Patents

Literature

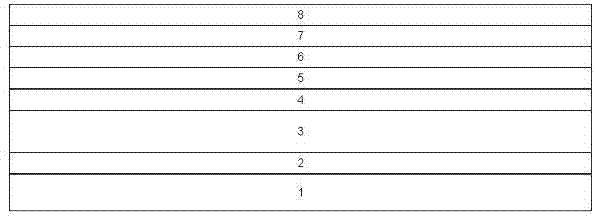

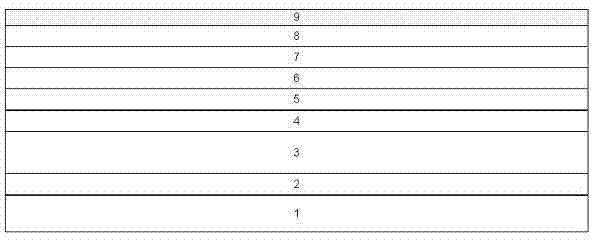

111results about How to "Avoid desoldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

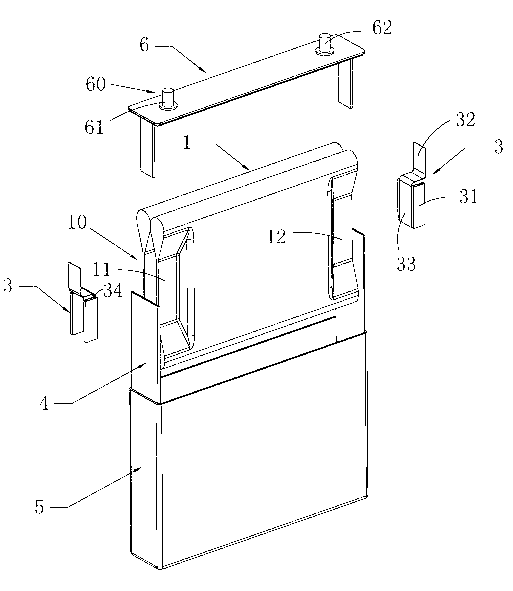

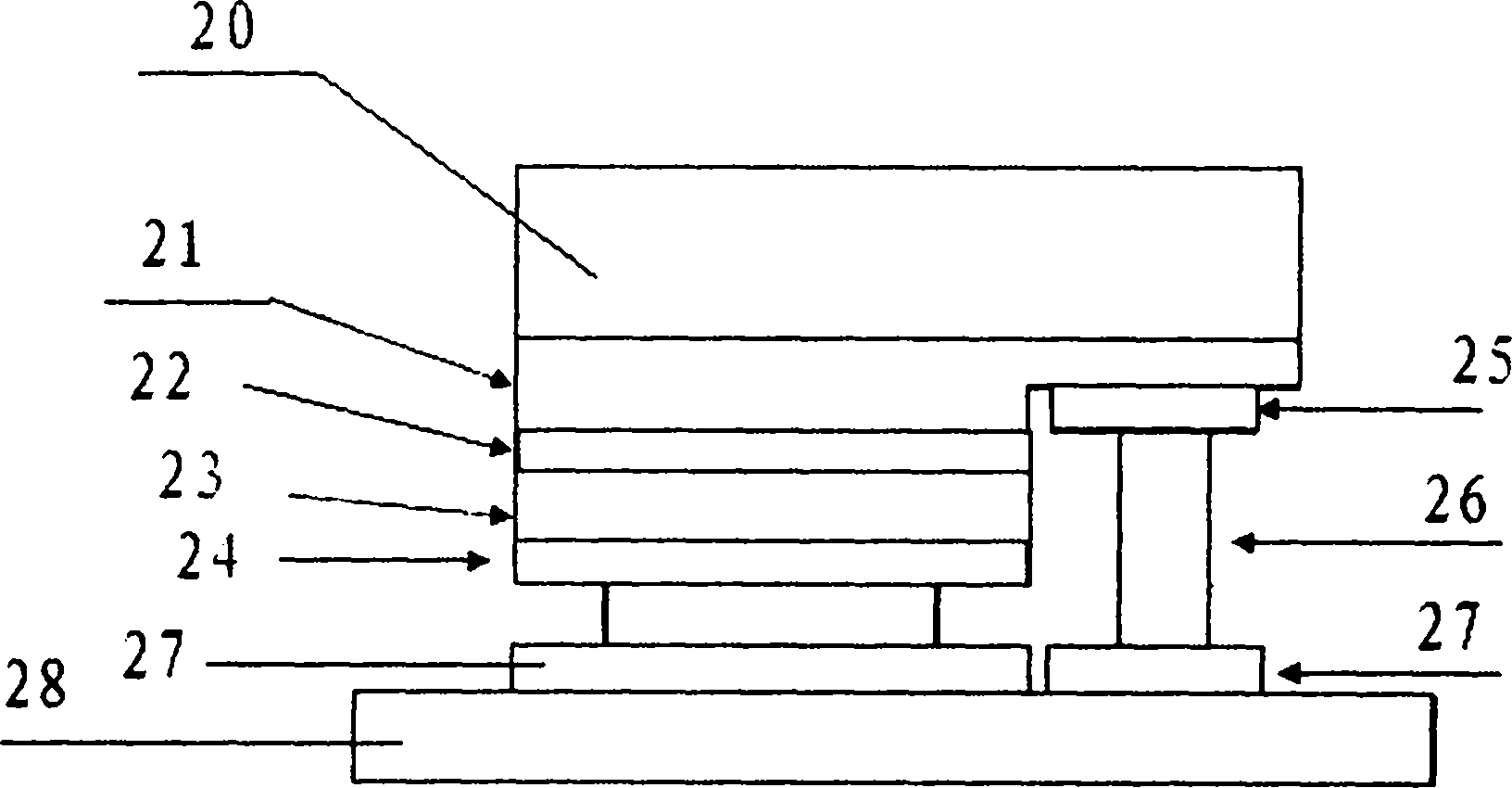

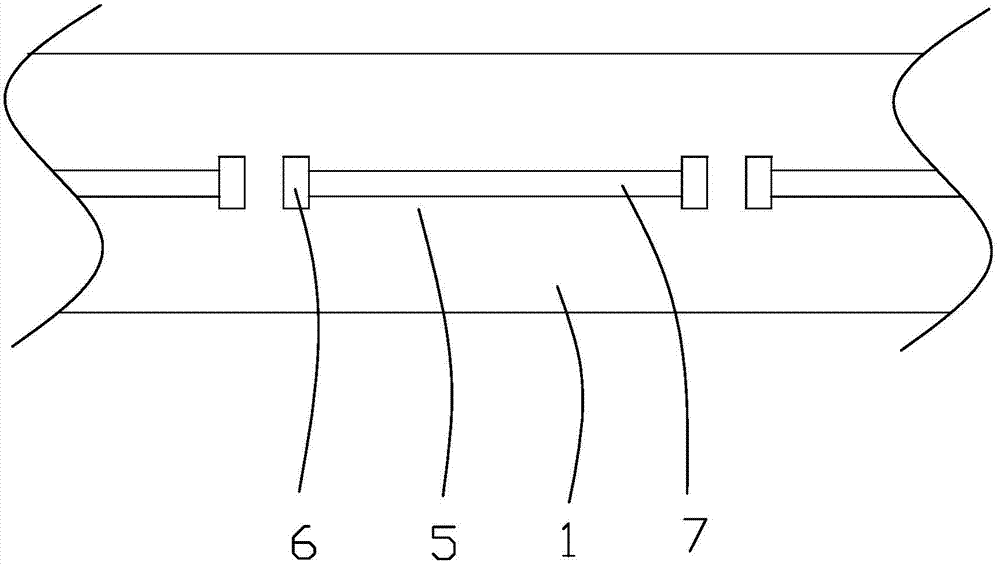

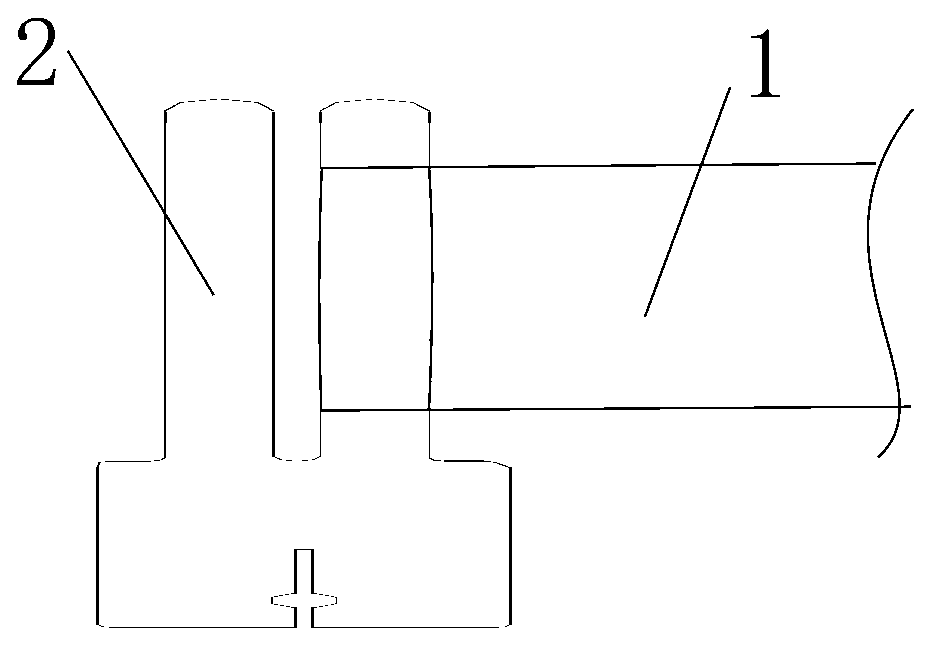

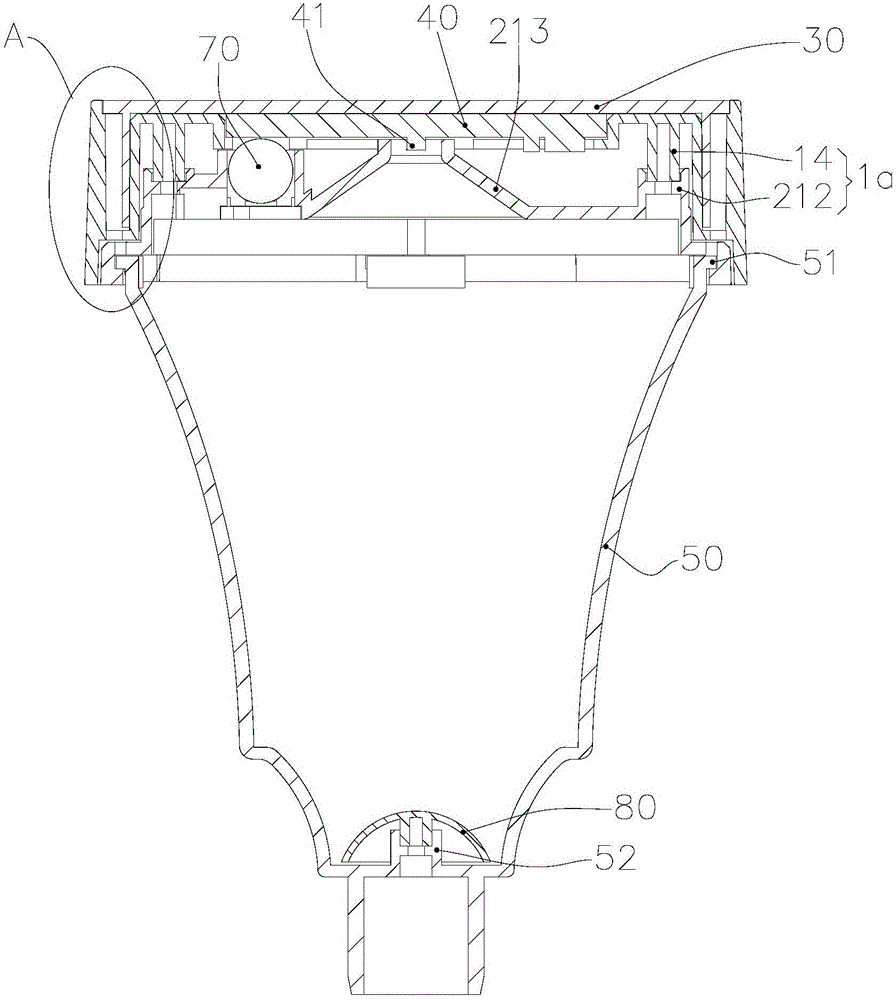

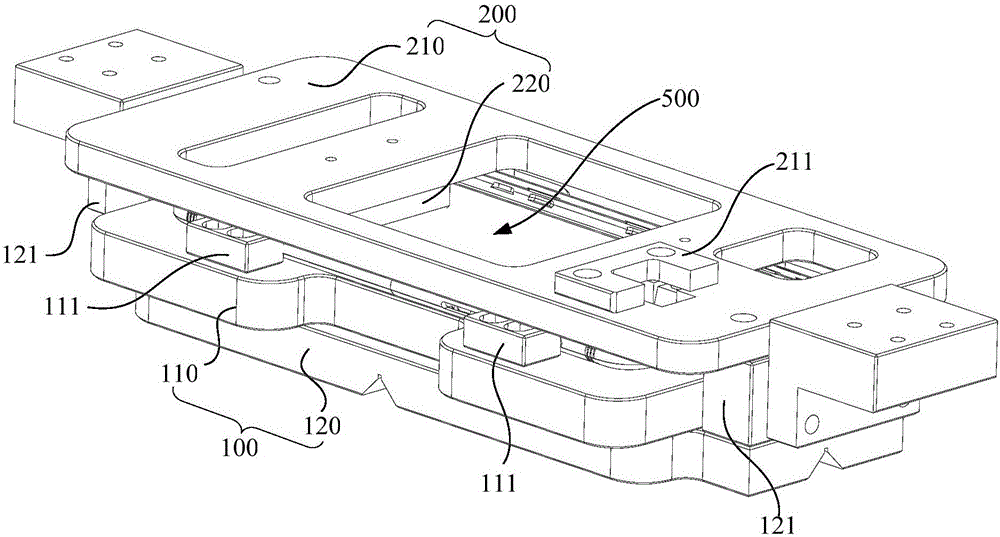

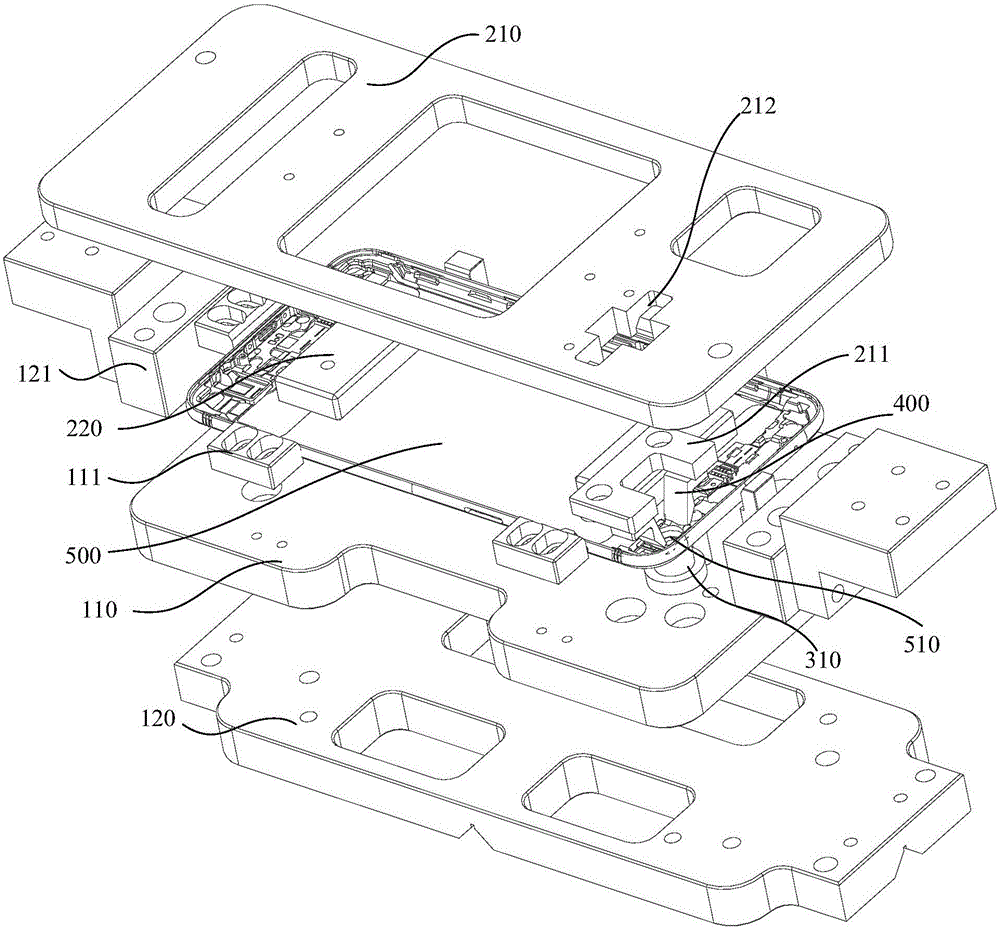

MIC sound guiding path structure and mobile terminal

InactiveCN105611011AAvoid desolderingSolve the problem of sound leakage through gapsTelephone set constructionsComputer terminalEngineering

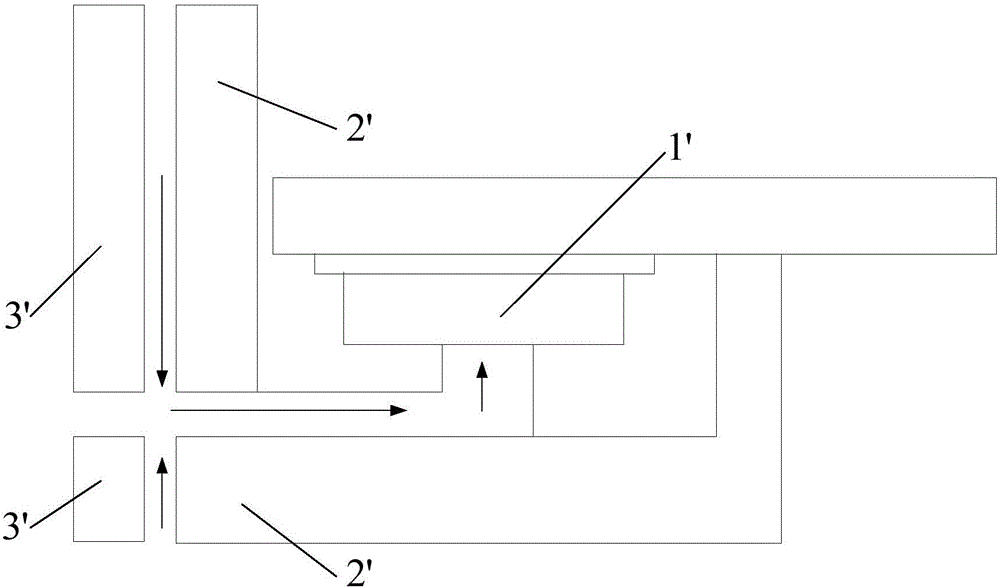

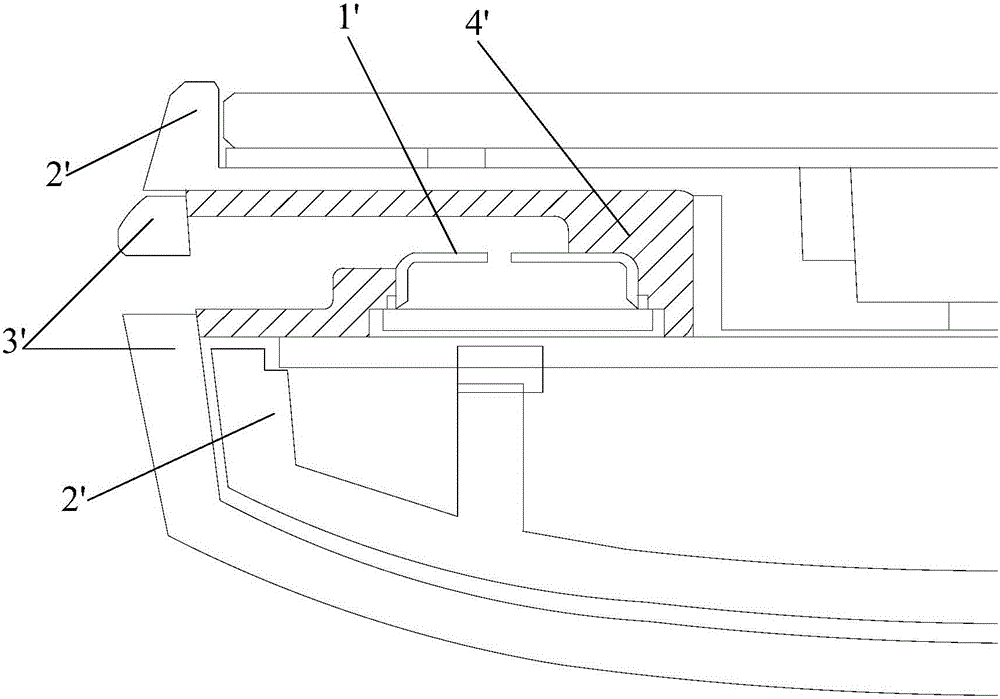

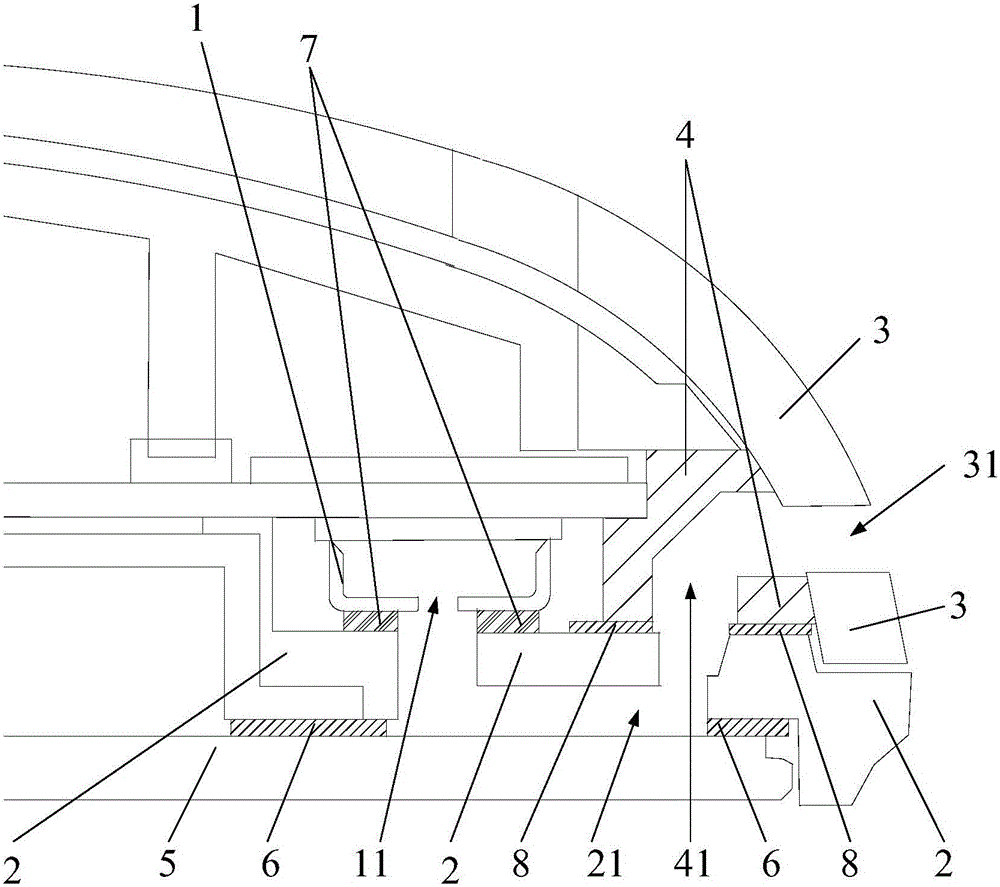

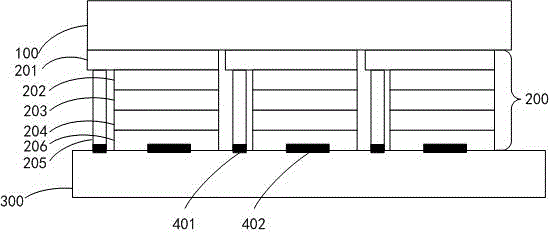

The invention provides an MIC sound guiding path structure and a mobile terminal. The MIC sound guiding path structure comprises a MIC device, a shell body, a battery cover and an independent rubber sleeve, wherein the MIC device comprises a working hole; a sound guiding channel is formed in the interior of the shell body, an outlet of the sound guiding channel is communicated with the working hole, and the shell body is in sealed connection with the MIC device; the battery cover is matched and connected with the shell body, and a sound inlet hole is formed in the battery cover; and a sound guiding through hole is formed in the interior of the independent rubber sleeve, a first end of the sound guiding through hole is communicated with the sound inlet hole, the independent rubber sleeve and the battery cover are sealed through extrusion interference, a second end of the sound guiding through hole is communicated with an inlet of the sound guiding channel, and the independent rubber sleeve is in sealed connection with the shell body. The MIC sound guiding path structure improves the sealing reliability of the MIC sound guiding path, and can avoid the problem of desoldering of the MIC device because the MIC device is impacted by the rubber sleeve.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Method for manufacturing inverted LED chip

InactiveCN102403425AImprove packaging yieldAvoid WeldingSemiconductor devicesOhmic contactLight reflection

Owner:俞国宏

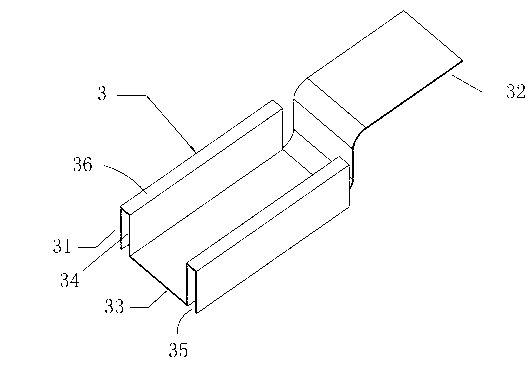

Electrical connector and cell

InactiveCN103296241AReasonable structureSmall footprintCell component detailsLaser beam welding apparatusElectricityElectrical battery

The invention provides an electrical connector comprising at least two accommodating parts which are used to respectively accommodate at least two electrode pole ears of two curled pole cores which are adjacent; an extension which is used to connect to an electrode terminal on a cover plate; and an interconnecting piece which is used to connect the accommodating parts with the extension. The invention also provides a cell with the electrical connector. The electrical connector of the invention is reasonable in structure, and can be used for accommodating more than two curled pole cores via laser welding, so that the occupied space by the electrical connector is reduced, the welding difficulty of electrical connector to the curled pole cores and the cover plate is reduced, and unsoldering and pseudo soldering can be avoided. The electrical connector is beneficial for the integral structure setting of the cell, and enables the volume energy density of the cell to be increased.

Owner:SHENZHEN BYD LITHIUM BATTERY

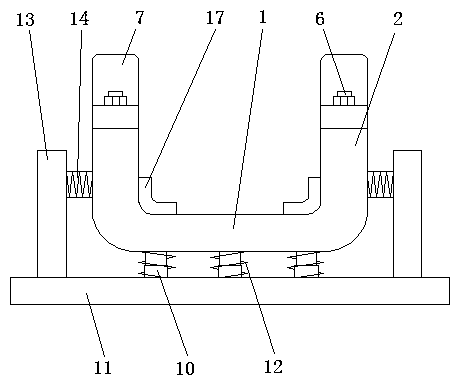

Semi-independent rear suspension of automobile torsion beam

InactiveCN103121384AGuaranteed lifeEasy for shot blastingResilient suspensionsTrailing armEngineering

A semi-independent rear suspension of an automobile torsion beam is in a detachable structure. The semi-independent rear suspension of the automobile torsion beam comprises a torsion beam welded part, a torsion bar welded part and a torsion bar stabilizer, wherein the torsion beam welded part is composed of a trailing arm, a wheel hub support, a spring seat, a horizontal beam and a horizontal beam reinforcing plate, wherein the trailing arm, the wheel hub support, the spring seat, the horizontal beam and the horizontal beam reinforcing plate are welded into one integrated structure. Welded nuts are arranged on the horizontal beam reinforcing plate. The torsion bar welded part comprises a torsion bar, torsion bar supports at two ends of the torsion bar and two cushion discs placed at the middle portion of the torsion bar, wherein the torsion bar, the torsion bar supports and the two cushion discs placed at the middle portion of the torsion bar are connected into one whole through a welding method and two welding nuts are arranged on each torsion bar support. One side of the torsion bar stabilizer is provided with an opening, and the torsion bar stabilizer is clamped between the two cushion discs at the middle portion of the torsion bar through the opening. The torsion bar stabilizer can not move left and right. The torsion bar welded part provided with the torsion bar stabilizer in an assembled mode is installed on the horizontal beam of the torsion beam welded part in a matched mode through the two bolts placed on each torsion bar support and one bolt is installed on the horizontal beam reinforcing plate in a matched mode. The semi-independent rear suspension of the torsion beam is dismountable, so that adjustment of the performance of the torsion beam and the replacement of the quick-wear torsion bar are benefited.

Owner:柳州孔辉汽车科技有限公司

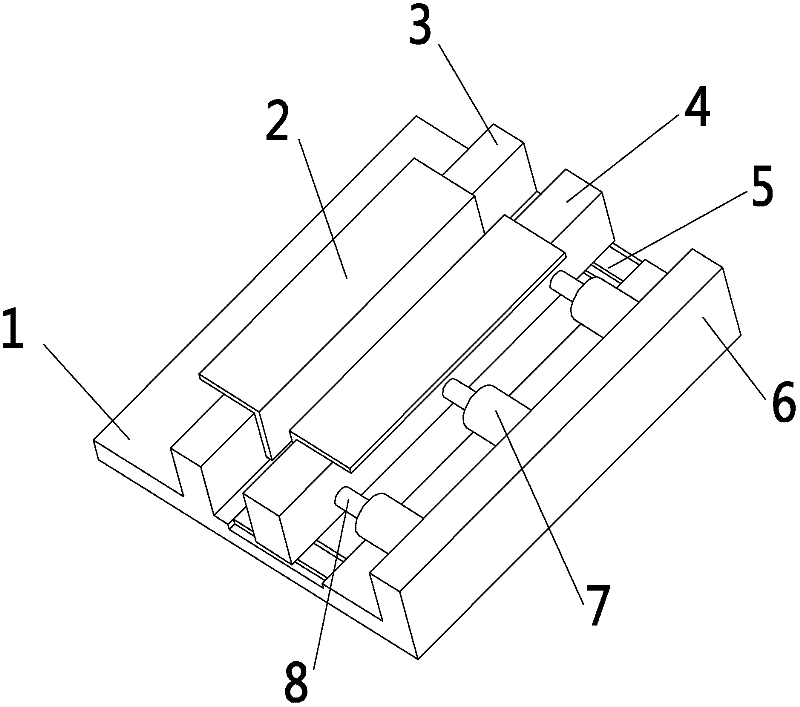

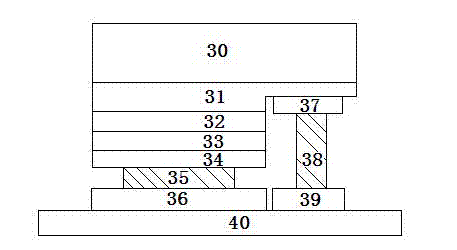

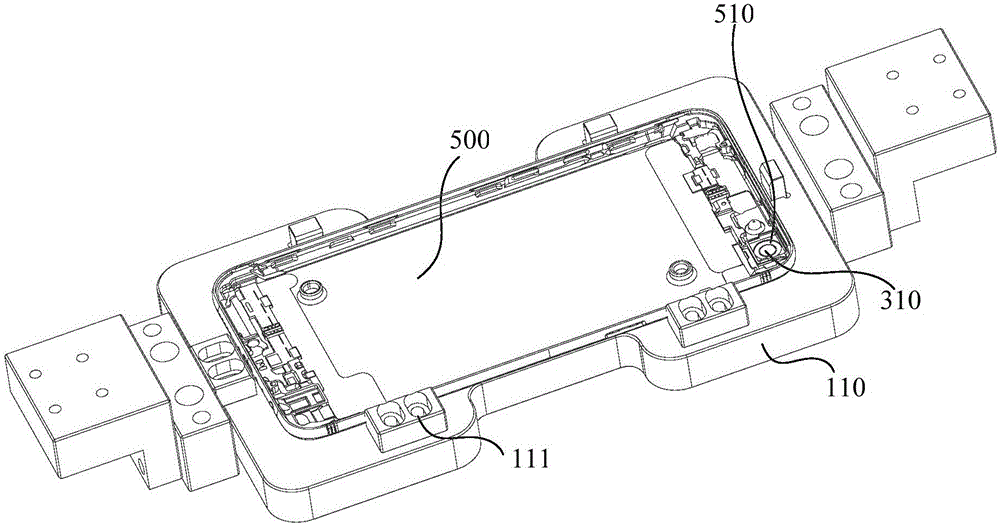

Angle steel welding fixture

InactiveCN102642105AAvoid desolderingGuaranteed service lifeWelding/cutting auxillary devicesAuxillary welding devicesMachining vibrationsArchitectural engineering

The invention discloses an angle steel welding fixture. The fixture comprises a base, a fixing plate and cylinders, wherein the base is an oblong plate; a positioning plate and a baffle are fixed above the base; the positioning plate is arranged at the front end of the base; the baffle is arranged at the rear end of the base; the fixing plate is arranged between the positioning plate and the baffle and can move back and forth on the base; the cylinders are fixed on the base and are arranged between the fixing plate and the baffle; the rear ends of the cylinder bodies are fixed on the baffle; and piston rods of the cylinders are fixedly connected with the fixing plate. When used for welding, the fixture has the following advantages: the angle steel is firmly welded, welding is convenient and fast to operate, the welding efficiency and quality are improved, the welded angle steel is prevented from sealing off due to machine vibration and the service life of the welded angle steel is ensured.

Owner:SUZHOU TANGFENG ELECTRICAL APPLIANCE

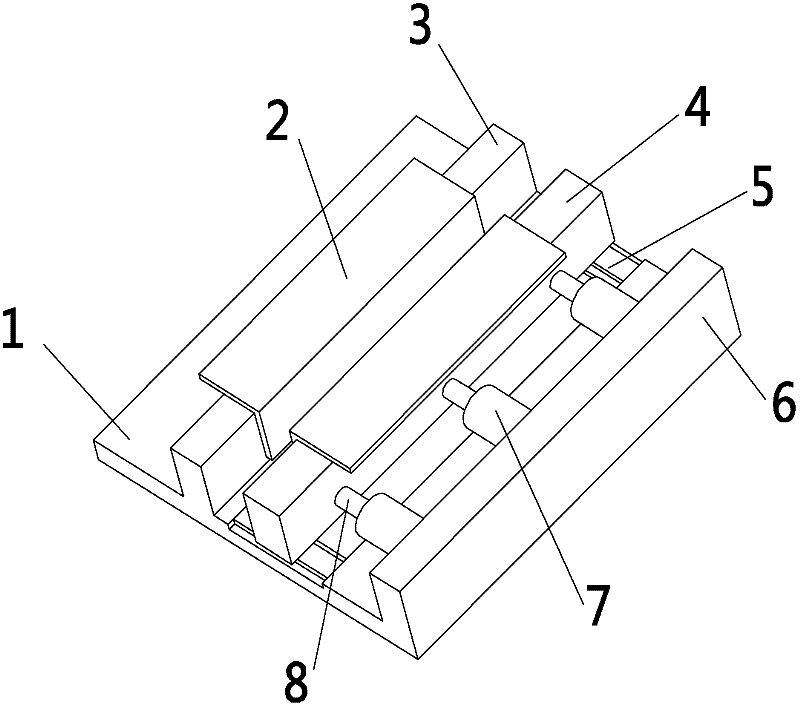

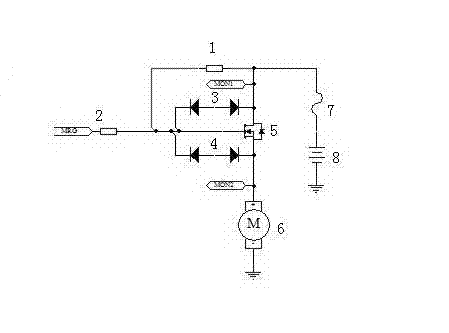

Direct current motor control circuit with heat protection function

InactiveCN103208780AAvoid smokingAvoid desolderingEmergency protective circuit arrangementsMOSFETSpontaneous combustion

The invention belongs to the field of direct current motor control and discloses a motor control circuit for preventing failure in a heat event in the working process of a direct current motor. In order to realize the function, the invention adopts the technical scheme that an intelligent voltage limiting module is additionally arranged on a gate and a drain of a metal oxide semiconductor field effect transistor (MOSFET) of a control loop; and if the gate and the drain are short-circuited, the intelligent voltage limiting module is started to limit voltage between the gate and a source to be smaller than starting voltage, so that an MOSFET is cut off even under the working condition, the phenomenon of spontaneous combustion caused by hot stack can be effectively avoided, and the reliability and safety of a direct current motor control circuit are ensured.

Owner:思与行科技(苏州)有限公司

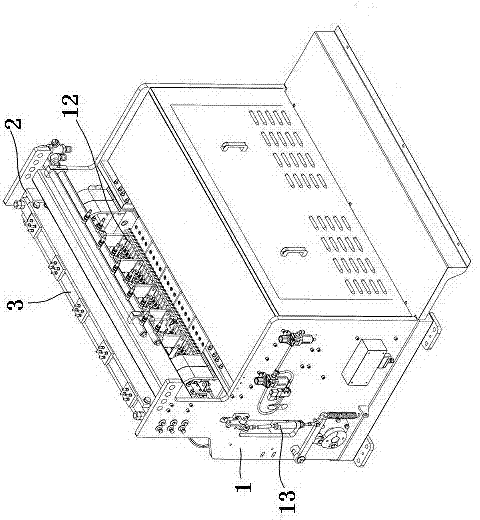

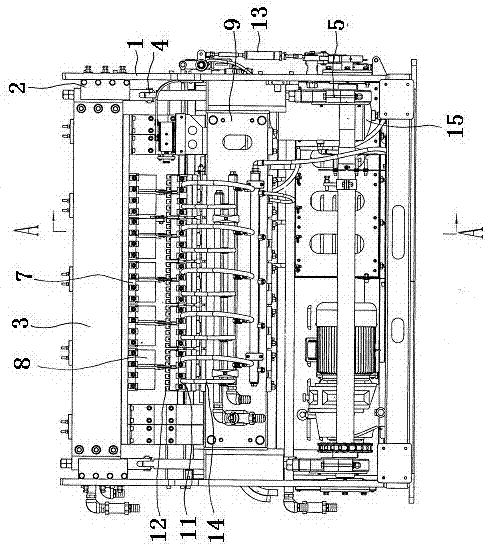

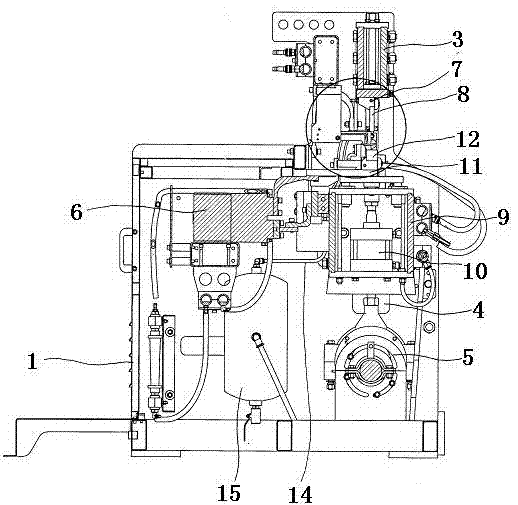

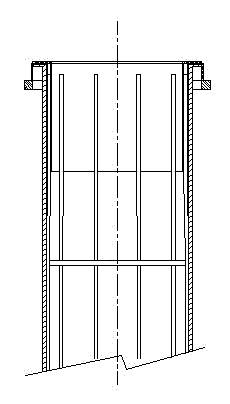

Benchmark mesh welding device for goods-shelf mesh and welding method thereof

The invention belongs to the technical field of wire mesh welding machines and welding methods, and discloses a benchmark mesh welding device for goods-shelf mesh and a welding method thereof. The benchmark mesh welding device for goods-shelf mesh is mainly and technically characterized in that a machine frame is included; an upper beam slide is arranged above the machine frame, an upper beam is arranged in the upper beam slide, an eccentric mechanism with a connecting rod is arranged near and below the machine frame, and the upper end of the connecting rod of the eccentric mechanism is connected with the upper beam; an upper electrode holder communicating with a transformer is fixedly connected with the upper beam, plate type upper electrodes are arranged on the upper electrode holder, and a lower beam is fixed on the portion, located below the upper electrode holder, of the machine frame; and a plurality of elastic top pressure bodies are arranged transversely on the upper beam, a lower electrode holder communicating with the transformer is arranged above the elastic top pressure bodies, upper electrodes are fixed to the upper electrode holder, and a clapping and leveling mechanism is arranged on the outer side of the machine frame. In the welding process, the pressure between an organzine and a tram in each welding sport is almost equal, welding quality is high, and mesh flatness is good.

Owner:河北骄阳焊工有限公司

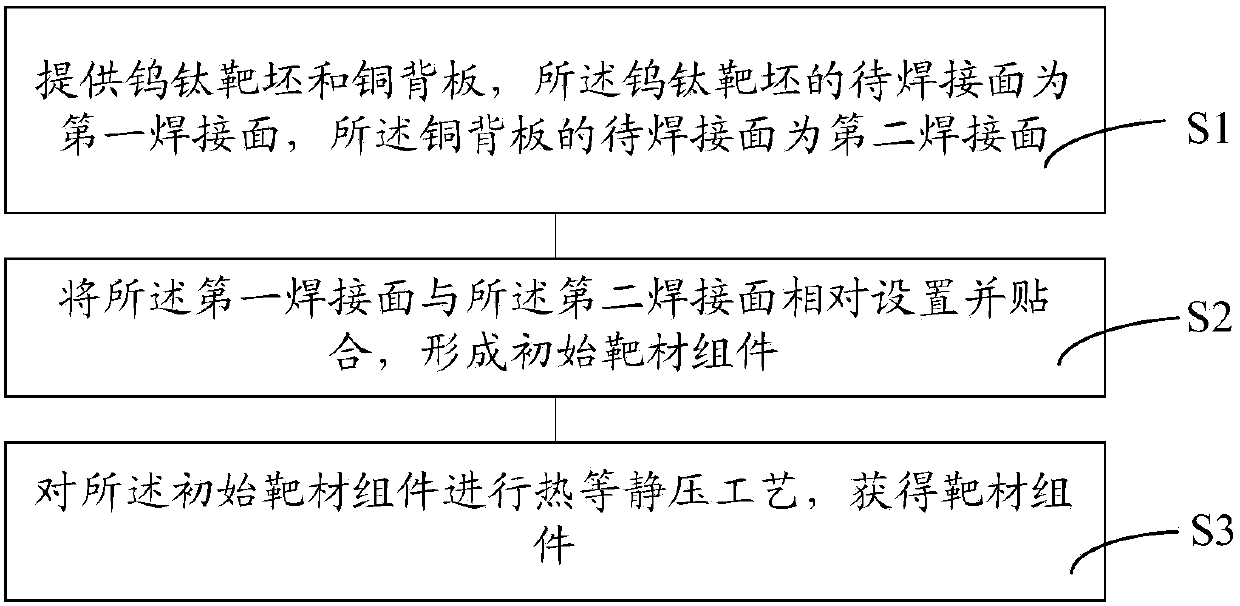

Manufacturing method of target module

InactiveCN107663631AAvoid desolderingRealize large area weldingVacuum evaporation coatingSputtering coatingTitaniumCopper

The invention provides a manufacturing method of a target module. The manufacturing method of the target module comprises the following steps: a tungsten titanium target blank and a copper back plateare provided, wherein a surface to be welded of the tungsten titanium target blank is a first welded surface, and a surface to be welded of the copper back plate is a second welded surface; the firstwelded surface and the second welded surface are oppositely arranged and bonded to form an initial target module; and a hot isostatic pressing process is performed on the initial target module to obtain the target module. As the hot isostatic pressing process is performed on the initial target module, large-area welding of the tungsten titanium target blank and the copper back plate can be realized, the bonding strength of the tungsten titanium target blank and the copper back plate can be improved, the formed target module can reach the welding bonding rate of above 99% and the welding strength of above 50 MPa, and desoldering of the target module in the use process can be prevented.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

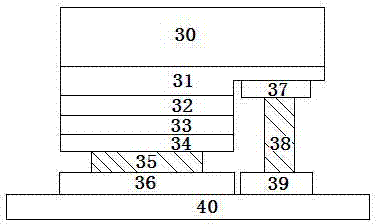

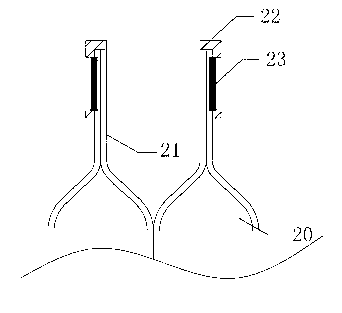

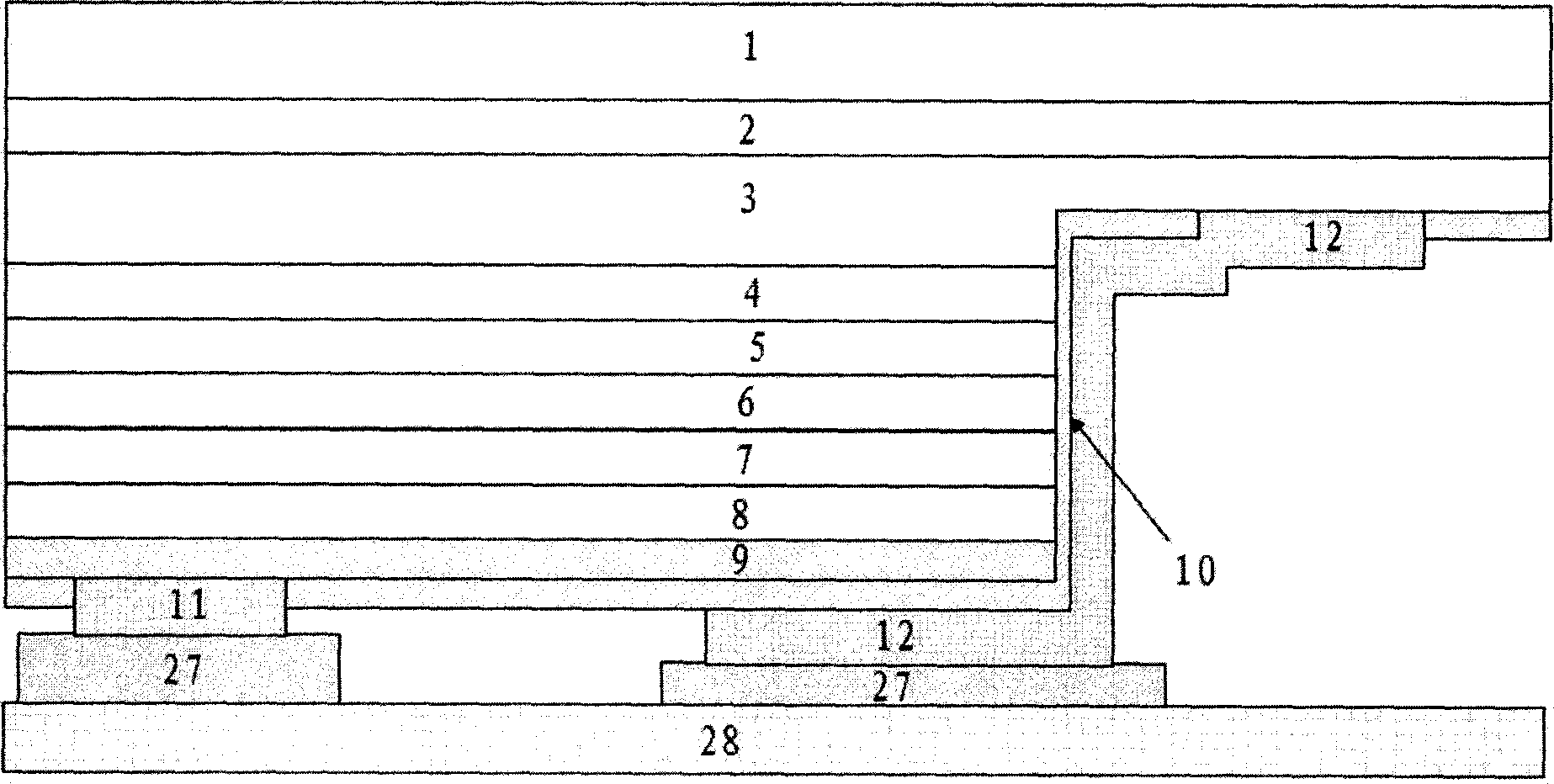

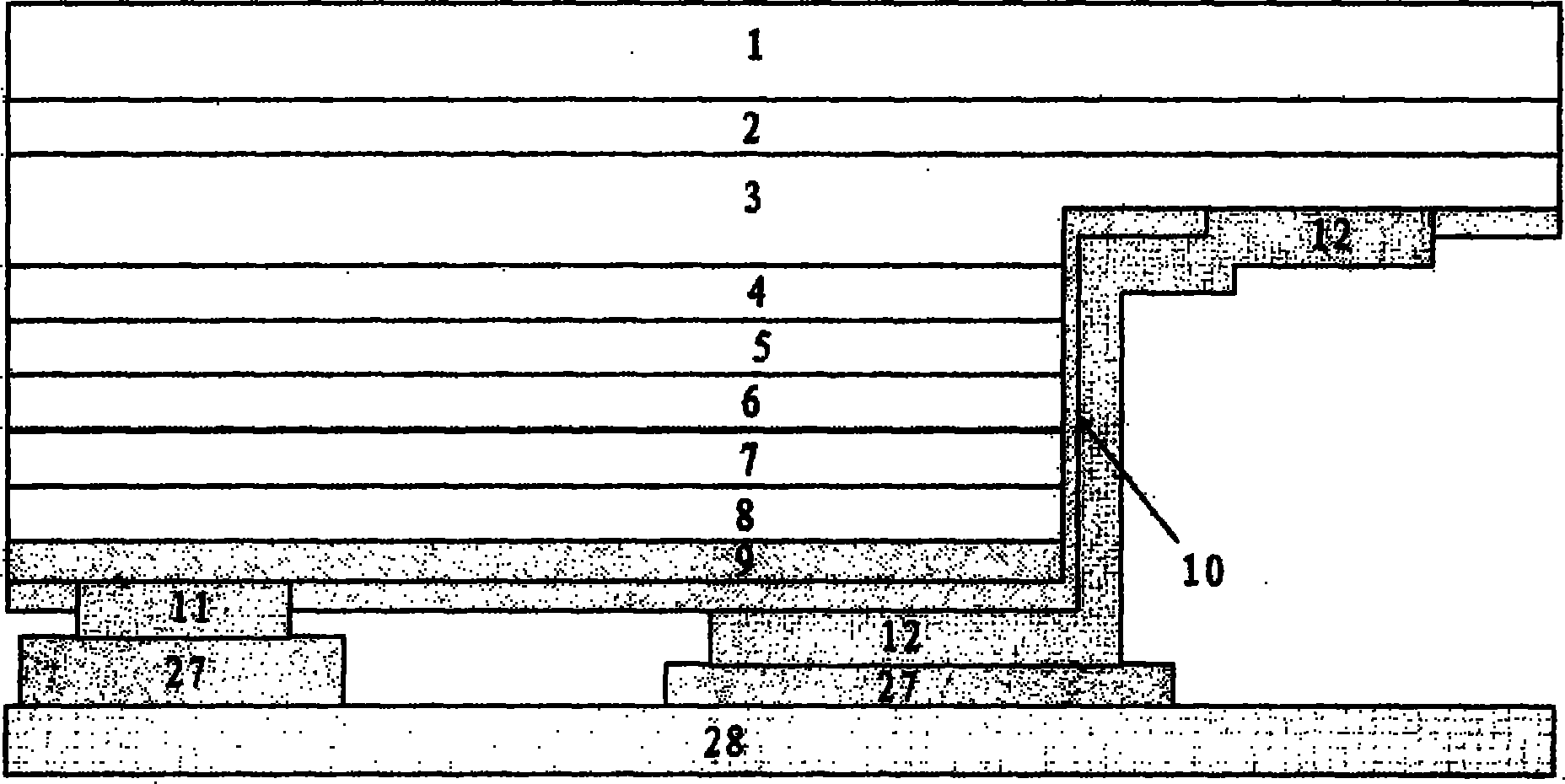

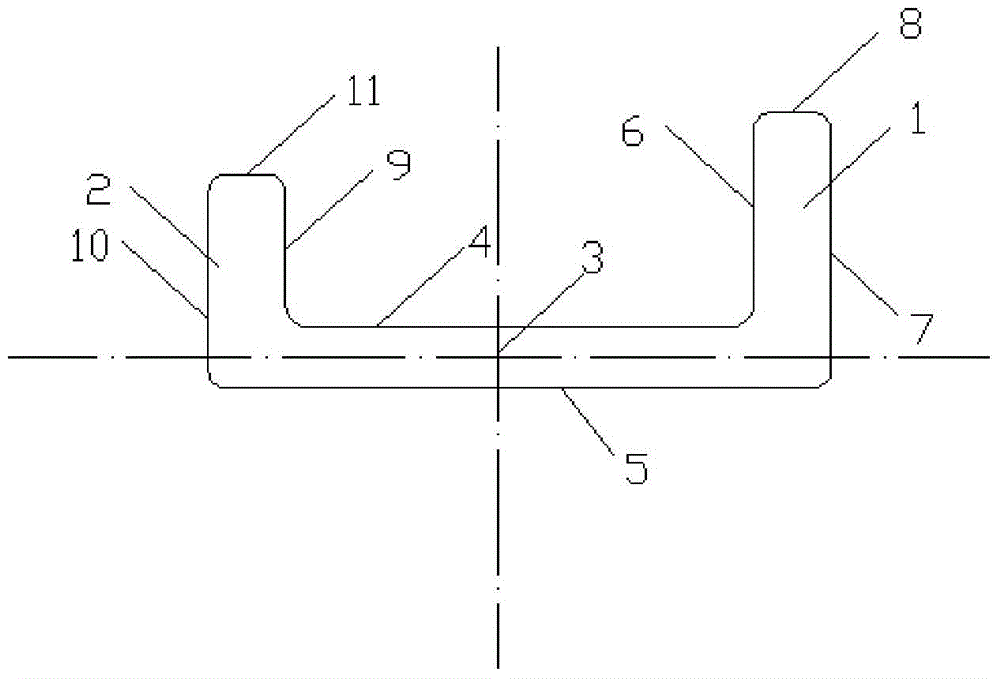

LED chip

The invention relates to an LED chip. The LED chip adopts the structure that an N-type electrode (22) adopts a staircase structure; the lower end of the N-type electrode (22) penetrates an insulating dielectric film (13) to be connected with an N-type layer (3); the middle part of the N-type electrode (22) is attached to the insulating dielectric film (13) at a vertical part; the upper end of the N-type electrode (22) is positioned above the insulating dielectric film (13) at the top, and extends towards the position of a P-type electrode (21); and the upper end of the N-type electrode (22) is connected with a second PCB board (23), and the N-type electrode (22) at the upper end and the P-type electrode (21) are provided with common soldering surfaces of which heights are equal or approximately equal. As the N-type electrode and the P-type electrode of the flip LED chip are provided with the common soldering surfaces of which heights are equal or approximately equal, the yield of packaging in the inverted-chip process of the LED chip is increased, and the phenomenon of inveracious soldering or desoldering of the electrode is avoided.

Owner:启东市天汾电动工具技术创新中心

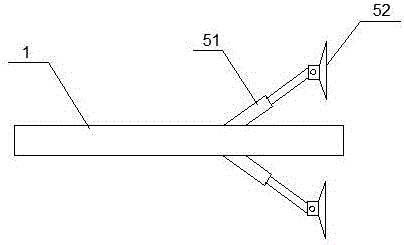

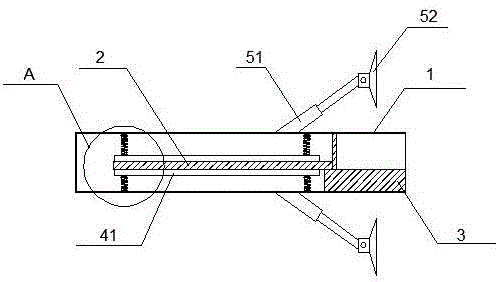

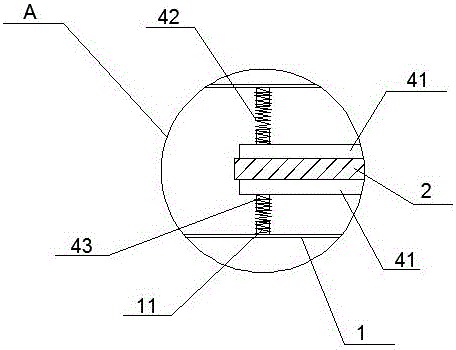

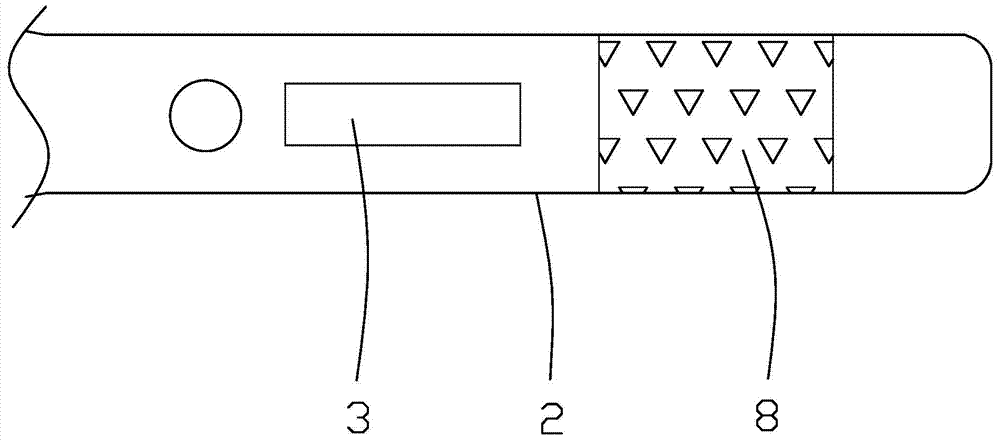

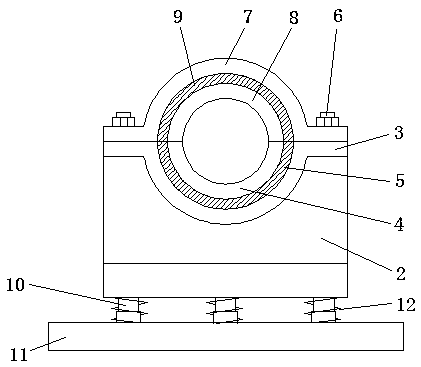

Vibration-damping anti-moving U disk

InactiveCN106295780AAvoid desolderingAvoid easily lost situationsRecord carriers used with machinesElastic vibrationEngineering

The invention relates to a vibration-damping anti-moving U disk including a casing, a chip, and a USB interface, the chip is welded to the USB interface, one end of the casing is open, the other end of the casing is closed, elastic vibration damping devices are symmetrically arranged on the upper and lower inner side surfaces of the casing, the chip is clamped between the two elastic vibration damping devices, the USB interface is arranged at the opening end of the casing, grooves are symmetrically arranged on the upper and lower inner side surfaces of the casing, and connecting rod sucker devices are rotationally arranged in the grooves. The vibration-damping anti-moving U disk is simple in structure and convenient to use, can effectively prevent the USB interface from unsoldering from the chip, alleviates the impact force, and protects the chip from being damaged.

Owner:WUHU ZHENHUA RONGKE INTELLIGENT TECH

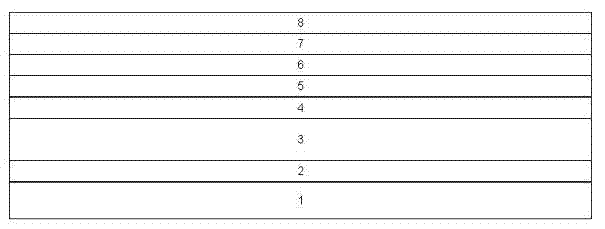

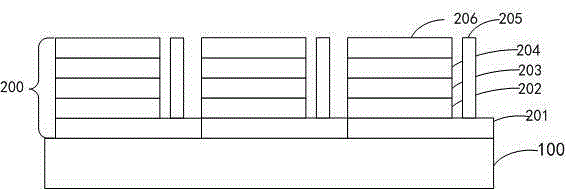

Manufacturing method of LED (light-emitting diode) chip with inverted structure

The invention relates to a manufacturing method of an LED (light-emitting diode) chip with an inverted structure. The LED chip comprises an N-type electrode formation region and a P-type electrode formation region, wherein the N-type electrode formation region comprises a substrate, a buffer layer, an N-type layer, an N-type respective limiting layer, an active region layer, a P-type respective limiting layer, a P-type layer, a P-type ohmic contact layer, a light reflecting layer and an insulating film; one end face of an N-type electrode passes through the insulating film so as to be connected with the light reflecting layer, and the other end face of the N-type electrode is connected with a heating panel through a PCB (printed circuit board); the P-type electrode formation region comprise a substrate, a buffer layer, an N-type layer and the insulating film, one end of a P-type electrode passes through the insulating film so as to be connected with the N-type layer, and the other end of the P-type electrode is connected with the heating panel by virtue of the PCB; and the two end faces, respectively connected with the PCB, of the N-type electrode and the P-type electrode are positioned at a same horizontal plane. The manufacturing method provided by the invention has the advantages that the N-type electrode and P-type electrode of the LED chip are manufactured in the same surface, the package yield of a chip inversion process is increased, thereby avoiding the occurrence of the electrode rosin joint or sealed-off state.

Owner:祝进田

Heat radiating process method for printed-circuit board

ActiveCN103037670AExcellent heat dissipationImprove insulation performanceCooling/ventilation/heating modificationsConductive materialsTemperature wave

The invention discloses a heat radiating process method for a printed-circuit board, belongs to electron technology, and applies to the technical field of avionics. The a cold plate is bonded on a printed-circuit board through a dedicated bonding device, a component is enabled to grovel on the cold plate, and heat radiating is carried out through the bonding membrane material and the cold plate, wherein the membrane material is arranged among the printed-circuit board base materials, the metal conducting materials on the inner portion and the surface of the printed-circuit board, the printed-circuit board and the cold plate. The cold plate is formed by arranging holes in an aluminium alloy plate according to the welding locating of the components of the printed-circuit board through hard anodic oxidation surface treatment. The bonding material between the printed-circuit board and the cold plate is a polyimide double-faced adhesive membrane. The bonding device is a convex thick steel mold plate and a concave thick steel mold plate with a certain curvature, and enables the printed-circuit board and the cold plate can be completed a flattening function simultaneously with bonding. The heat radiating process method for the printed-circuit board achieves the processing of the bonding and the flattening of the cold plate and the printed-circuit board at one time, solves the problem of product performance deterioration due to the fact that heat emitted by component after being powered on can not be released in time, increases the mechanical strength, the antiseptic property and the insulating property of the printed-circuit board, and restrains the layer splitting and the deformation of the printed-circuit board generated by high-temperature wave soldering.

Owner:SHAANXI QIANSHAN AVIONICS

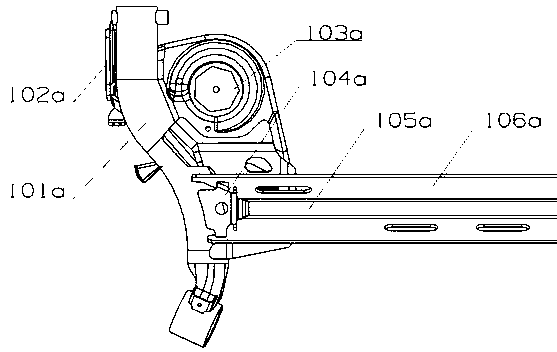

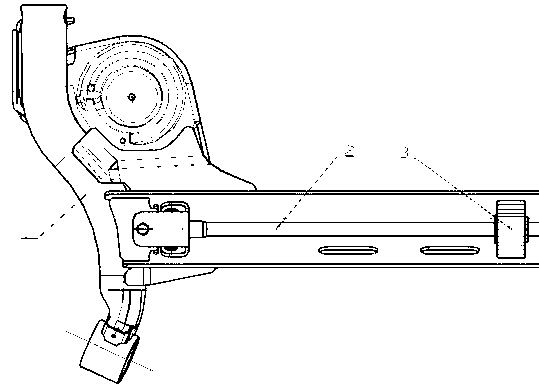

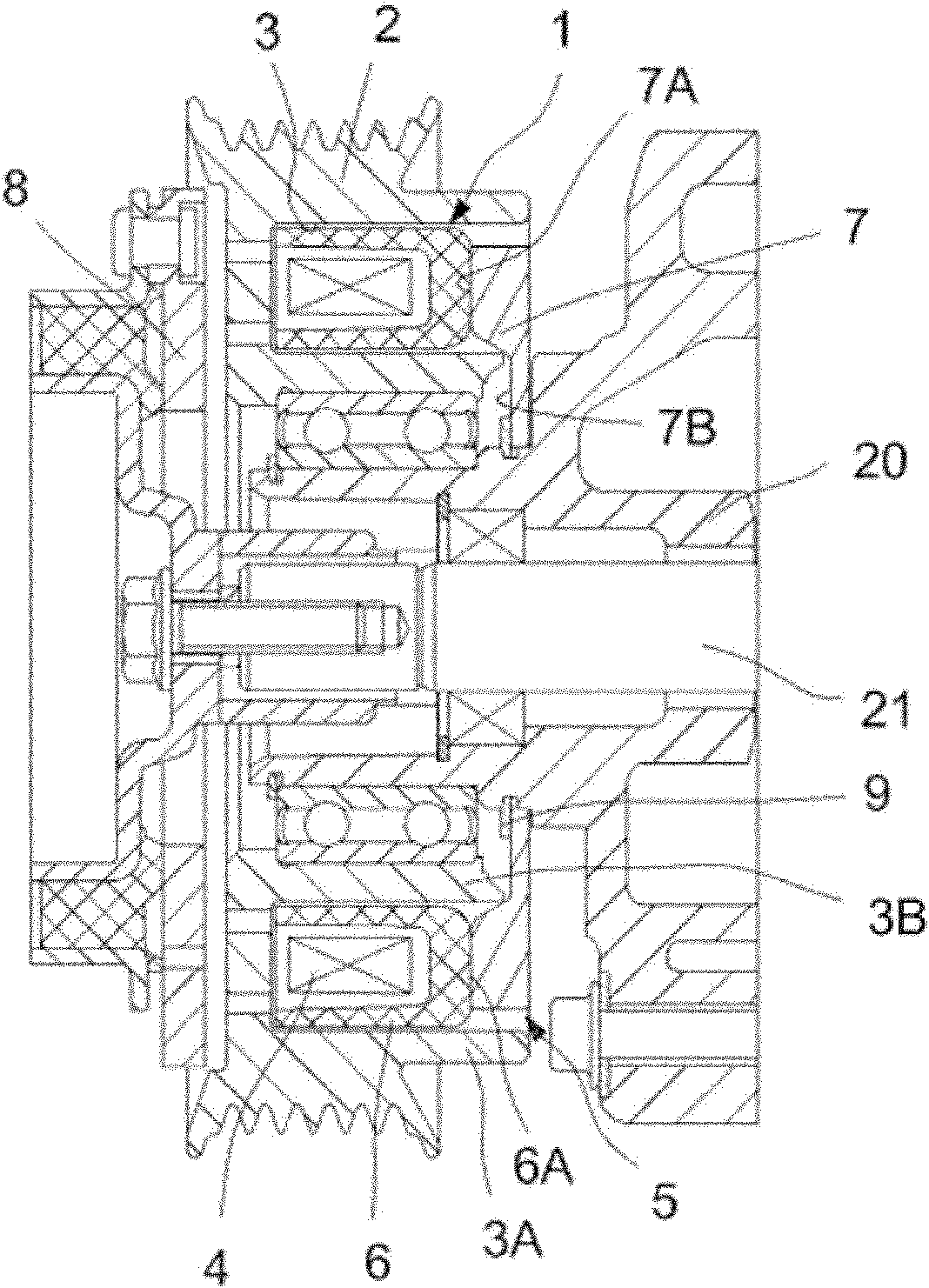

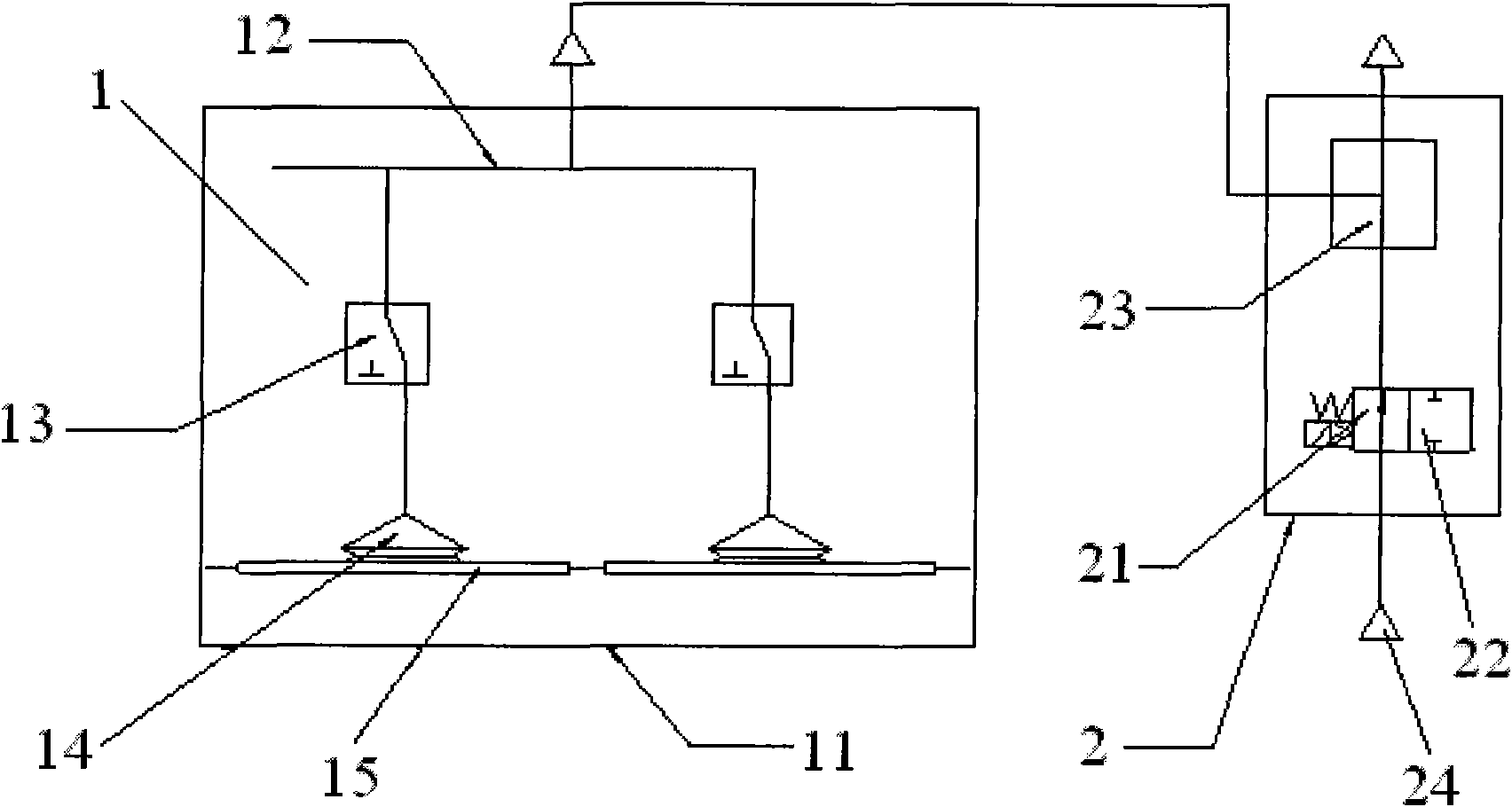

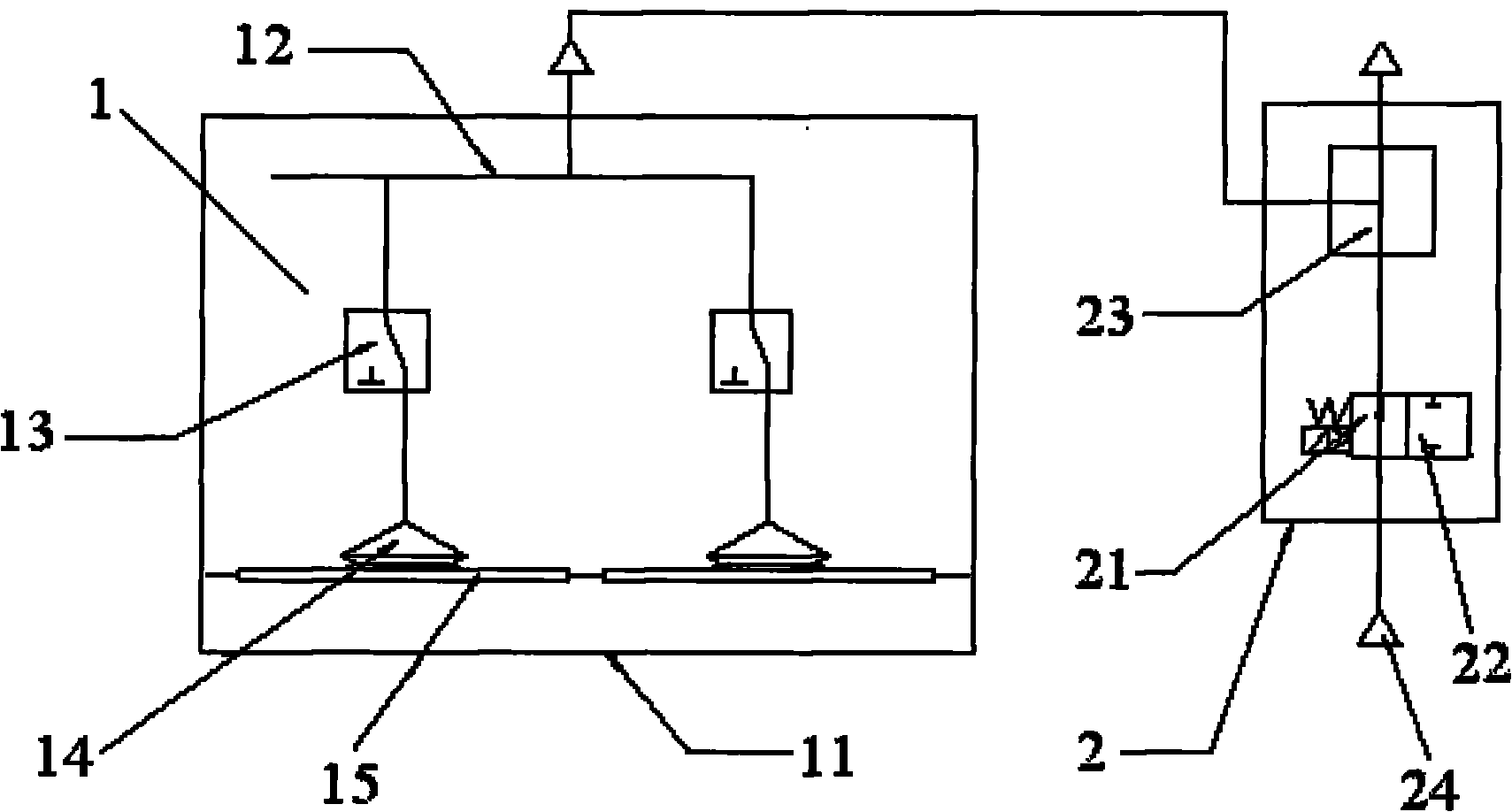

Electromagnetic clutch and manufacturing method of coil case thereof

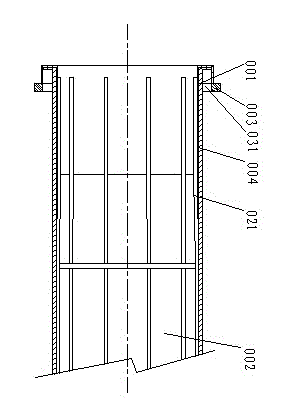

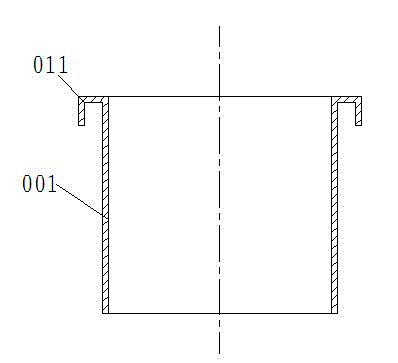

InactiveCN102562854AImprove flatnessIncrease contactMagnetically actuated clutchesElectromagnetic clutchEngineering

The invention discloses an electromagnetic clutch and a manufacturing method of a coil case thereof. The electromagnetic clutch comprises a coil block which comprises a coil case and a connection plate; the coil case comprises a cell body which is provided with a U-shaped cross section and is used to accommodate a coil; the connection plate is used to assemble the coil block on a front cylinder cover of a compressor; the connection plate is welded on the backside of the cell body; an inside annular face and an outside annular face are formed on one side of the connection plate; the inside annular face is fixed with the front cylinder cover; and the outside annular face is welded with the backside of the cell body. The electromagnetic clutch is characterized in that the inside annular face of the connection plate is a plane processed by cutting process, and on the side of the connection plate, the outside annular face is higher than the inside annular face. The manufacturing method includes the steps of: turning an inner race at one side of a connection plate blank to form the connection plate, so the side of the connection plate is provided with the outside annular face and the inside annular face which is made out through turning process and on the side of the connection plate, the outside annular face is higher than the inside annular face; and welding the outside annular face of the connecting plate with the backside of the cell body of the coil. With the manufacturing method provided by the invention, the weld strength between the coil case and the connection plate is enhanced and the coil case and the connection plate are not easy to loose weld.

Owner:SANDEN HUAYU AUTOMOTIVE AIR CONDITIONING CO LTD

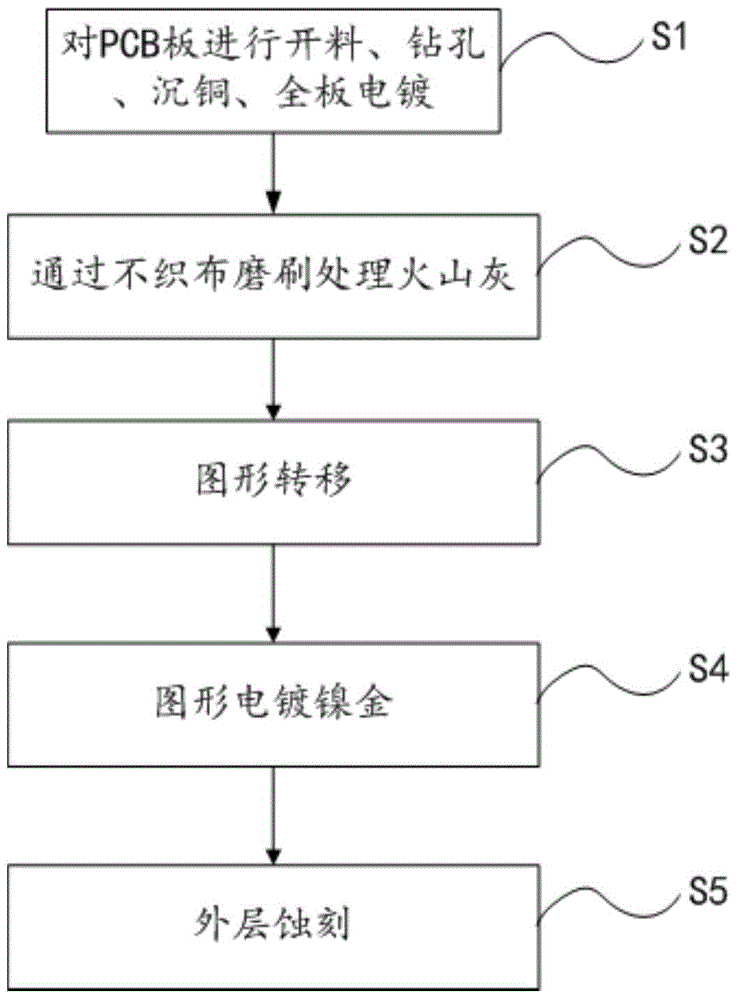

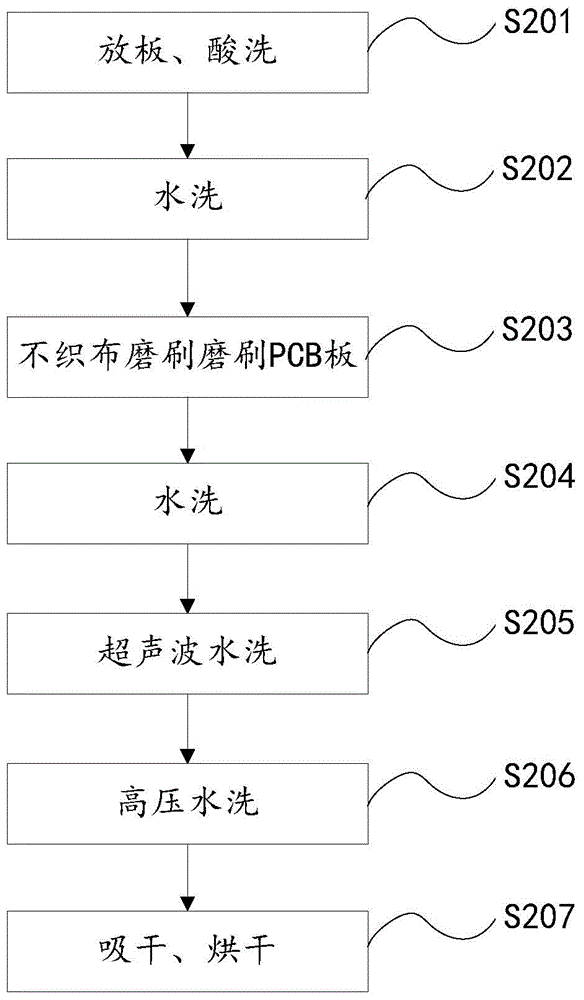

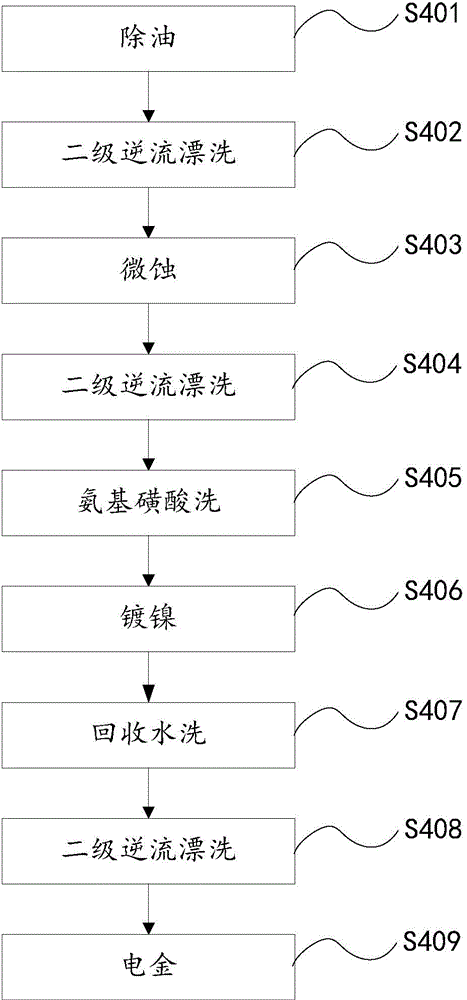

Printed circuit board (PCB) manufacturing method

ActiveCN104619123AReduce burrsReduce side erosionInsulating substrate metal adhesion improvementConductive material chemical/electrolytical removalCopper platingEtching

The invention relates to a PCB manufacturing method. The method comprises the steps of S1, performing cutting, drilling, electroless copper plating and full-board electroplating; S2, brushing and processing cinerite through non-woven fabrics; S3, pattern transfer; S4, pattern nickel gold electroplating; S5, outer layer etching. By the aid of the method, the PCB bonding tension value can reach 9N, compared with the prior art, the bonding tension value is improved greatly, the problems of bonding de-soldering, bonding deviation, poor bonding recognition and the like are solved effectively, and accordingly, the PCB quality is improved greatly.

Owner:HUIZHOU XINGZHIGUANG TECH

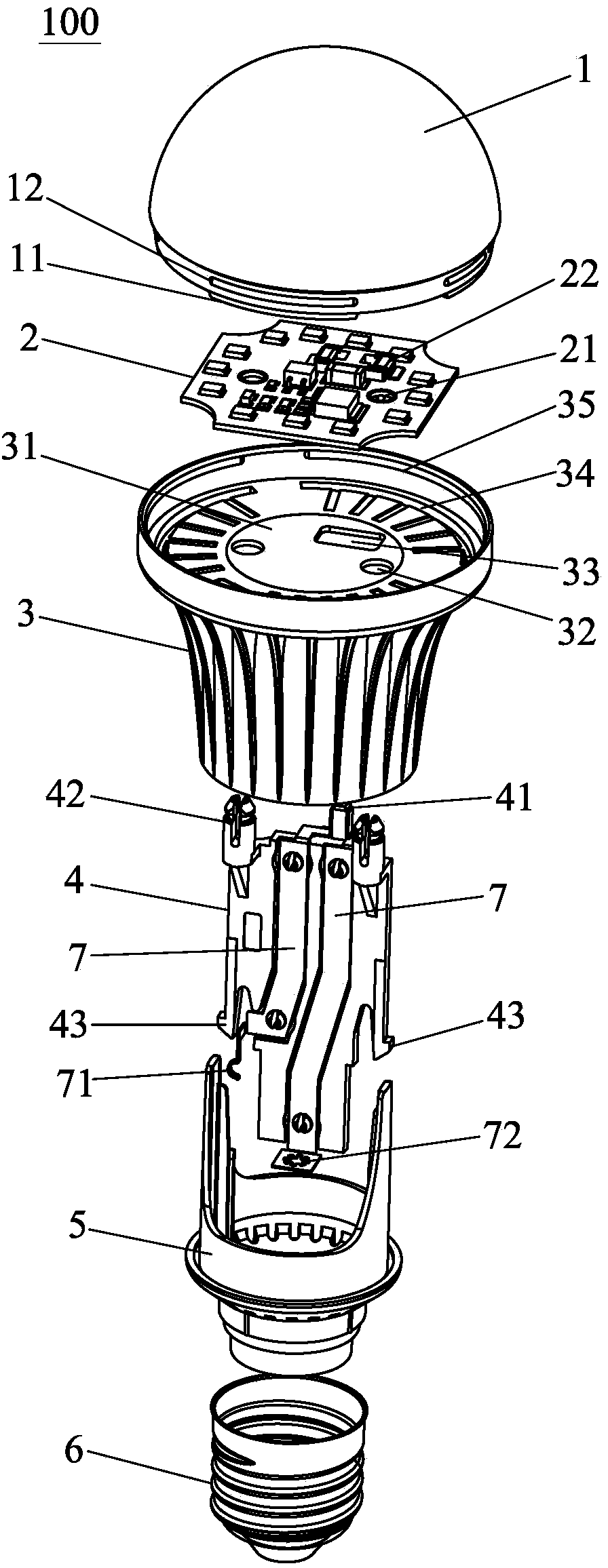

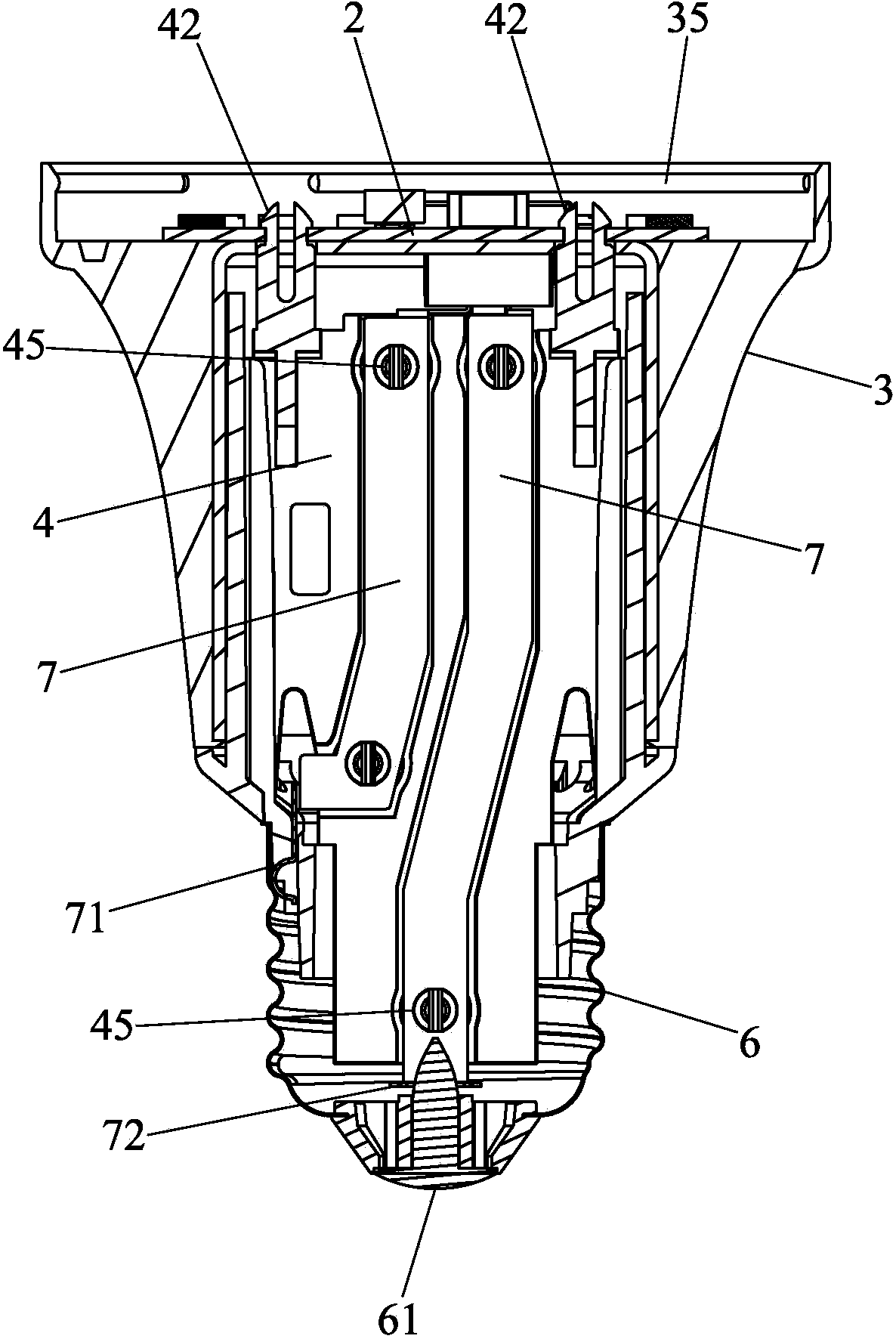

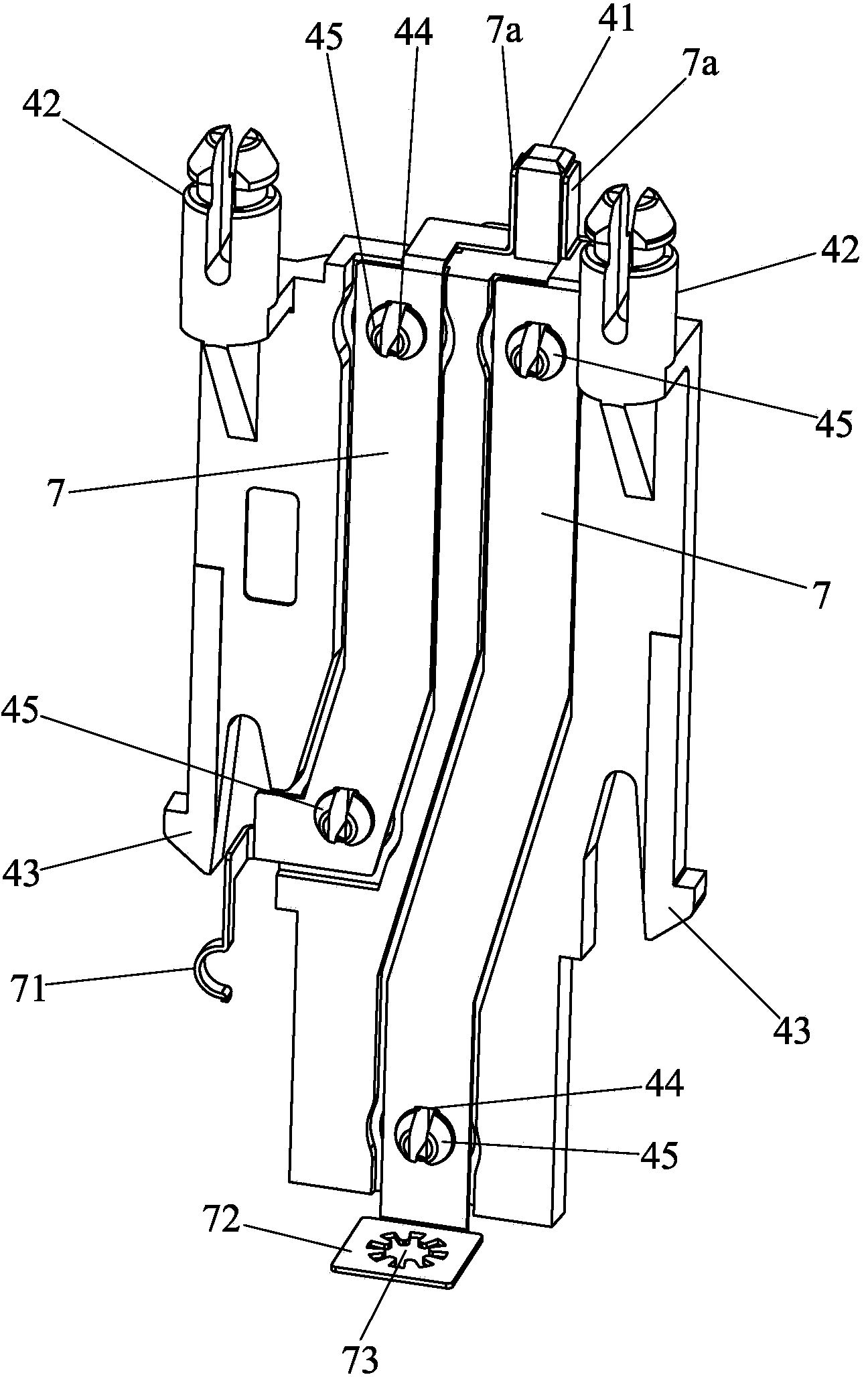

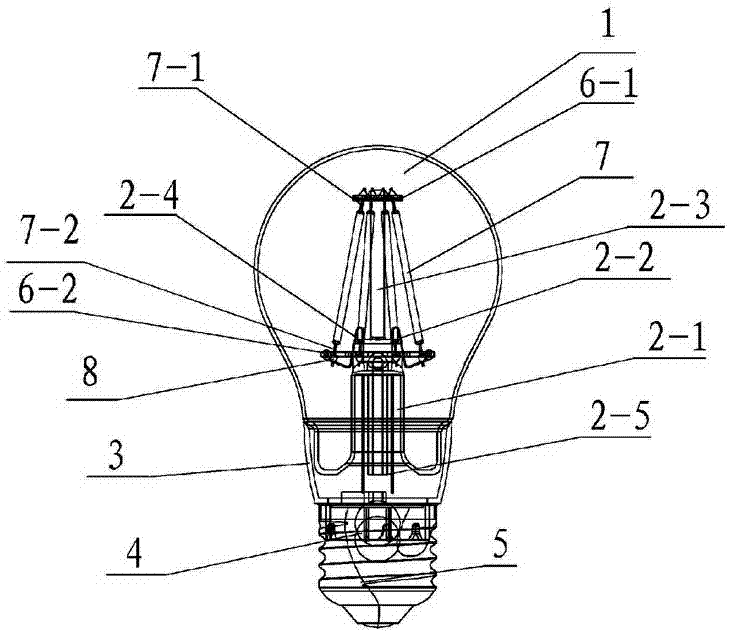

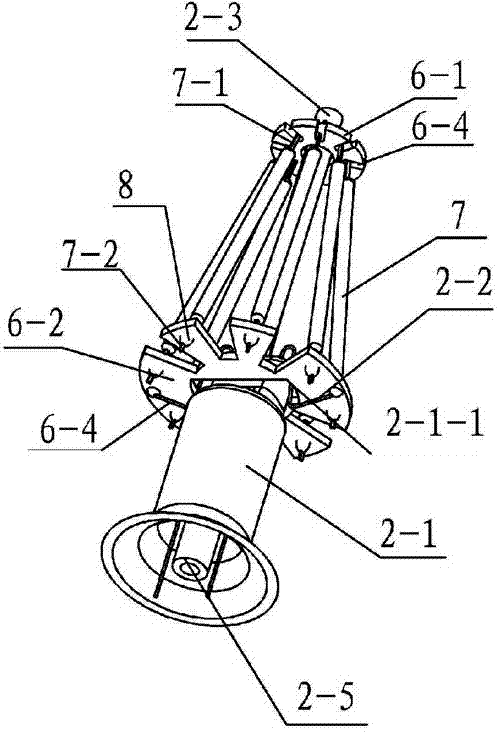

Full-automatic bulb lamp

InactiveCN104315380AEasy to assembleRealize automated productionLighting support devicesElectric lightingElectricityEngineering

The invention discloses a full-automatic bulb lamp. The full-automatic bulb lamp comprises a lampshade, a lamp panel, a lamp cup, a connecting piece, an inner sleeve, a lamp cap and two electricity-conductive elastic pieces. The upper end of the connecting piece protrudes upwards to form a positioning column. The electricity-conductive elastic pieces are fixed onto the connecting piece in a mutual insulated mode. The upper ends of the electricity-conductive elastic pieces are respectively positioned on two opposite sides of the positioning column. The connecting piece is buckled in the inner sleeve. A socket is arranged on the lamp panel, and two opposite elastic patches are arranged on the socket. The positioning column is inserted in the socket to enable the electricity-conductive elastic pieces to elastically and electrically contact with the elastic patches. The lampshade is buckled on the lamp cup. The lamp cap is in threaded connection with the lower end of the inner sleeve, and is in elastic and electric contact with one of the electricity-conductive elastic pieces. A rivet is arranged at the bottom of the lamp cap and is connected with the other electricity-conductive elastic piece in an insertion mode. The full-automatic bulb lamp is free from wire and screw connection, automatic production is realized, production efficiency is improved, and reliability is high.

Owner:OUTRACE TECH

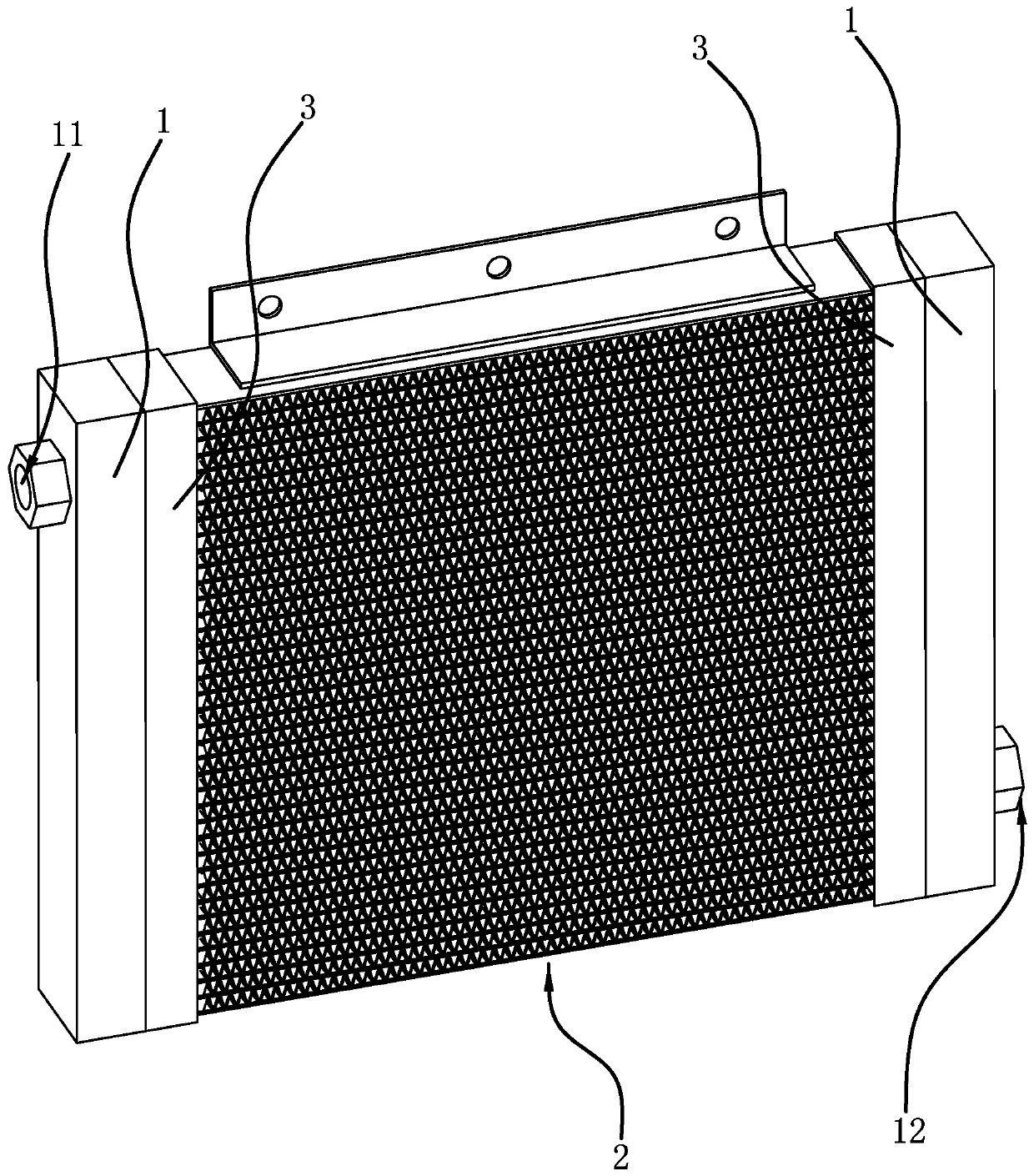

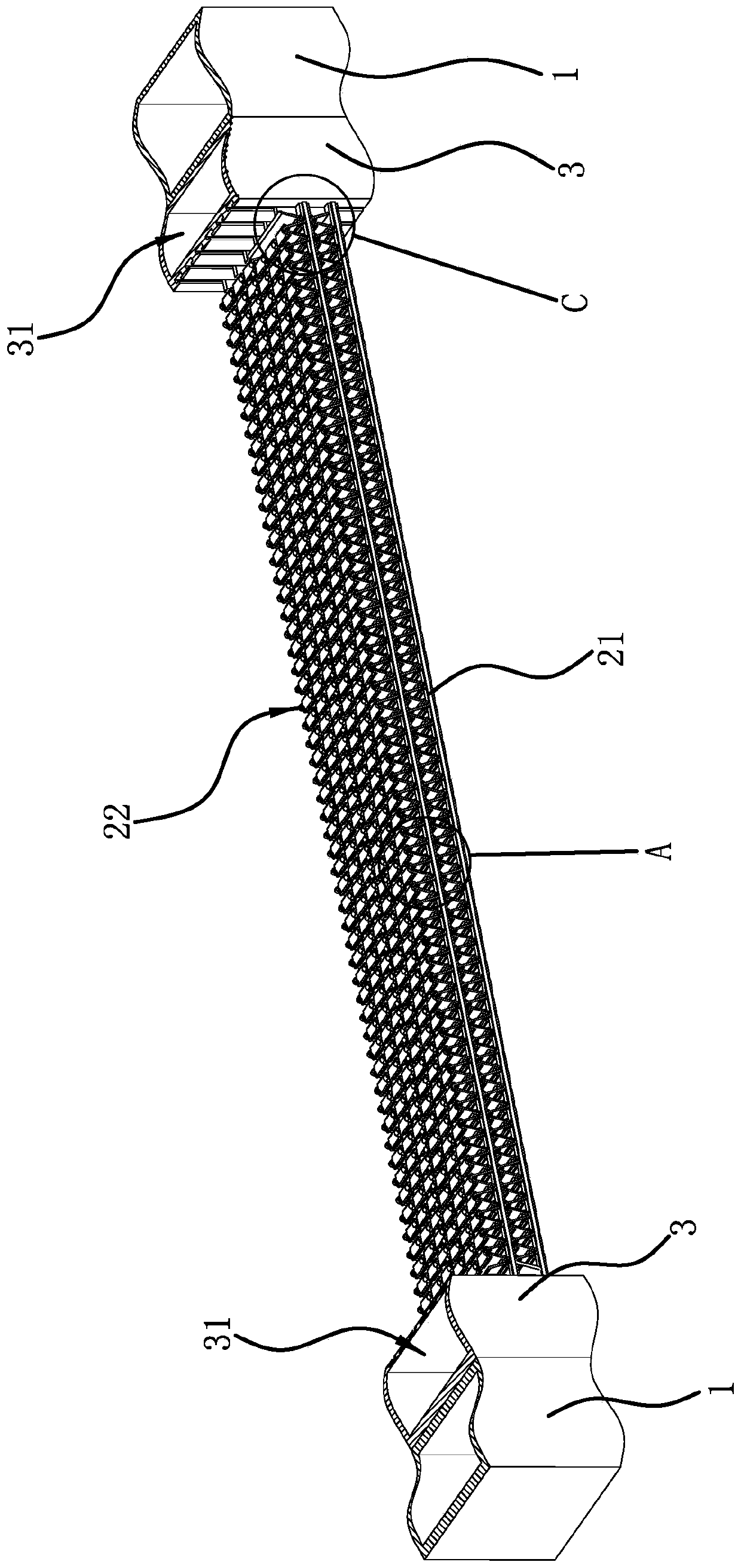

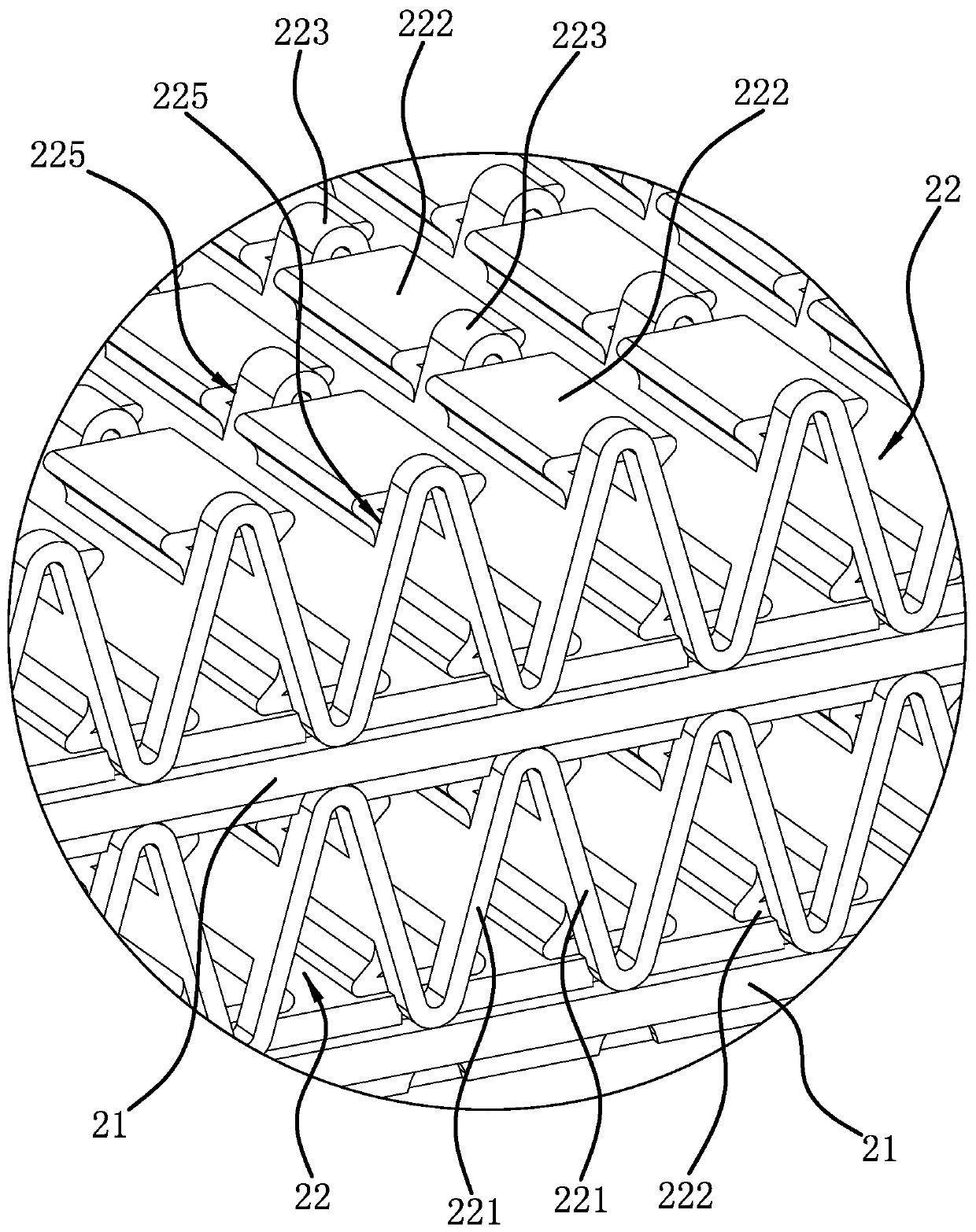

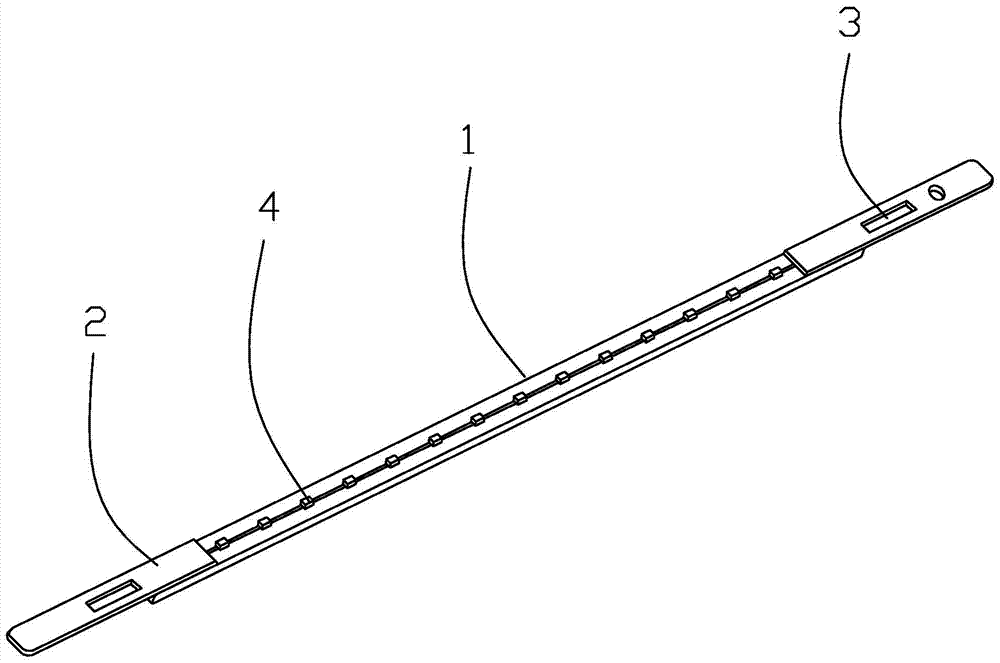

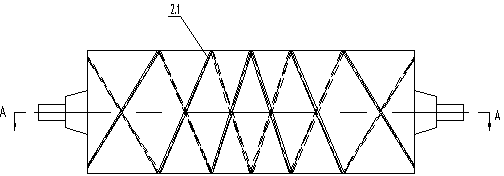

Universal cooler for efficiently removing oily water

ActiveCN109813144ABreak up fullySufficient heat exchangeStationary conduit assembliesHeat exchanger casingsEngineeringRefrigeration

The invention provides a universal cooler for efficiently removing oily water, and belongs to the technical field of refrigeration equipment. The problems that an existing cooler is poor in cooling performance and pressure resistance are solved. The universal cooler for efficiently removing oily water comprises two oil chambers and a core body located between the two oil chambers, the core body comprises a plurality of cooling pipes, two long strip-shaped cooling fins are arranged between ever two adjacent cooling pipes, the cooling fins comprise a plurality of inclined sections and bent portions, the inclined sections are crossed, clamped and positioned, the two opposite side faces of the cooling pipes are provided with a plurality of first positioning grooves, the bent portions of the cooling fins are concaved inwards to form a plurality of flat and straight heat exchange portions, a positioning portion is formed between every two adjacent heat exchange portions, the positioning portions are embedded into the first positioning grooves and welded and fixedly connected to the inner walls of the first positioning grooves, and the outer side faces of the heat exchange portions are infit with the side faces of the cooling pipes in a pressing mode. The universal cooler for efficiently removing oily water has high cooling performance and pressure resistance.

Owner:山东宏阳型材科技股份有限公司

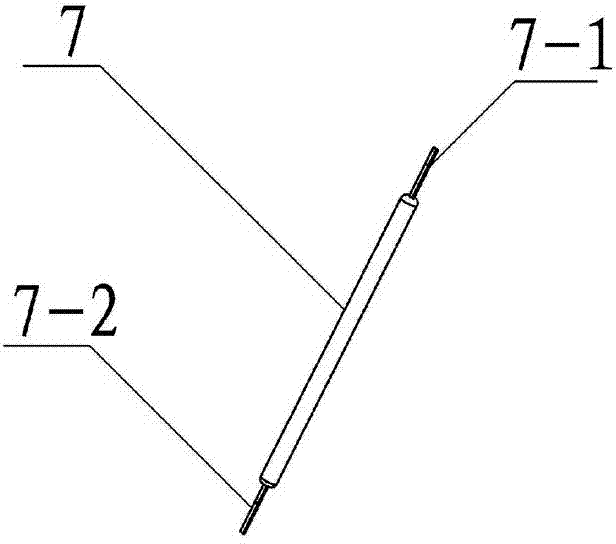

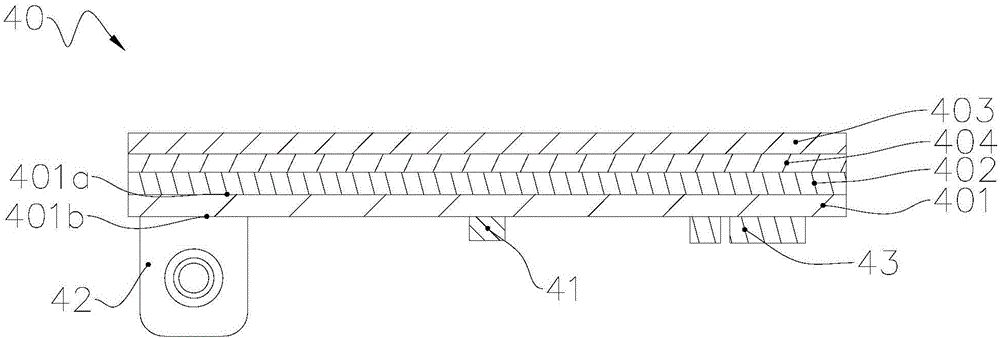

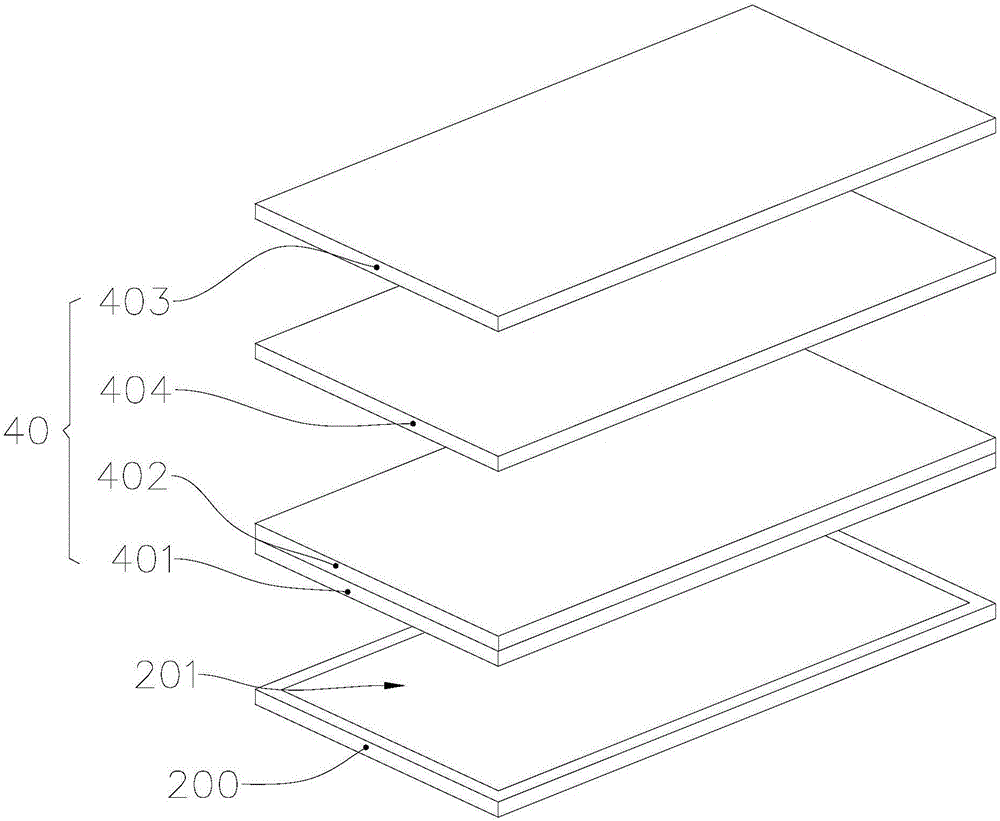

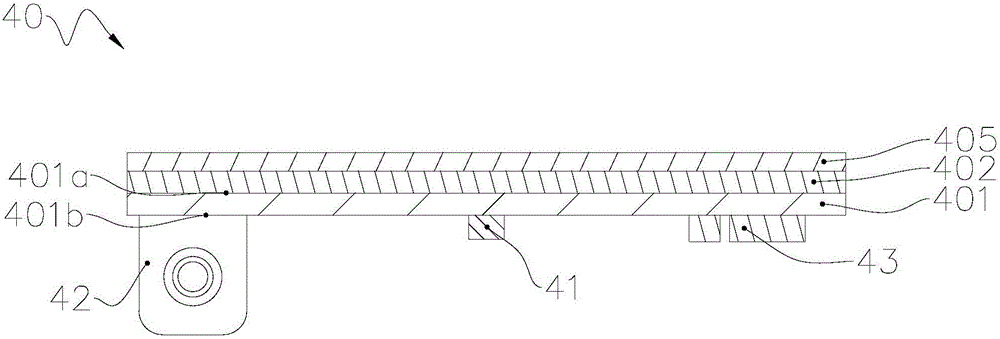

LED (Light Emitting Diode) lamp filament without bonding wire

ActiveCN104505453ALow costReduce leakageSolid-state devicesSemiconductor devicesEngineeringLuminescence

The invention relates to an LED (Light Emitting Diode) lamp filament without a bonding wire, and solves the problem of poor luminescence performance and heat dissipation of a traditional LED lamp filament. The lamp filament comprises a substrate, wherein a circuit is arranged on the surface of the substrate, LED chips are connected to the circuit, two ends of the substrate are connected with sheet metals, the circuit consists of a plurality of connecting circuits, each connecting circuit comprises two electric conduction silver layers which are connected through an electric conduction line, the LED chips are flip chips, and each LED chip is arranged between two adjacent connecting circuits for connecting the connecting circuits. The LED lamp filament has the advantages that a structure without the bonding wire is adopted, so that the cost is saved, the risks of the electric leakage and the dry joint of the LED since a porcelain nozzle has an impact on the LED chips in a welding process are greatly reduced, the packaging reliability and a production yield are greatly improved, and meanwhile the cost is lowered; and since the lamp filament and a lamp filament support are assembled in an embedding manner, the bad problems of the desoldering and the dry joint of the lamp filament of a light source in a traditional electric welding process can be avoided.

Owner:ZHEJIANG INTELED OPTOELECTRONICS TECH

LED chip and manufacturing method

The invention discloses an LED chip and a manufacturing method. The manufacturing method comprises steps of fixing substrates on sides of N type electrodes and P type electrodes of a plurality of luminescence microstructures, wherein the sides of the N type electrodes and the P type electrodes are away from a sapphire substrate, thinning and cutting a sapphire substrate, filling a gap between the luminescence microstructure and the substrate, strippingthe substrate by the laser, and cutting the substrate into independent LED chips, which enables the luminescence microstructure to be fully fixed on the substrate. The invention effectively prevents the light emitting microstructure from unsoldering and fragmentation.

Owner:FOSHAN NATIONSTAR SEMICON

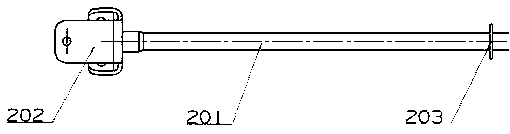

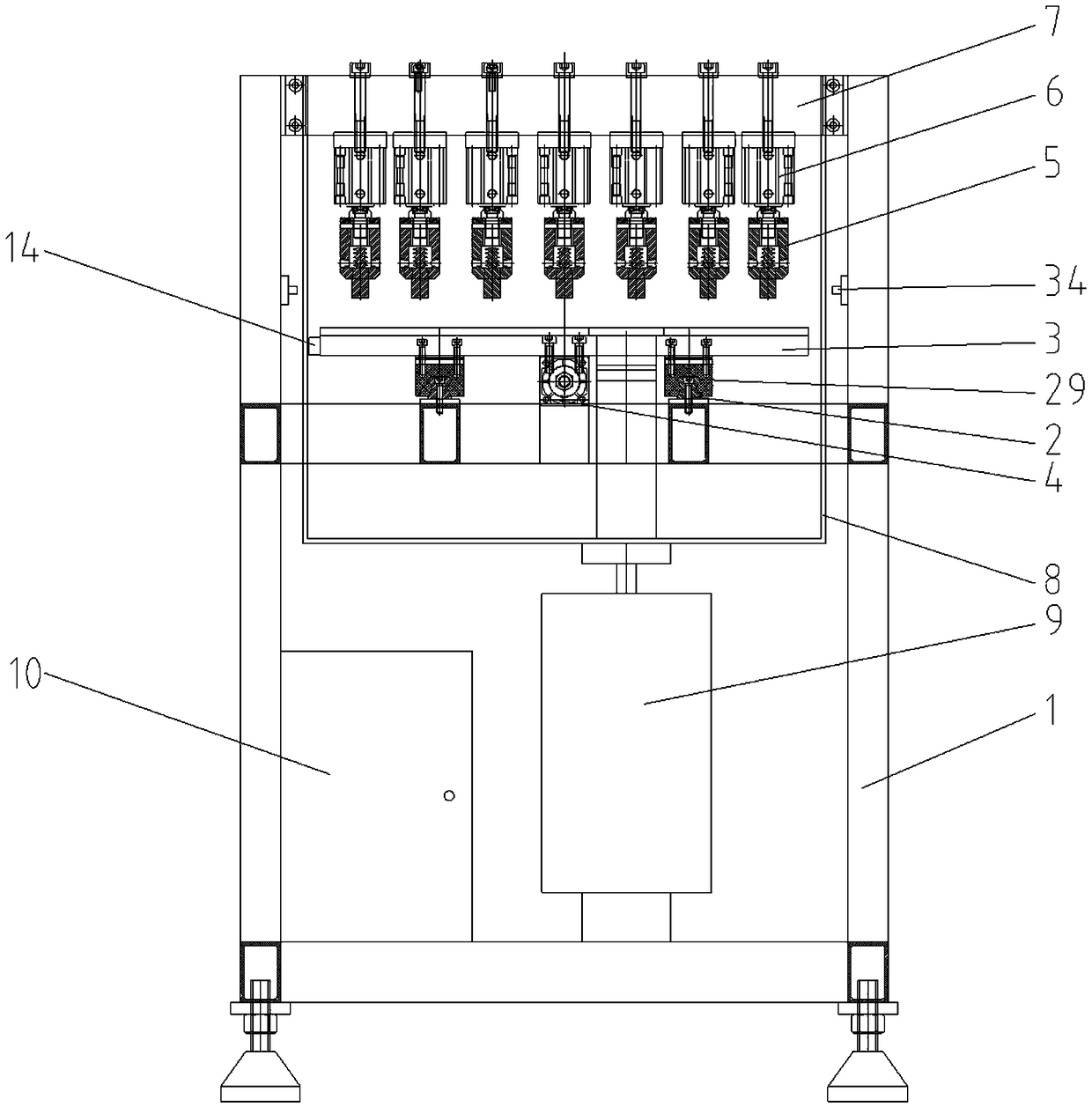

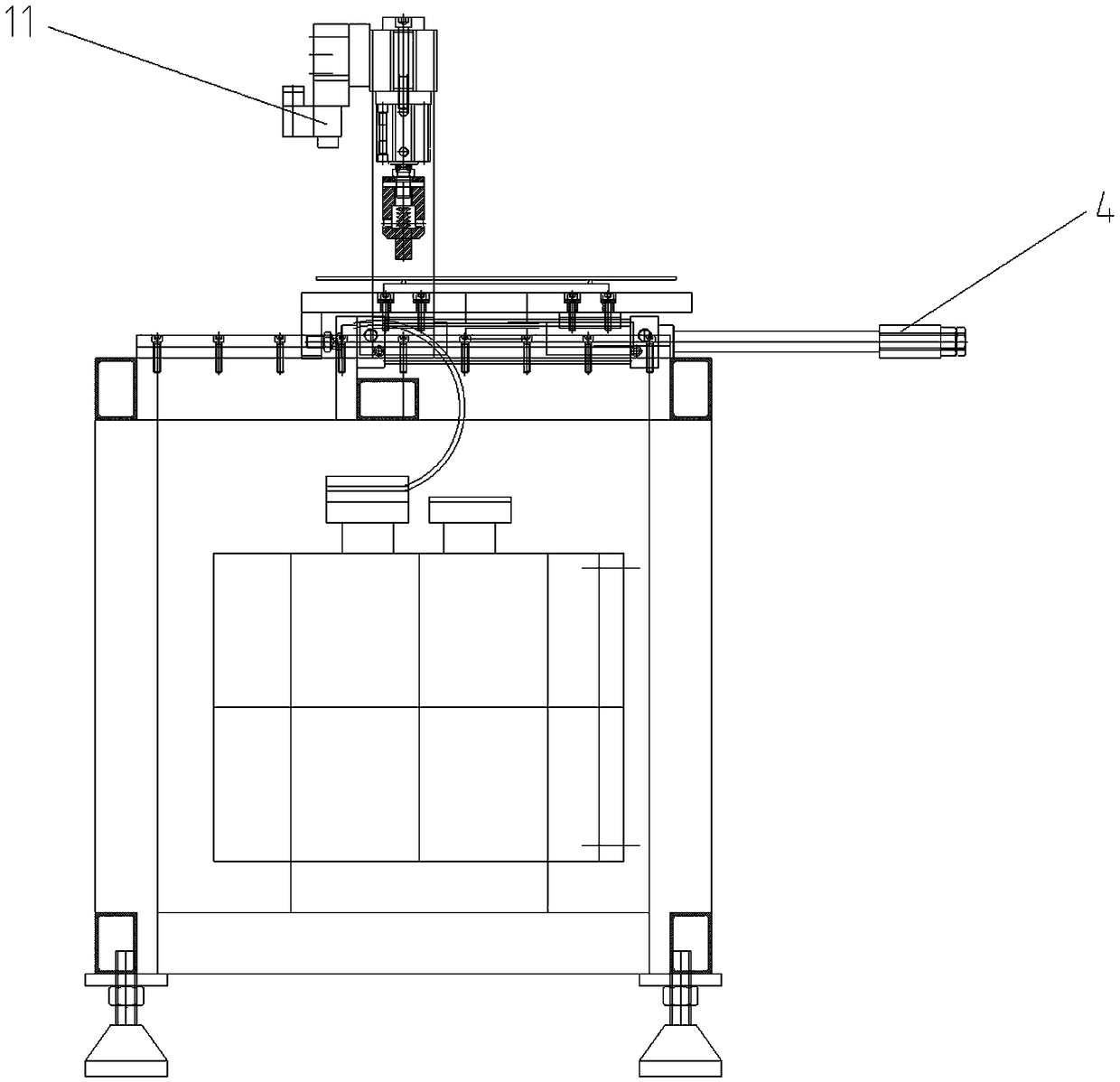

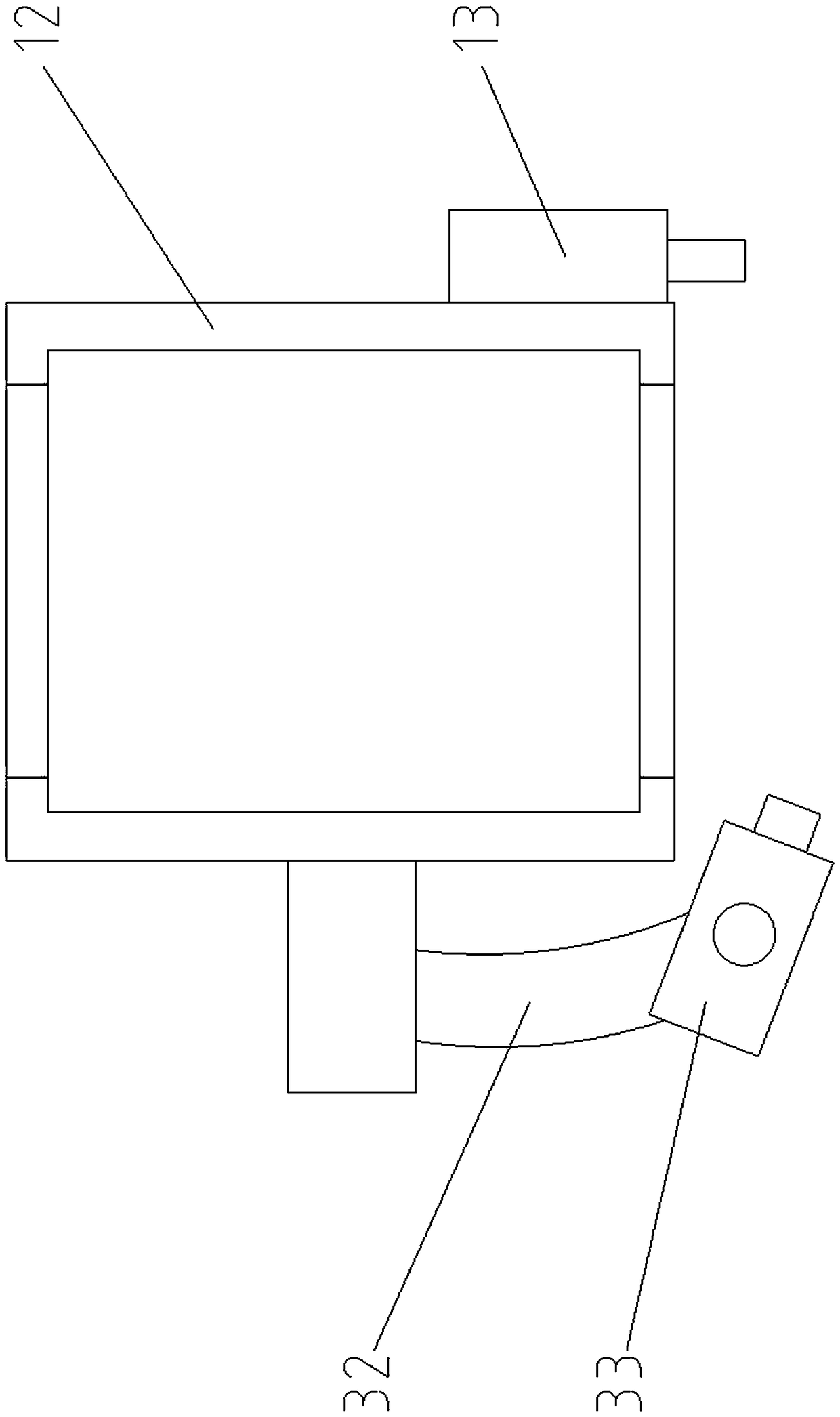

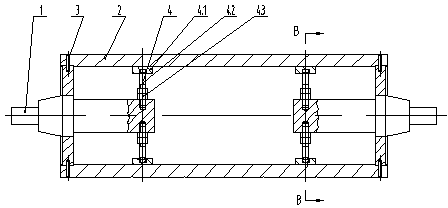

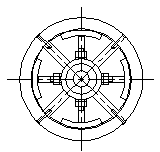

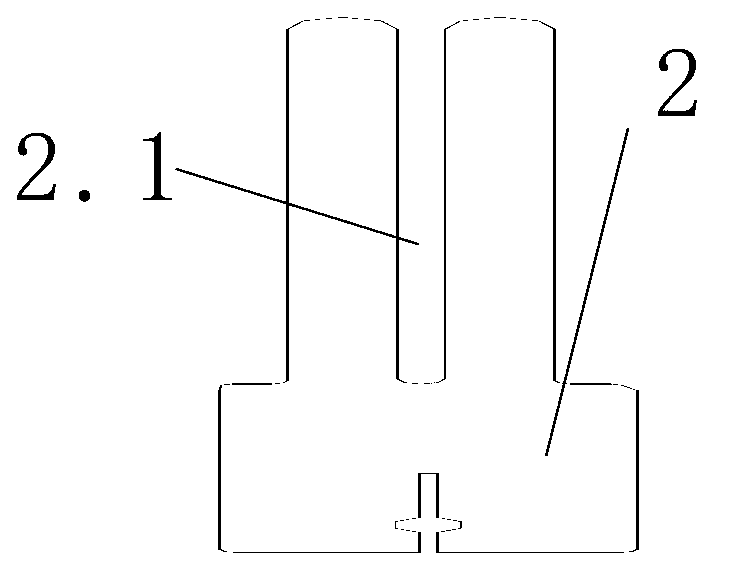

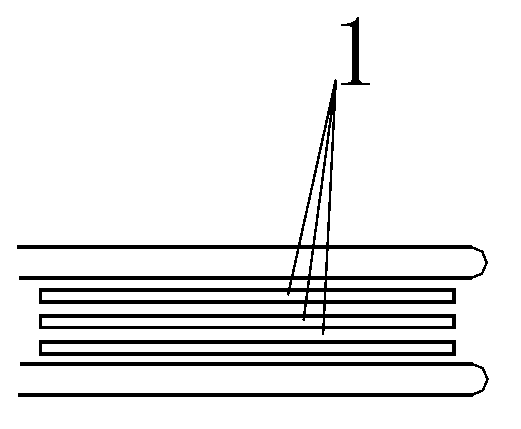

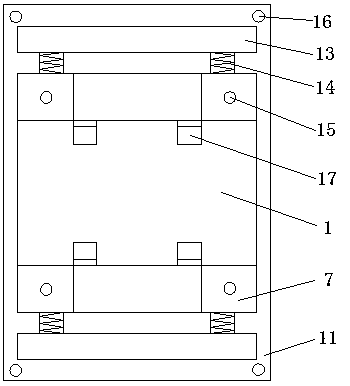

Metal mesh multi-point pressure welding mechanism and method

PendingCN108544073ANot easy to disengageAvoid desolderingWelding/soldering/cutting articlesMetal working apparatusMetal meshPower parameter

The invention relates to a metal mesh welding method, in particular to a metal mesh multi-point pressure welding mechanism and method. The technical problems that in the in the prior art, a welding machine cannot automatically conduct continuous multi-point welding and same-row welding, copper plates are prone to being disengaged during welding, the welding point temperature is not prone to beingcontrolled when being too high, and the de-welding phenomenon is serious are mainly solved. The metal mesh multi-point pressure welding mechanism comprises a rack; a linear sliding rail is arranged onthe rack; a worktable is slidably connected to the linear sliding rail and connected with a worktable air cylinder; a plurality of welding copper nozzles are arranged above the worktable and connected to lifting air cylinders which are fixed to a cross beam of the rack; the welding copper nozzles are connected with a welding machine transformer through conductive copper plates; the welding machine transformer, the worktable air cylinder and the lifting air cylinders are connected with a power parameter control cabinet through lines; and the welding machine transformer and the power parametercontrol cabinet are arranged on the lower portion of the rack.

Owner:HANGZHOU LANDA CRAFTS

LED (light-emitting diode) bulb

ActiveCN103672531ASimple structureQuick assemblyPoint-like light sourceElectric circuit arrangementsEngineeringCopper foil

An LED (light-emitting diode) bulb comprises a glass envelope, a stem, a plastic shell, an LED light source, a bulb cap and a group of LED light-emitting bars, wherein the top of a base of the stem is provided with a strip-shaped boss, an insulated central fixed column is upwardly extended from the center of the strip-shaped boss, the group of LED light-emitting bars are mounted on a first circuit board and a second circuit board, so that an LED light-emitting bar module is formed, the module is mounted on the strip-shaped boss and the central fixed column, and conductive copper foils are so arranged on the first circuit board and the second circuit board that the group of LED light-emitting bars are connected in series or in series and parallel, and the LED power supply supplies power to the group of LED light-emitting bars. The light-emitting bar module structure of the LED bulb can enhance the reliability of the LED bulb and prolong the service life of the LED bulb, the LED light-emitting bar module can be assembled alone in advance, consequently, mass production can be realized, the efficiency of production is increased, and the production cost is reduced.

Owner:FOSHAN ELECTRICAL & LIGHTING

Enhanced sinking roll

InactiveCN103993250AImprove flexural strengthAvoid eccentric wearHot-dipping/immersion processesEngineeringNodulations

The invention discloses an enhanced sinking roll including a roller and a roll shaft is fixed at both ends in a welding manner, a support structure is arranged on the roll shaft extending into the interior of the roller; the support structure is an adjustable support, comprises a support block, a screw and a nut; the support block is an arc block, the outer arc is consistent in radian with the inner wall of the roller; one end of the screw is fixedly connected with the outer wall of the roll shaft by the nut; and the other end of the screw is in floating connection with the support block; the support block supports the inner wall of the roller; the further improvement is that: the number of the support structure is 2; support blocks are arranged on the inner wall of the roller along the circumferential direction in even space; a radial hole is arranged at the matching position of the roller and the roll shaft, the hole is internally provided with a pin shaft tightly fitting with the hole; the pin shaft is fixedly connected with the roller by welding; an axial symmetric centerline of the roller is used as a dividing line, and spiral grooves with opposite directions of turning are arranged on the surface of the roller and on both sides of the dividing line. The roller strength is further improved, the problem of nodulation of the roller surface can be solved, and the service life of the sinking roll can be prolonged.

Owner:TAIZHOU SANJIANG SPECIAL STEEL MFG

Method for winding multi-pole-piece lithium battery winding core

ActiveCN102931441ASave raw materialsReduce production processFinal product manufactureSecondary cellsPole pieceWorking hours

Disclosed is a method for winding a multi-pole-piece lithium battery winding core. N pairs of positive pole pieces and negative pole pieces are sequentially inserted in diaphragms in an intersected mode and wound by a U-shaped winding needle in a rotation mode to obtain the battery winding core. According to the method for winding the multi-pole-piece lithium battery winding core, the existing U-shaped winding needle is used, a plurality of the diaphragms are stacked, same pairs of the positive pole pieces and the negative pole pieces are inserted in the diaphragms in an intersected mode in steps, and a plurality of positive pole lugs and negative pole plugs which correspond to the positive pole pieces and the negative pole pieces are stacked respectively and then wound into the winding core. According to the method, procedures are not increased, working hours are saved, and the method is particularly suitable for preparing various battery winding cores with high rates.

Owner:湖北宇隆新能源有限公司

Solar cell luminescent plate and manufacture method therefor

ActiveCN105845764AEasy to assembleAvoid WeldingElectric circuit arrangementsWith built-in powerSolderingEngineering

The invention relates to a solar cell luminescent plate and a manufacture method therefor. The solar cell luminescent plate provided in the invention comprises a line substrate, an LED lamp bead and a solar cell sheet. The line substrate comprises a first surface and a second surface opposite to the first surface, wherein the LED lamp bead is encapsulated on the second surface, and the solar cell sheet is arranged on the first surface. The solar cell sheet and the line substrate are integrated to form the solar cell luminescent plate. Compared with technologies of the prior art, the solar cell luminescent plate provided in the invention is advantageous in that convenience of assembling is realized; pseudo soldering, missing soldering, conductor unsoldering reverse installation of electrodes and the like can be prevented because conductor connection is not needed; convenience of detection and maintenance can be realized. Via use of the solar cell luminescent plate manufacture method provided in the invention, solar cell luminescent plate assembling difficulty is lowered, and product reliability and production efficiency are improved.

Owner:JIAWEI RENEWABLE ENERGY CO LTD

PM permanent magnet stepping motor bracket

The invention relates to a PM permanent magnet stepping motor bracket. The PM permanent magnet stepping motor bracket comprises a base; the two ends of the base are fixedly connected with side plates;the inner side bottom ends of the side plates are fixedly connected with reinforcing ribs; the bottoms of the reinforcing ribs are fixedly connected with the top of the base; the top parts of the side plates are fixedly connected with lower limiting chucks; the outer side of an inner cavity of each lower limiting chuck is fixedly connected with an arc-shaped baffling edge I; a rubber pad I is arranged on the inner side of the arc-shaped baffling edge I; the rubber pad I is glued with the inner wall of the corresponding lower limiting chuck; the two ends of the top of the lower limiting chuckare fixedly connected with double-screw bolts; and the top parts of the lower limiting chucks are connected with corresponding upper limiting chucks. The PM permanent magnet stepping motor bracket issimple in structure, convenient to use, and capable of preventing damage to the limiting chucks or the motor caused by relatively high fastening force, buffering vibration generated in motor operation, enabling motor fixation to be firmer and more reliable, without generating a phenomenon of loosening of a fastening mode, and enabling the motor to perform a stable operation.

Owner:JIANGSU WINCAP NEW ENERGY TECH CO LTD

Novel bag cage head integration part

InactiveCN102716620AReduce processing timeReduce manufacturing costDispersed particle filtrationFlangingEngineering

A novel bag cage head integration part belongs to air-box bag type dust collectors in the technical field of environment protection equipment. The novel bag cage head integration part comprises a cylindrical base, one end of the base is turned outwards to form a flanging, the novel bag cage head integration part is stamped at one step, a protective short pipe is removed, the manufacturing procedure of welding the protective short pipe and a head cover is omitted, the problem of desoldering of a general bag cage head cover and the protective short pipe is avoided, the manufacturing time of a bag cage is shortened, and the manufacturing cost of the bag cage is effectively reduced.

Owner:JIANGSU TAIQING ENVIRONMENTAL PROTECTION TECH

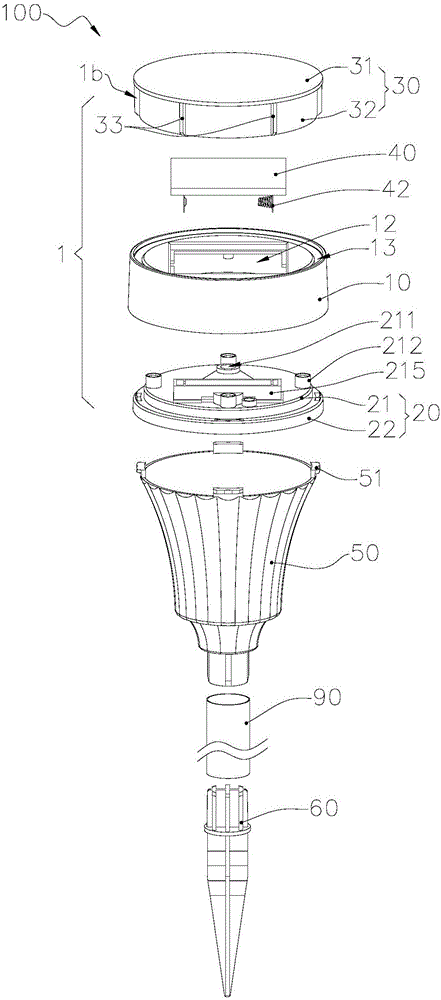

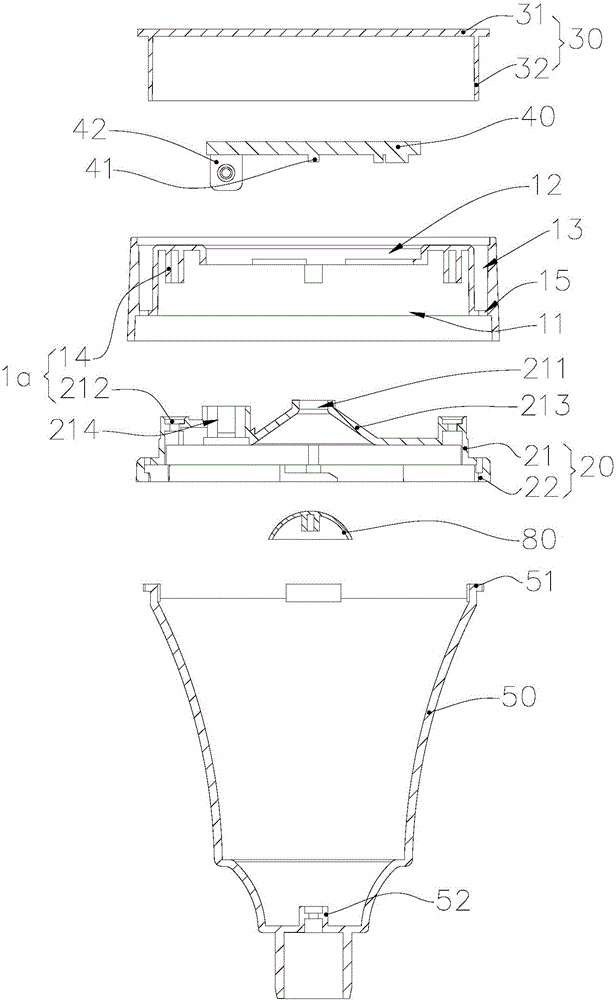

Lamp body structure and landscape lighting device

ActiveCN105841083AEasy to assembleAvoid WeldingMechanical apparatusOutdoor lightingBatch productionEngineering

The invention relates to the technical field of landscape lighting and provides a lamp body structure and a landscape lighting device. The lamp body structure provided by the invention comprises a lampshell, a solar battery lighting slab, a base and a top cover, wherein the lampshell is provided with a cavity for accommodating the base; a mounting groove for arranging and supporting the solar battery lighting slab is formed in the center of the top surface of the lampshell; the mounting groove is communicated with the cavity; the solar battery lighting slab comprises a circuit substrate, an LED (Light-Emitting Diode) lamp bead and a solar battery cell; the circuit substrate comprises a first surface and a second surface which is opposite to the first surface; the LED lamp bead is packaged on the second surface; the solar battery cell is arranged on the first surface; the solar battery cell and the circuit substrate are integrated to form the solar battery lighting slab. Compared with the prior art, the lamp body structure provided by the invention is more convenient to assemble and is convenient to detect and maintain. The landscape lighting device provided by the invention is simplified in structure and capable of satisfying the requirements of large-batch production.

Owner:JIAWEI RENEWABLE ENERGY CO LTD

Method for controlling wire rod routing in production process of copper-clad aluminum materials by clad-welding method

InactiveCN101530944AAvoid wrinkling and other problemsMovement speed is stableArc welding apparatusWire rodEngineering

The invention provides a method for controlling wire rod routing in the production process of copper-clad aluminum materials by a clad-welding method. The method comprises the following steps: in the production process of copper-clad aluminum wire rod, a copper strip, an aluminum wire and copper-clad aluminum wire blank moves forwards under the traction action of a guide wheel; when moving forwards, the copper strip gradually forms a circular copper pipe along the longitudinal direction under the extrusion of a plurality of pairs of forming rollers; a longitudinal seam of the circular copper pipe is continuously welded by argon arc welding; a servo motor controls the moving speed of the guide wheel to be matched with welding current of the argon arc welding so as to ensure the moving speed of the guide wheel to be stable and prevent the problems that the copper strip wrinkles, and the like; welding points on the longitudinal seam of the copper pipe is ensured to be positioned in a same horizontal line; and the servo motor controls the moving speed of the guide wheel to be matched with the welding current of the argon arc welding, thus avoiding loose welding or overwelding phenomenon caused by overhigh or overlow moving speed of the guide wheel when the welding current is fixed.

Owner:浙江恒飞控股有限公司

Safety sucker of solar cell string

InactiveCN102039597AAvoid desolderingImprove efficiencyFinal product manufactureGripping headsSolar cell

The invention relates to a safety sucker of a solar cell string, which comprises a sucker frame main body and a vacuum controller, wherein the top of the sucker frame main body is connected with a vacuum generator in the vacuum controller by a pipeline. Compared with the prior art, leads and cell pieces of the invention are not stressed; the phenomena of bending and torsion deformation, sealing off, split fragments and hidden defect deterioration, caused by manual lifting movement, are avoided; the safety sucker has better safety performance; in the movement of the sucker, the cell string is safely absorbed and cannot drop off; and the operation efficiency of the safety sucker is also improved.

Owner:CEEG SHANGHAI SOLAR SCI & TECH

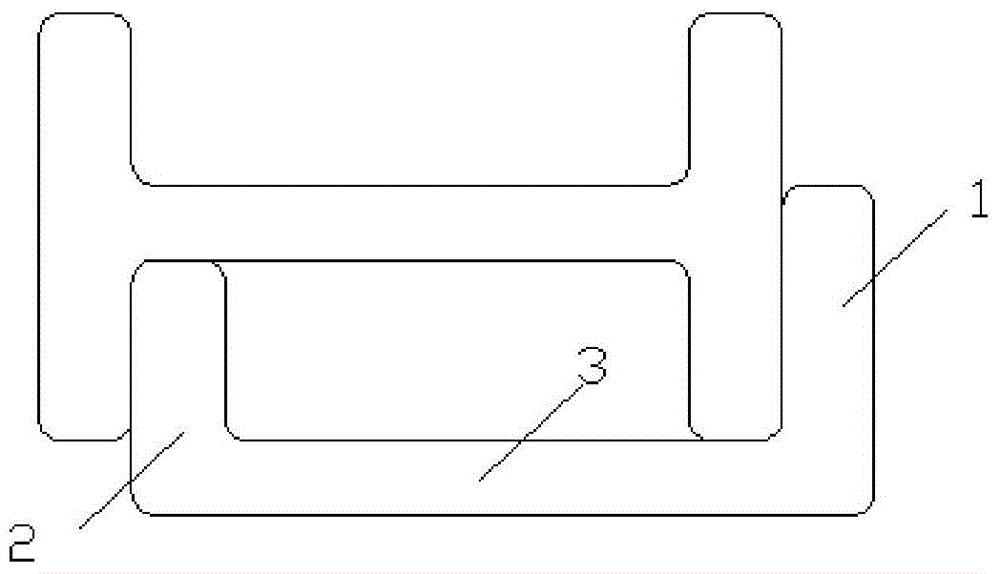

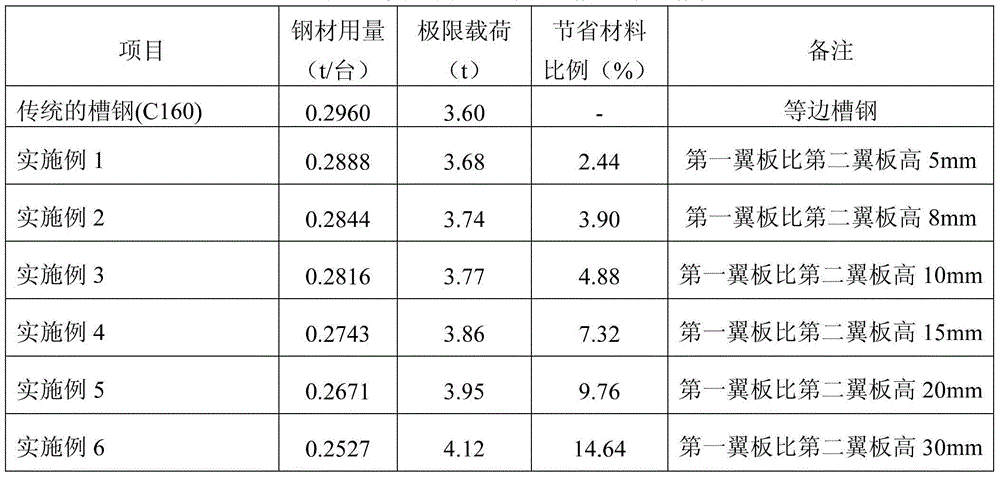

Hot-rolled inequilateral channel steel and application thereof

InactiveCN103557428AIncrease stiffnessAvoid deformationElongated constructional elementsLifting devicesMaterial consumptionSteel design

The invention relates to hot-rolled inequilateral channel steel. The hot-rolled inequilateral channel steel comprises a web and wing plates, wherein the wing plates comprise a first wing plate and a second wing plate; two ends of the web are connected with the first wing plate and the second wing plate respectively; the first wing plate and the second wing plate are located on the same side of the web, are parallel to each other and perpendicular to the web; and the height of the first wing plate is larger than that of the second wing plate. According to the hot-rolled inequilateral channel steel, the first wing plate and the second wing plate adopt an inequilateral design, the first wing plate is higher than the second wing plate by 5-30 mm, so that in combination production of a forklift truck gantry and under the same bearing capacity, steel material consumption is reduced, dead weight of a gantry system is reduced wholly, and the manufacturing cost of the gantry is reduced; and meanwhile, due to the inequilateral channel steel design, the inequilateral channel steel is attractive in appearance, not easy to deform and higher in bending resistibility, stable running of the roller is guaranteed, friction period between the roller and section steel is prolonged, and the service life of the channel steel is prolonged.

Owner:LAIWU IRON & STEEL GRP

Laser spot welding clamp

ActiveCN106735959AHigh positioning accuracyNot easy to shakeLaser beam welding apparatusEngineeringSpot welding

The invention relates to a laser spot welding clamp. The laser spot welding clamp comprises a first clamping mechanism, a second clamping mechanism and a Y-axis positioning mechanism, wherein the first clamping mechanism is provided with X-axis positioning blocks for positioning a workpiece, the second clamping mechanism comprises a second clamping plate connected to the first clamping mechanism and an abutting-pressing part connected to the second clamping plate and used for abutting against the workpiece, and the Y-axis positioning mechanism comprises a positioning column which is arranged on the first clamping mechanism and penetrates through a round hole and an elastic part arranged between the positioning column and the first clamping mechanism. According to the laser spot welding clamp, because only one positioning column is required to be arranged in the round hole of the workpiece in a penetrating mode to realize the positioning of the workpiece in the Y-axis direction, the structure of the clamp is simplified, the positioning precision of the workpiece is improved, the phenomena of false welding, unwelding and deviation in the welding process of an auxiliary material are avoided, and the welding quality of the product is guaranteed; and meanwhile, the clamping capability of the whole clamp is guaranteed, the workpiece is not prone to shake in the spot welding process, and the positioning stability of the workpiece is ensured.

Owner:DONGGUAN CHANGYING PRECISION TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com