Patents

Literature

1194results about How to "Guaranteed breathability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air conditioning seat

ActiveUS7931330B2Improve insulation performanceConstant elasticityVehicle seatsStoolsEngineeringAir conditioning

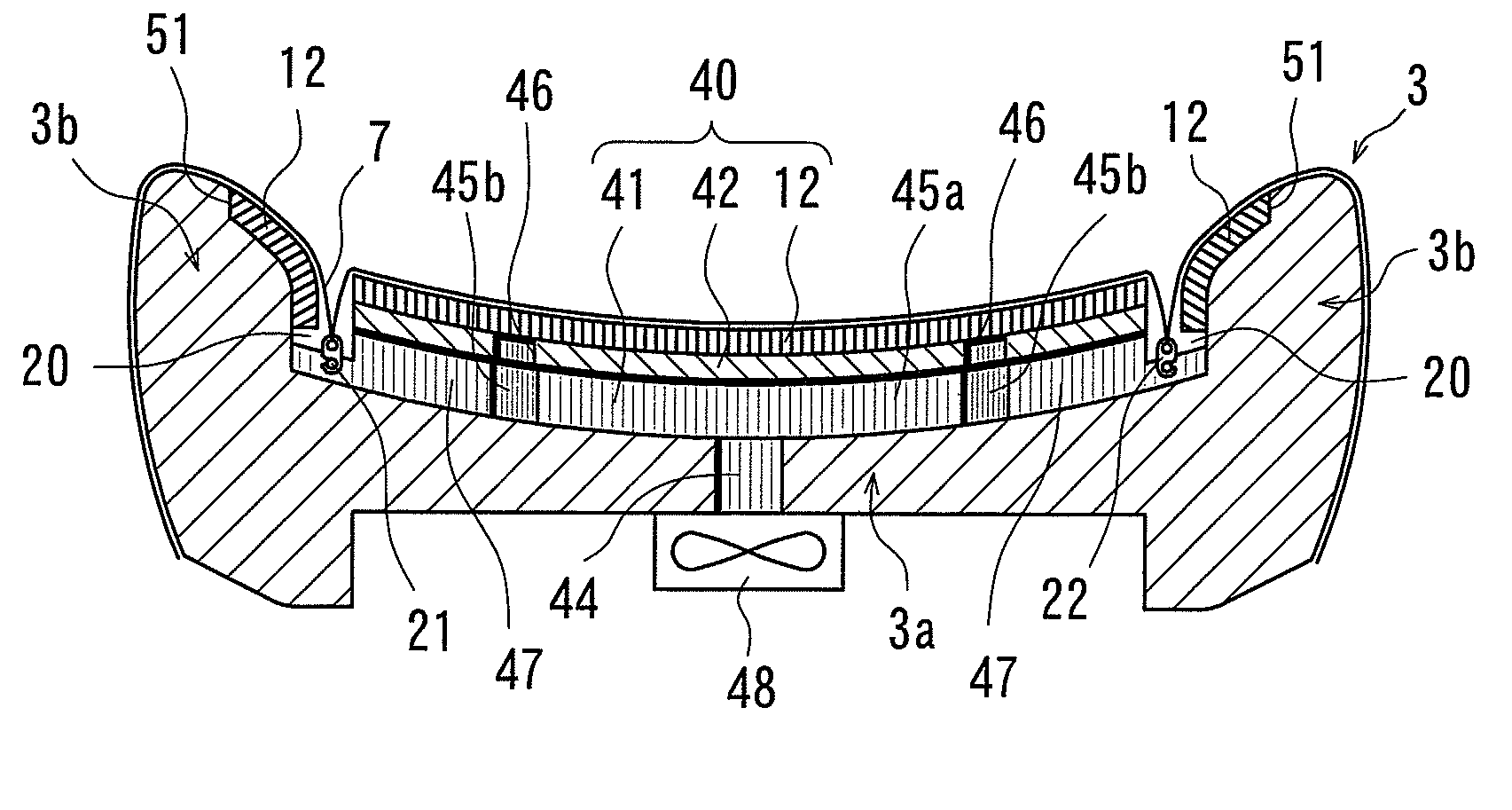

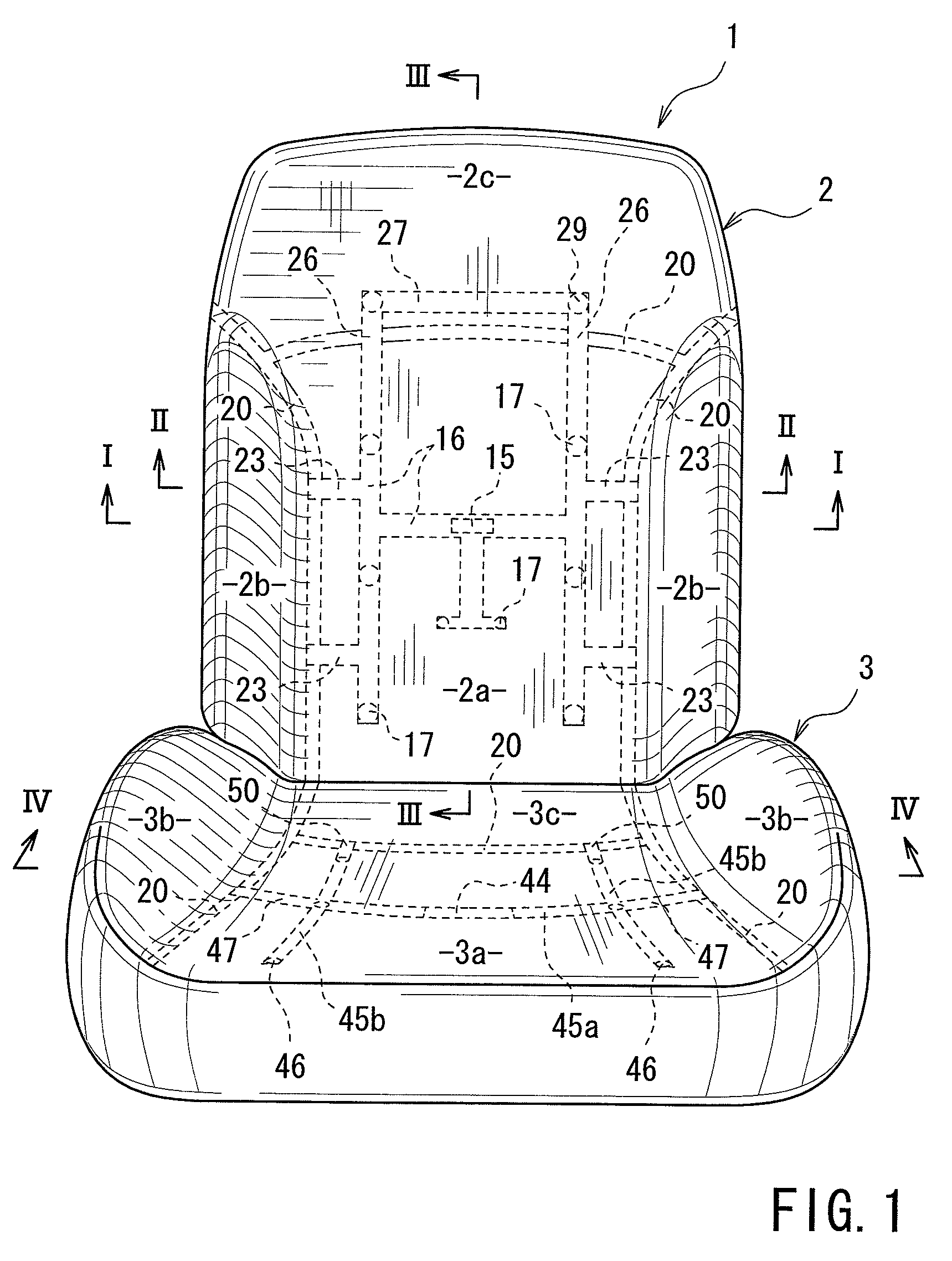

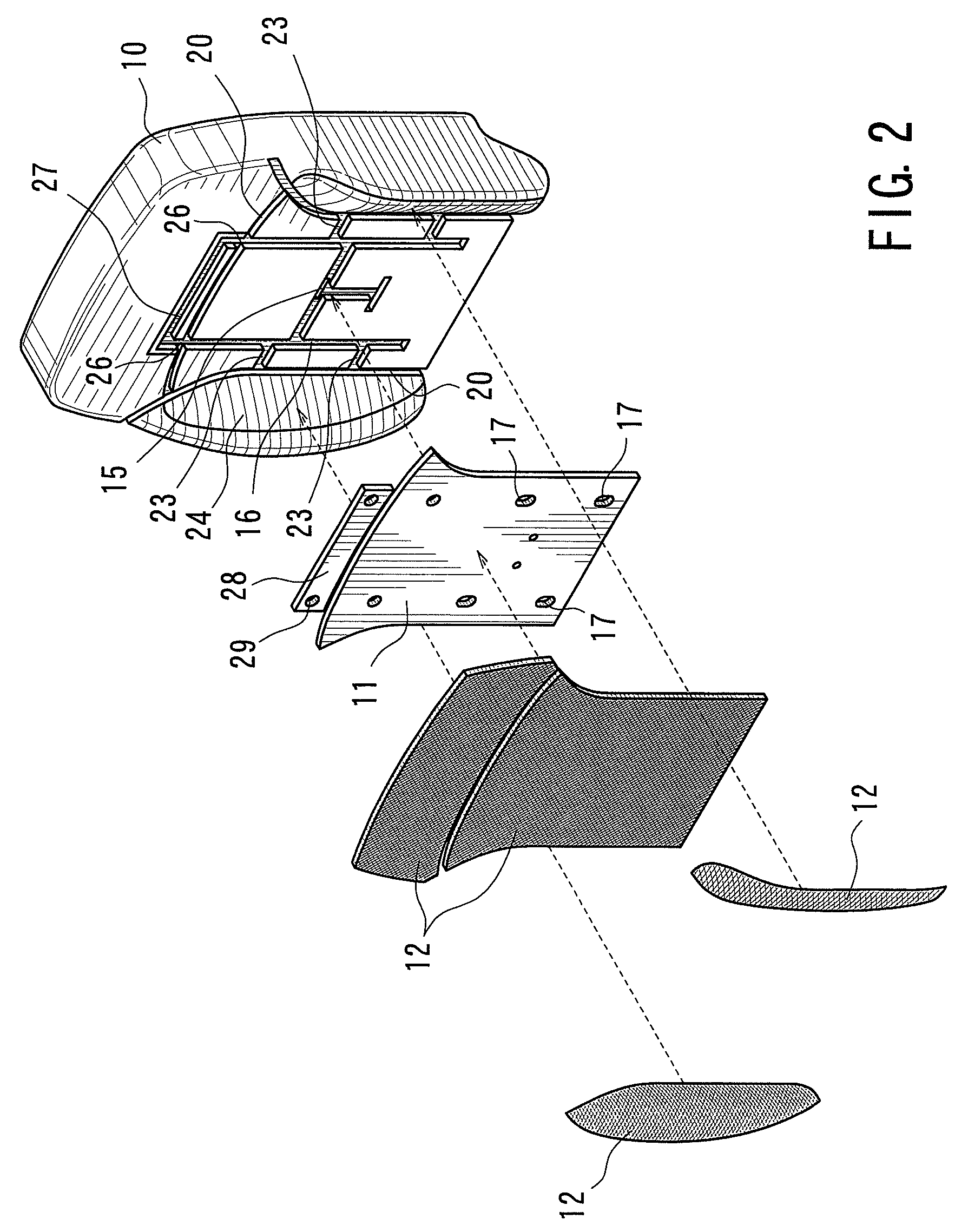

An air conditioning seat includes a seat pad having a seating portion and a side support portion, blowing means for blowing air to an air path formed at the seat pad, a seat cover covering the seat pad, and a net-like cushion member capable of permeating air in a thickness direction and in a plane direction. An air path is formed at the seating portion of the seat pad. A hanging groove in a groove-like shape is recessed and on a boundary line of the seating portion and the side support portion. The an air blow out port of the air path is covered by the net-like cushion member. A communicating path reaching the net-like cushion member of the side support portion from the air path of the seating portion is formed by passing a back side of the hanging member at inside of the hanging groove.

Owner:TOYOTA BOSHOKU KK +1

Universal health-care board and preparation method thereof

ActiveCN102514254AGood elastic recoveryGood strength and elasticityStuffed mattressesLamination ancillary operationsFiberSurface layer

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Cotton padding and preparation method thereof

The invention relates to a cotton padding, which comprises a cotton padding core, gauze screens and non-woven fabrics. Both upper surface and lower surface of the cotton padding core are provided with a layer of gauze screen and a layer of non-woven fabric in turn; the peripheries of the non-woven fabrics arranged on the upper surface and the lower surface are integrally quilted along the peripheral boundaries of the cotton padding core; the cotton padding core consists of the following components: cotton, hollow fibers, low-melting-point fibers and natural bamboo fibers; and the hollow fibers are at least one of far infrared hollow polyester short fibers, antibacterial polyester hollow fibers, bamboo carbon hollow polyester fibers, three-dimensional crimped hollow fibers and seven-hole polyester fibers. A preparation method comprises the following steps of: mixing, opening, combing, processing by using a random roller, paving, compacting, processing at a constant temperature, shaping, laying a net, rubbing, and reshaping. The components are reasonably proportioned, the processing technology is simple, and the prepared cotton padding has the characteristics of no caking, bacteria resistance and inhibition, health care, moisture absorption and air permeability, and is soft and fluffy and suitable for industrial production.

Owner:HUNAN PROVINCE CHANGSHA CITY AIWANTING HOME TEXTILES

Method for planting and cultivating rhizoma gastrodiae

The invention belongs to agricultural cultivation, and particularly relates to a method for planting and cultivating rhizoma gastrodiae. The method comprises the steps that corn flour is boiled to paste and mixed with activated carbon powder so that a mixture of the corn paste and activated carbon can be produced; the mixture is laid on a flat plate; after the mixture is in a gel state, bacteria sticks and rhizoma gastrodiae seeds are tightly coiled and then planted. According to the method, the rhizoma gastrodiae seeds can tightly surround the bacteria sticks, so that the germination rate and the inoculation rate of the seeds are improved and finally, the yield of rhizoma gastrodiae of the method is more than two times as much as that of a traditional rhizoma gastrodiae sowing method. On one hand, the corn paste can serve as compost of the rhizoma gastrodiae, the activated carbon powder is added to the corn paste, and therefore the air permeability is guaranteed; on the other hand, when the rhizoma gastrodiae is planted, the phenomenon that the rhizoma gastrodiae is constrained or damaged is avoided along with the process that the corn paste is gradually dissolved, so that operation and later-period temperature and humidity management are facilitated and the operable sowing method is provided for rhizoma gastrodiae concentration seeding and efficient industrialized sowing. In addition, according to the method, special paper is not needed, the method is easy to achieve, and cost is saved.

Owner:CHONGQING FUXINYANG EDIBLE FUNGUS

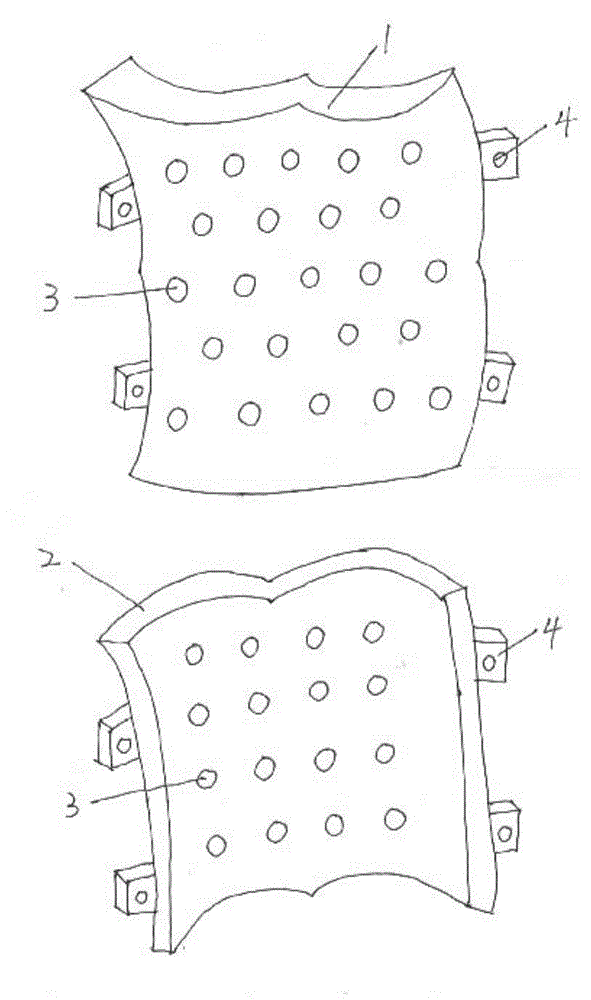

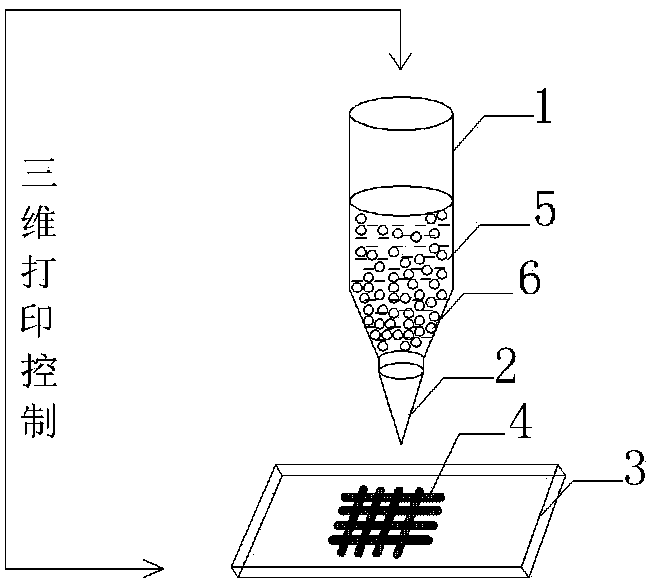

External fixation support formed through 3D printing and used for personalized orthopedic and manufacturing method thereof

InactiveCN104905899AEliminate tedious and time-consuming operationsImprove breathabilityMedical scienceSoftware designDimensional modeling

The invention discloses a method for manufacturing an external fixation support for personalized orthopedic by utilizing 3D printing. The method comprises the steps of conducting three-dimensional scanning on a postoperative patient in a traction state to obtain outer surface three-dimensional data of the position needed to be externally fixed of the postoperative patient, re-establishing a three-dimensional model of the position needed to be externally fixed according to the three-dimensional data, using software to design an external fixation support completely fit with the position needed to be externally of the patient and used for orthopedic, arranging air-permeable holes and fixing blocks on the support model and using polylactic acid as a raw material to obtain the external fixation support for orthopedic through 3D printing performed by a 3D printer. By means of the method, the external fixation support completely fit with the position needed to be externally of the patient and used for orthopedic can be manufactured, long-time shaping through plaster fixation is avoided, the degree of tightness can be adjusted, the external fixation support is light and air-permeable, and a more comfortable fixation mode is provided for the patient.

Owner:JIANGYIN RECONGENE BIOMEDICAL TECH

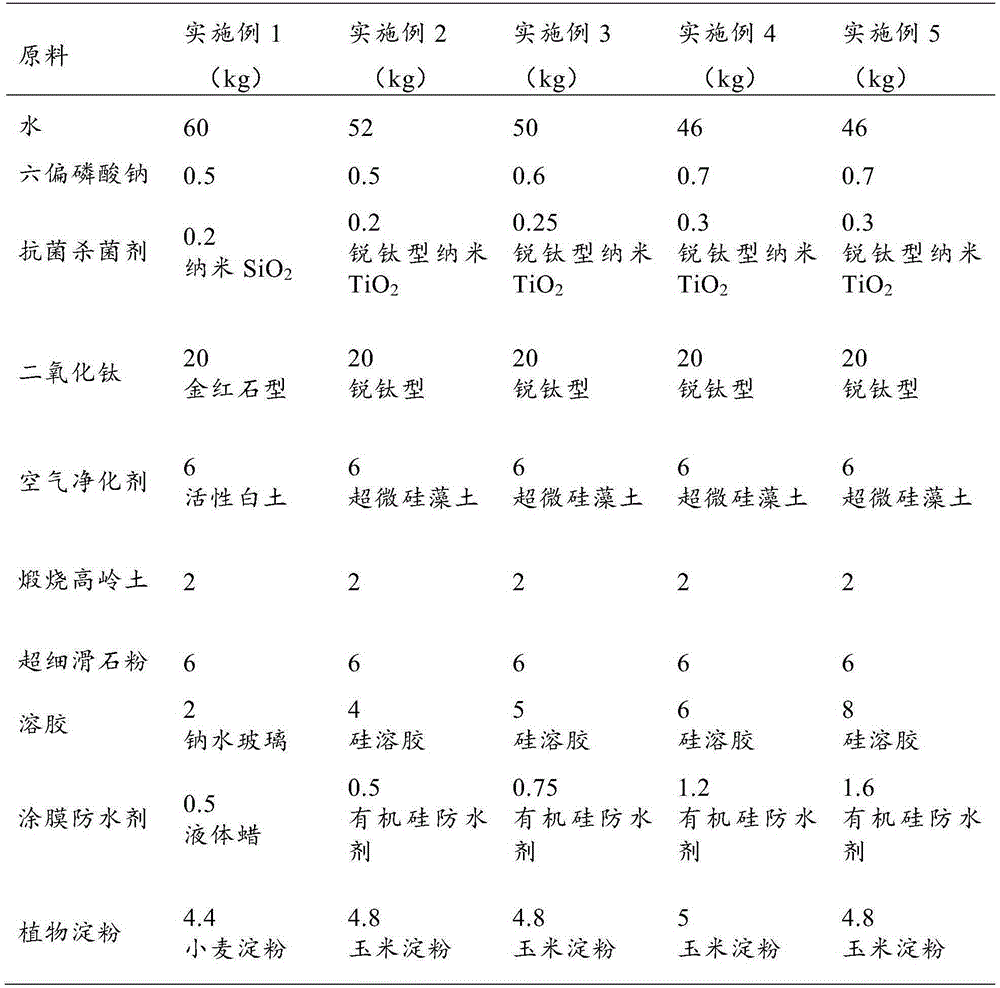

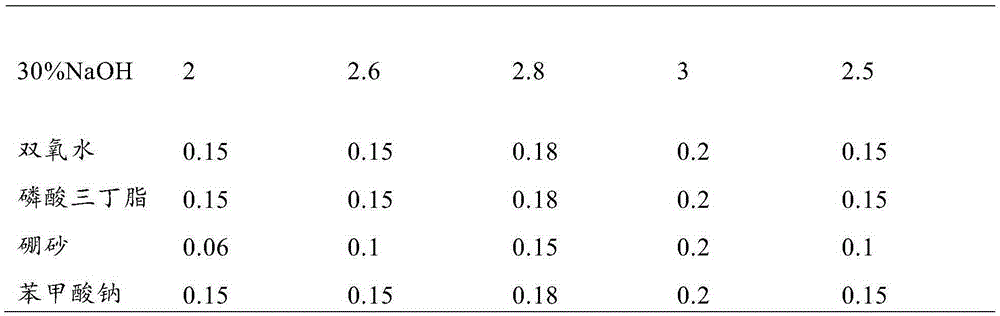

Plant ecological interior wall coating and preparation method thereof

ActiveCN105368164ALow NaOH contentImprove water resistanceStarch coatingsEcological environmentBinding force

The invention discloses a plant ecological interior wall coating and a preparation method thereof. The plant ecological interior wall coating is characterized by being prepared from a titanium dioxide filler, a borax crosslinking agent, an oxidizing agent, water, plant starch serving as a binding agent and sol serving as a binding agent modifier. According to the plant ecological interior wall coating, the plant starch is utilized as the binding agent, no synthetic resin emulsion is contained, complete biodegradation can be achieved, and the coating is an ecological environment-friendly interior wall coating in the true sense; the sol is added to serve as the binding agent modifier, the higher film coating binding force and film coating strength are achieved, and the technical property can reach the GB / T9756-2009 standard of a qualified synthetic resin emulsion interior wall coating product and is obviously suprior to the JC / T423-91 technical requirements for a water-soluble interior wall coating.

Owner:烟台阳光新材料技术有限公司

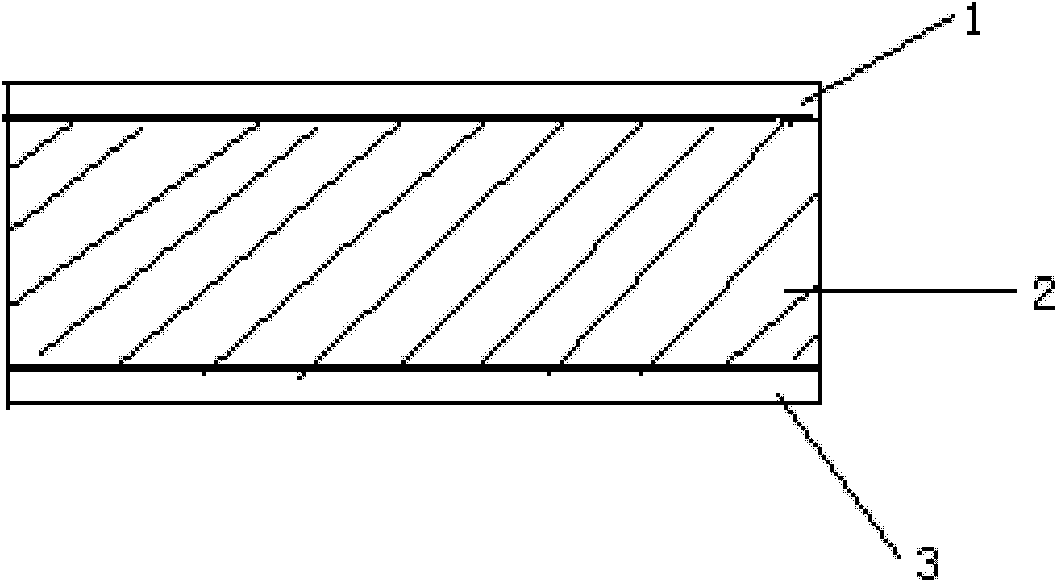

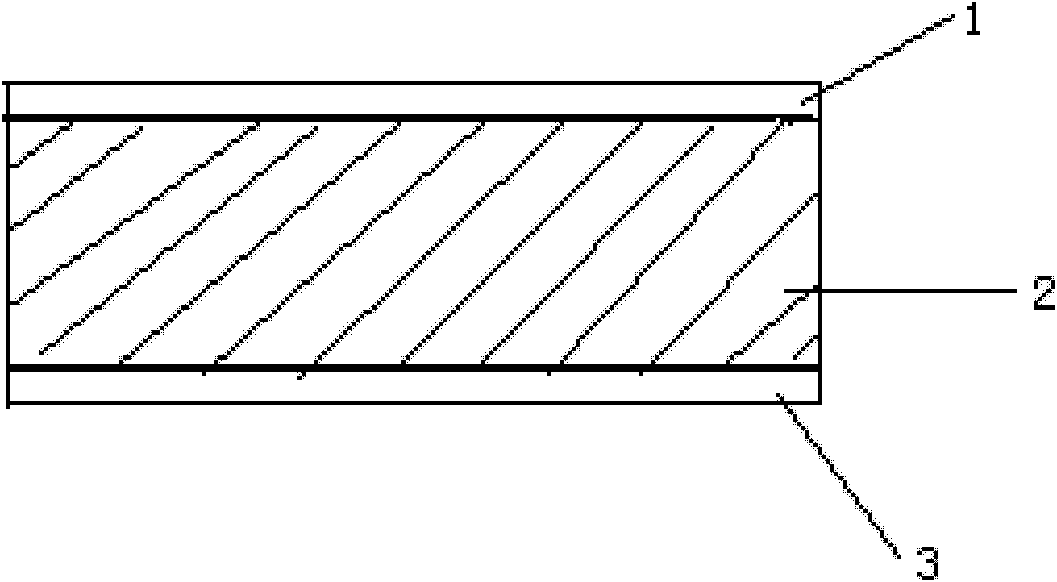

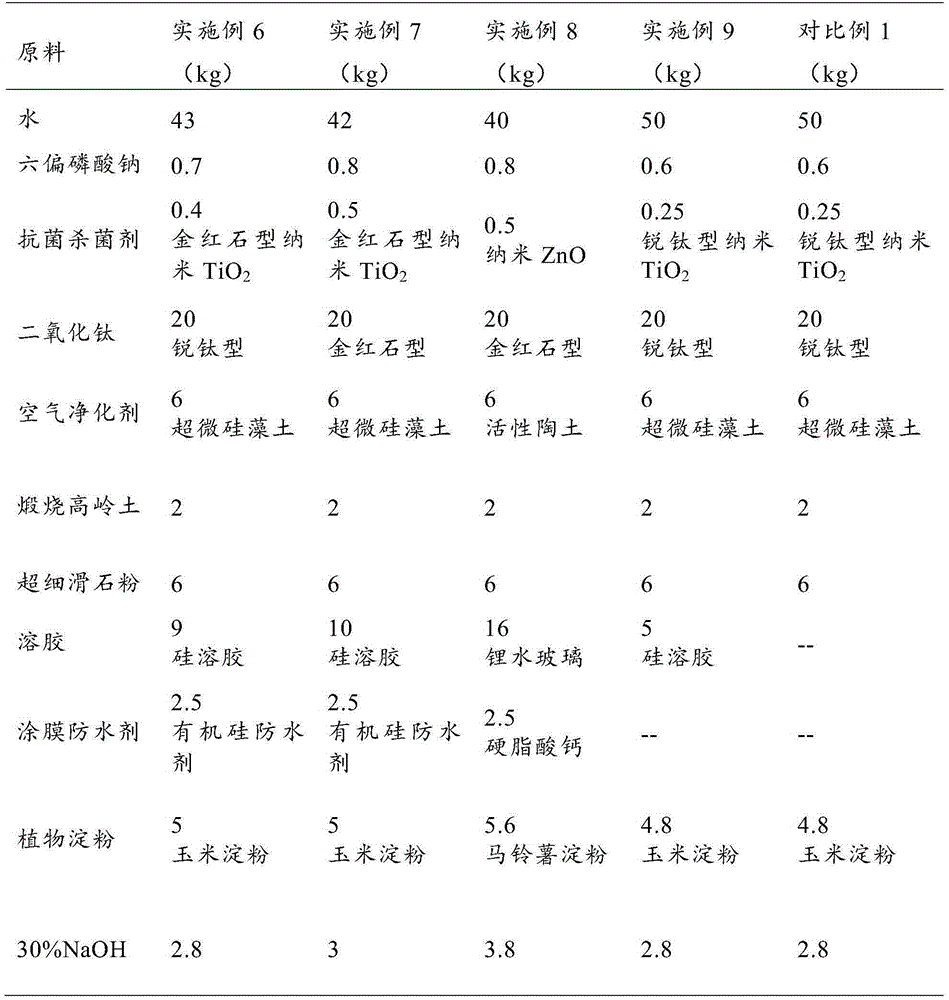

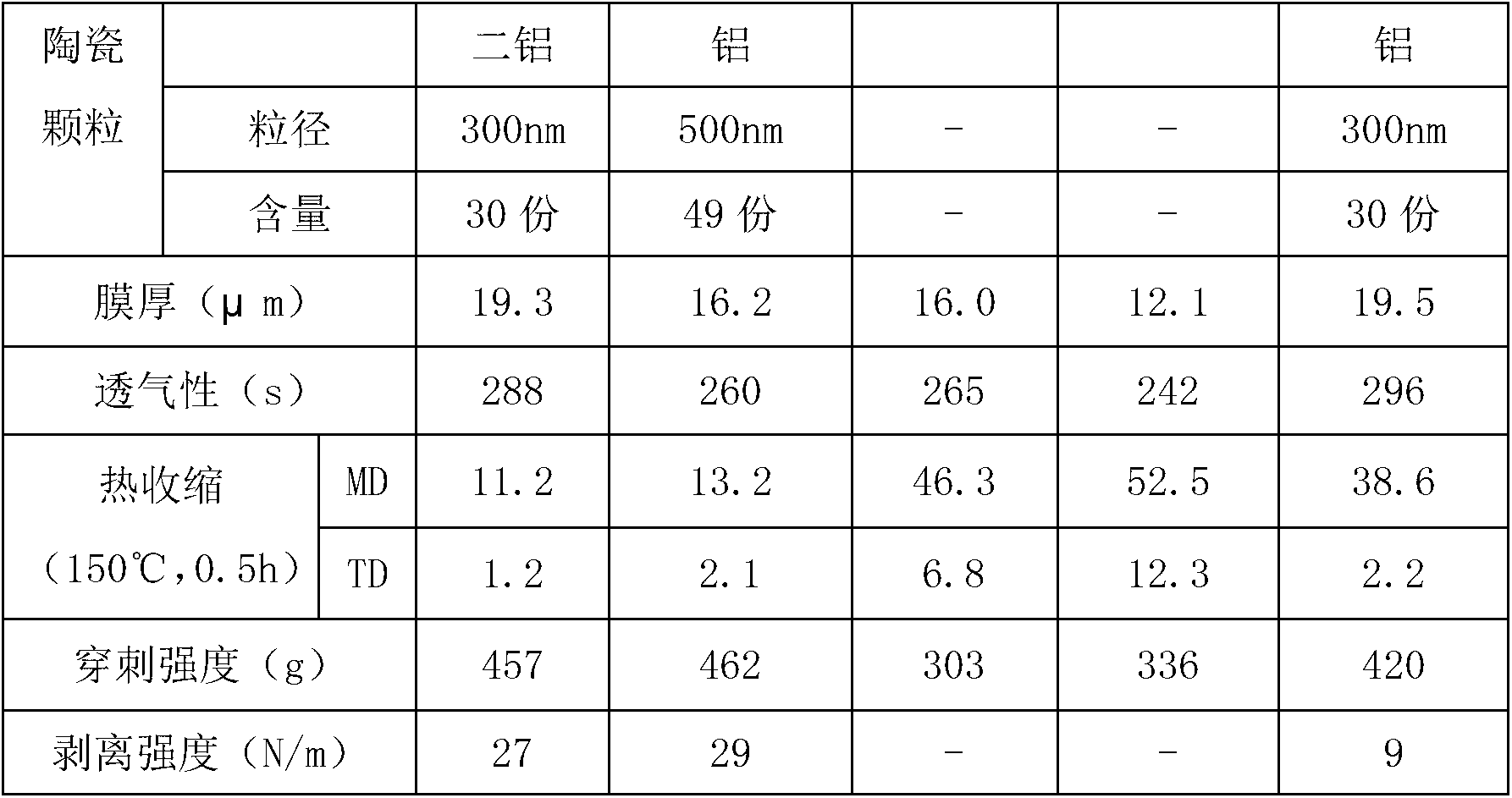

Composite film with high-temperature resistance layer, preparation method thereof and battery

ActiveCN103078075AHigh peel strengthAvoid powder sheddingCell component detailsComposite filmTemperature resistance

The application relates to the field of lithium batteries, and particularly discloses a composite film with a high-temperature resistance layer, a preparation method thereof and a battery. The composite film disclosed by the application comprises a base film and the high-temperature resistance layer, wherein the base film is a porous thermoplastic resin film; the high-temperature resistance layer is an inorganic ceramic layer containing ceramic particles; the inorganic ceramic layer is fixed on at least one surface of the porous thermoplastic resin film by polymerization; and the peel strength of the porous thermoplastic resin film and the inorganic ceramic layer is larger than or equal to 25 N / m under the condition of 180 DEG C. The invention further discloses the preparation method and the application of the composite film and the battery adopting the composite film. According to the application, the peel strength of inorganic ceramic layer and the porous thermoplastic resin film is greatly improved so as to effectively avoid a powder falling phenomenon of the inorganic ceramic particles in the composite film. Meanwhile, the composite film has excellent high temperature resistance performance, and can reduce battery short circuit phenomena caused by heat shrinkage of the composite film in the application.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

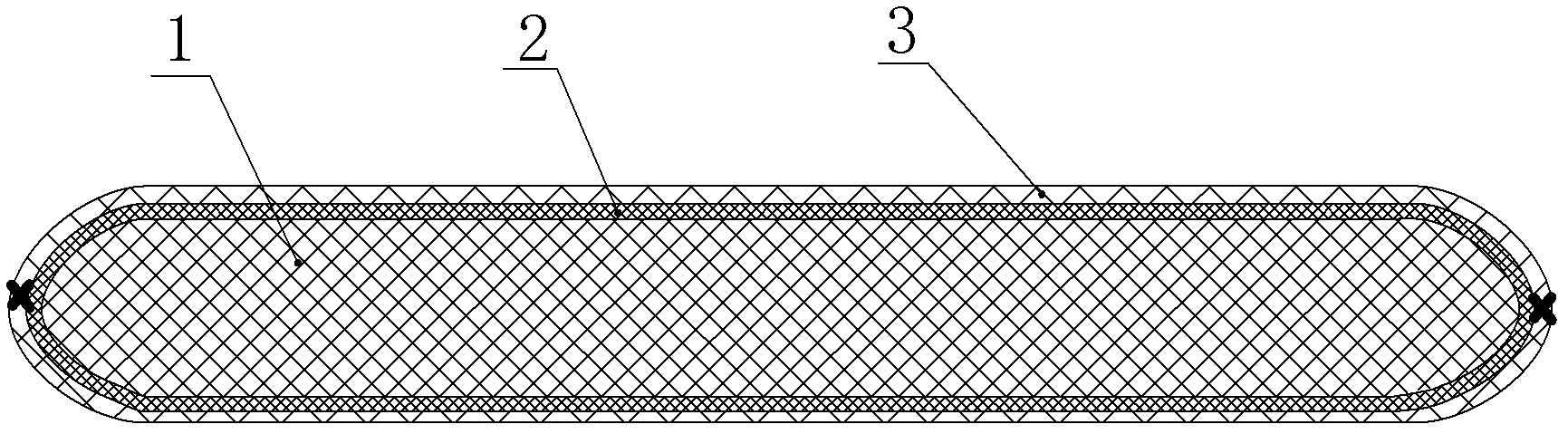

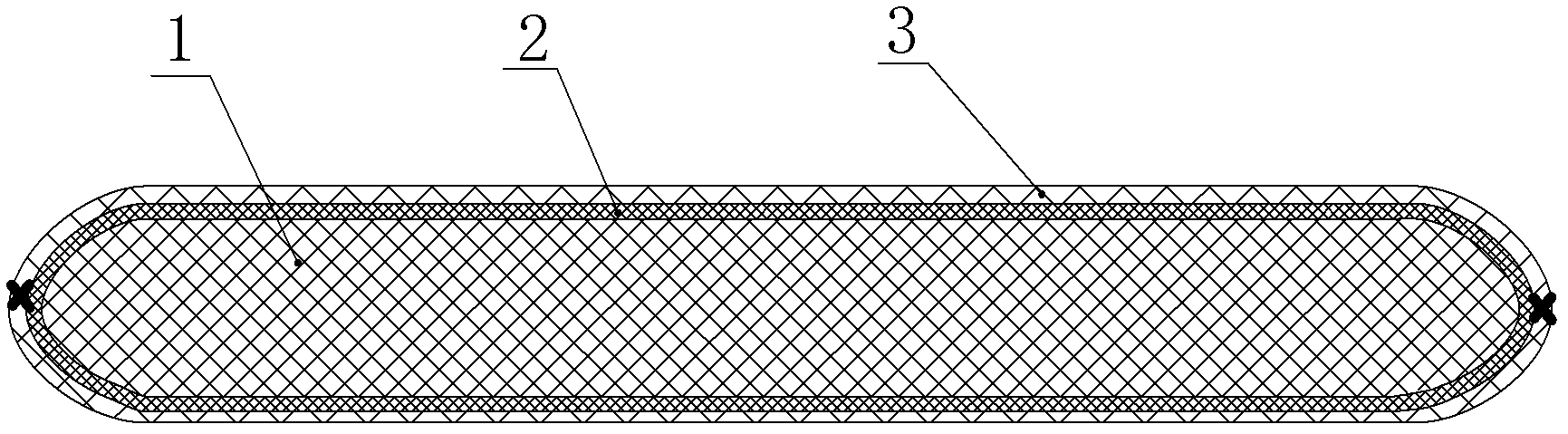

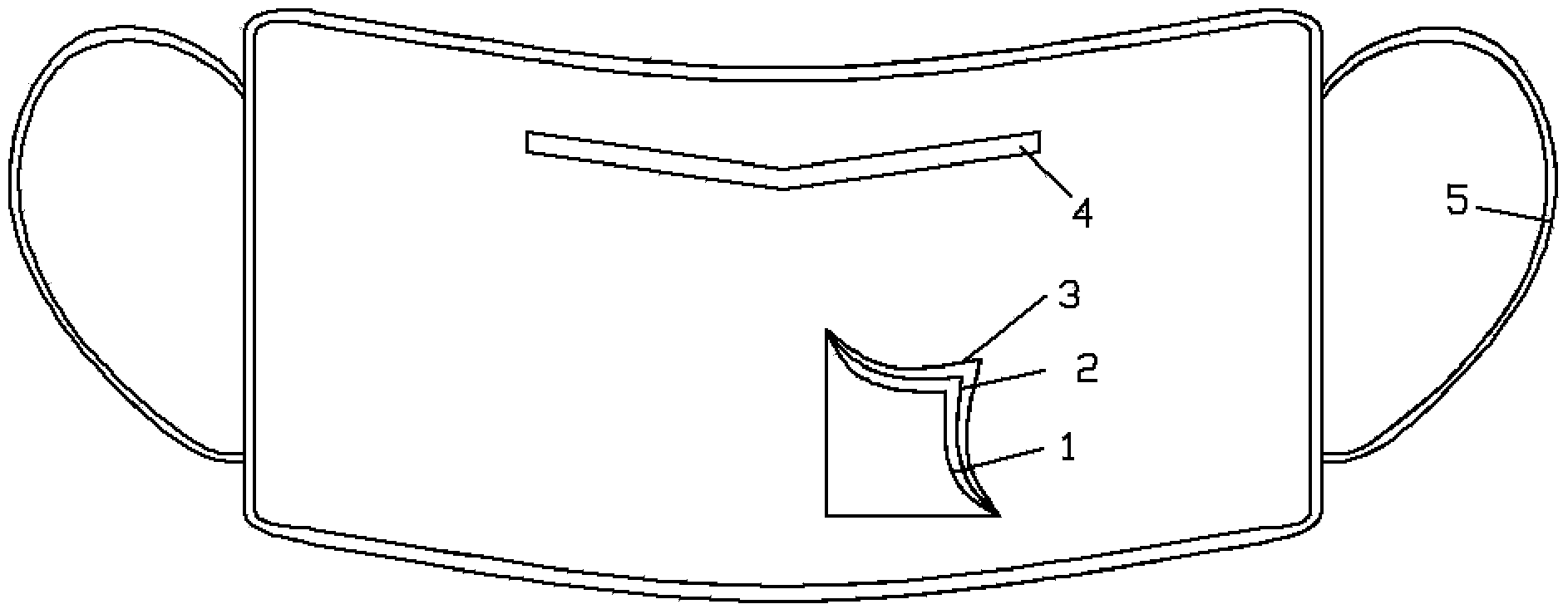

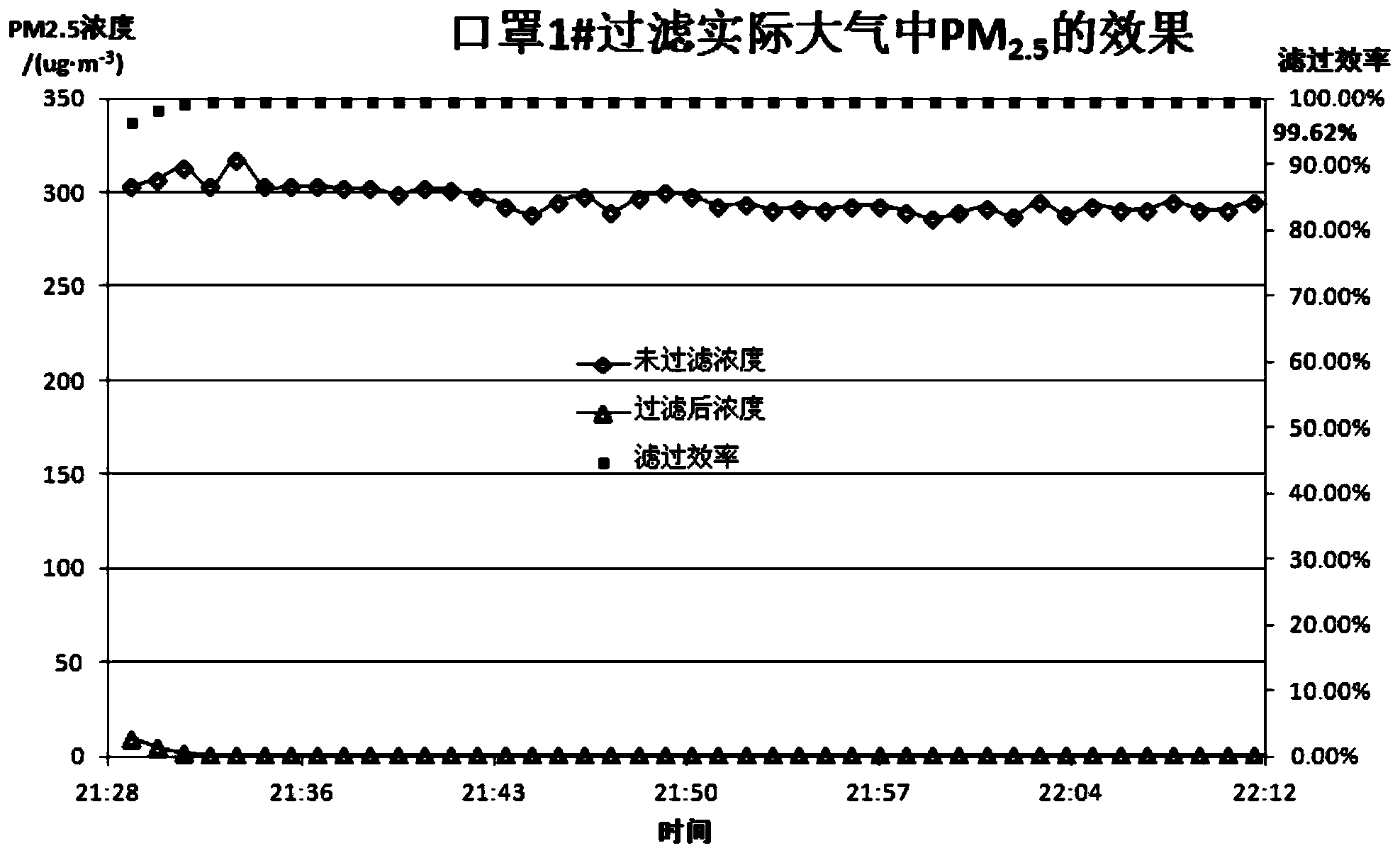

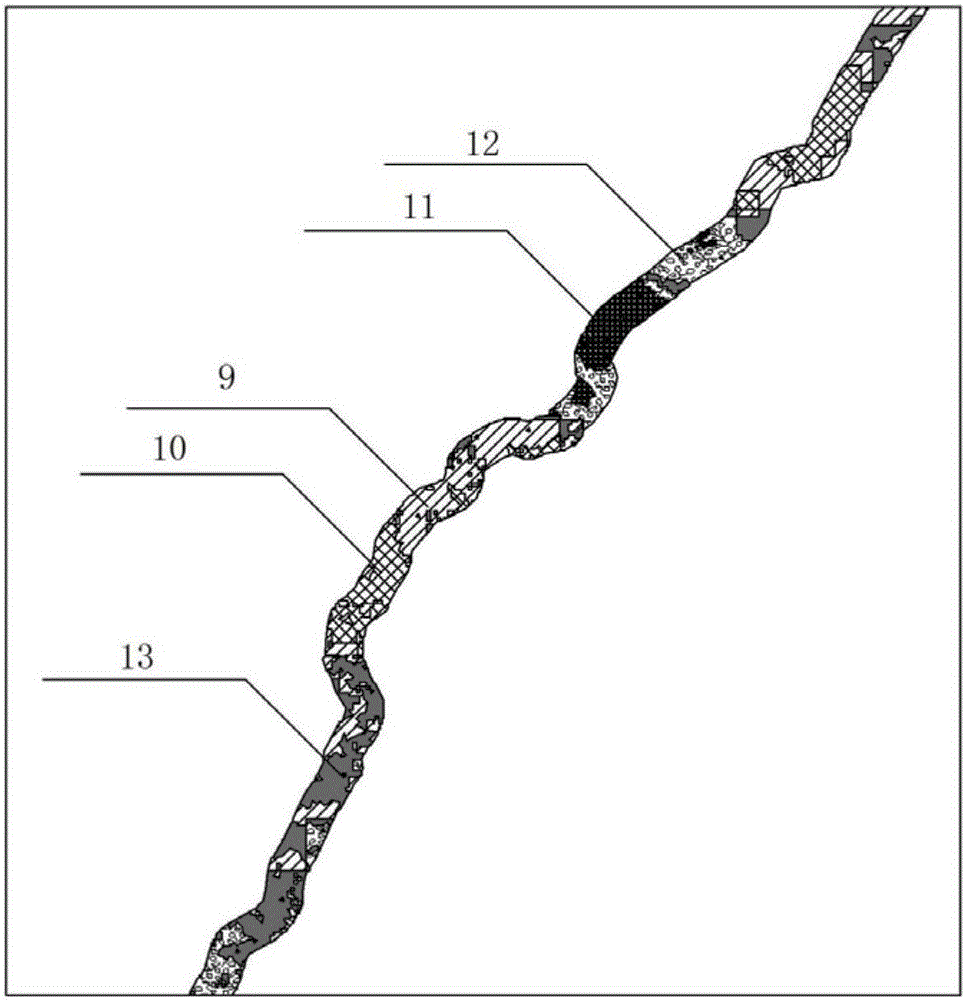

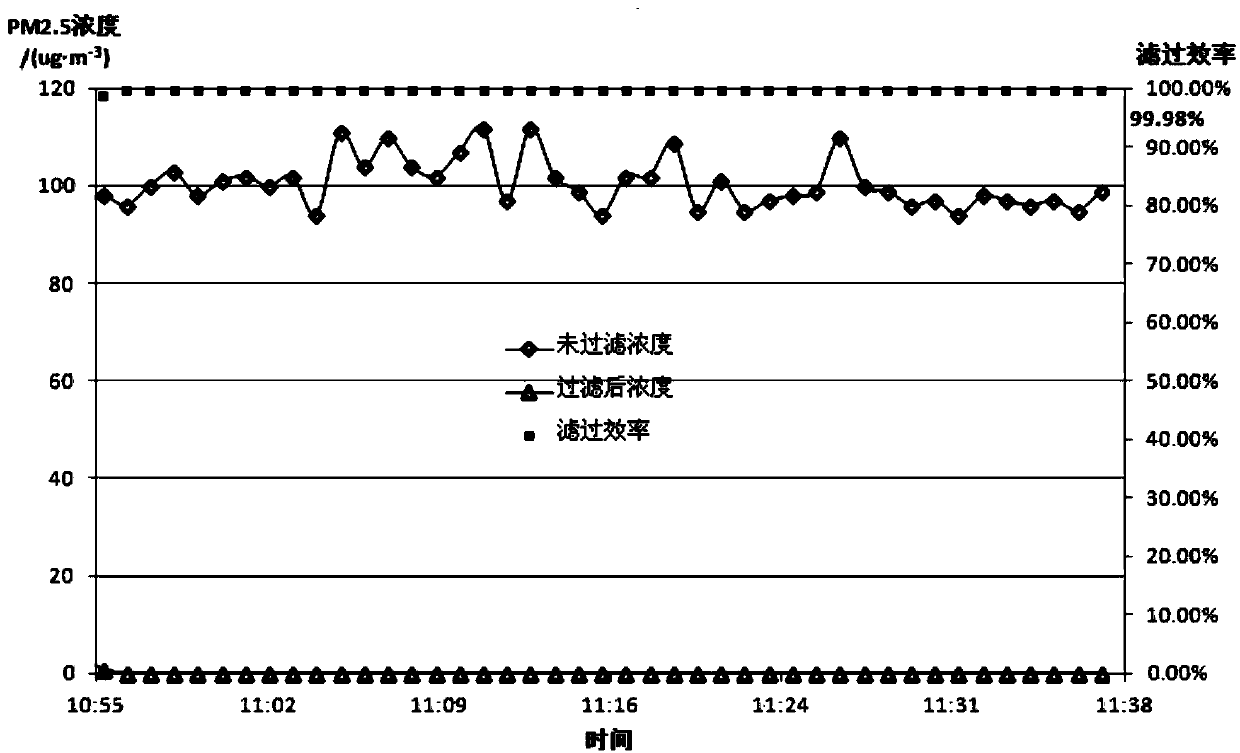

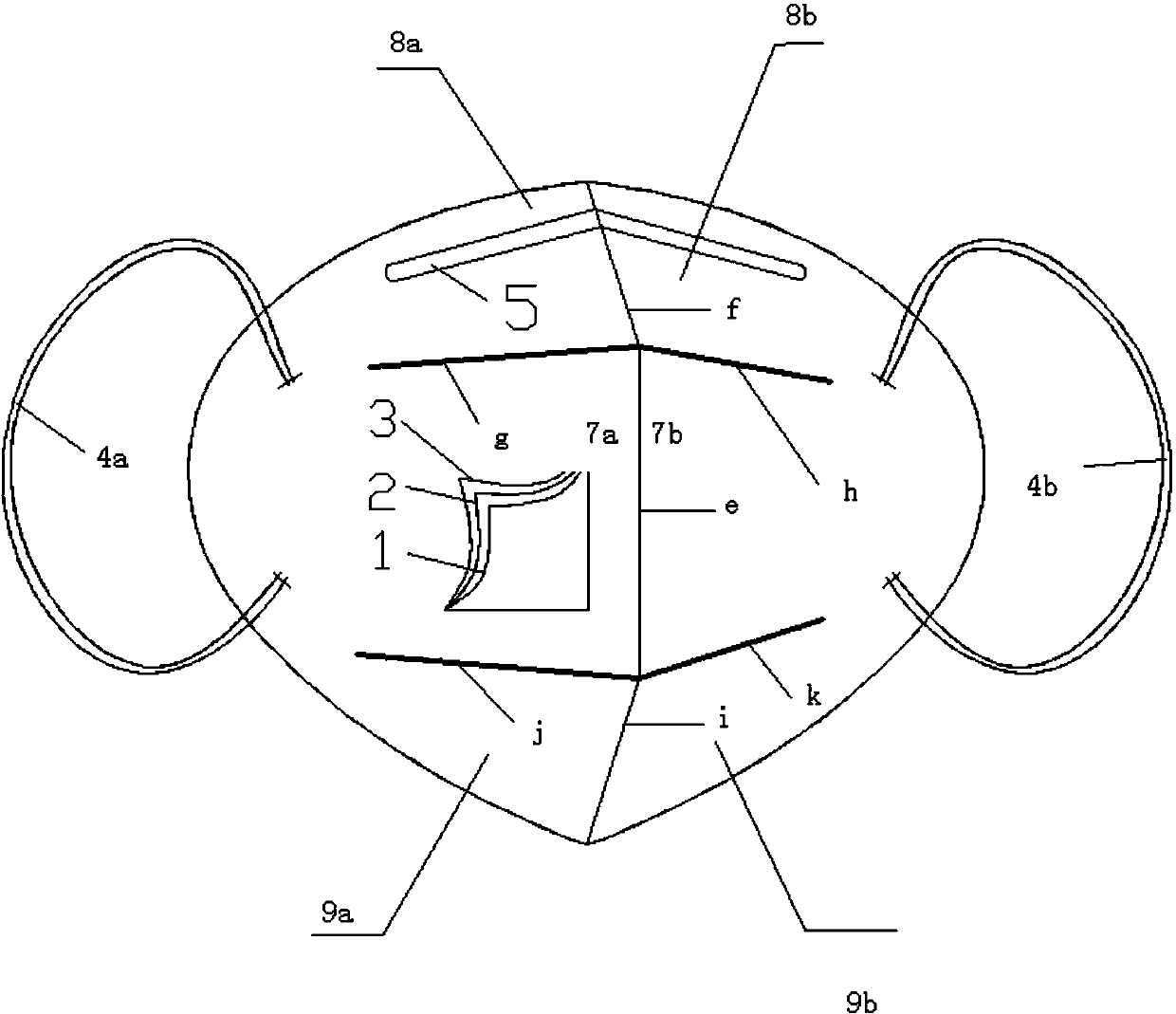

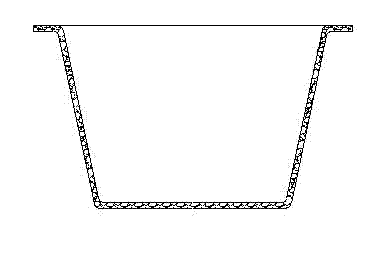

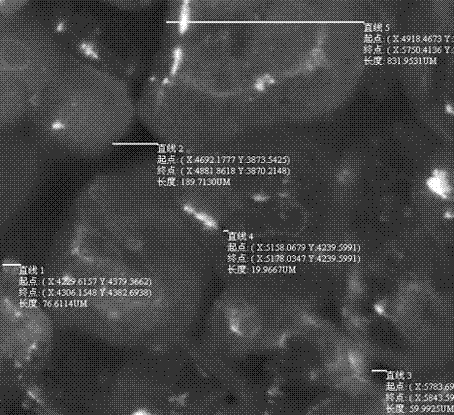

Planar mask for efficiently filtering PM 2.5

InactiveCN103637431AGood wearing feelingGood air permeabilityProtective garmentWoven fabricEngineering

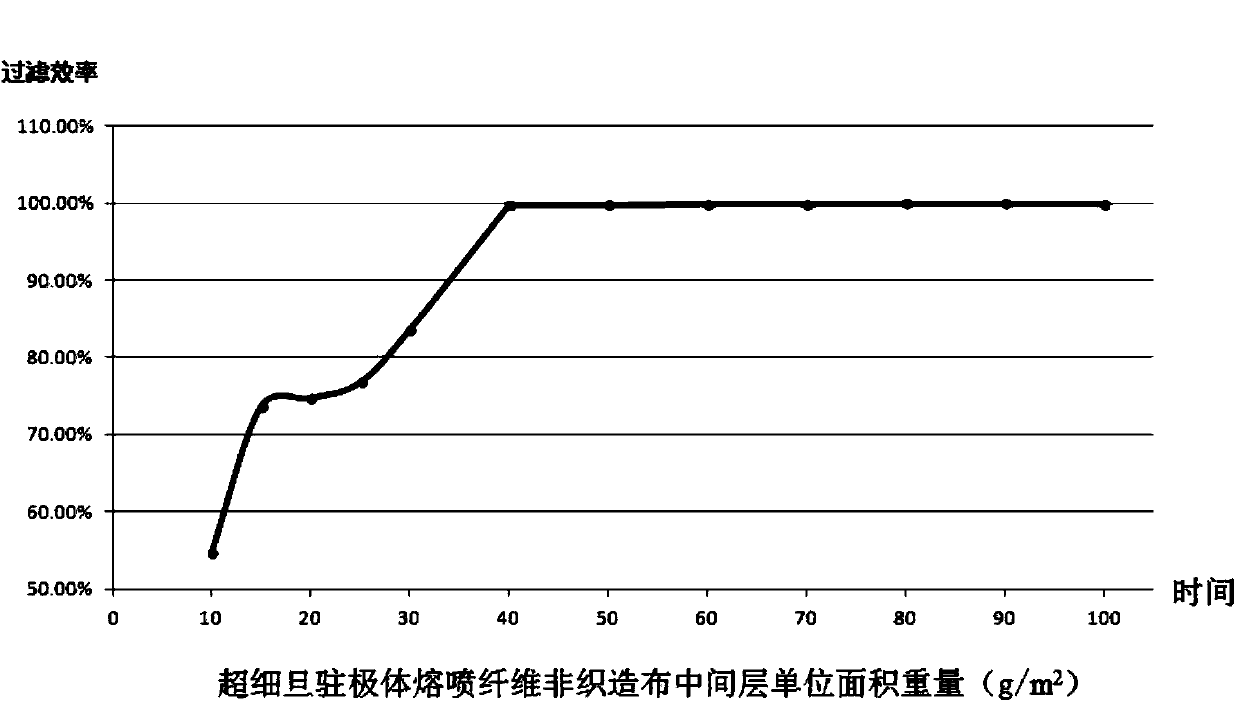

The invention relates to a planar mask for efficiently filtering PM 2.5. The planar mask comprises a mask body used for covering the mouth and the nose of a wearer. A pair of ear hooking portions are formed on the two sides of the mask body in an extending mode and used for being hooked on the ears of the wearer. The mask body is of a three-layer structure in a stacked mode, and the three-layer structure comprises a polypropylene fiber spunbonded non-woven fabric outer layer, a superfine fiber electret melt-blown non-woven fabric middle layer and a polypropylene fiber spunbonded non-woven fabric inner layer in sequence from outside to inside. The weight per unit area of the superfine fiber electret melt-blown non-woven fabric middle layer is 20-60g / m<2>. The planar mask for efficiently filtering the PM 2.5 has the advantages of being high in filtration rate and low in choked flow, has prominent obstruction and capturing capability for the PM 2.5 and is good in breathability, low in weight, comfortable to wear and high in PM 2.5 filtering efficiency in high level. The filtering efficiency can reach up to more than 99%, the weight is low, and breathability and comfortable sensation of the mask are ensured at the same time.

Owner:SHANDONG UNIV

Sand-stabilizing planting method

ActiveCN102763532AReduce irrigation water lossExtended growth cycleReceptacle cultivationOrganic fertilisersThermal insulationRoot system

The invention relates to a sand-stabilizing planting method, in particular to a sand-stabilizing planting method for sand stabilization and greening transformation of deserts. The sand-stabilizing planting method includes: sand-stabilizing plants are planted in sand-stabilizing containers, the sand-stabilizing containers are embedded in sand to form gridded plant belts, pores allowing for passage of no water molecules but gas molecules are formed among waterproof breathable particles of the sand-stabilizing containers so that water retention is achieved to promote plant growth; and further, required plants can be planted in the gridded plant belts. The sand-stabilizing planting method has the advantages that sand stabilization and loss prevention are achieved, the sand-stabilizing plants and the plants are planted in the sand-stabilizing containers so that irrigating water loss can be reduced, thermal insulation, ventilation and water storage, and plant roots can be protected so as to increase plant survival rate.

Owner:内蒙古仁创沙产业有限公司

Turf protection utilization method

ActiveCN106416652AImprove targetingHigh feasibilityAgriculture tools and machinesHops/wine cultivationRoad engineeringEngineering

A turf protection utilization method is provided for turf protection utilization programming and planning, and comprises the following steps: delimiting a turf protection level according to nature vegetation types and coverage; delimiting a vegetation retrieval level according to rainfall, temperature and soil factors; carrying out field investigation to check two said levels; superposing and delimiting a plurality of ecology control sections; determining the turf excavating technology according to the vegetation types and coverage in each ecology control section; selecting three protection technologies according to road engineering construction progress and turf utilization time intervals, wherein the three technologies include piled stacking, layered stacking, and skeleton layered temporary planting; determining three planting modes according to wind erosion and water erosion characteristics and propagation coefficients, wherein the three planting modes include a chessboard type, a tic-tac-toe mode and a bar stripped mode. The method can scientifically unify turf protection and utilization planning, storage and utilization, thus providing best ecology benefits; the turf protection utilization method is practical in applications.

Owner:CHINA ACAD OF TRANSPORTATION SCI

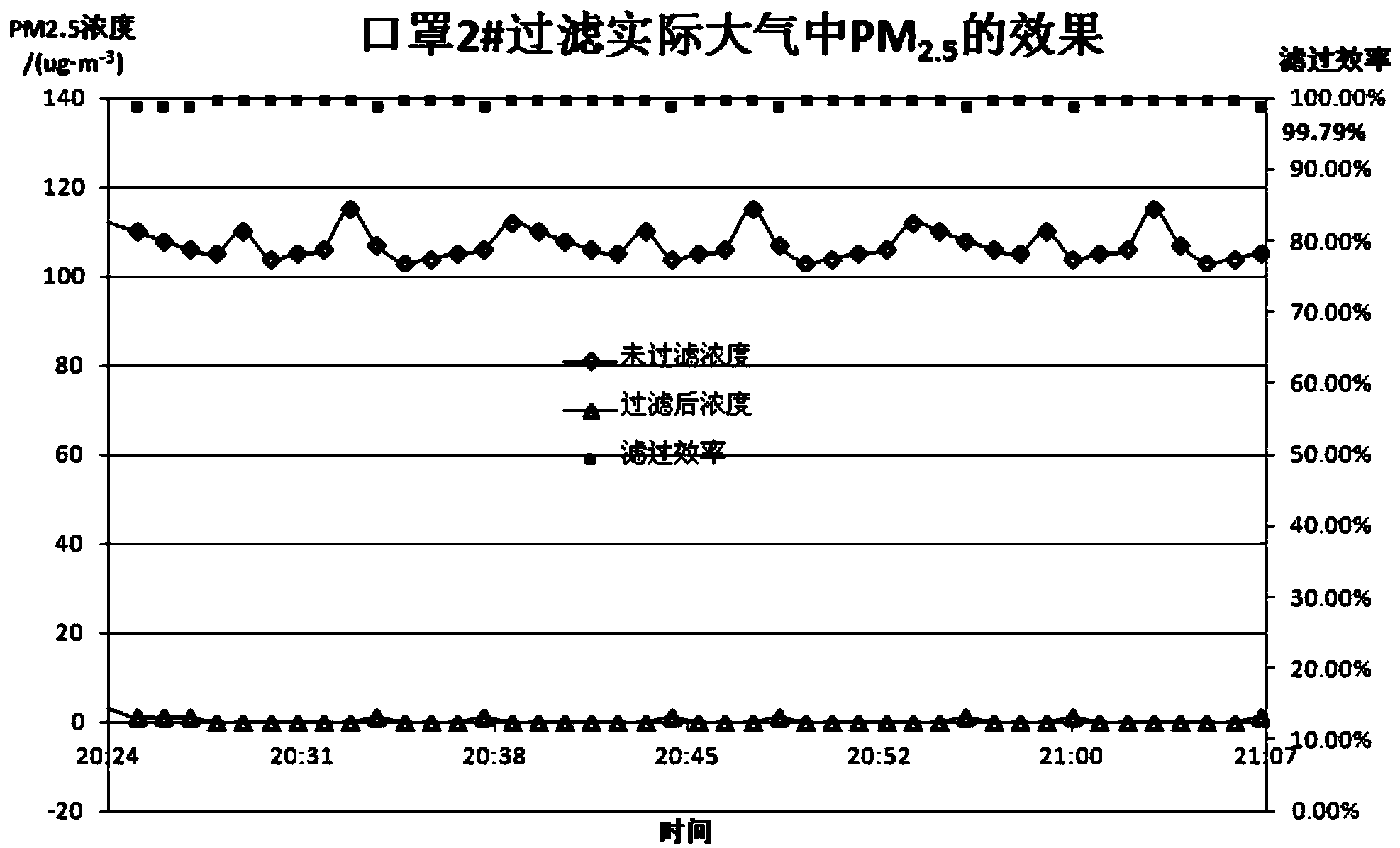

PM2.5C type mouth mask efficient in filtering

The invention relates to a PM2.5C type mouth mask efficient in filtering. The mouth mask comprises a mouth mask body, and the two sides of the mouth mask body extend out to form a pair of portions hung on ears. The mouth mask body comprises a left mouth and nose piece portion, a right mouth and nose piece portion, a left nose bridge piece portion, a right nose bridge piece portion, a left jaw piece portion and a right jaw piece portion, wherein the edge of the left nose bridge piece portion and the edge of the right nose bridge piece portion are combined, the mouth mask body is of a three-layer structure to form a laminated shape, and the weight of a middle layer made of ultra-fine electret melt-blown fiber non-woven cloth per unit area is 20-60g / m2. The PM2.5C type mouth mask efficient in filtering integrates air permeability, weight, wearing comfort and PM2.5 filtering efficiency of a mouth mask at a high level. The PM2.5 filtering efficiency of the mouth mask can reach more than 99% at most, the mouth mask is low in weight, and air permeability and comfort of the mouth mask are guaranteed at the same time. Water mist is prevented from being generated on lenses, warm air is prevented from accumulating on the inner side of the mouth mask, and bacteria are prevented from growing.

Owner:SHANDONG UNIV

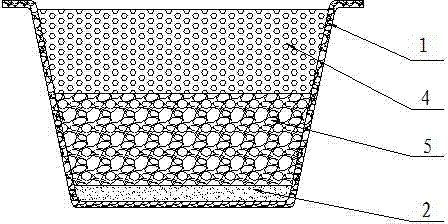

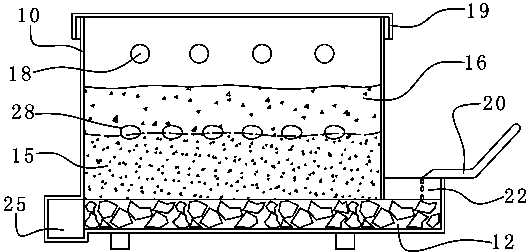

Anti-seepage air-permeable pot culture container and preparation method thereof

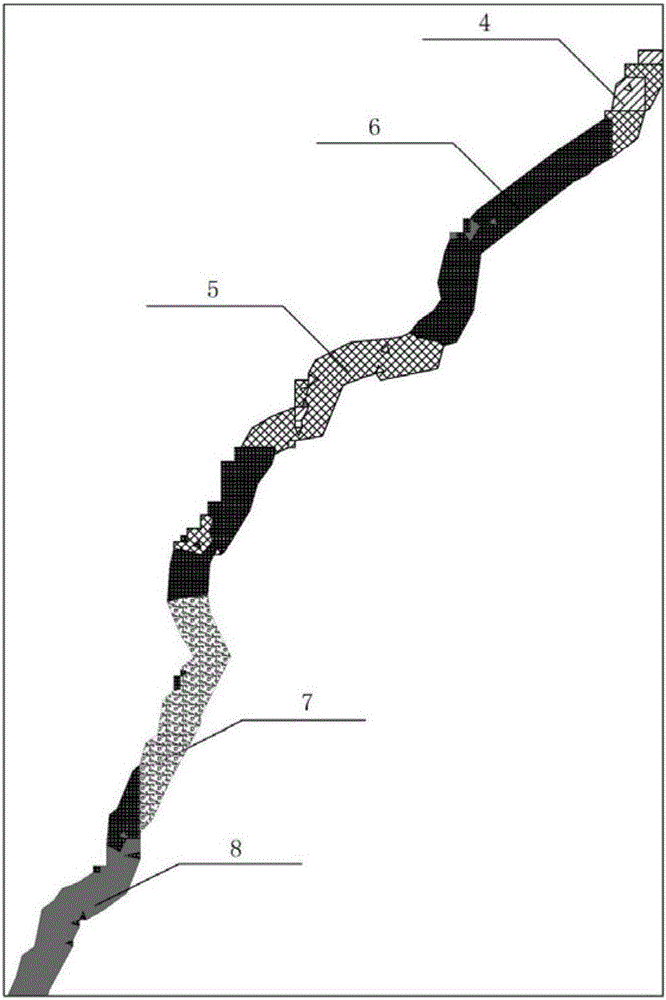

ActiveCN102475041APrevent extravasationGuaranteed breathabilityReceptacle cultivationLiquid waterPhysical chemistry

The invention relates to an anti-seepage air-permeable pot culture container. The pot culture container is provided with an open cavity, aggregate particles and water-repellent binder are stuck together to form the pot culture container, and pores through which air molecules rather than liquid water molecules can pass are formed between the neighboring aggregate particles. The aggregate particles are one of quartz sand, slag, ceramsite and glass beads or the mixture of any of quartz sand, slag, ceramsite and glass beads. The invention also discloses a preparation method for the anti-seepage air-permeable pot culture container. Since the invention applies the material with good anti-seepage and air-permeable properties to the pot culture container, the moisture for pot culture is effectively retained, so that the moisture needed by a plant is maintained, and moreover, while proofing water, the pot culture container also has the air-permeable property. The anti-seepage air-permeable pot culture container can be widely applied to the plantation of various potted plants, garden nursery transplantation and the plantation of crops in arid regions.

Owner:BEIJING RECHSAND SCI & TECH GRP

Double-layered composite biological dressing and adhesive-free compound technology thereof

ActiveCN104189945AGuaranteed breathabilityGuaranteed comfortAbsorbent padsBandagesFreeze-dryingBiological dressing

The invention provides a double-layered composite biological dressing and an adhesive-free compound technology thereof. The double-layered composite dressing comprises a chitosan fiber non-woven fabric layer and a spongy-shaped functional layer, wherein no adhesive is needed to bond the two layers. The preparation technology comprises the following steps: (1) chitosan fiber non-woven fabric is pre-cooled; (2) macromolecule chitosan, macromolecule collagen protein, micromolecule collagen protein and micromolecule chitosan in mass ratio of 0.7-1.3 to 0.1-0.3 to 0.7-1.3 to 0.1-0.3 are added in a faintly acid aqueous solution to prepare a spongy layer material solution; (3) the pre-cooled chitosan non-woven fabric is taken out and the spongy layer material solution is rapidly and uniformly sprayed on the non-woven fabric, wherein the spraying amount is 20-60 ml / 20*20 cm<2>; (4) the chitosan non-woven fabric sprayed with the spongy layer material solution is freeze-dried. The prepared double-layered composite dressing is firm in embedding connection between the two layers; the spongy functional layer has the function of promoting wound healing and prevents adhesion; the chitosan fiber non-woven fabric layer has the functions of favorable air permeability, comfort and bacterium resistance.

Owner:FUZHOU UNIV

Non-woven fabric with high elasticity and manufacturing method for same

InactiveCN107700076AIncrease elasticityImprove mechanical propertiesMelt spinning methodsConjugated synthetic polymer artificial filamentsElastomerPolymer science

The invention relates to a non-woven fabric with high elasticity and a manufacturing method for the same. The non-woven fabric is composed of the following raw material according to weight by percentage: 2 to 3% of polypropylene, 1 to 3% of slipping agent and the rest of polyolefin elastomers. Polypropylene, polyolefin elastomers and the slipping agent are selected for raw material of the non-woven fabric; the slipping agent can be composed of erucamide or oleamide; with the slipping agent, the raw material can be smoothly delivered after melting and extrusion and melt body viscosity can be reduced; material flowing property can be improved and adhesion between products cannot be produced; the non-woven fabric with high elasticity is produced via extrusion spinning technology parameters; the non-woven fabric obtained by the method has high elasticity and other kinetic performance; original non-woven fabric ventilating property can be maintained, smooth, soft and adhesive hand feeling can be achieved; and inadequate elasticity of the non-woven fabric can be overcome.

Owner:浙江吉和卫生材料有限公司

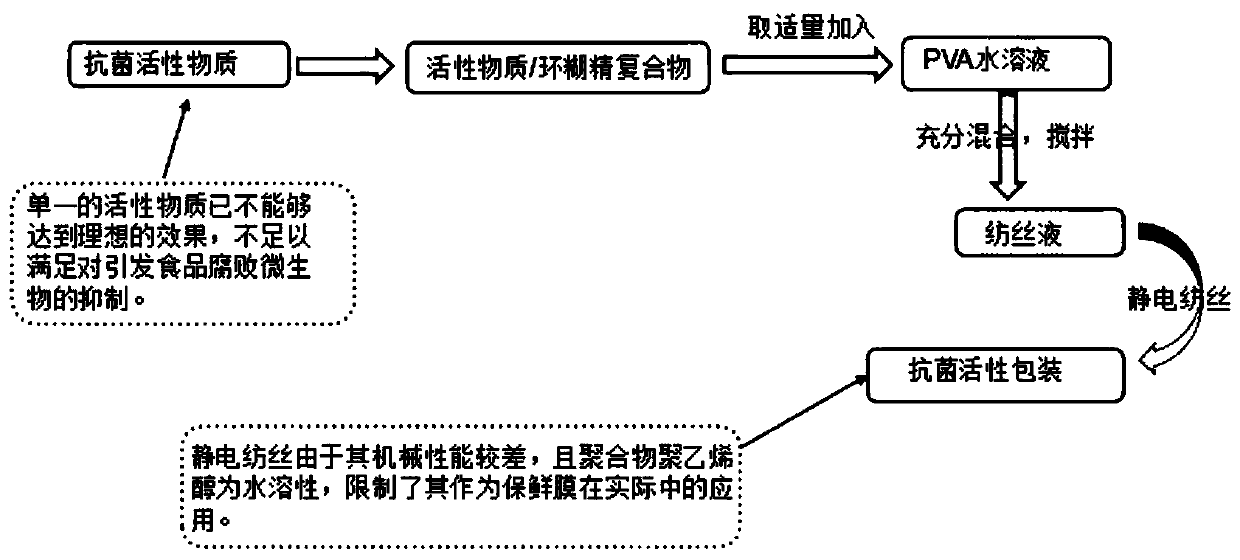

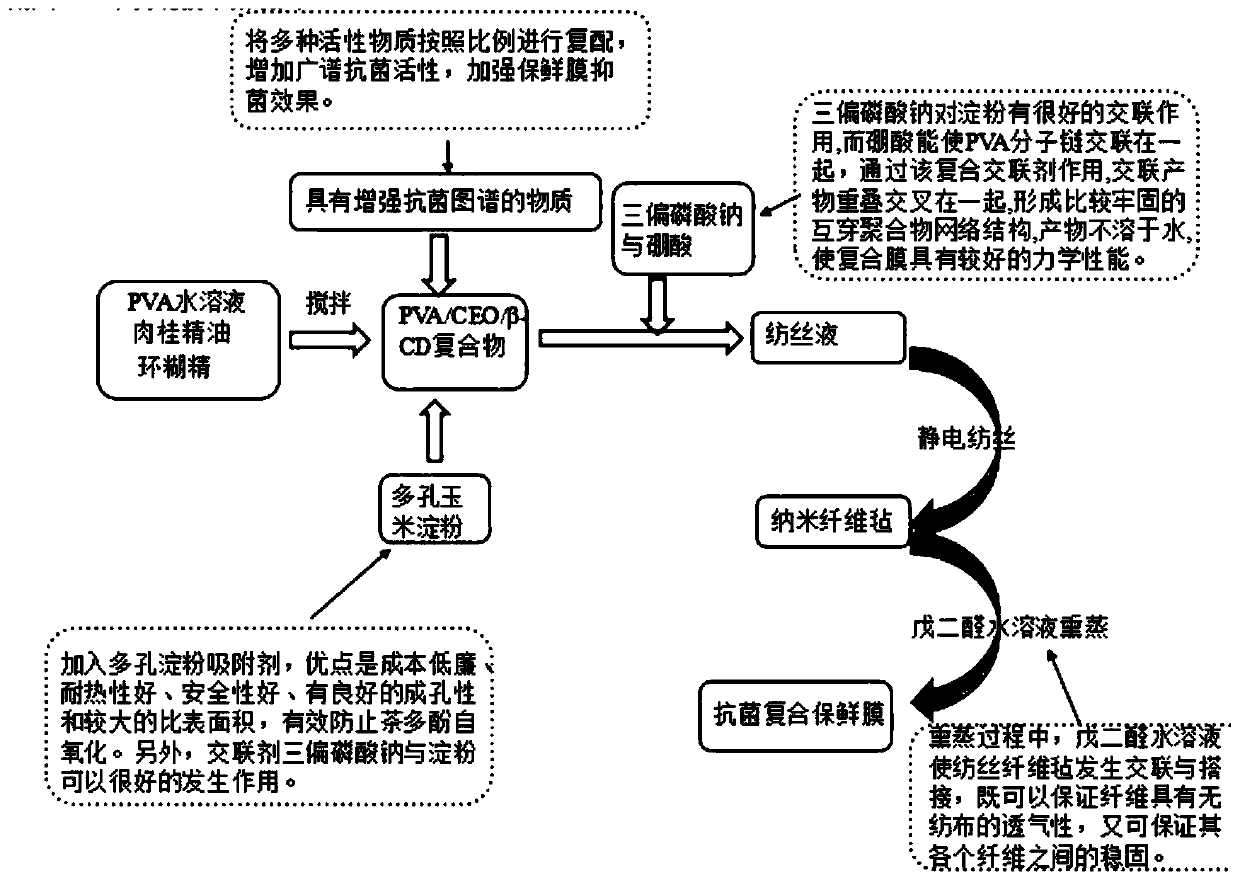

Preparation method of enhanced bacteriostatic and breathable composite fiber electrostatic spinning membrane

InactiveCN109881369AImprove the preservation effectExtended shelf lifeFibre typesMonocomponent synthetic polymer artificial filamentFiberCyclodextrin

The invention provides a preparation method of an enhanced bacteriostatic and breathable composite fiber electrostatic spinning membrane. The preparation method includes the following steps that 6-8 parts of polyvinyl alcohol are weighed and dissolved in 100 parts of 60-80 DEG C deionized water, and a PVA water solution is prepared; (2), 4 parts of active bacteriostatic substances are added into the PVC water solution, the active bacteriostatic substances are formed by mixing cinnamon essential oil, allicin, tea polyphenol and thyme essential oil according to the mass ratio of (2-4):(1-3):(0.5-2.5):(0.4-2.4), then 0.5-1.5 parts of cyclodextrin and 1-3 parts of corn porous starch are added, after the materials are fully mixed and stirred for 5-8 hours, 5-10 parts of sodium trimetaphosphateand boric acid complex are added for crosslinking, the sodium trimetaphosphate and boric acid complex is formed by compounding sodium trimetaphosphate and boric acid at the mass ratio of 4:5 until thesolution is uniform, and a spinning solution is obtained; (3), the spinning solution is arranged on an electrostatic spinning machine for spinning, and a spinning membrane is obtained; (4), the spinning membrane is subjected to glutaraldehyde fumigation crosslinking, and after the spinning membrane is dried in the air, the composite fiber electrostatic spinning membrane is obtained.

Owner:ZHEJIANG UNIV OF TECH

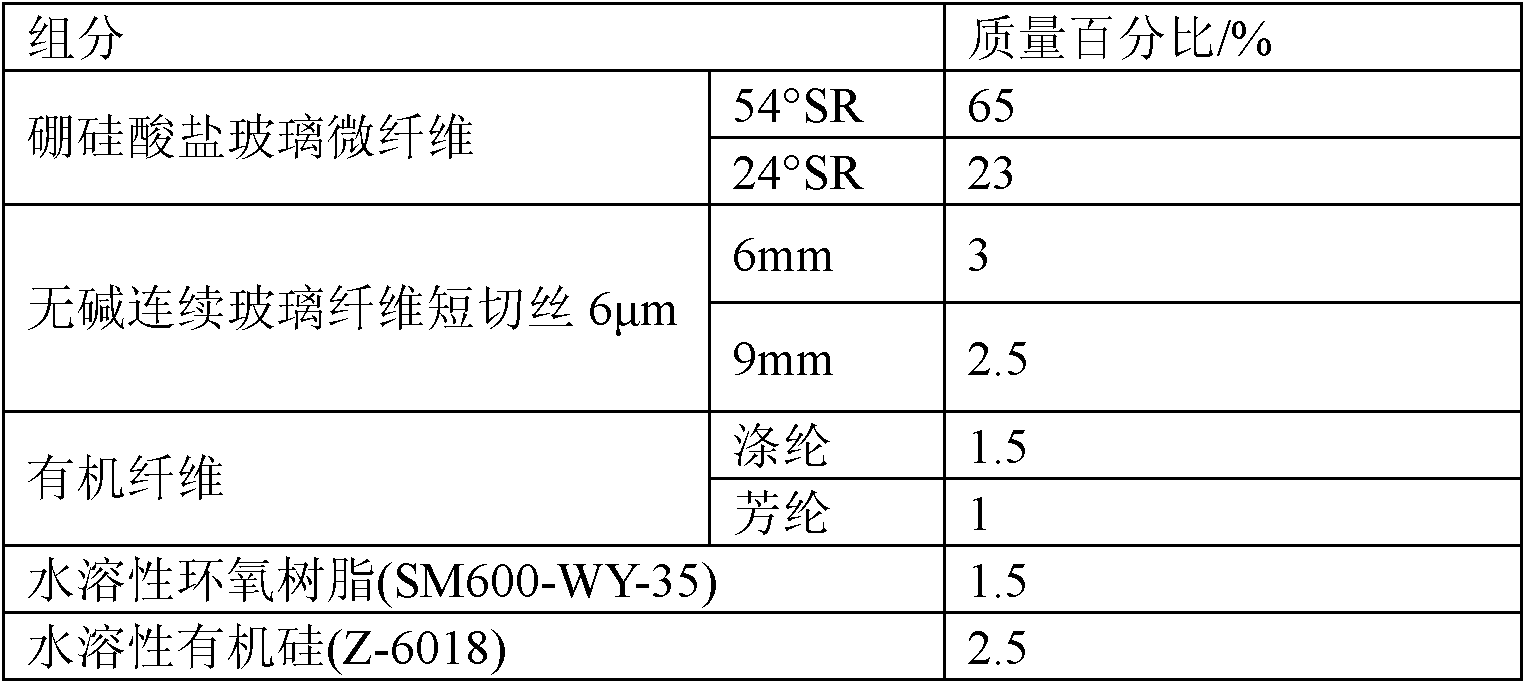

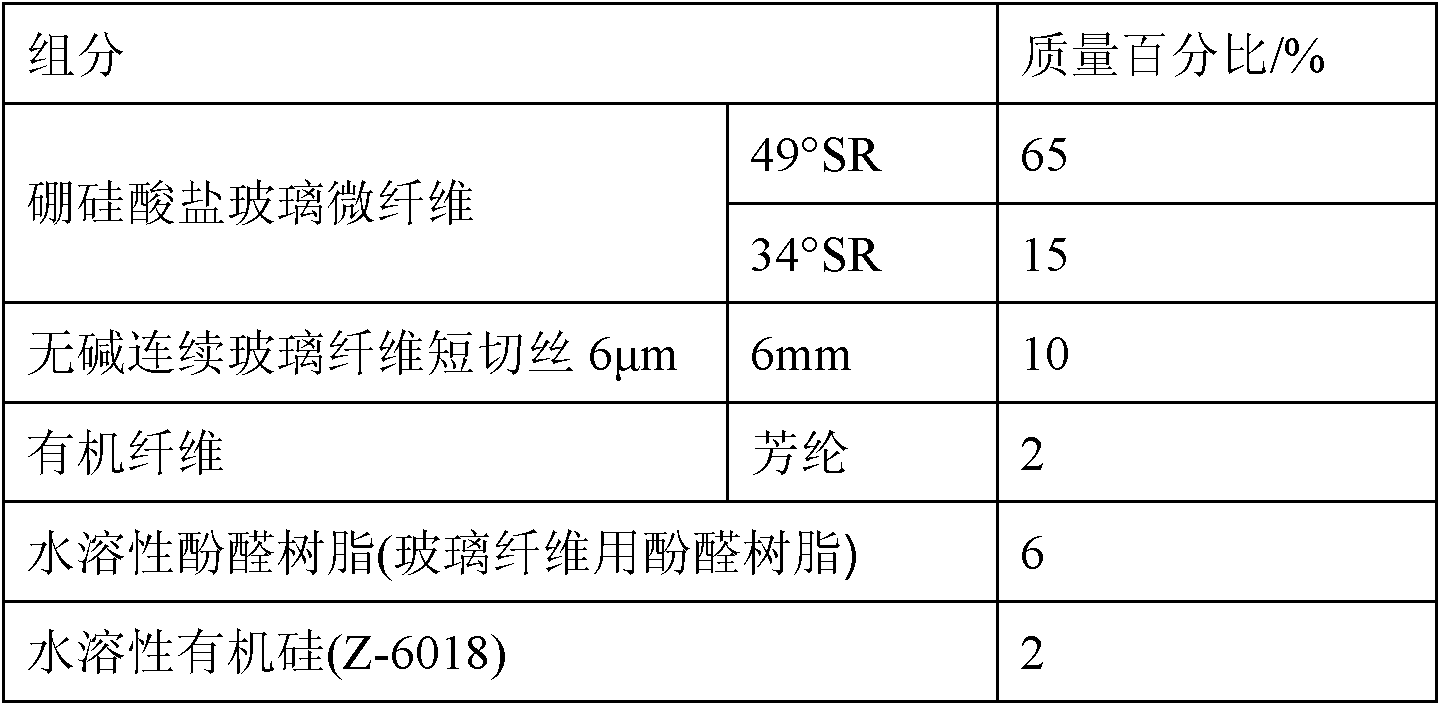

No-baffle high-temperature-resistant air filter paper and preparation method thereof

InactiveCN102505571AImprove filtration efficiencyHigh tensile strengthSynthetic cellulose/non-cellulose material pulp/paperFiltration separationEpoxyAcrylic resin

The invention relates to no-baffle high-temperature-resistant air filter paper and a preparation method thereof. The no-baffle high-temperature-resistant air filter paper comprises a glass fiber air filter layer and a resin layer formed on the surface of the glass fiber air filter layer, wherein the glass fiber air filter layer is formed by mixing the following materials in percentage by mass: 70-98% of borosilicate glass microfiber, 1-20% of no-alkali continuous glass fiber chopped strand and 1-10% of organic fiber; the resin layer is a water-soluble resin layer resistant to the temperature of 200-350 degrees centigrade and is formed by the way of mixing one or any two of water-soluble acrylic resin emulsion, water-soluble polyvinyl acetate emulsion, water-soluble phenolic resin emulsion, water-soluble organic silicon resin emulsion, water-soluble epoxy resin emulsion and water-soluble polytetrafluoroethylene emulsion in a volume ratio of 1:10 to 10:1, uniformly spraying or overflowing to the glass fiber air filter layer and drying, wherein the mass of the resin layer is 3-10% of that of the glass fiber air filter paper. The no-baffle high-temperature-resistant air filter paper provided by the invention has relatively high filter efficiency and relatively good high temperature resistance.

Owner:SINOMA SCI & TECH

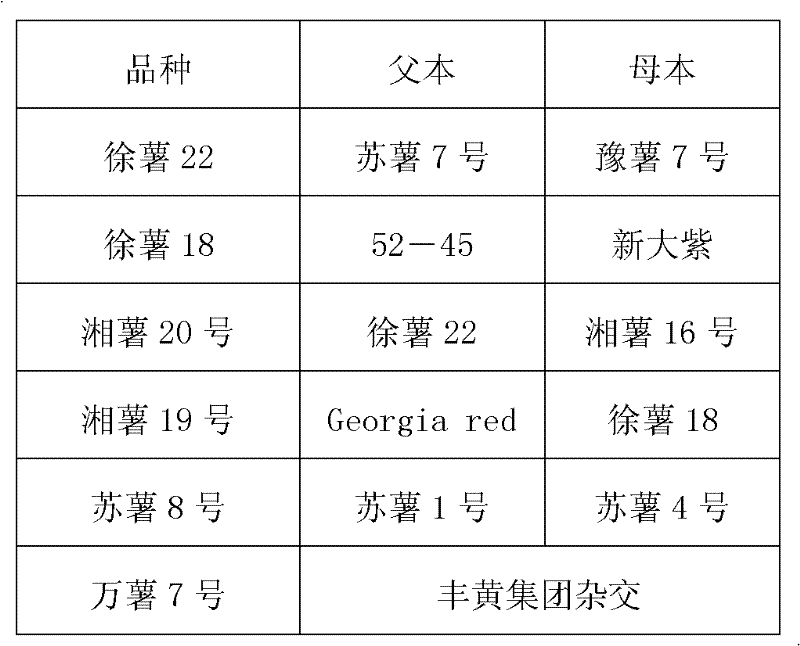

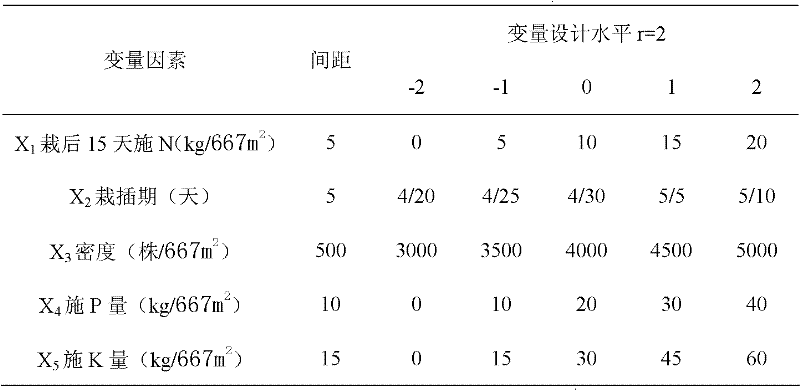

Sweet potato cultivation method in hills and mountains

The invention discloses a sweet potato cultivation method in hills and mountains, comprising the following steps of: A, selecting variety; B, raising seedlings: the seeding time is in March, the seeded potatoes are oblique in rows with head up and tail down, plant ash is covered after seeding, fine soil is covered, dual gold herbicide and glyphosate are sprayed on the ridges, and mulching film is coated; C, planting: considering that the blocks in hills and mountains have different sizes, micro-ridge single-row planting is adopted, the planting time of spring potato is in April, the planting time of summer potato is in May, the head and the middle of seedlings are cut, oblique planting is adopted, soil is covered, and moisture supply is maintained after planting; D, applying fertilizer: sweet potato is potassium-liking crop and the applied fertilizer is mainly organic fertilizer; and E, intertilling, weeding and earthing up: intertilling has the effect on breathing and is performed after planting, the depth becomes shallow, and weeding and earthing up are combined with intertilling. The method is easy and simple to operate, adopts micro-ridge single-row planting, efficiently uses the soil, causes the seedbed to be insulated, prompts the potato tubers to sprout quickly and abundantly, simultaneously can inhibit occurrence of black spot, and increases the yield by 20-30%.

Owner:湖南省作物研究所

Method for cultivating dendrobe

InactiveCN1748455AGuaranteed healthy growthPromote reproductionHorticulture methodsLiving treeNutrient solution

The dendrobe cultivating method is to fix live dendrobe on plant of live tree stem and bamboo or stump with bark, irrigate, apply nutritious liquid and provide shady and cool environment for dendrobe to grow. The said method provides moist growth environment, reduce disease and ensure healthy growth of dendrobe. In addition, the present invention can utilize space fully to lower the dendrobe cultivating cost.

Owner:刘俊

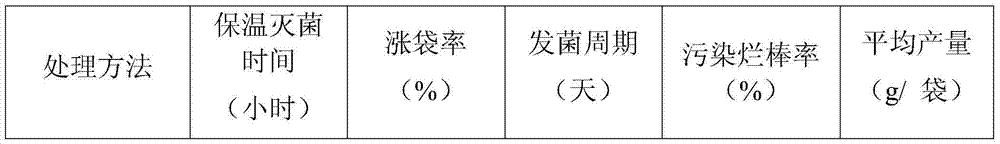

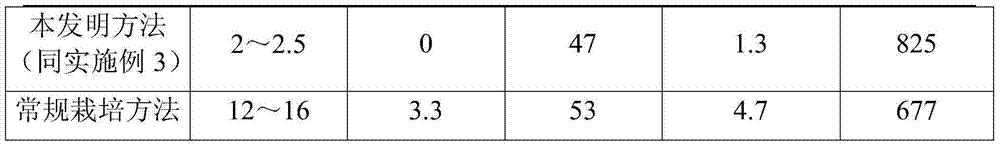

Method for improving preparing efficiency and yield and quality of shiitake sticks

ActiveCN104322276ASolve crackingSolve the scrapping problemCultivating equipmentsMushroom cultivationFisheryEdible mushroom

The invention discloses a method for improving preparing efficiency and yield and quality of shiitake sticks, and belongs to the production technical field of edible mushrooms. The method comprises the steps of (1) preparing cultivation inner bags; (2) preparing charge bars: 1) preparing a culture material and packaging the material into bags, and 2) sterilizing the charge bars; (3) inoculating and cultivating mushroom sticks: 1) preparing and inoculating a strain, 2) spawn running and cultivating the mushroom sticks, and 3) performing color change management for the mushroom sticks; (4) performing inducement for fruiting shiitakes, harvesting the shiitakes and changing dampness and the like. Compared with conventional cultivation method, the method has the characteristics of being obviously reduced in labor amount, simple in process and low in bag swelling up rate and stick polluted and rotten rate; the spawn running period is shortened to about 6 days; the average yield can reach 825 g / bag and is increased by 21.86%.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

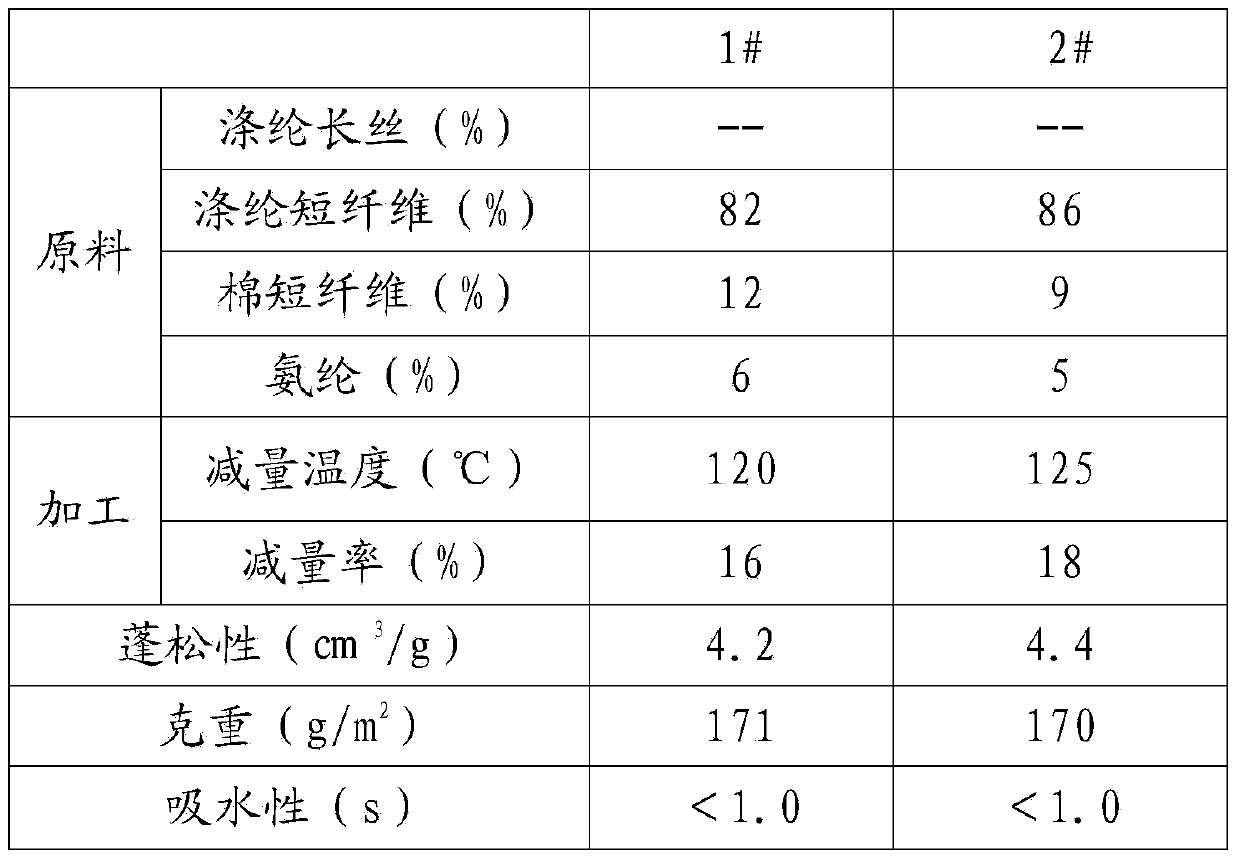

Knitted fabric and production method thereof

The invention provides knitted fabric. The knitted fabric is characterized in that the knitted fabric is composed of polyester staple fibers, cotton fibers and spandex, and the weave of the knitted fabric is fish scales and the derivative weave of the fish scales, wherein the content of the polyester staple fibers is 80% of the total mass of the fabric. In the process of knitting cloth with the knitted fabric, the temperature and the time of knitting, pre-shaping, refining, alkali peeling, dyeing, settling and shaping and other stages are limited, and therefore the elasticity, the air permeability, the comfort and the softness of the textile fabric are guaranteed.

Owner:上海缀菱纺织品有限公司

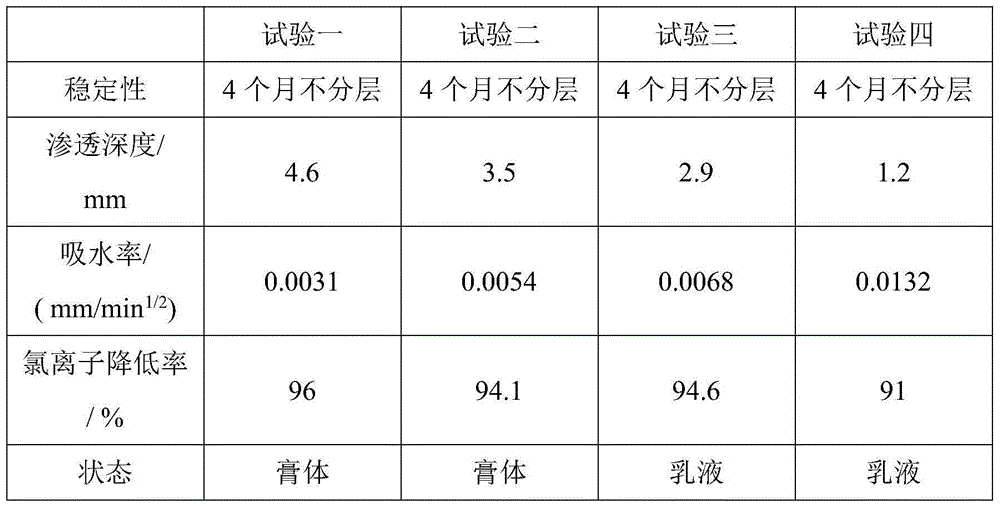

Preparation method for concrete silane paste impregnation waterproof agent

The invention provides a preparation method for a concrete silane paste impregnation waterproof agent, relates to a preparation method for an impregnation waterproof agent, and aims to solve the problems that the adhesion of existing liquid silane and silane emulsion is poor. The preparation method comprises the following steps: 1, weighing; 2, mixing to obtain a mixed solution; 3, performing initial reaction to obtain a reactant; 4, emulsifying to obtain the concrete silane paste impregnation waterproof agent. The preparation method has the advantages that the shortcoming of poor adhesion of liquid silane and silane emulsion is overcome, the construction is convenient, and multiple construction manners such as spraying, brushing and roll coating can be adopted for coating of vertical surfaces, so that the loss of active substances is reduced; the permeability of a pore structure of the material per se can be maintained; the waterproofness and permeability of the concrete silane paste impregnation waterproof agent are better than those of liquid silane and silane emulsion, the water absorption of a concrete structure can be reduced by 90% or above, the penetration depth of silane is increased, and silane can penetrate into the concrete surface at 3-4 mm. The method is mainly used for preparation of the concrete silane paste impregnation waterproof agent.

Owner:HARBIN INST OF TECH

Cultivation material composition for producing high-quality agaricus blazei and manure-free rice straw raw material cultivation method

InactiveCN102138441AReduce the problem of heavy metal cadmium content exceeding the standardGuaranteed breathabilityCultivating equipmentsSoilless cultivationPhosphoric acidMaterials processing

The invention discloses a cultivation material composition for producing high-quality agaricus blazei and a manure-free rice straw raw material cultivation method. The invention is characterized in that: the cultivation material composition comprises the following raw materials in part by weight: 1,000 to 1,500 parts of rice straw, 33 to 45 parts of ammonium bicarbonate, 35 to 45 parts of calciumsuperphosphate, 35 to 40 parts of gypsum and 34 to 50 parts of lime; and the rice straw raw material cultivation method comprises: raw material preparation and processing, namely primary fermentationof windrow, mushroom house selection and disinfection, secondary fermentation of culture materials on beds in the house, inoculation and culture, earthing and fruiting management, wherein the step ofraw material processing, namely primary fermentation, also comprises special pre-piling, pile building and pile turning. The method helps to effectively solve the problem that the content of heavy metals such as cadmium in the agaricus blazei exceeds a standard. Ammonium bicarbonate is used as a nitrogen source fertilizer in the cultivation materials, so damage caused by ammonia is prevented; theprocess is simple; the management is work-saving and labor-saving; the anlages of the agaricus blazei mushrooms is uniform and the mushroom shape is desirable; the yield and quality of the agaricus blazei mushrooms are high; and the artificial cultivation scale of the agaricus blazei can be enlarged.

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI

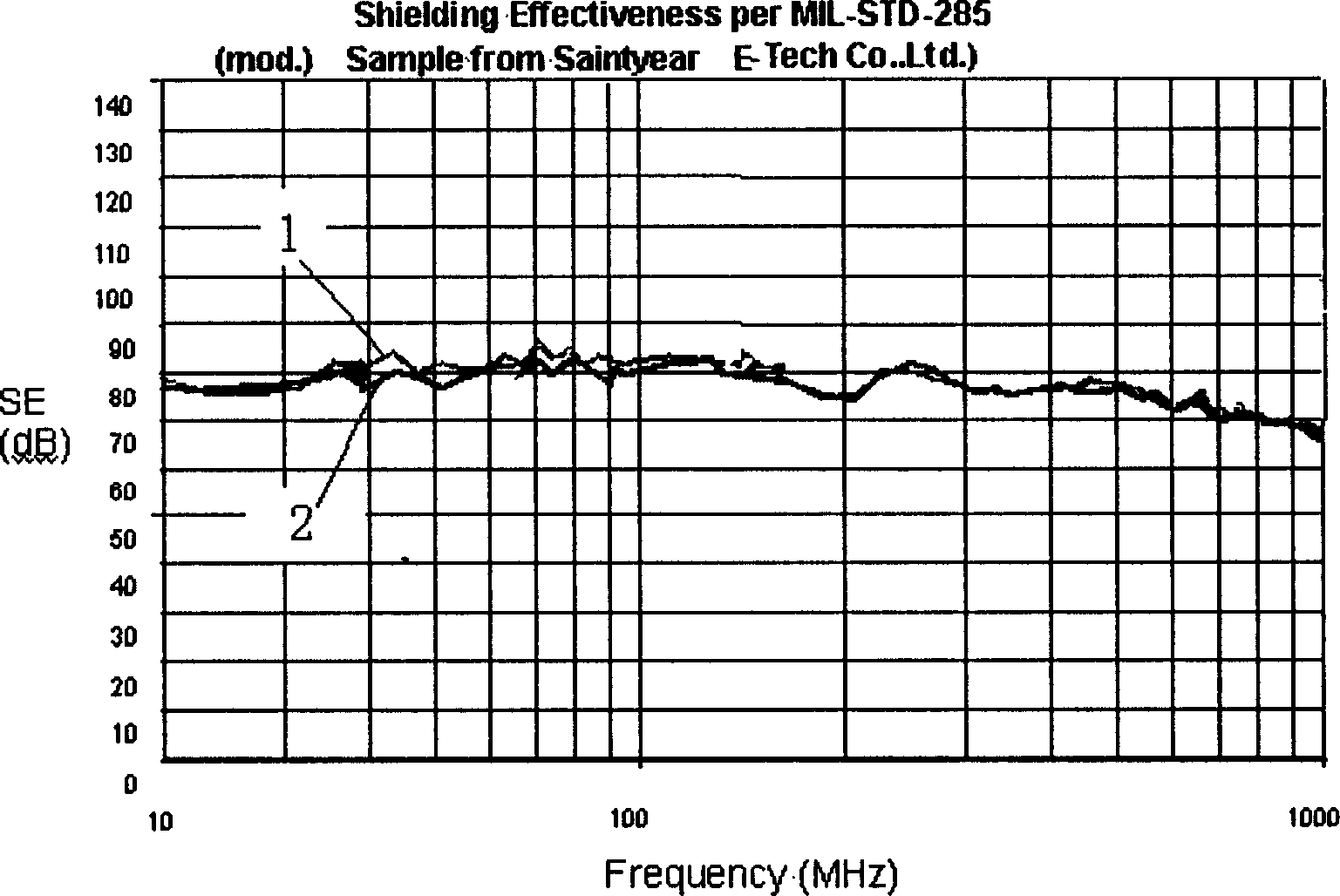

Copper-in-tin electromagnetic screen textile and method for preparing same

ActiveCN1621603AImprove conductivityEasy to brazeMagnetic/electric field screeningFibre treatmentCopper platingSulfur

The present invention is one kind of copper-in-tin electromagnetic shielding fabric and its preparation process. Onto the surface of non-metal fabric base fiber, metal copper is first plated chemically and tin is then electroplated to form composite conducting copper-tin film to obtain electromagnetic shielding fabric. The base fiber may be nylon, Dacron or orlon. The electromagnetic shielding fabric has high conducting performance, is weldble, flexible and ventilative, and can isolates sulfur in insulating material.

Owner:DONGHUA UNIV

Preparation method of biomass iron coke for blast furnace

InactiveCN108219807AImprove responseHigh strengthSpecial form destructive distillationHigh intensityComponents of crude oil

The invention discloses a preparation method of biomass iron coke for a blast furnace. The iron coke has the characteristics of high reactivity and high strength, and has a certain protective effect on original large blocks of coke, and meanwhile, the breathability of the blast furnace is maintained; the emission amount of CO2 can be reduced, and the production of the blast furnace can also be ensured; the iron coke prepared by the preparation method is low in energy consumption and low in investment; biomass coke is taken as a main raw material; the biomass coke is large in storage capacity and can be renewed, so that reasonable utilization of resources can be realized; the production cost is low; meanwhile, the problem that iron-making industry relies heavily on fossil energy is solved;according to the method, carbon-containing pellets can be produced, and dust, such as converter dust, blast furnace mash gas dust and sintering machine head dust, of an iron and steel plant can also be recycled; the production cost is reduced. The biomass components are superior to those of coal ash; clean production can be realized; energy conversation and emission reduction can be realized; low-sulphur low-phosphorus final products are obtained.

Owner:ANGANG STEEL CO LTD

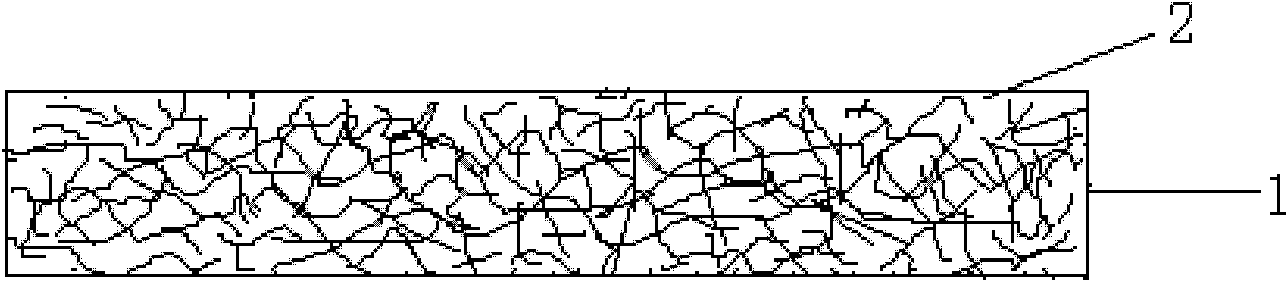

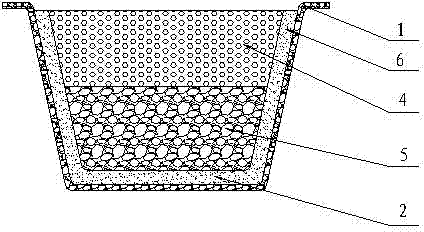

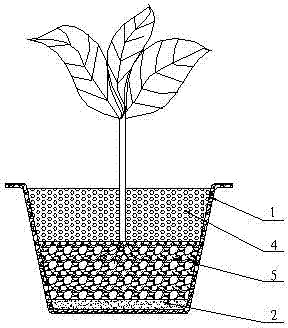

Potted planting container and potted plant

ActiveCN102475040APrevent extravasationGuaranteed breathabilityReceptacle cultivationPlant cultivationBotany

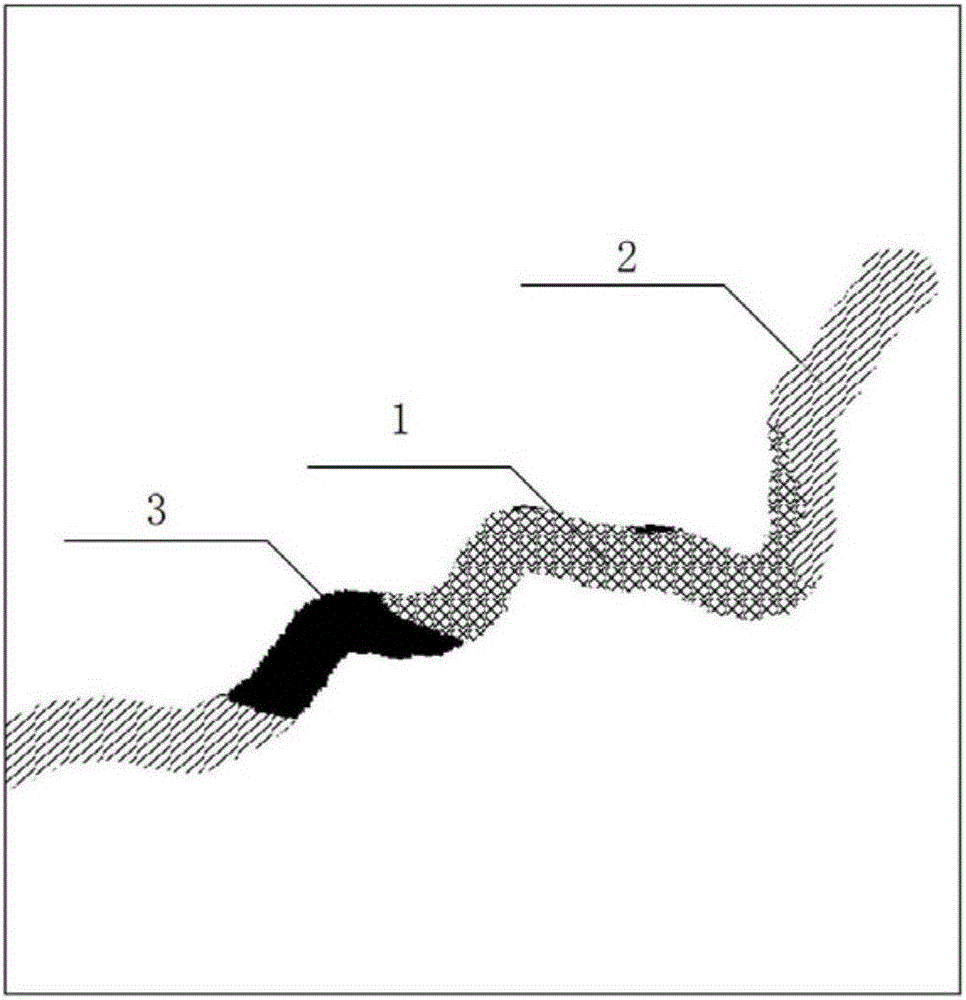

The invention relates to a potted planting container which comprises a potted container (1) with an opening, a bottom impermeable layer (2) and a planting layer. The bottom impermeable layer (2) is arranged at the bottom of the potted container (1). The planting layer is paved at the upper part of the bottom impermeable layer (2). A lateral impermeable layer (6) for preventing the side wall of the potted container (1) from being leaked out is paved between the lateral surface of the planting layer and the container wall of the potted container (1). The lateral impermeable layer (6) and the bottom impermeable layer (2) are waterproof breathable particle layers. According to the invention, due to the utilization of excellent seepage prevention and water retention performances of the impermeable layers, water permeating downwards in a potted plant is effectively prevented by the impermeable layers, water watered into a planting pot is prevented from flowing out of a pot bottom, and the moisture required in the plant is maintained. Moreover, the potted planting container has a breathable performance when having a waterproof performance. Meanwhile, the invention discloses the potted plant applying the potted planting container. The potted planting container is widely applied to plant cultivation, particularly cultivation of hydrophilous plants.

Owner:BEIJING RECHSAND SCI & TECH GRP

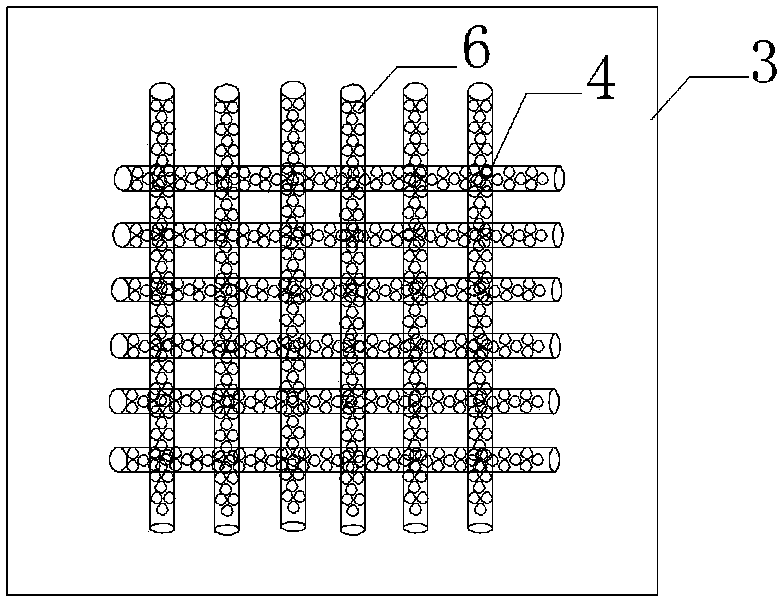

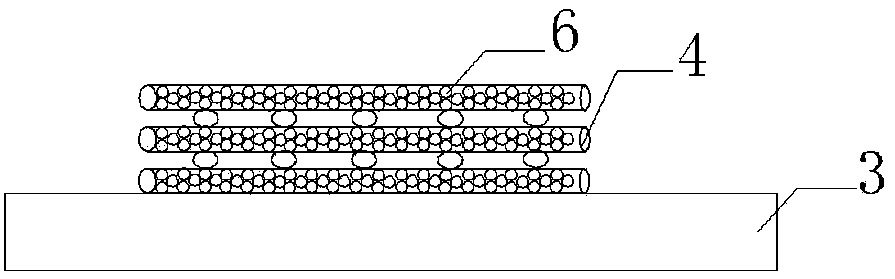

3D-printing wound dressing material based on silk microsphere bio-ink and preparation method thereof

ActiveCN107744601APromote recombinationGuaranteed mechanical propertiesAbsorbent padsMicrocapsulesWound dressingMicrosphere

The invention provides a 3D-printing wound dressing material based on silk microsphere bio-ink and a preparation method thereof. The preparation method includes the following steps: transferring silkmicrosphere bio-ink, which includes silk protein microspheres coating aspirin, silk protein water solution, ultraviolet initiator and polyvinyl alcohol ester, into a syringe of a 3D-printing machine;with a cotton gauze as a base printing cloth, printing the surface of the cotton gauze with the silk microsphere bio-ink according to a periodically circulated cross-network structure model; and rapidly curing and shaping the 3D-printing wound dressing material under ultraviolet irradiation. The product is based on 3D-printing technology, wherein the formed cross-network structure contains regularly arranged silk microspheres, and the silk microsphere bio-ink coating layer cures on the surface of the cotton gauze and does not completely penetrate through the cotton gauze. The 3D-printing wounddressing material has good mechanical performance and biocompatibility and excellent slow-release performance, can protect a wound for a long time and can accelerate healing of the wounding.

Owner:YANCHENG INST OF IND TECH

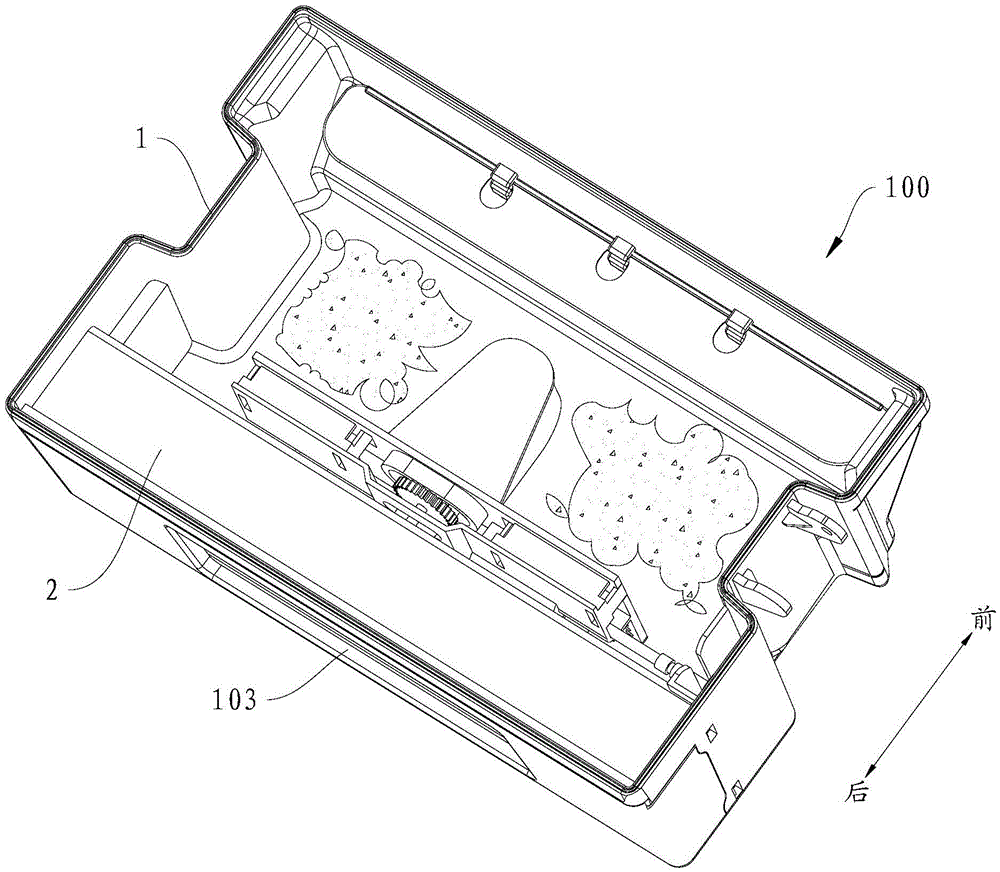

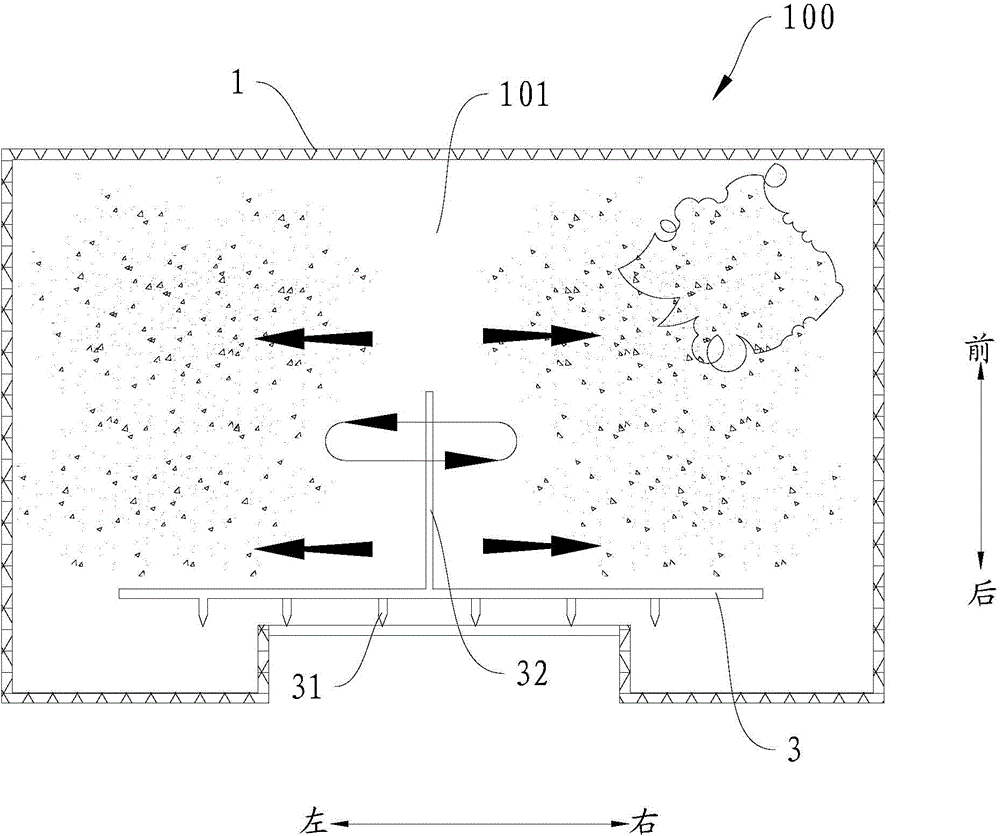

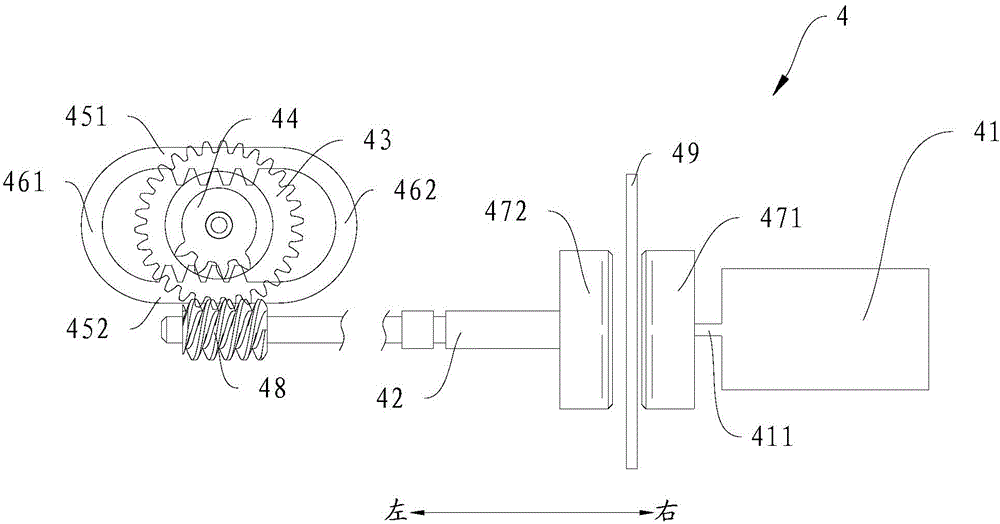

Intelligent dust collector and dust box assembly thereof

ActiveCN105078367AExtended use timeKeep breathableCleaning filter meansSuction filtersEngineeringReciprocating motion

The invention discloses an intelligent dust collector and a dust box assembly thereof. The dust box assembly of the intelligent dust collector comprises a dust box, a filter device, a dust scraper and a driving device. An accommodating cavity is formed in the dust box, a dust collecting opening which is communicated with the accommodating cavity is formed in the front wall of the dust box, and an exhaust port which is communicated with the accommodating cavity is arranged on the rear wall of the dust box; the filter device is arranged in the accommodating cavity, and the exhaust port can be closed by the filter device; the dust scraper is movably arranged at the front of the filter device along the left-right direction and is parallel to the front surface of the filter device, dust scraping ribs which are used for removing dust are arranged on the surface, which faces the filter device, of the dust scraper, and the side edges of the dust scraping ribs cling onto the surface of the filter device; the driving device is connected with the dust scraper and is used for driving the dust scraper to reciprocate. The intelligent dust collector and the dust box assembly in an embodiment of the invention have the advantages that the dust on the front surface of the filter device can be conveniently scraped, accordingly, the permeability of the filter device can be kept for a long time, and air flow channels of the dust box can keep smooth.

Owner:MIDEA ROBOZONE TECH CO LTD

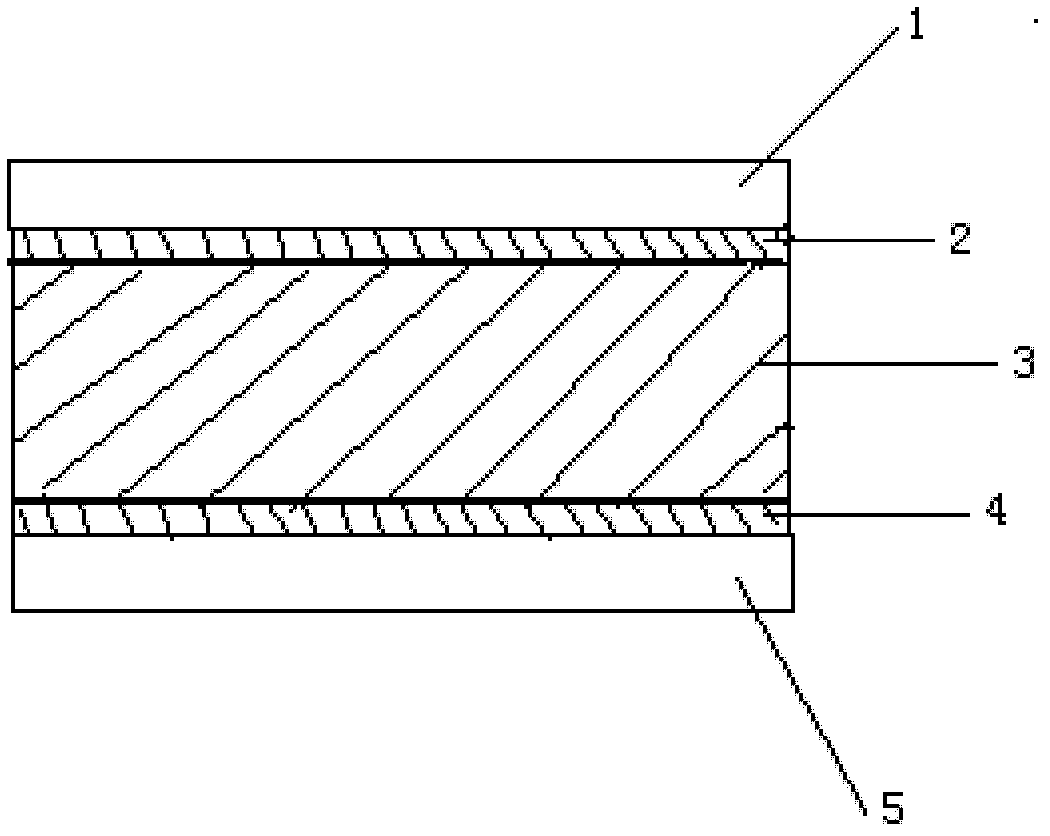

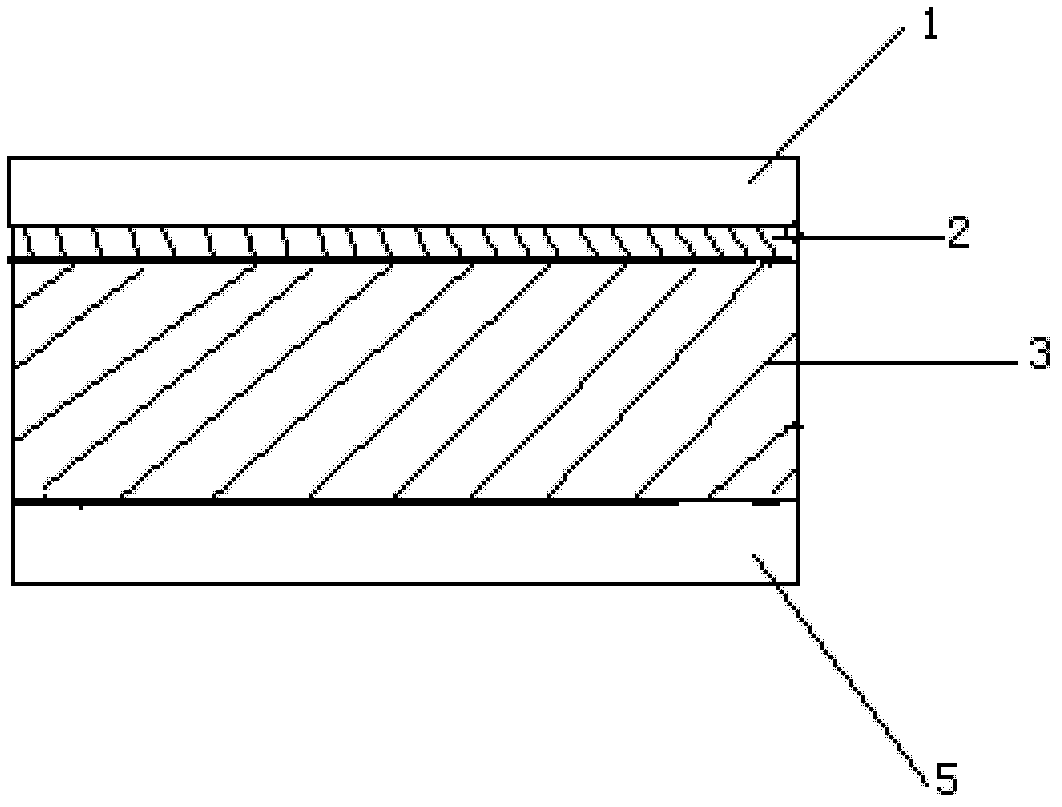

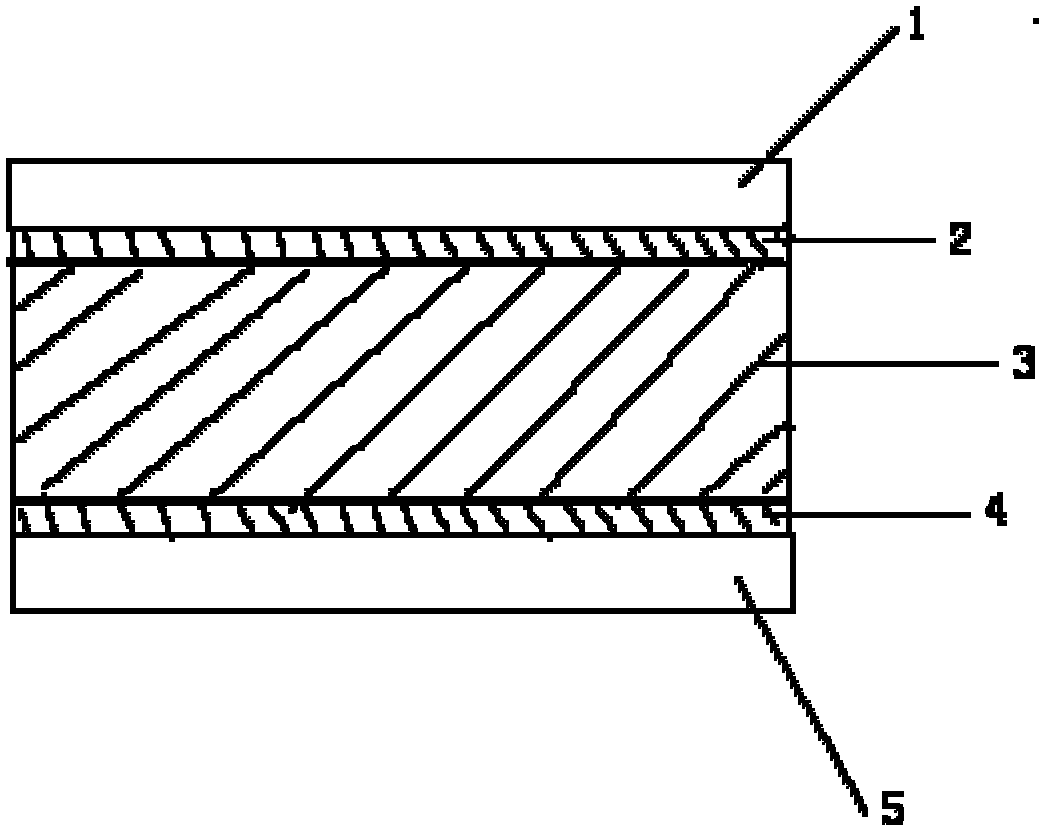

Composite health care pad and manufacture method thereof

InactiveCN102514257AGuaranteed performanceGuaranteed breathabilityStuffed mattressesLamination ancillary operationsFiberSurface layer

The invention discloses a composite health care pad, which comprises a middle layer, wherein an upper surface layer and a lower surface layer are respectively arranged on the upper surface and the lower surface of the middle layer, a layer of blocking layer is respectively arranged between the middle layer and the upper surface layer and / or between the middle layer and the lower surface layer. The upper surface layer and the lower surface layer are non-woven layers containing 5%-50% low-melting-point fibers, and the middle layer is a non-woven layer containing the following components: fibrilia and 5%-50% of low-melting-point fibers. The blocking layers are non-woven layers containing 5%-100% of fibrilia, and the content of fibrilia in the composite health care pad ranges from 5% to 65%. The invention further discloses a manufacture method of the composite health care pad, which includes the following steps: respectively manufacturing the middle layer, the upper surface layer, the lower surface layer and the blocking layers, sequentially overlaying all the layers, and carrying out procedures including drying in a drying oven, cold rolling, cooling, cutting, inspection and packing. The composite health care pad and the manufacture method thereof solve the problems that the existing mattress can become damp and mildewed easily, can be damaged by worms, is apt to be layered, and is poor in ventilation and inconvenient to use caused by the fact that hard fibers in the middle of the mattress prick out.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Lost foam casting (LFC) method without roasting by using precise paraffin wax model sample and high-performance coating shell mould

InactiveCN102632196AGood coating performanceGuaranteed StrengthFoundry mouldsFoundry coresParaffin waxPhysical chemistry

The invention discloses a lost foam casting (LFC) method without roasting by using a precise paraffin wax model sample and a high-performance coating shell mould, comprising the following steps of: (1) manufacturing the paraffin wax model sample; (2) preparing a coating; (3) coating the coating and drying; (4) dewaxing the shell mould and recovering; (5) boxing the shell mould and filling sand; (6) burning out the residual wax under a negative pressure; and (7) pouring molten metal. The LFC method without roasting by using a precise paraffin wax model sample and a high-performance coating shell mould disclosed by the invention is simple in process, low in cost, less in energy consumption, high in efficiency, and more stable in casting quality; and silica sol having the same weight with Guilin No. 5 is added in the coating on an inner layer, so that the coating property of the coating on the wax model can be obviously improved, thus ensuring finish degree, and the coating is suitable for castings with various different materials. The coating on an outer layer is low in cost after being compounded of coarse and fine quartz sand and powder, the procedure of scattering dry sand layer by layer is cancelled, and the strength, stiffness and air permeability of the coating are ensured. Test detection indicates that the coating on the inner layer or the coating on the outer layer has a normal-temperature strength of greater than 1.5 MPa and the air permeability of 1.3 cm<2> / Pa.min after being dried, has strength being greater than 1.35 MPa and air permeability being 1.5 cm<2> / Pa.min after being roasted for 10 minutes at 1000 DEG C.

Owner:刘玉满 +1

Terrapin hatching device

The invention discloses a terrapin hatching device which comprises a tank, a hydrophobic layer, a fine sand layer and a soft covering layer, wherein the hydrophobic layer is arranged on the bottommost side in the tank; the fine sand layer is located on the upper side of the hydrophobic layer; the soft covering layer is located on the upper side of the fine sand layer, and a ventilation cavity is formed in the upper side of the soft covering layer; air vents are formed in the tank and correspond to the ventilation cavity; a top cover is buckled at the top of the tank; one side of the bottom of the tank extends outwards to form an opening groove; the hydrophobic layer penetrates through the side wall of the bottom of the tank and continuously extends to the bottom of the opening groove; and a warm water supply pipe is arranged on the upper side of the opening groove, and a drainage channel communicated with the tank is formed in the side opposite to the opening groove. The terrapin hatching device provides a hatching environment for hatching of terrapin spawn, and a hatching tank can be naturally infiltrated and moistened, keep constant temperature and provide heat, and is naturally soft and permeable.

Owner:电白县星火水生野生动物繁育场

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com