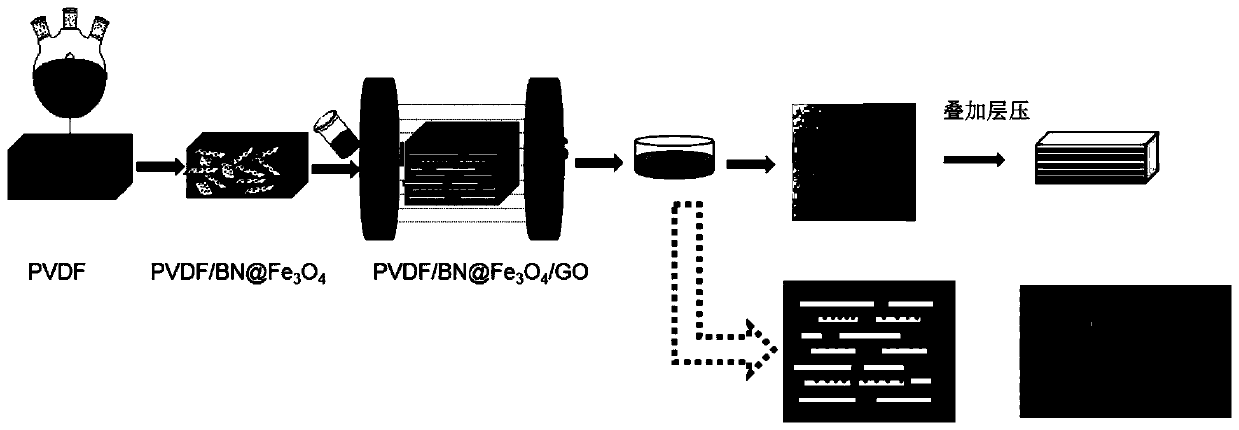

Method of utilizing magnetic field orientation to prepare brick-mud structure heat-conducting polymer composite material

A technology of thermally conductive composite materials and thermally conductive polymers is applied in the field of preparation of polymer composite materials, which can solve the problems of high cost of raw materials, complicated preparation process, and difficulty in making good use of the structural characteristics of fillers, etc., so as to improve the interface thermal resistance, The effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

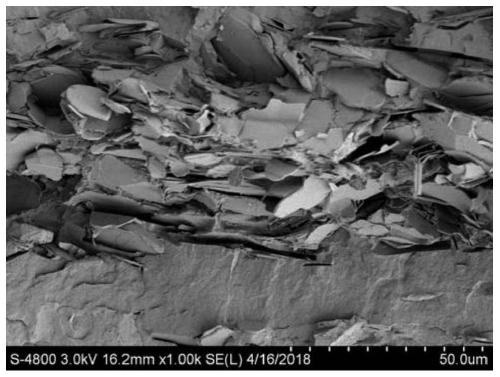

Method used

Image

Examples

Embodiment 1

[0029] 1. Ingredients

[0030] PVDF 89%,

[0031] BN 10%,

[0032] GO 1%.

[0033] 1. Preparation

[0034] (1) Add BN to distilled water and stir for 15 minutes, after ultrasonic dispersion treatment at 25°C for 24h, perform suction filtration, and freeze-dry at -50 to -60°C for 24h.

[0035] (2) Add the BN obtained above to the Piranha treatment solution (concentrated H 2 SO 4 :30%H 2 o 2 =7:3), the solid-liquid ratio of BN and Piranha treatment solution is 1g:30mL, stirred at 25°C for 2h, centrifuged at 4000-6000r / min, filtered, washed, dried at 80°C for 6h, and the modified sex BN;

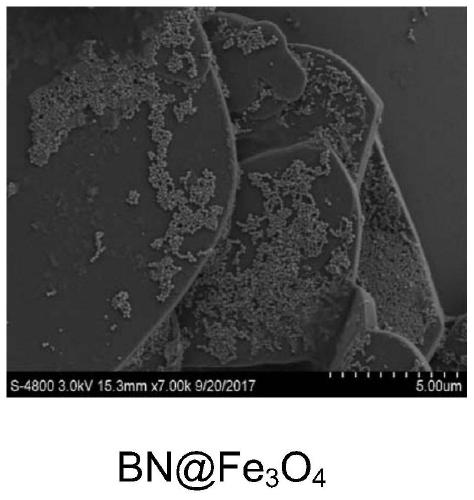

[0036] (3) Add modified BN to ethylene glycol, sonicate for 24h, and then add FeCl 3 ·6H 2 O and sodium acetate trihydrate (mass ratio 1:2.7) were stirred for 2 hours, and the mass ratio of FeCl 3 ·6H 2 O: BN=1:6, pour it into a 150mL reactor, react at 200°C for 8h, cool to room temperature after the reaction, and prepare BN@Fe 3 o 4 ;

[0037] (4) The BN@Fe prepared above 3 o ...

Embodiment 2

[0055] 1. Ingredients

[0056] PVDF 79%,

[0057] BN 20%,

[0058] GO 1%.

[0059] 2. Preparation

[0060] (1) Add BN to distilled water and stir for 15 minutes, after ultrasonic dispersion treatment at 25°C for 24h, perform suction filtration, and freeze-dry at -50 to -60°C for 24h.

[0061] (2) Add the BN obtained above to the Piranha treatment solution (concentrated H 2 SO 4 :30%H 2 o 2 =7:3), the solid-liquid ratio of BN and Piranha treatment solution is 1g:30mL, stirred at 25°C for 2h, centrifuged at 4000-6000r / min, filtered, washed, dried at 80°C for 6h, and the modified sex BN;

[0062] (3) Add modified BN to ethylene glycol, sonicate for 24h, and then add FeCl 3 ·6H 2 O and sodium acetate trihydrate (mass ratio 1:2.7) were stirred for 2 hours, and the mass ratio of FeCl 3 ·6H 2 O: BN=1:6, pour it into a 150mL reactor, react at 200°C for 8h, cool to room temperature after the reaction, and prepare BN@Fe 3 o 4 ;

[0063] (4) The BN@Fe prepared above 3 o ...

Embodiment 3

[0081] 1. Ingredients

[0082] PVDF 69%,

[0083] BN 30%,

[0084] GO 1%.

[0085] 2. Preparation

[0086] (1) Add BN to distilled water and stir for 15 minutes, after ultrasonic dispersion treatment at 25°C for 24h, perform suction filtration, and freeze-dry at -50 to -60°C for 24h.

[0087] (2) Add the BN obtained above to the Piranha treatment solution (concentrated H 2 SO 4 :30%H 2 o 2 =7:3), the solid-liquid ratio of BN and Piranha treatment solution is 1g:30mL, stirred at 25°C for 2h, centrifuged at 4000-6000r / min, filtered, washed, dried at 80°C for 6h, and the modified sex BN;

[0088] (3) Add modified BN to ethylene glycol, sonicate for 24h, and then add FeCl 3 ·6H 2 O and sodium acetate trihydrate (mass ratio 1:2.7) were stirred for 2 hours, and the mass ratio of FeCl 3 ·6H 2 O: BN=1:6, pour it into a 150mL reactor, react at 200°C for 8h, cool to room temperature after the reaction, and prepare BN@Fe 3 o 4 ;

[0089] (4) The BN@Fe prepared above 3 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com