Ceramide dispersion, and process for producing same

A technology of ceramide and manufacturing method, which is applied in the direction of amide active ingredients, chemical instruments and methods, and medical preparations of non-active ingredients, etc., which can solve the problem of compromising safety, usability, inability to make ceramide transparent and soluble, and difficulty in ensuring overtime Stability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

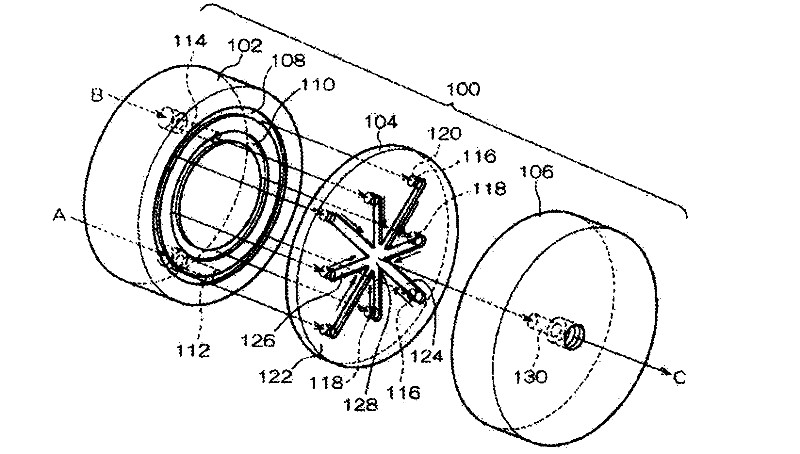

[0244] When the micro-mixer is used in the preparation of small particle size emulsion as one of the microchemical processes, due to the low energy and low heat generation, compared with the usual stirring emulsification dispersion method and high-pressure homogenizer emulsification dispersion, it is easy to obtain uniform particle size , A good emulsion or dispersant with excellent storage stability. It is the best method for emulsification containing natural ingredients that are easily deteriorated by heat.

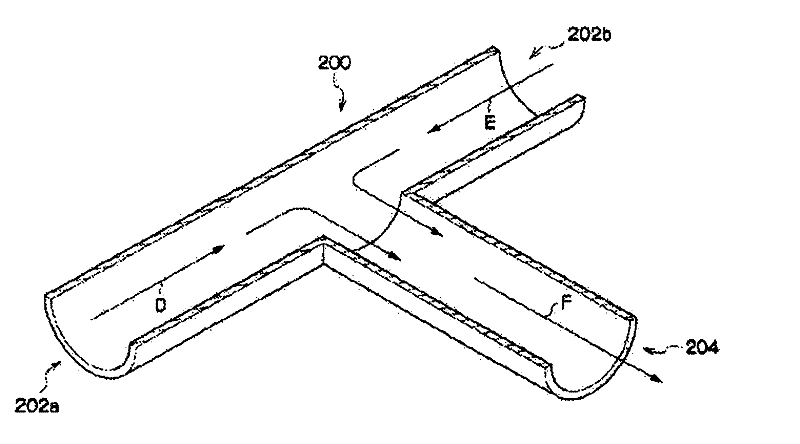

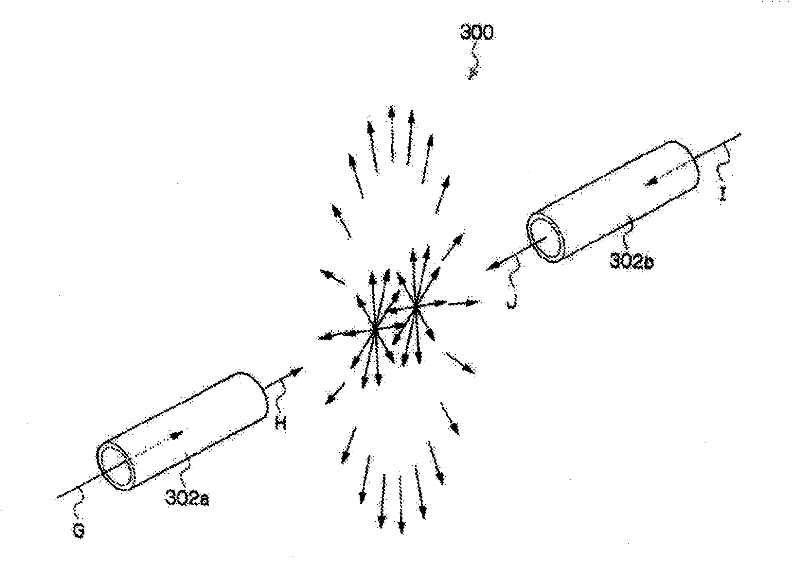

[0245] The outline of the method of emulsifying or dispersing using a micro mixer is to divide the water phase and the oil phase into minute spaces, and to make the respective minute spaces contact or collide with each other. This is obviously different from the membrane emulsification method and the fine channel emulsification method, which are methods in which only one is divided into a small space and the other is bulk. Effect. There are devices of various structur...

Embodiment 1

[0300] The components described in the following oil phase liquid 1 were stirred at room temperature for about 30 minutes to prepare oil phase liquid 1. In addition, for the following aqueous phase liquid 1, add inulin lauryl carbamate (INUTEC SP1: manufactured by SIBER HEGNER, Japan; the same below) to pure water, heat to about 50°C, and stir well to dissolve it. The remaining ingredients were added and mixed, and the temperature of the liquid was adjusted to 30°C.

[0301]

[0302]

[0303]

[0304]

[0305]

[0306] (pH=7.4 of the final ceramide dispersion)

[0307] The obtained oil phase liquid 1 (oil phase) and water (water phase) were micromixed (dispersed) with a collision type KM micromixer 100 / 100 at a ratio (mass ratio) of 1:7 to obtain ceramide Dispersion 1. In addition, the usage conditions of the micromixer are as follows.

[0308] -Microchannel-

[0309] oil side microchannel

[0310] Section shape / width / depth / length=rectangular / 70μm / 100μm / 10mm ...

Embodiment 2

[0317] The oil phase liquid 1 and the water phase liquid 1 in Example 1 were changed to the following oil phase liquid 2 and the water phase liquid 2, and mixed in the same manner as in Example 1, and the liquid temperature was adjusted to 28°C, Micromixing was carried out in the same manner as in Example 1 to obtain a ceramide dispersion 2. Then, 90 parts of the obtained ceramide dispersion liquid 2 and 10 parts of 1,3-butanediol were added, mixed and stirred well, and then concentrated, and concentrated in the same manner as in Example 1 to obtain a ceramide dispersion B. .

[0318]

[0319]

[0320]

[0321]

[0322] (pH=7.7 of final ceramide dispersion)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com