Carbon-based composite electrode material and preparation method thereof, and application of the carbon-based composite electrode material to super capacitor

A composite electrode, carbon-based material technology, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of cumbersome process, easily damaged templates, and insufficient charge-discharge cycle stability of polymer electrode materials, so as to improve the active area. , The effect of good charge-discharge cycle stability and high capacitance capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This example is used to illustrate the preparation method of the carbon-based composite electrode material of the present invention.

[0049] The concentration to 20mL is 1molL -1 HClO 4 Add aniline monomer (Sinopharm Group Chemical Reagent Co., Ltd., analytically pure) to the aqueous solution to obtain a concentration of 0.1molL -1 Aniline monomer solution.

[0050] The graphene dispersion is prepared through the following process: first, natural graphite is oxidized to graphene oxide by the Hummers method. The process is to mix 5g of flaky natural graphite (Sinopharm Chemical Reagent Co., Ltd.) and 2g of sodium nitrate (Sinopharm Chemical Reagent Co., Ltd.), and add 120mL of concentrated sulfuric acid (98wt%, Sinopharm Chemical Reagent Co., Ltd.) . Stir in an ice bath, and slowly add 15 g of potassium permanganate. After 2-3 hours of reaction, add 300 mL of deionized water to the reaction solution, raise the temperature to 100° C. and continue the reaction for 30 ...

Embodiment 2

[0053] This example is used to illustrate the preparation method of the composite electrode material of the present invention.

[0054] The concentration to 20mL is 1.5molL -1 HClO 4 Add aniline monomer (Sinopharm Group Chemical Reagent Co., Ltd., analytically pure) to the aqueous solution to obtain a concentration of 0.1molL -1 Aniline monomer solution.

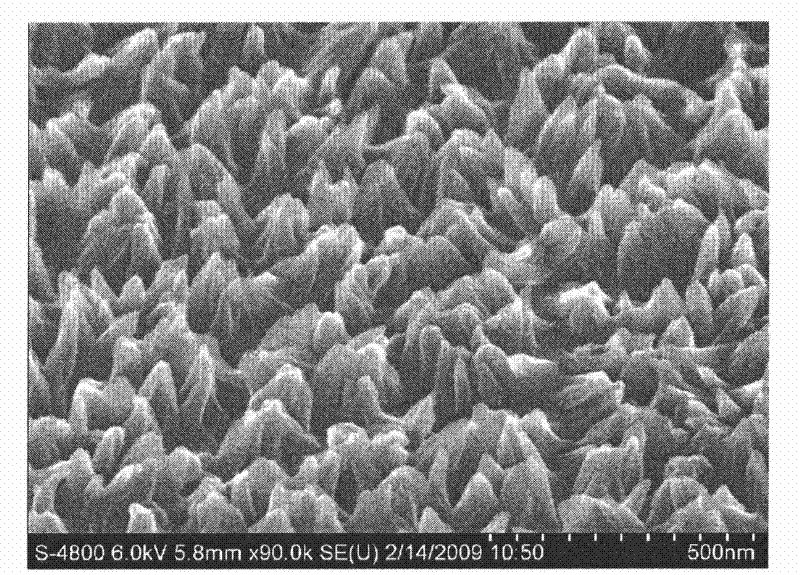

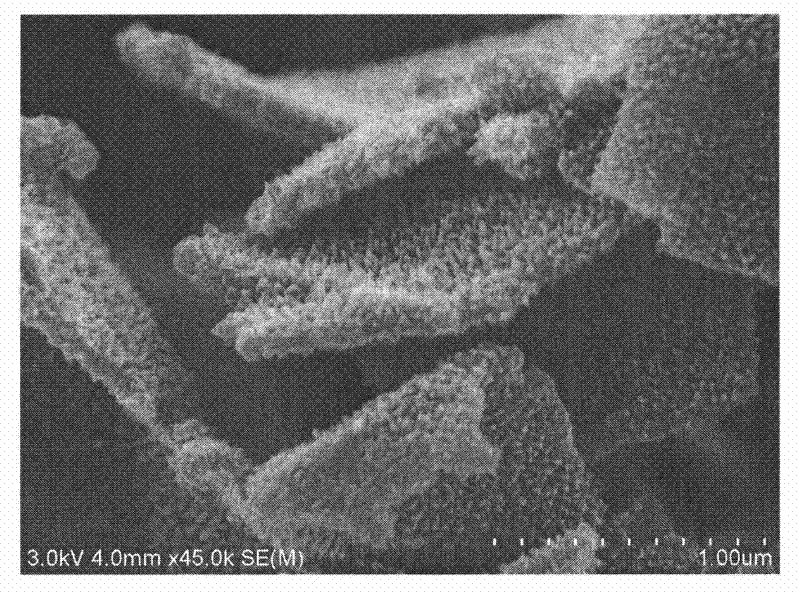

[0055] At a temperature of 25 °C, commercial carbon paper (10 × 30 mm, 0.19 mm, Toray carbon paper, Japan Toray Co., Ltd., Toray carbon paper) was used as the working electrode, and a Pt sheet (15 × 30 mm, 0.2 mm) was used as the counter electrode. A mercury electrode is used as a reference electrode, and the above-mentioned aniline monomer solution is used as an electrolyte, and a constant current method is adopted, and the current density is 0.01mAcm -2 , energized for 2 hours, a layer of green polyaniline nanowire array (can be seen by scanning electron microscope) was deposited on the surface of the working electrode....

Embodiment 3

[0057] This example is used to illustrate the preparation method of the carbon-based composite electrode material of the present invention.

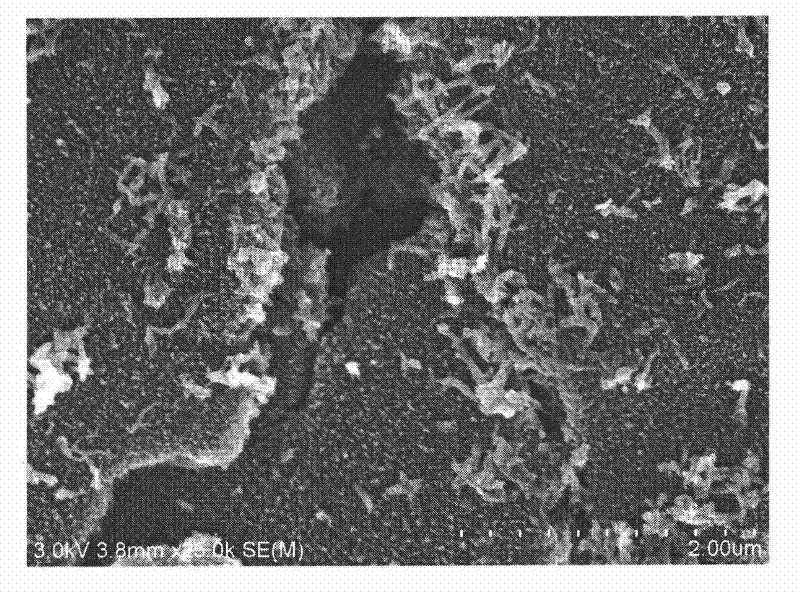

[0058] The concentration to 20mL is 1molL -1 HClO 4 Add aniline monomer (Sinopharm Group Chemical Reagent Co., Ltd., analytically pure) to the aqueous solution to make its concentration 0.05molL -1 . To which adding 9mL concentration is 1mg / mL graphene oxide dispersion solution (prepared according to the method described in Example 1), then adding oxidant ammonium persulfate, making its concentration 0.034molL -1 . The reaction was stirred for 24 hours at a temperature of -10°C. After the reaction, filter and separate the solid sample, and use a concentration of 0.1molL -1 HClO 4 The solution washed the sample three times (5 mL each time) to obtain a composite electrode material of polyaniline and graphene oxide deposited on the surface of graphene oxide with a layer of polyaniline nanowire arrays. It can be estimated from the ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com