Reducing integrated connecting pipe

A technology of connecting pipes and diameter reduction, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc. It can solve the problems of increased noise, weak rigidity, and many solder joints of the evaporator, and achieves reduced desoldering, good rigidity, and Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

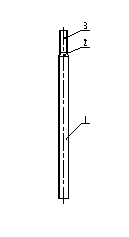

[0012] The reduced-diameter integrated connecting pipe shown in the accompanying drawing has its main body as an elongated hollow metal pipe 1, and a connecting pipe 3 is provided at the end of the elongated hollow metal pipe 1. In this embodiment, the connecting pipe 3 is made of elongated and hollow The metal tube 1 is formed by reducing the diameter of the tube end, and its outer diameter is slightly smaller than the inner diameter of the elongated hollow metal tube 1 , and is connected with the elongated hollow metal tube 1 by a transition pipe 2 .

[0013] When the present invention is used for connecting the inlet and outlet pipes of each evaporator, the pipe ends of the inlet and outlet pipes of two adjacent evaporators are respectively fixedly connected with the elongated hollow metal tube 1 of the present invention, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com