Metal mesh multi-point pressure welding mechanism and method

A metal mesh and welding mechanism technology, applied in welding/welding/cutting items, welding equipment, metal processing, etc., can solve problems such as desoldering, easy detachment of copper plates, and difficult control of soldering point temperature, etc., to achieve production efficiency High, not easy to disengage, prevent desoldering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

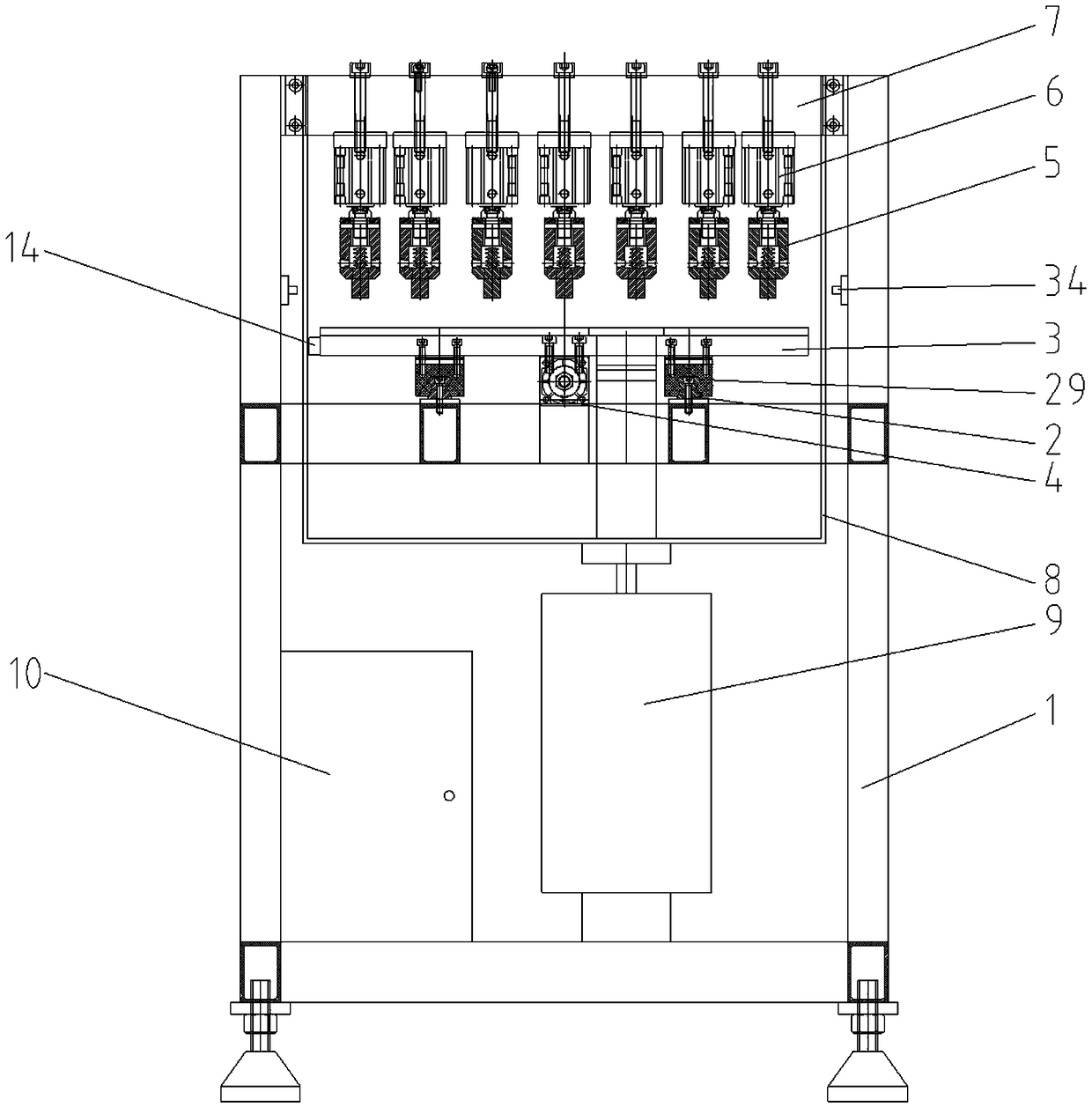

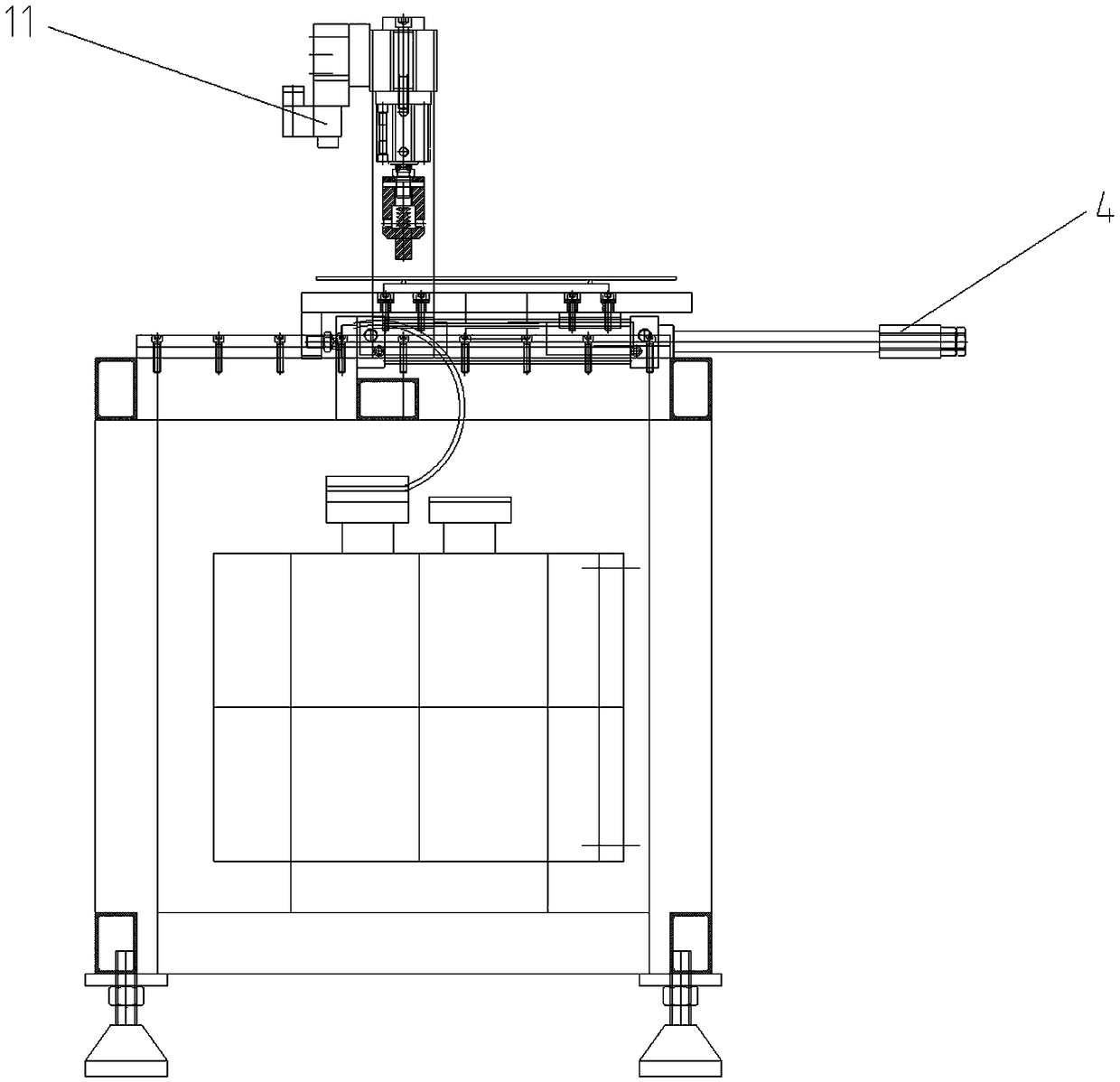

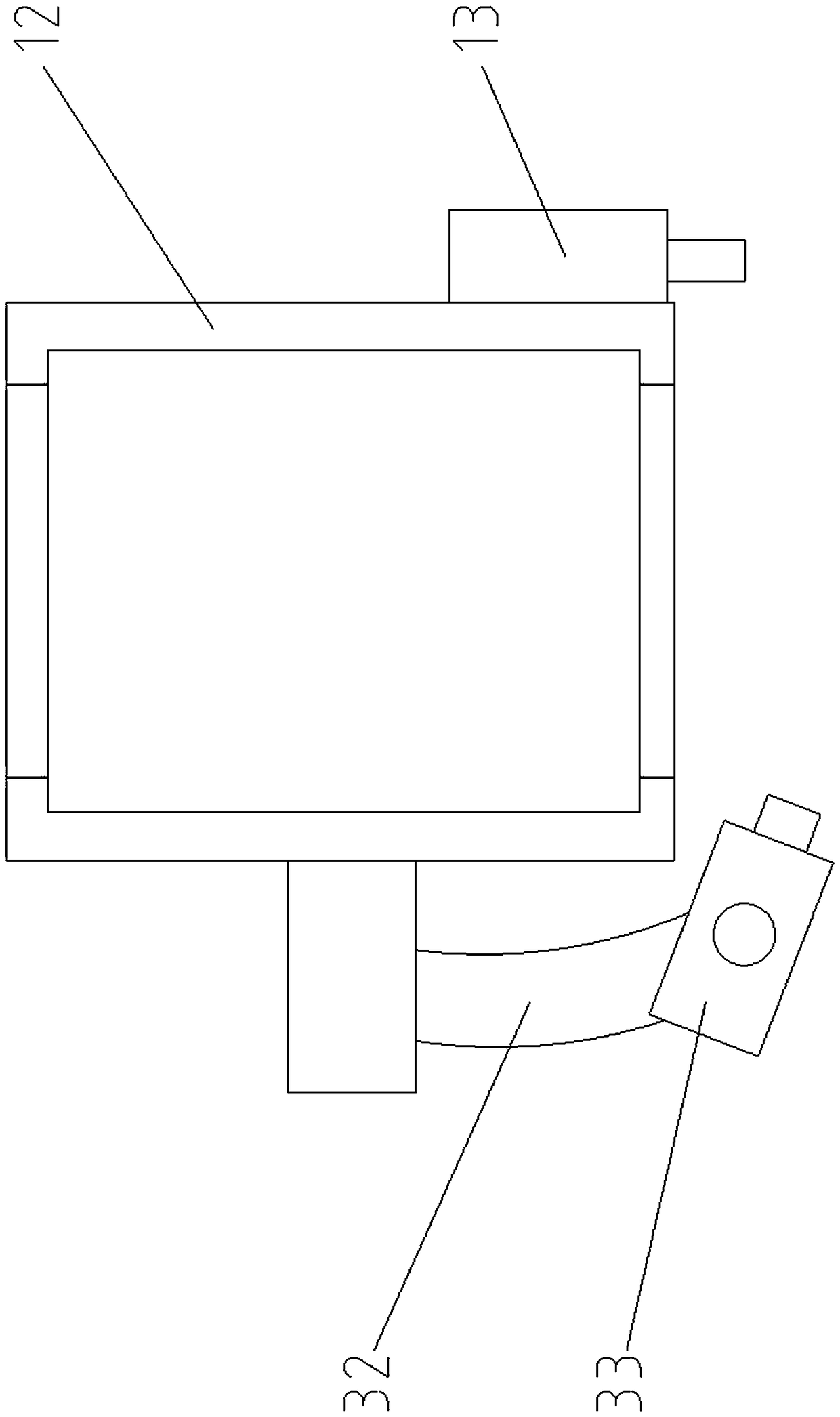

[0026] Embodiment: a kind of metal mesh sheet multi-point pressure welding welding mechanism of this example, as figure 1 , figure 2 , including a frame 1, a linear slide rail 2 is arranged on the frame, a workbench 3 is slidably connected to the linear slide rail, the workbench is connected to the workbench cylinder 4, and a plurality of welding copper nozzles 5 are arranged on the top of the workbench. Mouth is connected on the lifting cylinder 6, and lifting cylinder is fixed on the crossbeam 7 of frame, and lifting cylinder is connected with pneumatic solenoid valve 11, and pneumatic solenoid valve is connected power parameter control cabinet 10 by line. The welding copper nozzle is connected to the welding machine transformer 9 through the conductive copper plate 8, and the welding machine transformer, the workbench cylinder and the lifting cylinder are connected to the power parameter control cabinet 10 through lines, and the welding machine transformer and the power pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com