Patents

Literature

129 results about "Polymer electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

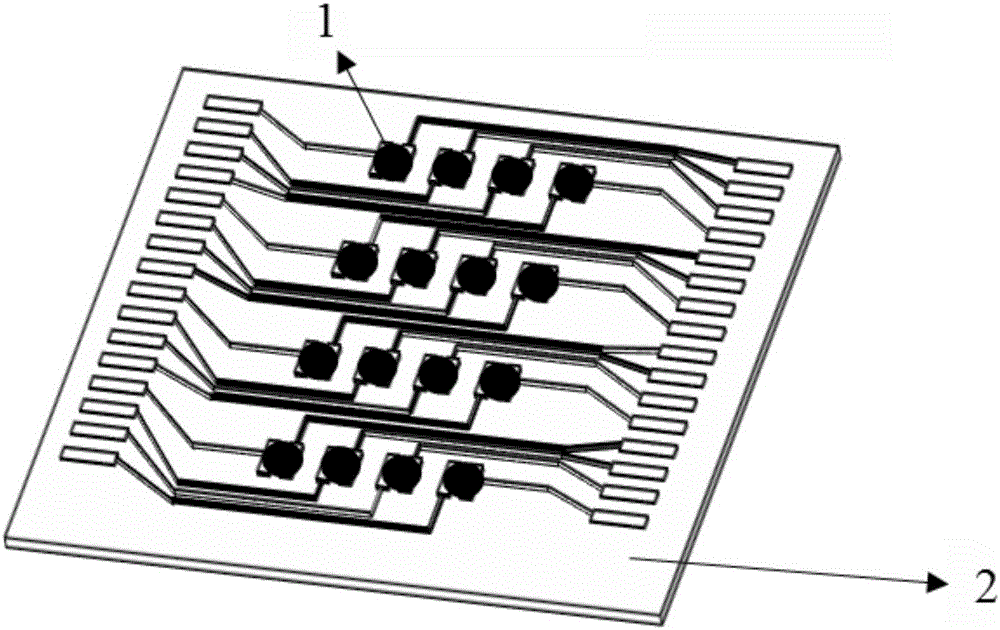

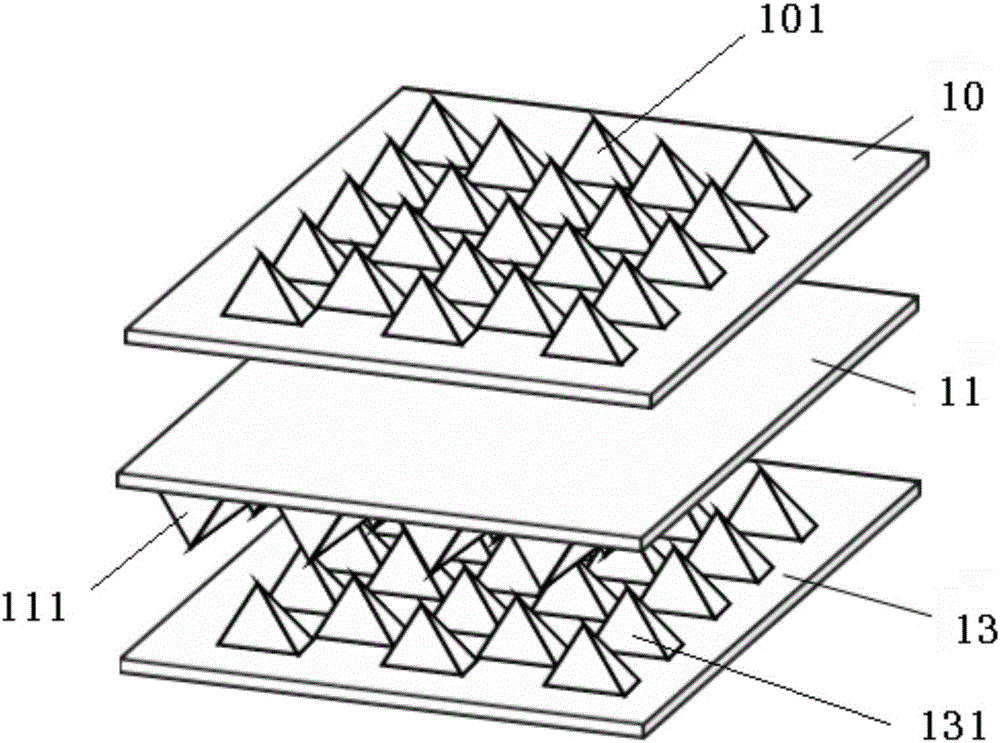

Flexible piezoresistive touch sensor array and preparation method thereof

ActiveCN106197774AIncreased pressure sensitivityImprove electrical isolationForce measurement using piezo-resistive materialsSensor arrayLow voltage

The invention provides a flexible piezoresistive touch sensor array and a preparation method thereof. The sensor array comprises N*N separated piezoresistive layers and a coplanar electrode layer. The piezoresistive layers are arranged on the coplanar electrode layer. Each piezoresistive layer comprises an upper finger pressing layer, a middle sensitive layer and a bottom sensitive layer, wherein the three layers are each provided with a micro pyramid; the coplanar electrode layer comprises a polymer electrode substrate and N*N gold electrode pairs located on the polymer electrode substrate. The piezoresistive layers adopt polymer films with the micro pyramid, and due to the three-layer structure, the sensitivity of the sensor at the low-voltage region can be greatly improved. In addition, in order to overcome the defect that a traditional touch sensor is large in crosstalk due to a sandwiched structure, the coplanar electrode layer is adopted, all electrodes are located on the same plane, each piezoresistive layer is attached to the corresponding electrode pair, the piezoresistive units are completely separated, and the sensitivity and anti-interference capacity of the sensor are effectively improved.

Owner:SHANGHAI JIAO TONG UNIV

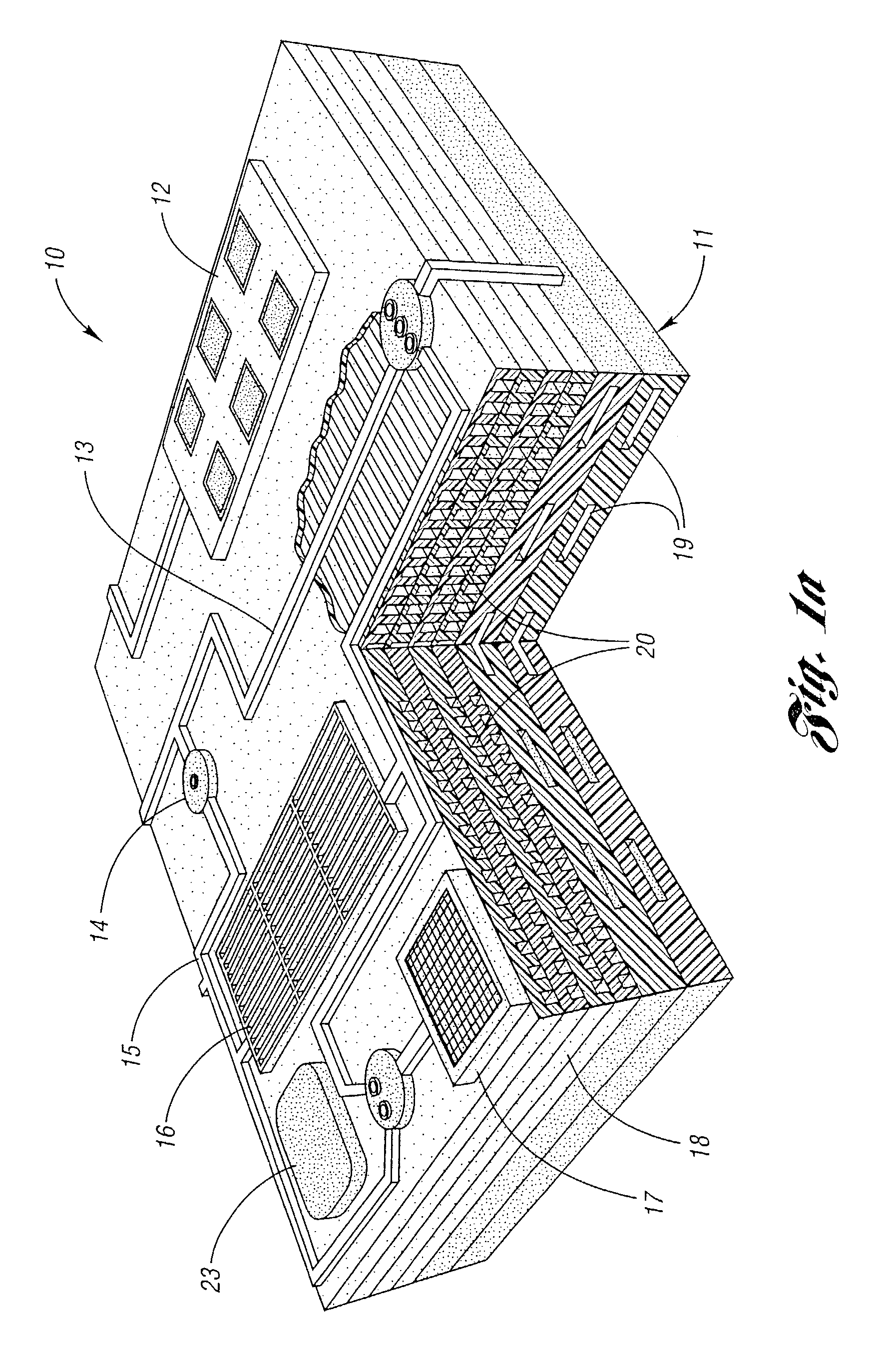

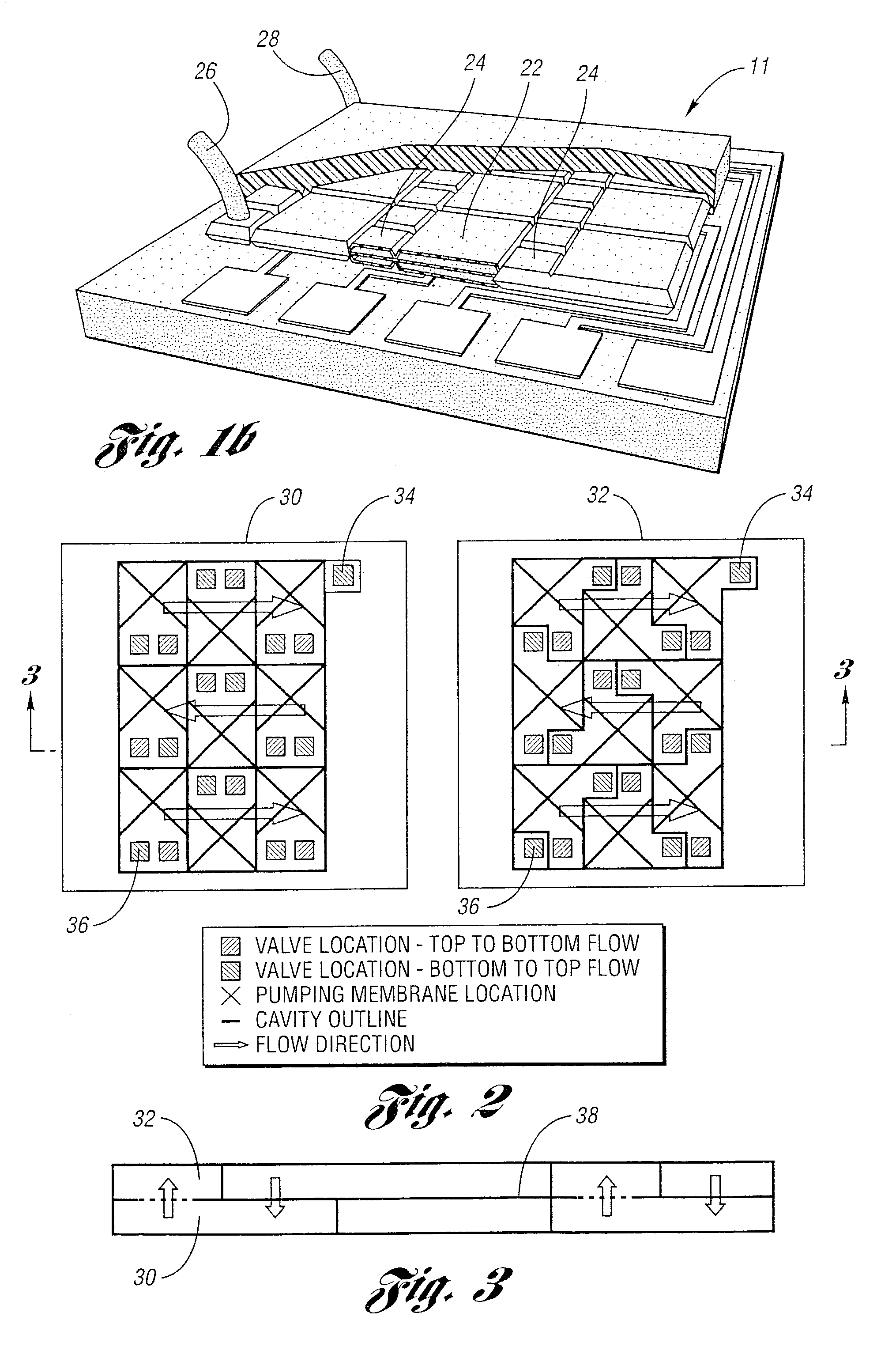

Micropump assembly for a microgas chromatograph and the like

A MEMS-fabricated microvacuum pump assembly is provided. The pump assembly is designed to operate in air and can be easily integrated into MEMS-fabricated microfluidic systems. The pump assembly includes a series of pumping cavities with electrostatically-actuated membranes interconnected by electrostatically-actuated microvalves. A large deflection electrostatic actuator has a curved fixed drive electrode and a flat movable polymer electrode. The curved electrodes are fabricated by buckling the electrode out-of-plane using compressive stress, and the large deflection parallel-plane electrostatic actuators are formed by using the curved electrode. The curved electrode allows the movable electrode to travel over larger distances than is possible using a flat electrode, with lower voltage. The movable electrode is a flat parylene membrane that is placed on top of the curved electrode using a wafer-level transfer and parylene bonding process. Using this approach, large out-of-plane deflection of the parylene membrane is achieved using a voltage smaller than is achievable using flat parallel-plate electrodes.

Owner:RGT UNIV OF MICHIGAN

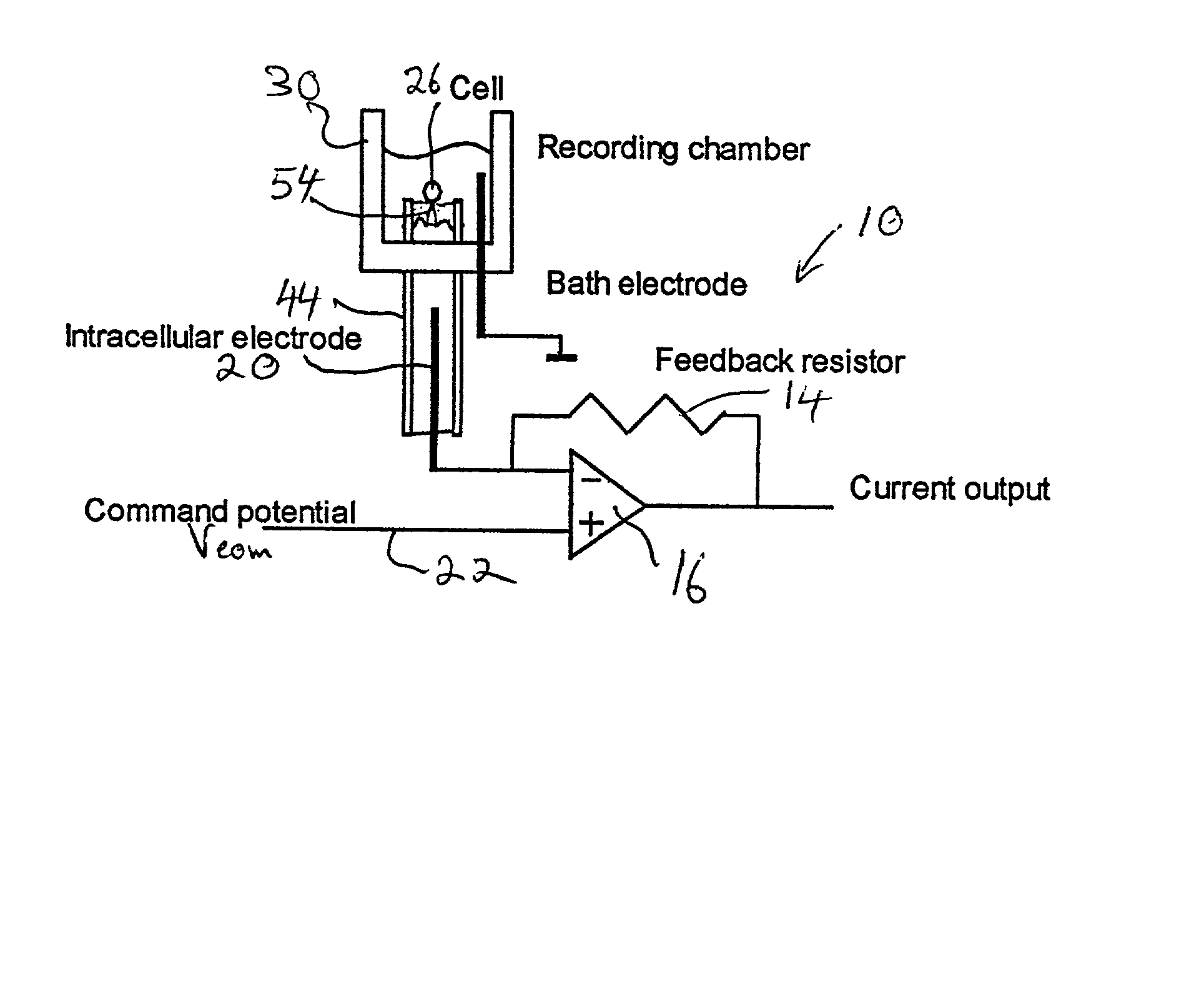

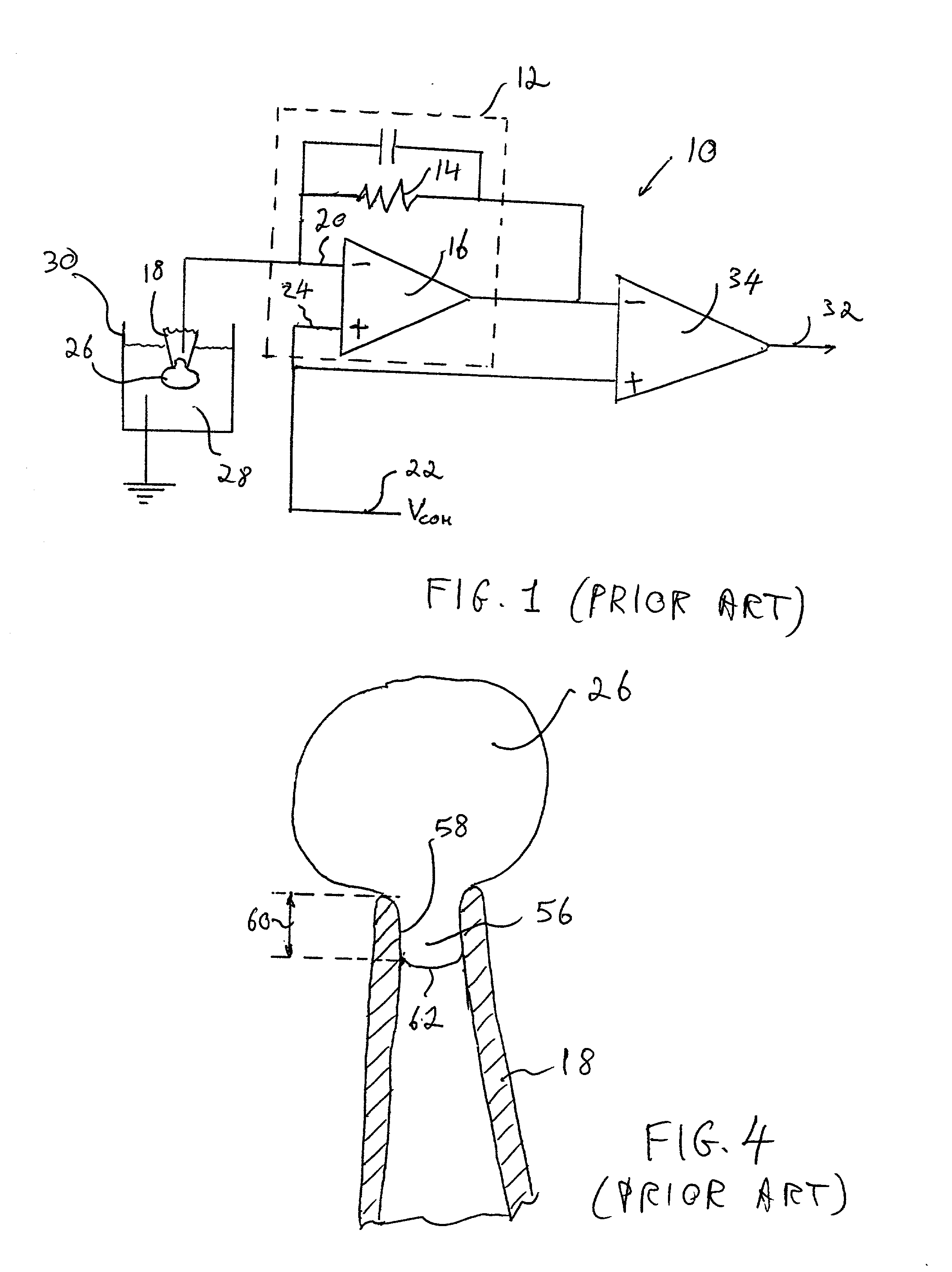

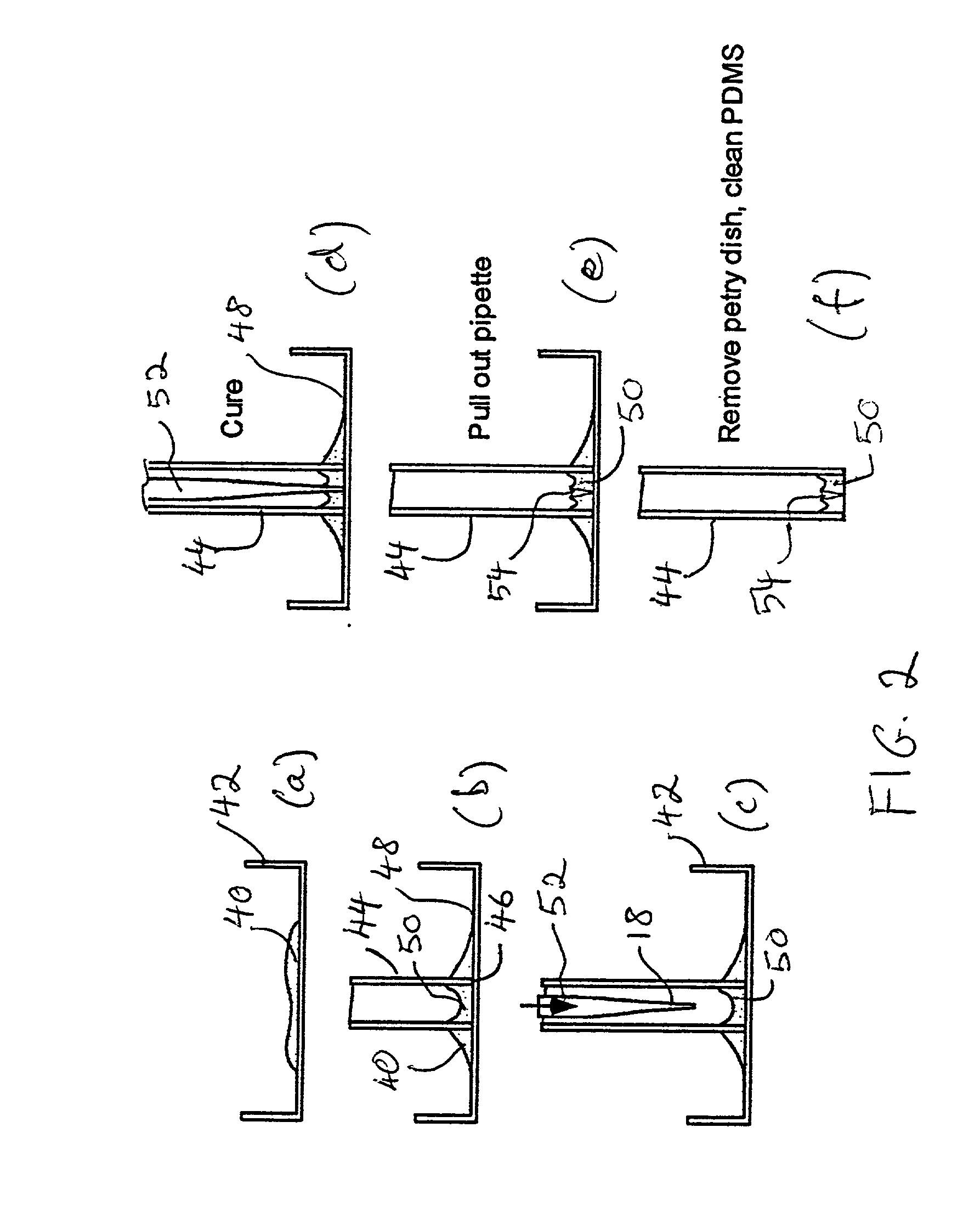

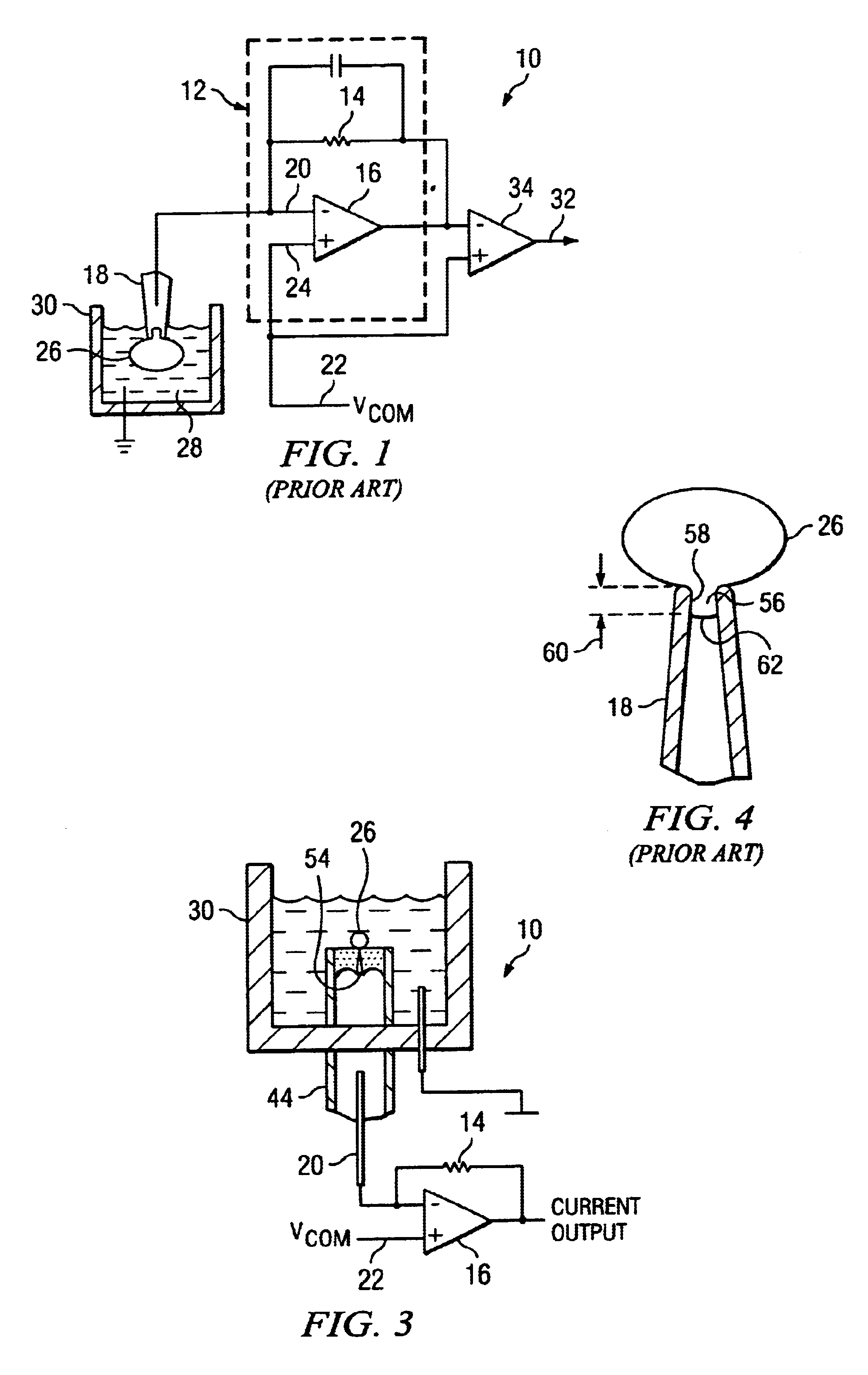

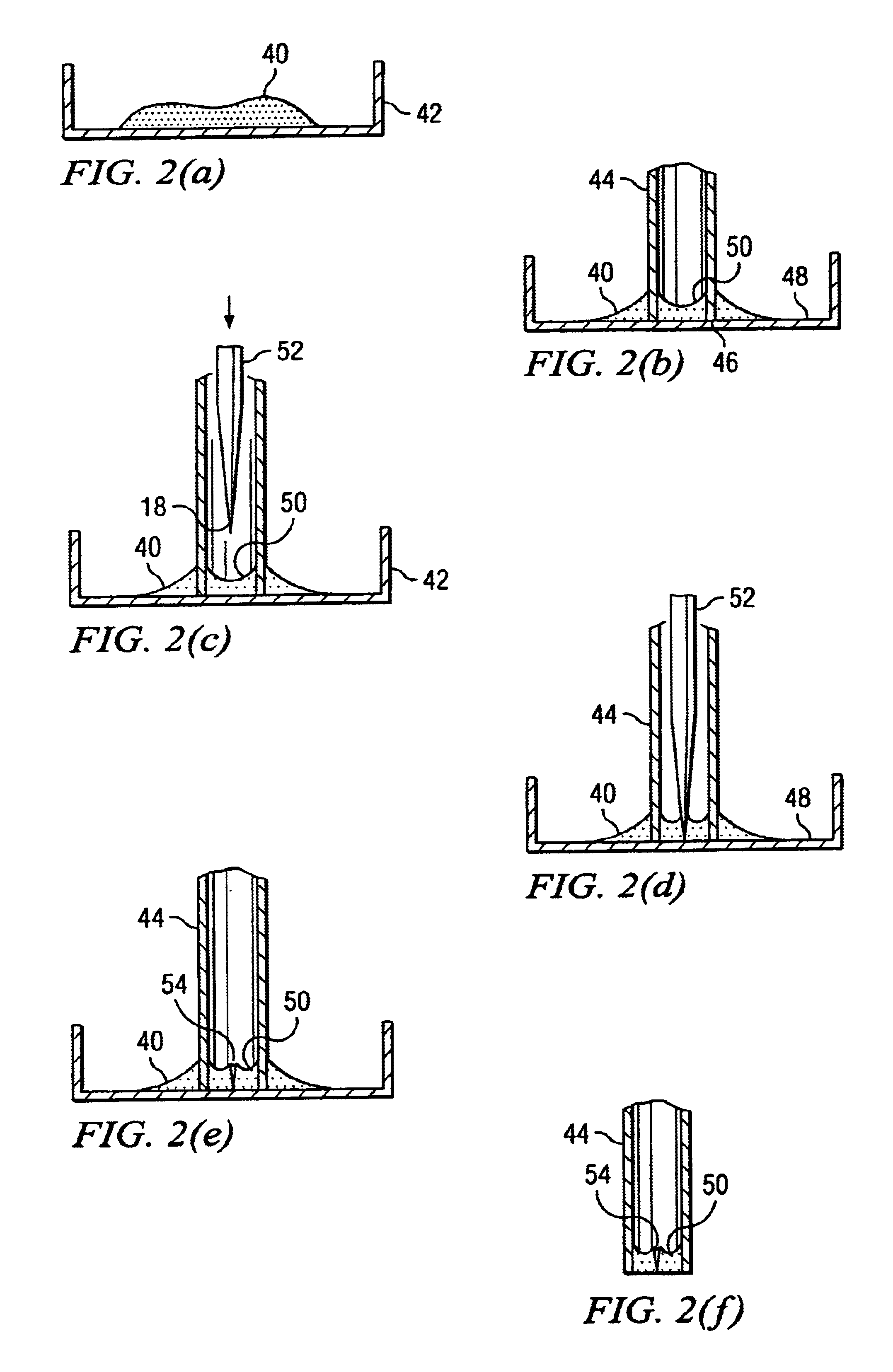

Polymeric electrode for electrophysiological testing

InactiveUS20020195337A1Reduce manual operationsSuitable for useImmobilised enzymesBioreactor/fermenter combinationsBiological membraneBiomedical engineering

A polymeric material such as PDMS is molded into an electrode structure containing a micron-size aperture for receiving and forming a giga-ohm seal with a biological membrane One end of a tube is filled with uncured polymeric material and pressed against a support surface to prevent drainage. A conventional micropipette having a size suitable for sliding through the tube is introduced, tip first, into the tube and is allowed to fall through the polymeric material and rest against the support surface. The assembly is heated to cure the polymer and the micropipette is removed from the tube, thereby leaving a polymeric plug at the end of the tube with an aperture suitable in shape and size for patch-clamp giga-ohm seal electrode applications. A multi-well tray with a polymeric electrode plug in each well is constructed using the same approach.

Owner:MOLECULAR DEVICES

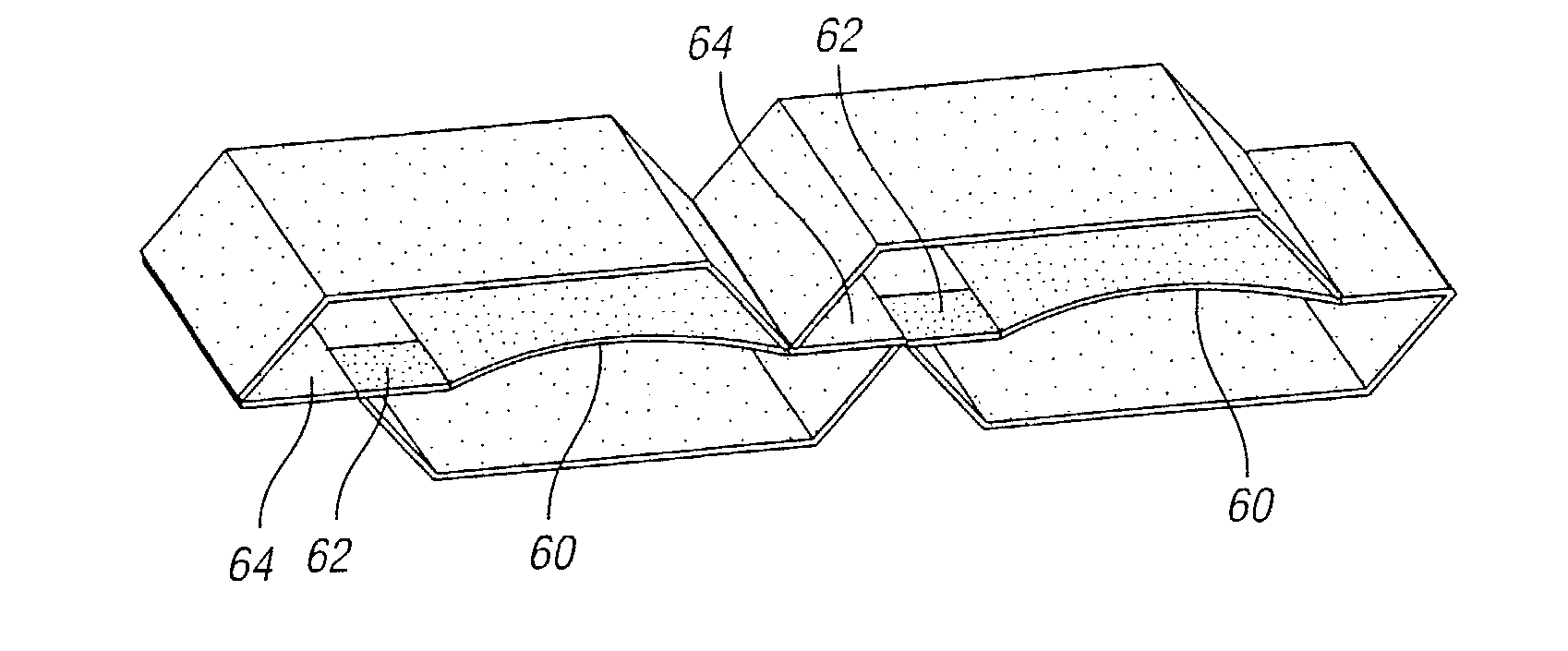

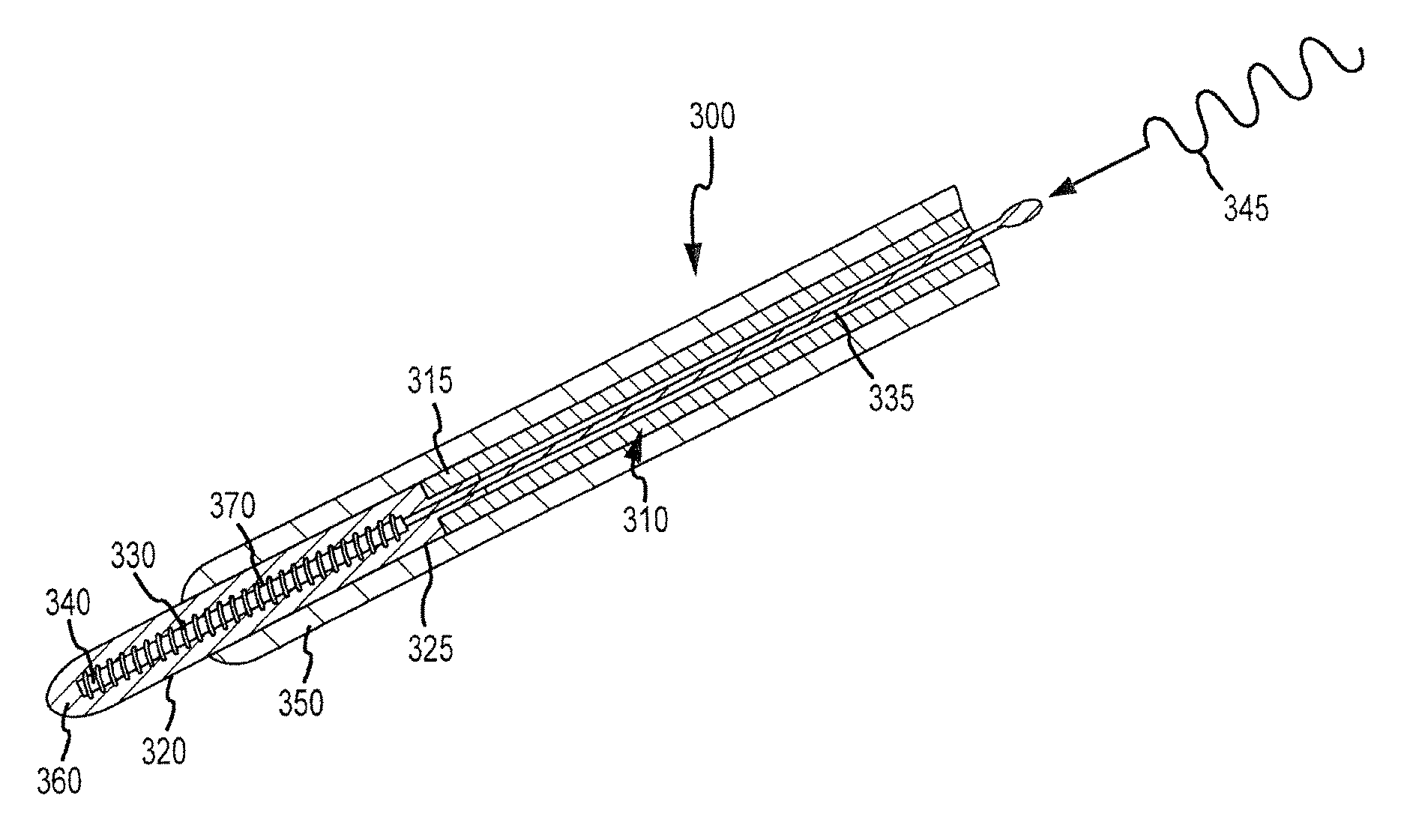

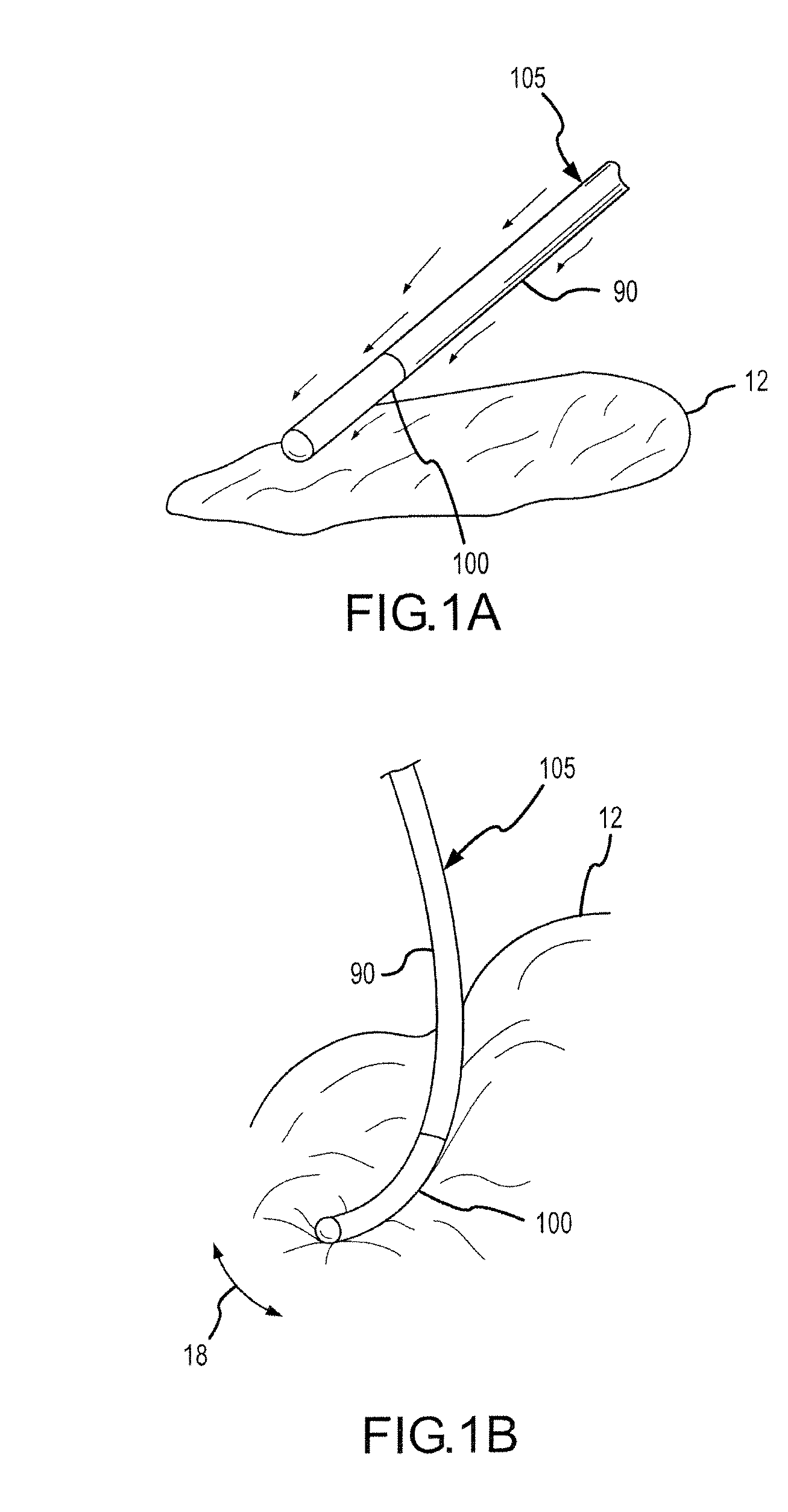

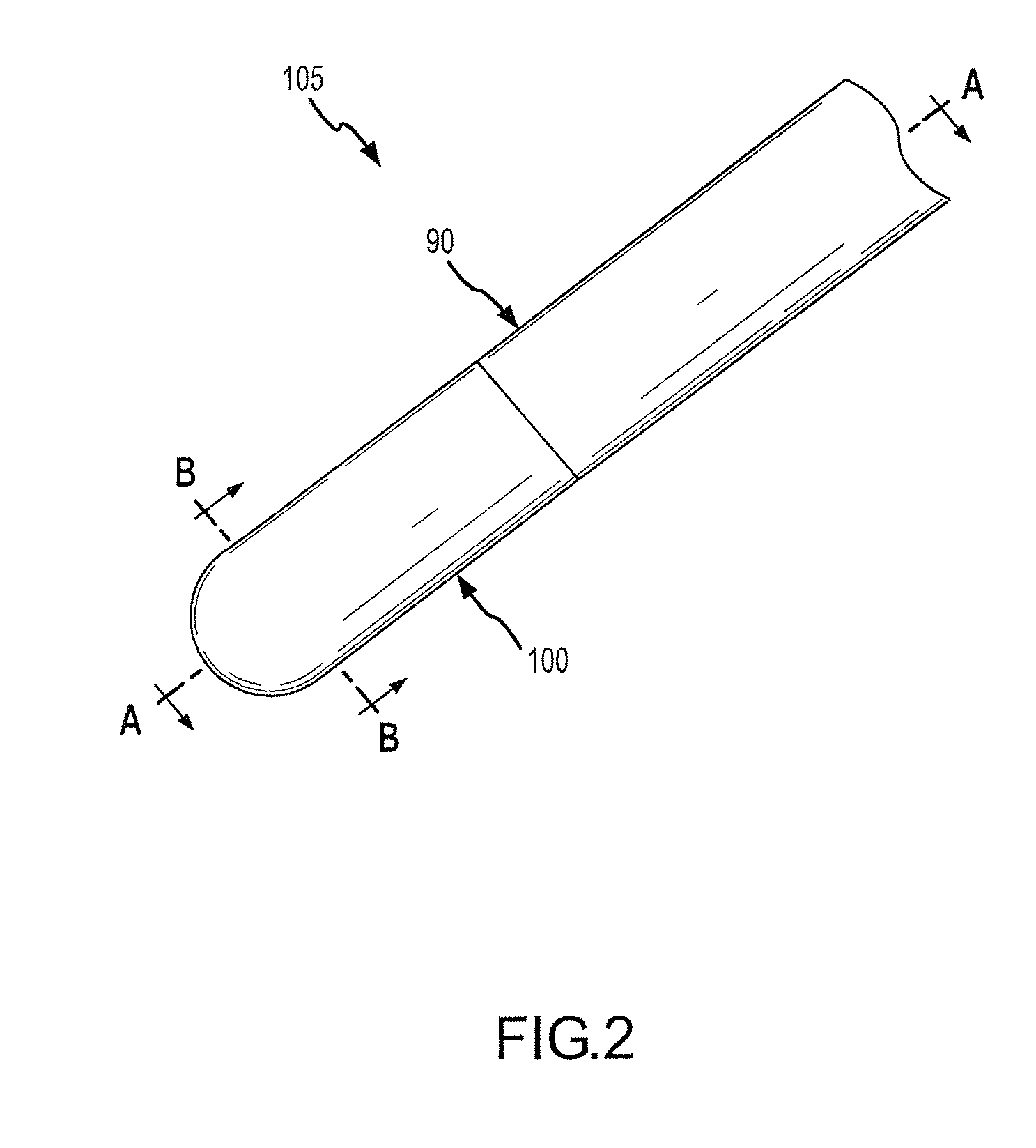

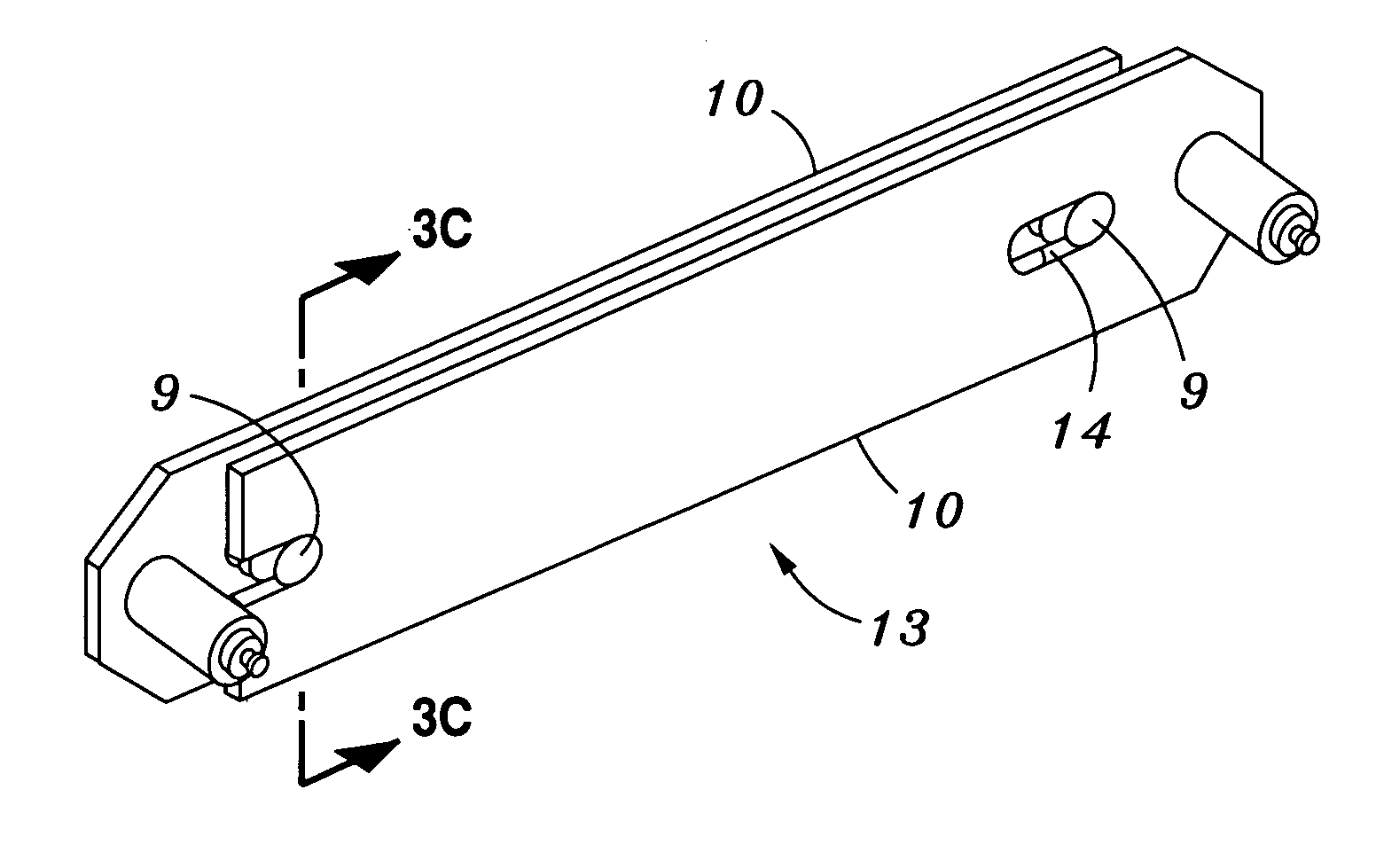

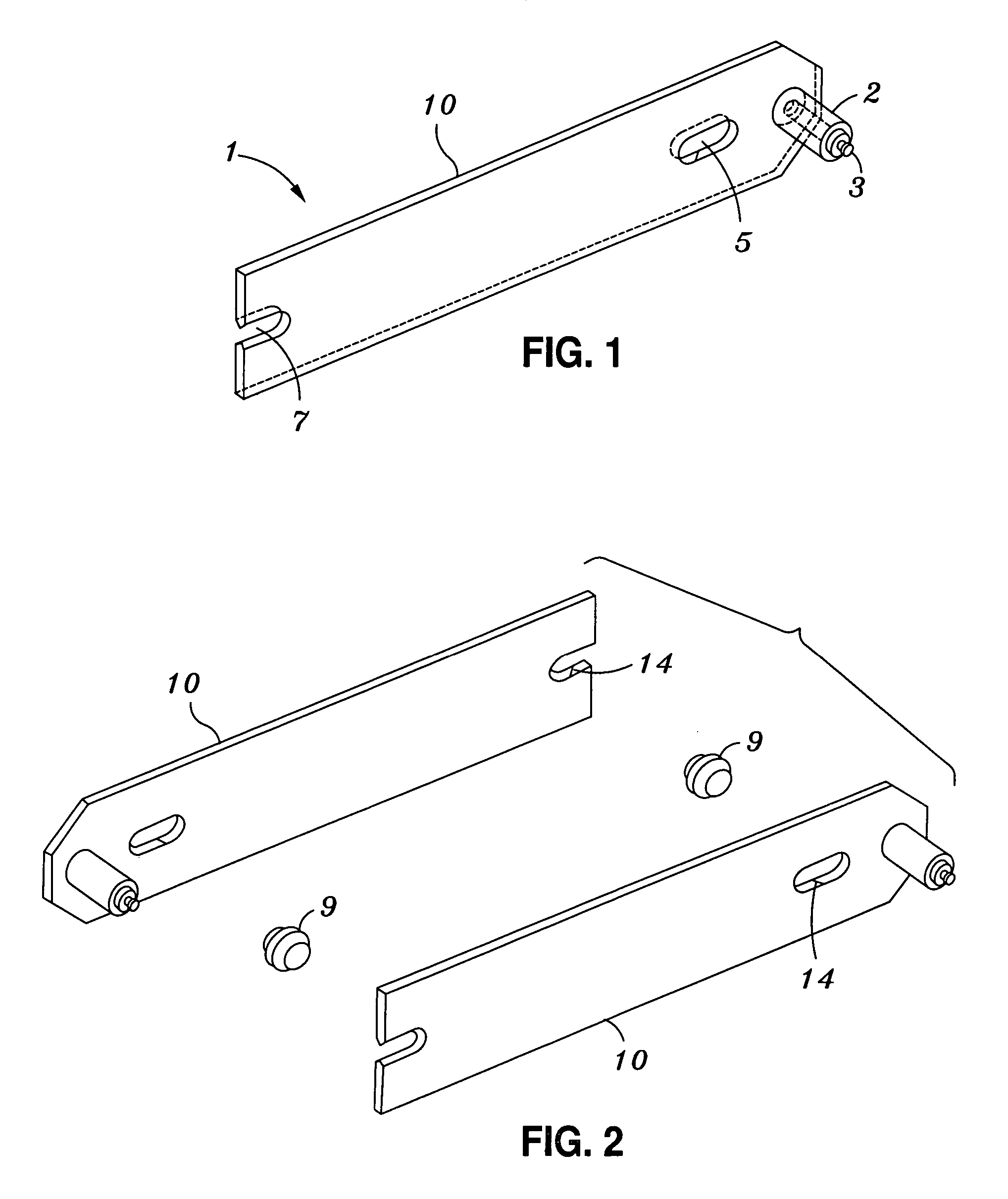

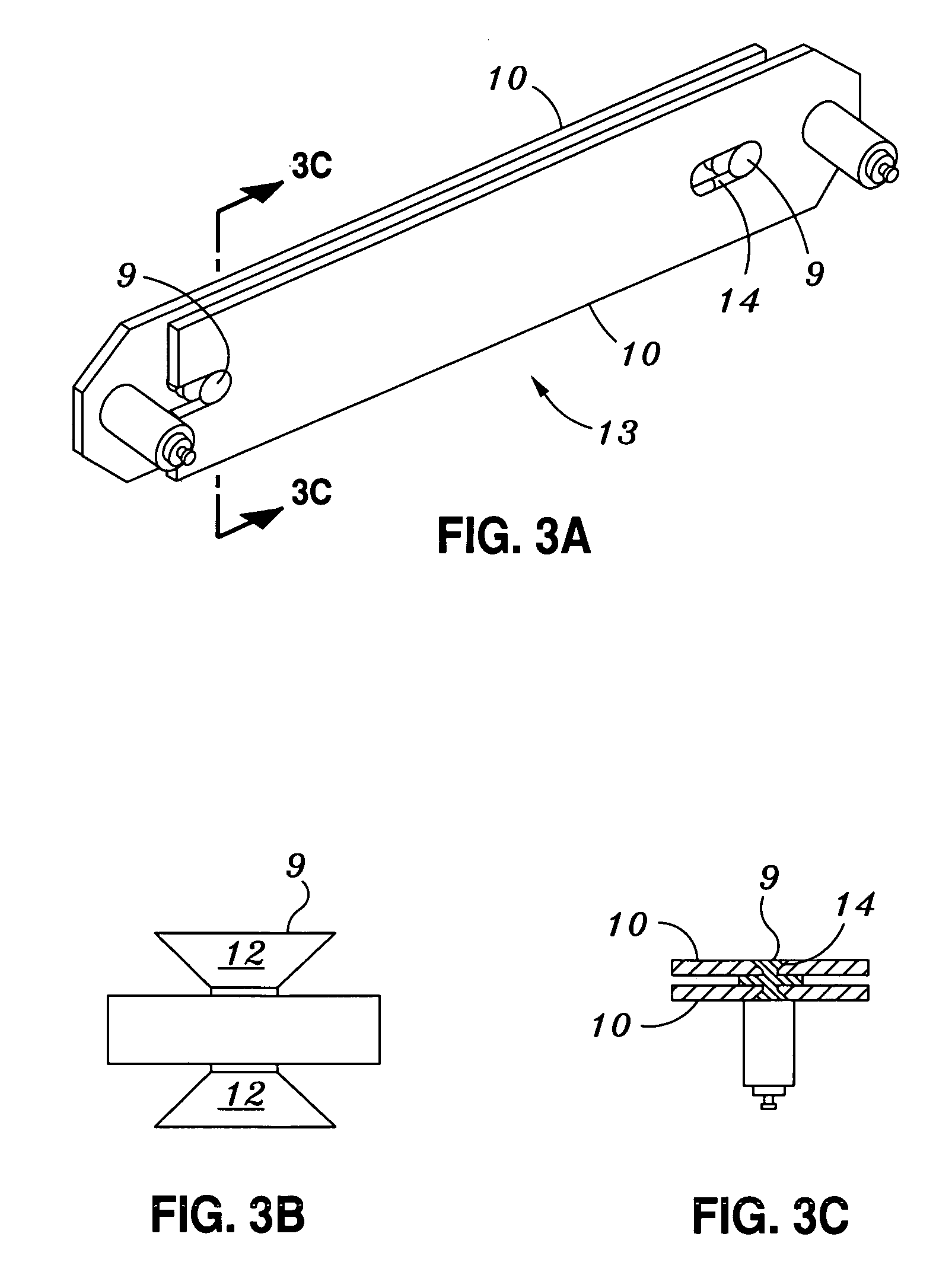

Adjustable length flexible polymer electrode catheter and method for ablation

ActiveUS8500731B2Adjustable lengthImprove abilitiesSurgical instruments using microwavesConductive polymerLinear displacement

An ablation catheter includes a flexible elongated shaft having a flexible electrode at its distal end. The flexible electrode includes an inner, flexible, electrically-conductive element and an outer, flexible, electrically-conductive polymer layer in electrical contact with the inner, flexible, electrically-conductive element. The catheter further includes an electrically insulative sheath surrounding at least a portion of the flexible electrode and a linear displacement mechanism capable of adjusting at least one of the electrically insulative sheath and the flexible electrode to vary a length of the flexible electrode exposed at the distal end of the shaft. Also disclosed is an adjustable length ablation electrode and methods of ablating tissue.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

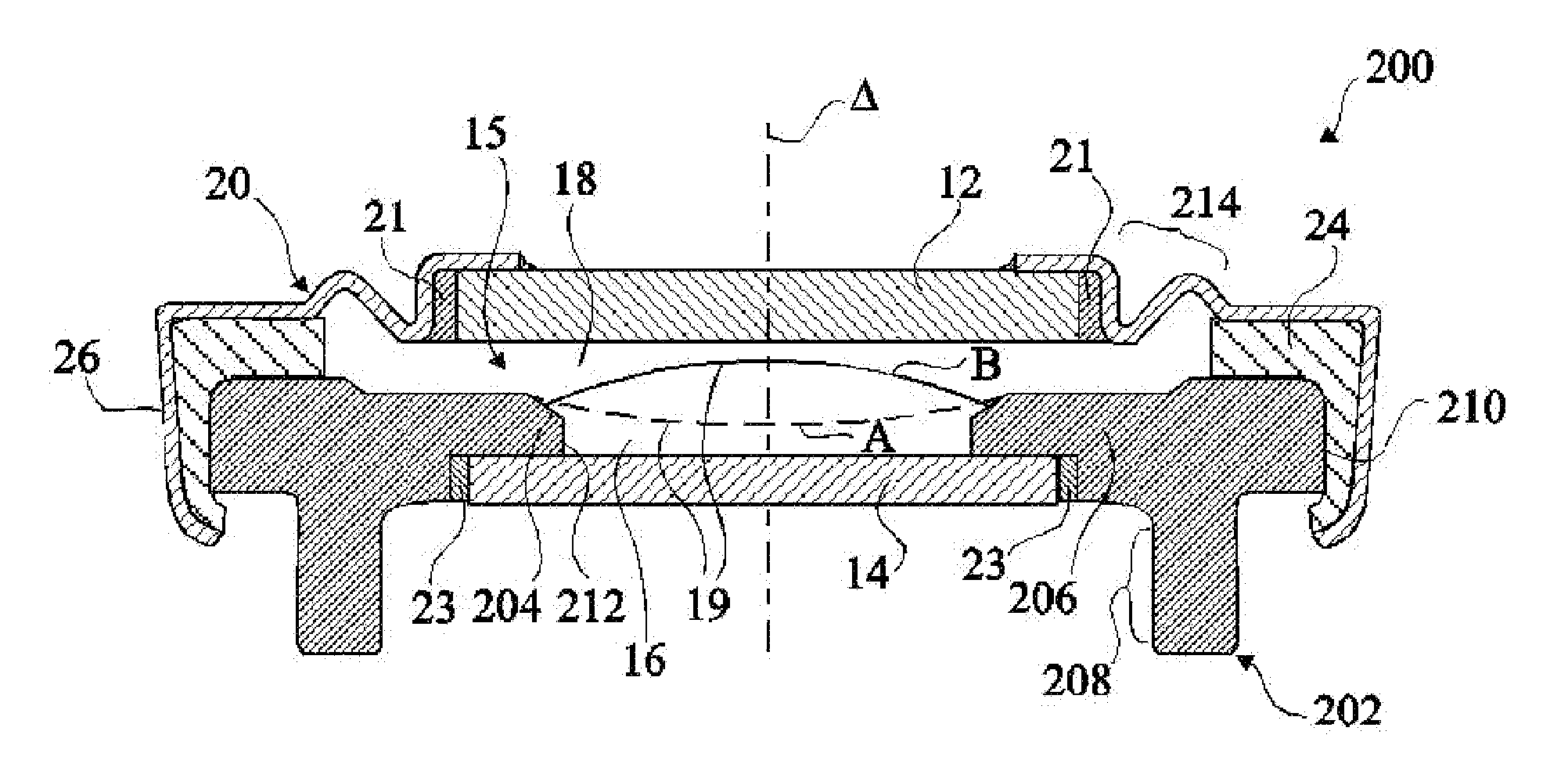

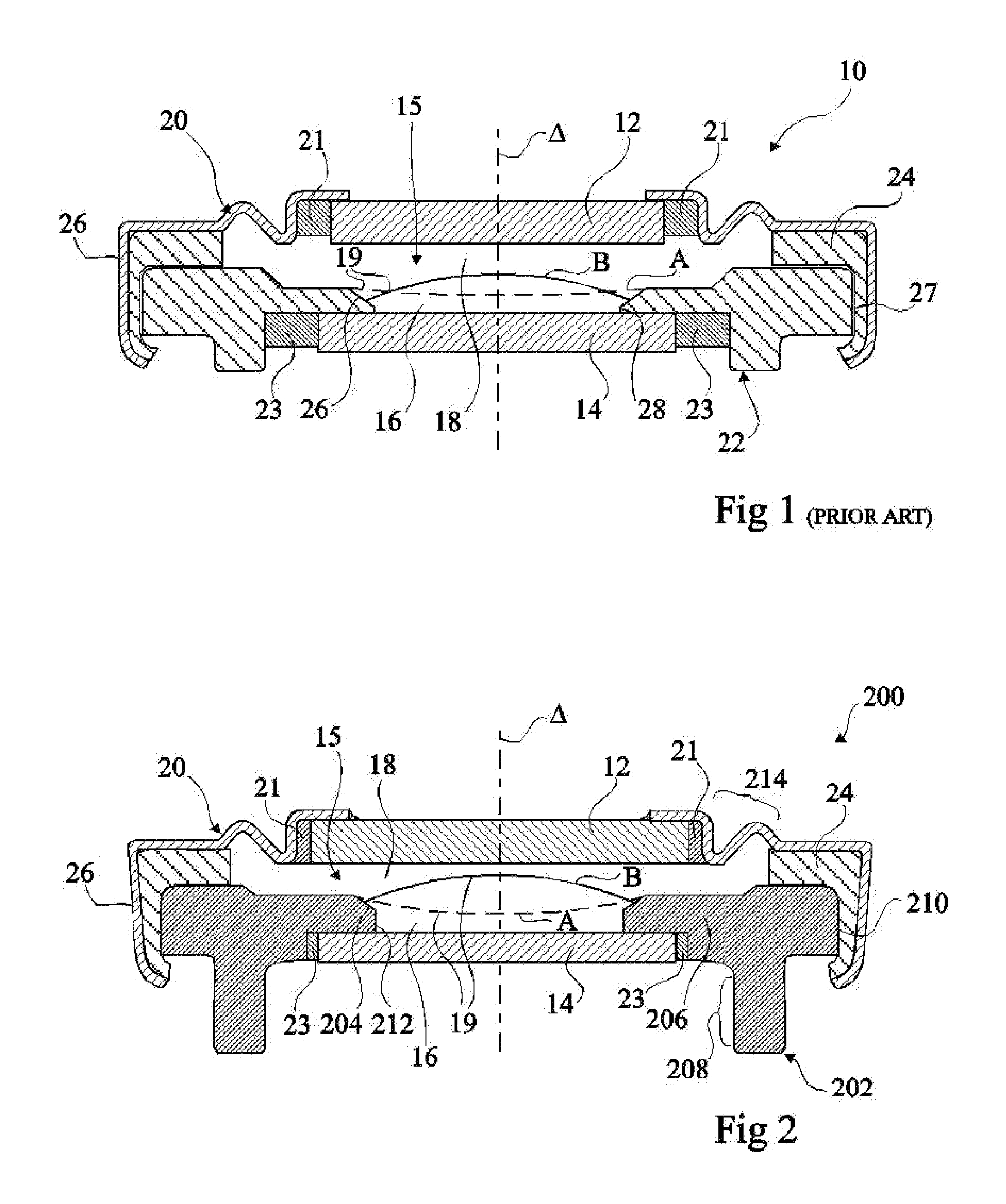

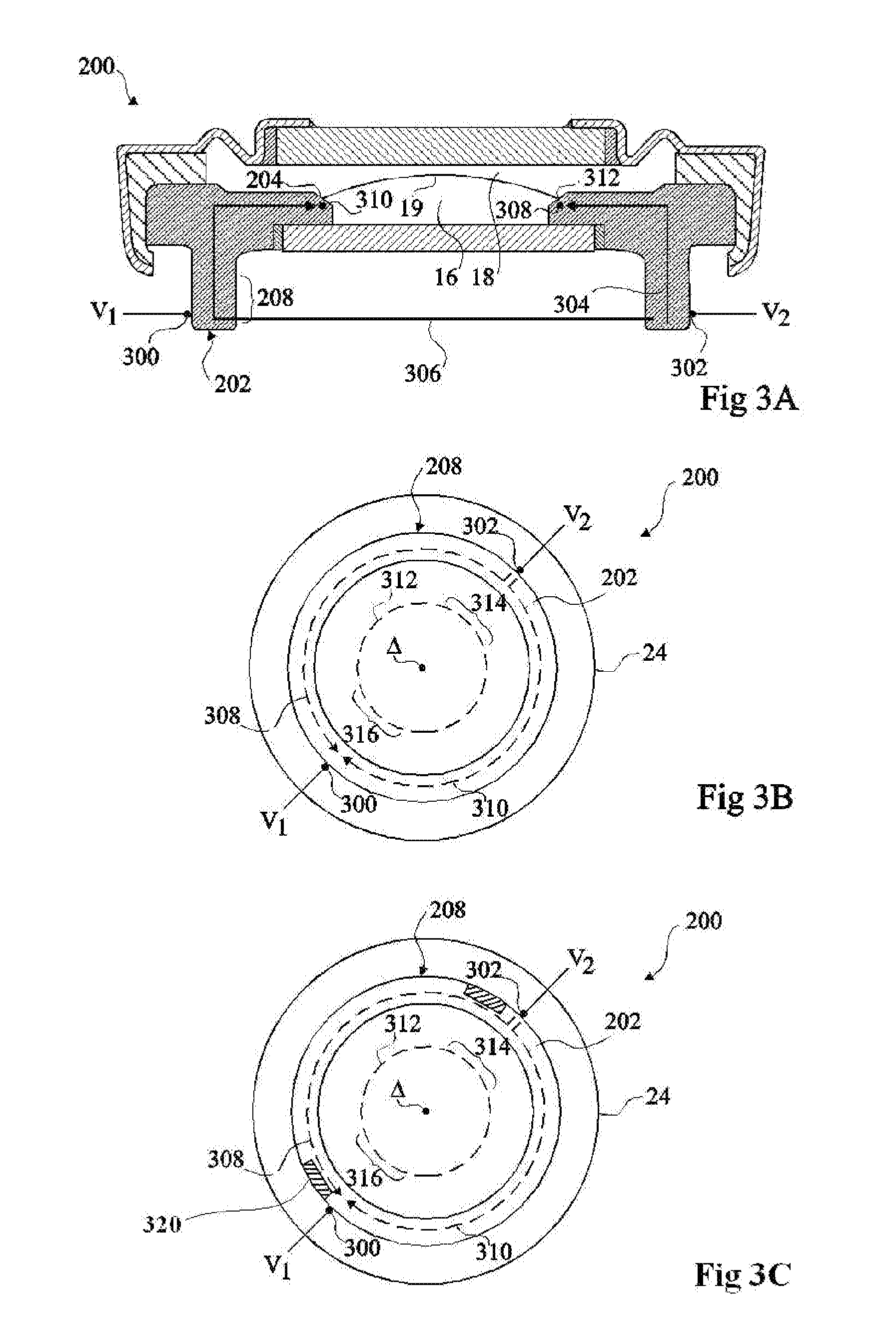

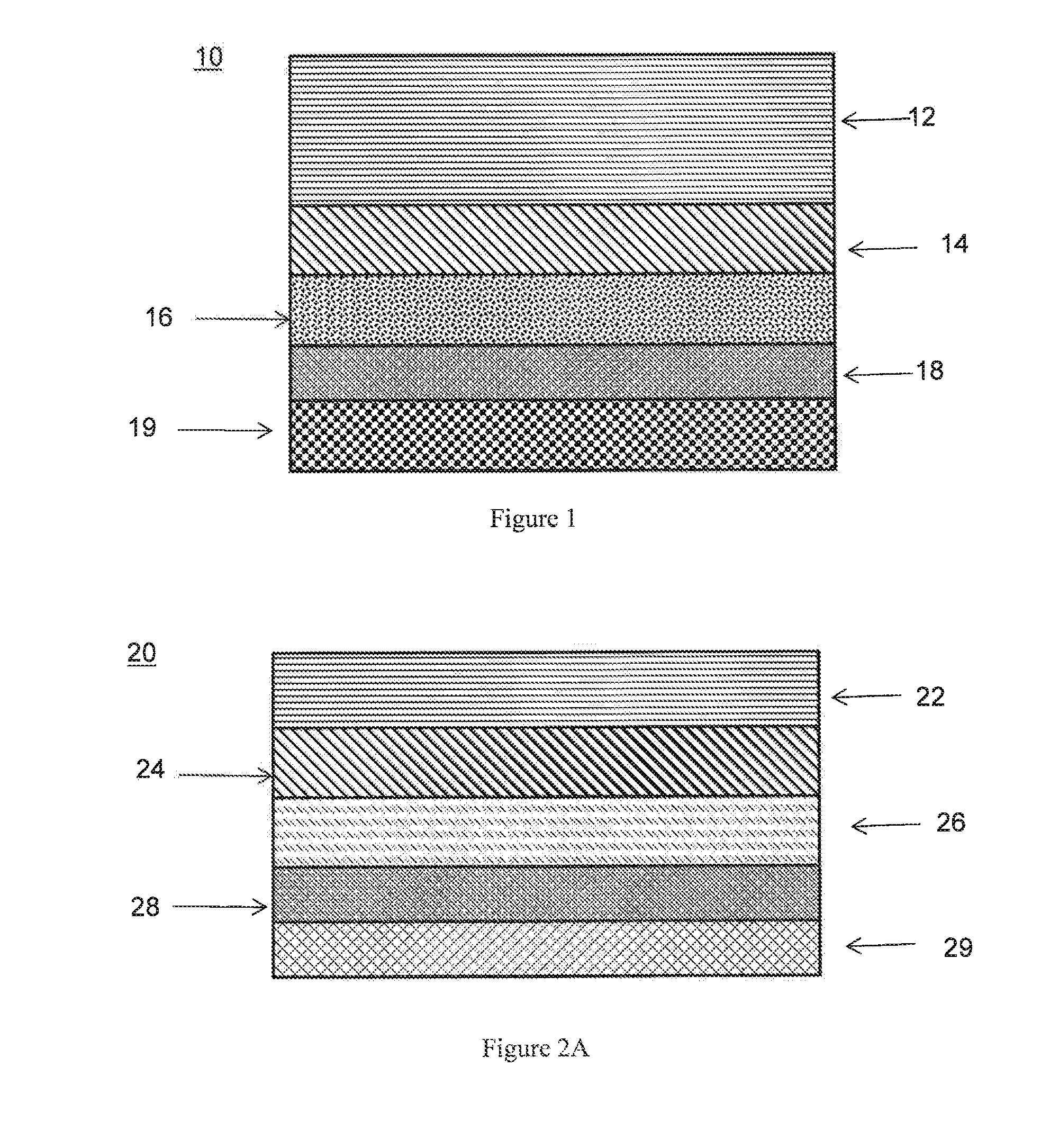

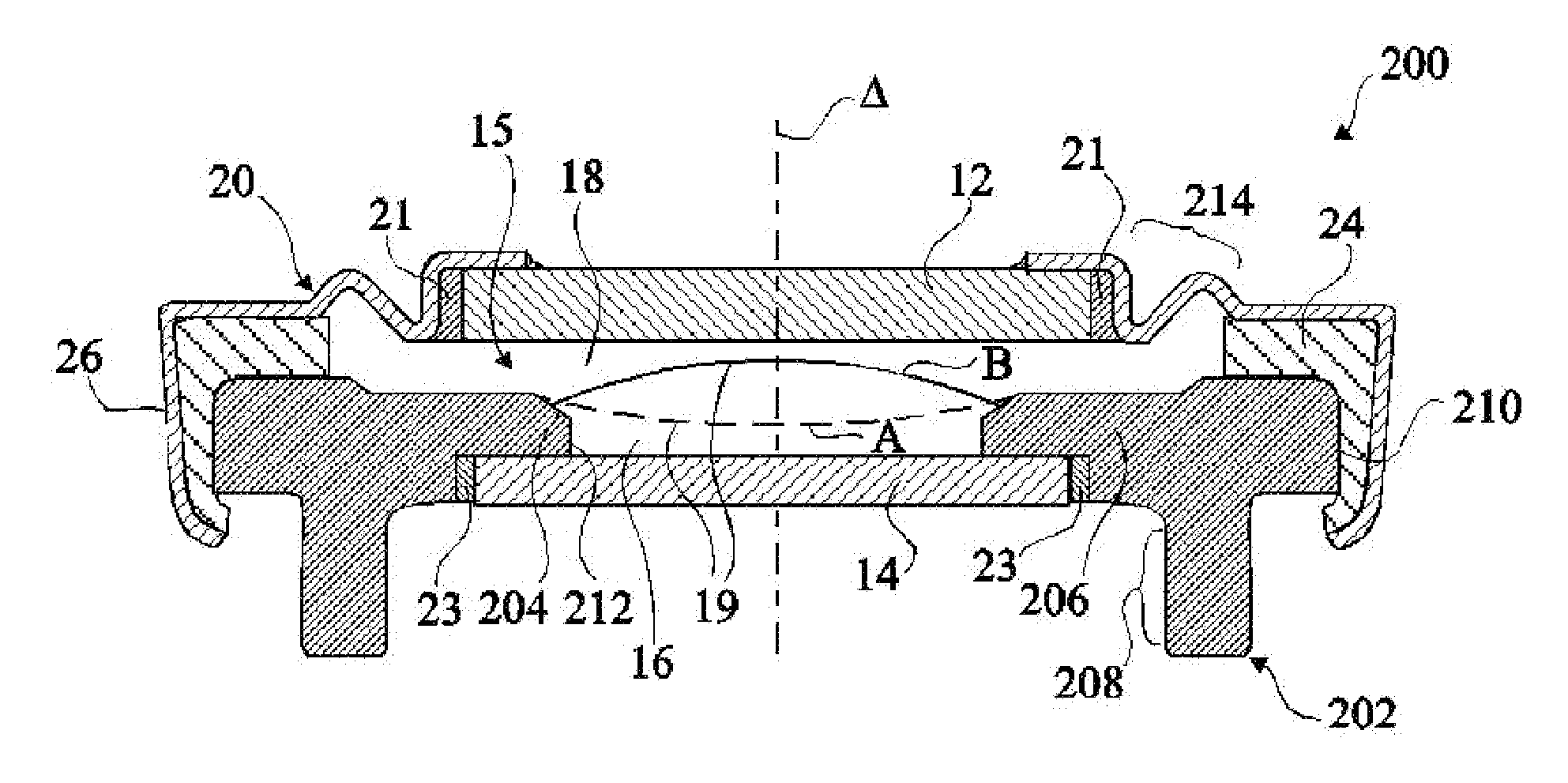

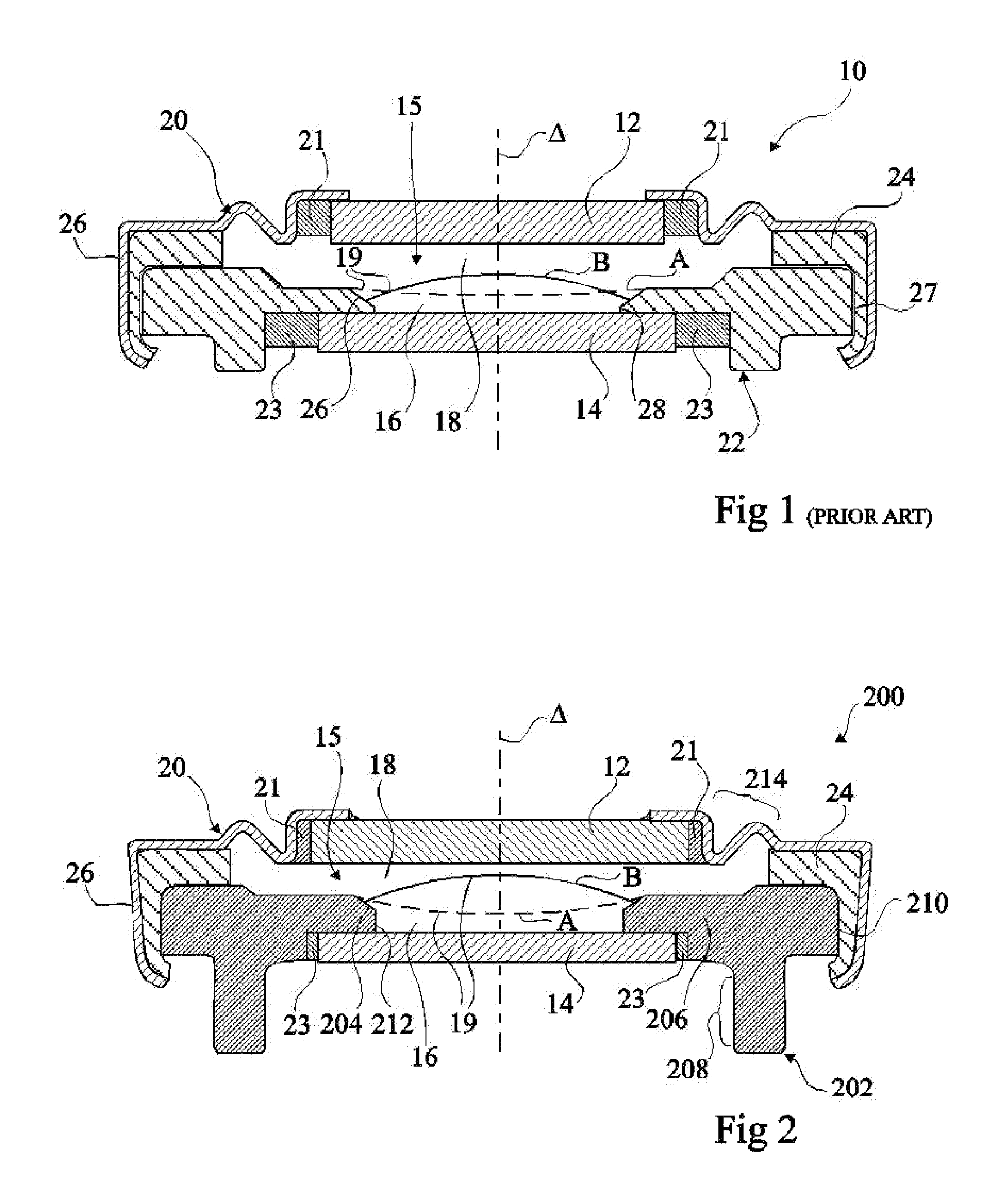

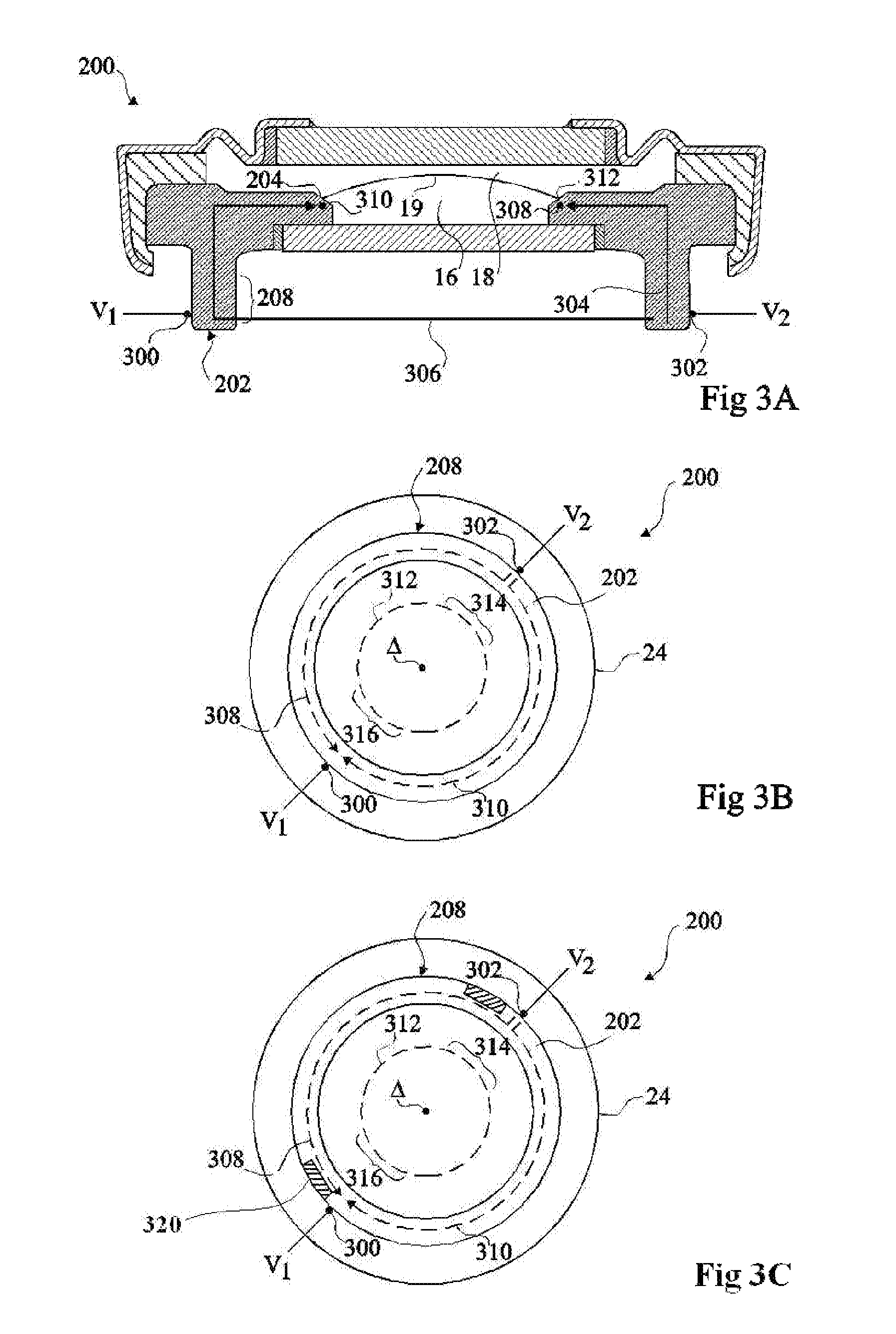

Electrowetting device with polymer electrode

The invention concerns an electrowetting optical device comprising a chamber (15) comprising first and second immiscible liquids (16, 18) contacting each other at a liquid-liquid interface (19), the first liquid being an insulating liquid and the second liquid being a conducting liquid; a first electrode (20) in the contact with the second liquid; and a second electrode (202) insulated from the first and second liquids by an insulating layer, wherein the second electrode is formed of a conductive molded polymer material, wherein the curvature of said liquid-liquid interface is controllable by application of a voltage between said first and second electrodes.

Owner:INVENIOS FRANCE SAS

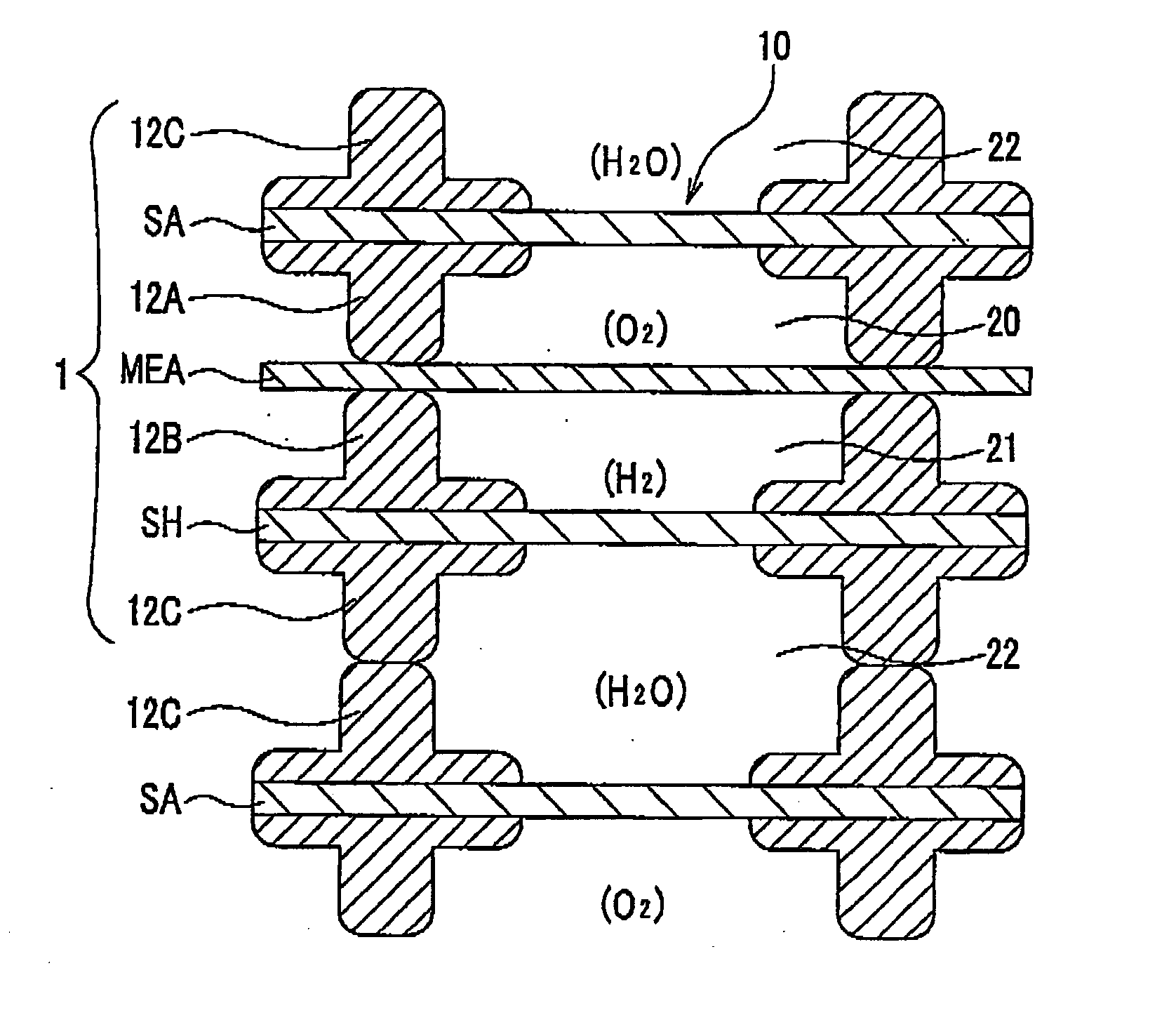

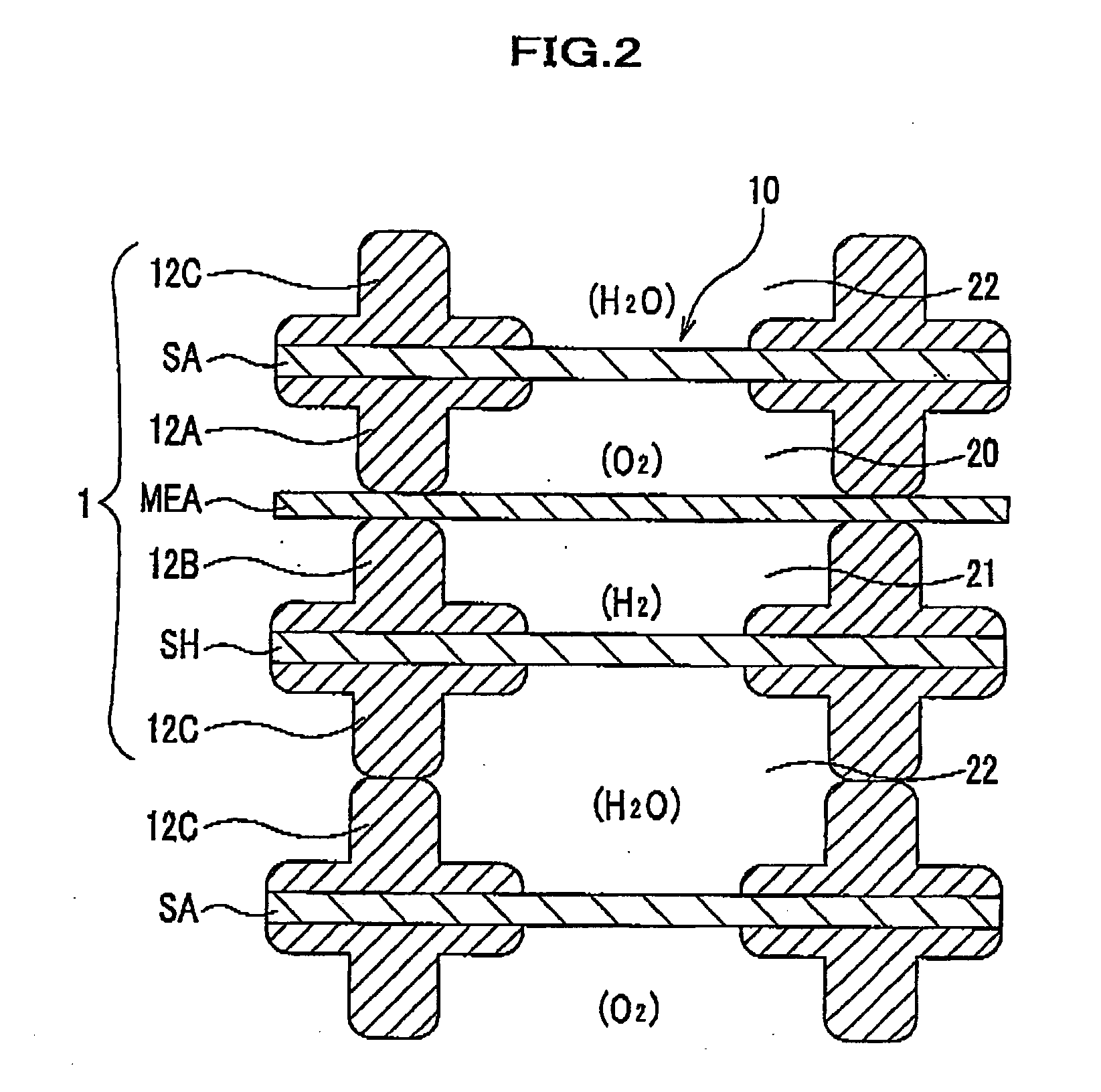

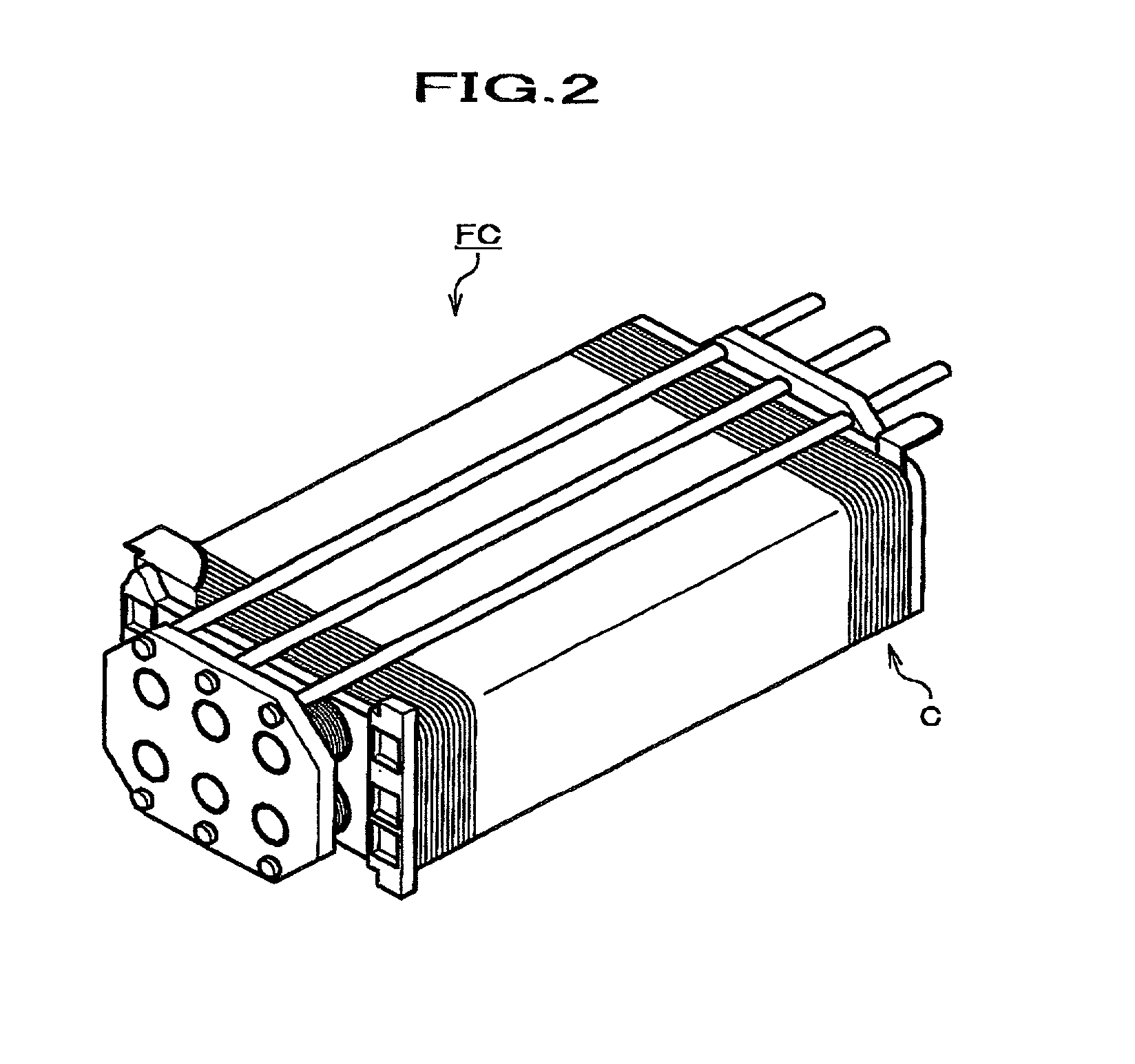

Seal construction for fuel cell

A seal-separator conjugation for a fuel cell which clamps a membrane electrode assembly sandwiching both surfaces of a polymer electrode membrane, comprising seals on a front surface and a rear surface of the separator at least at one end of the separator is disclosed. The conjugation is produced by pre-forming a rubber material or rubber materials into pre-formed seals within a mold having at least one supporting member for positioning the seal; inserting a separator between the pre-formed seals; and vulcanizing the pre-formed seals into the final seals while maintaining the pre-formed seals and the separator.

Owner:HONDA MOTOR CO LTD

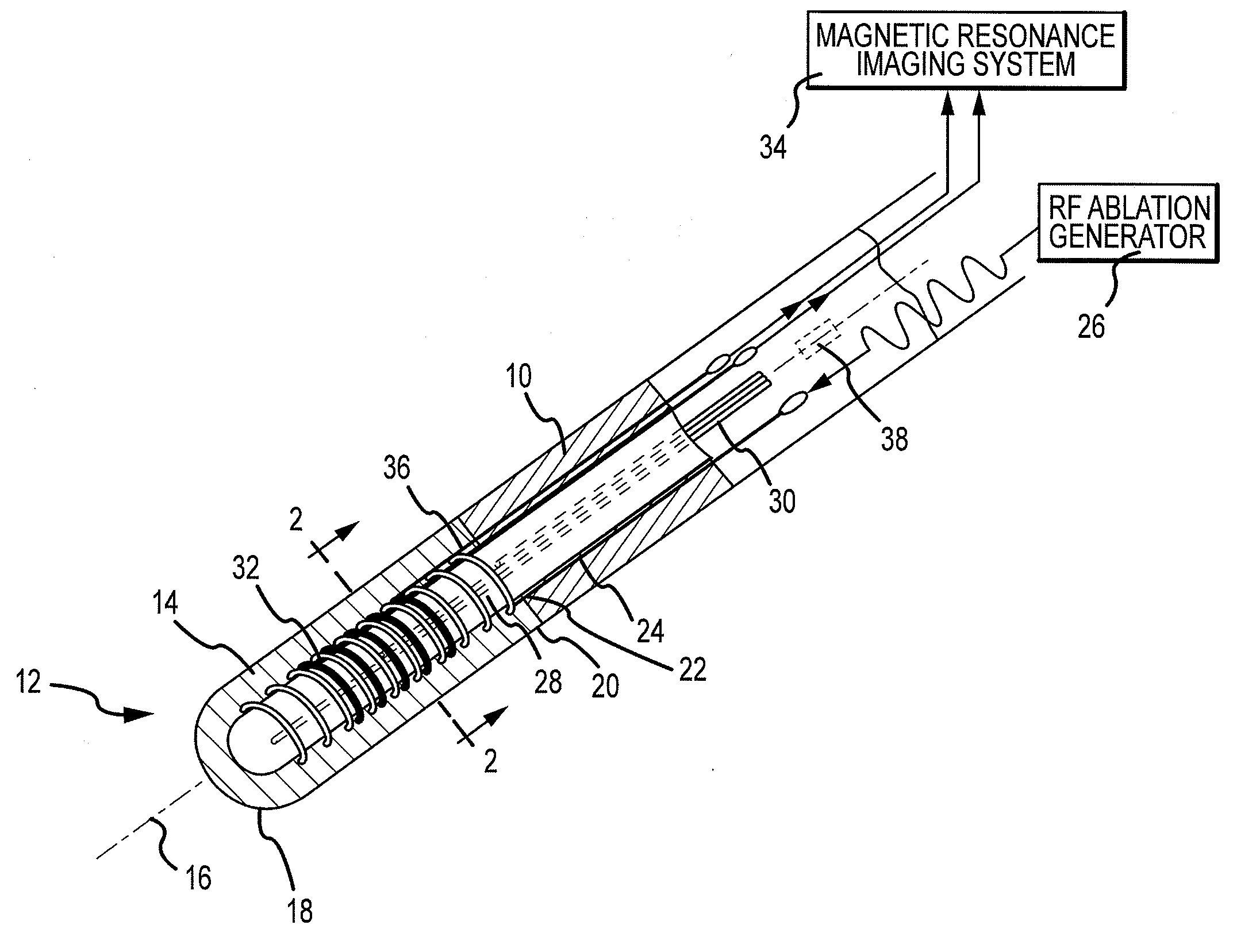

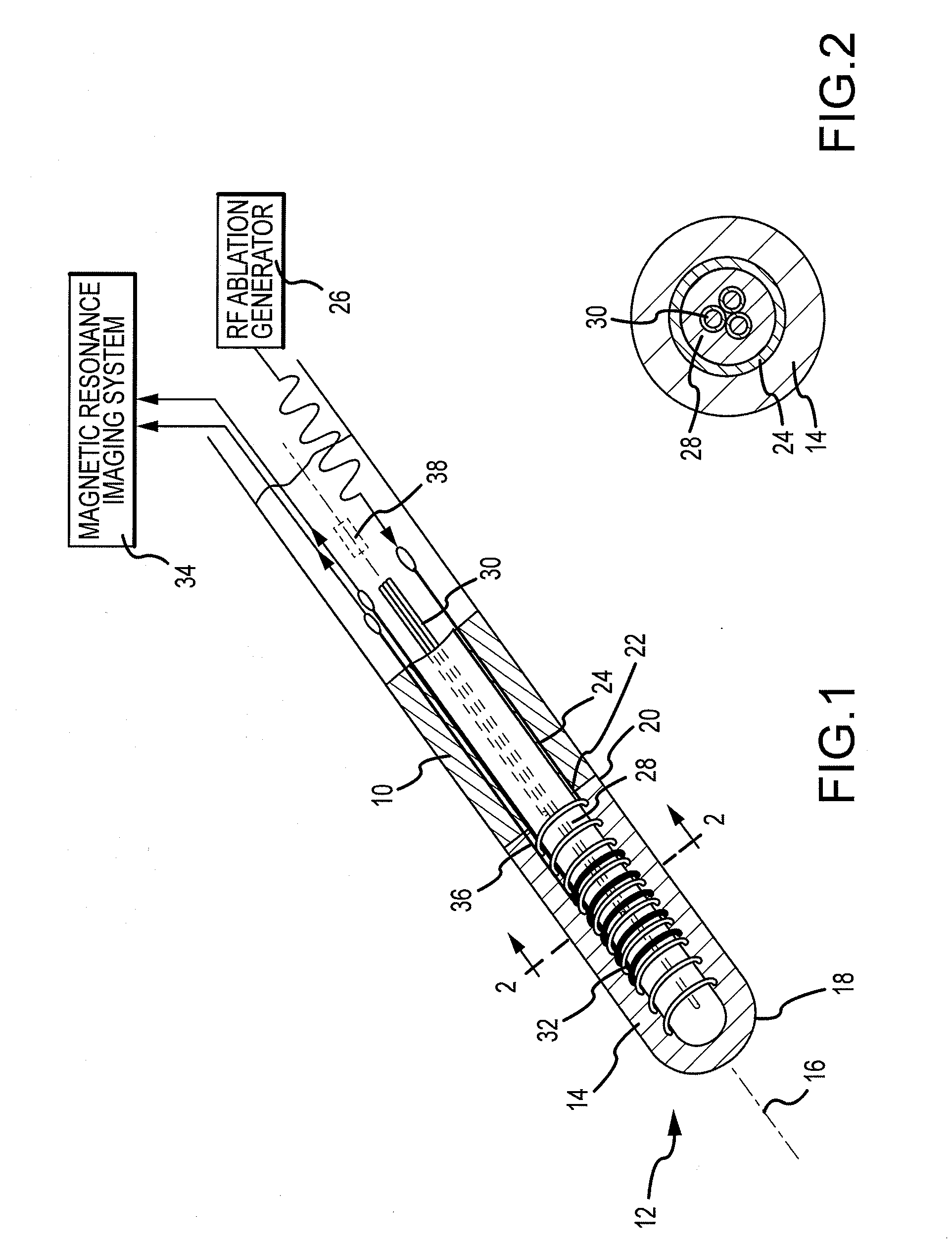

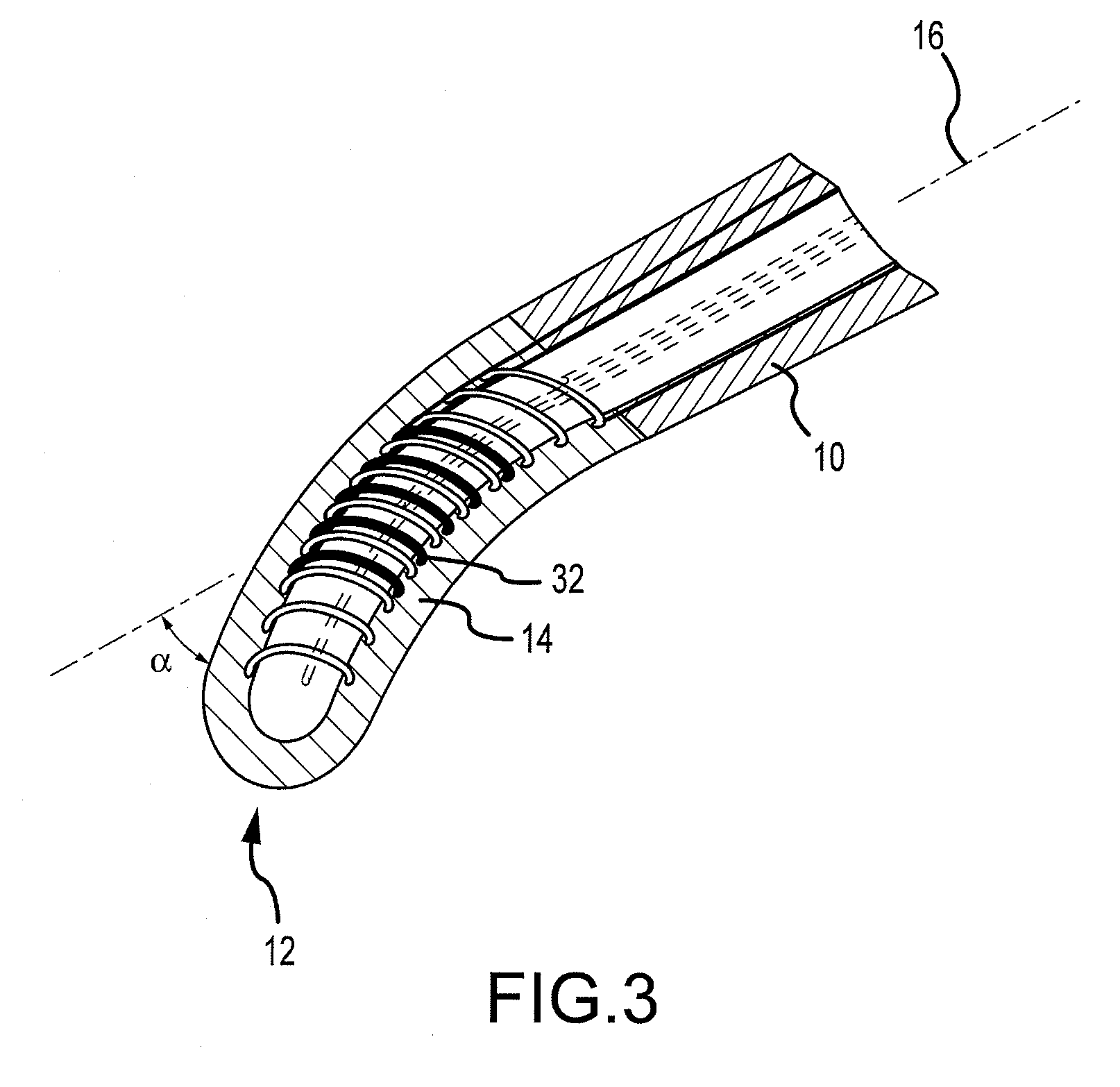

Flexible polymer electrode for mri-guided positioning and radio frequency ablation

An electrode for use on a medical device is disclosed. The electrode may have a main body of electrically conductive material extending along an axis and may have a proximal end and a distal end. The electrode may also include a magnetic resonance imaging (MRI) tracking coil disposed in the body. The MRI tracking coil may comprise electrically insulated wire. A catheter including an electrode, as well as a method for determining the location of an electrode, are also disclosed.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

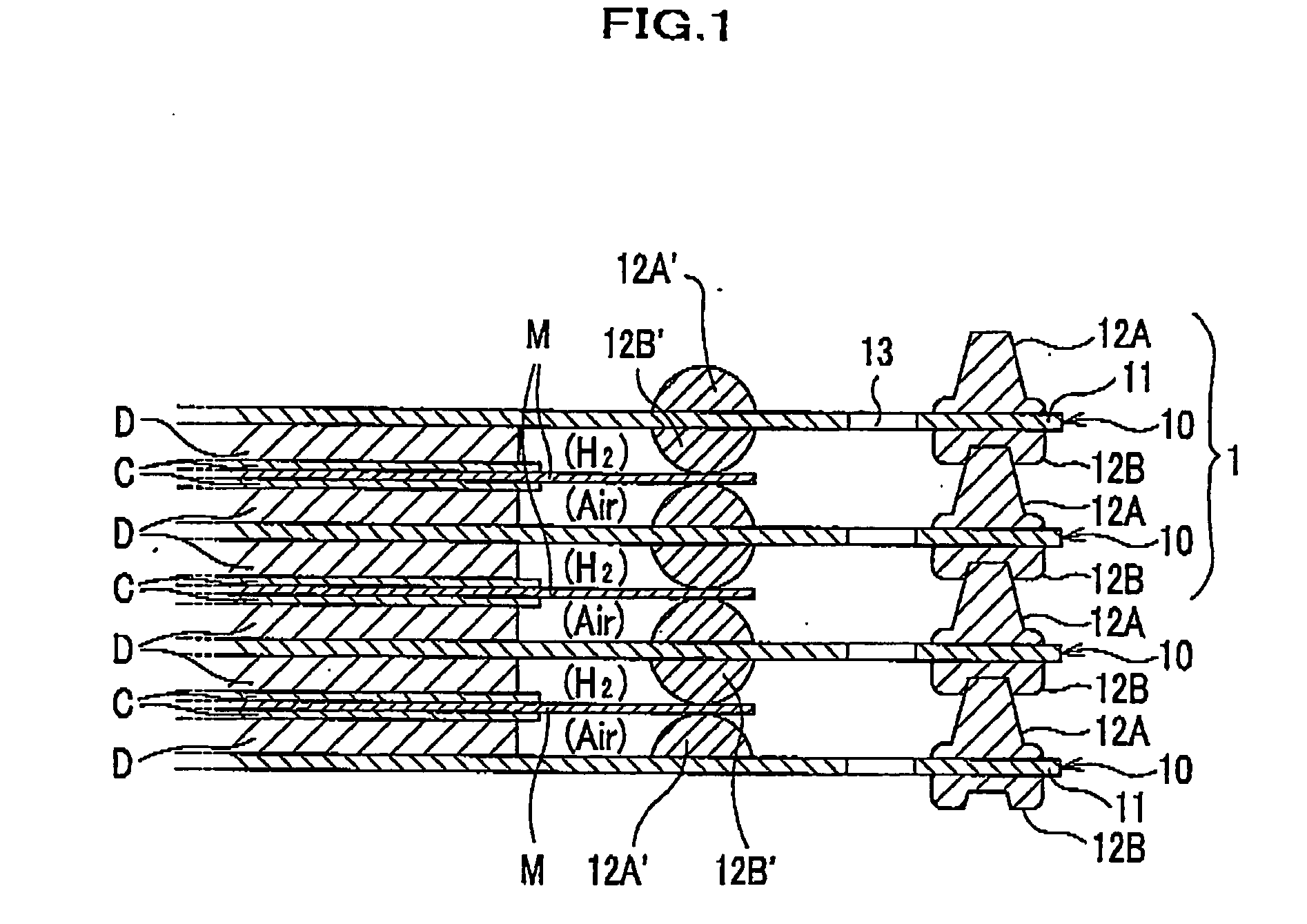

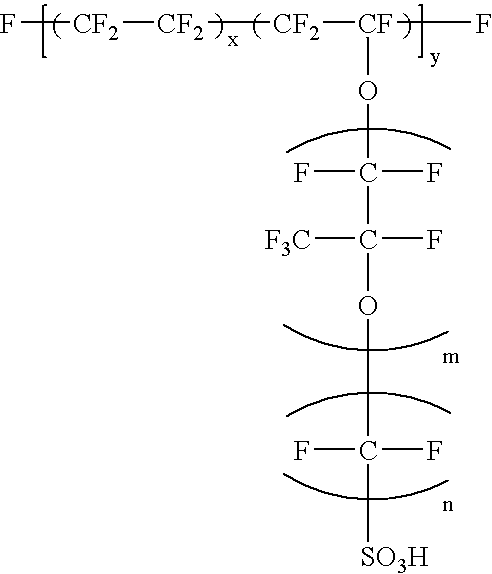

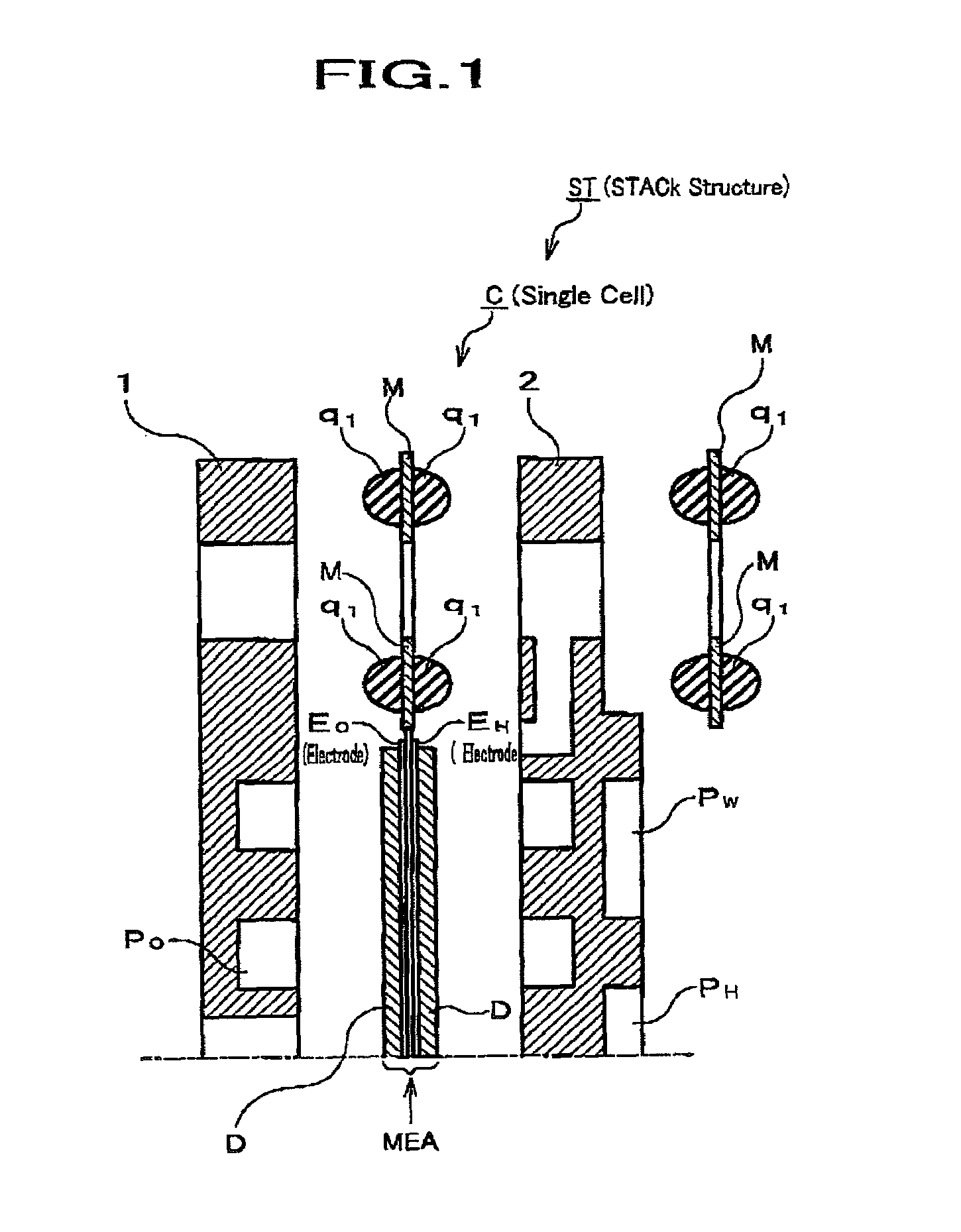

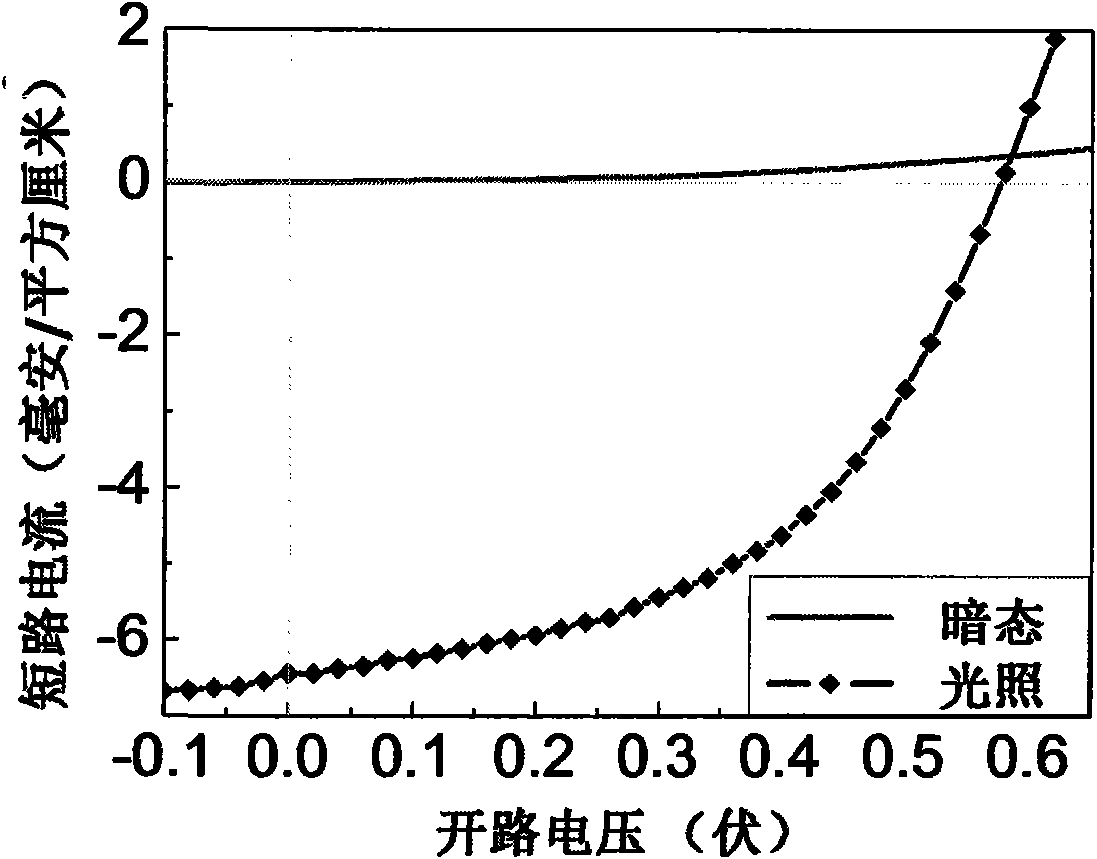

Polymer electrolyte type fuel cell

InactiveUS6818339B1Low water absorptionHigh water-repellencyFuel cell auxillariesActive material electrodesHigh current densityConductive polymer

The present specification discloses a polymer electrolyte fuel cell characterized in that each of the cathode and the anode comprises catalyst particles, a hydrogen ion-conductive polymer electrode, a conductive porous base material and a water repellent agent, and water repellency of at least one of the cathode and the anode varies in a direction of thickness or in a plane direction. As such, by varying the degree of the water repellency of the cathode and the anode on the basis of a position, an excellent polymer electrolyte fuel cell having a high discharge characteristic or more specifically a high current-voltage characteristic in a high current density range.

Owner:PANASONIC CORP

Method of metallizing dielectric film

InactiveUS20150231802A1Layered product treatmentPiezoelectric/electrostriction/magnetostriction machinesDielectricPolymer science

The present invention provides a method of producing a metallized polymer-electrode composite comprising transferring a conductive metal foil from a metal transfer film to a surface of a polymer film The inventive method may be used to produce a polymer film with optionally textured, conductive metal electrodes on one or both sides. The method of Hie invention may find utility in producing electroactive polymer transducers and other thin film devices requiring flexibility or stretchability such as thin film batteries, sensors, speakers, reflective plastic displays, solar cells, and supercapacitors.

Owner:PARKER HANNIFIN CORP

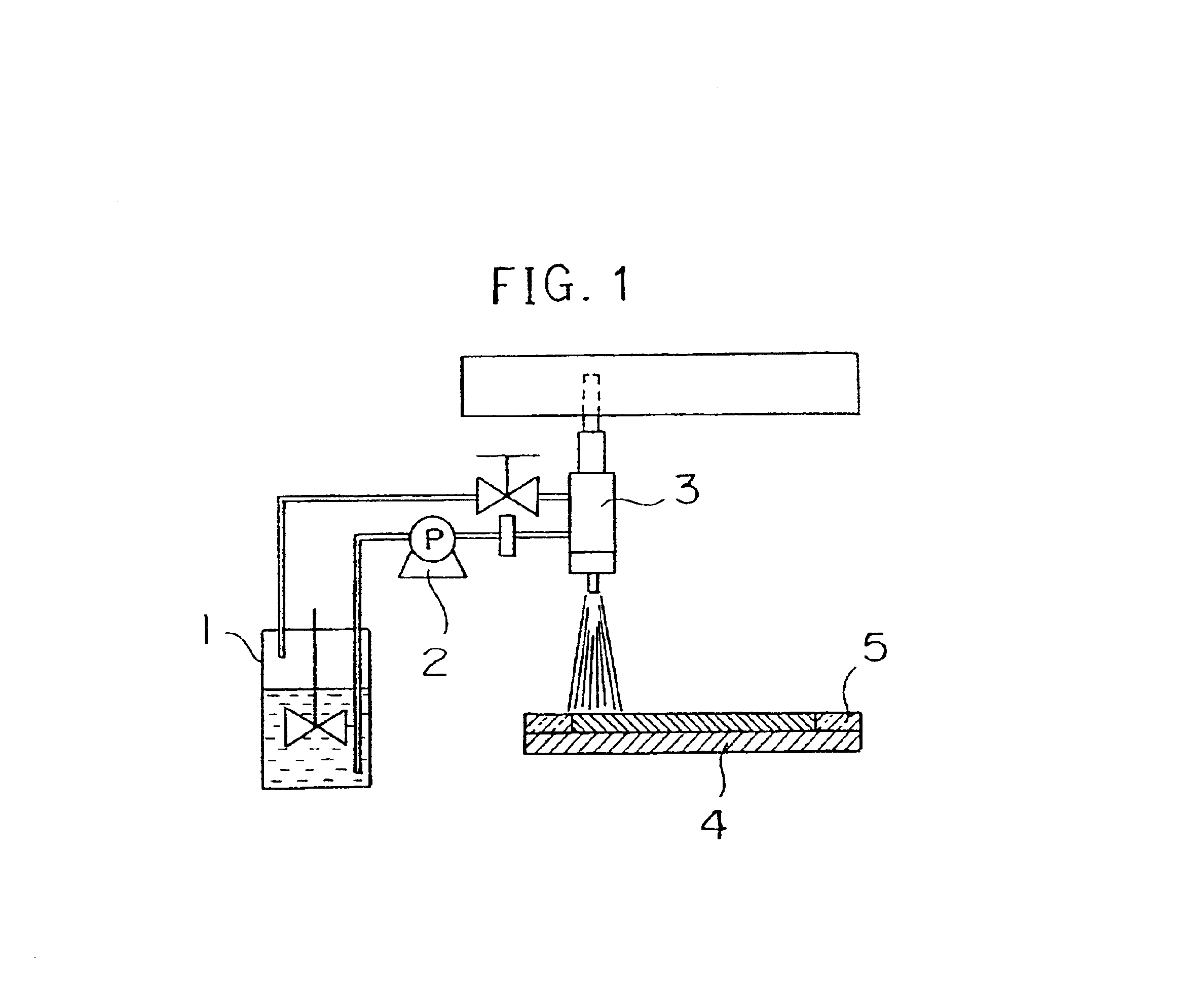

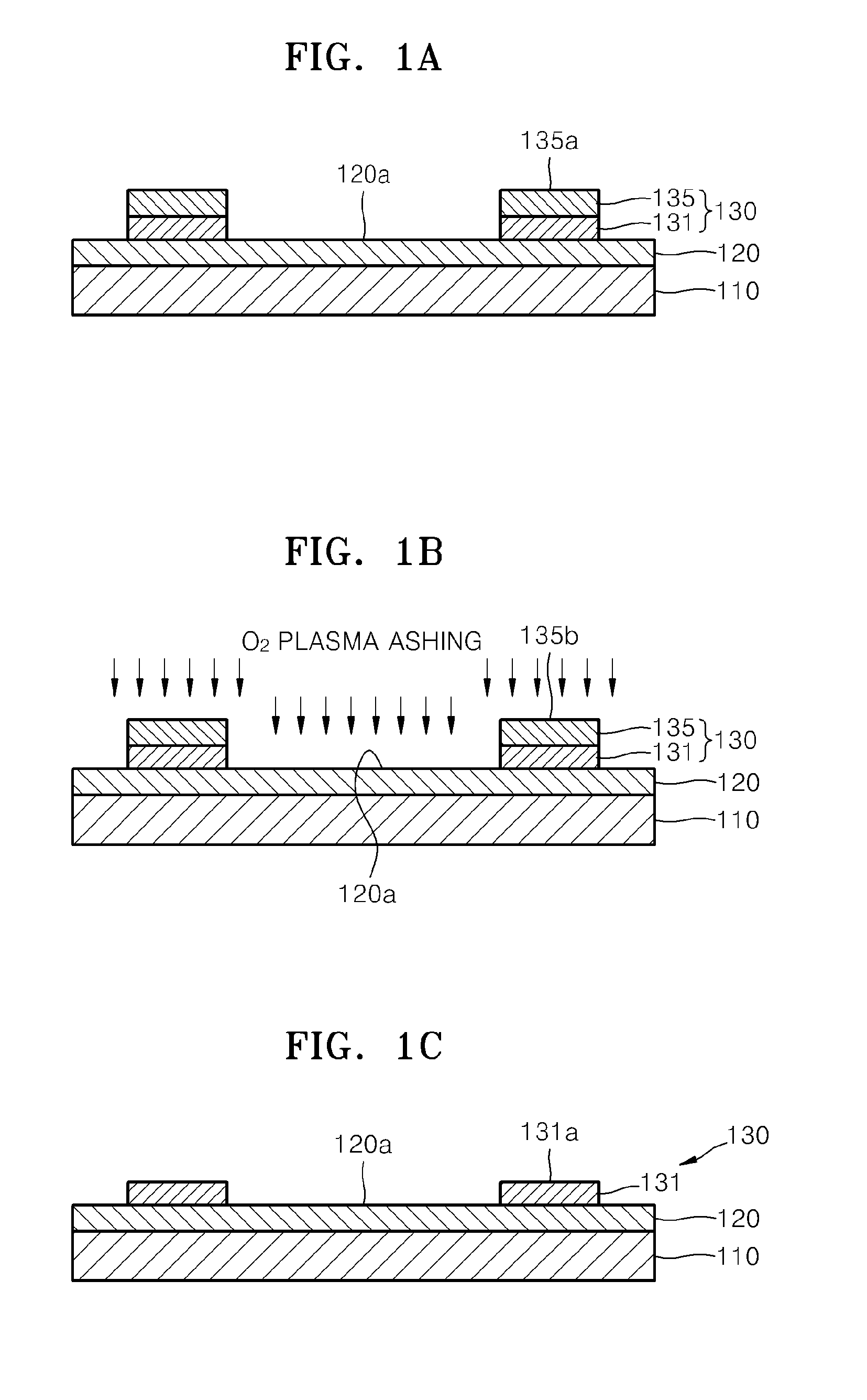

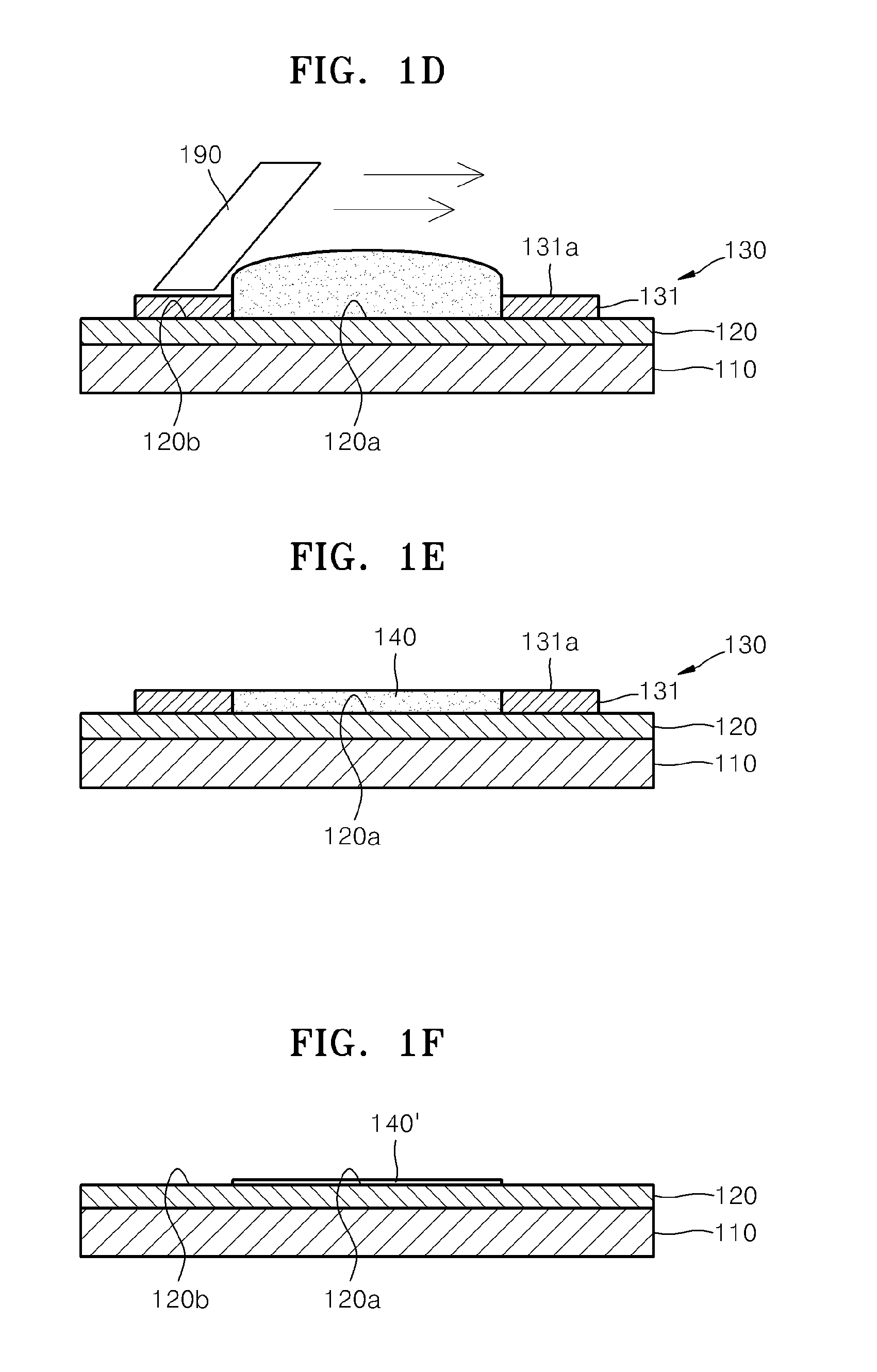

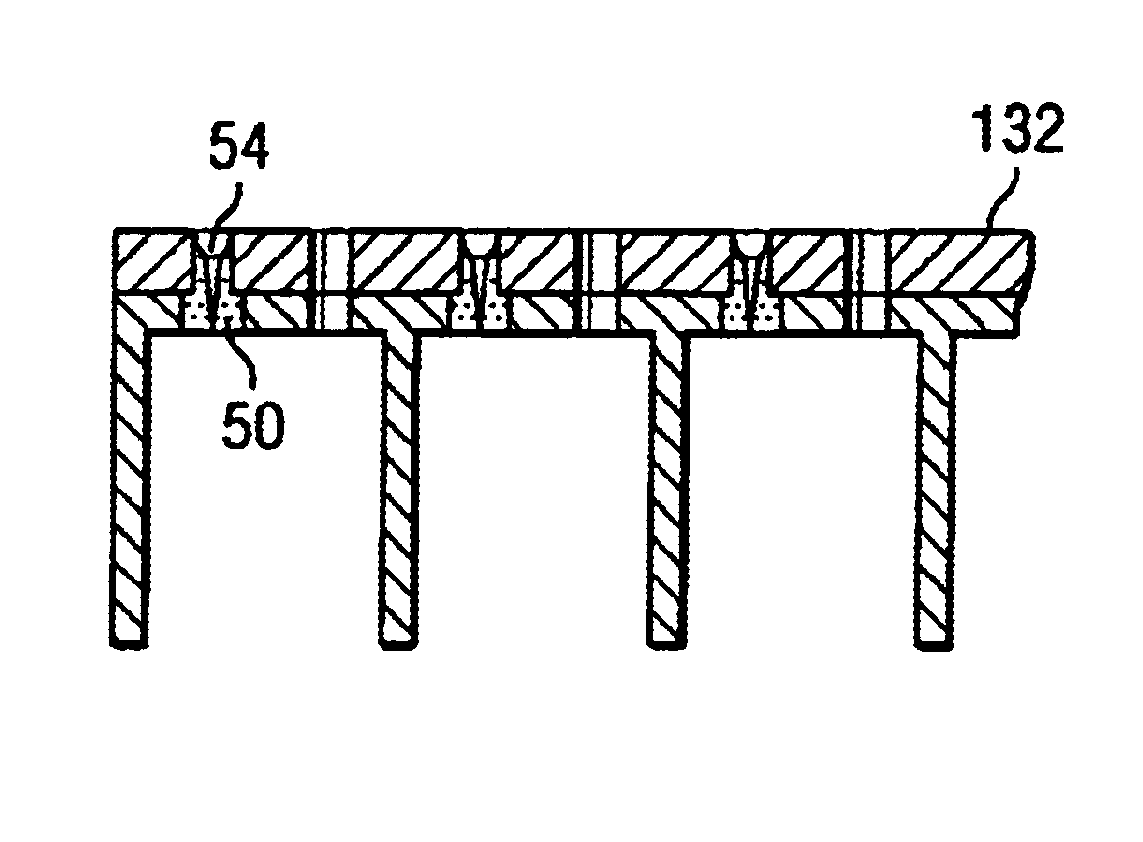

Method of manufacturing polymer electrode and polymer actuator employing the polymer electrode

ActiveUS20120200200A1Piezoelectric/electrostrictive device manufacture/assemblyConductive layers on insulating-supportsPolymer scienceConductive polymer

A method of manufacturing a polymer electrode and a polymer actuator employing the polymer electrode, the method including: adhering a shadow mask onto a substrate, forming a hydrophilic electrode pattern on the substrate, coating the hydrophilic electrode pattern of the substrate with a conductive polymer water solution, removing the shadow mask, and drying the conductive polymer water solution, thus forming the polymer electrode. The method may be applied to electrodes disposed on both surfaces of a polymer deformation layer of a polymer actuator.

Owner:SAMSUNG ELECTRONICS CO LTD

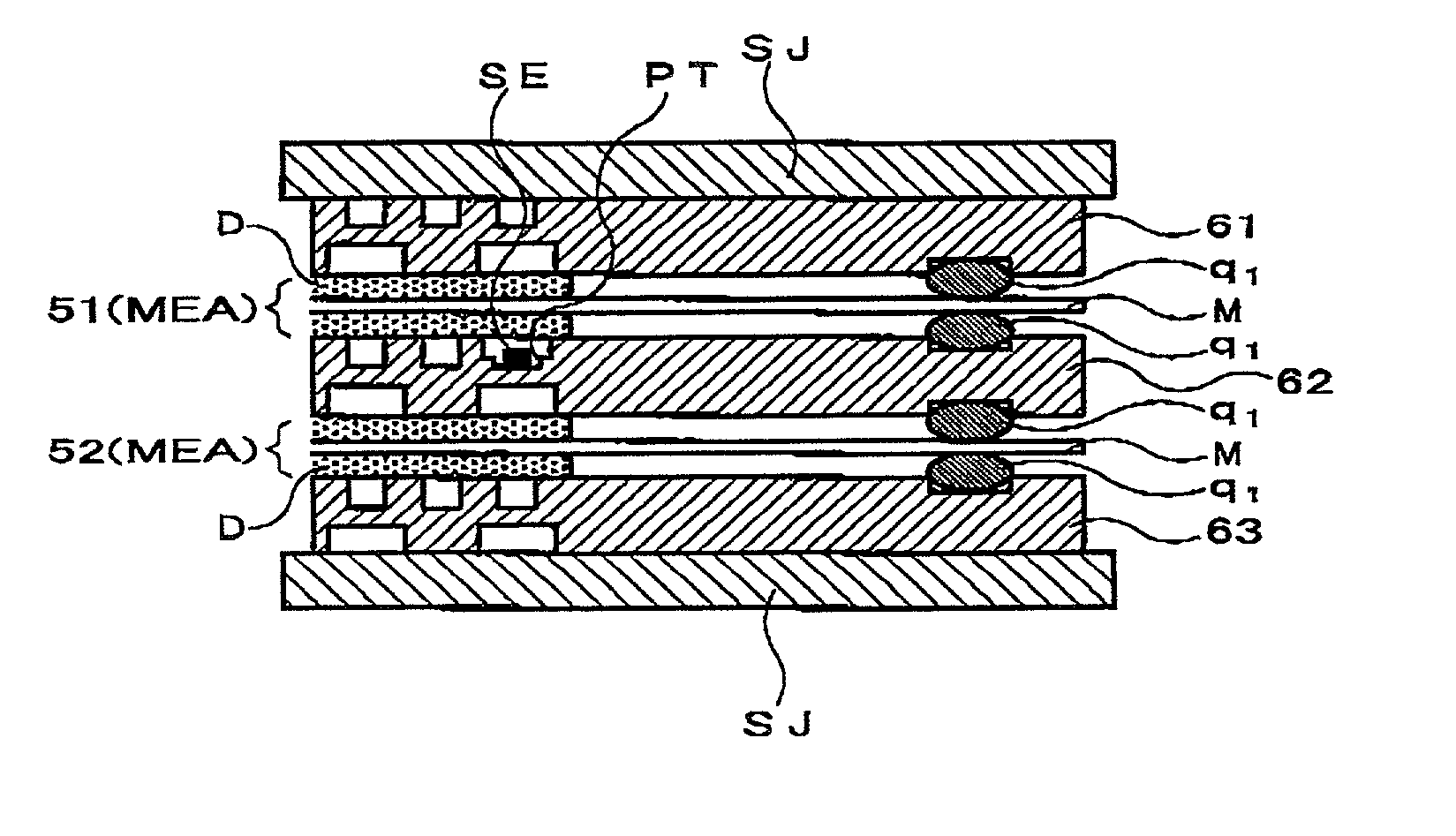

Liquid thermosetting sealing agent for polymer electrode membrane fuel cell, single cell formed with sealing agent, its process, and process for regenerating polymer electrode membrane fuel cell

InactiveUS7138201B2Improve sealingIncrease production capacityFuel cells groupingPrimary cell maintainance/servicingFuel cellsEngineering

A liquid thermosetting sealing agent for a polymer electrode membrane fuel cell having separators and a membrane electrode assembly laminated, whose the viscosity at the application is from 1,000 to 9,000 Pa·S, can be used to prepare a highly durable seal for a polymer electrode membrane fuel cell, to produce a single cell having a highly durable seal and to recover the fuel cell whose seal becomes abnormality.

Owner:HONDA MOTOR CO LTD

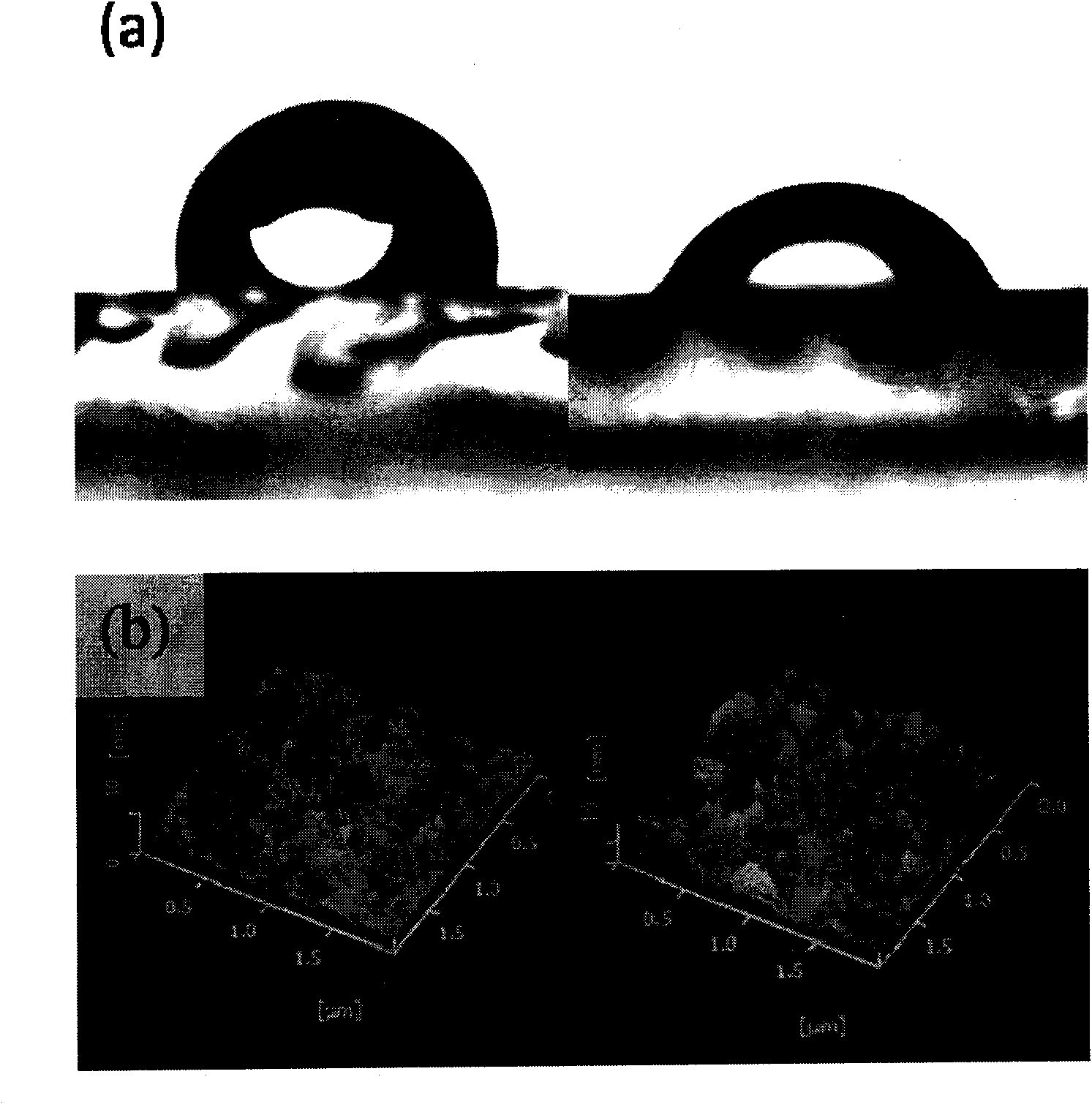

Method needing no vacuum process to prepare organic polymer solar cell

InactiveCN101661994ASimple manufacturing processImprove production efficiencySolid-state devicesSemiconductor/solid-state device manufacturingTin dioxideIndium

The invention provides a method needing no vacuum process to prepare an organic polymer solar cell. Indium oxide-tin dioxide (ITO) modified by zinc oxide (ZnO) or titanium oxide (TiO2) and the like, or tin dioxide (FTO) substrate doped with fluorine are taken as a cathode of the battery, and a polymer electrode with high conductivity is taken as an anode of the battery so as to compose the solar cell structure; a layer of hydrophobic polymer active layer modified by self-assembled amphiphilic molecules on water and oil is added between the active layer and the polymer electrode so that the surface of the active layer changes from hydrophobic to hydrophile, thus leading the solution of the water-soluble polymer electrode material with high conductivity to form an electrode film with good film-forming capability on the active layer; the whole preparation process of the solar cell is completed by a solution wet method, the method avoids the defects that in the vacuum evaporating and plating process of the metal electrode, the cost is high, the equipment dependency is strong, the process is complex, the energy consumption is high and the preparation in large area is difficult, furthermore, the method effectively simplifies the preparation process of the device.

Owner:JILIN UNIV

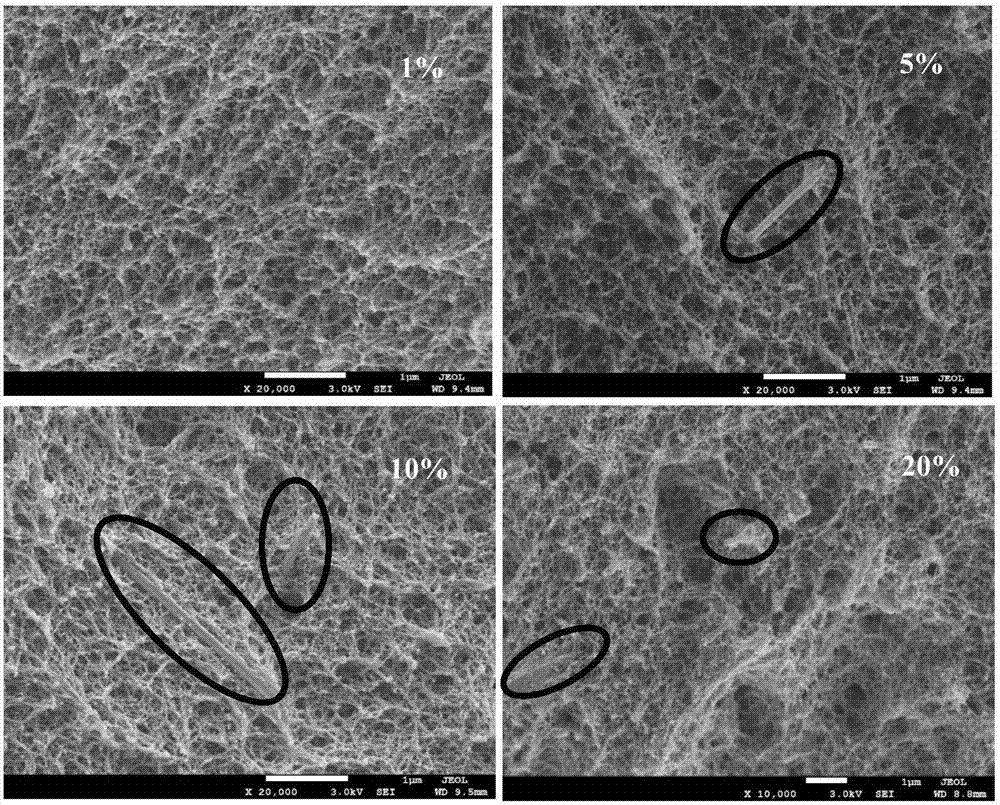

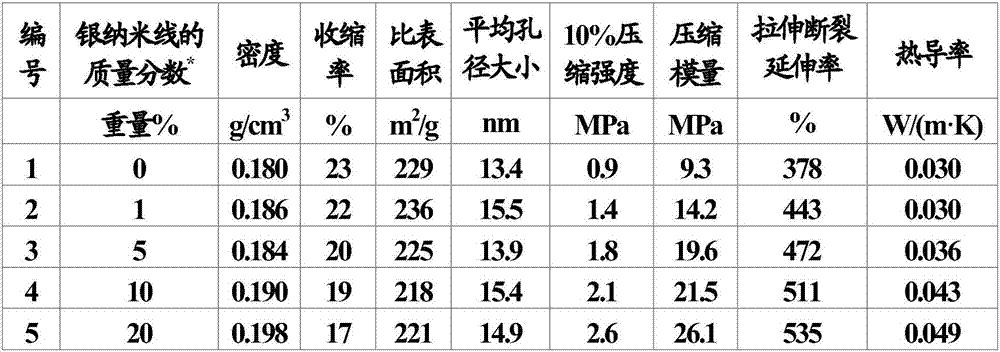

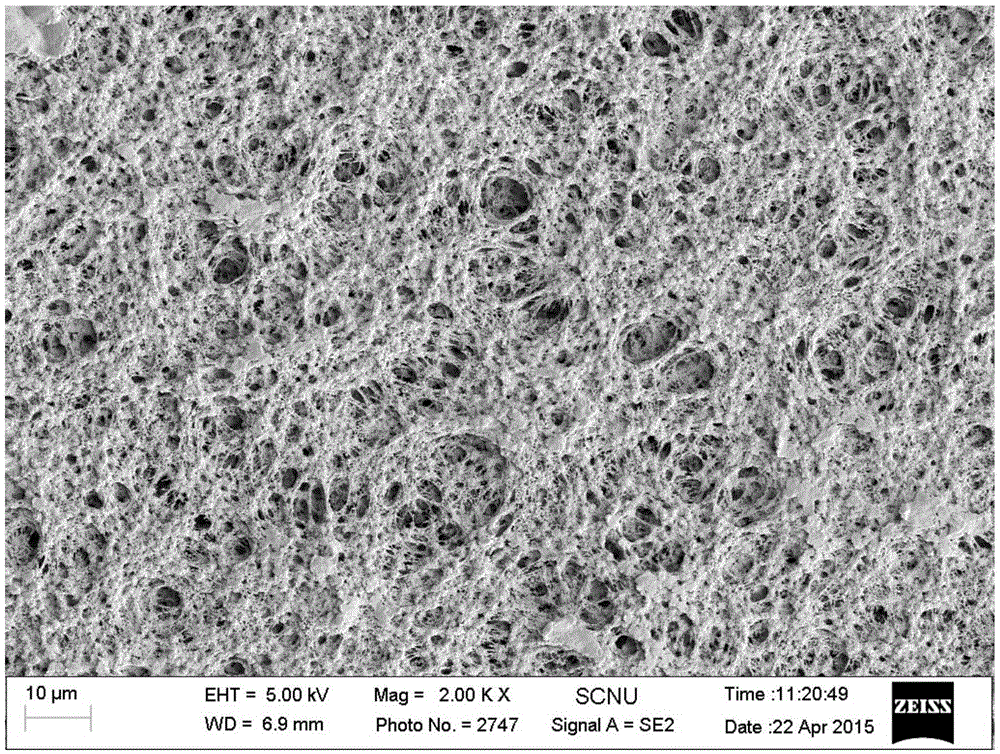

Polyimide aerogel with crosslinked surface functionalized nanoparticles and preparation method thereof

The invention relates to polyimide aerogel and a preparation method thereof, and in particular relates to polyimide aerogel with crosslinked surface functionalized nanoparticles and a preparation method thereof. The preparation method of the aerogel comprises the following steps: functionalizing surfaces of the nanoparticles; synthesizing a polyamide acid precursor; preparing polyimide wet gel by adopting functionalized nanoparticles as a crosslinking agent; and carrying out supercritical drying, so that the crosslinked polyimide aerogel is obtained. The polyimide aerogel provided by the invention has a stable and narrowly distributed mesoporous structure and is large in specific surface area, good in heat resistance and stable in physicochemical properties, and different performance characteristics, including better toughness, rigidity, heat insulation property, dielectric property, conductivity, electromagnetic shielding property and the like, can be given to the aerogel, so that the polyimide aerogel can further serve as a polymer electrode material, an adsorption catalysis carrier, a porous thermal insulation material, an electromagnetic shielding material and the like.

Owner:BEIHANG UNIV

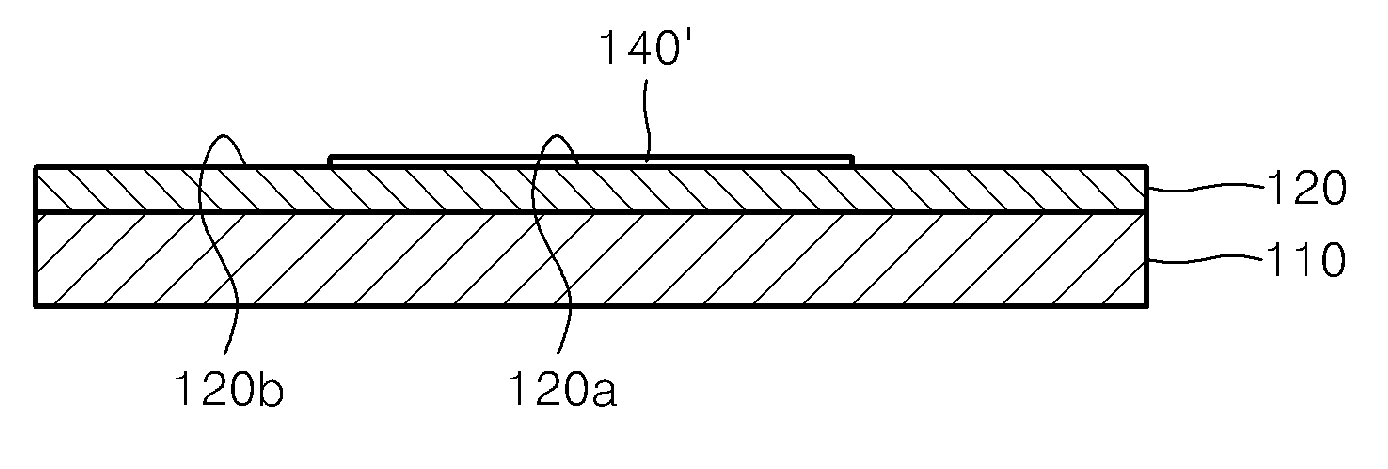

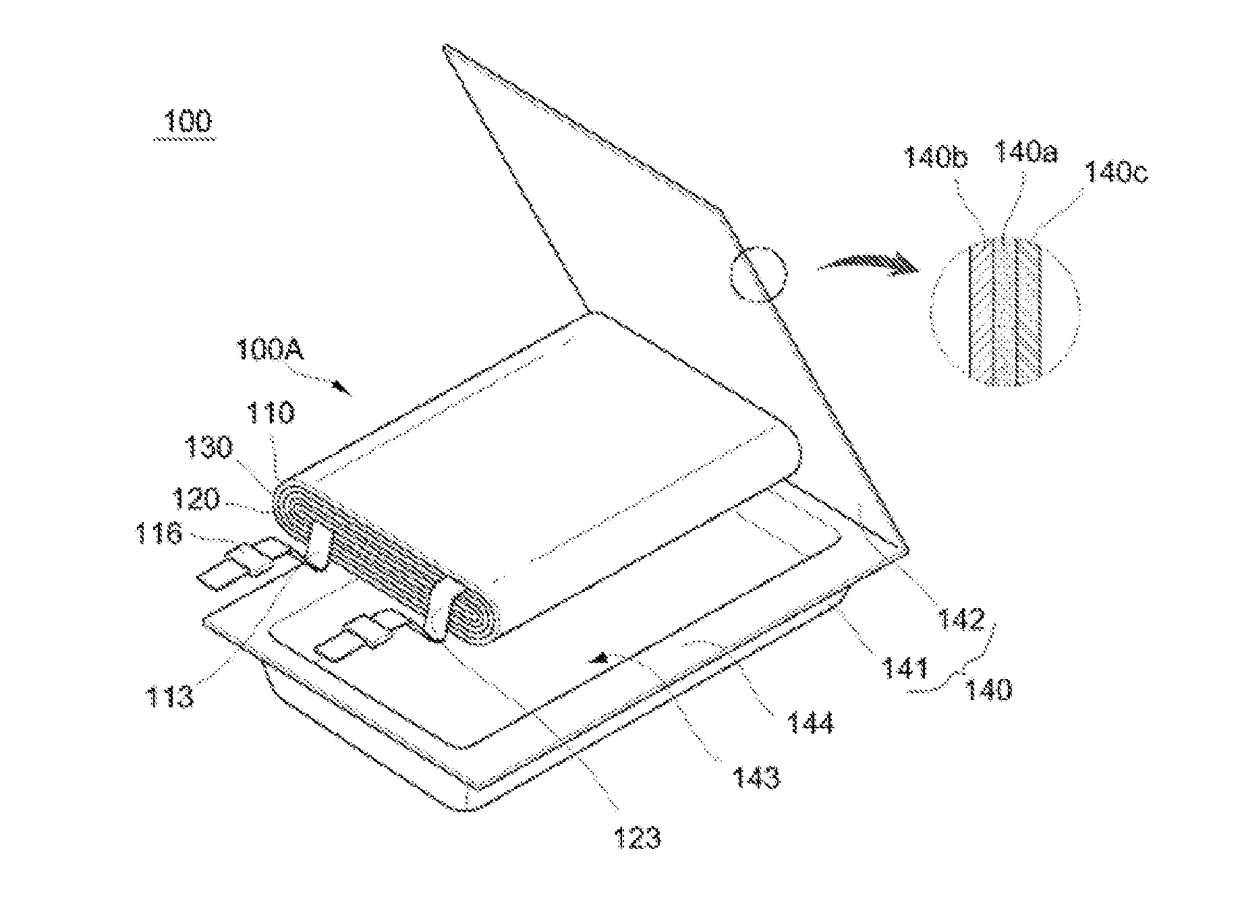

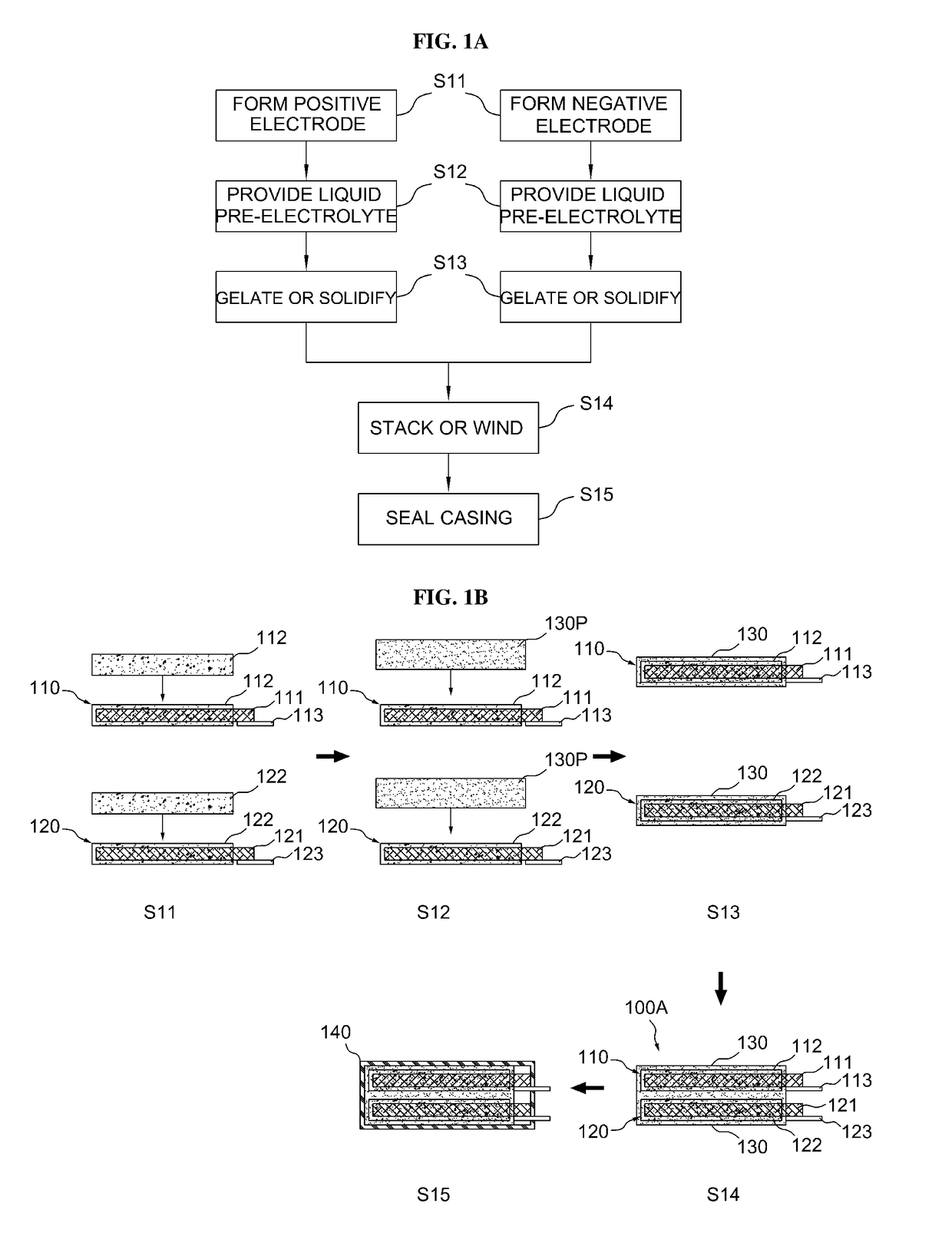

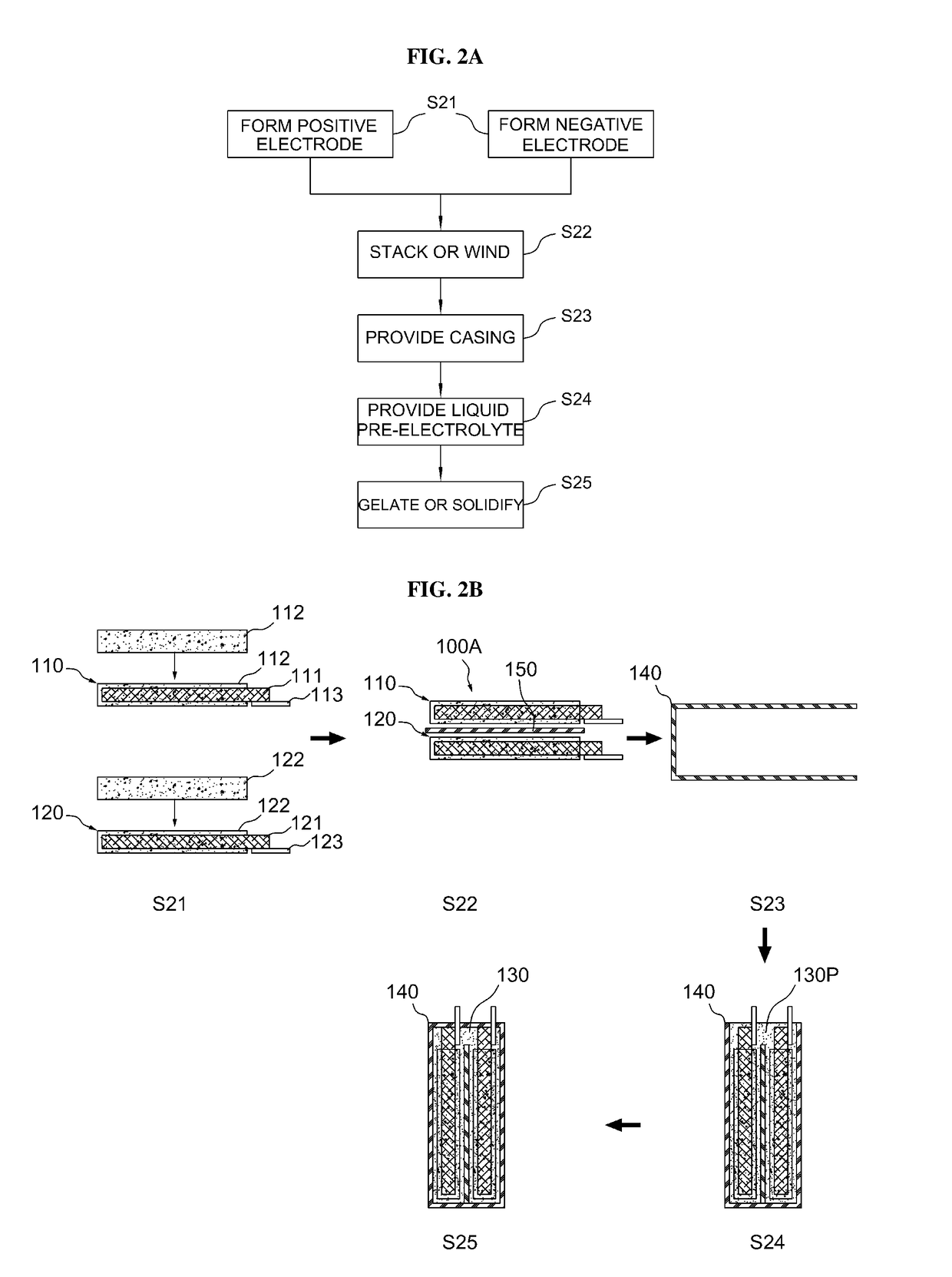

Flexible secondary battery and method for manufacturing same

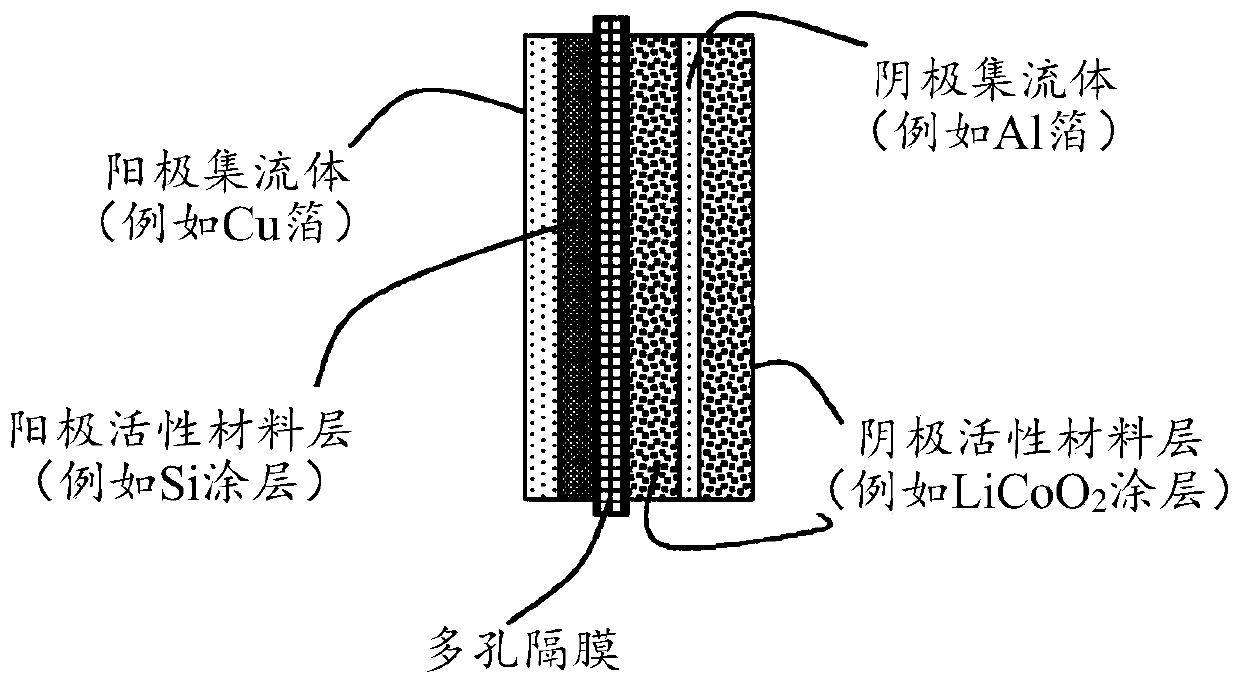

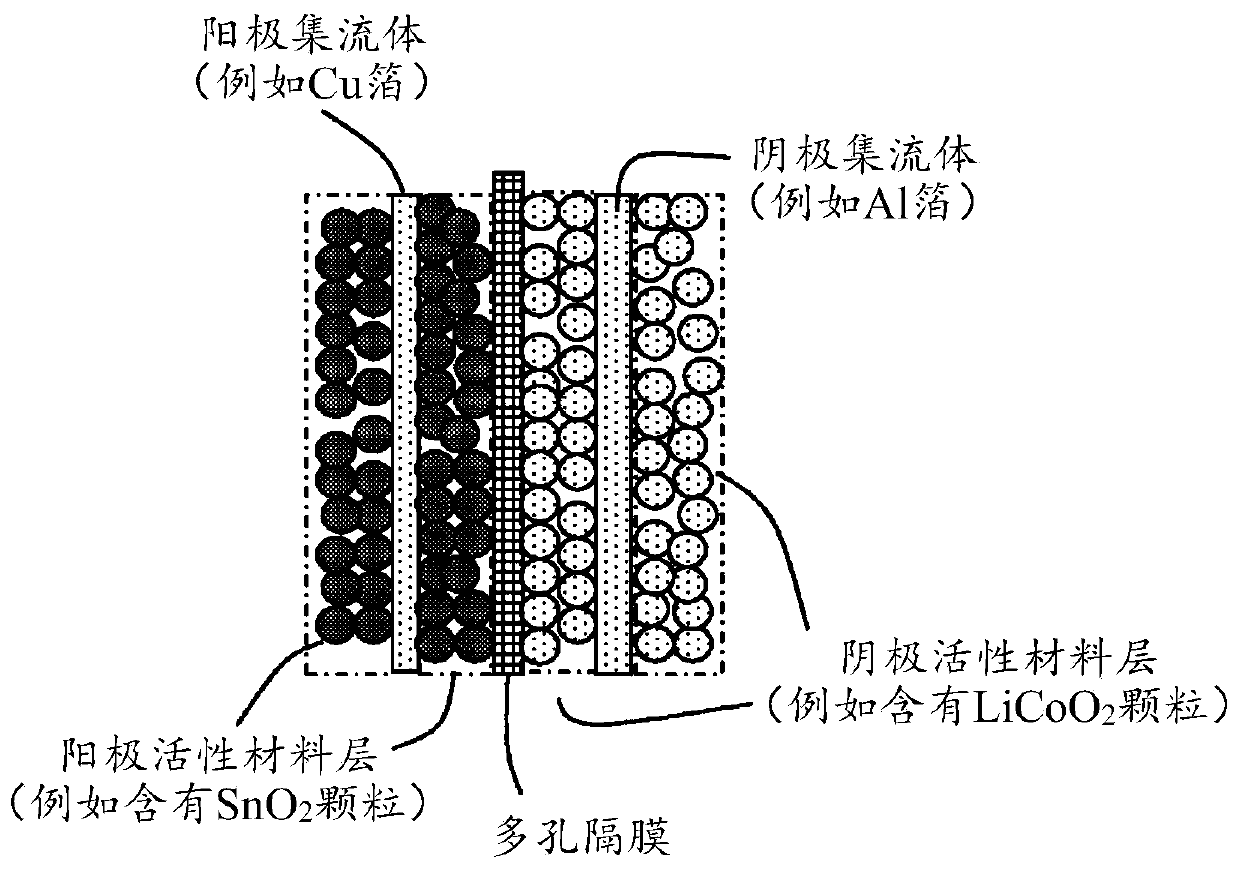

ActiveUS20170288255A1High-temperature operationImprove wettabilityFinal product manufactureElectrode carriers/collectorsElectrical batteryEngineering

Provided are a flexible secondary battery and a method of manufacturing the same. The method includes forming an electrode including a metal fiber-like current collector and an active material combined with the metal fiber-like current collector; and providing a liquid pre-electrolyte that may be either thermally polymerized or crosslinked to the electrode and applying heat thereto, such that the liquid pre-electrolyte is integrated with the electrode and forms a gelated or solidified polymer electrode.

Owner:JENAX

Multifunctional composite material based on graphene and polymer fibers and preparation method and application thereof

ActiveCN110323451AImprove thermal conductivityImprove conductivityPhysical/chemical process catalystsMagnetic/electric field screeningYarnFiber

The invention discloses a multifunctional composite material based on graphene and polymer fibers and a preparation method and application of the multifunctional composite material. A three-dimensional fiber conductive network product with the polarity-rich surface and the core-shell structure is prepared by taking the non-woven fabric as a framework, thereby inhibiting the shuttle effect in the sulfur positive electrode simultaneously, and alleviating the dendritic crystal growth problem of the lithium negative electrode so as to improve the whole performance of the lithium-sulfur battery. The lithium-sulfur battery can be used in the fields of electrocatalysis, microbial fuel cells, polymer electrode membrane electrolysis and metal-air batteries due to the characteristics of high conductivity and high specific surface area so as to provide the advantages. The composite film product is obtained by reinforcing the graphene sheet with the non-woven fabric fiber yarns, has flexibility and remarkable heat conduction, electric conduction and electromagnetic shielding properties, and can ensure safe and long-acting use of related electronic equipment.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

A novel composite electrolyte material

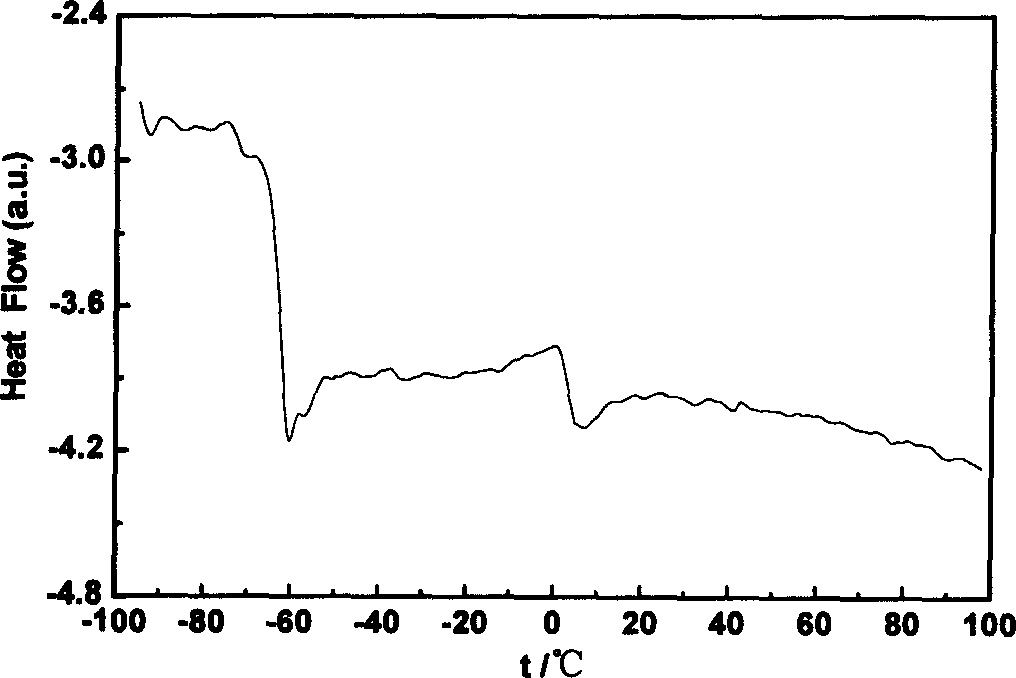

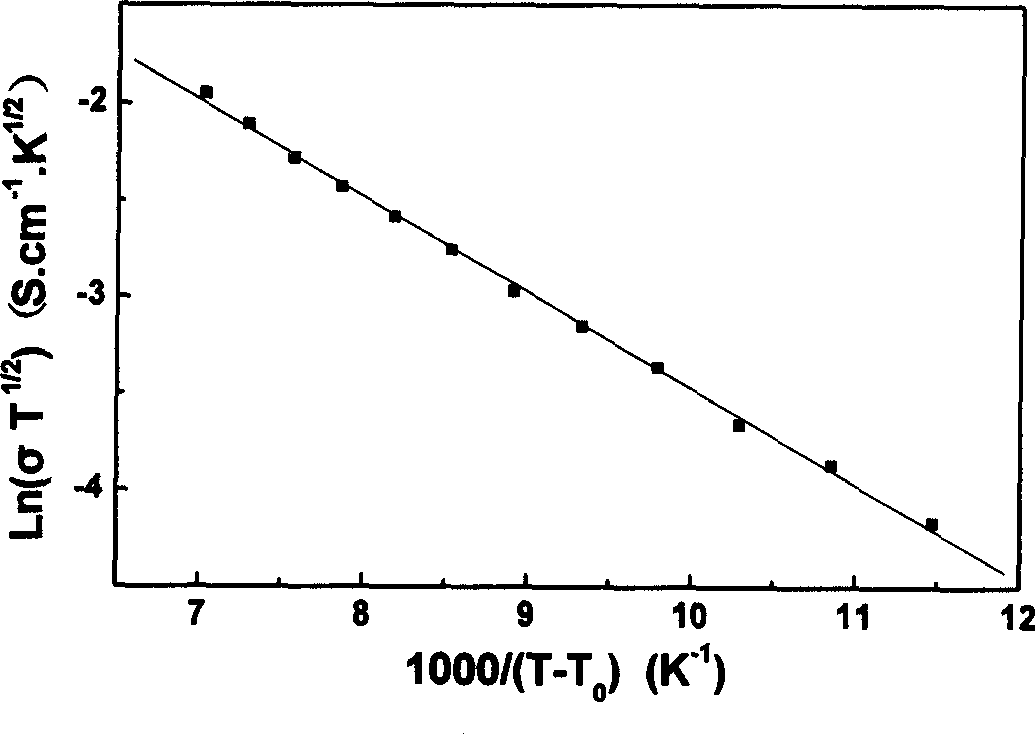

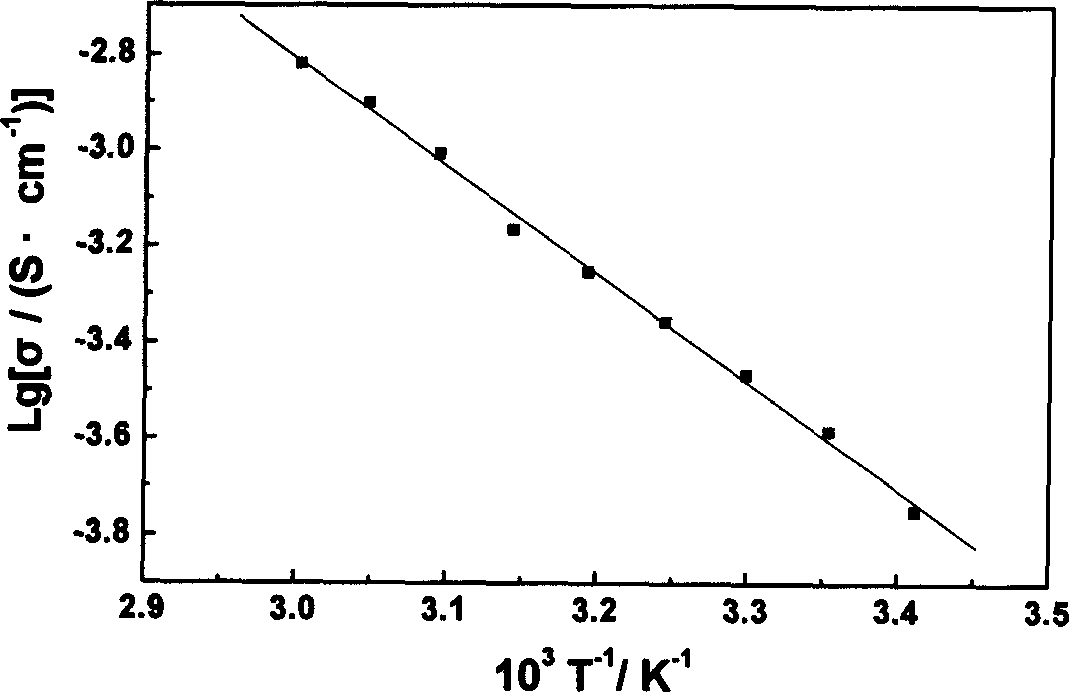

InactiveCN1547216ALess corrosiveLarge liquid rangeConductive materialCapacitor electrolytes/absorbentsCapacitanceComposite electrolyte

The invention is a kind of compound electrolyte which is based on new room temperature or low temperature fused salt (also named as ion liquid) material, and the organic solvent and polymer material are added in. the electrolyte has a good thermal stabilization, broad chemical window and high ion conducting performance, especially on aspect of safety, it is better than the liquid electrolyte in businesslike lithium ion battery. The invention adjusts the proportion and components of the negative and positive ion in the fused salt, and adds in the organic solvent and polymer, the room temperature and low temperature fused salt electrolyte, the gel polymer electrode, the solid polymer electrode and so on can be acquired, the invention has a broad prospect in lithium ion battery and electrochemical super capacitance aspects.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

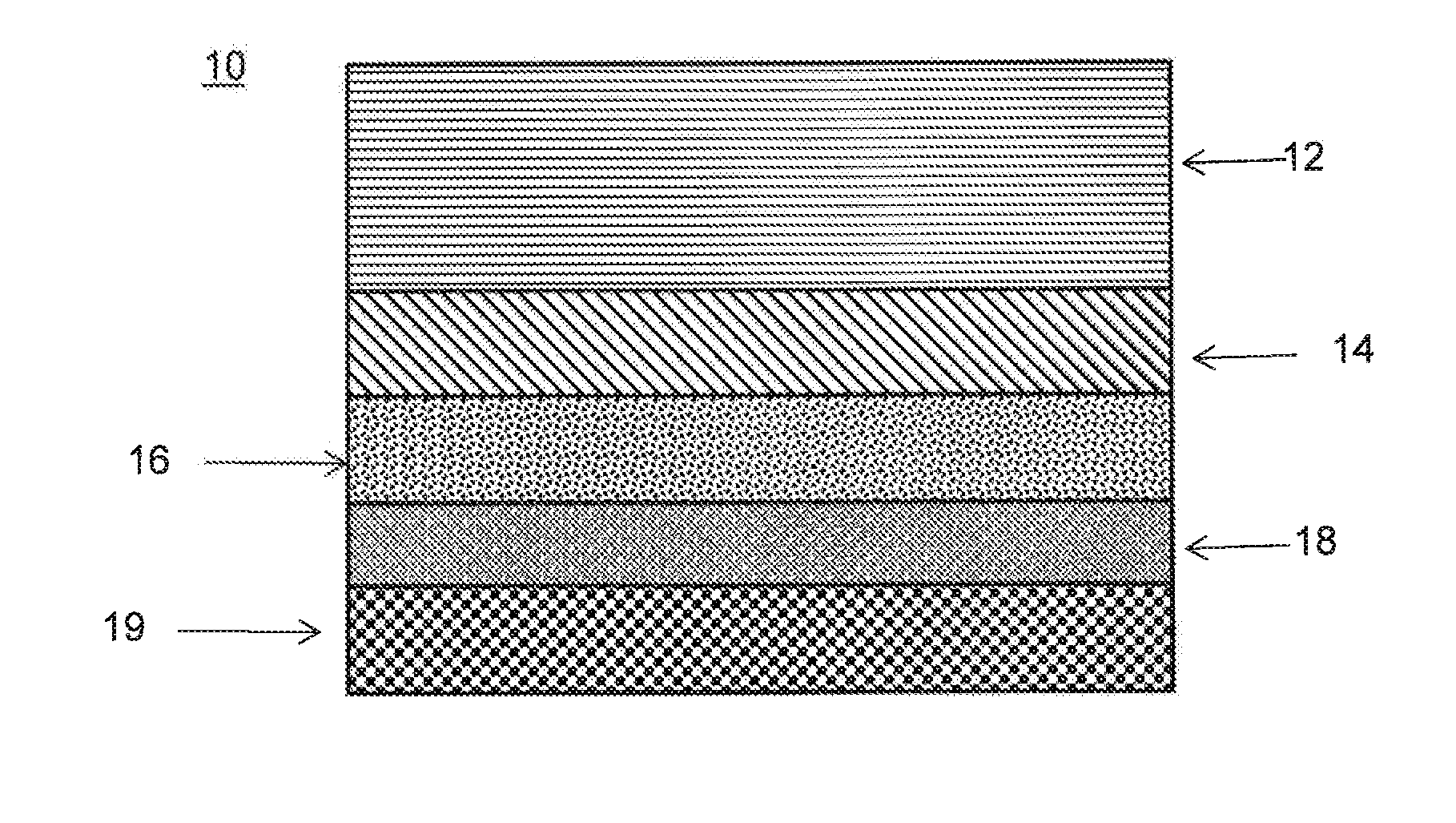

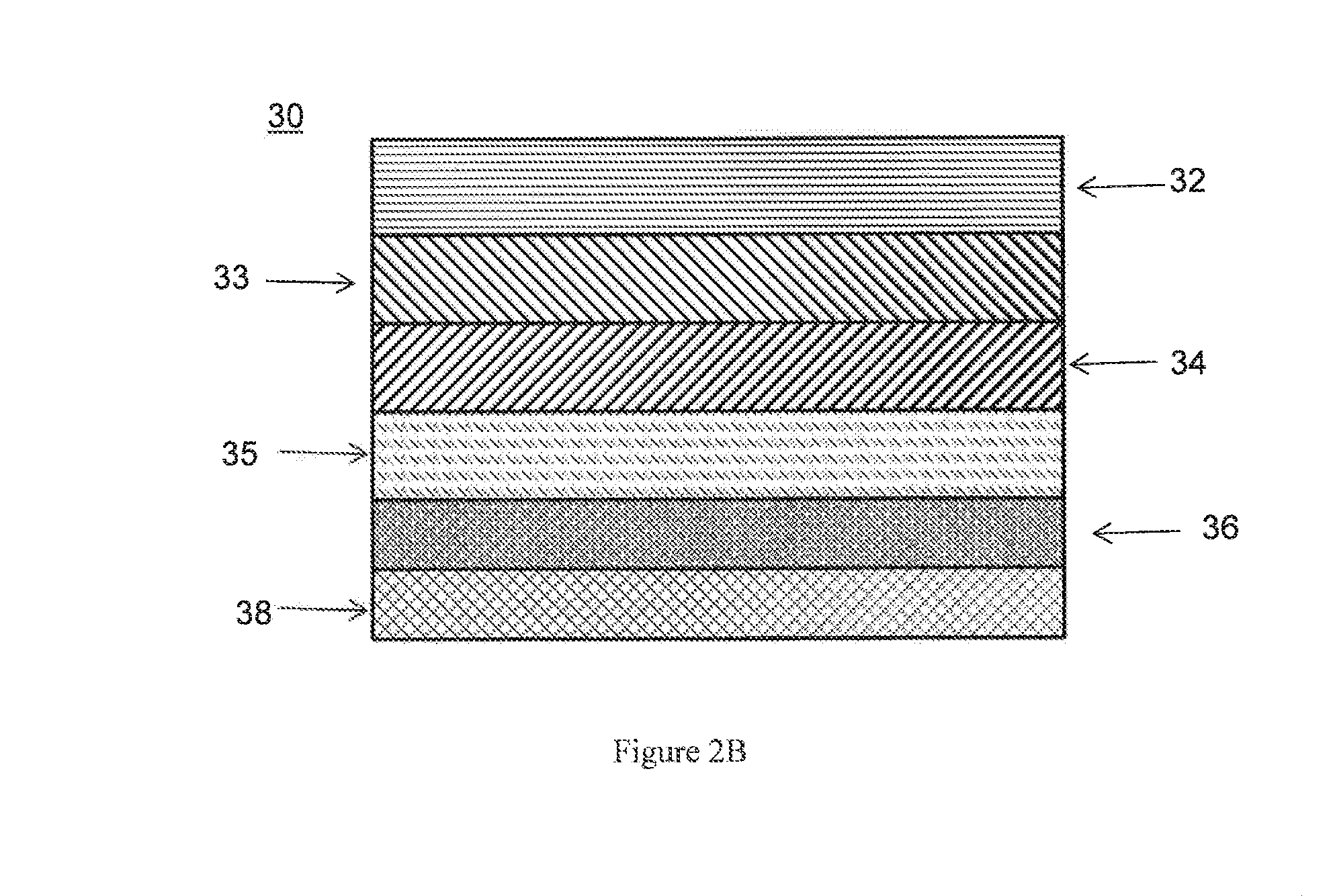

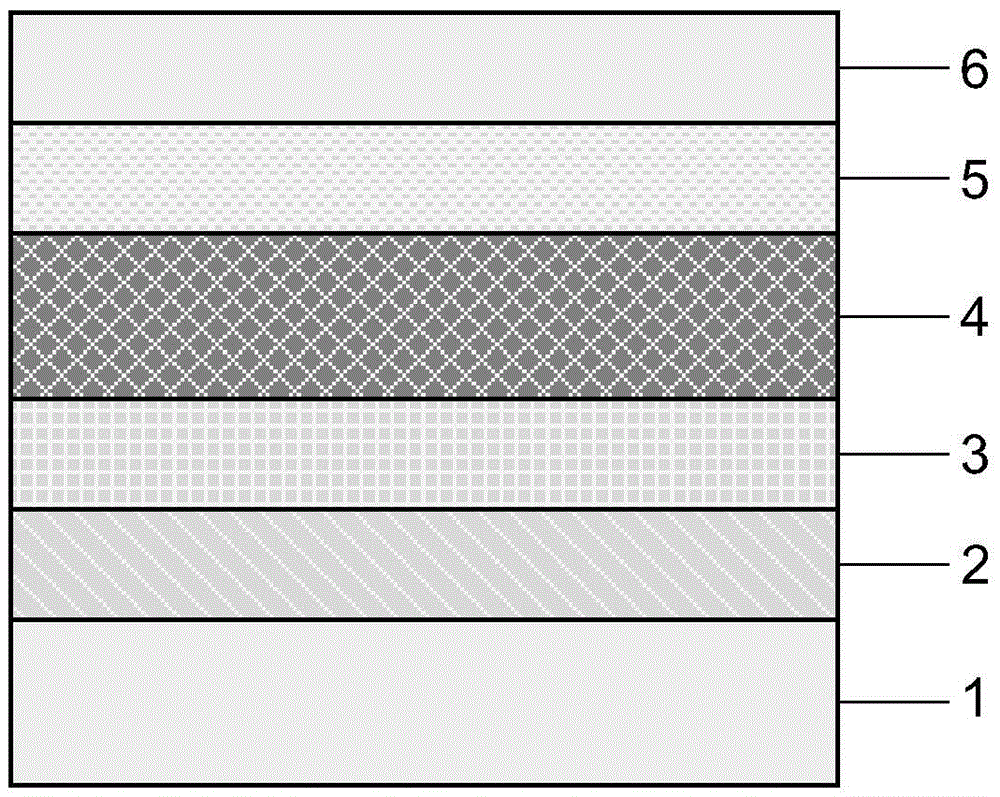

Graphene/polymer electrode-based flexible perovskite solar cell and preparation

InactiveCN105489767AHigh light transmittanceImprove conductivityFinal product manufactureSolid-state devicesPerovskite solar cellTransmittance

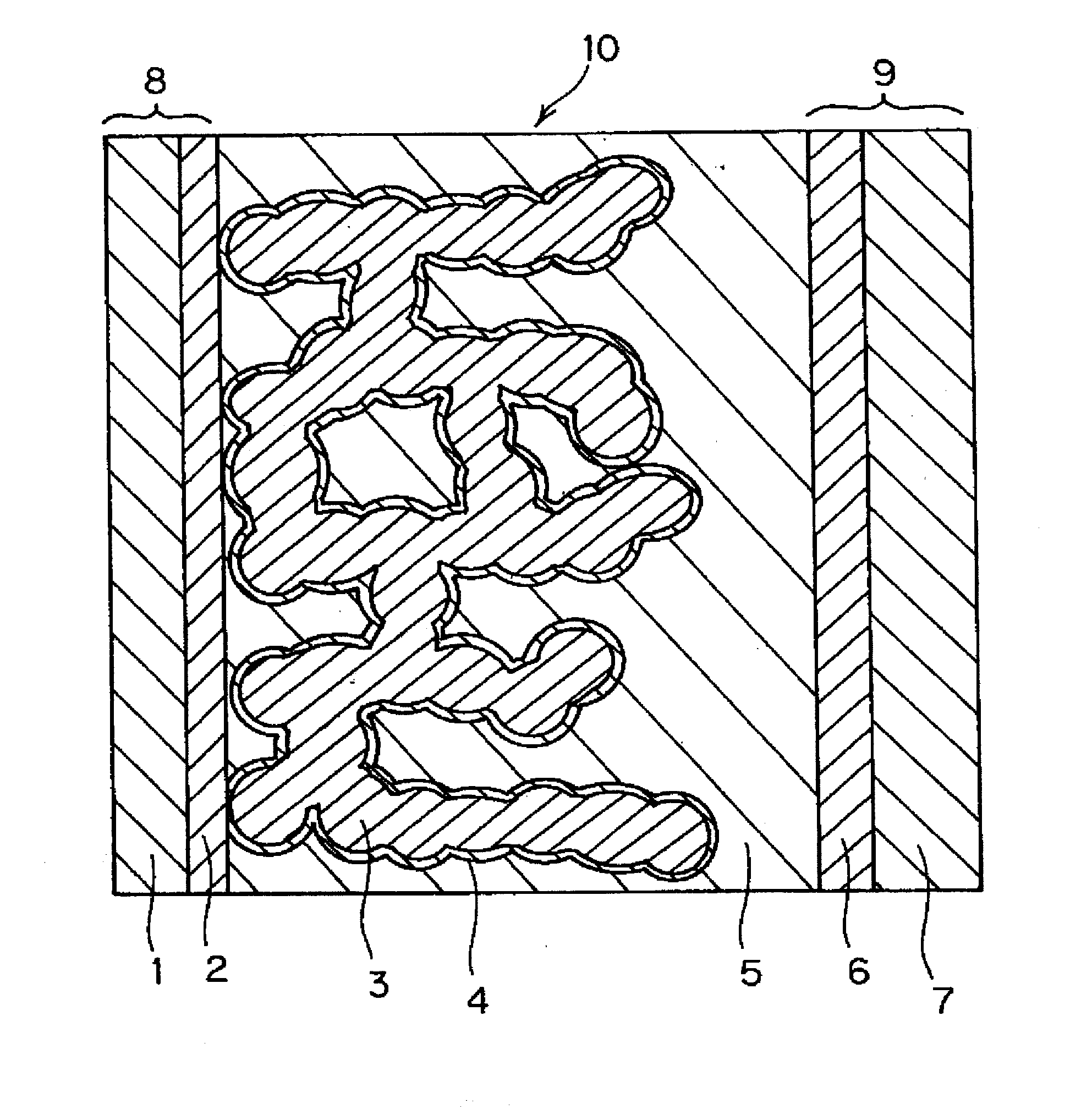

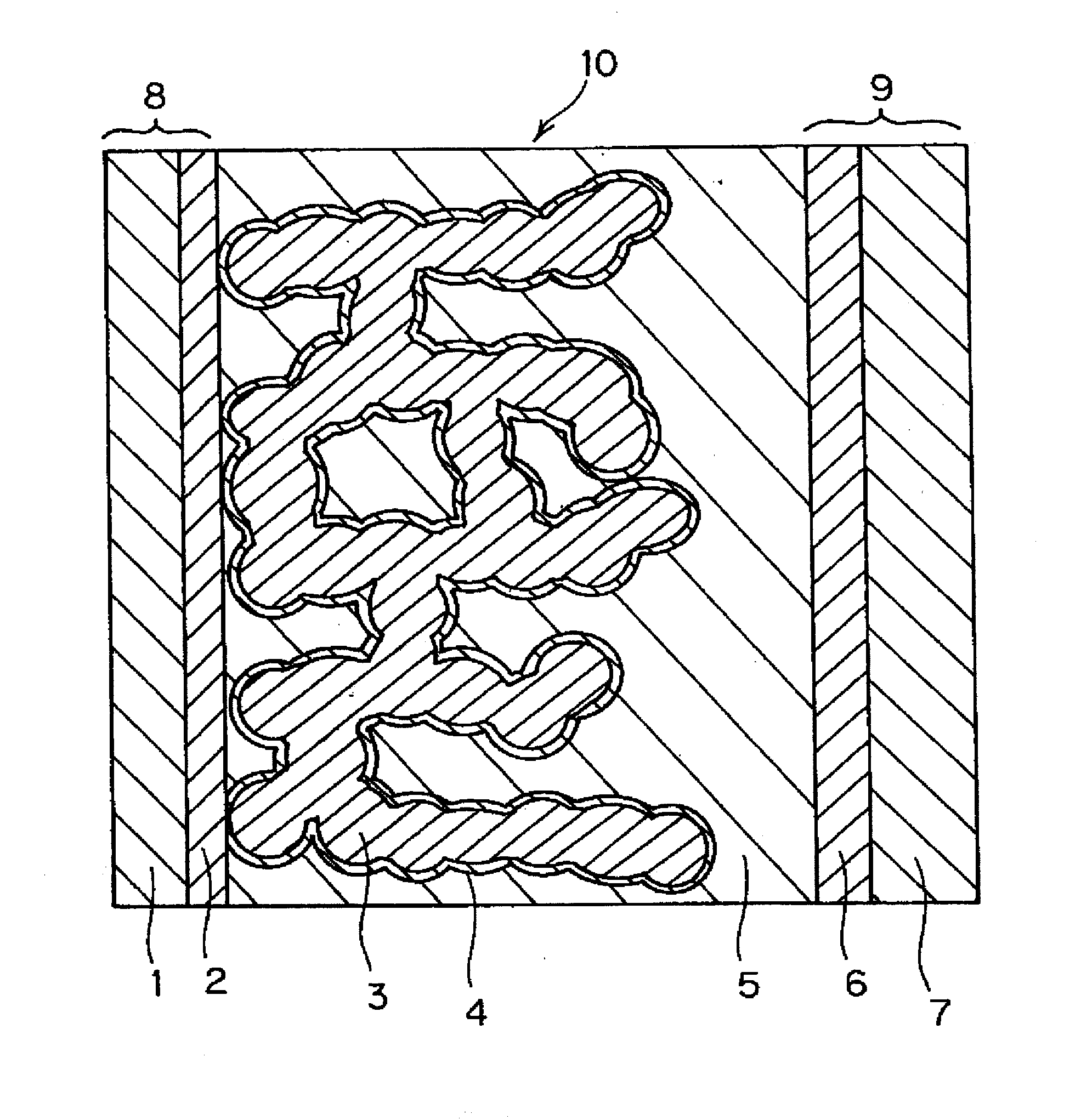

The invention relates to a graphene / polymer composite transparent electrode-based flexible perovskite solar cell and a preparation of the flexible perovskite solar cell. The graphene / polymer composite transparent electrode-based flexible perovskite solar cell comprises a flexible substrate (1), a graphene / polymer composite transparent electrode (2), a hole transport layer (3), a perovskite light absorption layer (4), an electron transport layer (5) and a back electrode (6), wherein the composite transparent electrode is formed by graphene and a conductive high-molecular polymer. The graphene / polymer composite transparent electrode-based flexible perovskite solar cell has the advantages of good light transmittance, conductivity, flexibility and stability, low production cost and high photoelectric conversion efficiency, and is easy to flexibly integrate and applicable to large-scale industrial production of the solar cell.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

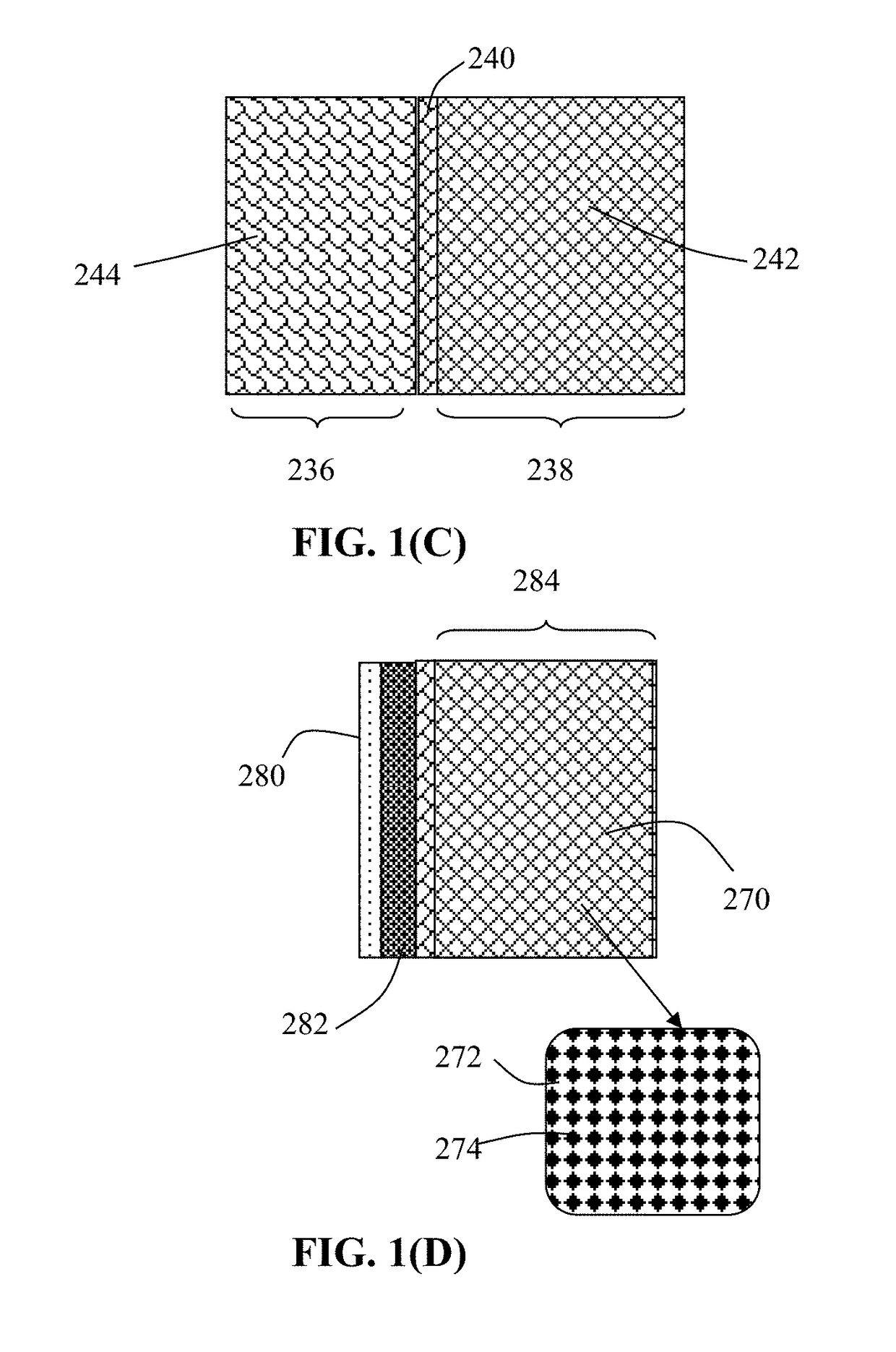

Shape-conformable alkali metal battery having a conductive and deformable quasi-solid polymer electrode

ActiveCN110679009AElectrode manufacturing processesElectrolytic inorganic material coatingElectrical batteryConducting pathway

Provided is method of preparing an alkali metal cell, the method comprising: (a) combining a quantity of an active material, a quantity of an electrolyte, and a conductive additive to form a deformable and conductive electrode material, wherein the conductive additive, containing conductive filaments, forms a 3D network of electron-conducting pathways and the electrolyte contains an alkali salt and an ion-conducting polymer dissolved or dispersed in a solvent; (b) forming the electrode material into a quasi-solid polymer electrode, wherein the forming includes deforming the electrode materialinto an electrode shape without interrupting the 3D network of electron-conducting pathways such that the electrode maintains an electrical conductivity no less than 10-6 S / cm; (c) forming a second electrode; and (d) forming an alkali metal cell by combining the quasi-solid electrode and the second electrode. The second electrode may also be a quasi-solid polymer electrode.

Owner:NANOTEK INSTR

Polymeric electrode for electrophysiological testing

InactiveUS6899800B2Simple and reliable processReduce manual operationsImmobilised enzymesBioreactor/fermenter combinationsBiological membraneBiomedical engineering

A polymeric material such as PDMS is molded into an electrode structure containing a micron-size aperture for receiving and forming a giga-ohm seal with a biological membrane. One end of a tube is filled with uncured polymeric material and pressed against a support surface to prevent drainage. A conventional micropipette having a size suitable for sliding through the tube is introduced, tip first, into the tube and is allowed to fall through the polymeric material and rest against the support surface. The assembly is heated to cure the polymer and the micropipette is removed from the tube, thereby leaving a polymeric plug at the end of the tube with an aperture suitable in shape and size for patch-clamp giga-ohm seal electrode applications. A multi-well tray with a polymeric electrode plug in each well is constructed using the same approach.

Owner:MOLECULAR DEVICES

Shape-Conformable Alkali Metal Battery Having a Conductive and Deformable Quasi-solid Polymer Electrode

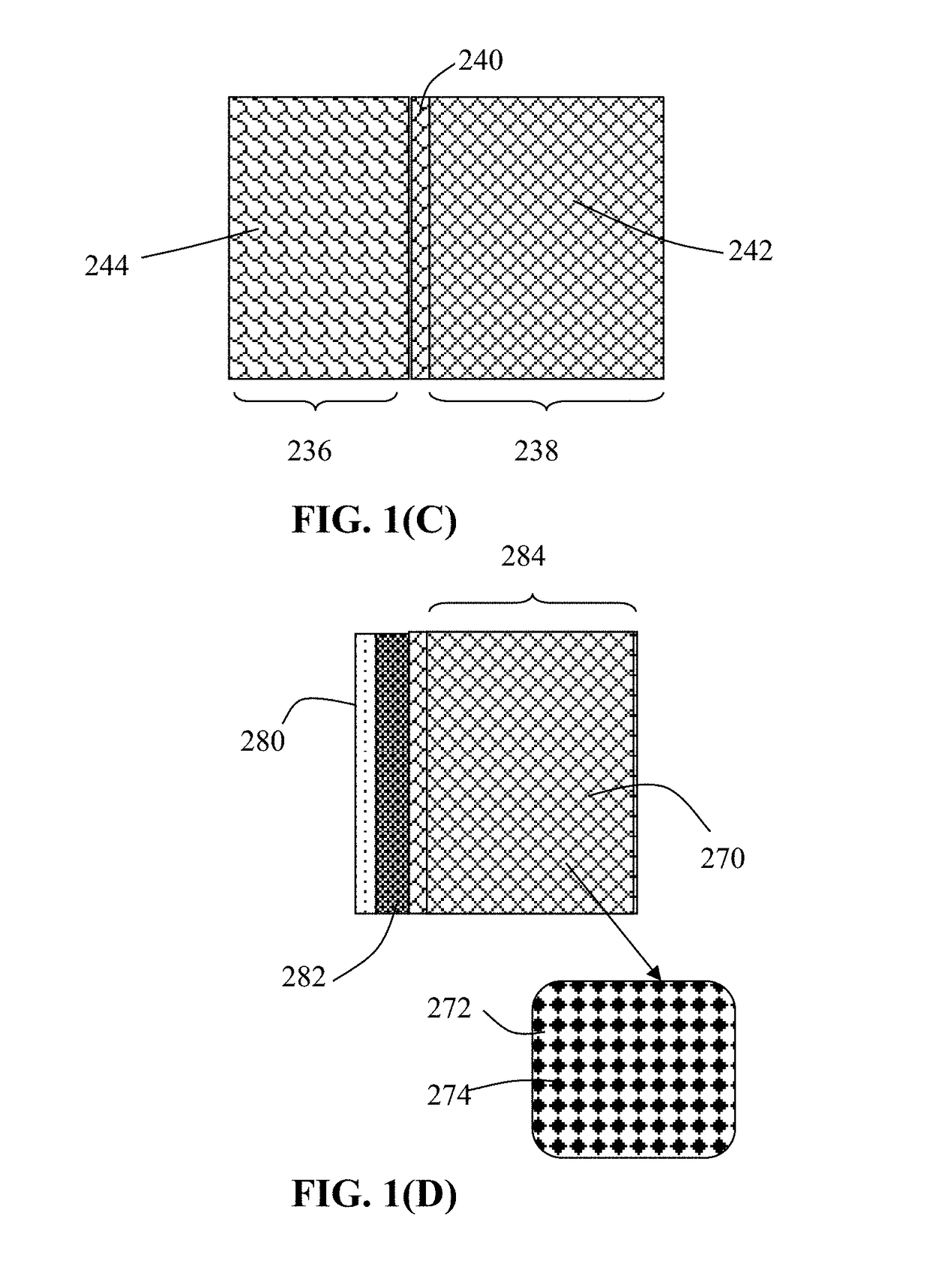

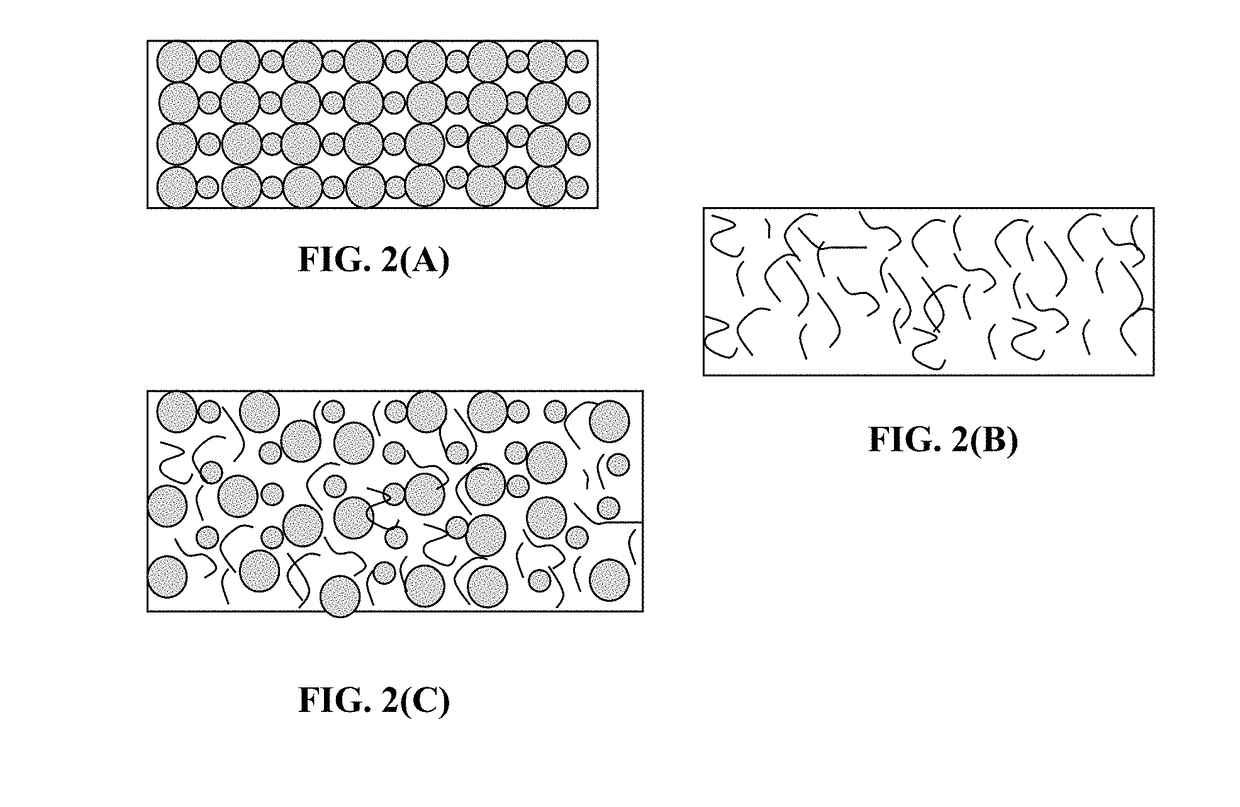

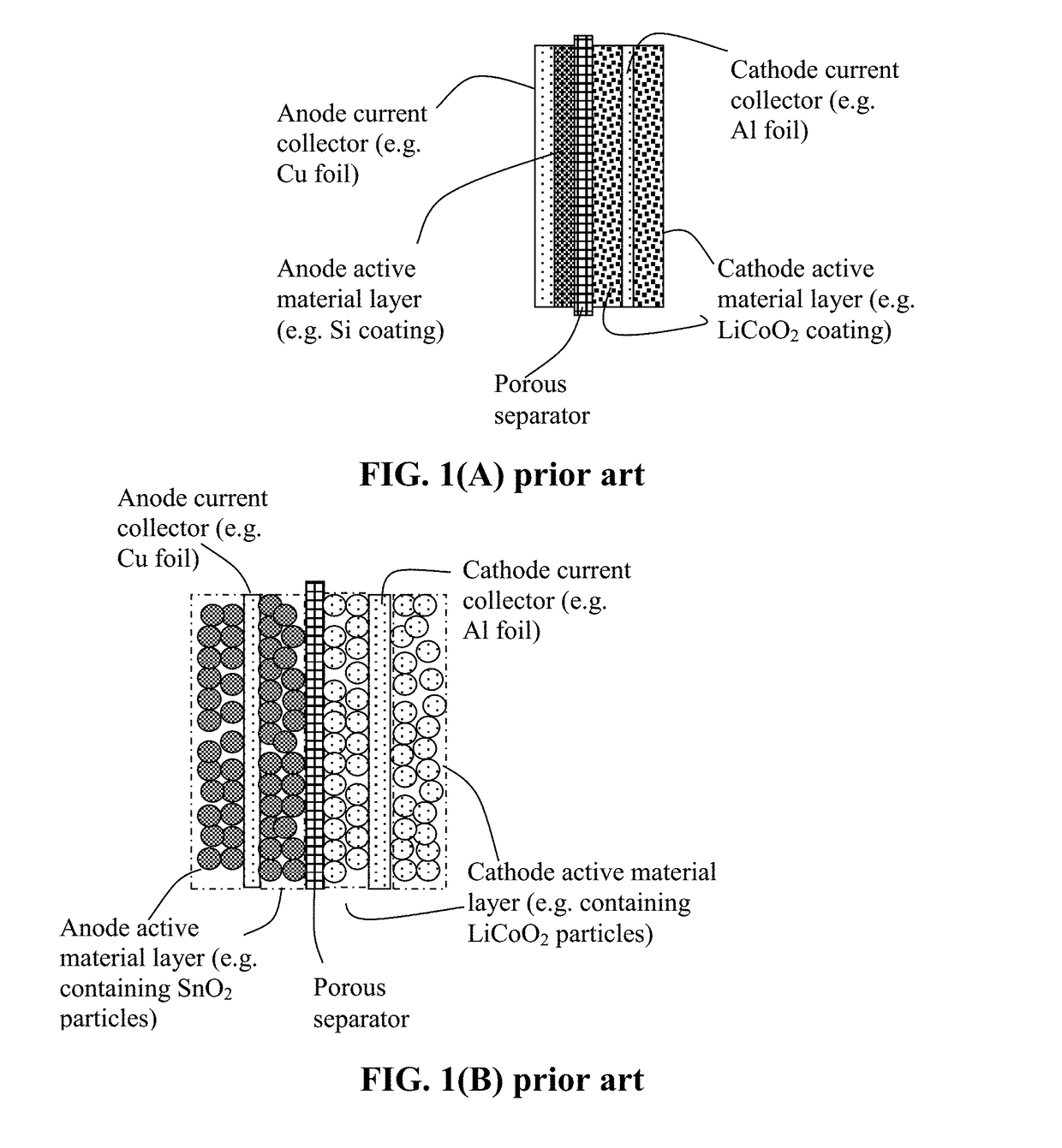

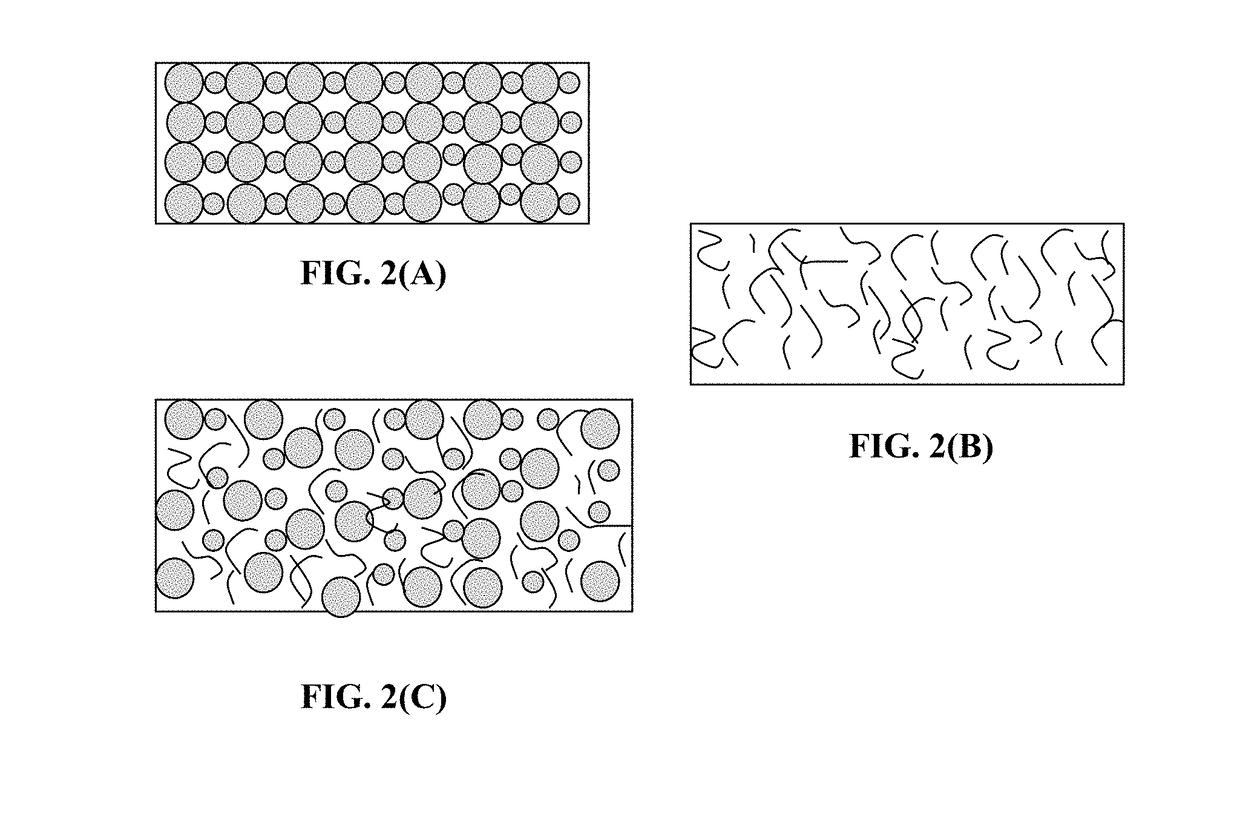

ActiveUS20180351200A1High active material mass loadingLow overhead weightHybrid capacitor separatorsSolid electrolytesConducting pathwayMass loading

Provided is an alkali metal cell comprising: (a) a quasi-solid cathode containing 30% to 95% by volume of a cathode active material, about 5% to about 40% by volume of a first electrolyte containing an alkali salt dissolved in a solvent and an ion-conducting polymer dissolved, dispersed in or impregnated by a solvent, and about 0.01% to about 30% by volume of a conductive additive wherein the conductive additive, containing conductive filaments, forms a 3D network of electron-conducting pathways such that the quasi-solid electrode has an electrical conductivity from about 10−6 S / cm to about 300 S / cm; (b) an anode; and (c) an ion-conducting membrane or porous separator disposed between the anode and the quasi-solid cathode; wherein the quasi-solid cathode has a thickness from 200 μm to 100 cm and a cathode active material having an active material mass loading greater than 10 mg / cm2.

Owner:GLOBAL GRAPHENE GRP INC

Method of Producing a Shape-Conformable Alkali Metal Battery Having a Conductive and Deformable Quasi-solid Polymer Electrode

ActiveUS20180351201A1High densityLow overhead weight and volumeHybrid capacitor electrolytesHybrid capacitor electrodesPolymer scienceConducting pathway

Provided is method of preparing an alkali metal cell, the method comprising: (a) combining a quantity of an active material, a quantity of an electrolyte, and a conductive additive to form a deformable and conductive electrode material, wherein the conductive additive, containing conductive filaments, forms a 3D network of electron-conducting pathways and the electrolyte contains an alkali salt and an ion-conducting polymer dissolved or dispersed in a solvent; (b) forming the electrode material into a quasi-solid polymer electrode, wherein the forming includes deforming the electrode material into an electrode shape without interrupting the 3D network of electron-conducting pathways such that the electrode maintains an electrical conductivity no less than 10−6 S / cm; (c) forming a second electrode; and (d) forming an alkali metal cell by combining the quasi-solid electrode and the second electrode. The second electrode may also be a quasi-solid polymer electrode.

Owner:GLOBAL GRAPHENE GRP INC

High-temperature stable fibriform lithium air battery and preparation method thereof

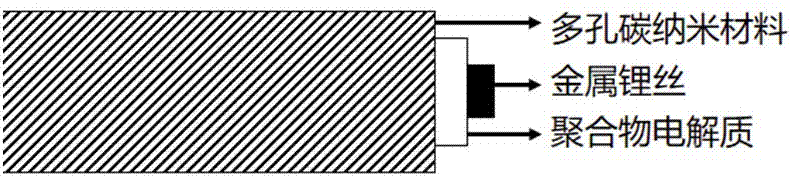

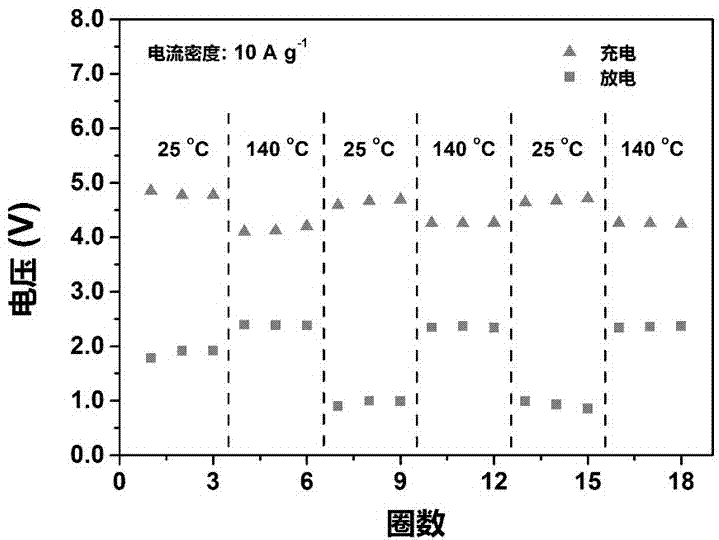

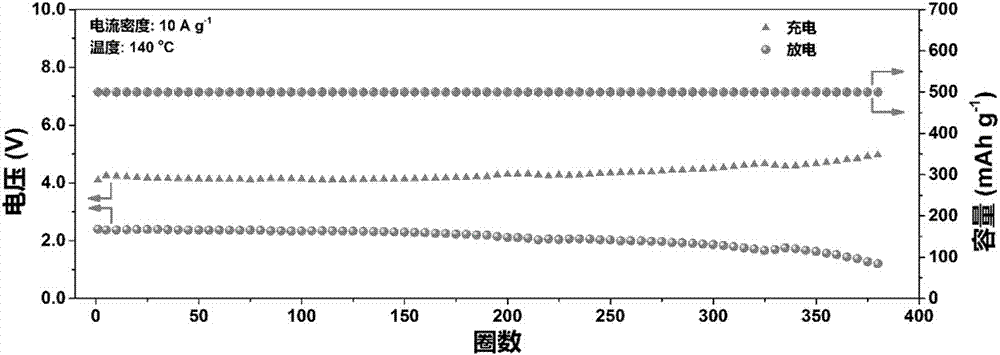

InactiveCN106935905AStable jobLow vapor pressureSolid electrolytesFuel and secondary cellsLithium metalElectrical battery

The invention belongs to the technical field of new energy sources, and specifically relates to a high-temperature stable fibriform lithium air battery and a preparation method thereof. A traditional lithium air battery is restricted by inflammable, explosive and volatile characteristics of an organic electrolyte, the traditional lithium air battery is always unbearable for relatively high temperature in actual using process, and the liquid condition of the electrolyte also has a leakage pollution risk frequently, so that the application of the battery as a flexible fibriform wearable energy source device is restricted. However, ionic liquid has relatively low vapor pressure, relatively wide electrochemical window and excellent stability, so that the fibriform lithium air battery has excellent application prospect. Based on the ionic liquid and a macromolecule skeleton material, a solid polymer electrode capable of resisting high temperature is prepared, and the solid polymer electrode is combined with an orientation carbon nano tube thin film and lithium metal, so that the high-temperature stable fibriform lithium air battery is constructed. The battery can operate stably at the temperature reaching up to 140 DEG C, more than 380 cycles of charge and discharge can be cycled under high current of 10 A g<-1>, and the battery has relatively large application prospect in the field of high-temperature-resistant fabric.

Owner:FUDAN UNIV

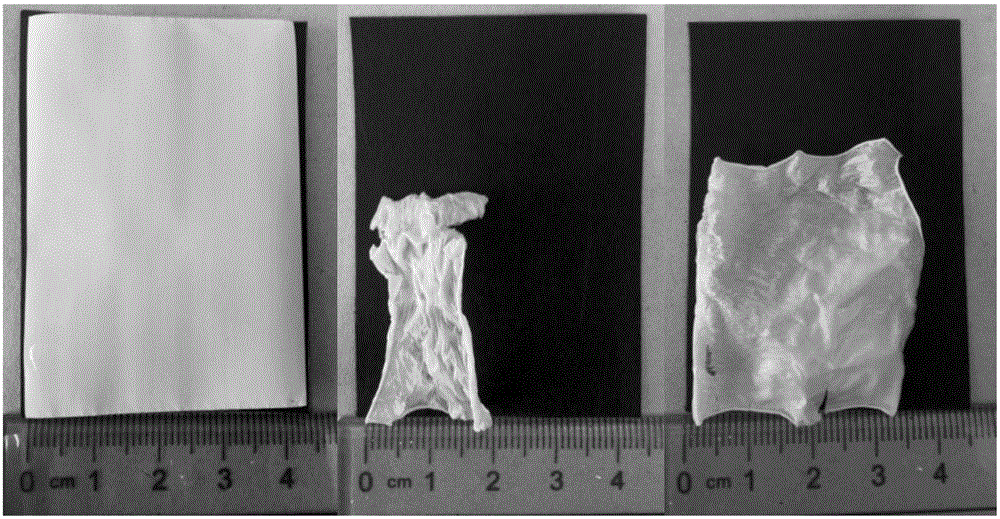

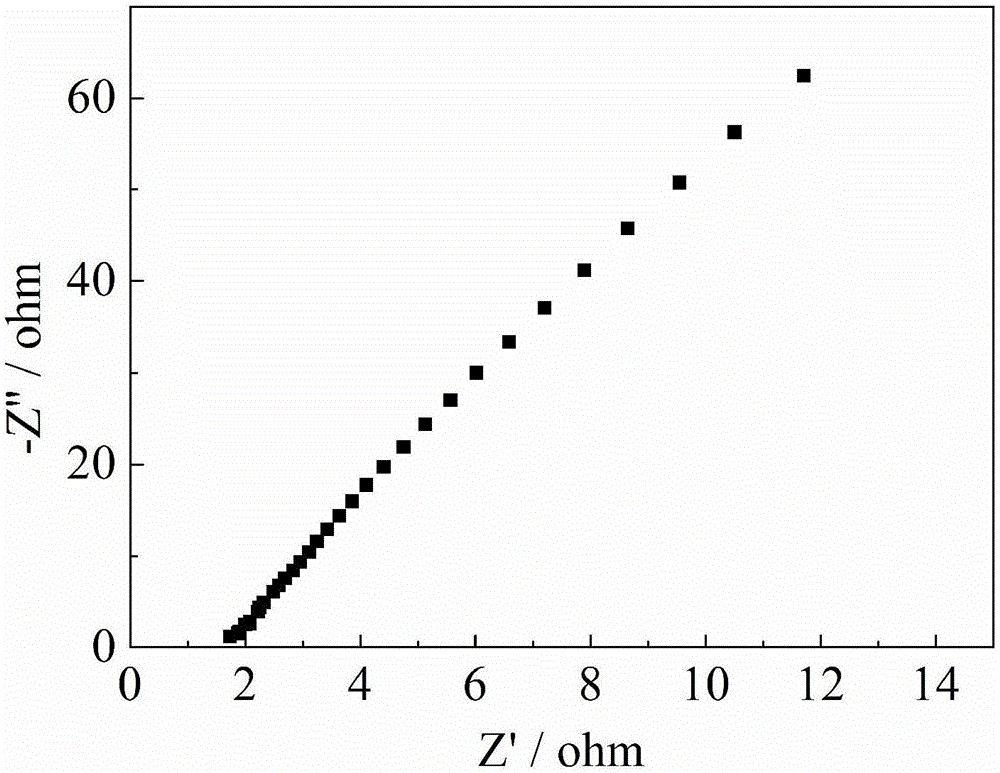

Gel polymer electrolyte for lithium ion battery, and preparation method thereof

InactiveCN105119012AImproved resistance to heat shrinkageImprove conductivitySolid electrolytesSecondary cellsPolymer sciencePolyolefin

The invention discloses a gel polymer electrolyte for a lithium ion battery, and a preparation method thereof. The gel polymer electrode is composed of a polymer film as a substrate, and an electrolyte adsorbed to the polymer film; and the polymer film is made through the following steps: co-dissolving Carbomer resin, polyvinylidene fluoride and cellulose acetate butyrate in a solvent, mechanically stirring to form a liquid, coating the liquid, and solidifying the coated liquid on a polyolefin micro-porous film. The preparation method of the gel polymer electrolyte comprises the following steps: co-dissolving polyvinylidene fluoride and cellulose acetate butyrate in the solvent to prepare a liquid 1, adding the Carbomer resin to the liquid, fully stirring to form a liquid 2, immersing the polyolefin micro-porous film in the liquid 2, drying, immersing the dried polymer film in the electrolyte, and taking out the immersed film. The polymer lithium ion battery comprises the gel polymer electrolyte, a positive electrode and a negative electrode. The gel polymer electrolyte has the advantages of thermal contraction resistance, high conductivity and high electrochemical stability.

Owner:SOUTH CHINA NORMAL UNIVERSITY

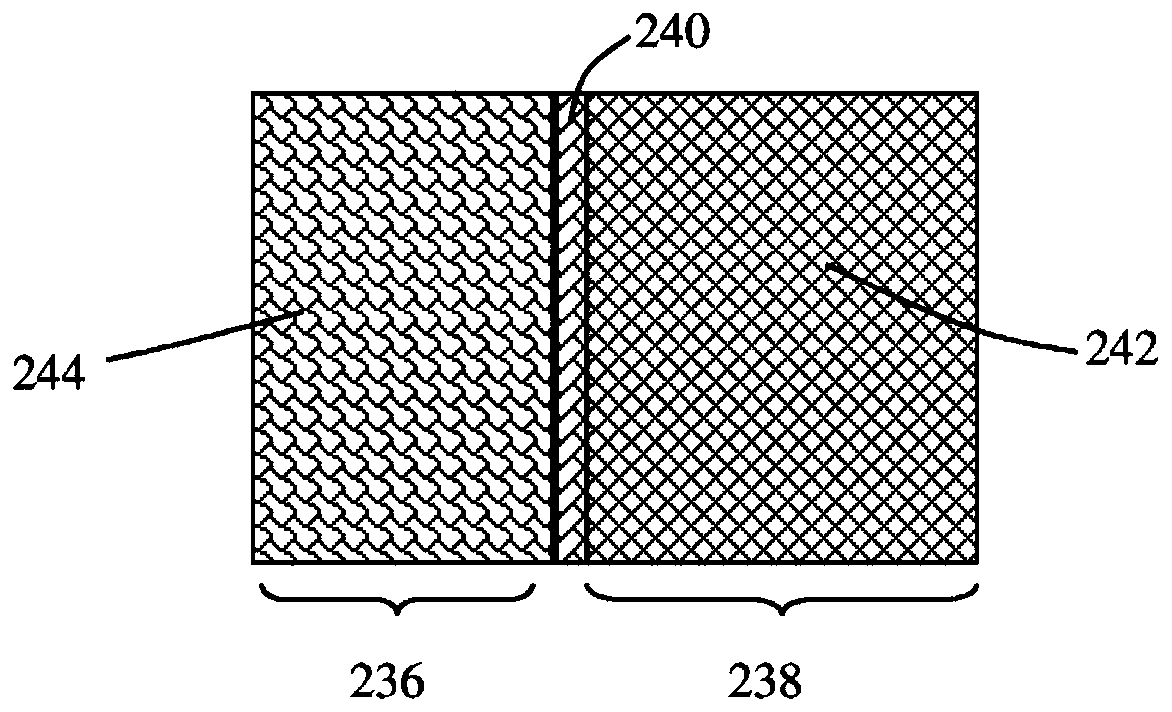

Electrowetting device with polymer electrode

The invention concerns an electrowetting optical device comprising a chamber (15) comprising first and second immiscible liquids (16, 18) contacting each other at a liquid-liquid interface (19), the first liquid being an insulating liquid and the second liquid being a conducting liquid; a first electrode (20) in the contact with the second liquid; and a second electrode (202) insulated from the first and second liquids by an insulating layer, wherein the second electrode is formed of a conductive molded polymer material, wherein the curvature of said liquid-liquid interface is controllable by application of a voltage between said first and second electrodes.

Owner:INVENIOS FRANCE SAS

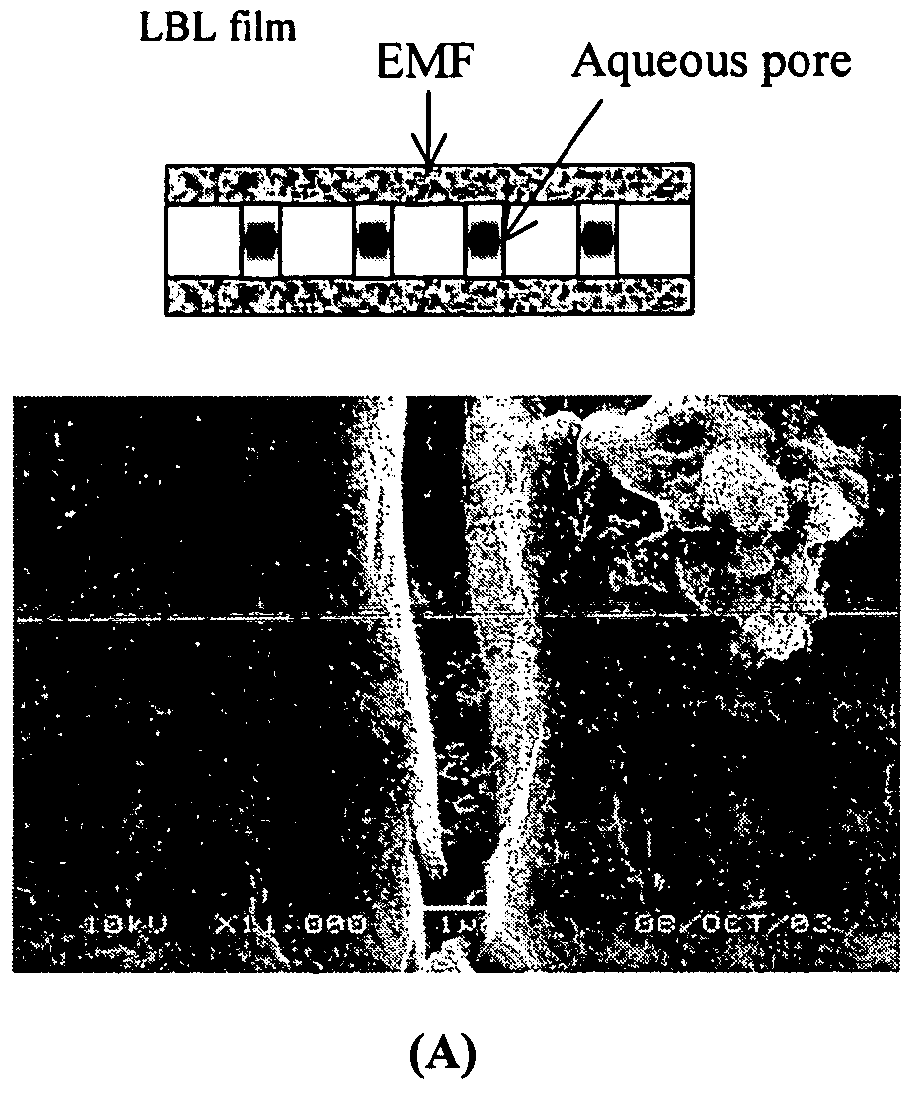

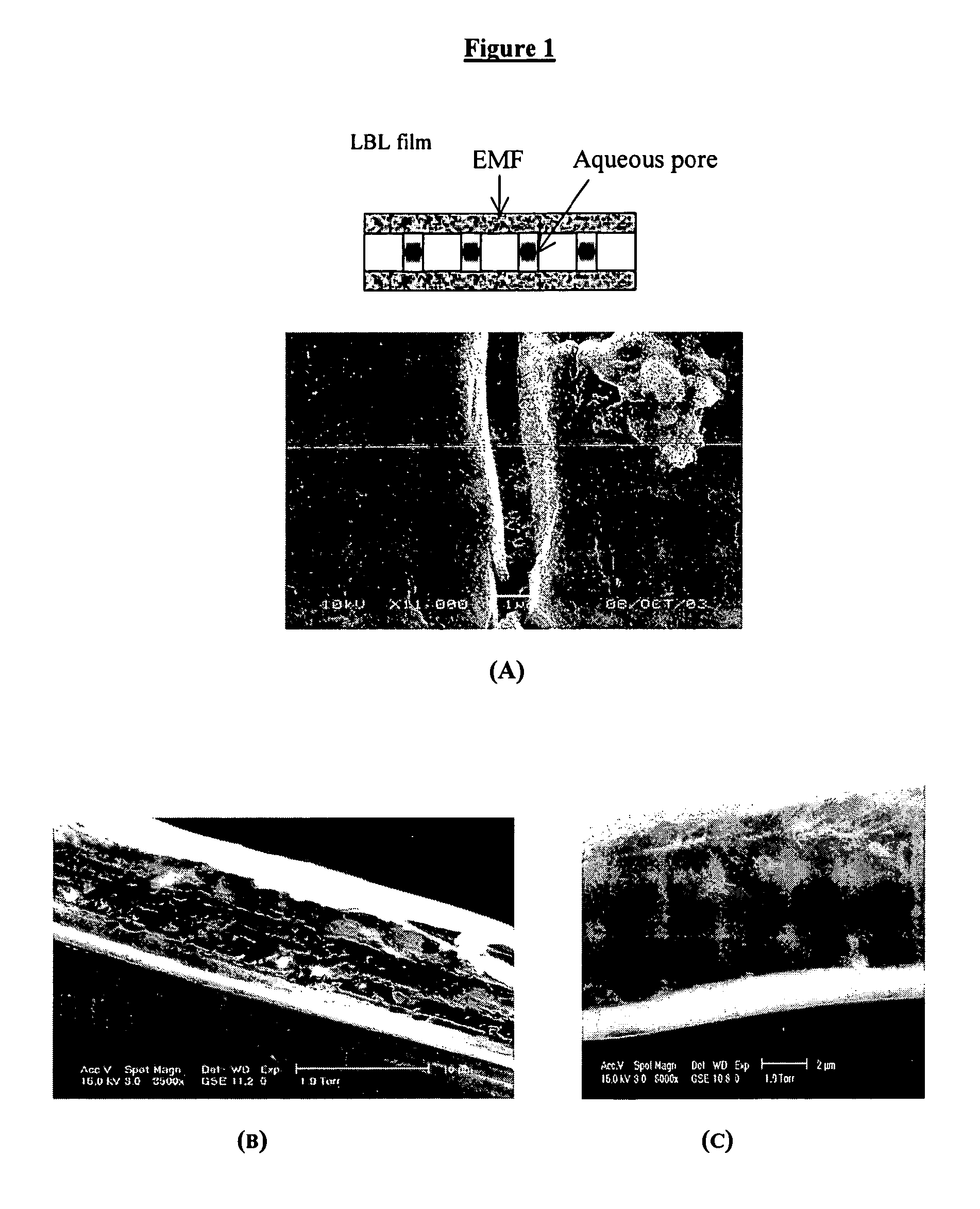

Carbon-Polymer Electrochemical Systems and Methods of Fabricating Them Using Layer-by-Layer Technology

One aspect of the invention provides ion-exchange and gas-diffusion membranes, fabricated by a layer-by-layer approach, for use, e.g., in electrochemical cells; a process for making membrane electrode assemblies fabricated using porous frameworks, LBL composite membranes and LBL carbon-Polymer electrodes; and the application of the membrane and electrode assemblies to a variety of devices, both electrochemical and otherwise.

Owner:MASSACHUSETTS INST OF TECH

Method for producing electroconductive polymer electrode, and dye-sensitized solar cell equipped with the same

InactiveUS20110000527A1Improve electrode performanceEasy to patternElectrolytic capacitorsFinal product manufactureArylConductive polymer

A method for producing an electroconductive polymer electrode that is excellent in electroconductivity and catalyst capability, is easily patterned, is high in use efficiency of a coating solution, and can produce conveniently with good reproducibility and productivity, and a dye-sensitized solar cell with an excellent conversion efficiency obtained by using the same are provided. Specifically, such a method is employed that a solution containing a monomer of an electroconductive polymer, a pyrrolidone compound represented by the following general formula (1) as a polymerization controlling agent and an oxidizing agent is coated on an electrode substrate, and then the monomer is polymerized by oxidation polymerization to form an electroconductive polymer electrode.wherein in the formula (1), R1 represents an alkyl group or an aryl group.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

Triazine ring covalent organic polymer and electrode material, as well as preparation method and application thereof

ActiveCN108976417AGood electron conduction efficiencyModification controllableDispersed particle separationWater/sewage treatmentMolten stateCapacitance

The invention relates to a triazine ring covalent organic polymer and an electrode material, as well as a preparation method and application thereof. The preparation method of the triazine ring covalent organic polymer comprises the following steps: S1, mixing nitrile monomer and zinc chloride, reacting for 40-80 hours under a zinc chloride molten state to obtain black solid, wherein the molar ratio of the nitrile monomer to the zinc chloride is 1:(1-15); and S2, dissolving, filtering and drying the black solid obtained in the S1 to obtain the triazine ring covalent organic polymer. The preparation method is simple in process and low in cost, is easily for large-scale production, and has a great application space in the field of membrane capacitance deionizing and desalting. The triazine ring covalent organic polymer has excellent electro-adsorption performance due to nitrogen-doped heteroatom effect and microporous effect, has excellent hydrophily, chemical stability, thermal stability and electron conducting efficiency; and double electrode layers are generated in the adsorbing process, and a great amount of charged particles are adsorbed.

Owner:GUANGDONG UNIV OF TECH

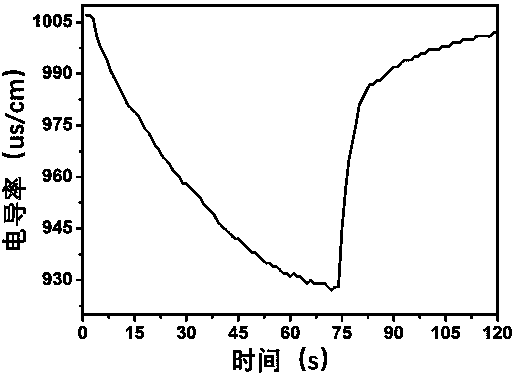

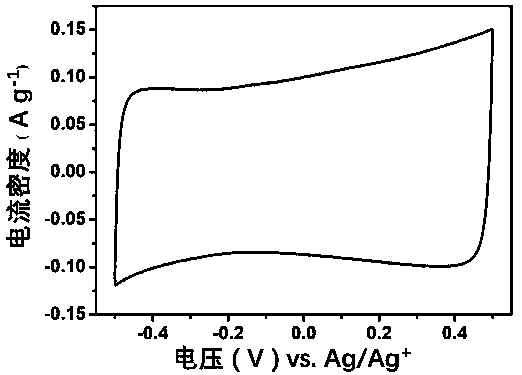

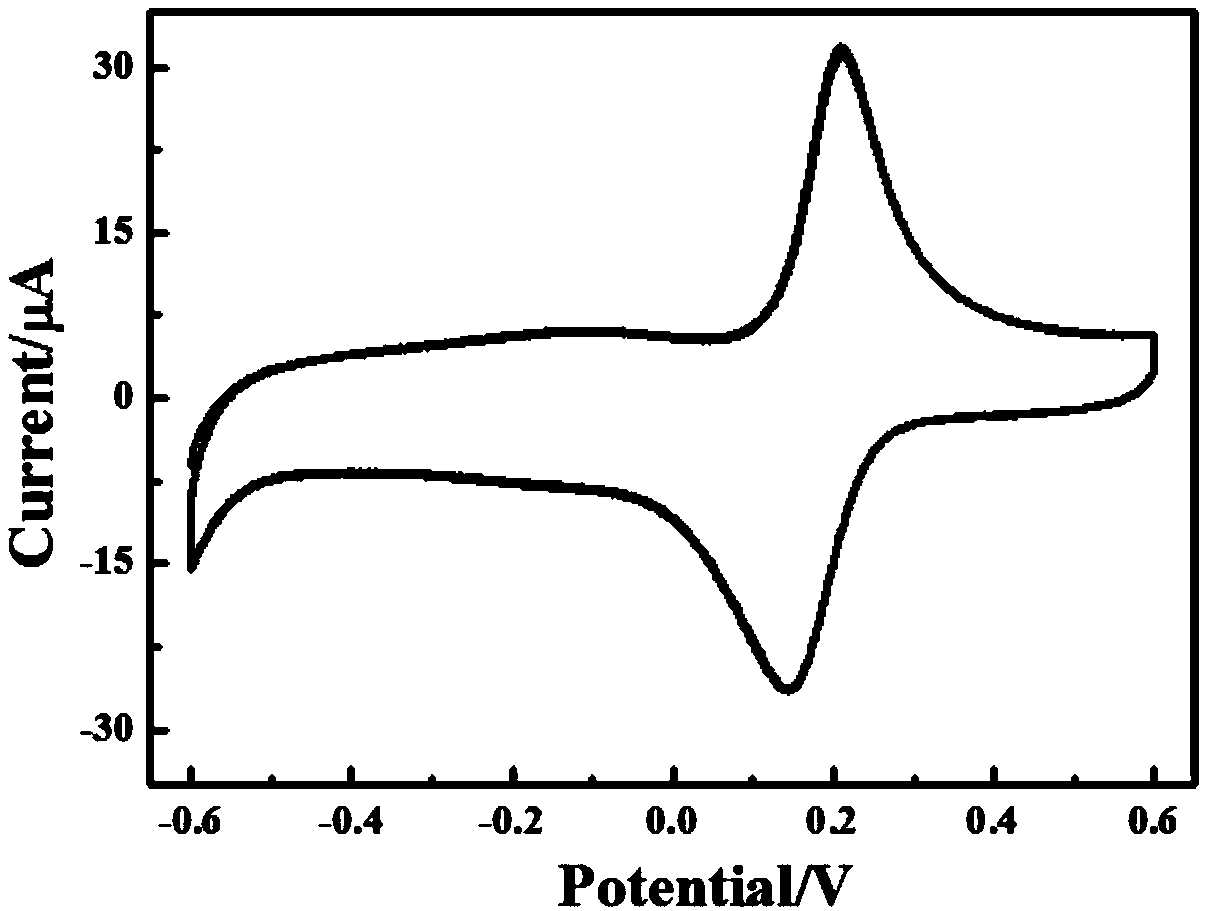

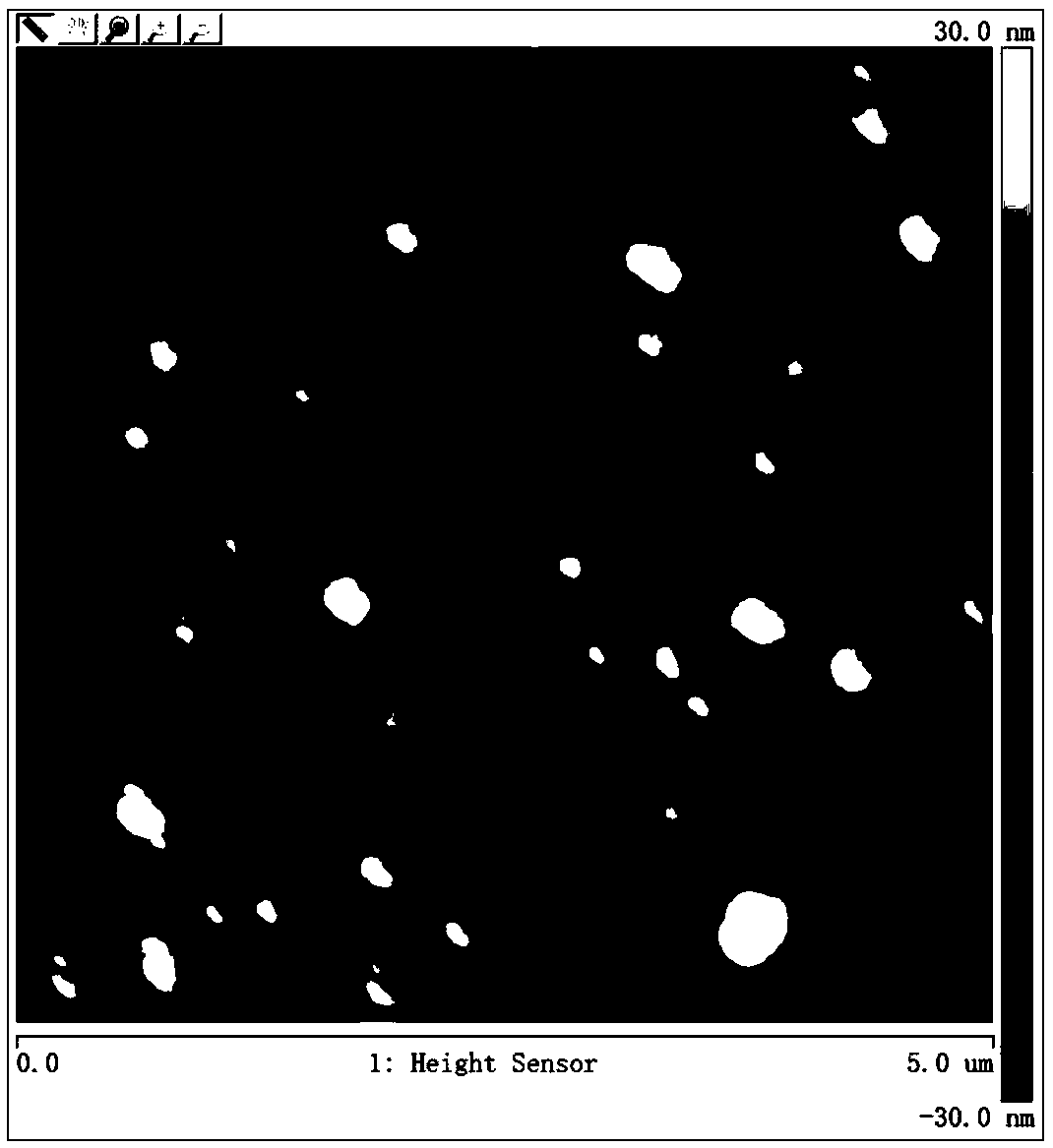

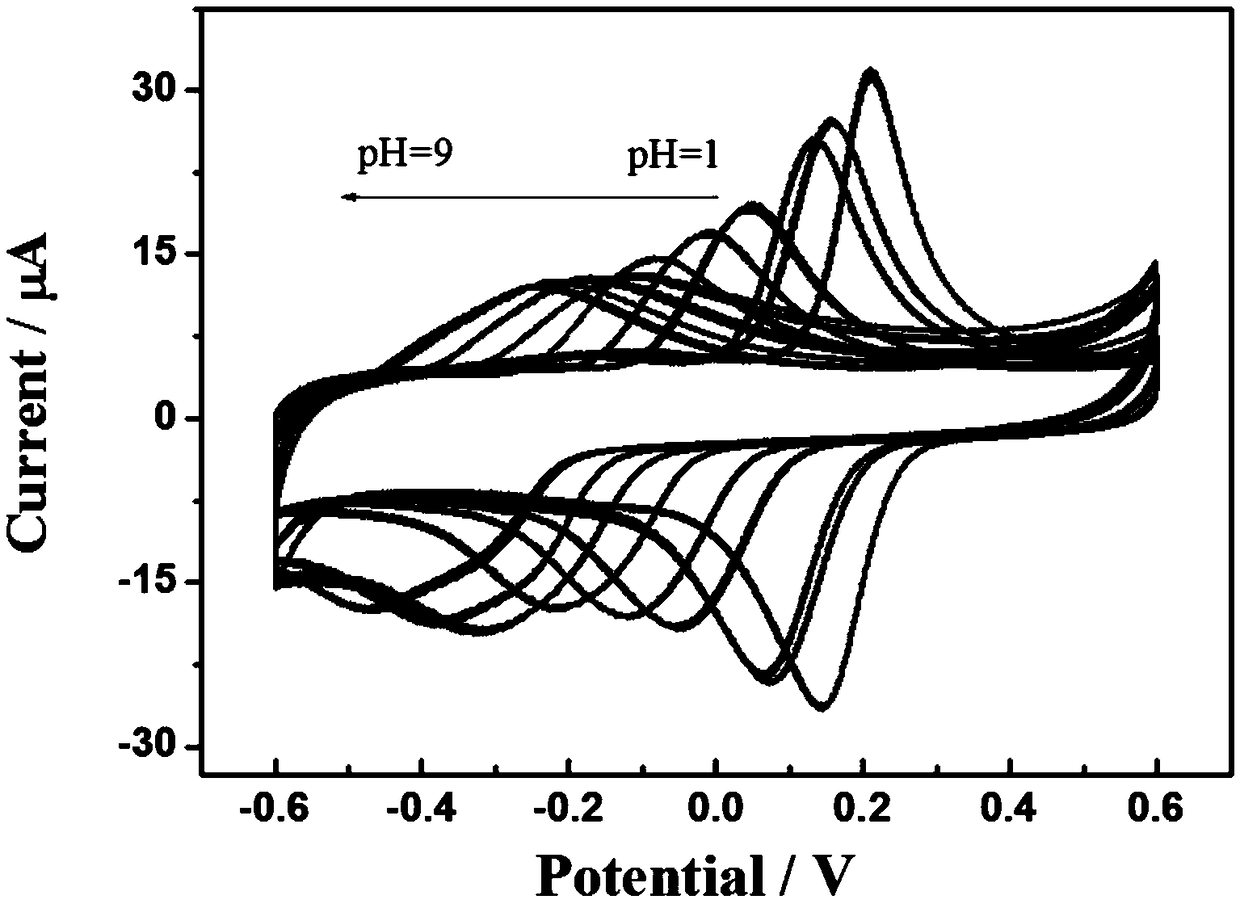

Method for rapidly preparing polymelamine conductive polymer electrode and application thereof

ActiveCN109358102APH accurate measurementMake fastMaterial electrochemical variablesSolventRedox Activity

The invention discloses a method for rapidly preparing a polymelamine conductive polymer electrode and an application thereof. The melamine conductive polymer electrode can be rapidly prepared under the condition of solid state electrochemical polymerization and by taking melamine as a monomer, water as a solvent, and glassy carbon as a working electrode. A polymelamine conductive polymer film with redox activity is obtained on the surface of the electrode. Cyclic voltammetry testing is carried out on the polymelamine conductive polymer electrode in solutions with different pH to obtain a series of redox peaks, and pH values of the solutions can be detected according to the relationship between the pH value of the solution and the oxidation peak potential value. The method has the advantages of being green, controllable, simple in operation, and the like, can be used for quantitative detection of the pH values in water samples, and is rapid and accurate in detection.

Owner:HUNAN UNIV OF SCI & TECH

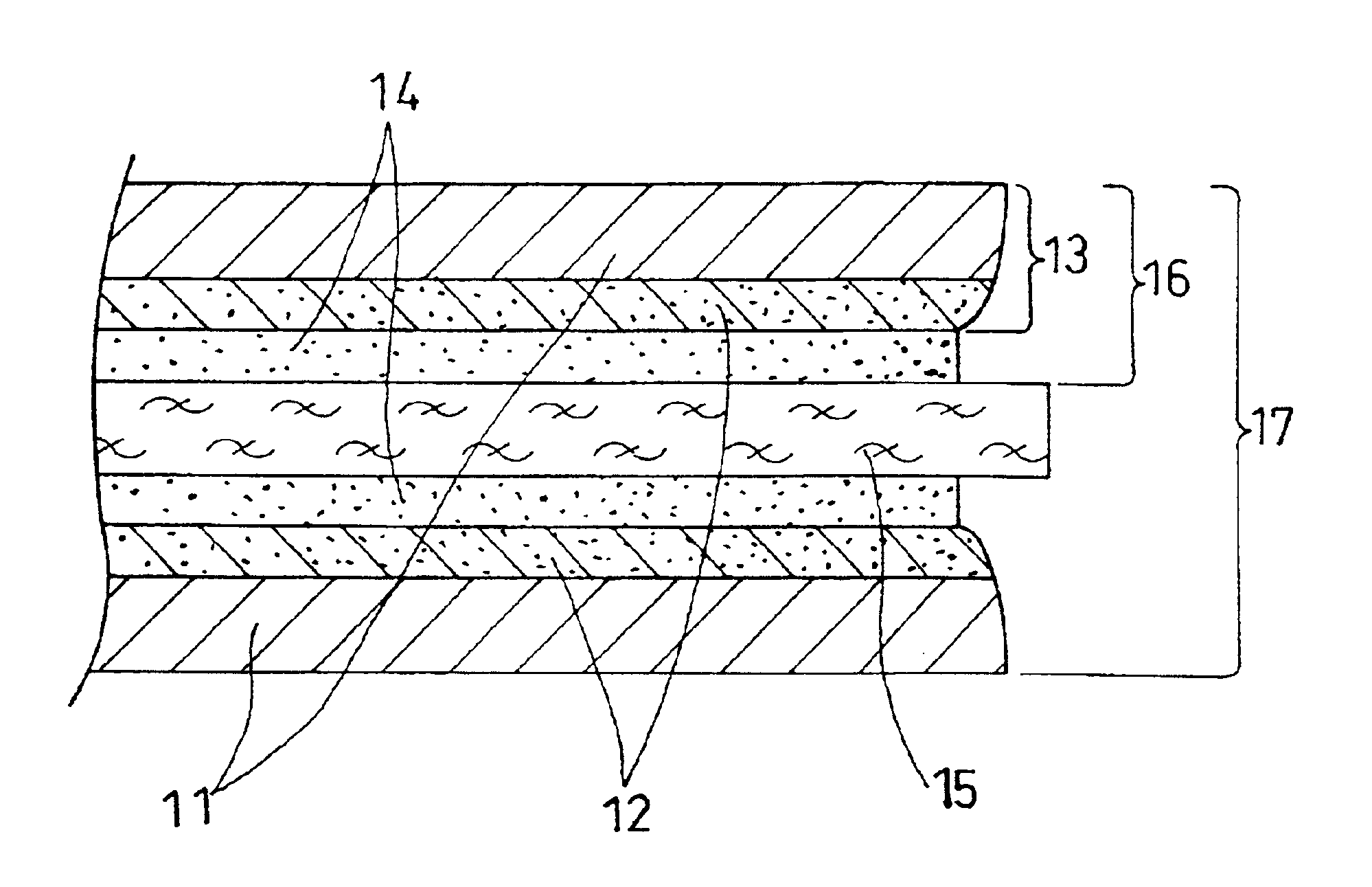

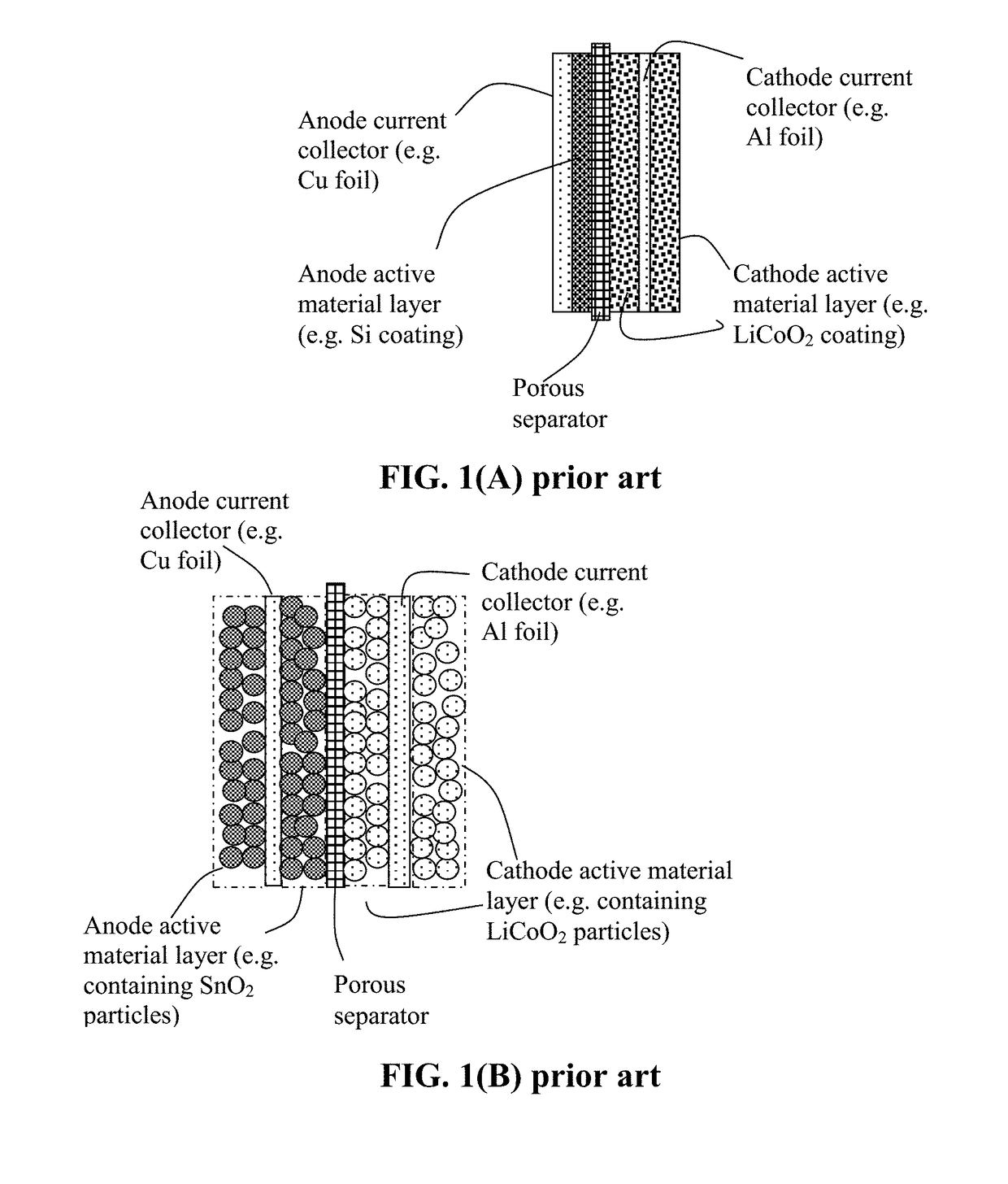

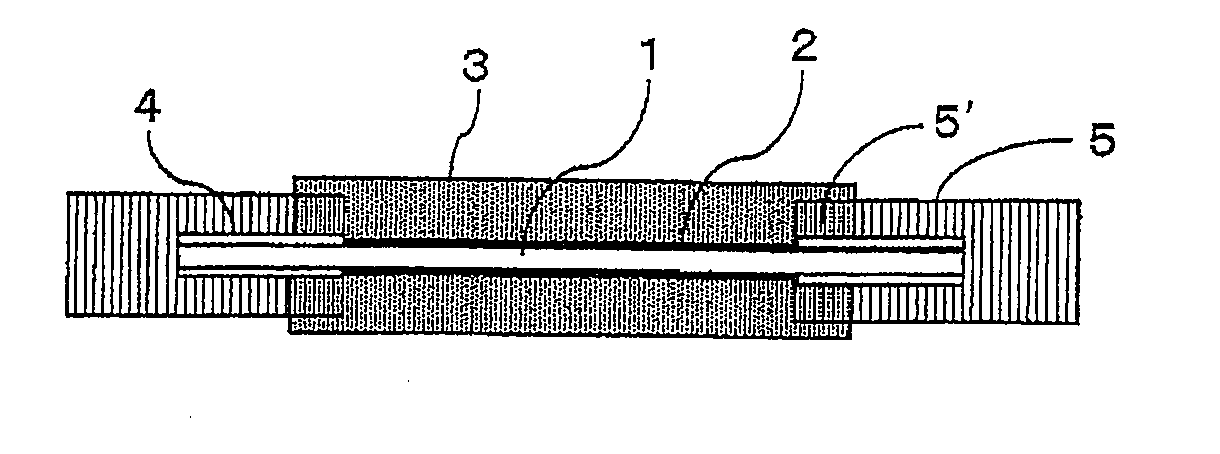

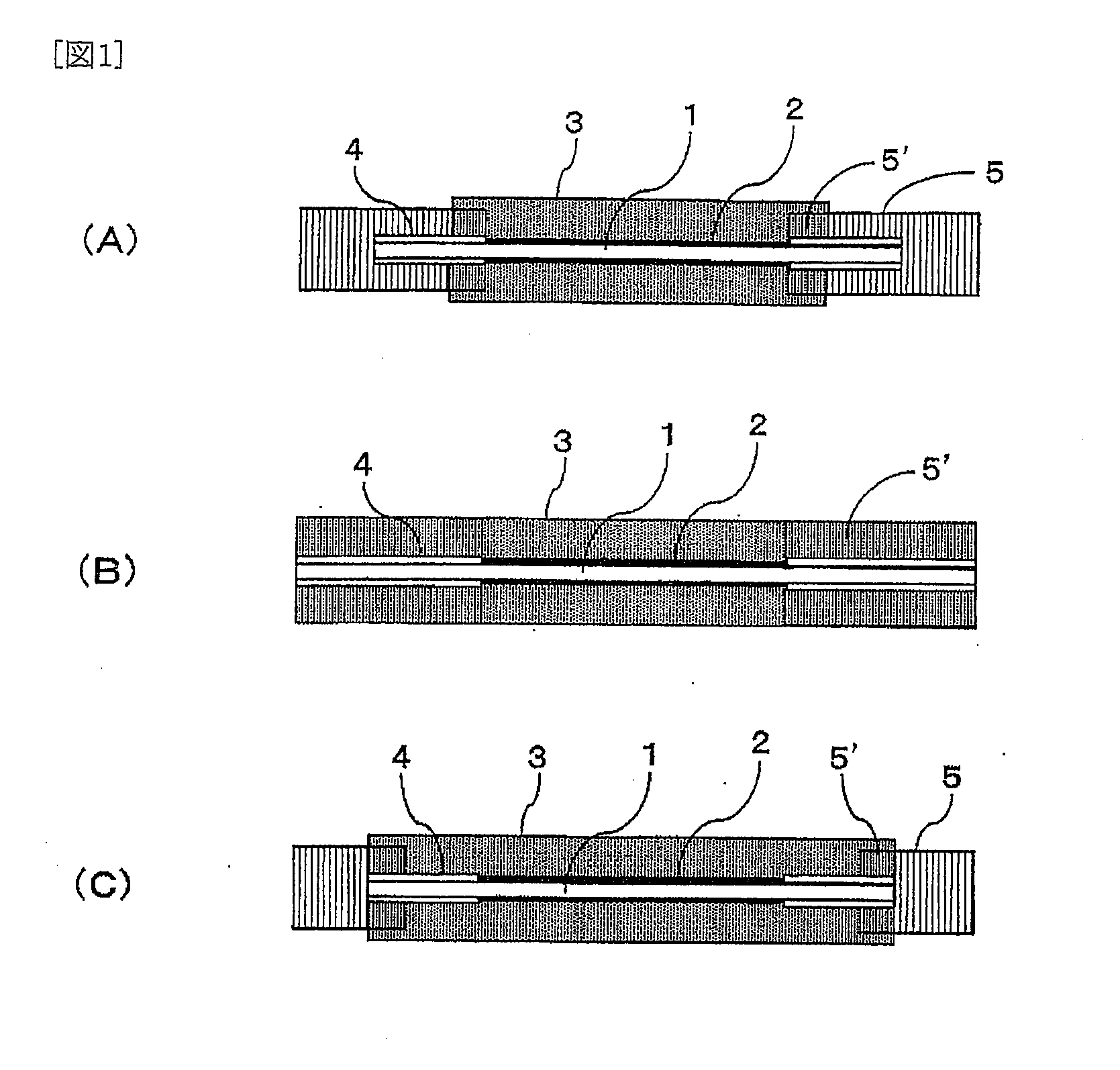

Membrane Electrode Joint Product and Solid Polymer Electrolyte Fuel Battery

InactiveUS20110045380A1Inferior in strengthImprove power generation efficiencyCell electrodesSolid electrolyte fuel cellsPolymer electrolytesAir tightness

The objective of the present invention is to provide a membrane electrode assembly, and a solid polymer electrolyte fuel cell having the assembly. The assembly has a member that has excellent gas sealing properties, and at the same time, is capable of improving electrode membrane strength. In the assembly, the polymer electrode membrane is not deteriorated. Further, the assembly is easy to be built up, since the number of components is small. The membrane electrode assembly for a solid polymer electrolyte fuel cell of the present invention is characterized in comprising a polymer electrolyte membrane, a fuel electrode layer and an air electrode layer located respectively on each surface of the membrane, and a fuel electrode diffusing layer and an air electrode diffusing layer located respectively on the fuel electrode layer and the air electrode layer; wherein an area of a planer section of the polymer electrolyte membrane is slightly larger than areas of planer sections of the fuel electrode layer and the air electrode layer; a reinforcing frame formed of a thermosetting resin is located on a part of the polymer electrolyte membrane where the fuel electrode layer or the air electrode layer is not formed on one side or both sides thereof; and a protective later exists in at least a part between the polymer electrolyte membrane and the reinforcing frame.

Owner:JAPAN GORE TEX INC

Infra-red radiant panel heater using PTC conductive polymeric electrodes

InactiveUS20070280655A1Domestic stoves or rangesOhmic-resistance electrodesEngineeringInfra-red color

An infrared radiant panel heater utilizing a liquid-tight enclosure with at least one surface emissive of infrared energy by liquid inside the enclosure. A pair of polymeric electrodes having the property of positive temperature cut off are submerged in the liquid inside the enclosure, near the bottom thereof. Liquid is heated by electrical current flowing through the liquid between the electrodes. Convective flow of liquid distributes heated liquid throughout the enclosure. The cutoff temperature can be selected by electrolyte concentration in the liquid (usually water and sodium chloride) and the properties of the electrodes. In some embodiments a reversed face of the enclosure is reflective, so that most of the infrared energy is directed into the room rather than against a wall.

Owner:CHAPUT IVANHOE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com