Patents

Literature

63 results about "Conducting pathway" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

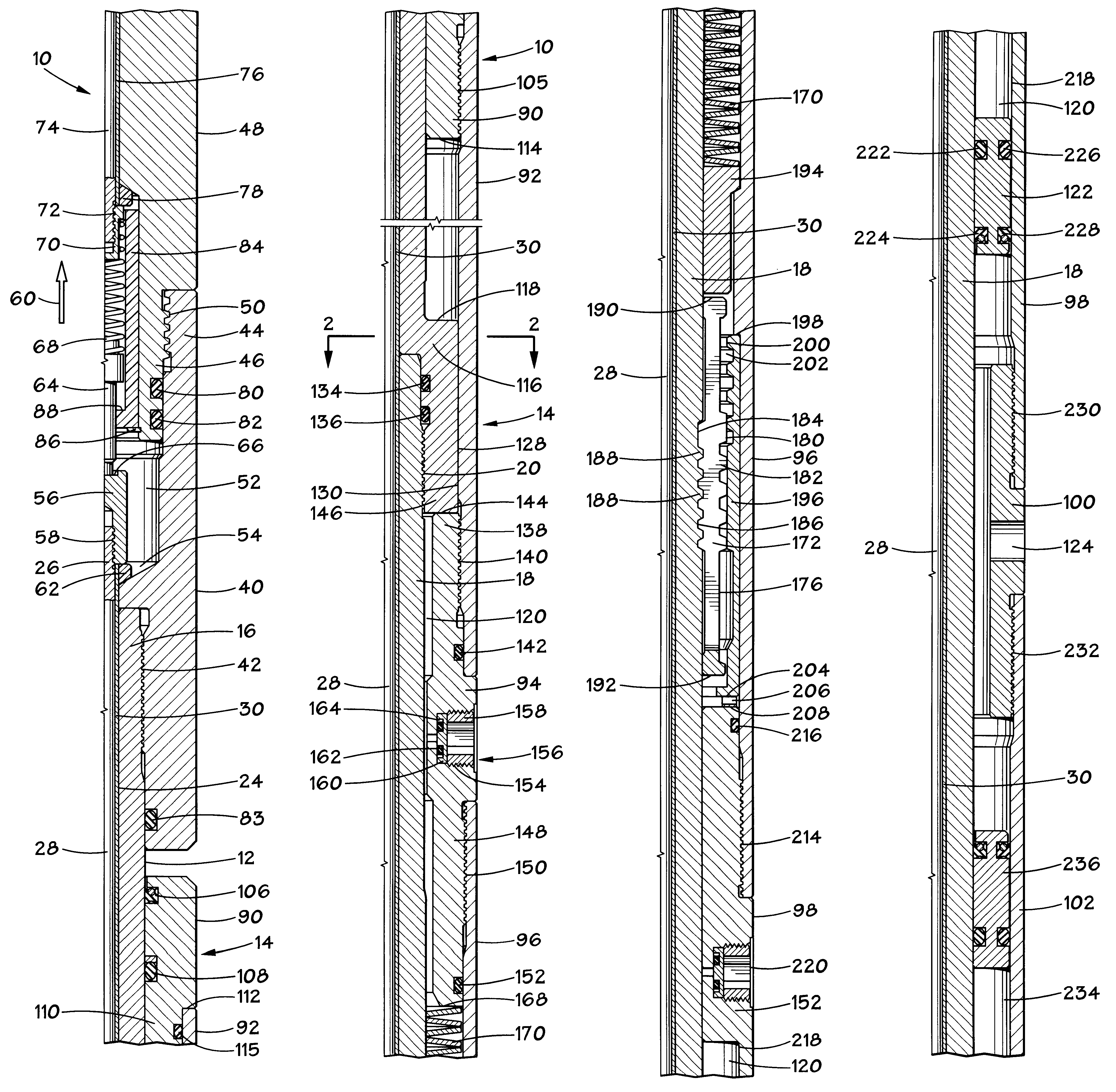

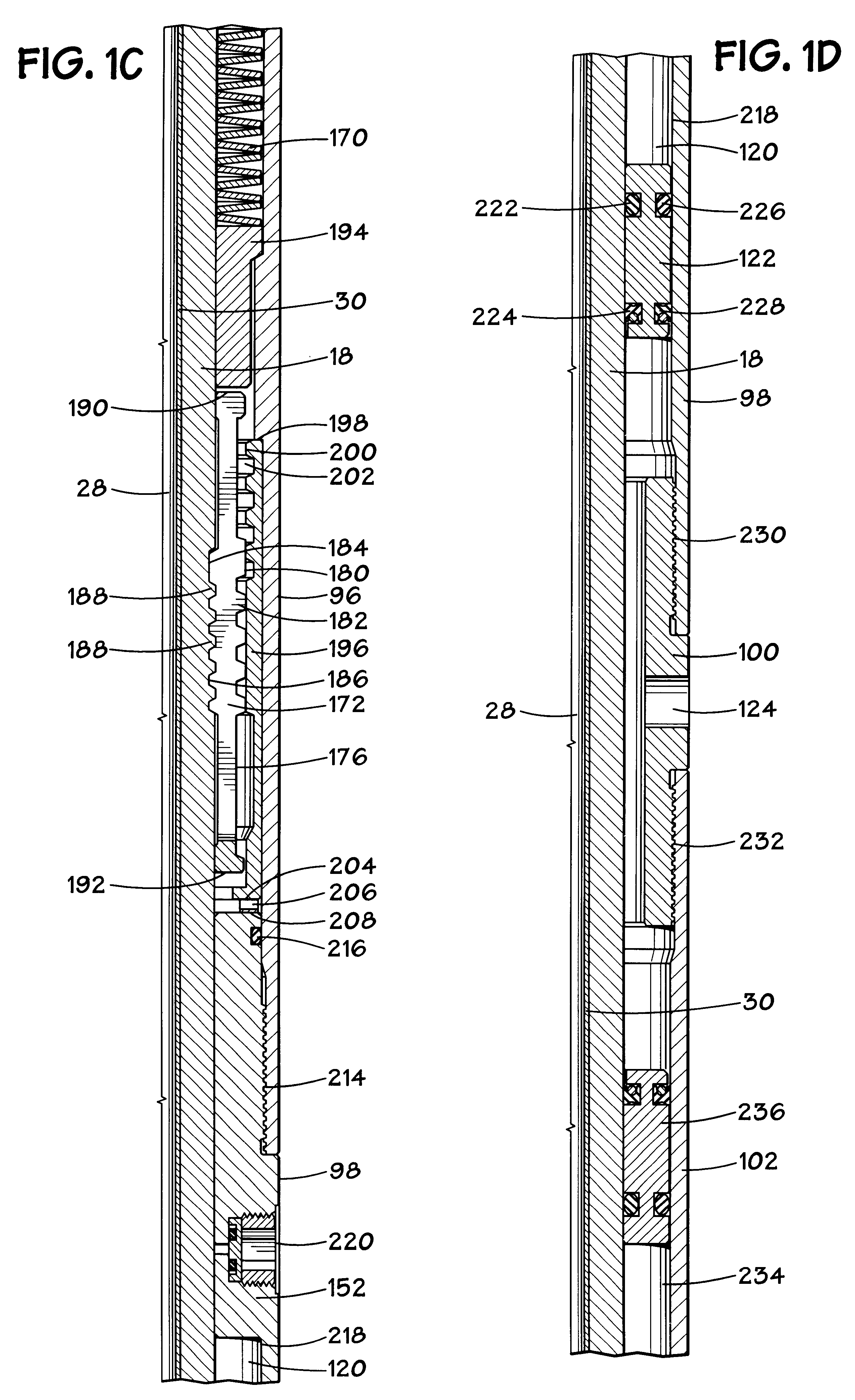

Downhole tool with electrical conductor

Various embodiments of a downhole tool with a telescoping conductor member are provided. In one aspect, a downhole tool is provided that includes and a mandrel telescopically positioned in the housing. The mandrel and the housing define a pressure compensated substantially sealed chamber containing a volume of a non-conducting fluid. A conductor member is positioned in the housing for providing an electrically conducting pathway. The conductor member has a first segment and a second segment. The first segment is moveable with the mandrel and relative to the second segment. A portion of the conductor member is electrically insulated from an ambient fluid by the non-conducting fluid. A first biasing member is provided for maintaining a conducting pathway between the first segment and the second segment. The tool provides for electrical transmission in a telescoping tool.

Owner:HALLIBURTON ENERGY SERVICES INC

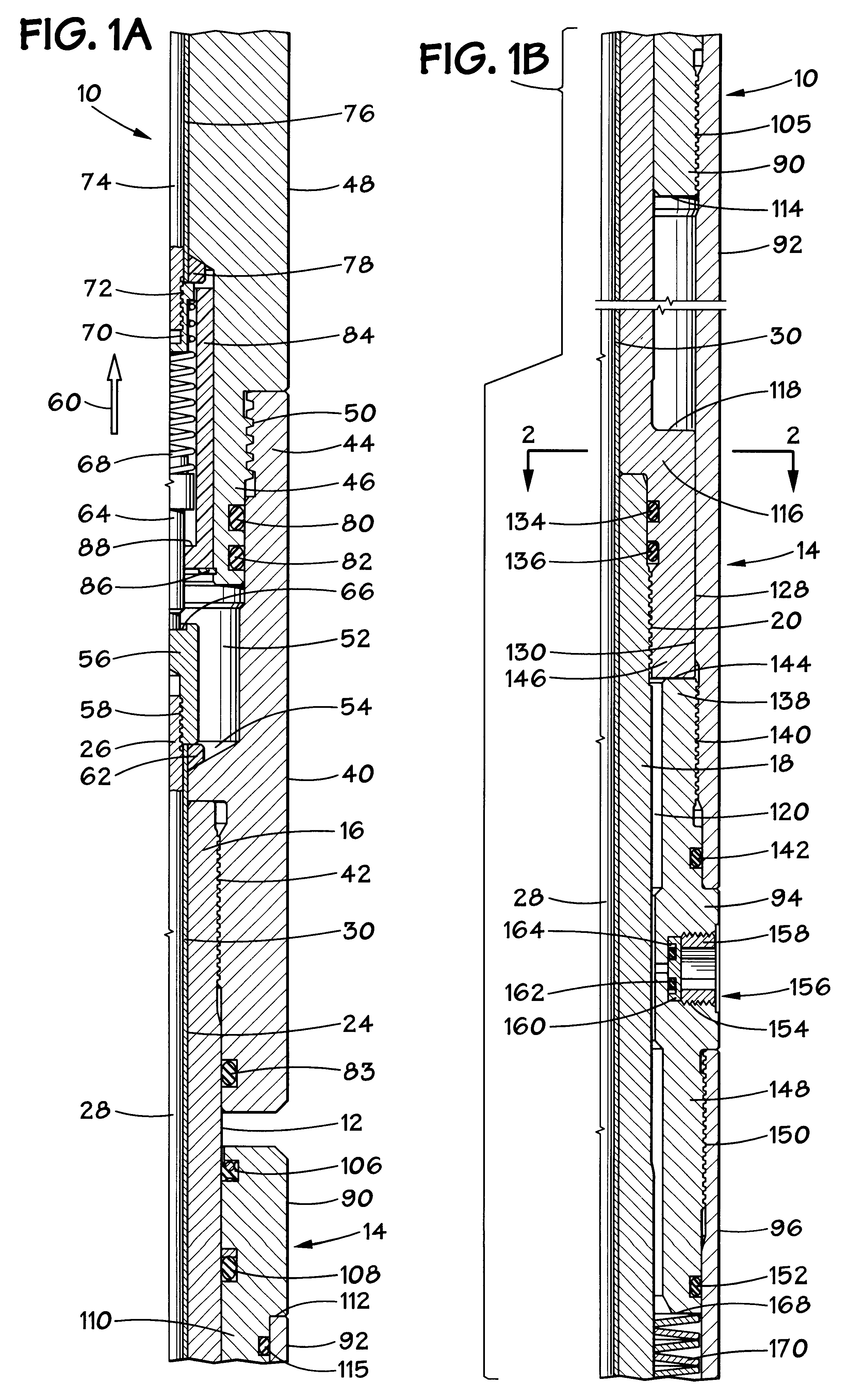

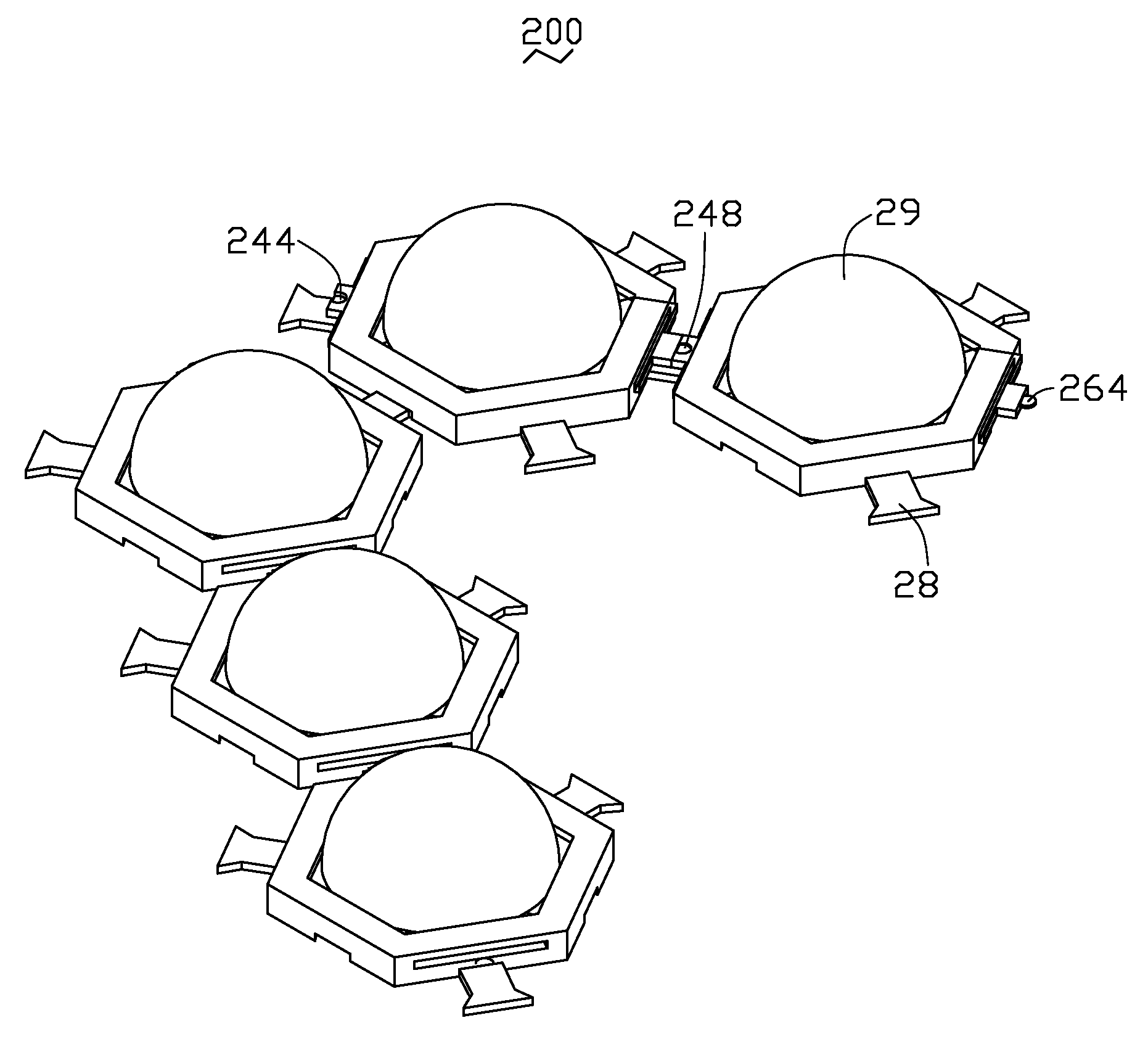

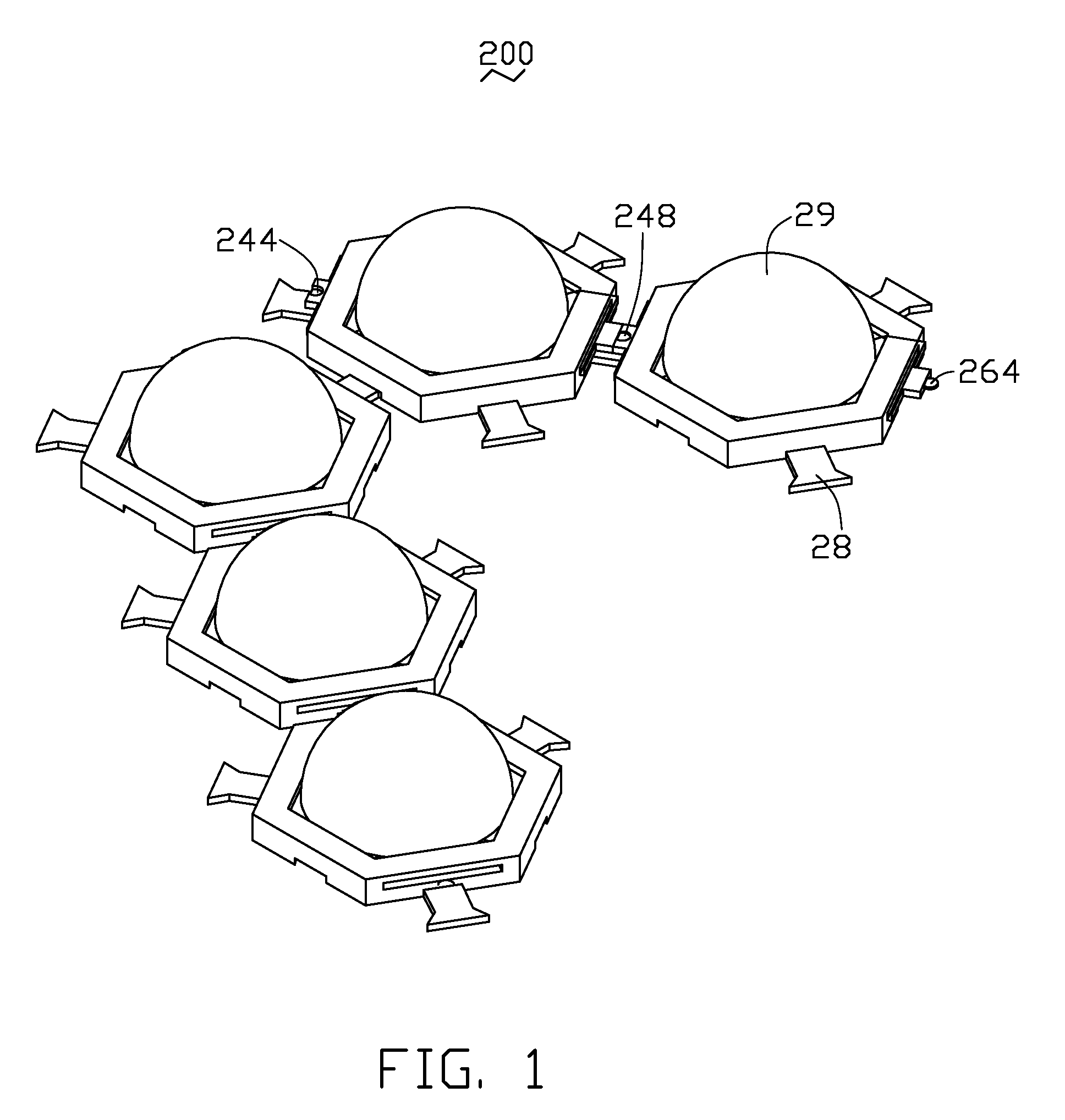

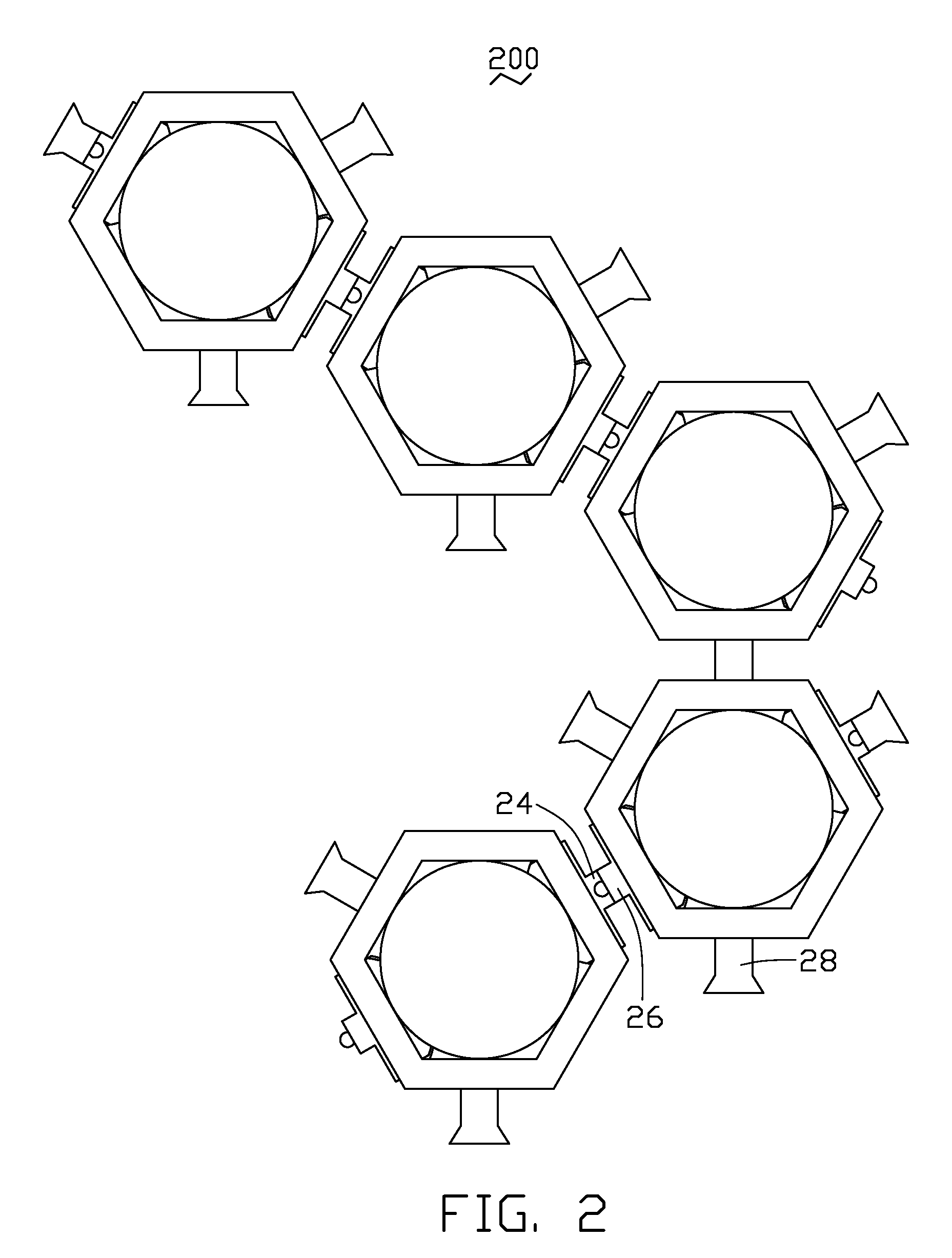

LED assembly with separated thermal and electrical structures thereof

InactiveUS20090236616A1Convenient lightingExtend your lifeLighting heating/cooling arrangementsSolid-state devicesConducting pathwayElectrical structure

An LED assembly includes a substrate and a plurality of LEDs mounted on the substrate. Each LED comprises an LED die, a base supporting the LED die thereon and thermally contacting the substrate to take heat generated by the LED die to the substrate, a pair of leads electrically connecting the LED die to input a current to the LED die, and an encapsulant enveloping the LED die. The pair of leads hover above the substrate to separate an electrical route of the LED assembly from a heat conducting pathway thereof. Furthermore, each LED has a plurality of legs extending raidally from the base thereof to fit in the base of an adjacent LED, to thereby engagingly lock with the adjacent LED.

Owner:HON HAI PRECISION IND CO LTD

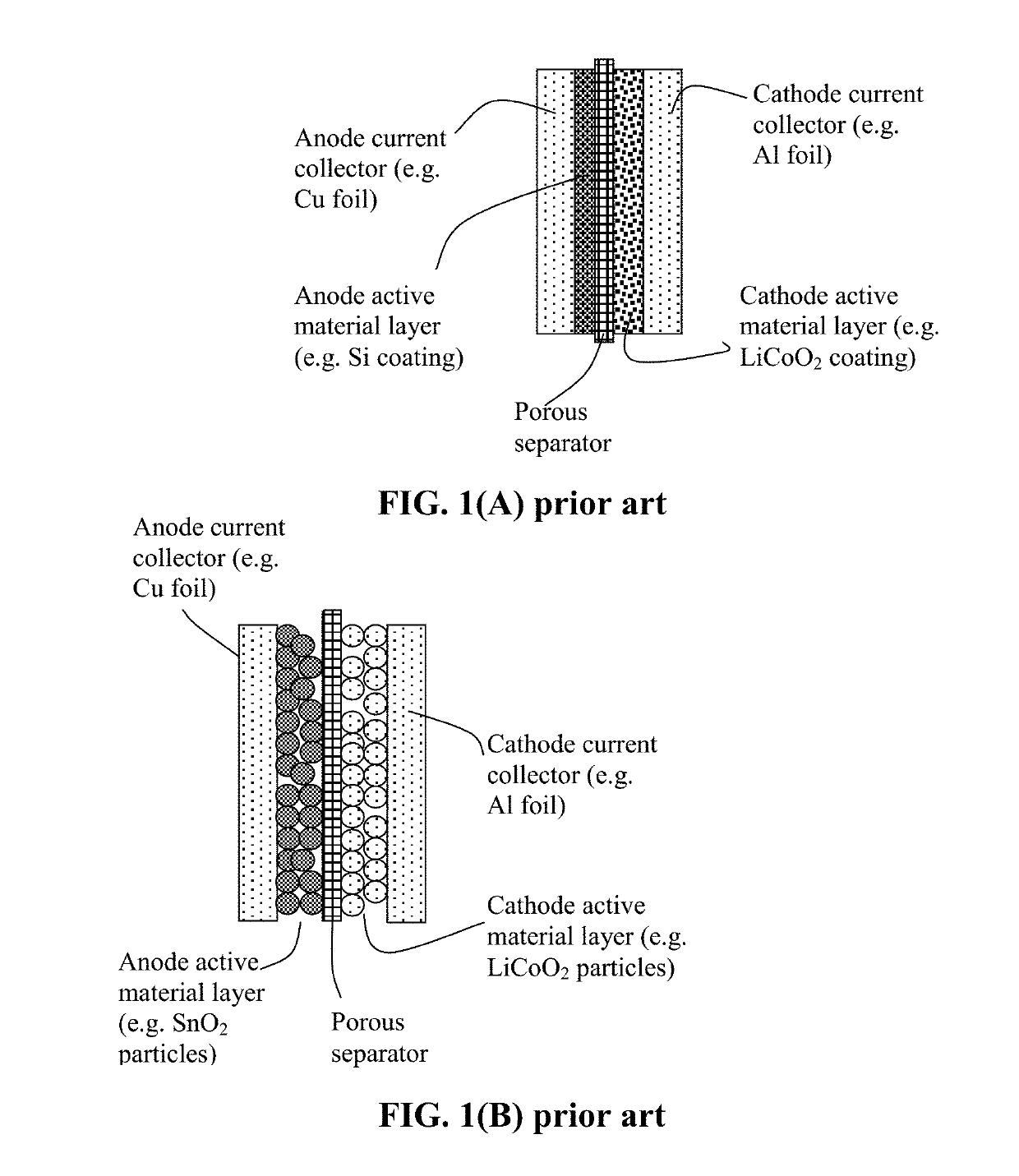

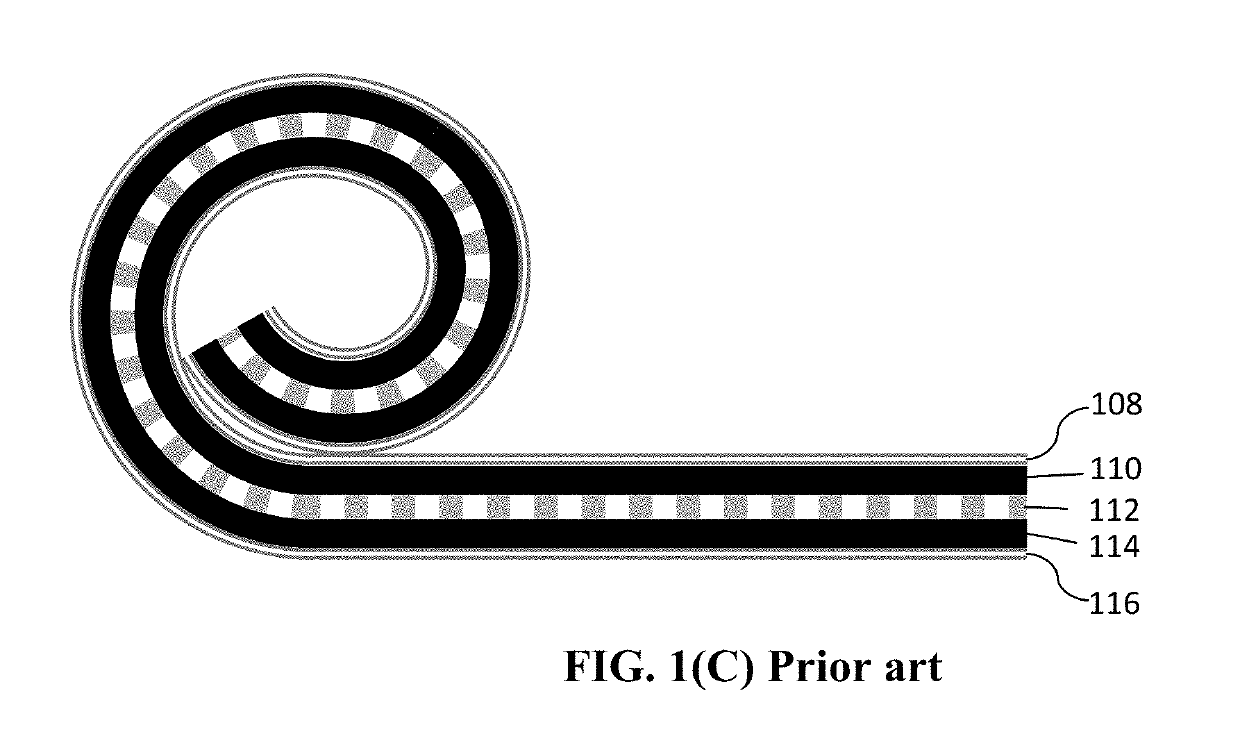

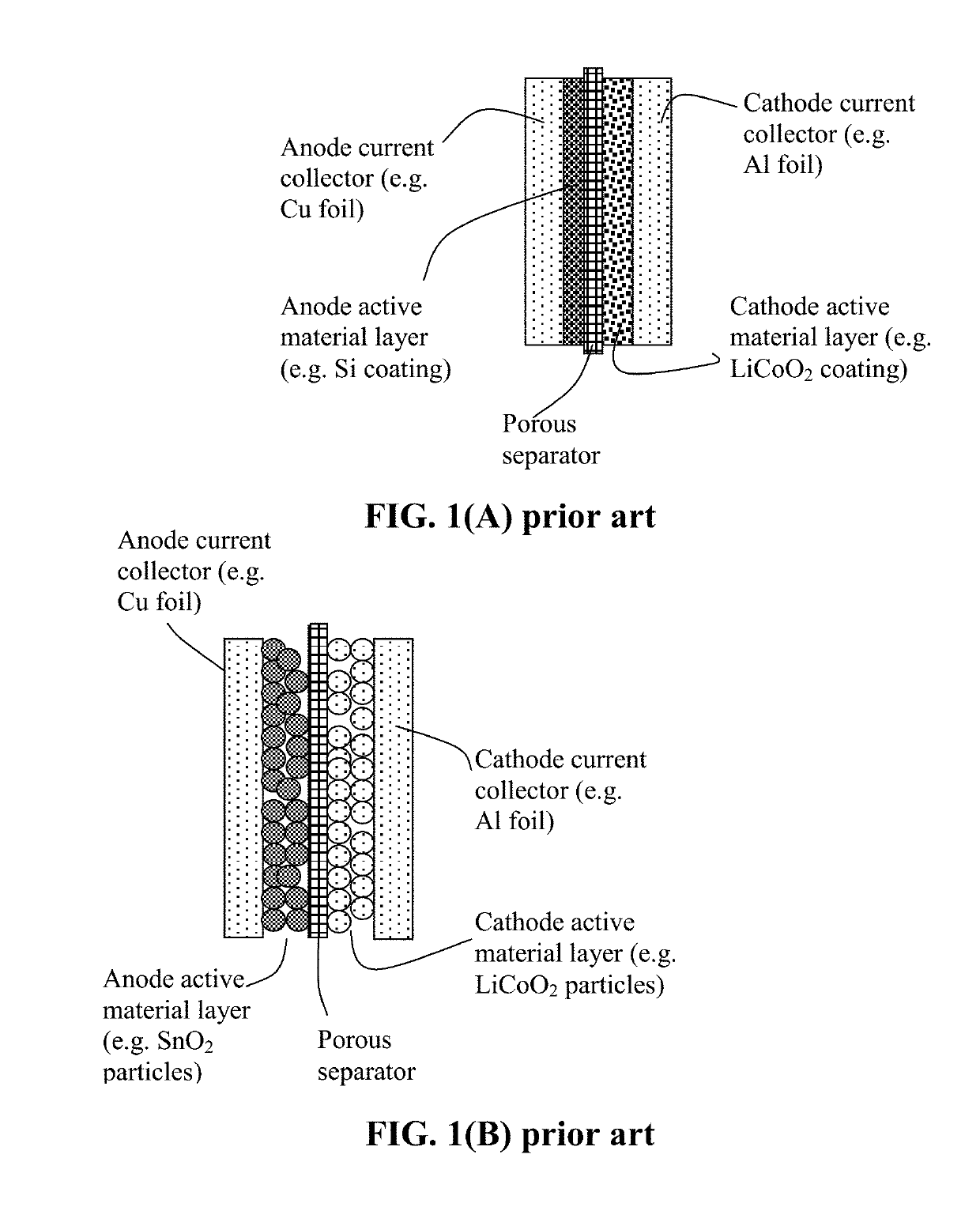

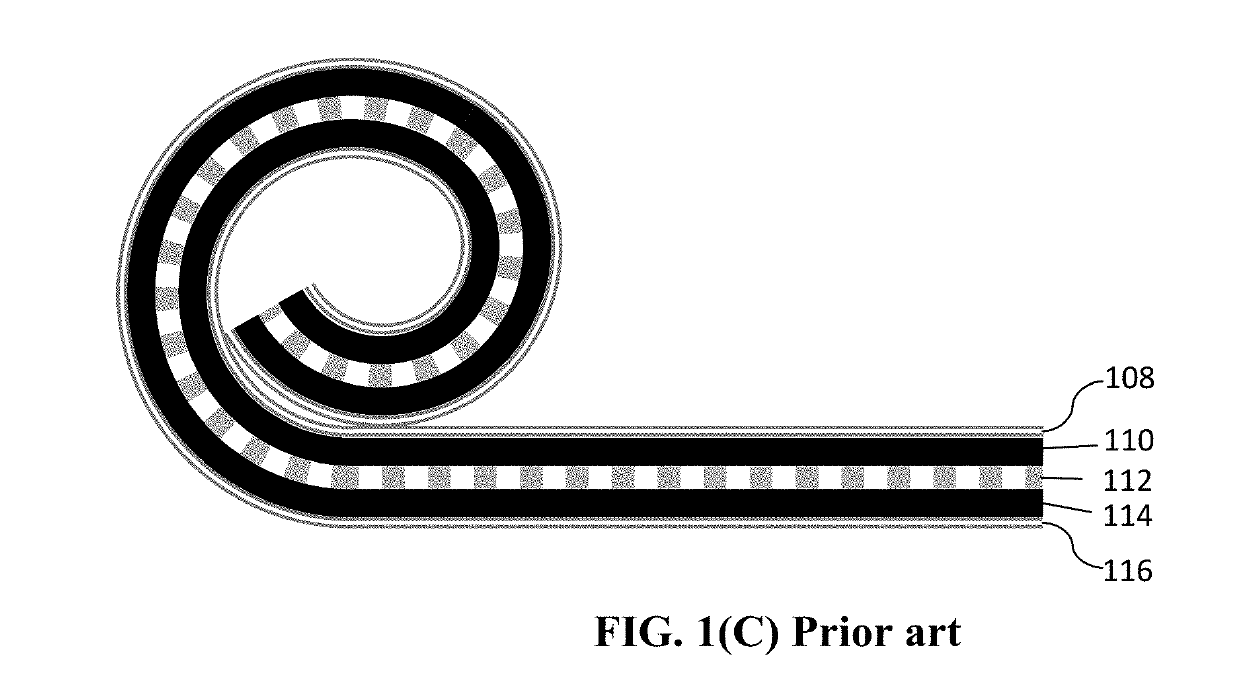

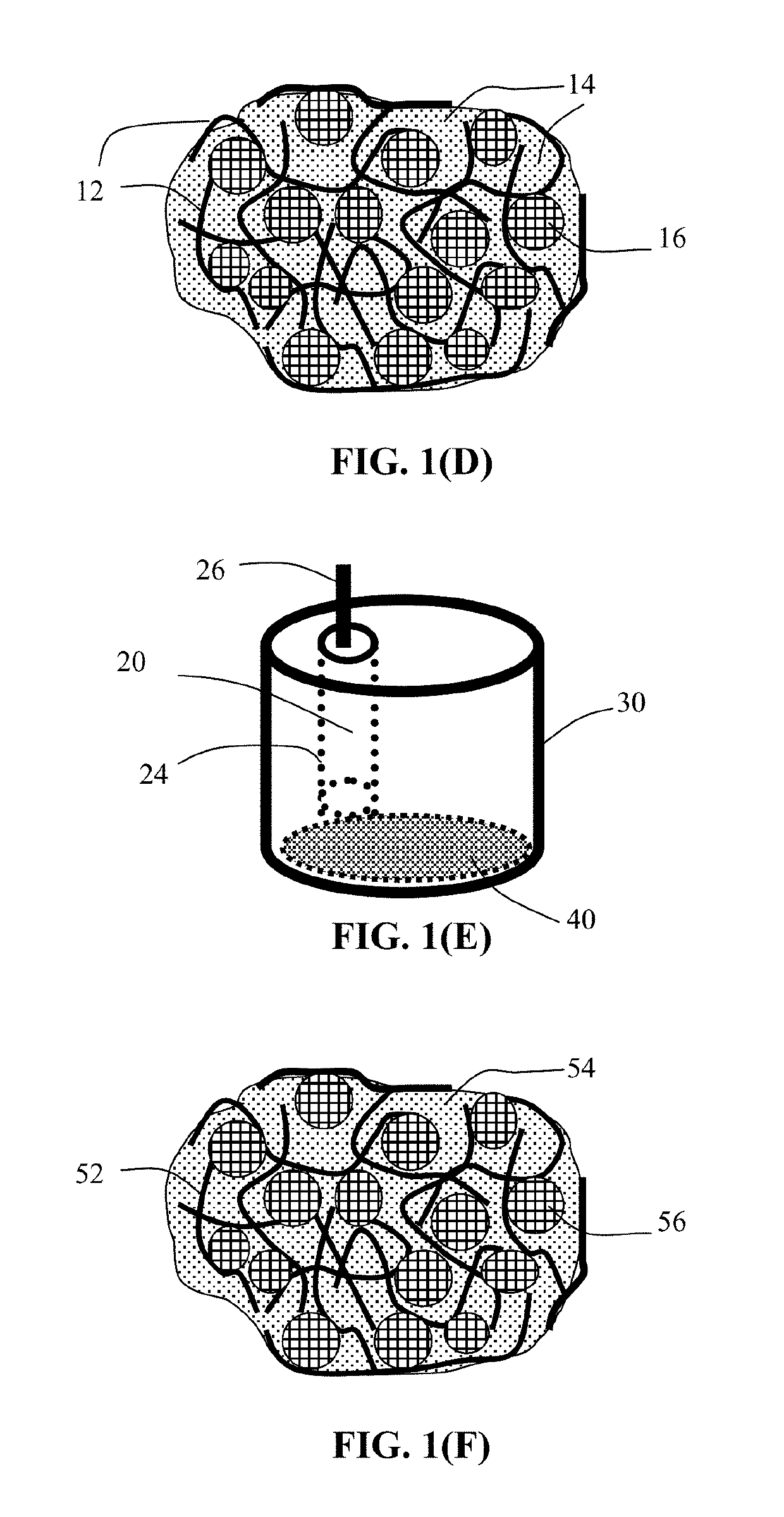

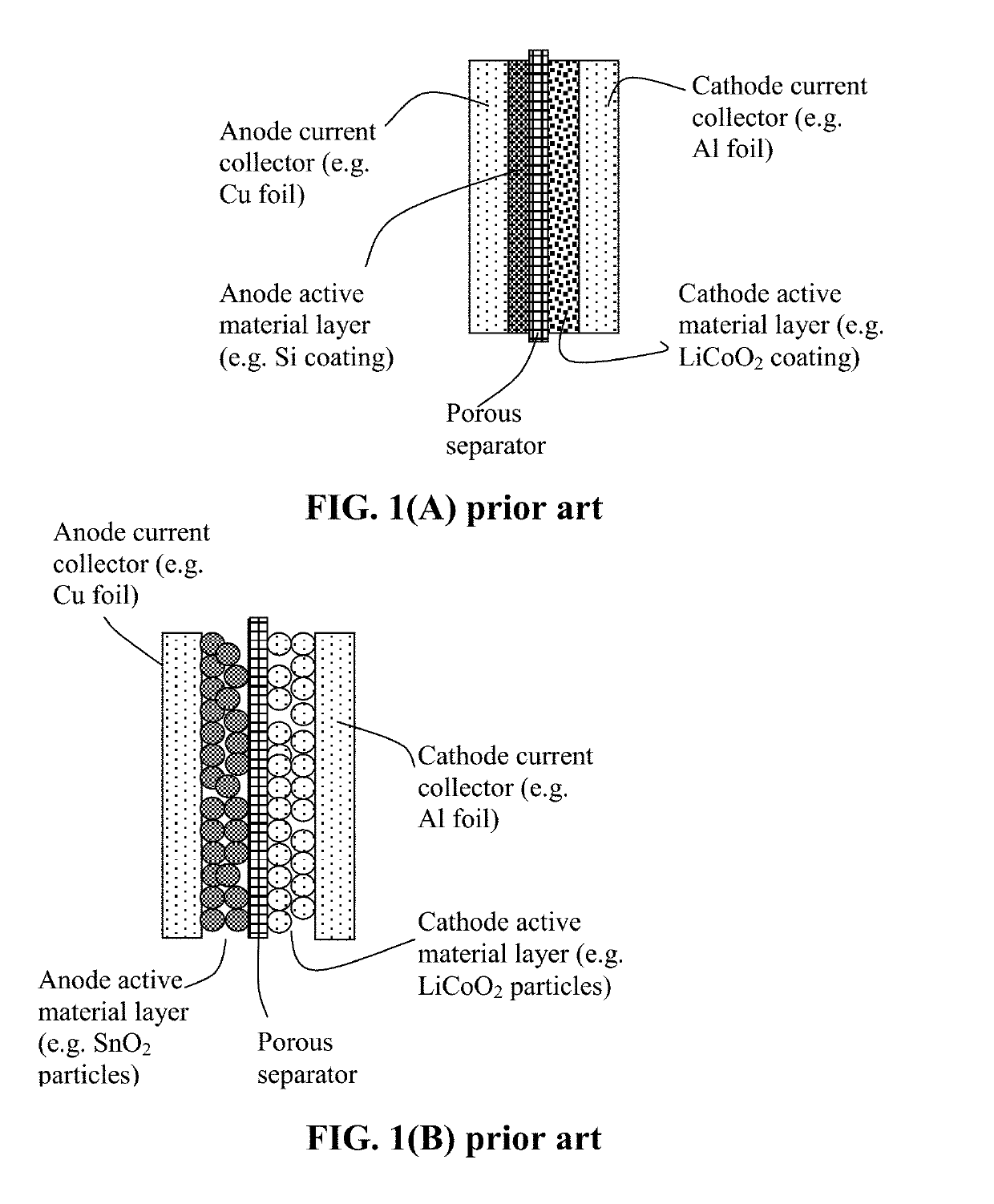

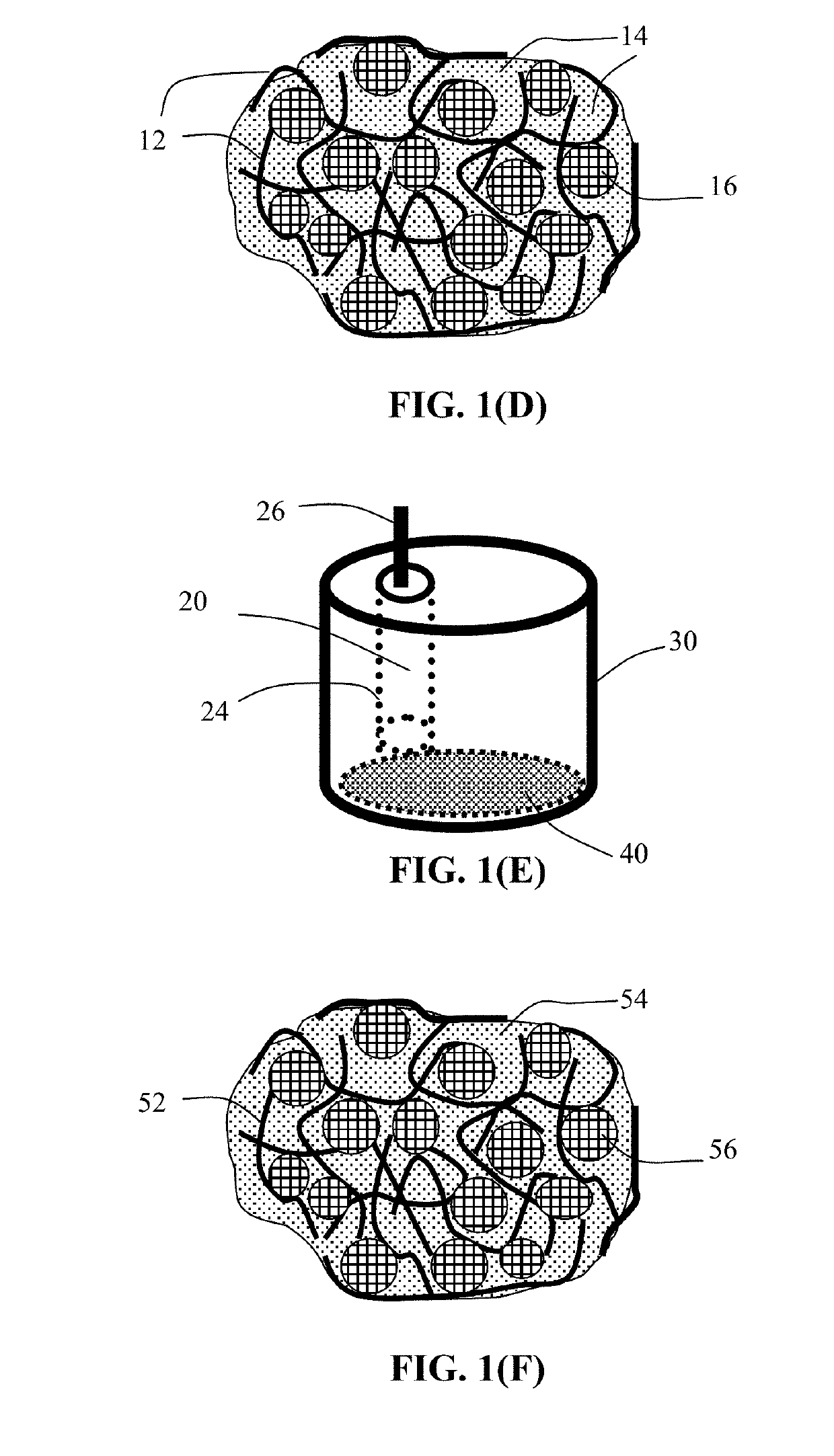

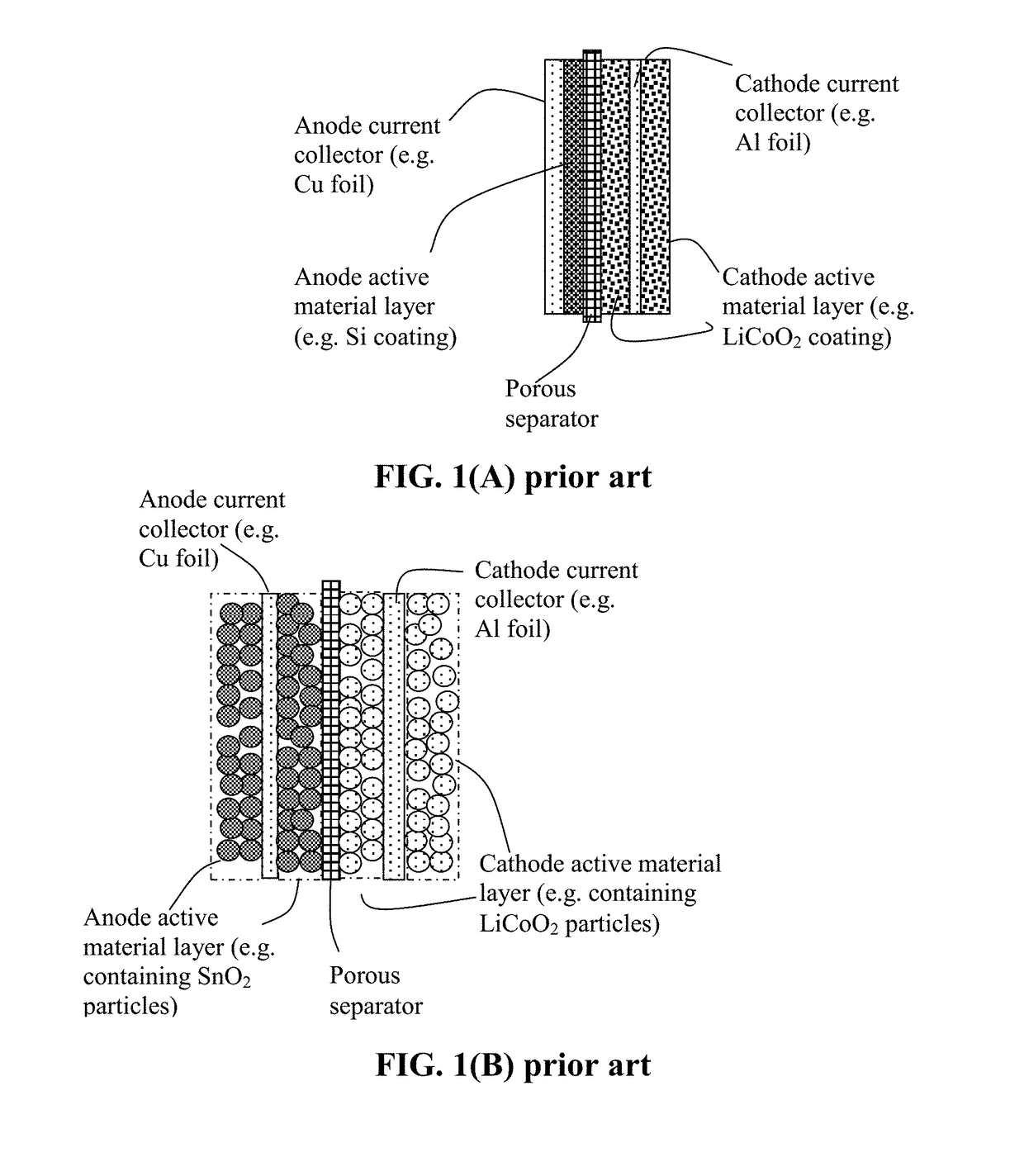

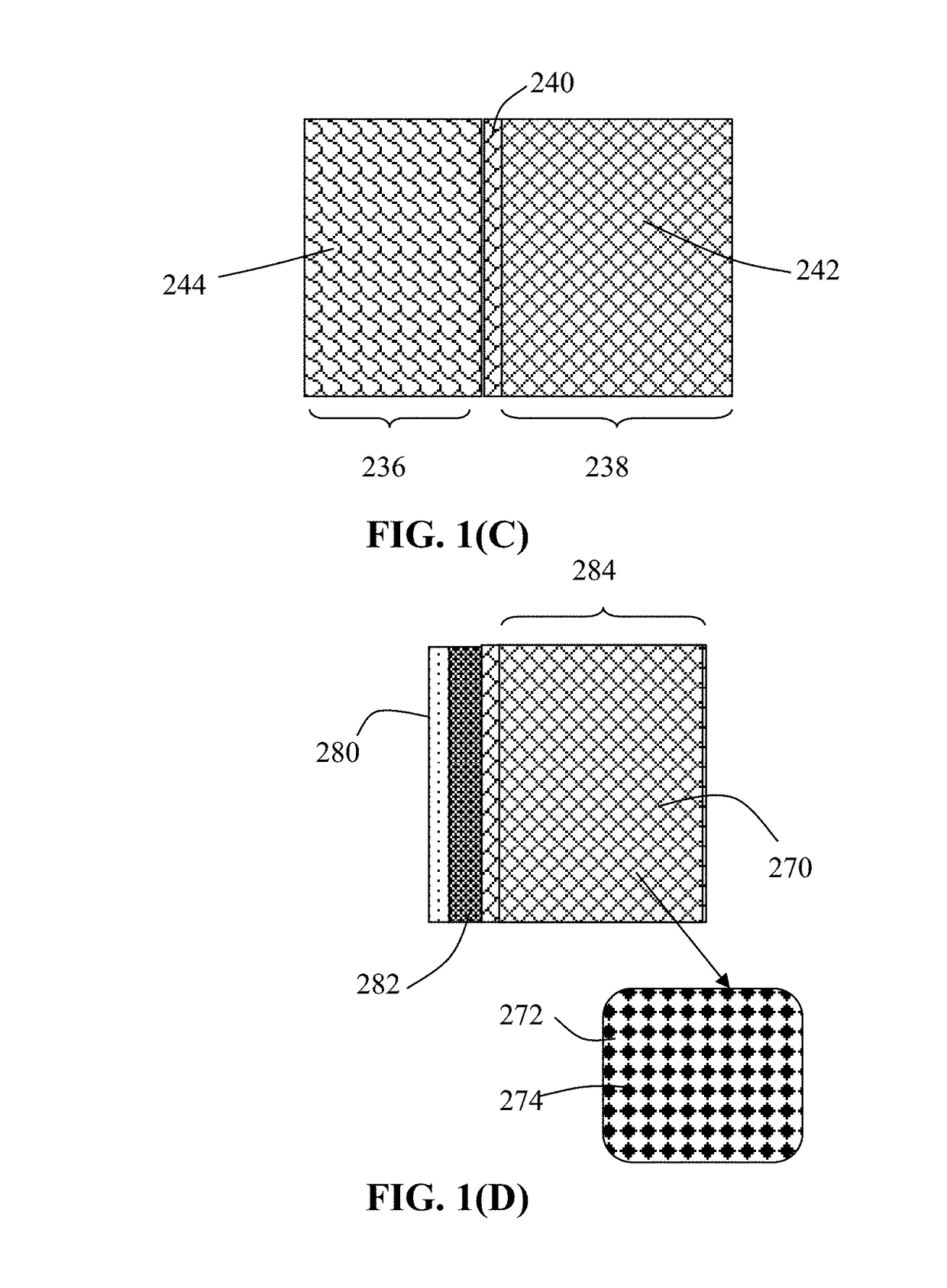

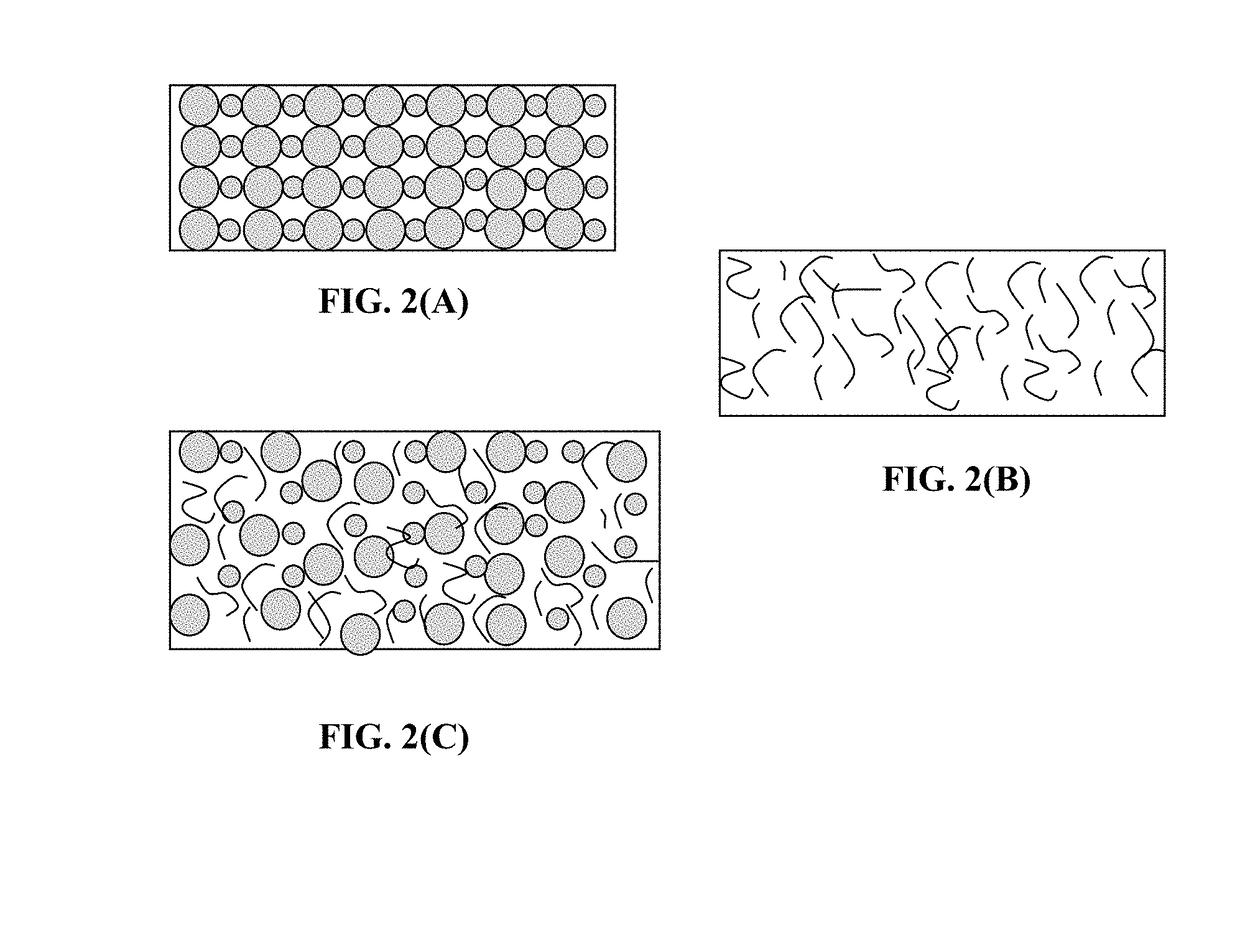

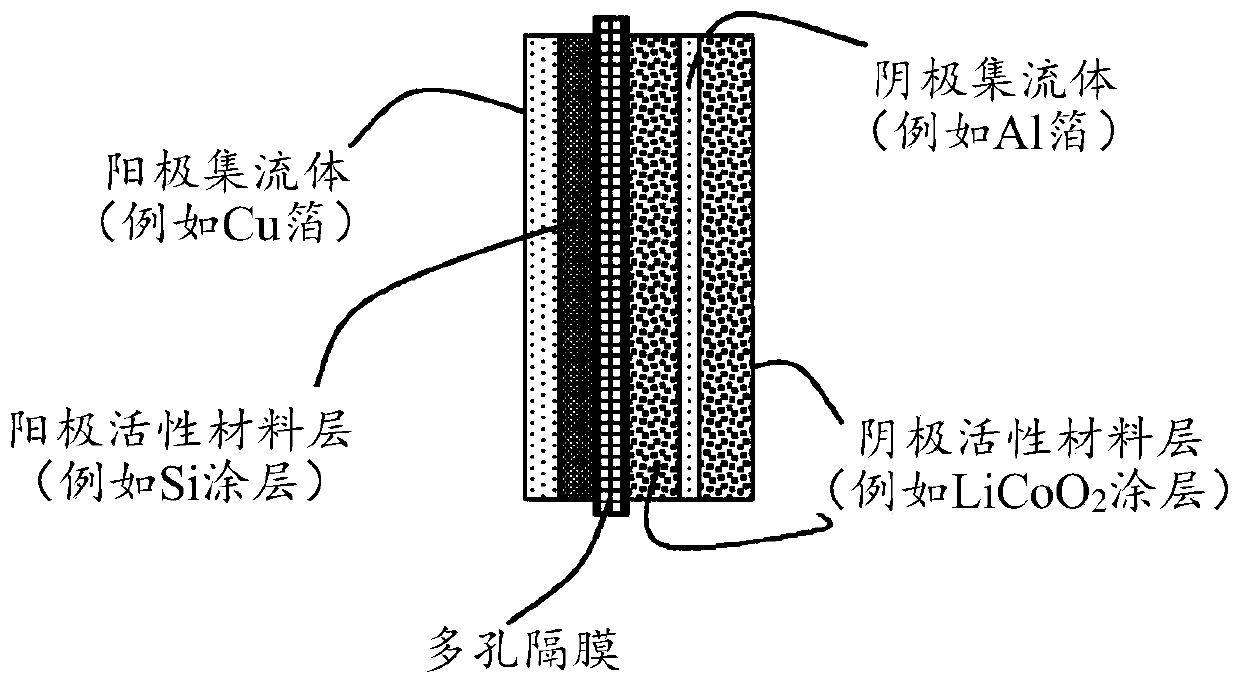

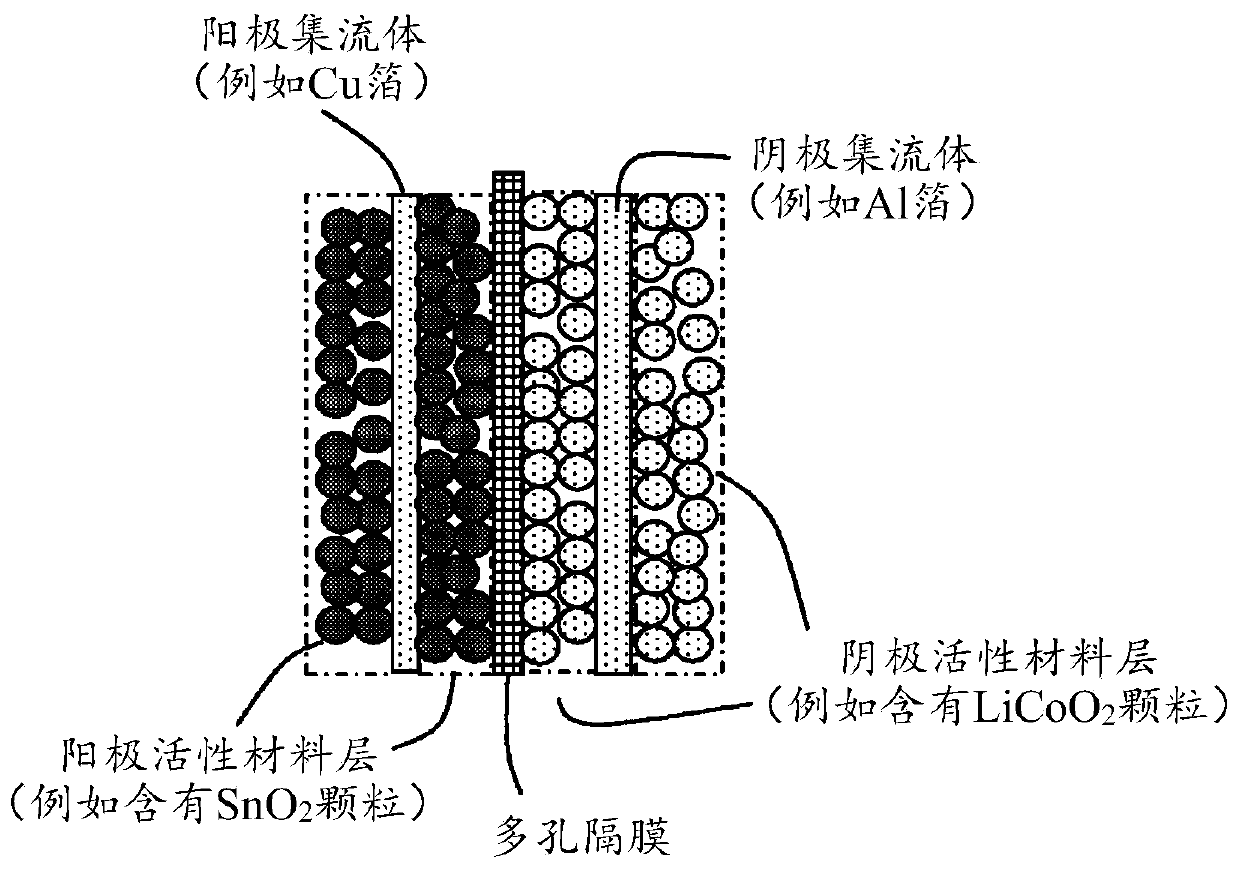

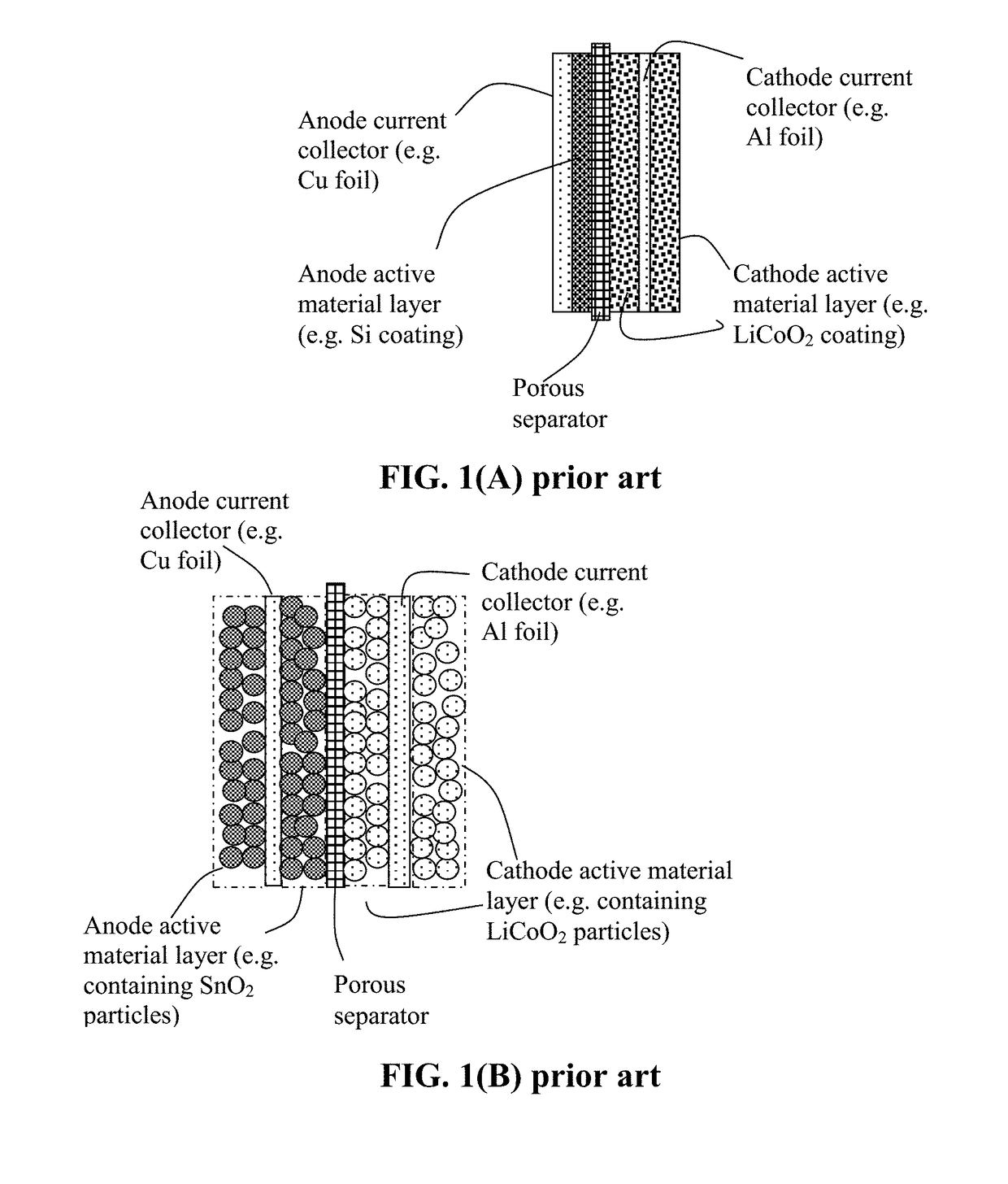

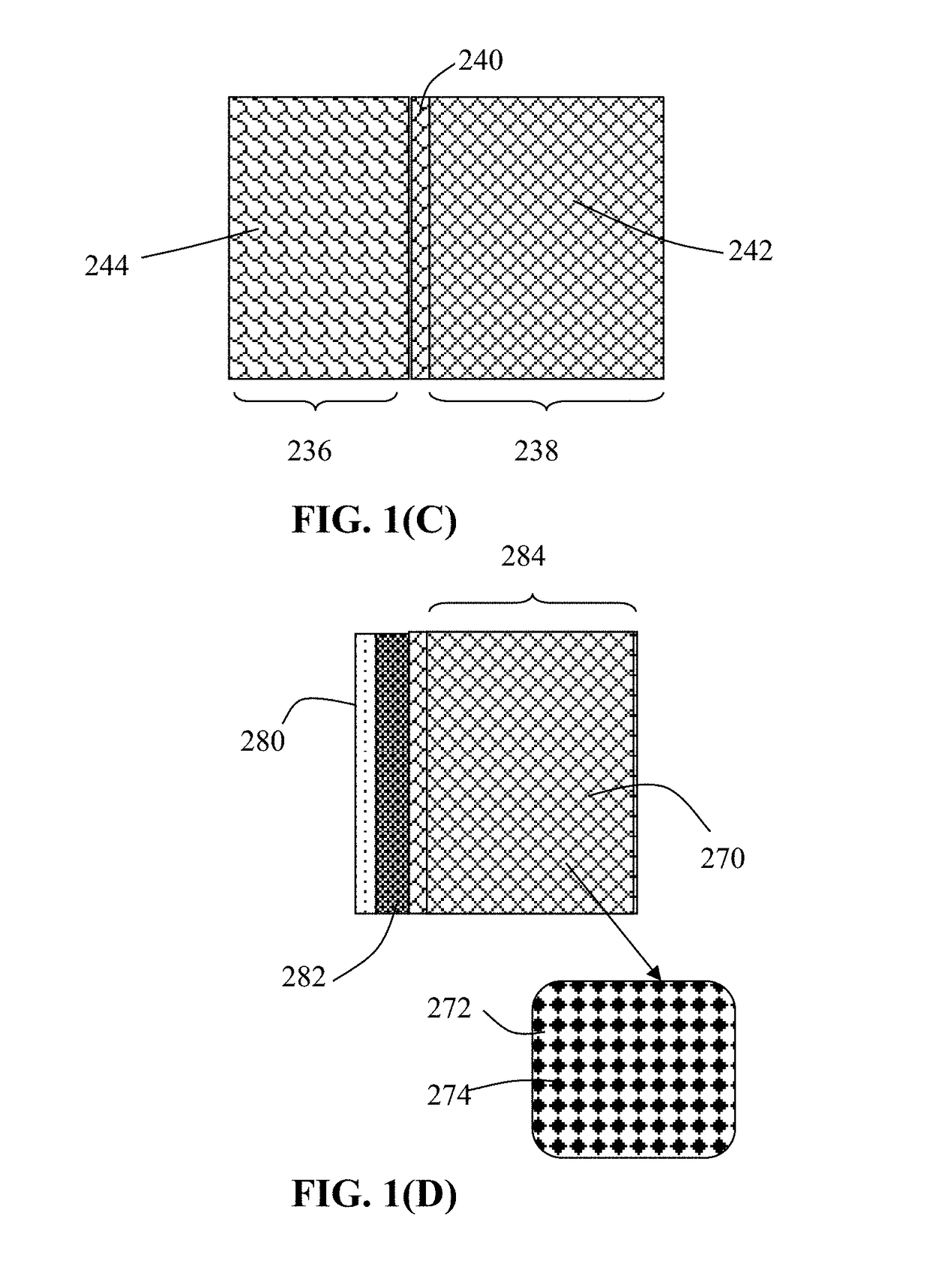

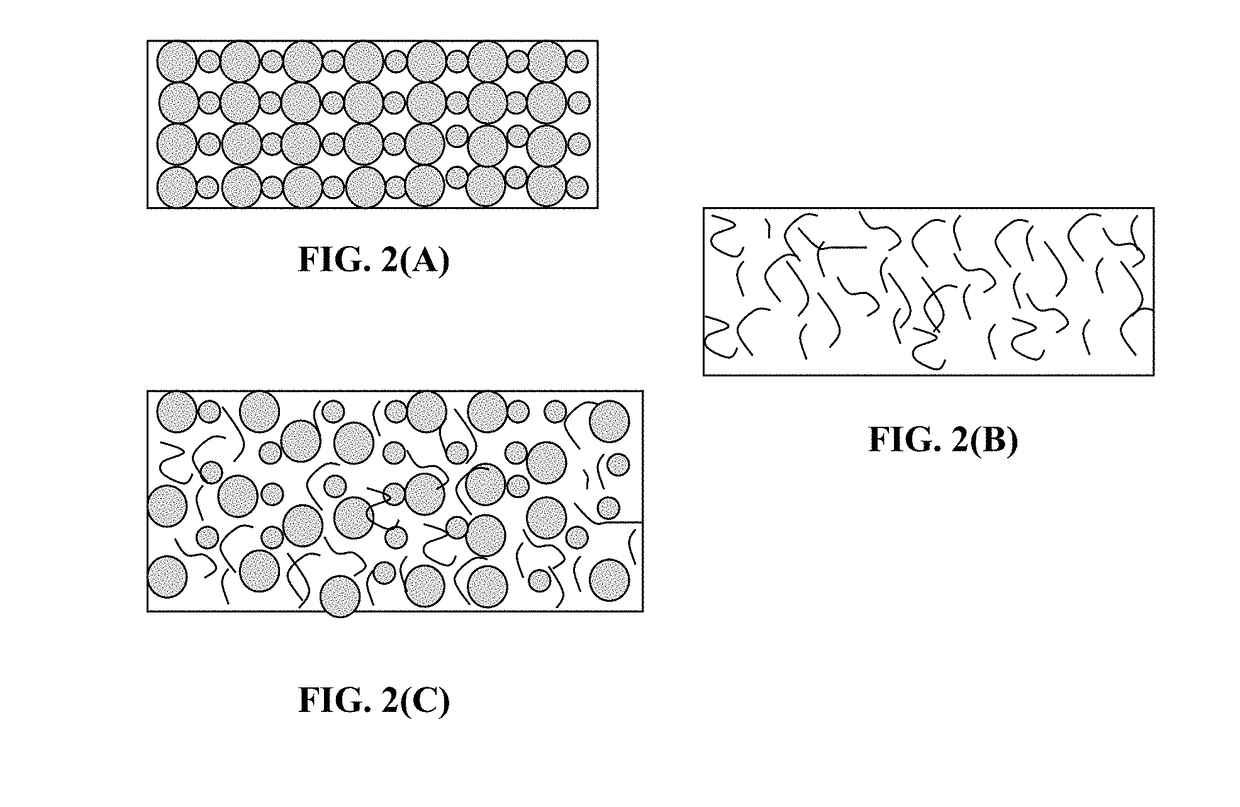

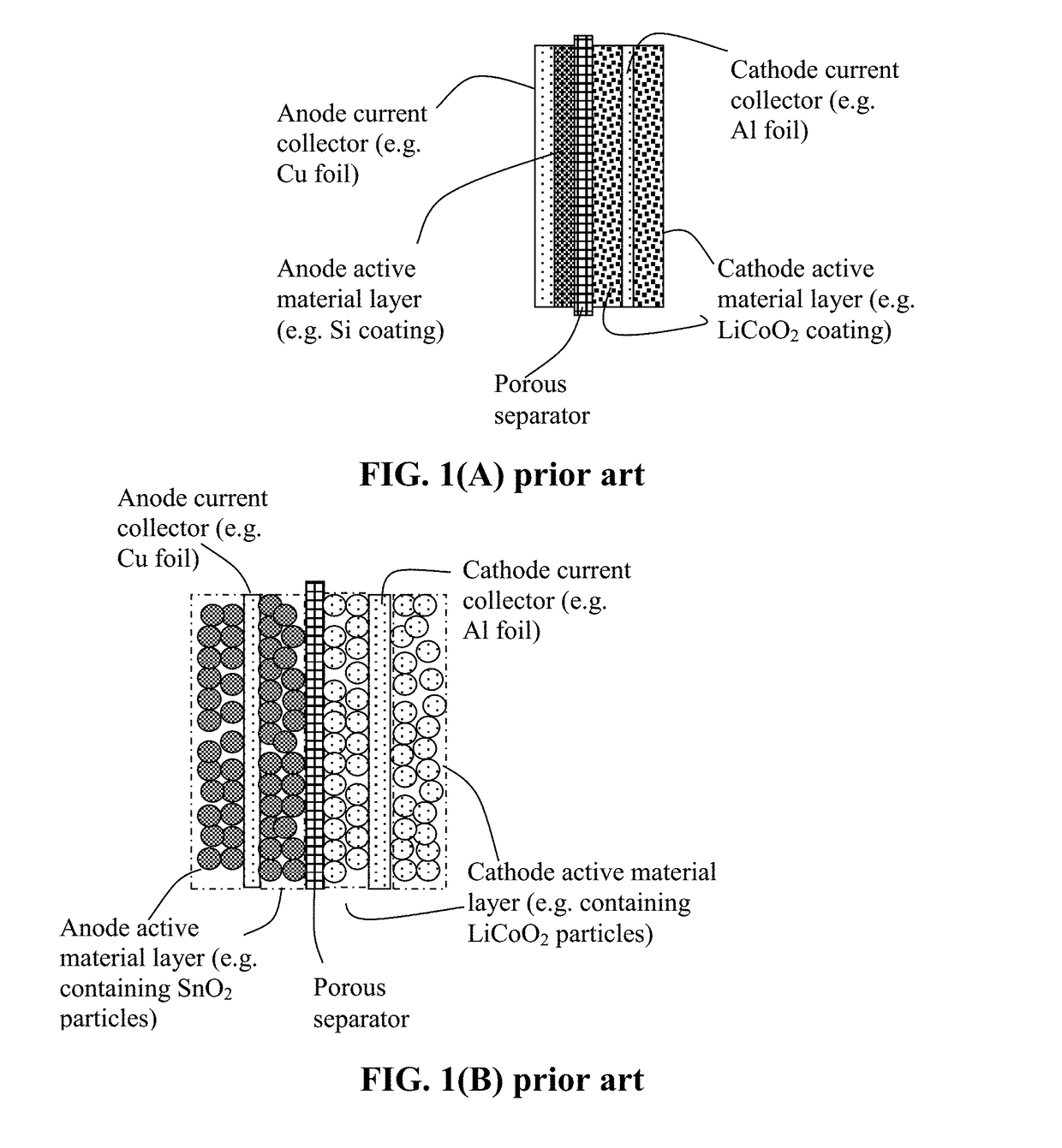

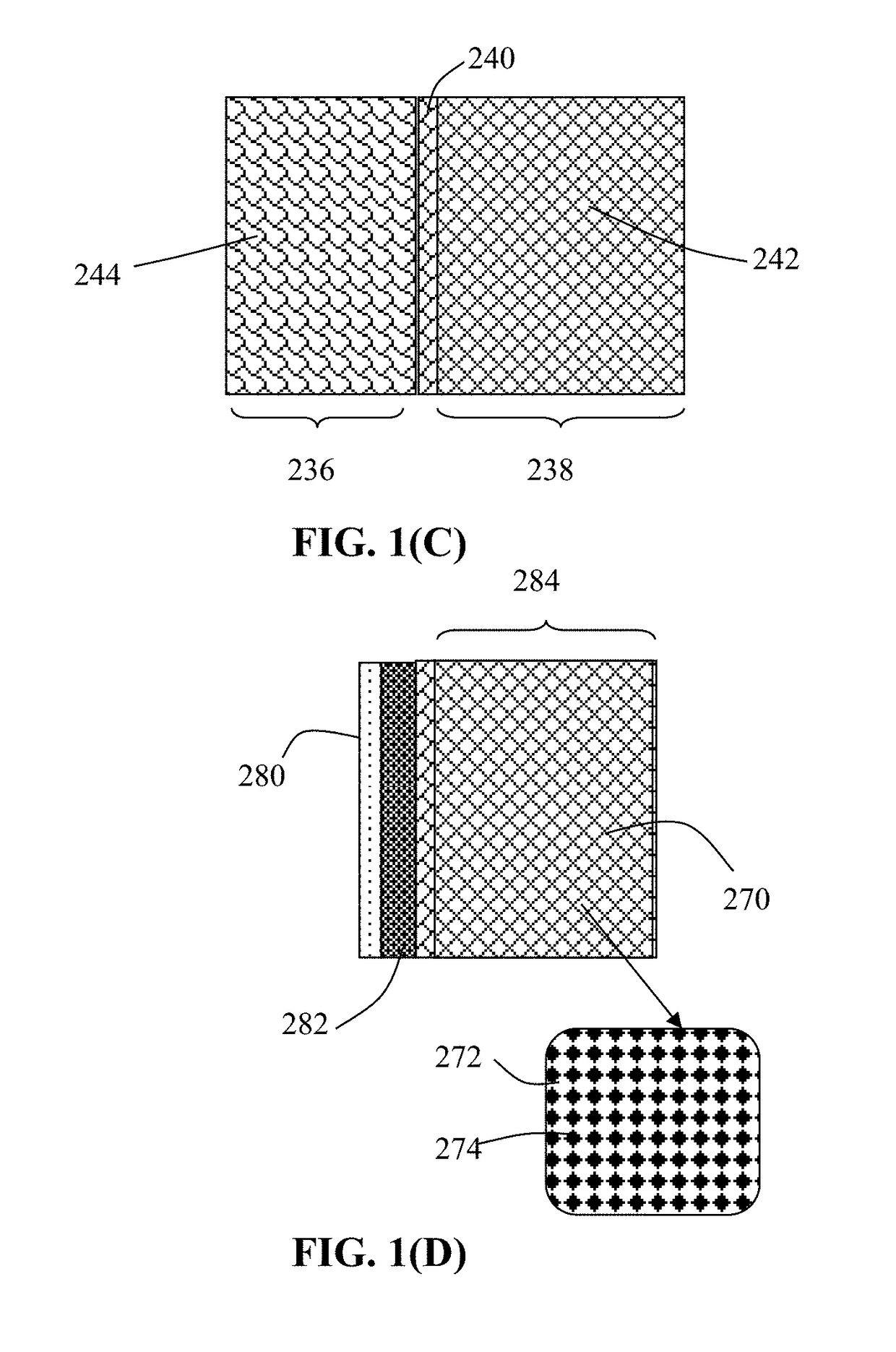

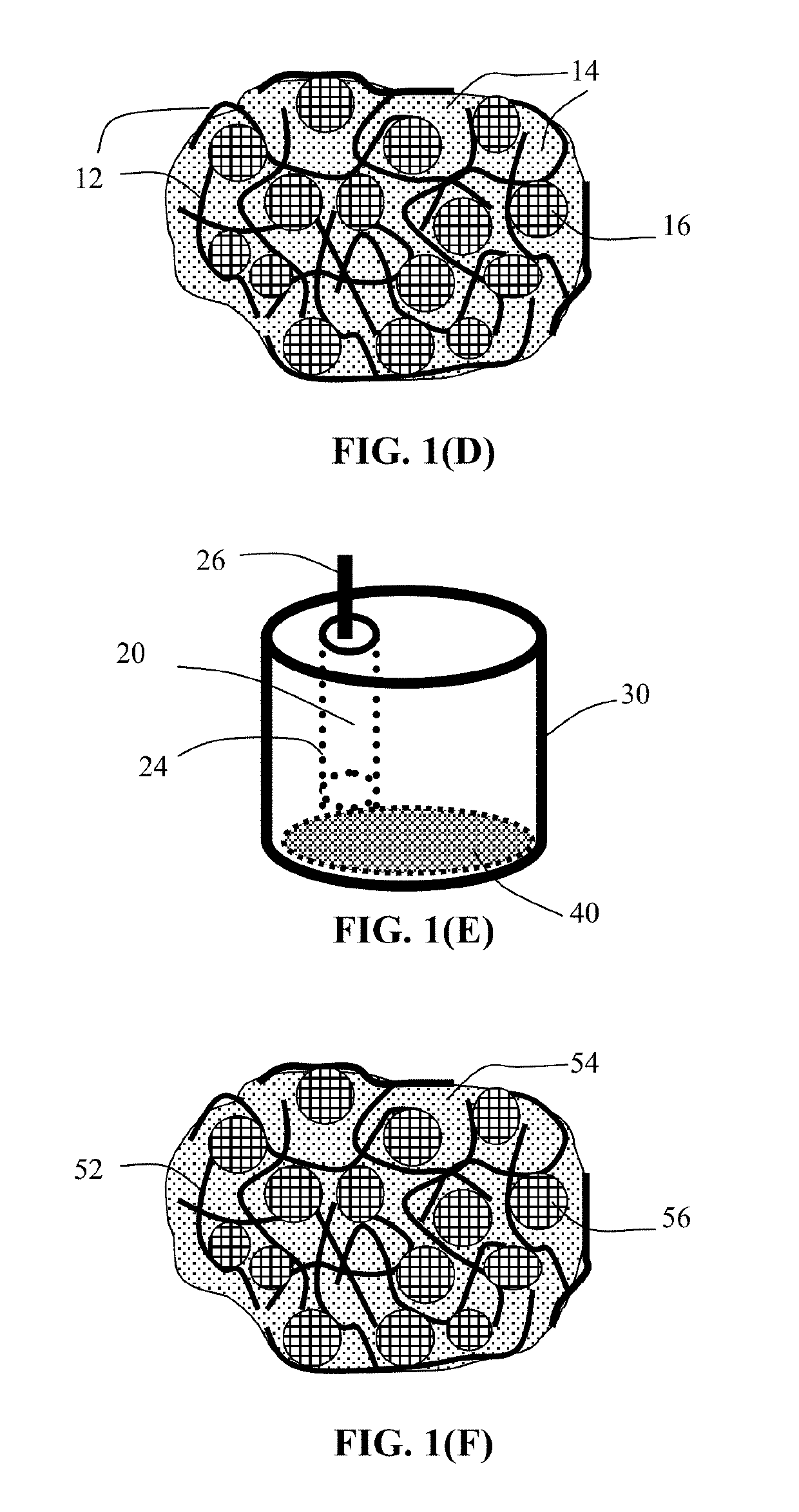

Anode Particulates or Cathode Particulates and Alkali Metal Batteries Containing Same

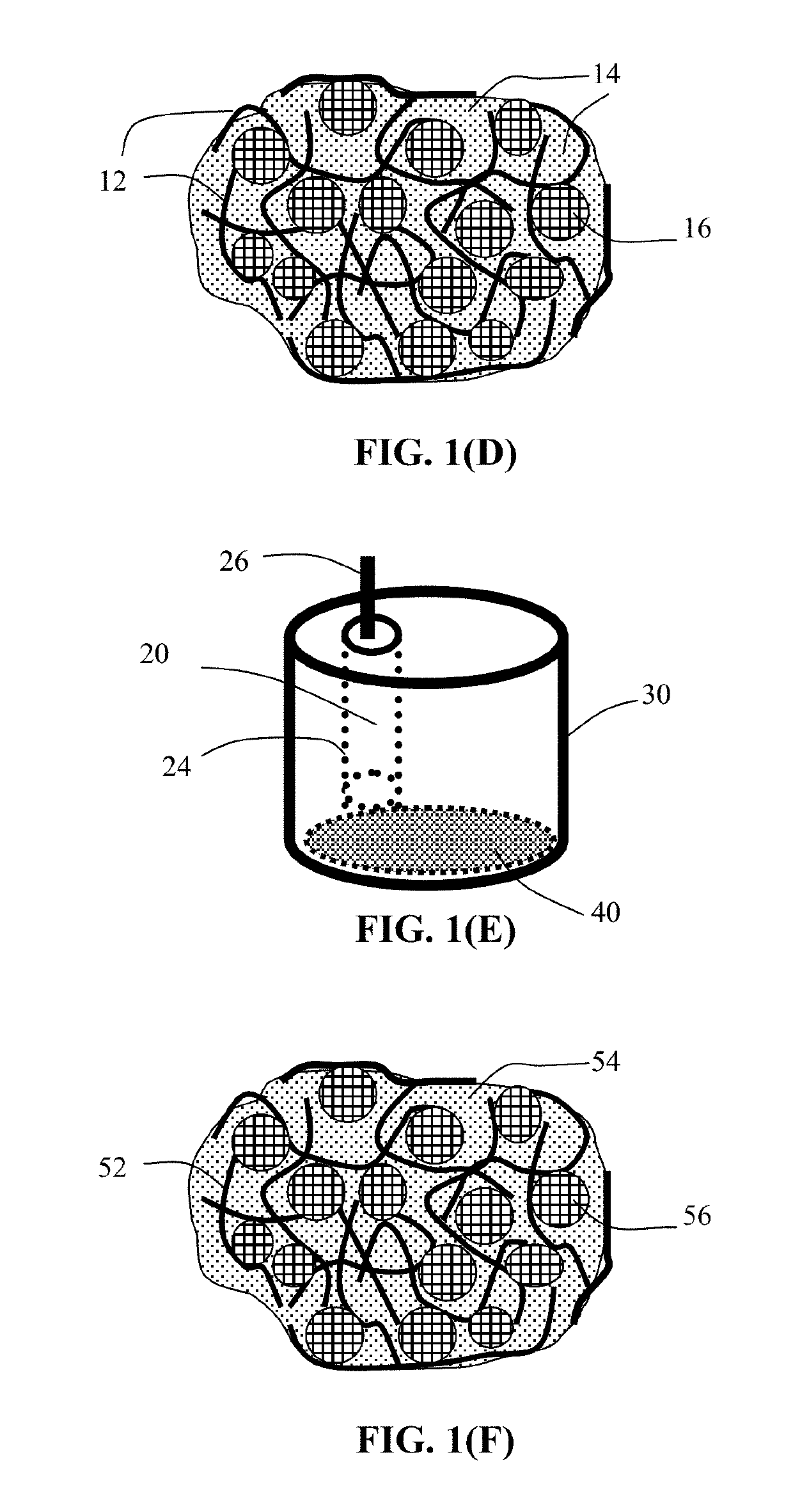

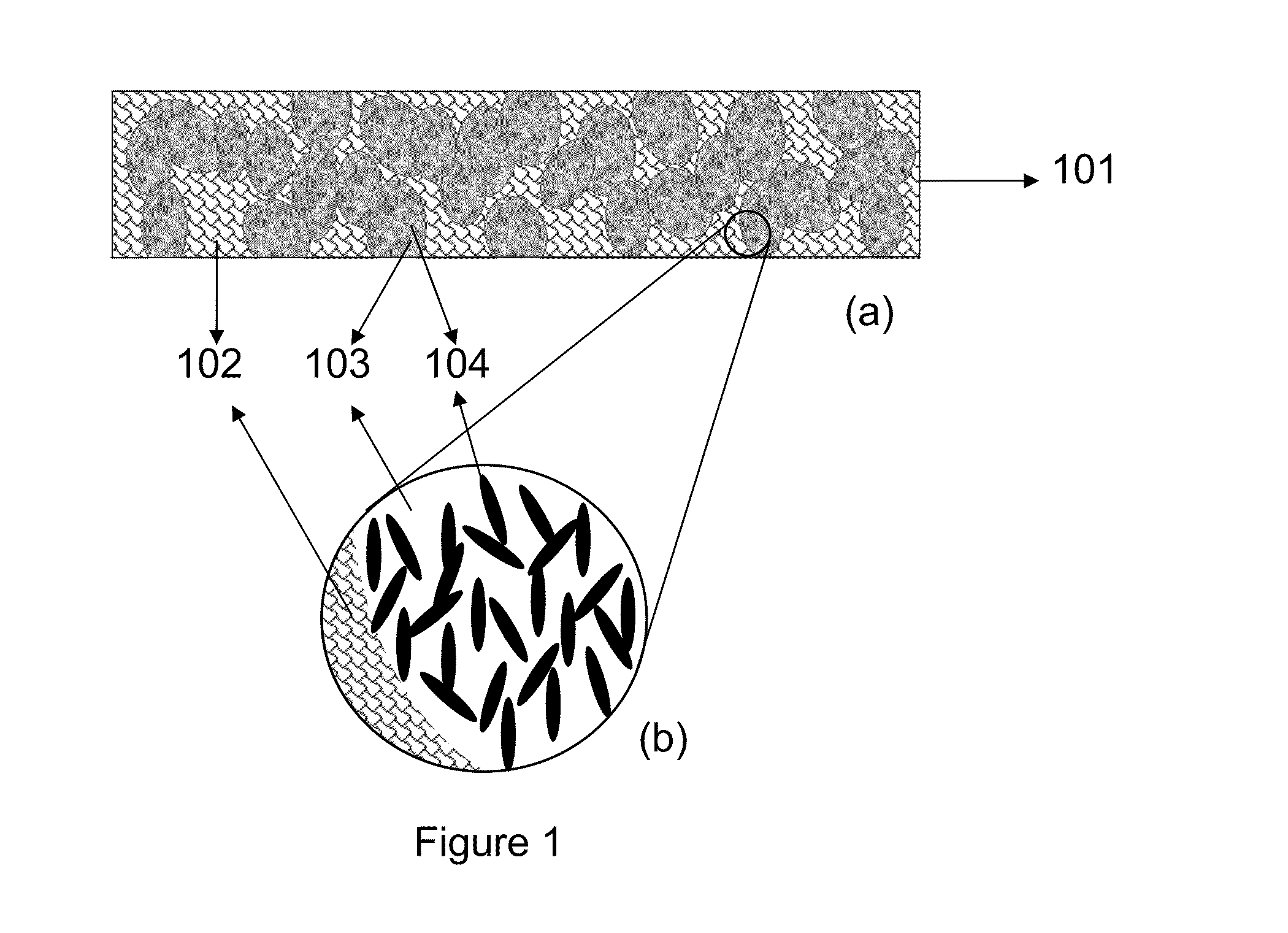

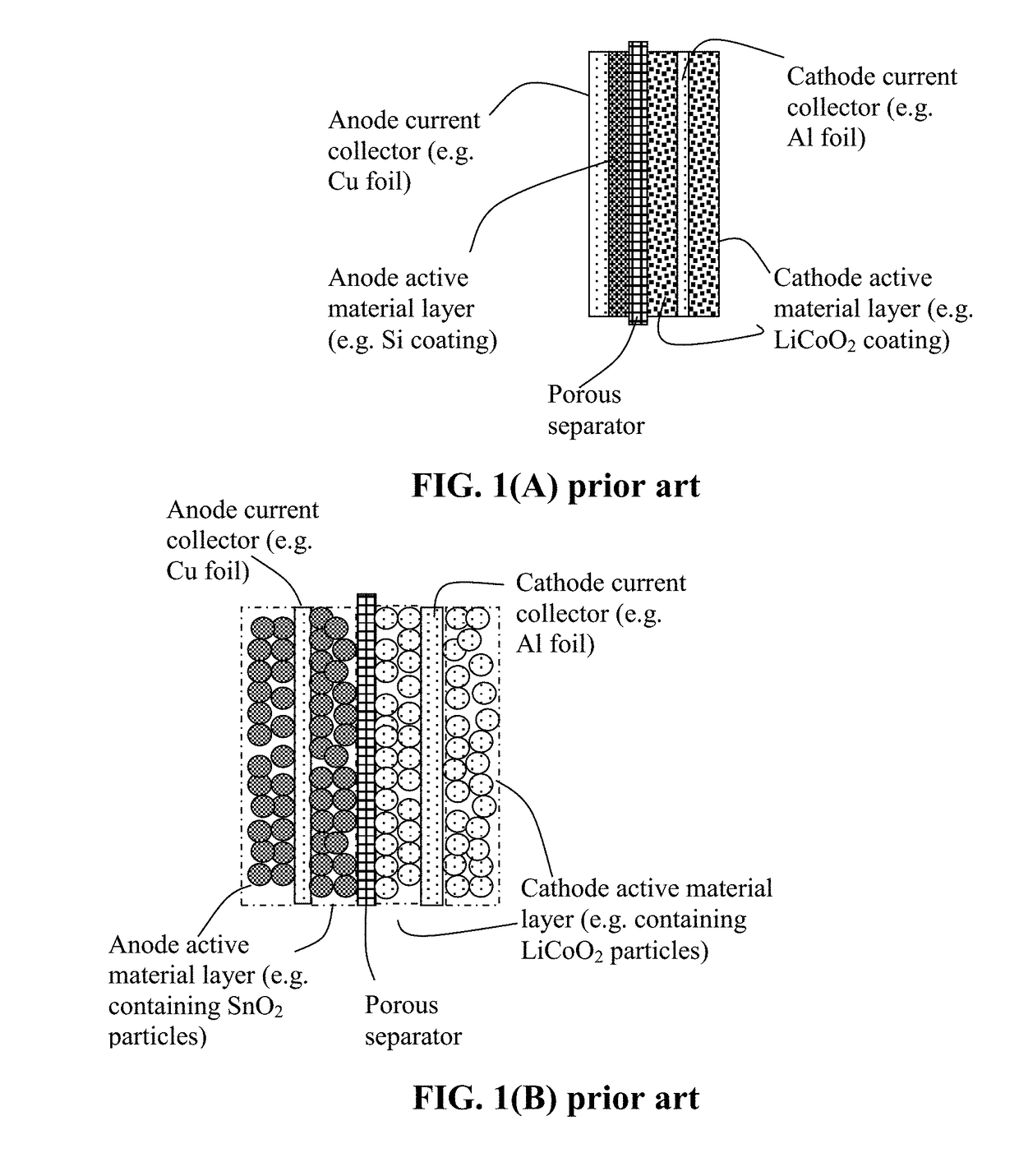

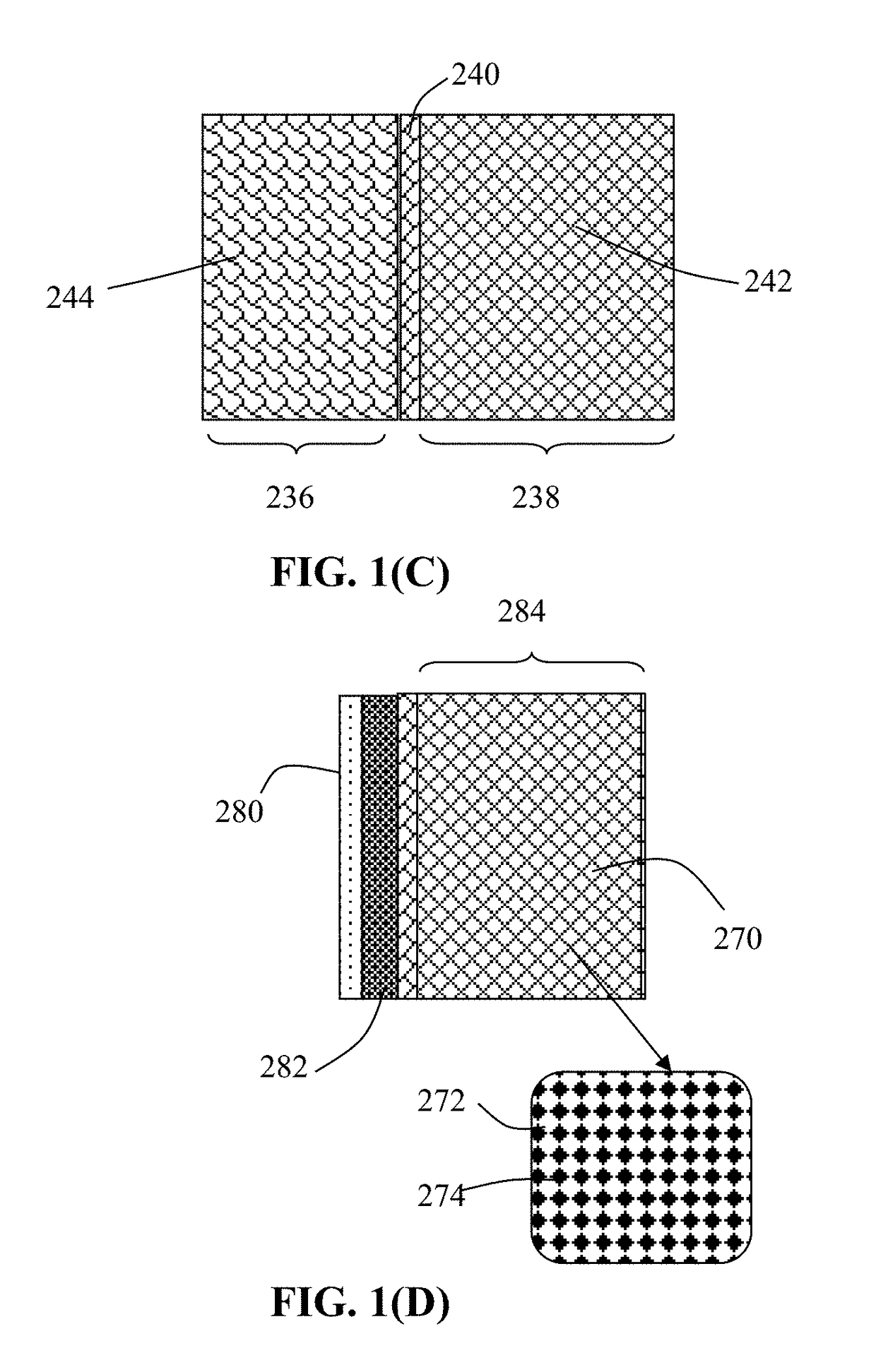

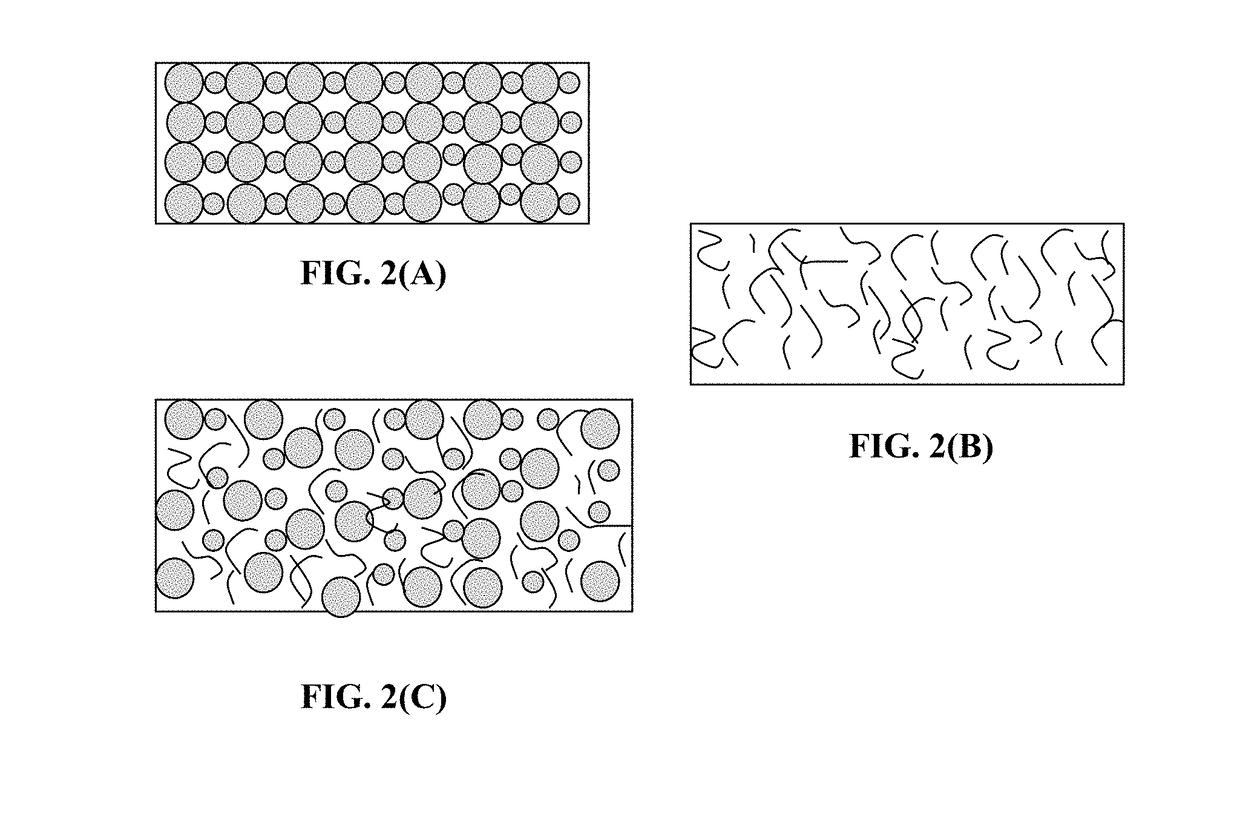

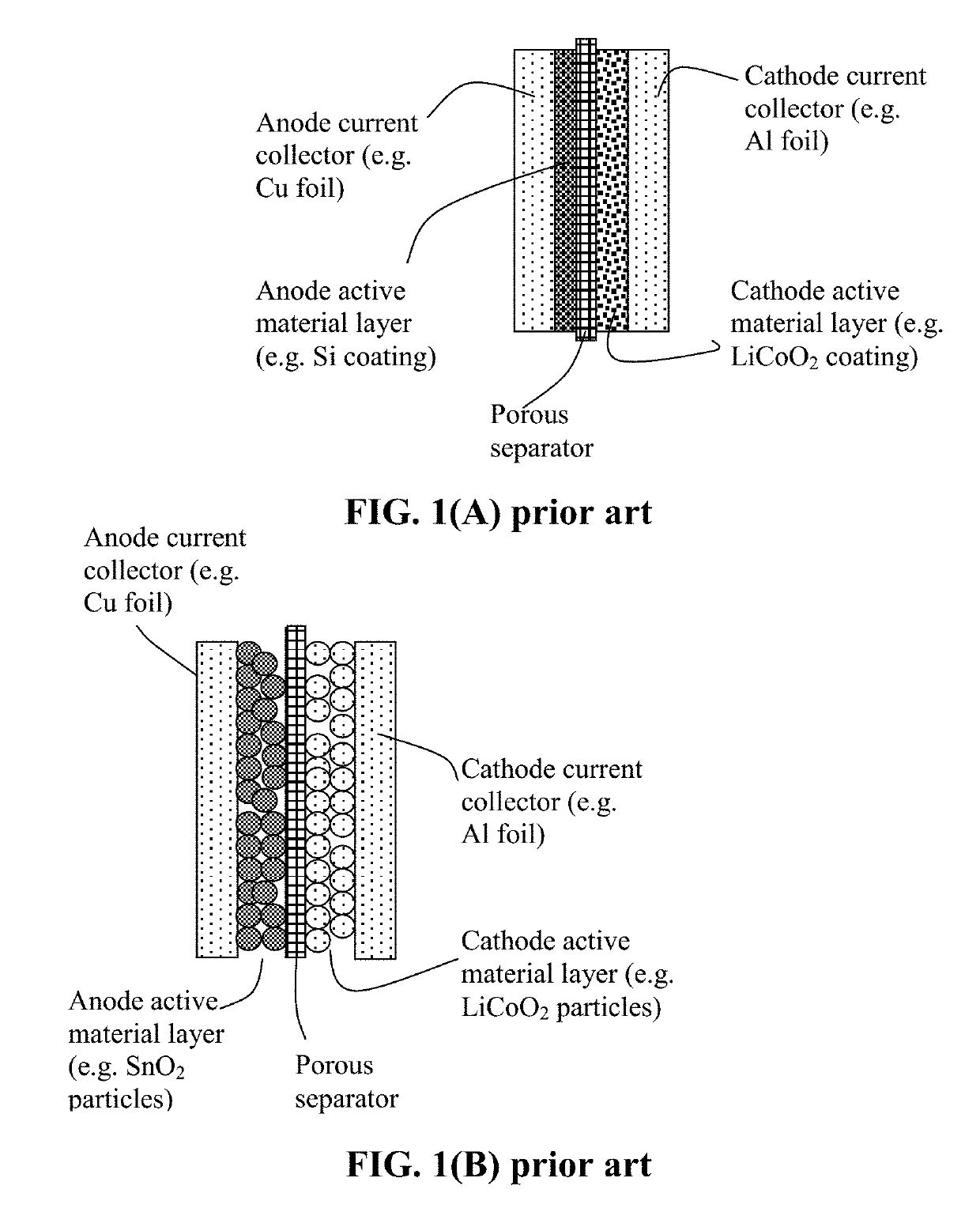

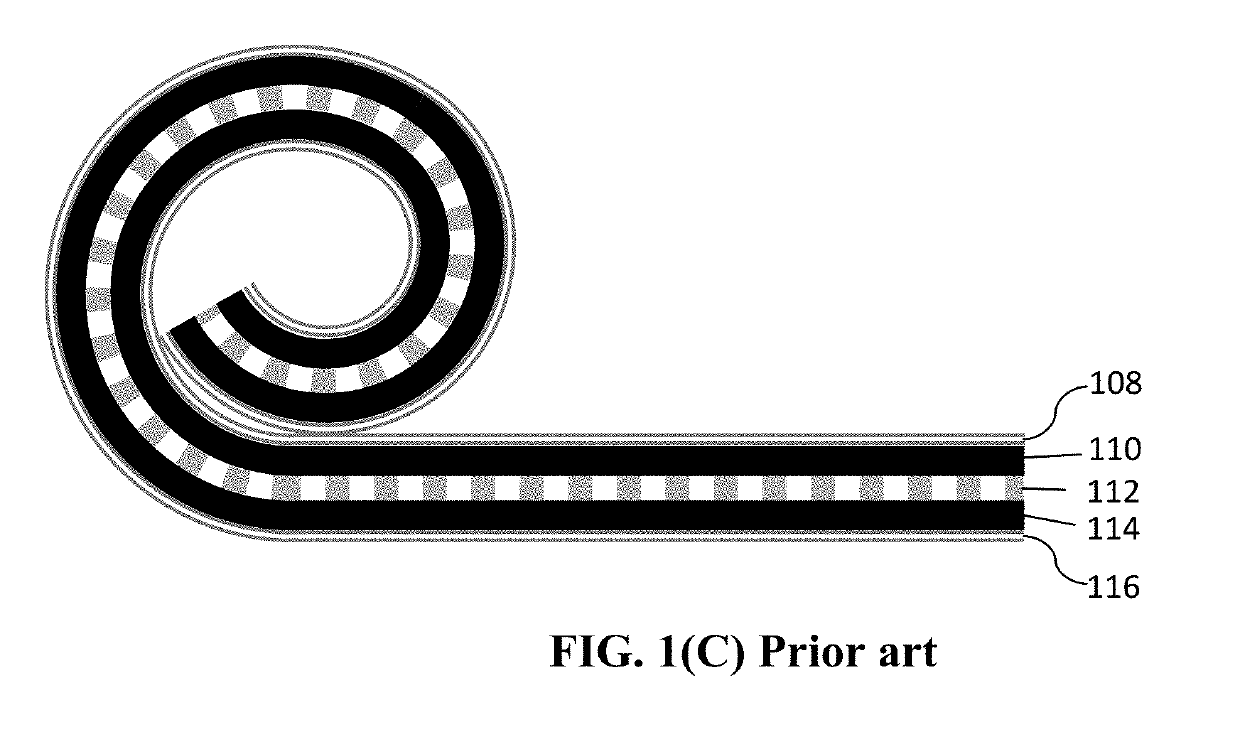

Provided is an anode particulate, having a dimension from 10 nm to 100 μm, for use in an alkali metal battery, the particulate comprising (i) an anode active material capable of reversibly absorbing and desorbing lithium ions or sodium ions, (ii) an electron-conducting material, and (iii) a lithium ion-conducting or sodium ion-conducting electrolyte, wherein the electron-conducting material forms a three dimensional network of electron-conducting pathways in electronic contact with the anode active material and the electrolyte forms a three dimensional network of lithium ion- or sodium ion-conducting channels in ionic contact with the anode active material. The particulate can be of any shape, but preferably spherical or ellipsoidal in shape. Also provided is a cathode in a particulate form containing a cathode active material, an electron-conducting material forming a three dimensional network of electron-conducting pathways, and a lithium ion-conducting or sodium ion-conducting electrolyte forming a three dimensional network of ion-conducting channels.

Owner:GLOBAL GRAPHENE GRP INC

Highly conductive composites

InactiveUS20110214284A1Decreased percolation thresholdLow percolation thresholdConductive materialPretreated surfacesConductive polymerConducting pathway

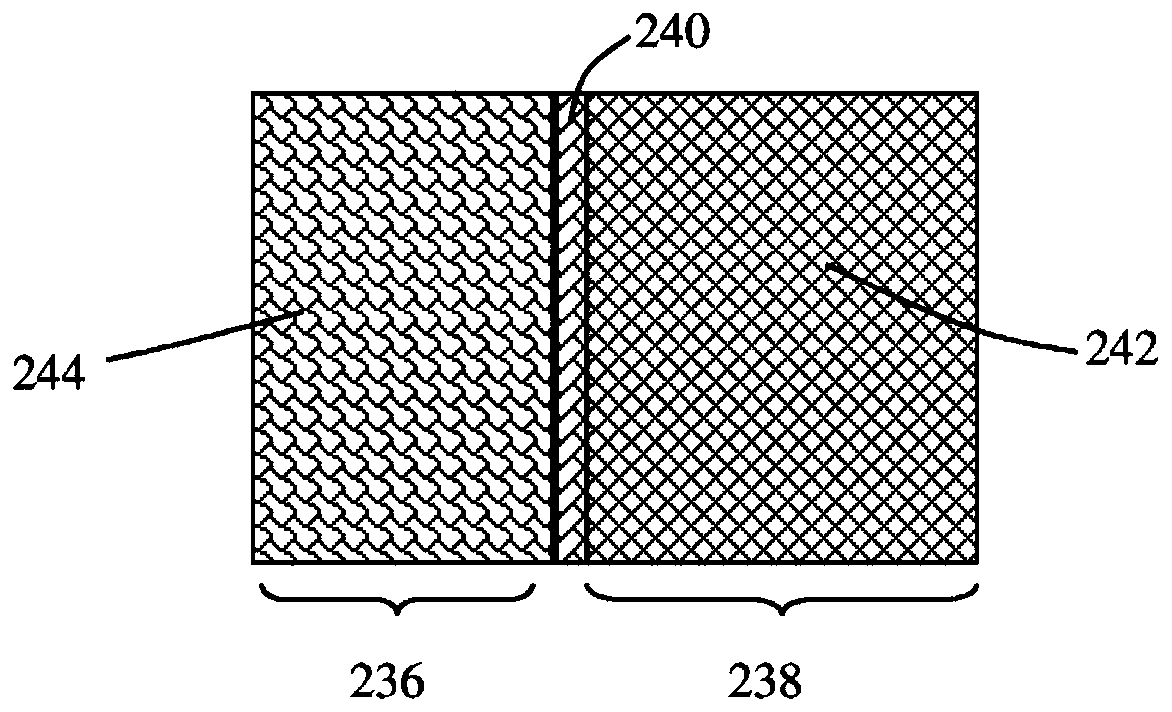

Domain segregation of polymer blends or block copolymers in the presence of thermal conducting high aspect ratio nanocrystals leads to preferential placement of conductive filler either inside one domain, which promote the self-assembly of a thermal and / or electrical conducting pathway composed of high aspect ratio filler. The self-assembly of such thermal and / or electrical conducting pathway effectively enhances the thermal and / or electrical conductivity of the composite with significantly less amount of filler.

Owner:PIXELLIGENT TECH LLC

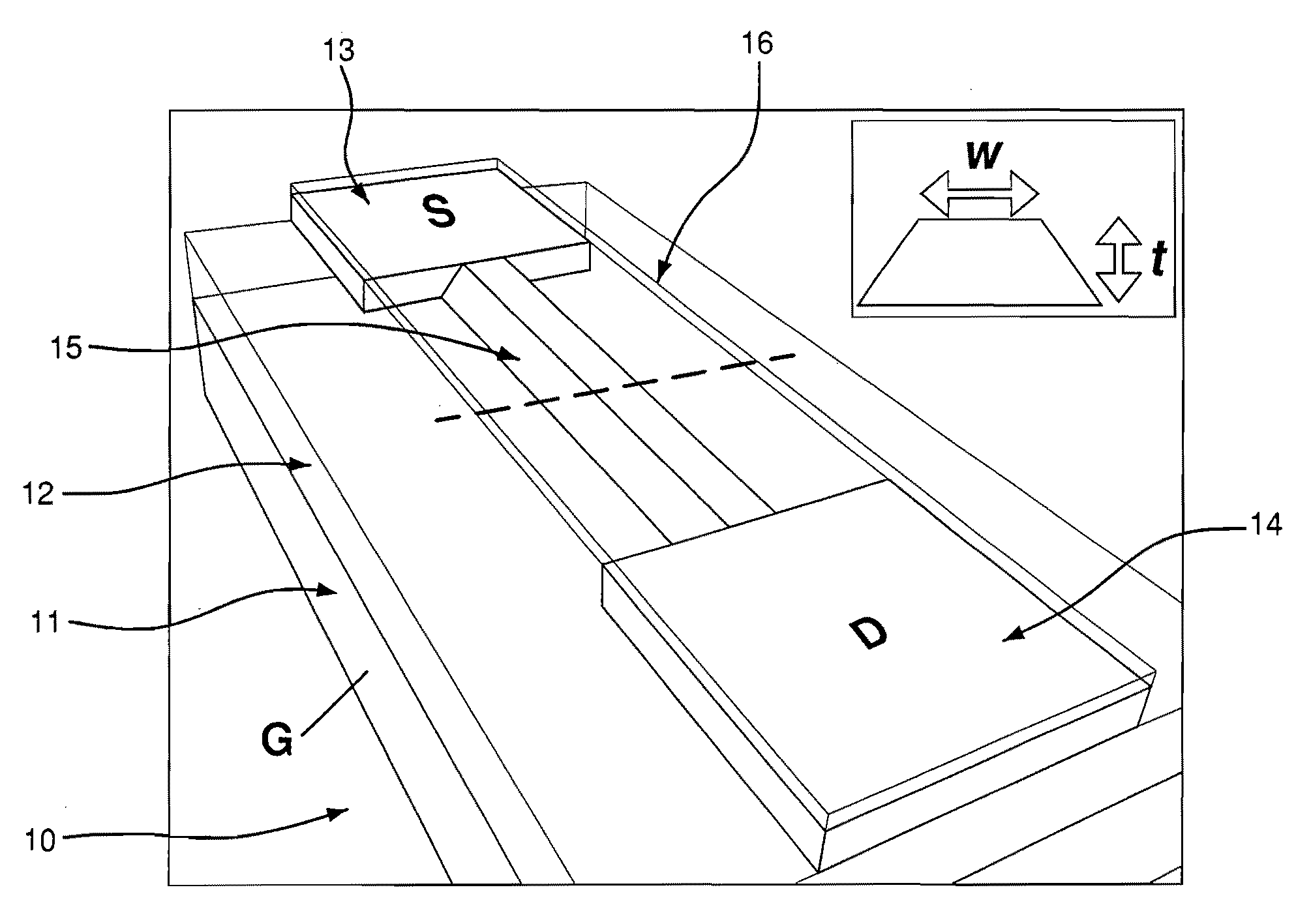

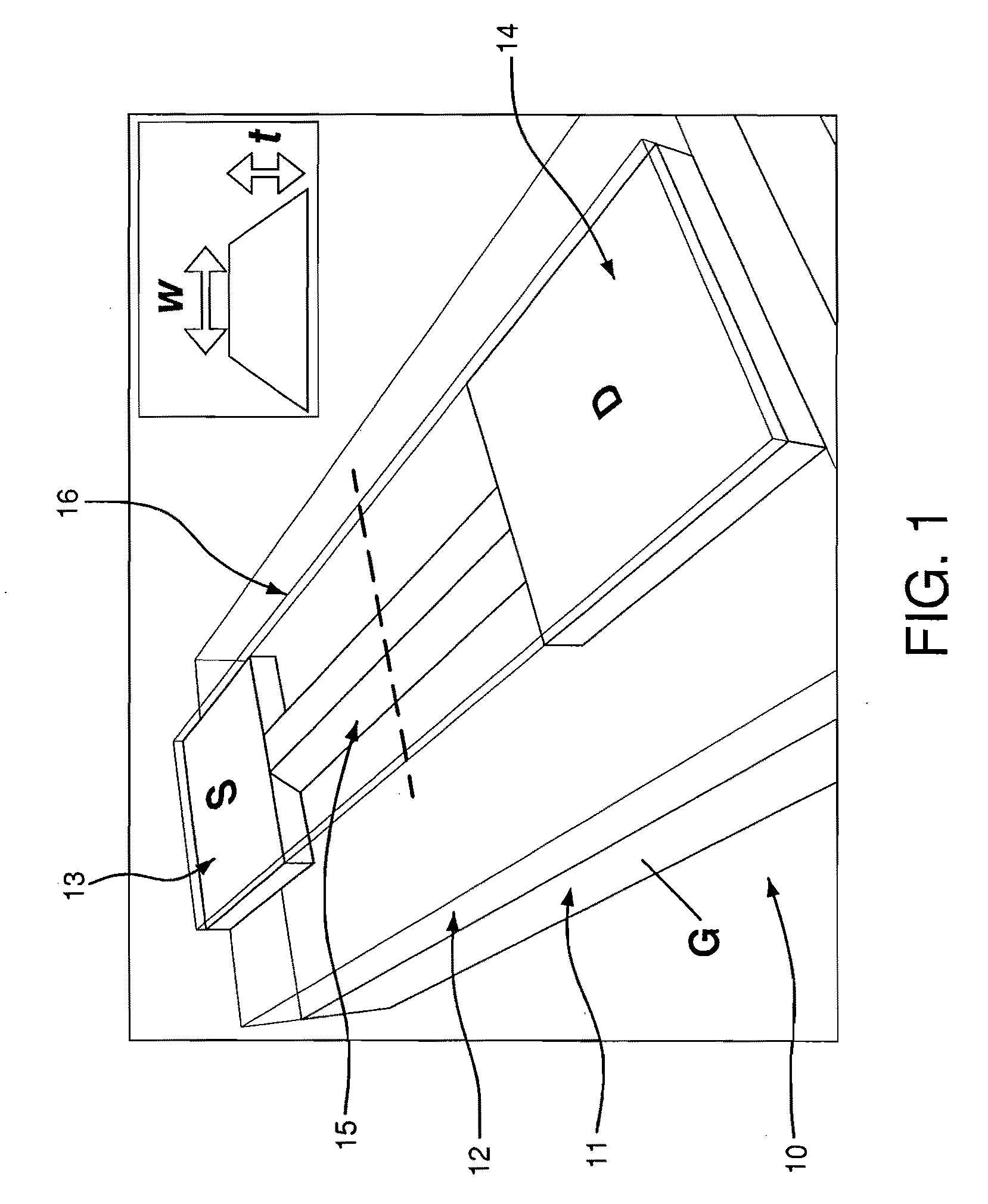

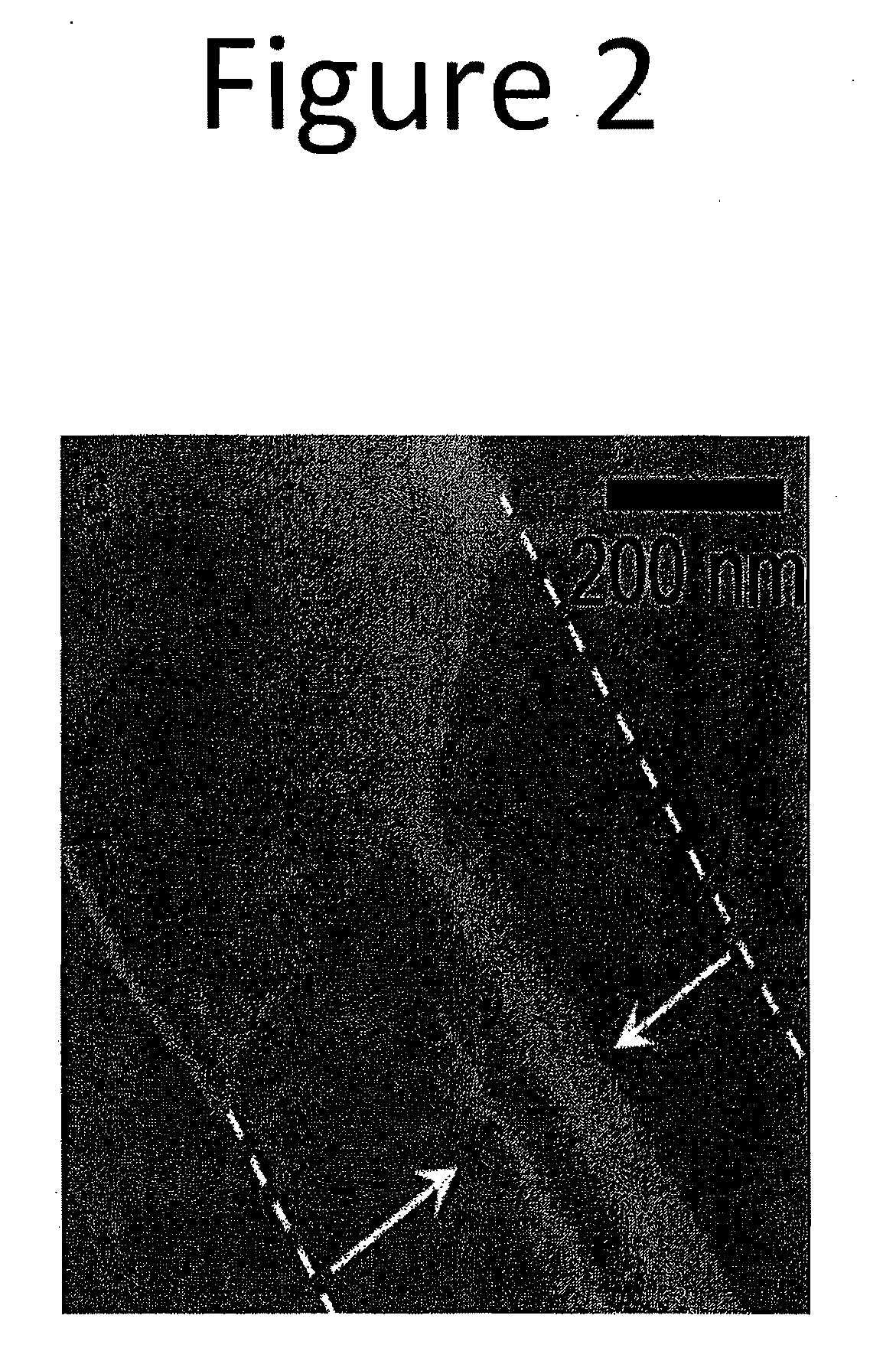

Systems and Methods for CMOS-Compatible Silicon Nano-Wire Sensors with Biochemical and Cellular Interfaces

ActiveUS20100297608A1High sensitivityIncrease the areaMicrobiological testing/measurementNanoinformaticsSemiconductor materialsConducting pathway

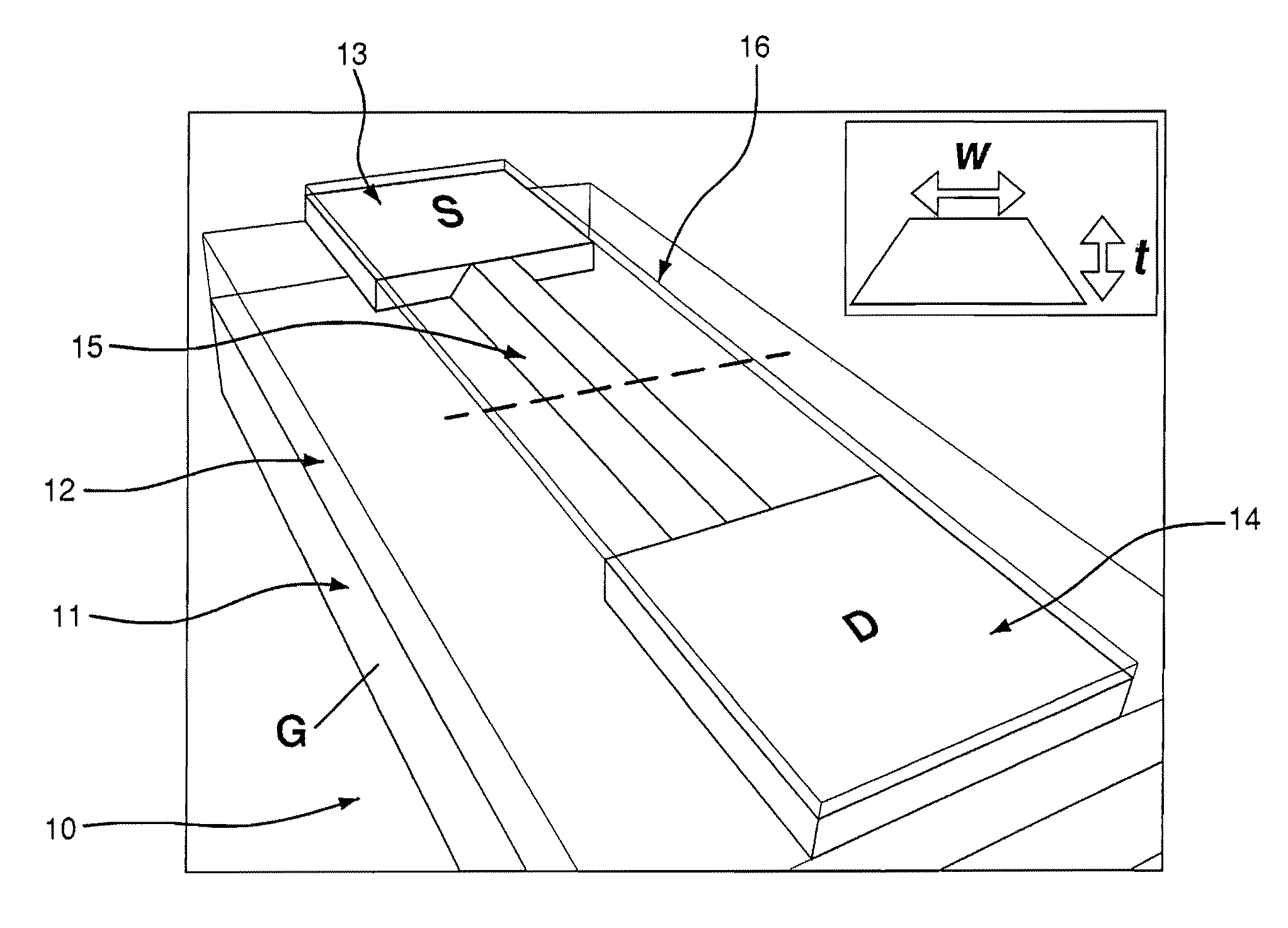

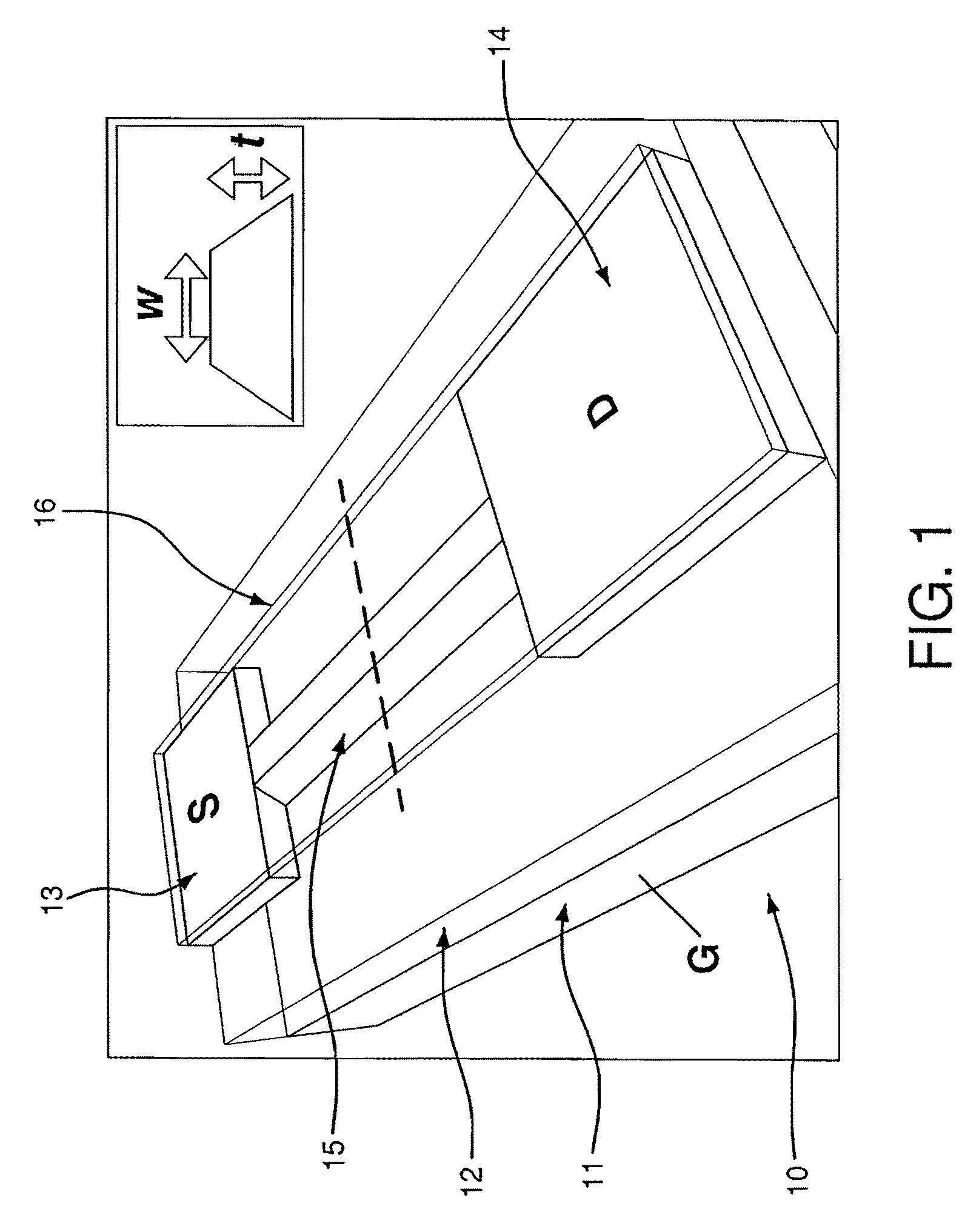

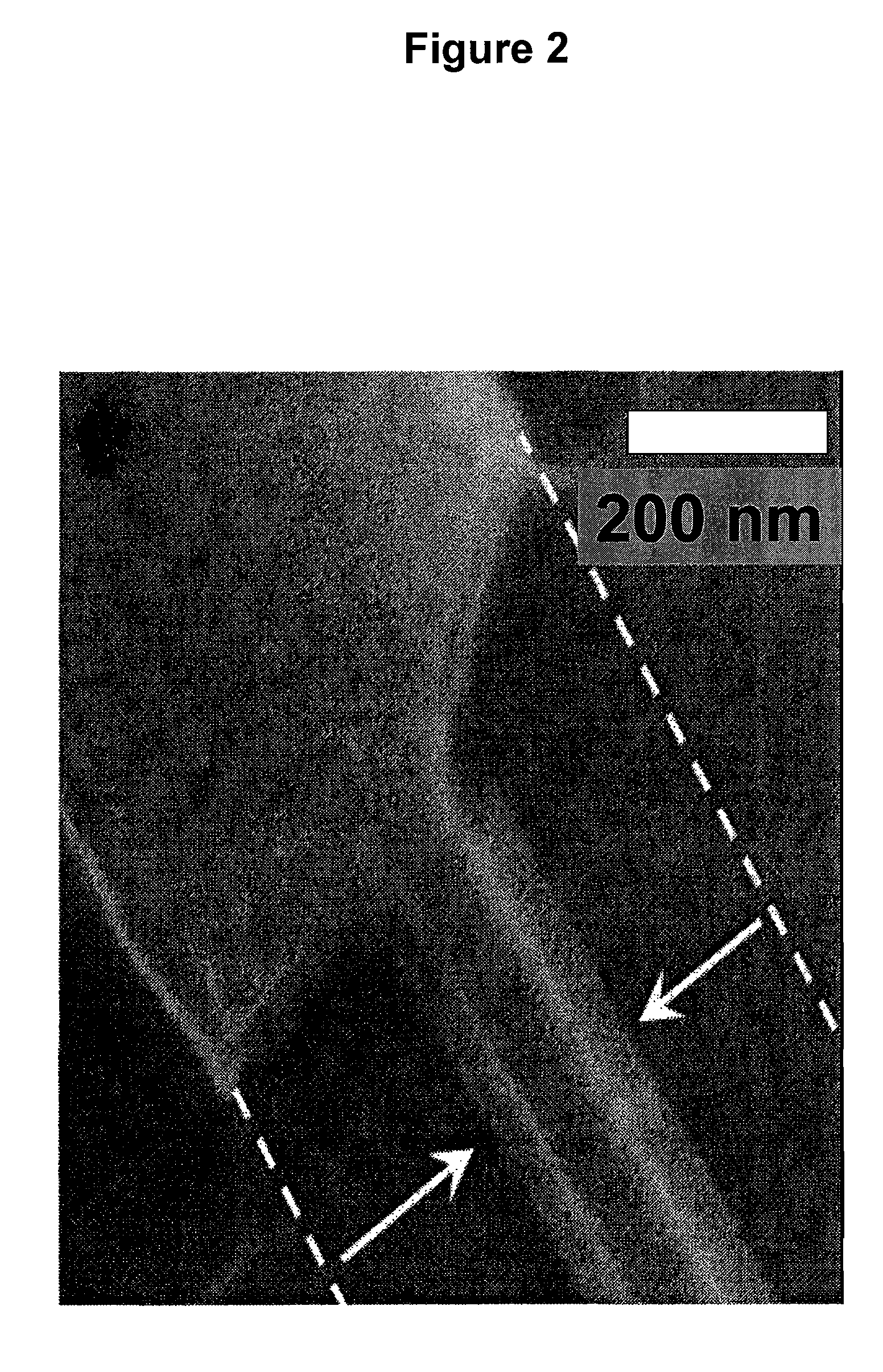

The systems and methods described herein include a sensor for suitable for sensing chemical and biological substances. The sensor comprises a semiconductor layer formed in or on a substrate and a channel having nano-scale dimensions formed in the semiconductor layer, where the structure creates an electrically conducting pathway between a first contact and a second contact on the semiconductor layer. In certain preferred embodiments, the nano-scale channel has a trapezoidal cross-section with an effective width and exposed lateral faces, where the effective width is selected to have same order of magnitude as a Debye length (LD) of the semiconductor material of which the semiconductor layer is formed.

Owner:YALE UNIV

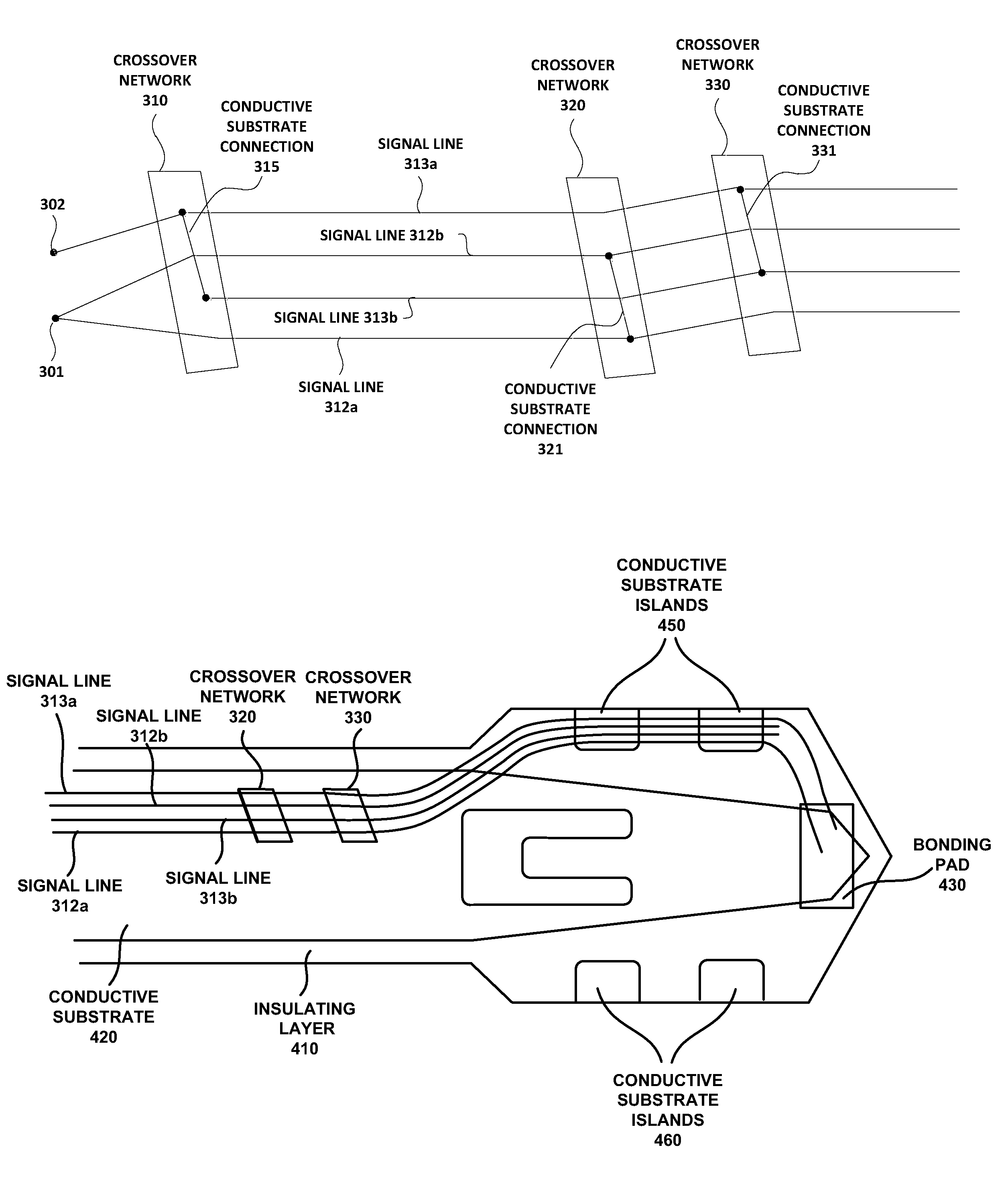

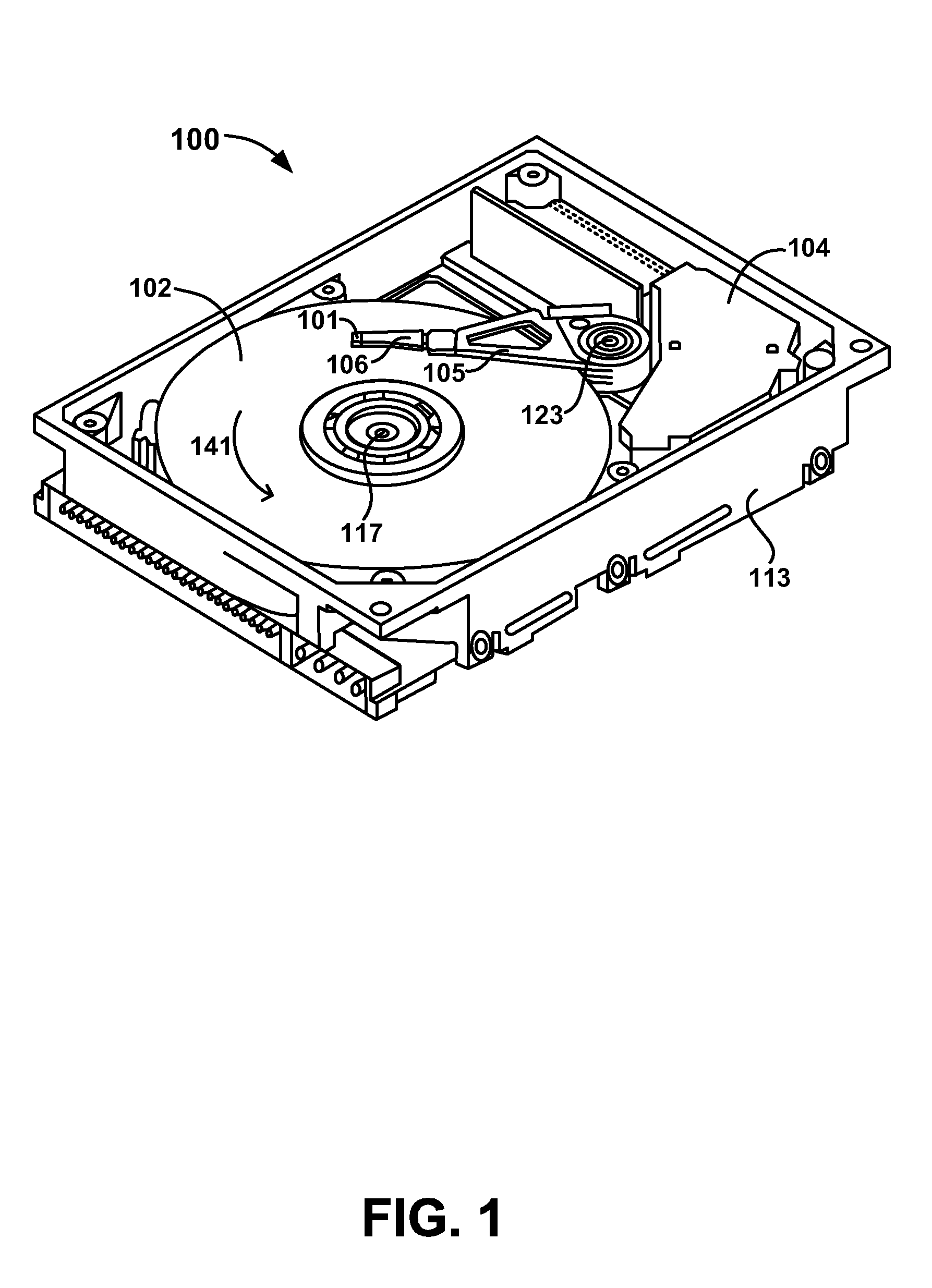

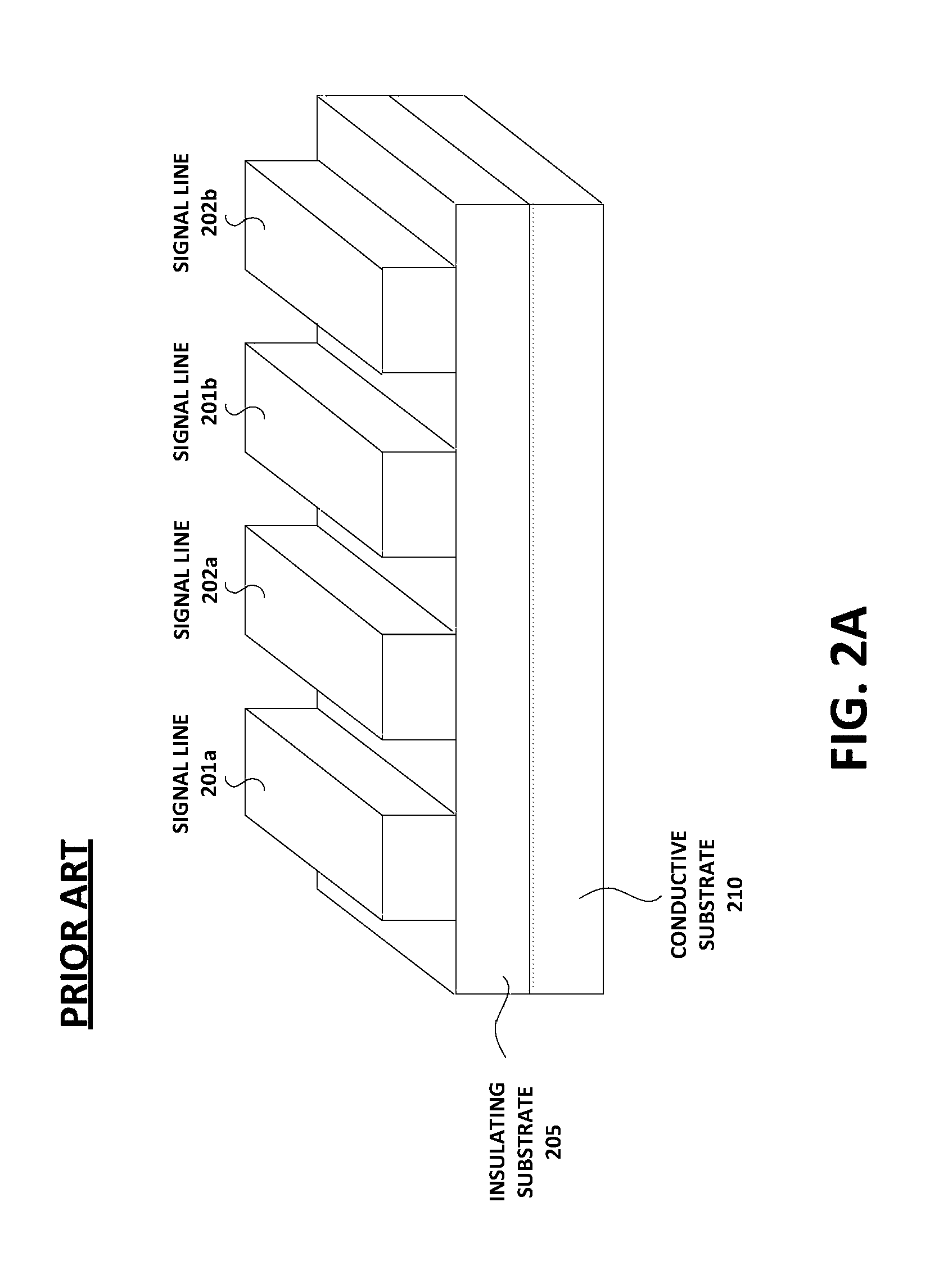

Tunable microstrip signal transmission path in a hard disk drive

Owner:WESTERN DIGITAL TECH INC

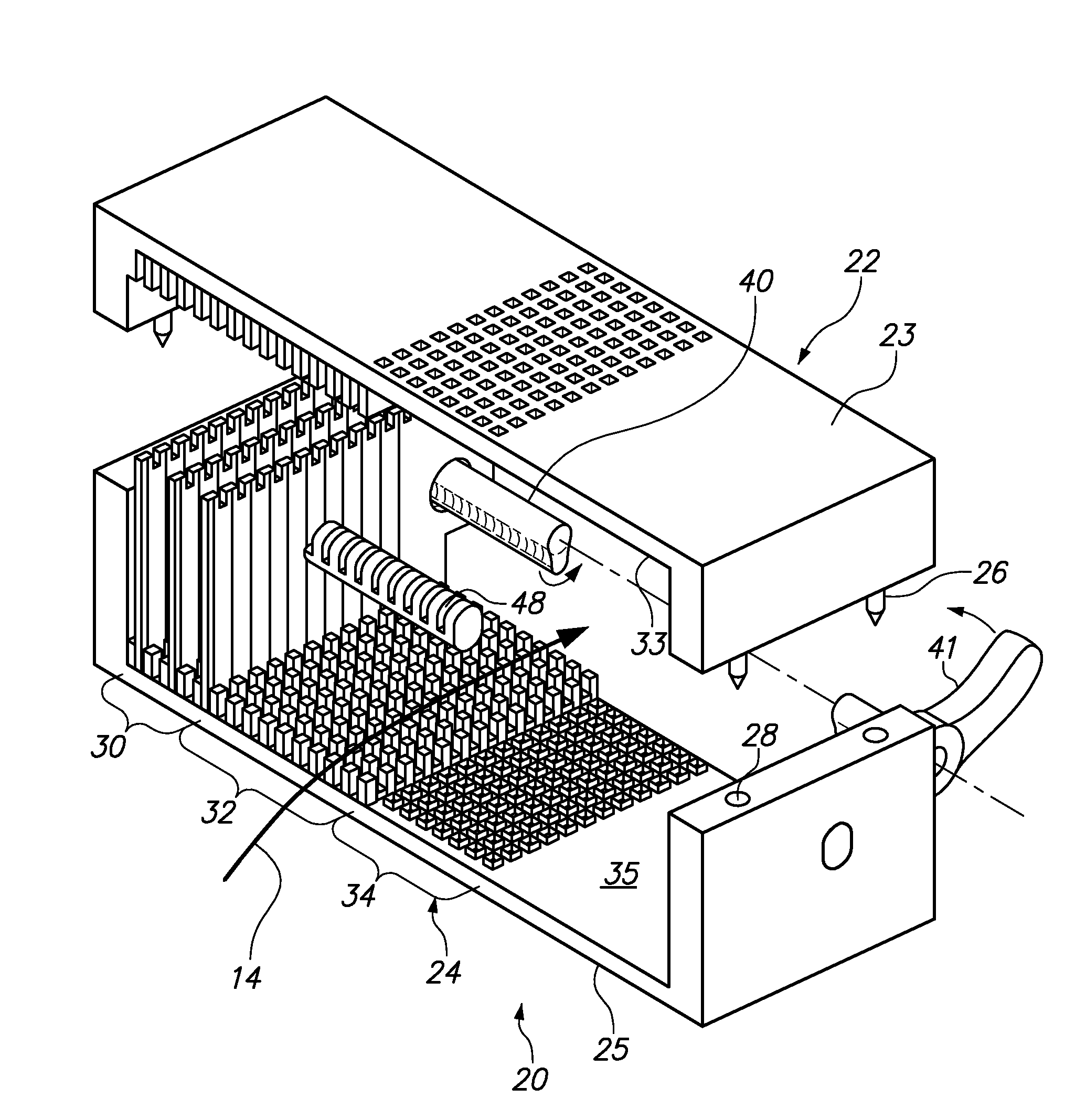

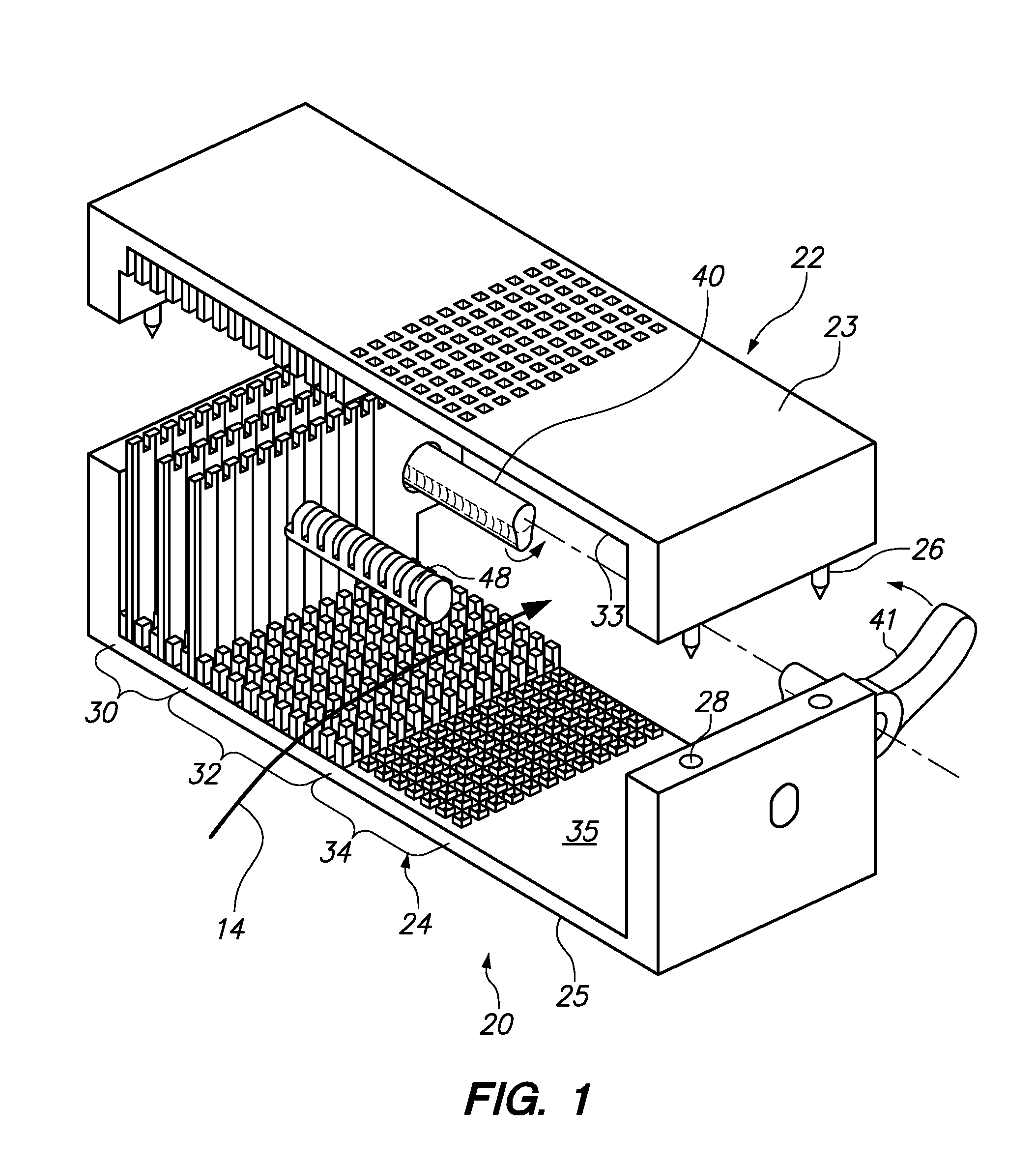

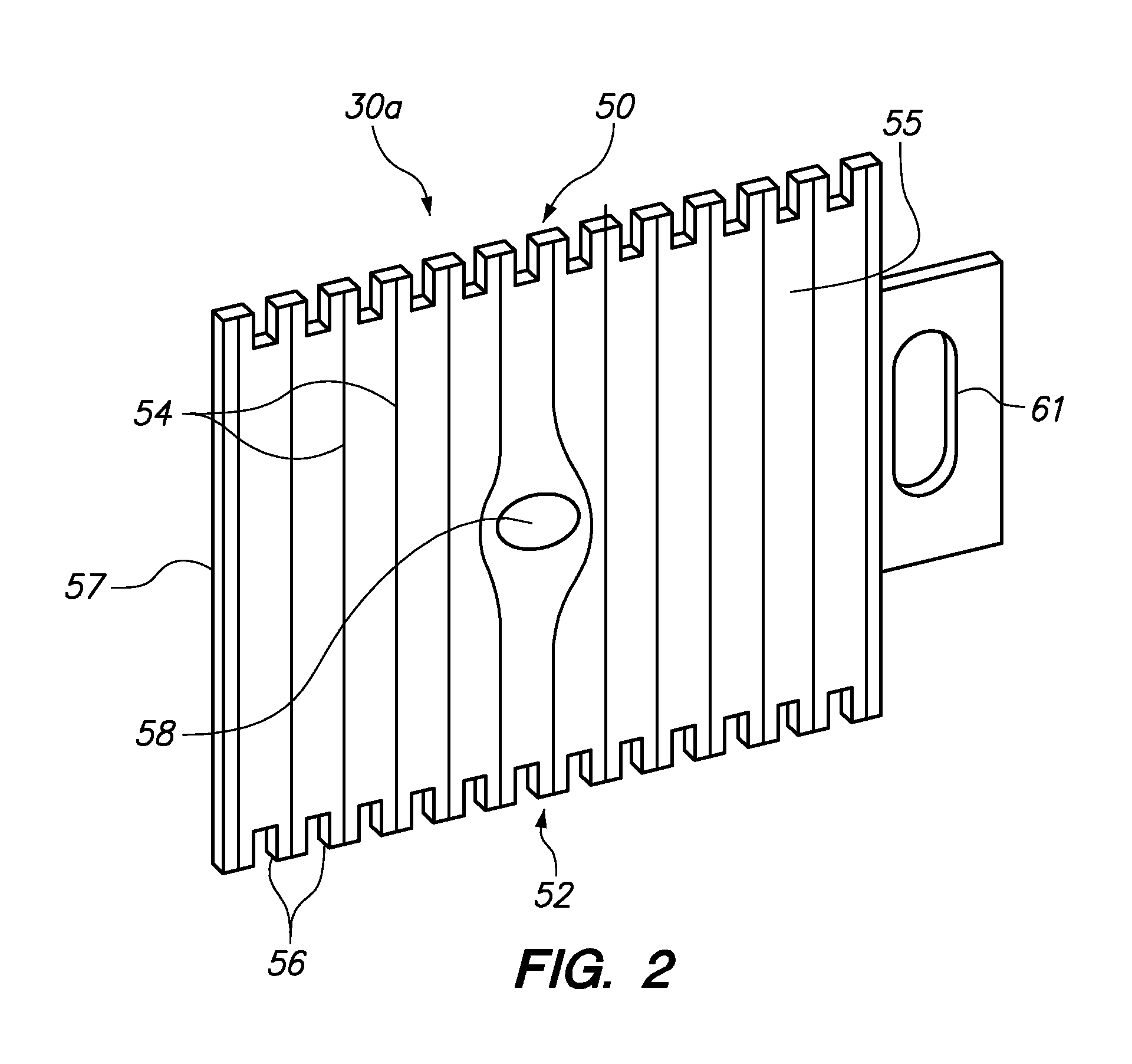

High speed mezzanine connector

ActiveUS7390194B1Reduce airflowLower insertion forceLine/current collector detailsCoupling contact membersConducting pathwayEngineering

A reduced insertion force mezzanine connector is used to couple first and second circuit boards. In one embodiment a connector frame has a first end disposed against the first circuit board and defining a first wall, and an opposing second end disposed against the second circuit board and defining a second wall generally parallel with the first wall. A plurality of wafers are disposed. Each wafer has a first edge in sliding contact with the first wall and an opposing second edge in sliding contact with the second wall. A plurality of electrically conducting pathways extend along each wafer from the first edge to the second edge. A wafer guide structure defines a plurality of wafer-support aisles on the first and second walls for receiving the edges of the wafers to constrain the wafers with a fixed spacing and generally parallel alignment. A plurality of terminals are biased to protrude laterally into each wafer support aisle, and are spaced along the wafer support aisle such that each wafer is movable within the respective wafer support aisle between a first position, wherein each electrically conducting pathway is disposed between adjacent terminals, to a second position, wherein each electrically conducting pathway is in electrical contact with a terminal on the first wall and an associated terminal on the second wall.

Owner:LENOVO GLOBAL TECH INT LTD

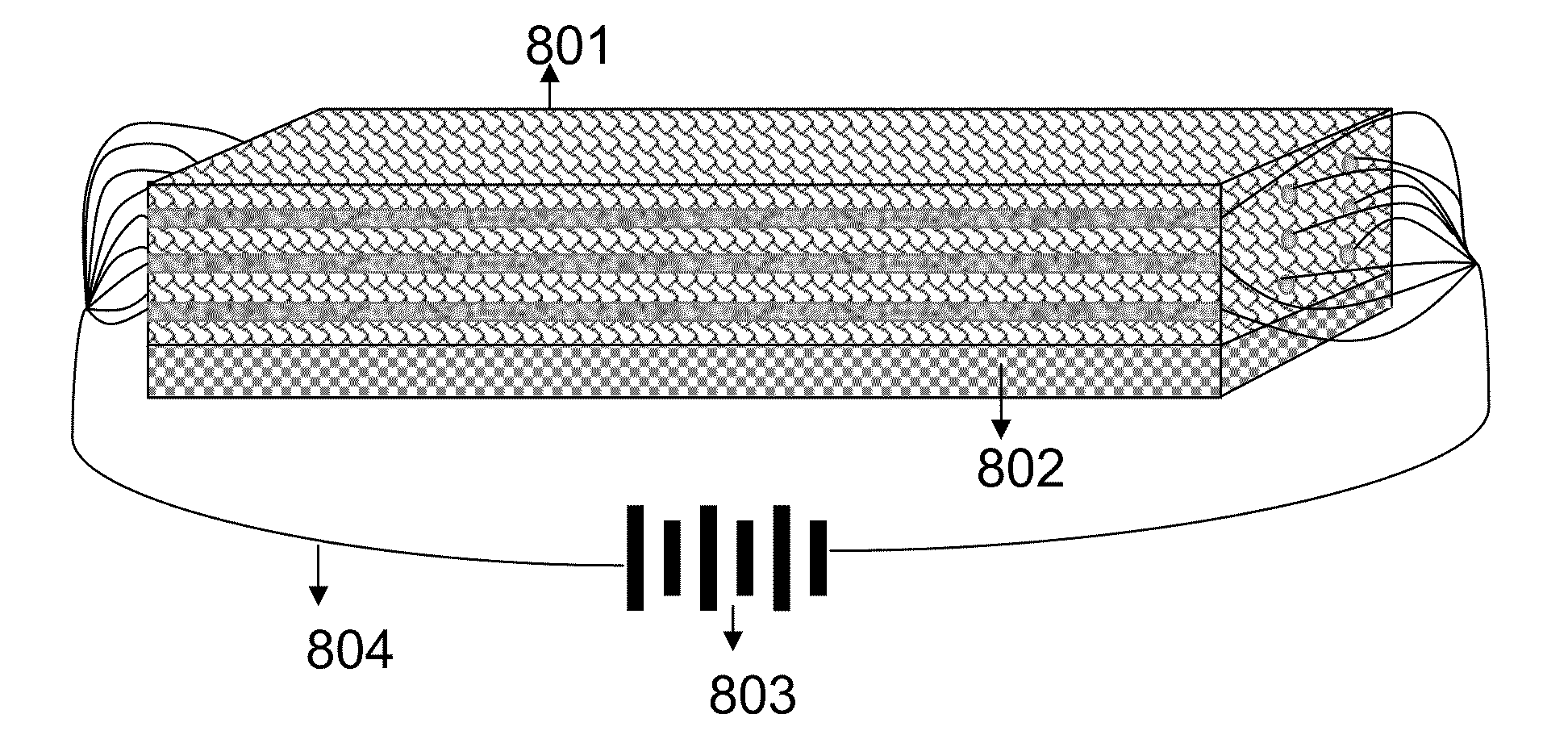

Method of Producing Participate Electrode Materials for Alkali Metal Batteries

PendingUS20190173079A1Secondary cellsNon-aqueous electrolyte accumulator electrodesParticulatesLiquid medium

Provided is method of producing anode or cathode particulates for an alkali metal battery. The method comprises: (a) preparing a slurry containing particles of an anode or cathode active material, an electron-conducting material, and a lithium or sodium salt and an optional polymer dissolved in a volatile liquid medium; and (b) conducting a particulate-forming means to convert the slurry into multiple anode or cathode particulates, wherein an anode or a cathode particulate is composed of (i) particles of the active material, (ii) the electron-conducting material, and (iii) lithium or sodium salt, the optional polymer, and the volatile liquid medium, wherein the electron-conducting material forms a 3D network of electron-conducting pathways wherein the anode or cathode particulate has an electrical conductivity from about 10−7 S / cm to 300 S / cm; and (c) partially or completely removing the volatile liquid medium from the multiple anode particulates or cathode

Owner:GLOBAL GRAPHENE GRP INC

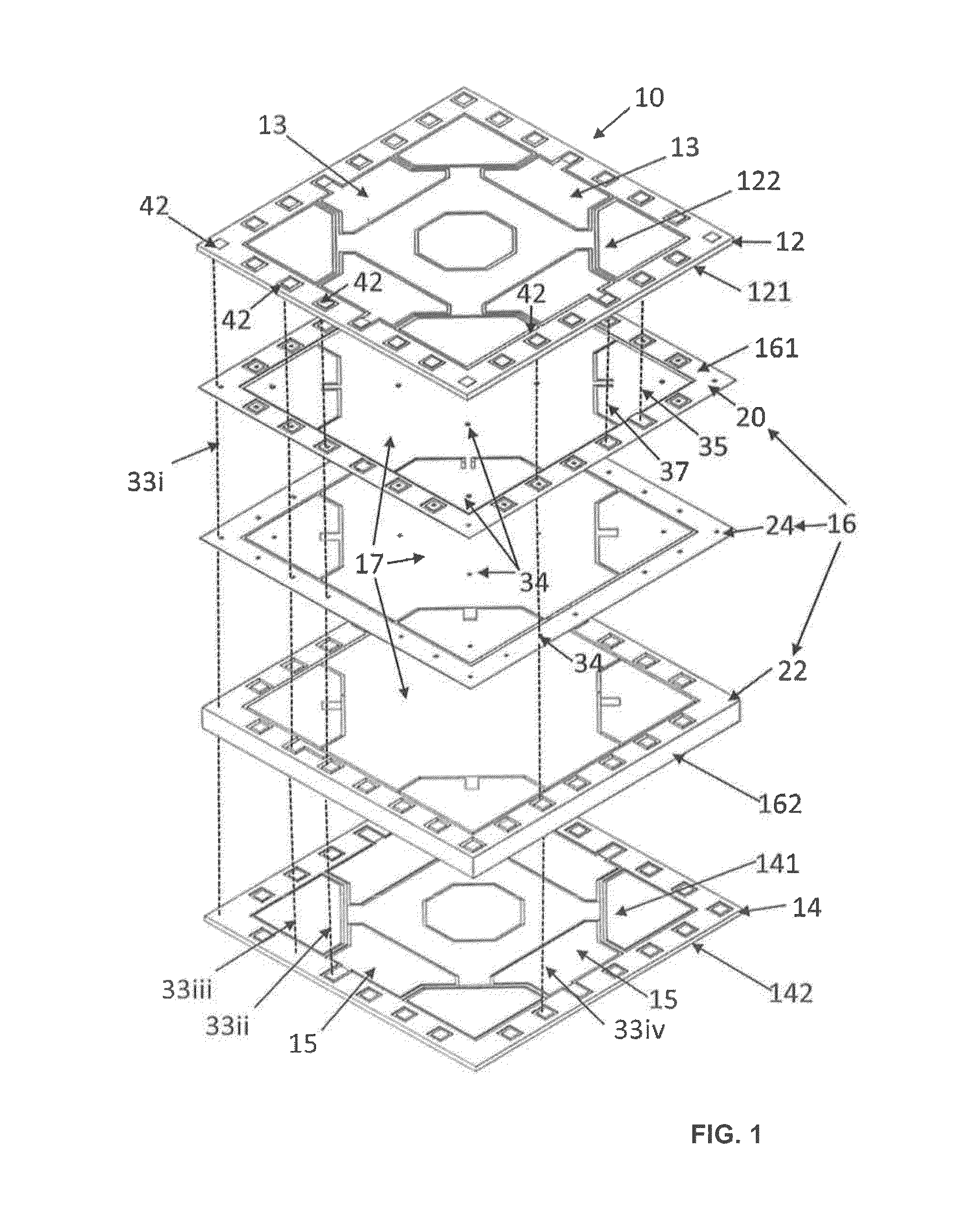

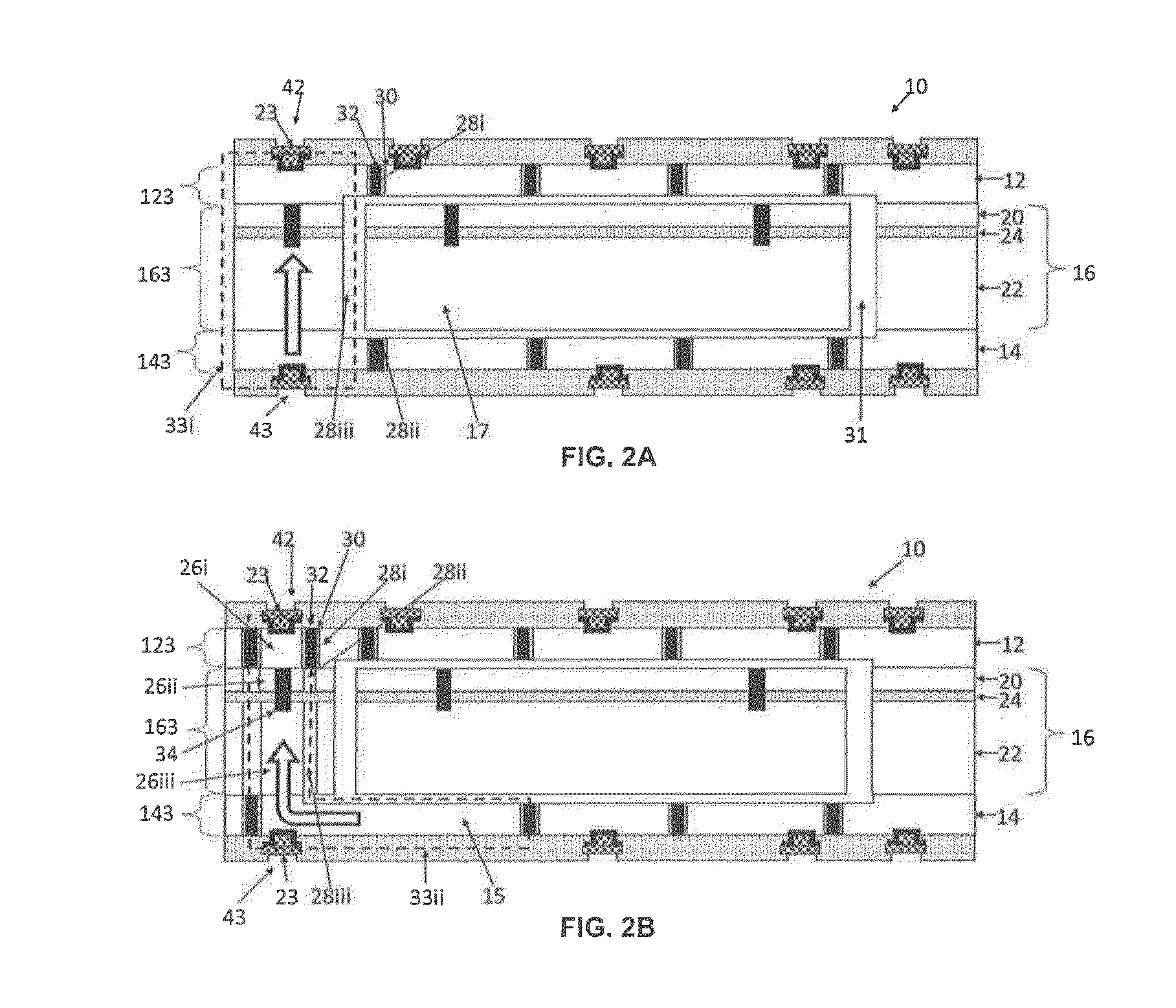

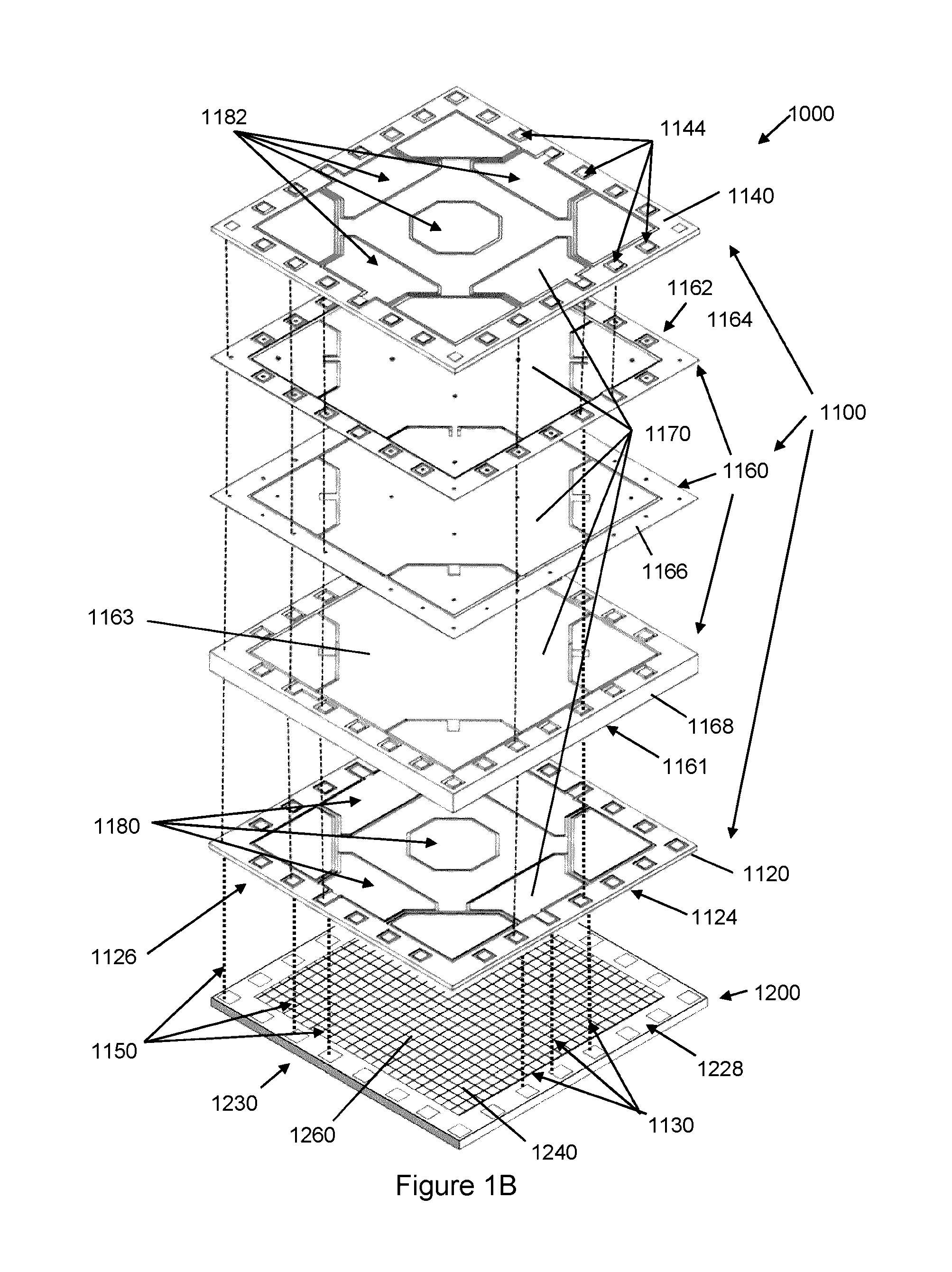

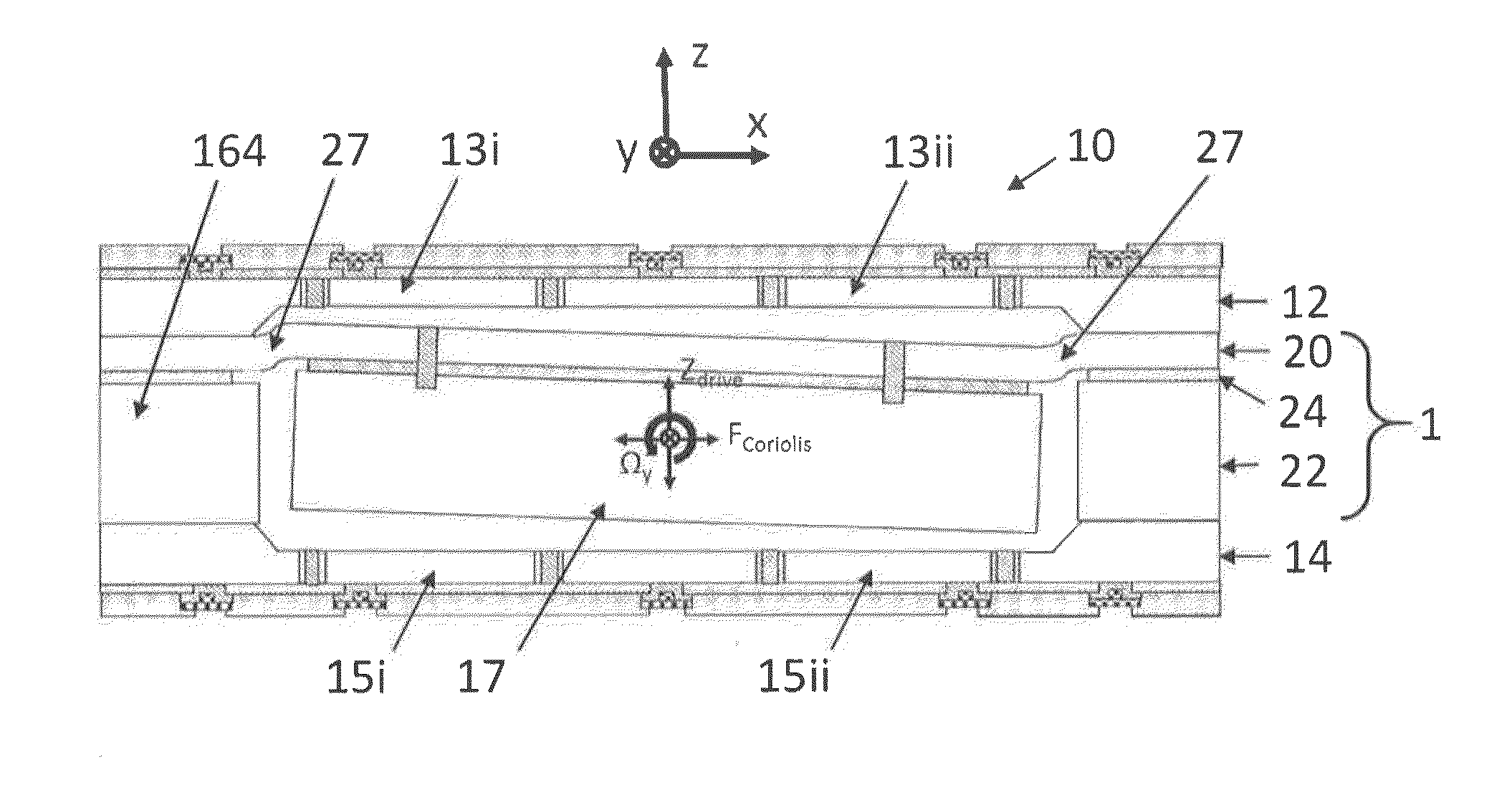

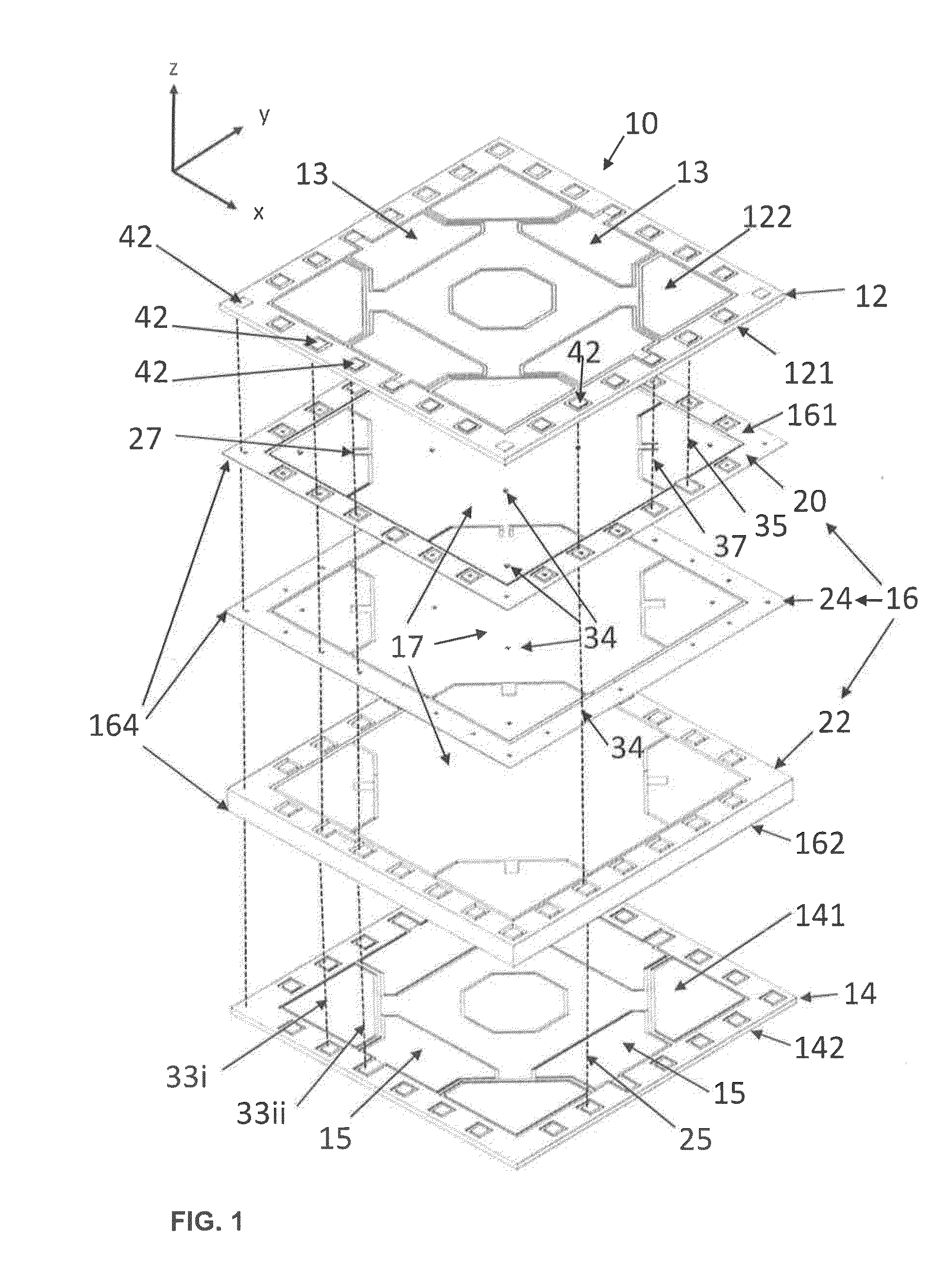

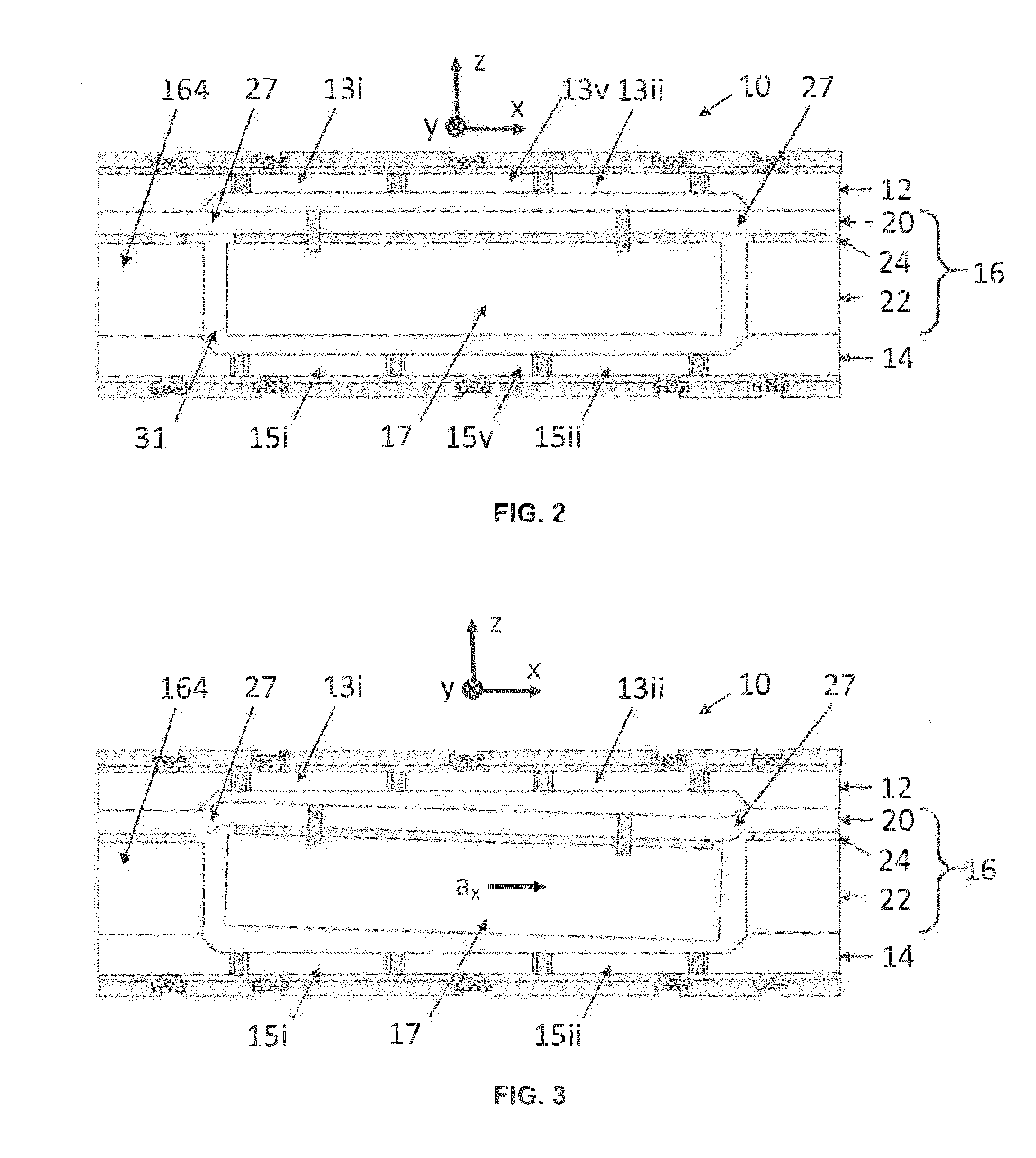

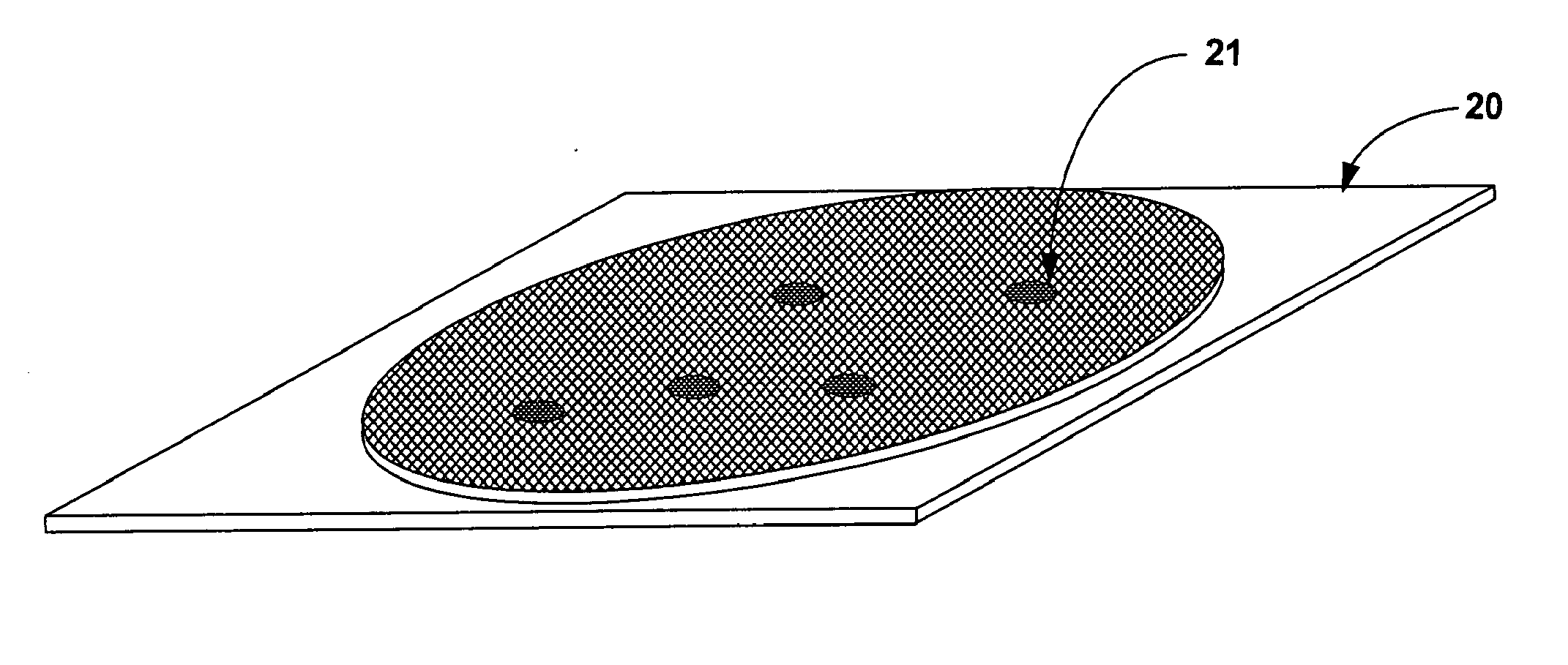

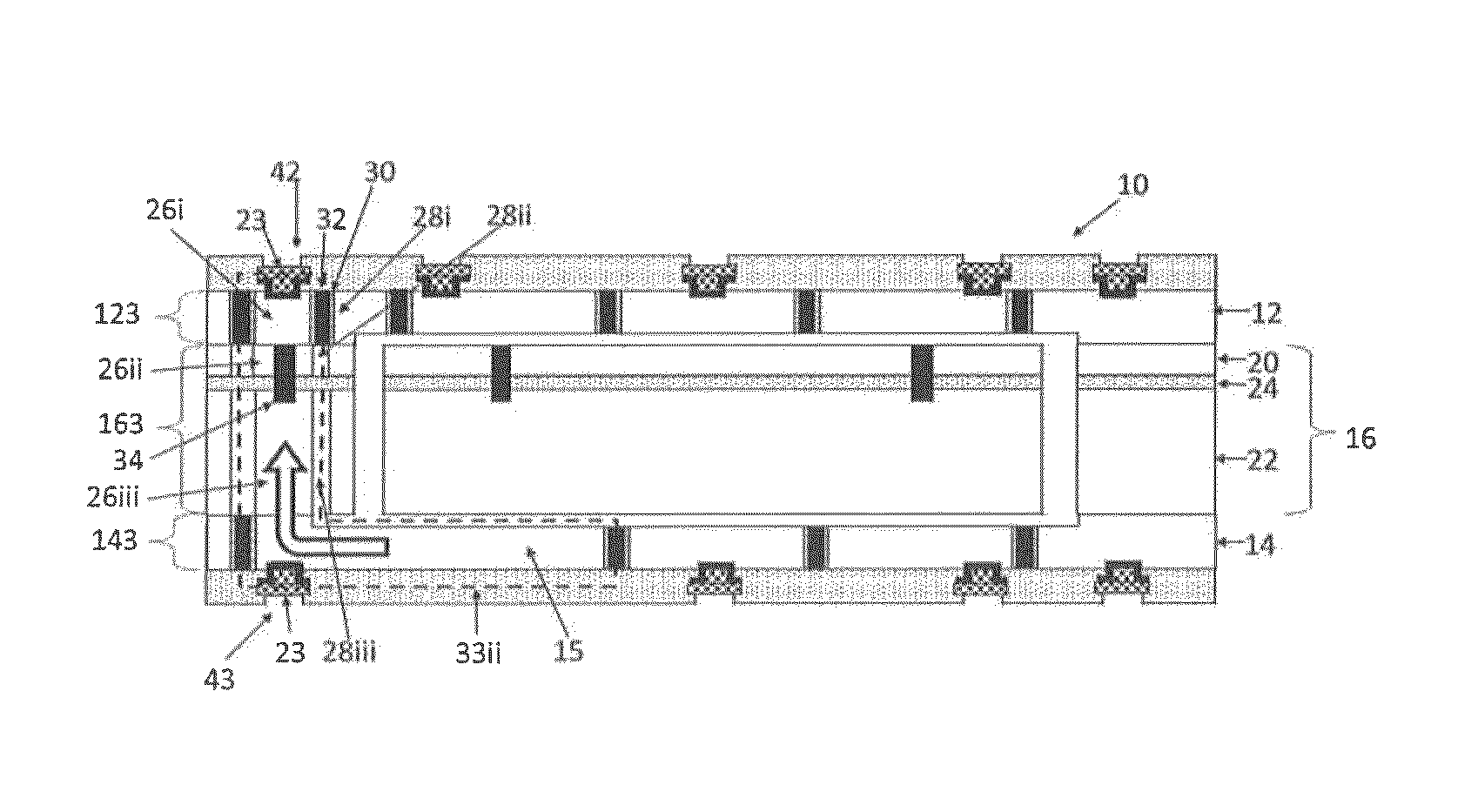

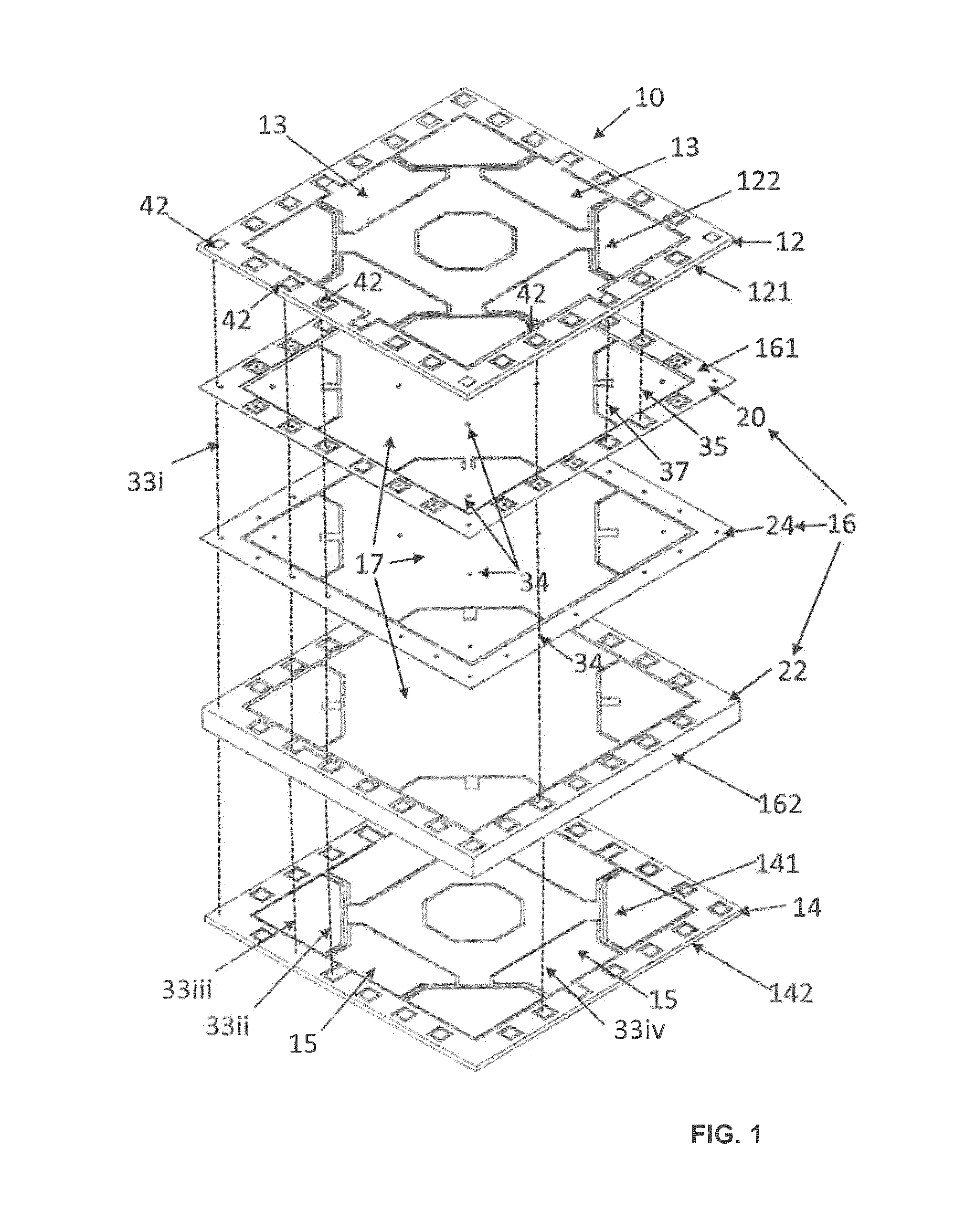

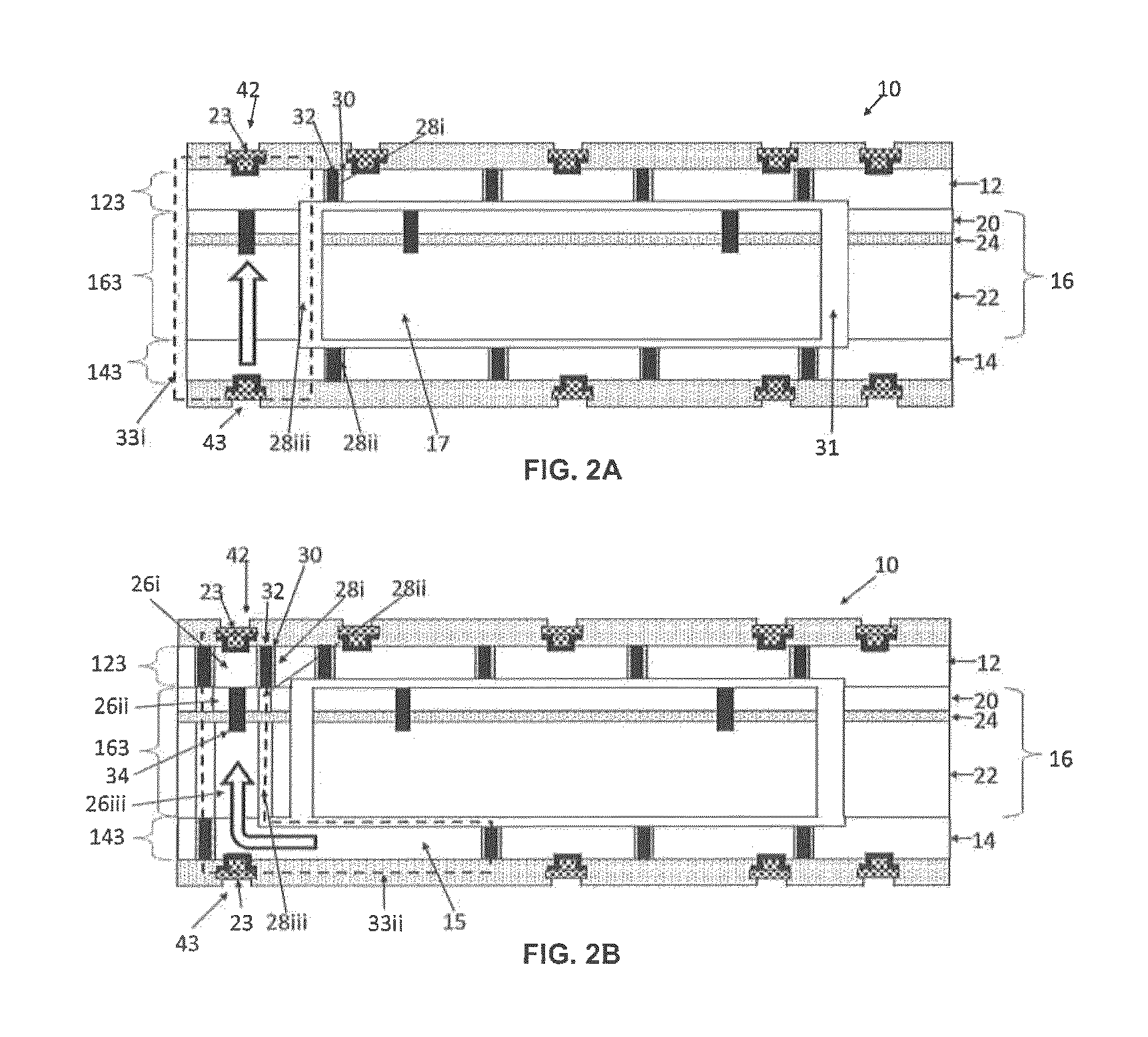

MEMS device and method of manufacturing

ActiveUS20150191345A1Cost-effective manufacturing methodDecorative surface effectsSemiconductor/solid-state device detailsConducting pathwayEngineering

A MEMS device is provided. The device includes a MEMS wafer, a top cap wafer and a bottom cap wafer. The top and bottom cap wafers are respectively bonded to first and second sides of the MEMS wafer, the MEMS and cap wafers being electrically conductive. The outer side of the top cap wafer is provided with electrical contacts. The MEMS wafer, the top cap wafer and the bottom cap wafer define a cavity for housing a MEMS structure. The device includes insulated conducting pathways extending from within the bottom cap wafer, through the MEMS wafer and through the top cap wafer. The pathways are connected to the respective electrical contacts on the top cap wafer, for routing electrical signals from the bottom cap wafer to the electrical contacts on the top cap wafer. A method of manufacturing the MEMS device is also provided.

Owner:MOTION ENGINE

Anode Particulates or Cathode Particulates and Alkali Metal Batteries

Provided is an anode particulate, having a dimension from 10 nm to 300 μm, for use in an alkali metal battery, the particulate comprising (i) an anode active material capable of reversibly absorbing / desorbing lithium or sodium ions, (ii) an electron-conducting material, and (iii) a lithium or sodium salt with an optional polymer or its monomer, but without a liquid solvent, for an electrolyte, wherein the electron-conducting material forms a 3D network of electron-conducting pathways in electronic contact with the anode active material and the lithium or sodium salt is in physical contact with the anode active material (so that the salt, when later impregnated with a liquid solvent, becomes an electrolyte forming a 3D network of lithium or sodium ion-conducting channels in ionic contact with the anode active material). The particulate can be of any shape, but preferably spherical or ellipsoidal in shape. Also provided is a cathode particulate.

Owner:GLOBAL GRAPHENE GRP INC

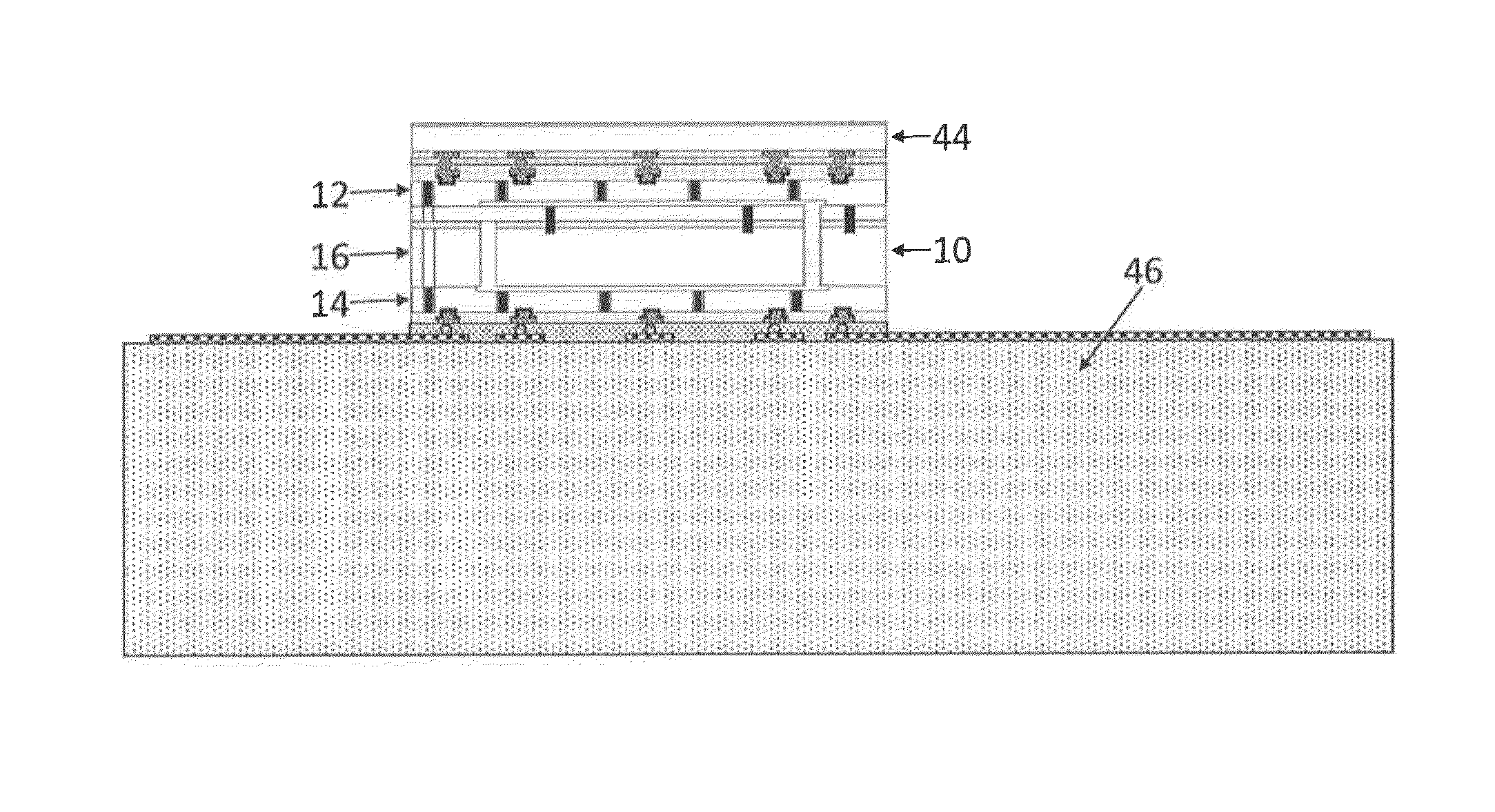

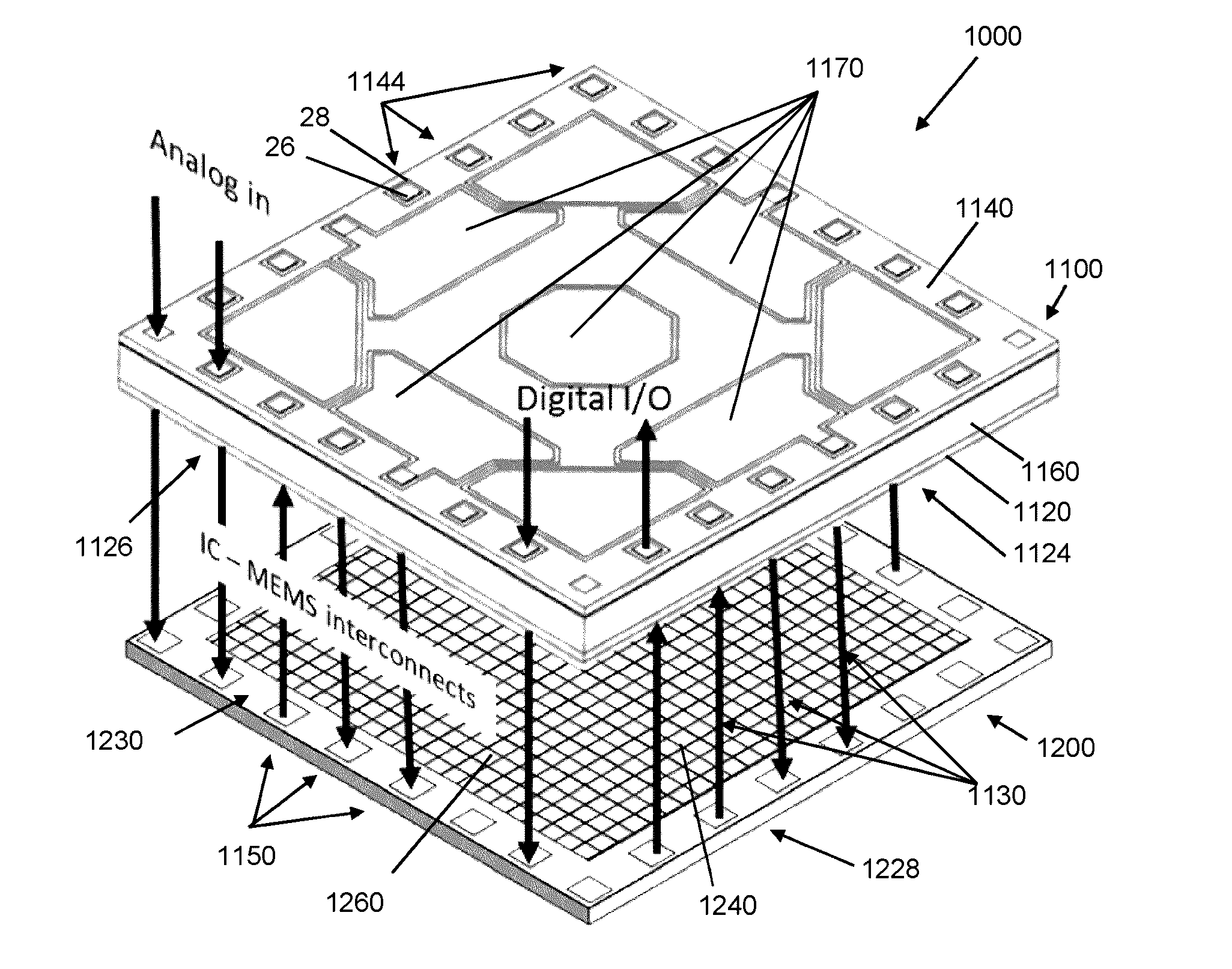

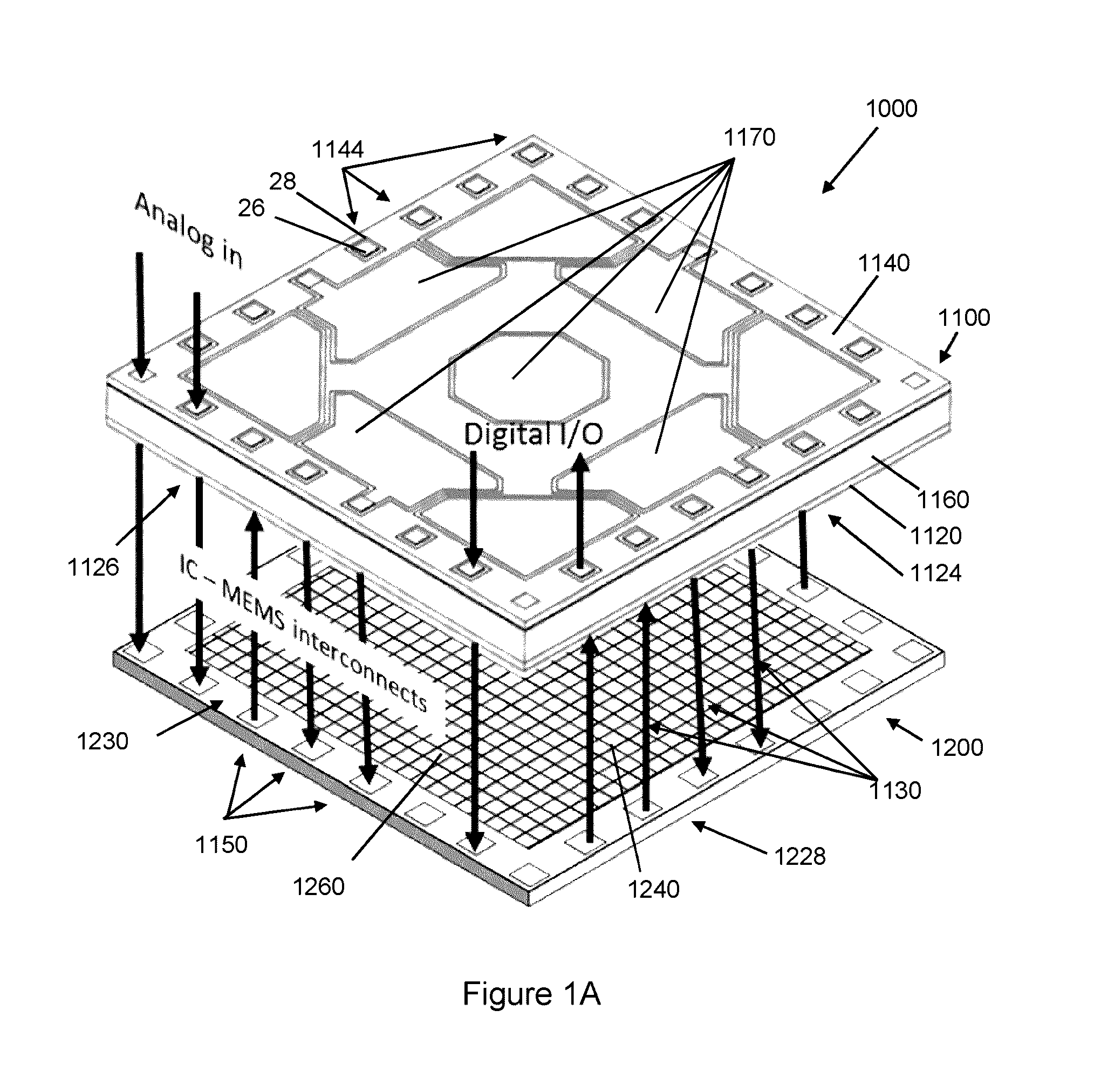

Integrated MEMS system

ActiveUS20160320426A1Acceleration measurement using interia forcesSolid-state devicesFirst pathwayConducting pathway

The present invention provides a 3D System (“3DS”) MEMS architecture that enables the integration of MEMS devices with IC chips to form a System on Chip (SoC) or System in Package (SiP). The integrated MEMS system comprises at least one MEMS chip, including MEMS transducers, and at least one IC chip, including not only MEMS processing circuitry, but also additional / auxiliary circuitry to process auxiliary signals. The MEMS chip can include first and second insulated conducting pathways. The first pathways conduct the MEMS-signals between the transducers and the IC chip, for processing; and the second conducting pathways can extend through the entire thickness of the MEMS chip, to conduct auxiliary signals, such as power, RF, I / Os, to the IC chip, to be processed the additional circuitry.

Owner:MOTION ENGINE

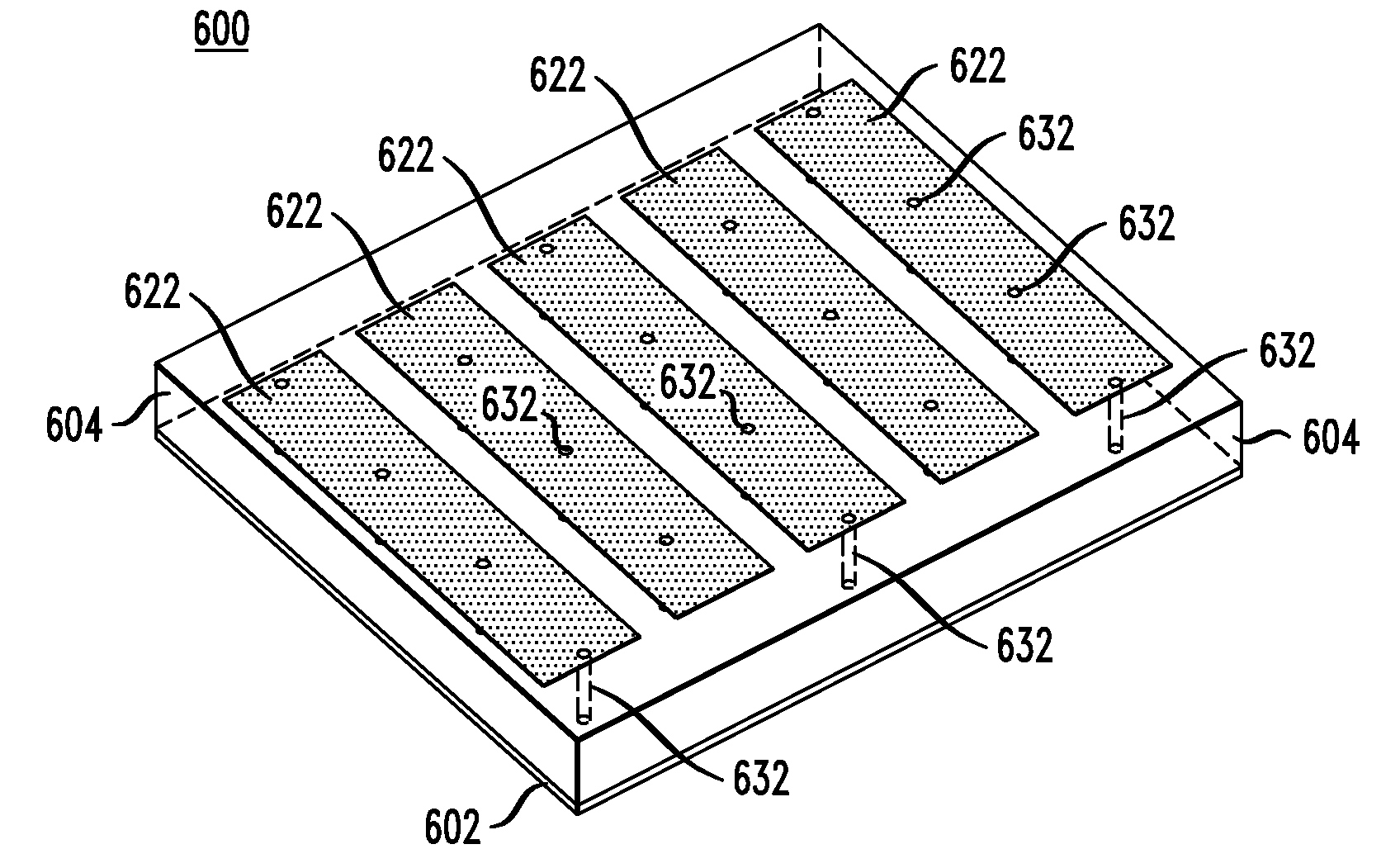

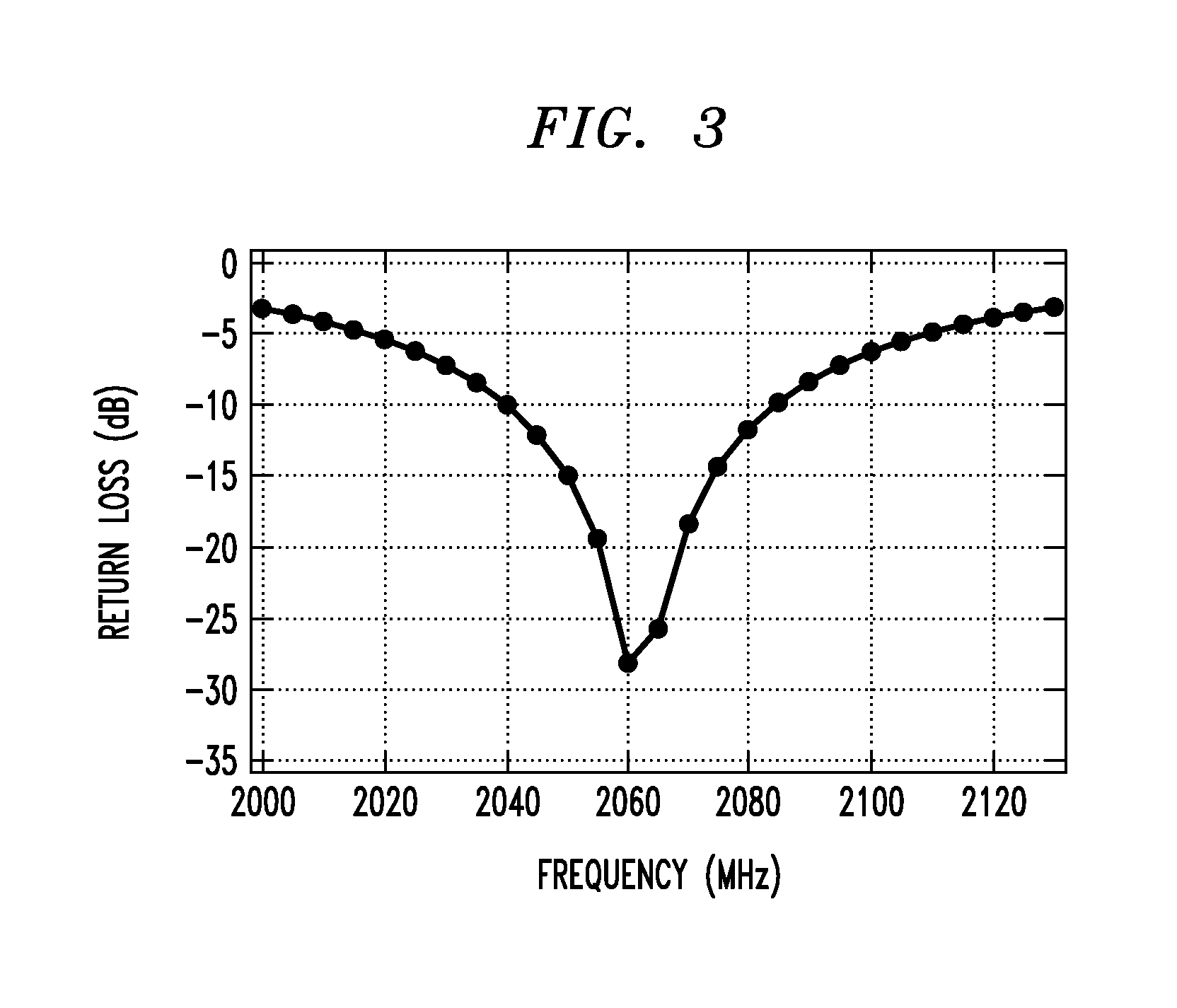

Strip-array antenna

ActiveUS20080258978A1Simultaneous aerial operationsRadiating elements structural formsOffset distanceConducting pathway

A representative embodiment of the invention provides an antenna having an electrically conducting ground plane and an array of electrically conducting strips located at an offset distance from the ground plane. Electrically conducting pathways, each attached to the middle portion of the corresponding strip, connect the strips to the ground plane. Electrically conducting lips, each attached to an edge of the corresponding conducting strip, extend about halfway toward the ground plane. The size of the array is smaller than the wavelength of the fundamental radiation mode supported by the antenna. Advantageously, the antenna has a bandwidth about three times larger than that of a comparably sized prior-art patch antenna.

Owner:LGS INNOVATIONS

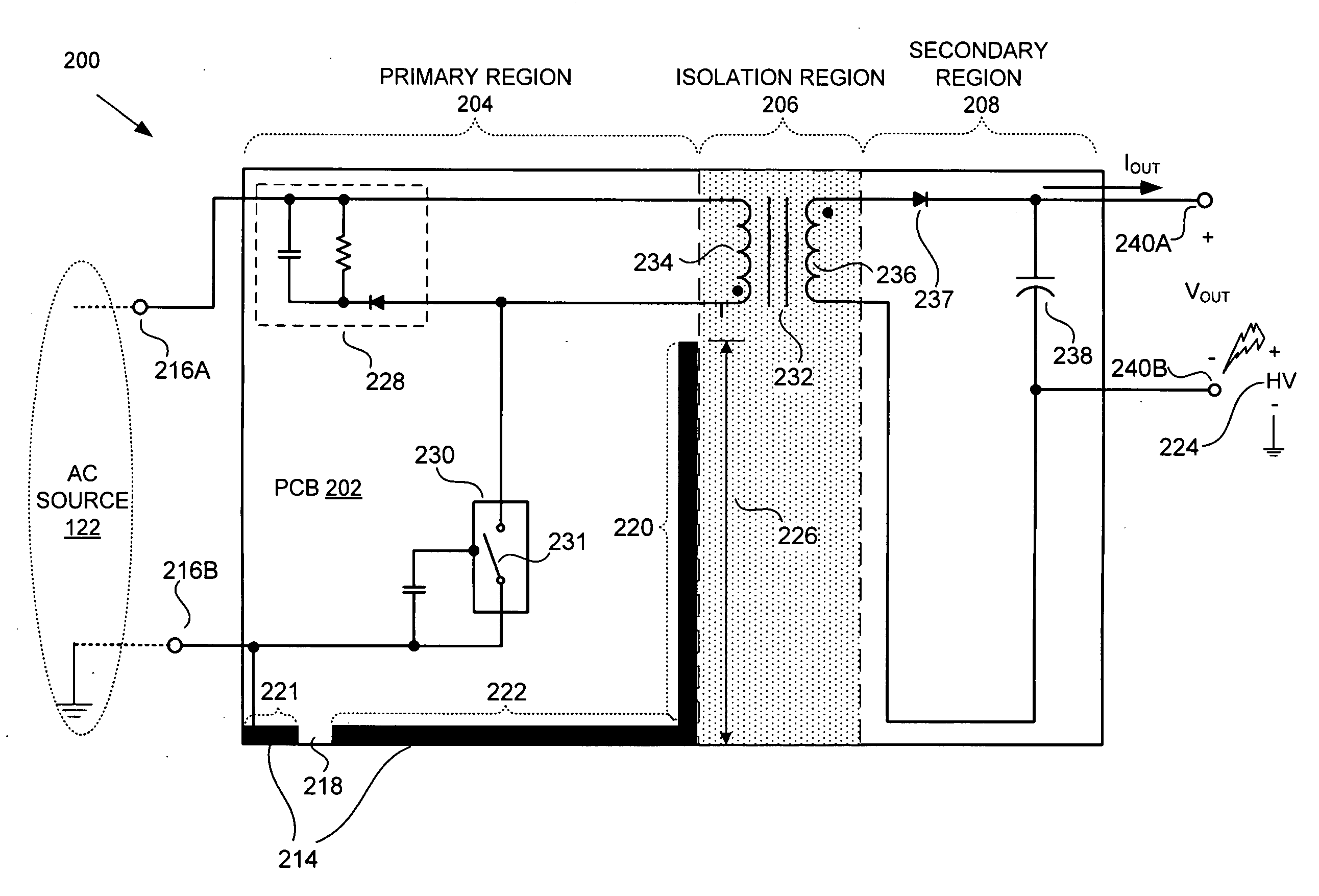

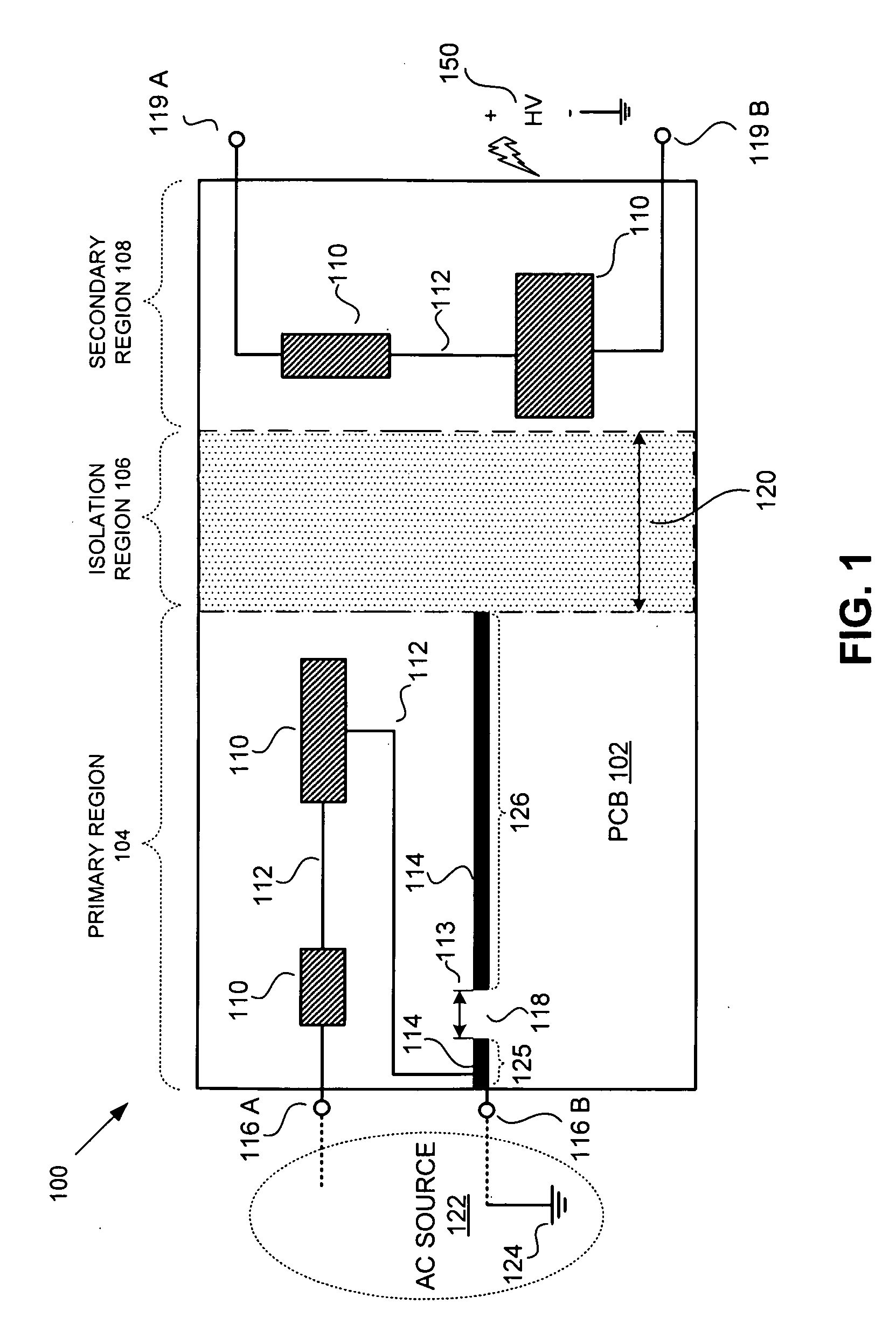

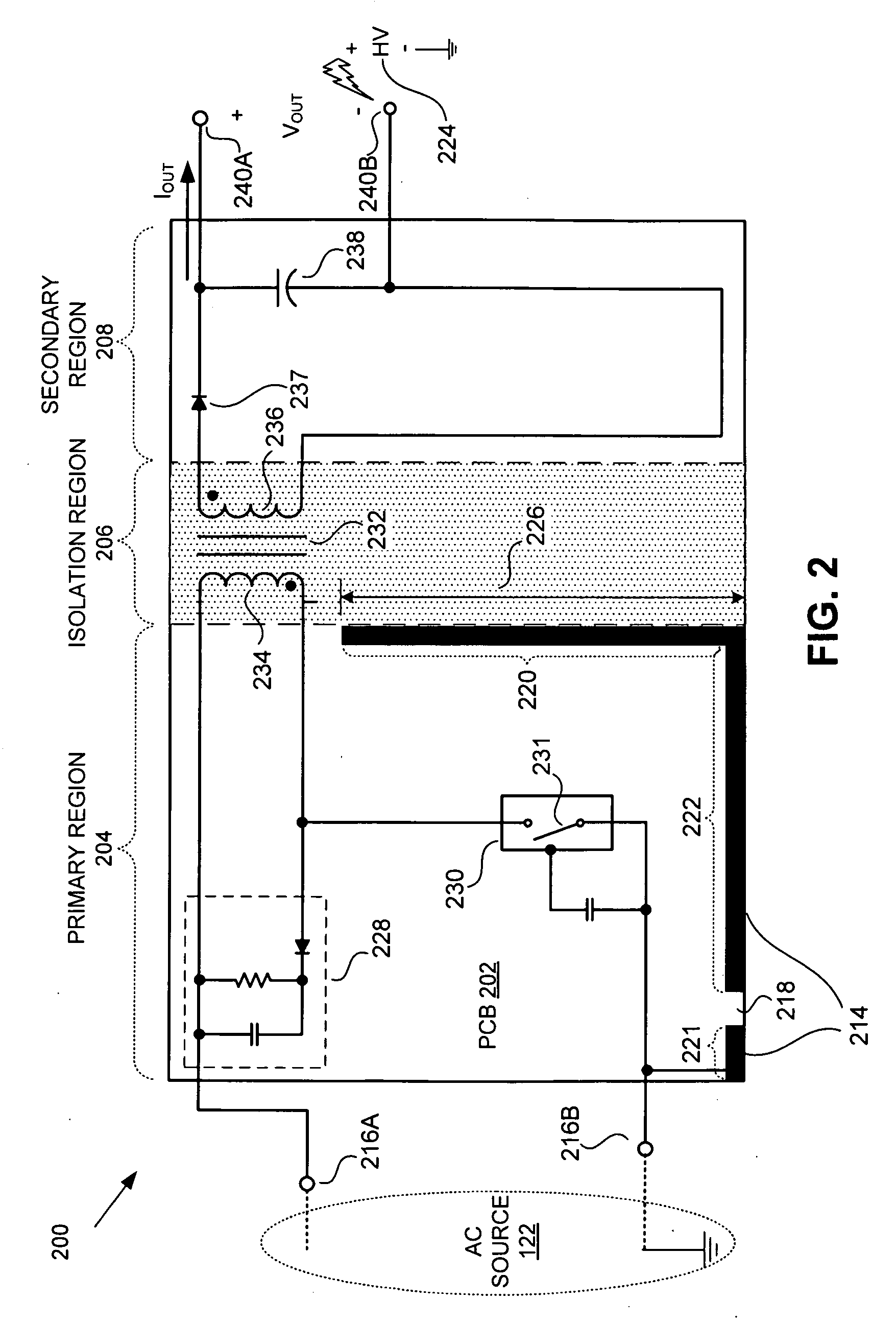

Electrostatic discharge conducting pathway having a noise filter spark gap

InactiveUS20100039838A1Printed circuitsEmergency protective arrangements for limiting excess voltage/currentConducting pathwayPrinted circuit board

A printed circuit board includes a primary region, a secondary region and an isolation region disposed between the primary region and the secondary region to galvanically isolate the primary region from the secondary region. The primary region is to be coupled to an AC source. The primary region also includes an electrostatic discharge (ESD) conducting pathway to redirect current to the AC source that crosses the isolation region. A spark gap is included in the ESD conducting pathway to filter noise and to provide a current path to the AC source for the current that crosses the isolation region.

Owner:POWER INTEGRATIONS INC

MEMS motion sensor and method of manufacturing

PendingUS20150260519A1Raise the resonant frequencySemiconductor/solid-state device manufacturingSpeed measurement using gyroscopic effectsConducting pathwayEngineering

A MEMS motion sensor and its manufacturing method are provided. The sensor includes a MEMS wafer including a proof mass and flexible springs suspending the proof mass and enabling the proof mass to move relative to an outer frame along mutually orthogonal x, y and z axes. The sensor includes top and bottom cap wafers including top and bottom cap electrodes forming capacitors with the proof mass, the electrodes being configured to detect a motion of the proof mass. Electrical contacts are provided on the top cap wafer, some of which are connected to the respective top cap electrodes, while others are connected to the respective bottom cap electrodes by way of insulated conducting pathways, extending along the z axis from one of the respective bottom cap electrodes and upward successively through the bottom cap wafer, the outer frame of the MEMS wafer and the top cap wafer.

Owner:MOTION ENGINE

Electrically conductive paste, and electrical and electronic device comprising the same

ActiveUS20110049439A1Reduce resistanceImprove heat-cycle reliability of connectionPrinted circuit assemblingPrinted circuit aspectsConducting pathwayAlloy

Disclosed is an electrically conductive paste which enables to reduce the level of void growth in a conducting pathway formed in a joint part produced after curing the electrically conductive paste in the implementation of an electronic component on a circuit board by using the electrically conductive paste, and which contains a reduced amount of a viscosity-adjusting / thixotropy-imparting additive. Two Sn-containing low-melting-point alloy particles having different melting points and different average particle diameters are selected as electrically conductive filler components to be used in an electrically conductive paste, and the two alloy particles are mixed at a predetermined ratio for use.

Owner:PANASONIC CORP

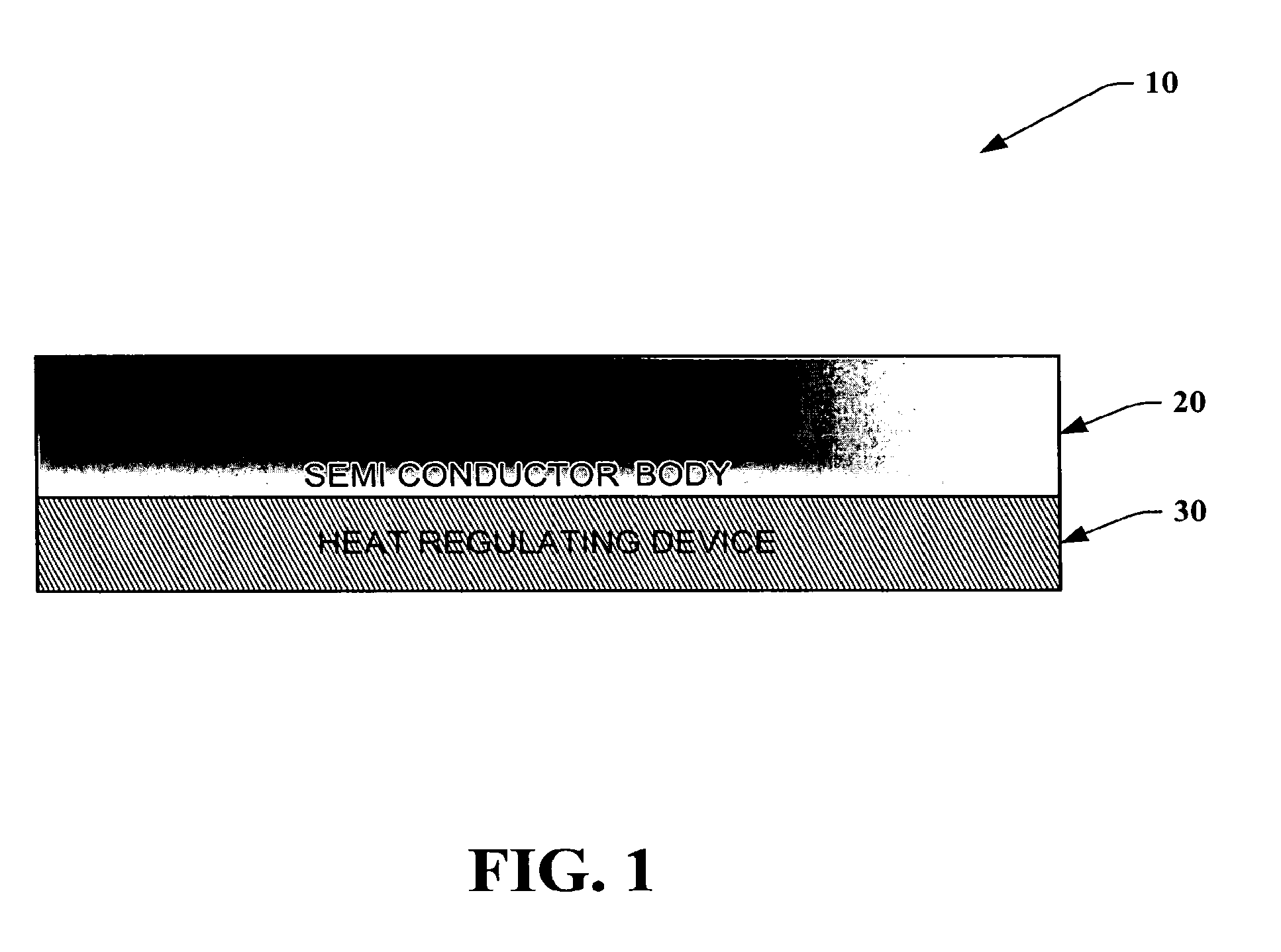

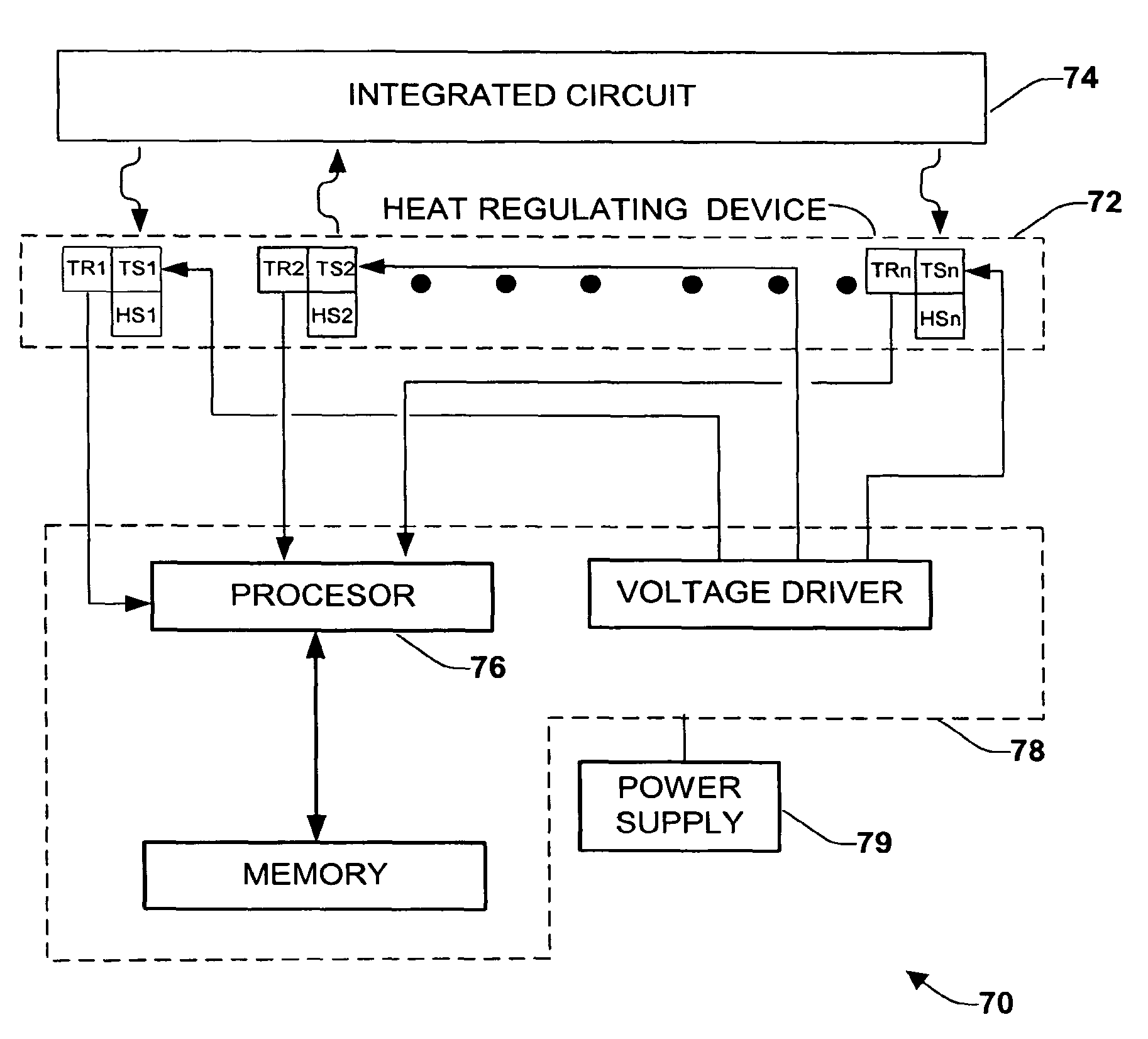

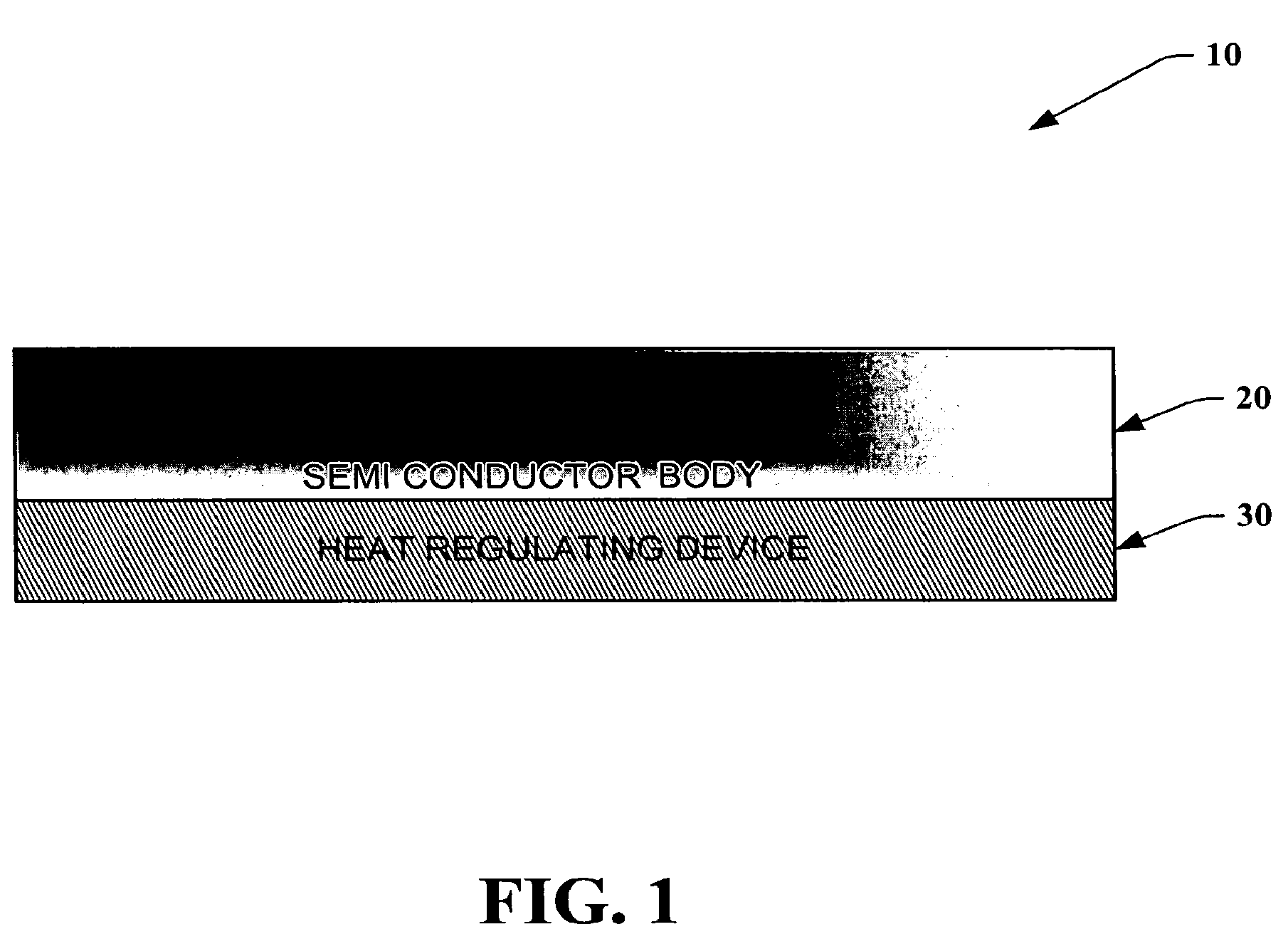

Heat regulating device for an integrated circuit

InactiveUS20090288425A1Uniform temperature gradientReduce accumulationDomestic cooling apparatusTemperatue controlHeat conductingConducting pathway

The present invention provides for a system and method for regulating and monitoring heat dissipation of an integrated circuit by employing a heat regulating device with a thermal structure net work assembly. Each thermal structure can act as a heat conducting pathway for inducing heat into and / or dissipating heat away from the integrated circuit, thus creating a more uniform temperature gradient across the semiconductor body.

Owner:GLOBALFOUNDRIES INC

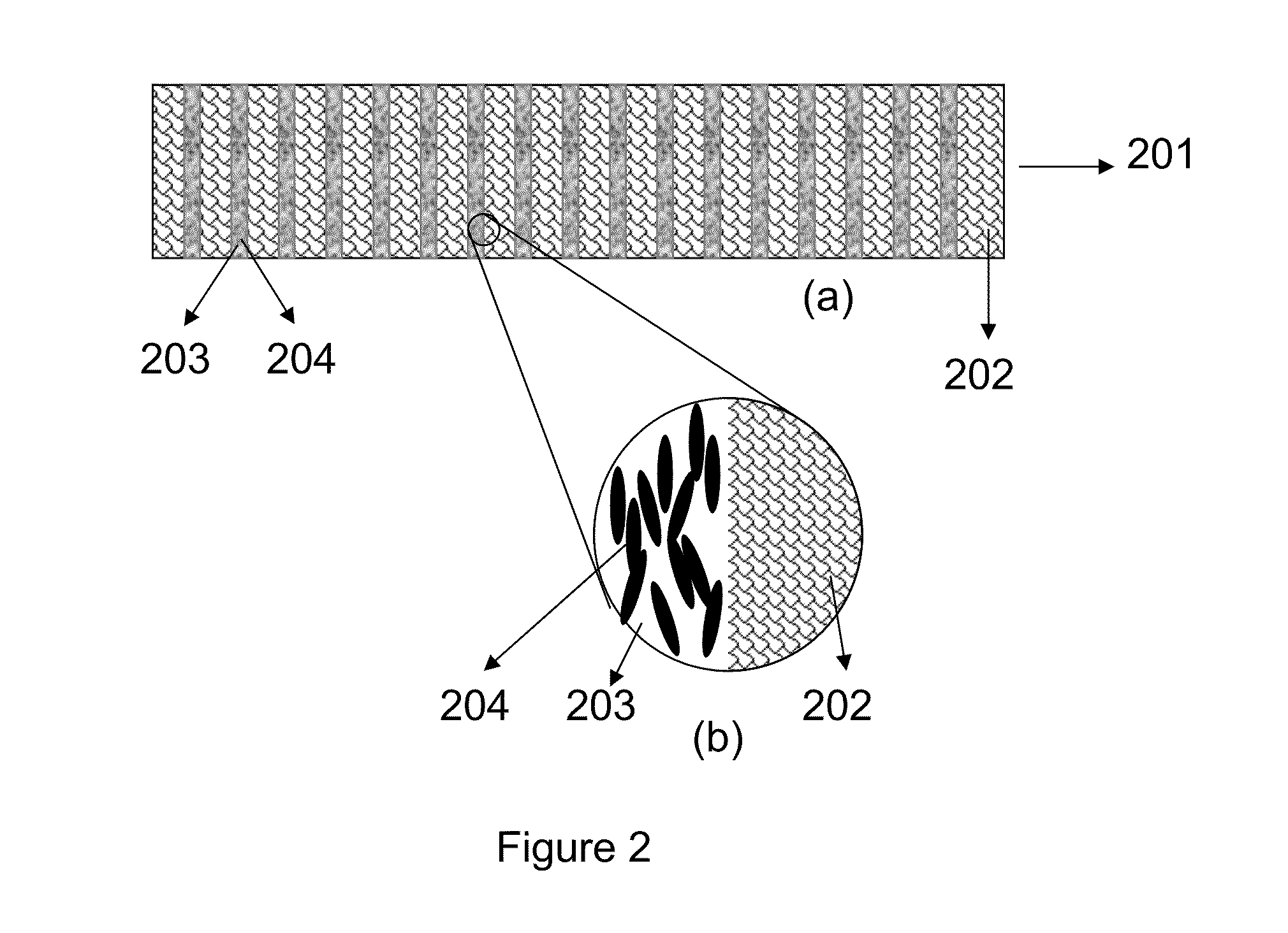

Method of Producing Shape-Conformable Alkali Metal-Sulfur Battery Having a Deformable and Conductive Quasi-Solid Electrode

ActiveUS20190006721A1Large capacityImprove the immunityElectrode manufacturing processesHybrid capacitor electrodesElectrical batteryConducting pathway

Provided is a method of preparing an alkali-sulfur cell comprising: (a) combining a quantity of an active material, a quantity of an electrolyte containing an alkali salt dissolved in a solvent, and a conductive additive to form a deformable and electrically conductive electrode material, wherein the conductive additive, containing conductive filaments, forms a 3D network of electron-conducting pathways; (b) forming the electrode material into a quasi-solid electrode (the first electrode), wherein the forming step includes deforming the electrode material into an electrode shape without interrupting the 3D network of electron-conducting pathways such that the electrode maintains an electrical conductivity no less than 10−6 S / cm; (c) forming a second electrode (the second electrode may be a quasi-solid electrode as well); and (d) forming an alkali-sulfur cell by combining the quasi-solid electrode and the second electrode having an ion-conducting separator disposed between the two electrodes.

Owner:GLOBAL GRAPHENE GRP INC

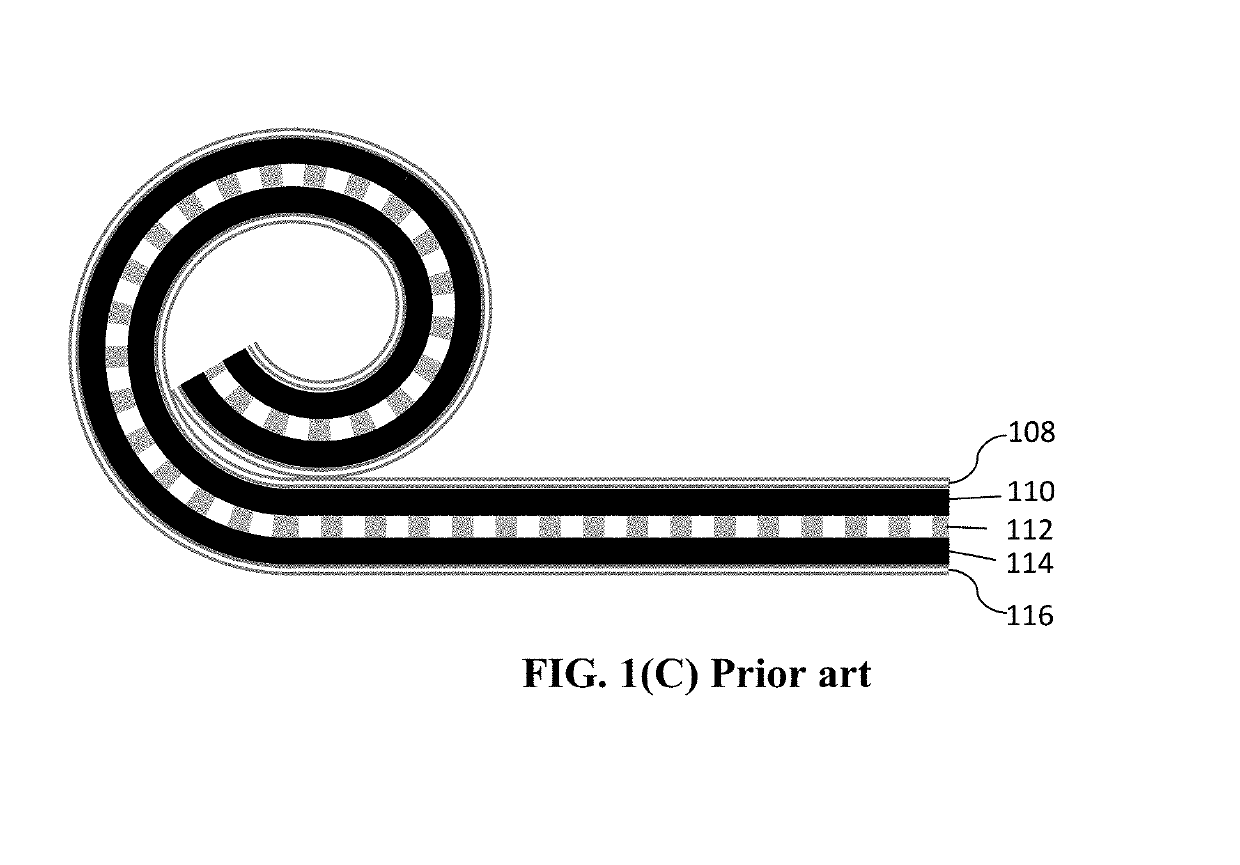

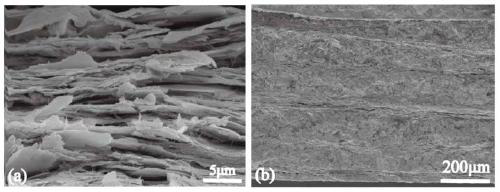

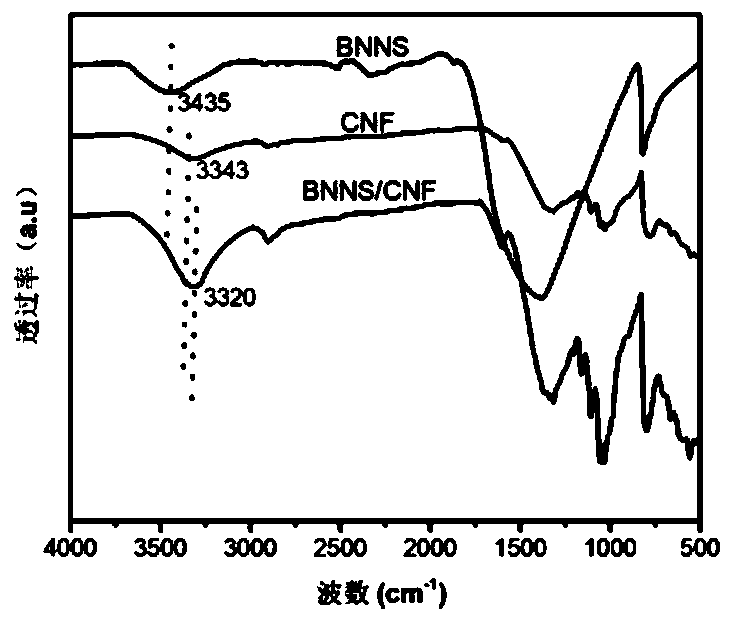

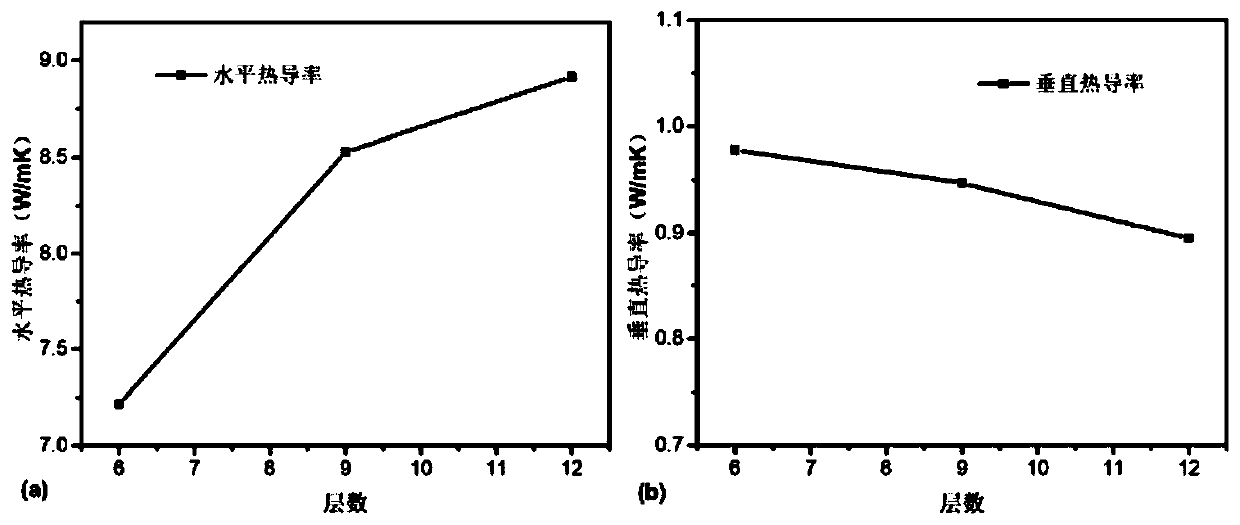

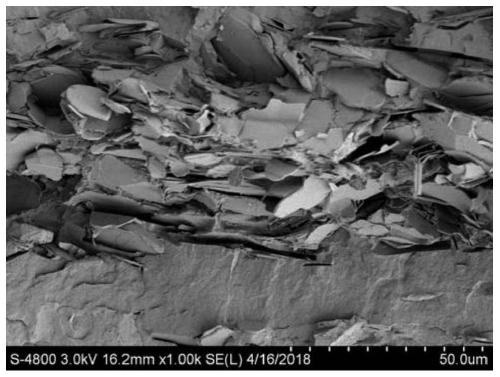

Multi-layer structured heat conducting composite containing heat conducting film and preparation method of multi-layer structured heat conducting composite

ActiveCN109913185ASimple methodGood effectLaminationLamination apparatusDielectric lossConducting pathway

The invention discloses a multi-layer structured heat conducting composite containing a heat conducting film and a preparation method of the multi-layer structured heat conducting composite. The multi-layer structured heat conducting composite is prepared by steps as follows: epoxy resin is taken as a matrix, the heat conducting film with high heat conductivity is taken as a heat conducting medium, flaky hexagonal boron nitride and granular heat conducting filler are used for compound filling, and then the multi-layer structured heat conducting composite is prepared by layer-by-layer stacking,pre-curing and hot press molding. The multi-layer structured heat conducting composite has the following advantages: flaky hexagonal boron nitride is horizontally oriented under hot press condition and forms a heat conducting pathway in the horizontal direction together with the horizontally laid heat conducting film; the granular heat conducting filler plays a bridging role in the system and fills gaps between flaky hexagonal boron nitride, so that a heat conducting network is perfect, and a heat conducting pathway in the vertical direction is constructed. The horizontal heat conductivity ofthe composite is increased by 4639%, the vertical heat conductivity of the composite is increased by 439%, and the composite has the advantages of high heat conductivity, good heat stability, low dielectric constant and dielectric loss, excellent mechanical properties and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method of Producing Shape-Conformable Alkali Metal-Sulfur Battery

ActiveUS20180351198A1Large capacityImprove the immunitySolid electrolytesNon-aqueous electrolyte accumulator electrodesCarbon compositesConducting pathway

Provided is method of preparing an alkali metal-sulfur cell, comprising: (a) combining a quantity of a cathode active material (selected from sulfur, a metal-sulfur compound, a sulfur-carbon composite, a sulfur-graphene composite, a sulfur-graphite composite, an organic sulfur compound, a sulfur-polymer composite or a combination thereof), a quantity of an electrolyte, and a conductive additive to form a deformable cathode material, wherein the conductive additive, containing conductive filaments, forms a 3D network of electron-conducting pathways and the electrolyte contains an alkali salt and an ion-conducting polymer dissolved or dispersed in a solvent; (b) forming the cathode material into a quasi-solid cathode, wherein the forming includes deforming the cathode material into an electrode shape without interrupting the 3D network of electron-conducting pathways such that the cathode maintains an electrical conductivity no less than 10−6 S / cm; (c) forming an anode; and (d) forming a cell by combining the cathode and the anode.

Owner:GLOBAL GRAPHENE GRP INC

Shape-conformable alkali metal battery having a conductive and deformable quasi-solid polymer electrode

ActiveCN110679009AElectrode manufacturing processesElectrolytic inorganic material coatingElectrical batteryConducting pathway

Provided is method of preparing an alkali metal cell, the method comprising: (a) combining a quantity of an active material, a quantity of an electrolyte, and a conductive additive to form a deformable and conductive electrode material, wherein the conductive additive, containing conductive filaments, forms a 3D network of electron-conducting pathways and the electrolyte contains an alkali salt and an ion-conducting polymer dissolved or dispersed in a solvent; (b) forming the electrode material into a quasi-solid polymer electrode, wherein the forming includes deforming the electrode materialinto an electrode shape without interrupting the 3D network of electron-conducting pathways such that the electrode maintains an electrical conductivity no less than 10-6 S / cm; (c) forming a second electrode; and (d) forming an alkali metal cell by combining the quasi-solid electrode and the second electrode. The second electrode may also be a quasi-solid polymer electrode.

Owner:NANOTEK INSTR

Nanoelectronic-enzyme linked immunosorbent assay system and method

ActiveUS9188594B2Bioreactor/fermenter combinationsBiological substance pretreatmentsConducting pathwayNanosensor

The present invention relates to a device and method for determining the presence of a specific compound in solution. The device includes a nanosensor having an electrically conducting pathway between at least a first and second contact. The device also includes a first receptor, suitable for binding a specific compound in the solution, attached to the nanosensor, and a second receptor also suitable for binding the specific compound while the specific compound is bound to the first receptor. The second receptor is attached to an enzyme added to the solution. When the solution having the second receptor is added to the device, and a second compound that is a substrate for the enzyme is subsequently added to the solution, a measured difference in an electrical property in the device before and after the application of the second compound is indicative of the presence of the specific compound in the solution.

Owner:YALE UNIV

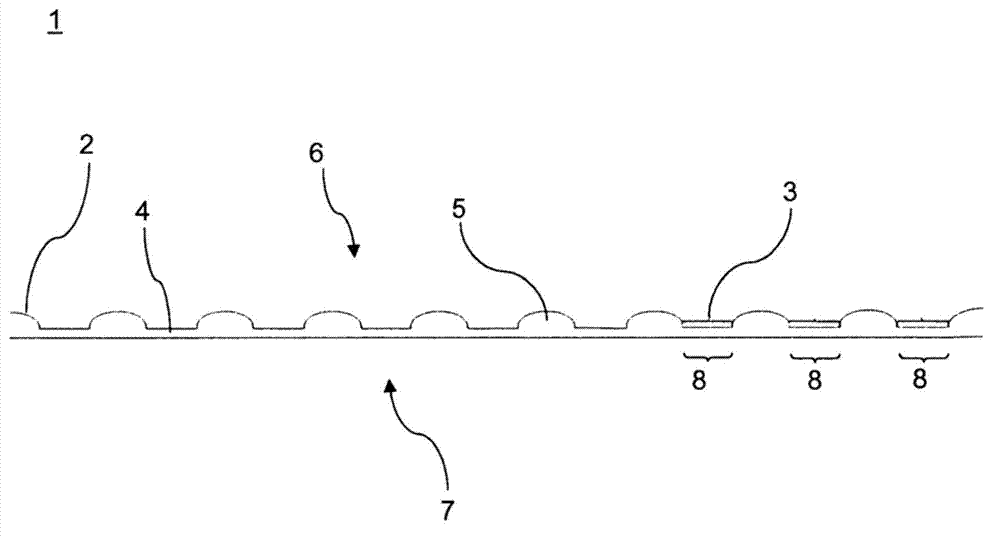

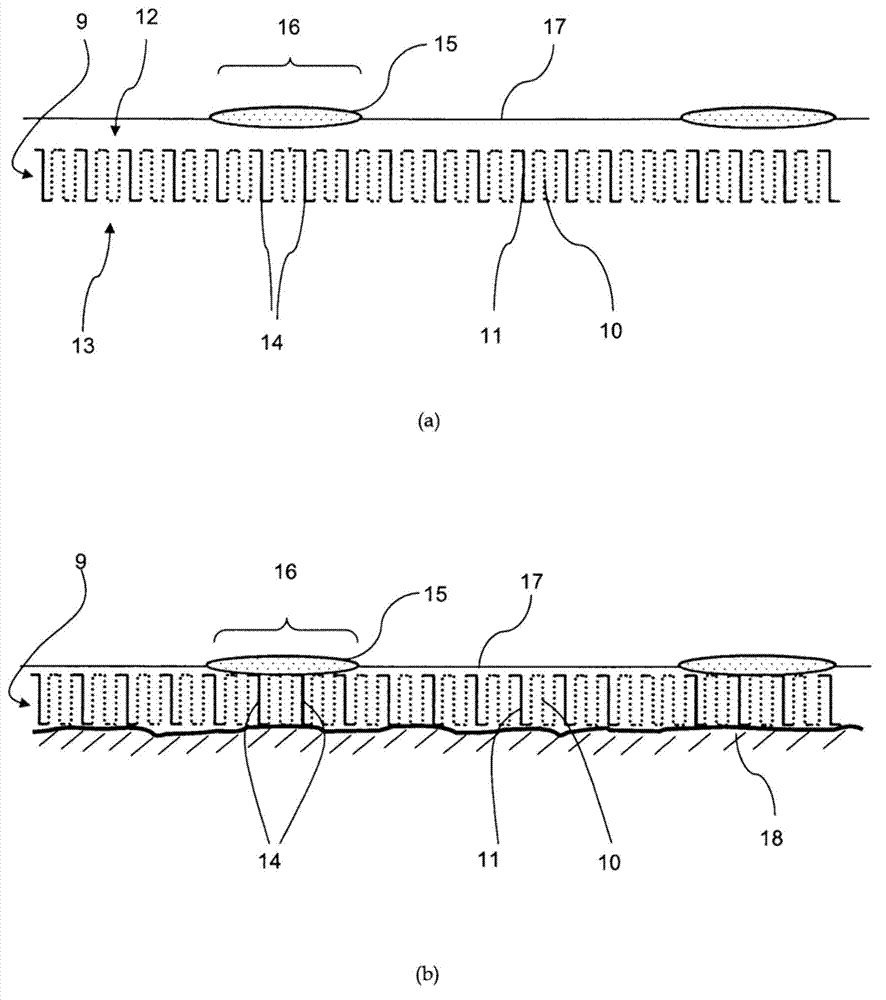

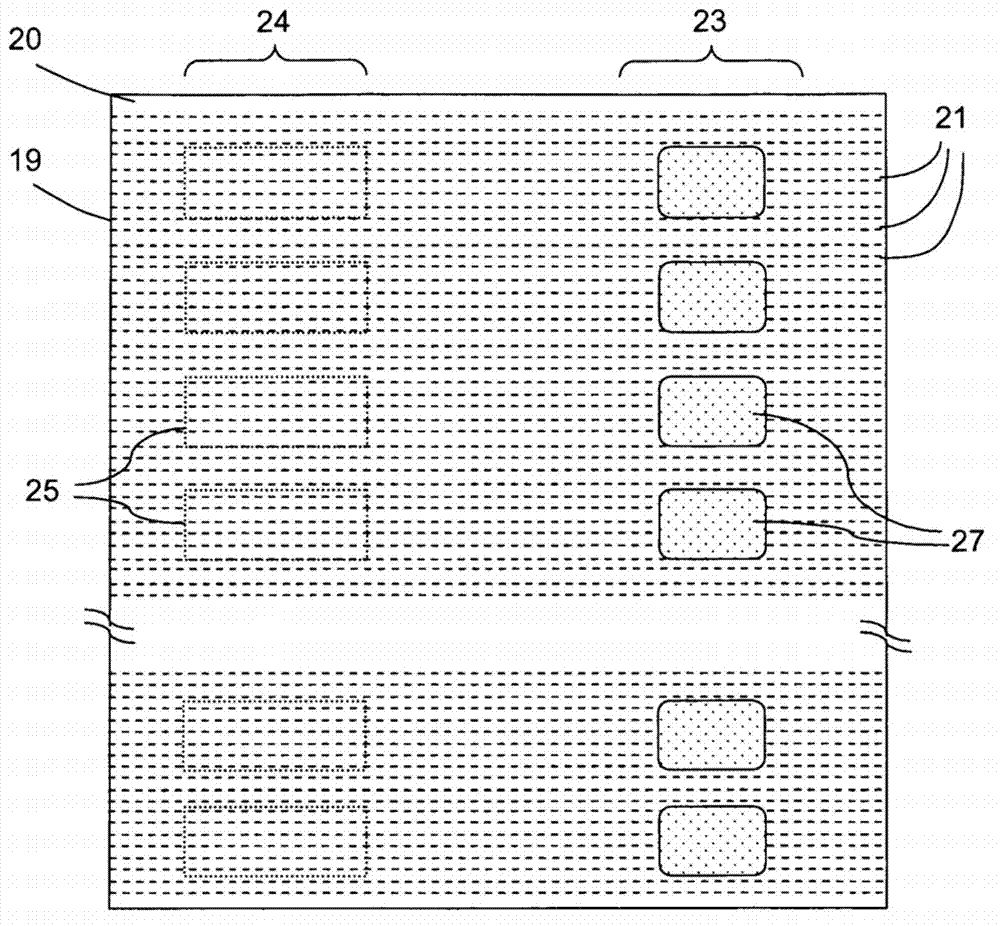

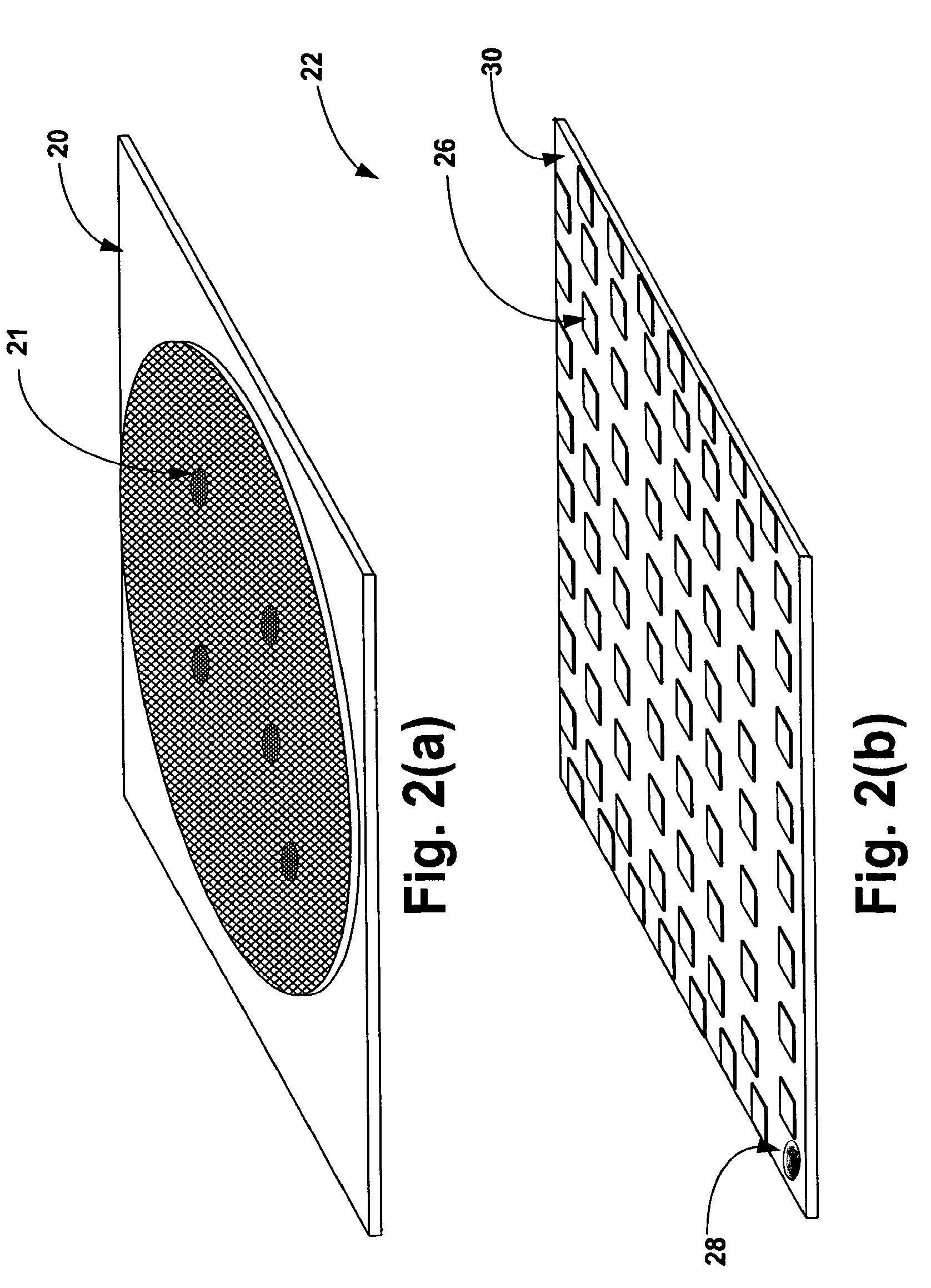

Electrode sensor and use of electrode sensor as EIT electrode

ActiveCN102970925AGuaranteed breathabilityReduce manufacturing costContact member manufacturingElectrocardiographyConducting pathwaySkin contact

Electrode sensor comprising an array of spaced apart individual contact elements (27', 41), and an interface structure (30, 35) for forming contact between said contact elements and the skin; said interface structure comprising an interface layer of an essentially electrically insulating or poorly electrically conducting material (20', 29, 37) defining a skin (31) contact surface on one side and an array contact surface on the other side of the interface layer, a first pattern of an electrically conducting material on the array contact surface, a second pattern of an electrically conducting material on the skin contact surface, and electrical pathways (21', 39) connecting the first pattern with the second pattern; whereas, the first pattern comprises pattern elements, each individual contact element (27', 41) comprises a contacting surface area large enough to cover several pattern elements of said first pattern when contacting the array contact surface of the interface structure, and by contacting distinct sections of the first pattern with said individual contact elements, groups of electrical pathways establish contact further with distinct sections of the second pattern, so that an individual contact element (27', 41) defines an individual effective electrode on the skin contact surface. Method of manufacturing said electrode sensor, comprising the steps of: providing said interface structure, creating a first pattern of an electrically conducting material on its array contact surface, a second pattern of an electrically conducting material on its skin contact surface, electrically conducting pathways connecting the first pattern with the second pattern, and contacting sections of the electrically conducting first pattern with an array of spaced apart contact elements.

Owner:斯威斯托姆公开股份有限公司

Shape-Conformable Alkali Metal Battery Having a Conductive and Deformable Quasi-solid Polymer Electrode

ActiveUS20180351200A1High active material mass loadingLow overhead weightHybrid capacitor separatorsSolid electrolytesConducting pathwayMass loading

Provided is an alkali metal cell comprising: (a) a quasi-solid cathode containing 30% to 95% by volume of a cathode active material, about 5% to about 40% by volume of a first electrolyte containing an alkali salt dissolved in a solvent and an ion-conducting polymer dissolved, dispersed in or impregnated by a solvent, and about 0.01% to about 30% by volume of a conductive additive wherein the conductive additive, containing conductive filaments, forms a 3D network of electron-conducting pathways such that the quasi-solid electrode has an electrical conductivity from about 10−6 S / cm to about 300 S / cm; (b) an anode; and (c) an ion-conducting membrane or porous separator disposed between the anode and the quasi-solid cathode; wherein the quasi-solid cathode has a thickness from 200 μm to 100 cm and a cathode active material having an active material mass loading greater than 10 mg / cm2.

Owner:GLOBAL GRAPHENE GRP INC

Method of Producing a Shape-Conformable Alkali Metal Battery Having a Conductive and Deformable Quasi-solid Polymer Electrode

ActiveUS20180351201A1High densityLow overhead weight and volumeHybrid capacitor electrolytesHybrid capacitor electrodesPolymer scienceConducting pathway

Provided is method of preparing an alkali metal cell, the method comprising: (a) combining a quantity of an active material, a quantity of an electrolyte, and a conductive additive to form a deformable and conductive electrode material, wherein the conductive additive, containing conductive filaments, forms a 3D network of electron-conducting pathways and the electrolyte contains an alkali salt and an ion-conducting polymer dissolved or dispersed in a solvent; (b) forming the electrode material into a quasi-solid polymer electrode, wherein the forming includes deforming the electrode material into an electrode shape without interrupting the 3D network of electron-conducting pathways such that the electrode maintains an electrical conductivity no less than 10−6 S / cm; (c) forming a second electrode; and (d) forming an alkali metal cell by combining the quasi-solid electrode and the second electrode. The second electrode may also be a quasi-solid polymer electrode.

Owner:GLOBAL GRAPHENE GRP INC

Method of Producing Anode or Cathode Participates for Alkali Metal Batteries

Provided is method of producing anode or cathode particulates for an alkali metal battery. The method comprises: (a) preparing a slurry containing particles of an anode or cathode active material, an electron-conducting material, and an electrolyte containing a lithium salt or sodium salt and an optional polymer dissolved in a liquid solvent; and (b) conducting a particulate-forming means to convert the slurry into multiple anode or cathode particulates, wherein an anode or a cathode particulate is composed of (i) particles of the active material, (ii) the electron-conducting material, and (iii) an electrolyte, wherein the electron-conducting material forms a 3D network of electron-conducting pathways and the electrolyte forms a 3D network of lithium ion- or sodium ion-conducting channels and wherein the anode particulate or cathode particulate has a dimension from 10 nm to 100 μm and an electrical conductivity from about 10−6 S / cm to about 300 S / cm.

Owner:GLOBAL GRAPHENE GRP INC

3D MEMS device and method of manufacturing

A MEMS device is provided. The device includes a MEMS wafer, a top cap wafer and a bottom cap wafer. The top and bottom cap wafers are respectively bonded to first and second sides of the MEMS wafer, the MEMS and cap wafers being electrically conductive. The outer side of the top cap wafer is provided with electrical contacts. The MEMS wafer, the top cap wafer and the bottom cap wafer define a cavity for housing a MEMS structure. The device includes insulated conducting pathways extending from within the bottom cap wafer, through the MEMS wafer and through the top cap wafer. The pathways are connected to the respective electrical contacts on the top cap wafer, for routing electrical signals from the bottom cap wafer to the electrical contacts on the top cap wafer. A method of manufacturing the MEMS device is also provided.

Owner:MOTION ENGINE

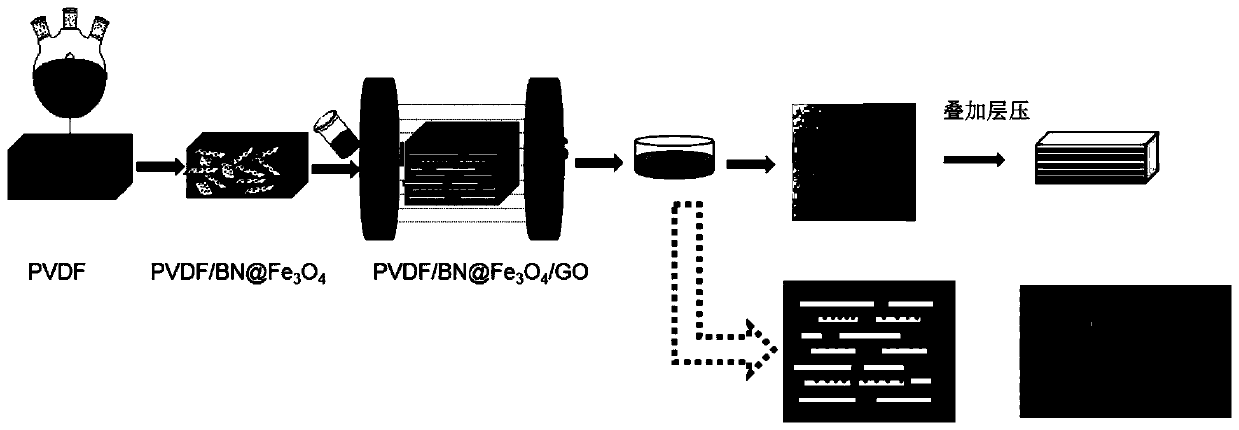

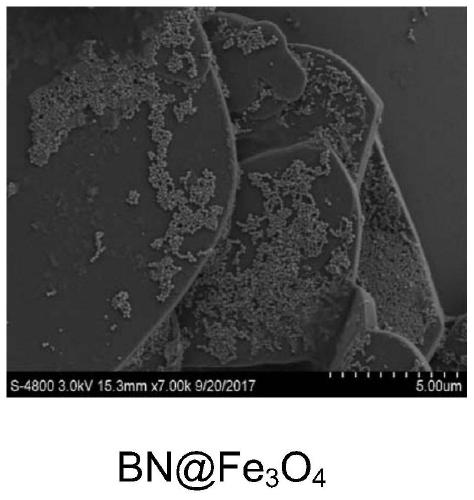

Method of utilizing magnetic field orientation to prepare brick-mud structure heat-conducting polymer composite material

ActiveCN109825010AIncrease the number ofEasy to synthesizeHeat-exchange elementsBrickConducting pathway

The invention discloses a method of utilizing magnetic field orientation to prepare a brick-mud structure heat-conducting polymer composite material. The method includes: ultrasonically treating BN, using a Piranha solution to treat the same, adopting a solvothermal method to prepare treated BN into BN@Fe3O4 magnetic filler, well mixing BN@Fe3O4, graphene oxide and polyvinylidene fluoride in a solvent, heating concentrate until solid content is 70-75%, putting the concentrate into a magnetic field to enable BN@Fe3O4 to be directionally arranged, and drying to volatilize the solvent to obtain the brick-mud structure heat-conducting composite material. The magnetic field is utilized to enable BN@Fe3O4 to be in directional arrangement in a polymer matrix to serve as 'brick' of the composite material, graphene oxide is self-assembled in PVDF with BN@Fe3O4 to form a heat-conducting pathway to serve as 'mud' of the composite material, interface heat resistance with PVDF can be improved, andhigher heat-conducting coefficient can be acquired under certain consumption of the heat-conducting filler.

Owner:ANHUI UNIVERSITY

Mitigating heat in an integrated circuit

InactiveUS8028531B2Reduce accumulationReduce concentrationDomestic cooling apparatusTemperatue controlHeat conductingConducting pathway

The present invention provides for a system and method for regulating and monitoring heat dissipation of an integrated circuit by employing a heat regulating device with a thermal structure net work assembly. Each thermal structure can act as a heat conducting pathway for inducing heat into and / or dissipating heat away from the integrated circuit, thus creating a more uniform temperature gradient across the semiconductor body.

Owner:GLOBALFOUNDRIES INC

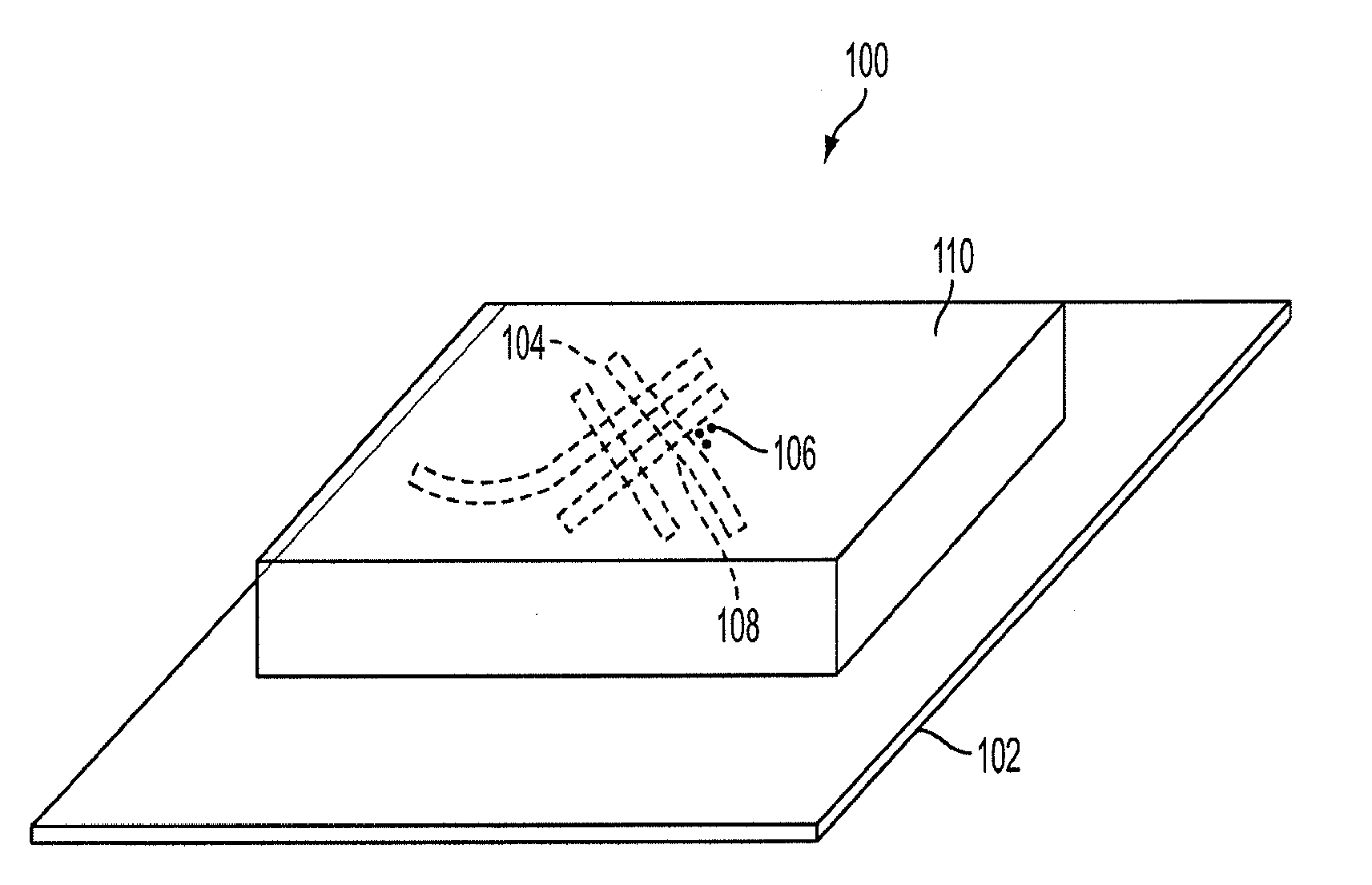

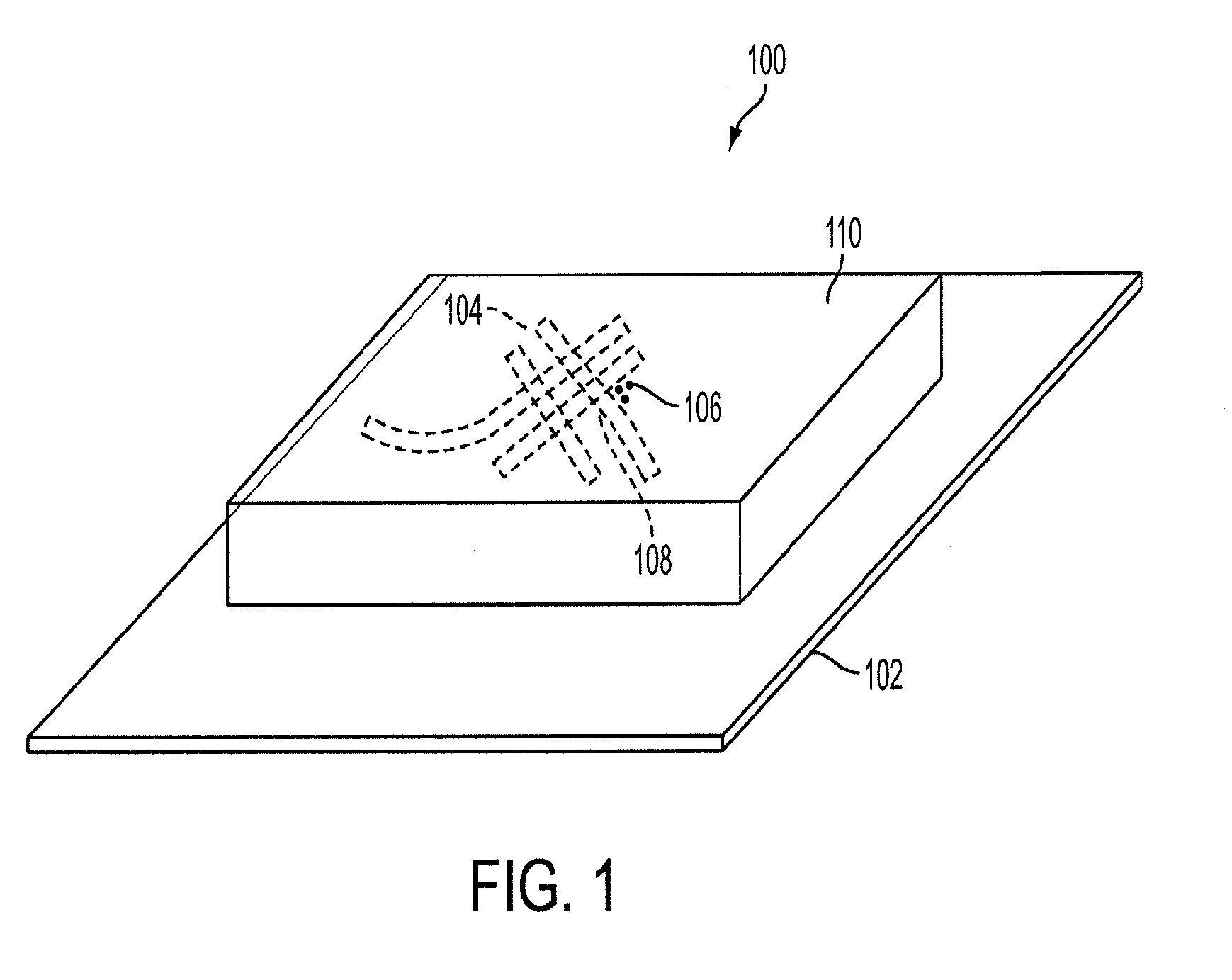

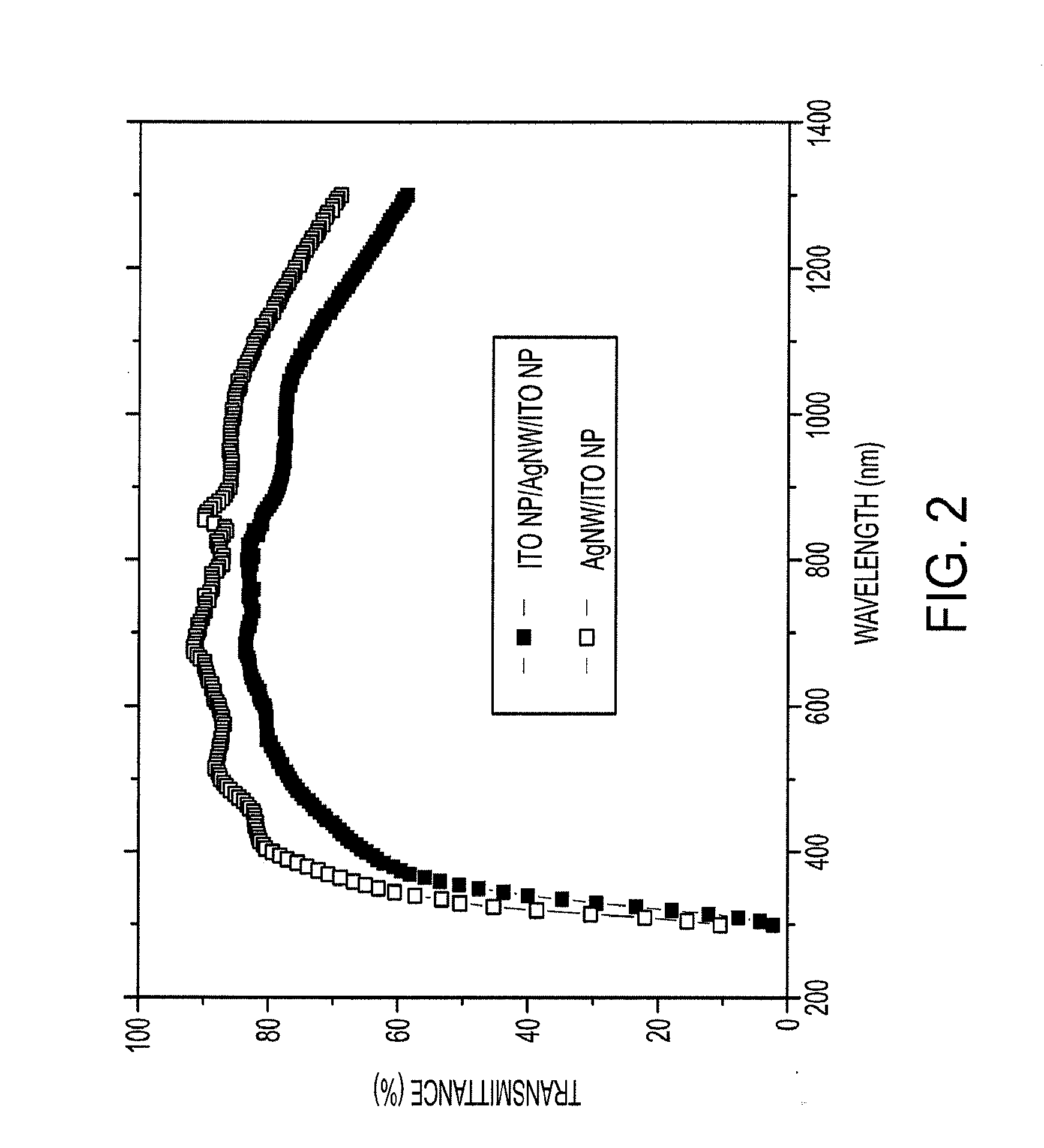

Solution processed nanoparticle-nanowire composite film as a transparent conductor for opto-electronic devices

An electro-optic device includes a substructure, a layer of nanowires deposited on the substructure so as to form a network of nanowires having electrically connected junctions at overlapping nanowire portions and defining spaces void of the nanowires, and a plurality of electrically conducting and optically transparent nanoparticles disposed to at least partially fill a plurality of the spaces to provide additional electrically conducting pathways for the network of nanowires across the spaces. The network of nanowires and the plurality of electrically conducting and optically transparent nanoparticles form at least a portion of an optically transparent electrode of the electro-optic device.

Owner:RGT UNIV OF CALIFORNIA

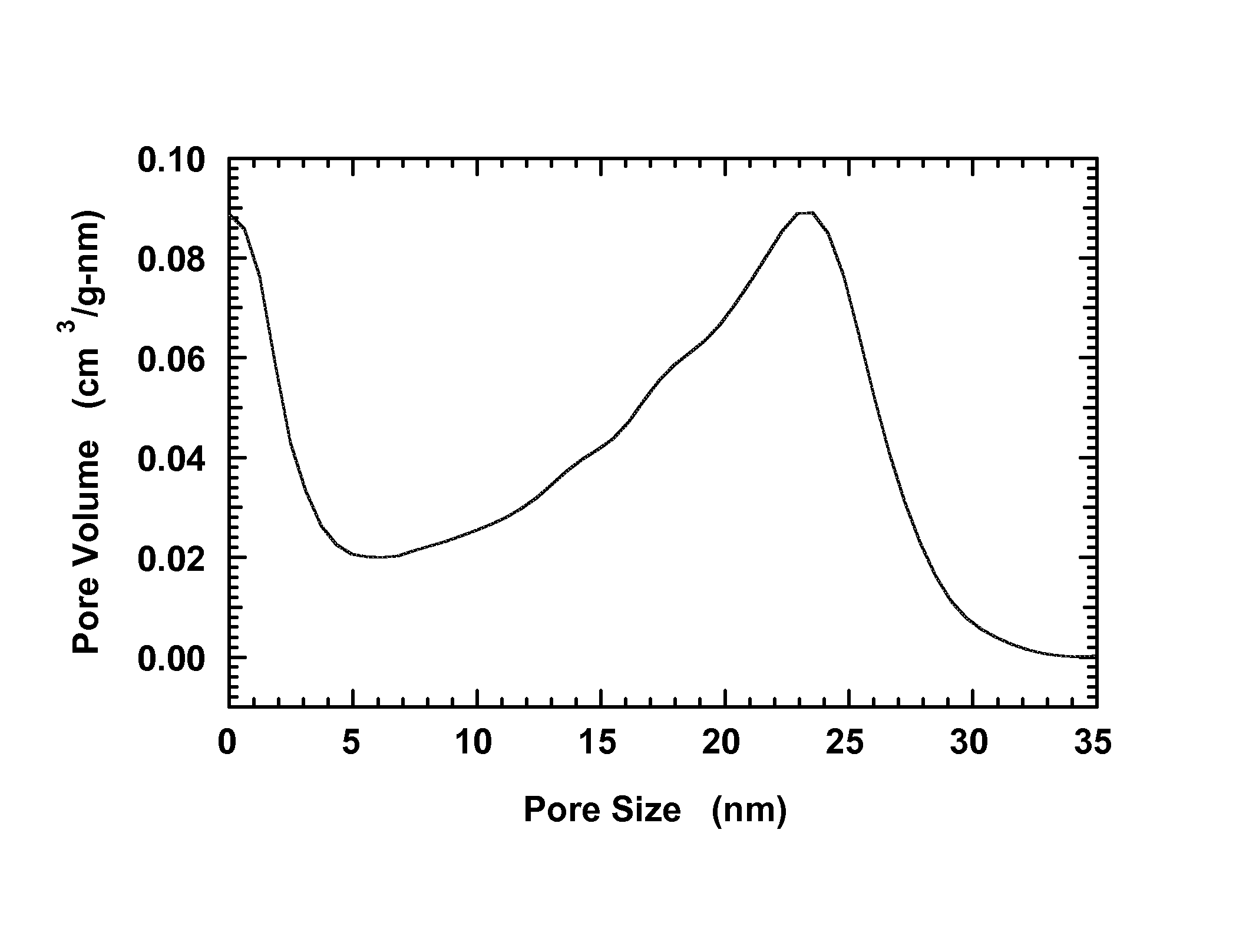

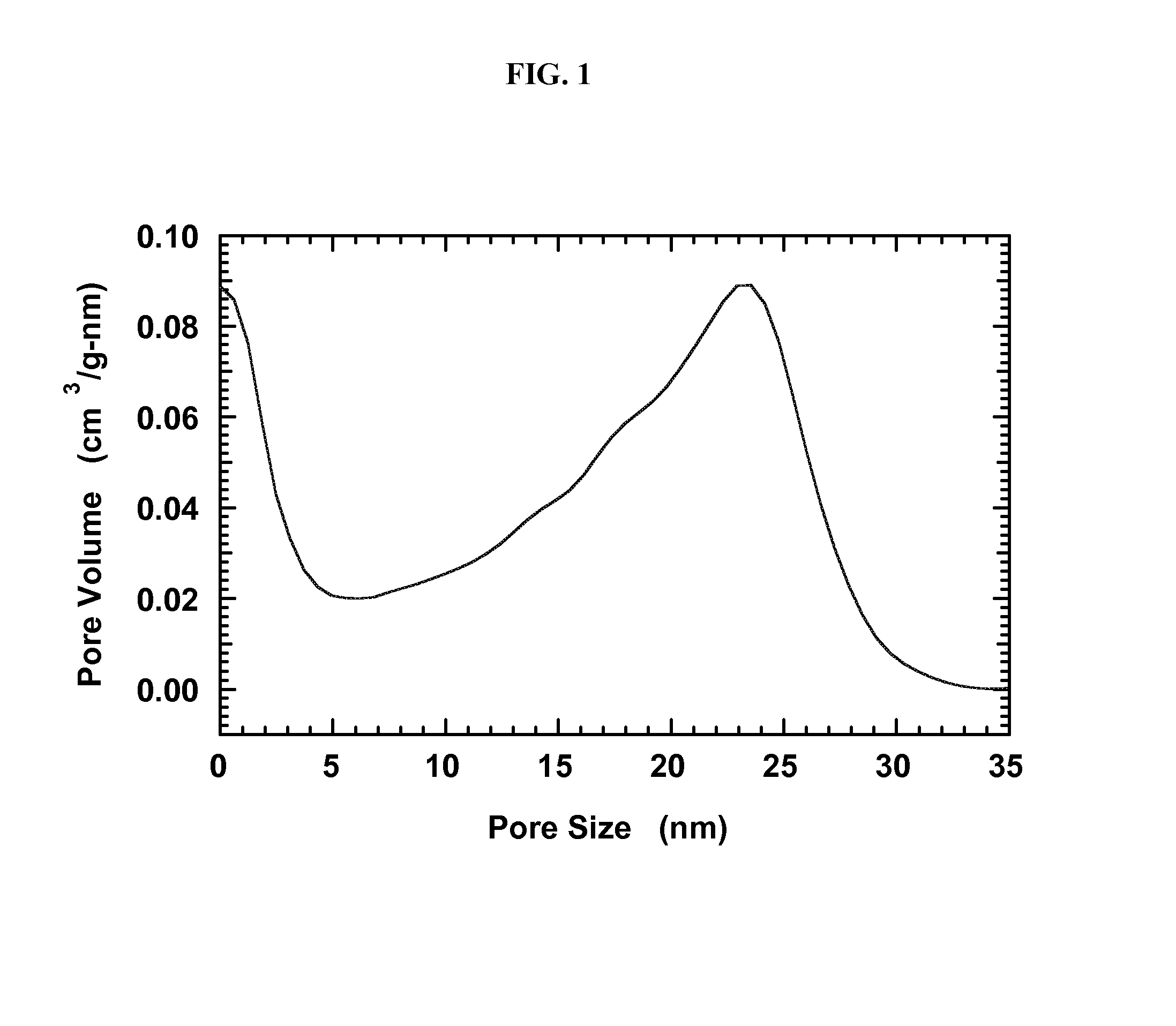

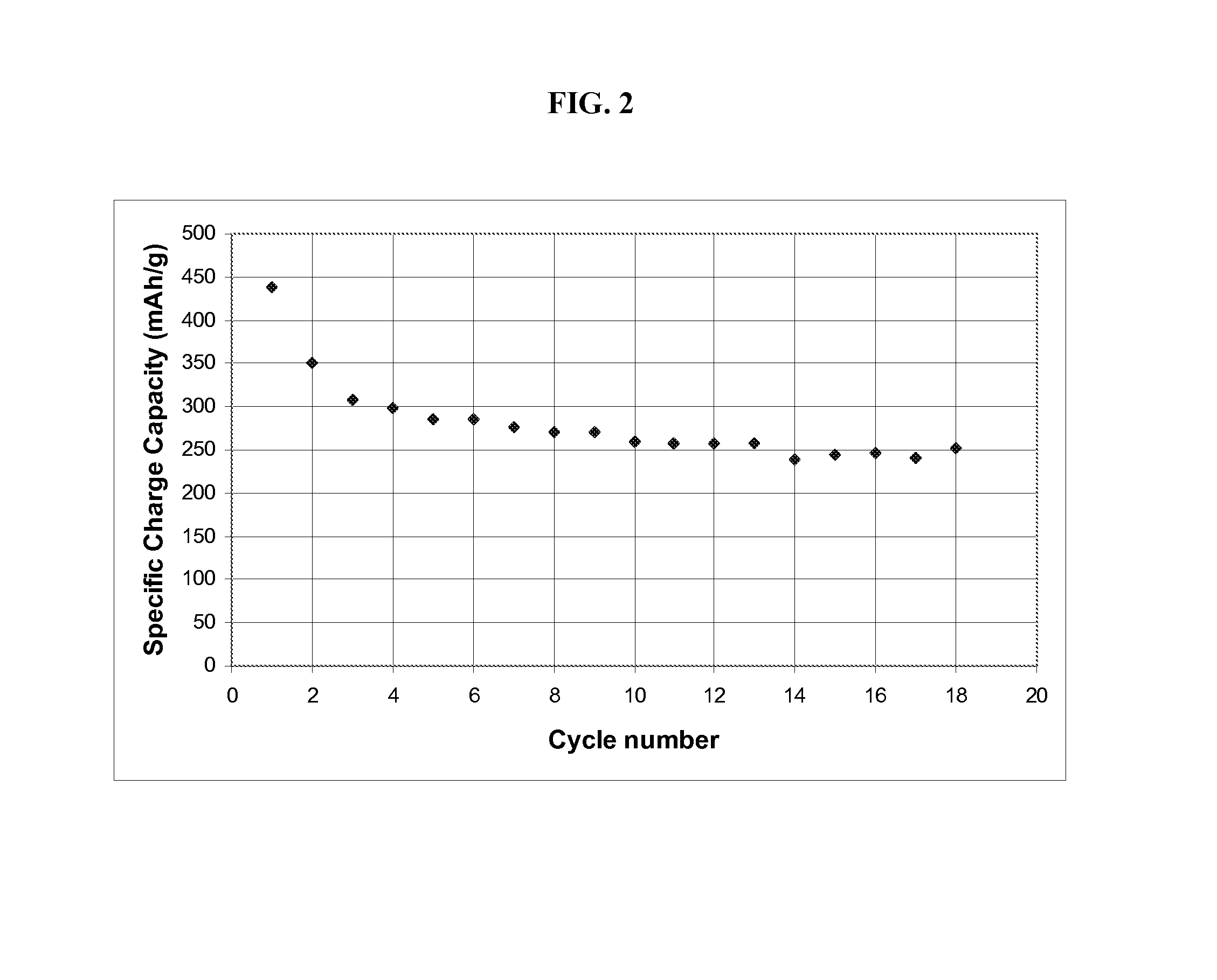

Porous conductive scaffolds containing battery materials

InactiveUS8920978B1Reduce sinteringMaterial nanotechnologyElectrode manufacturing processesConducting pathwayNanoparticle

The present invention provides a battery electrode comprising an active battery material enclosed in the pores of a conductive nanoporous scaffold. The pores in the scaffold constrain the dimensions for the active battery material and inhibit sintering, which results in better cycling stability, longer battery lifetime, and greater power through less agglomeration. Additionally, the scaffold forms electrically conducting pathways to the active battery nanoparticles that are dispersed. In some variations, a battery electrode of the invention includes an electrically conductive scaffold material with pores having at least one length dimension selected from about 0.5 nm to about 100 nm, and an oxide material contained within the pores, wherein the oxide material is electrochemically active.

Owner:HRL LAB

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com