Electromagnetic clutch and manufacturing method of coil case thereof

A technology of electromagnetic clutch and manufacturing method, applied in the direction of magnetic drive clutch, clutch, non-mechanical drive clutch, etc., can solve the problems of easy de-soldering, inability to fit well, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

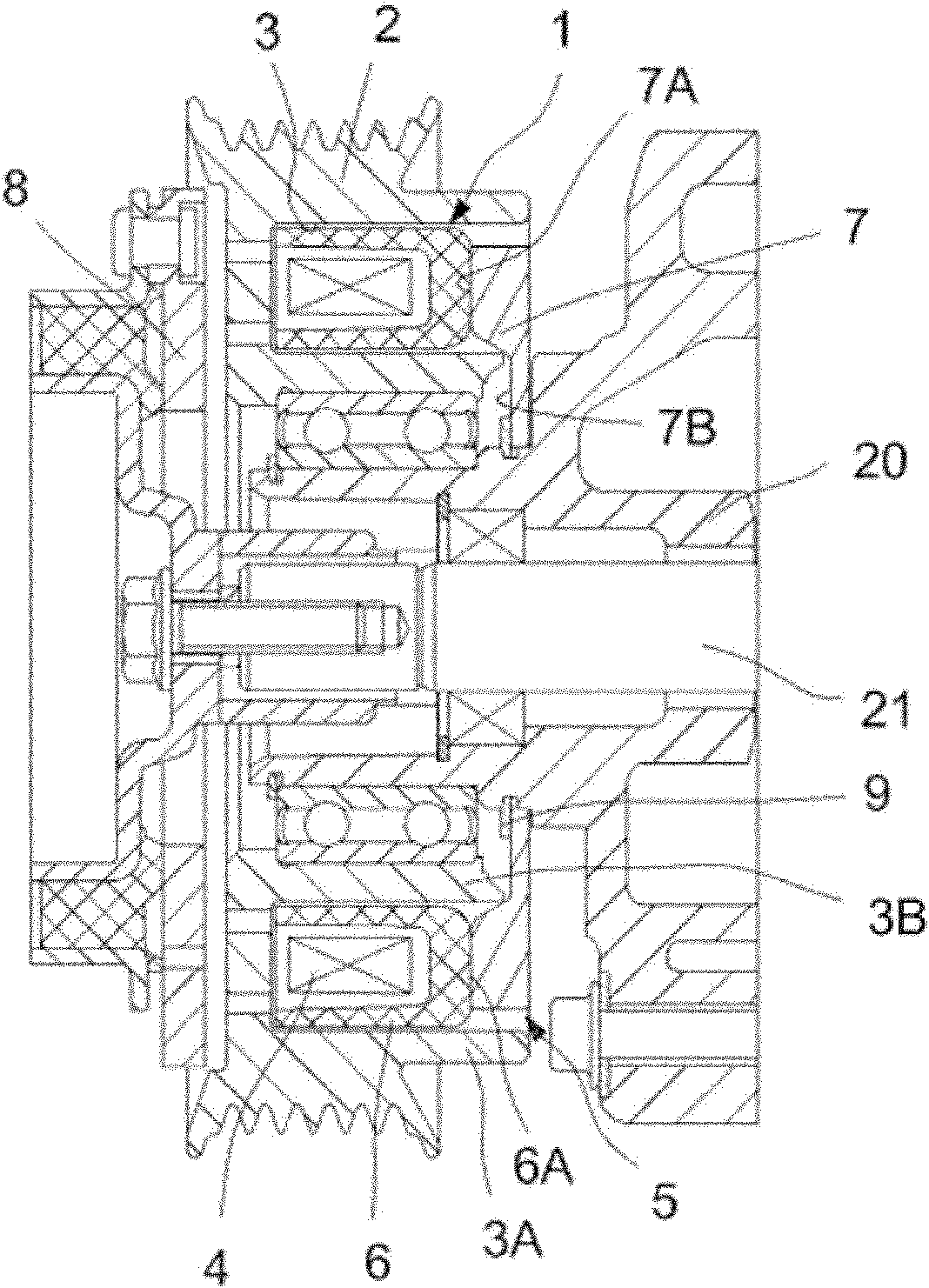

[0026] The electromagnetic clutch is the driving mechanism of the compressor, which is connected to the main shaft of the compressor, and mainly includes a pulley, a coil assembly, and a suction cup. Such as figure 2 As shown, the coil assembly 1 is accommodated in the ring groove 3 of the pulley 2, and the two are not in contact with each other, and there is a gap.

[0027] The coil assembly 1 is mainly composed of a coil 4 and a coil case 5 . The coil housing 5 has a U-shaped tank body 6 , the coil 4 is cast and fixed in the tank body 6 with epoxy resin, and a connecting plate 7 is welded to the back side 6A of the tank body 6 . Such as Figure 4 with Figure 5 As shown, one side of the connecting plate 7 has an outer annular surface 7A and an inner annular surface 7B. The back side 6A of the tank body 6 is welded with the outer ring surface 7A of the connecting plate 7, and the inner ring surface 7B of the connecting plate 7 is fixed on the front cylinder head 20 by, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com