High-temperature stable fibriform lithium air battery and preparation method thereof

A lithium-air battery, high-temperature stable technology, applied in secondary batteries, secondary battery repair/maintenance, fuel cell-type half-cells and secondary battery-type half-cells, etc., can solve harsh conditions, insufficient flexibility, Complicated electrolyte preparation and other issues, to achieve the effect of low vapor pressure, wide electrochemical window, and superior stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

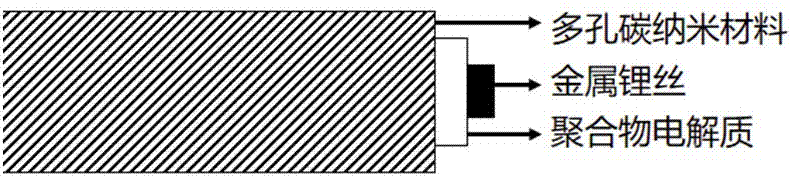

[0028] (1) Preparation of metal lithium wire negative electrode: take a piece of metal lithium wire with a diameter of 1 mm that has a smooth surface and has not been oxidized, and then take a section of copper wire, insert part of it into the metal lithium wire, and lead out the electrode;

[0029] (2) Preparation of polymer solution: Mix particles of (polyvinylidene fluoride-hexafluoropropylene) copolymer with N-methylpyrrolidone at a mass ratio of 3:7, stir at 60°C for 10 h, and dissolve completely to obtain Colorless clear transparent viscous liquid, namely (polyvinylidene fluoride-hexafluoropropylene) copolymer N-methylpyrrolidone solution;

[0030] (3) Solution preparation of lithium salt and ionic liquid: Lithium salt bistrifluoromethanesulfonimide lithium and ionic liquid 1-n-butyl-1-methylpyrrolidine bis(trifluoromethylsulfonyl)imide The amine and acetonitrile solution are mixed according to the mass ratio of 2:3:3, and the colorless clear transparent liquid is obtain...

Embodiment 2

[0035] (1) Preparation of metal lithium wire negative electrode: Take a piece of metal lithium wire with a diameter of 2 mm and a smooth surface that has not been oxidized, and then take a piece of aluminum wire, insert part of it into the metal lithium wire, and lead out the electrode;

[0036] (2) Preparation of polymer solution: Mix particles of (polyvinylidene fluoride-hexafluoropropylene) copolymer with N-methylpyrrolidone at a mass ratio of 4:6, stir at 70 °C for 10 h, and dissolve completely to obtain Colorless clear transparent viscous liquid, namely (polyvinylidene fluoride-hexafluoropropylene) copolymer N-methylpyrrolidone solution;

[0037](3) Solution preparation of lithium salt and ionic liquid: Lithium salt bistrifluoromethanesulfonimide lithium and ionic liquid 1-n-butyl-1-methylpyrrolidine bis(trifluoromethylsulfonyl)imide The amine and acetonitrile solution are mixed according to the mass ratio of 2.5:4:3.5, and the ultrasonic solution is uniform to obtain a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com