Chip apparent defect detection method

A defect detection and appearance technology, applied in measuring devices, image data processing, instruments, etc., can solve problems such as false detection, high work intensity, and limitation of SOP chip accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

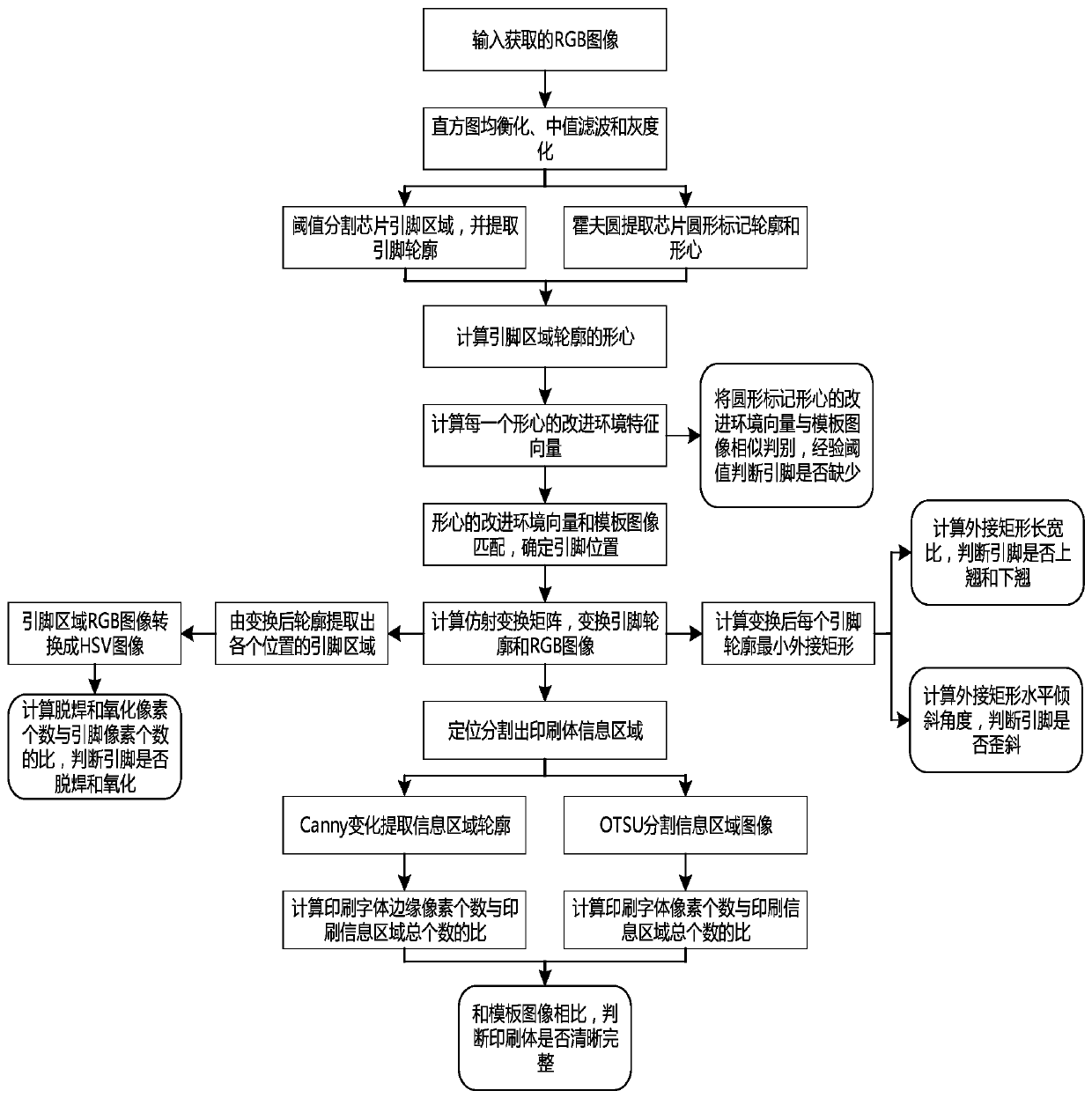

[0097] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

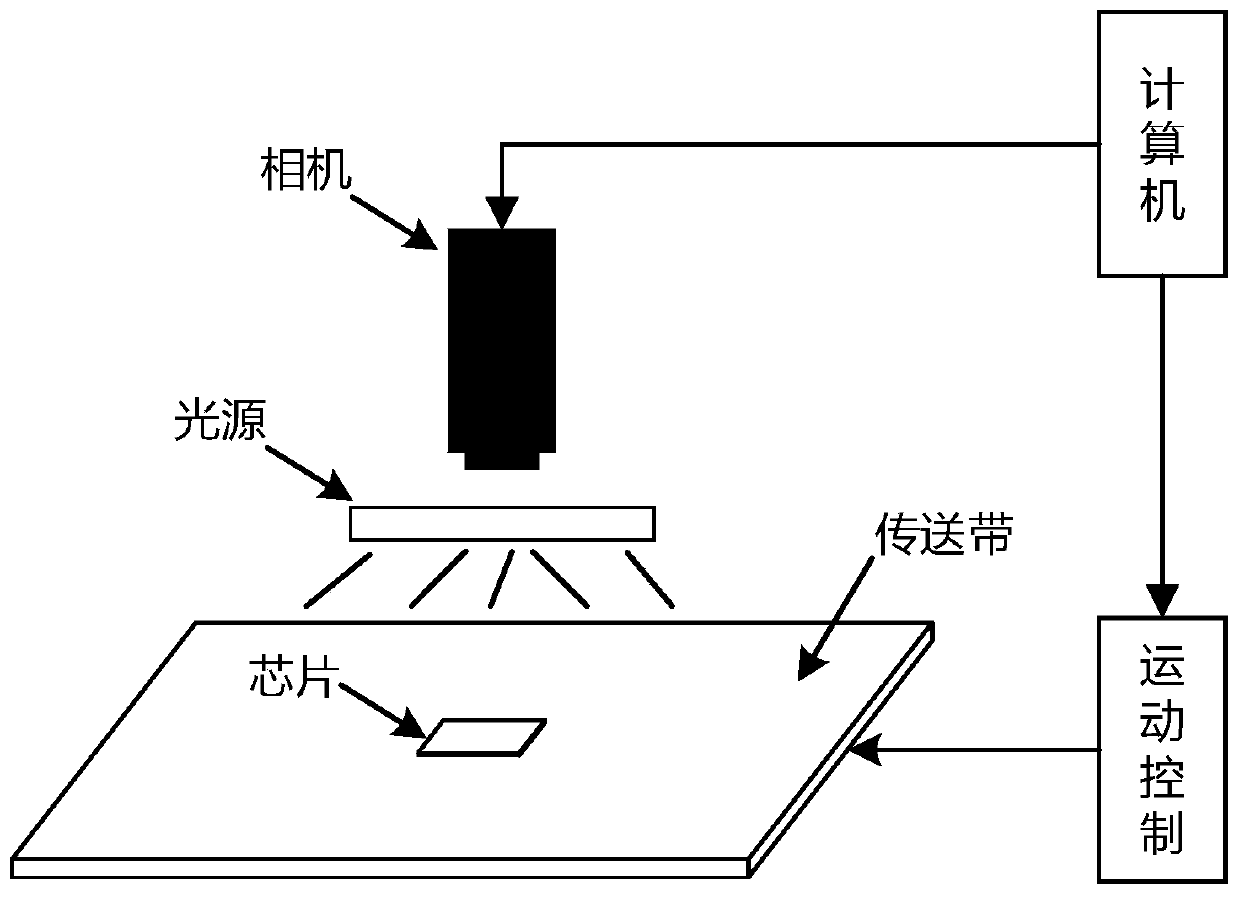

[0098] figure 2 It is a schematic diagram of the hardware structure of the SOP chip defect detection system of the present invention. Before detection, an industrial color CCD camera and light source should be installed above the target chip. The computer controls the camera to shoot and the conveyor belt to move. When the chip moves to the bottom of the camera, the chip is photographed. During the detection, it is required that there is no object interference around the chip, the background of the conveyor belt is black, and at the same time, the light is sufficient, the circular mark is clearly illuminated, the pin brightness is relatively high, and the camera resolution is clear enough.

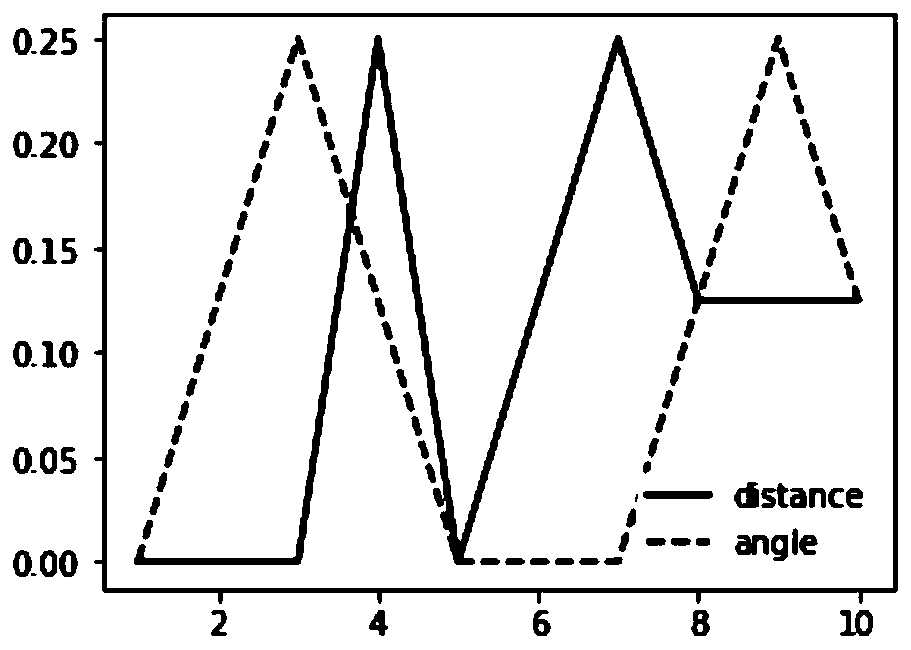

[0099] image 3 A modified environment vector representing a circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com