dual function pt-iro 2 Nanowire electrocatalyst and its preparation method and fuel cell

A bifunctional catalyst, pt-iro2 technology, applied in the field of electrocatalysis, can solve problems such as unsolved defects, and achieve the effects of easy removal, high active area, and simple operation of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

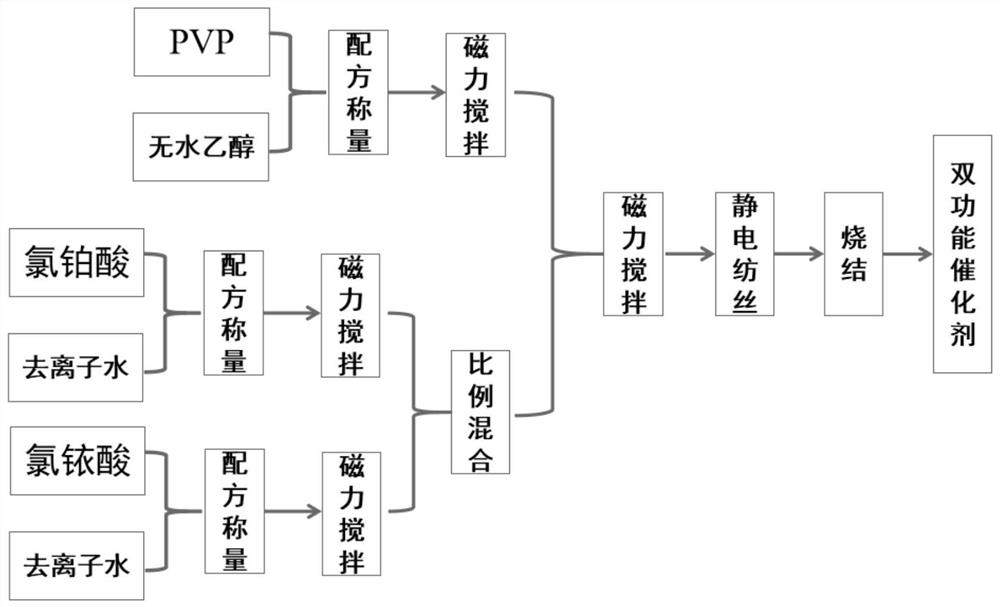

[0030] Step 1, take a certain amount of polyvinylpyrrolidone and add absolute ethanol, and stir magnetically to prepare an 8wt% PVP solution.

[0031] Step 2, respectively take 1 g of chloroiridic acid and chloroplatinic acid and add deionized water and stir to obtain a chloroplatinic acid solution and a chloroiridic acid solution with a Pt and Ir content of 0.34 mol / L.

[0032] Step 3, after mixing the solution in step 2 according to the ratio of Pt / Ir=1:9, add a certain amount of the PVP solution in step 1, and magnetically stir for 12 hours to obtain the spinning precursor solution.

[0033] Step 4, adding the precursor solution into the electrospinning equipment, the spinning voltage is 12KV, the spinning distance is 10cm, and the solution propulsion rate is 0.15ml / h.

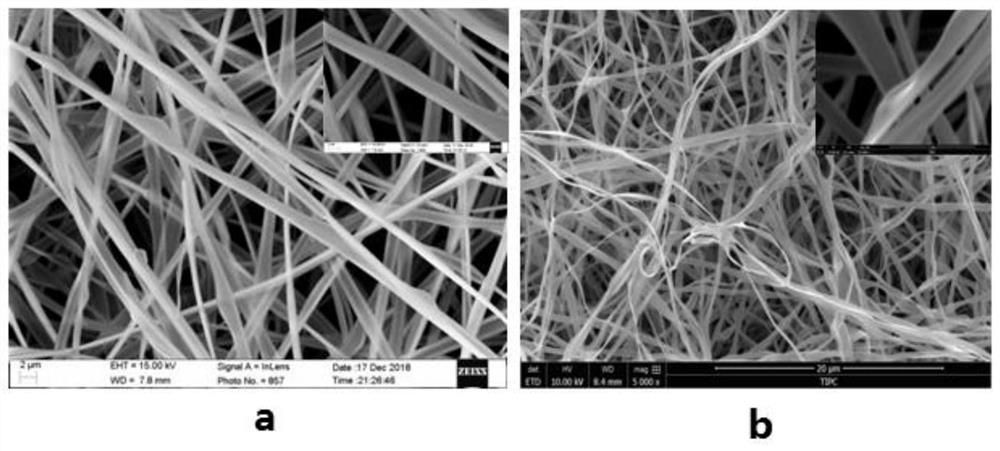

[0034] Step 5: Collect the spun nanofibers (flat ribbon structure, width 200nm-600nm) and calcinate them in an air atmosphere at a heating rate of 0.75°C / min, first raise the temperature to 260°C and keep i...

Embodiment 2

[0036] Step 1, take a certain amount of polyvinylpyrrolidone and add absolute ethanol, and stir magnetically to prepare an 8wt% PVP solution.

[0037] Step 2, respectively take 1 g of chloroiridic acid and chloroplatinic acid and add deionized water and stir to obtain a chloroplatinic acid solution and a chloroiridic acid solution with a Pt and Ir content of 0.17 mol / L.

[0038] Step 3, after mixing the solution in step 2 according to the ratio of Pt / Ir=1:9, add a certain amount of the PVP solution in step 1, and magnetically stir for 12 hours to obtain the spinning precursor solution.

[0039] Step 4, adding the precursor solution into the electrospinning equipment, the spinning voltage is 12KV, the spinning distance is 10cm, and the solution propulsion rate is 0.15ml / h.

[0040] Step 5: Collect the spun nanofibers (nanowire structure, diameter 220nm-350nm) and calcinate them in an air atmosphere at a heating rate of 0.75°C / min, first raise the temperature to 260°C for 1 hour...

Embodiment 3

[0042] Step 1, take a certain amount of polyvinylpyrrolidone and add absolute ethanol, and stir magnetically to prepare an 8wt% PVP solution.

[0043] In step 2, 1 g of chloroiridic acid and chloroplatinic acid were added into deionized water and stirred to obtain a chloroplatinic acid solution and a chloroiridic acid solution with a Pt and Ir content of 0.085 mol / L.

[0044] Step 3, after mixing the solution in step 2 according to the ratio of Pt / Ir=3:7, add a certain amount of the PVP solution in step 1, and magnetically stir for 12 hours to obtain the spinning precursor solution.

[0045] Step 4, adding the precursor solution into the electrospinning equipment, the spinning voltage is 12KV, the spinning distance is 10cm, and the solution propulsion rate is 0.15ml / h.

[0046] Step 5: Collect the spun nanofibers (nanowire structure, diameter 220nm-250nm, good uniformity) and calcinate them in an air atmosphere at a heating rate of 0.75°C / min. 350°C for 1 hour, and finally he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com