Anti-seepage air-permeable pot culture container and preparation method thereof

A technology of potting containers and gas molecules, which is applied in botany equipment and methods, container cultivation, gardening, etc., and can solve the problems that potting containers cannot have anti-seepage, air permeability and water storage properties at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

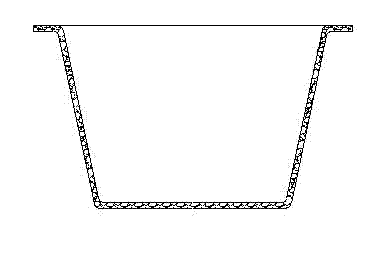

[0060] figure 1 It is the anti-permeation gas potting container of the present invention, the anti-permeation gas potting container 1 has an open cavity, and the pores of 0.01-0.2 mm formed between adjacent aggregate particles are spread all over the potting container, Pores in this size range can allow gas molecules to pass through smoothly, and can effectively prevent liquid water molecules from penetrating.

[0061] The aggregate particles are a mixture of quartz sand and slag at a weight ratio of 5:1, the particle size of the quartz sand is 0.075-0.3 mm, the particle size of the slag is 0.1-0.3 mm, and the hydrophobic binder contains Fluorine epoxy resin binder 2,2-bisphenol-based hexafluoropropane diglycidyl ether, hydrophobic binder and aggregate particles are used at a weight ratio of 1:99.

[0062] Described potting container 1 is to make by following method:

[0063] a. Mix the aggregate particles with the hydrophobic binder and pour into the mixer to stir evenly;...

Embodiment 2

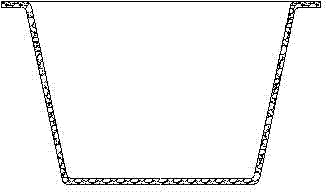

[0068] The air-proof potted plant container 1 in this embodiment has an open cavity, and the potted plant container is covered with pores of 0.02-0.3 mm formed between adjacent aggregate particles, and the pores in this size range can make gas molecules Smooth enough to pass through, and can effectively prevent liquid water molecules from penetrating.

[0069] The aggregate particles are formed by mixing ceramsite and glass microspheres at a weight ratio of 2:1, the particle size of the ceramsite is 0.075-0.6 mm, and the particle size of the glass microspheres is 0.04-0.15 mm.

[0070] The hydrophobic binder is a silicon-containing epoxy resin binder diphenylsilane modified bisphenol A epoxy resin, and the hydrophobic binder and aggregate particles are used in a weight ratio of 1:49.

[0071] The aggregate particles are coated with hydrophobic epoxy resin, and the hydrophobic epoxy resin is 8wt% of the aggregate particles. The hydrophobic epoxy resin is prepared by copolymeri...

Embodiment 3

[0082] The anti-permeation air potting container 1 in the present embodiment has an open cavity, and the potting container is covered with pores of 0.001-0.2 mm formed between adjacent aggregate particles, and the pores in this size range can make gas molecules Smooth enough to pass through, and can effectively prevent liquid water molecules from penetrating.

[0083] The aggregate particles are mixed with ceramsite and quartz sand at a weight ratio of 1:4, the particle size of the ceramsite is 0.05-0.3 mm, and the particle size of the quartz sand is 0.06-0.112 mm.

[0084] The hydrophobic binder is a silicone binder methylphenylpolysiloxane resin, and the hydrophobic binder and aggregate particles are used in a weight ratio of 3:97.

[0085] The aggregate particles are coated with hydrophobic polytetrafluoroethylene, and the hydrophobic polytetrafluoroethylene accounts for 3wt% of the aggregate particles.

[0086] The method that the hydrophobic polytetrafluoroethylene is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com