Patents

Literature

195results about How to "Increase active area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

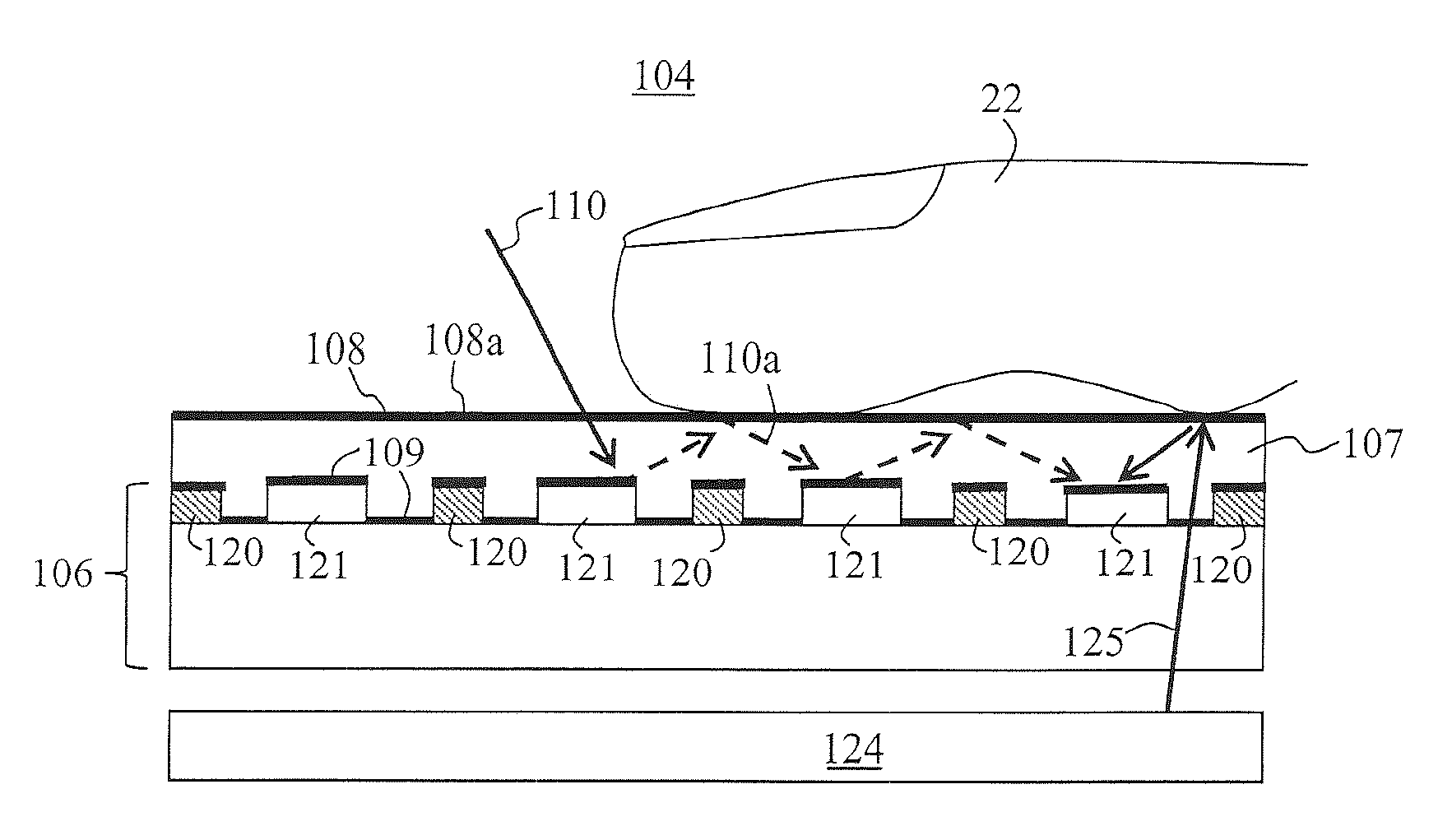

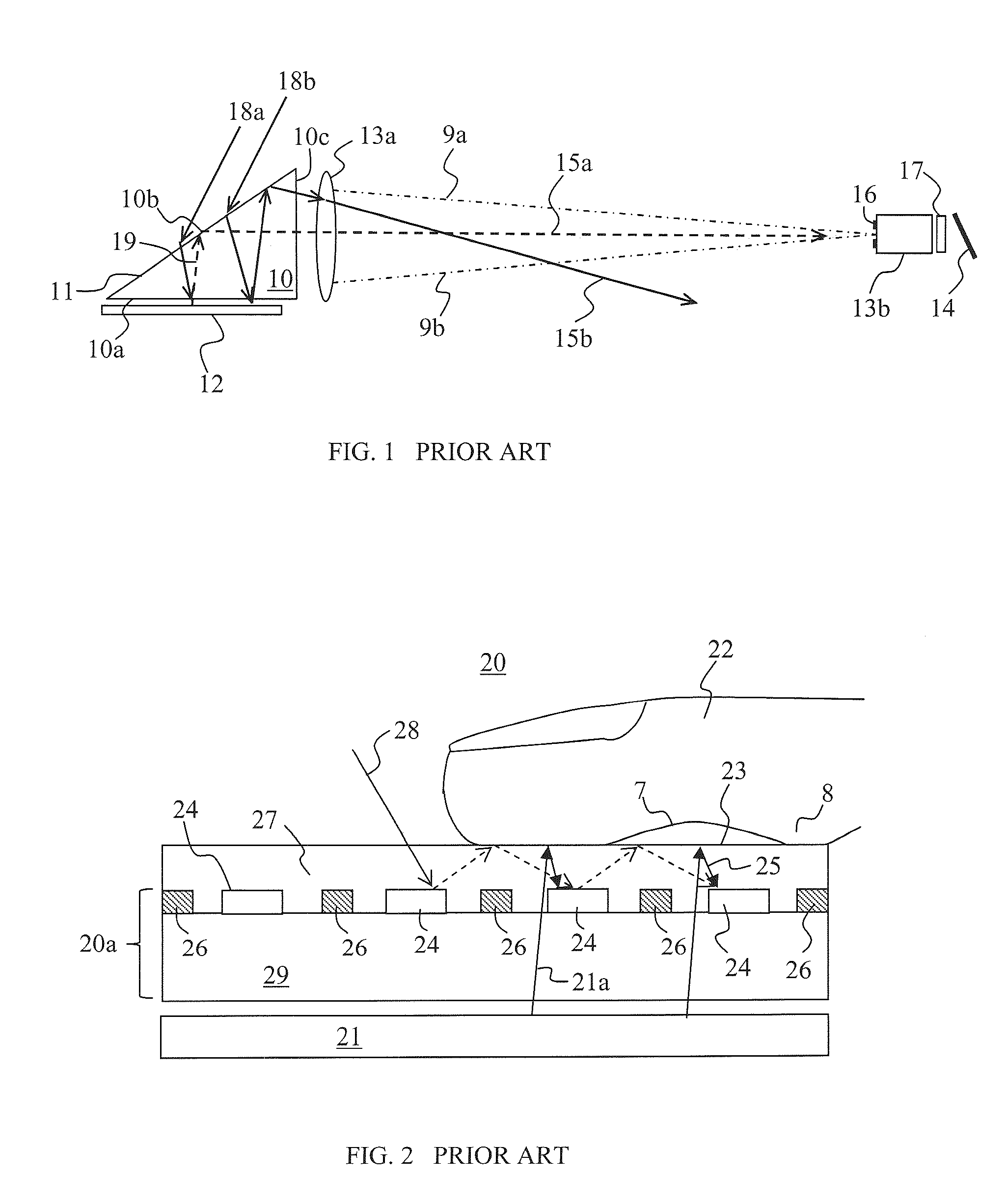

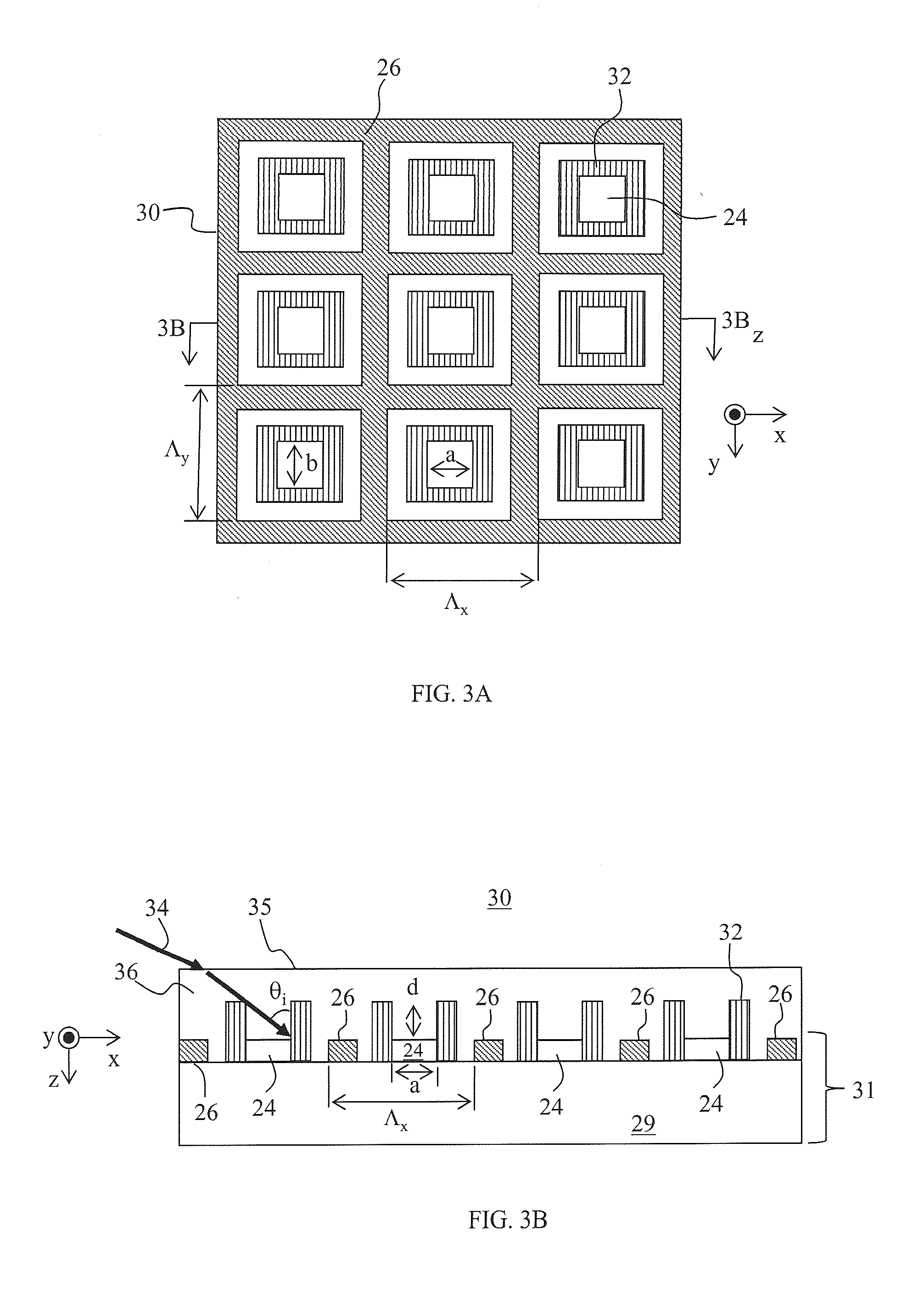

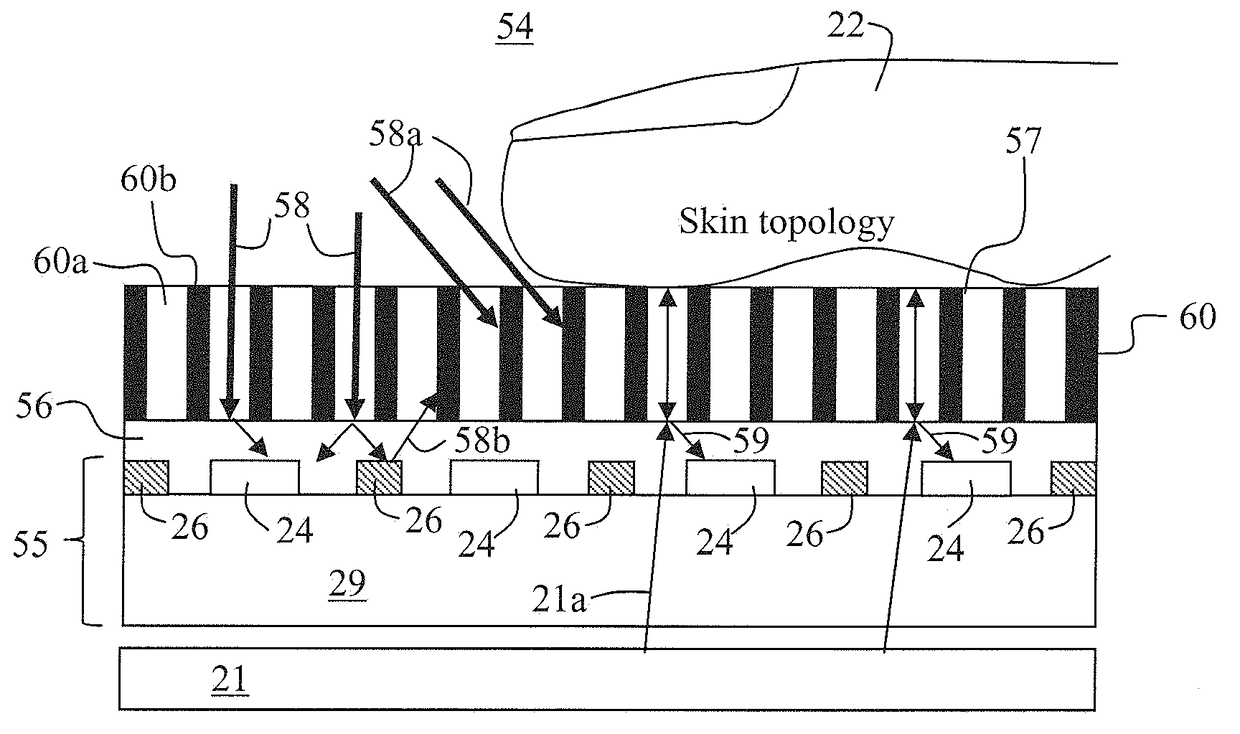

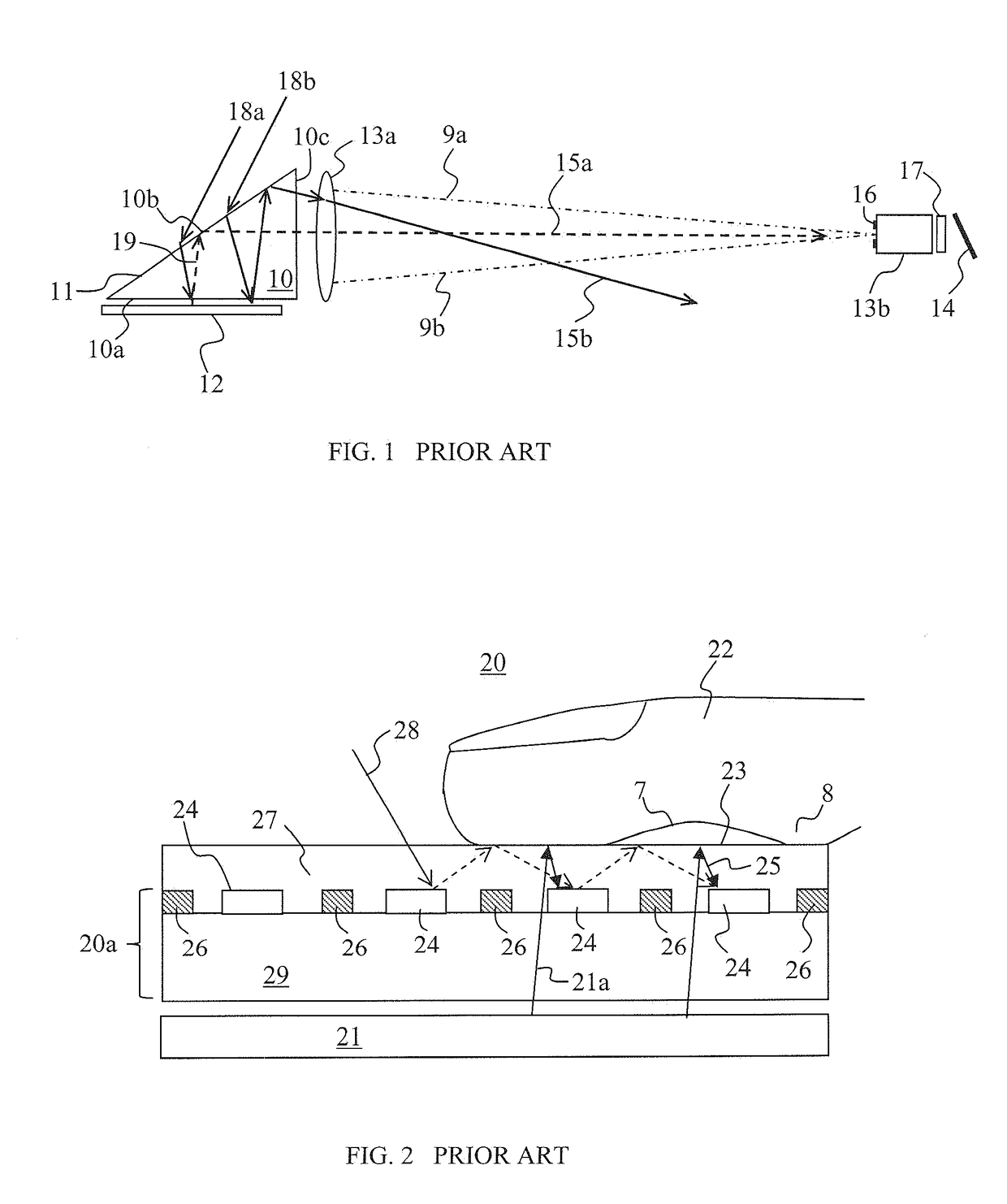

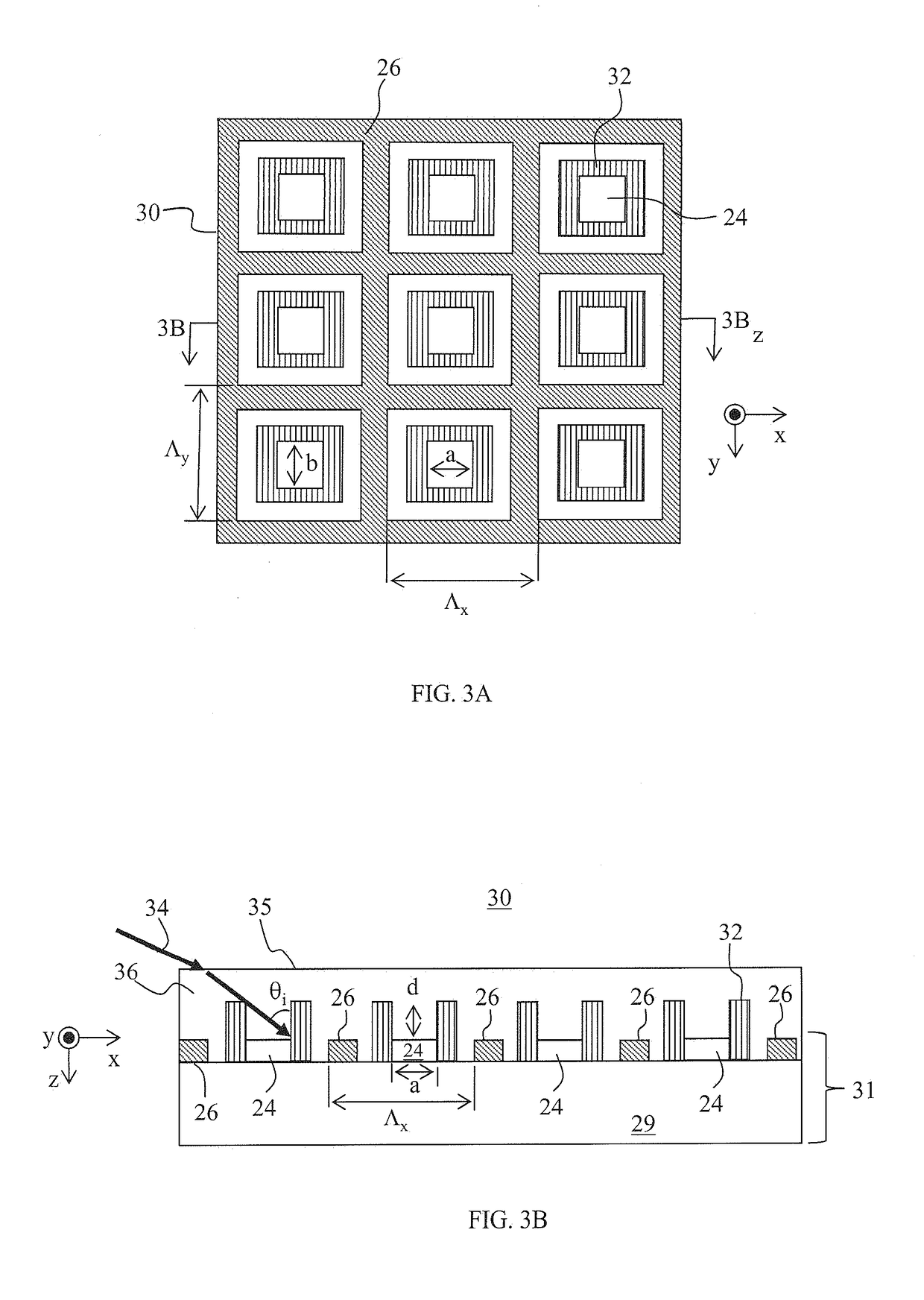

Ambient light rejection for non-imaging contact sensors

ActiveUS20130120760A1Reduce the amount requiredEnhance the imagePerson identificationUsing optical meansLight sensingMagnification

A sensor for capturing images of skin topology is provided having a platen, and a one or two-dimensional array of light sensing pixel elements for receiving light representative of skin topology when skin, such as finger(s), are present upon the platen. Such sensor being improved by structures, layers, or methods for reducing or blocking ambient light which would hinder the light sensing pixel elements from sensing the light representative of skin topology. The sensors are non-imaging contact sensors as they have platen to contact skin to be imaged, and do not require optics, such as lenses for focusing and / or magnification, to enable proper capture of light representative of skin topology on the sensor's light sensing pixel elements.

Owner:HID GLOBAL CORP

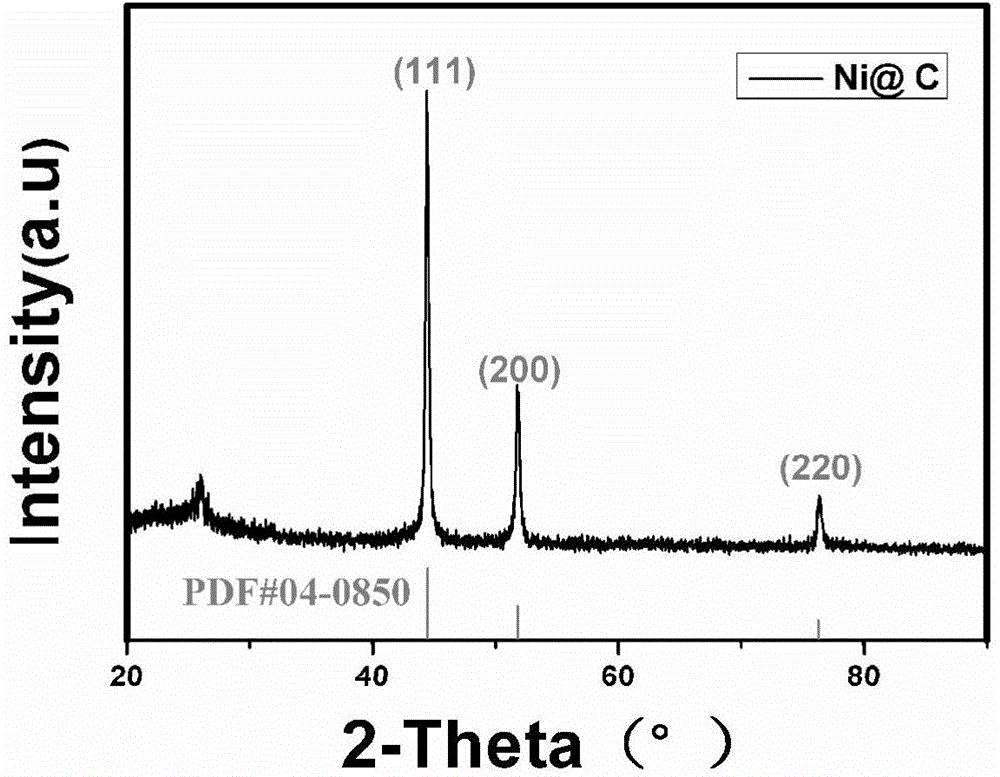

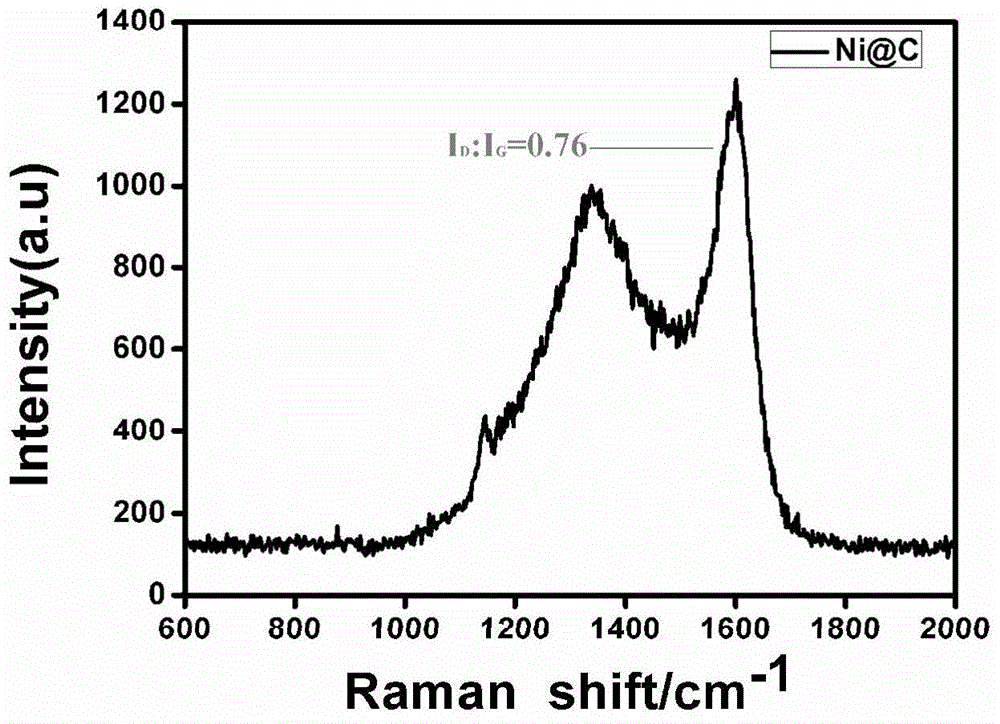

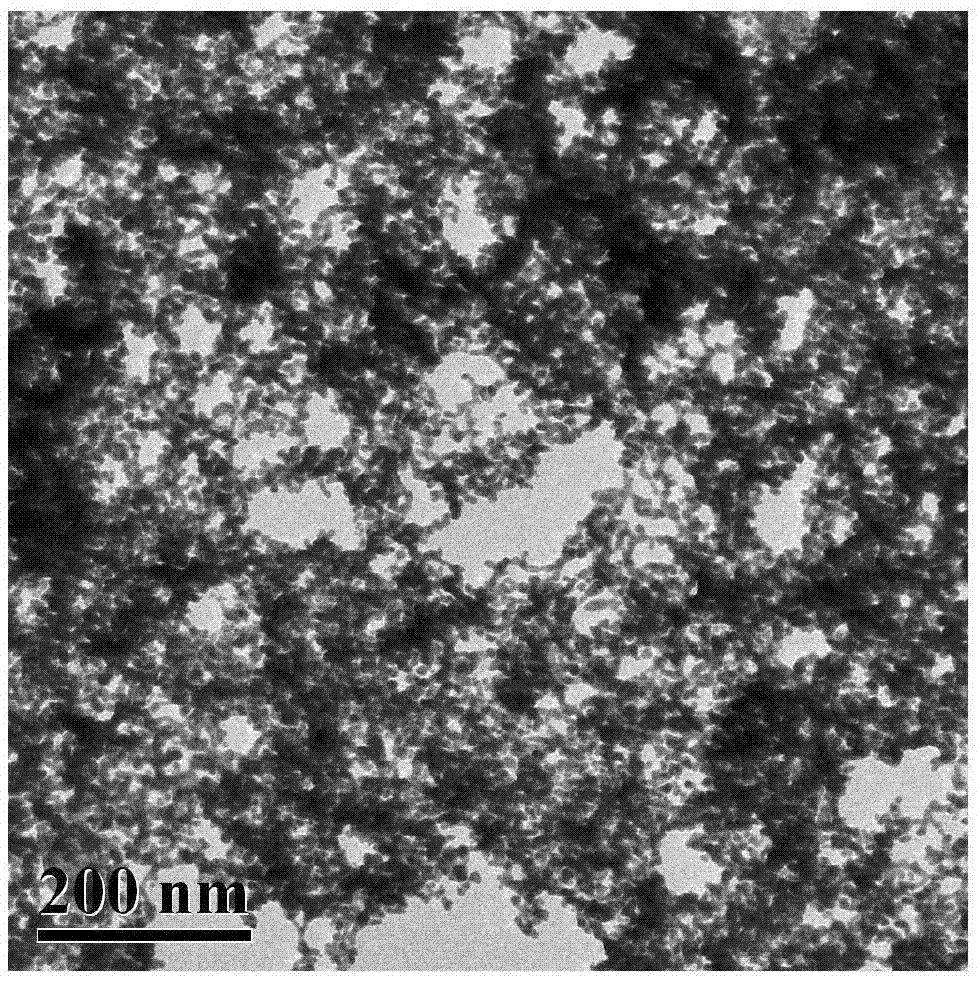

Lithium ion battery cathode material embedded nano metal loaded carbon nanosheet as well as preparation method and application thereof

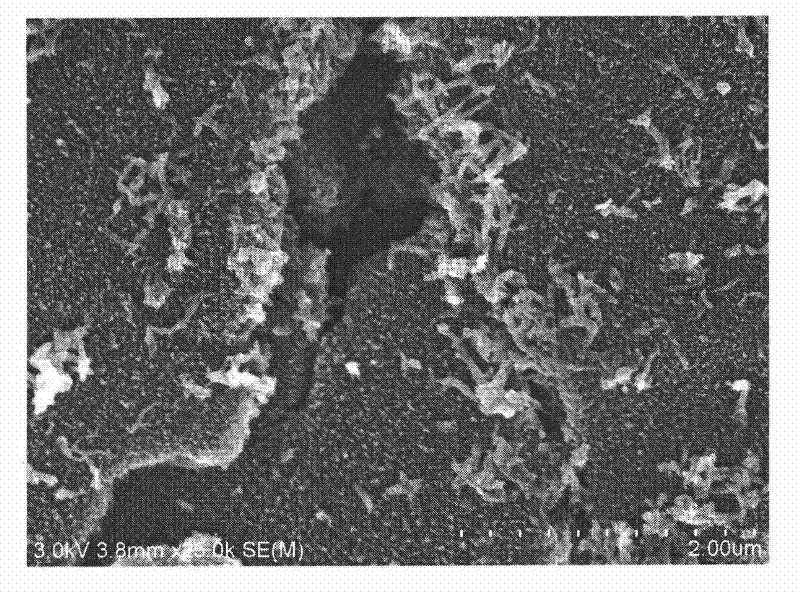

InactiveCN104538595AUniform sizeRegular shapeMaterial nanotechnologyCell electrodesChemistryCarbon source

The invention discloses a lithium ion battery cathode material embedded nano metal loaded carbon nanosheet as well as a preparation method and an application thereof. By taking sugar (chitosan, cane sugar, fructose and glucose) as a carbon source, nitrate of transitional metals (Fe, Co and Ni) as a metal source and a catalyst and inert salts (sodium sulfate, sodium chloride, potassium chloride and cesium chloride) as a template and a dispersant, a two-dimensional carbon nanosheet which uniformly loads embedded nickel (or iron or cobalt) nanoparticles is prepared by a pyrolytic method in one step. The two-dimensional carbon nanosheet which uniformly loads embedded nickel (or iron or cobalt) nanoparticles prepared by the method is high in degree of graphitization, relatively high in specific surface area and high in conductivity, uniform in distribution and easy to separate, and the surface of the nanosheet is in a porous structure. The nanosheet as the lithium ion battery cathode material has relatively good circulating and rate performances.

Owner:NANJING NORMAL UNIVERSITY

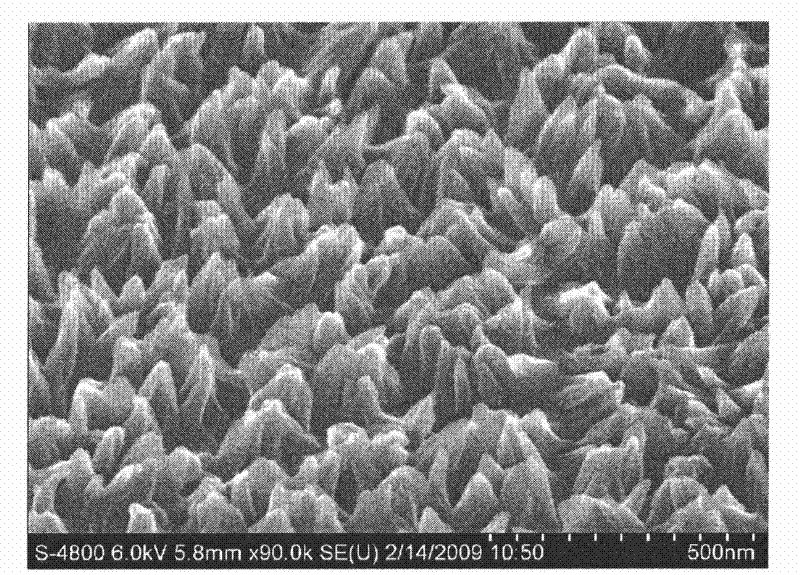

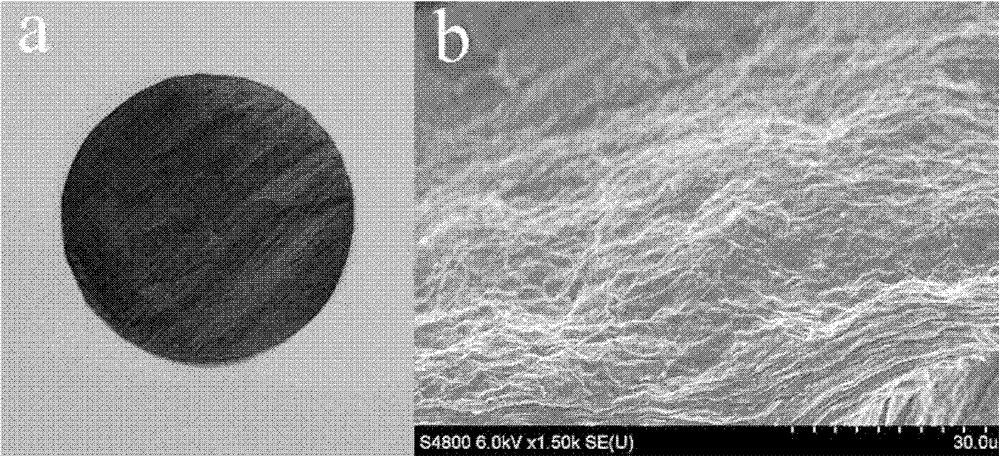

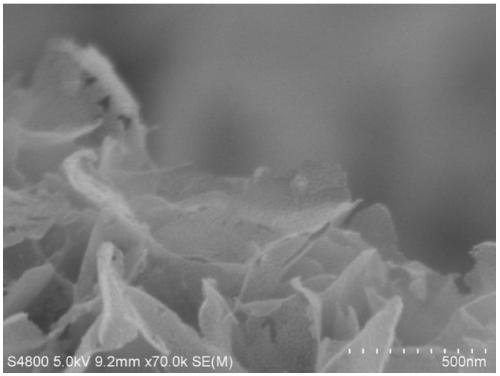

Carbon-based composite electrode material and preparation method thereof, and application of the carbon-based composite electrode material to super capacitor

InactiveCN102222565ALarge specific surface areaLower internal resistanceElectrolytic capacitorsCapacitanceNano structuring

The invention relates to a carbon-based composite electrode material and a preparation method thereof, and application of the carbon-based composite electrode material to a super capacitor. The electrode material contains a conductive polymer and a carbon-based material. The conductive polymer is attached to a surface of the carbon-based material in a manner of a nanowire array of a conductive polymer, wherein the arrangement of the nanowire array of the conductive polymer is in a good order; besides, a diameter of the nanowire of the nanowire array of the conductive polymer is 40 to 100 nm and a length of the nanowire is 100 to 1500 nm. The carbon-based composite electrode material provide in the invention has a large specific surface area, so that an active area of a conductive polymer is substantially improved and thus high capacitance can be obtained; besides, the carbon-based composite electrode material provide in the invention has a highly ordered nano structure, so that a transmission path of an electrolyte ion is reduced and an internal resistance of an electrode is also reduced; therefore, the ion in an electrode material can be diffused and transmitted conveniently, and thus high power density can be obtained.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

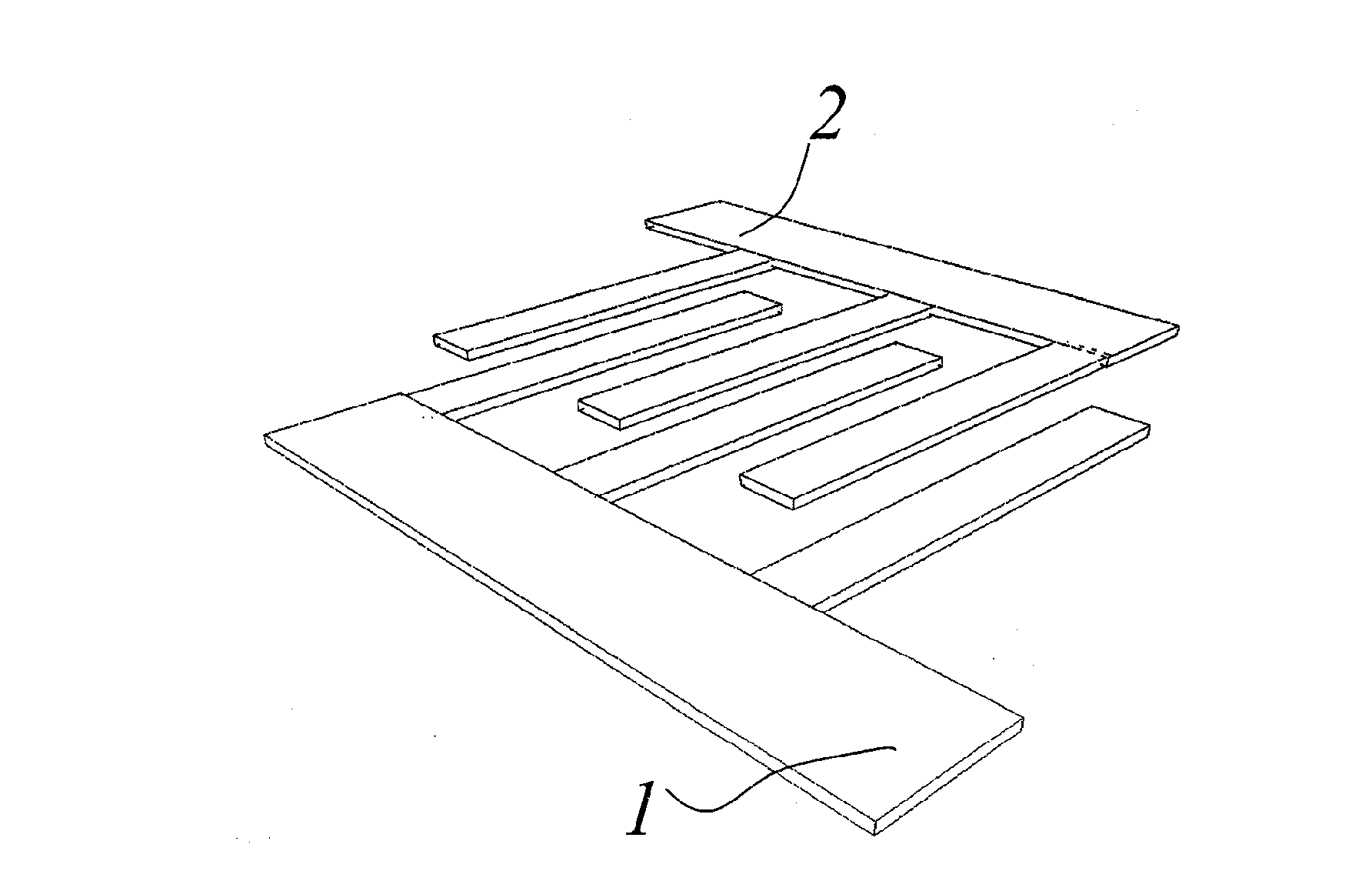

Flexible supercapacitor and preparation method thereof

InactiveCN102737851ASimple preparation processLow costHybrid capacitor electrodesElectrolytic capacitorsCapacitancePolymer chemistry

The invention provides a flexible supercapacitor. The flexible supercapacitor comprises a housing, two electrodes facing each other and separated with each other, and electrolyte between the two electrodes. The two electrodes facing each other and the electrolyte between the two electrodes are accommodated in the housing. The supercapacitor is characterized in that the electrodes are composed of a conducting polymer and a carbon-based material, and the conducting polymer attaches to a surface of the carbon-based material in a form of a nanowire array of the conducting polymer. The invention also provides a preparation method for the flexible supercapacitor. The flexible supercapacitor prepared by the method has high capacitance, good charge-discharge cycling stability, and is low in cost and simple in preparation technology.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

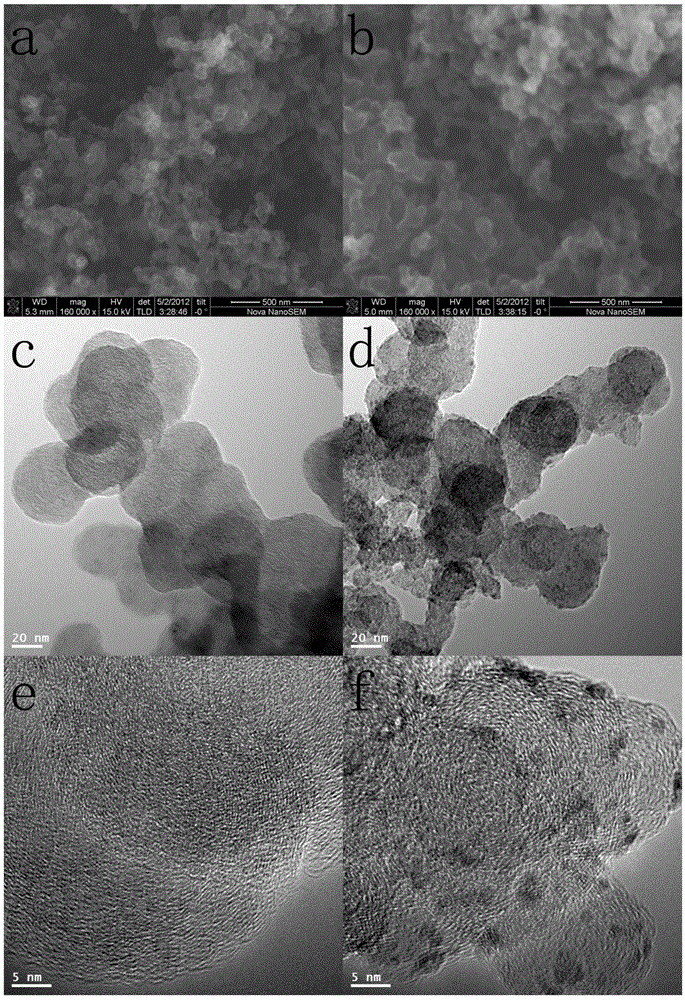

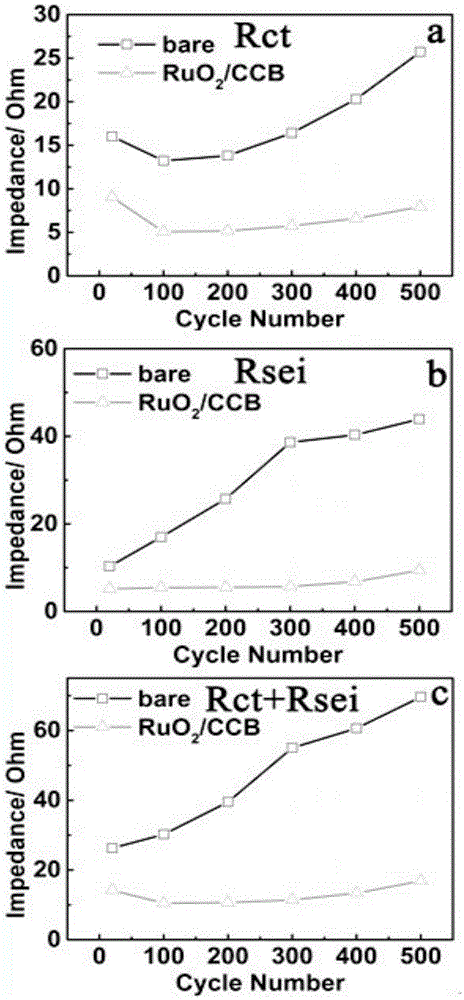

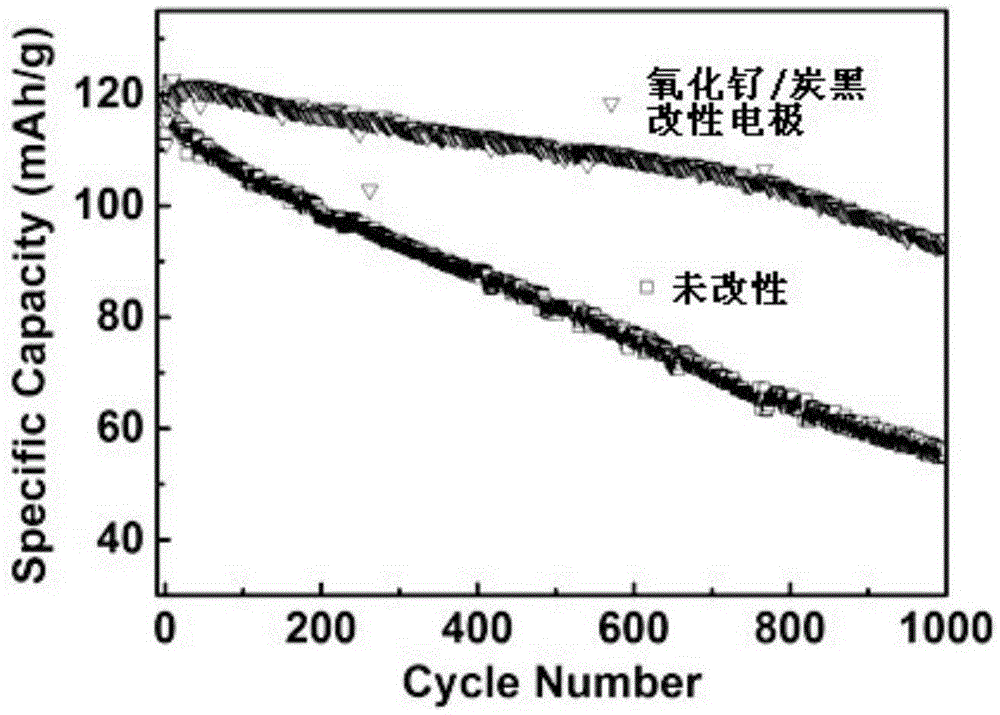

Method for modifying positive electrode of lithium ion battery by adding metal oxide/carbon composite material

ActiveCN105390700AEvenly dispersedAchieve electrode modificationCell electrodesCarbon compositesSodium-ion battery

The invention discloses a method for modifying a positive electrode of a lithium ion battery by adding a metal oxide / carbon composite material, and belongs to the technical field of secondary lithium ion batteries. The modification method comprises: mechanically mixing a positive electrode active material of the lithium ion battery with an electrode additive, wherein the electrode additive is the composite material and consists of two parts of a conductive carbon material carrier and a metal oxide load. The electrode additive can reduce the rate of increment of impedance of the positive electrode of the lithium ion battery along with charging / discharging cycle, thereby achieving the purpose of improving the cycle performance of the lithium ion battery.

Owner:HARBIN INST OF TECH

Ambient light rejection for non-imaging contact sensors

ActiveUS10024655B2Reduce the amount requiredEnhance the imagePerson identificationUsing optical meansLight sensingMagnification

A sensor for capturing images of skin topology is provided having a platen, and a one or two-dimensional array of light sensing pixel elements for receiving light representative of skin topology when skin, such as finger(s), are present upon the platen. Such sensor being improved by structures, layers, or methods for reducing or blocking ambient light which would hinder the light sensing pixel elements from sensing the light representative of skin topology. The sensors are non-imaging contact sensors as they have platen to contact skin to be imaged, and do not require optics, such as lenses for focusing and / or magnification, to enable proper capture of light representative of skin topology on the sensor's light sensing pixel elements.

Owner:HID GLOBAL CORP

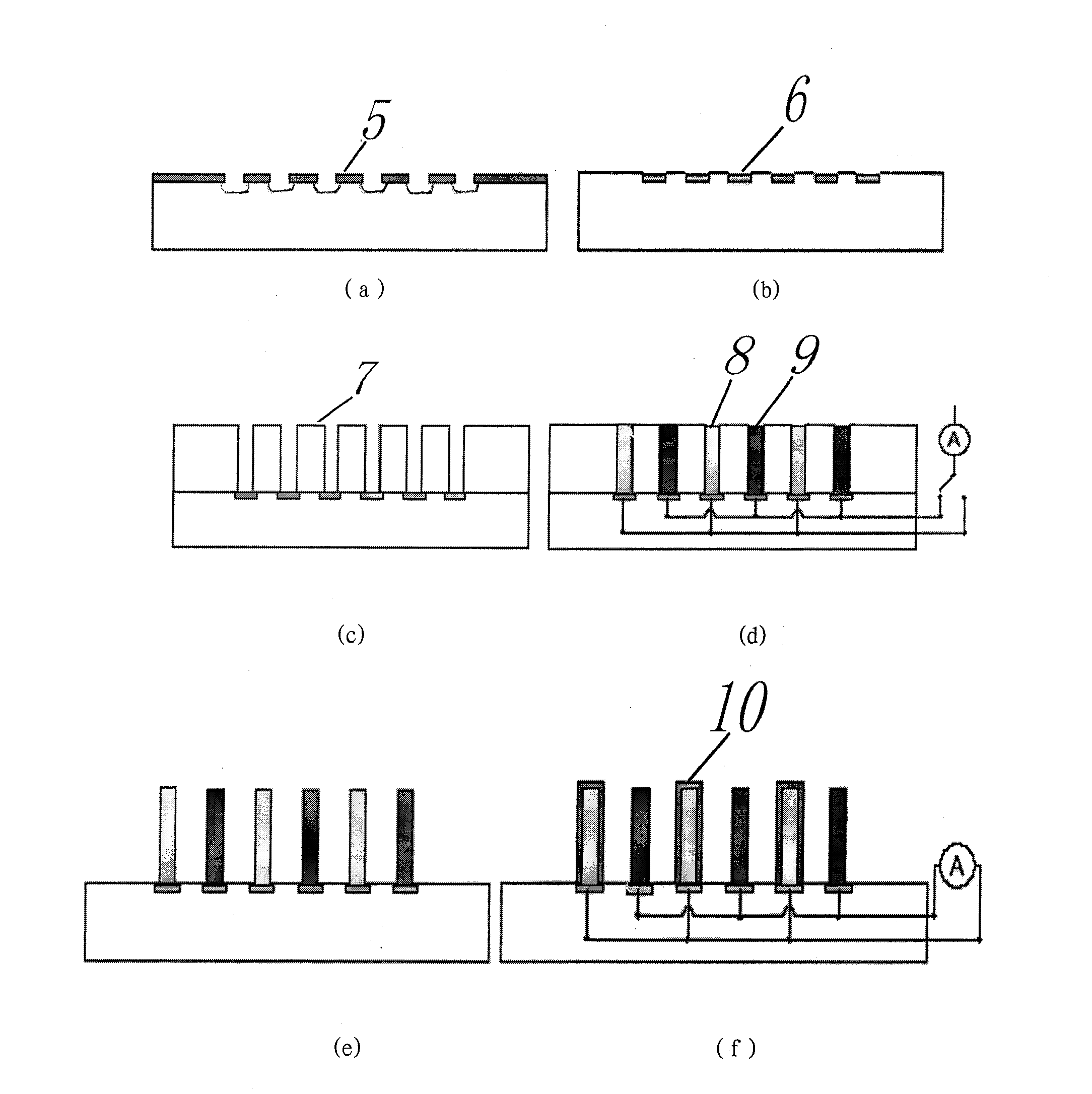

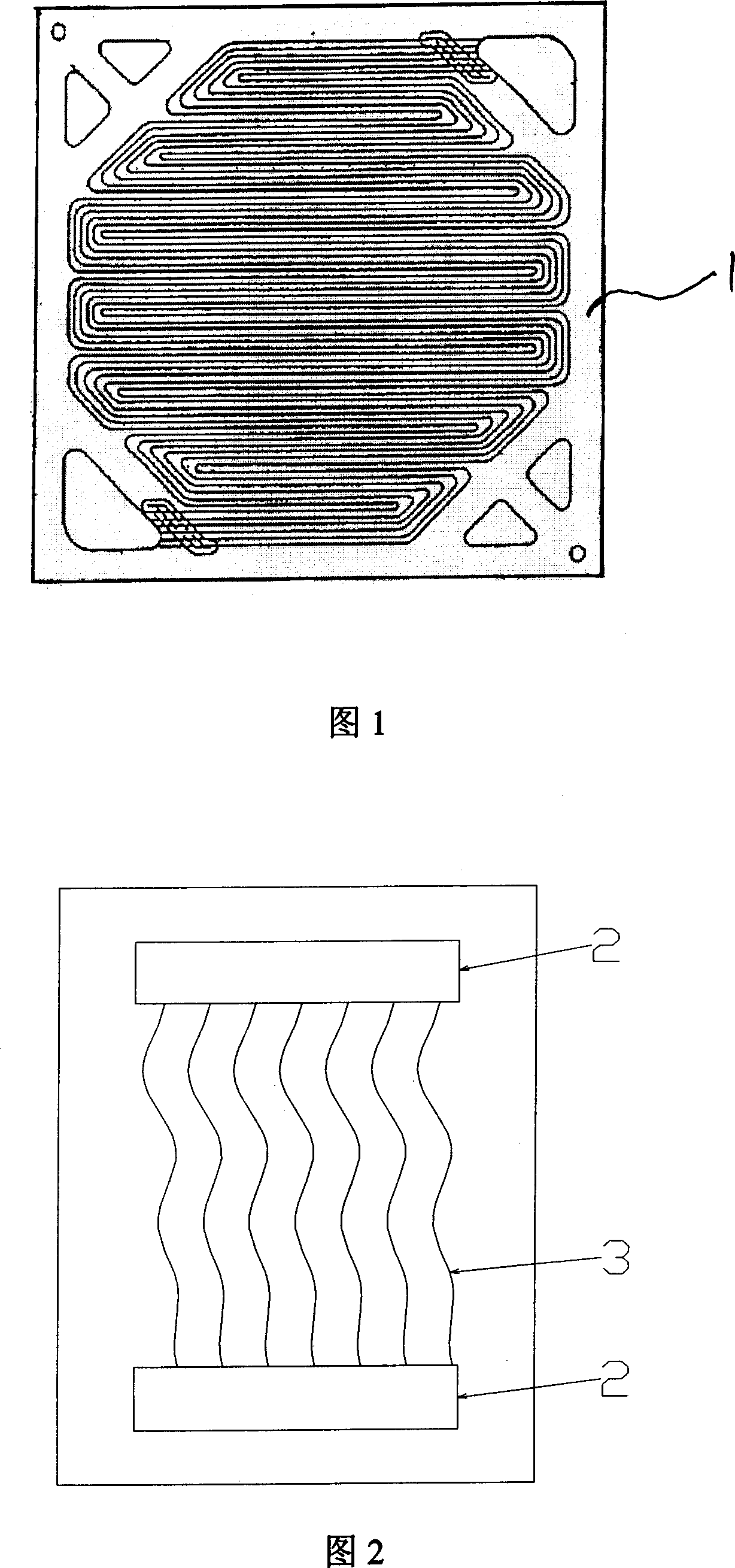

Poly-pyrrole minisize super capacitor based on MEMS technique and method for manufacturing the same

InactiveCN101325130AGood high current discharge performanceIncrease energy densityCapacitor electrolytes/absorbentsSecondary cellsSilicon matrixSolid state electrolyte

The invention discloses a polypyrrole minitype super capacitor in the range of the capacitor manufacturing technology based on MEMS technology and the preparation method thereof. The polypyrrole minitype super capacitor adopts the structure that a metal comb two-dimensional plane structure as a current collector is prepared on the surface of the silicon matrix by utilizing the micro-machining technology; a comb-shaped polypyrrole active electrode is prepared on the surface of the current collector by adopting the method of polypyrrole substance being prepared by the electric precipitation method; a layer of gel solid electrolyte is covered on the surface of the comb-shaped polypyrrole electrode and between a positive electrode and a negative electrode; and a layer of polyimide material is covered on the surface of the structure to accomplish the encapsulation of the minitype super capacitor. The MEMS-based manufacturing technology has the characteristic that the process is simple, and is suitable for mass manufacture. The minitype super capacitor has the advantages of small volume, high energy storage and stable performance, and is widely applicable to micro-robot electronic intelligence systems, chemical sensors, battlefield friend-or-foe identification devices, distributed type battlefield sensors and other fields.

Owner:TSINGHUA UNIV

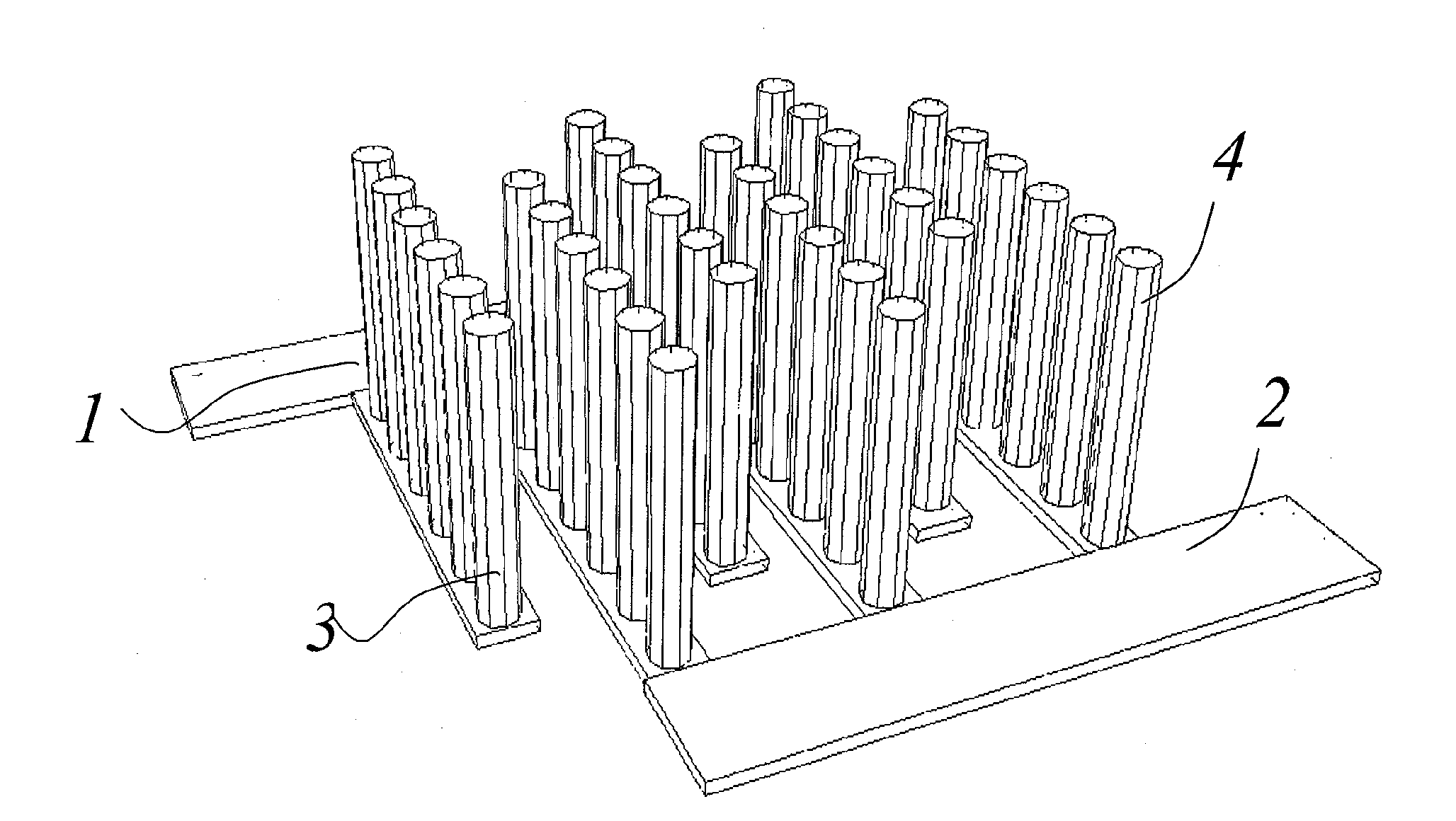

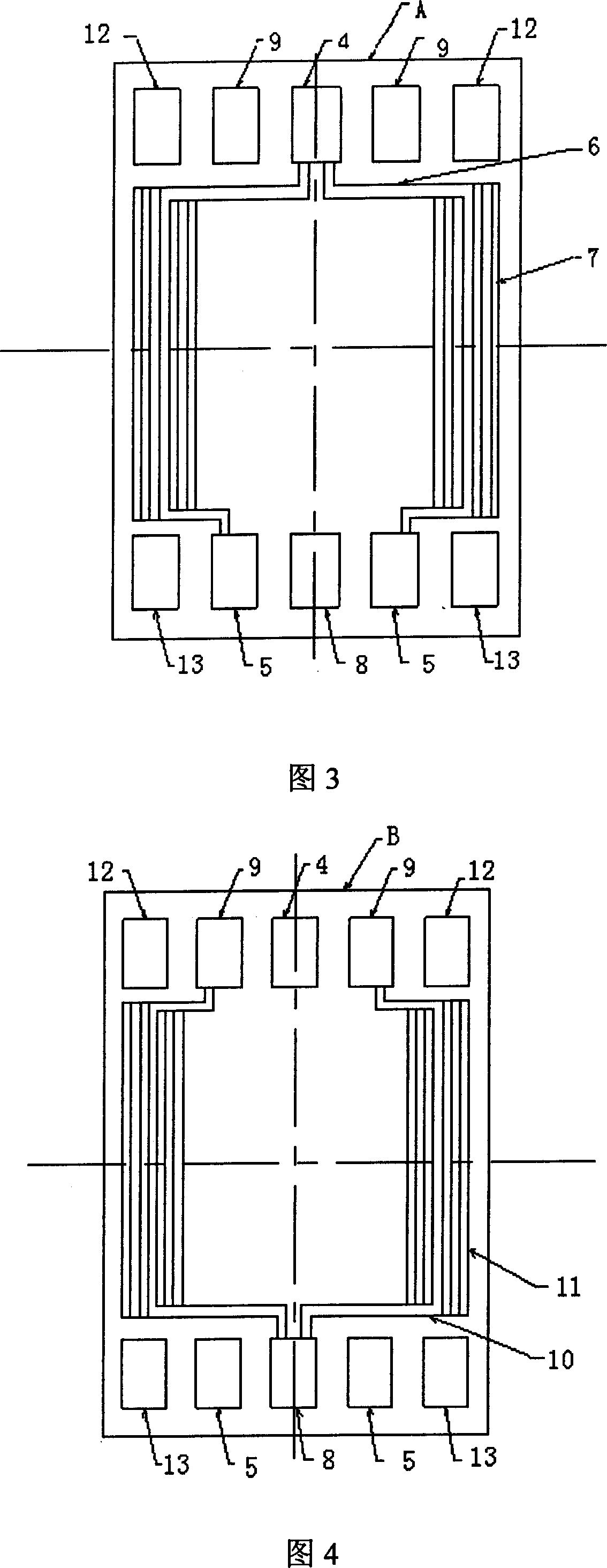

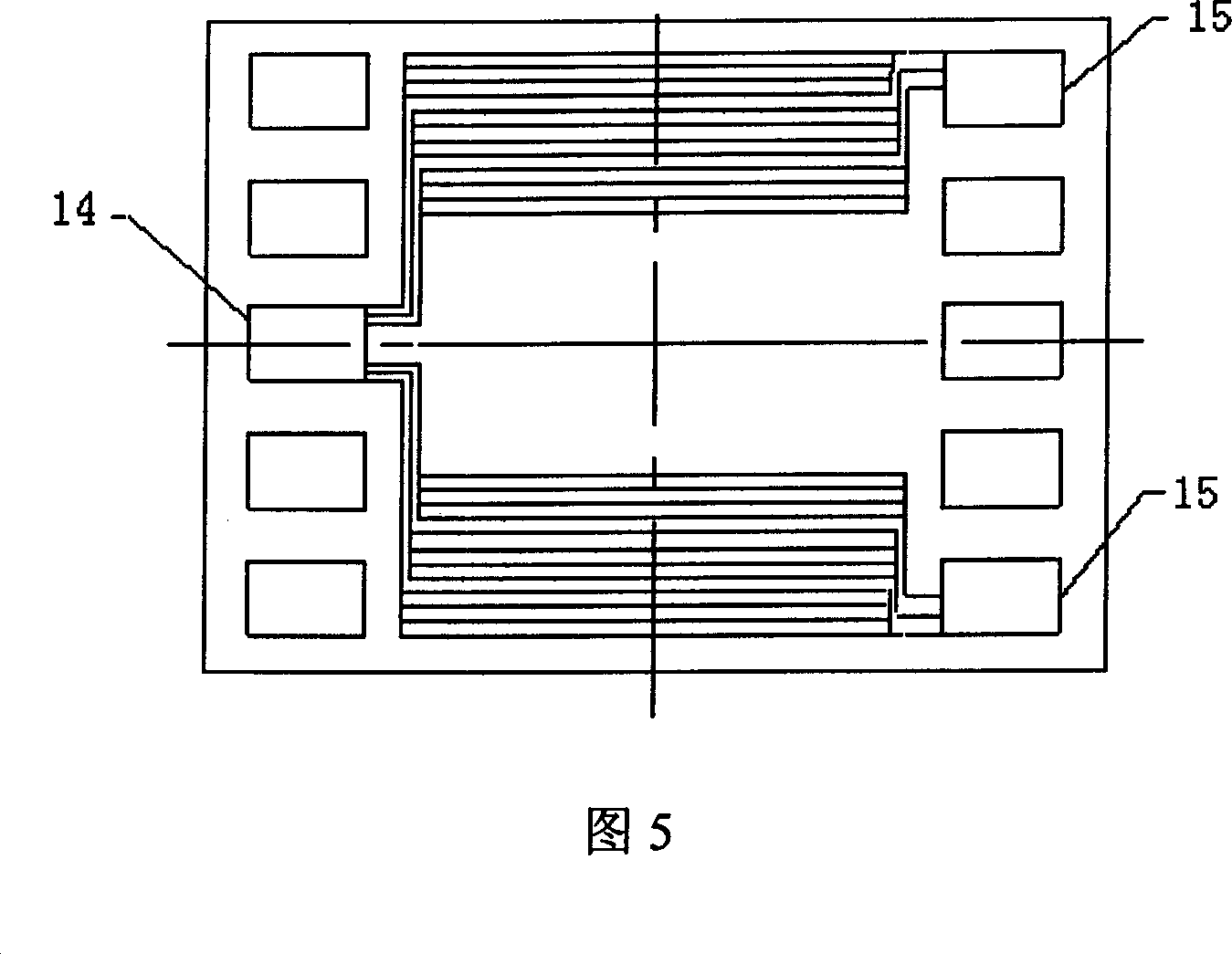

Three dimensional structure micro zinc-nickel battery applying to microsystems and preparation method thereof

InactiveCN101515655AIncrease active areaImprove power storage performanceFinal product manufacturePrimary cellsSolid state electrolyteManufacturing technology

The invention discloses a three dimensional structure micro zinc-nickel battery applying to microsystems and a preparation method thereof, which belongs to the micro battery fabrication technique field. The structure of the micro zinc-nickel battery is as follows: preparing gold combdent two dimensional plane structural current collector on the silicon substrate surface by adopting micro processing technique, preparing three dimensional stereo space structural nickel microcolumn anode and zinc microcolumn cathode on the current collector surface, depositing nickel oxide active electrode substance on the nickel microcolumn anode surface, filling and covering a layer of gel-like solid electrolyte between the anode and cathode of the three dimensional stereo space structure, and covering a layer of polyimide material on the battery surface for finishing encapsulation of the micro zinc-nickel battery. The fabrication technique based on microsystems technique is characterized of simple technique, being suitable for batch production and the like. The micro zinc-nickel battery is characterized of small volume, high storage energy, stable performance and the like, which applies widely to micro robot electronic intelligent system, chemical sensor, battlefield friend or foe identification equipment, distributed battlefield sensor and the like.

Owner:TSINGHUA UNIV

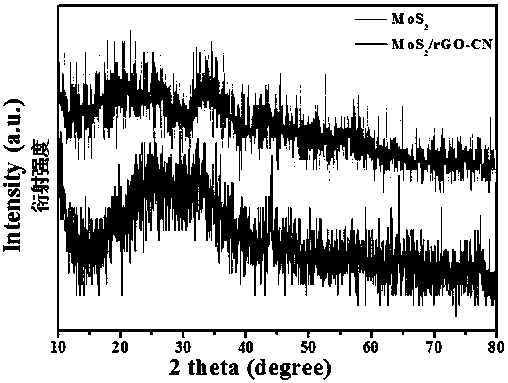

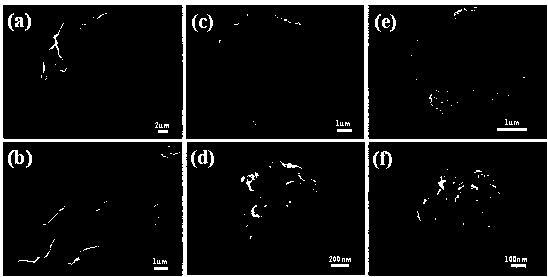

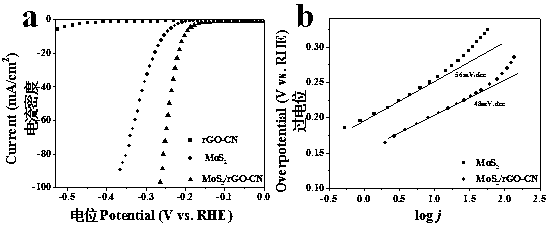

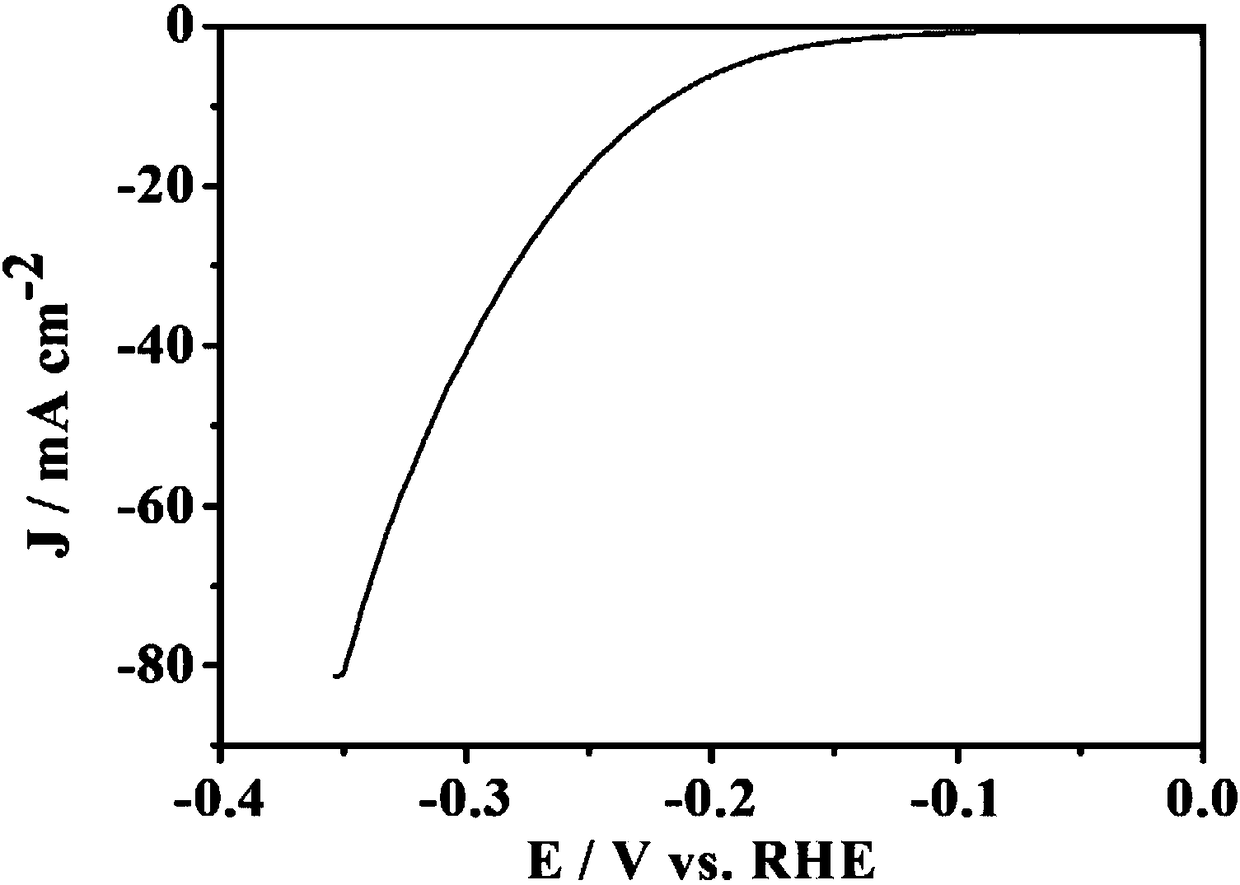

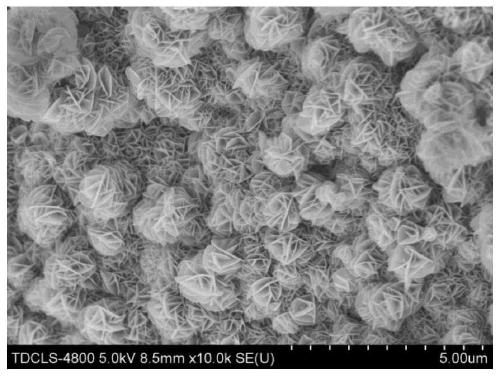

Preparation method and application of MoS2/rGO-CN composite material

ActiveCN107670679AReduce accumulationImprove conductivityPhysical/chemical process catalystsElectrodesN dimethylformamideDissolution

The invention belongs to the technical field of electrocatalytic hydrogen evolution, and relates to a preparation method and application of a molybdenum disulfide / reduced graphene oxide-nitrogen carbide (MoS2 / rGO-CN) composite material. The preparation method comprises the steps of: firstly adding graphite oxide into deionized water, adding melamine into the obtained mixture, then performing ultrasound dissolution so as to form a colloidal solution, adopting a hydrothermal method to prepare aerogel of reduced graphene oxide-nitrogen carbide, and then performing a solvothermal reaction to obtain the target product by adopting ammonium tetrathiomolybdate as a molybdenum source and a sulfur source and N,N-dimethylformamide as a solvent. The preparation method of the aerogel of the reduced graphene oxide-nitrogen carbide is simple and high in yield, and since the MoS2 / rGO-CN is prepared by using the one-step solvothermal method, the preparation method has low cost and high repeatability and facilitates large-scale synthesis; by means of the prepared MoS2 / rGO-CN composite material, the accumulation of the molybdenum disulfide is reduced, and the quantity of active sites is increased; the conductivity and the active area of the MoS2 can be improved through the combination of the MoS2 with the rGO-CN, and when the prepared MoS2 / rGO-CN composite material is applied to an electrocatalytic hydrogen evolution reaction, excellent catalytic performance can be exhibited, and when the current density is 10 mA.cm<-2>, the overpotential is 203 mV, and the Tafel slope is 48 mV.dec<-1>.

Owner:JIANGSU UNIV

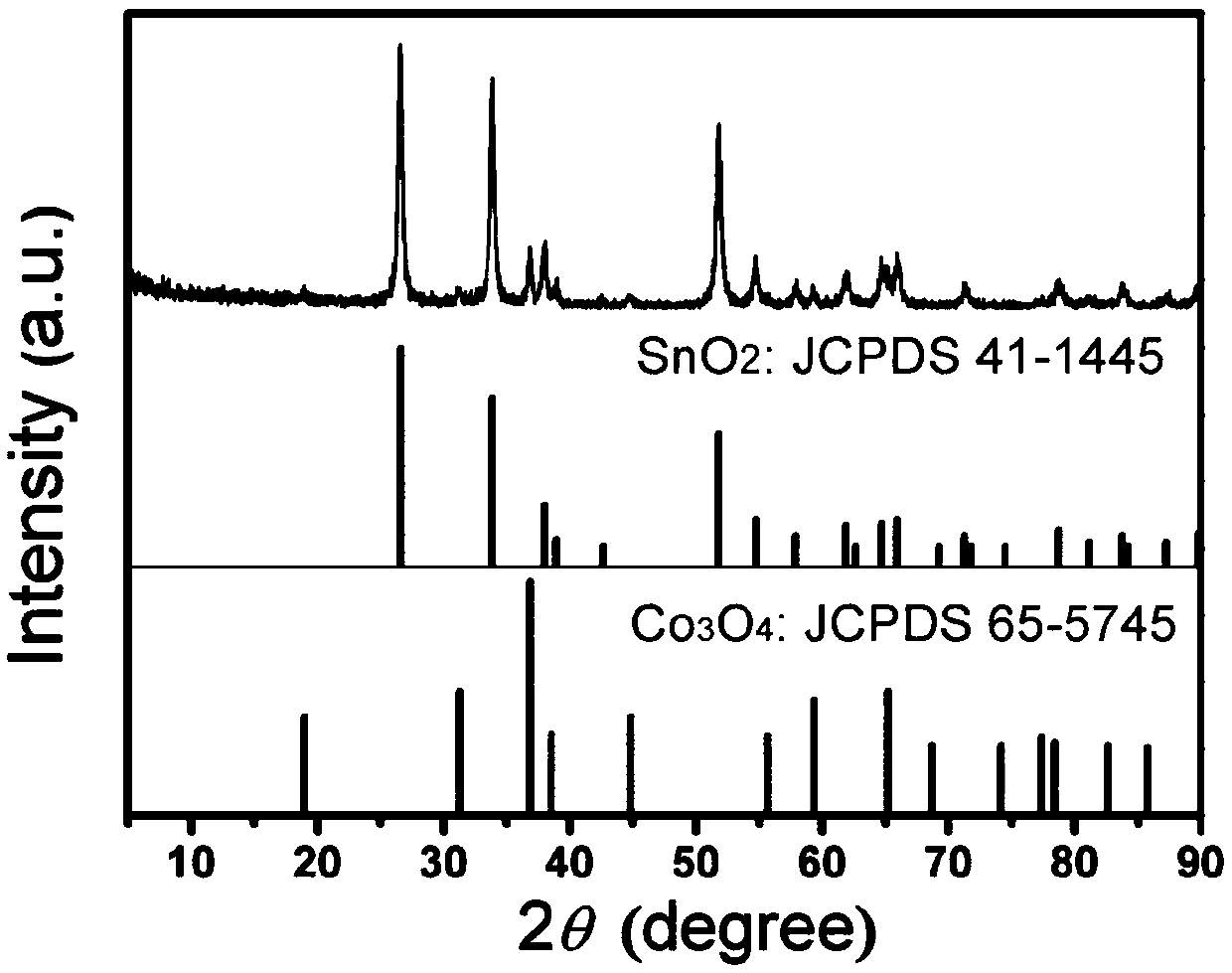

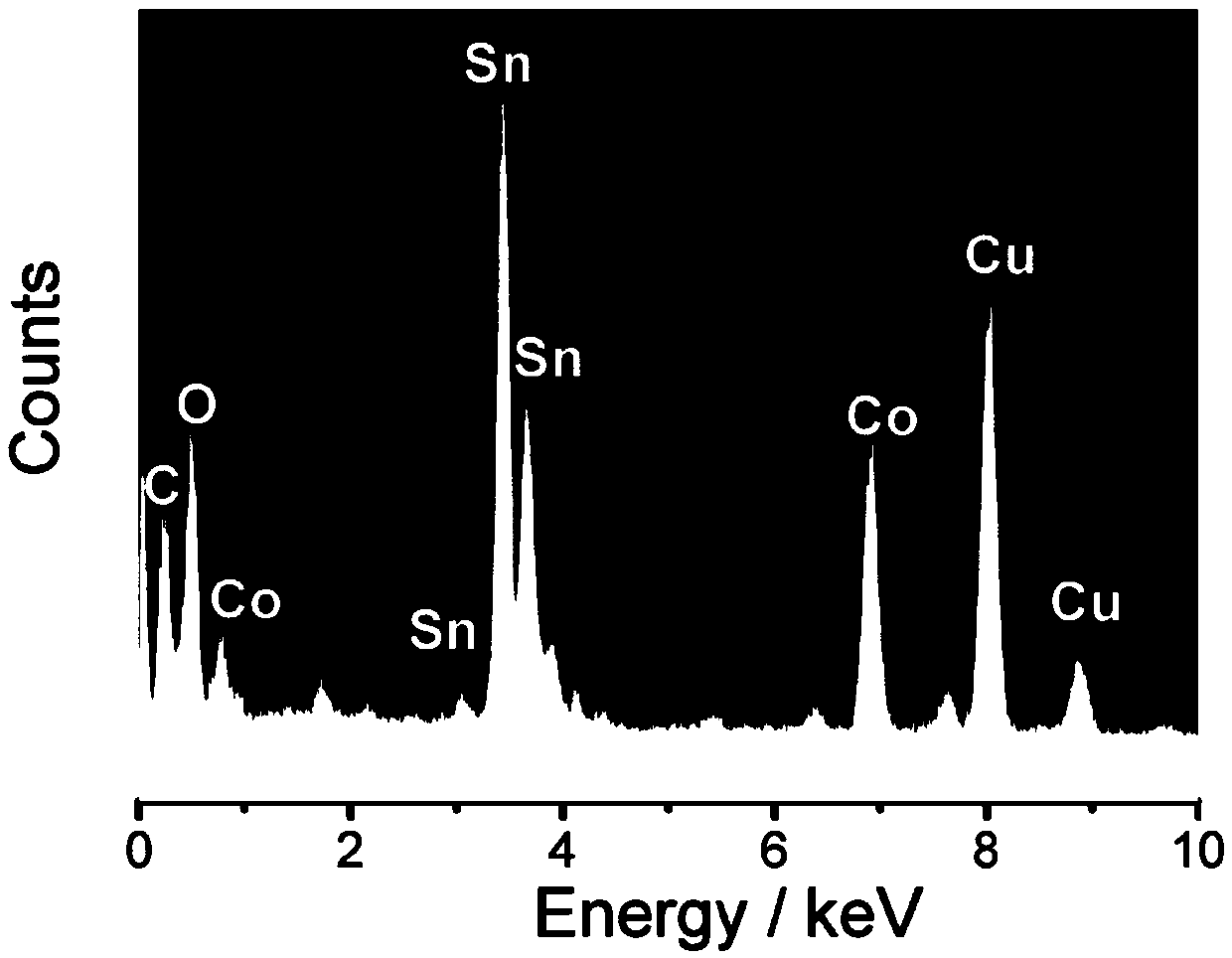

Hollow SnO2/Co3O4 hybrid nanotube as well as preparation method and application thereof

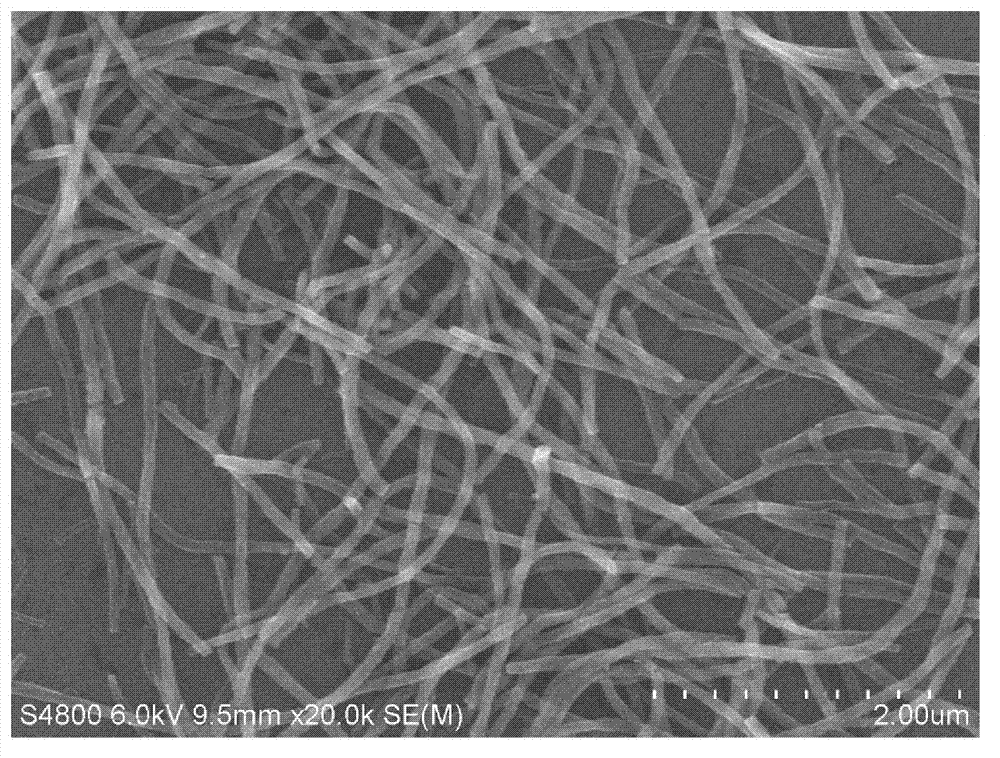

InactiveCN105514369AHigh specific capacityImprove stabilityMaterial nanotechnologyCell electrodesAir atmosphereSpinning

The invention discloses a hollow SnO2 / Co3O4 hybrid nanotube as well as a preparation method thereof. According to the method, an electrostatic spinning technique is adopted, a polymer is taken as a work medium, an organic solvent is taken as a dispersing agent, cobalt nitrate and tin tetrachloride are taken as precursors, polymer nanofibers containing uniformly distributed Co(II) and Sn(IV) are prepared, and then the hollow SnO2 / Co3O4 hybrid nanotube is prepared through sequential preoxidation and high-temperature calcination in an air atmosphere. Compared with preparation methods such as a template method, a coaxial electrostatic spinning method and the like, the method is simple and easy to implement and low in cost, the structure of the obtained hollow nanotube is controllable, and large-scale production can be realized. The hollow SnO2 / Co3O4 hybrid nanotube prepared with the method has the advantages of large specific surface area, multiple active sites, small density, high buffering capacity and the like; the hollow SnO2 / Co3O4 hybrid nanotube serving as a lithium ion battery anode material has excellent cycle performance and rate capability.

Owner:NANJING NORMAL UNIVERSITY

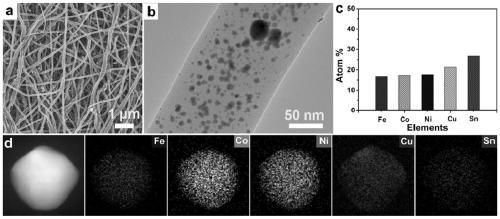

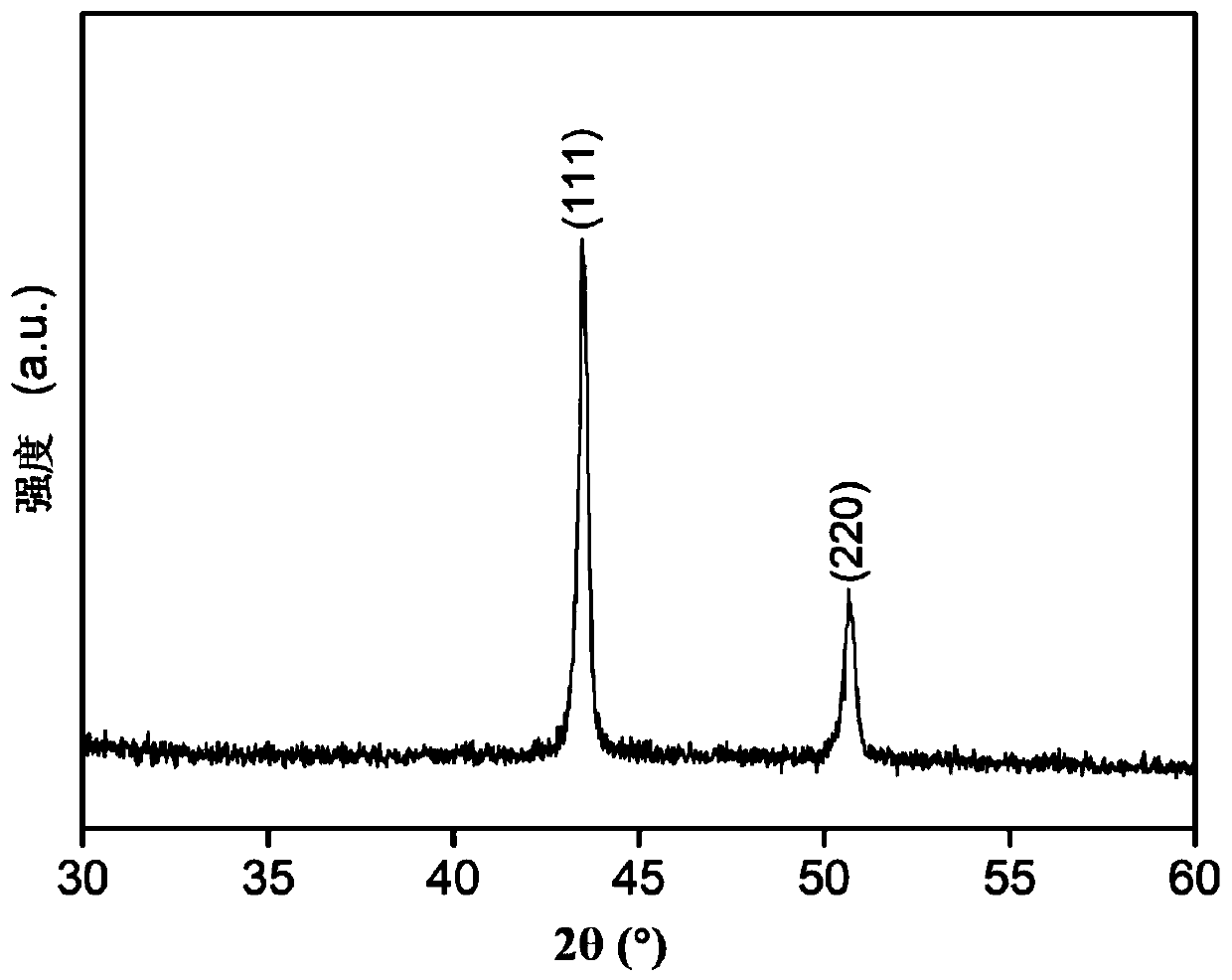

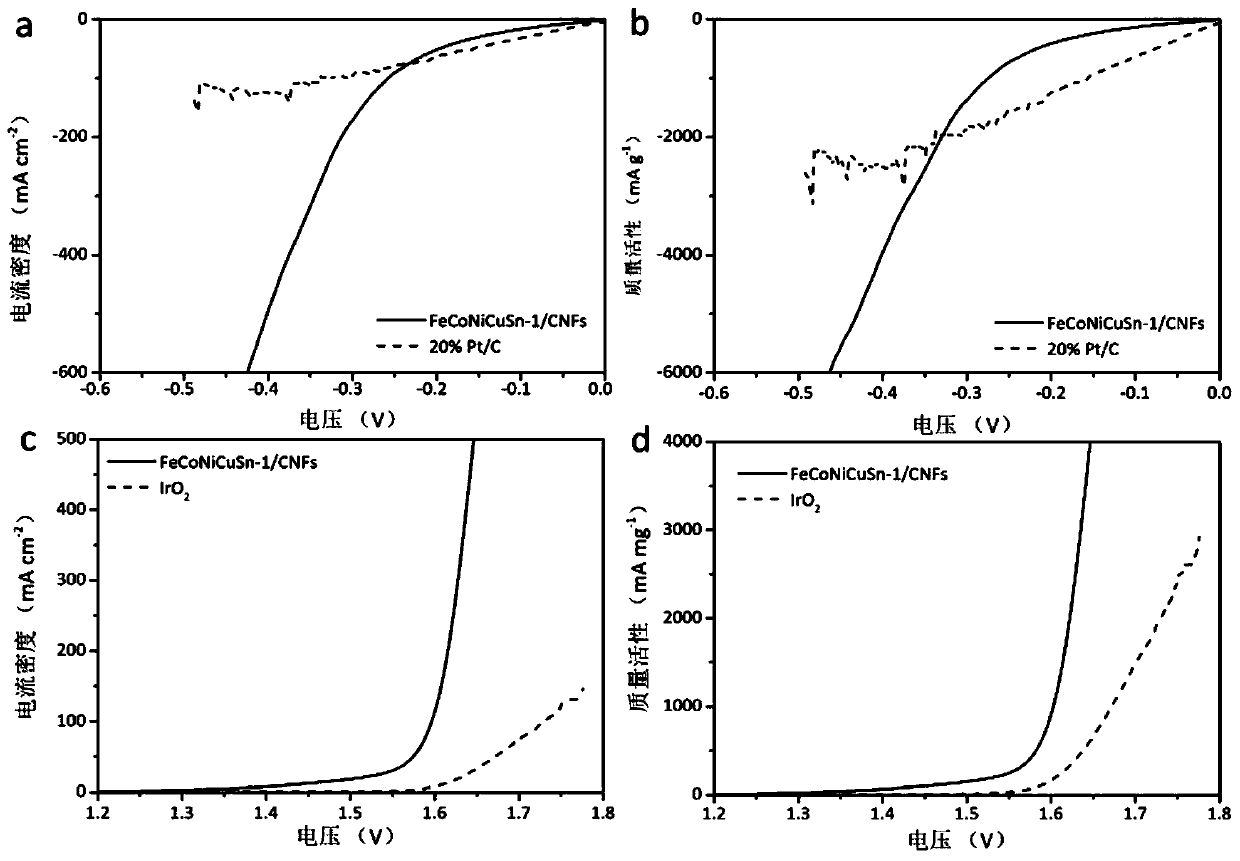

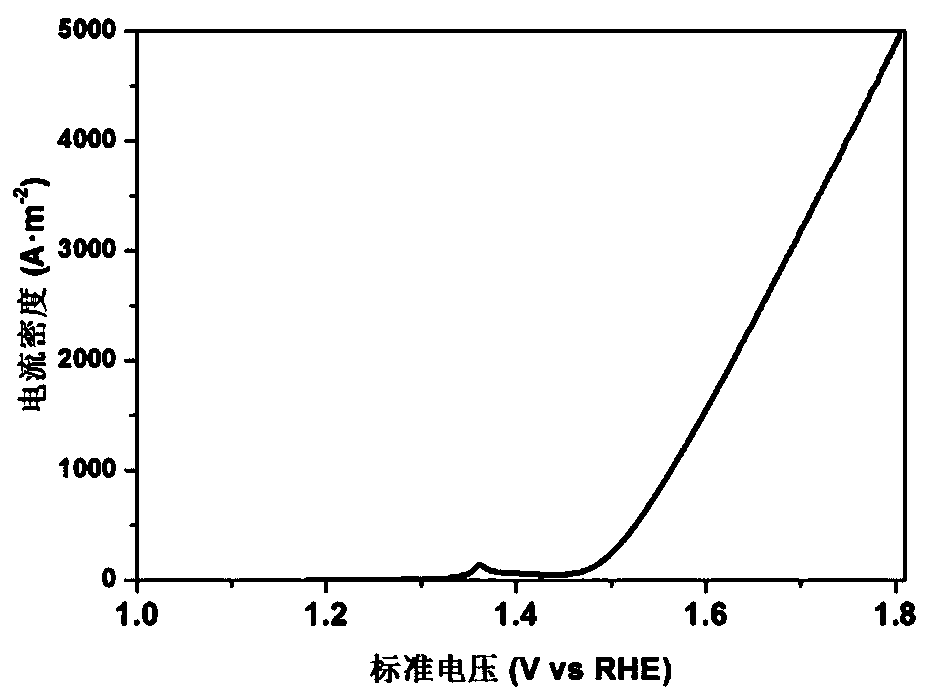

Iron-cobalt-nickel-copper-based high-entropy alloy water electrolysis catalytic material and preparation method thereof

ActiveCN111185188AHigh catalytic activityIncrease active areaMaterial nanotechnologyCatalyst activation/preparationHigh entropy alloysAlloy nanoparticle

The invention discloses an iron-cobalt-nickel-copper-based high-entropy alloy water electrolysis catalytic material and a preparation method thereof, and belongs to the technical field of composite material preparation. The water electrolysis catalytic material is composed of a reaction active matter and a carrier, wherein the reaction active matter is iron-cobalt-nickel-copper-tin, iron-cobalt-nickel-copper-manganese, iron-cobalt-nickel-copper-vanadium and other iron-cobalt-nickel-copper-based high-entropy alloy nanoparticles, and the carrier is a carbon nanofiber material prepared through anelectrostatic spinning method. The prepared water electrolysis catalytic material has a high specific surface area, diffusion of electrolytic solution and desorption of gas are facilitated, hydrogenand oxygen can be produced under an alkaline condition, and the hydrogen production rate under high voltage is far higher than that of a 20% Pt / C electrode; and carbon nanofibers can effectively protect the high-entropy alloy nanoparticles from being eroded by an electrolytic solution, so that the catalytic material is endowed with good stability.

Owner:JIANGNAN UNIV

Catalyst used for proton exchanging film fuel battery and method for producing the same

InactiveCN101404331AImprove performanceReduce performanceCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPrillProton

A catalyst used for proton exchange membrane fuel cells and a preparation method thereof relate to the catalyst used for fuel cells and the preparation method thereof. The invention solves the problem of performance attenuation of the existing catalyst used for fuel cells caused by carbon carrier corrosion and prill glomeration. The catalyst used for the proton exchange membrane fuel cells is made from nano-carbon black material, mesoporous oxide conductive ceramics and prill. The preparation method comprises the following steps: 1. preparing mixed solution D; 2. preparing mixed solution E; 3. preparing mixed solution F; 4. preparing precipitate X; 5. preparing catalyst carrier; 6. preparing mixed solution G; 7. obtaining precipitate Y; 8. adjusting the pH of the precipitate Y, drying the precipitate Y and obtaining the catalyst. The carrier used by the preparation of the catalyst is not easy to erode, and the prill has good dispersiveness, so that the obtained product has good activity and the battery prepared by the catalyst has stable performance; the invention has simple preparation technique and easy obtained products.

Owner:HARBIN INST OF TECH

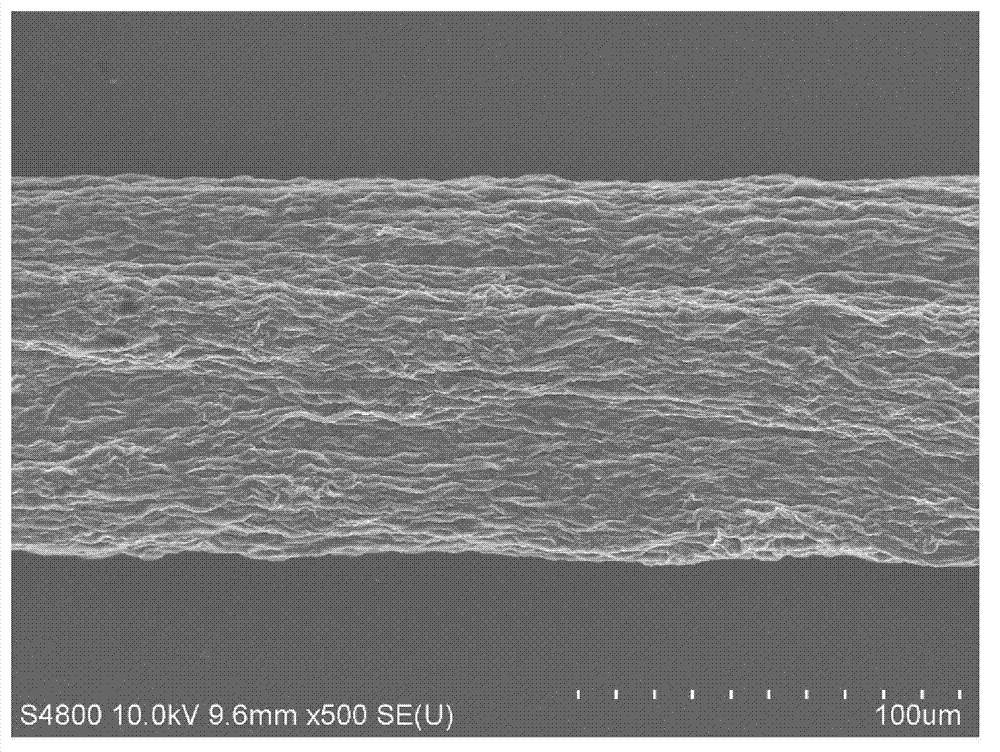

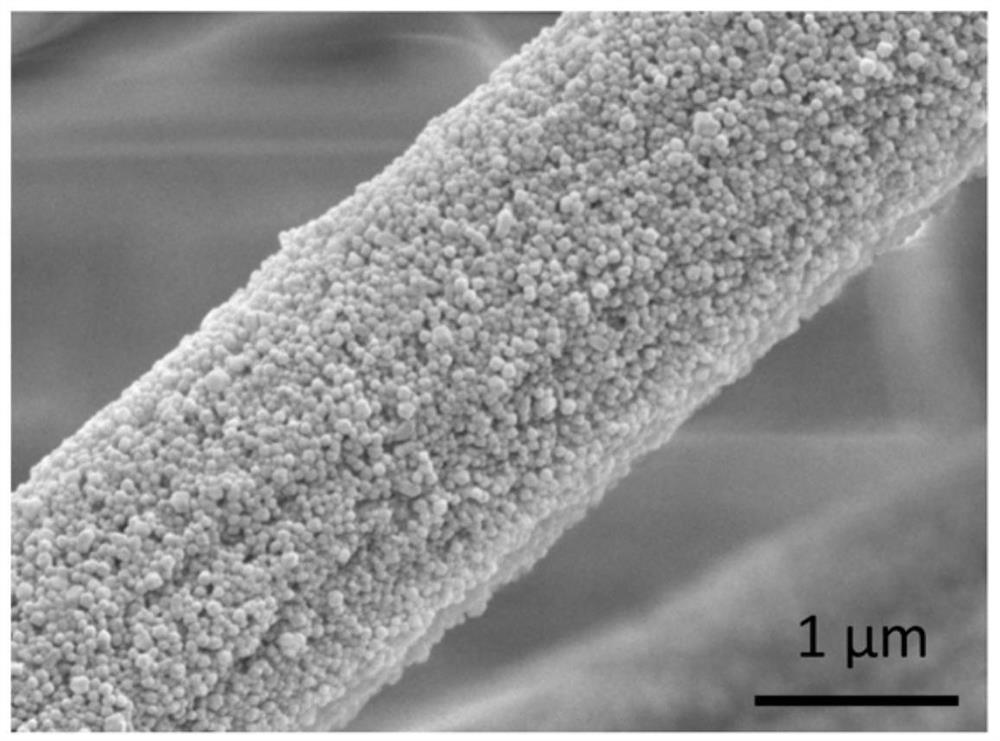

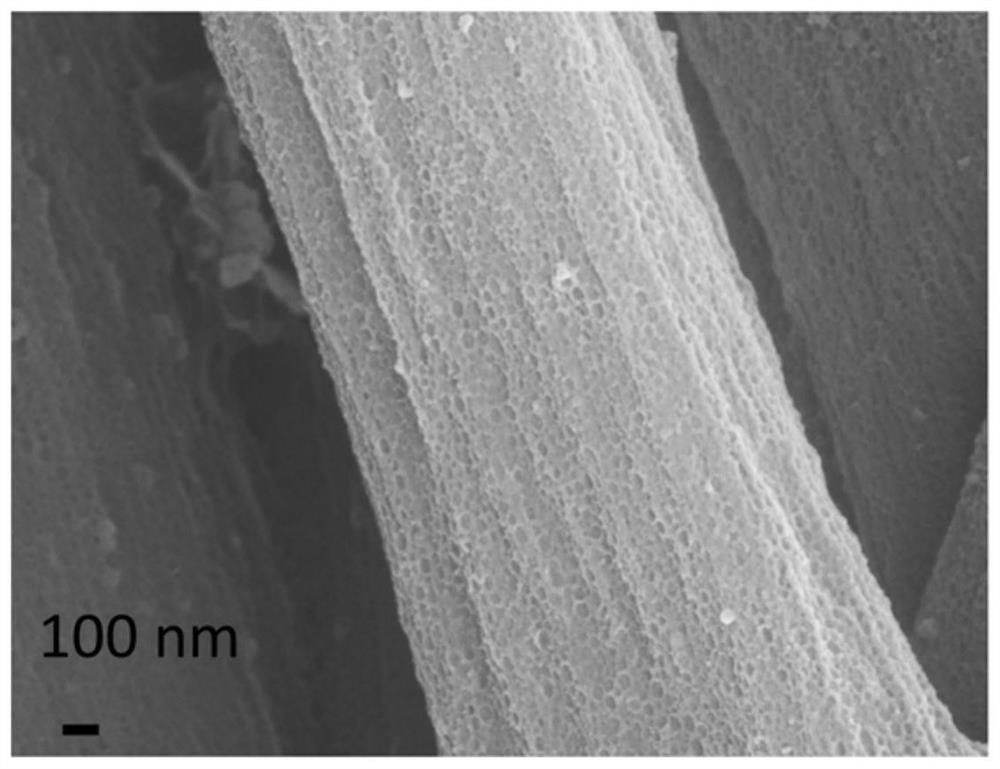

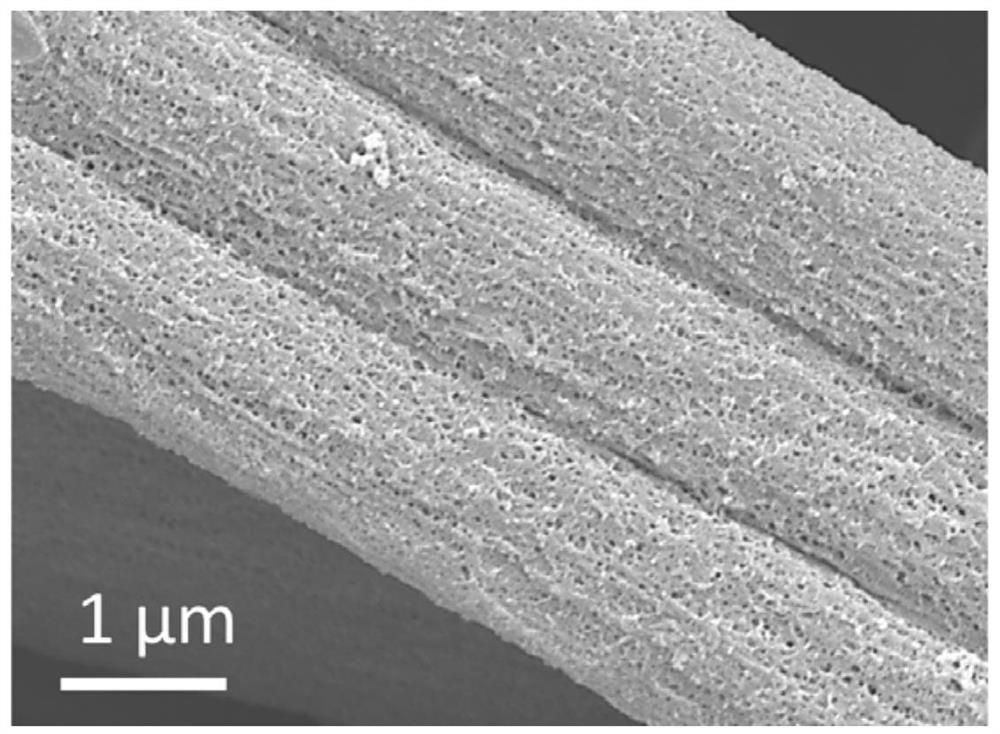

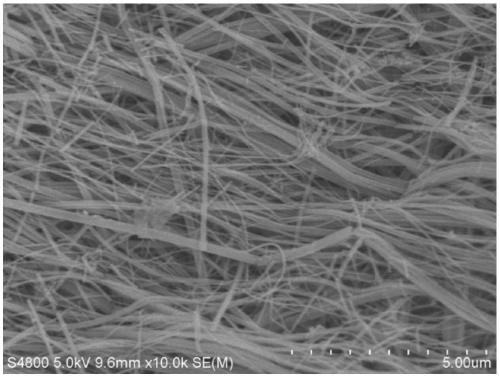

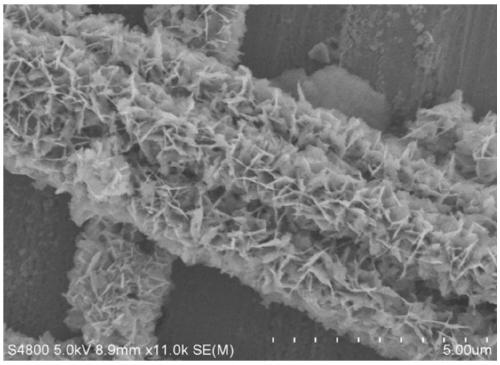

Carbon-based composite fiber electrode material, manufacturing method and application thereof

ActiveCN103198932AIncrease capacityIncrease active areaHybrid capacitor electrodesCapacitor manufactureConductive polymerSupercapacitor

The invention relates to a single-step manufacturing method of a carbon-based composite fiber electrode material and the carbon-based composite fiber electrode material manufactured by the single-step manufacturing method of the carbon-based composite fiber electrode material. The electrode material comprises a conductive polymer and a carbon-based material, and the conductive polymer is distributed in the carbon-based composite material in the mode of conductive polymer nanowires. The diameter of the conductive polymer nanowires is 40 nm to 100 nm, and the length of the conductive polymer nanowires is 1 micron to 10 microns. The manufacturing method of the carbon-based composite fiber is novel in technology, and concise in method, and greatly simplifies steps of the preparation of the electrode materials. The carbon-based composite fiber electrode material is large in specific surface area and good in suppleness, and greatly improves volume of a super capacitor and mechanical capacity of the super capacitor.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

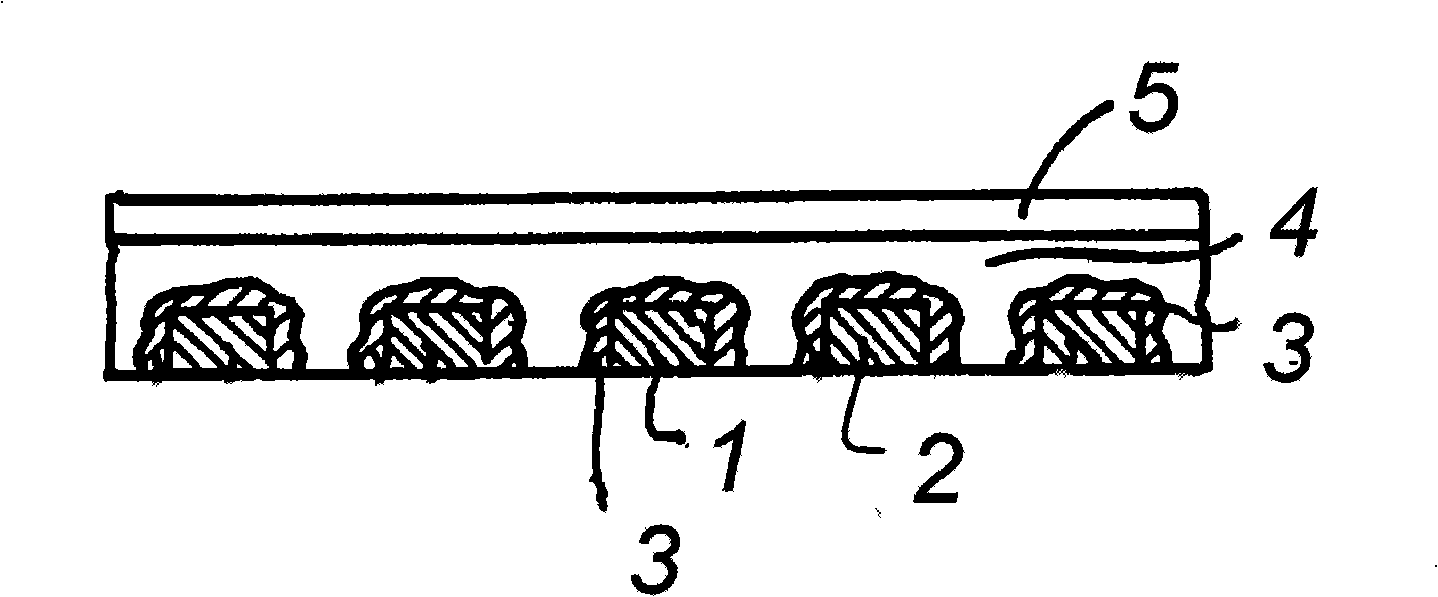

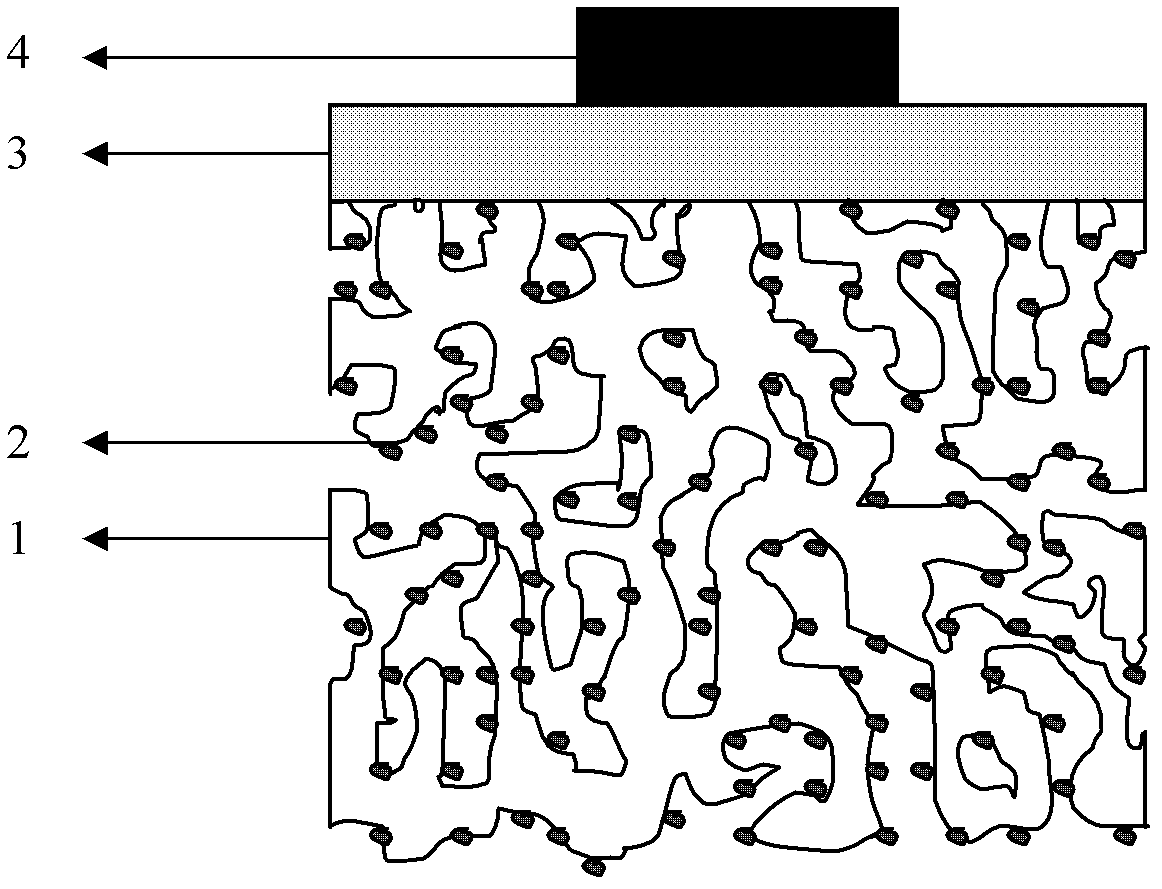

Three-layered structured oxide fuel cell supported by stainless steel and preparation method thereof

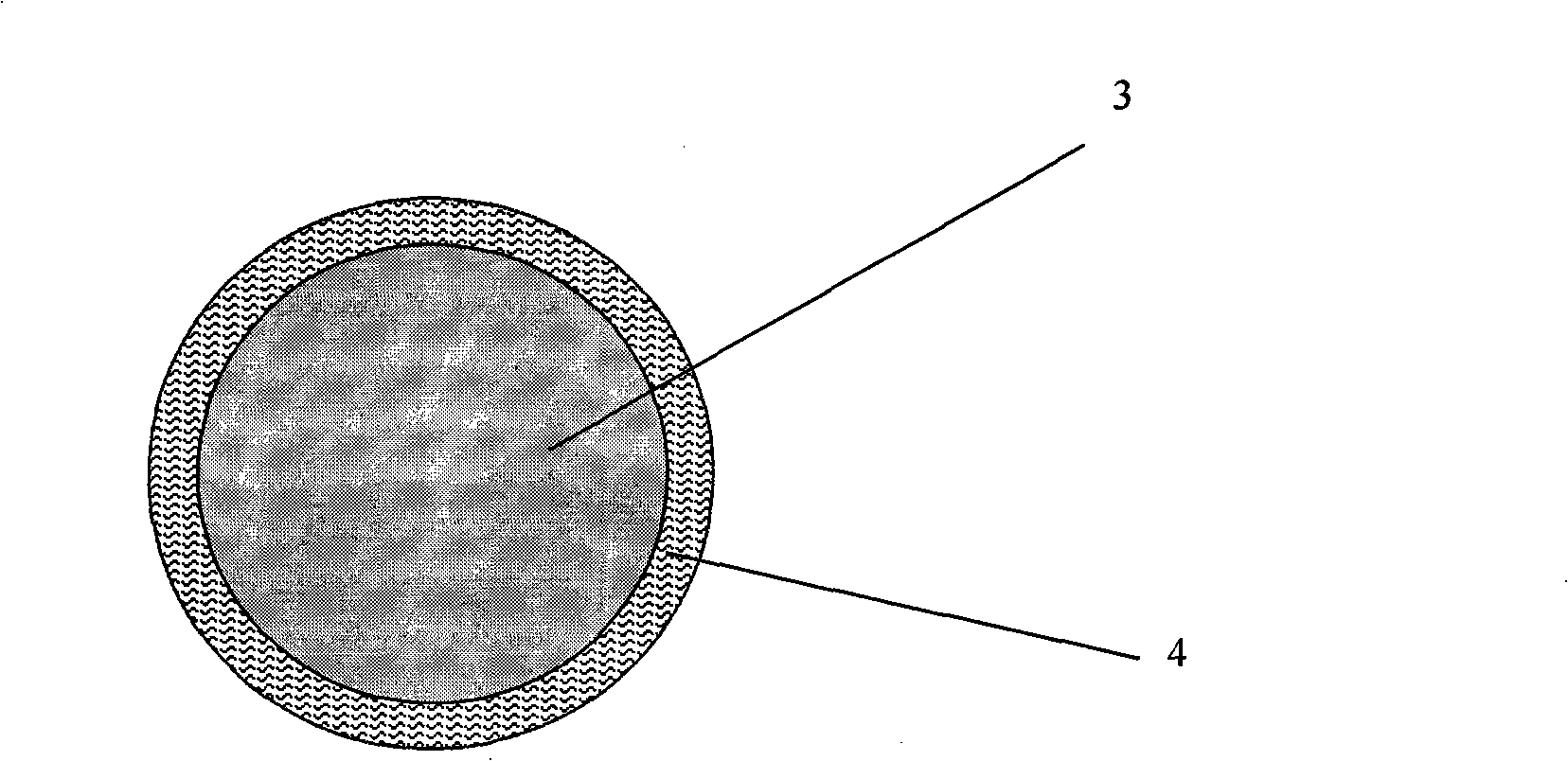

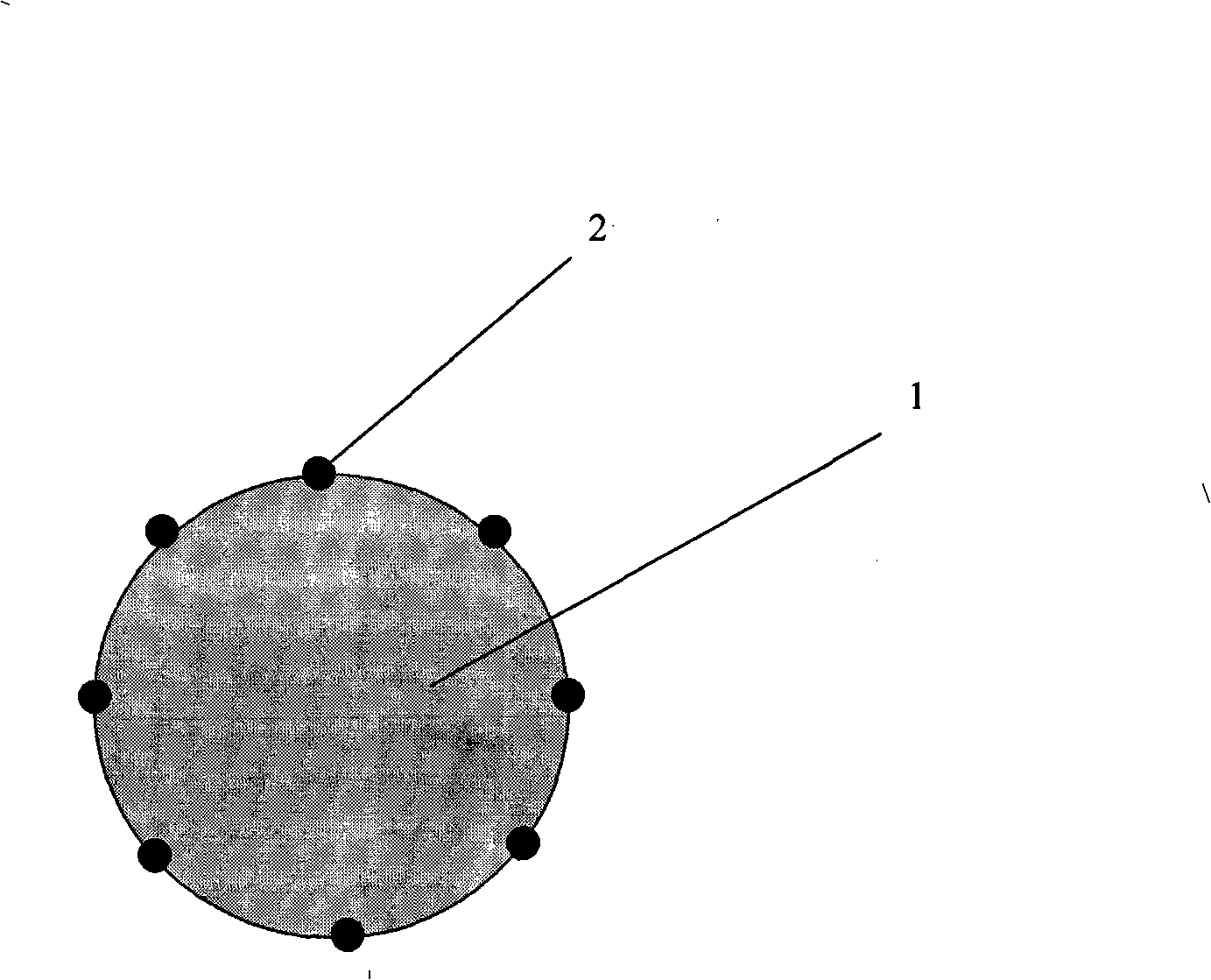

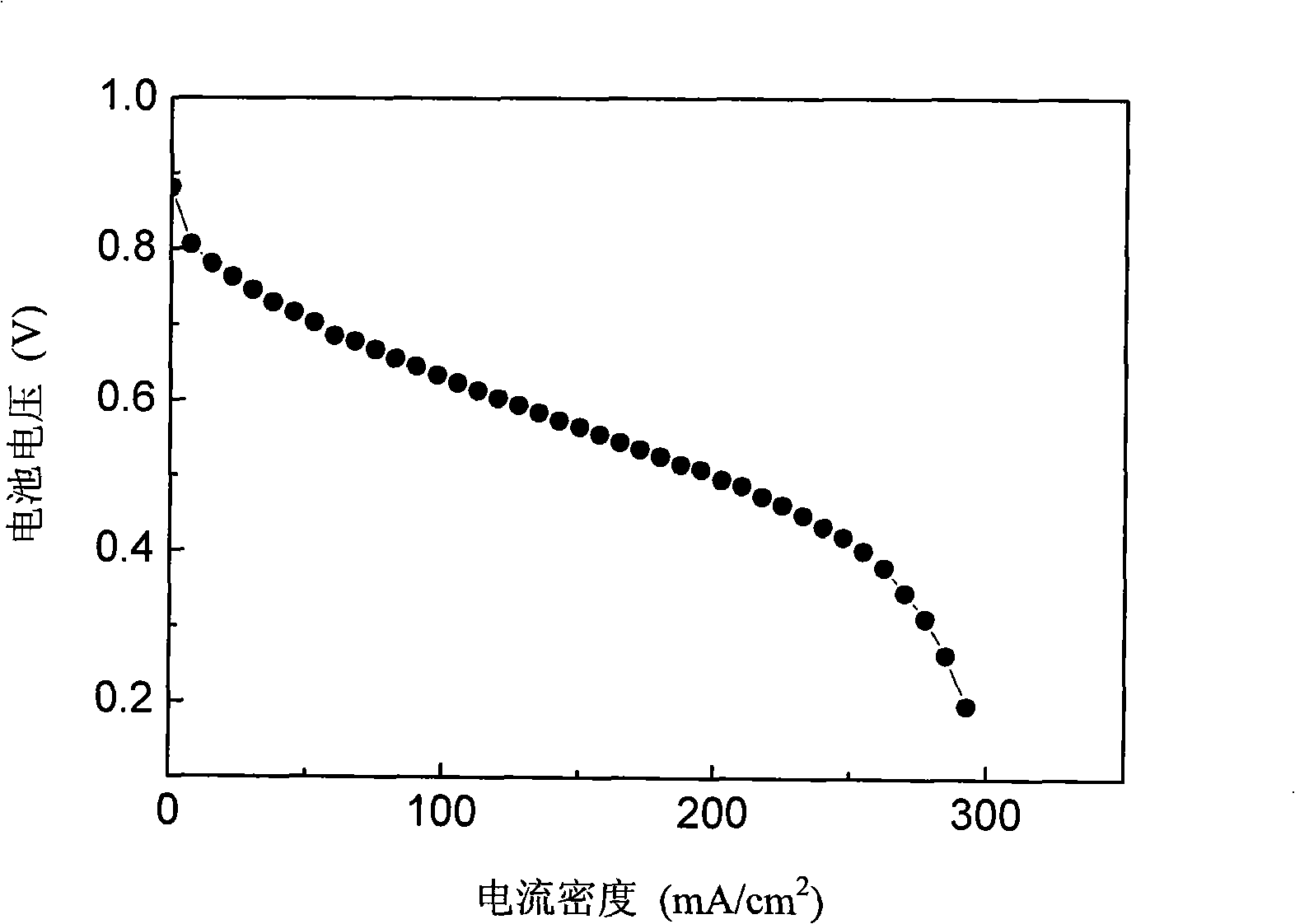

InactiveCN102437358AExtended cycleStable outputSolid electrolyte fuel cellsFuel cell detailsElectrochemical responsePorosity

The invention relates to solid fuel battery, in particular to a solid oxide fuel cell supported by stainless steel and a preparation method thereof. A cell structure comprises an anode 1, an electrolyte film 3 and a cathode 4; the anode 1 is a porous stainless steel supported body, wherein the pore of the porous stainless steel supported body contains catalyst 2 capable of catalyzing an electrochemical reaction of the solid oxide fuel cell anode; the thickness of the stainless steel supported body is 0.1 mm to 3 mm; the porosity is 10% to 60%, while the thickness of a compact electrolyte film is 2 microns to 80 microns. The solid oxide fuel cell supported by the stainless steel is proved that the cell has good output performance and resistance to oxidization and reduction.

Owner:UNIV OF SCI & TECH OF CHINA

Metal-doped nitrogen-containing carbon-based catalyst of fuel cell and application thereof

ActiveCN103682379AStructurally effective regulationEffective control of morphologyCell electrodesFuel cellsReduction ActivitySurface-active agents

The invention relates to a metal-doped nitrogen-containing carbon-based catalyst of a fuel cell and application of the catalyst. The catalyst adopts organic surface active agents as a protection agent and a structural guide agent and adopts an aromatic compound and aldehyde as reaction monomers, metal elements are added in the reaction process to obtain a polymer-metal compound, and the polymer-metal compound is dried and then is subjected to high-temperature processing with inert gas or / and ammonia gas to finally obtain the metal-doped nitrogen-containing carbon-based catalyst. When the metal-doped nitrogen-containing carbon-based catalyst is used as a cathode catalyst of a proton exchange membrane fuel cell and a direct-methanol fuel cell, the oxide reduction activity, stability and toxicity resistance are excellent; moreover, the catalyst has an environment-friendly effect, is low in cost, controllable in aperture, high in specific surface area and rich in resource and can substitute for platinum to serve as an electric catalyst of the proton exchange membrane fuel cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

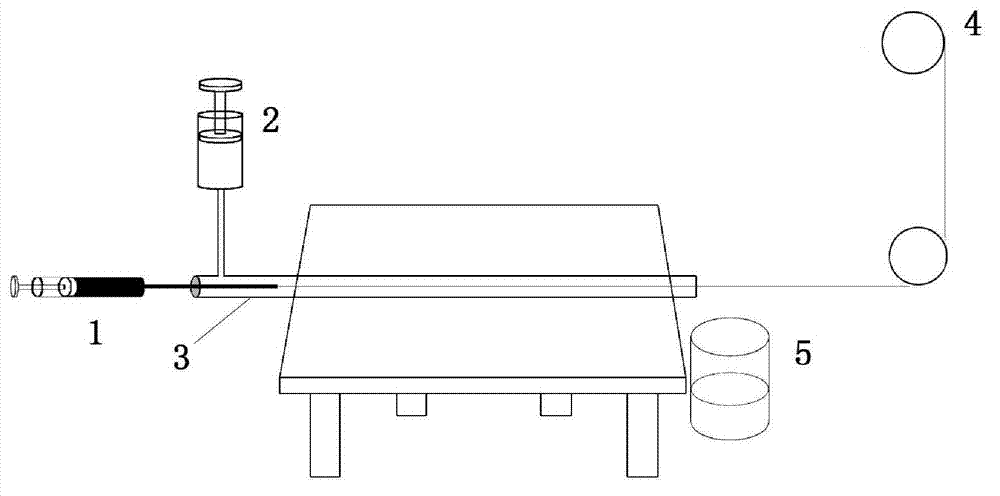

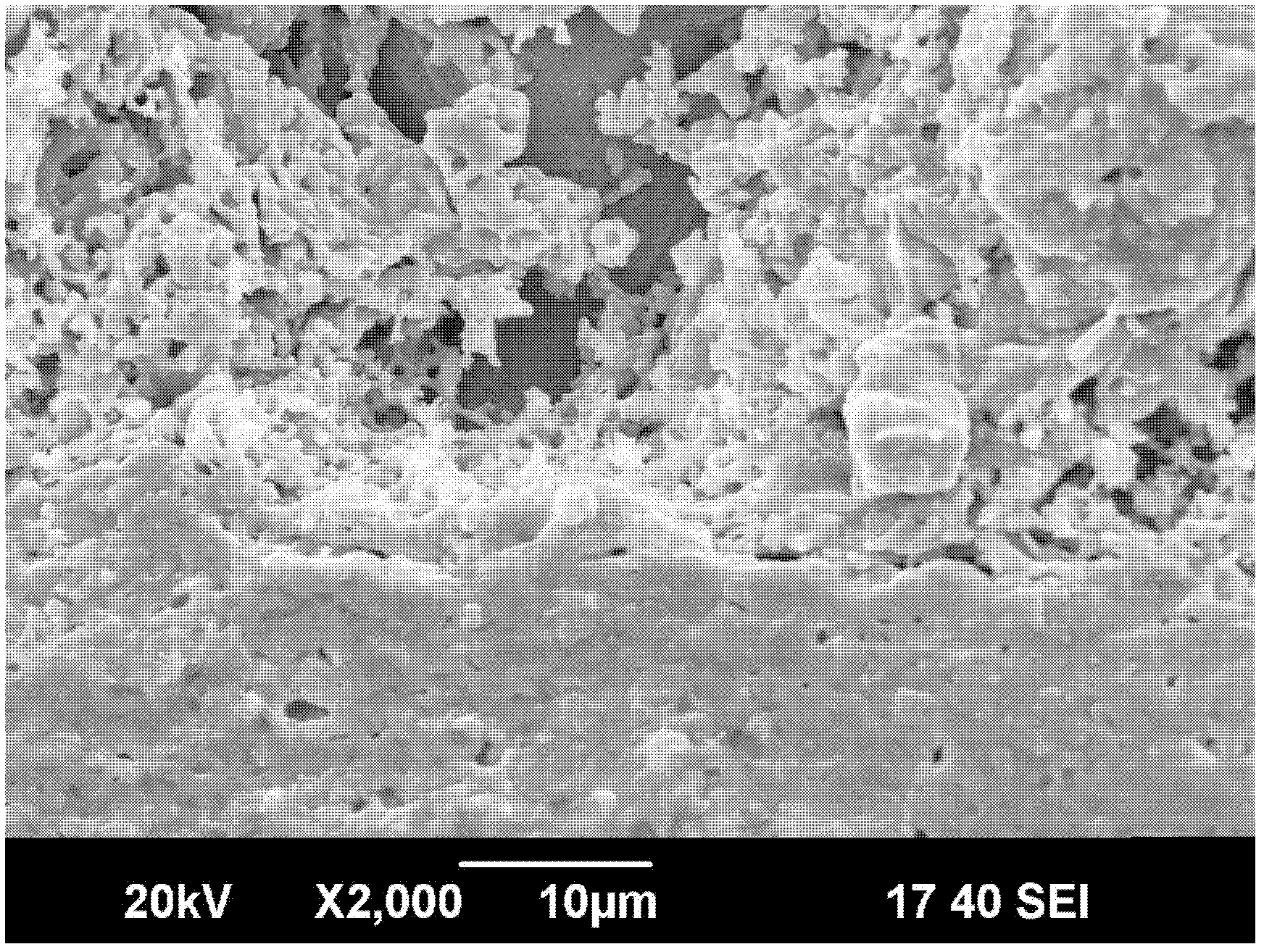

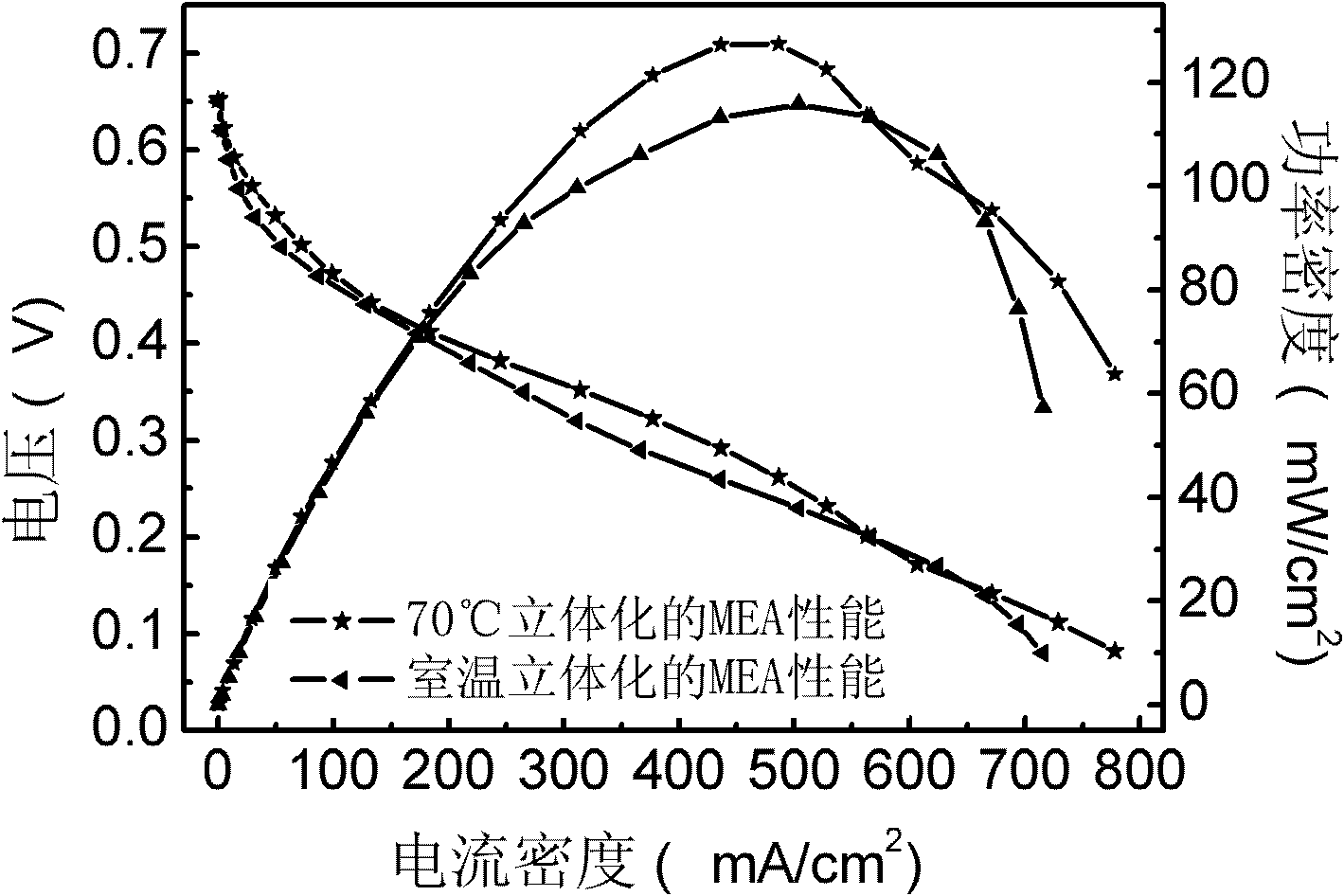

Electrospinning and electrostatic spraying method for membrane electrode CCM

PendingCN106848355AIncrease active areaIncrease profitLiquid surface applicatorsCell electrodesPorosityConcentration polarization

The present invention discloses an electrospinning and electrostatic spraying method for a membrane electrode CCM. According to the present invention, the catalyst layer having the nanometer film structure is obtained by using the electrospinning and electrostatic spraying method, wherein the catalyst layer structure has a high specific surface area so as to increase the three-phase reaction interface, increase the active area of the catalytic layer, and improve the catalyst utilization rate; the polymer nano-fiber membrane has high porosity, such that the mass transfer is easily performed, and the concentration polarization is effectively reduced; and the nano-scale catalytic particles obtained through electrostatic spraying are uniformly distributed on the nano-fiber structure so as to reduce the platinum loading and improve the catalytic performance.

Owner:NANJING UNIV

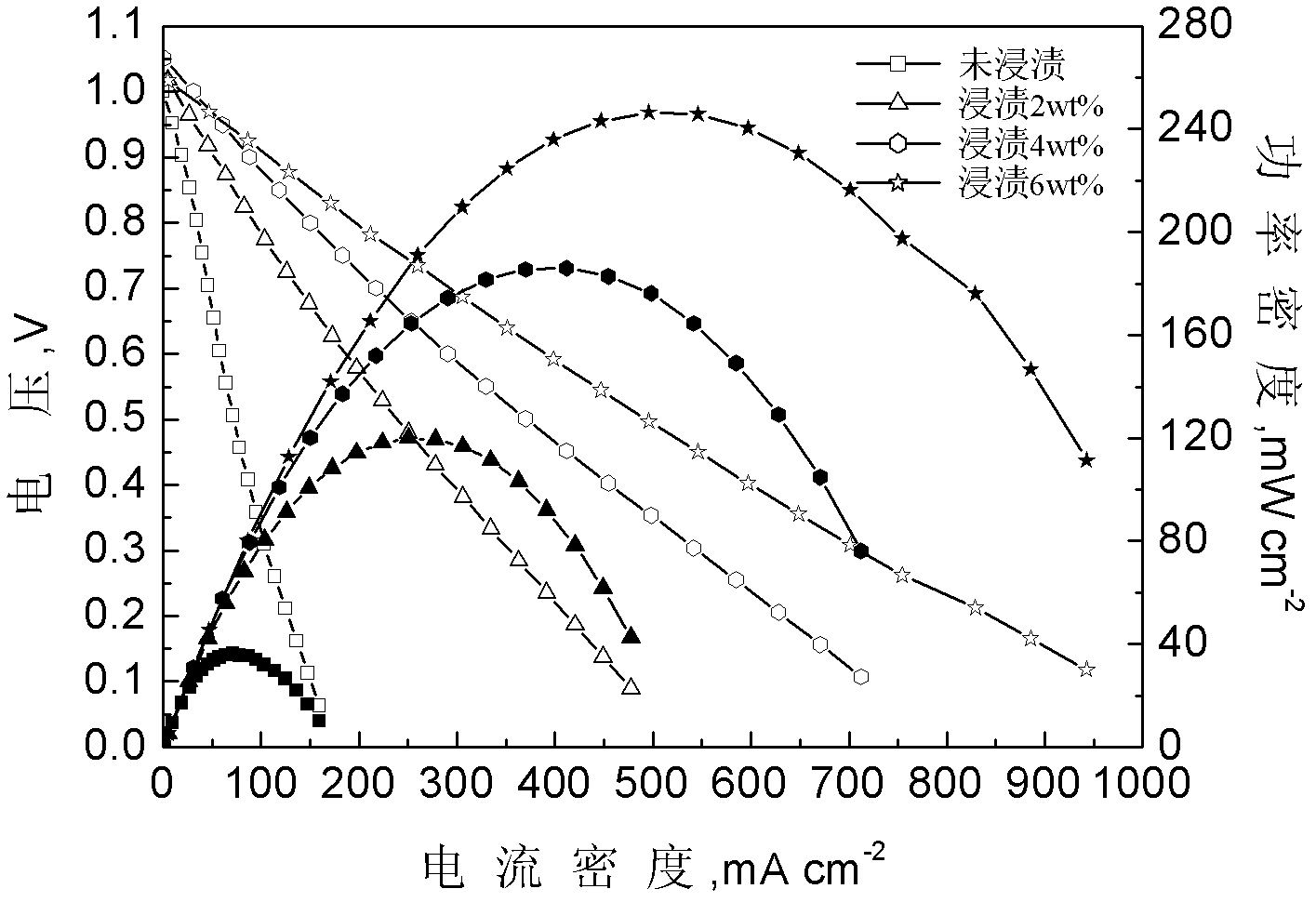

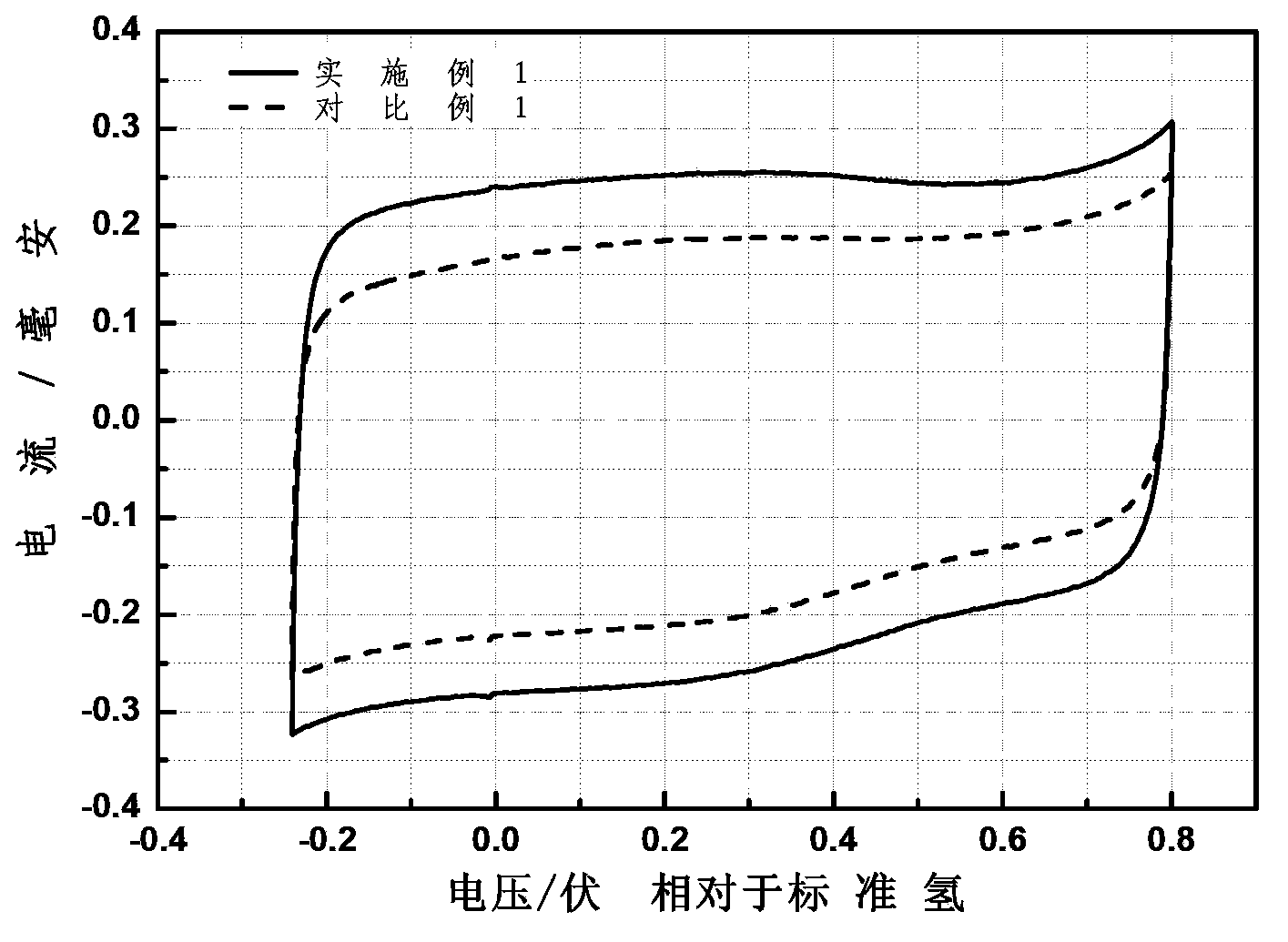

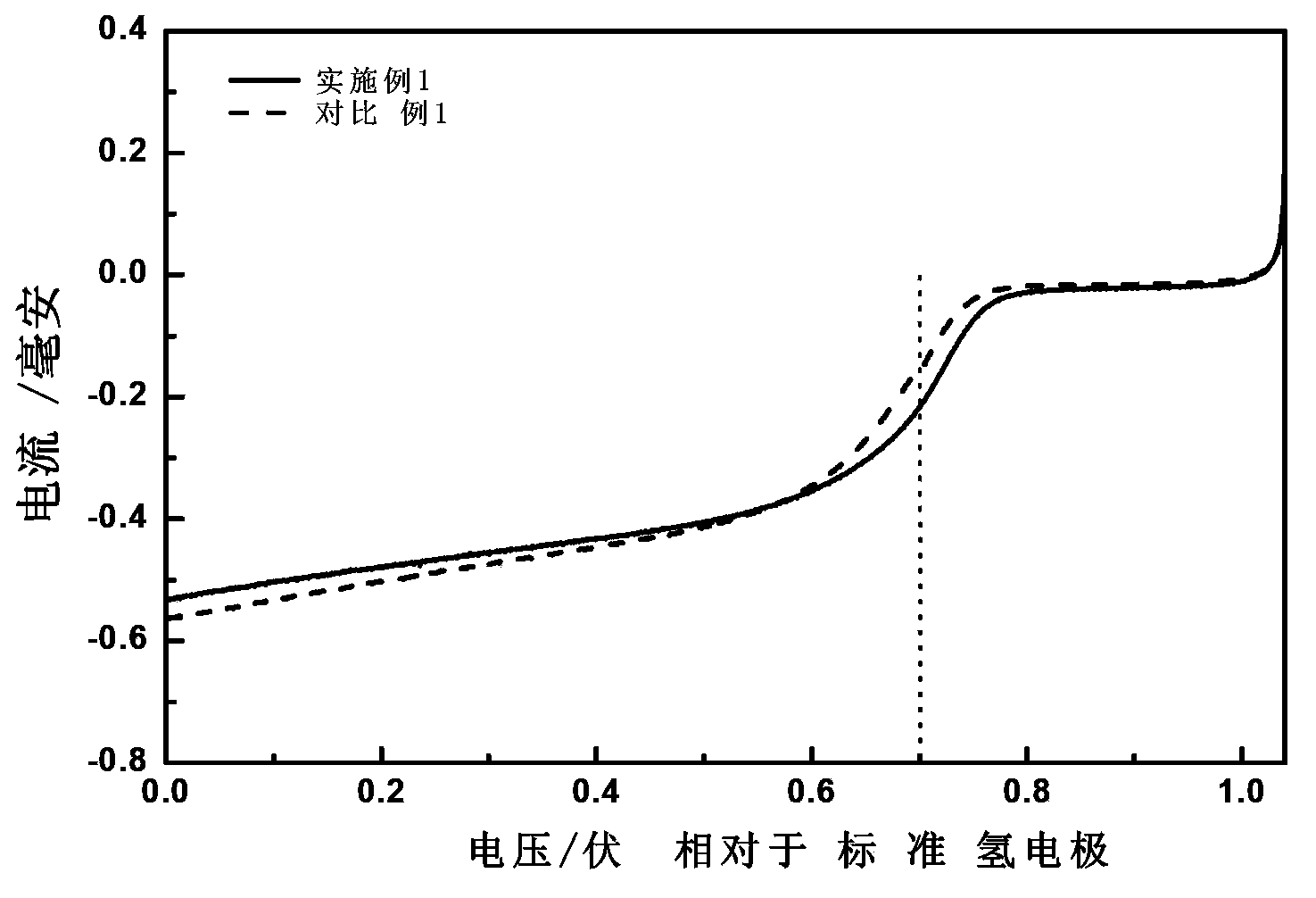

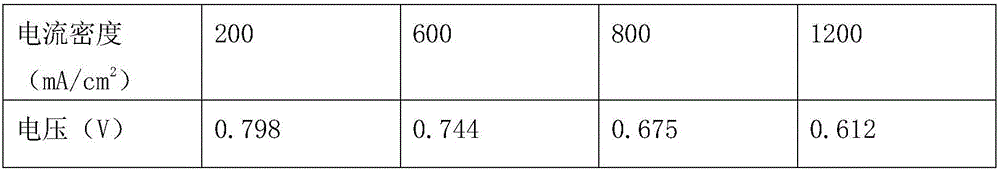

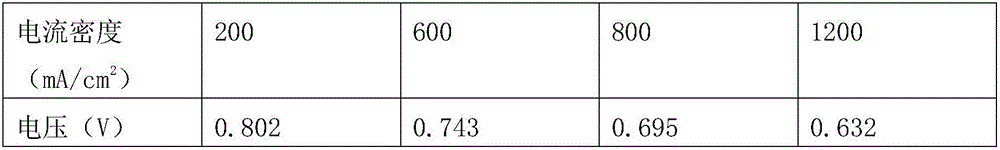

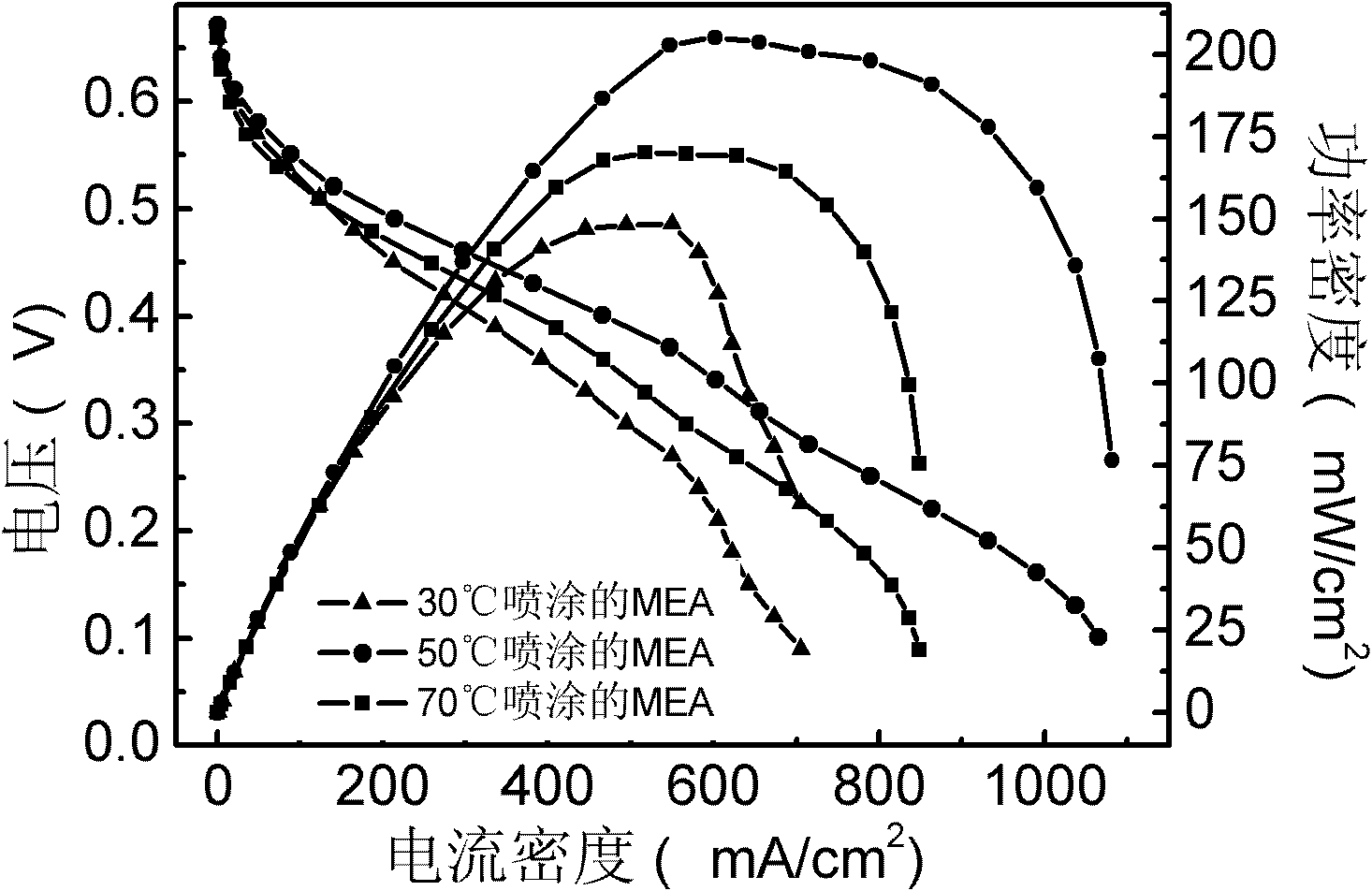

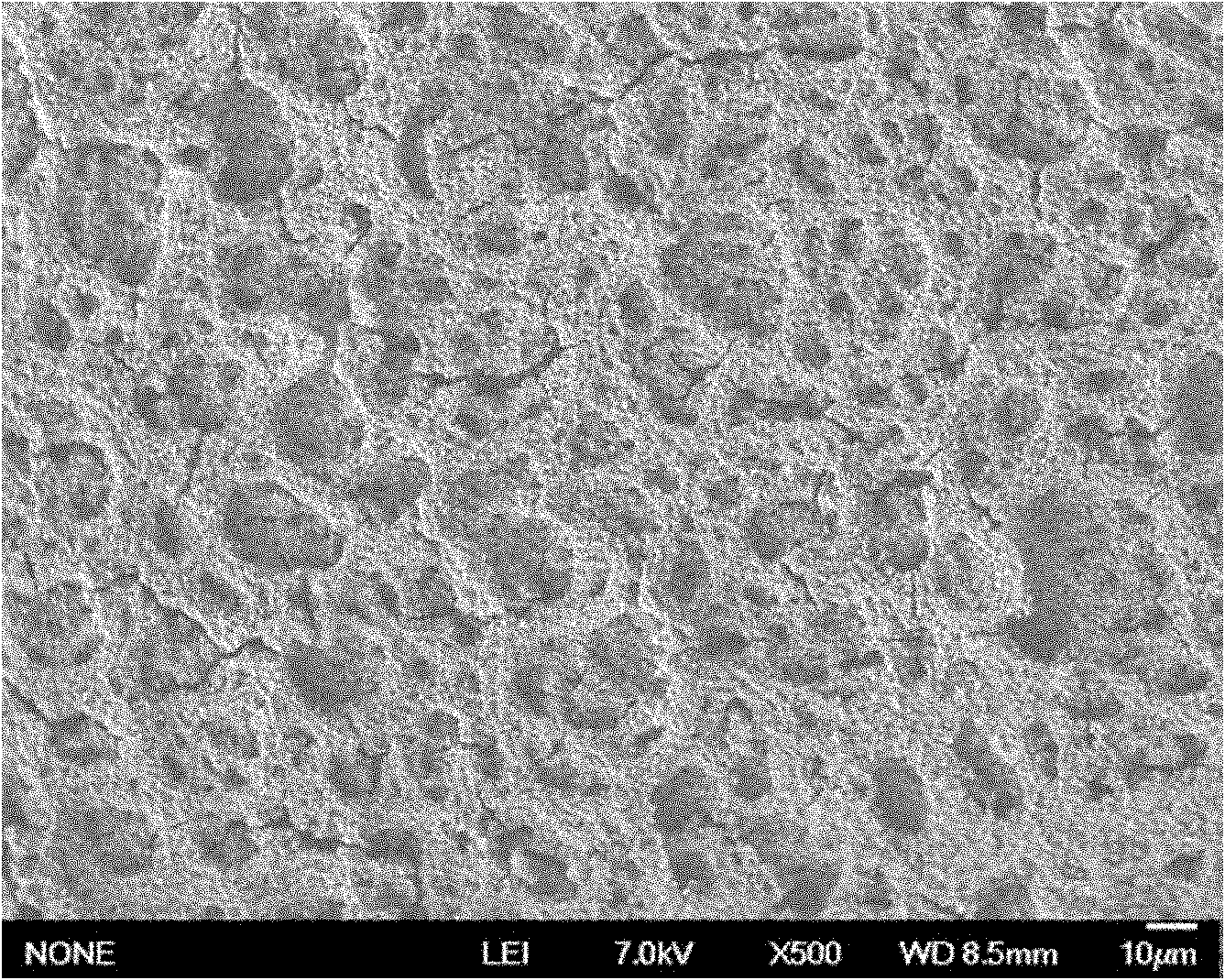

Preparation method for three-dimensional network structure membrane electrode for direct methanol fuel cell

The invention discloses a preparation method for a three-dimensional network structure membrane electrode for a direct methanol fuel cell, belonging to the technical field of the structure and the manufacture of the efficient membrane electrode assembly of the direct methanol fuel cell. A catalysis layer in the membrane electrode prepared by the temperature controlling ultrasound spraying processis adopted to realize the three-dimensional network structure of the catalysis layer; the amount of active sites exposed on a three-phase interface, of the catalyst, is added to provide a path for gas and liquid transmission; a carbon cloth subjected to hydrophobicity processing serves as a diffusion layer; an Nafion membrane serves as a proton exchange membrane; Pt black and PtRu black serve as catalysts, and propyl alcohol serves as a diffusion agent; a Nafion solution serves as a binder in the catalysis layer, and a PTFE (polytetrafluoroethylene) membrane or tinfoil serves as a transferring medium; the catalysis layer is transferred and pressed on two sides of the proton exchange membrane from the transferring medium; and finally, the diffusion layer is arranged on the catalysis layer by hot pressing. The formed laminar combination is the membrane electrode. The membrane electrode prepared with the method has the three-dimensional network structure and has the advantages of evenly distributed pores and centralized pore diameter, the active area of the catalysis layer is obviously enlarged, and the output power density of the cell is obviously improved.

Owner:UNIV OF SCI & TECH BEIJING

Porous electrode for flow battery and preparation method of porous electrode

ActiveCN111785978ALarge specific surface areaIncrease active areaCell electrodesHeating/cooling textile fabricsChemistryAcetamide

The invention provides a porous electrode for a flow battery and a preparation method of the porous electrode, and relates to the field of flow batteries. The preparation method comprises the following steps: S1, adding polyacrylonitrile and a metal salt into N, N-dimethylformamide or N, N-dimethylacetamide, carrying out heating and mixing until polyacrylonitrile and the metal salt are dissolved,so as to obtain an electrospinning stock solution; S2, carrying out electrostatic spinning by using the electrospinning stock solution to obtain an electrospun fiber membrane; S3, dissolving an organic ligand in a solvent to obtain an organic ligand solution, soaking the electrospun fibrous membrane in the organic ligand solution for a period of time, and generating MOF particles in situ on the surface of the electrospun fibrous yarn; and S4, carrying out pre-oxidation on the fibers with the MOF particles deposited on the surfaces, and then carrying out carbonization in an inert gas atmosphereto obtain the porous electrode. The porous electrode prepared in the invention has a large specific surface area, is helpful for reducing the activation loss of the battery and improving the performance of the battery, and can be suitable for various flow batteries.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

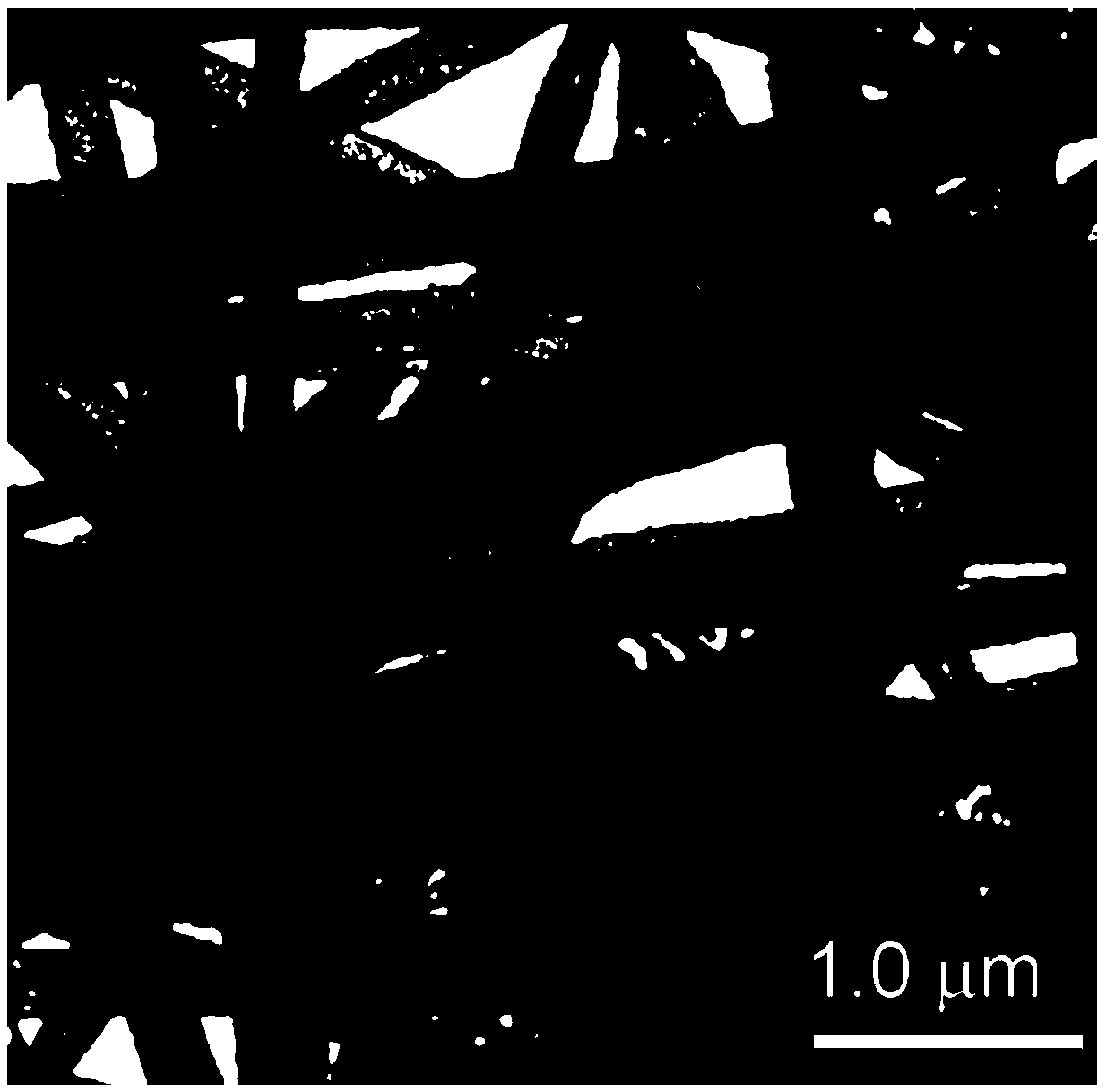

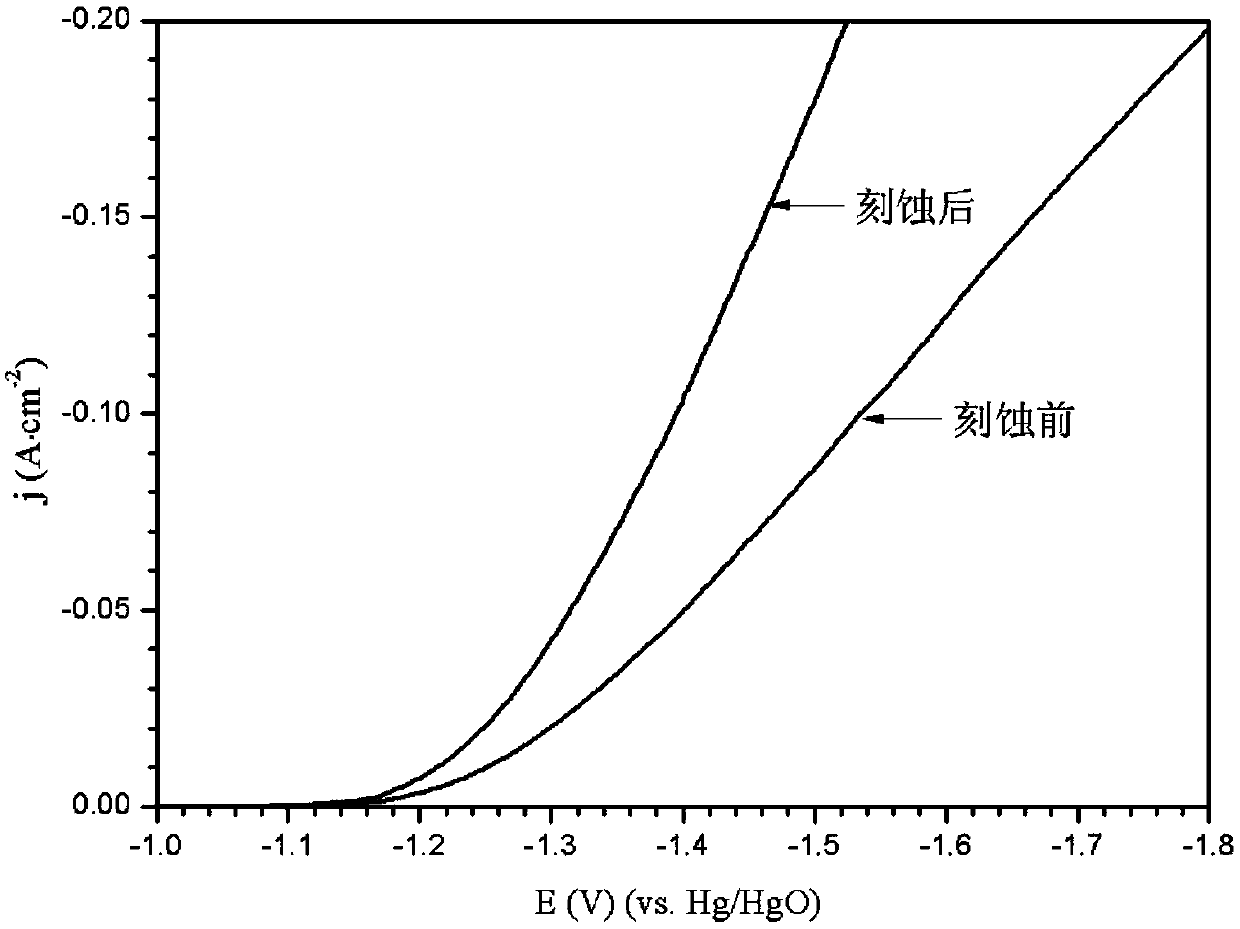

Etching method capable of increasing electrochemical active area of nickel foam electrode

The invention relates to an etching method capable of increasing the electrochemical active area of a nickel foam electrode, belonging to the fields of surface treatment technology for materials and electrocatalysis. According to the invention, a chemical etching solution with hydrochloric acid and an oxidizing agent as main components is used for soaking and etching of the nickel foam electrode,and the nickel foam electrode with a large active area and high stability is prepared by controlling etching time and the concentration of the etching solution. The prepared nickel foam electrode canprovide more active sites for hydrogen evolution and oxygen evolution of electrolysed water and reduce energy consumption in electrolysis. The etching method is simple in process and suitable for large-scale industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

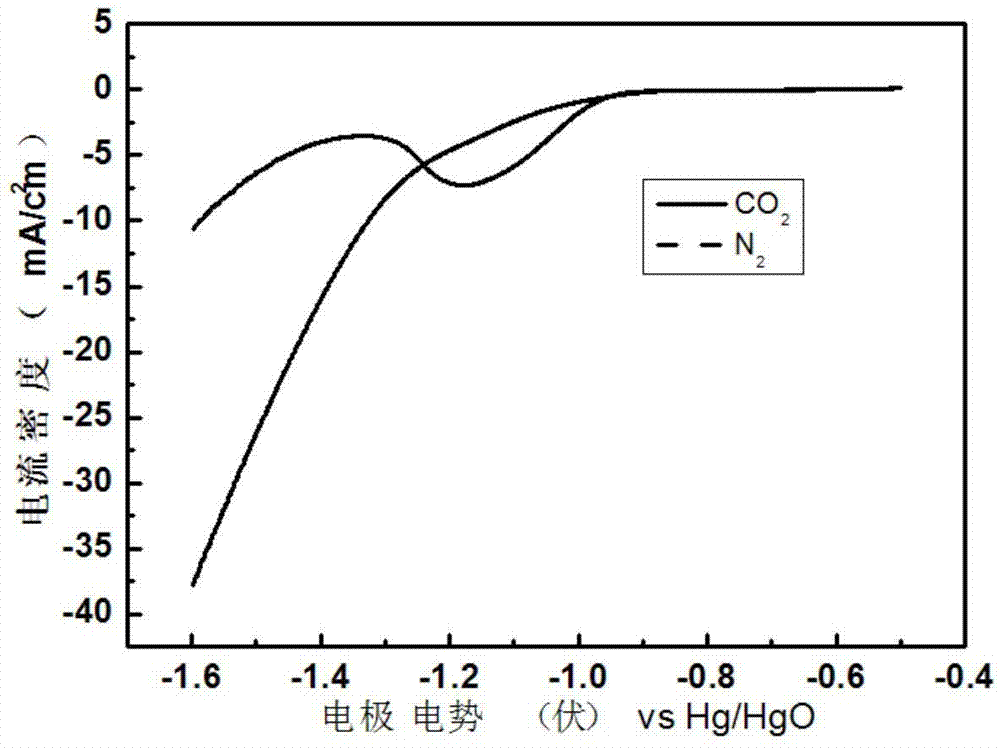

Preparation method of electrode used for CO2 electrochemical reduction reaction

The invention relates to a preparation method of an electrode used for CO2 electrochemical reduction reaction. The electrode is prepared with foam copper, a copper wire mesh, a copper foil, a copper plate, a titanium wire mesh or a titanium plate as a substrate. The preparation method includes the steps of uniformly mixing a copper precursor solution being 0.01-2.0 M in concentrate and a template agent being 0.01-1.5 M in concentrate according to the molar ratio of 5:1-1:20 and magnetically stirring the solution for more than 30 min; moving the solution into a reaction kettle, immersing the substrate into the solution and performing a sealing reaction for 4-12 h; moving the substrate out from the reaction kettle, washing and drying the substrate, and performing thermal treatment to the substrate at 300-800 DEG C for 1-5 h under protection of an inert gas or an oxidizing atmosphere to obtain the substrate to which metal oxides are attached; and performing electrochemical reduction to the substrate to which metal oxides are attached in an acidic electrolyte to obtain the electrode. The preparation method is simple in preparation method and is suitable for large-scale production. The electrode is large in specific surface area and is high in CO2 oxygen reduction catalytic performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

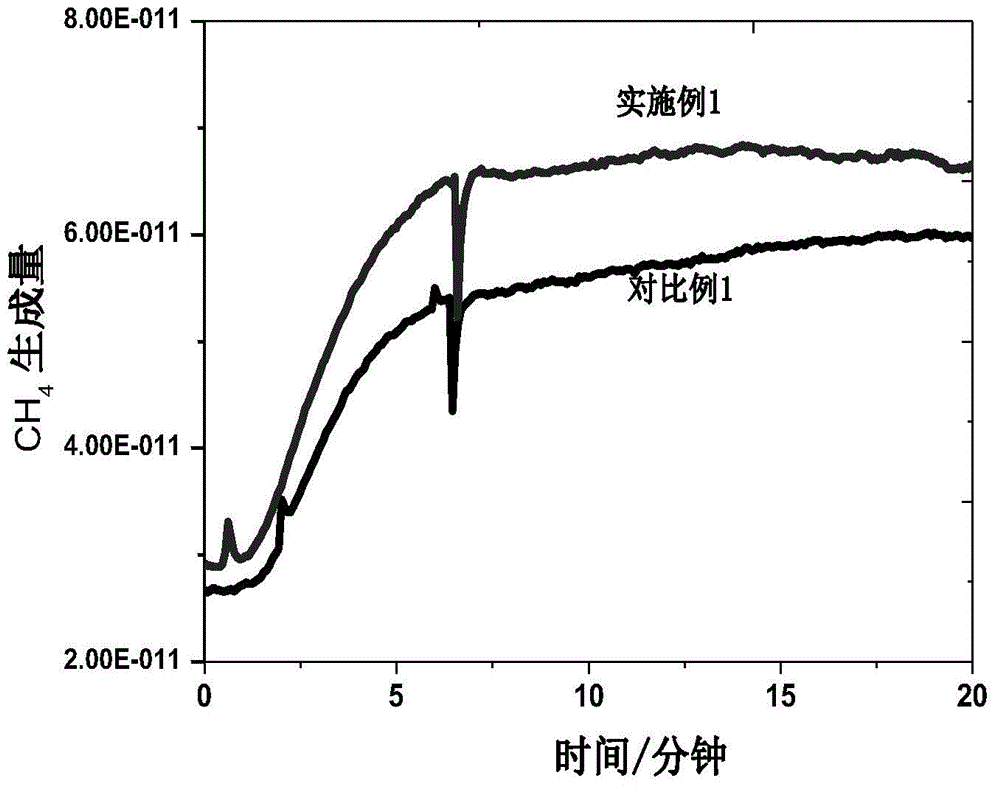

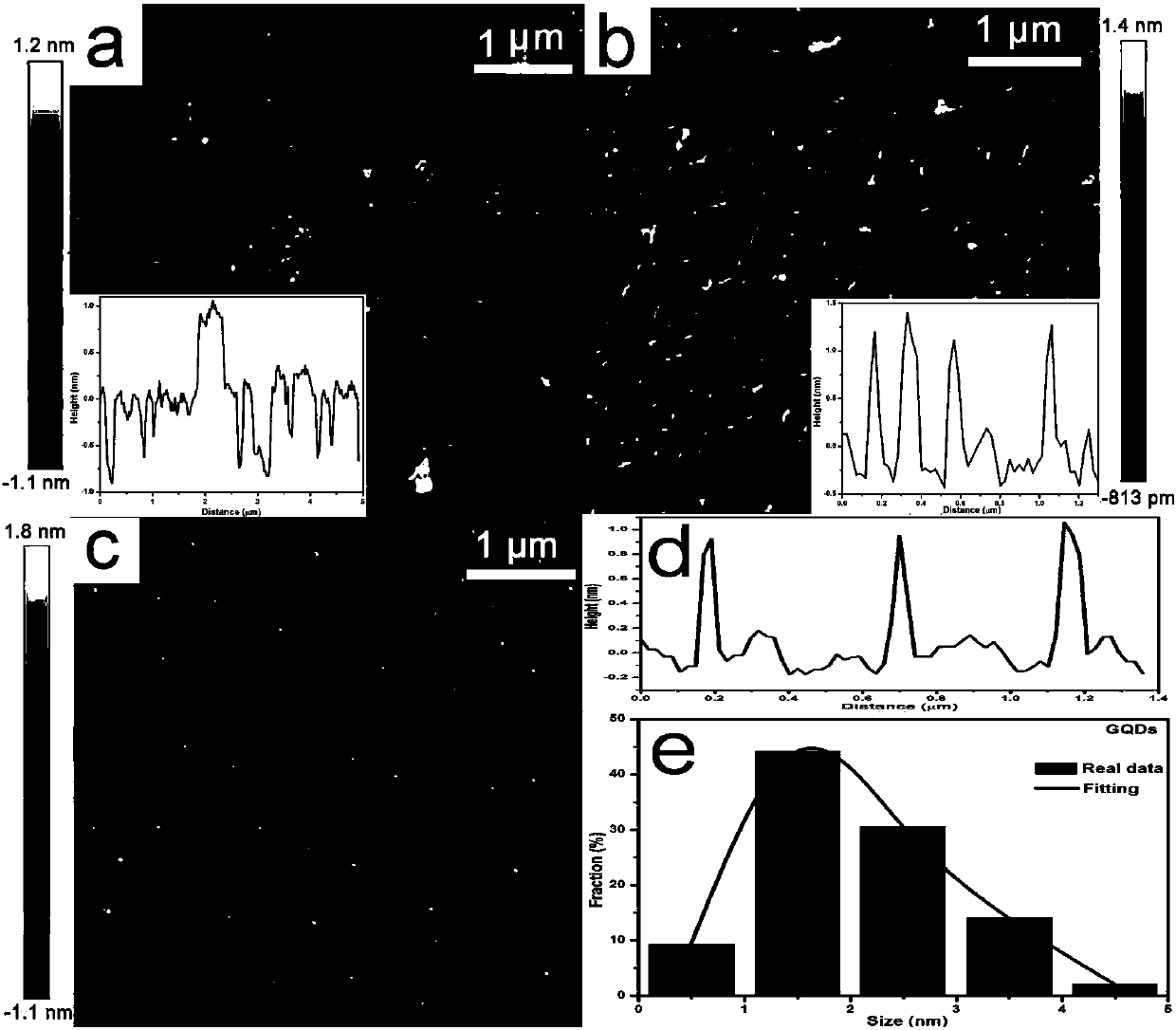

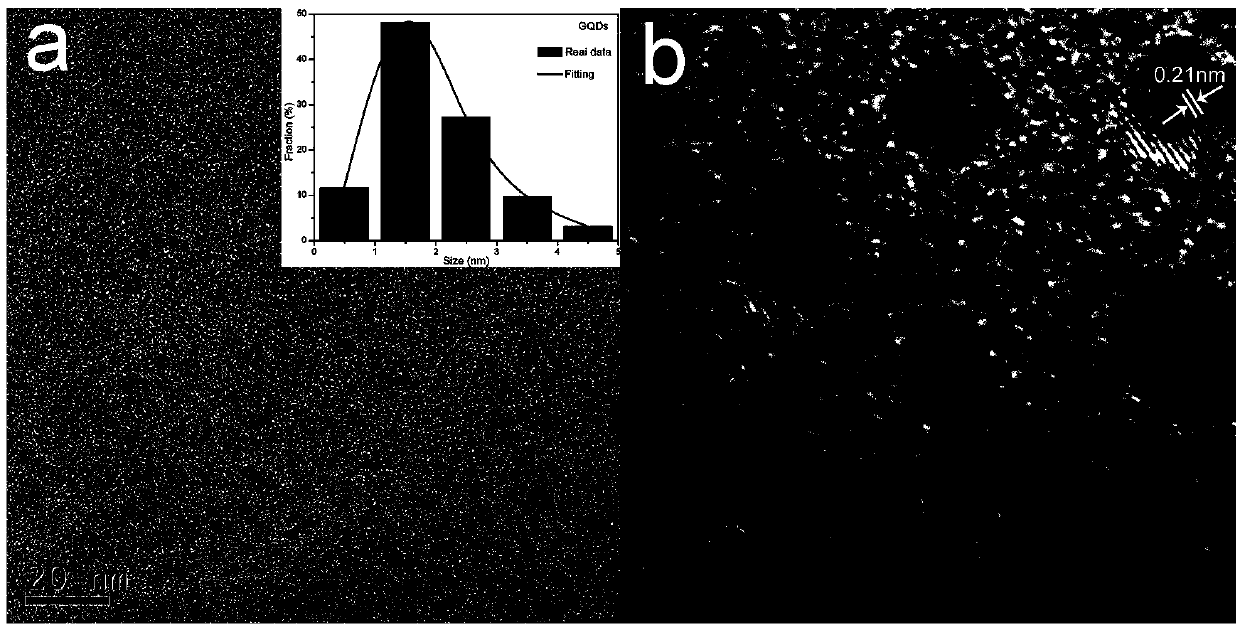

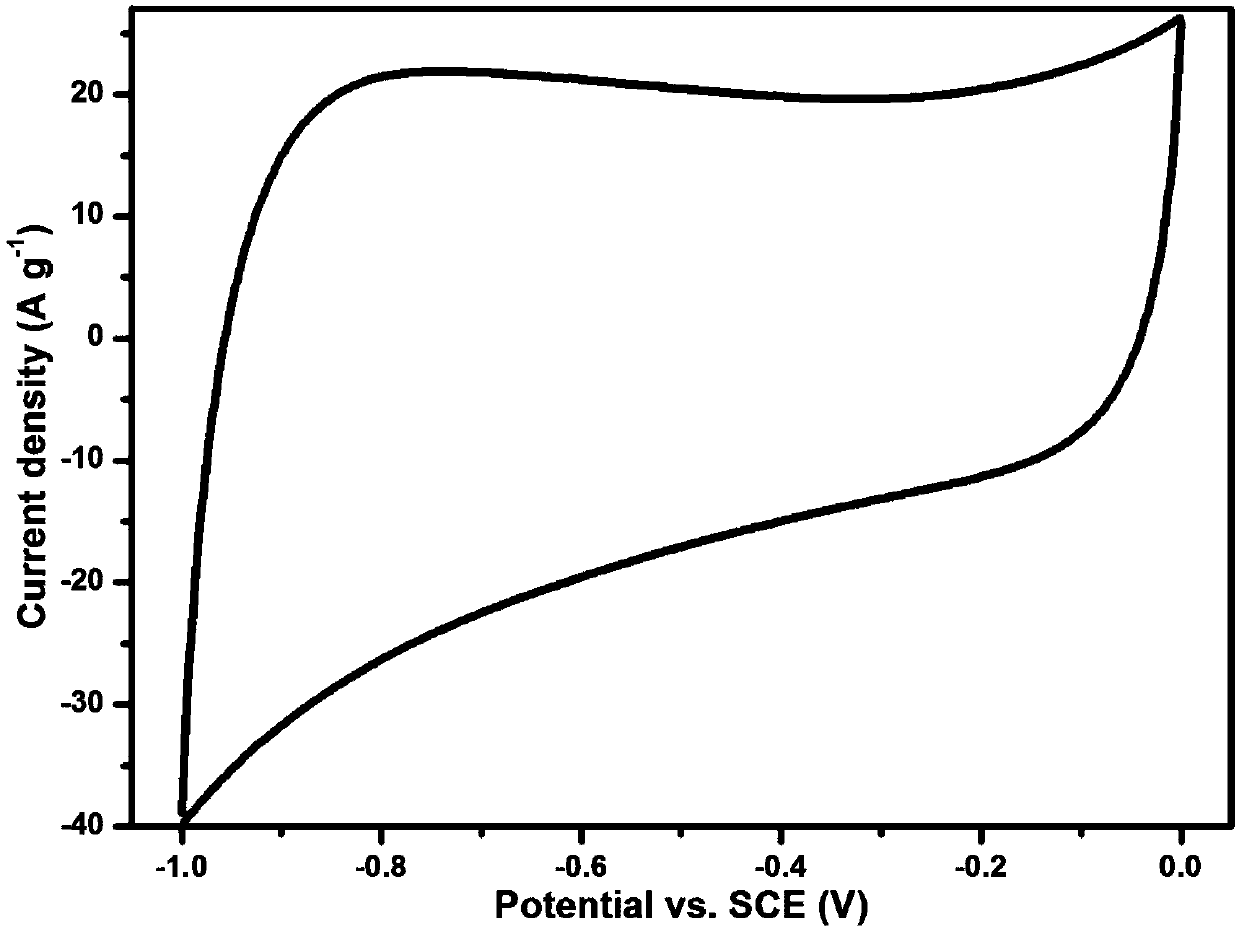

Preparation method and application of uniform-size graphene quantum dots

ActiveCN107601466AGood dispersionPromote oxidationHybrid capacitor electrodesCell electrodesCarbon–carbon bondHeat treated

The invention provides a preparation method and application of uniform-size graphene quantum dots. The method adopts a strategy from top to bottom; oxidized graphene is used as raw materials; an ultrasonic auxiliary hydrothermal method is used; the ultrasonic mechanical stress is used for assisting the high oxidation effect of nitric acid for cutting carbon-carbon bonds; then, high-temperature heat treatment is performed to prepare a pure graphene quantum dot material with the uniformly distributed size. The method process is simple; the conditions are mild; the prepared graphene quantum dotshave good purity degree, small particle diameter and uniformly distributed size. Used as an electrode material of an energy storage device, the prepared graphene quantum dot material shows excellent electrical conductivity, high specific capacity, excellent rate performance, fast ion adsorption and transmission rate and long cycle service life; good application potential is realized in the field of energy storage devices.

Owner:QINGDAO UNIV OF SCI & TECH

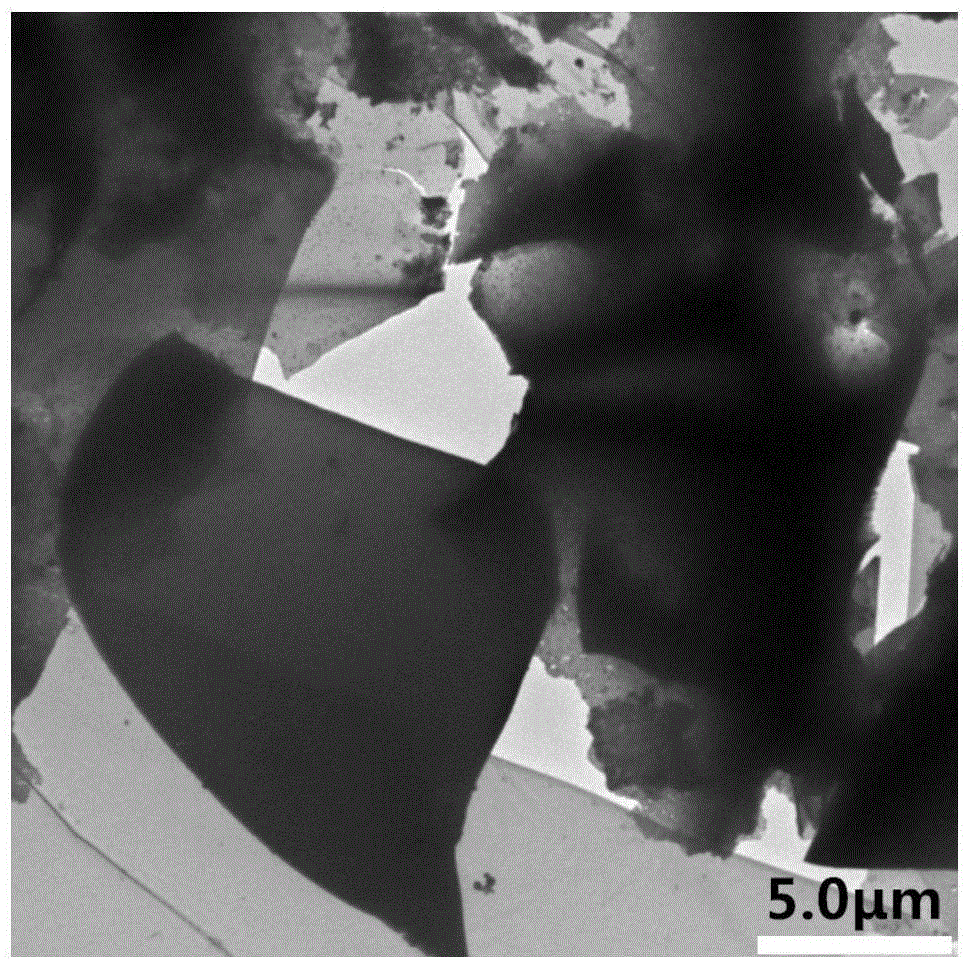

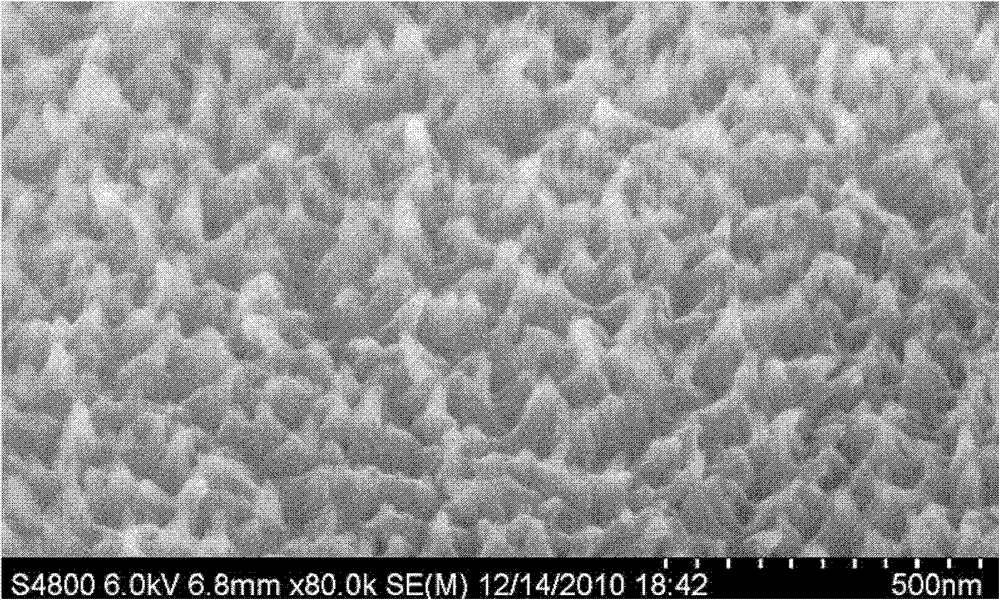

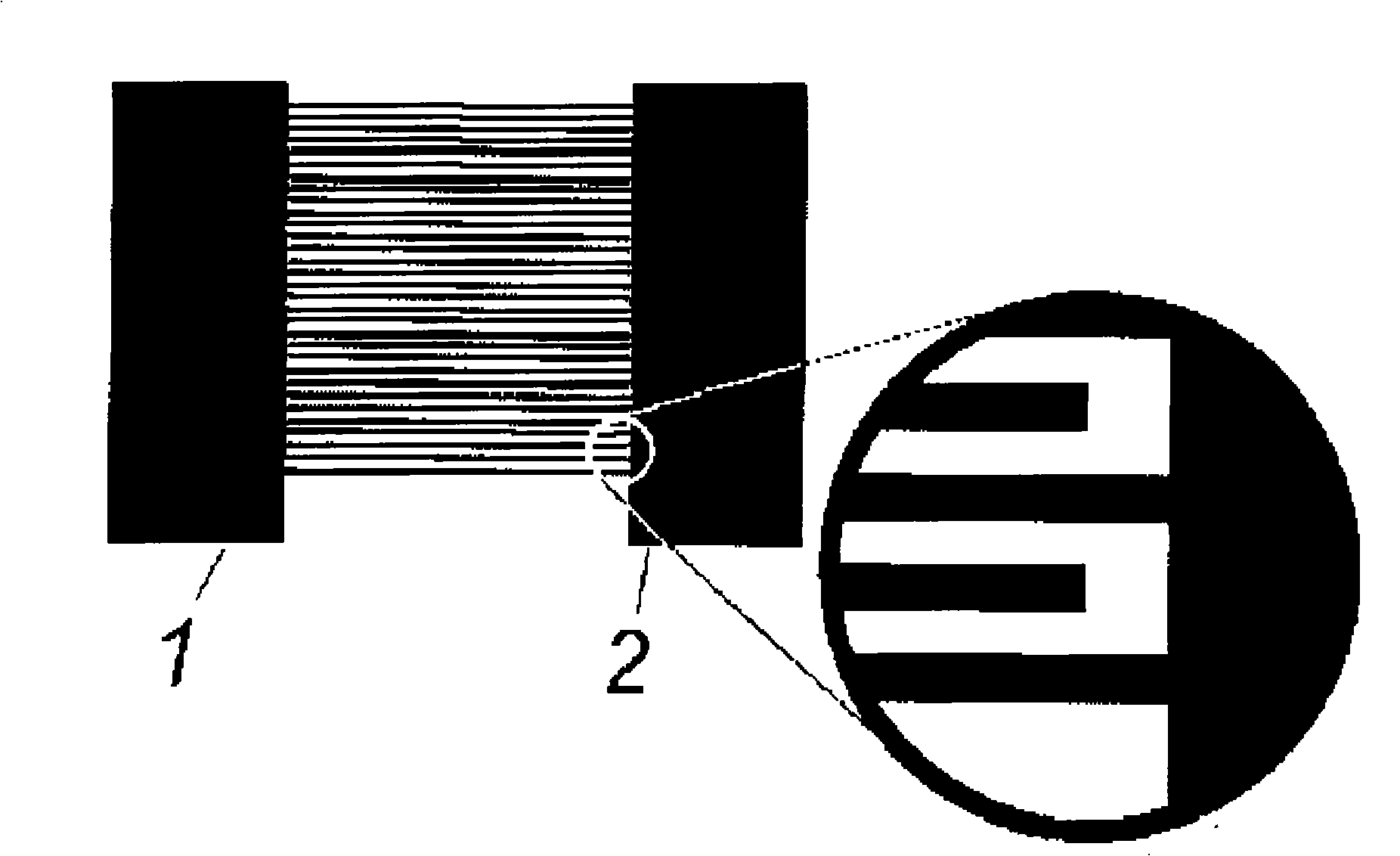

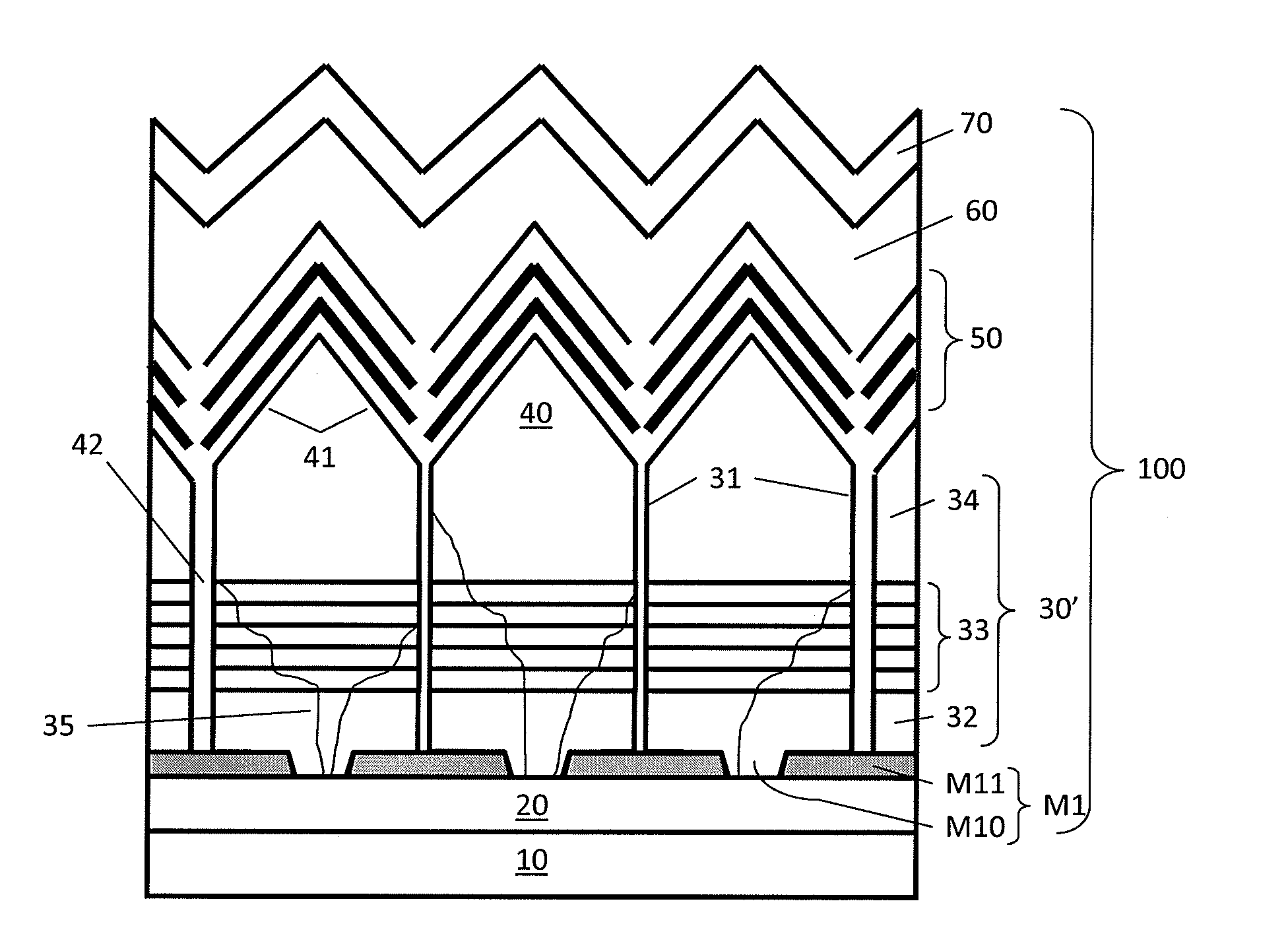

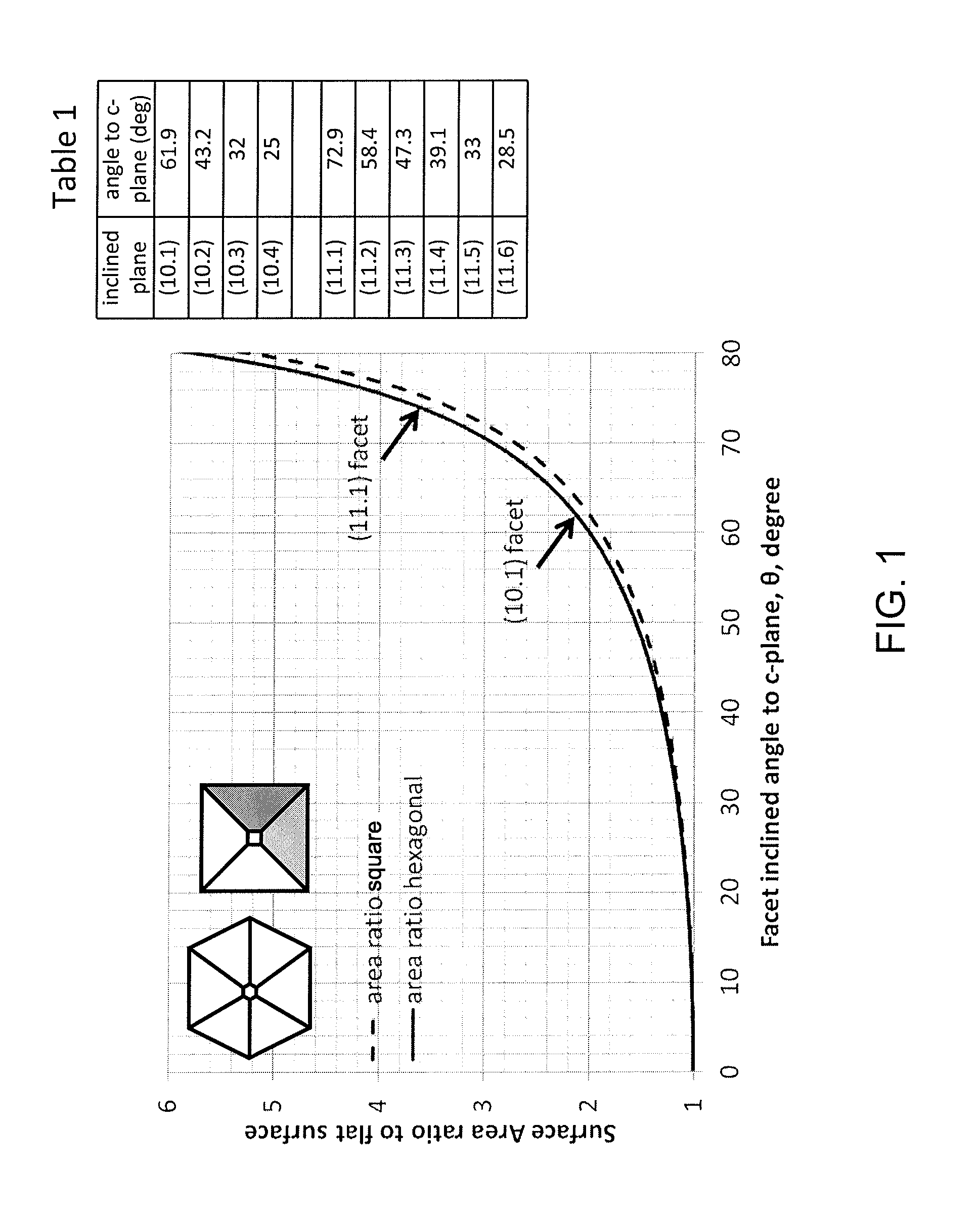

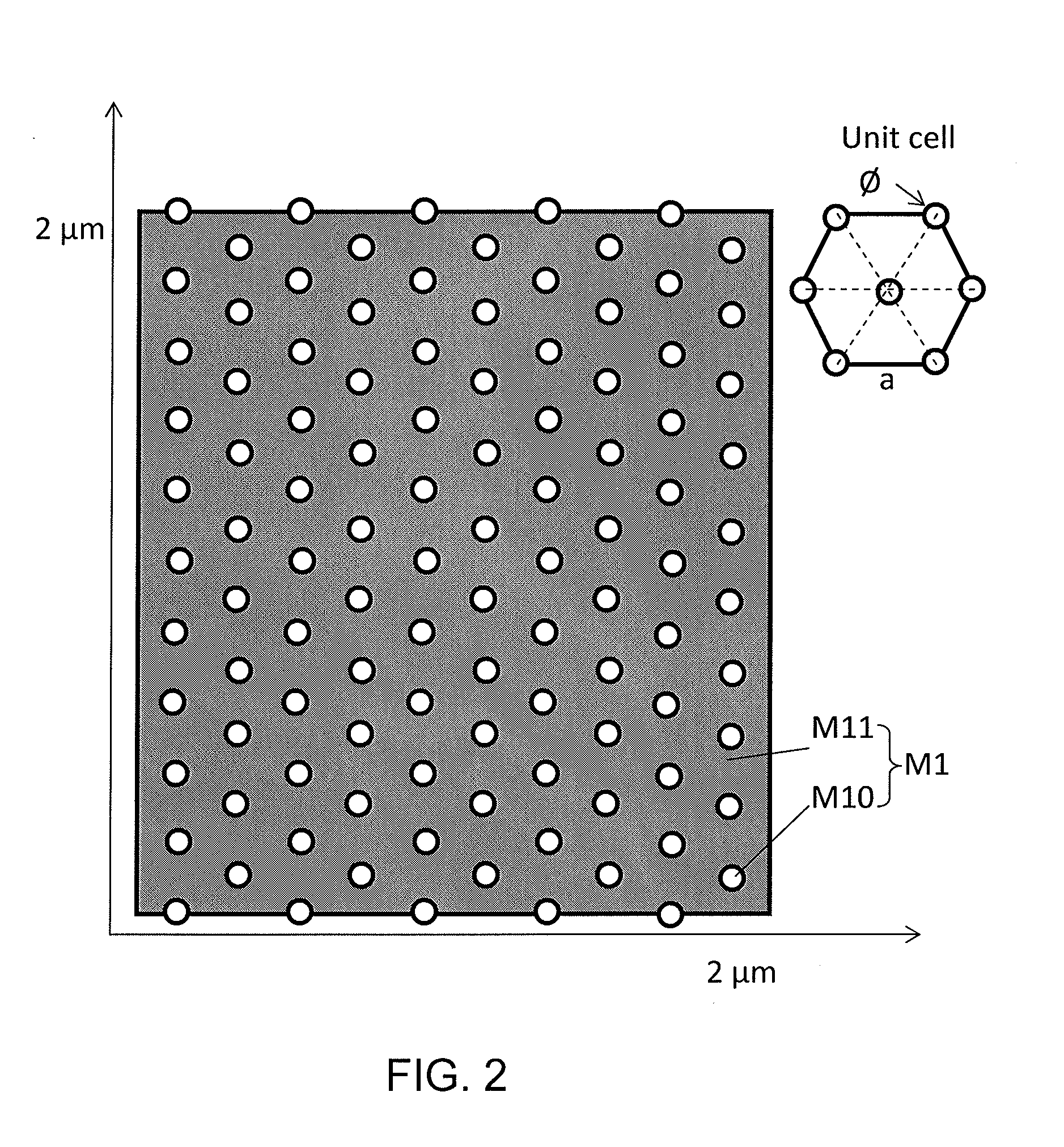

Submicro-facet light-emitting device and method for fabricating the same

InactiveUS20140191187A1Enhance current-sustaining capacityImprove light extractionSemiconductor/solid-state device manufacturingSemiconductor devicesLight emitting deviceFacet

A light emitting device comprises an n-type layer, a p-type layer, and an active region sandwiched between the n-type layer and the p-type layer, wherein the active-region has a wavy structure with nano or micro fluctuations in its thickness direction. The n-type layer comprises crystal facets on its upper surface, and the active-region is conformally formed on the upper surface of the n-type layer and substantially follows the shape of the crystal facets so as to form the wavy structure. A method for fabricating the same is also provided.

Owner:ZHEJIANG INVENLUX TECH

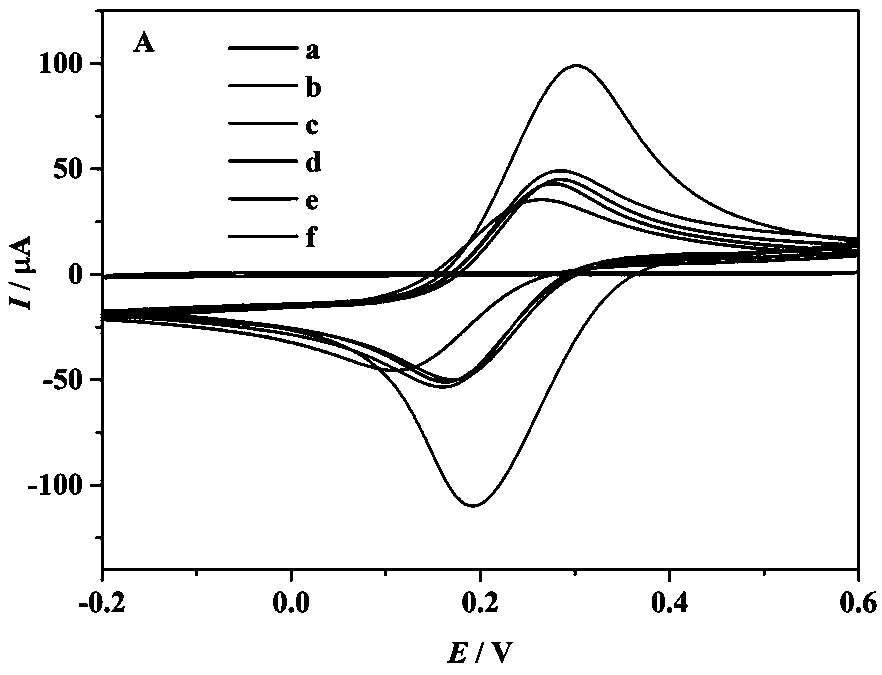

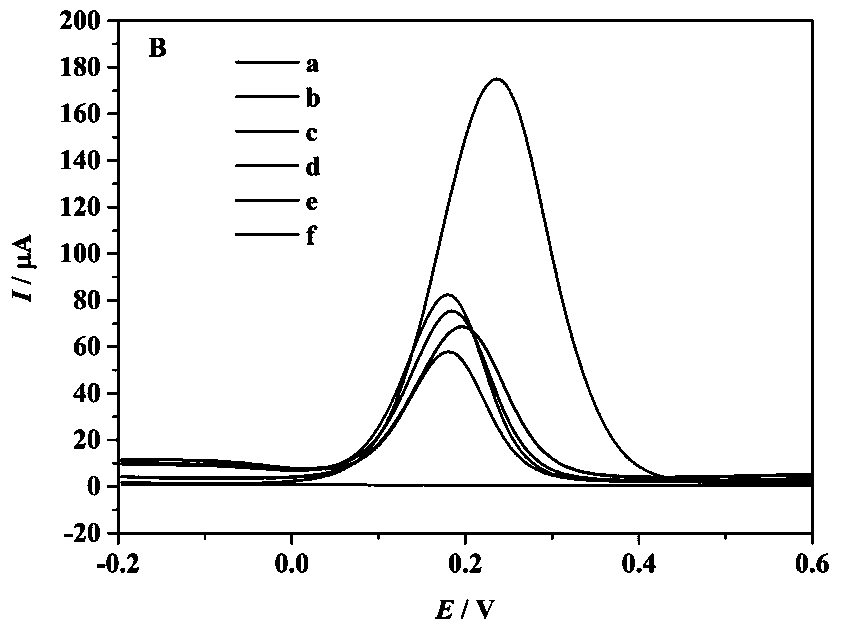

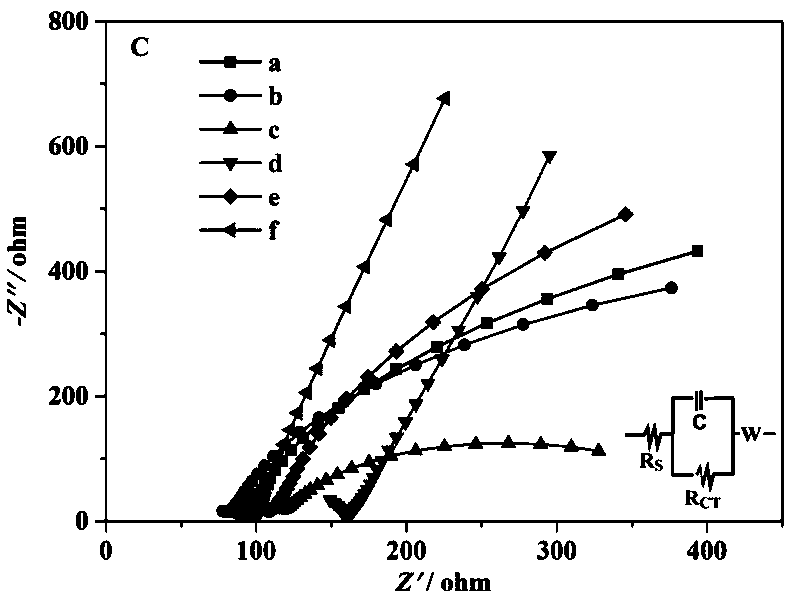

Preparation method of molecularly imprinted sensor based on carbon quantum dot/hollow nickel base material composite film modified glassy carbon electrode and application thereof

InactiveCN110208344AEasy to operateLow costMaterial electrochemical variablesComposite filmFunctional monomer

The invention belongs to the technical field of preparation of electrochemical sensors, and relates to a preparation method of a molecularly imprinted sensor based on a carbon quantum dot / a hollow nickel base material composite film modified glassy carbon electrode. The preparation method comprises the following steps of firstly depositing a Ni-Cu alloy layer in a three-electrode system, and thendealloying and removing copper to obtain a nano hollow nickel sphere layer; preparing an environment-friendly carbon quantum dot solution by adopting a biomass material, and modifying a glassy carbonelectrode coated with a nano hollow nickel sphere by using a composite solution of the carbon quantum dot and chitosan; and taking 3-aminophenylboronic acid as a functional monomer, and preparing themolecular imprinted sensor which has specific recognition response to the template molecular glucose on the surface of the glassy carbon electrode modified by a composite film through an electrochemical polymerization method. The preparation method of the molecularly imprinted sensor based on the carbon quantum dot / the hollow nickel base material composite film modified glassy carbon electrode provided by the invention effectively improves the active area and the electron transport performance. Combined with the molecular imprinting technology, the molecularly imprinted sensor with specific recognition response to glucose is prepared, and the molecularly imprinted sensor has the advantages of being simple in operation, low in cost, high in selectivity and sensitivity, and is expected to bepractical.

Owner:JIANGSU UNIV

Indium-based two-component or three-component nanocatalyst as well as preparation and application thereof

InactiveCN106890639AEasy to operateMild conditionsGas treatmentDispersed particle separationIridiumNano catalyst

The invention relates to a supported type or non-supported type indium-based two-component or three-component nanocatalyst. The second or third component catalyst is one of platinum, palladium, gold, iridium, copper, silver, tin and lead, and in the catalyst, the molar ratio of indium to the second component or the total molar sum of the second component and the third component is 9 / 1-1 / 9; and when the catalyst is a carbon supported indium-based two-component or three-component nanocatalyst, metals in the catalyst account for 10-90% of the total mass of the catalyst. Preparation steps of the catalyst are as follows: introducing inert gas into prepared precursor solution, reducing, washing, and drying, so that the catalyst is obtained. The catalyst is a CO2 electrochemical reduction catalyst, a NOx removal catalyst and an organic molecule aqueous phase allylation catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

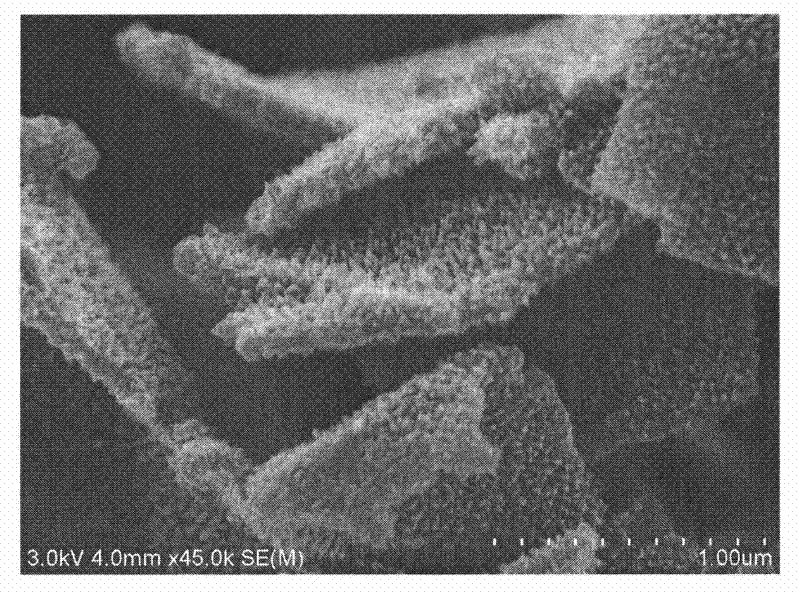

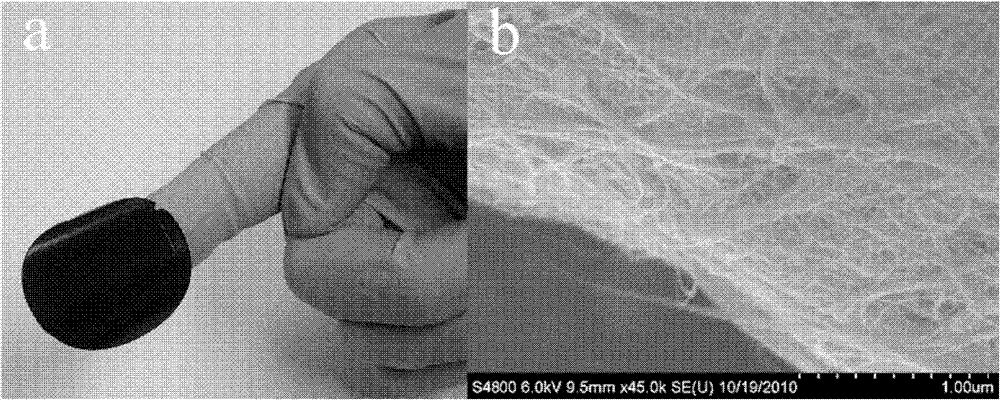

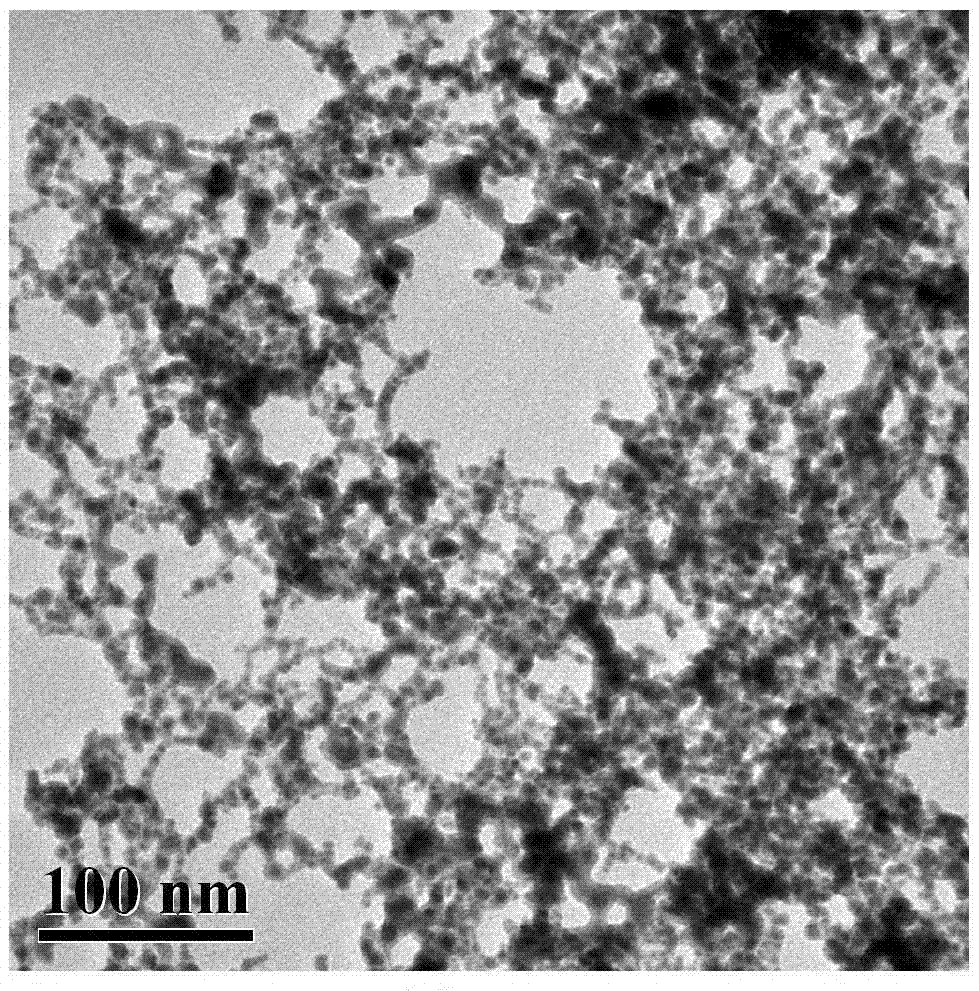

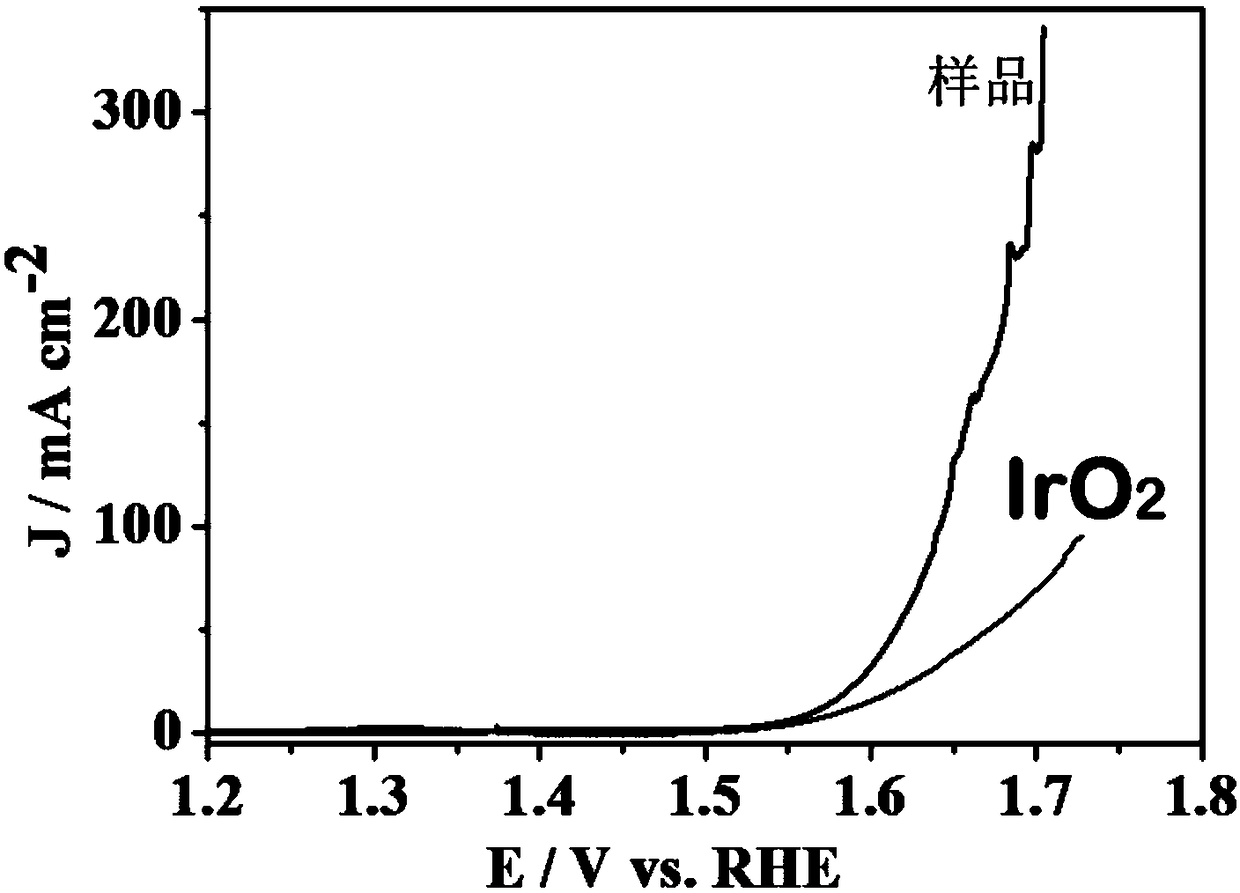

Carbon-containing nickel-cladded single-walled carbon nanotube composite, and preparation method and application thereof

ActiveCN108220997ALow costEasy to operateMaterial nanotechnologyElectrodesElectronic transmissionElectrolysis

The invention belongs to the field of energy catalytic materials and particularly relates to a carbon-containing nickel-cladded single-walled carbon nanotube composite, and a preparation method and application thereof. An electrolysis water catalyst for the carbon-containing nickel-cladded single-walled carbon nanotube composite is prepared by one-step synthesis through a DC arc method. The wholeprocess is easy and convenient to operate and easy to carry out. Graphite, nickel metal and alloy are used as main raw materials. The electrolysis water catalyst is low in cost and beneficial to large-scale preparation. The prepared electrolysis water catalyst has a natural porous net structure with single-walled carbon nanotubes serving as a network framework. The electrolysis water catalyst is good in electric conductivity and quite beneficial to electronic transmission and gas precipitation in the electrolysis water reaction process. The composite as the electrolysis water anode catalyst has more excellent catalytic activity than an iridium oxide catalyst commonly used in the industry and also has the hydrogen evolution catalytic activity.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

A flow guiding polarized plate of fuel battery

The invention relates to guiding board of fuel battery, said guiding board is guiding two-way board, said guiding two-way board comprises positive air guiding groove board; negative hydrogen guiding groove board and middle cooling flow interlayer, said guiding two-way board possesses flow hole for air, hydrogen, cooling liquid and guiding groove which is connected between flow holes; said flow hole which air or hydrogen in and out is single hole for in, two or more hole for out, the guiding groove which is designed between air or hydrogen holes is designed to direct flow groove or nearly direct flow groove; said flow hole for cooling liquid is single hole or double holes or more holes for in, two holes or more holes for out, guiding groove which is set between flow hole for cooling liquid is designed to direct flow groove or nearly direct flow groove. Comparing with current technique, the invention can decrease resistance and pressure reduction, liquid can flow on liquid field evenly, effective area can be increased; jam of guiding groove can be avoided.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

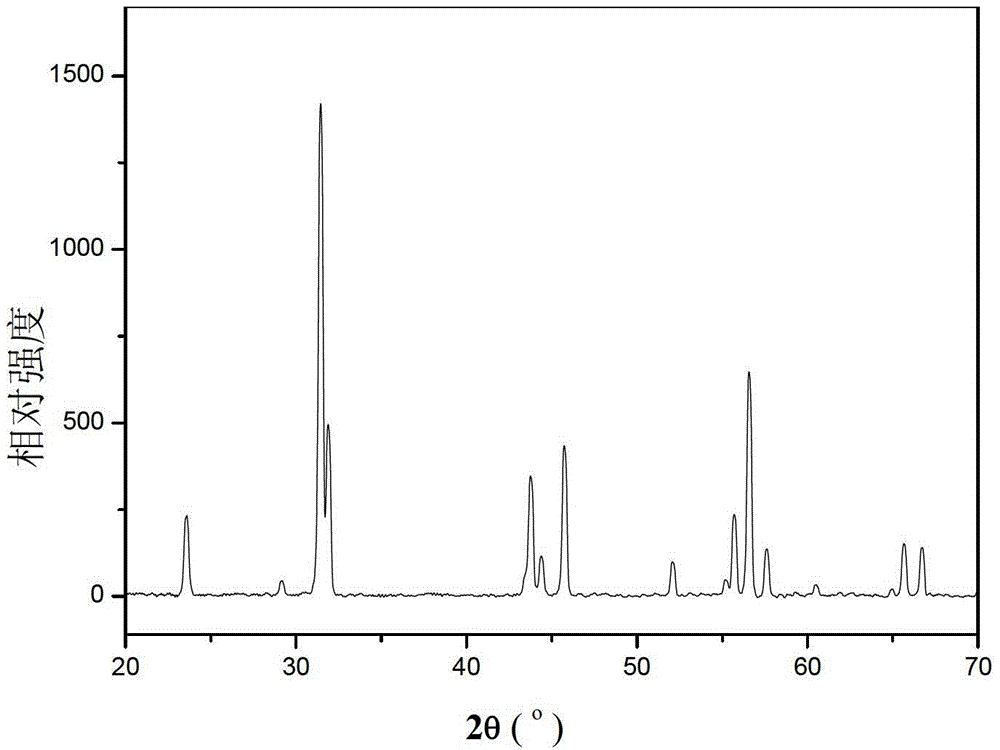

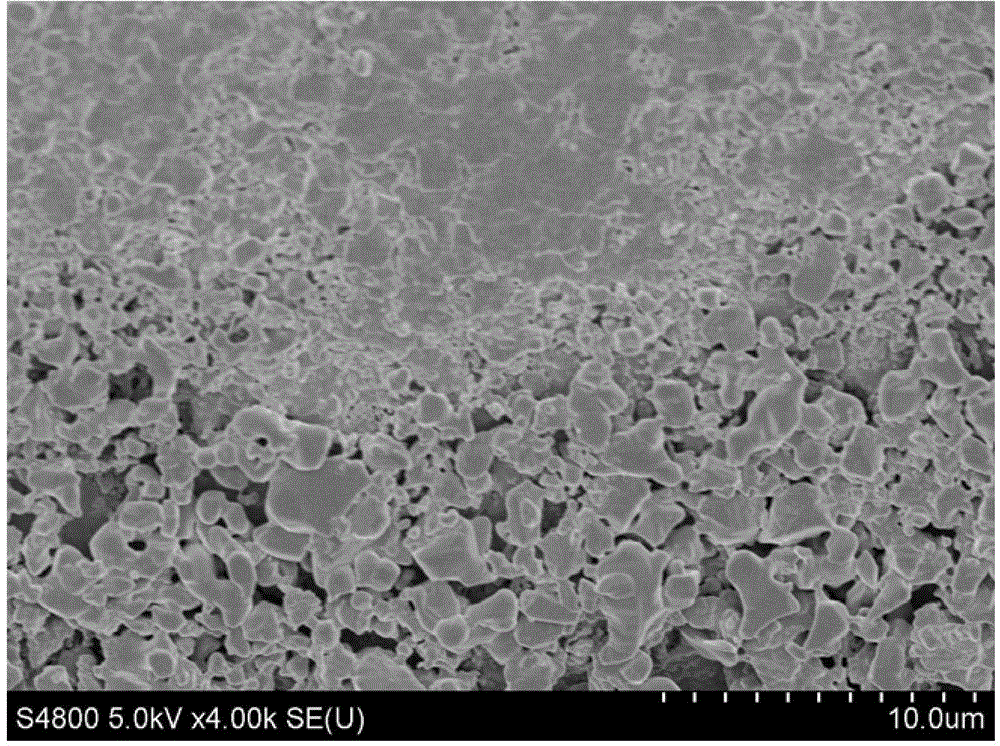

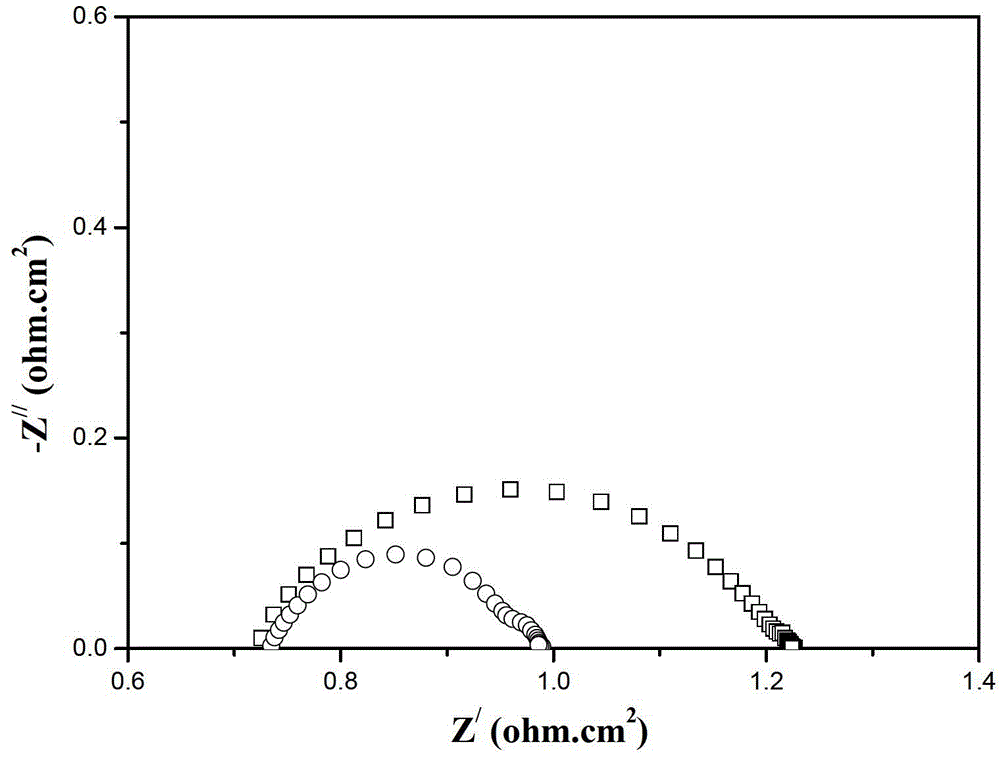

Solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 and preparation method thereof

InactiveCN103151533AImprove electrochemical performanceIncreased mixed conductivityCell electrodesComposite cathodeFuel cells

The invention relates to a solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 and a preparation method thereof. The invention relates to a cell composite cathode material and a preparation method thereof, aiming at solving the problem that the catalytic activity and electro-chemical property of the cathode material are pool. The solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 is made of Ln2CuO4 and solid electrolyte Ce0.9Gd0.1O1.95; the method comprises the steps of: I. weighing; II. preparing mixed stock; III. preparing a prefabricated body; and IV. preparing the solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95. According to the solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 and the preparation method thereof, the reaction active site of the cathode is extended into the overall cathode material, the active region of the oxygen reduction reaction can be enlarged, and the electrochemical property of the cathode can be improved. The preparation method is used for preparing solid oxide fuel cell composite cathode.

Owner:HEILONGJIANG UNIV

Iron-doped copper sulfide nanosheet material with rich defects and preparation method and application thereof

The invention discloses an iron-doped copper sulfide nanosheet material with rich defects and a preparation method and application thereof. The method comprises the following steps of adding a coppersalt solution into a thiourea solution, and rapidly forming a white floccule solution during stirring; mixing a ferrous salt solution with the white floccule solution under stirring, conducting stirring for 15 minutes, then transferring the solution into a reaction kettle, conducting a hydrothermal reaction for 12-15 hours at 140-160 DEG C, and conducting centrifugation, washing and drying to obtain the material. The iron-doped copper sulfide nanosheet material has the advantages that the iron-doped copper sulfide nanosheet material with the rich defects coats foamed nickel and serves as a working electrode material for electrolyzing water, the high stability and a large specific surface area are achieved, a larger activity area is provided, and therefore the water can be fast and efficiently electrolyzed.

Owner:ANHUI NORMAL UNIV

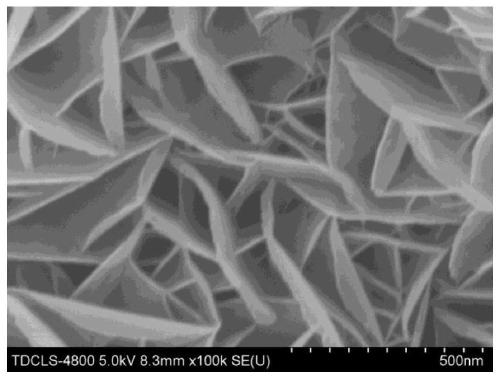

Self-supporting doped metal hydroxide nanosheet electrode material, and preparation method and application thereof

InactiveCN110468427AAchieving Density ActivityImprove cycle stabilityMetal/metal-oxides/metal-hydroxide catalystsElectrodesElectrolysisHydrogen

The invention discloses a self-supporting doped metal hydroxide nanosheet electrode material. The material includes: a conductive matrix; and an active material layer, wherein the active material layer is a self-supporting doped metal hydroxide nanosheet, is anchored to the surface of the conductive matrix, and supports and outwardly extends at a certain cross angle. The invention also discloses apreparation method of the self-supporting doped metal hydroxide nano-sheet electrode material, and an application of the material in industrial water electrolysis, for producing hydrogen and oxygen,under a large current density. The self-supporting ultrathin doped metal hydroxide nanosheet electrode material of the present invention can realize the electrolytic water current density activity of500 mA / cm<2> or more and a good cycle stability when used in electric water activity.

Owner:TIANJIN UNIV

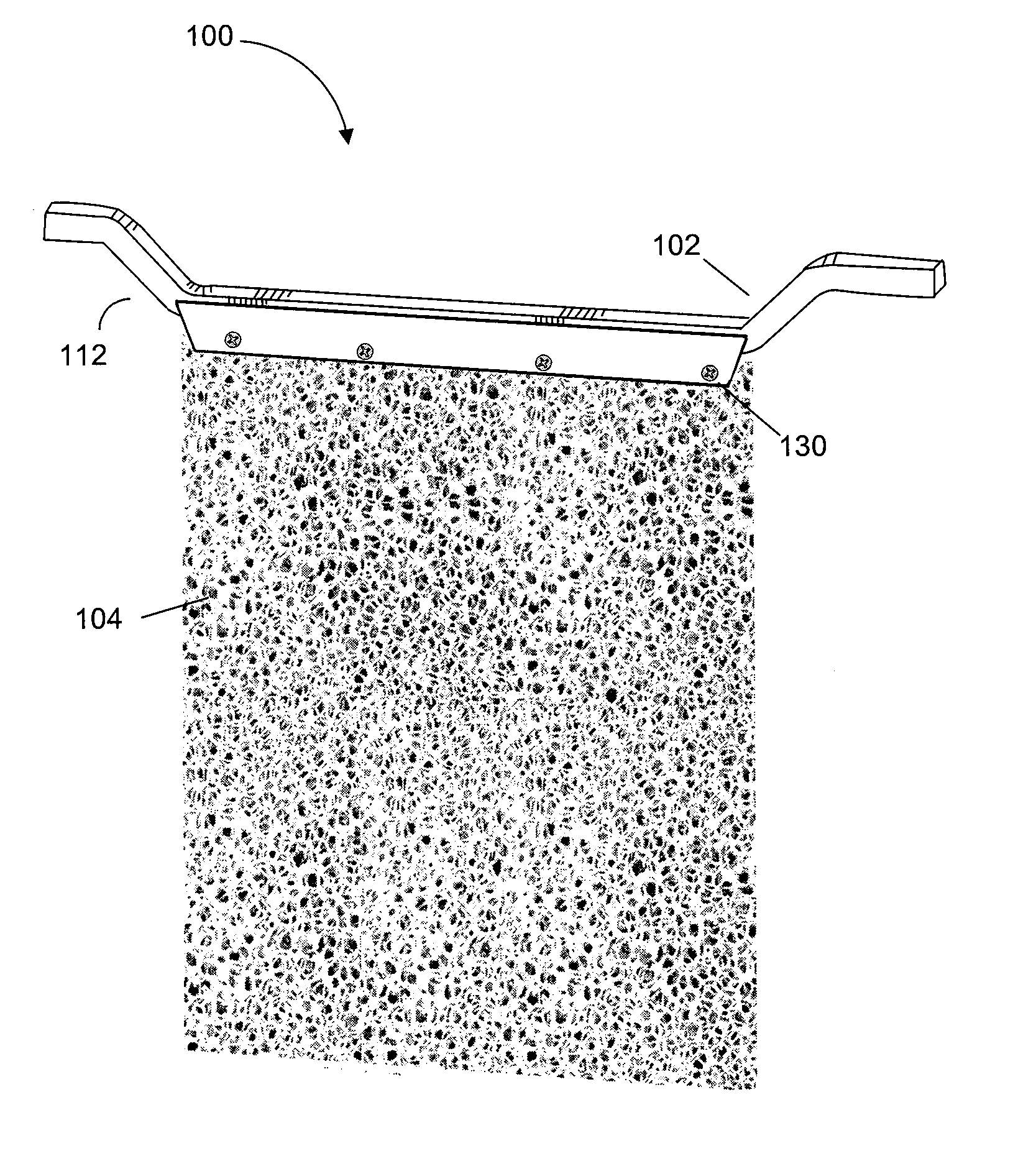

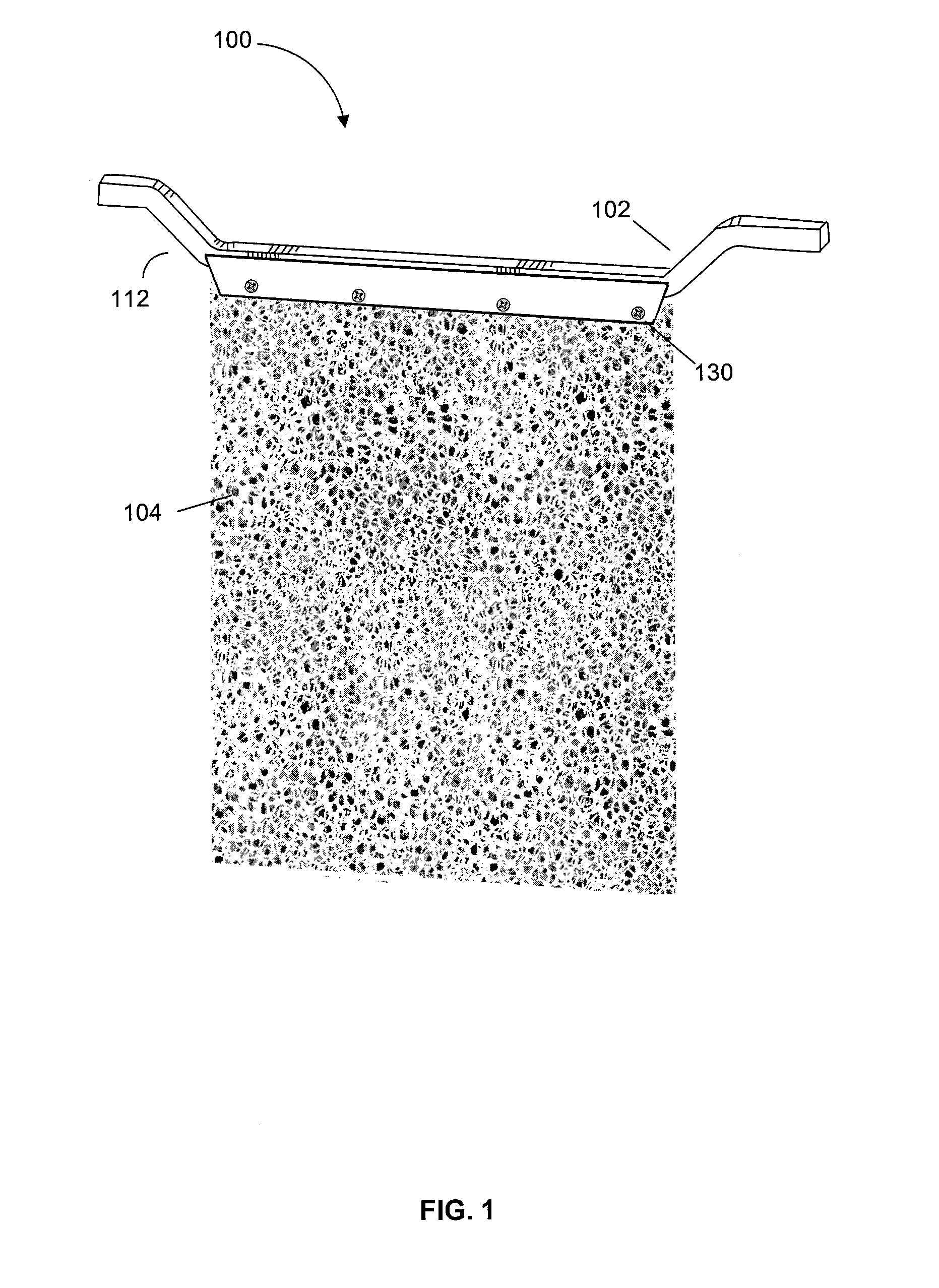

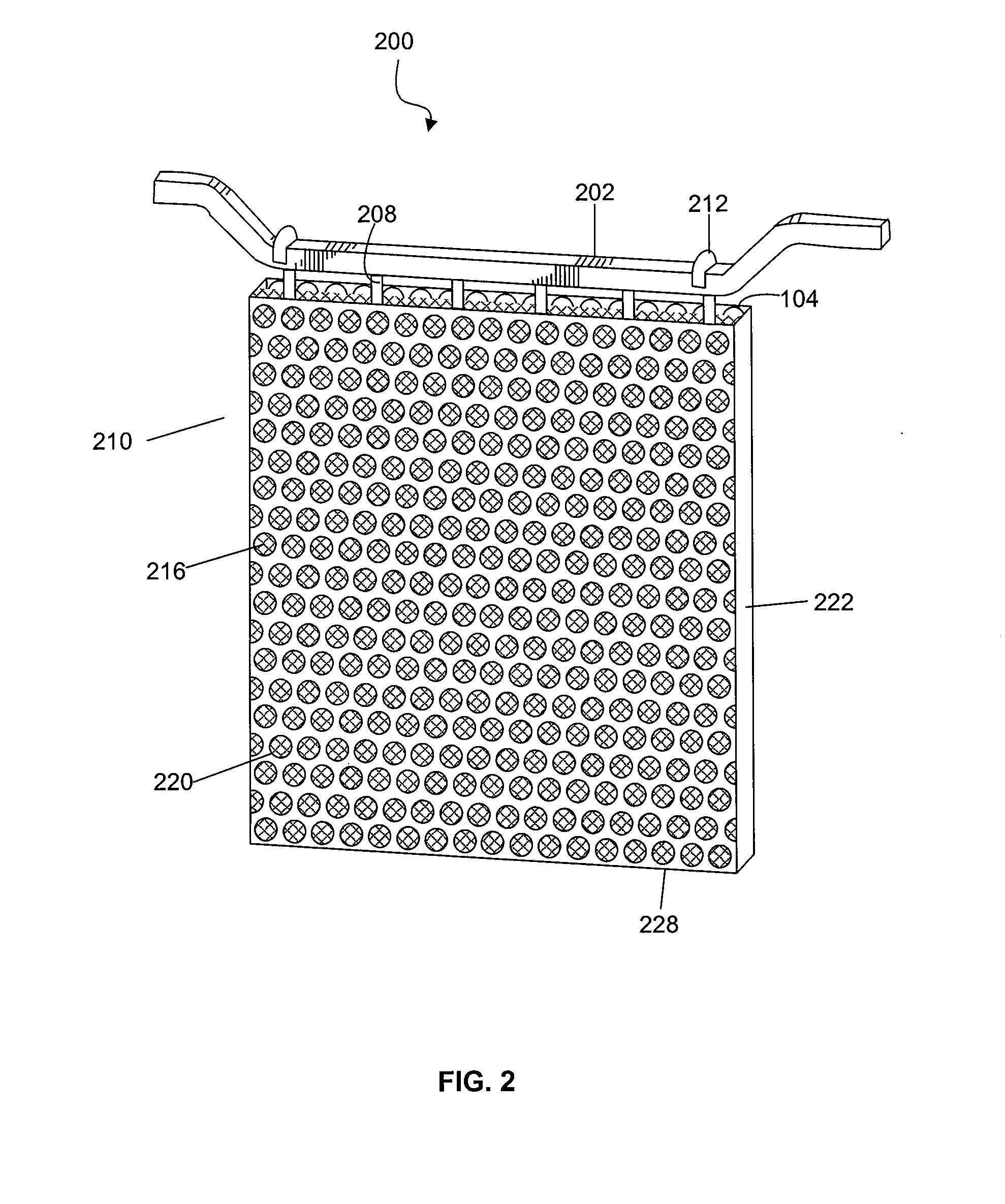

High surface area cathode assembly, system including the assembly, and method of using same

InactiveUS20130153435A1Increase active areaImprove efficiencyMachining electrodesCellsEngineeringElectron

A cathode assembly, a system including the cathode assembly, and method of using the assembly and system are disclosed. The cathode assembly includes high surface area material to allow efficient recovery of metal at reduced current densities at the cathode, which allows increased rates of metal recovery to be obtained, while maintaining desired properties of the electrowon metal.

Owner:FREEPORT MCMORAN COPPER & GOLD INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com