A novel composite electrolyte material

A composite electrolyte and electrolyte technology, which is applied in the application field of high-energy battery and electronic equipment technology field, can solve the problems of poor thermal stability, high freezing point, and potential safety hazards of liquid electrolyte system, and achieve good electrochemical performance, good thermal stability, The effect of a large liquid range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

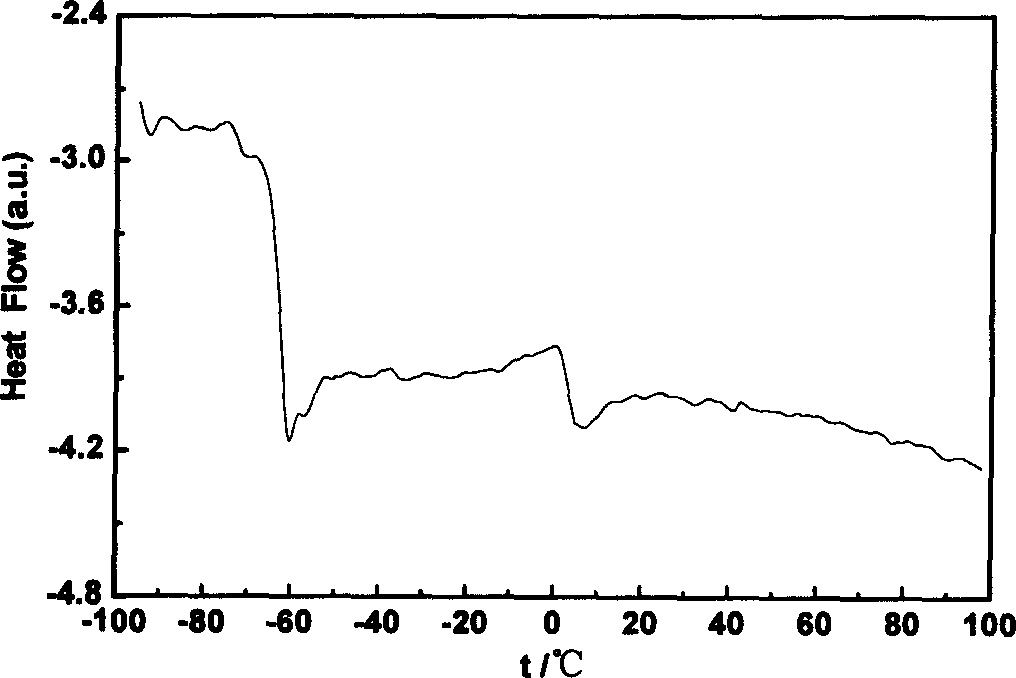

[0046] LiN(CF 3 SO 2 ) 2 After drying with acetamide, put it into the glove box (the content of water is less than 1ppm), weigh 20gLiN(CF 3 SO 2 ) 2 And 30g of acetamide in a weighing bottle, after stirring at room temperature, it becomes a transparent liquid, forming a molten salt at room temperature. Its thermal properties were measured with a DSC2010 (TA company, USA) differential scanning calorimeter, and its melting point was -60°C.

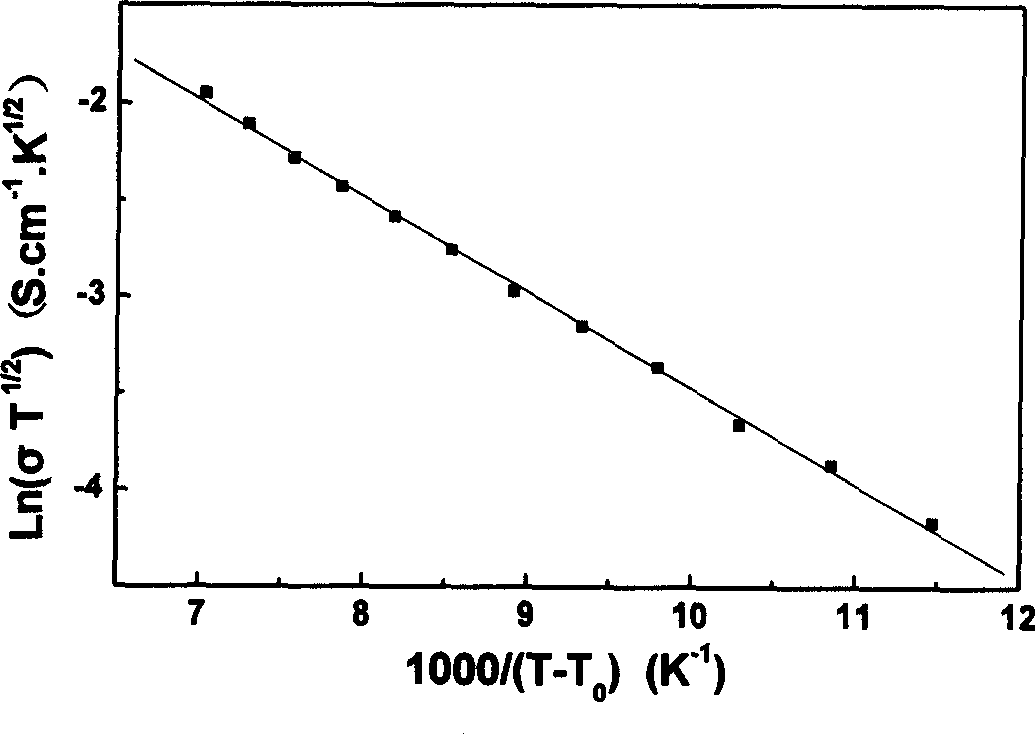

[0047] Put this sample into the platinum bright conductivity electrode (Russell, Shanghai), use the CHI 660A (USA) type electrochemical workstation to adopt the AC impedance method to measure its conductivity in the range of 1Hz-100KHz, and its room temperature (25 ℃) conductivity It is 1.2mS / cm; combined with WD4005(F) high and low temperature box (Yinhe, Chongqing) to measure the conductivity of the sample at different temperatures, the relationship between the conductivity and temperature variation curve is in line with the VTF equat...

Embodiment 2

[0052] LiN(CF 3 SO 2 ) 2 After drying with ethylene urea, put it into the glove box (the content of water is less than 1ppm), weigh 20gLiN(CF 3 SO 2 ) 2 and 40g of acetamide in a weighing bottle, slowly heated to 50°C to melt it and turn it into a transparent liquid. After natural cooling, a low-temperature molten salt is formed. The sample is left standing at room temperature and remains liquid for a long time, which is a supercooled liquid. Its thermal properties were measured with a DSC2010 differential scanning calorimeter, and its melting point was 45°C.

[0053] Put the sample into the platinum bright conductivity electrode, use the CHI 660A electrochemical workstation to measure its conductivity in the range of 1Hz-100KHz by using the AC impedance method, and its room temperature (25°C) conductivity is 0.5mS / cm; and WD4005 The (F) type high and low temperature box is used to measure the conductivity of the sample at different temperatures, and the relationship bet...

Embodiment 3

[0058] LiClO 4 After drying with acetamide, put it into the glove box (the content of water is less than 1ppm), weigh 20gLiClO 4 And 30g of acetamide in a weighing bottle, after stirring at room temperature, it becomes a transparent liquid, forming a molten salt at room temperature. Its thermal properties were measured with a DSC2010 differential scanning calorimeter, and its melting point was -22°C.

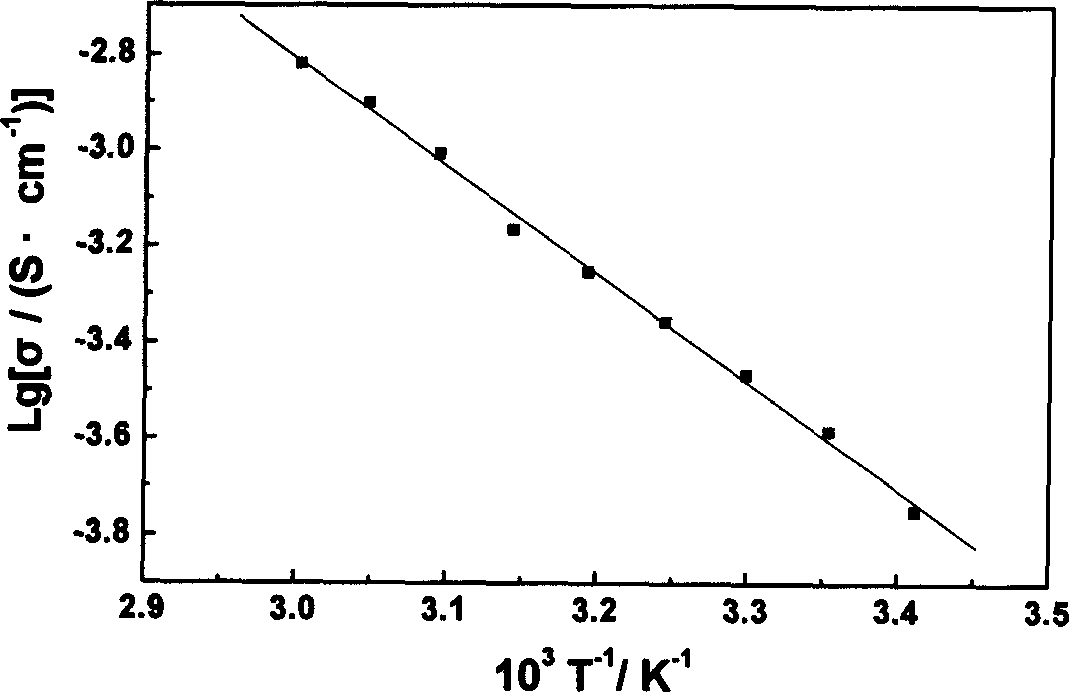

[0059] Put the sample into the platinum bright conductivity electrode, use the CHI660A electrochemical workstation to measure its conductivity in the range of 1Hz-100KHz by using the AC impedance method, and its room temperature (25°C) conductivity is 2.6mS / cm; and WD4005 ( The F) type high and low temperature box is used to measure the conductivity of the sample at different temperatures, and the relationship between the conductivity and temperature variation curve conforms to the Arrhenius equation. The sample was loaded into a glass three-electrode electrochemical cell whos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com