Adhesive composition, adhesive obtained using same, and adhesive for polarizing plate

A technology of adhesives and compositions, applied in the fields of adhesive compositions, adhesives, and adhesives for polarizing plates, can solve problems such as poor display, uneven display, and easy electrification, and achieve stability over time Excellent, excellent reworkability, excellent antistatic performance and durability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10、 comparative example 1~7

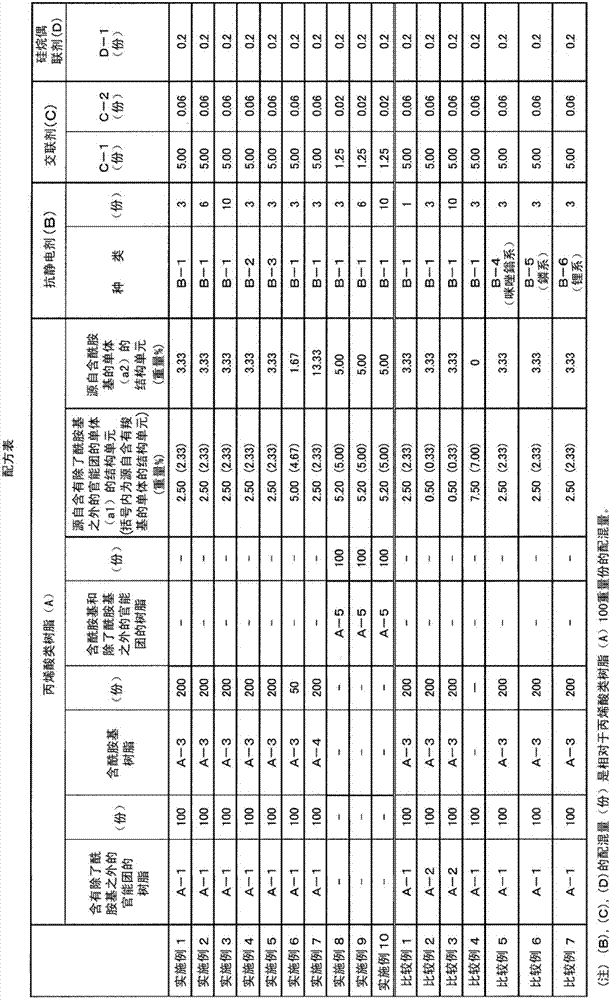

[0151] [Preparation of Adhesive Composition (Solution)]

[0152] Prepared as above, prepared each compounding component was compounded at the ratio shown in the following Table 2 to prepare an adhesive composition, which was diluted with ethyl acetate to prepare an adhesive composition solution ( Solid content concentration 13%). In addition, in the following Table 2, each compounding quantity of an antistatic agent (B), a crosslinking agent (C), and a silane coupling agent (D) is the whole acrylic resin (A) being 100. The converted value is the part by weight.

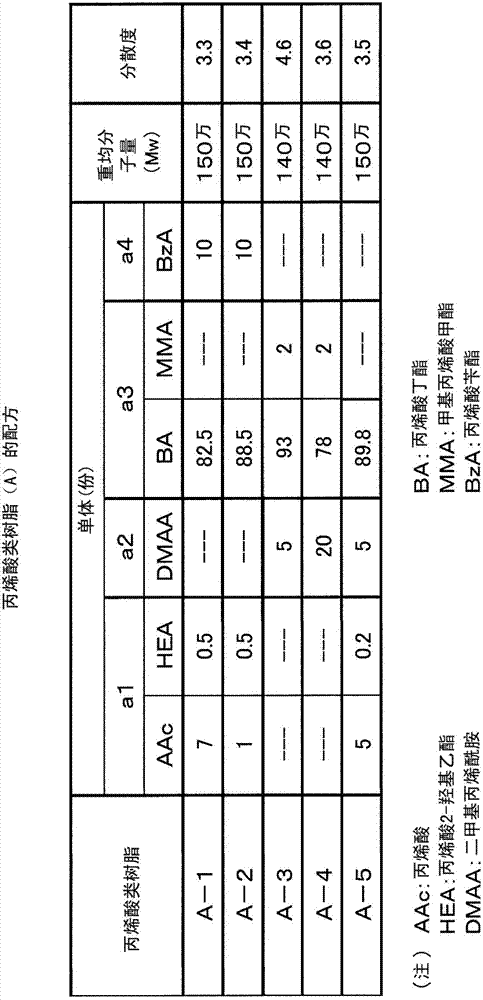

[0153] [Table 2]

[0154]

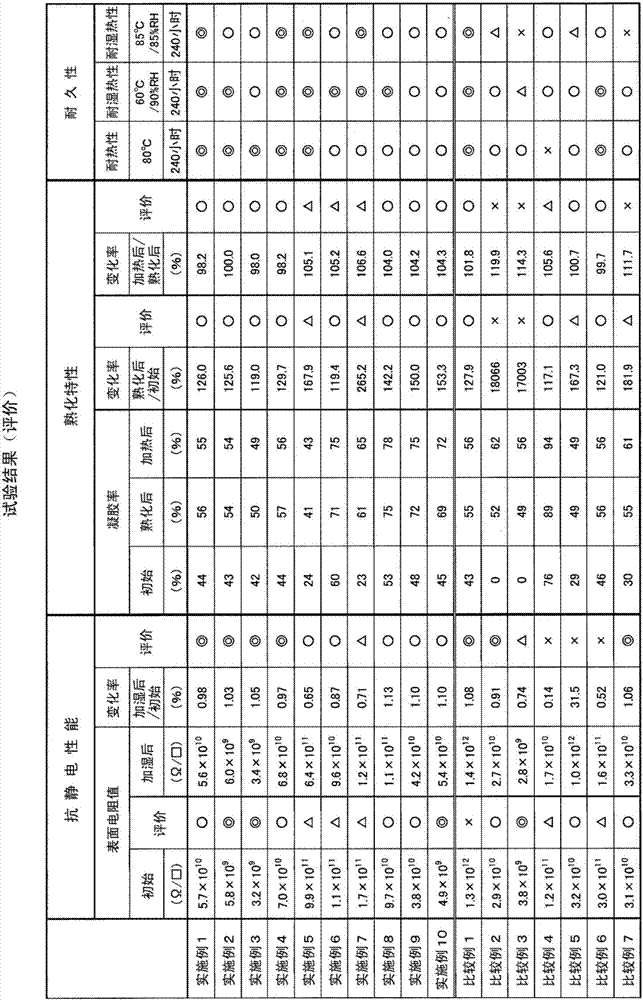

[0155] Next, the adhesive composition solutions of Examples and Comparative Examples were applied to a polyester-based release sheet so that the thickness after drying was 25 μm, and after drying at 100° C. for 3 minutes, the formed adhesive was assembled. The material layer was transferred to a polarizing plate (protective film: TAC film manufactured by Fujifilm Co., Ltd.), and aged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com