Graphene/polymer electrode-based flexible perovskite solar cell and preparation

A technology of solar cells and polymers, applied in the field of solar cells, can solve the problems of flexibility, light transmittance, and conductivity of flexible transparent electrodes, and achieve easy flexible integration, high photoelectric conversion efficiency, and good light transmittance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

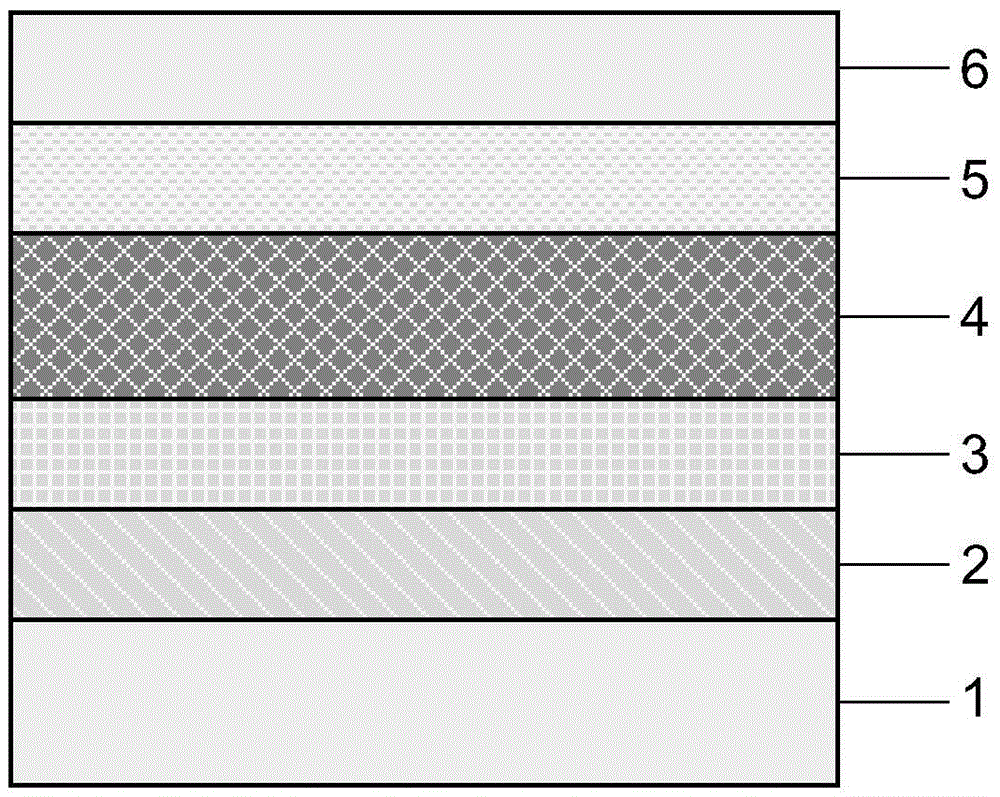

[0026] The structure of the flexible perovskite solar cell based on the graphene / polymer composite transparent electrode of the present embodiment is as follows figure 1 As shown, the preparation method steps of the flexible perovskite solar cell based on the graphene / polymer composite transparent electrode in this embodiment are as follows:

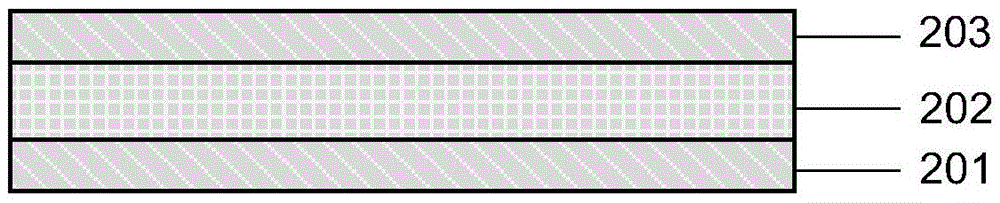

[0027] 1. Preparation of lower layer graphene 201: transfer a layer of graphene film on a 10um thick PET substrate, the PET substrate is a flexible substrate 1;

[0028] 2. Preparation of conductive polymer 202: Spin-coat polythiophene on the surface of the graphene film, wherein 0.3% surfactant is added to the polythiophene solution, and the thickness obtained after the film is annealed is 10 nm;

[0029] 3. Prepare the upper layer graphene 203: transfer a layer of graphene film on the surface of the polythiophene film to form a graphene / polymer composite transparent electrode 2;

[0030] 4. Preparation of hole transport layer 3: Spin-...

Embodiment 2

[0036] The structure of the flexible perovskite solar cell based on the graphene / polymer composite transparent electrode of the present embodiment is as follows figure 1 As shown, the preparation method steps of the flexible perovskite solar cell based on the graphene / polymer composite transparent electrode in this embodiment are as follows:

[0037] 1. Preparation of lower layer graphene 201: transfer 2 layers of graphene film on a 100um thick PI substrate, the PI substrate is a flexible substrate 1;

[0038] 2. Preparation of conductive polymer 202: Scrape-coat polyethylene on the surface of the graphene film, wherein 0.5% surfactant is added to the polythiophene solution, and the thickness obtained after the film is annealed is 50nm;

[0039] 3. Prepare upper layer graphene 203: transfer two layers of graphene film on the surface of polythiophene film to form graphene / polymer composite transparent electrode 2;

[0040] 4. Preparation of hole transport layer 3: scrape-coat ...

Embodiment 3

[0046] The structure of the flexible perovskite solar cell based on the graphene / polymer composite transparent electrode of the present embodiment is as follows figure 1 As shown, the preparation method steps of the flexible perovskite solar cell based on the graphene / polymer composite transparent electrode in this embodiment are as follows:

[0047] 1. Preparation of lower layer graphene 201: transfer 3 layers of graphene film on a 100um thick PEN substrate, the PEN substrate is a flexible substrate 1;

[0048] 2. Preparation of conductive polymer 202: Inkjet printing polyethylenedioxythiophene-polystyrene sulfonate on the surface of graphene film, in which polyethylenedioxythiophene-polystyrenesulfonate solution is added with 1% Surfactant, the thickness obtained after film annealing is 100nm;

[0049] 3. Preparation of upper layer graphene 203: transfer 3 layers of graphene film on the surface of polyethylenedioxythiophene-polystyrene sulfonate film to form graphene / polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com