Washing solution for surface of electroless tin plating film, replenishing solution for said washing solution, and method for forming tin plating layer

A cleaning solution and coating technology, which is applied in the reinforcement of conductive patterns, cleaning/polishing of conductive patterns, coating, etc., can solve the problems of step pollution, reduce the advantages of continuous productivity of horizontal transportation, and improve efficiency without difficulty Excellent effect of crystallization and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

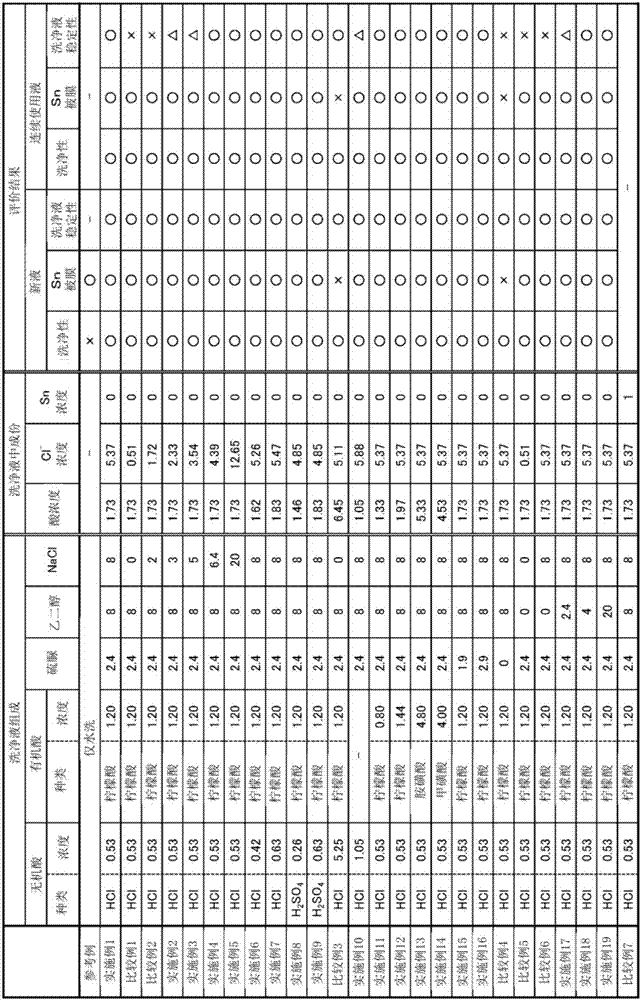

Embodiment 1 to Embodiment 19 and comparative example 1 to comparative example 7

[0074] (wash with new solution)

[0075] Electroless tin plating was performed in the same manner as in the aforementioned reference example. After immersing the copper-clad laminate taken out from the plating solution in the cleaning solution (25° C.) of the composition shown in Table 1 for 10 seconds, it was washed with water and dried in the same manner as the reference example. Also, in Comparative Example 7, an attempt was made to adjust the solution by blending tin salt (stannous sulfate) so that the tin concentration became 1% by weight, but the following evaluation was not performed because part of the tin salt was not dissolved.

[0076] (cleaning with continuous use fluid)

[0077] Add 30 parts by weight of the above-mentioned replacement tin plating solution to 100 parts by weight of the new solution shown in Table 1 (composition is equivalent to the cleaning solution after being brought into the plating solution due to continuous use; tin concentration is 0.27% by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com