LED (Light Emitting Diode) lamp filament without bonding wire

A technology of LED filament and no welding wire, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of LED filament luminescence and insufficient heat dissipation, so as to improve packaging reliability and production yield, reduce costs, The effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

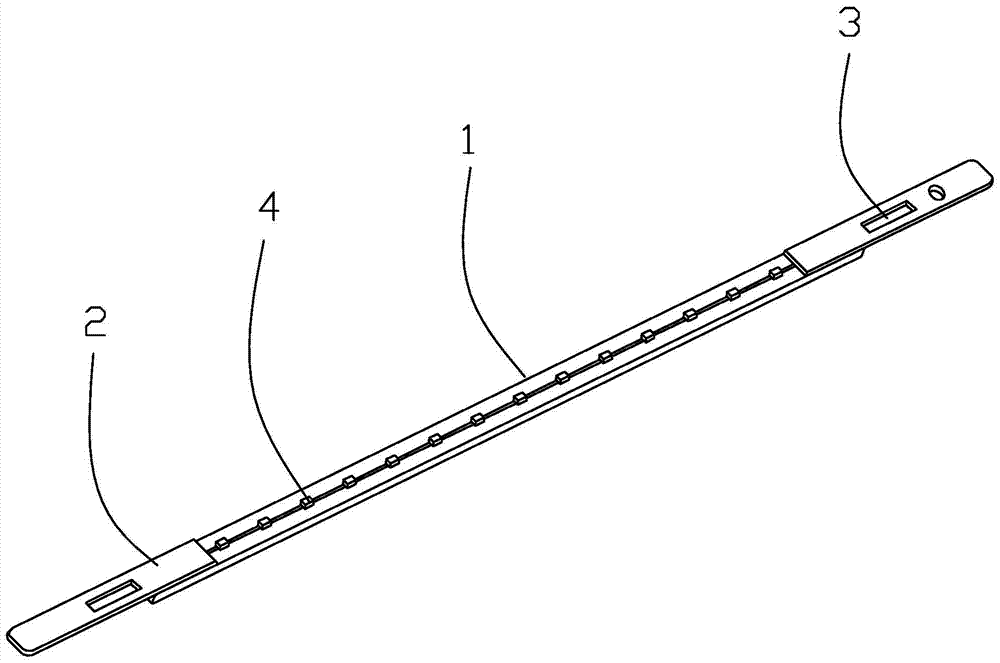

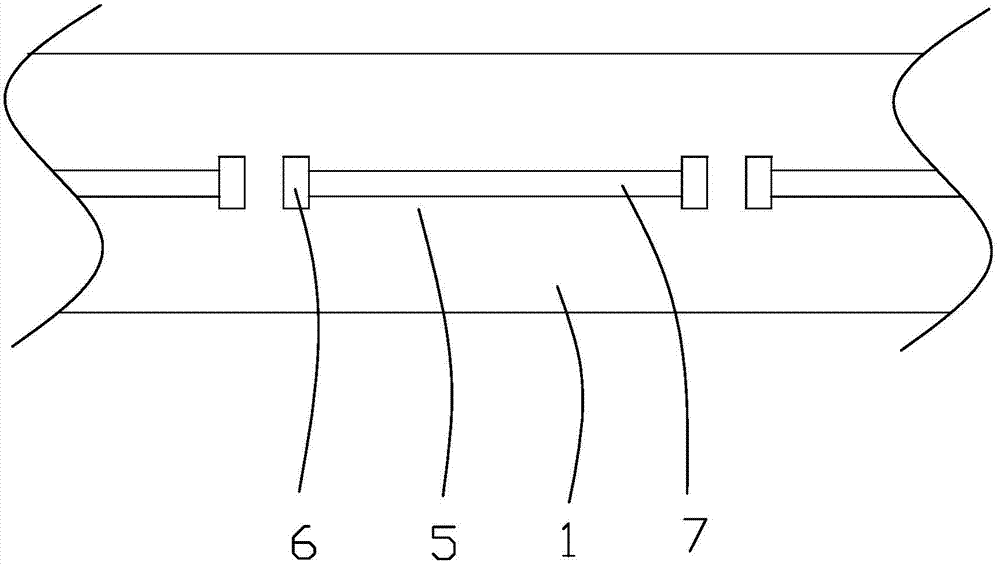

[0022] In this embodiment, a wire-free LED filament, such as figure 1 As shown, including a substrate 1, a circuit is arranged on the surface of the substrate. The circuit is composed of a number of connecting circuits 5. The connecting circuit includes two electric silver layers 6. The electric silver layers are made by sintering with a thick film process, and the electric silver layers are passed through The conductive circuit 7 is connected, and the conductive circuit is made of transparent conductive material or conductive paste. The connection circuits are disconnected from each other and are not connected to each other. The LED chip is connected to the adjacent connection circuit. The LED chip adopts a flip chip. The conductive silver layer is connected.

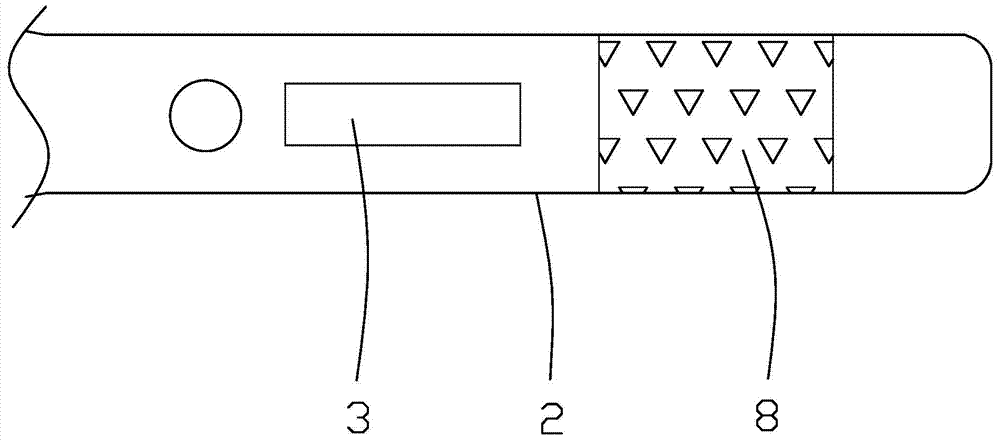

[0023] Both ends of the substrate are bonded with metal sheets, such as figure 1 and image 3 As shown, a roughened area 8 is provided on the surface of the metal sheet close to the rear end, and the roughened area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com