Patents

Literature

223 results about "MICRO MIXER" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

General purpose laboratory equipment labeled or promoted for a specific medical use is a device that is intended to prepare or examine specimens from the human body and that is labeled or promoted for a specific medical use.

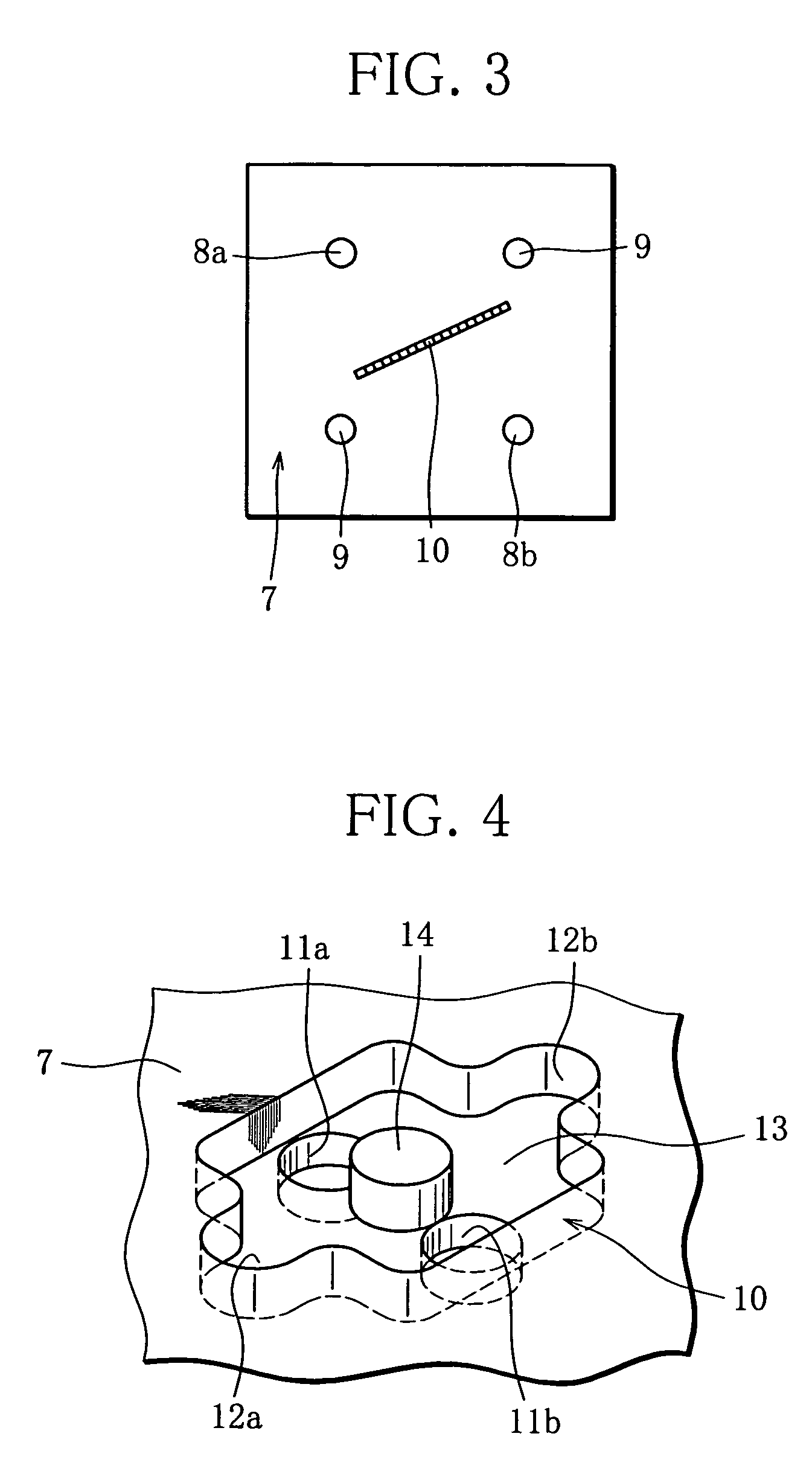

Microfluid driving device

InactiveUS6743636B2Easy to prepareMicrofluid drivingTransportation and packagingWithdrawing sample devicesMICRO MIXERElectrical and Electronics engineering

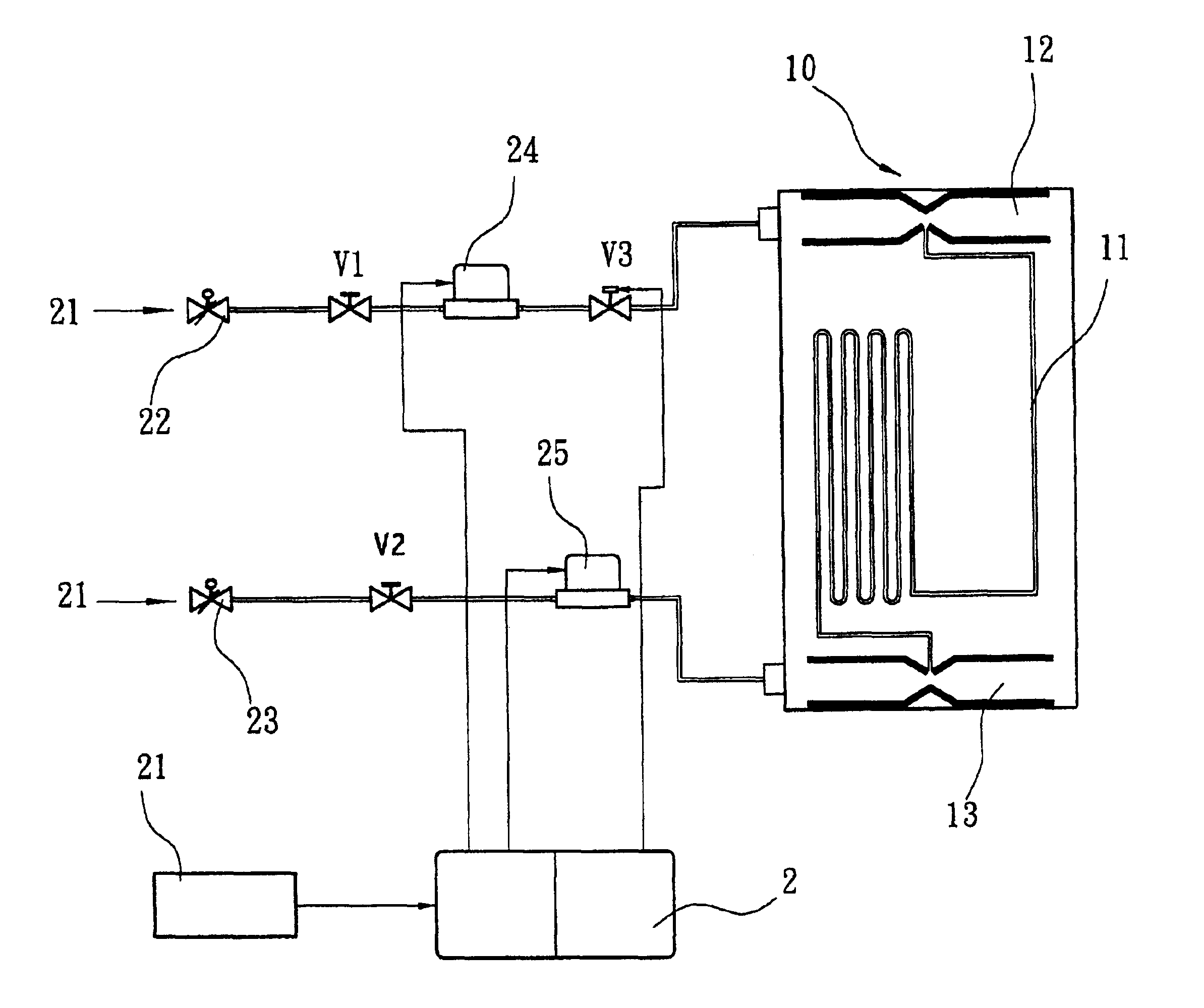

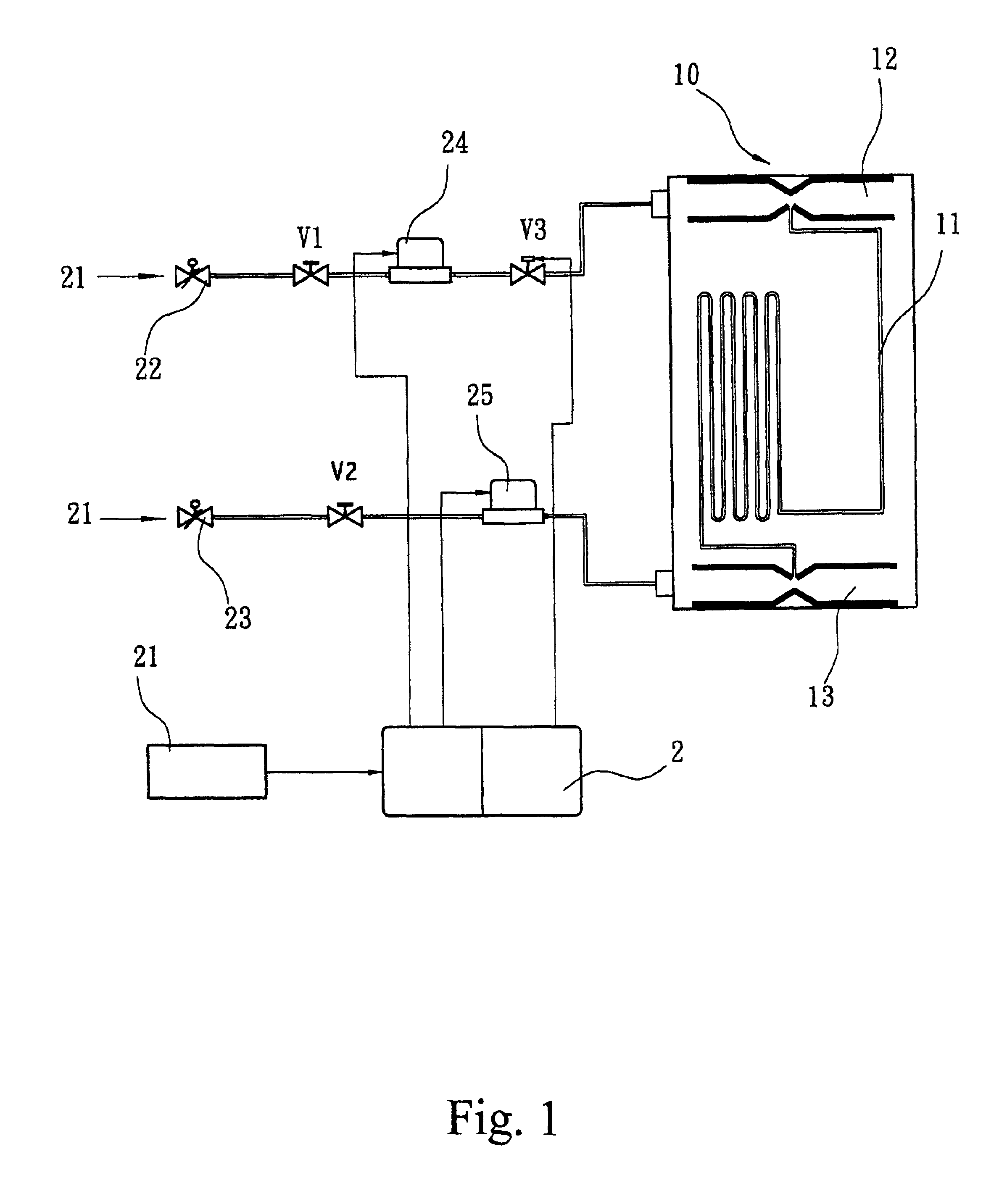

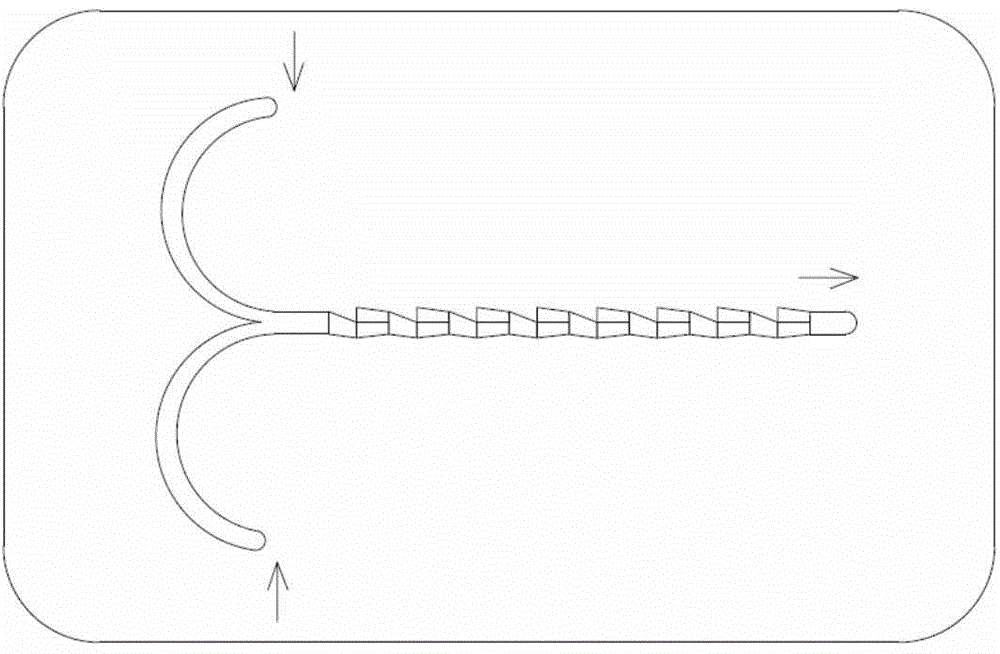

A microfluid driving device is provided. The microfluid driving device of this invention comprises microfluid driving platform prepared in a chip, which platform comprises at least two miniature Venturi pumps, at least one microchannel and optionally micro mixers or micro reactors in said microchannel; an external pneumatic flow supply and control module that provides selectively different air flows; and an interface device connecting said microfluid driving platform and said external pneumatic flow supply and control module. The air flows supplied by said the pneumatic flow supply and control module are supplied under selected flow rates and frequencies to said at least two Venturi pumps through said interface device, such that the microfluid inside said microchannel may be driven forward or backward or halt and the transportation, mixing and reaction of the microfluid may be accomplished.

Owner:IND TECH RES INST

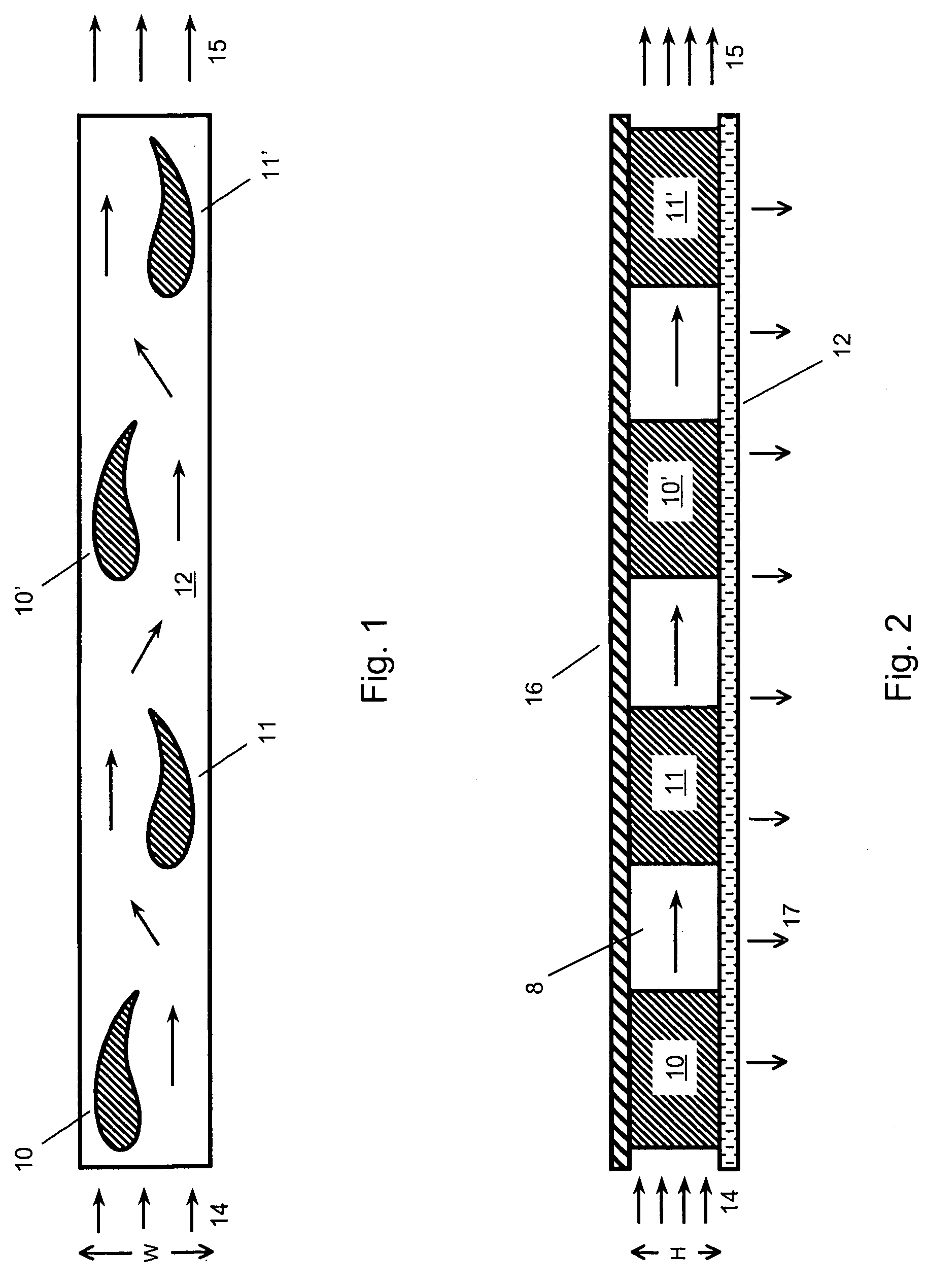

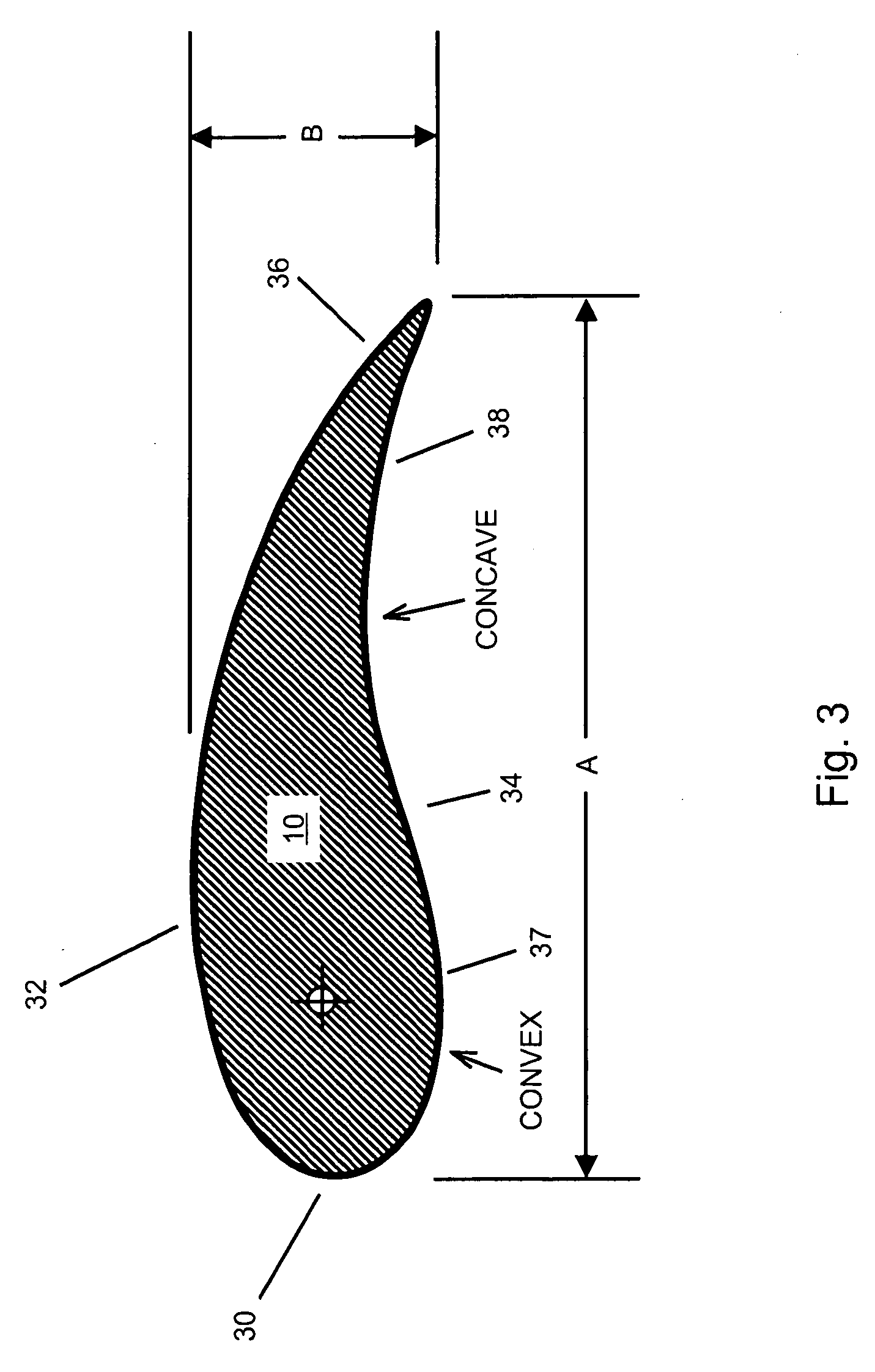

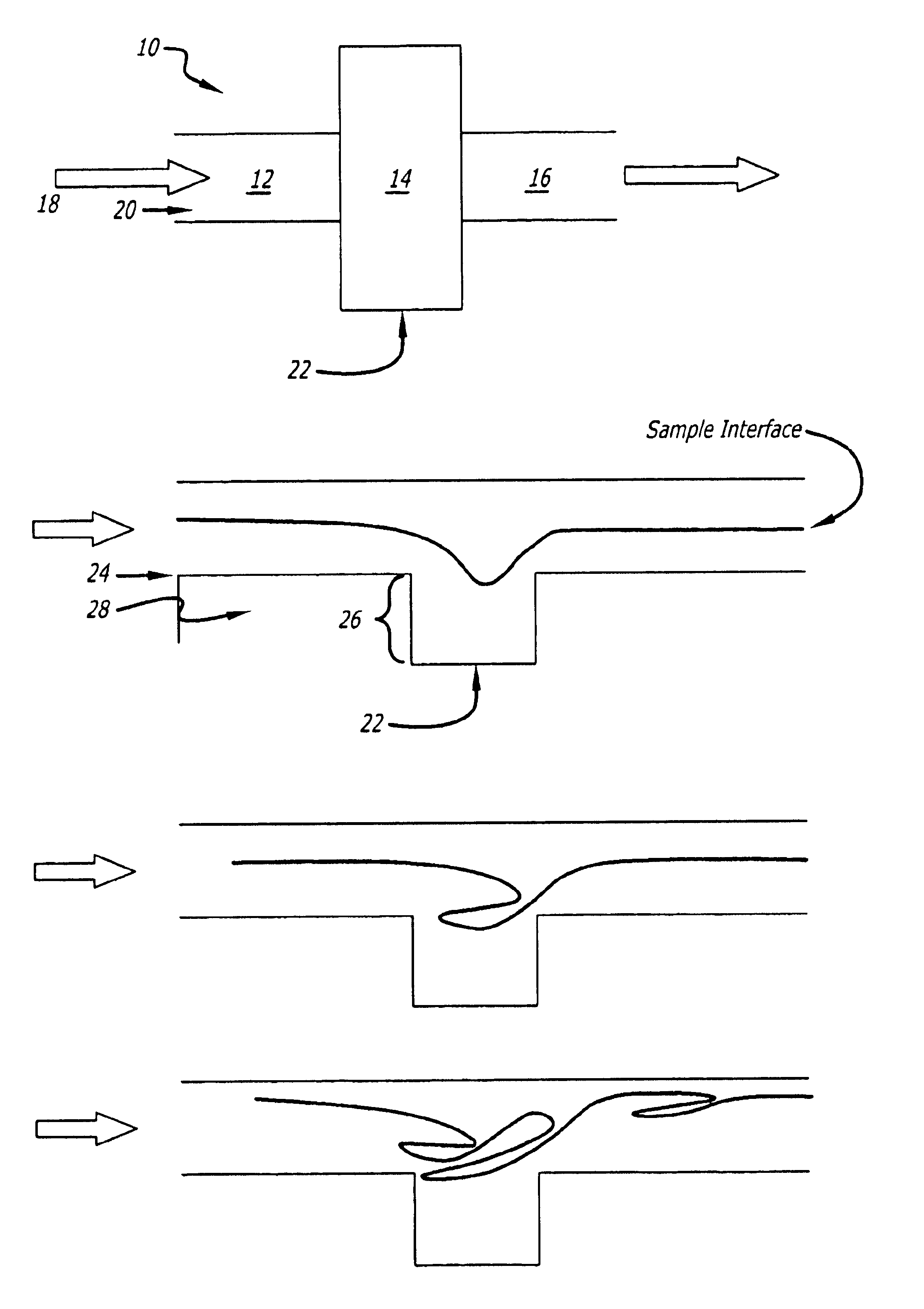

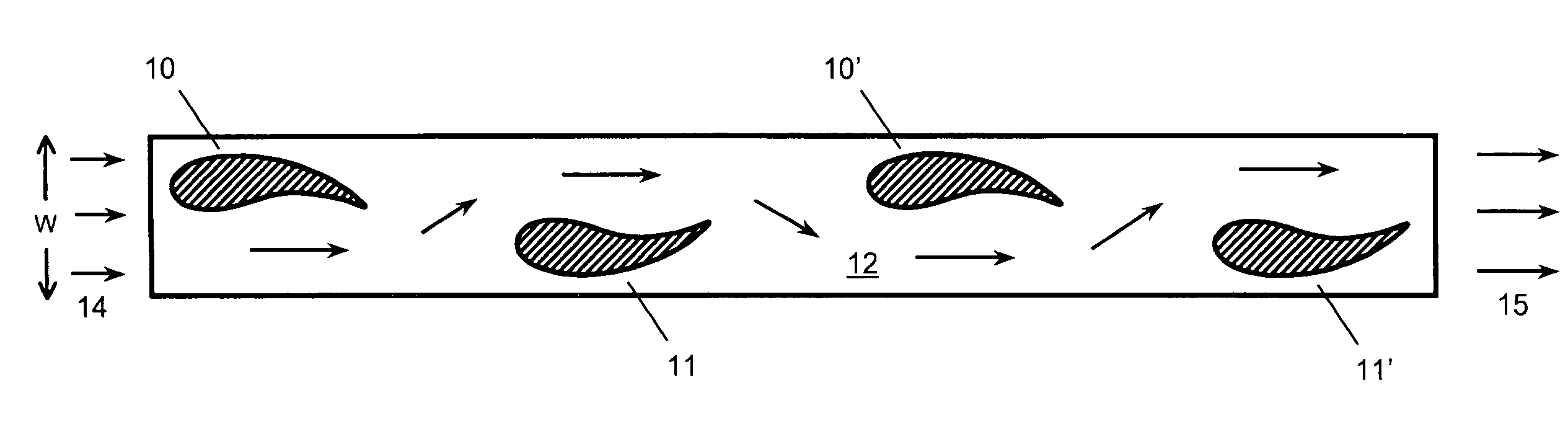

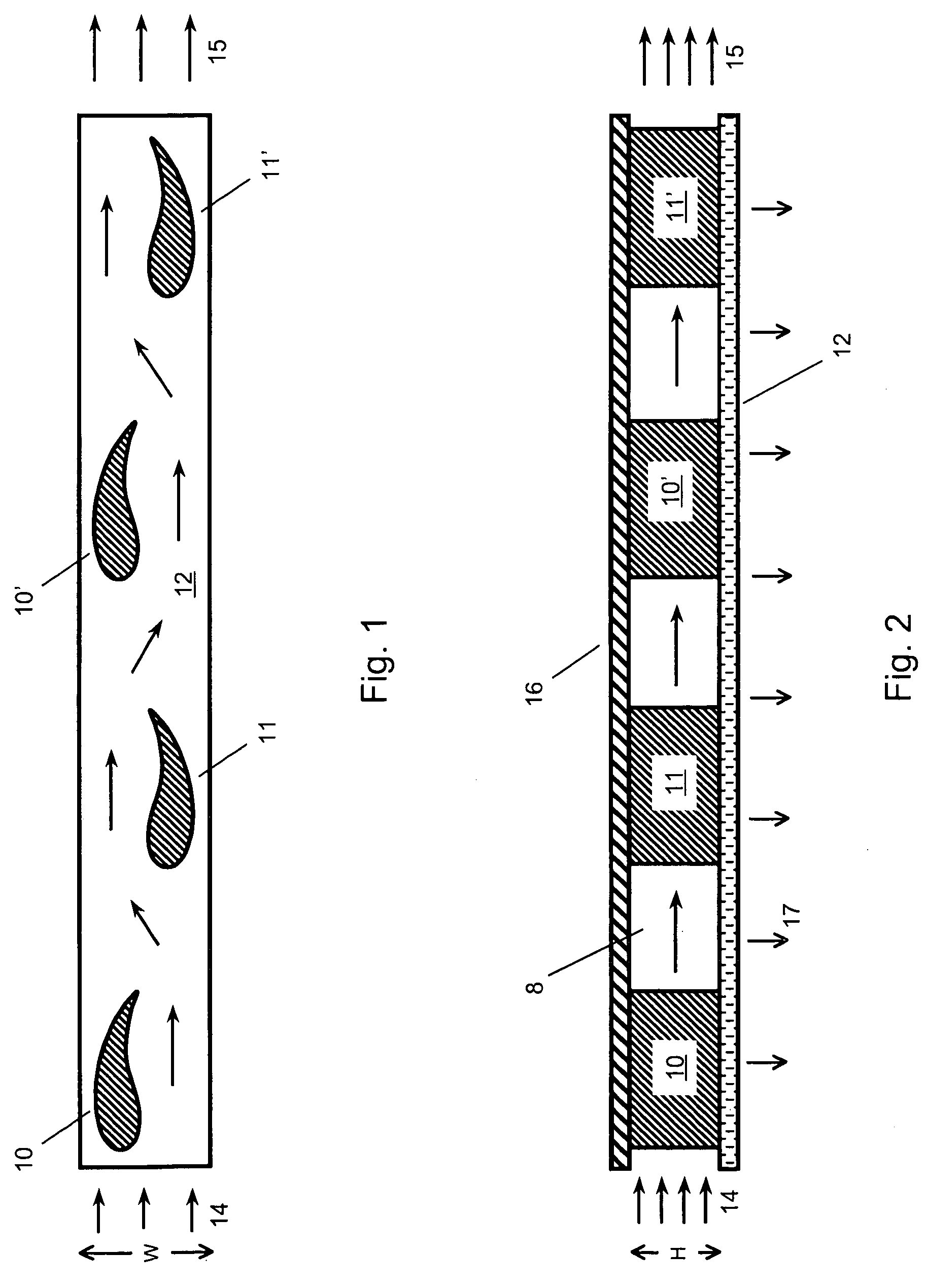

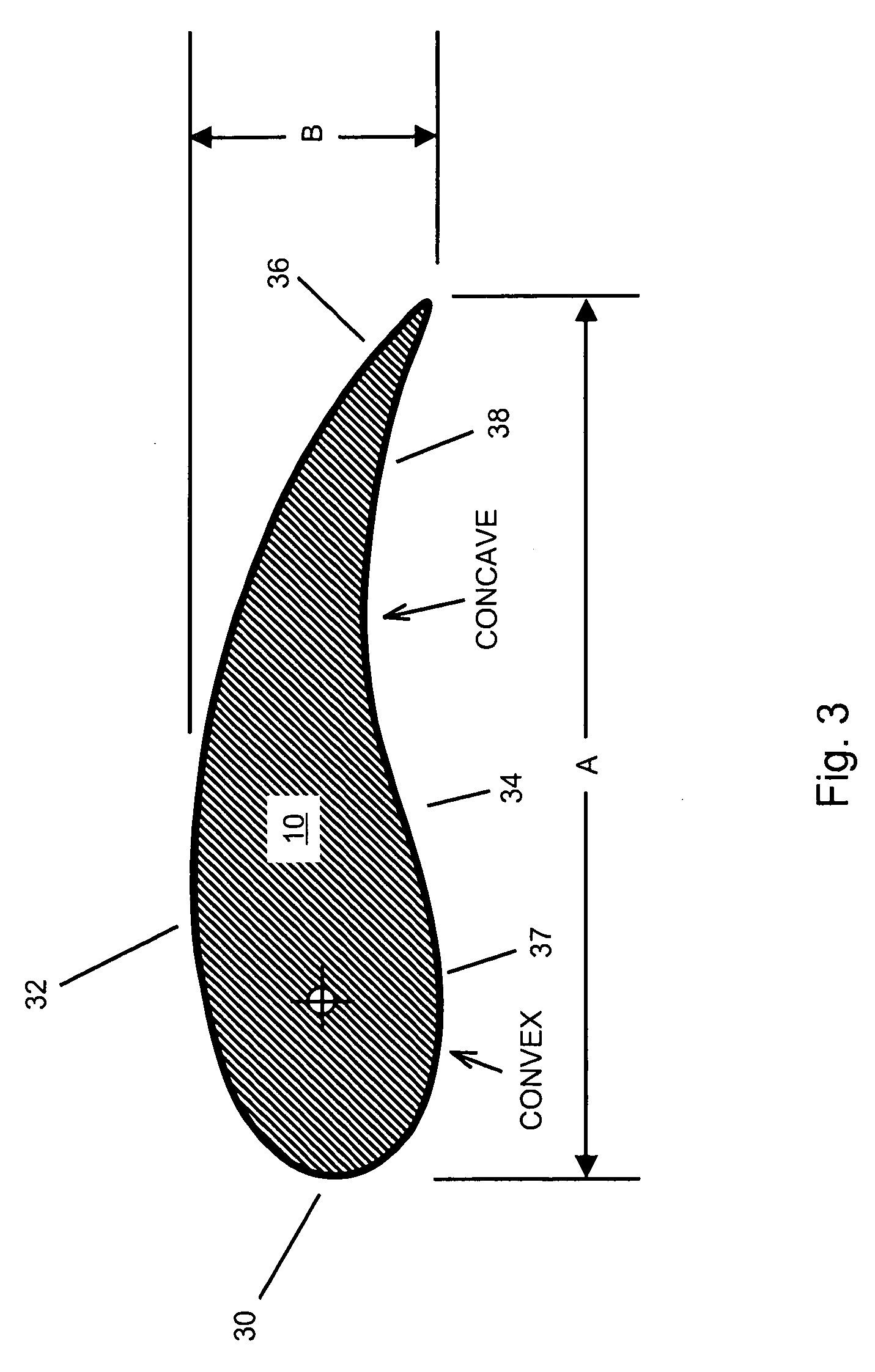

Airfoil-Shaped Micro-Mixers for Reducing Fouling on Membrane Surfaces

ActiveUS20100118642A1Enhance fluid mixingMinimized pressure dropSemi-permeable membranesMembranesFiltrationMembrane channel

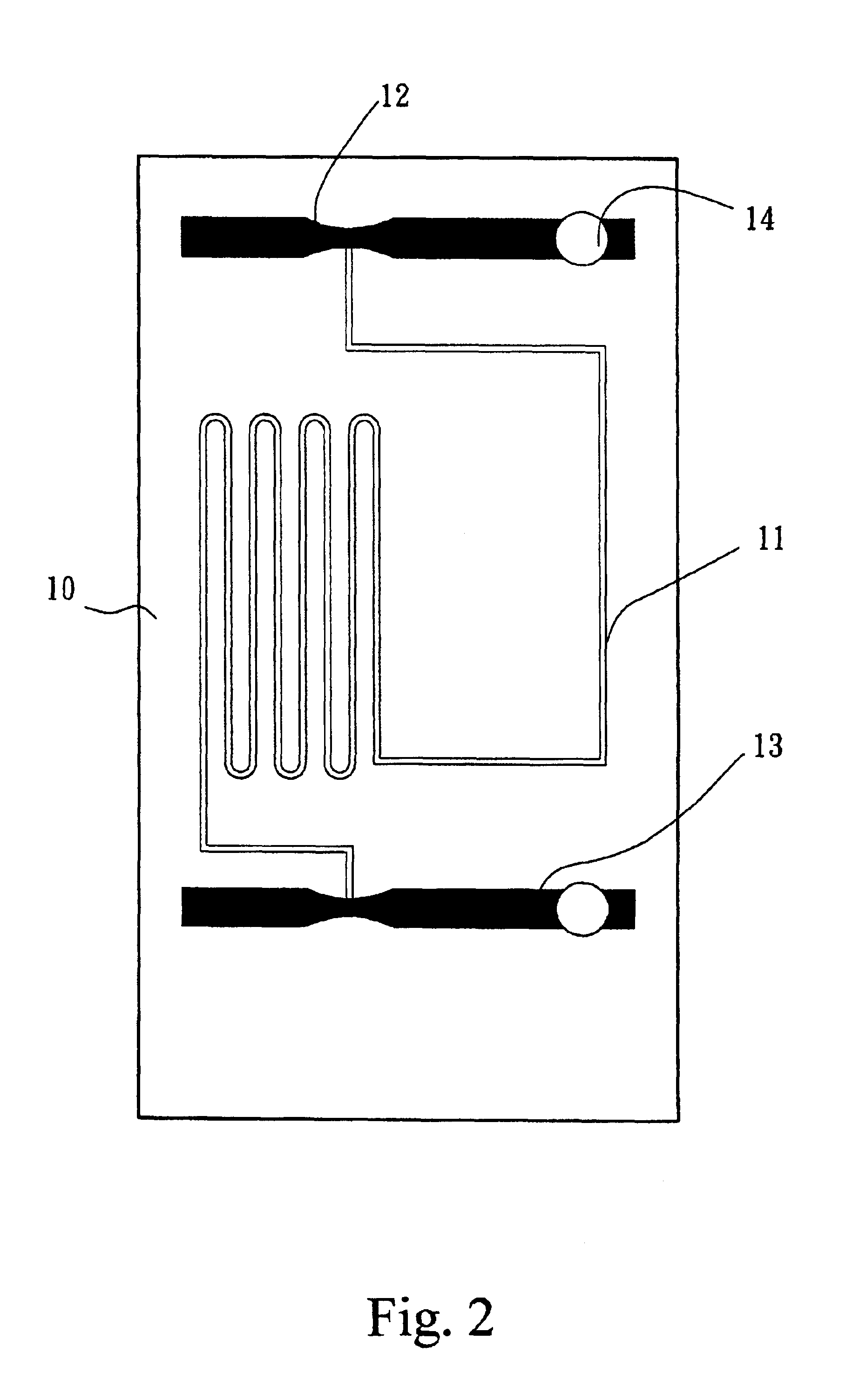

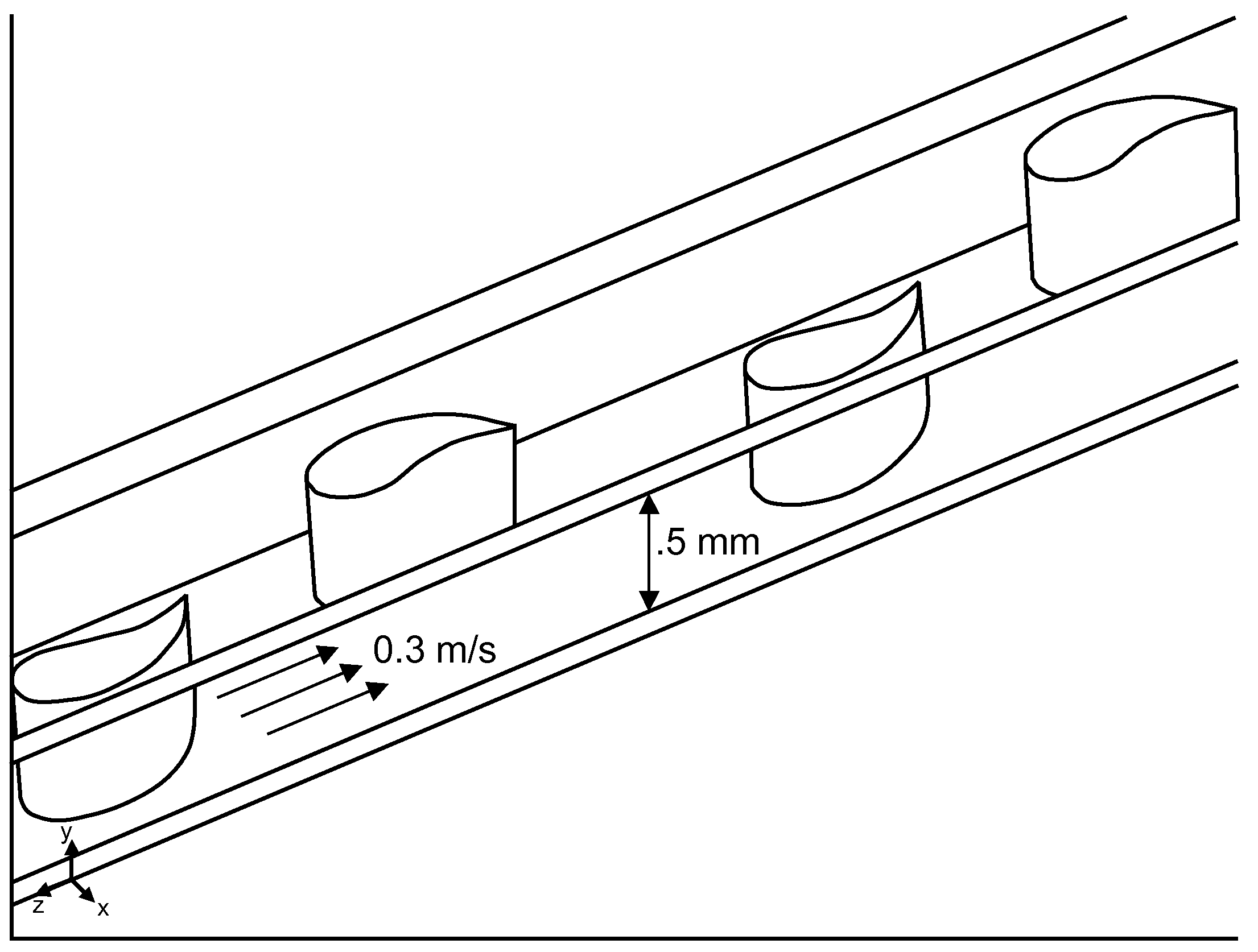

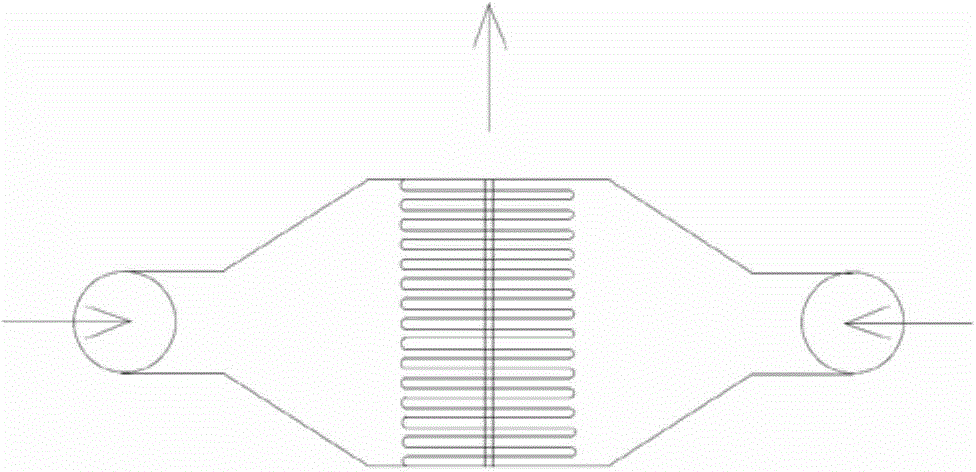

An array of airfoil-shaped micro-mixers that enhances fluid mixing within permeable membrane channels, such as used in reverse-osmosis filtration units, while minimizing additional pressure drop. The enhanced mixing reduces fouling of the membrane surfaces. The airfoil-shaped micro-mixer can also be coated with or comprised of biofouling-resistant (biocidal / germicidal) ingredients.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

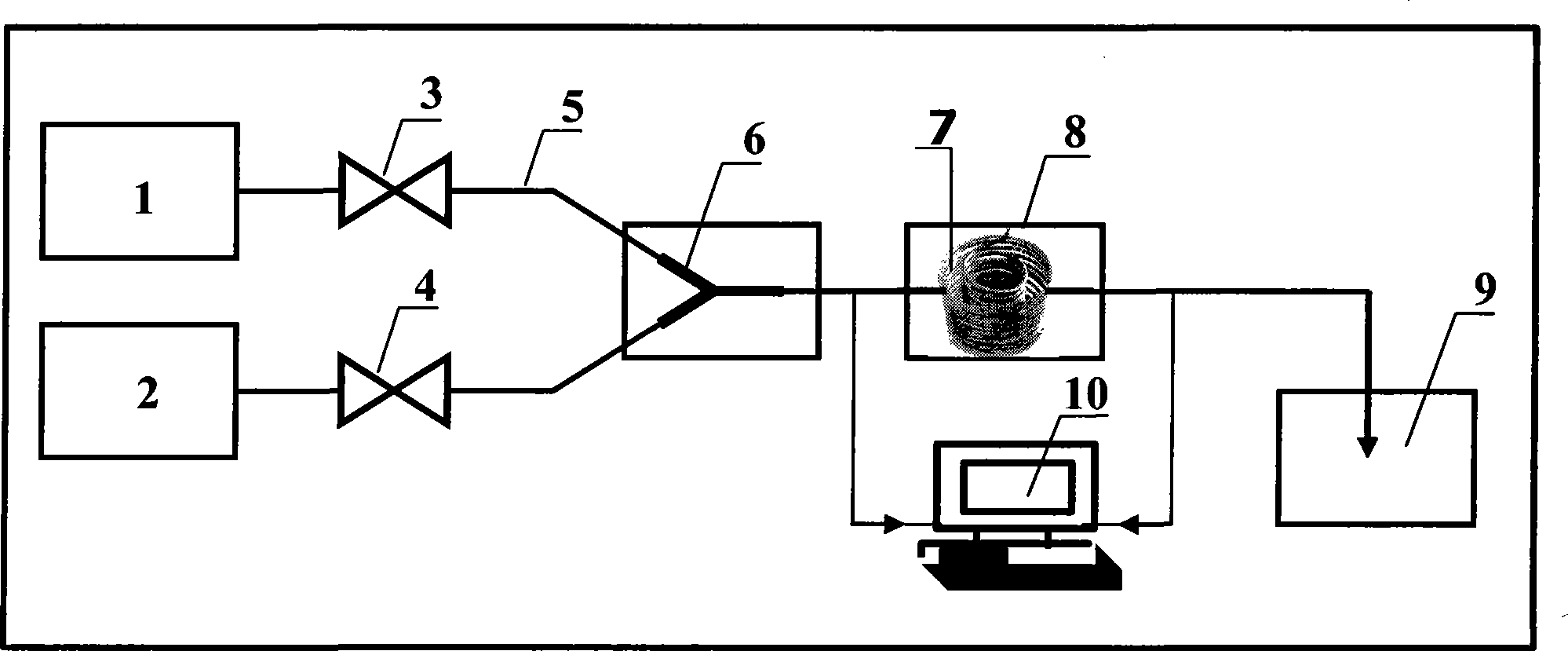

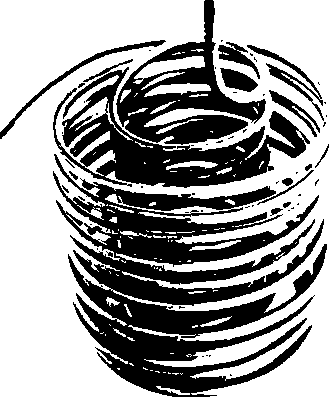

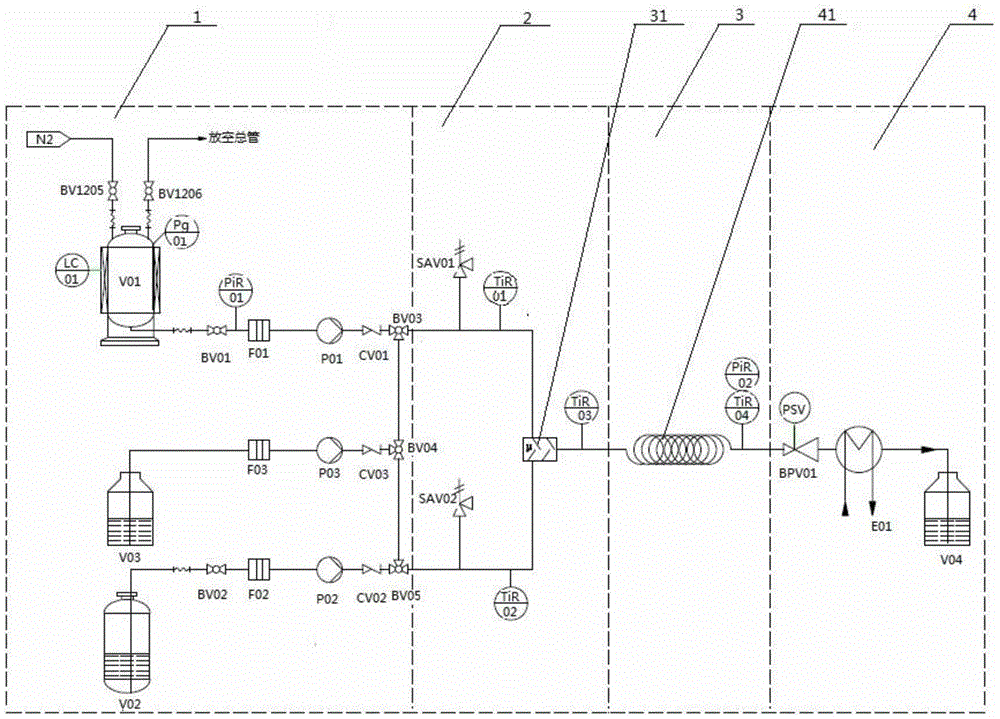

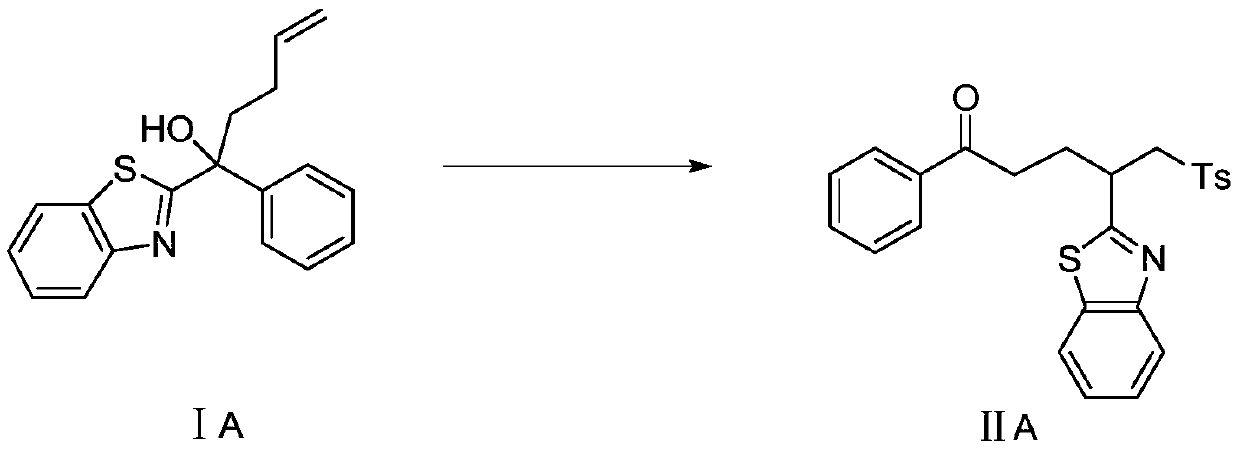

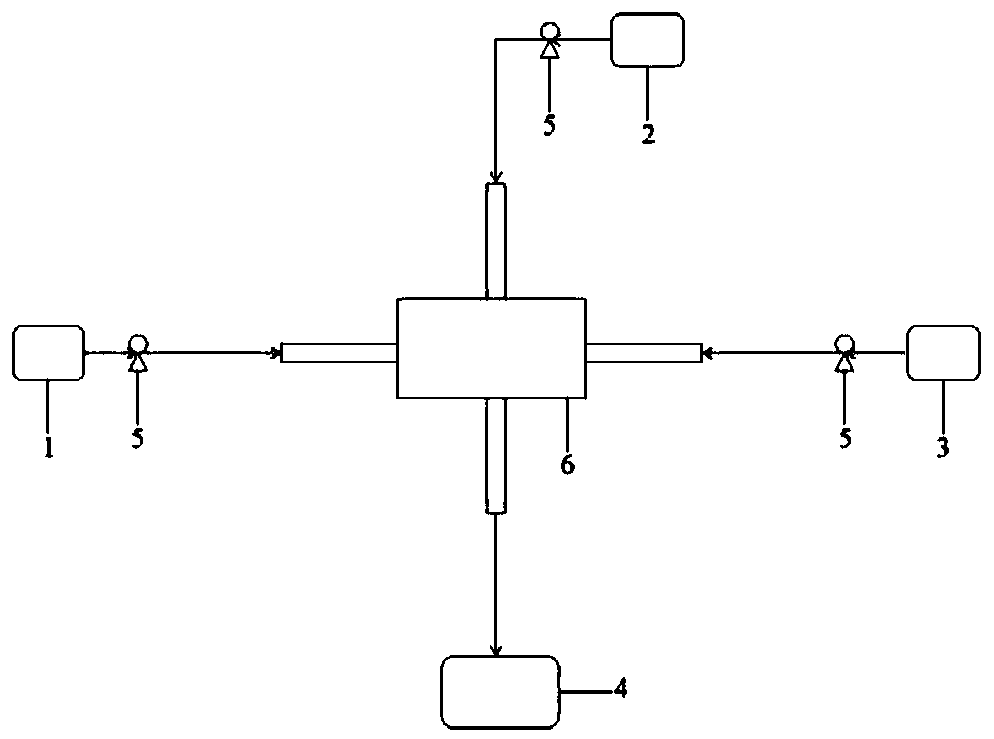

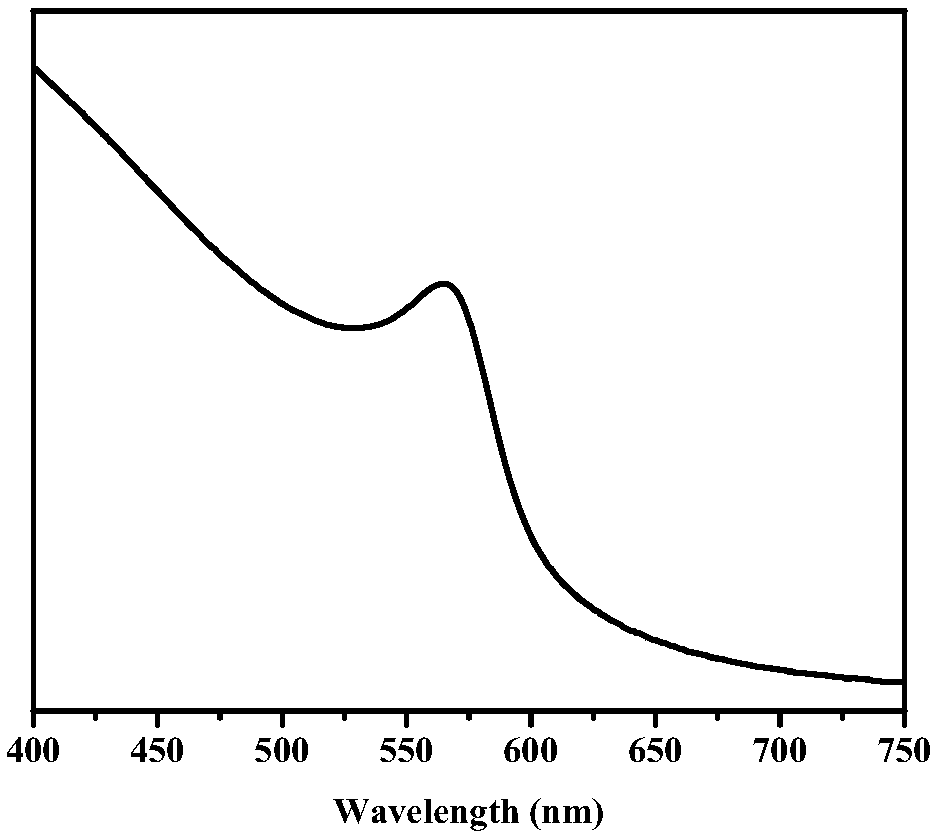

Continuous current micro-reactor and preparation method and use thereof

The invention relates to a continuous flow micro-reactor for medicine and fine chemical production and preparation and application thereof. The invention belongs to the technical field of the micro-reactor and preparation and application thereof. The reactor device consists of a liquor storage tank, a constant flow pump, a micro-mixer, serpentiform double helix capillary reaction pipes, an optical detector, a constant temperature bath and a connecting duct. The continuous flow micro-reactor is capable of making a reactant move back and forth continuously and spirally in the internal and external path coiled reaction pipes, thereby avoiding the phenomenon of local overheating for the reaction in the prior reactor vessel. The invention also provides a preparation method for the reactor and a method for synthesizing chalcone compounds through the reactor. The continuous flow micro-reactor has the advantages of compact structure, simple preparation, convenient use, high reaction efficiency, low power consumption, little pollution, and the like. The continuous flow micro-reactor can carry out continuous production and on-line tracking of the reaction process and has bright market prospect.

Owner:HAINAN UNIVERSITY

Micro-mixer

InactiveUS20060028908A1Turbulence be causeValve arrangementsTransportation and packagingEngineeringElectrical impulse

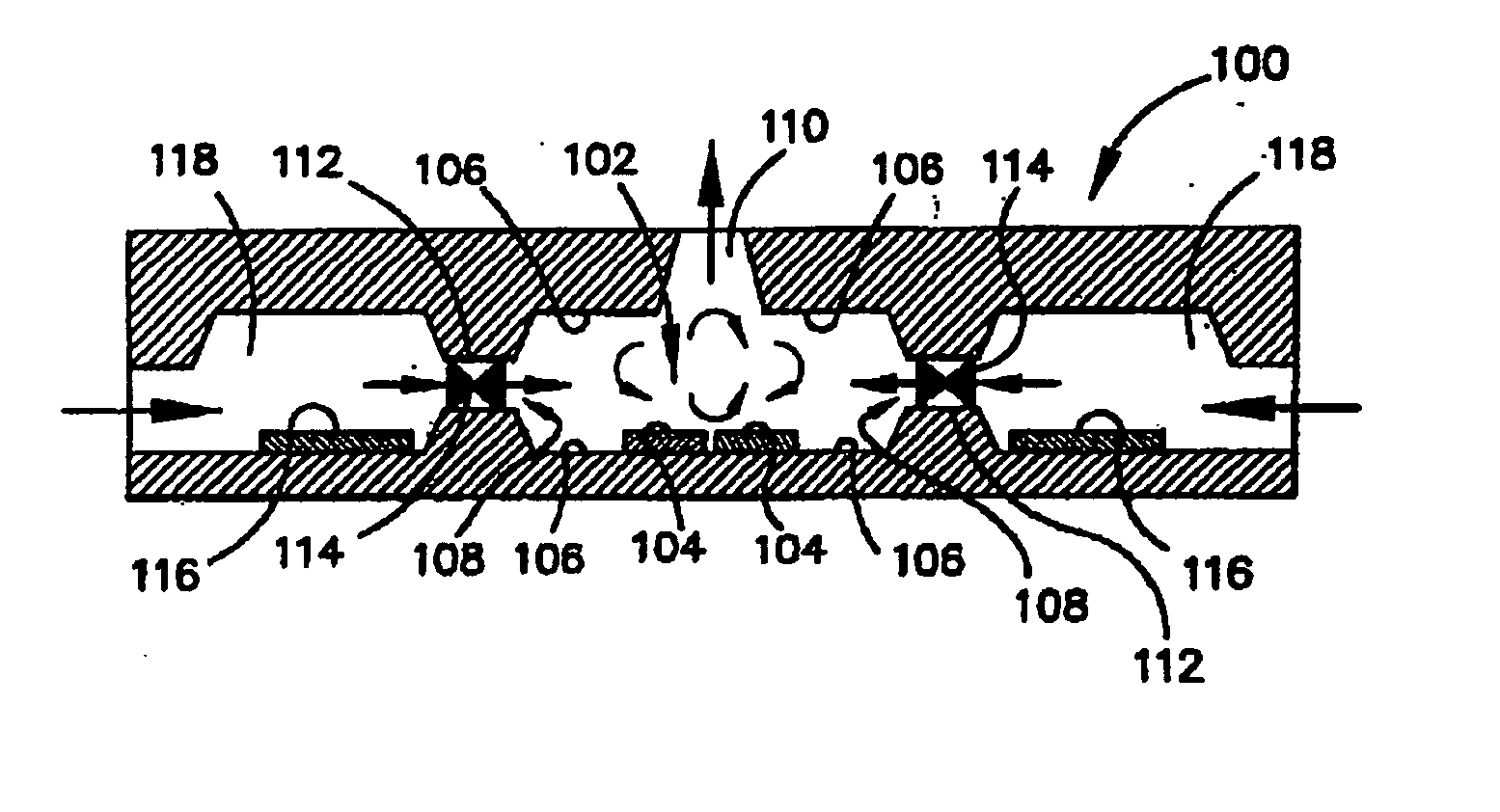

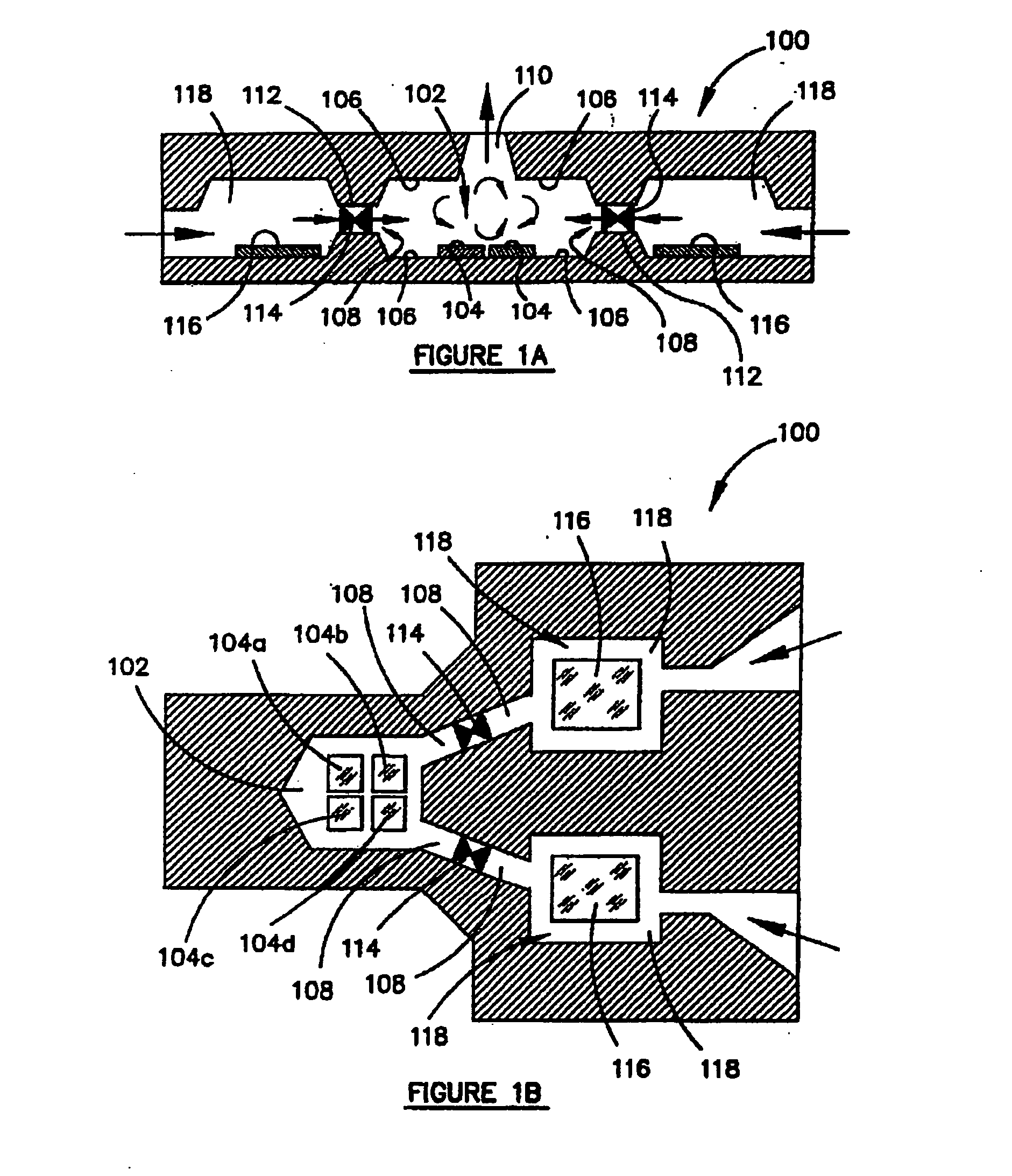

A micro-mixer 100 having a body in which there is disposed a micro-mixing chamber for mixing liquid. Micro-channels 108 extend from an external surface of the body of the micro-mixer 100 to the micro-mixing chamber 102 and define passageways for supplying liquid into the micro-mixing chamber 102. The micro-mixer 100 also has an electrical circuit that includes an electrical pulse generator that is connected to two or more spaced electrical heating elements 104 located in the mixing chamber 102 that receive electrical pulses from the pulse generator. In use, electrical pulses received by the heating elements 104 cause the heating elements to heat liquid in the mixing chamber in regions locally of each of the heating elements and thereby generating a vapour bubble which will, in turn, cause turbulence and mixing of liquid within the micro-mixing chamber.

Owner:HEWLETT PACKARD DEV CO LP

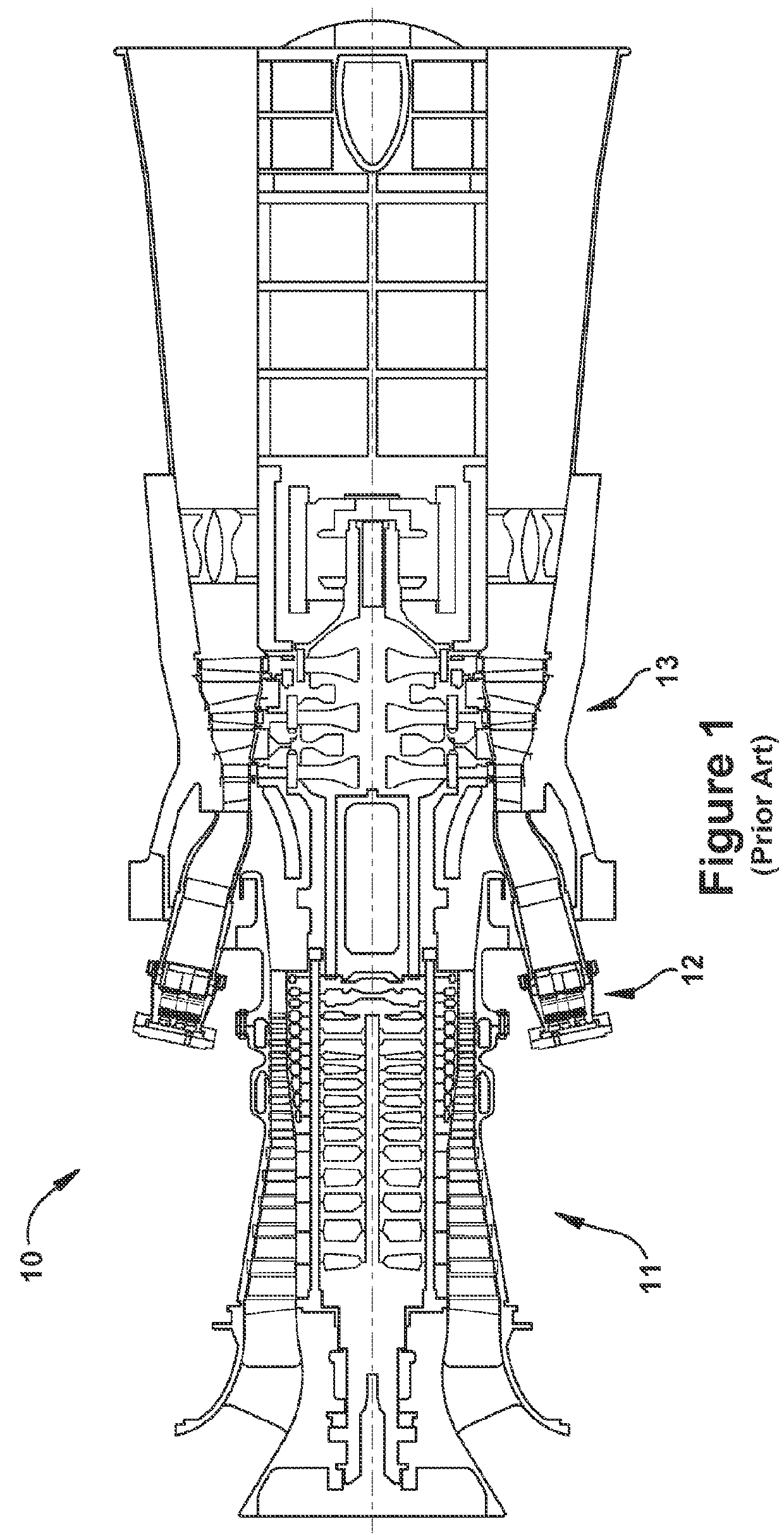

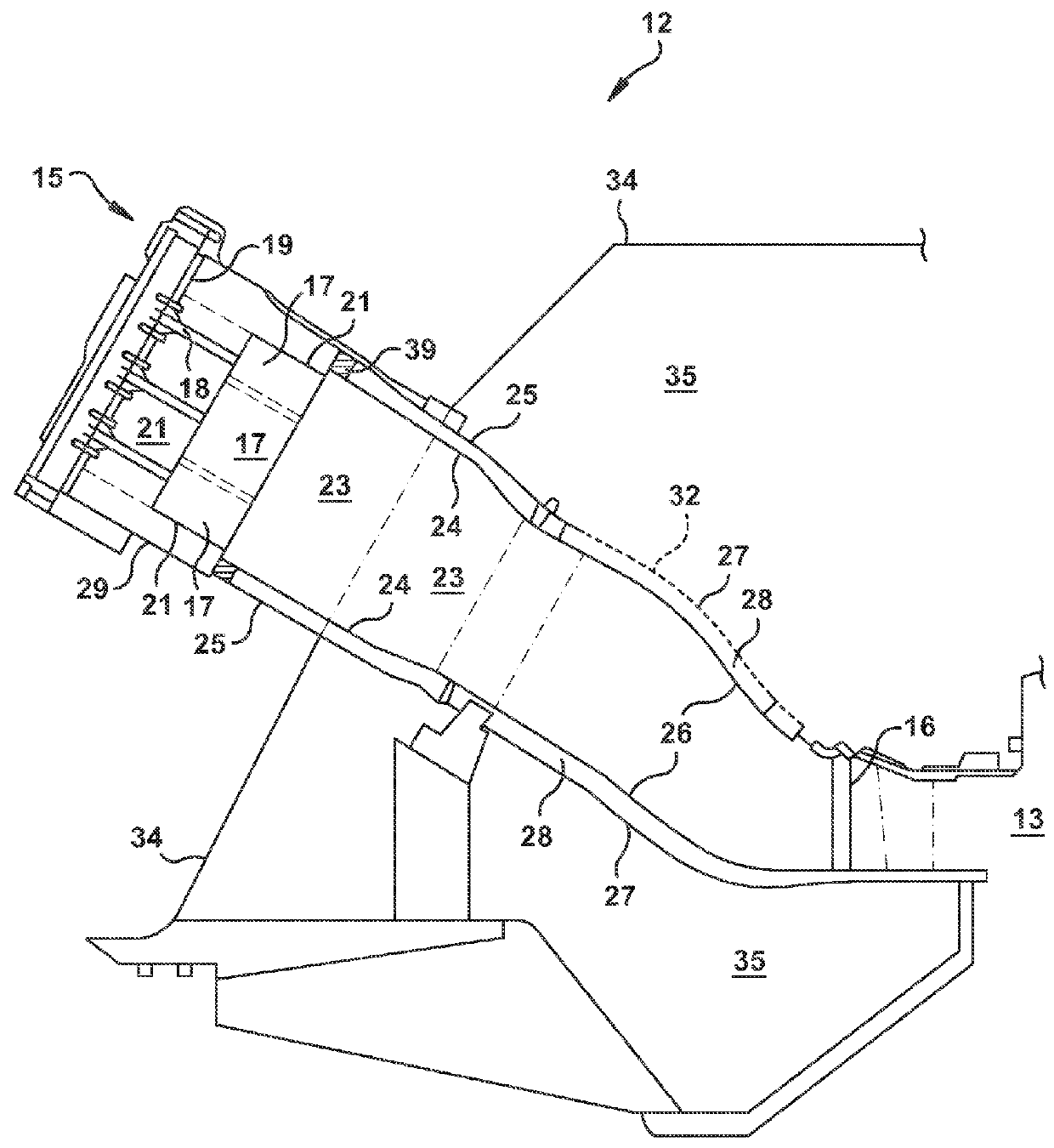

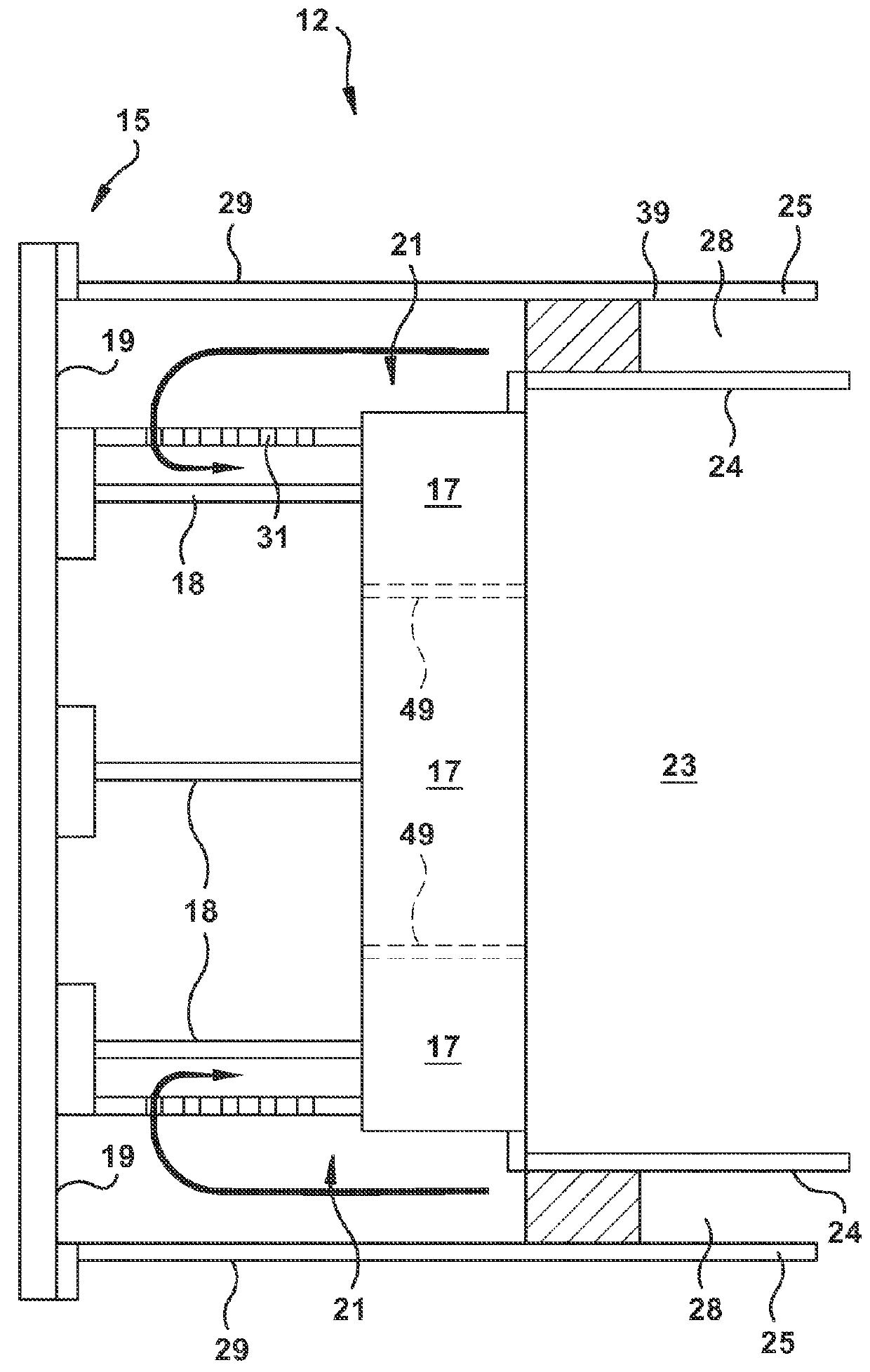

Combustor nozzles in gas turbine engines

A micro-mixer nozzle for use in a combustor of a combustion turbine engine, the micro-mixer nozzle including: a fuel plenum defined by a shroud wall connecting a periphery of a forward tube sheet to a periphery of an aft tubesheet; a plurality of mixing tubes extending across the fuel plenum for mixing a supply of compressed air and fuel, each of the mixing tubes forming a passageway between an inlet formed through the forward tubesheet and an outlet formed through the aft tubesheet; and a wall mixing tube formed in the shroud wall.

Owner:GENERAL ELECTRIC CO

Microreactor device for producing 2-hydroxyethylhydrazine and preparation process

ActiveCN104876833AEthylene oxide accumulationNo accumulationHydrazine preparationMicroreactor2-hydroxyethylhydrazine

The invention discloses a microreactor device for producing 2-hydroxyethylhydrazine and preparation process. The device comprises a feeding system, a mixing system, a reaction system, a backpressure valve, a cooling receiving system, a washing system and an external circulating bathing system, wherein the feeding system comprises a hydrazine hydrate storing tank, an oxirane storing tank and a feeding pump; the mixing system comprises a CPMM or SIMM or Starlam serial micro mixer; the reaction system comprises a rimule reactor section; the pressure of the backpressure valve ranges from 0 to 15MPa; the cooling receiving system comprises a CRMH serial micro heat exchanger and a receiving storing tank; the washing system comprises a washing storing tank and a washing pump which are connected in series; the hydrazine hydrate storing tank or oxirane storing tank, the feeding pump, the micro mixer, the rimule reactor, the backpressure valve, the micro heat exchanger and the receiving storing tank are connected in series; the mixing system, the reaction system and the cooling receiving system are respectively arranged at the circulating bathing system.

Owner:大连微凯化学有限公司

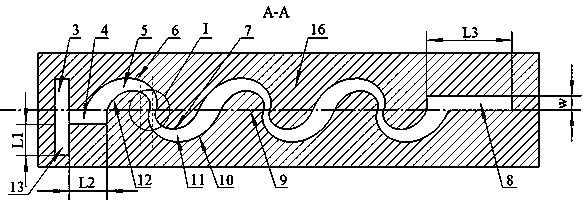

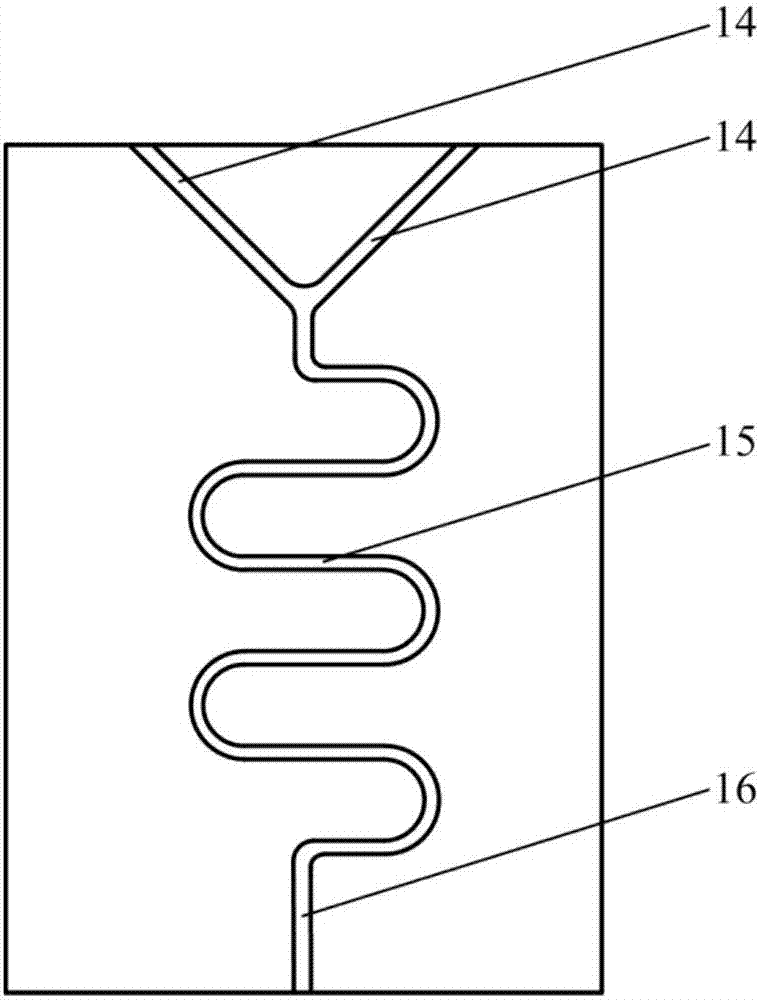

S-type passive micro-mixer

InactiveCN103638853APromote formationIncrease contact areaMixersLaboratory glasswaresHelical lineMain channel

Owner:JIANGSU UNIV

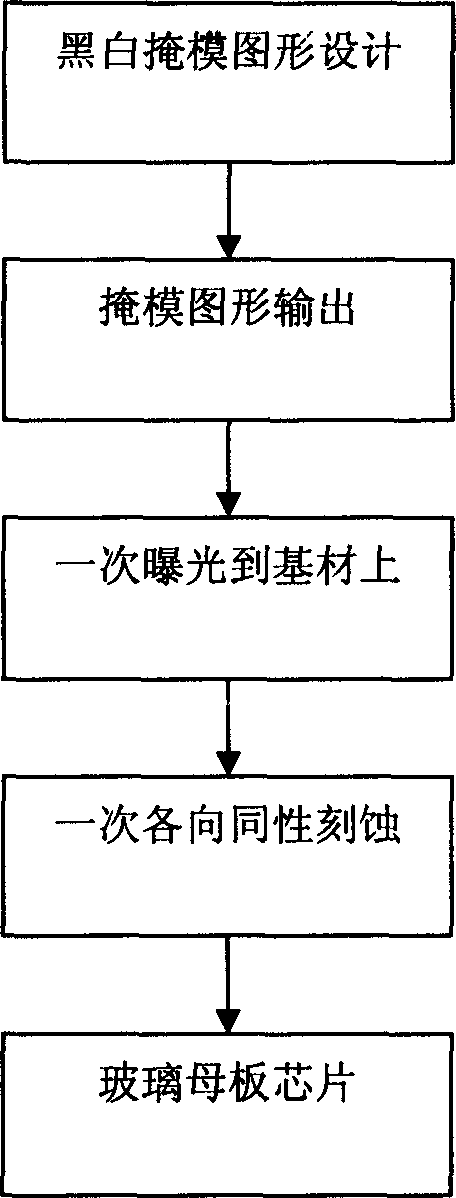

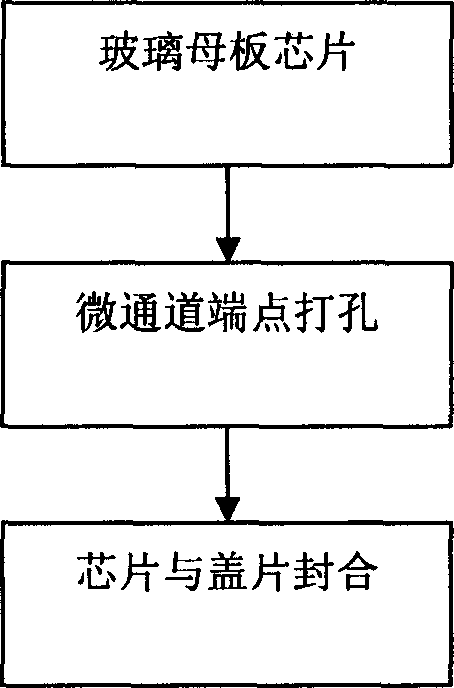

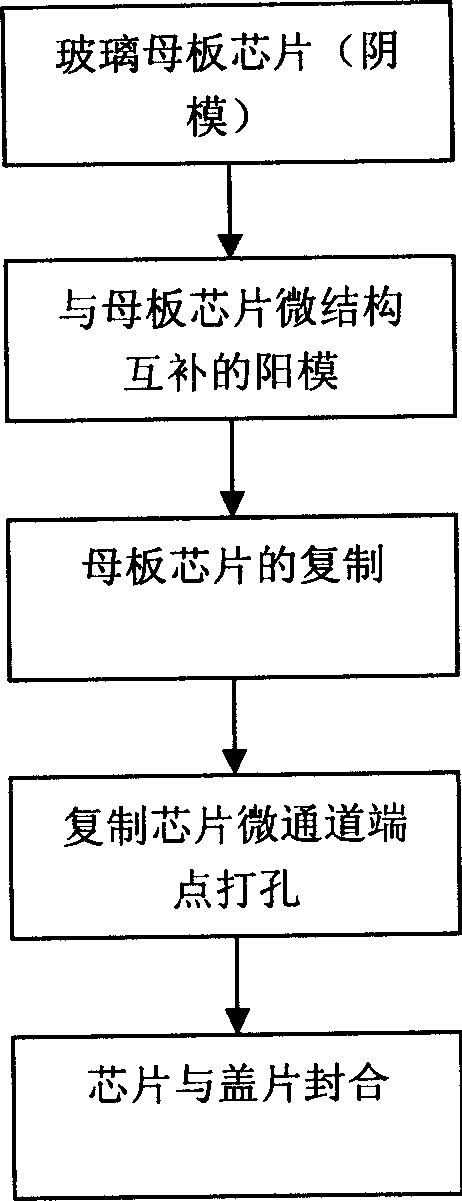

Method for producing passive micro-mixer and micro-reactor in micro-flow control chip

InactiveCN1811421AFacilitates flow mixingAchieve replicationSemiconductor/solid-state device manufacturingBiological testingMicroreactorGlass chip

The present invention relates to a method for making passive micromixer and microreactor in microfluidic chip. Said method includes the following steps: firstly, making glass mother die chip whose bottom surface and side surface have submicrostructure, utilizing glass mother plate chip to prepare all-glass chip or all-glass mixed chip whose three faces or all-channel have submicrostructure, or utilizing the process of pouring polymer to obtain the male die complementary with glass mother plate microstructure, utilizing said male die to make secondary pouring and duplication so as to obtain the chip of polymer base material with glass, mother plate structure, then further making packaging combination to obtain all-polymer mixed chip or composite chip.

Owner:NORTHEASTERN UNIV

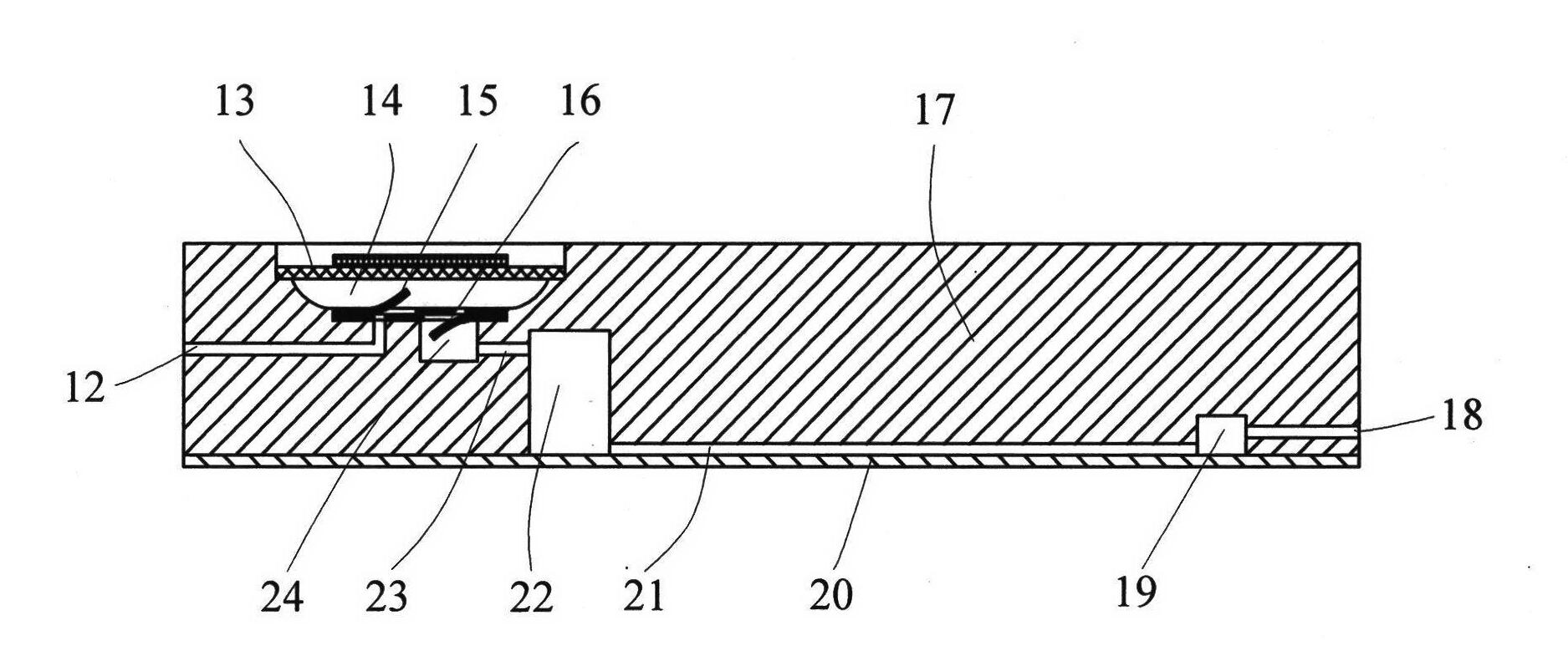

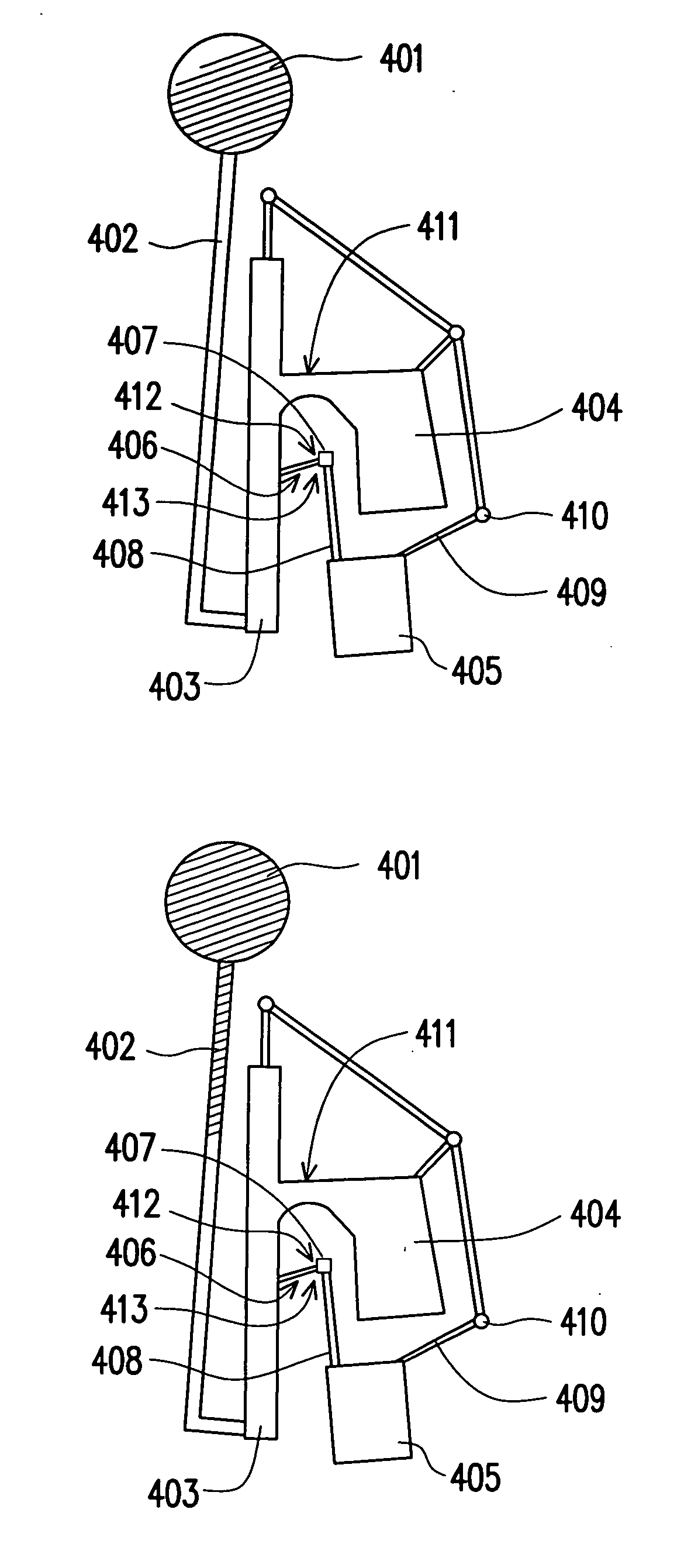

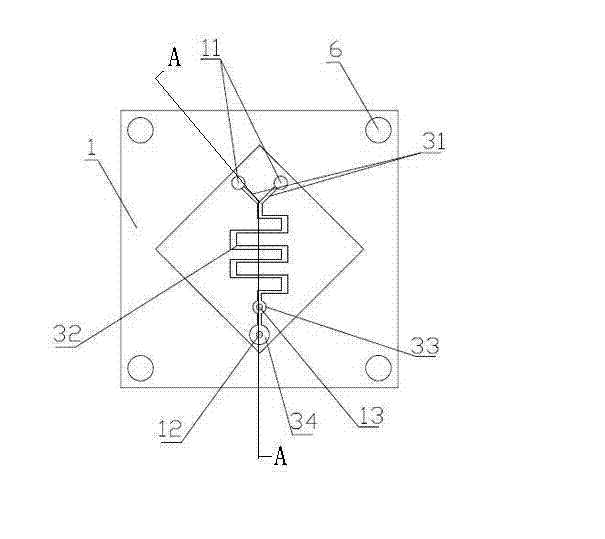

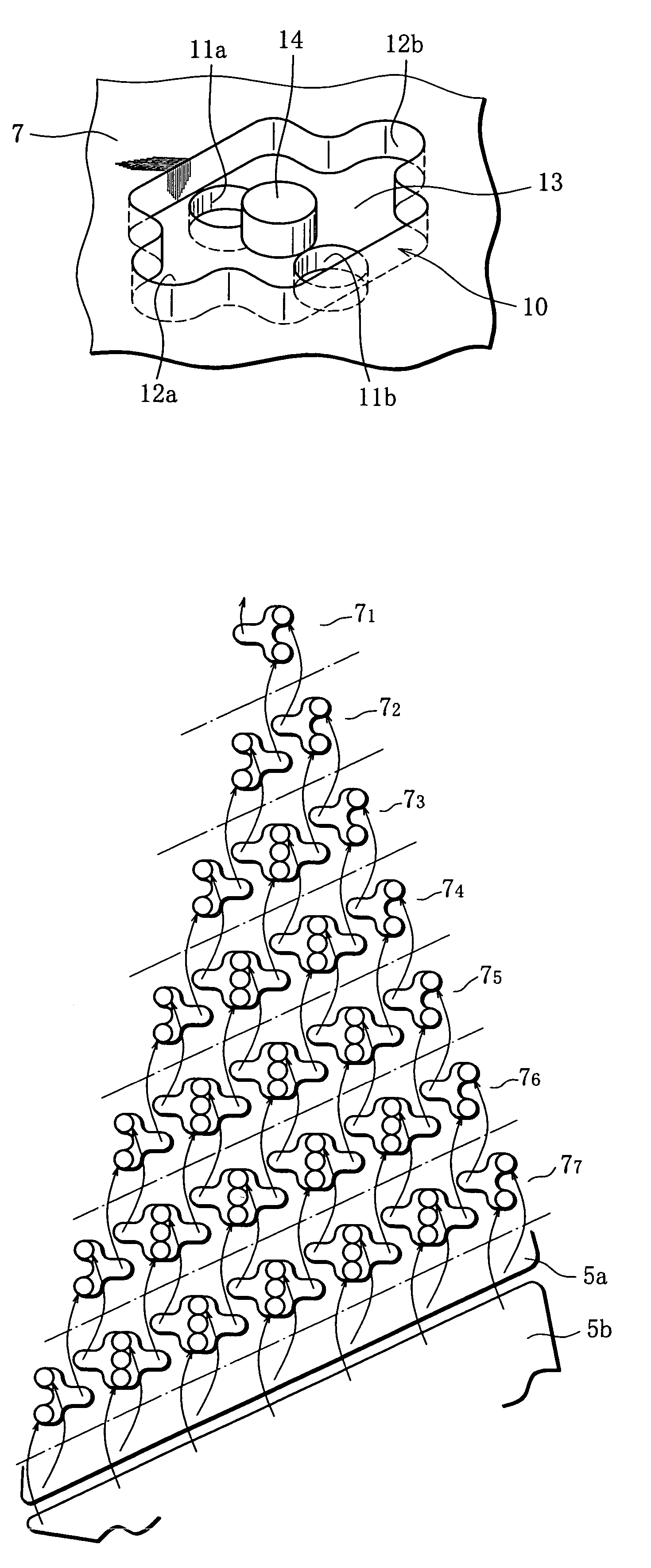

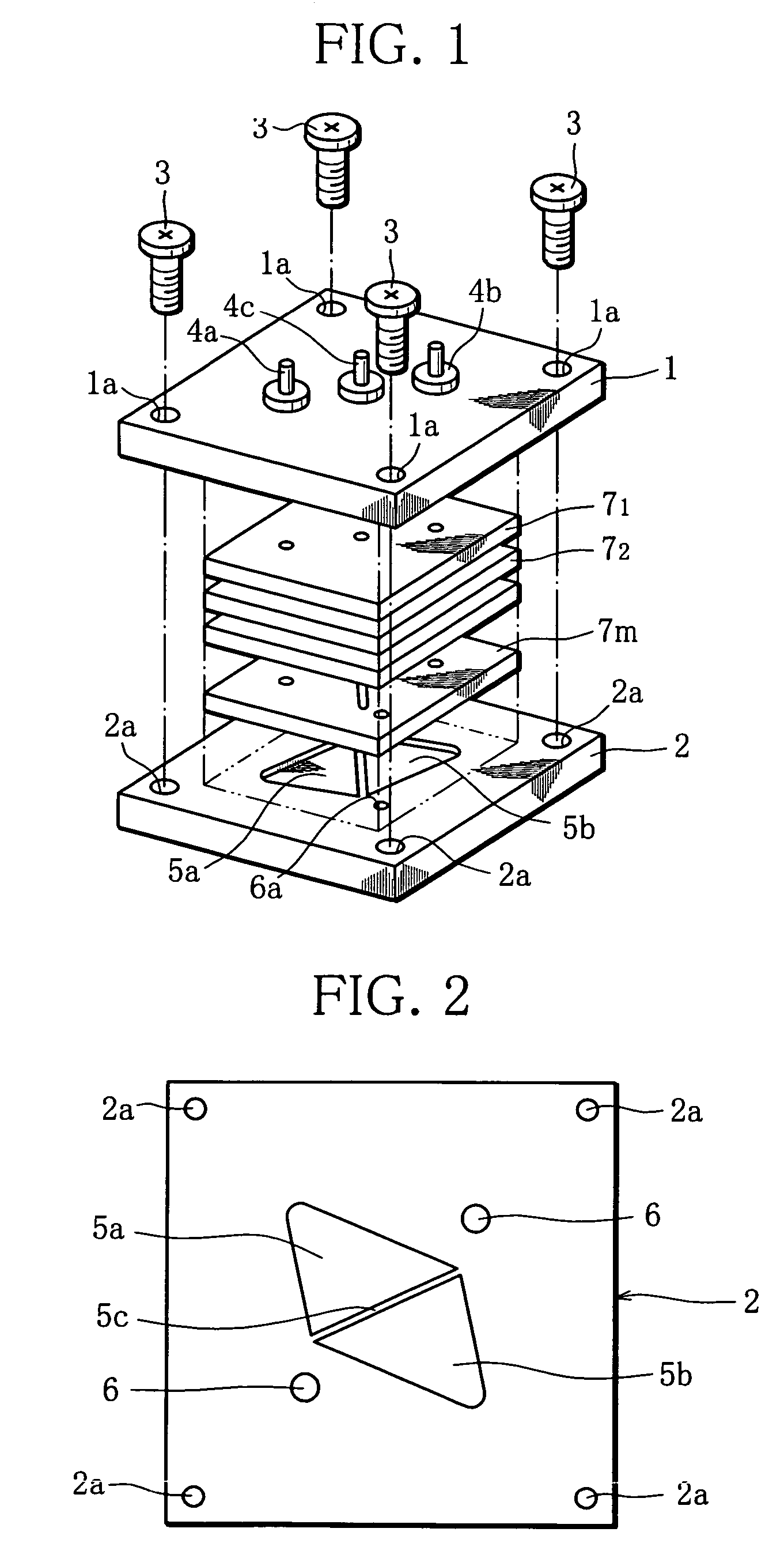

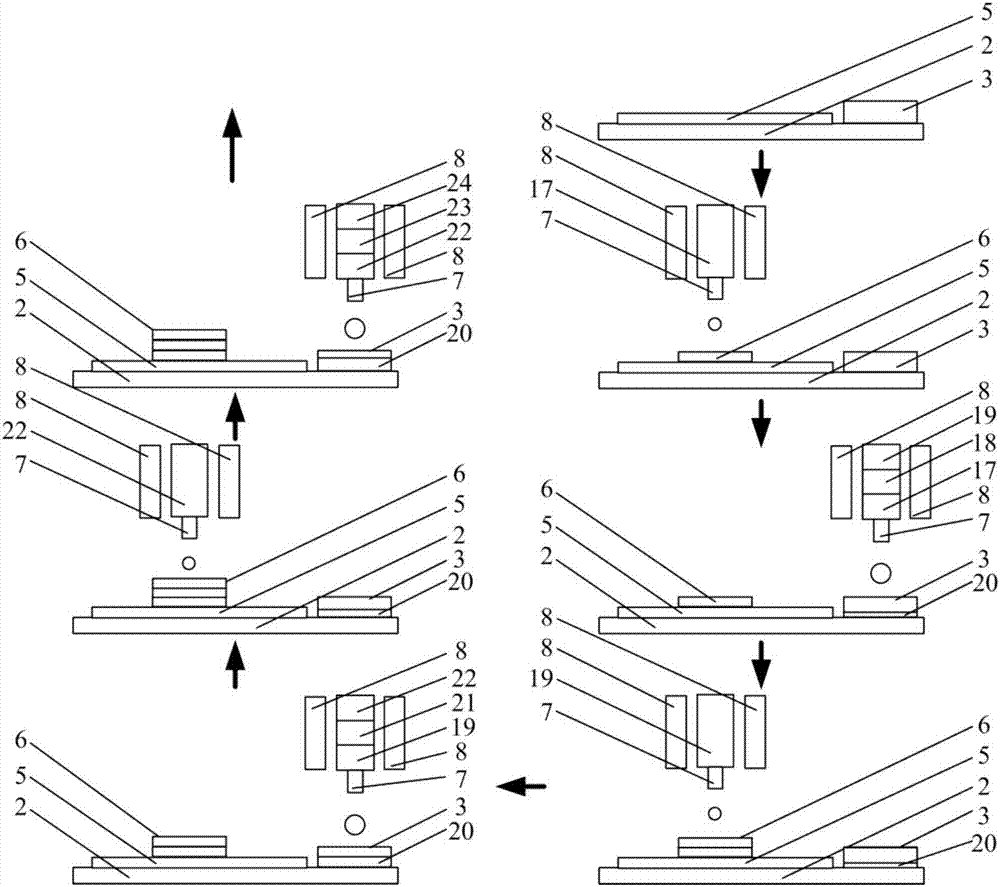

Piezoelectrically actuated micro-mixer, manufacturing method and control method of piezoelectrically actuated micro-mixer

InactiveCN102671572ALarge controllable rangeImprove mixing efficiencyMixer accessoriesPump controlElectricityEngineering

The invention discloses a piezoelectrically actuated micro-mixer, a manufacturing method and a control method of the piezoelectrically actuated micro-mixer, belonging to the technical field of a micro-mixer. With the adoption of the micro-mixer, a micro-fluid drive unit (namely a piezoelectric pump) and a micro-mixing unit (namely a mixing runner) are integrated into a whole via an overall PDMS (polydimethylsiloxan) substrate; a single chip piezoelectric vibrator and a one-way valve block are encapsulated together with the PDMS substrate to form the piezoelectric pump; a glass base plate is encapsulated together with the PDMS substrate to form the mixing runner; and the piezoelectric vibrator is stimulated by adopting different voltages, frequencies, different waveforms and phase staggered drive electric signals so as to achieve high-frequency pulsating displacement mixing of the micro-fluid in a micro-mixing runner. With the adoption of the piezoelectrically actuated micro-mixer, the defects of low mixing efficiency, long time and the like caused by that the micro-fluid is mixed by laminar diffusion under a micro-scale are effectively overcome, so that efficient turbulent mixing is realized. The piezoelectrically actuated micro-mixer disclosed by the invention has the advantages of being simple in manufacturing method, low in cost, high in mixing efficiency, short in time, small in volume and easy in integration, and capability of widely applying to the fields such as analytical chemistry, micro-chemical system, environment monitoring, life science and the like.

Owner:JILIN UNIV

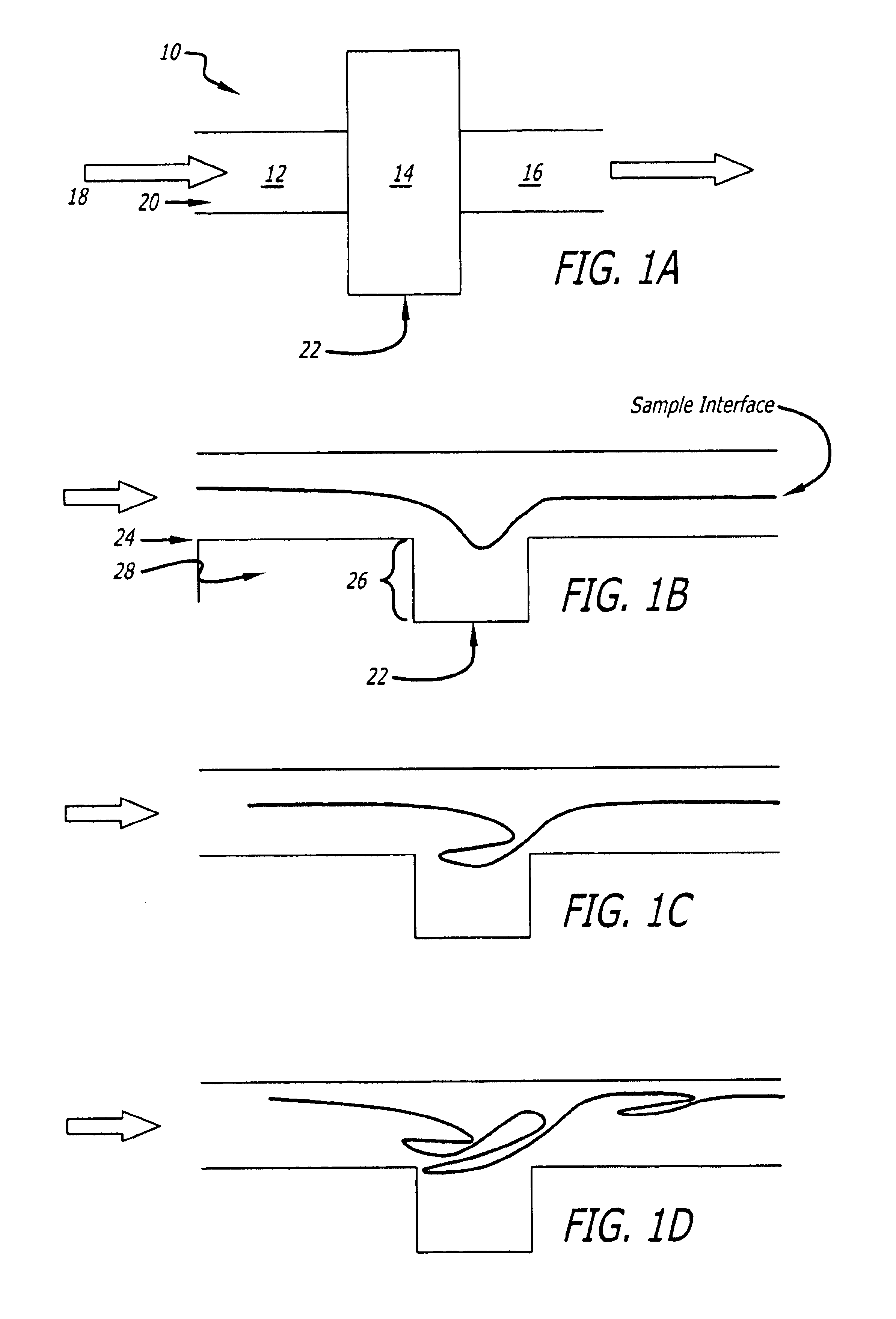

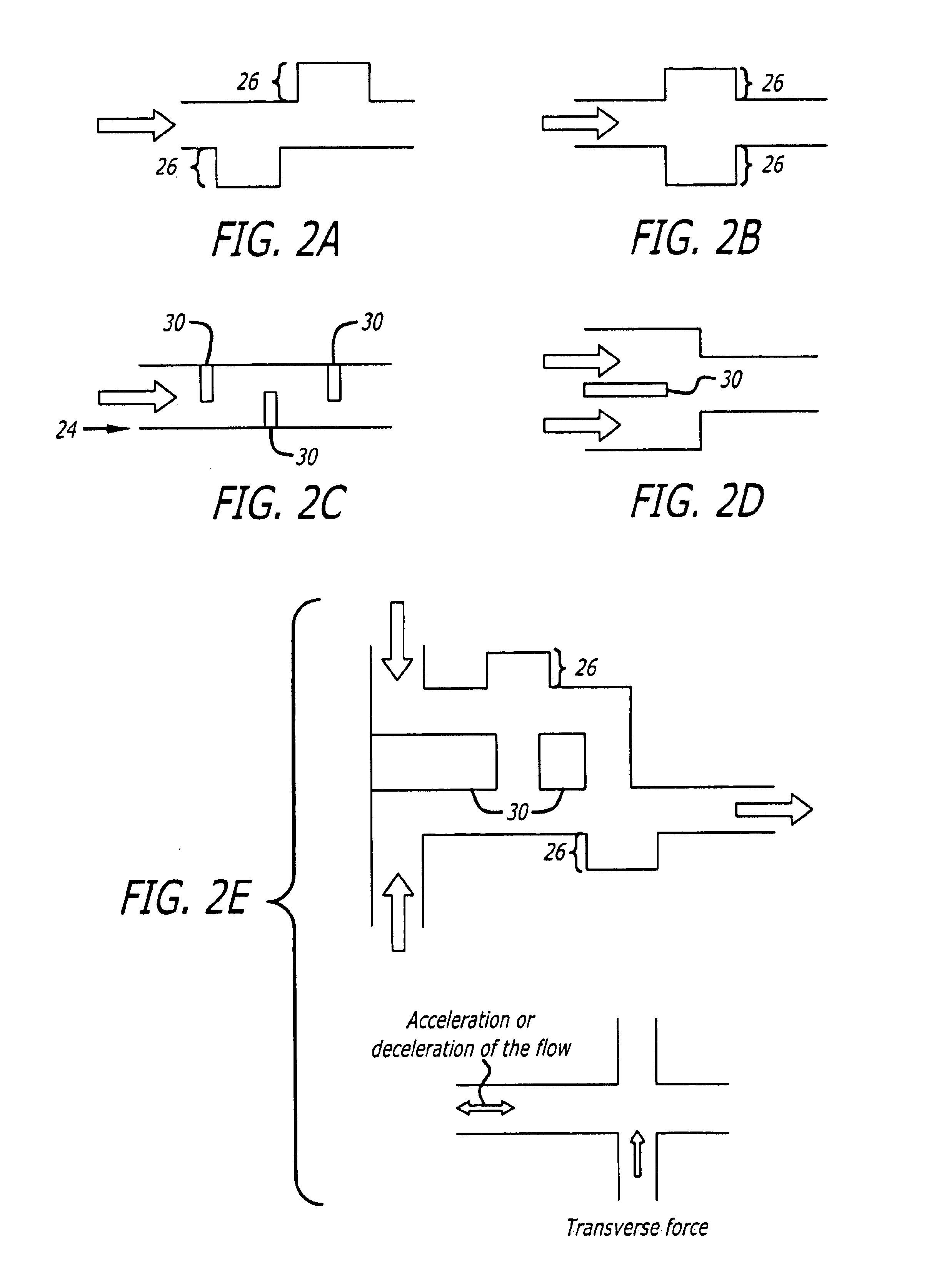

Micro chaotic mixer

InactiveUS6902313B2Simple structureEasily integrated into any microdeviceElectrolysis componentsShaking/oscillating/vibrating mixersTransverse forceChaotic

A micro mixer for use in a microdevice which utilizes time-varying force fields to induce bulk fluid and / or sample component motion leading to homogenization of sample components. Time-varying force fields employed includes at least one of a physical displacement field, electrical field, pressure field or magnetic field to generate transverse forces which induce the mixing of samples within the micro mixer.

Owner:UNIVERSTIY OF CALIFORNIA

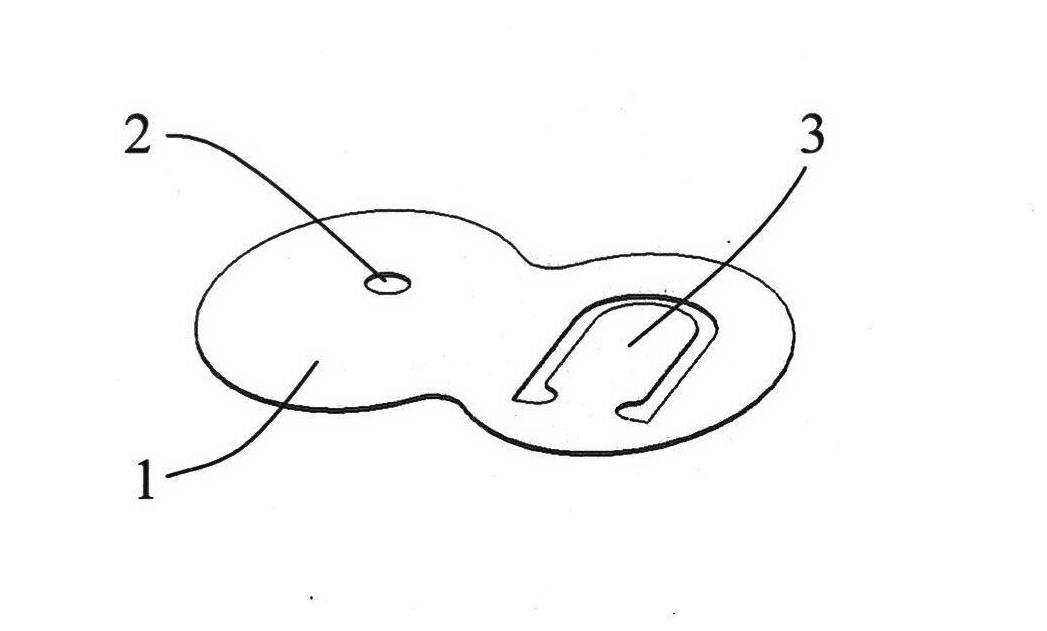

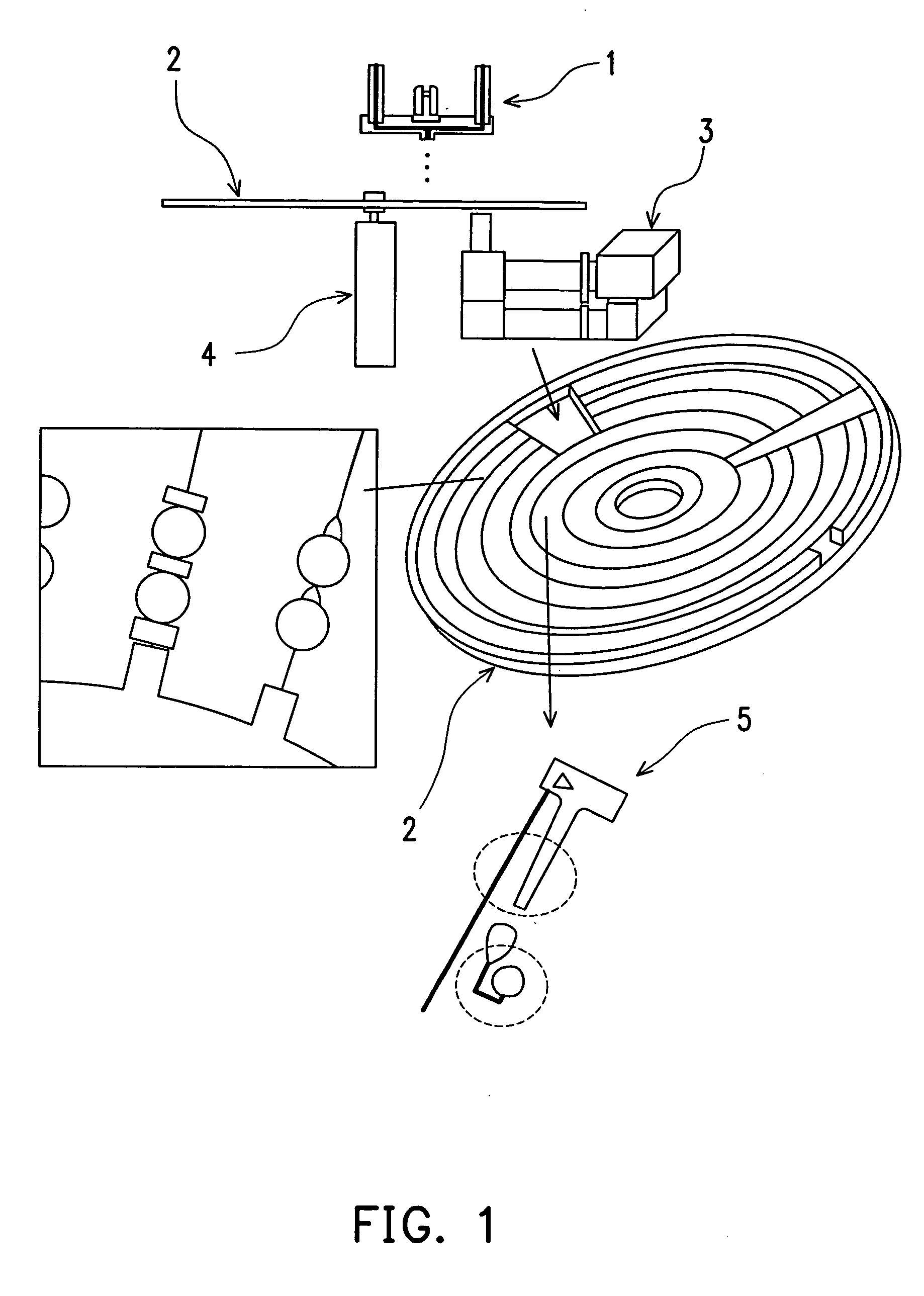

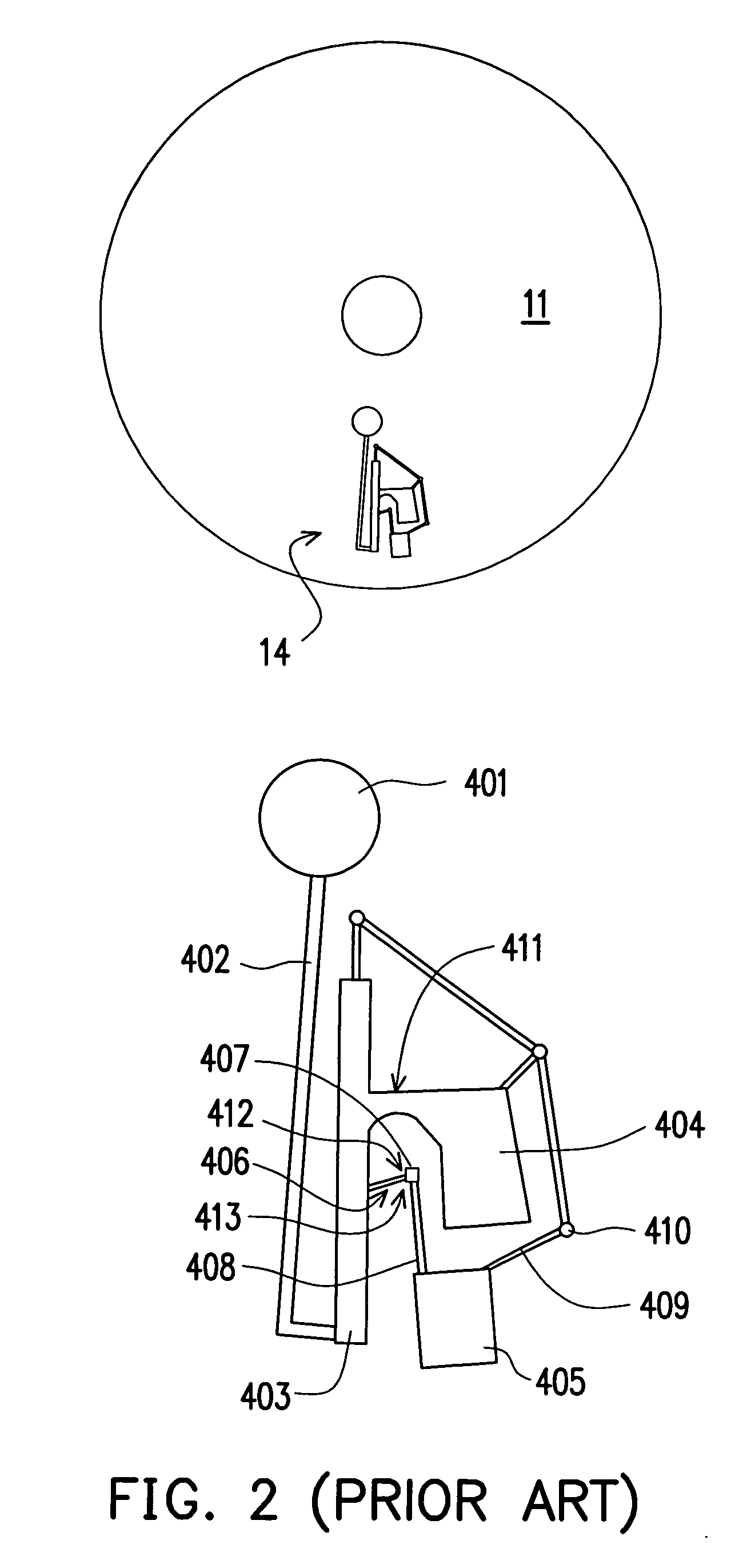

Blood micro-separator

InactiveUS20060263265A1Analysis using chemical indicatorsLaboratory glasswaresMicro devicesRed blood cell

A micro-separator for separating red blood cells from blood serum in a blood sample is provided. The main mechanism driving the separation of the blood sample is centrifugal force. With physical mechanisms including surface tension and functional microstructures, the red blood cells and the blood serum in a small volume of blood (about 25 micro-liters) are separated. The entire micro-separation apparatus is disposed on a disk-shaped structure. The micro-separator can integrate with other micro-devices such as micro-mixers, micro-distributors or micro-reactors to form a fully functional apparatus. Combining the rotary driver of a CD player and an optical inspection device with a signal processing system, an inexpensive, fully automatic, parallel-processing inspection system is produced. The micro-separator has a simple structure with no movable components, and its separation mechanism does not depend on either filter papers or micro-pore structures so blockage is prevented and it can easily combine with other microfluidic devices.

Owner:NAT CHUNG SHAN INST SCI & TECH

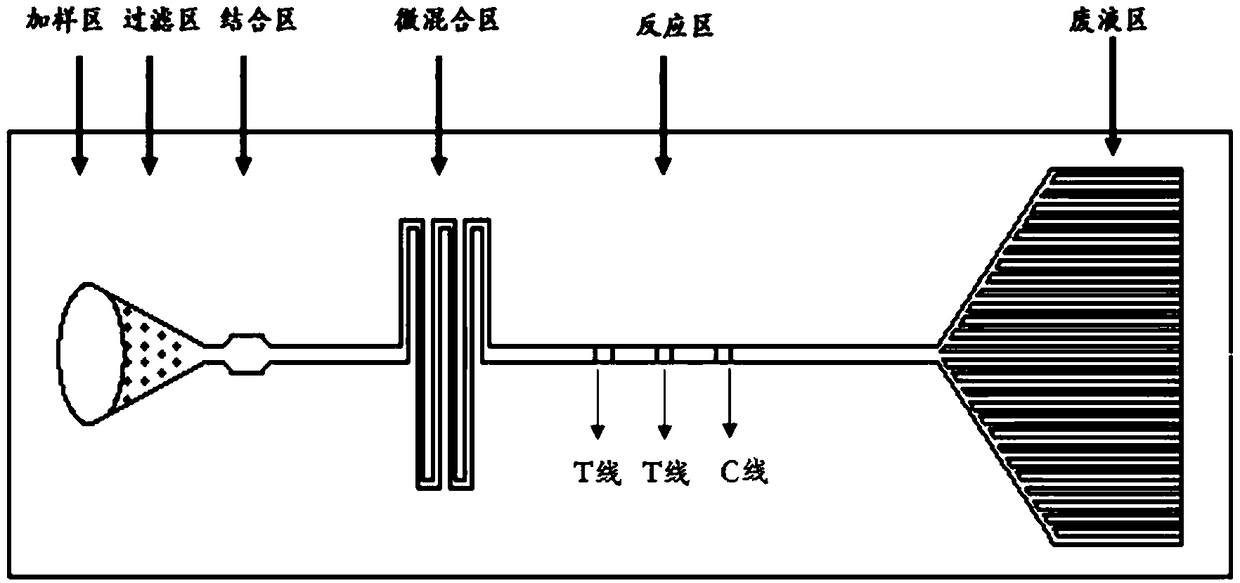

Micro-fluidic chip according to time-resolved fluorescent technique, preparation method of micro-fluidic chip and application of micro-fluidic chip

InactiveCN108080042AHigh precisionHigh sensitivityLaboratory glasswaresMaterial analysisAntigenSingle sample

The invention belongs to the field of immunology, and particularly relates to a micro-fluidic chip according to a time-resolved fluorescent technique, a preparation method of the micro-fluidic chip and an application of the micro-fluidic chip. The micro-fluidic chip according to the time-resolved fluorescent technique comprises a sample adding area, a filtering area, a time-resolved fluorescent micro-sphere antibody or antibody compound binding area, a micro-mixer, a reaction area and a waste liquid area. According to the micro-fluidic chip, antigens or antibodies marked by time-resolved fluorescent nano-particles, light stability is strong, sensitivity is high, and interference of samples can be effectively avoided. The antigens or antibodies of a plurality of items to be detected can besimultaneously marked on the micro-fluidic chip, a plurality of items of a single sample can be simultaneously detected, efficiency is improved, and sample cost and time cost are saved. The preparation method of the micro-fluidic chip is simple, detection accuracy is high, low difference between batches and high stability are ensured, and full quantitative detection of the samples can be realized.

Owner:成都微康生物科技有限公司

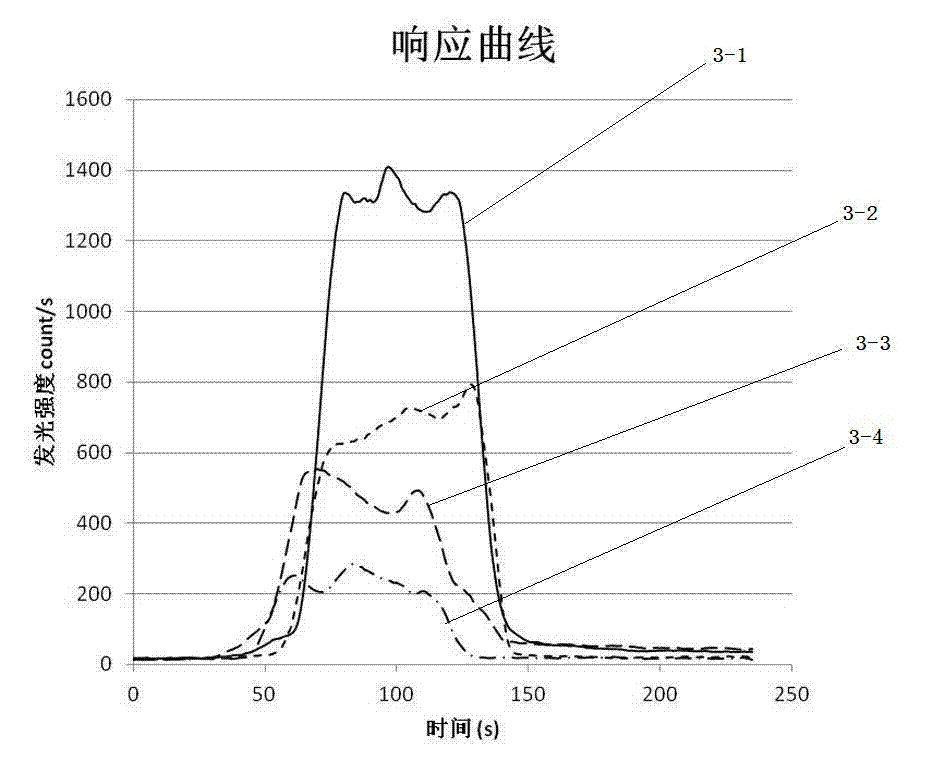

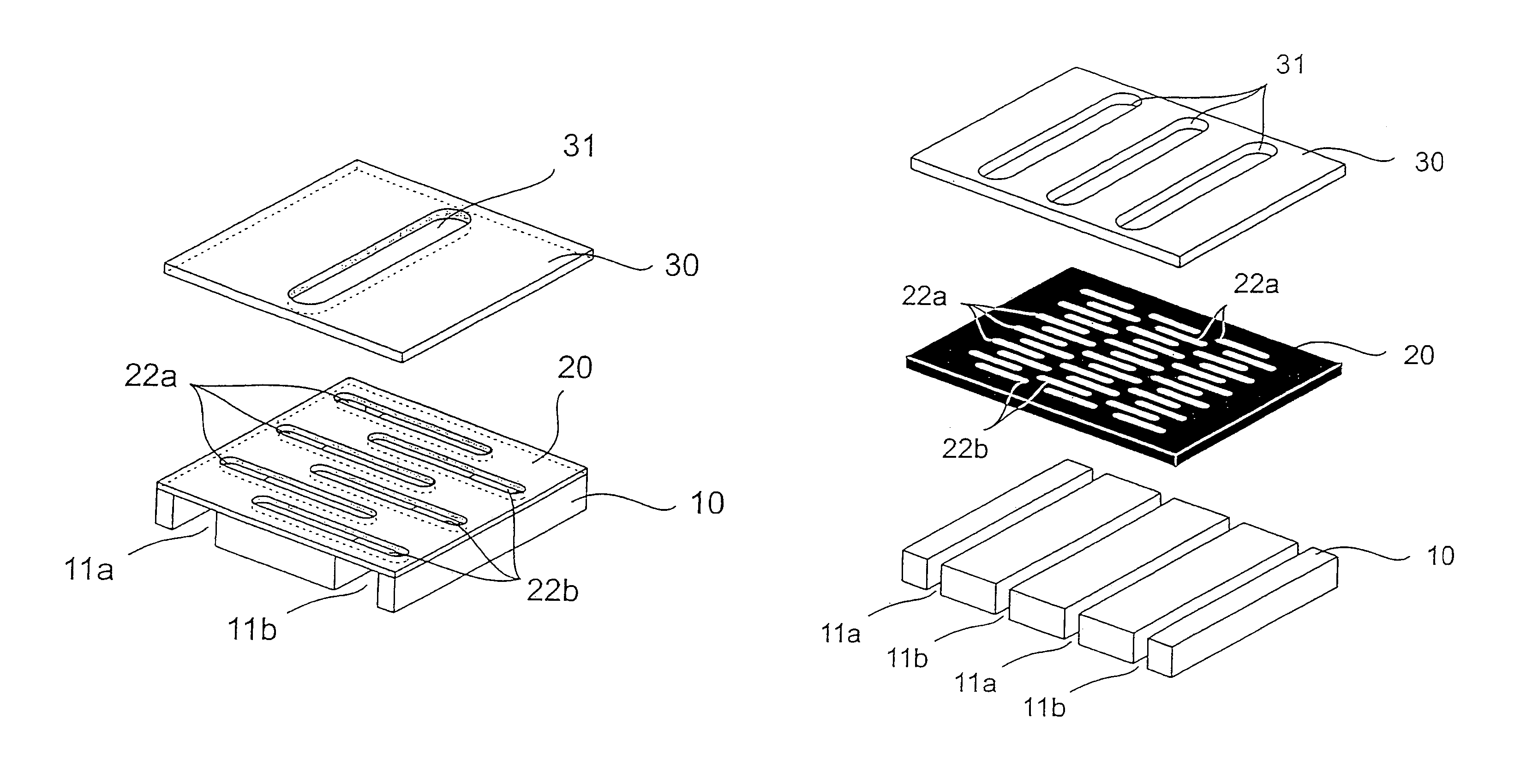

Microfluidic chip for biological chemiluminescence detection and manufacturing method thereof

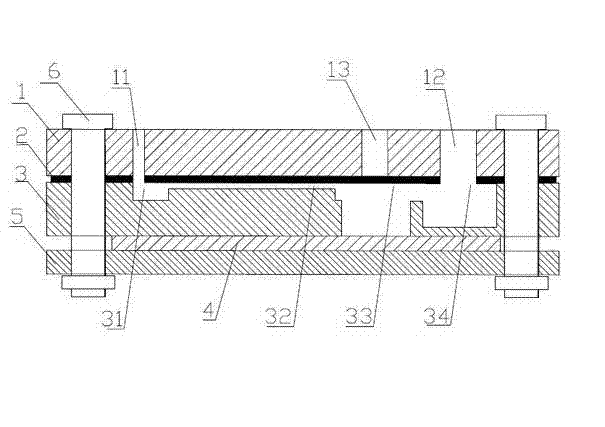

InactiveCN102788780APromotes fast and thorough mixingIncreased reaction luminescence intensityChemiluminescene/bioluminescenceLaboratory glasswaresLuminous intensityAdhesive

The invention discloses a microfluidic chip for biological chemiluminescence detection. The chip comprises an interface layer, a transparent layer, a channel layer, a reflecting layer and a fixed layer, which are sequentially arranged from top to bottom. The layers are connected by adhesives and fixed by fasteners; the interface layer is provided with a liquid inlet hole, a liquid outlet hole and an optical fiber interface; the channel layer is provided with a liquid inlet flow channel, a micro mixer, a detecting pool and a waste liquid buffer pool, which are successively communicate with each other; the transparent layer is arranged between the optical fiber interface and the detecting pool; the detecting pool is opened to the lower surface of the channel layer; and the bottom of the detecting pool is connected with the reflecting layer. The invention also discloses a manufacturing method of the microfluidic chip. The microfluidic chip improves reaction luminescence intensity of the detection solution and optical detection efficiency, and has advantages of simple preparation method, convenient operation, fast detection, high sensitivity, and accurate detection result.

Owner:ZHEJIANG UNIV

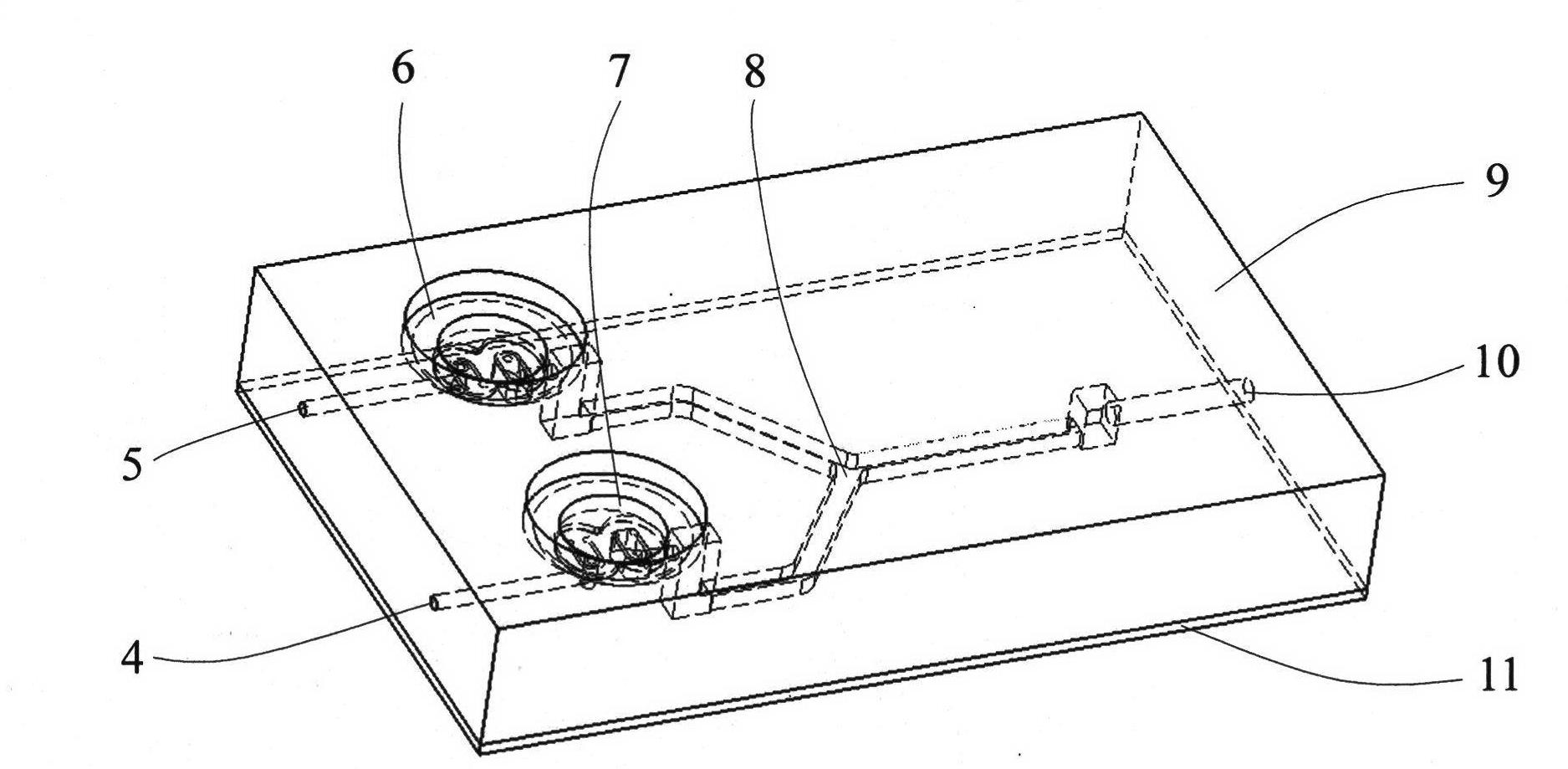

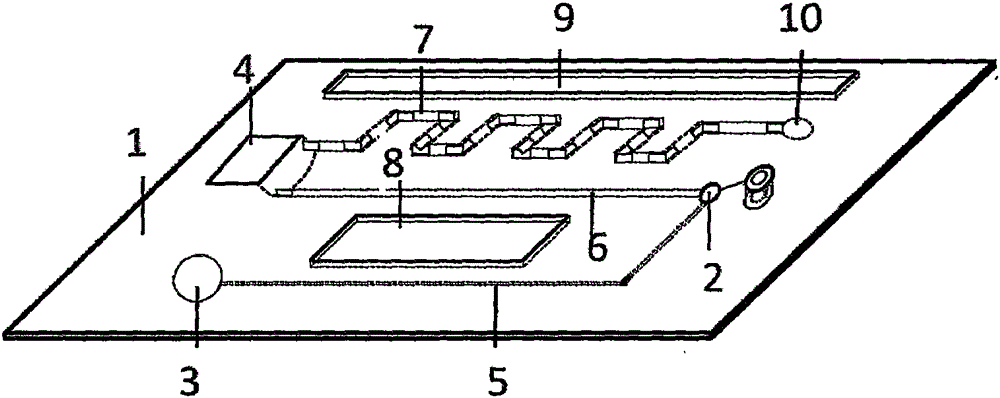

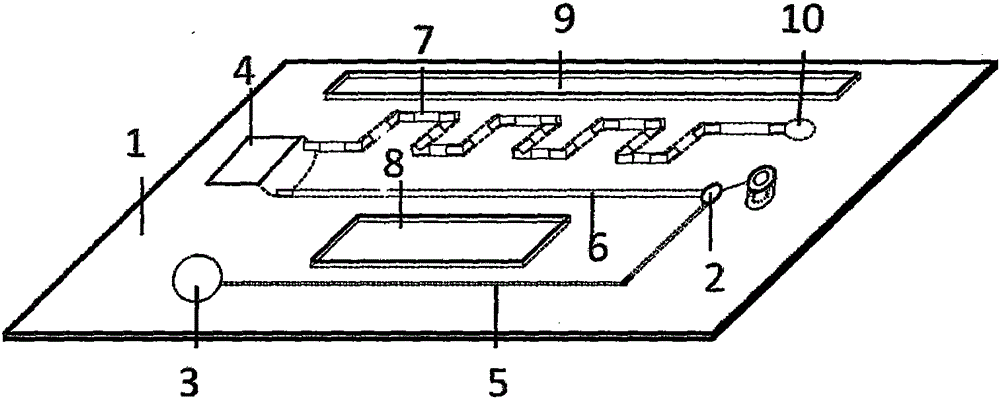

Micro-fluidic chip for multi-object quantitative detection based on magnetic particle chemiluminescence

ActiveCN105259164AAccurate detectionRealize intelligent controlChemiluminescene/bioluminescenceLaboratory glasswaresEngineeringMICRO MIXER

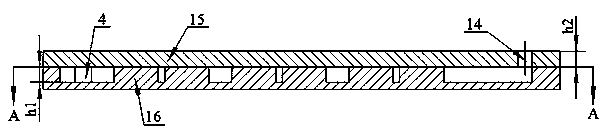

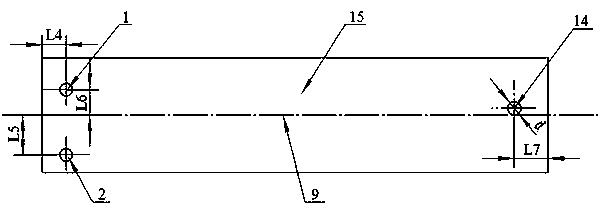

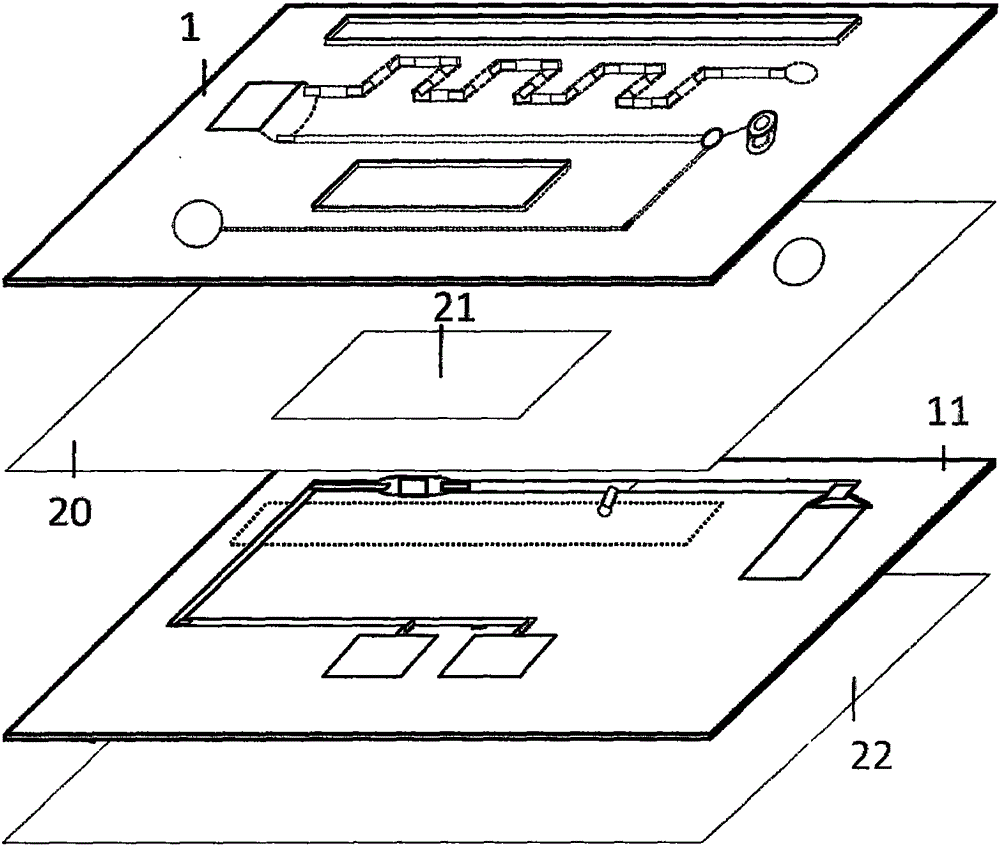

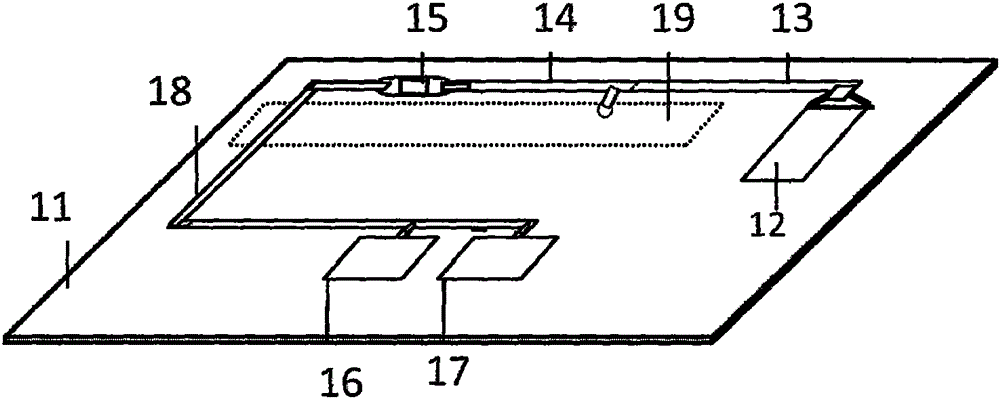

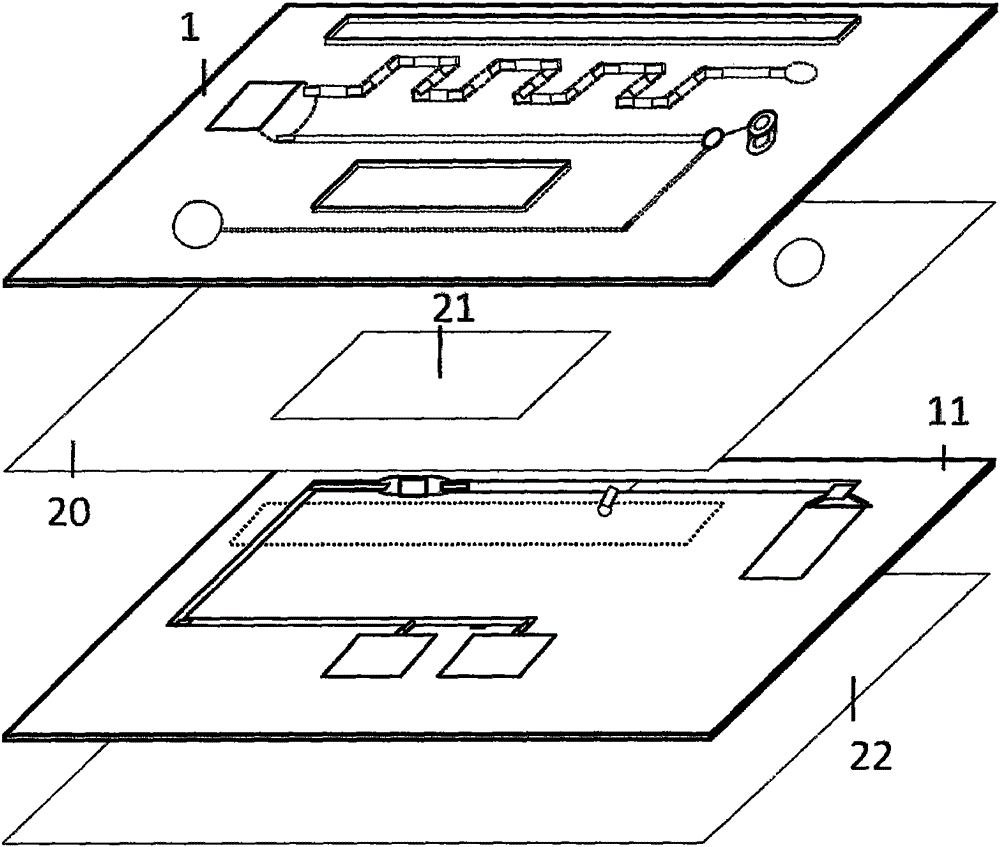

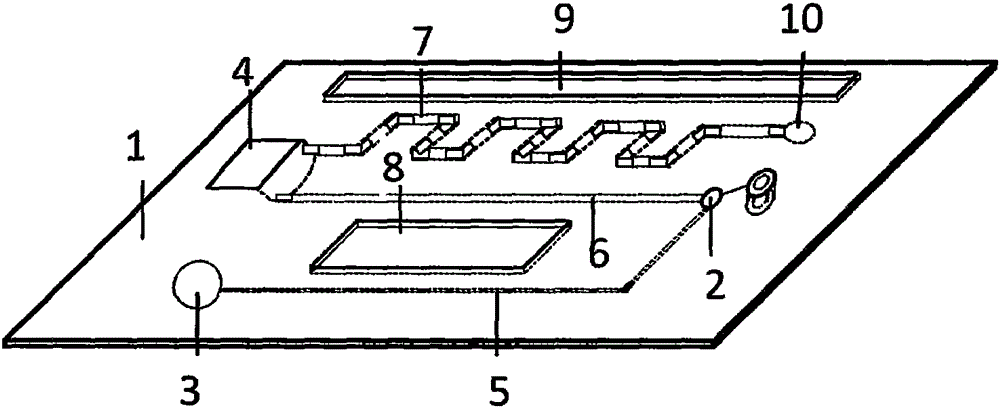

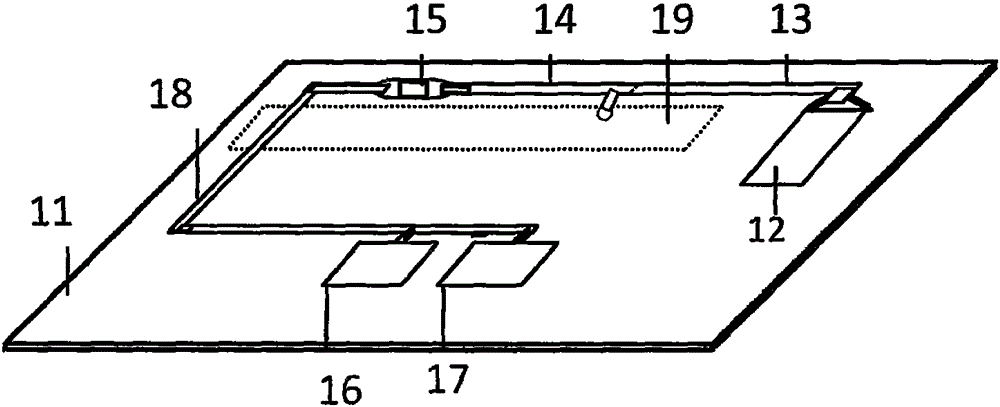

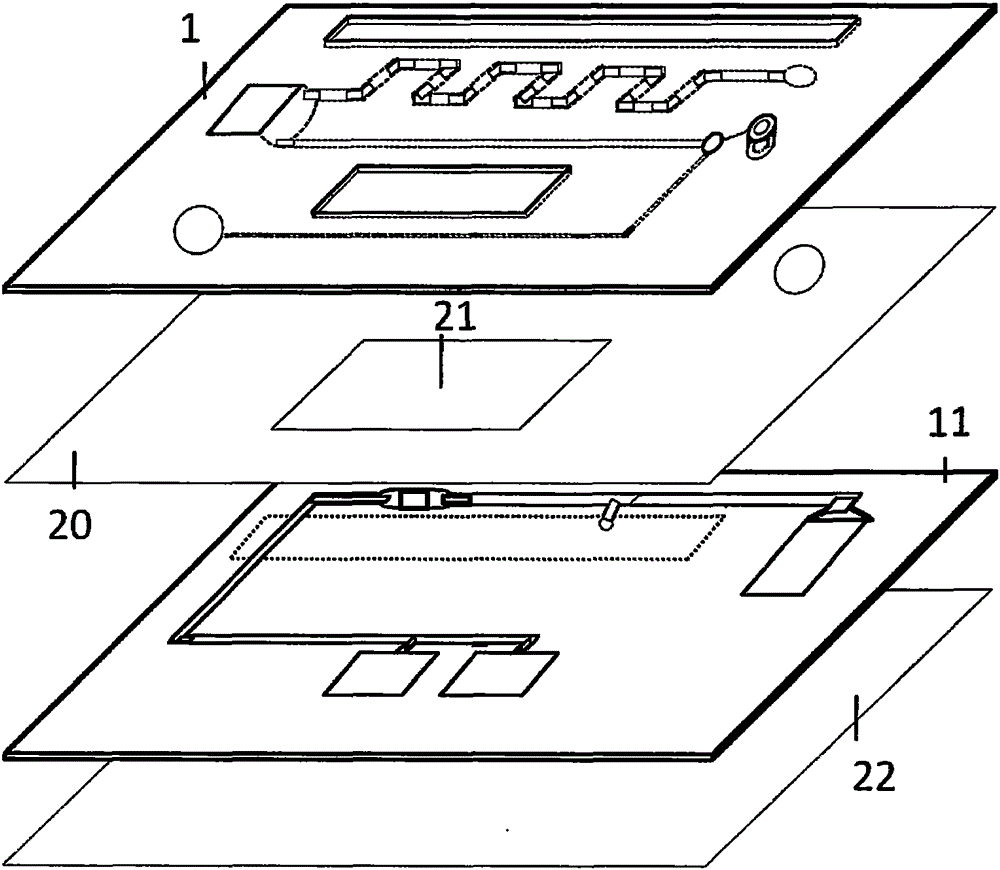

The invention relates to a micro-fluidic chip for multi-object quantitative detection based on magnetic particle chemiluminescence. The micro-fluidic chip is of a double-layer structure and comprises a cover plate (1) and a bottom plate (11), wherein an air pump (3), an air flow micro-channel (5), a sample adding hole (2), a sample liquid flowing channel (6), a first biomarker storage pool (4), a micro-mixer (7) and a transition area (10) on the cover plate (1) are connected in sequence. A filter (12), a reaction chamber (13), a cleaning area (14), a detection chamber (15) and a solution release channel (18) on the bottom plate (11) are connected in sequence, and the detection chamber (15) is connected with a luminous liquid storage pool (16) and a cleaning fluid storage pool (17) respectively through the solution release channel (18).

Owner:SHENZHEN HUAMAIXINGWEI MEDICAL TECH CO LTD

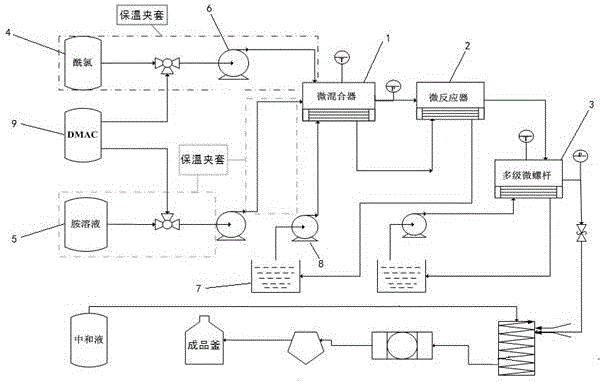

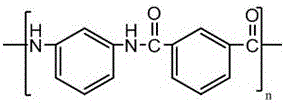

Continuous micro-reaction device and method for preparing meta-aramid resin and product

ActiveCN106478940AEasy transferReduce polydispersityChemical/physical/physico-chemical microreactorsMonocomponent polyamides artificial filamentAfter treatmentEngineering

A continuous micro-reaction device for preparing meta-aramid resin comprises a prepolymerization system, a polycondensation system, an after-treatment system and a heat exchange system, wherein the prepolymerization system, the polycondensation system and the after-treatment system are connected in sequence, and the heat exchange system is connected with the prepolymerization system and the polycondensation system to control temperatures of the prepolymerization system and the polycondensation system. The continuous micro-reaction device is characterized in that the prepolymerisation system comprises a raw material storage device, a micro-mixer and a micro-reactor which are connected in sequence; the polycondensation system comprises a multistage micro-screw device, and the micro-reactor is connected with multistage micro-screw device. The continuous micro-reaction device for preparing the meta-aramid resin improves the heat transfer effect at the polycondensation stage and the mass transfer effect at the polycondensation stage during preparation of the meta-aramid resin, and achieves the purpose of improving the performance of a meta-aramid resin product. The invention further provides a continuous micro-reaction method for preparing the meta-aramid resin and the product.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Airfoil-shaped micro-mixers for reducing fouling on membrane surfaces

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

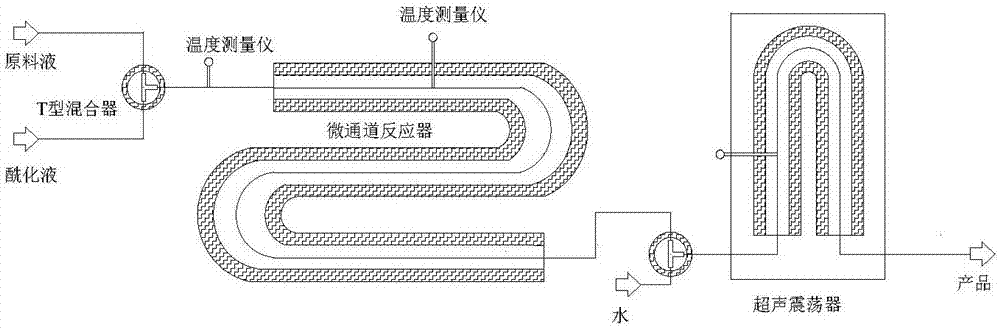

Method for synthesizing acyl naphthalene by using micro-channel reactor

InactiveCN107879909AImprove airtightnessImprove securityCarbonyl compound preparation by condensationCarbonyl compound separation/purificationWater bathsIce water

The invention discloses a method for synthesizing acyl naphthalene by using a micro-channel reactor. The method comprises the following steps: (1) preparing acylation liquid, namely adding nitrobenzene and anhydrous aluminum chloride into a reactor in a low-temperature tank, finally adding acyl chloride, and controlling the temperature in the reactor to be 0-3 DEG C; (2) preparing a feed solution,namely adding nitrobenzene and 2-methyl naphthalene into a reactor provided with a stirrer; (3) reacting, namely injecting the feed solution and the acylation liquid into a micro mixer to be mixed, and feeding into the micro-channel reactor to be reacted; (4) washing, namely enabling the product discharged from the micro-channel reactor to enter the micro mixer again so as to be washed, enablingthe mixture into the micro-channel reactor, controlling the reactor temperature to 40-50 DEG C, and performing ultrasonic oscillation outside the reactor; (5) performing reduced pressure distillation,namely separating the products obtained in the step (4), and performing vacuum decompression to 500-1000Pa so as to obtain a crude product 2-methyl-6-acyl naphthalene; and (6) recrystallizing, namelyadding the crude product obtained in the step (5) into a solvent of 50-60 DEG C, stirring and dissolving, naturally cooling and crystallizing, continuously cooling and crystallizing in an ice-water bath, and finally filtering to obtain the purified product 2-methyl-6-acyl naphthalene.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

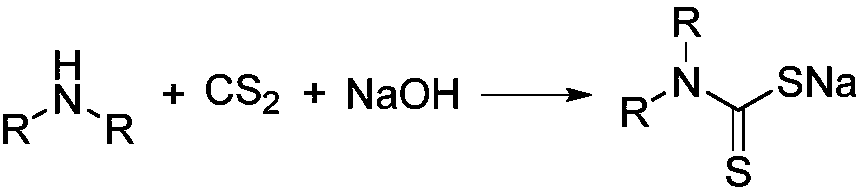

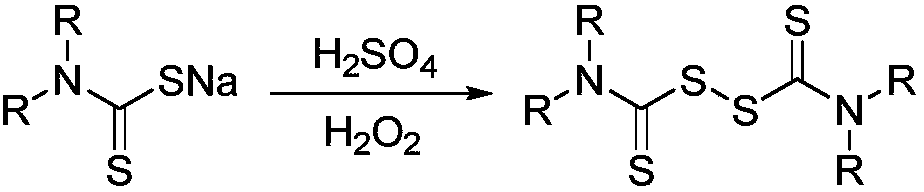

Micro-reaction method for continuous synthesis of thiuram disulfide

The invention discloses a method for producing thiuram disulfide as thiofide by a continuous micro-reaction system. According to the method, three processes including secondary amine-NaOH solution mixing, CS2-secondary amine condensation reaction and sodium dithiocarbamate oxidation reaction are sequentially completed by a micro-mixer and a micro-reactor which are connected in series; reaction materials are efficiently mixed by the micro-reaction device, and side reactions such as overoxidation and the like are avoided; by means of a series-integrated operation mode, production efficiency is improved, and product stability is improved. The method can be applied to production of multiple thiuram vulcanizing agents such as tetramethyl thiuram disulfide, tetraethylthiuram disulfide, tetrabutylthiuram disulfide and the like, the yield can reach 98% or higher, and product purity is high.

Owner:WILLING NEW MATERIALS TECH CO LTD +1

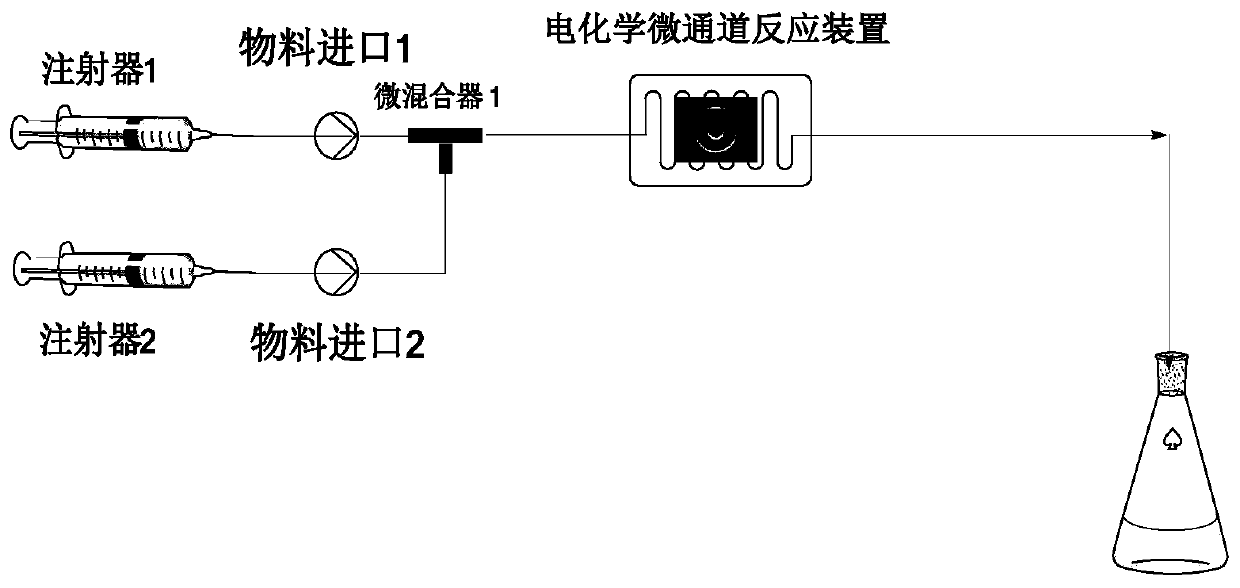

Method for preparing sulfone compound by utilizing electrochemical micro-channel technology

ActiveCN110106515ACheap and easy to getNo residueElectrolysis componentsElectrolytic organic productionPower flowAcetonitrile

The invention discloses a method for preparing a sulfone compound by utilizing an electrochemical micro-channel technology. A compound I is dissolved with an acetonitrile and dichloroethane mixed solvent, and the mixture is loaded in an injector 1 after being completely dissolved; 4-methyl benzenesulfinate and electrolyte are dissolved with an acetonitrile and dichloroethane mixed solvent, and themixture is loaded into an injector 2 after being completely dissolved; the materials in the injector 1 and the materials in the syringe 2 are pumped into a micro-mixer of a micro-channel reaction device at the same time to be mixed, and the materials are completely mixed and then pumped into the electrochemical micro-channel reaction device, react under a constant current and are oxidized to obtain the sulfone compound. The method has the advantages that the method is safe and environmentally friendly, the raw materials are low in price and easy to obtain, highly toxic reactant residues are avoided, the reaction speed is high and the efficiency is high; a sulfone compound product prepared through the preparation method has the advantages of high purity, high acidification degree and the like, and is suitable for large-scale preparation.

Owner:NANJING UNIV OF TECH

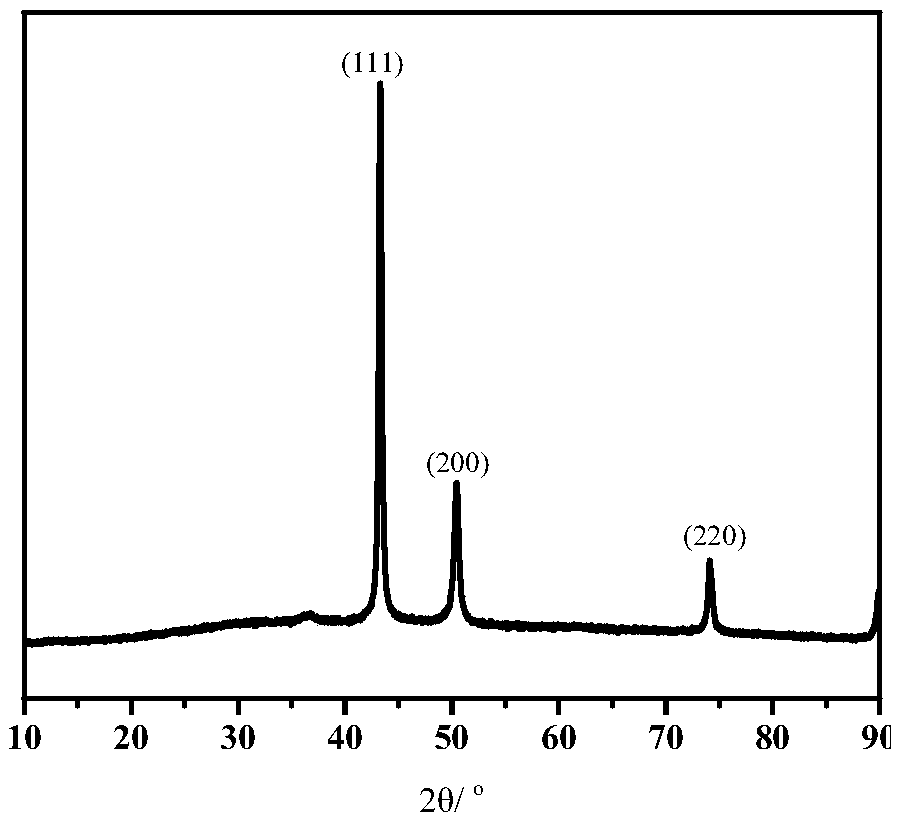

Continuous preparation method of nano-copper

ActiveCN108941599AProne to agglomerationPrecise control of pumping volumeNanotechnologyNano copperNucleation

The invention provides a continuous preparation method of nano-copper. The continuous preparation method of the nano-copper comprises the steps that a dispersing agent is dissolved in water, copper slat is added, the pH is adjusted, and then a copper slat dispersion solution is obtained; a reducing agent is dissolved in water, so that a reducing solution is obtained; the protective agent is dissolved in water, so that a protective solution is obtained; and finally, after the prepared copper slat dispersion solution, the reducing solution and the protective solution are fed into a micro-mixer to perform a reaction, the product is purified, and then nano-copper is obtained. Compared with the prior art, the continuous preparation method of the nano-copper achieves continuous preparation of the nano-copper in the manner that the dispersion solution, the reducing solution and the protective solution are independently prepared first of all, and then the three mixed solutions conduct the reaction through the micro-mixer to prepare the nanometer copper; the test conditions are gentle, purification is easy in the later period, cost is low, the micromixing time is shortened, nucleation and growth of crystals can be effectively controlled, and the prepared nano-copper particles are small and uniform in particle size; and the adopted protective agent enables nano-copper colloid to keep stable and avoid agglomeration for a long time.

Owner:珠海市彩龙科技有限公司

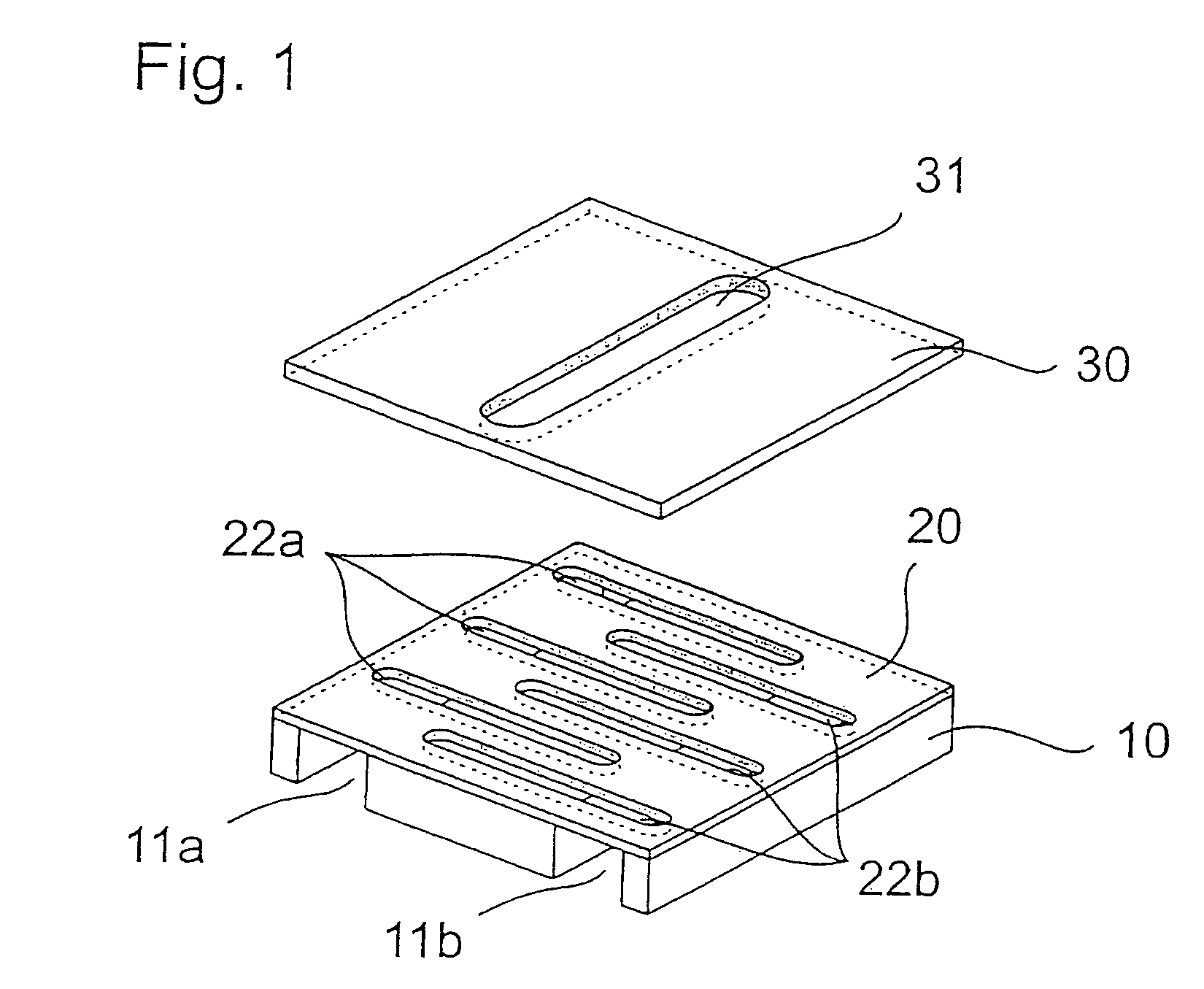

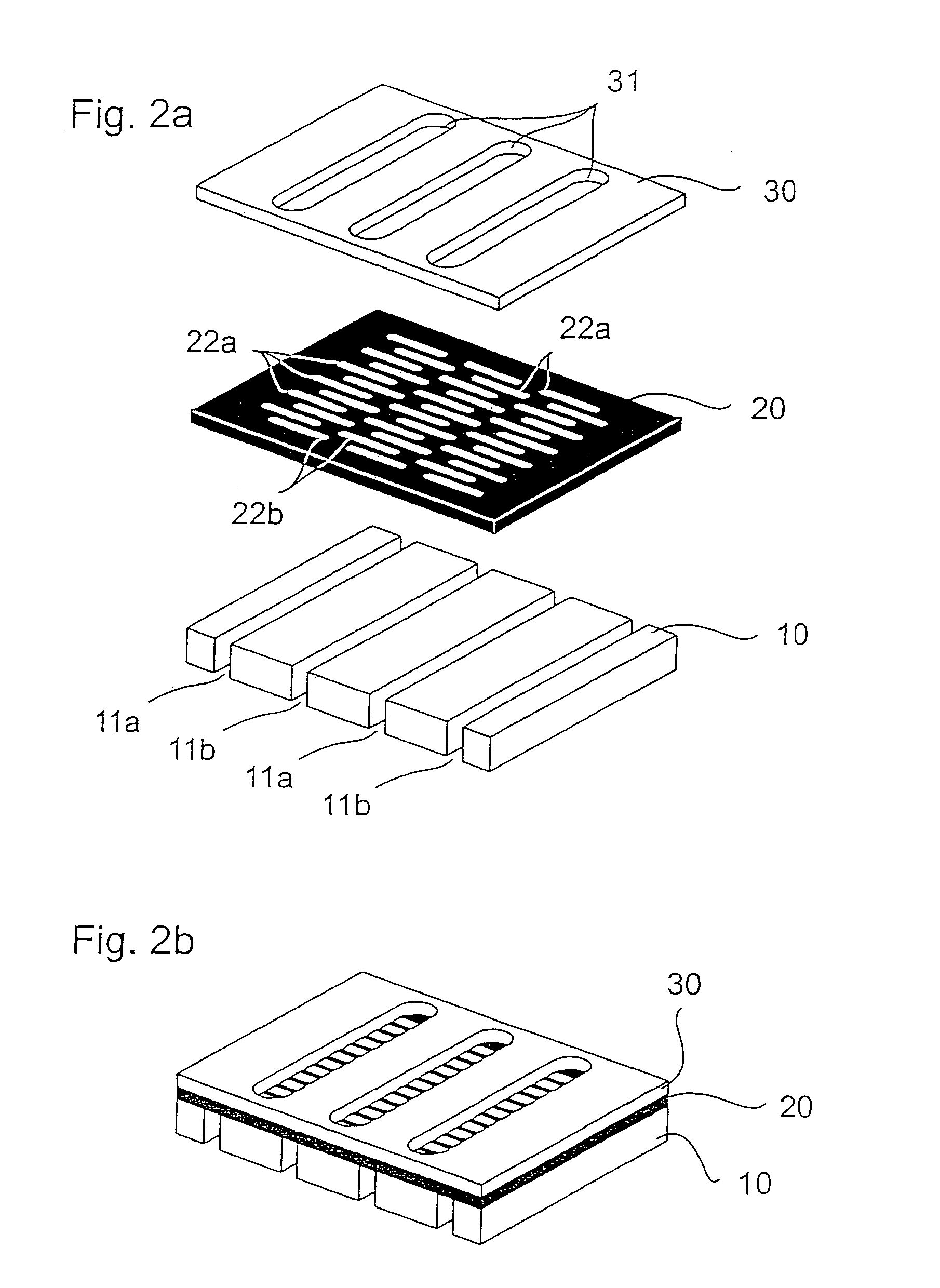

Micromixer

InactiveUS7066641B2Improve the mixing effectEasy to produceFlow mixersFixed microstructural devicesEngineeringMICRO MIXER

Owner:YAMATAKE HONEYWELL CO LTD

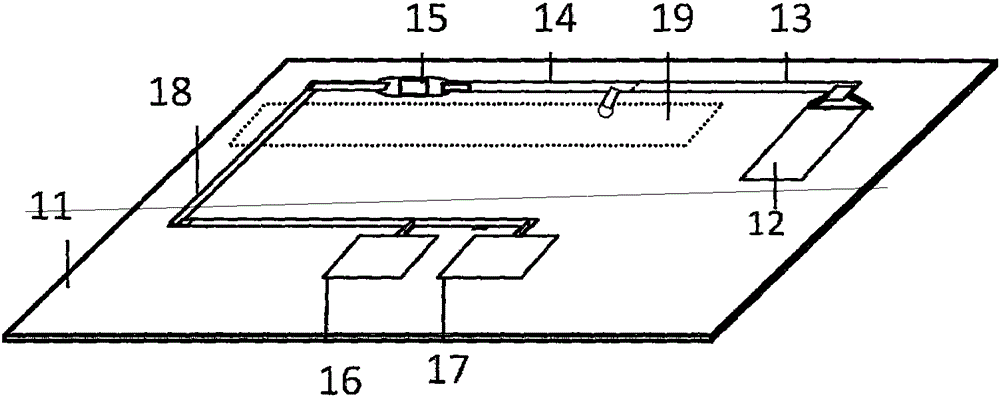

Magnetic micro-particle chemiluminescence micro-fluidic chip for quantitatively detecting C-reaction protein

ActiveCN105195242AEasy to operateReliable resultsLaboratory glasswaresBiological testingMicro fluidicMICRO MIXER

The invention discloses a magnetic micro-particle chemiluminescence micro-fluidic chip for quantitatively detecting a C-reaction protein. The magnetic micro-particle chemiluminescence micro-fluidic chip structurally comprises a cover plate (1) and a bottom plate (11), wherein a sampling opening (2), a sample liquid flow channel (6), a first biomarker storage pool (4), a micro-mixer (7) and a transitional area (10) on the cover plate (1) are connected in sequence; a filter (12), a reaction pool (13), a cleaning pool (14), a detection pool (15) and a solution release channel (18) on the bottom plate (11) are connected in sequence; a detection pool (15) on the bottom plate (11) is connected with a cleaning liquid storage pool (16) and a luminous liquid storage pool (17) through the solution release channel (18).

Owner:SHENZHEN HUAMAIXINGWEI MEDICAL TECH CO LTD

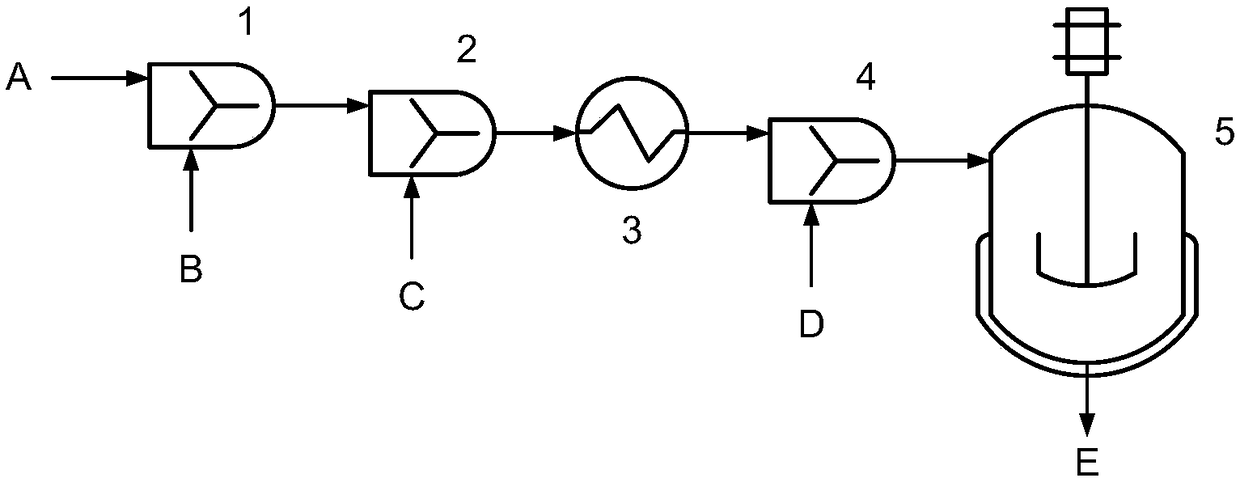

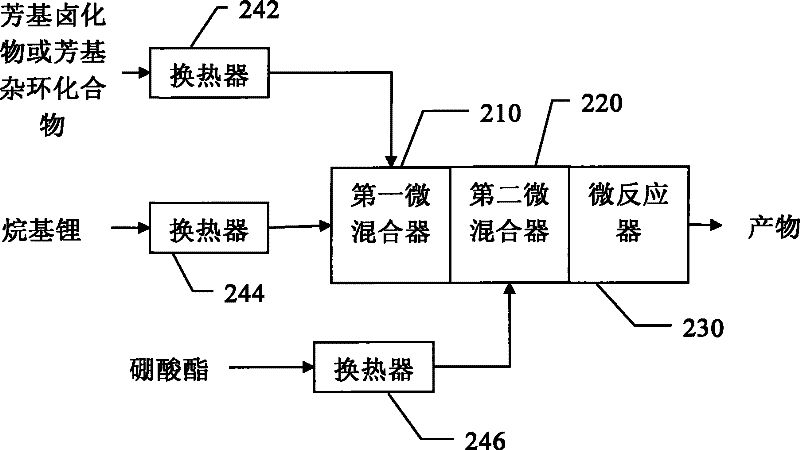

Method and apparatus for continuously producing aryl boric acid

InactiveCN102190676AAvoid it happening againEasy to removeGroup 3/13 element organic compoundsLithiumBoric acid

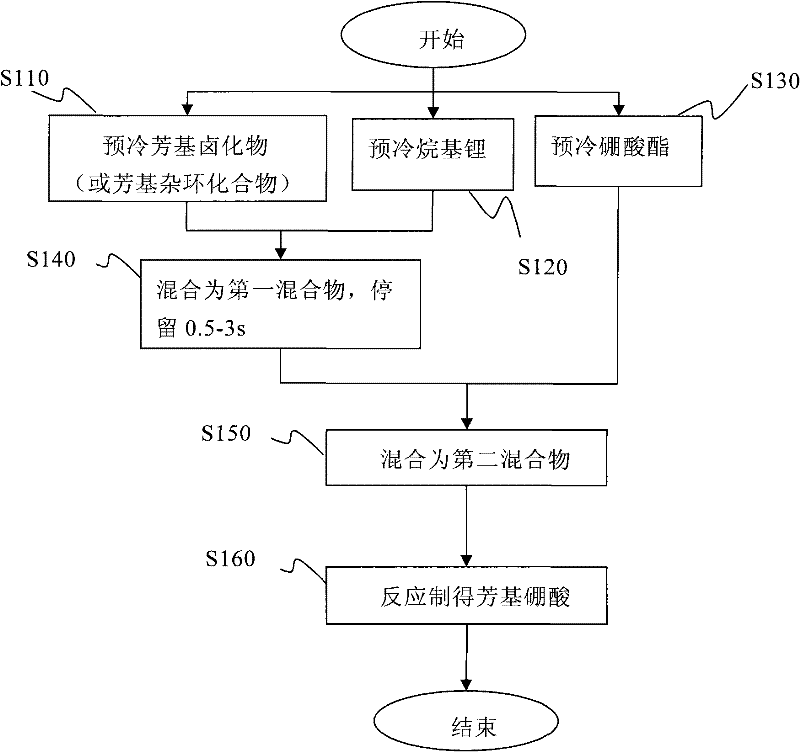

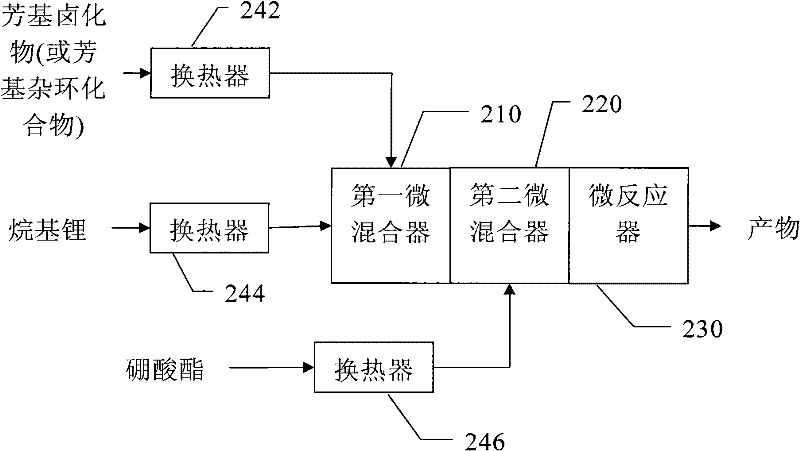

The invention relates to a method and an apparatus for continuously producing aryl boric acid. The method comprises the following steps: a first mixture is obtained by mixing aryl halide or an aryl heterocyclic compound with lithium alkyl in a first micro mixer, and a stay period of the first mixture is 0.5 to 3 s; a second mixture is obtained by mixing the first mixture with boric acid ester in a second micro mixer; and aryl boric acid is prepared by carrying out a reaction on the second mixture in a micro reactor. According to the method and the apparatus provided by the invention, aryl boric acid can be prepared continuously, rapidly and safely to achieve industrialization of aryl boric acid.

Owner:BAYER TECH & ENG SHANGHAI

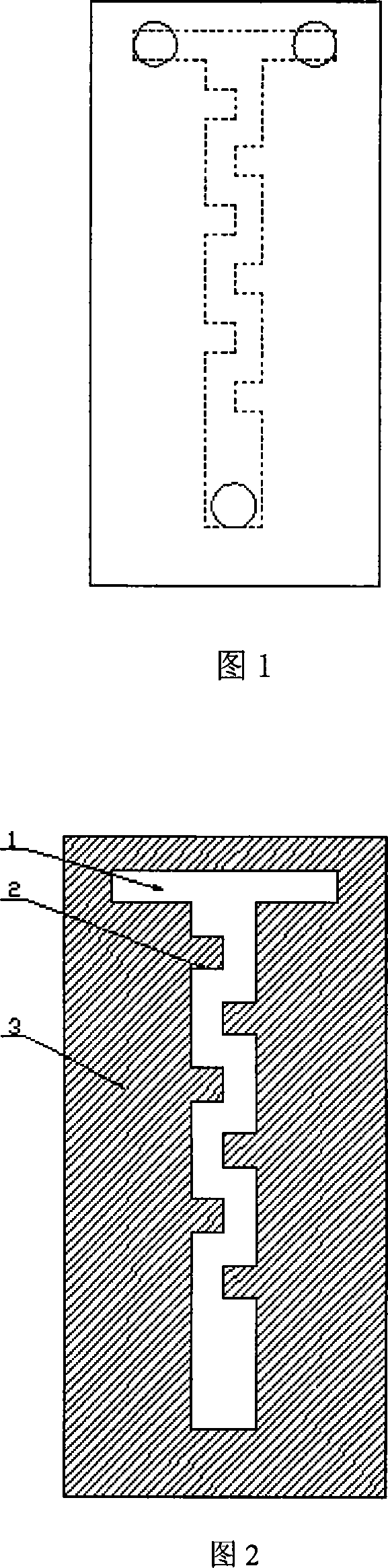

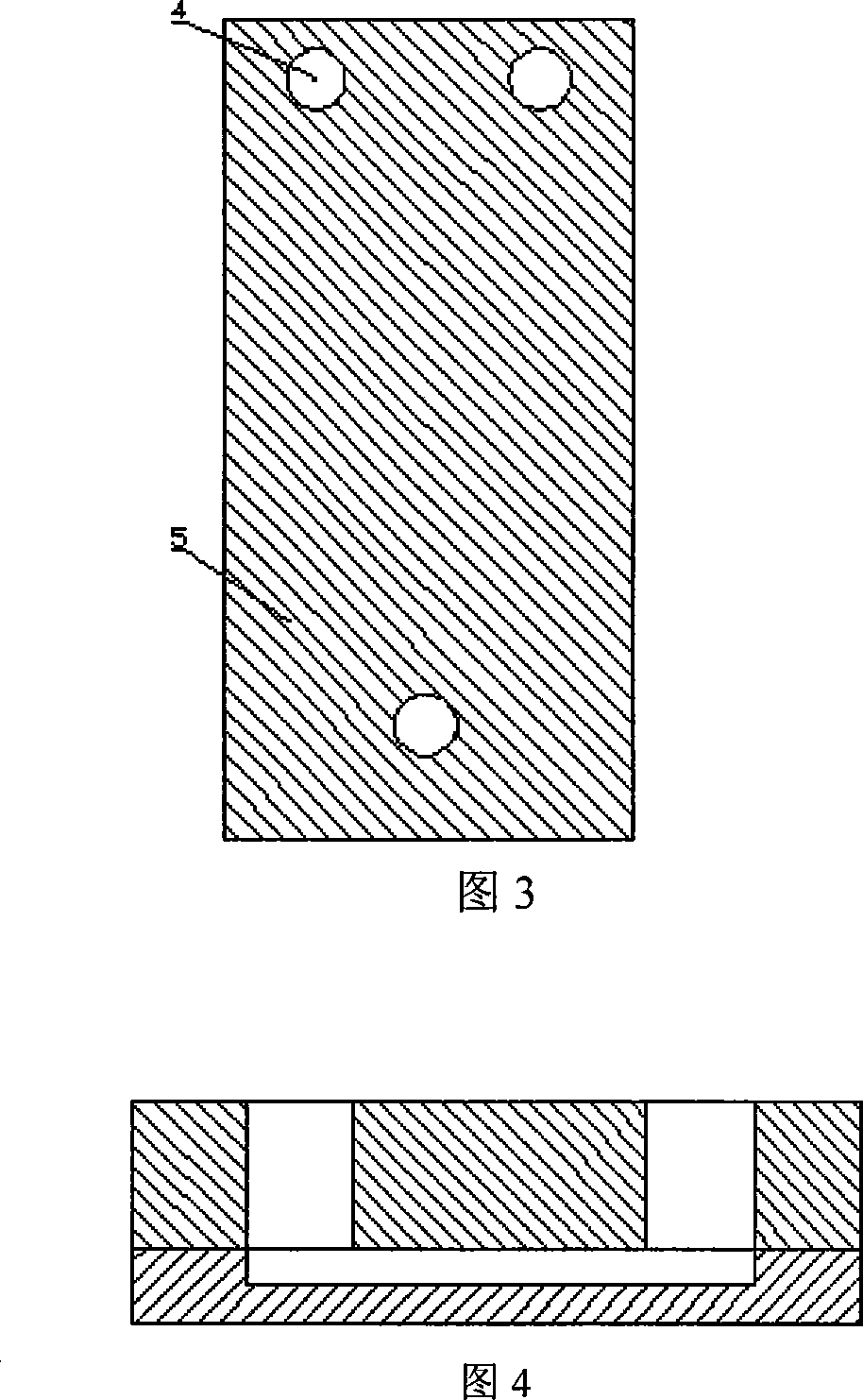

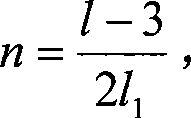

Mini mixer capable of uniform mixing gas mixture rapidly, and preparation method

InactiveCN101091887AWell mixedReduce distanceFlow mixersMixing gases with gases/vapoursKeelEddy current

The invention publishes a micro mixer which can uniform mix gas fast and its preparation method, it involves the gas-mixing area of technology, it has joined the raised ridge in the original miniature T mixer's hybrid channel, the height of the raised ridge is consistent with the depth of the hybrid channel, the raised keel's width is half as large as hybrid channel, and the length is consistent with the width. The raised ridge distributes dividable along the both sides of the mixed channel, there has been a raised ridge's width between the neighboring raised ridge, and arranges separately. The number of the raised ridge lies on the hybrid channel's length, n= (l-3) / 2l1, n expresses the raised ridge's integer, l expresses hybrid channel's length, l1 is the raised keel's length of side. The design advantages of the invention is: join the raised ridge after the hybrid channel may cause the two gases to be pressed when they flow through the raised ridge to reduce the distances between them, it can help to mix the diffusion; and because the speed increases when the gas flow through the raised ridge, it can easily produce the eddy current and increase the two contacted areas, and it is also good to mix the gases; in addition, it may produce backflow near the downstream of the raised ridge, and strengthens the two gas mixed performance.

Owner:JIANGSU UNIV

Magnetic particulate chemiluminescent micro-fluidic chip for quantitatively detecting myohemoglobin

ActiveCN105195243AHigh sensitivityGood repeatabilityChemiluminescene/bioluminescenceLaboratory glasswaresParticulatesLiquid storage tank

The invention discloses a magnetic particulate chemiluminescent micro-fluidic chip for quantitatively detecting myohemoglobin. The structure of the magnetic particulate chemiluminescent micro-fluidic chip mainly comprises a cover piece (1) and a bottom piece (11), wherein an air pump (3), an airflow micro-channel (5), a sample feeding hole (2), a sample liquid flowing channel (6), a first biological marker storage tank (4), a micro-mixer (7) and a transition region (10) on the cover piece (1) are connected in sequence; a filter (12), a reaction tank (13), a washing tank (14), a detection tank (15) and a solution releasing channel (18) on the bottom piece (11) are connected in sequence; the detection tank (15) on the bottom piece (11) is connected with a washing liquid storage tank (16) and a luminescent liquid storage tank (17) through the solution releasing channel (18).

Owner:SHENZHEN HUAMAIXINGWEI MEDICAL TECH CO LTD

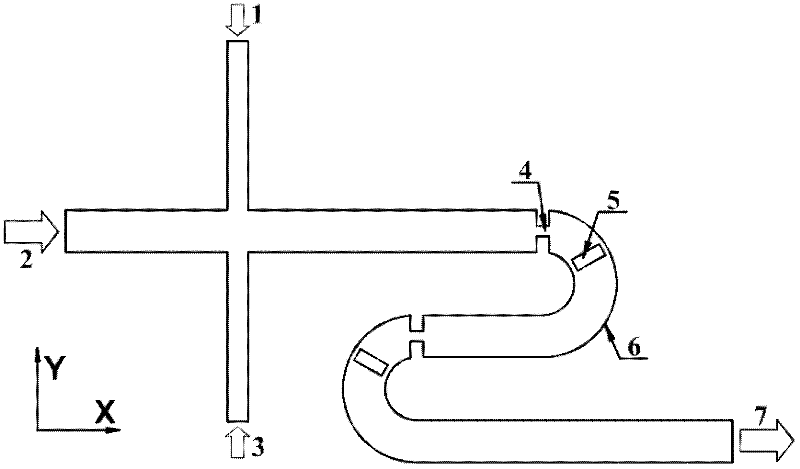

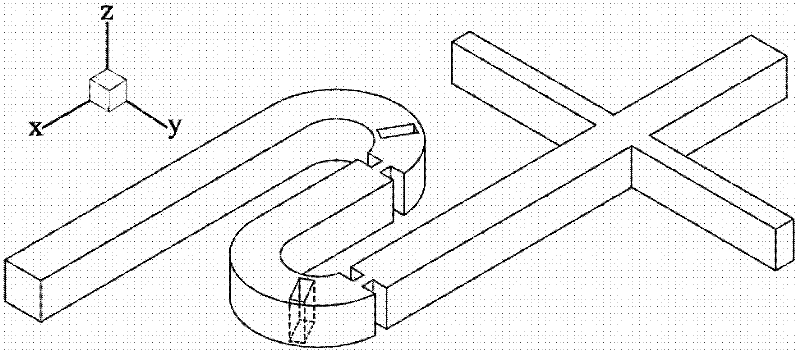

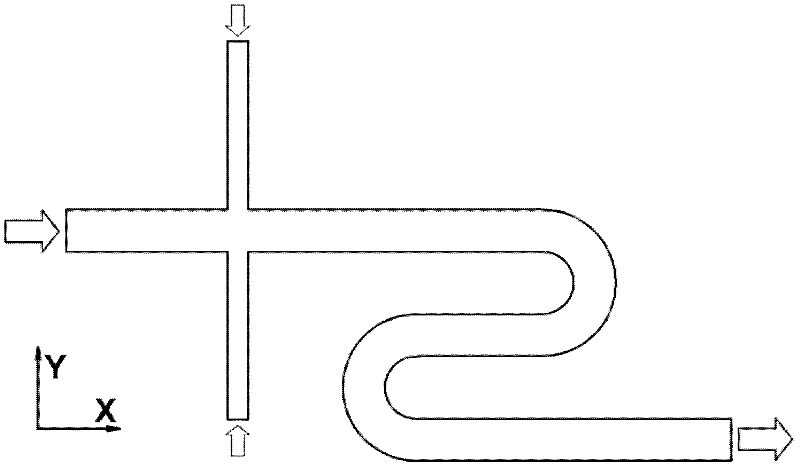

Planar passive micro mixer based on vortex forming structure enhanced mixing

InactiveCN102233241AIncrease contact areaIncrease disturbanceFlow mixersMixing methodsMicrofluidic chipMICRO MIXER

The invention discloses a planar passive micro mixer based on vortex forming structure enhanced mixing, relating to the field of micro fluid mixing in micro total analysis systems and micro fluid control chips as well as the related fields. The micro mixer is formed by connecting a straight passage, a cross passage, a first C-shaped passage and a second C-shaped passage; a passage outlet is formed at a straight passage outlet connected with the second C-shaped passage, and vortex forming structures are arranged in the C-shaped passages; and the end arm of the cross passage, which is opposite to the connected C-shaped passage, is provided with a second passage inlet (2), and the end arm vertical to the end arm is provided with a first passage inlet (2) and a third passage inlet (3) respectively. Compared with a planar passive micro mixer without the vortex forming structures, the planar passive micro mixer based on vortex forming structure enhanced mixing has the advantage of obviously enhancing the mixing strength of the micro fluid in the passages because several kinds of vortex generated by the vortex forming structures are generated in different dimensional planes respectively.

Owner:BEIJING UNIV OF TECH

Preparation method of nanometer iron phosphate

ActiveCN102408102AHigh purityIncrease productivityNanotechnologyPhosphorus compoundsNanoparticlePhosphoric acid

The invention discloses a preparation method of nanometer iron phosphate, which belongs to the field of chemistry and chemical engineering. The method comprises the following steps of: previously adding proper amount of ferric iron salt water solution of phosphoric acid as iron source; taking phosphate water solution as phosphorus source; using micro mixer to quickly mix the iron source with the phosphorus source to obtain iron phosphate precursor with better monodispersity in a state of nanometer particle; and using normal pressure hydrothermal method to directly process product slurry to obtain nanometer iron phosphate material with high purity and average particle size of about 100nm. The method has the advantages of simple preparation process, high production efficiency, high product purity, uniform particle size, good monodispersity and easy industrial amplification.

Owner:TSINGHUA UNIV

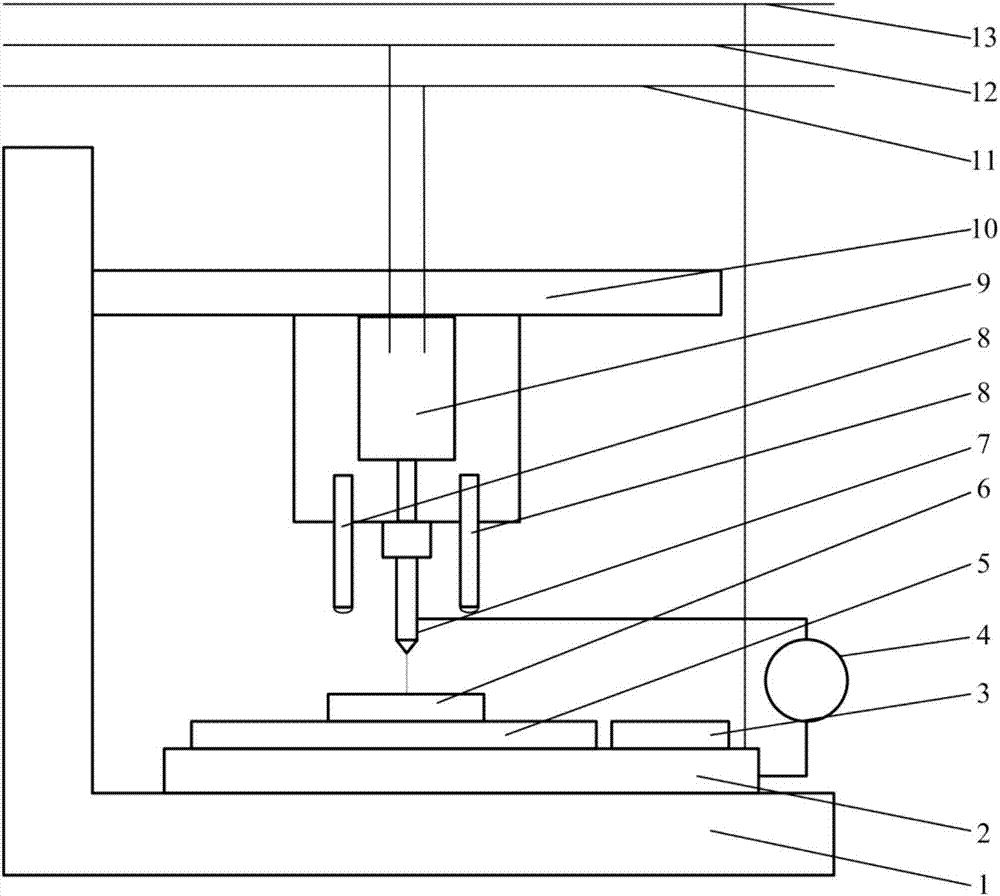

Multi-material micro-scale 3D printing device and printing method thereof

InactiveCN107187017AWell mixedRealize printingAdditive manufacturing apparatus3D object support structuresMulti materialUltraviolet lights

The invention discloses a multi-material micro-scale 3D printing device and printing method. The multi-material micro-scale 3D printing device comprises an electric fluid power nozzle system used for mixing and printing various materials. The nozzle system comprise a feeding device, a micro-mixing device, ultraviolet light curing lights and a micro-nozzle. The feeding device is provided with a plurality of micro-injection pumps and feeding pipelines. A passive micro-mixer used for effectively mixing the high-viscosity-difference materials is arranged in the micro-mixing device and comprises two or more fluid inlet flow channels, a mixing flow channel and a fluid outlet flow channel. The two or more fluid inlet flow channels are connected with the feeding pipelines of the feeding device. The mixing flow channel is of a flow channel structure capable of effectively micro-mixing high-viscosity-difference fluids and other fluids. The fluid outlet flow channel is connected with the micro-nozzle. The ultraviolet light curing lights are mounted around an outlet of the micro-nozzle.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

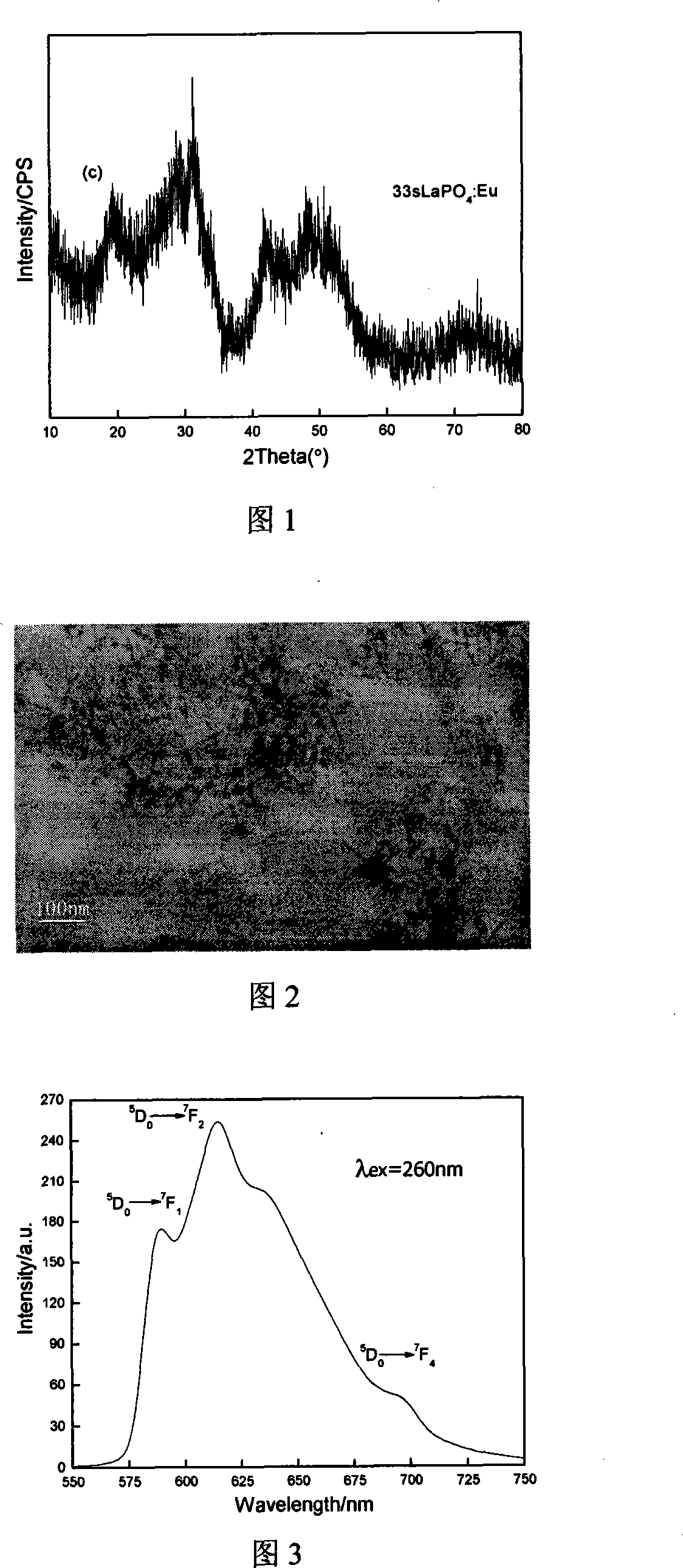

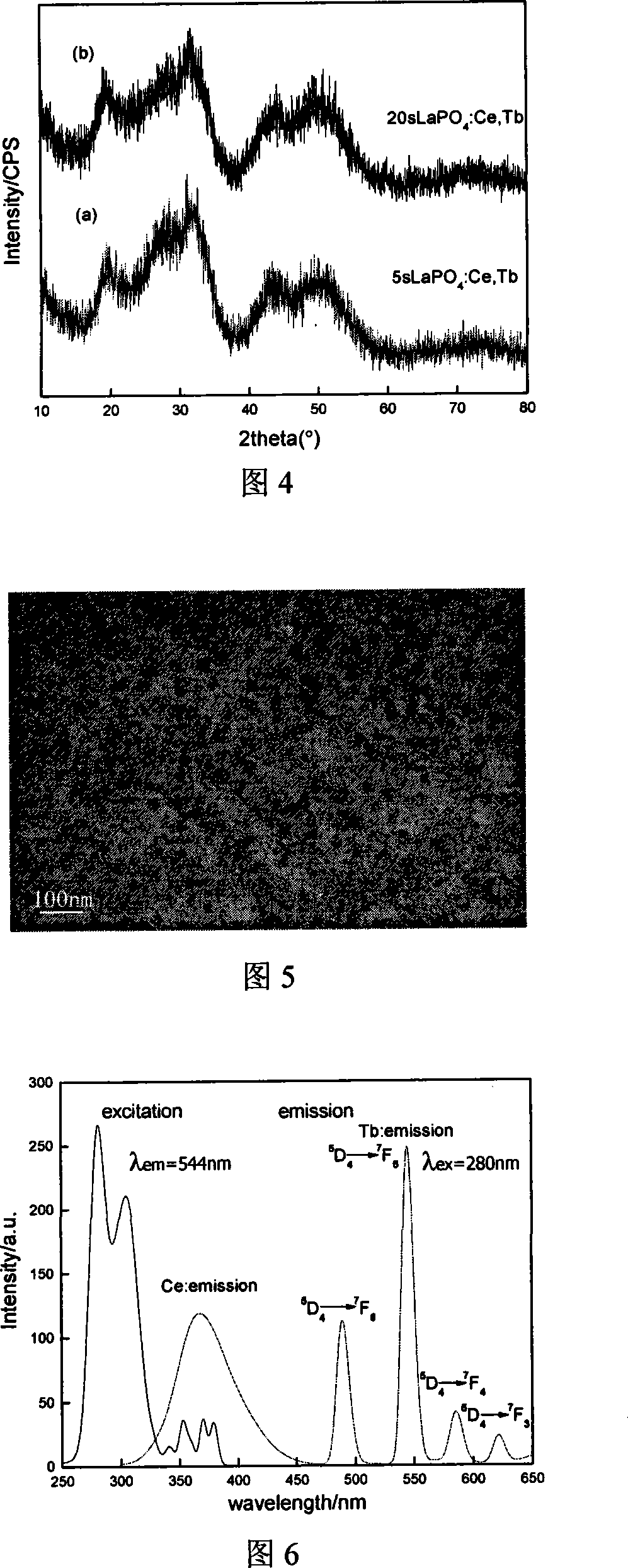

Method for preparing rare-earth doped lanthanum phosphate nano luminous particles

The invention relates to a method for preparing luminescent nano-particles of rare earth doped with lanthanum phosphate, comprising the following steps: preparing stock solutions including lanthanum nitrate polyol solution doped with rare earth element of Ln and polyol solution of NaH2PO4-2H2O; mixing the stock solutions in a micro mixer and heating the mixture in oil under constant temperature after the mixture enters the micro-channels, after which the mixture will react to produce polyol solution of luminescent nano-particles of rare earth doped with lanthanum phosphate; obtaining luminescence nano-particles of rare earth doped with lanthanum phosphate by extracting, washing and centrifugal separation. With simple technology and easy for batch production, the obtained nano-particles are provided with small particles, good dispersibility and fluorescence.

Owner:DONGHUA UNIV

Static lamination micro mixer

ActiveUS7909502B2Easy to cleanProduced economicallySemi-permeable membranesOther chemical processesEngineeringMICRO MIXER

Static lamination micro mixer comprising at least one slotted plate having slot openings and an aperture plate having aperture slots arranged above the slotted plate.

Owner:EHRFELD MIKROTECHNIK BTS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com