Continuous preparation method of nano-copper

A nano-copper and copper salt technology, applied in nanotechnology and other directions, can solve the problems of harsh preparation conditions, high purification cost, and difficulty in continuous preparation of nano-copper, and achieve the effects of controlling nucleation and growth, simple process flow, and continuous preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

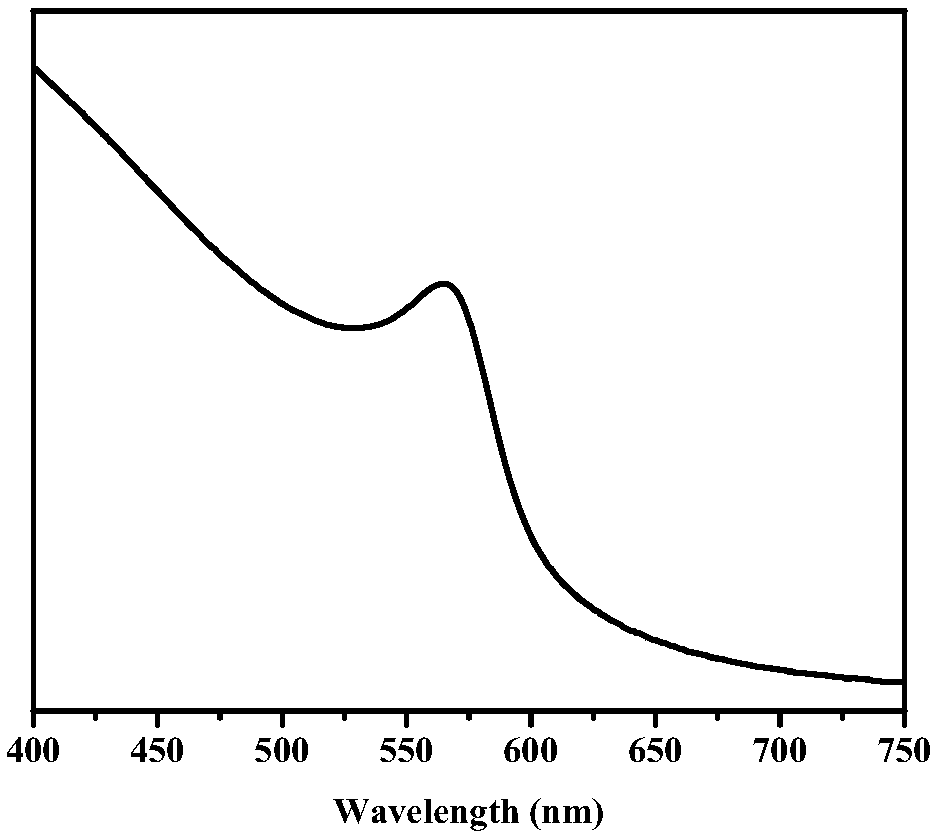

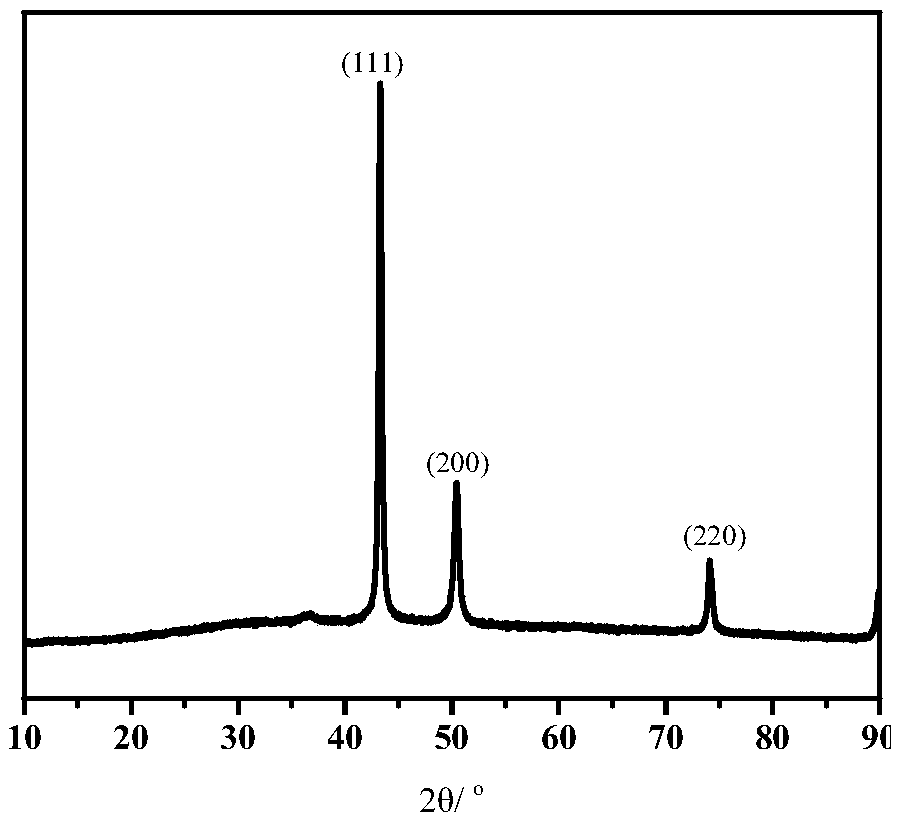

[0044] The present embodiment has prepared nano-copper A, and concrete steps are:

[0045] (1) Dissolve 50g of copper sulfate in deionized water, stir evenly, add a certain amount of ammonia water, adjust the pH to 12, and form a copper ammonia complex. The solution changes from light blue to dark blue, and then add the dispersant to the copper salt solution , stirring evenly to prepare a copper salt dispersion, the dispersant is sodium dodecylbenzenesulfonate, wherein the molar ratio of the copper salt to the dispersant is 1:2;

[0046] (2) dissolving the reducing agent in deionized water, stirring evenly to prepare a reducing solution, the reducing agent is hydrazine hydrate, and the ratio of the copper salt to the reducing agent is 1:2.5;

[0047] (3) Dissolving the protective agent in deionized water to prepare a protective solution, the protective agent is polyvinylpyrrolidone, and the molar ratio of the copper salt to the protective agent is 1:5;

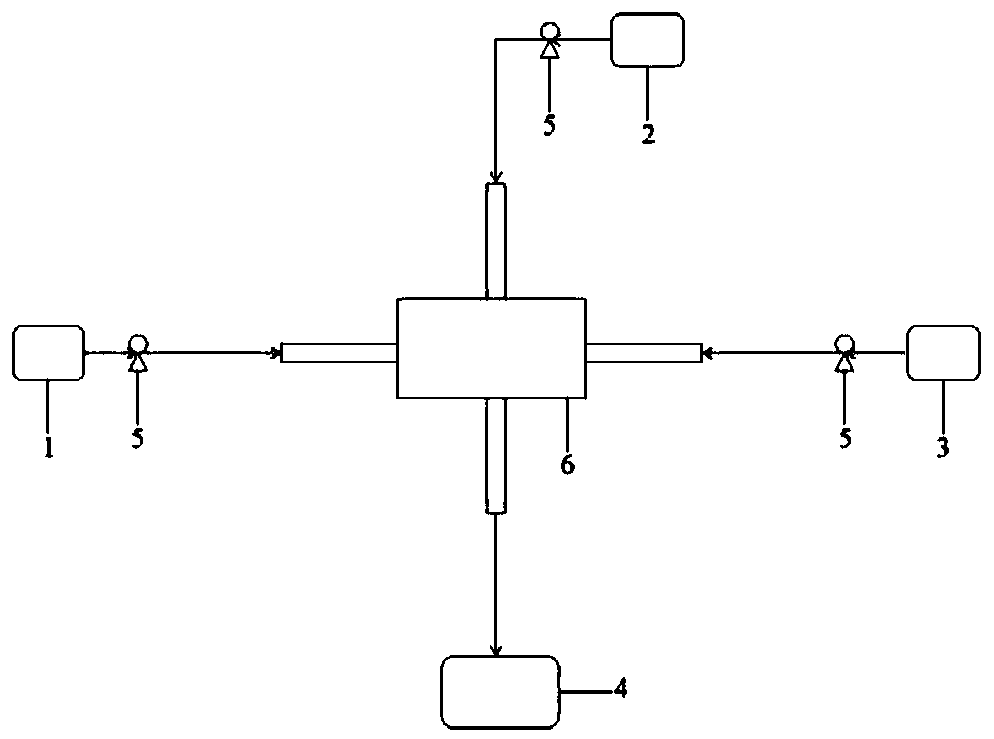

[0048] (4) Use a cons...

Embodiment 2

[0053] The present embodiment has prepared nano-copper B, and concrete steps are:

[0054] (1) Dissolve 50g of copper nitrate in deionized water, stir evenly, add a certain amount of ammonia water to make the solution change from light blue to dark blue to form a copper ammonia complex, adjust the pH to 10, then add the dispersant to the copper salt solution, Stir evenly to prepare a copper salt dispersant mixed solution. The dispersant is fatty alcohol polyoxyethylene ether and fatty alcohol polyoxyethylene ether sodium sulfate mixed in a molar ratio of 1:1, wherein the molar ratio of copper salt to dispersant is 1:6;

[0055] (2) dissolving the reducing agent in deionized water, stirring evenly to prepare a reducing solution, the reducing agent is sodium borohydride, and the ratio of the copper salt to the reducing agent is 1:5;

[0056] (3) Dissolving the protective agent in deionized water to prepare a protective solution, the protective agent is polyvinylpyrrolidone and s...

Embodiment 3

[0060] The present embodiment has prepared nano-copper C, and concrete steps are:

[0061] (1) Take 50g of copper chloride and dissolve it in deionized water, stir evenly, add a certain amount of ammonia water to make the solution change from light blue to dark blue to form a copper ammonium complex, and adjust the pH to 13. Then add the dispersant to the copper salt solution, stir evenly to prepare a mixed solution of copper salt dispersant, the dispersant is lignosulfonate, and the molar ratio of copper salt to dispersant is 1:10;

[0062] (2) dissolving the reducing agent in deionized water, stirring evenly to prepare a reducing solution, the reducing agent is ascorbic acid, and the ratio of the copper salt to the reducing agent is 1:10;

[0063] (3) The protective agent is dissolved in deionized water to prepare a protective solution. The protective agent is hexadecyltrimethylammonium bromide, and the molar ratio of the copper salt to the protective agent is 1:10;

[0064...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com