Hot-melt pressure-sensitive adhesive for paper diaper and production method thereof

A technology of hot-melt pressure-sensitive adhesives and production methods, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problems of structural layer detachment, effective improvement of bonding strength, etc., and achieve fluidity Strong, non-irritating, low-sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

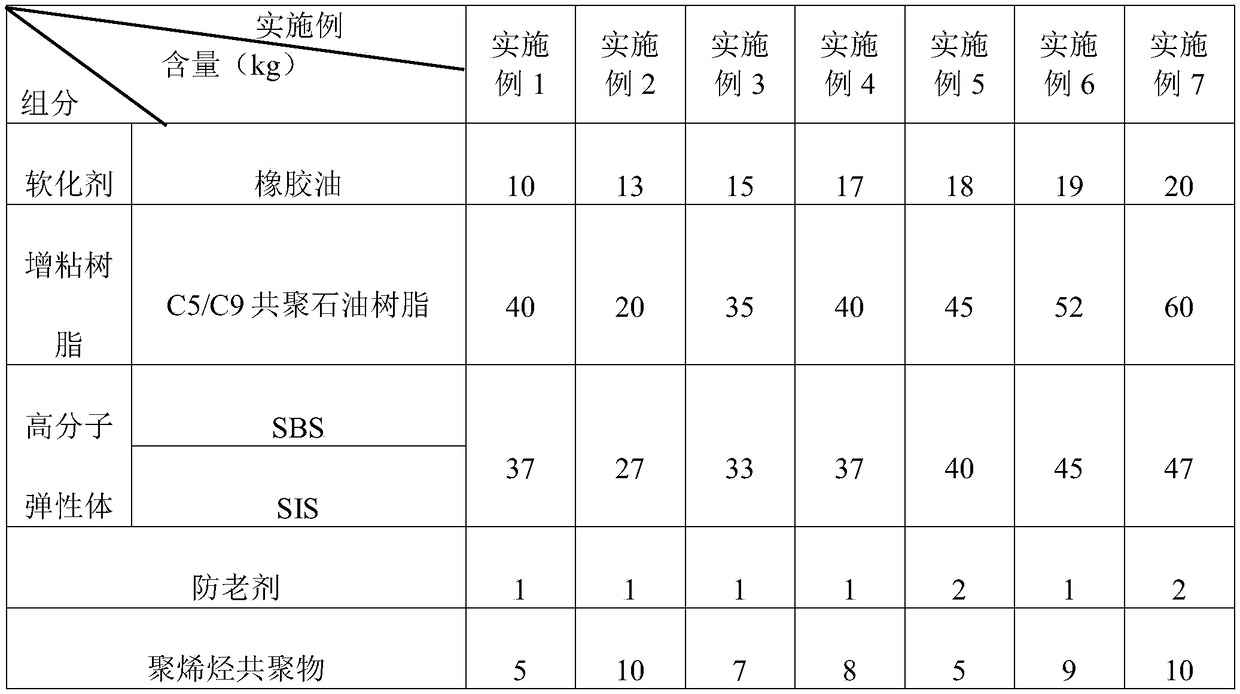

[0046] Example 1-7: A hot-melt pressure-sensitive adhesive for diapers, including components and corresponding contents as shown in Table 1. Among them, the softener is rubber oil, the tackifying resin is C5 / C9 copolymerized petroleum resin, and the polymer elastomer is a compound of SBS and SIS, and the weight ratio of the two compounds is 1.8:2.

Embodiment 8

[0047] Embodiment 8: A hot-melt pressure-sensitive adhesive for diapers. The difference from Embodiment 1 is that the tackifying resin is a terpene resin.

Embodiment 9

[0048] Example 9: Hot-melt pressure-sensitive adhesive for diapers. The difference from Example 1 is that the tackifying resin is a mixture of terpene resin and C5 / C9 copolymerized petroleum resin, and the weight ratio of the two is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com