Environment-friendly composite plastic and preparation method thereof

A composite plastic, environmentally friendly technology, applied in the field of environmental protection, can solve the problems of insignificant modification effect and reduced performance, and achieve the effect of improving performance in all aspects, improving performance, and improving thermodynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

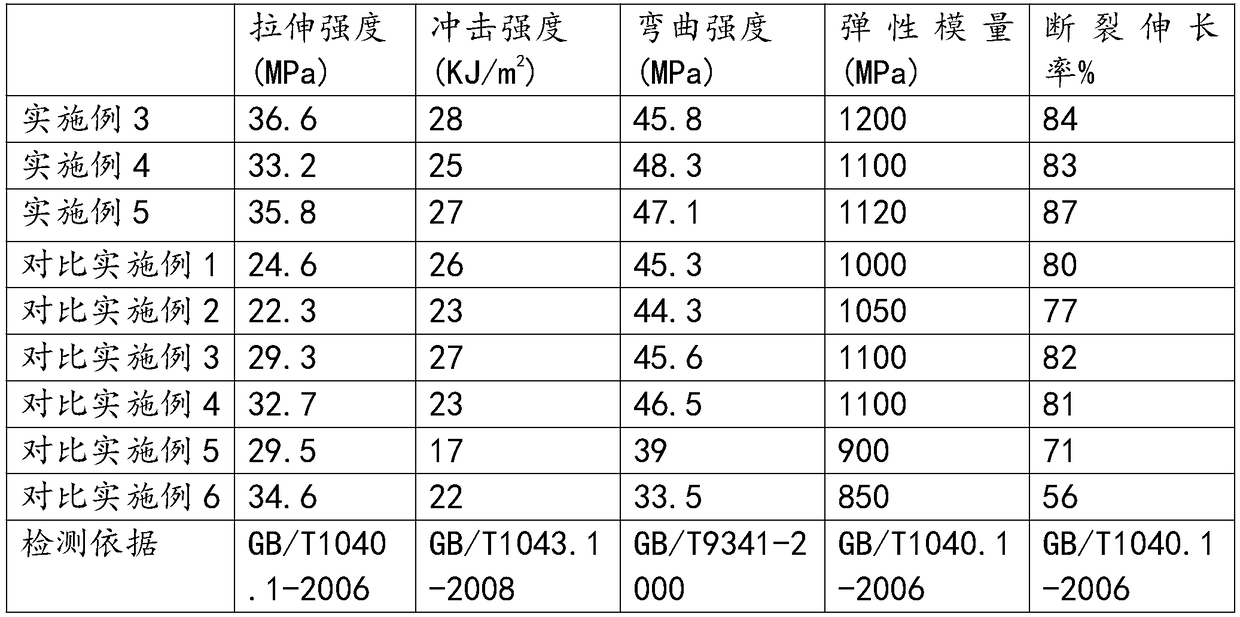

Examples

Embodiment 1

[0035] Preparation of Modified Zeolite Powder

[0036] Add 1 kg of zeolite to a ball mill for grinding and crushing, soak in 5% nitric acid for 5 hours, filter, wash until neutral, dry, and then put it into a muffle furnace for gradient calcination. The specific calcination steps are: (a) at 400 ° C (b) heat up to 800°C at a heating rate of 15°C / min, and keep calcination at this temperature for 50 minutes; (c) heat up to 1000°C at a heating rate of 5°C / min, and Calcining at lower temperature for 30 minutes, after the calcination, naturally cool to room temperature, grind and sieve to obtain the activated zeolite powder, the particle size of the activated zeolite powder is 7-85nm.

Embodiment 2

[0038] Preparation of modified calcium carbonate

[0039]Weigh 1kg of calcium carbonate and add it to the reaction flask, add 5L of solvent ethanol, heat to 75°C, and stir under reflux for 30min. After the calcium carbonate is completely dispersed into a suspension, add 90g of stearic acid drop by drop. After the addition is complete, Continue stirring for 1 hour, filter, vacuum-dry at 45°C for 10 hours, and grind for later use.

Embodiment 3

[0041] An environment-friendly composite plastic, the parts by weight of each raw material are: 200 parts of high-density polyethylene, 24 parts of straw powder, 6 parts of modified zeolite powder, 8 parts of modified calcium carbonate, 4 parts of coupling agent, and 5 parts of plasticizer 3 parts, heat stabilizer 3 parts, compatibilizer 2 parts;

[0042] The coupling agent is a titanate coupling agent;

[0043] Described plasticizer is butyl benzyl phthalate;

[0044] Described thermal stabilizer is zinc stearate;

[0045] The compatibilizer is polyethylene glycol;

[0046] A preparation method of an environment-friendly composite plastic, specifically comprising the following steps:

[0047] S1, the pretreatment of rice straw powder: after rice straw is air-dried, pulverize into powder with pulverizer, pass 20 mesh sieves, put into blast drying box and dry at 100 ℃ for 5h, the moisture content of the rice straw powder after drying is 1.1%;

[0048] S2. Wood-plastic compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com