Tube target desoldering device and using method thereof

A desoldering and tube target technology, applied in welding equipment, ion implantation plating, coating, etc., can solve the problems of high pressure, long process time, low heating efficiency, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

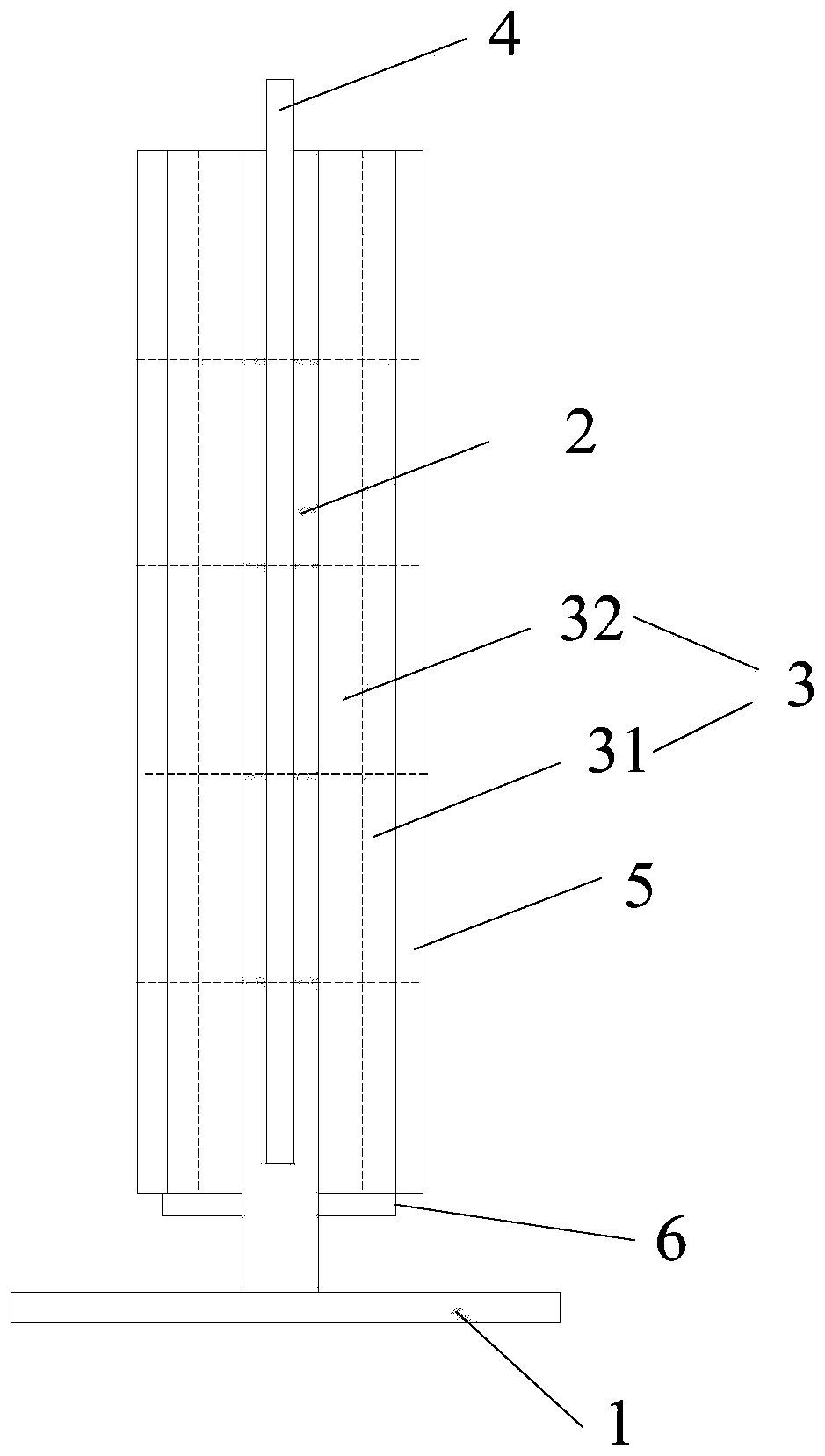

[0056] This embodiment provides a tube target desoldering device, the structure schematic diagram of the device is as follows figure 1 As shown, it includes a desoldering station and a heating assembly, the desoldering station includes a desoldering base plate 1 and a hollow tube 2 vertically fixed on the desoldering base plate 1, and the tube target 3 to be desoldered is set on the outside of the hollow tube 2; The heating assembly includes a heating rod 4 and at least one heating ring 5 , the heating rod 4 is arranged inside the hollow tube 2 , and the heating ring 5 is sleeved on the outside of the tube target 3 to be desoldered sequentially from bottom to top.

[0057] A circular ring 6 is provided on the outside of the lower part of the hollow tube 2 , and there is a gap between the circular ring 6 and the desoldering bottom plate 1 ; the bottom of the tube target 3 to be desoldered is in direct contact with the circular ring 6 .

[0058] The materials of the desoldering ...

Embodiment 2

[0064] This embodiment provides a tube target desoldering device, the device includes a desoldering station and a heating assembly, the desoldering station includes a desoldering base plate 1 and a hollow tube 2 vertically fixed on the desoldering base plate 1, to be The desoldering tube target 3 is set on the outside of the hollow tube 2; the heating assembly includes a heating rod 4 and at least one heating ring 5, the heating rod 4 is arranged inside the hollow tube 2, and the heating ring 5 is sequentially arranged from bottom to top Set on the outside of the pipe target 3 to be desoldered.

[0065] A circular ring 6 is provided on the outside of the lower part of the hollow tube 2 , and there is a gap between the circular ring 6 and the desoldering bottom plate 1 ; the bottom of the tube target 3 to be desoldered is in direct contact with the circular ring 6 .

[0066] The materials of the desoldering bottom plate 1 and the hollow tube 2 are stainless steel, and the mater...

Embodiment 3

[0072] This embodiment provides a tube target de-soldering device, the structure of the device refers to the structure in Example 1, the only difference is: the device does not include the ring 6, that is, the bottom of the tube target 3 to be de-soldered and the de-soldered The base plate 1 is in direct contact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com