Adhesive composition and optical member using the same

A technology for optical components and adhesives, applied in the directions of optical components, non-polymer adhesive additives, adhesive types, etc., can solve the problems of reduced durability, poor initial bonding strength, etc., and achieve excellent creep performance , excellent bonding strength, excellent anti-leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

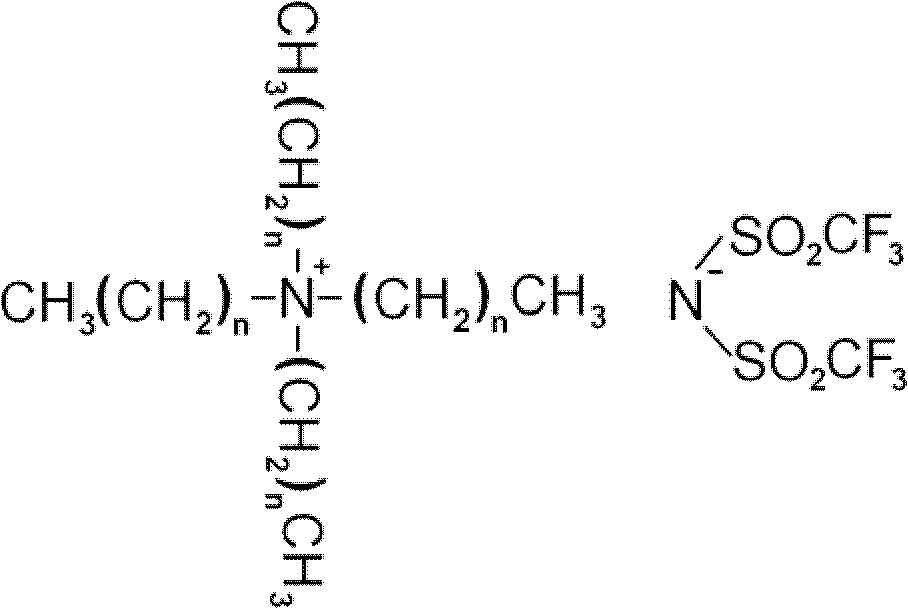

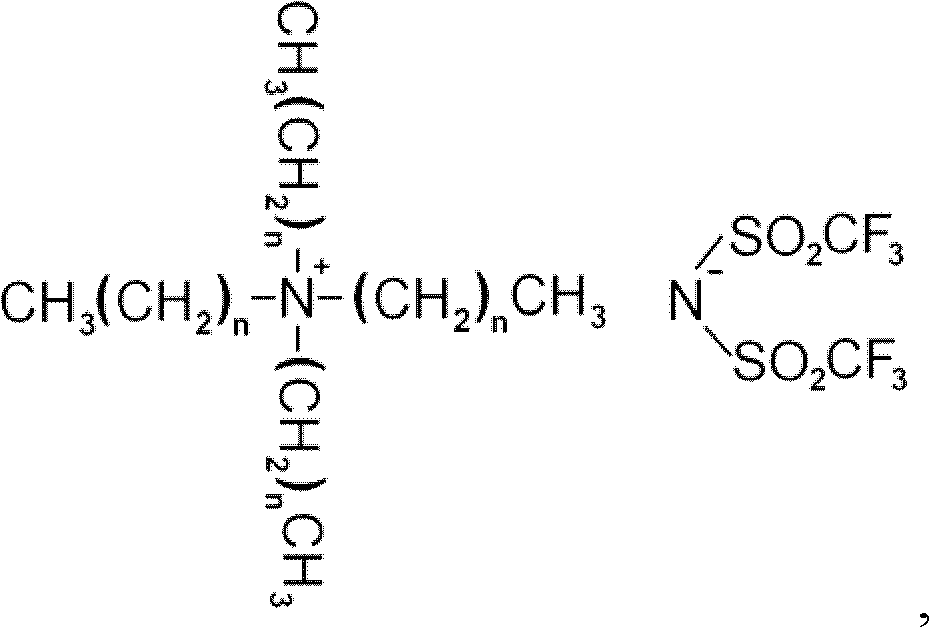

Method used

Image

Examples

Embodiment 1 to 4

[0080] The above components were mixed according to the compositions listed in Table 1, and to the mixture was added 20 parts by weight of methyl ethyl ketone as a diluent, and uniformly stirred for 20 minutes, thereby preparing a coating solution. The adhesive coating solution was deposited on a release film to a dry thickness of 25 μm to prepare an adhesive sheet, followed by aging at 35° C. and 45% RH. Then, the properties of the adhesive were evaluated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com