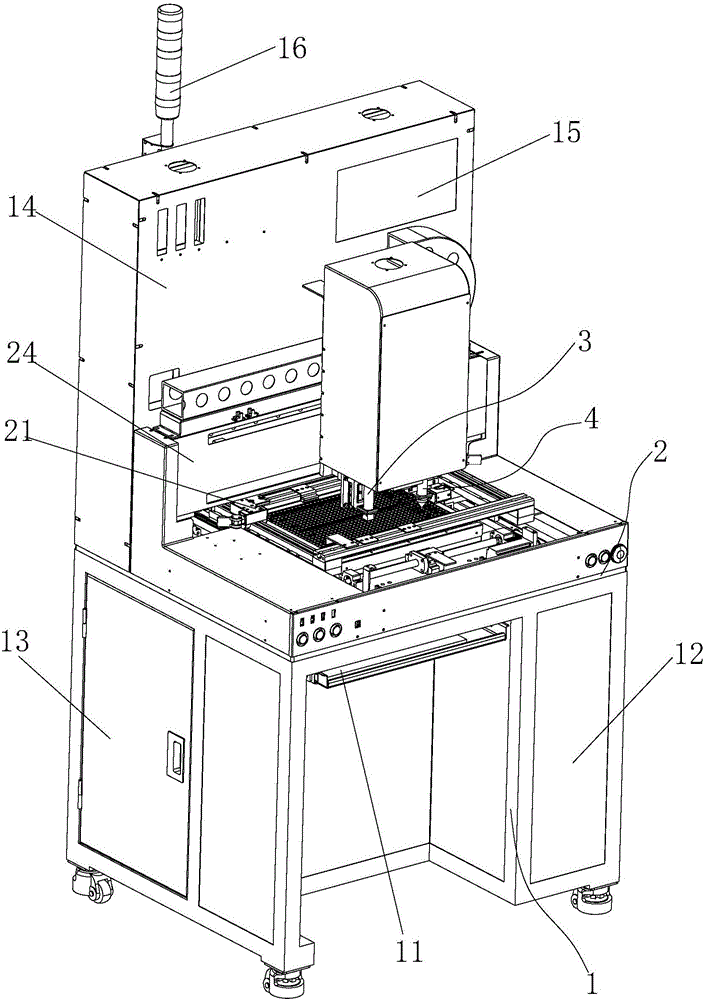

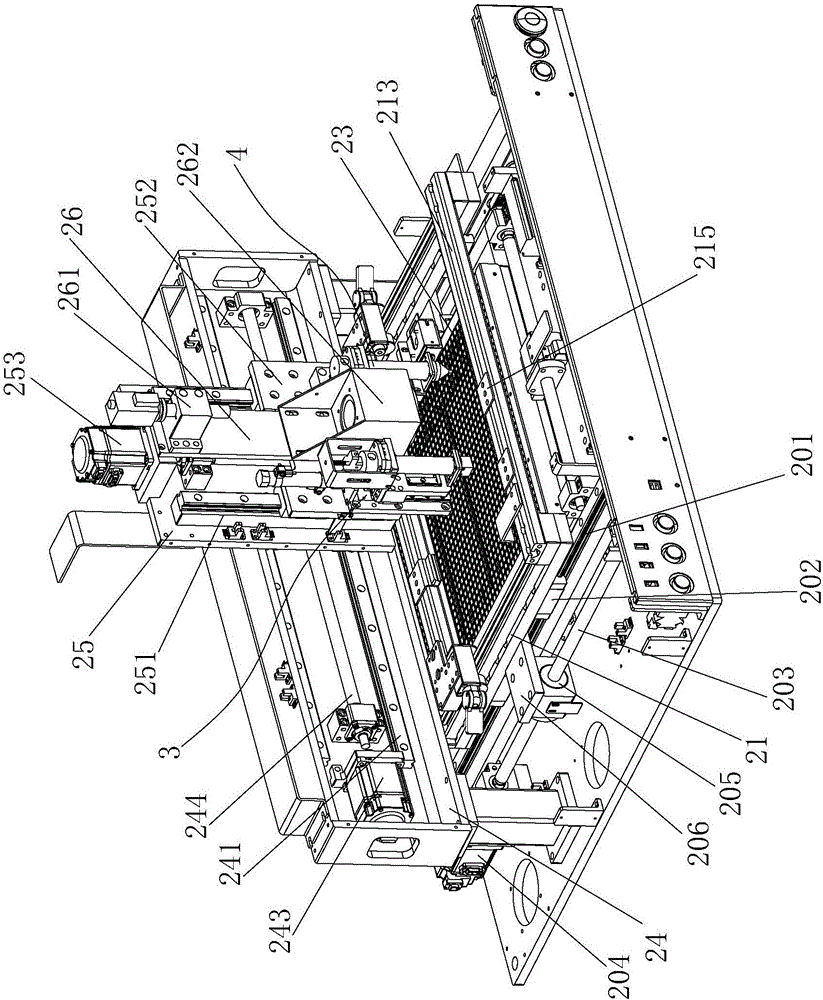

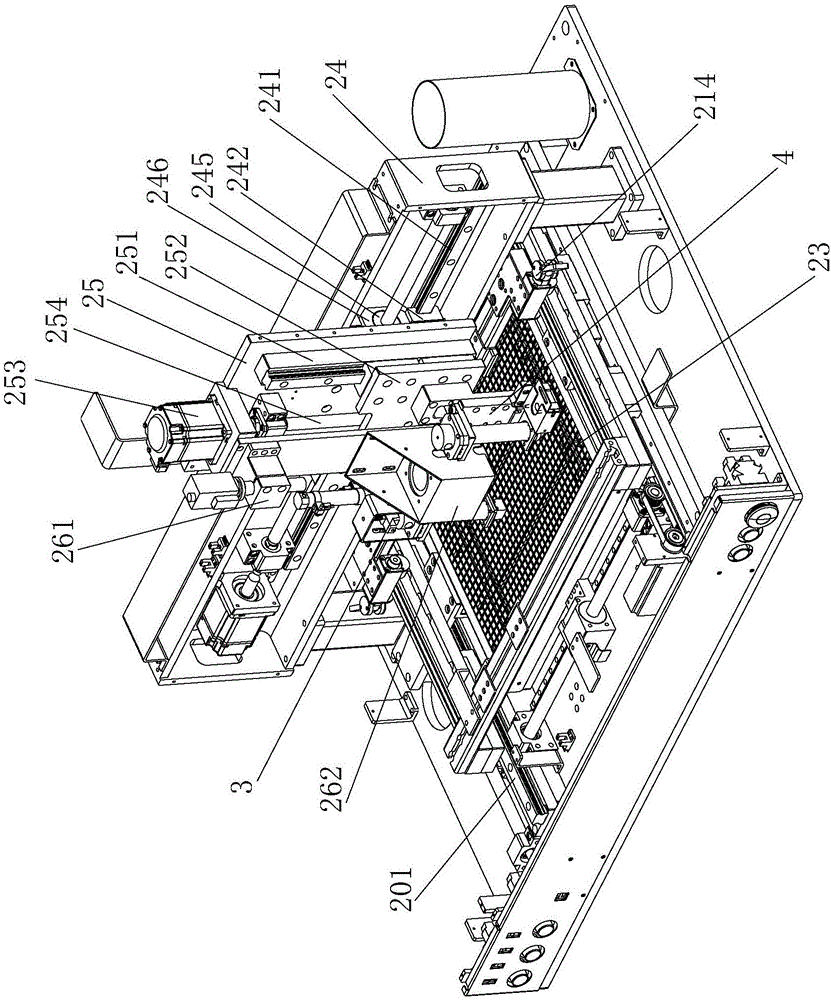

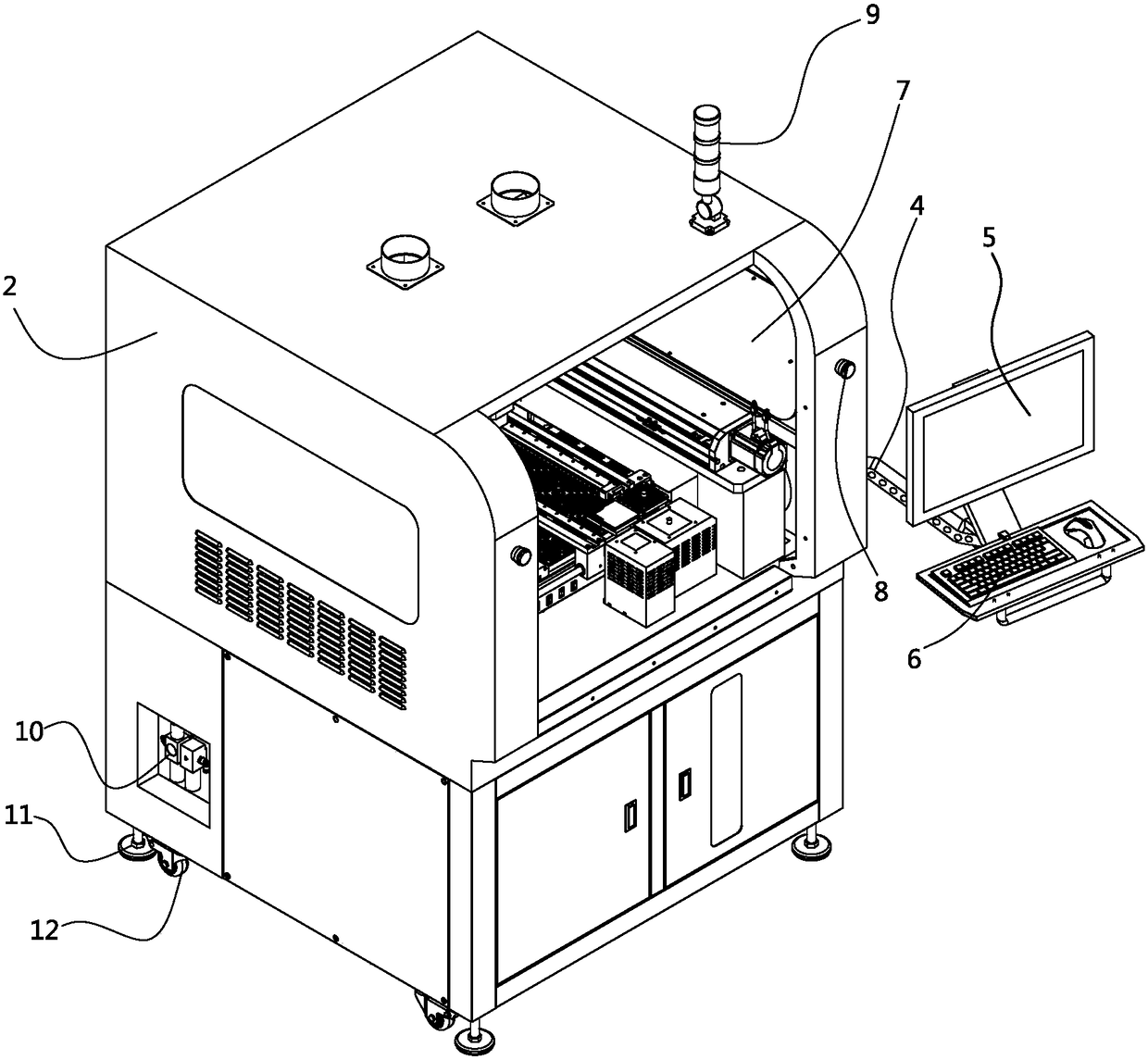

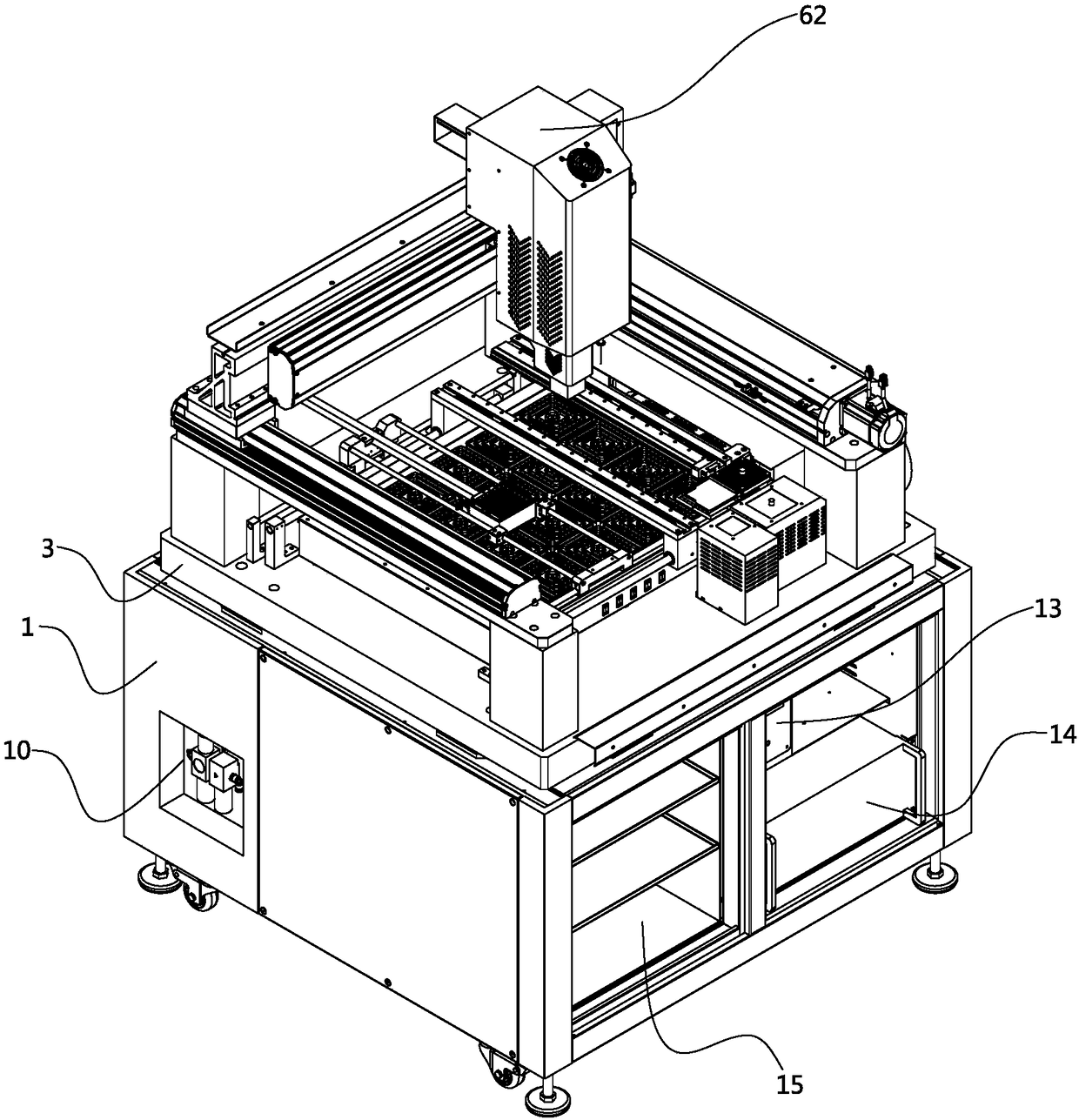

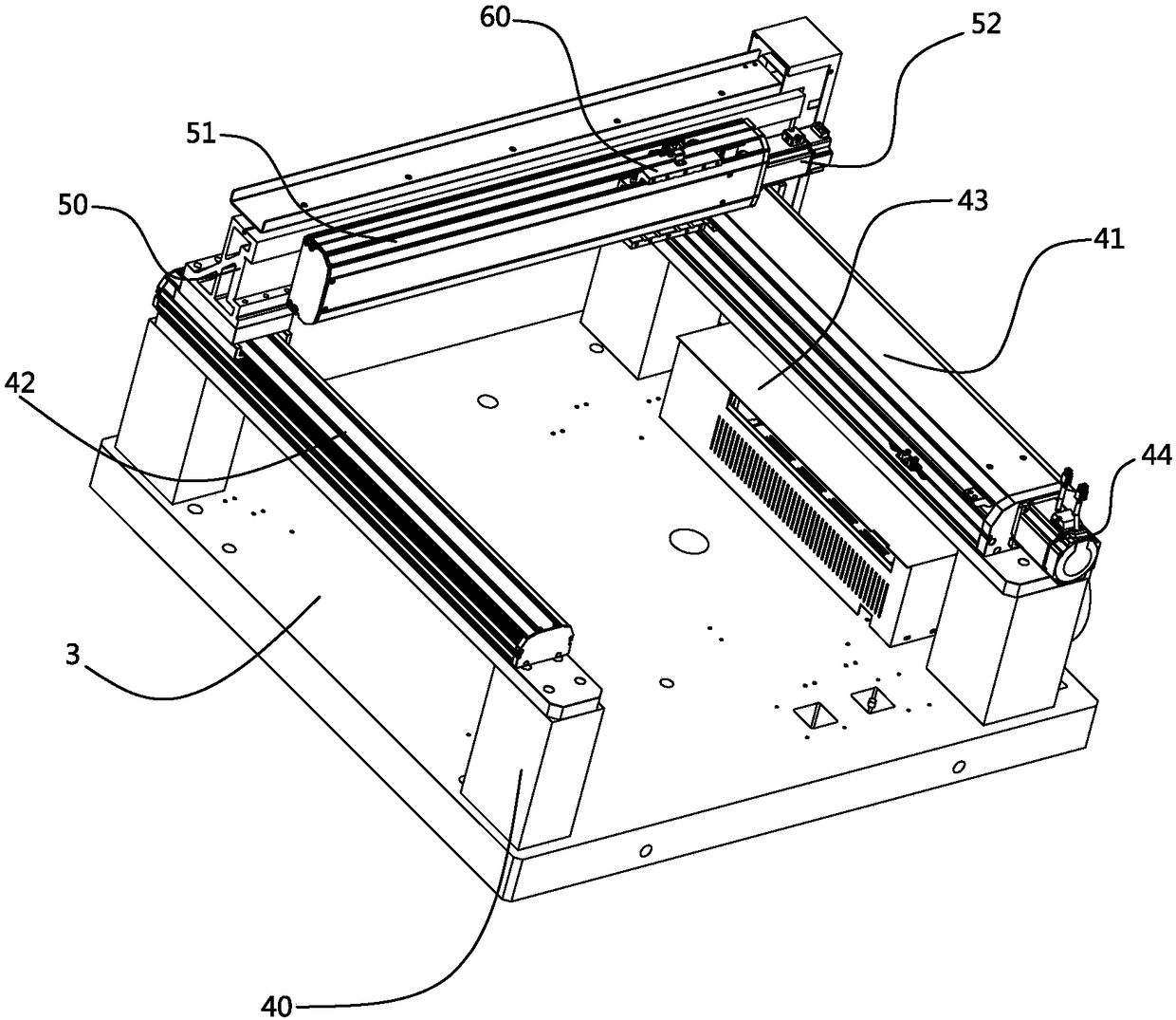

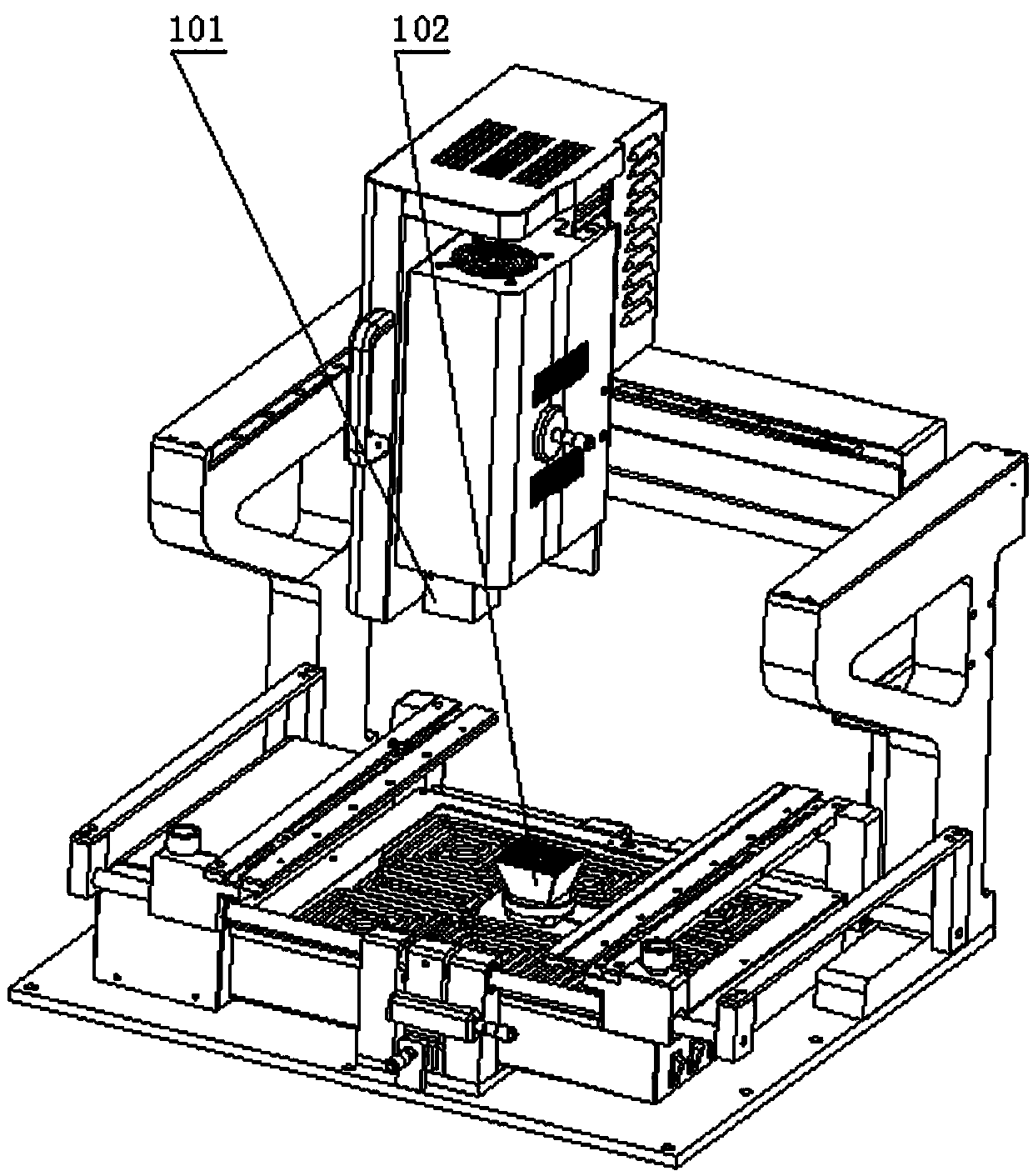

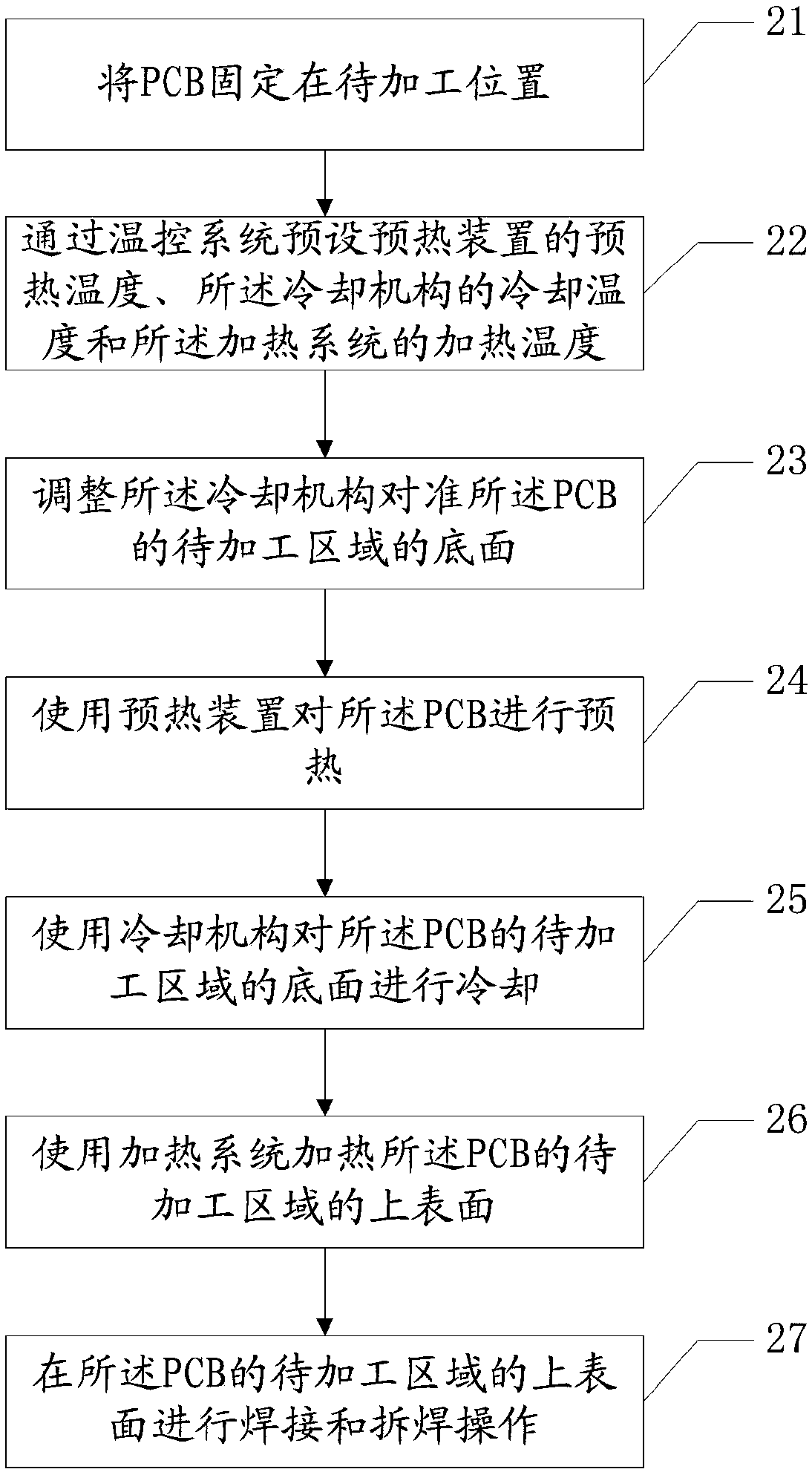

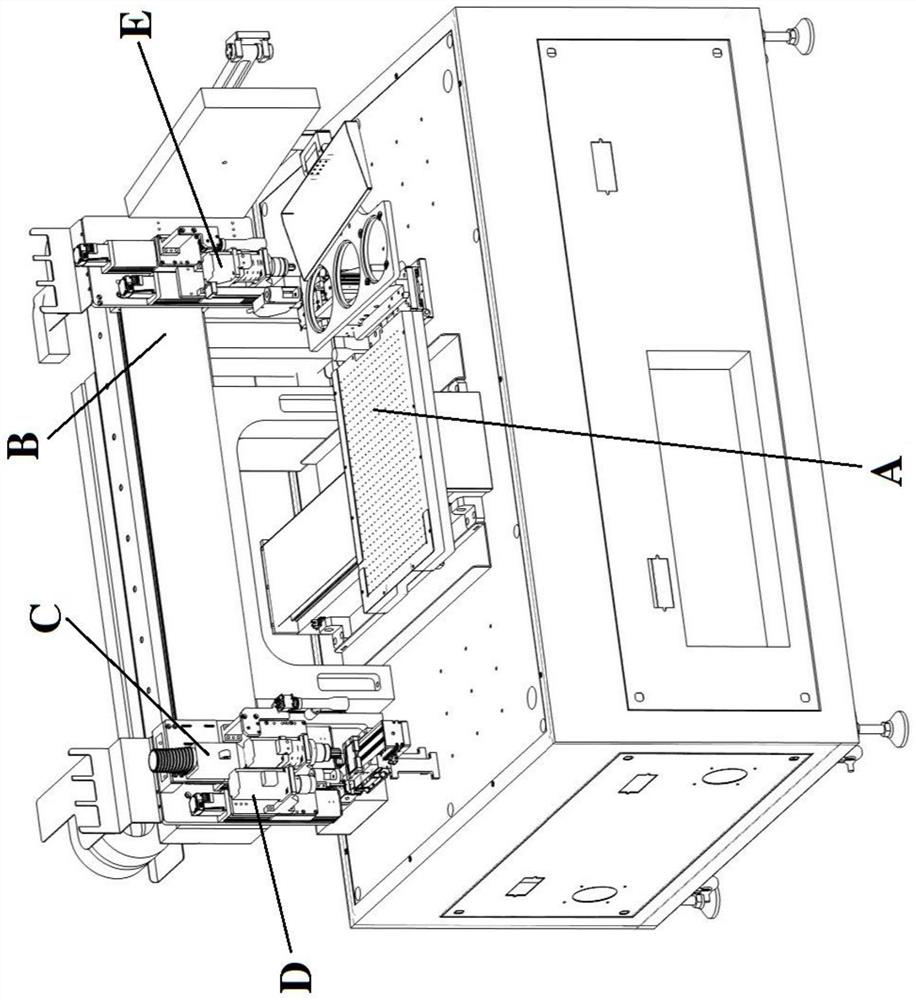

Fully-automatic vision BGA repairing work station

ActiveCN108419430AAccurate automatic identificationAvoid the phenomenon of quality qualityPrinted circuit assemblingElectrical componentsEngineeringWorkstation

The invention relates to a fully-automatic vision BGA repairing work station. The work station comprises a rack, a fuselage outer cover and a rack platform. The two sides of the rack platform are provided with Y-axis moving mechanisms, X-axis moving mechanisms are arranged on one end of each of the two-side Y-axis moving mechanisms, a Z-axis moving mechanism is arranged above the X-axis moving mechanisms, a lower-portion double-temperature area structure is arranged below the two-side Y-axis moving mechanisms, and the lower-portion double-temperature area structure is directly installed on therack platform so as to form the fully-automatic vision BGA repairing work station. A machine adopts a computer control mode to drive the X-axis moving mechanisms, the Y-axis moving mechanisms and theZ-axis moving mechanism to complete X-axis direction, Y-axis direction, the Z-axis direction and R axis (R angle) intelligent motion system operation. Accurate alignment is realized, an absorption material and a pasting and installation height are automatically identified, and automatic alignment, automatic pasting and installation, automatic welding and automatic desoldering operation are performed so that an effect of increasing the quality of an attached SMT patch component is achieved.

Owner:SHENZHEN ZHUO MAO TECH

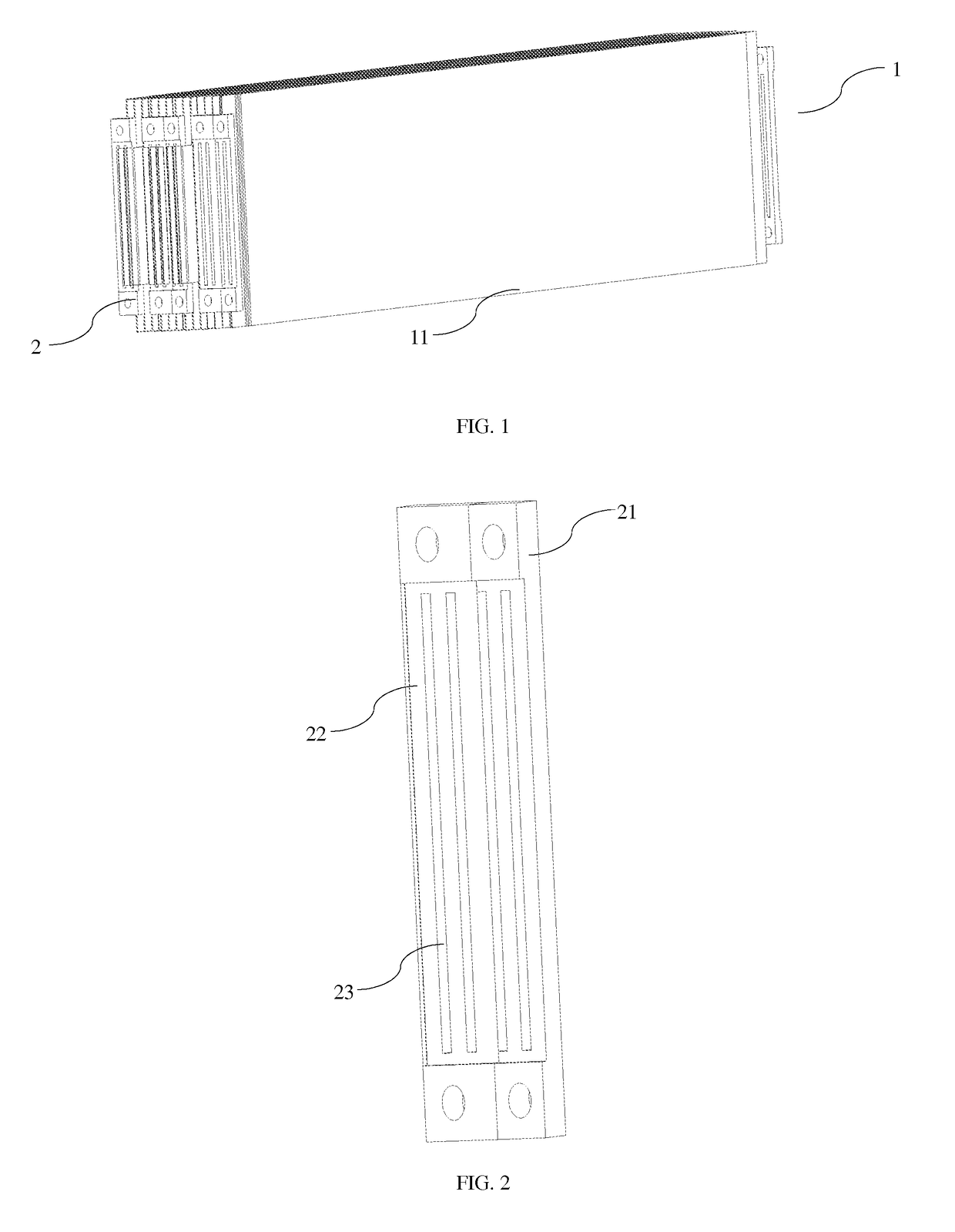

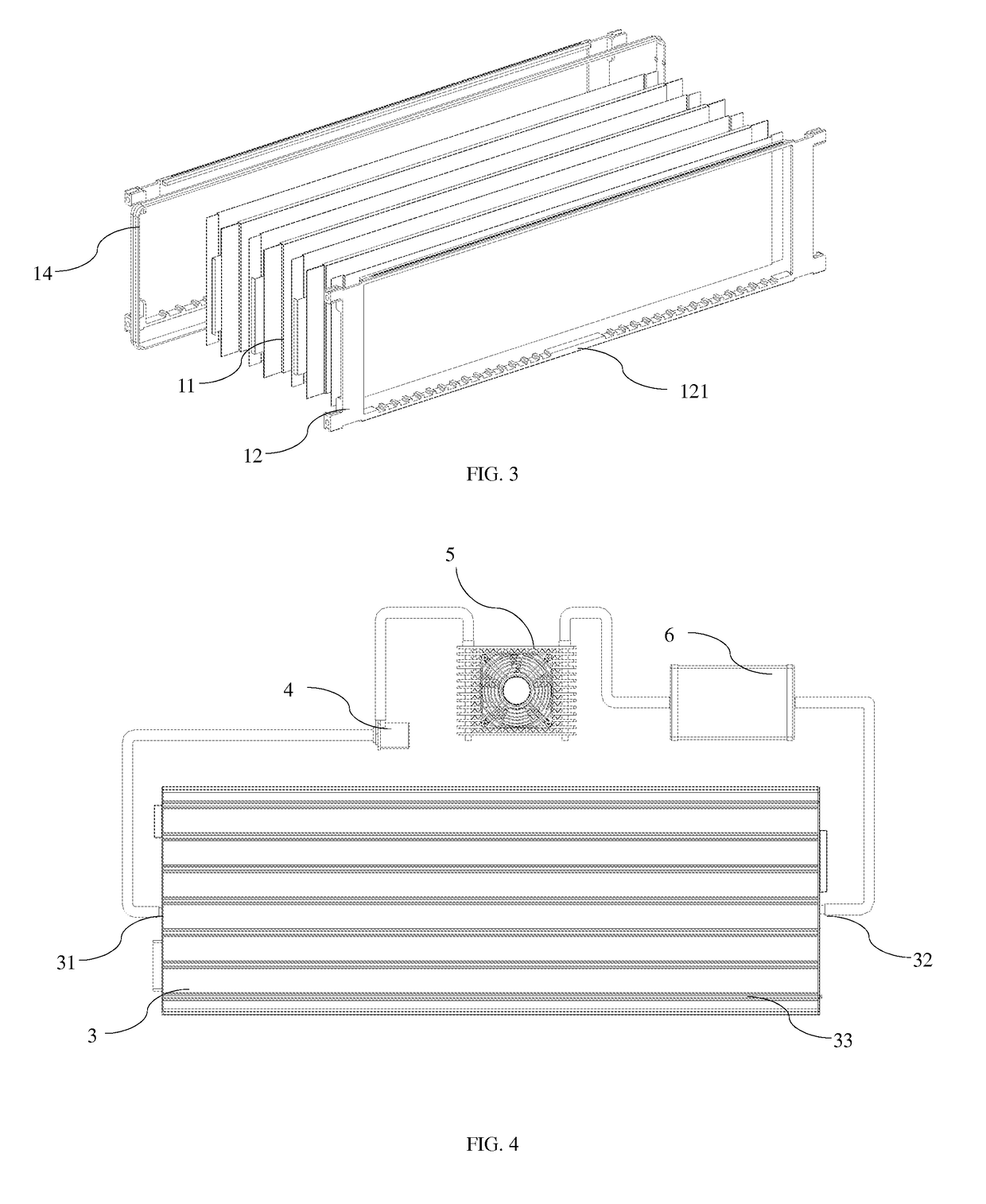

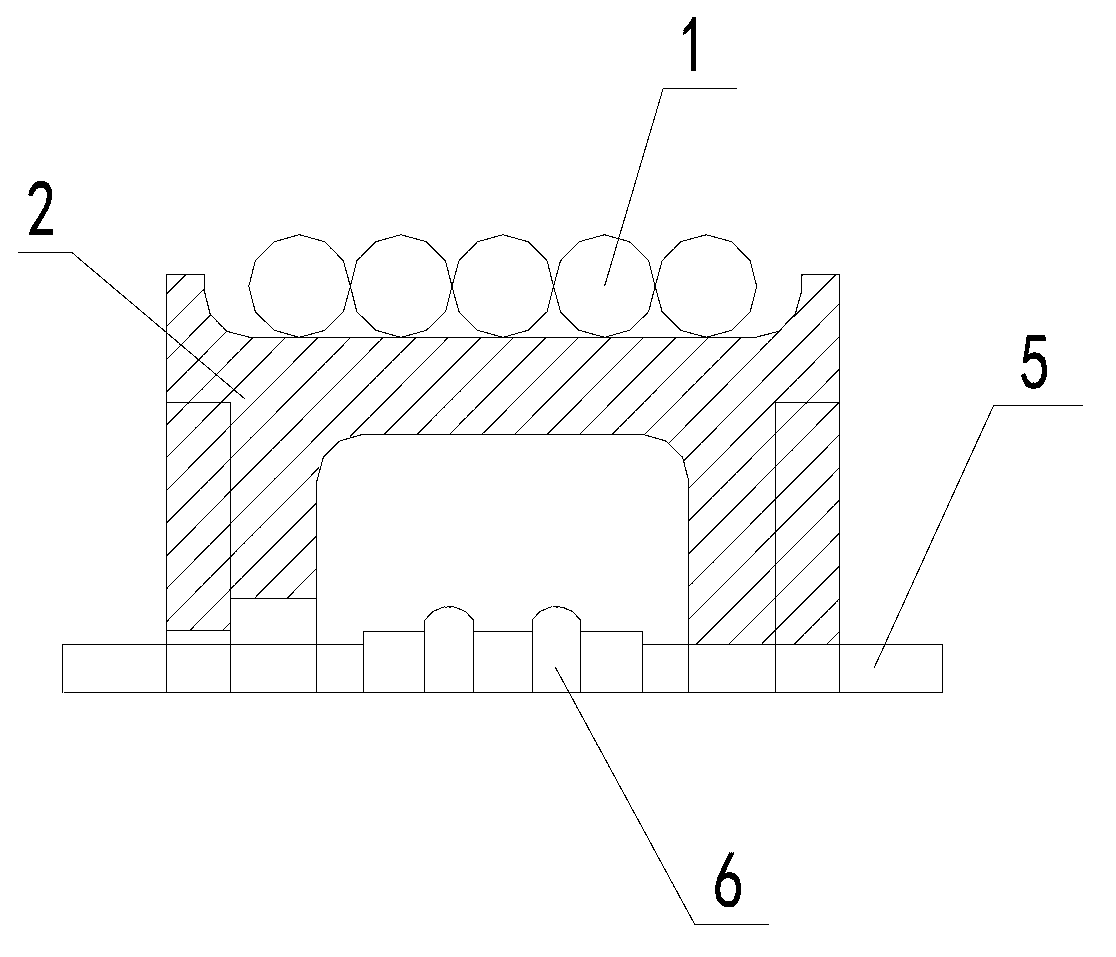

LED chip

The invention relates to an LED chip. The LED chip adopts the structure that an N-type electrode (22) adopts a staircase structure; the lower end of the N-type electrode (22) penetrates an insulating dielectric film (13) to be connected with an N-type layer (3); the middle part of the N-type electrode (22) is attached to the insulating dielectric film (13) at a vertical part; the upper end of the N-type electrode (22) is positioned above the insulating dielectric film (13) at the top, and extends towards the position of a P-type electrode (21); and the upper end of the N-type electrode (22) is connected with a second PCB board (23), and the N-type electrode (22) at the upper end and the P-type electrode (21) are provided with common soldering surfaces of which heights are equal or approximately equal. As the N-type electrode and the P-type electrode of the flip LED chip are provided with the common soldering surfaces of which heights are equal or approximately equal, the yield of packaging in the inverted-chip process of the LED chip is increased, and the phenomenon of inveracious soldering or desoldering of the electrode is avoided.

Owner:启东市天汾电动工具技术创新中心

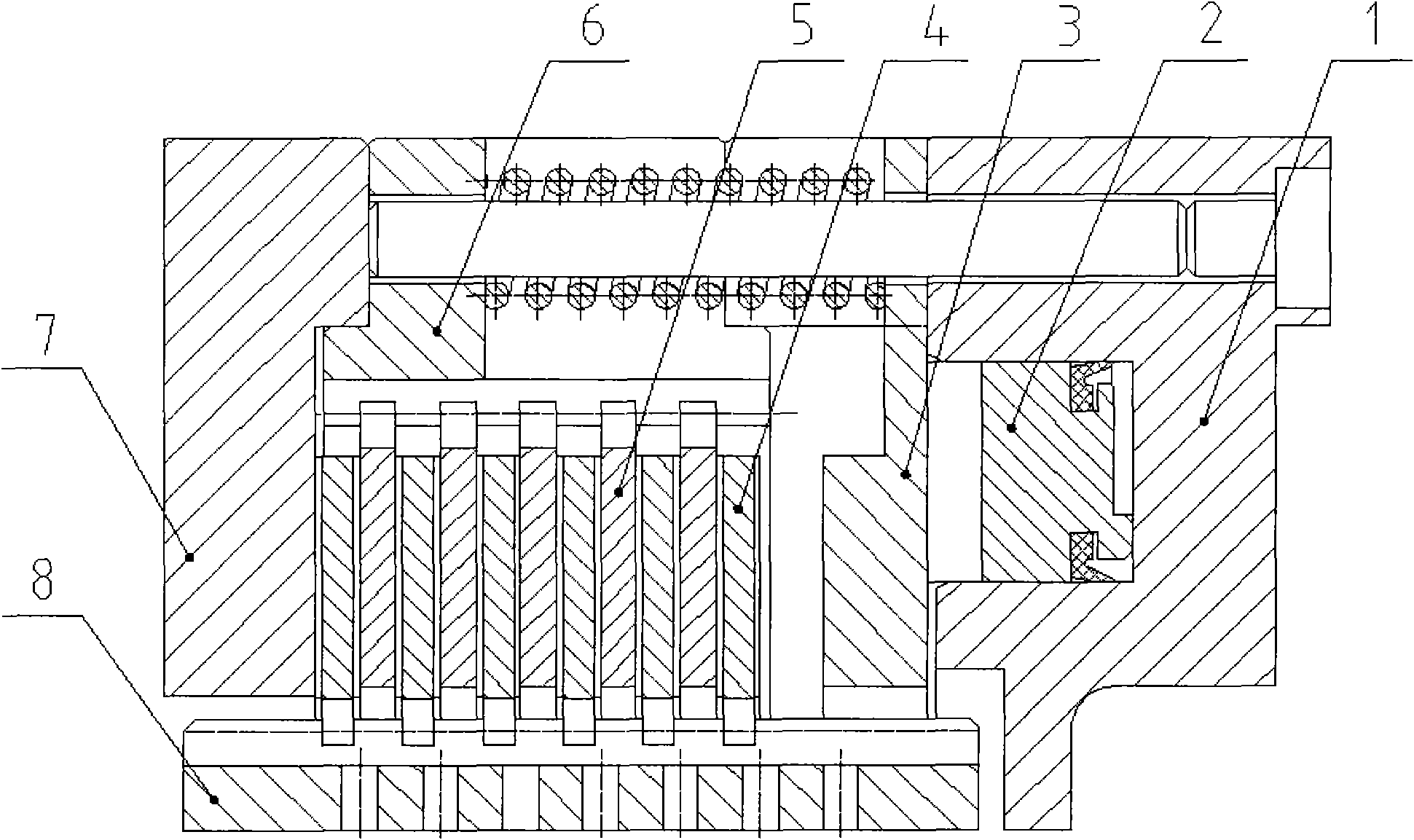

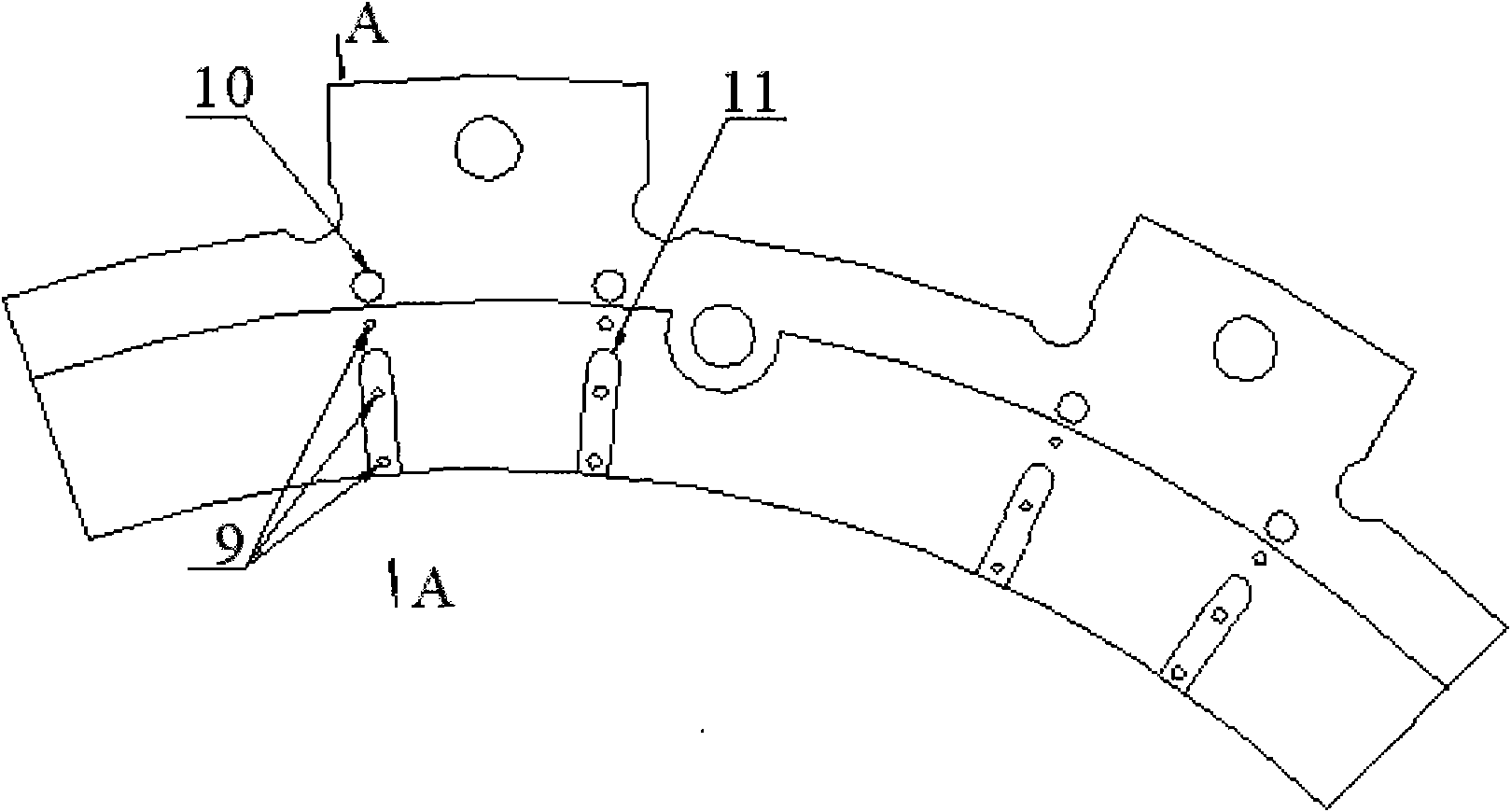

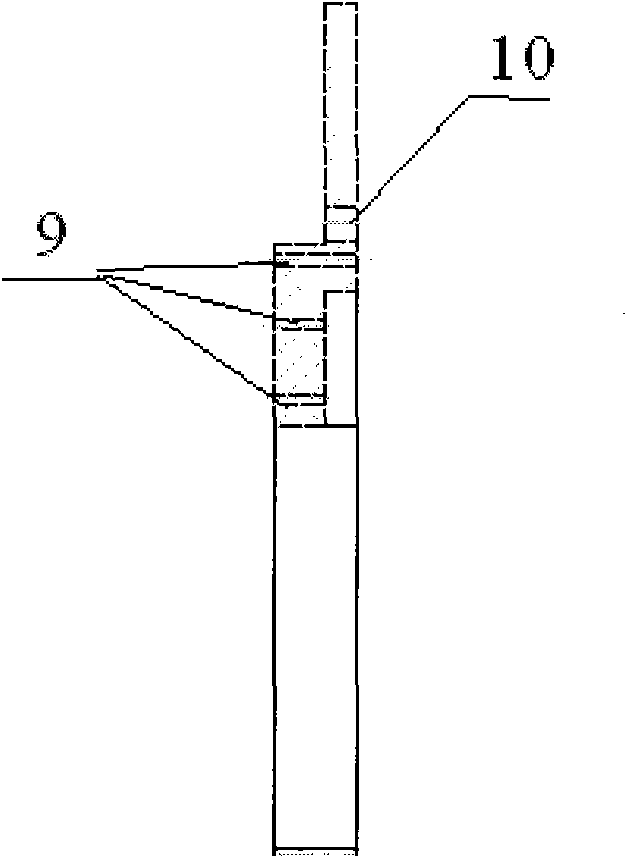

Friction pair dynamic temperature field test method for crawler gear shift mechanism and press plate thereof

InactiveCN101957242ASolve the installationSolve positioningThermometers using electric/magnetic elementsUsing electrical meansTemperature responseThermocouple Wire

The invention relates to the technical field of trail tests, in particular to a friction pair dynamic temperature field test method for a crawler gear shift mechanism. A press plate of a controller is provided with 1.2-1.7 mm through holes, three through holes of each group are uniformly distributed along the radius direction, a super-long thermocouple temperature sensor which is a thermocouple wire particularly, is adopted to be embedded into a guide slot, and high-temperature sealant is used for fixing the thermocouple. The invention firstly solves the problems of the installation, the positioning and the signal transmission of the temperature sensor, response speed and the like of the gear shift controller. The invention also overcomes the technical difficulties that the installation and thesoldering of the thermocouple are difficult, the sensor is embrittled and can not be installed after high-temperature desoldering and sensor high-temperature calibration, high-speed spin friction causes sensor abrasion and the like; the real-time measurement of the friction pair temperature of the controller is realized, and the method has verification and instruction actions on the design of heat load reduction and improvement measures; and the method overcomes the influences of lubricating oil, high temperature, vibrations and other factors on installation conditions and temperature response speed, and can be applied to real vehicle tests.

Owner:CHINA NORTH VEHICLE RES INST

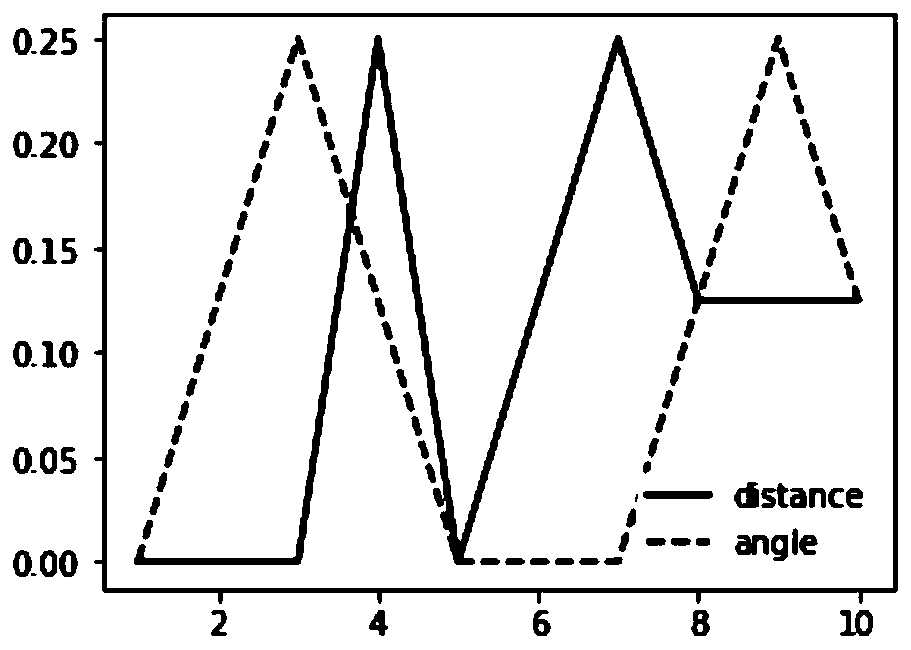

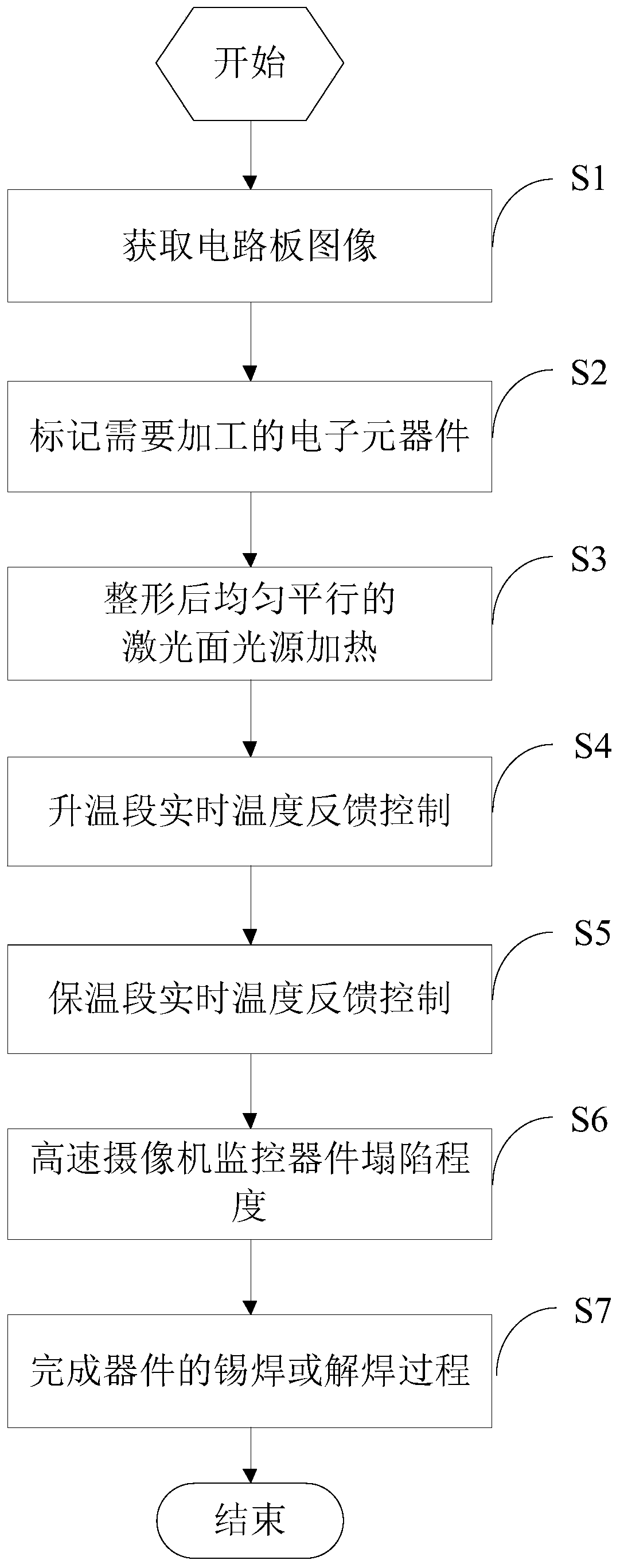

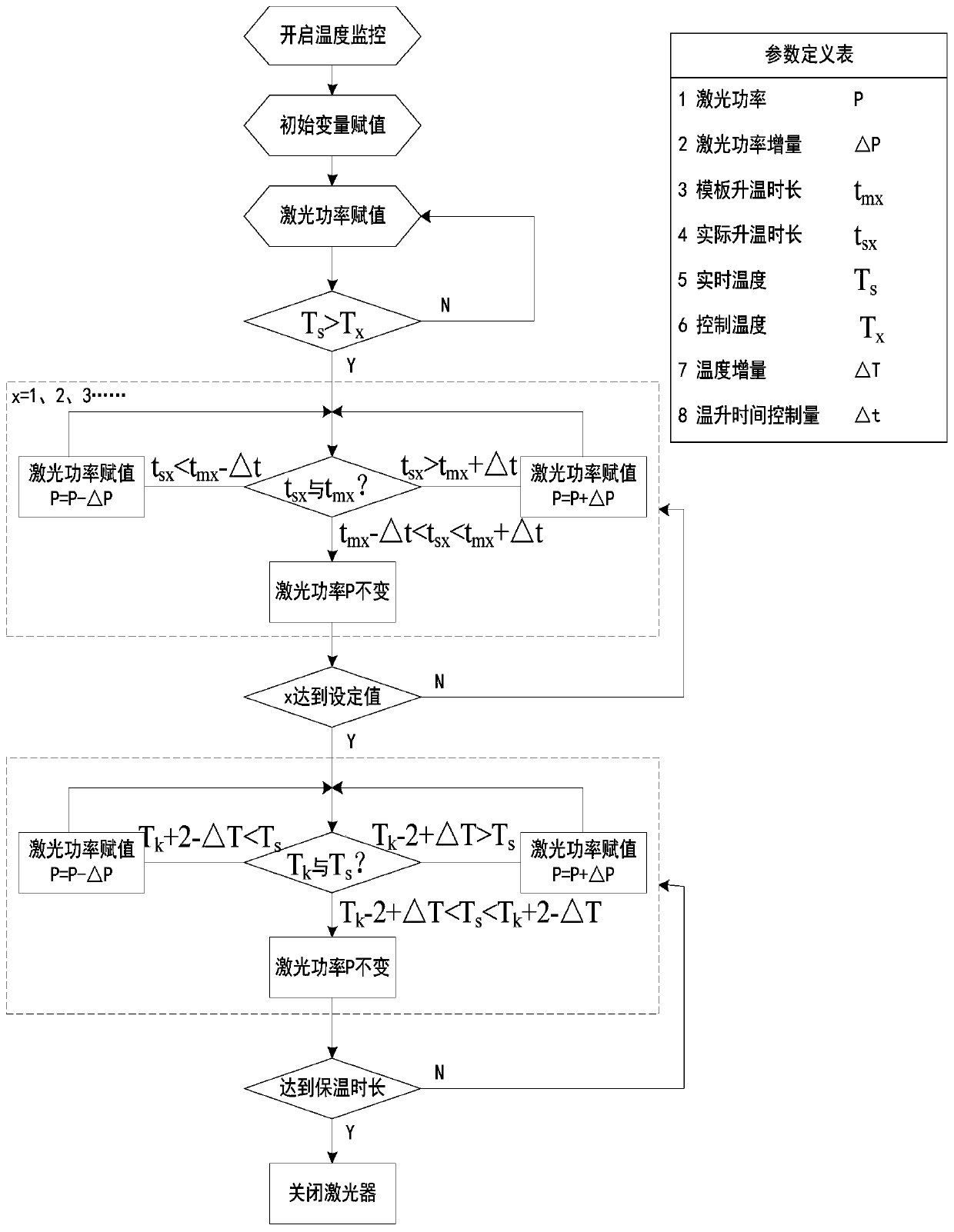

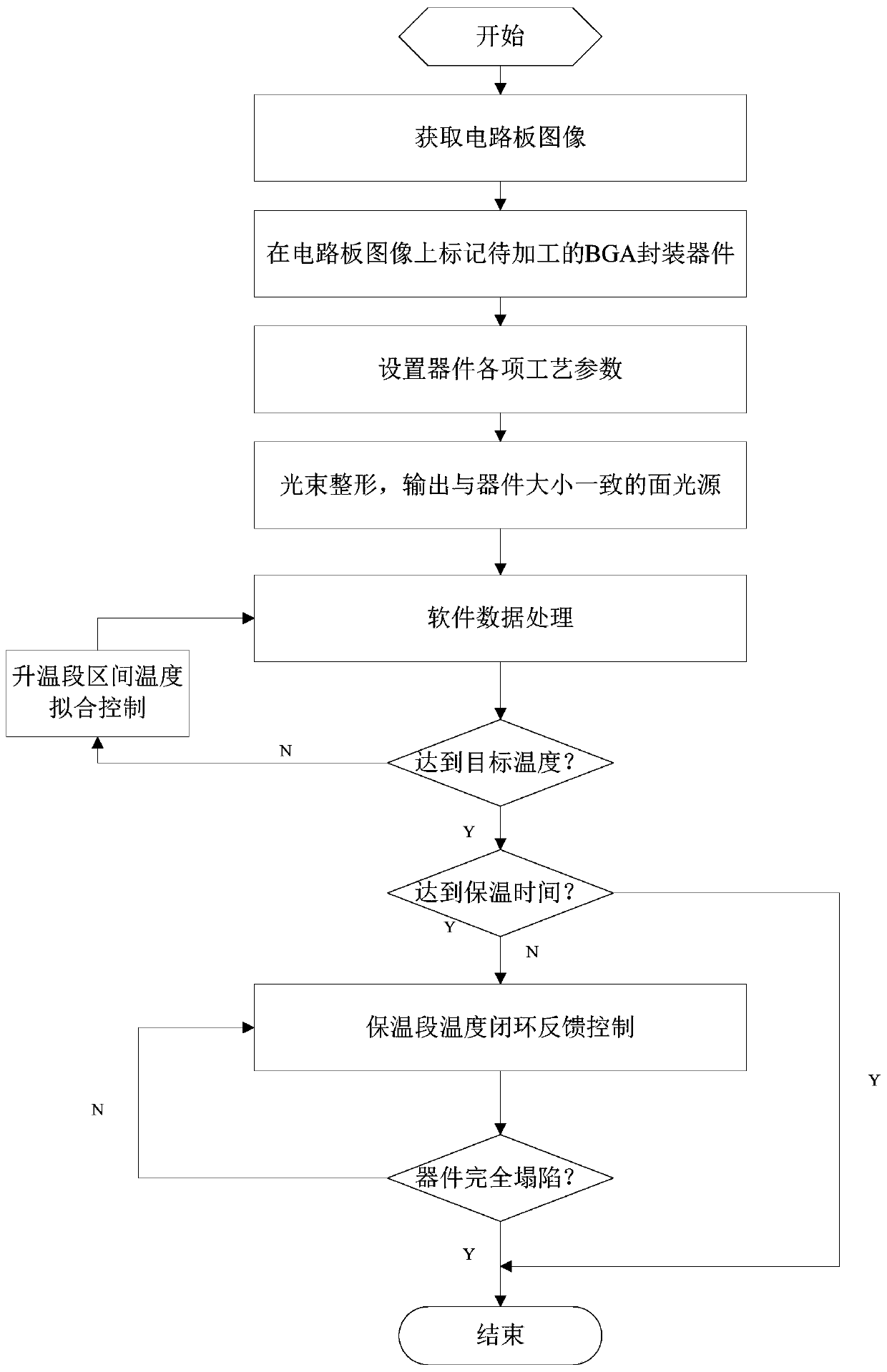

Ball grid array (BGA) packaging device laser tin soldering and desoldering method

ActiveCN109834355AAchieve solderingImplementor desolderingSoldering apparatusClosed loop feedbackEngineering

The invention discloses a ball grid array (BGA) packaging device laser tin soldering and desoldering method. The BGA packaging device laser tin soldering and desoldering method comprises the steps that a circuit board image collected by a camera is received; a BGA packaging device needing to be subjected to tin soldering or desoldering is marked on the circuit board image according to user operation instructions; laser beams of a laser device are shaped into a parallel uniform surface light beam with the same size as the marked BGA packaging device for heating; the power of the laser device issubjected to closed loop feedback control; whether the BGA packaging device is fully collapsed or not is judged by image processing; and the heating heat preservation of the laser device is maintained until the BGA packaging device is fully collapsed. According to the technical scheme, a laser beam shaping device is adopted to shape point light sources into a surface light source with the same size as the device for heating the device, it is ensured that the device is heated uniformly, solder balls are fully molten, while the tin soldering or desoldering of electronic parts and components adopting the BGA packaging mode is realized accurately and rapidly, peripheral adjacent devices and back part coincidence devices cannot be damaged.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

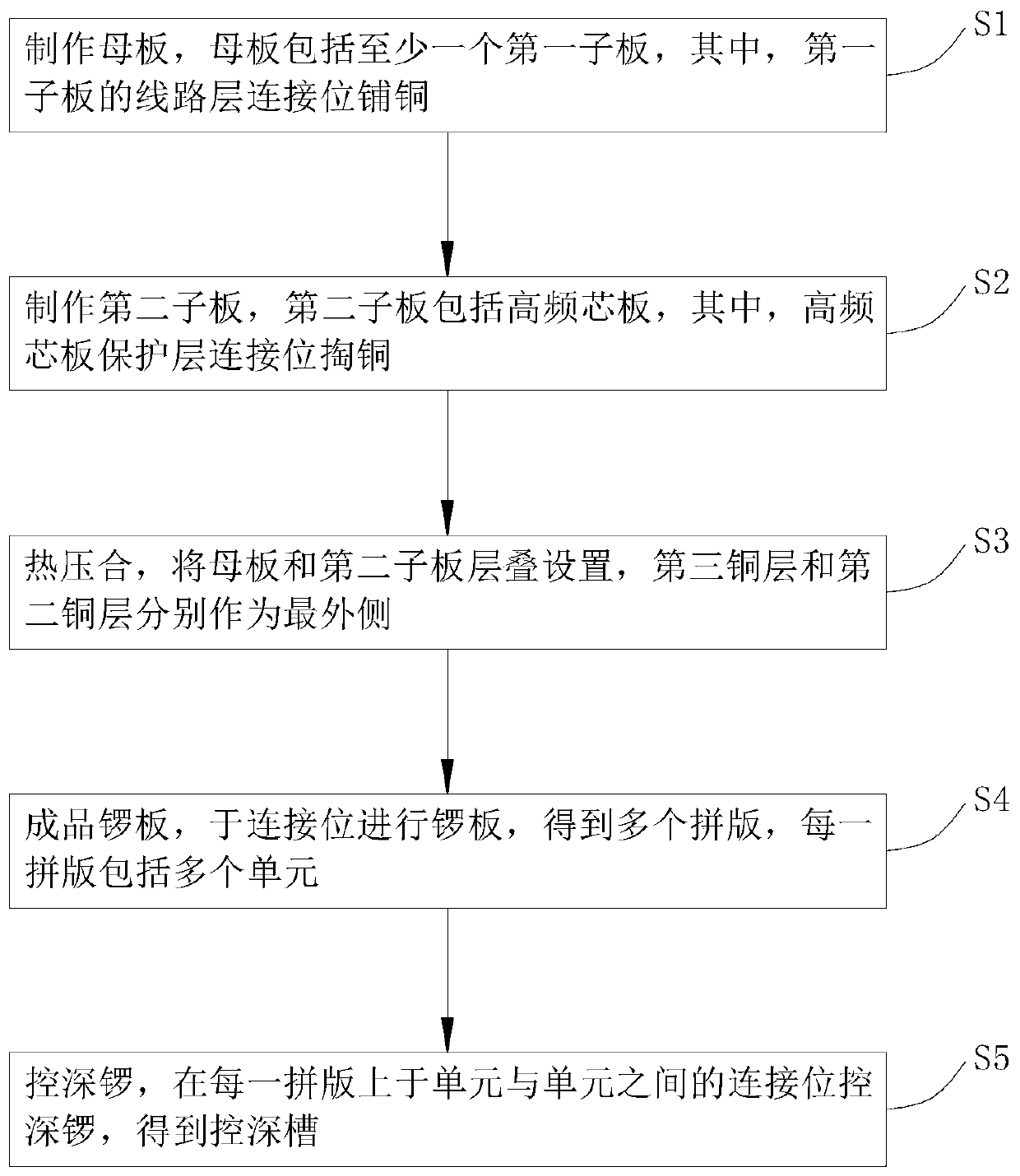

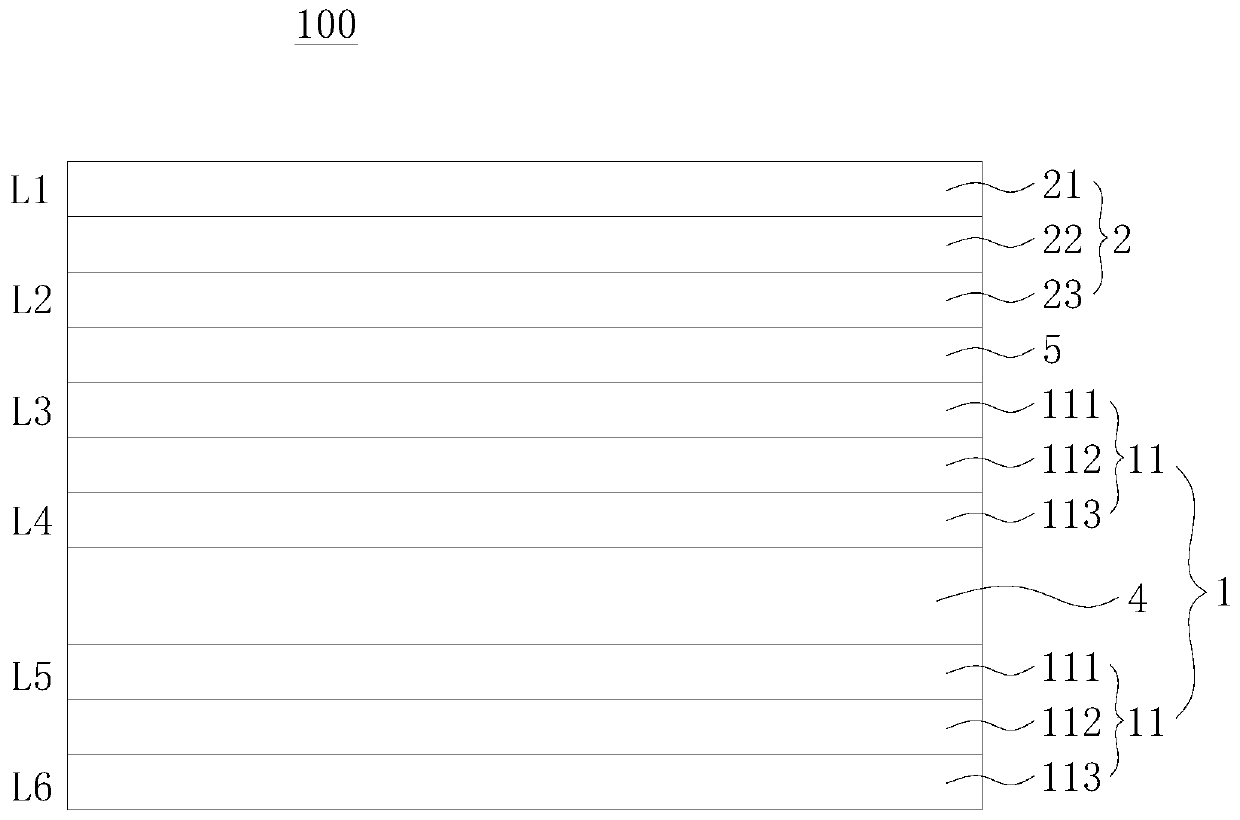

Manufacturing method of asymmetric plate

ActiveCN111511129AReduce warpageSolve WeldingPrinted circuit aspectsPrinted circuits stress/warp reductionDaughterboardSoldering

The invention is applicable to the technical field of circuit plate manufacturing, and provides a manufacturing method of an asymmetric plate. The manufacturing method of the asymmetric plate comprises the steps of manufacturing a mother plate, manufacturing a second daughter plate, carrying out thermal compression bonding on the mother plate and the second daughter plate, finished plate milling,and further comprises at least one of the three steps of laying copper on the connection positions, except the second copper layer on the outermost layer, of the mother plate to obtain a copper layingarea, digging copper at the connection position of a third copper layer protection layer when the second daughter plate is manufactured and performing depth control milling on each spliced plate fromone side of the second core plate at the connection position to obtain a depth control groove after the finished plate is milled.Any one of the three steps is beneficial to reducing the warping degree of the asymmetric plate after being heated, so that the problems of pseudo soldering and desoldering of a customer after a circuit plate finished product is assembled are solved, and the reliabilityof the product is improved.

Owner:SHENZHEN KINWONG ELECTRONICS

Spring contact for connectors

InactiveUS20050042939A1Quick installationEasy to removeCoupling contact membersElectric connection basesElectrical connectionEngineering

A spring contact design used to connect varied electrical components to circuit boards such that the components may be installed onto the board and thereafter removed without soldering and desoldering of the component leads is disclosed. The inventive contacts use integral flexible elements and appropriate contact element shaping to ensure solid multiple electrical connection points between the contact and the electrical component lead. With the use of the inventive spring contacts, components may be easily installed onto a circuit board and tested to ensure functional performance and, if necessary, may be removed or replaced without the need for time consuming soldering and desoldering of the component leads to the board contacts. The inventive contacts are designed to ensure sound electrical connection with component leads of different cross sections, shapes and sizes. Use of the inventive contacts in housings sized and shaped for different electrical components are also disclosed.

Owner:TE CONNECTIVITY CORP

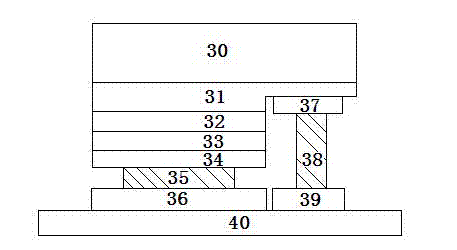

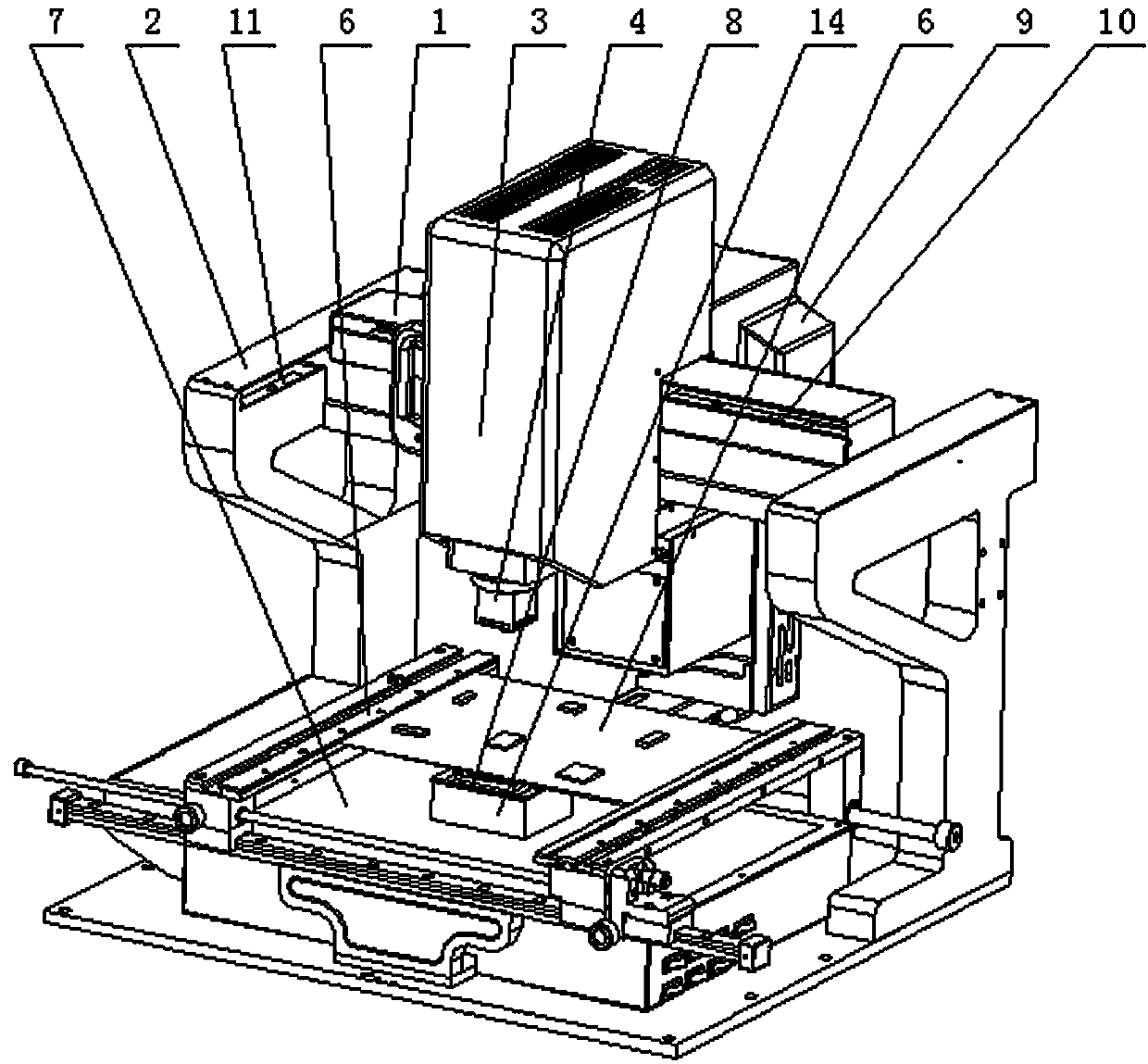

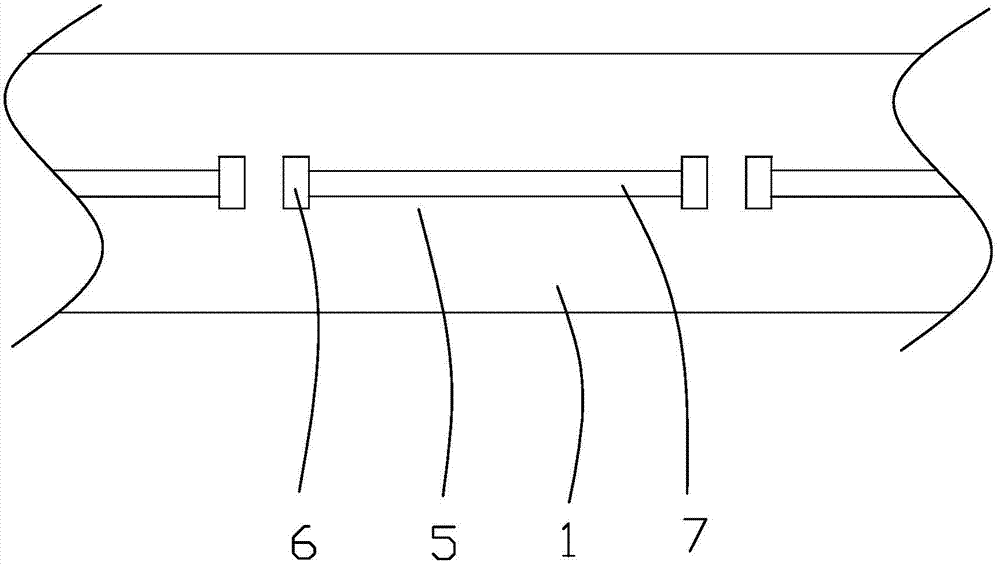

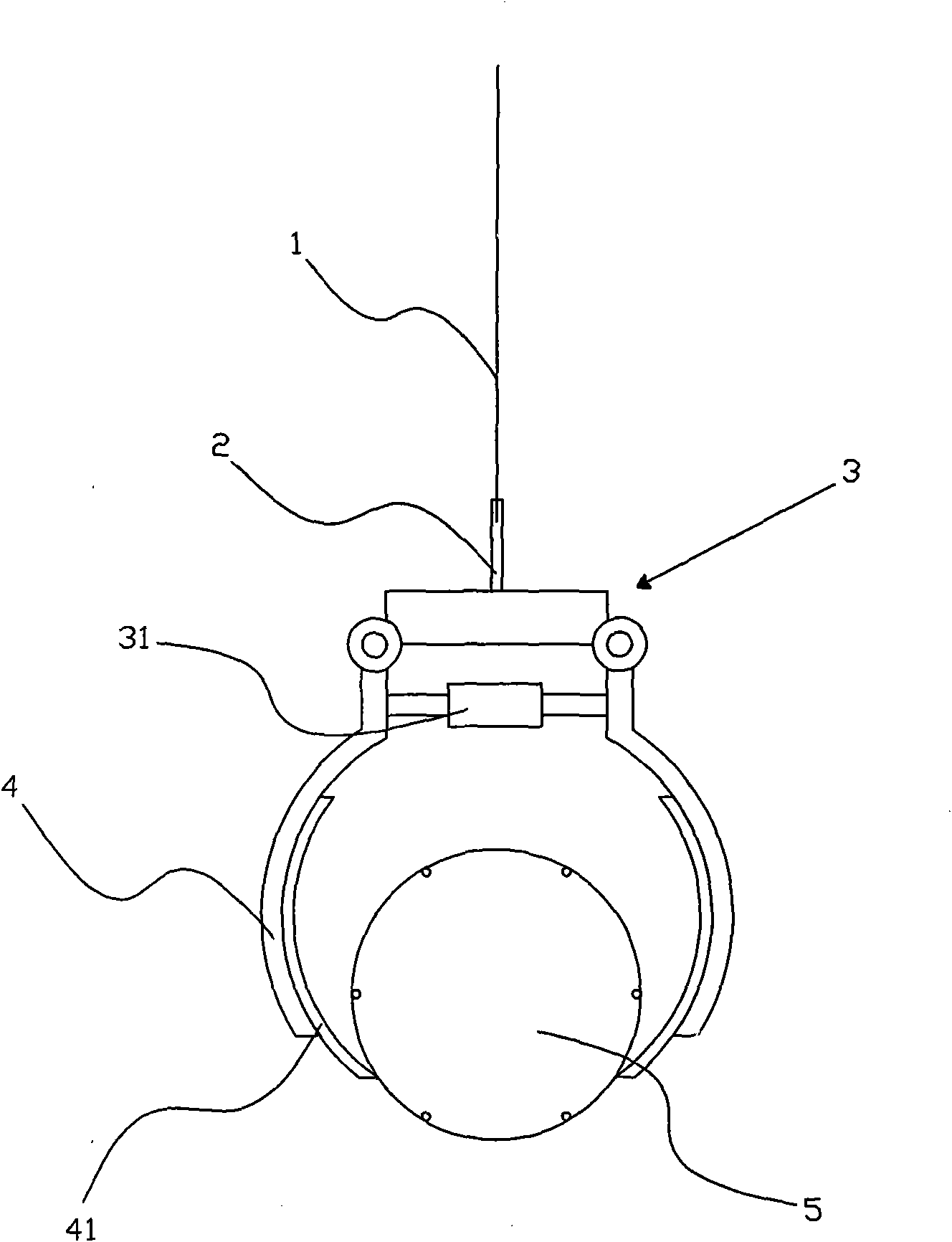

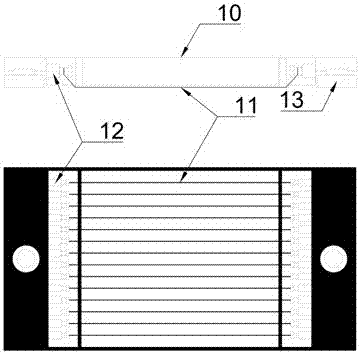

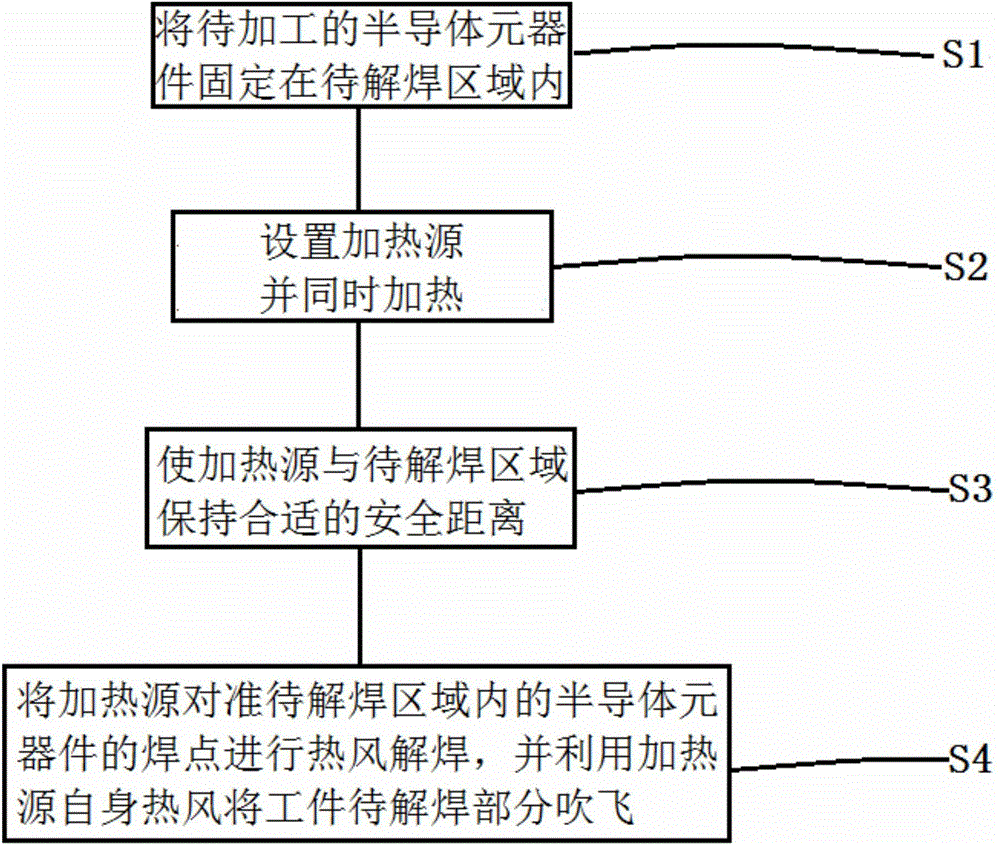

Integrated desoldering system conducting upper hot air heating and lower hot air heating synchronously

ActiveCN103752974ASimple structurePrevent deformation, sinking and bendingHeating appliancesMetal working apparatusSurface mountingBall screw

Provided is an integrated desoldering system conducting upper hot air heating and lower hot air heating synchronously. The integrated desoldering system comprises an upper heating device, a lower heating device and a synchronization mechanism. The upper heating device is composed of an upper heating group, an X-axis cross beam, a Y-axis cross beam, an upper heating cover, an upper heating tuyere, an X-direction guide rail, a Y-direction guide rail, a Z-direction guide rail, a ball screw and an upper synchronous wheel. The lower heating device is composed of a lower heating group and a heater through-connection body. The synchronization mechanism is composed of a manipulator front fixing plate, a manipulator upper arm, an arm connecting part, a manipulator front arm, an upper inductor, a lifting induction sheet, a lower inductor, a manipulator rear fixing plate, manipulator side fixing plates, a manipulator upper fixing plate, a ball screw, a lead screw nut, an arm braking component and a manipulator lower fixing plate. According to the integrated desoldering system conducting upper hot air heating and lower hot air heating synchronously, the upper heating group and the lower heating group move synchronously and move freely in the X direction, the Y direction and the Z direction; the desoldering and surface mount precision is effectively guaranteed; the automation is high, and the working efficiency is improved.

Owner:SHENZHEN ZHUO MAO TECH

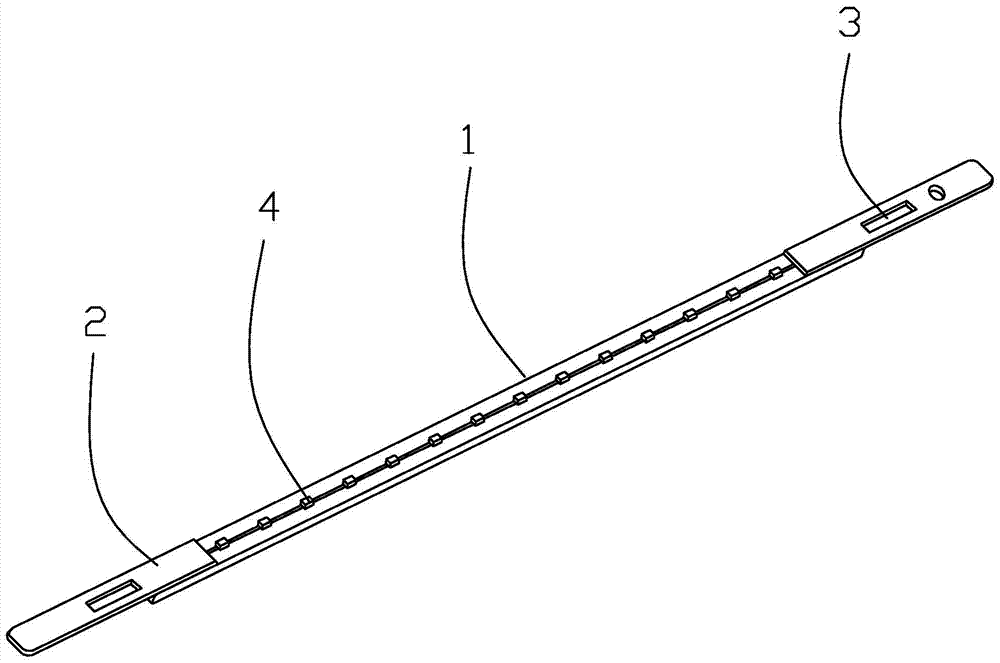

LED (Light Emitting Diode) lamp filament without bonding wire

ActiveCN104505453ALow costReduce leakageSolid-state devicesSemiconductor devicesEngineeringLuminescence

The invention relates to an LED (Light Emitting Diode) lamp filament without a bonding wire, and solves the problem of poor luminescence performance and heat dissipation of a traditional LED lamp filament. The lamp filament comprises a substrate, wherein a circuit is arranged on the surface of the substrate, LED chips are connected to the circuit, two ends of the substrate are connected with sheet metals, the circuit consists of a plurality of connecting circuits, each connecting circuit comprises two electric conduction silver layers which are connected through an electric conduction line, the LED chips are flip chips, and each LED chip is arranged between two adjacent connecting circuits for connecting the connecting circuits. The LED lamp filament has the advantages that a structure without the bonding wire is adopted, so that the cost is saved, the risks of the electric leakage and the dry joint of the LED since a porcelain nozzle has an impact on the LED chips in a welding process are greatly reduced, the packaging reliability and a production yield are greatly improved, and meanwhile the cost is lowered; and since the lamp filament and a lamp filament support are assembled in an embedding manner, the bad problems of the desoldering and the dry joint of the lamp filament of a light source in a traditional electric welding process can be avoided.

Owner:ZHEJIANG INTELED OPTOELECTRONICS TECH

Dead-soft tin-coated copper belt for solar cell

InactiveCN102592702ALow costImprove power generation efficiencySingle bars/rods/wires/strips conductorsMetal/alloy conductorsAlloy coatingSoldering

The invention relates to a dead-soft tin-coated copper belt for a solar cell. The dead-soft tin-coated copper belt comprises a copper material substrate and alloy coatings, wherein the alloy coatings are uniformly coated on the front and the back surfaces of the copper material substrate to form the tin-coated copper belt. The thickness of each of the front alloy coating and the back alloy coating on the copper material substrate is 0.01-0.03mm. The tin-coated copper belt has the yield strength being less than or equal to 50 N / mm<2>, the tensile strength being larger than or equal to 135 N / mm<2>, and the percentage elongation of being larger than or equal to 15%. The tin-coated copper belt is clung to the solar cell when being soldered with the solar cell, thus insufficient soldering, desoldering and deviation soldering caused by coiling and arching are avoided, power generation efficiency of the solar cell can be comprehensively increased, fragment rate is reduced, cost is saved and profit space is expanded for customers, and the product competitiveness is also improved.

Owner:WUXI SVECK TECH

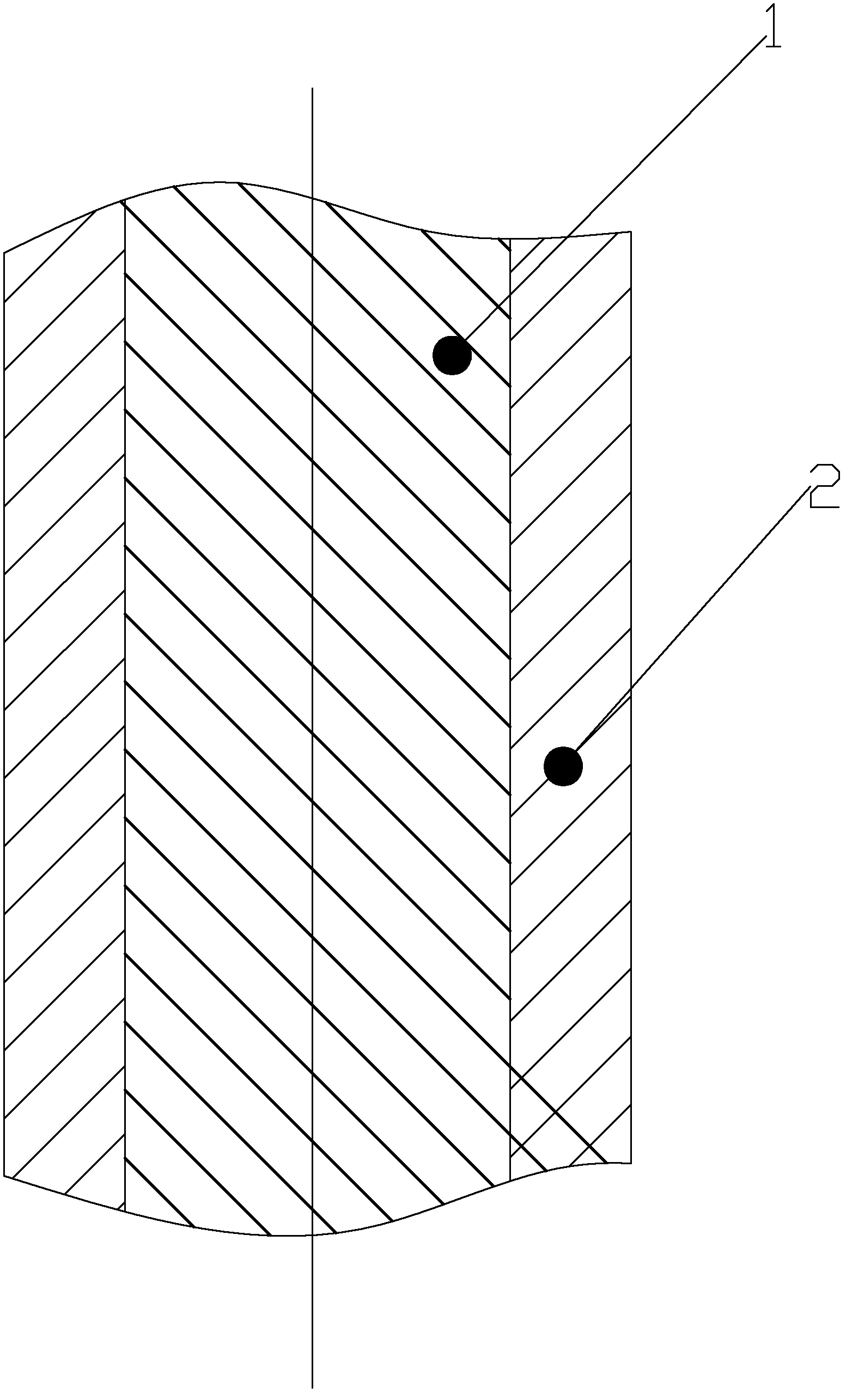

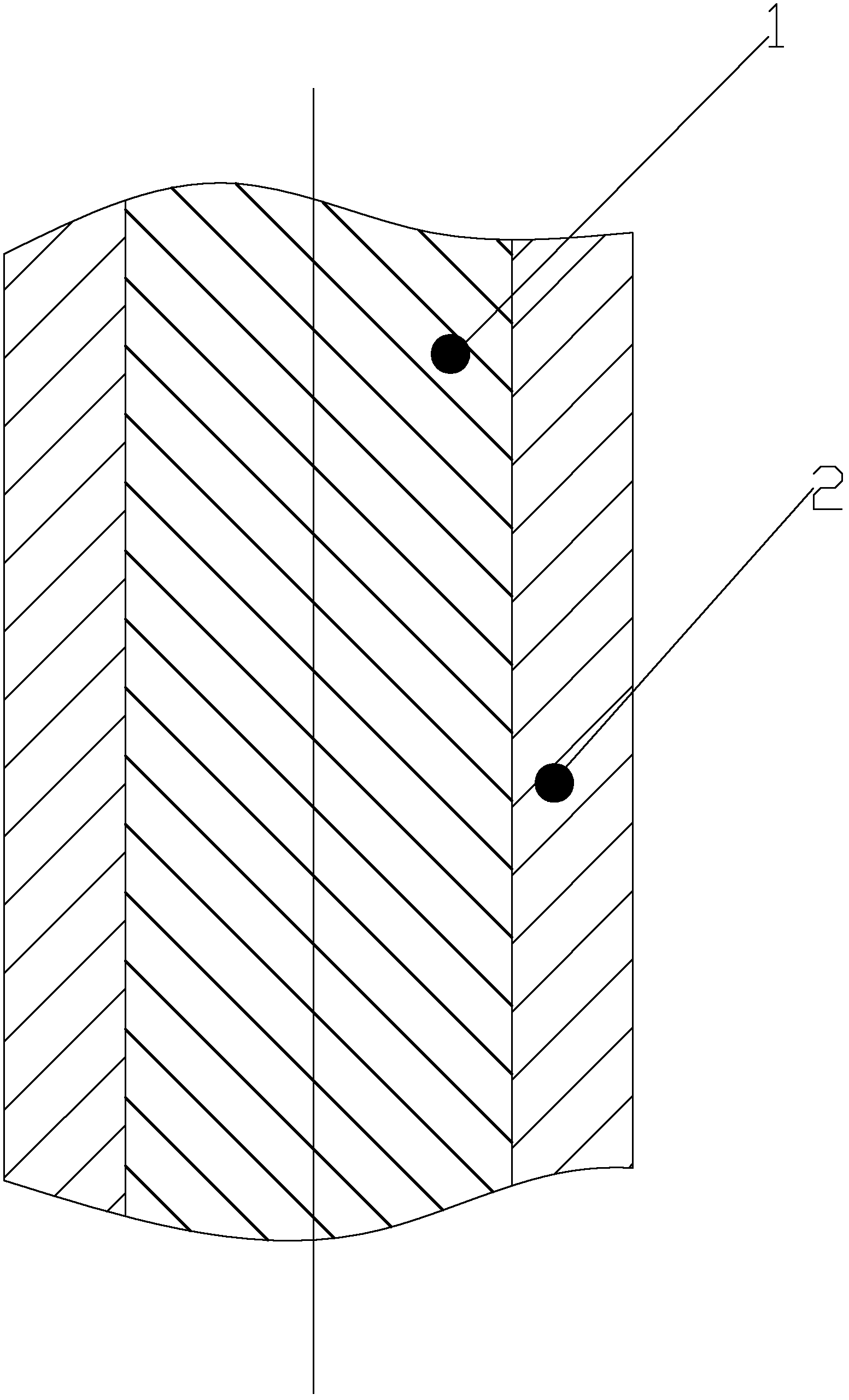

Reducing integrated connecting pipe

The invention discloses a reducing integrated connecting pipe. A main body of the reducing integrated connecting pipe is a slender hollow metal pipe; the pipe end of the slender hollow metal pipe is provided with a connecting adapter tube; the connecting adapter tube is formed by reducing the diameter of the pipe end of the slender hollow metal pipe; the outer diameter of the connecting adapter tube is slightly less than the inner diameter of the slender hollow metal pipe; and the connecting adapter tube is connected with the slender hollow metal pipe by a transition adapter tube. When the reducing integrated connecting pipe is used for connecting each evaporator inlet and outlet pipe, the pipe ends of two adjacent evaporator inlet and outlet pipes are respectively and fixedly connected with the reducing integrated connecting pipe and the unreduced slender hollow metal pipe, a pipe orifice of the unreduced slender hollow metal pipe is inserted into an inner hole of the connecting adapter tube of the reducing integrated connecting pipe and then the sealing welding is carried out, so that the connection of each evaporator inlet and outlet pipe can be completed. When the reducing integrated connecting pipe is used for carrying out connection of the evaporator inlet and outlet pipes, half the number of welding spots can be reduced; and additionally, the reducing integrated connecting pipe has good rigidity, so that the possibility of desoldering and leakage of the connecting position is greatly reduced and the noise of evaporators is also reduced.

Owner:JIANGSU XINCHENG ELECTRICAL APPLIANCE GENERAL FACTORY

Steel cage lifting device for tubular pile industry

InactiveCN101774504AEven by forceWork safely and efficientlyLoad-engaging elementsBulkheads/pilesManipulatorDesoldering

The invention discloses a steel cage lifting method for the tubular pile industry, which comprises steel wire ropes connected on a crane. The lower parts of the steel wire rope are lifted with a bracket. Two or more steel wire ropes are provided. The bracket is fixedly provided with a clamping mechanism. Both ends of the clamping mechanism are provided with expansion links. The tail ends of the expansion links are connected with mechanical arms. The lifting process of the steel cage does not need the operator to hook the cage and adopts the mechanical arms to clamp so that the stress of each point of the steel cage is uniform, the phenomenons of deformation or desoldering, cracking and the like of the steel cage cannot occur, and the working process is safer and more efficient.

Owner:GUANGDONG SANHE PILE CO LTD

Multi-main-grid crystalline silicon solar battery piece and welding method

PendingCN107221567AWill not shiftNo desolderingFinal product manufacturePhotovoltaic energy generationSilver electrodeElectrical battery

The invention provides a multi-main-grid crystalline silicon solar battery piece. The multi-main-grid crystalline silicon solar battery piece comprises a battery body, a front electrode and a back electrode, wherein the front electrode comprises a plurality of auxiliary grid lines arranged in a uniformly-spaced manner along the vertical direction and a plurality of thin grid lines arranged in the uniformly-spaced manner along the horizontal direction, bonding pads are arranged on the auxiliary grid lines, the widths of the bonding pads are smaller than or equal to 1 mm, and the connection, along the vertical direction, of the bonding pads adopts curve connection; the back electrode are back silver electrodes arranged in the uniformly-spaced manner along the horizontal direction, and the widths of the back electrodes are smaller than or equal to 2 mm. Through the change for the arrangement of the back electrodes of the battery piece and a specific welding method, the multi-main-grid battery piece is stable and firm in welding in the automatic series welding process, solder strips on the back of the multi-main-grid battery piece are free of excursion or desoldering, the welding quality is improved, the solder strips on the front and back can be attached to the multi-main-grid battery piece all the time, and a good welding effect is formed.

Owner:LIANYUNGANG SHENZHOU NEW ENERGY

Liquid-cooled battery pack system

ActiveUS9774065B2Excellent heat resistance and electrical insulation and hydrophobicityHigh fire point propertySecondary cellsCell component detailsElectrical batteryEngineering

Owner:MICROVAST

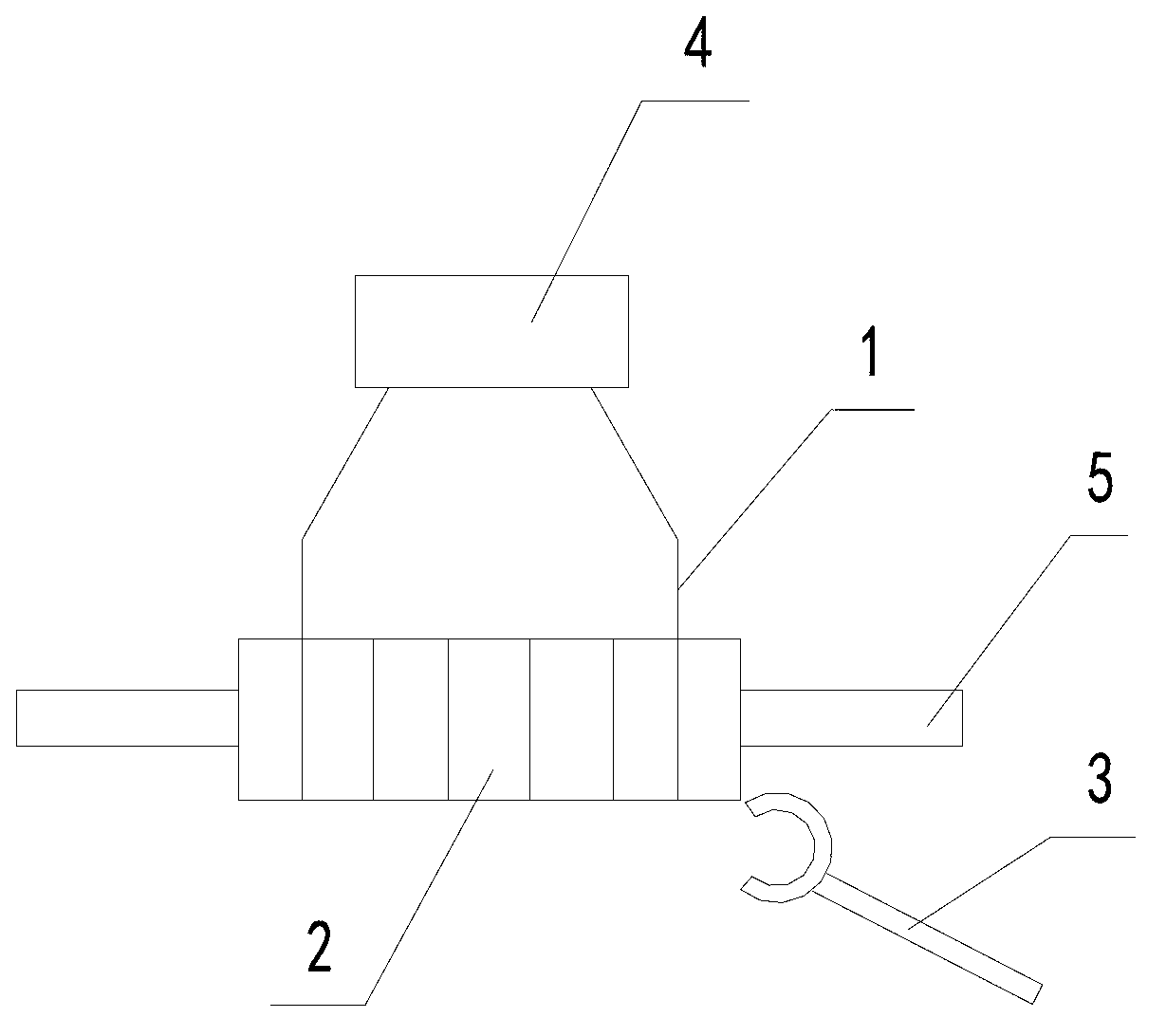

Desoldering method of semiconductor device

InactiveCN105983743ASituations that do not cause damageImprove yield rateSoldering apparatusPower semiconductor deviceEngineering

The invention discloses a desoldering method of a semiconductor device. The method comprises following steps: fixing the semiconductor device to be machined in the region to be desoldered; arranging a heating source and heating simultaneously; enabling the heating source to keep the proper safety distance with the region to be desoldered; enabling the heating source to align at the welding spot of the semiconductor device in the region to be desoldered for desoldering with hot water, and utilizing self hot water of the heating source to blow away the part to be desoldered of a workpiece. The above steps can process samples at high efficiency for multiple times and improves yield rate and processing efficiency of a conventional distributive physical method. In addition, the above steps are high in safety. Due to the adjustable desoldering temperature and distance, the occasion of physical separation technology that samples are damaged due to mis-operation is avoided; and push force generated by expansion at high temperature such that a desoldering and separation process is safer.

Owner:厦门睿析检测技术有限公司

Induction duct-desoldering device and desoldering method

The invention discloses an induction duct-desoldering device and an desoldering method. The induction duct-desoldering device comprises an induction coil, an induction power supply, a protective copper sleeve and a pair of dismantling pincers matched with the protective copper sleeve, and the induction coil is wound on the protective copper sleeve, and is connected with the induction power supply. The desoldering method includes the following steps: (1) the protective copper sleeve is mounted at a bush position on a duct to be desoldered, and a bush is mounted on the duct; (2) the induction coil is wound on the protective copper sleeve; (3) the induction coil is connected with the induction power supply; (4) after water or gas is filled into the protective copper sleeve, the induction coil is utilized to heat the duct; and (5) after the duct is heated to required temperature for a required period of time, the dismantling pincers is used for moving the protective copper sleeve, so that the bush in the protective copper sleeve is separated from the duct, and thereby desoldering is finished. The invention has the advantages that the duct in an aeroengine can be unwelded and reused, the duct can be uniformly heated, the brazing quality is increased, and the requirements of the assembly, repair, product quality and the like of the engine are met.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

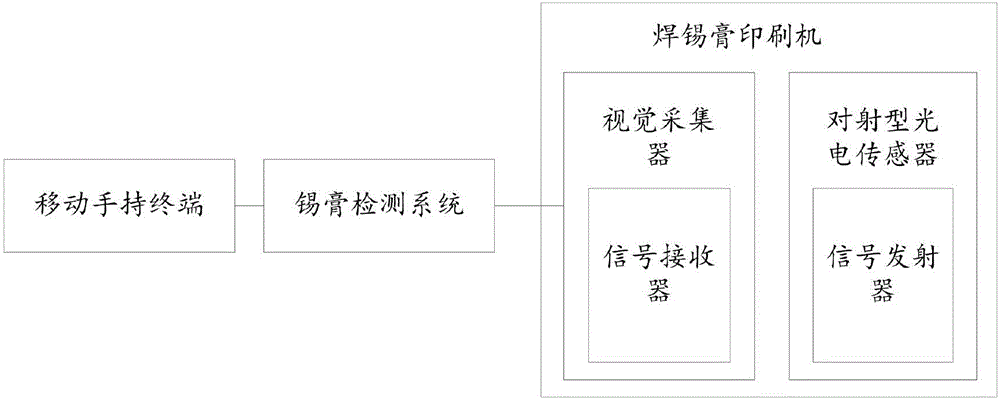

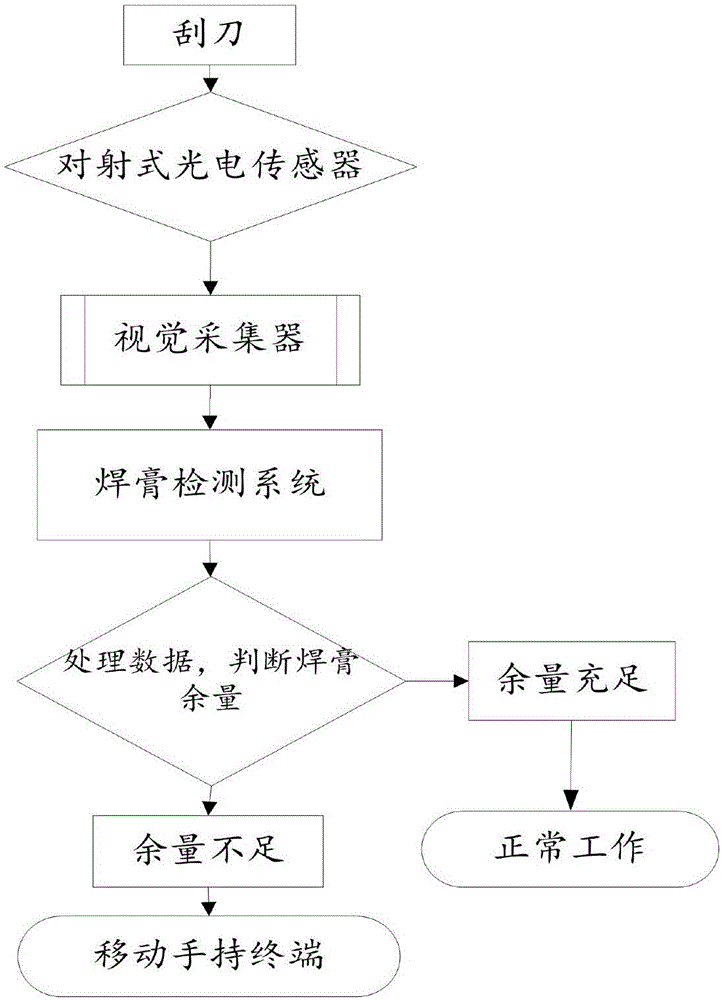

Method for intelligently detecting residual amount of solder paste of soldering paste printer

A method for intelligently detecting the residual amount of solder paste of a soldering paste printer specifically comprises the following steps that when a scraper in the soldering paste printer moves to an opposite-emitting photoelectric sensor, the light path of the scraper is cut off, the opposite-emitting photoelectric sensor sends signals to a signal receiver of a visual collector through a signal projector; after the visual collector receives the signals, image acquisition is conducted, and then acquired image information is sent into a solder paste detecting system; the solder paste detecting system calculates and processes the image information, and then the residual amount of soldering paste is obtained; once the residual amount exceeds the maximum value and the minimum value of a set threshold value range, the solder paste detecting system sends corresponding warning information to a mobile handheld terminal of relevant personnel through WIFI to remind the relevant personnel to handle the problem in time. According to the method for intelligently detecting the residual amount of the solder paste of the soldering paste printer, accuracy is greatly improved, the manual operation difficulty is lowered, and defects of insufficient solder, desoldering, bridging and the like can be prevented.

Owner:DALIAN EVERYDAY GOOD ELECTRONICS

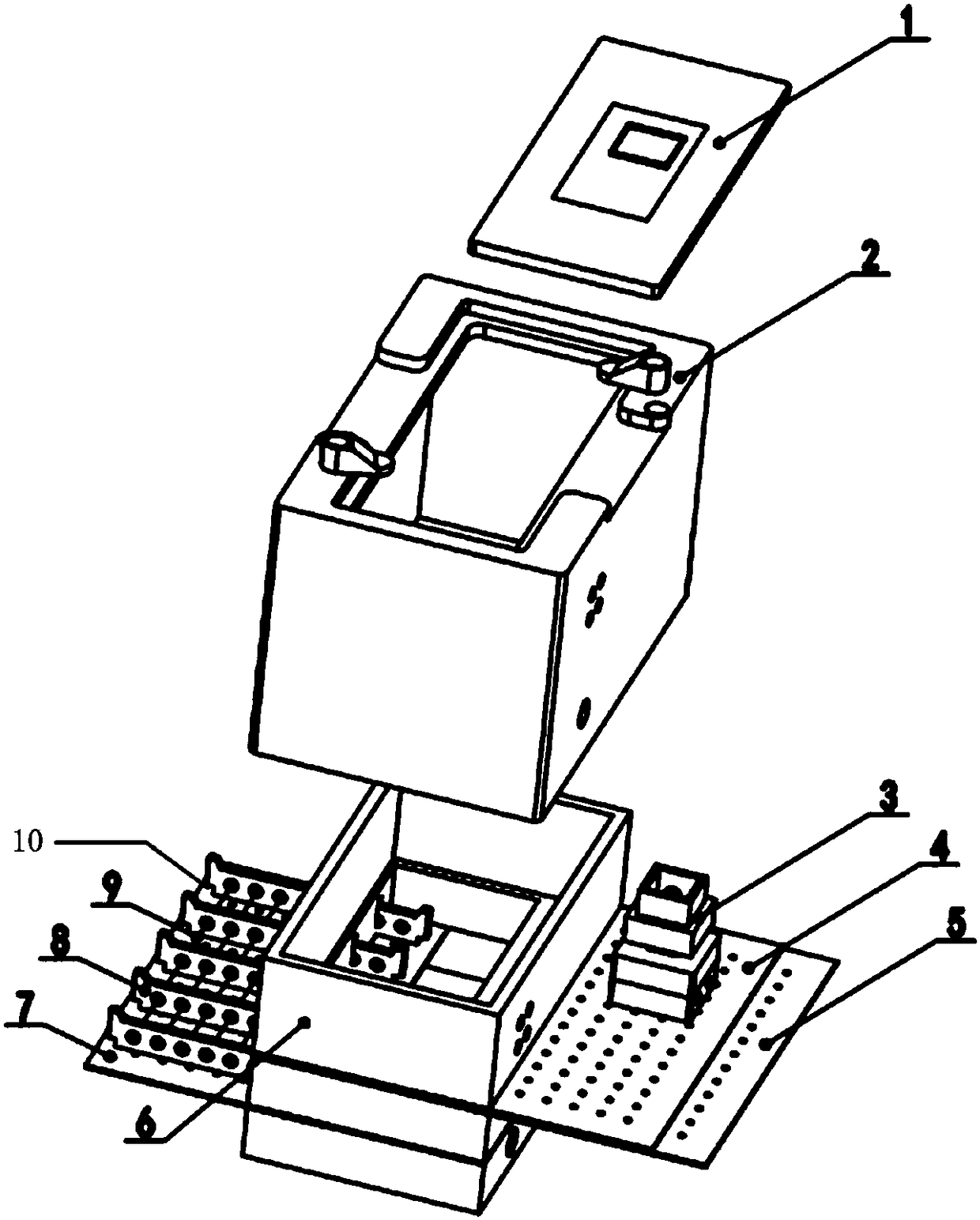

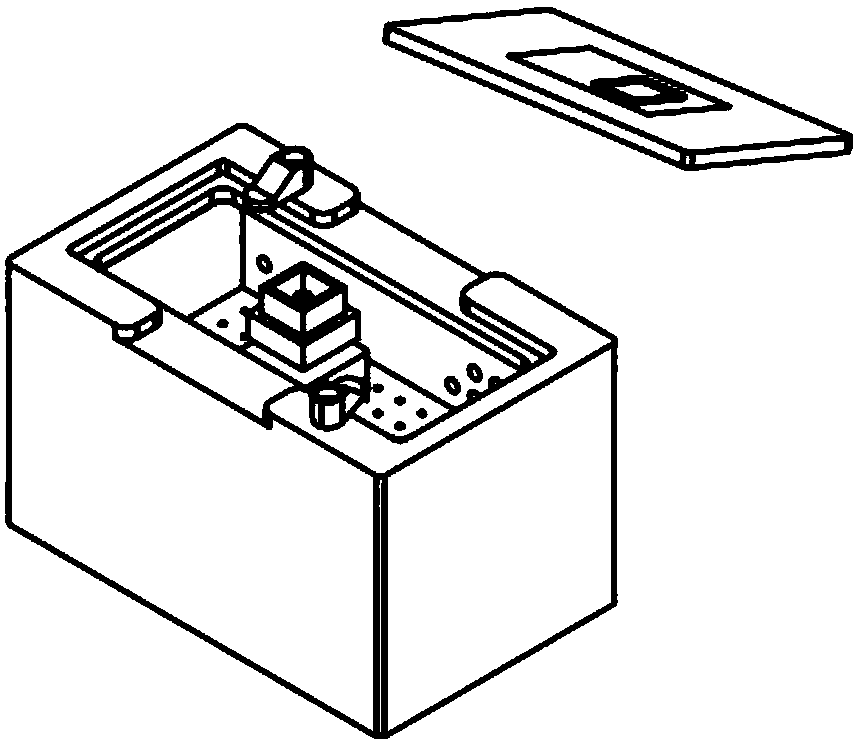

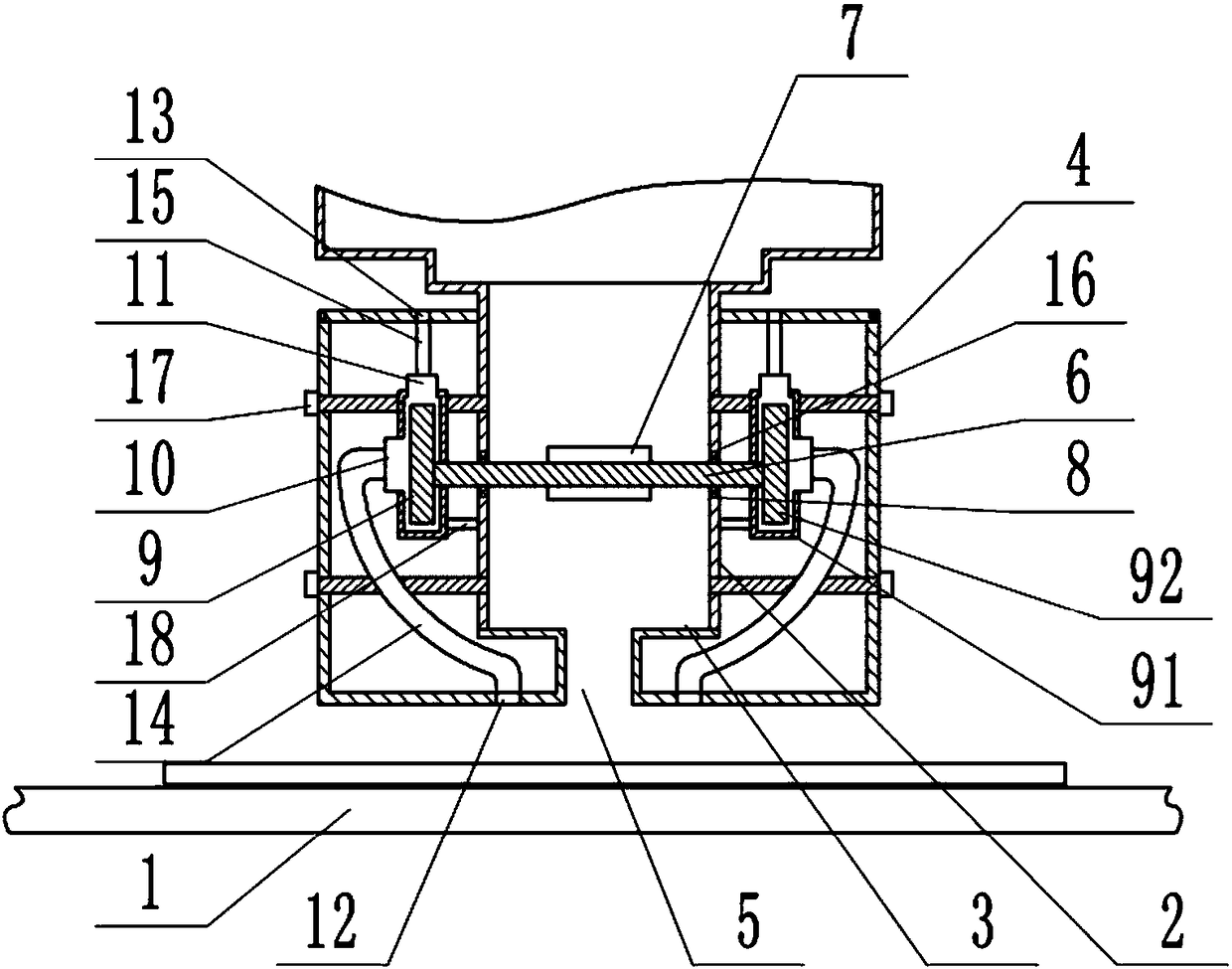

PCB soldering and desoldering device

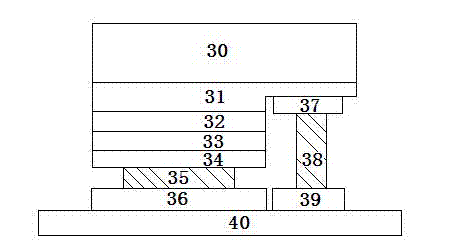

PendingCN108465897AWarm up and stabilizeEasy to weldMetal working apparatusSoldering auxillary devicesDip solderingTemperature difference

The embodiment of the invention discloses a PCB soldering and desoldering device. The PCB soldering and desoldering device is used for providing a temperature difference environmental condition for PCB soldering and desoldering, thus efficiency of PCB soldering and desoldering is improved, and the success rate of PCB soldering and desoldering is increased. According to a method, the PCB solderingand desoldering device comprises a jig, an outer wall, a cooling mechanism, a preheating device and a bottom support plate; the jig is fixed to the upper portion of the outer wall and used for fixinga to-be-machined PCB; the cooling mechanism and the preheating device are located inside the outer wall, and the cooling mechanism is located on the preheating device; and the preheating device is fixed to the bottom support plate. Therefore, by means of the preheating device, the PCB can be preheated stably; the cooling mechanism is matched, the soldering and desoldering temperature difference ofa to-be-machined area of the PCB is achieved, and the temperature difference environmental condition is provided for soldering and desoldering; influence on devices around soldered and desoldered elements can be reduced conveniently; and thus, efficiency of PCB soldering and desoldering is improved, and the success rate of PCB soldering and desoldering is increased.

Owner:深圳市汇能光电科技有限公司 +1

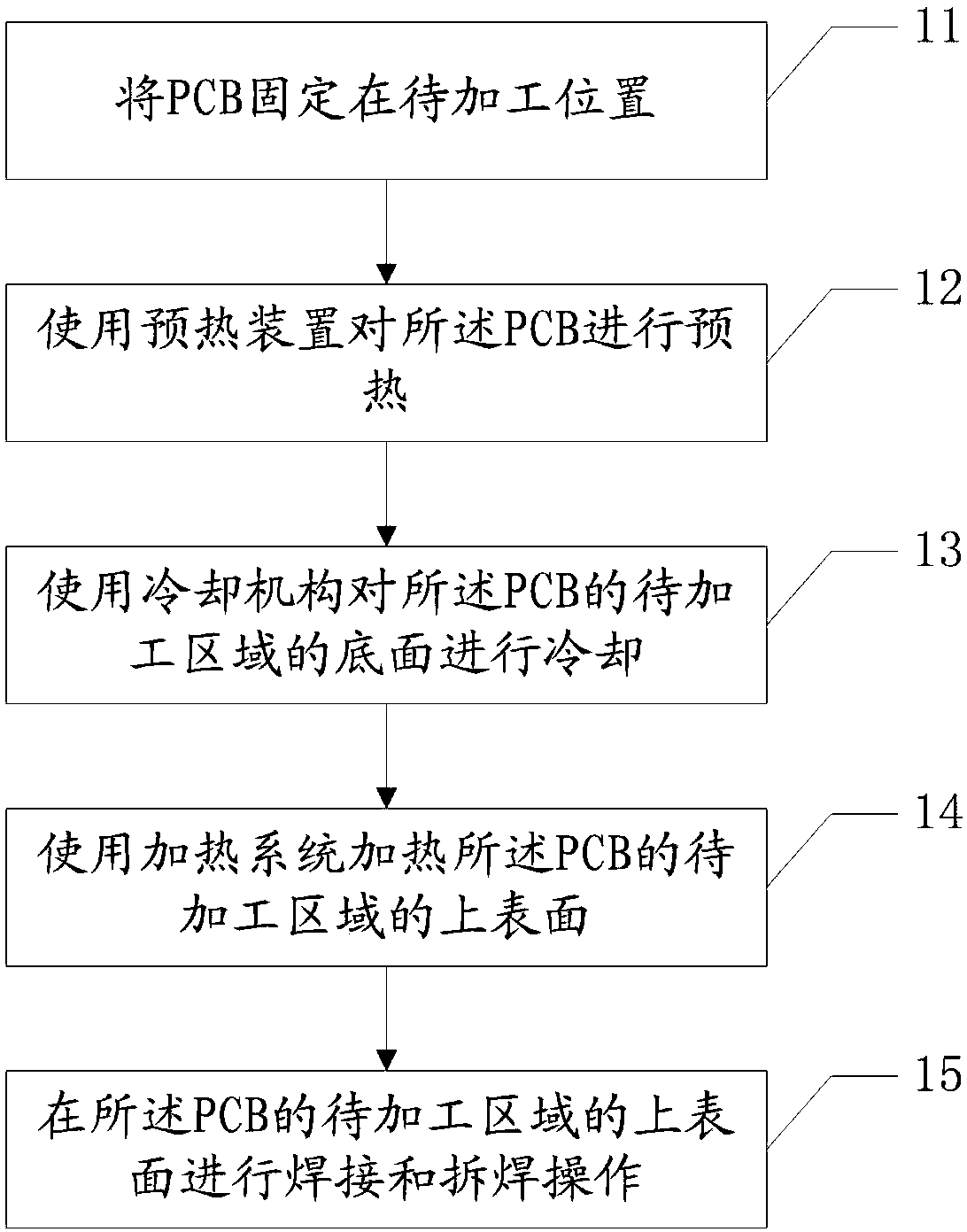

Soldering and desoldering method and device of PCB component

InactiveCN108436211AWarm up and stabilizeImprove cooling effectHeating appliancesPrinted circuitsDip solderingEngineering

The embodiment of the invention discloses a soldering and desoldering method and device of PCB component, and aims at supplying a temperature difference environment condition for PCB soldering and desoldering in order to improve the PCB soldering and desoldering efficiency and success rate. The method in the embodiment comprises the steps of fixing the PCB to a position for processing; preheatingthe PCB through a preheating device; cooling the bottom surface of an area, to be processed, of the PCB through a cooling mechanism; heating the upper surface of the area, to be processed, of the PCBthrough a heating system; and performing soldering and desoldering operation on the upper surface of the area, to be processed, of the PCB. According to the method, the PCB is stably preheated throughthe preheating device; the area, to be processed, of the PCB is cooled through the cooling mechanism; and then the upper surface of the area, to be processed, of the PCB is heated through the heatingsystem, thus the soldering and desoldering temperature difference is realized, and the influence on components surrounding soldering and desoldering elements and components can be decreased, and as aresult, the PCB soldering and desoldering efficiency and success rate can be improved.

Owner:深圳市微组半导体科技有限公司 +1

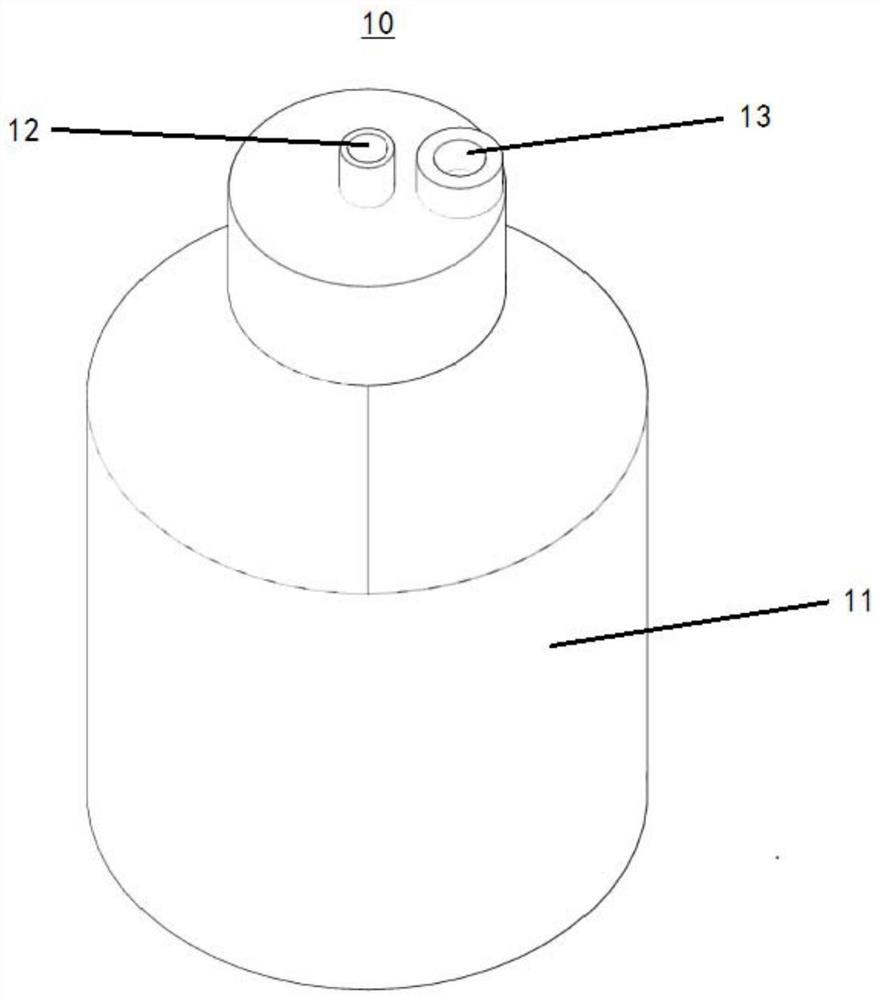

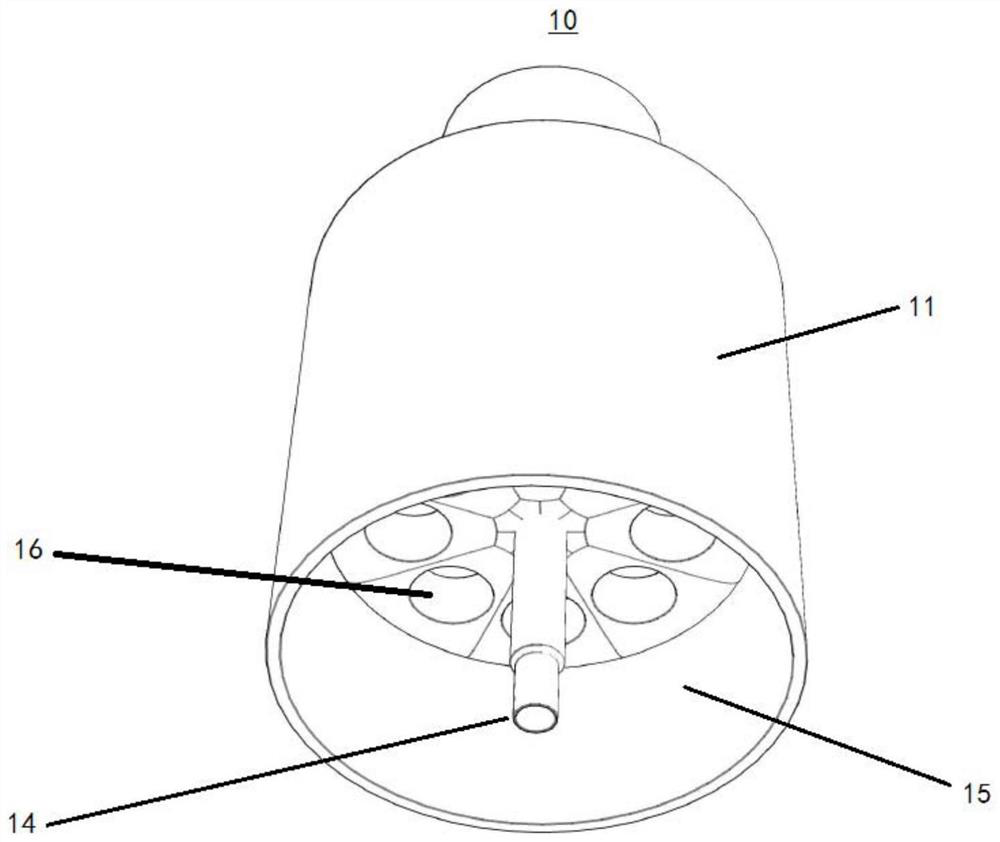

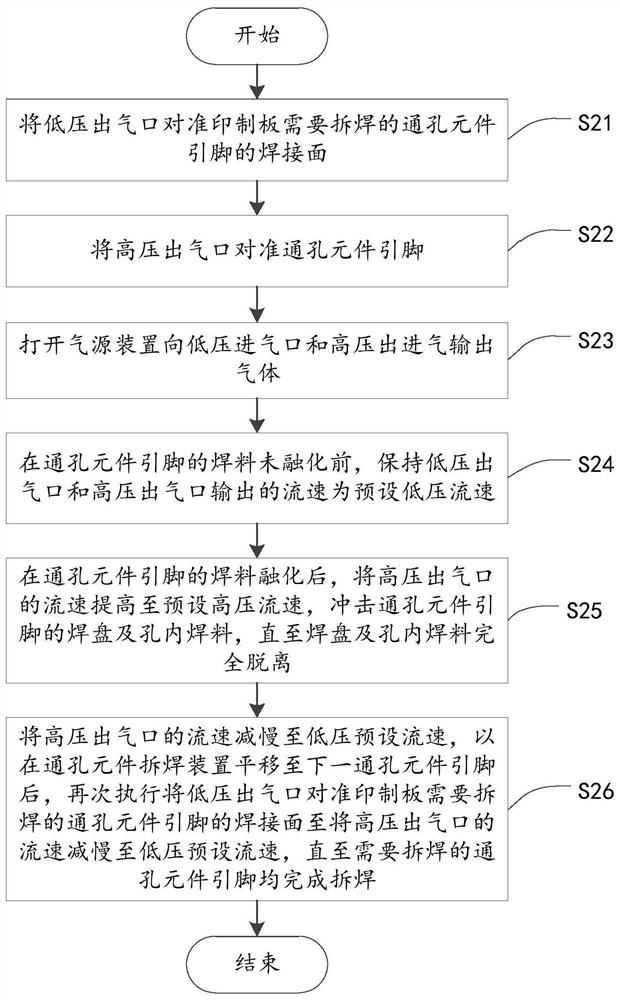

Desoldering device, system and method for through-hole component

InactiveCN111702282ALow flatnessThere is no problem of sudden changes in ambient temperaturePrinted circuits repair/correctingMetal working apparatusEngineeringMechanics

The application provides a desoldering device, system and method for a through-hole component, and relates to the technical field of circuit board welding. The device comprises a cylindrical shell; ahigh-pressure gas passage and a low-pressure gas passage are arranged in the shell; a high-pressure gas inlet of the high-pressure gas passage and a low-pressure gas inlet of the low-pressure gas passage are arranged at the top end of the shell; a high-pressure gas outlet of the high-pressure gas passage and a low-pressure gas outlet of the low-pressure gas passage are arranged at the bottom end of the shell; the low-pressure gas passage is arranged by surrounding the high-pressure gas passage; the high-pressure gas inlet communicates with a high-pressure gas outlet of a gas source device; andthe low-pressure gas inlet communicates with a low-pressure gas outlet of the gas source device. The device continuously and uniformly heats a pad of the through-hole component by low-pressure gas, and applies uniform thrust to the pad and through holes by the high-pressure gas to complete desoldering, thus avoiding mechanical damage, and improving the success rate and efficiency of desoldering.

Owner:MAIPU COMM TECH CO LTD

Method for manufacturing inverted LED chip

ActiveCN102931311AImprove packaging yieldAvoid WeldingSemiconductor devicesOhmic contactLight reflection

Owner:江苏百凌电器有限公司

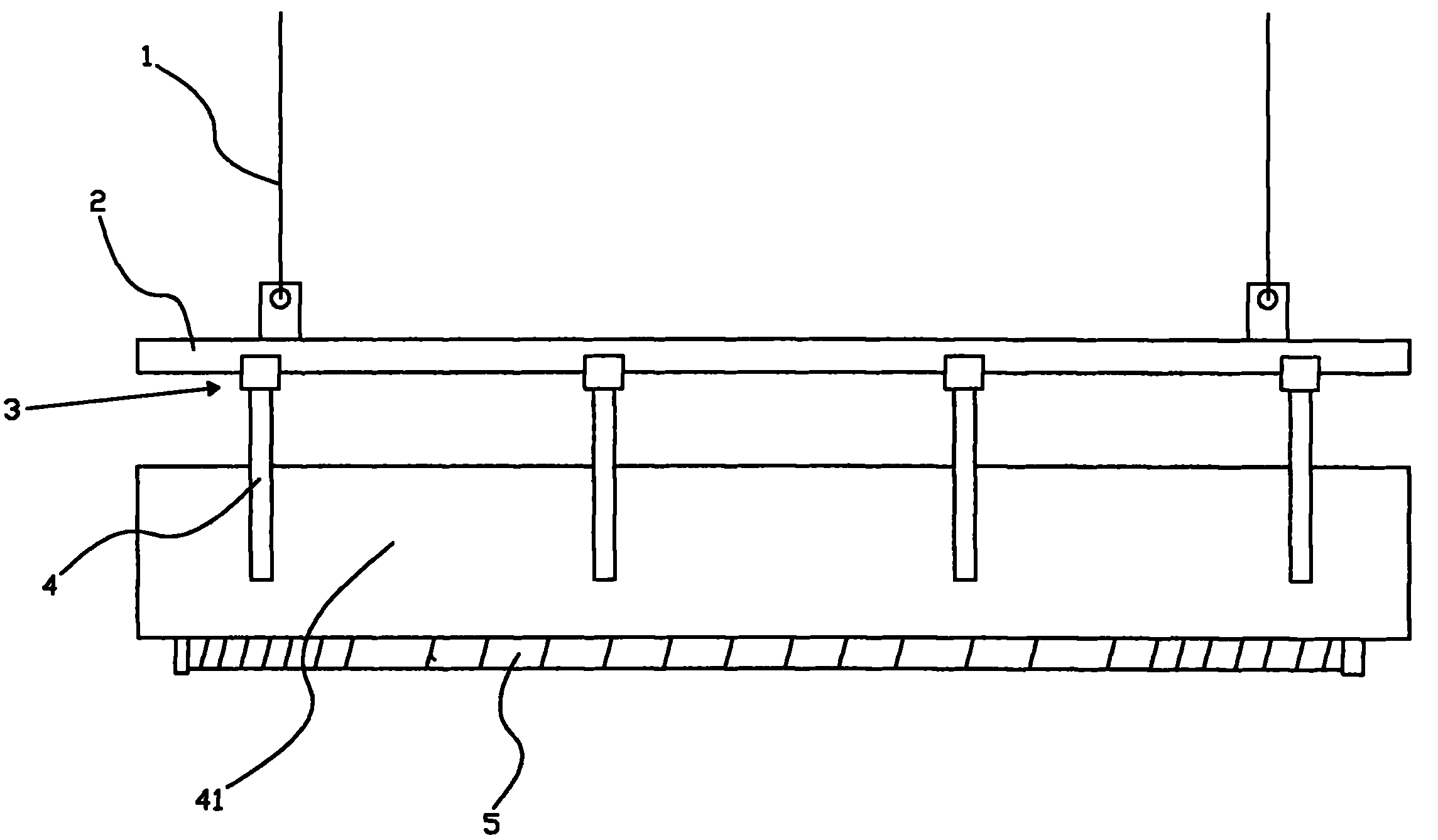

Tube target desoldering device and using method thereof

ActiveCN110270730AEvenly heatedEfficient recyclingSoldering apparatusVacuum evaporation coatingEngineeringDesoldering

The invention provides a tube target desoldering device and a using method thereof. The device comprises a desoldering table and a heating assembly, the desoldering comprises a desoldering bottom plate and a hollow tube vertically fixed on the desoldering bottom plate, the to-be-welded tube target is arranged on the outer side of the hollow tube in a sleeved mode; the heating assembly comprises a heating rod and at least one heating ring, the heating rod is arranged inside the hollow tube, and the heating ring is arranged on the outer side of the to-be-welded pipe target in sequence from bottom to top. According to the tube target desoldering device, the target material in the tube target and the back tube can be uniformly heated through the combination of a supporting structure and a heating assembly, when the welding flux is heated and molten, the separation of the target material and the back tube is realized, and the solder can be effectively recycled; the device is simple in structure and simple and convenient to use, the temperature is controllable in the desoldering process, the desoldering efficiency is high, and the device is especially suitable for off-welding separation of tubular target materials.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

BGA rework station provided with adjustable air outlet

ActiveCN108235589AAvoidance of circumstancesShorten desoldering timePrinted circuit secondary treatmentImpellerPulp and paper industry

The invention discloses a BGA rework station provided with an adjustable air outlet and relates to the field of integrated circuit maintenance equipment. The BGA rework station comprises the air outlet formed at a hot air nozzle, the hot air nozzle is sleeved with an adjusting case, and an opening with the size smaller than that of the air outlet is formed in the adjusting case; a rotary shaft isrotationally connected in the hot air nozzle, a first impeller is fixedly connected onto the rotary shaft, and two ends of the rotary shaft extend into the adjusting case; two ends of the rotary shaftare sleeved with centrifugal fans, each centrifugal fan comprises a suction port and an output port, a through hole is also formed in one side, where the opening is formed, of the adjusting case, anair outlet is formed in one side, away from the opening, of the adjusting case, a delivery pipeline and an exhaust pipeline are arranged in the adjusting case, the through hole and the suction port are communicated through the delivery pipeline, and the output port and the air outlet are communicated with the exhaust pipeline. The problems that the size of air outlets of existing BGA rework station cannot be adjusted and air blown out by the air outlets diffuse all around to affect BGA chips not needing desoldering are solved, and the BGA rework station is mainly applied to dismounting and welding in the BGA chip rework process.

Owner:重庆川乾科技有限公司

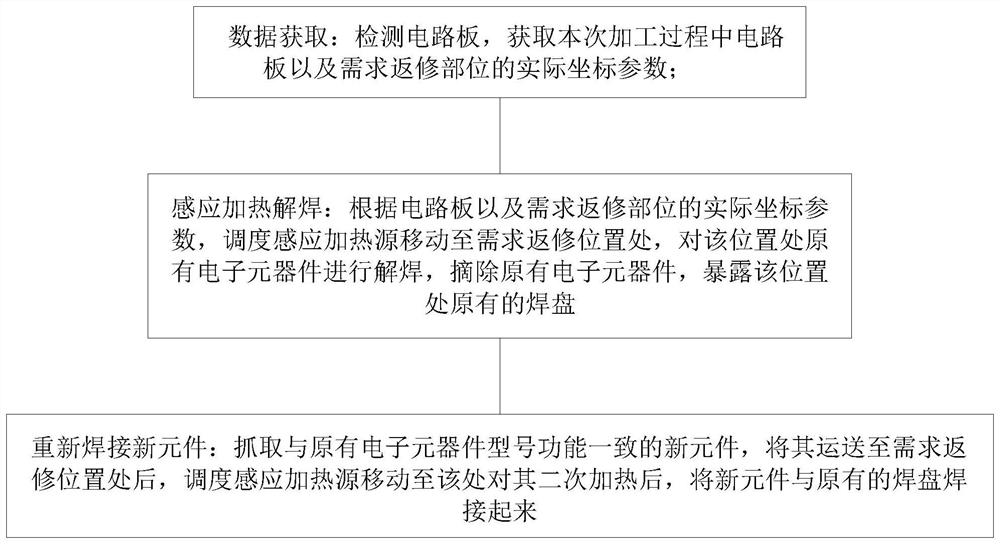

Circuit board repairing method based on movable induction heating

PendingCN114515880AImprove rework efficiencyFlexible processingIncreasing energy efficiencyHeating appliancesData acquisitionProcess engineering

The invention discloses a movable heating circuit board repair method, which comprises the steps of S1, data acquisition, S2, induction heating desoldering, S3, new element resoldering and the like. The movable heating circuit board repair method has the advantages of being flexible in machining, high in repair efficiency, high in repair success rate, wide in machining coverage, high in adaptability, sufficient in heat, high in heat source controllability, capable of meeting the desoldering or welding requirements of elements in a wide size range, capable of well achieving the expected heating effect, accurate in positioning, high in repair efficiency, high in repair efficiency, high in repair success rate and high in heat source controllability. And the work is stable.

Owner:广东粤灿半导体设备有限公司

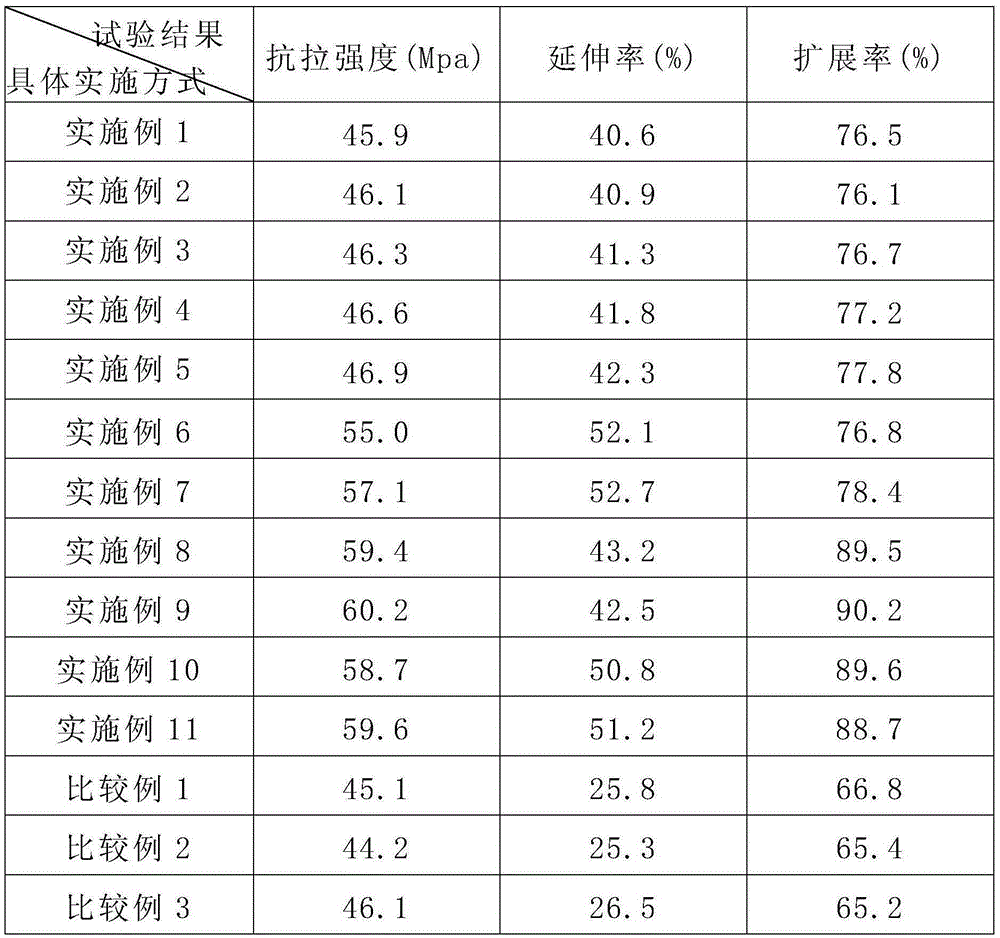

Antioxidant tin-copper alloy brazing filler metal

ActiveCN105290642APrevent oxidation and corrosionImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaSlagSoldering

The invention relates to an antioxidant tin-copper alloy brazing filler metal, belongs to the technical field of welding materials, solves the problems about how to reduce the output of welding slag and improve the oxidation resistance of the brazing filler metal, and provides the antioxidant tin-copper alloy brazing filler metal. The alloy brazing filler metal comprises the following components by mass percent: 0%-1.0% of Ag, 0.1%-1.0% of Cu, 0.01%-3.0% of an antioxidant welding-aiding material, and the balance of Sn and unavoidable impurity elements. According to the antioxidant tin-copper alloy brazing filler metal, the antioxidative protective function can be improved, the air and the environment are prevented from oxidizing and corroding the brazing filler metal, the oxidization resistance of the brazing filler metal is improved, the welding performance is improved, the weldability is improved, and the reject ratio of pseudo soldering and desoldering is decreased, so that the welding slag and oxidizing slag are reduced, the product is enabled to have relatively good mechanical performance, and the tensile strength, electrical conductivity, weldability and elongation are improved.

Owner:上海一远电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com