Patents

Literature

45results about How to "Guaranteed air permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

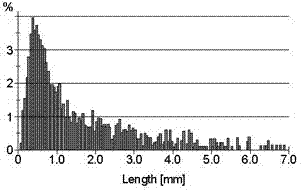

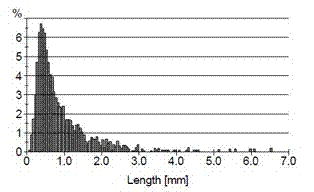

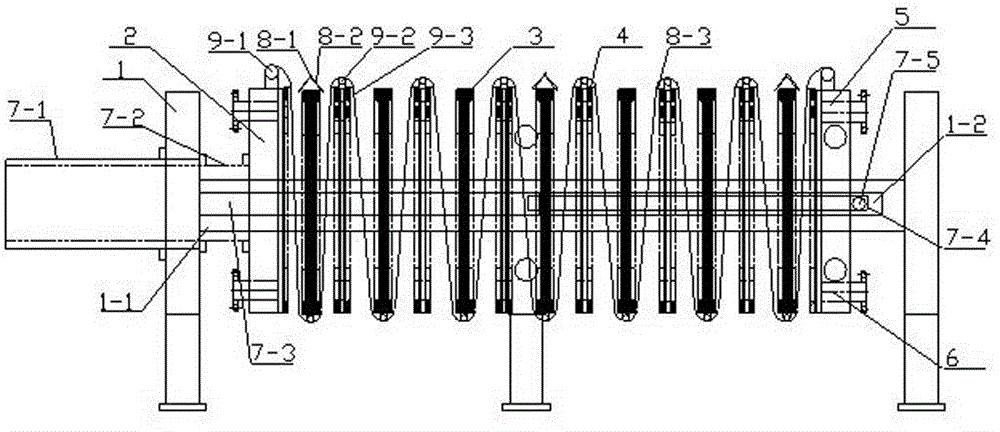

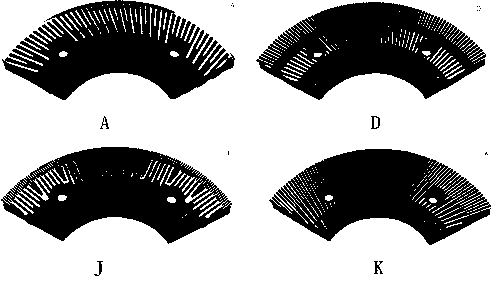

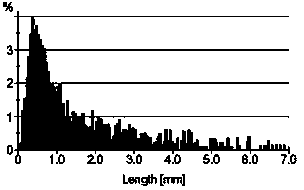

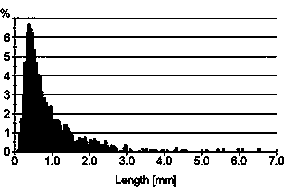

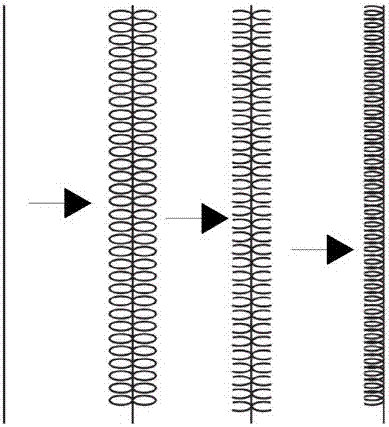

Method for preparing tobacco sheet paper base from tobacco stems

The invention discloses a method for preparing tobacco sheet paper base from tobacco stems as raw materials by adopting the paper making process. The method comprises the following steps: impregnating, pulping and making sheets. The invention changes the traditional technological prejudice and custom of controlling the pulping by controlling the current of a pulping machine and innovatively realizes the pulping by controlling the pulping disc, the pulping gaps, the pulping segments and the pulping concentration. The condition of the pulping process is optimized systematically, two or three segments of pulping are adopted, the pulping concentration is controlled at 20%, and the pulping gaps for the first and second segments of pulping are respectively 0.4mm and 0.20mm. Through studying and analyzing the relation between the pulping process and the performance of the tobacco stem fiber integrally, the controllable optimum pulping condition is summarized, the longest fiber of the tobacco stem pulp, the highest bulk of the formed paper and the good quality of the reconstituted tobacco are guaranteed, the performance of the tobacco sheet paper base is improved comprehensively, and finally the technological basis is provided for improving the quality of the tobacco sheets and the cigarettes.

Owner:CHINA TOBACCO GUANGDONG IND +1

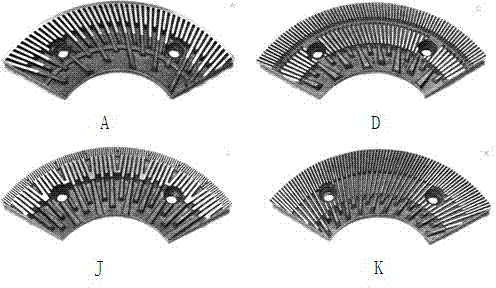

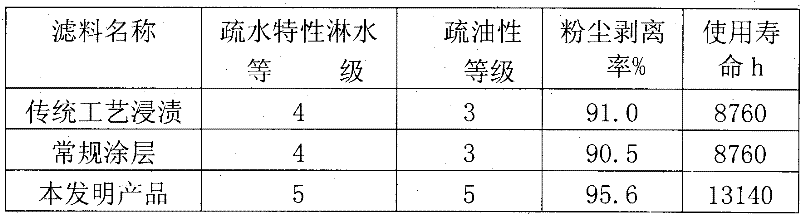

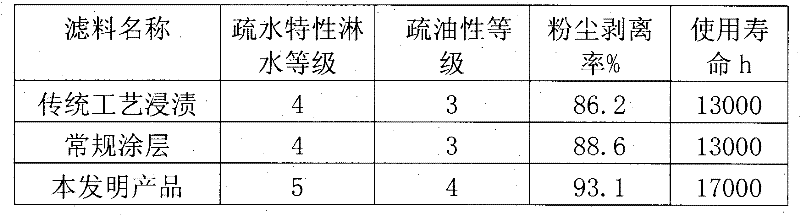

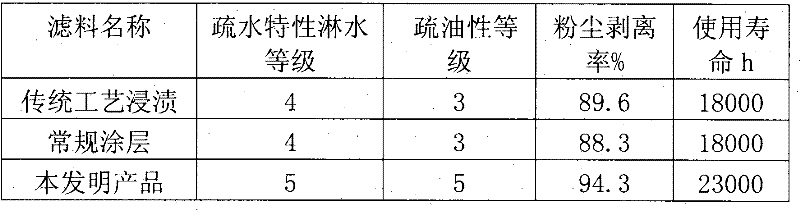

Preparation method for water-repelling grease-proofing easy-ash-removal filter material

Owner:JIANGSU DINGSHENG FILTER BAG CO LTD

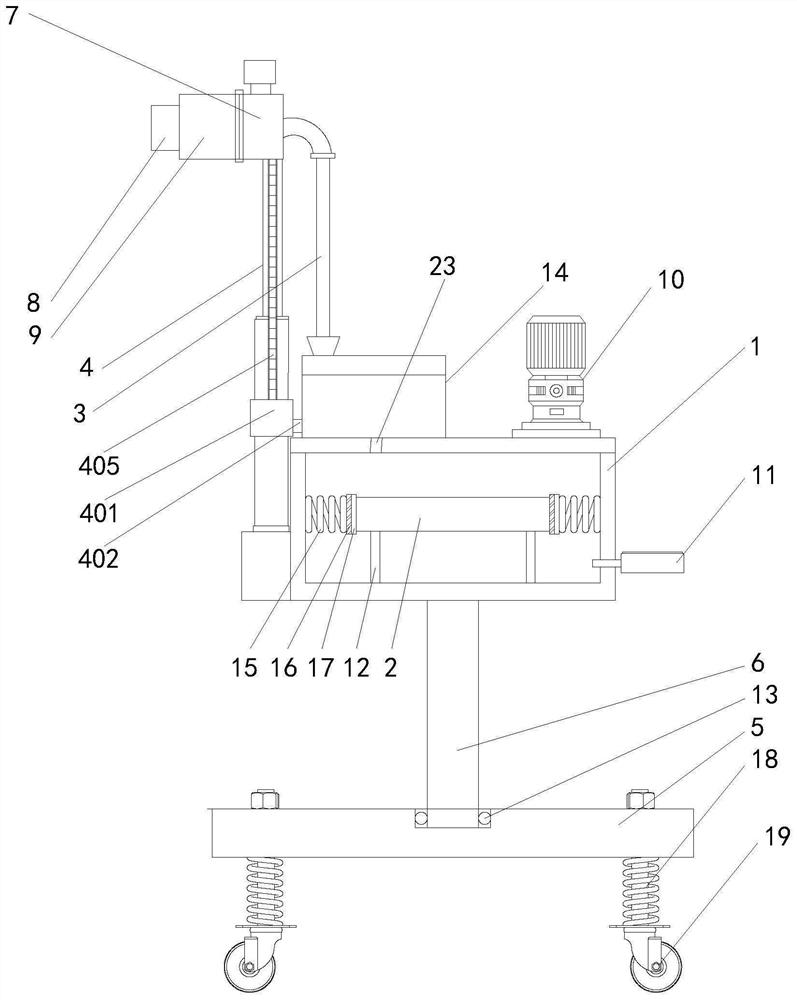

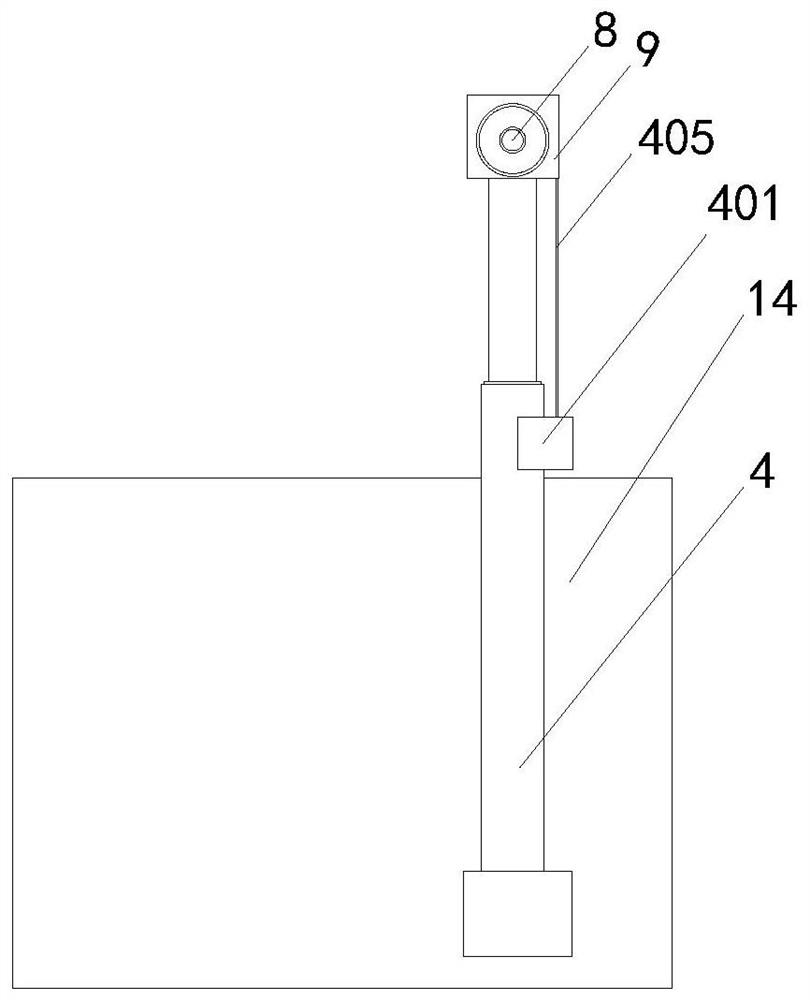

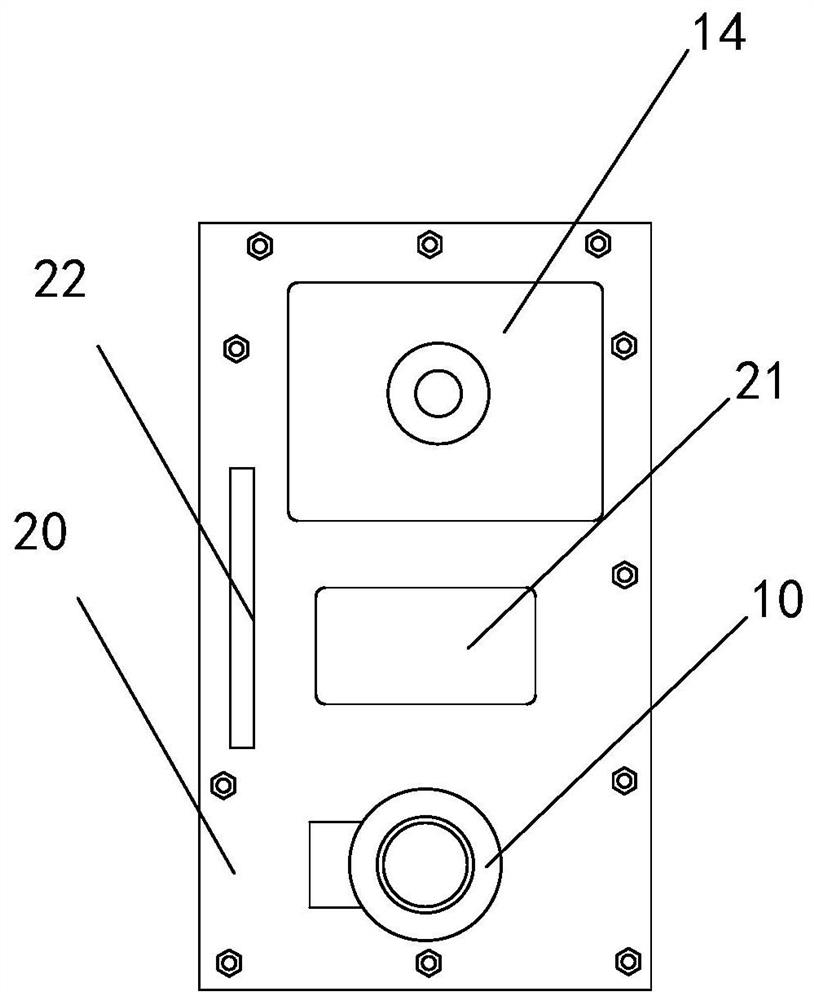

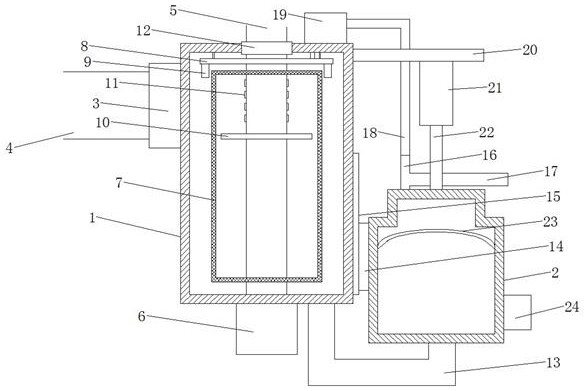

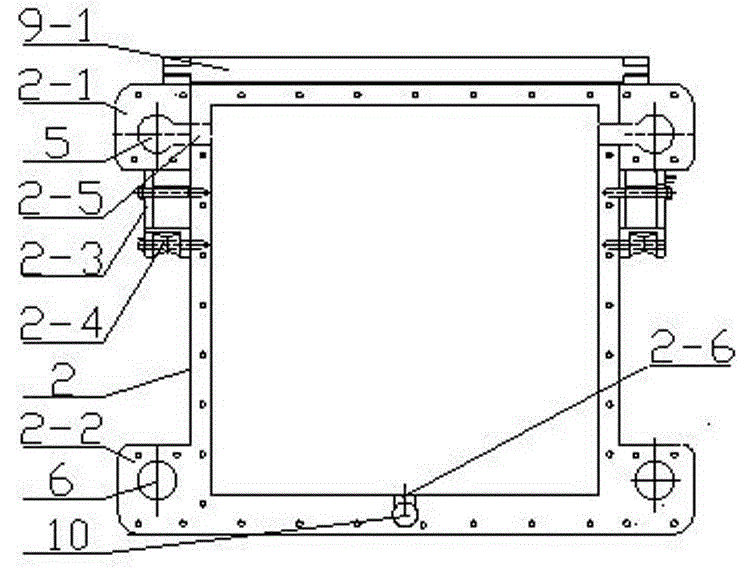

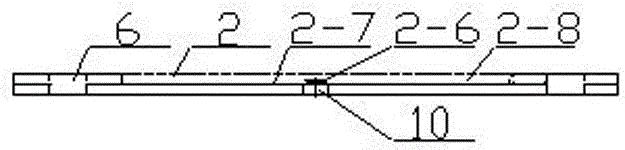

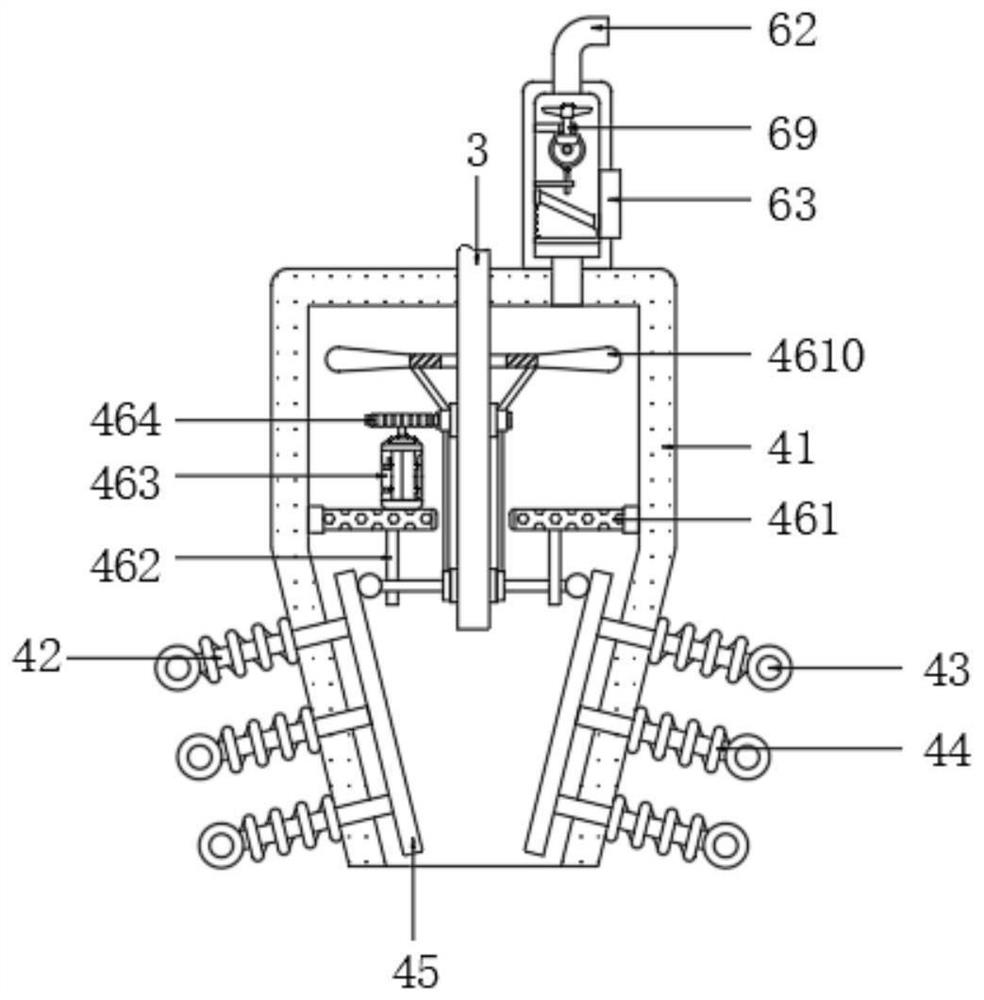

Solid and liquid separator for materials

ActiveCN103657176AImprove stressThe moisture content of solids is reducedFiltration separationPush and pullLocking mechanism

The invention discloses a solid and liquid separator for materials. The solid and liquid separator comprises a frame, press plates, filter plates, a push-and-pull locking mechanism, a filter cloth mechanism, a filter cloth regeneration mechanism and a cleaning mechanism which are arranged on the frame, wherein the press plates and the filter plates are arranged on the frame in a sliding way alternately, and are matched to extrude a material, so that solid and liquid of the material can be separated; the push-and-pull locking mechanism is used for locking, pushing away all the press plates and filter plates, so that solid-liquid separation operation can be performed, or the material can be discharged; the filter cloth mechanism is used for separating solid and liquid of the material when the material is extruded; the filter cloth regeneration mechanism is used for washing to regenerate the filter cloth after the material is discharged; the cleaning mechanism is used for cleaning the material attached to the separator after solid and liquid of the material are separated. The solid and liquid separator has the characteristics of reasonable design, high structure strength, convenience in operation, complete solid and liquid separation, high separation efficiency, convenience in cleaning, long service life, log maintenance frequency, high reliability, strong practicality and the like, and is beneficial for greatly increasing production benefit of enterprises.

Owner:四川宝凯鑫诚环保科技有限公司

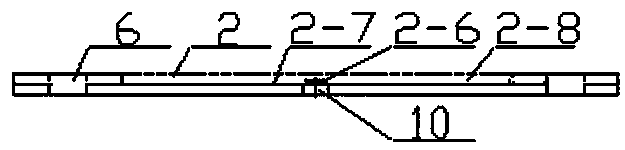

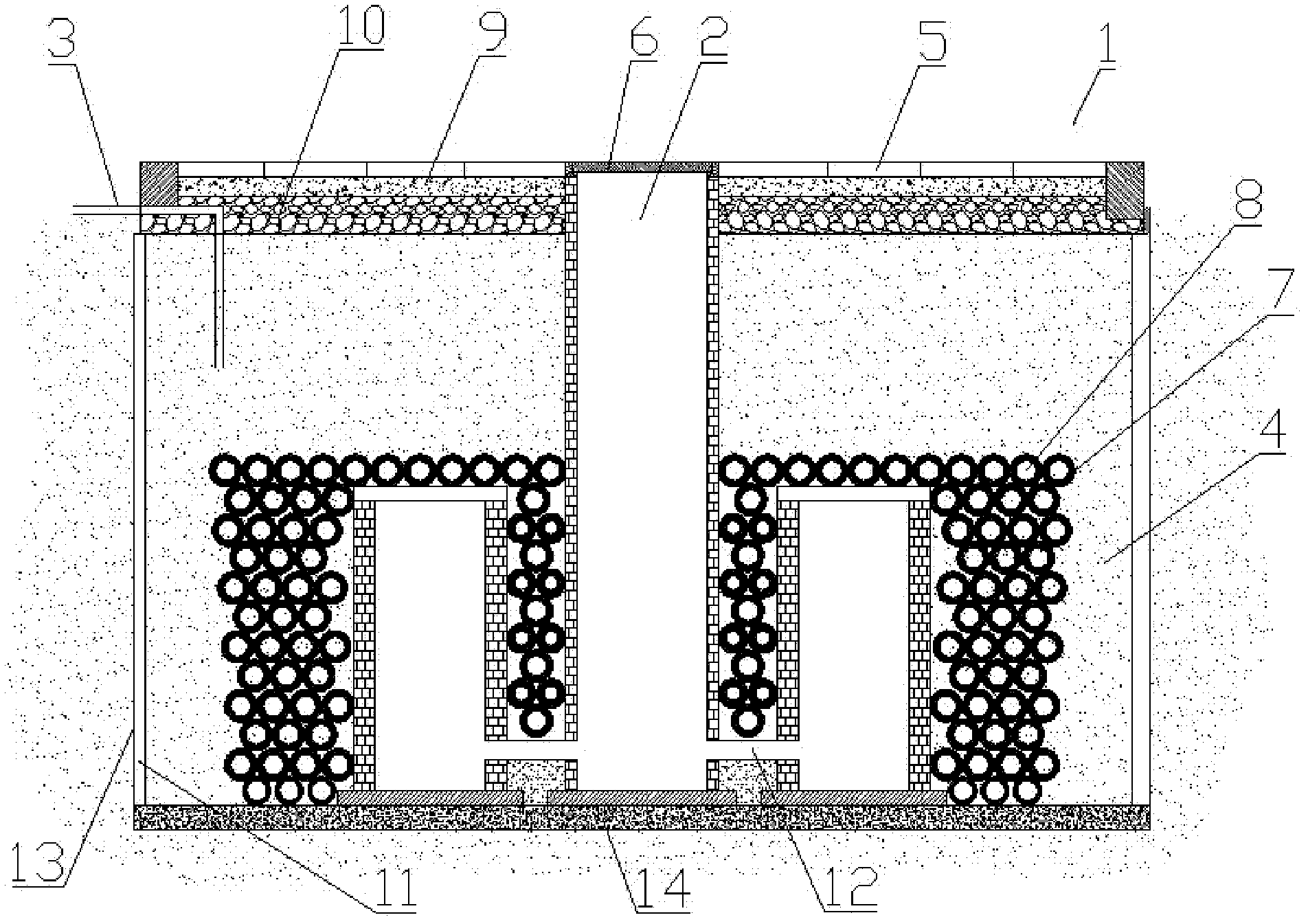

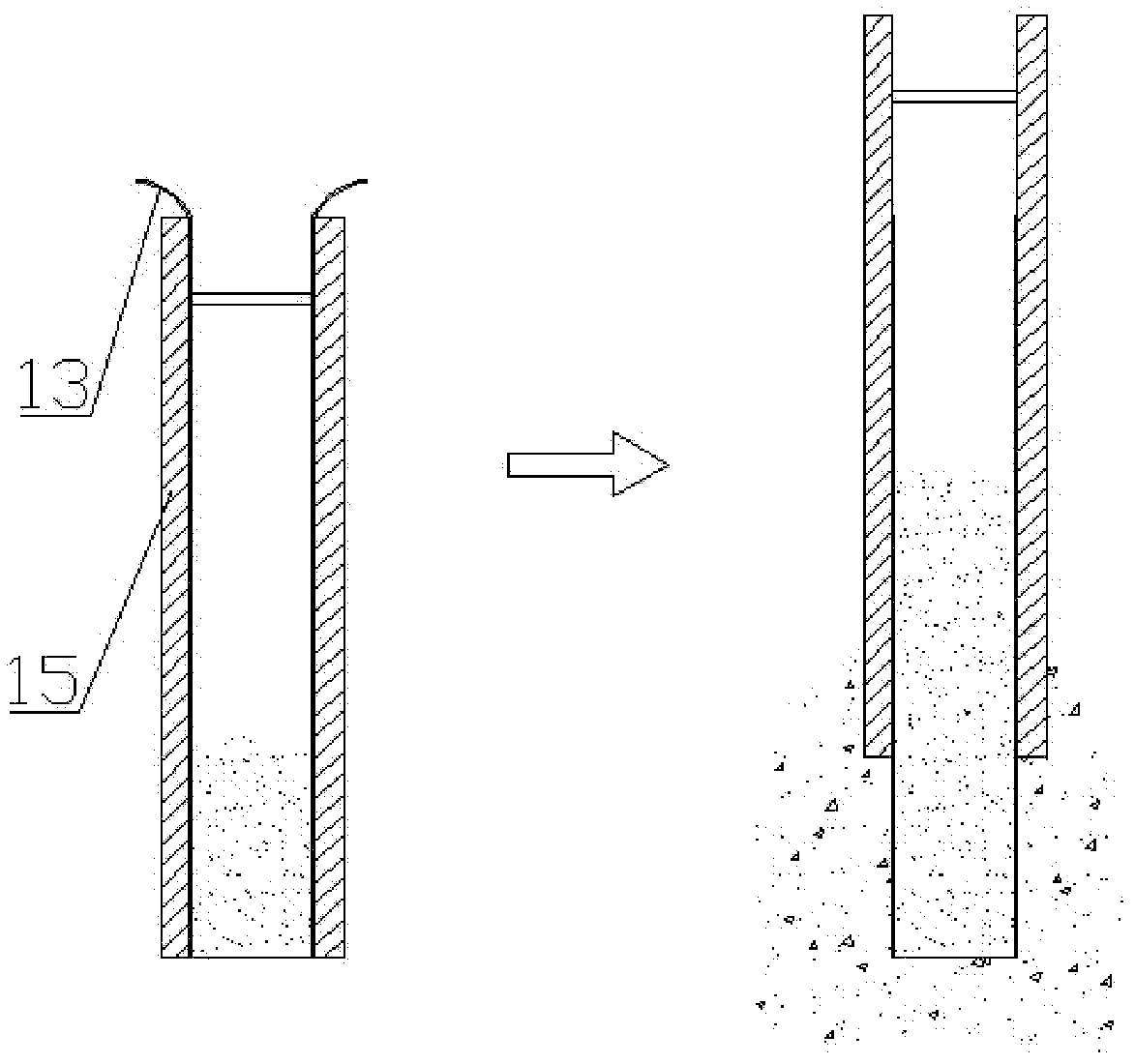

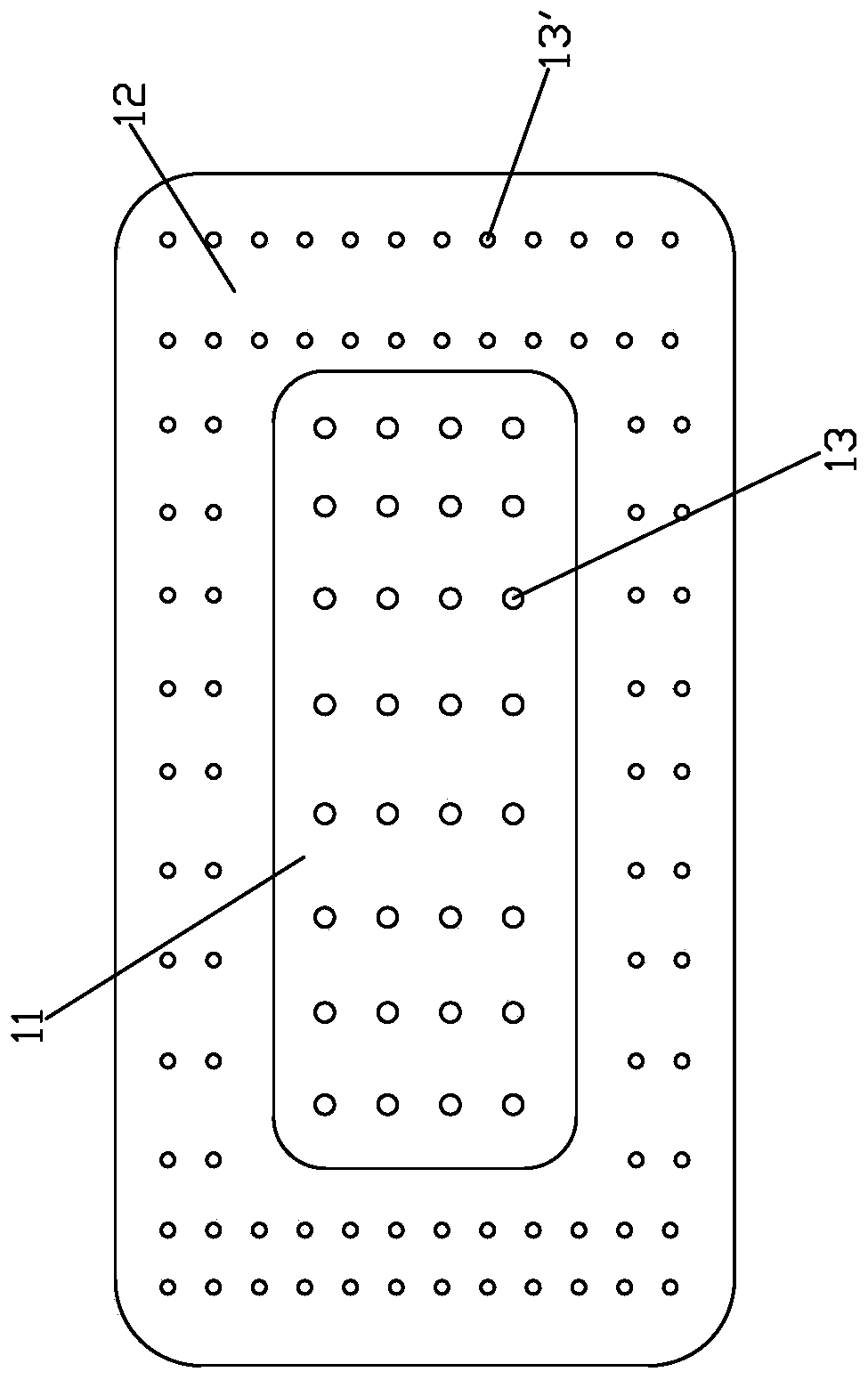

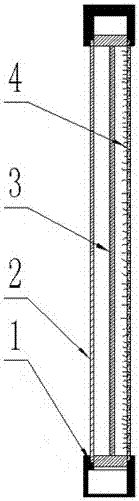

Water storage system

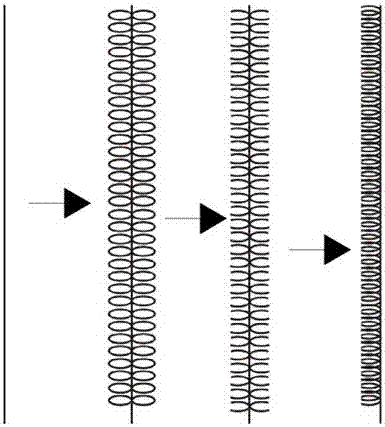

ActiveCN103174189AGuaranteed anti-seepage effectGuaranteed air permeabilitySewerage structuresGeneral water supply conservationWater storageWater quality

The invention relates to a water collection and purification system, in particular to a water storage system which is firm in building and easy to construct. The water storage system comprises a water storage container, a water collection well and water permeability padding which is filled between the water collection well and the water storage container, water is filled into the water storage container through a water inlet pipe or a water permeability surface layer paved above the padding, the container wall is a seepage prevention air permeability wall which is composed of seepage prevention air permeability particles, the boundary of the seepage prevention air permeability wall is limited through air permeability wall bags, and fine sand particles are piled up on two sides of the seepage prevention air permeability wall to fix the seepage prevention air permeability wall in a squeezing mode. The container wall of the water storage system adopts the air permeability wall bags and are filled with the seepage prevention air permeability particles, thin sand are filled on two sides of the side wall to squeeze and reinforce the side wall, the water can be prevented from being leaked outwardly through seepage prevention performance of the seepage prevention air permeability particles, so that the seepage prevention performance of the water storage system is ensured, meanwhile, an air permeability degree of the whole water storage system is also ensured through the air permeability performance of the seepage prevention air permeability particles, and the stored water is enabled not to go bad easily.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

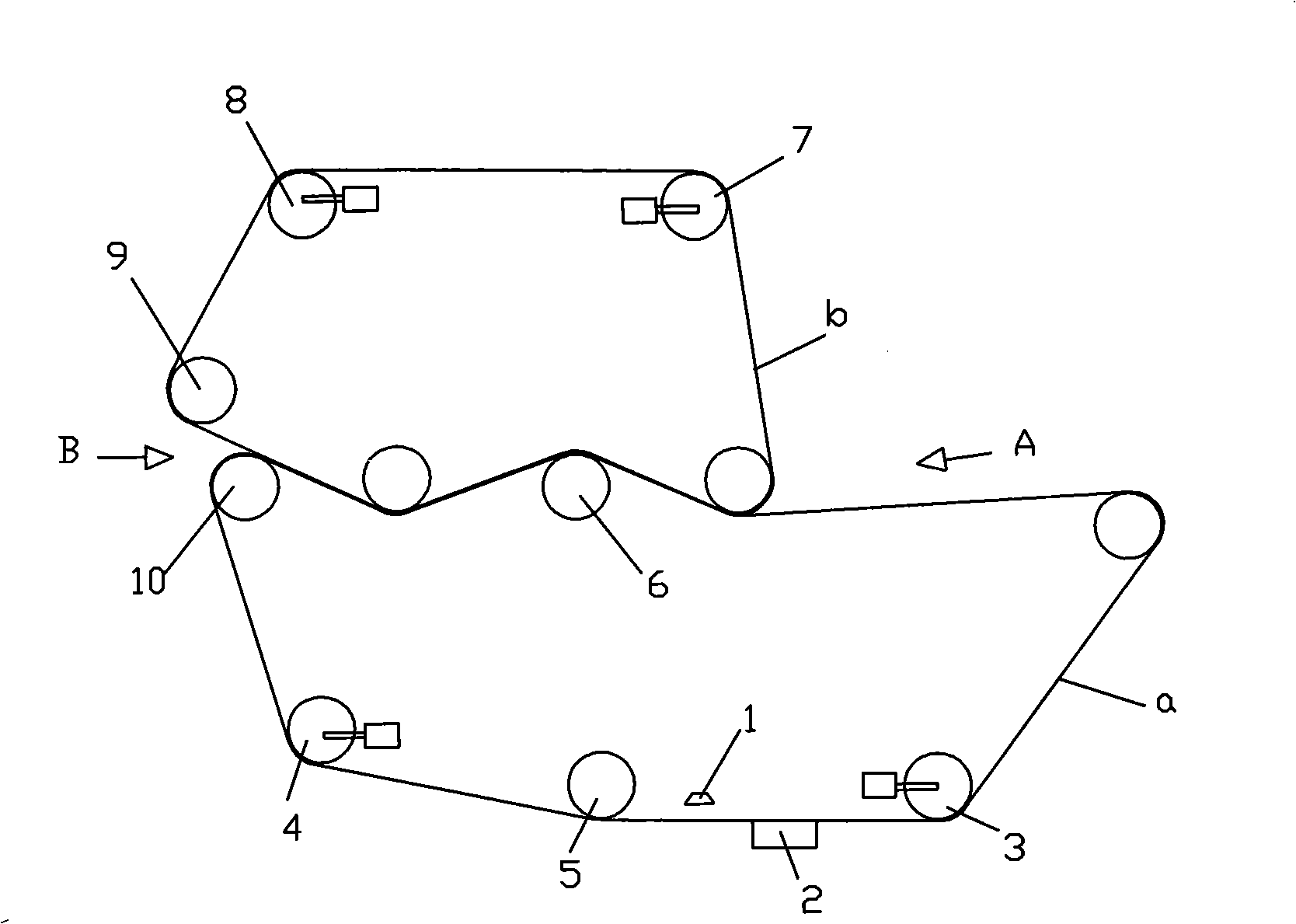

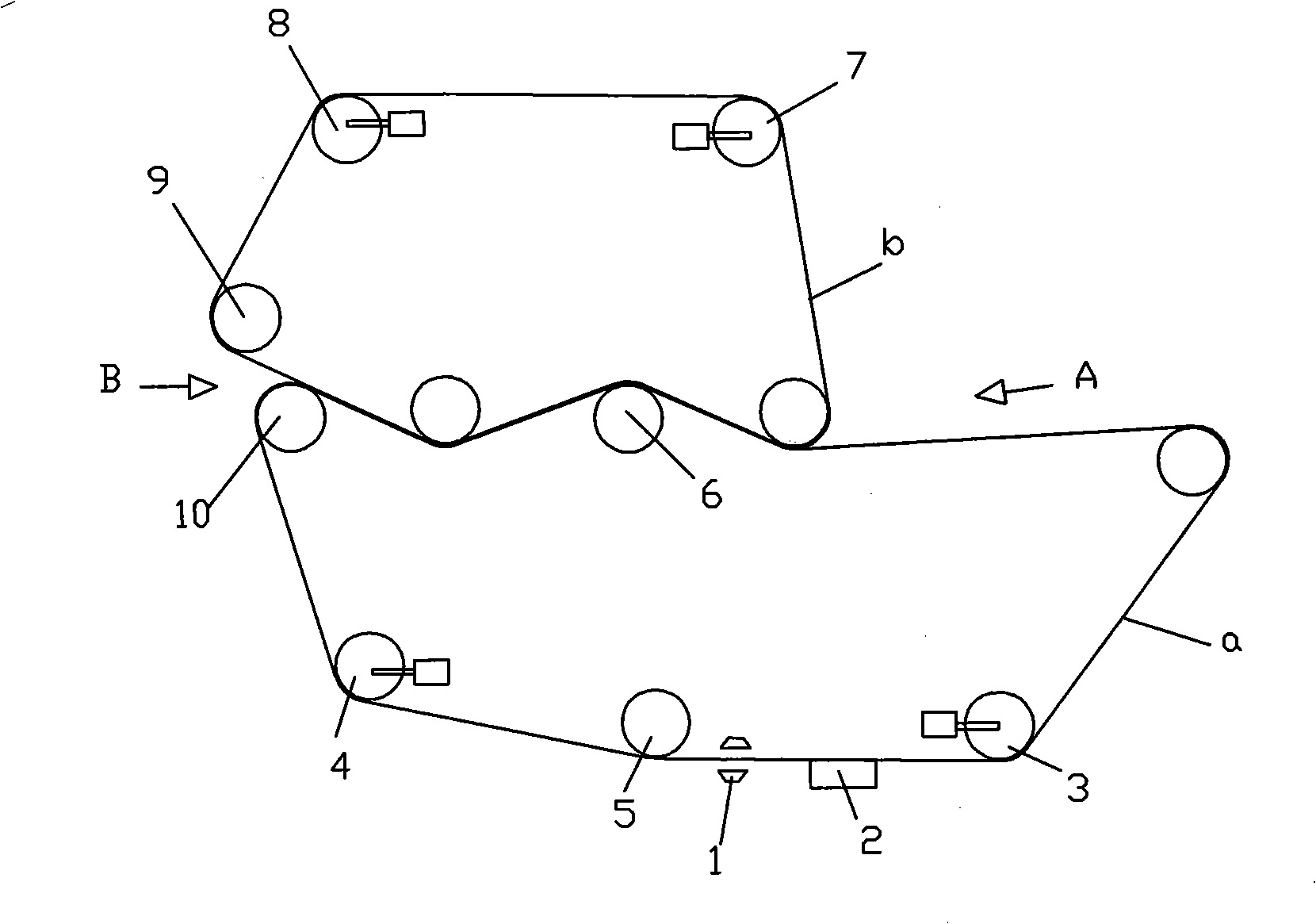

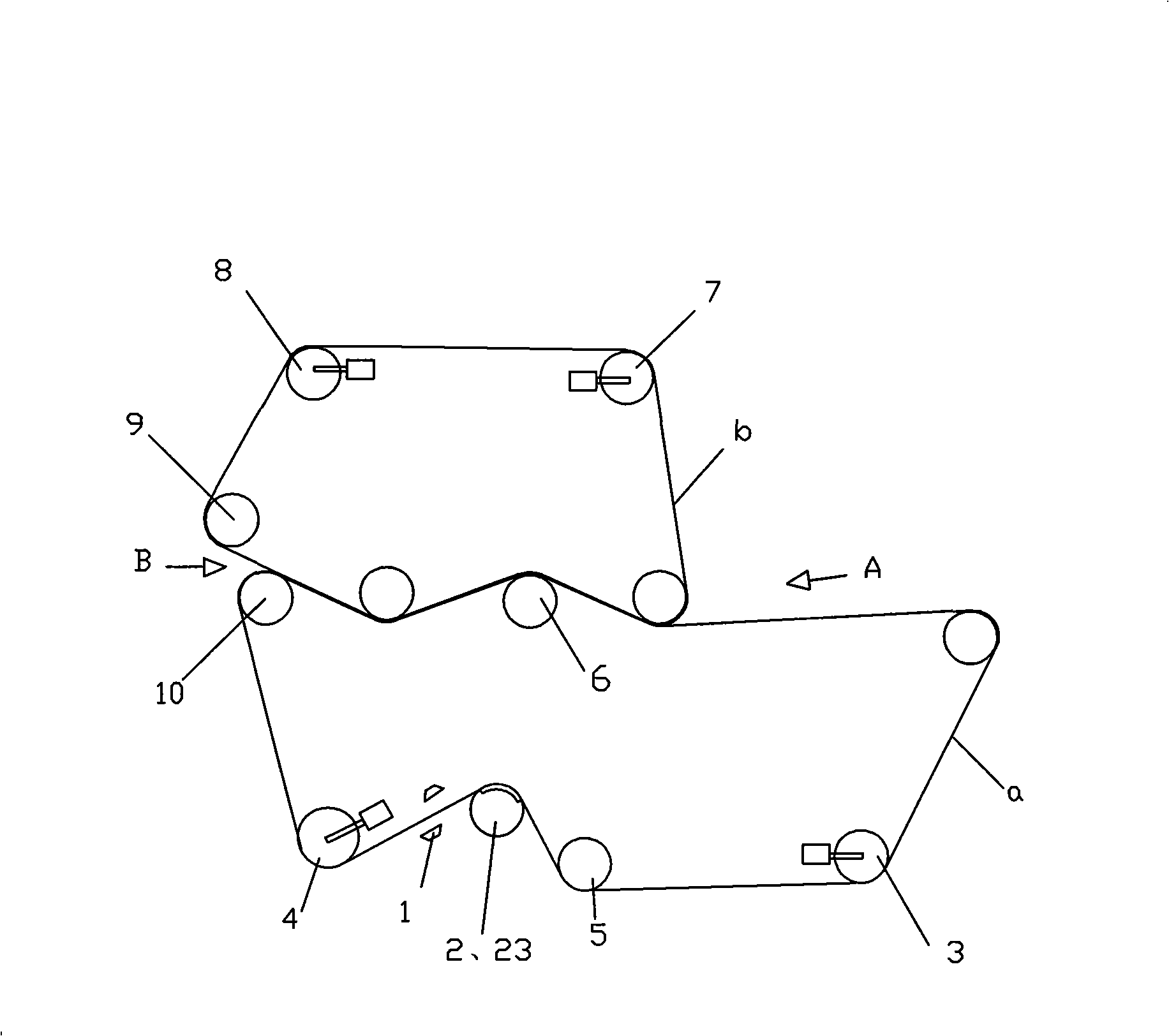

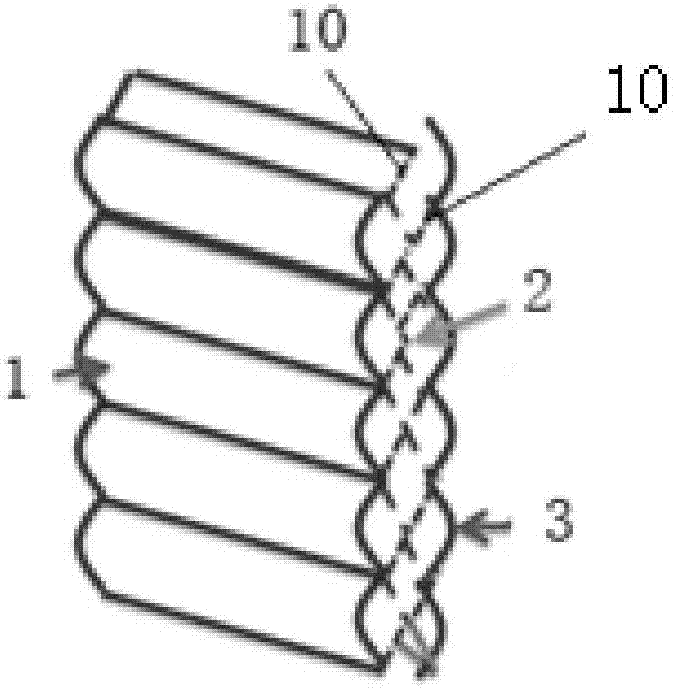

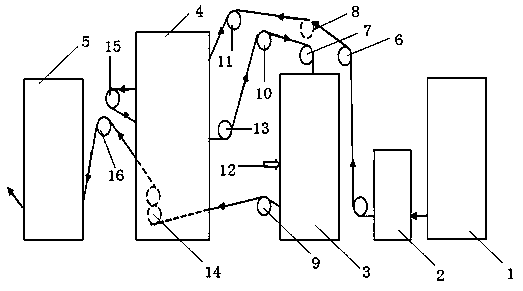

Method for cleaning and regenerating filter belt

InactiveCN101301545AGuaranteed air permeabilityEasy to cleanMoving filtering element filtersActivated sludgeSprayer

The invention discloses a regeneration method for cleaning filtrating belt which adopts a vacuum cleaning regeneration filtrating belt method, the method includes cleaning steps of water spray cleaning and steps of vacuum draw suction cleaning, the steps of water spray cleaning is performed firstly, after that the vacuum draw cleaning is performed, the step of water spray cleaning is performed by a water sprayer after discharging at the discharge port of the squeezing filtrating part of the belt type press filter, the step of vacuum suction cleaning is performed by a vacuum suction device after discharging at the discharge port of the squeezing filtrating part of the belt type press filter, and the water sprayer is mounted behead in front of the vacuum draw device. The invention overcomes the existing defects of the present technology, and has advantages of convenient manipulation and good cleaning effect, and especially is suitable for processing activated sludge with stronger stick force and cleaning the band press filter filtrating belt operating in high-tension, and the regeneration rate of the filtrating belt can be more than 60% after the filtrating belt is cleaned.

Owner:ZHEJIANG HUAZHANG TECH

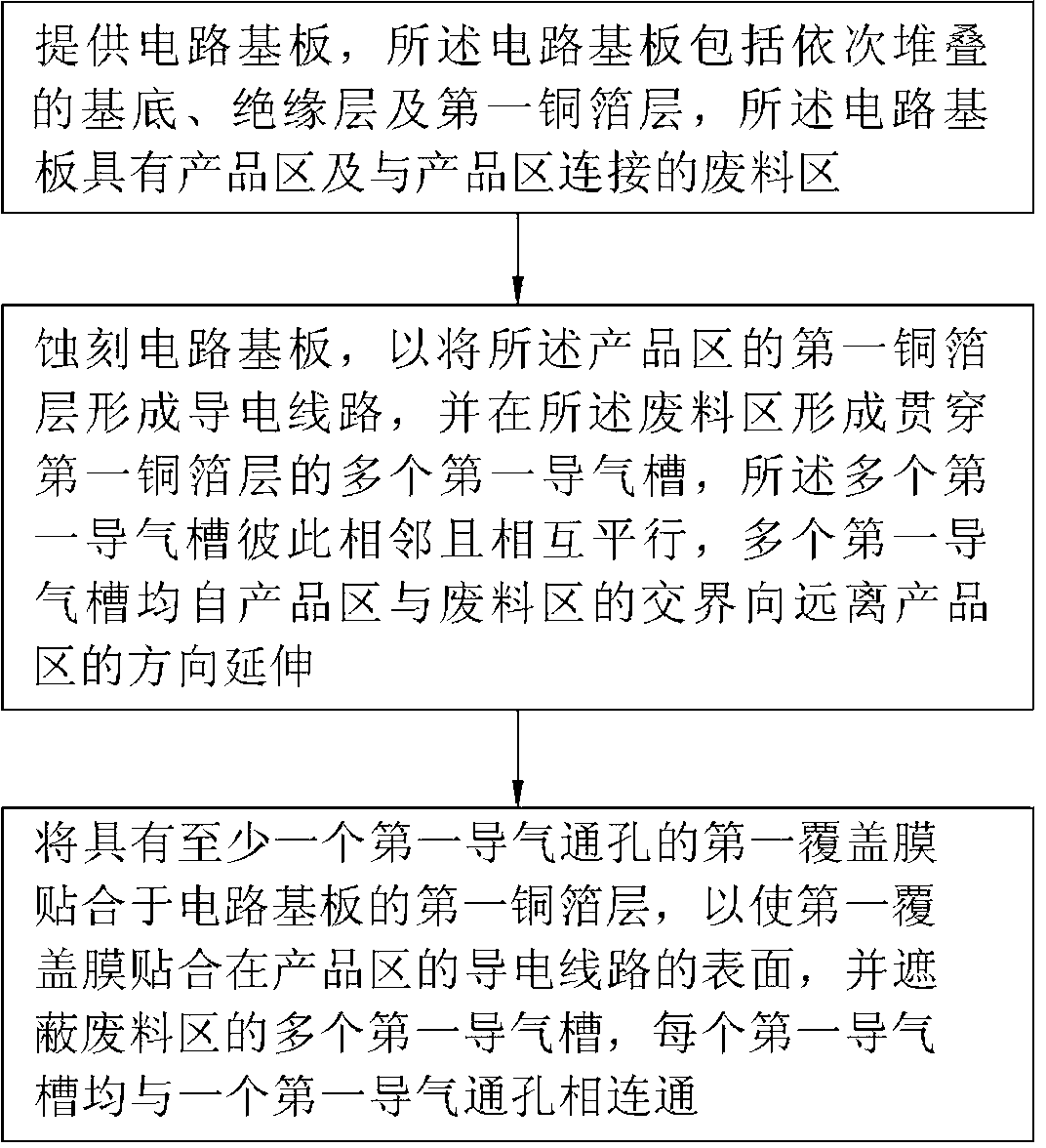

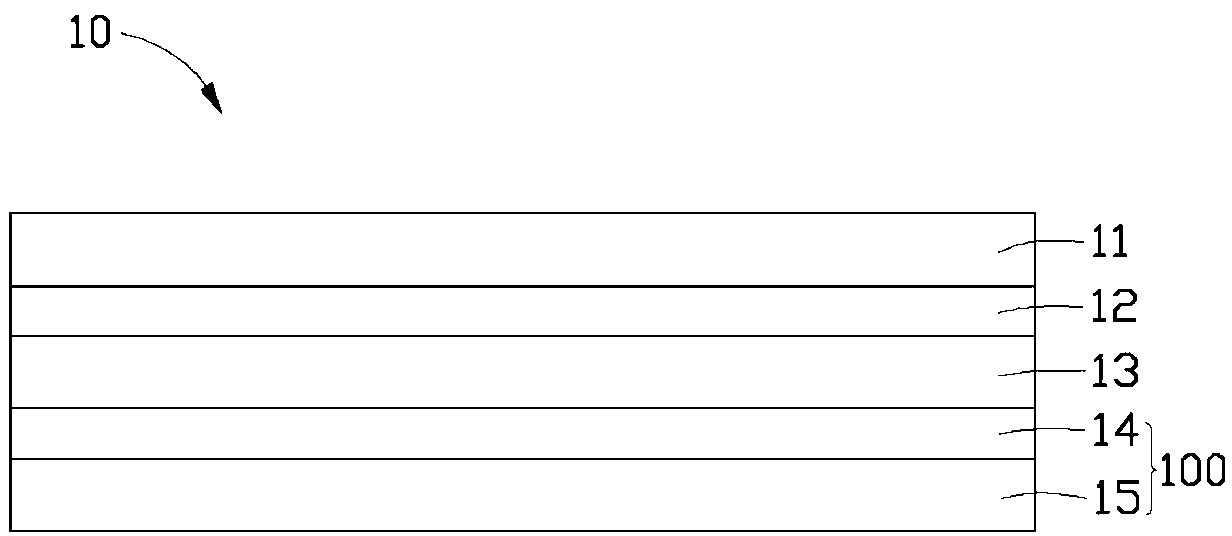

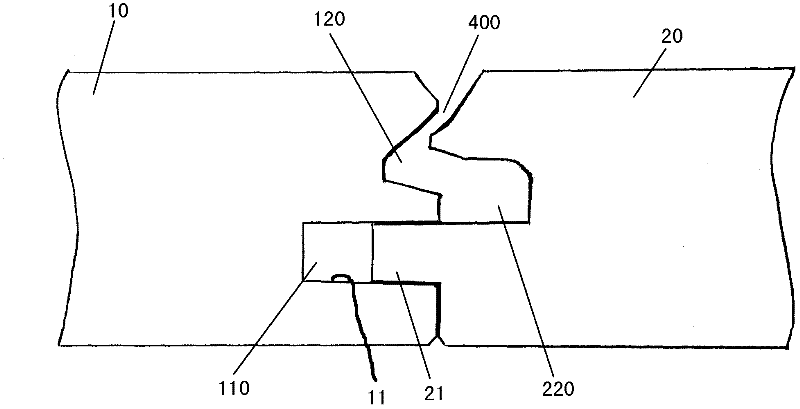

Circuit board and manufacturing method thereof

ActiveCN103327748AImprove qualitySmooth appearancePrinted circuit detailsNon-metallic protective coating applicationElectricityCopper foil

The invention provides a manufacturing method of a circuit board. The manufacturing method of the circuit board comprises the steps that a circuit substrate with a product zone and a waste zone is offered and the circuit substrate comprises a substrate body, an insulating layer and a copper foil layer which are sequentially stacked; the circuit substrate is etched, so that an electricity conductive circuit is formed on the copper foil layer of the product zone, a plurality of air guiding grooves penetrating through the copper foil layer are formed in the waste zone, the air guiding grooves are mutually adjacent and mutually parallel and extend in the direction far away from the product zone from a border of the product zone and the waste zone; a covering film provided with at least one air guiding through hole is attached to the copper foil layer, so that the covering film is attached to the surface of the electricity conductive circuit and covers the air guiding grooves, and each air guiding groove is communicated with one air guiding through hole. The invention further provides the circuit board manufactured through the manufacturing method.

Owner:HONGQISHENG PRECISION ELECTRONICS (QINHUANGDAO) CO LTD +1

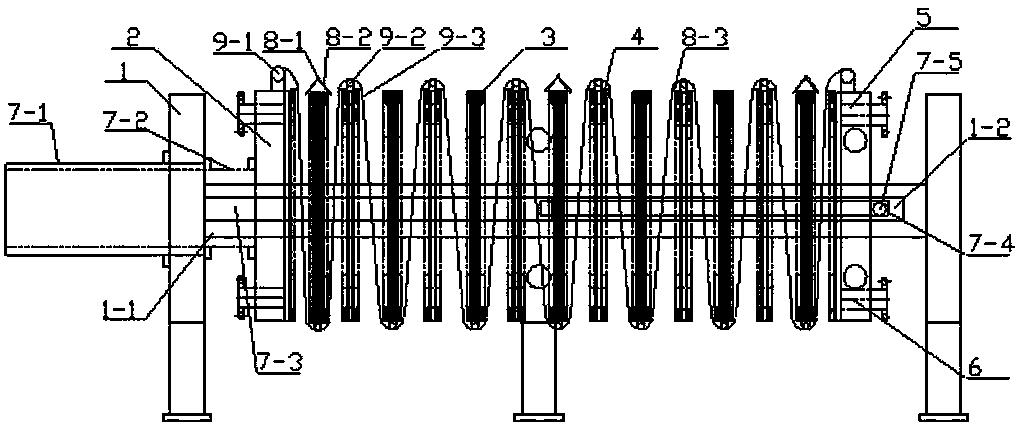

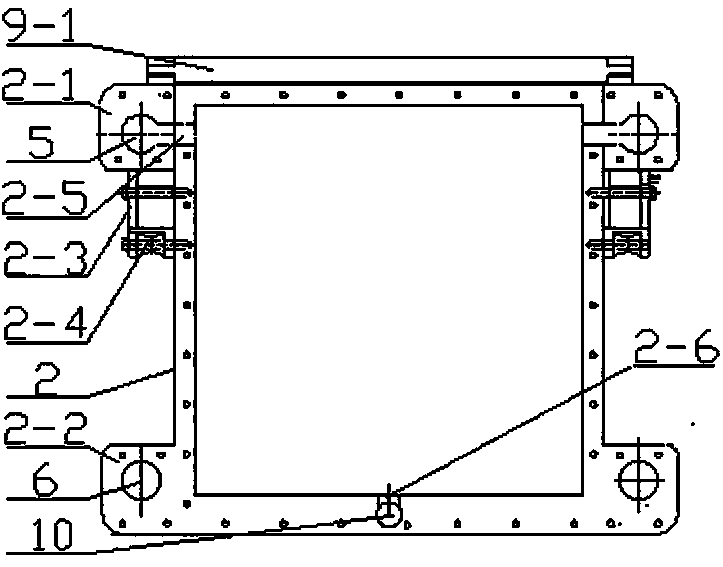

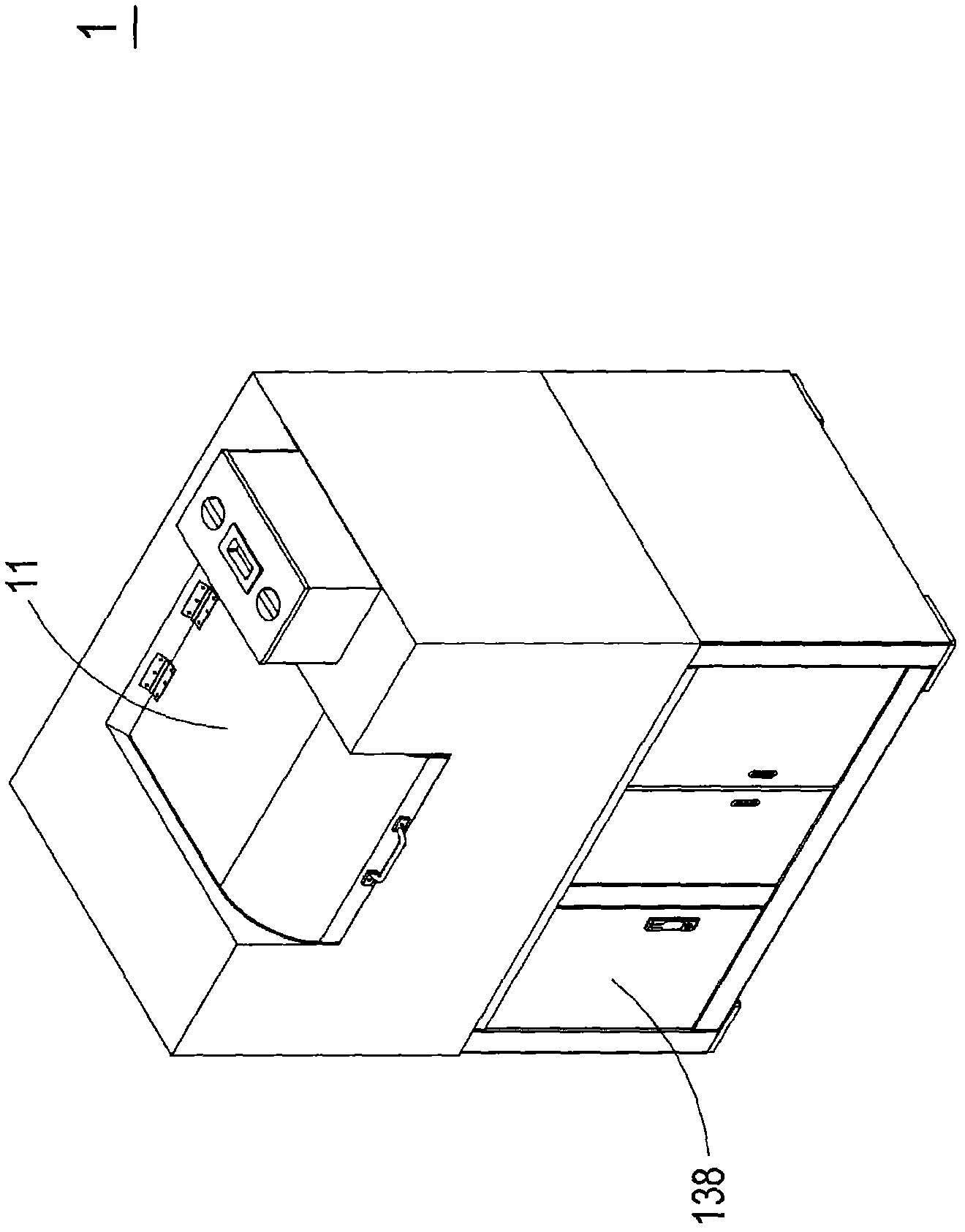

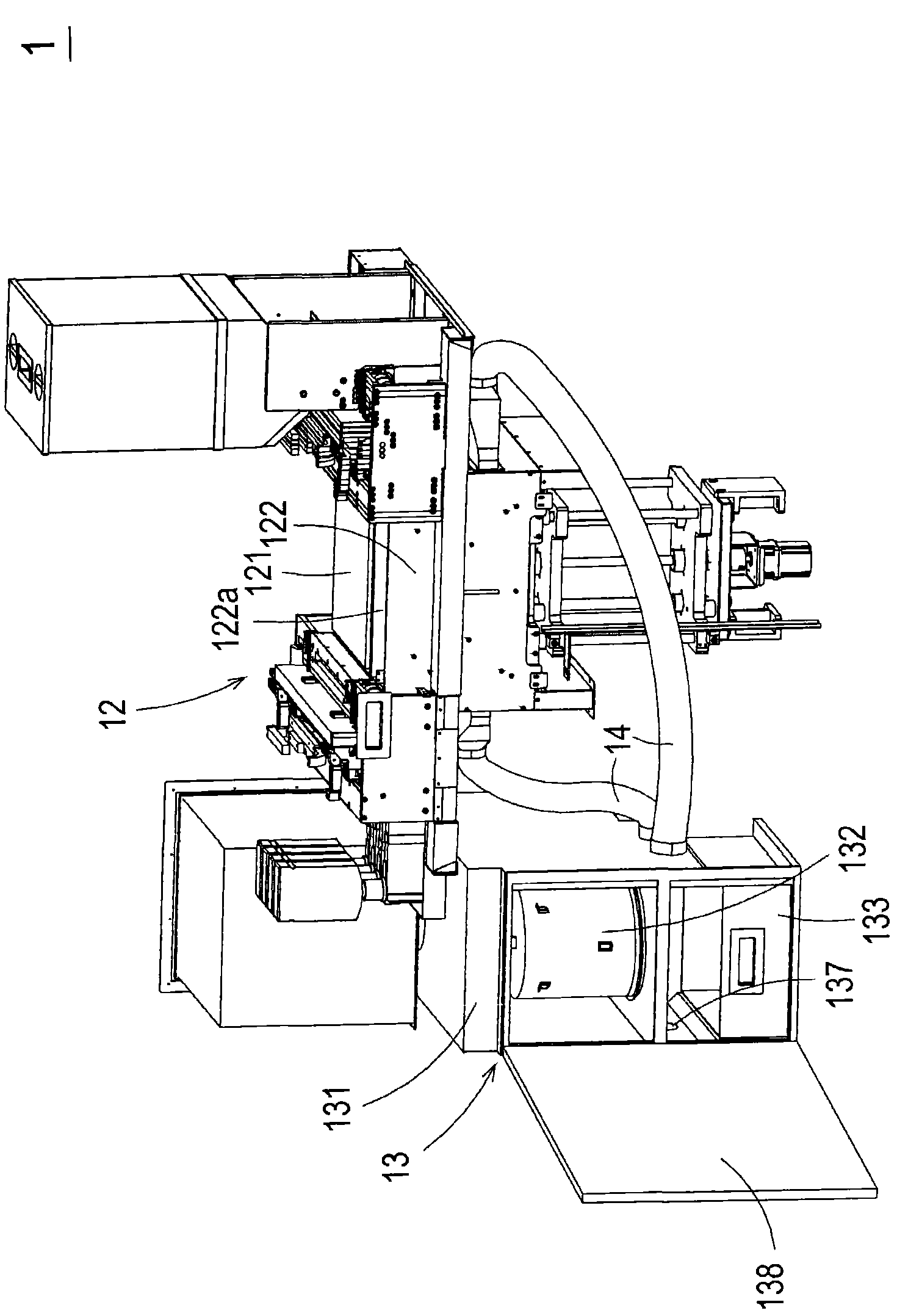

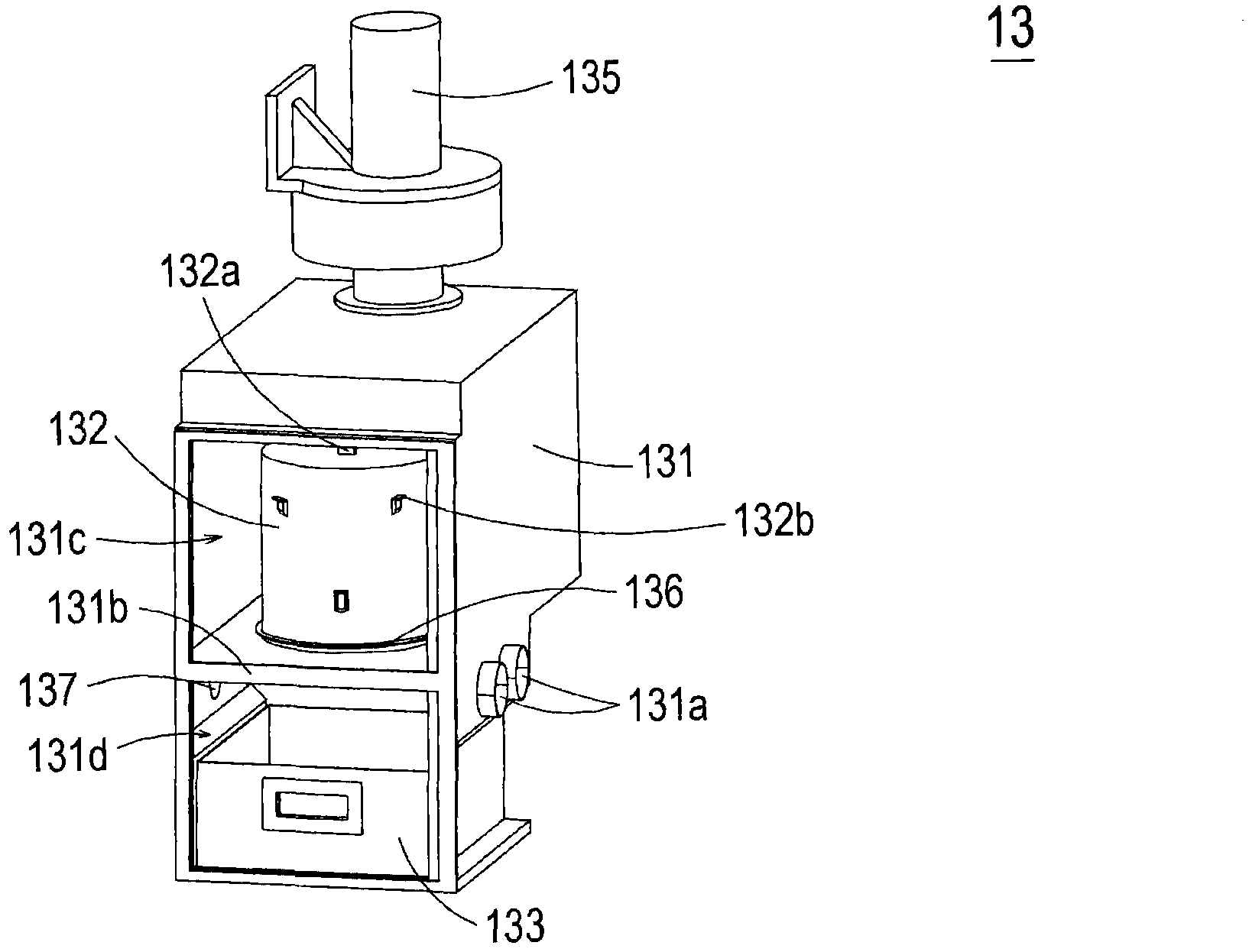

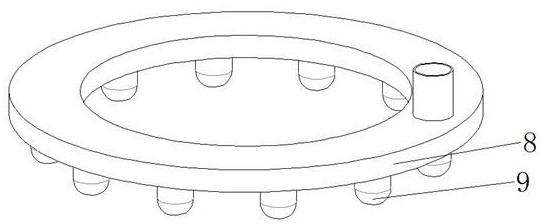

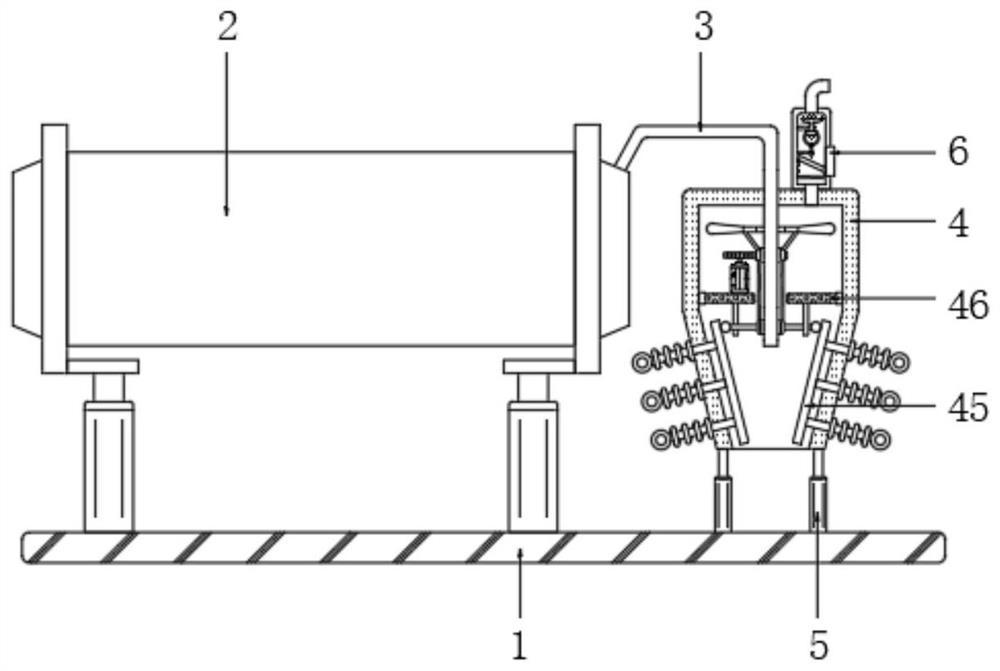

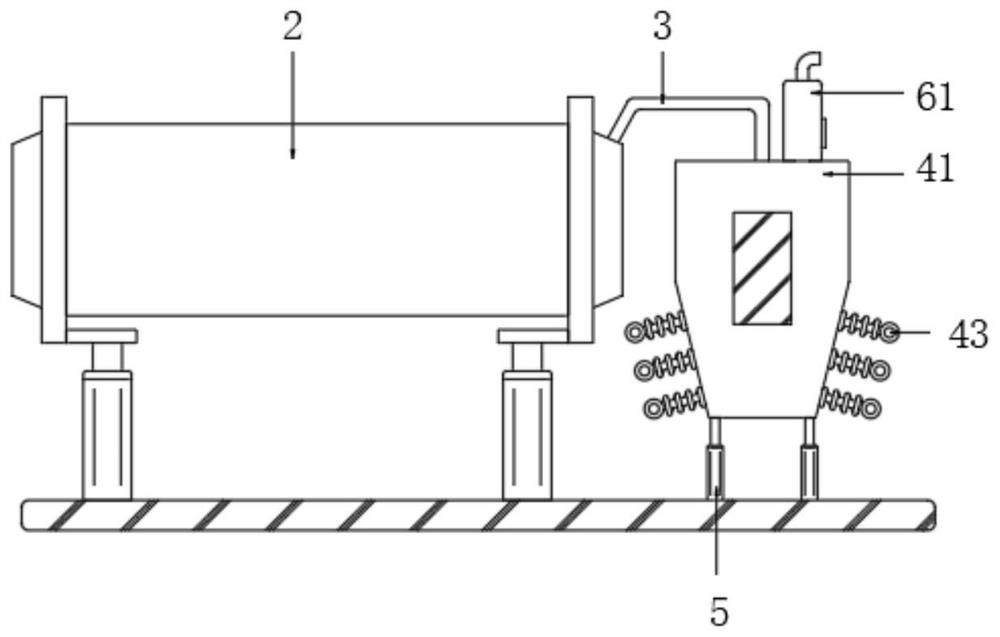

Powder filtering system and self cleaning assembly thereof

InactiveCN103042019AGuaranteed air permeabilityGuaranteed negative pressureDispersed particle filtrationDirt cleaningFilter systemFilter element

The invention relates to a powder filtering system which is used for sucking and filtering powder flying when a three-dimensional molding mechanism operates. The powder filtering system comprises a casing, a powder filtering element, a recovery construction member and an air sucking device, wherein the casing is provided with a sucking port, a first space and a second space communicated with the first space, and the sucking port is connected with the space. The powder filtering element is arranged in the first space and provided with a self cleaning assembly, the recovery construction member is arranged in the second space, the air sucking device is communicated with the first space to enable the first space to form a negative pressure state and produce sucking force to lead powder sucked form the sucking port in the second space, then the powder is transmitted to the powder filtering element to filter and block, and the self cleaning assembly can shake the powder adhered to the powder filtering element to recover the blocked powder to the recovery construction member.

Owner:MICROJET TECH

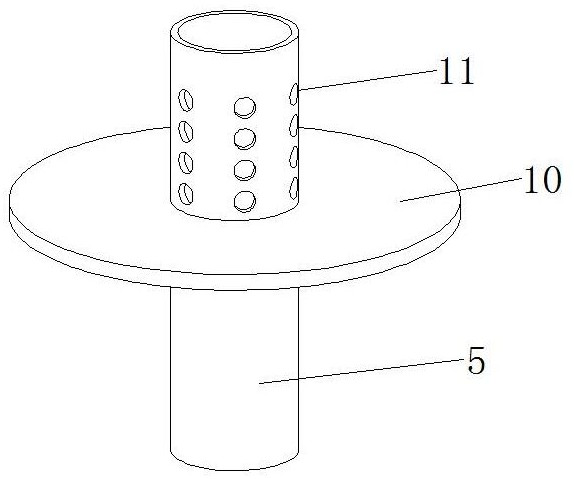

VOC online monitor for organic acid environment

InactiveCN111610293AConvenient sampling and testingPlay a thrustWithdrawing sample devicesGas analyser construction detailsOrganic acidProcess engineering

The invention relates to a VOC online monitor for an organic acid environment. The monitor comprises a monitor body, and a monitoring cavity is formed in the inner side of the monitor body; a cleaningopening is formed in the top of the monitor body; the cleaning opening is communicated with the monitoring cavity; a sealing cover is arranged at the top of the monitor body; the sealing cover is provided with an air inlet hole and an air outlet hole; a vacuum pump is mounted on the upper surface of the sealing cover; an extraction opening of the vacuum pump is communicated with the air outlet hole; an air pressure monitor is installed on the side face of the monitor body, the upper portion of the air inlet hole is communicated with a communicating pipe, one end of the communicating pipe is communicated with an electromagnetic valve, the communicating pipe is communicated with an air outlet of an air inlet non-return mechanism through the electromagnetic valve, and an air inlet of the airinlet non-return mechanism is communicated with an air inlet unit. The movable range of the air inlet unit can be greatly enlarged through a lifting mechanism, so that sampling detection work is conducted on air of different heights.

Owner:合肥汇酷谷生物技术有限公司

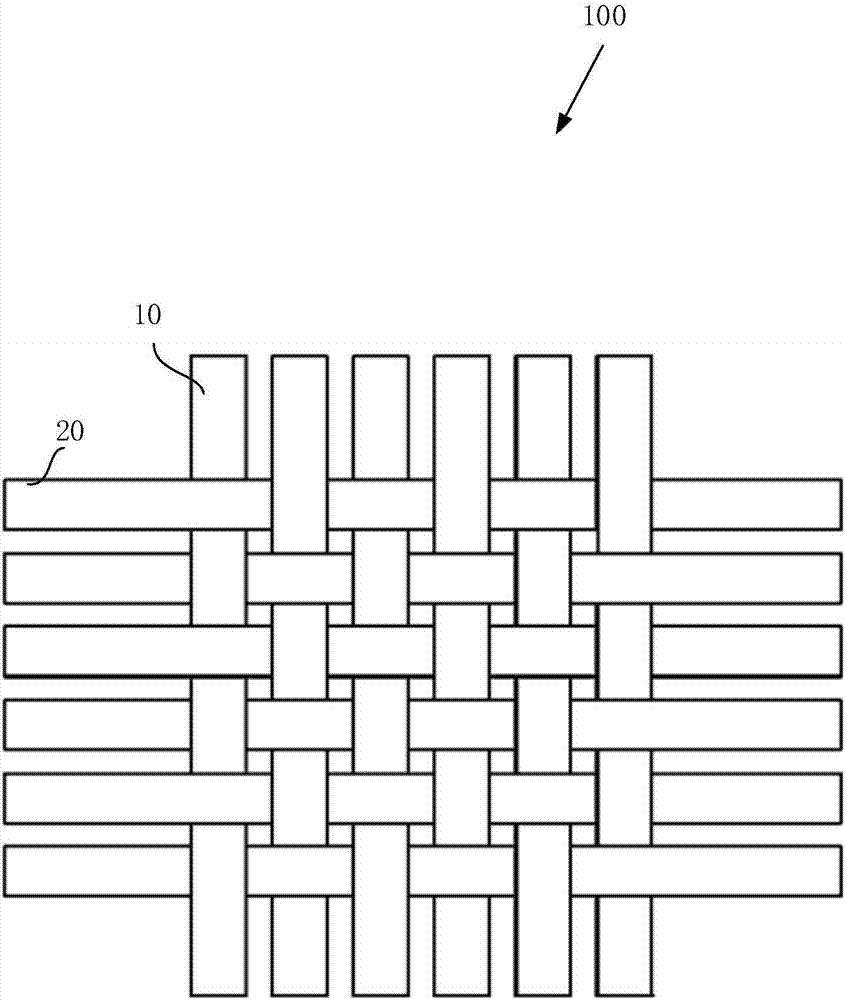

Textile fabric and application thereof

ActiveCN107083603AWill not cause uneven thicknessAvoid wrinklesOrnamental textile articlesMulti-ply fabricsSurface layerEngineering

The application of the invention aims at providing the textile fabric and application of the textile fabric, wherein the textile fabric is formed by mutually weaving a plurality of warps and wefts and comprises a surface layer, a lining layer and a middle layer arranged between the surface layer and the lining layer. Each part of the warp is part of the surface layer, the lining layer and the middle layer, and the warp shuttles among the surface layer, the middle layer and the lining layer and alternately circulates. In addition, after the warps are mutually woven with the wefts in the surface layer, the middle layer and the lining layer, and a connecting surface distributed in a staggered manner and a plurality of three-dimensional cavities used for being filled with down feather are formed between the surface layer and the lining layer. Compared with the prior art, the structure does not cause uneven thickness of the whole textile fabric, the phenomenon of wrinkles is avoided, and the condition that the heat retaining property is relatively bad because of a gap between the adjacent two three-dimensional cavities is not caused. Furthermore, the structure is acquired without artificial cutting and stitching, therefore, the working efficiency is greatly improved, and the labor cost is lowered.

Owner:浙江懿纱纺织科技有限公司

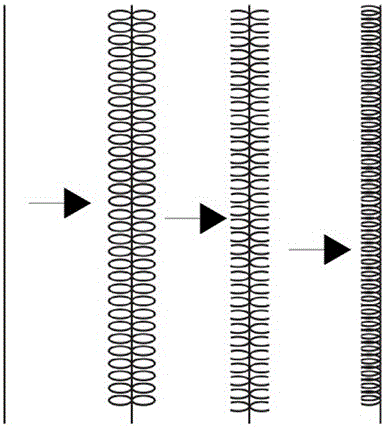

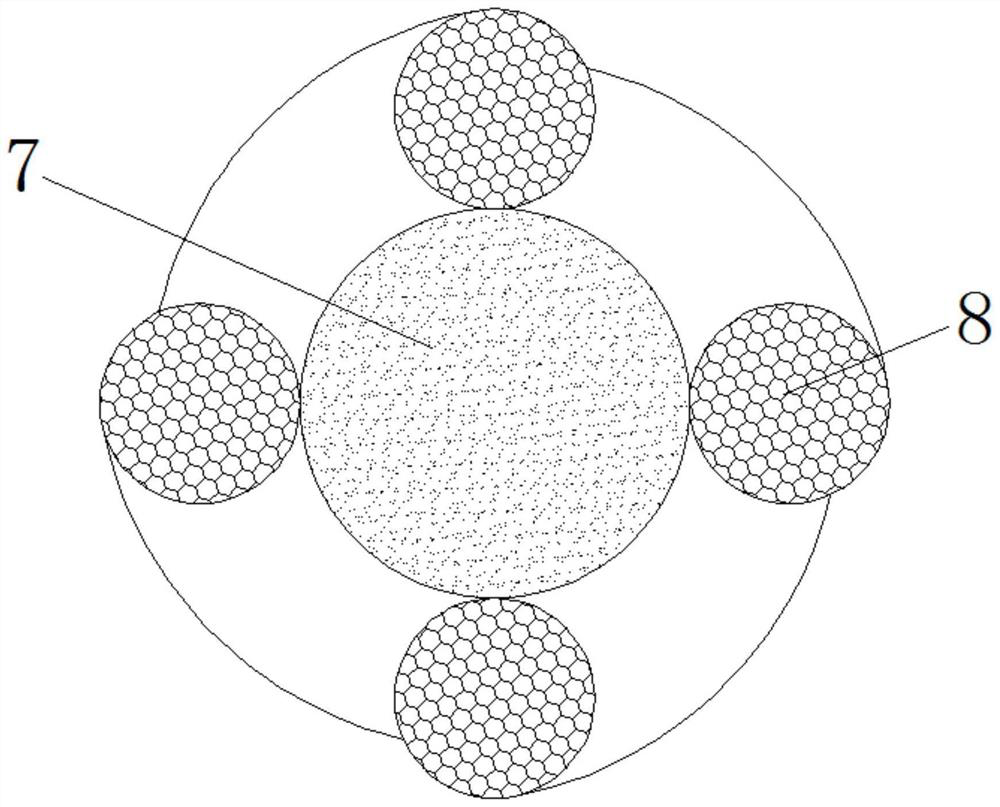

Diaphragm for battery and preparation method thereof

ActiveCN108963168AGuaranteed air permeabilityImprove adhesionCell component detailsHardnessEngineering

The invention belongs to the technical field of batteries, in particular to a separator for batteries and a preparation method thereof. The separator for battery comprises a base film, an aramid coating and a composite coating of PVDF and PMMA. On the premise of guaranteeing the permeability of the separator, the adhesive force is improved, the adhesion between the separator and the battery electrode sheet is good, the interface resistance is reduced, and the cell hardness is improved. A method for prepare a separator for a battery. The composite coating of PVDF and PMMA was obtained by spraying the mixture of PVDF and PMMA on the aramid coatings. The prepared separator has low permeability and value-added, good adhesion to the battery electrode, and can improve the rate discharge and cycle performance of the battery.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

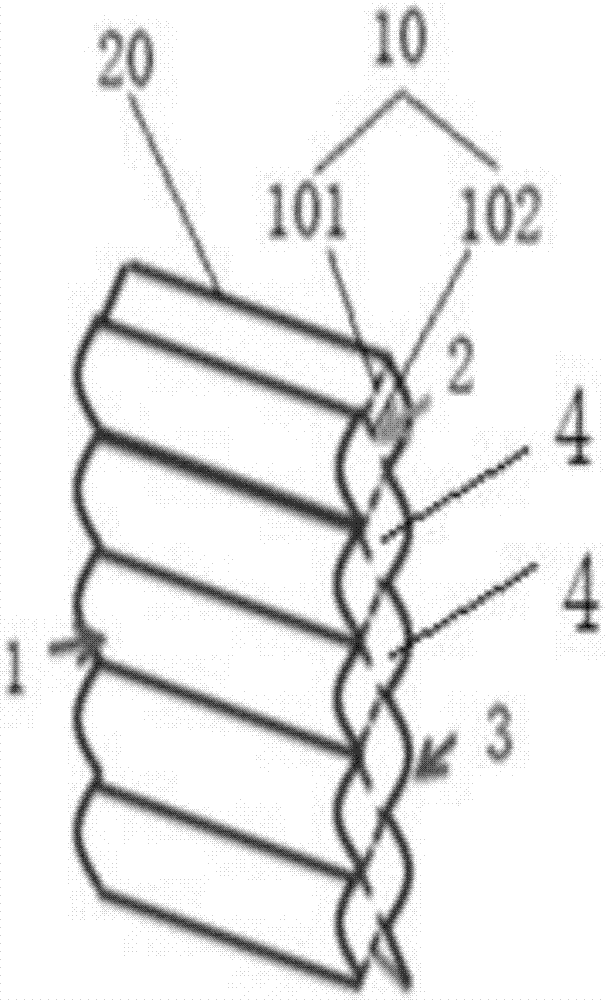

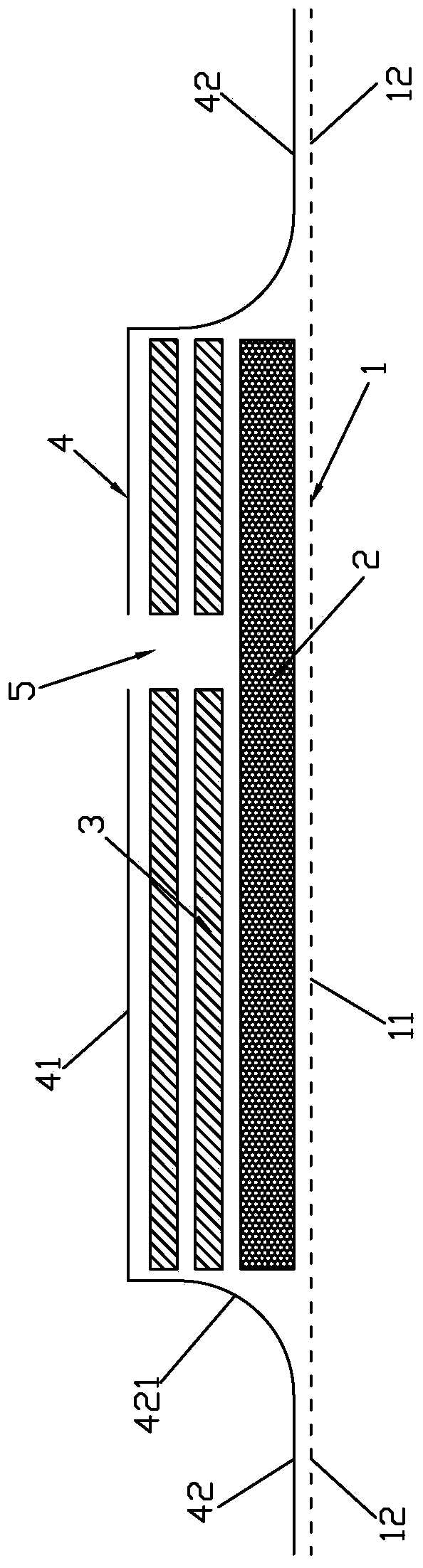

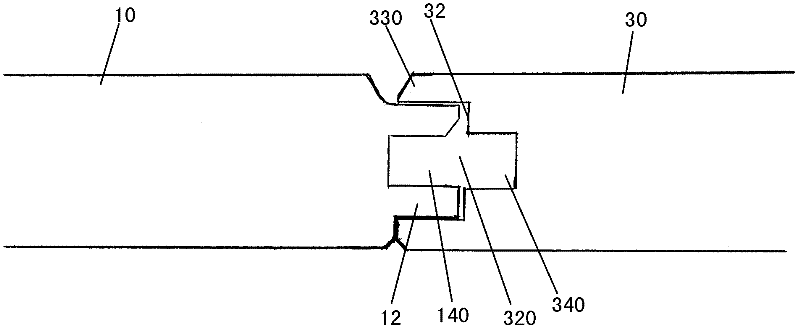

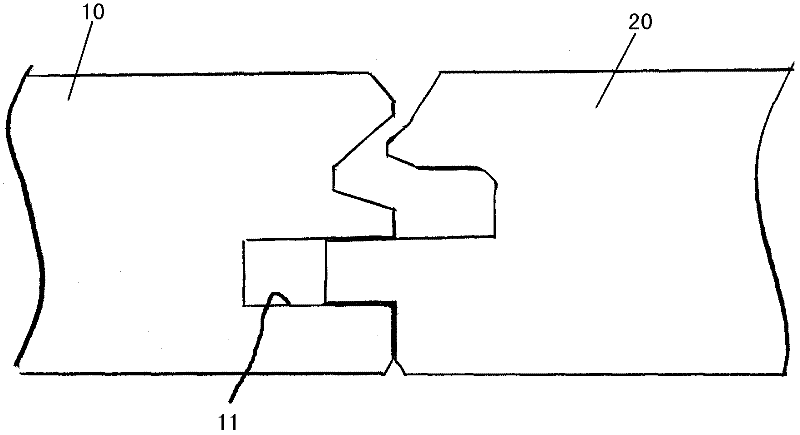

Convection tide-discharge heat conducting wood floor block and wood floor spliced thereby

ActiveCN101492955AGuaranteed air permeabilityCovering/liningsHot-air central heatingSolid woodHeat conducting

The invention discloses convection-type damp-discharging and heat-conducting solid wood floor blocks, which can be spliced to form the damp-discharging and heat-conducting solid wood floor and the back of which is formed with a longitudinally-through air guide groove, a longitudinal first end forms a transverse groove, a transverse first side forms a longitudinal tenon, a longitudinal second side forms a longitudinal groove, and the air guide groove is communicated with the transverse groove; the invention is characterized in that the bottom of the transverse groove forms a transverse convection groove, the depth of the longitudinal groove is larger than the length of the longitudinal tenon, the bottom of the longitudinal groove forms a longitudinal convection groove, the transverse convection groove and the longitudinal convection groove are at least partially intercrossed to be communicated with each other, two solid wood floor blocks form a transverse joint seam by abutting the longitudinal first end of one solid wood floor block against to the longitudinal second end of the other solid wood floor block, and the longitudinal convection groove is communicated with the transverse joint seam.

Owner:陈洪淳

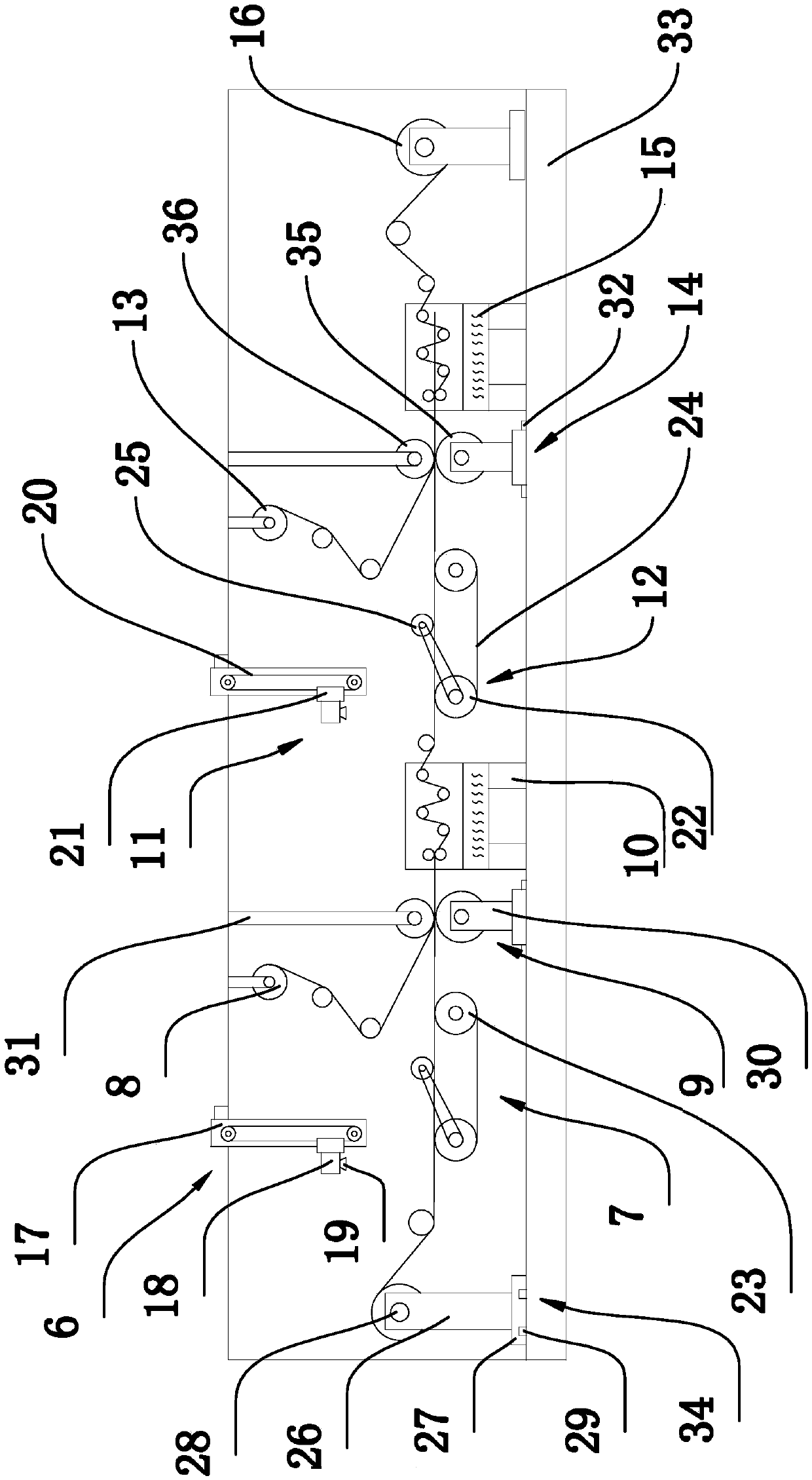

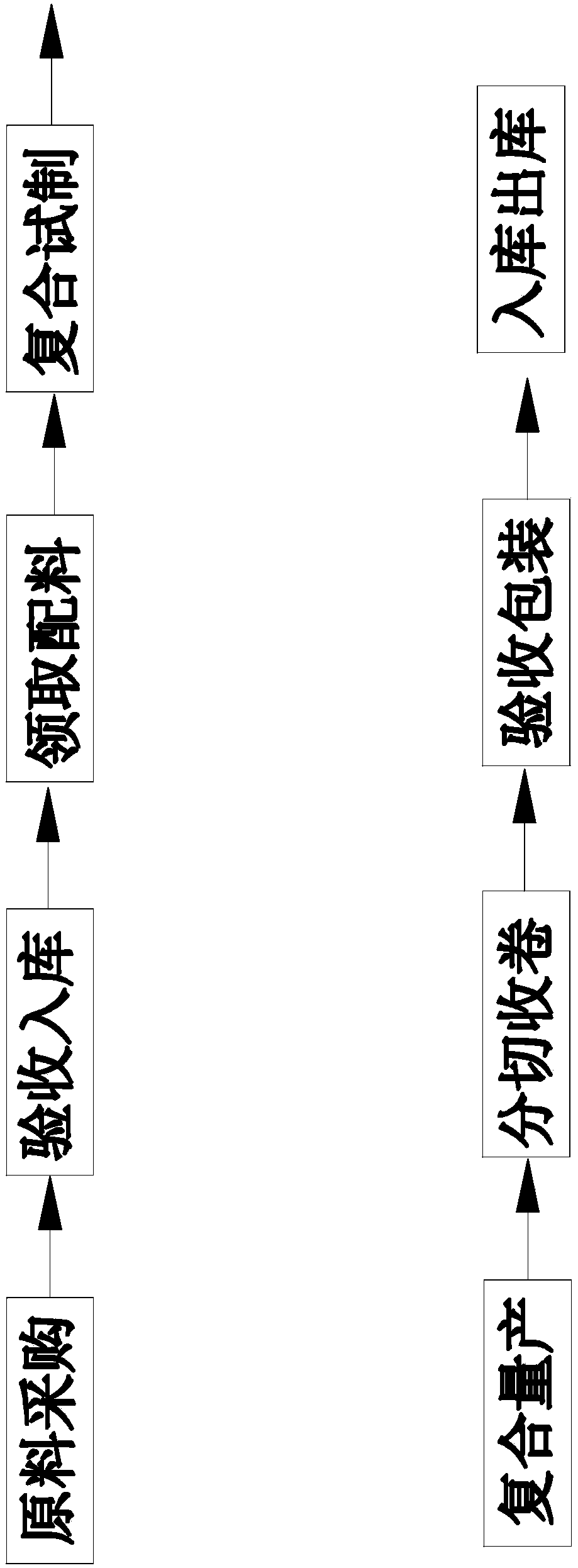

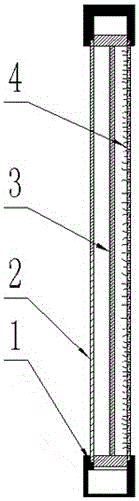

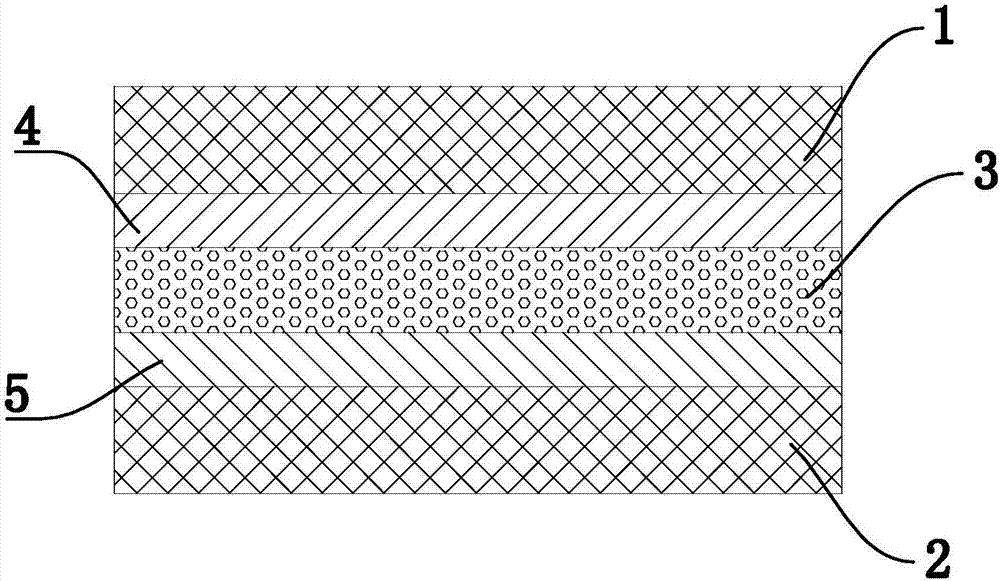

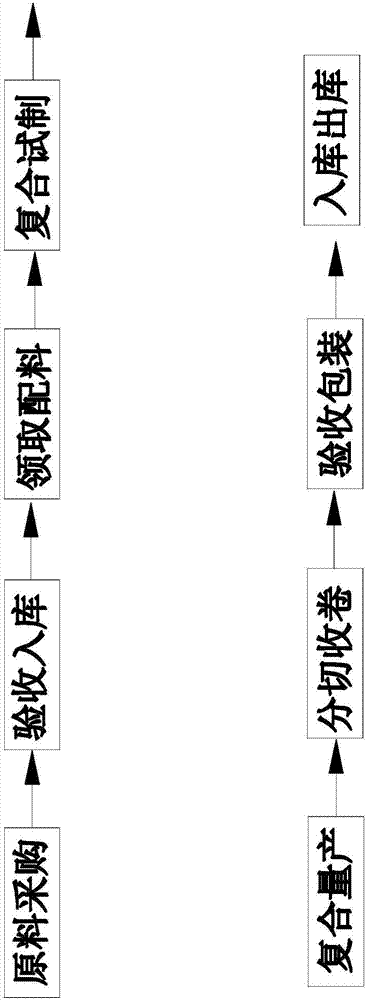

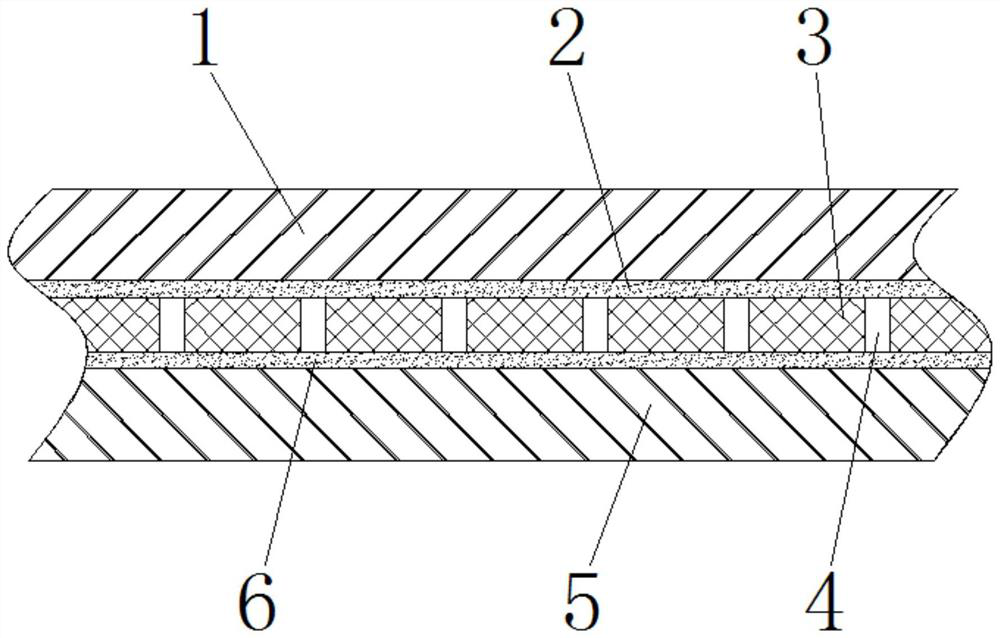

Preparation method of disposable surgical protective clothing material

InactiveCN107696620AImprove breathabilityGuaranteed air permeabilitySynthetic resin layered productsLaminationAdditive ingredientGram

The invention provides a preparation method of a disposable surgical protective clothing material. The surgical protective clothing material comprises a first non-woven fabric layer, a second non-woven fabric layer and a breathable film layer, the breathable film layer is arranged between the first non-woven fabric layer and the second non-woven fabric layer, and the first non-woven fabric layer and the breathable film layer are compounded through a first adhesive layer, the breathable film layer and the second non-woven fabric layer are compounded through a second adhesive layer; the first non-woven fabric layer and the second non-woven fabric layer employ same water-repellent non-woven fabrics, the breathable film layer is a polyethylene breathable film, the thickness of the first non-woven fabric layer and the second non-woven fabric layer are same, the thickness of the first adhesive layer and the second adhesive layer are consistent, the gram weight of the first non-woven fabric layer and the second non-woven fabric layer are both 1-1.2 times the gram weight of the breathable film layer, and the gram weight of the first adhesive layer and the second adhesive layer are both 0.1to 0.15 times the gram weight of the breathable film layer. The preparation method includes the following steps: A) raw material purchasing; B) acceptance storage; C) ingredient getting; D) trial manufacture through compounding; E) mass production through compounding; F) cutting and reeling; G) acceptance packing; and H) warehousing and dispatching.

Owner:浙江麦普拉科技股份有限公司

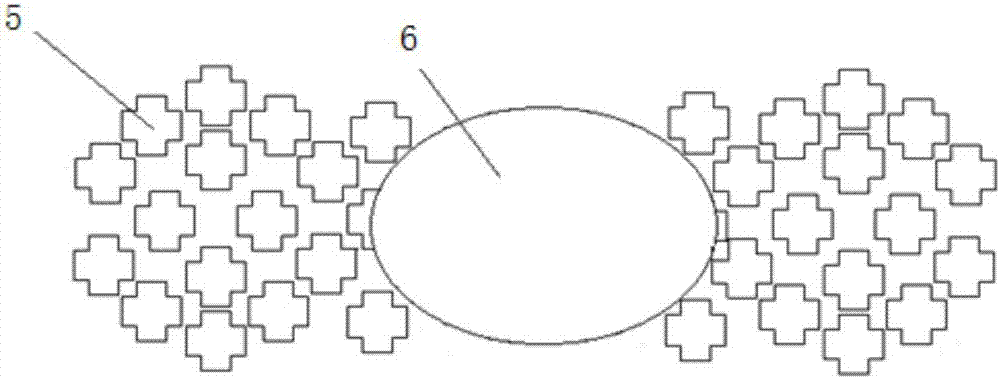

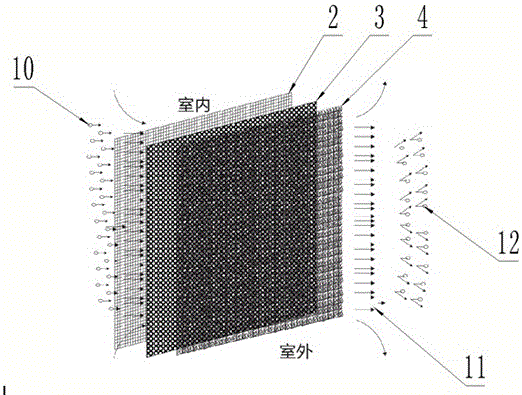

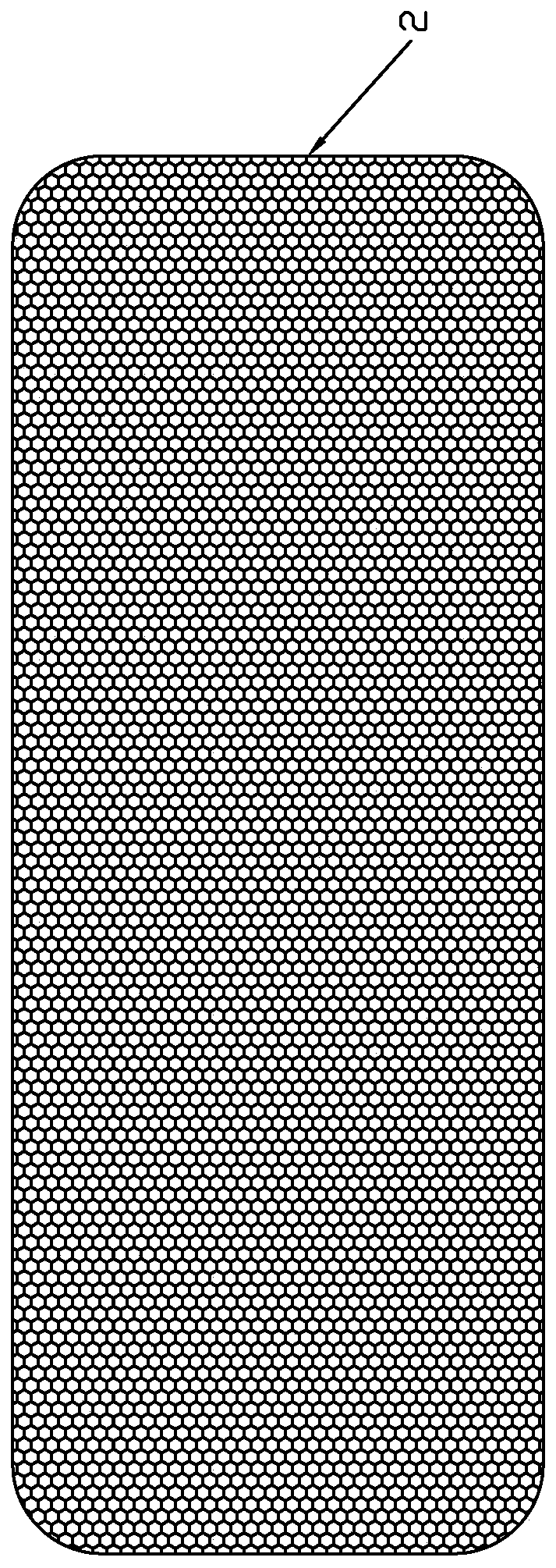

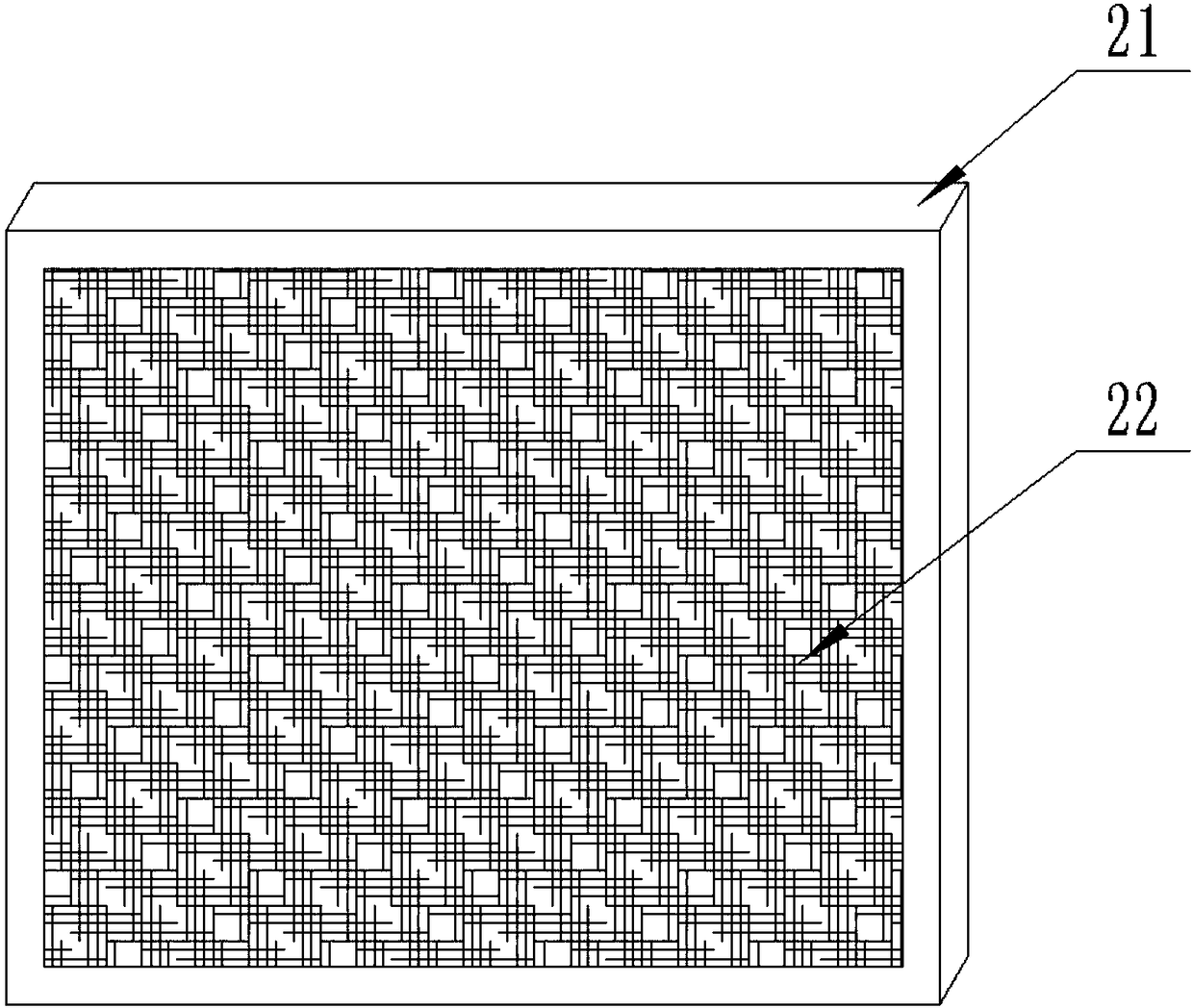

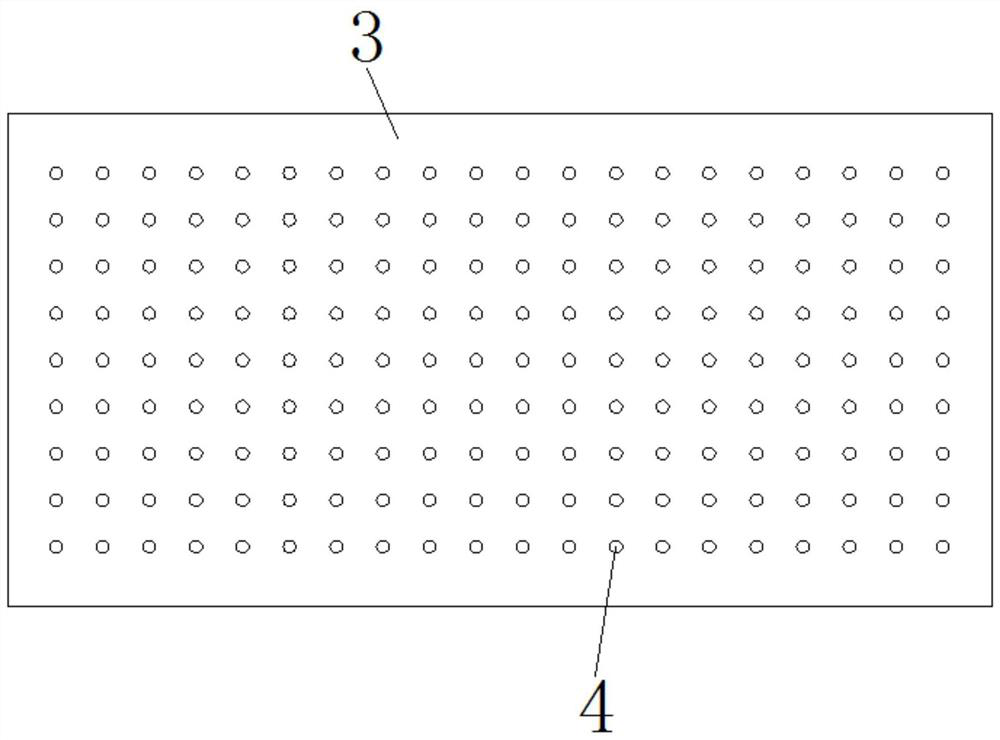

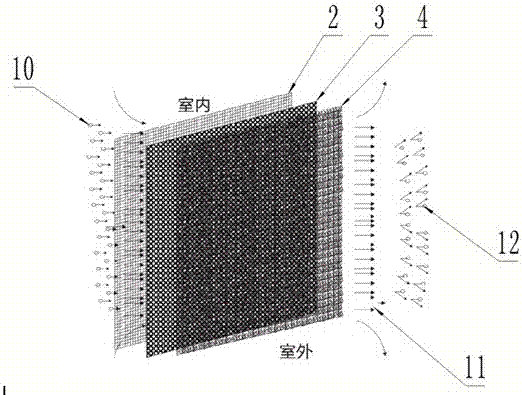

Multi-function anti-haze window based on metal cellular network

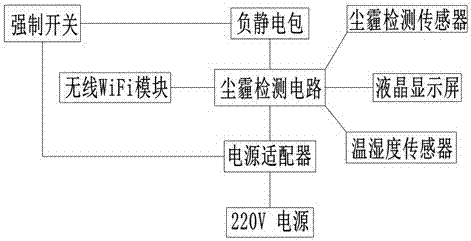

ActiveCN106121497AGuaranteed air permeabilityEnhance the effect of static haze isolationInsect protectionVacuum evaporation coatingPush and pullWindow screen

The invention discloses a multi-function anti-haze window based on a metal cellular network. The multi-function anti-haze window based on the metal cellular network comprises a window frame, window screen nets, an electrostatic generator and a master control electrical circuit; the window frame is composed of an insulated inner frame body and an outer frame body; the insulated inner frame body is used for unfolding the window screen nets; the outer frame body is used for being combined with a push and pull slide way of a window screen; the window screen nets are composed of three nets, namely an electric conductive screen net with fringes, a static electricity storage screen net and an insulated screen net in sequence; and the electric conductive screen net with fringes is connected with the negative static electrode of the electrostatic generator. The multi-function anti-haze window based on the metal cellular network has the advantages of energy saving, good anti-haze effect, excellent breathability and the like.

Owner:邵 辉

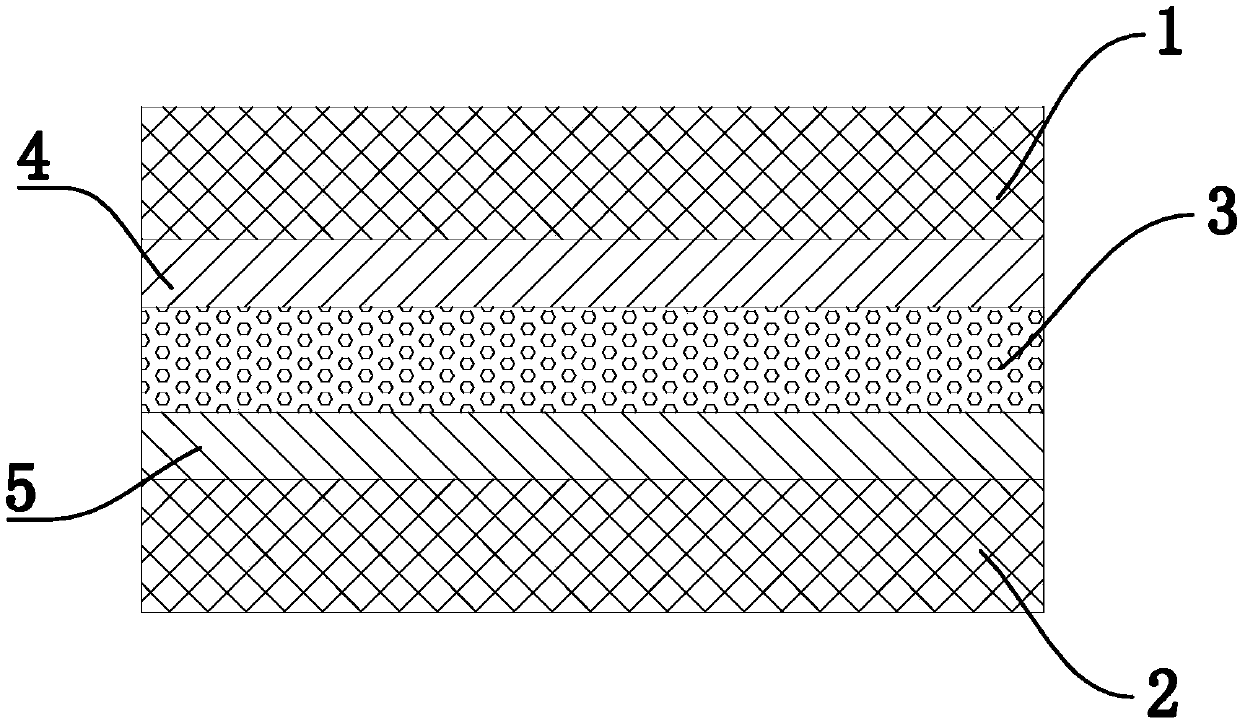

Disposable operation protective clothing material and preparation method thereof

InactiveCN106926523AImprove breathabilityGuaranteed air permeabilitySynthetic resin layered productsLaminationAdditive ingredientGram

The invention provides a disposable surgical protective clothing material and a preparation method thereof. The surgical protective clothing material includes a non-woven fabric layer 1, a non-woven fabric layer 2 and a breathable film layer, and the breathable film layer is arranged on the non-woven fabric layer 1 and the non-woven fabric layer. Between the second woven fabric layer, the first non-woven fabric layer and the air-permeable film layer are bonded and compounded through the adhesive layer one, and the air-permeable film layer and the second non-woven fabric layer are bonded and compounded through the second adhesive layer; the first non-woven fabric layer and the non-woven fabric layer The second woven fabric layer is the same water-repellent non-woven fabric, the breathable film layer is a polyethylene breathable film, the thickness of the first non-woven fabric layer is the same as that of the second non-woven fabric layer, and the thickness of the first adhesive layer is the same as that of the second adhesive layer. The gram weight of the non-woven fabric layer 1 and the non-woven fabric layer 2 is 1 to 1.2 times the gram weight of the breathable film layer, and the gram weight of the adhesive layer 1 and the adhesive layer 2 is 0.1 times the gram weight of the breathable film layer. ~0.15 times; the preparation method of surgical protective clothing materials includes steps: A) raw material procurement; B) inspection and storage; C) receiving ingredients; D) compound trial production; E) compound mass production; F) slitting and winding; G) Acceptance of packaging; H) storage and delivery.

Owner:浙江麦普拉科技股份有限公司

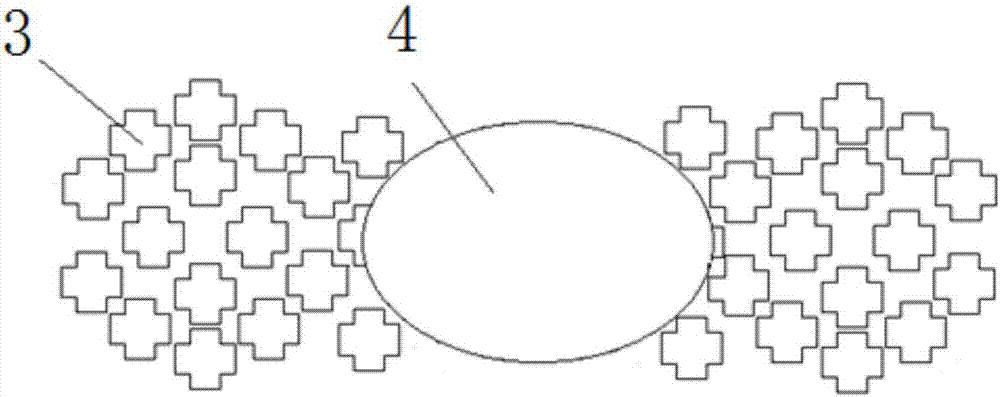

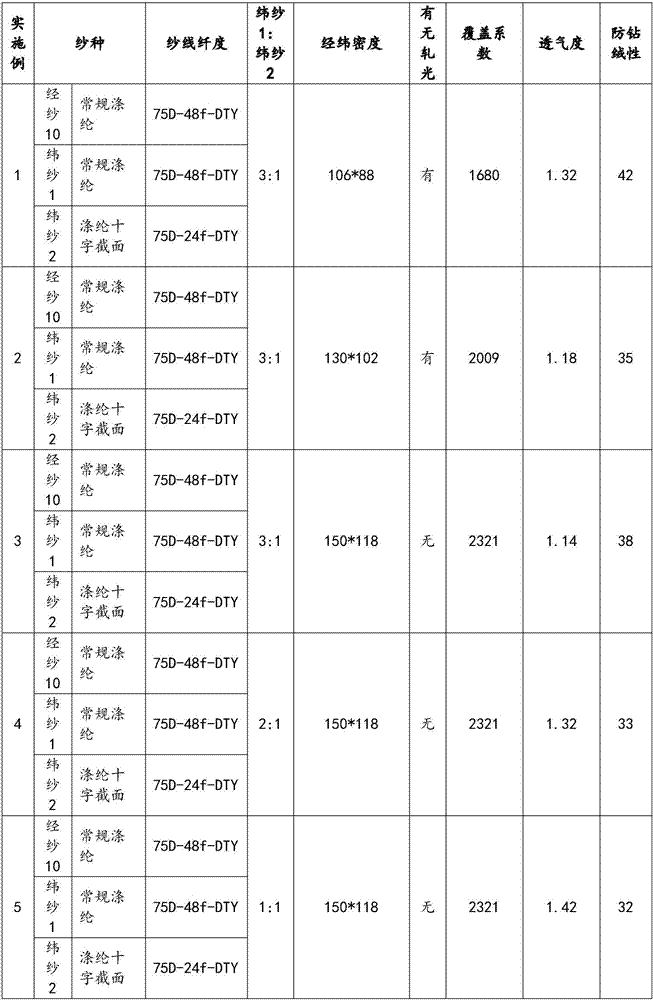

Fabric and application thereof

The invention aims at providing a fabric and application thereof. The fabric is composed of a lot of interwoven warp and weft, at least one of the warp and weft of the fabric comprises profiled fiber yarn composed of multiple profiled fibers, and the weight of the profiled fiber yarn accounts for a preset proportion in the fabric. After the profiled fiber yarn is interwoven with non-profiled fiber yarn in the fabric, the cover factor of the fabric is bigger than or equal to 1600. The fabric has smaller and more holes of which the diameters are smaller than those of down feather compared with a traditional fiber fabric under the same warp and weft density due to the profiled fiber yarn, accordingly the down feather can be prevented from unthreading from the fabric, and meanwhile the air permeability of the fabric is improved while the downproofness is ensured with the help of the quantity advantage of the holes.

Owner:浙江懿纱纺织科技有限公司

Medical device for managing damaged tissue exudate

PendingCN110584881AStrong bonding abilityAvoid easy cloggingAdhesive dressingsIntravenous devicesEdge regionDamages tissue

The invention discloses a medical device for managing damaged tissue exudate. The medical device comprises a basal layer, a conducting layer, a liquid storing layer and an exhaust layer which are connected together in an assembling manner, and the basal layer, the conducting layer, the liquid storing layer and the exhaust layer have parts which are sequentially connected together; the liquid storing layer and the exhaust layer form a liquid storing and exhaust part; negative pressure holes formed in a penetrating manner are formed in the liquid storing and exhaust part; an exudate through holeis formed in the basal layer in a penetrating manner; the exhaust layer has a first central region of which at least one part faces the top surface of the liquid storing layer and a first edge regionsurrounding the first central region; and the air permeability of the first central region of the exhaust layer is greater than that of the first edge region.

Owner:DABO MEDICAL TECH CO LTD +1

Convection humidity-discharging and heat-conducting solid wood floor block and spliced solid wood floor thereof

Convection humidity-discharging and heat-conducting solid wood floor block, which can be spliced into a humidity-discharging and heat-conducting solid wood floor, the back surface is formed with a longitudinal though air-conducting groove, the first end in the longitudinal direction is formed with a transverse groove, the first side in the transverse direction is formed with a longitudinal rabbet, the second side in the longitudinal direction is formed with a vertical groove, and the air-conducting groove is communicated with the transverse groove, wherein the bottom of the transverse groove is formed with a transverse convection groove, the depth of the vertical groove is larger than the length of the vertical rabbet, the bottom of the vertical groove is formed with a vertical convection groove, at least parts of the transverse convection groove and the vertical convection groove are intersected form being communicated with each other, a transverse joint is retained after the first end in the longitudinal direction of one of two solid wood floor blocks is pressed to the second end in the longitudinal direction of the other one, and the vertical convection grooves are communicated with the transverse joint.

Owner:陈洪淳

Smart vent window

PendingCN108222802AGuaranteed air permeabilityRealize the effect of static haze isolationInsect protectionPower-operated mechanismWindow openingEmbedded system

The invention discloses a smart vent window comprising a window frame, an external window, an electrostatic window body and smart control system. The external window is mounted on the window frame, the electrostatic window body is mounted on the window frame, the smart control system comprises an air detection unit, a control unit and an electric window-opening unit, the air detection device is mounted on the window frame, the electric window-opening unit is connected with the external window, and the air detection device, the electrostatic window body and the electric window-opening device are respectively connected with the control unit. The smart vent window has the advantages of intelligently isolating and absorbing haze in high speed and the like.

Owner:广州市爱因电子有限公司

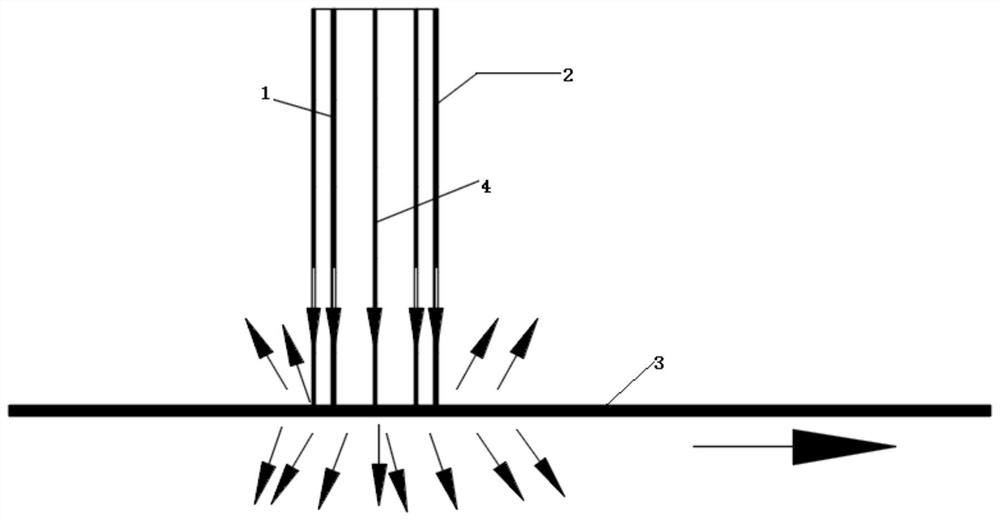

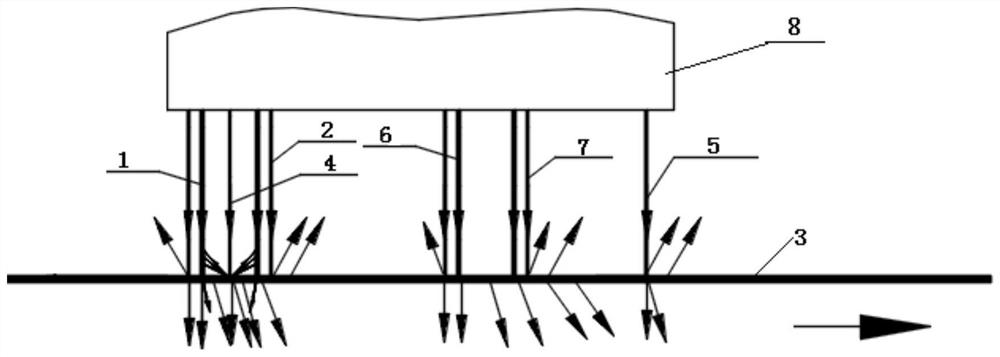

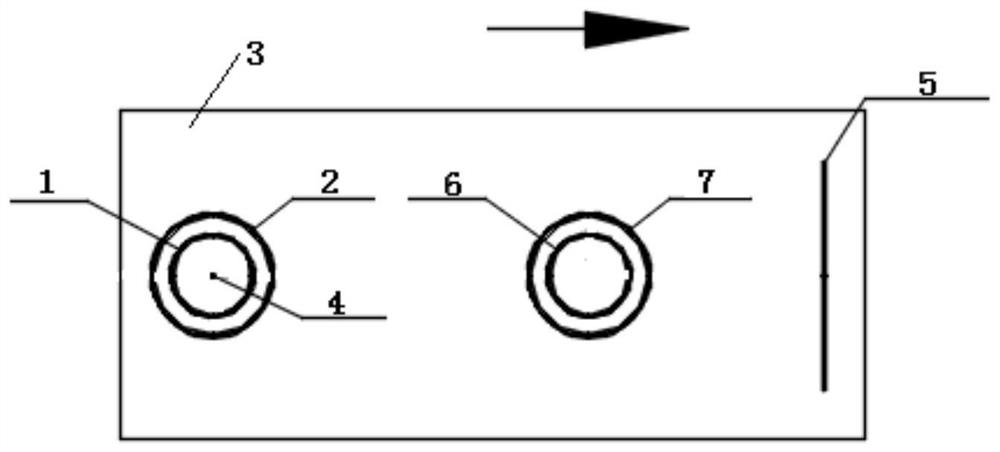

Silk screen cleaning device and method

PendingCN111974737AReduce wasteReduce secondary pollutionDrying gas arrangementsCleaning using liquidsPollutantAir knife

The invention provides a silk screen cleaning device and method. The silk screen cleaning device comprises a body. The body comprises a first air knife set. The first air knife set comprises a first annular air knife, a second annular air knife and a cleaning liquid nozzle. The cleaning liquid is sealed by the first air knife, part of the reflected cleaning liquid is carried by the high-pressure gas of the first air knife to be sprayed to a silk screen, and therefore the cleaning efficiency is improved, the waste caused by the situation that the cleaning liquid is reflected is reduced, and thephenomenon that the reflected cleaning liquid and pollutants which can be carried by the cleaning liquid splash to other regions and cause the secondary pollution is reduced. The internal air knife is encircled by the external air knife, the airflow of the internal air knife is sealed by the external air knife, even though part of the gas of the internal air knife is reflected, the gas cannot escape from the external air knife and is carried by the external air knife to move towards the silk screen again, and therefore the airflow of the internal air knife only can be centralized to pass through the silk screen, the force and the efficiency of drying / cleaning operation of the silk screen are improved, and the air permeability of the silk screen is guaranteed.

Owner:福涞堡造纸技术(上海)有限公司

Automatic printing paper waste discharging device

InactiveCN112426819AGuaranteed air permeabilityImprove collection effectDispersed particle filtrationTransportation and packagingPapermakingSewage

The invention relates to the field of papermaking, and particularly discloses an automatic printing paper waste discharging device which comprises a shell, a water tank, a suction fan, an air inlet pipe and an air outlet pipe. A separation net cylinder fixed to the outer side of the air outlet pipe is arranged in the shell, and a plurality of air inlet holes are evenly formed in the side wall, corresponding to the top end in the separation net cylinder, of the air outlet pipe. The lower side of a water spraying pipe is uniformly communicated with a plurality of vertical nozzles; the bottom ofthe water tank is communicated with the bottom of the shell through a drain pipe; a sliding seat is slidably connected to the sliding rail; and a filter screen is fixedly mounted in the water tank. Waste is separated from air by arranging the rotary separation net barrel in the shell and flushed under the action of downward water spraying, so that the waste is mixed into water, and the air passingability of the separation net barrel is guaranteed; sewage with waste enters the water tank from the bottom, the water tank moves up and down, and internal water is discharged according to differentheights of the water tank.

Owner:枣庄市天龙纸业有限公司

Solid and liquid separator for materials

ActiveCN103657176BImprove stressThe moisture content of solids is reducedFiltration separationPush and pullLocking mechanism

The invention discloses a solid and liquid separator for materials. The solid and liquid separator comprises a frame, press plates, filter plates, a push-and-pull locking mechanism, a filter cloth mechanism, a filter cloth regeneration mechanism and a cleaning mechanism which are arranged on the frame, wherein the press plates and the filter plates are arranged on the frame in a sliding way alternately, and are matched to extrude a material, so that solid and liquid of the material can be separated; the push-and-pull locking mechanism is used for locking, pushing away all the press plates and filter plates, so that solid-liquid separation operation can be performed, or the material can be discharged; the filter cloth mechanism is used for separating solid and liquid of the material when the material is extruded; the filter cloth regeneration mechanism is used for washing to regenerate the filter cloth after the material is discharged; the cleaning mechanism is used for cleaning the material attached to the separator after solid and liquid of the material are separated. The solid and liquid separator has the characteristics of reasonable design, high structure strength, convenience in operation, complete solid and liquid separation, high separation efficiency, convenience in cleaning, long service life, log maintenance frequency, high reliability, strong practicality and the like, and is beneficial for greatly increasing production benefit of enterprises.

Owner:四川宝凯鑫诚环保科技有限公司

Method for preparing tobacco sheet paper base from tobacco stems

The invention discloses a preparation method of tobacco sheet paper base made from tobacco stems. Tobacco stems are used as raw materials to prepare paper, including the steps of dipping, refining, beating, and sheeting; the invention changes the traditional technical prejudice and habit of controlling the refining by controlling the current of the refiner, and creatively adopts the control of grinding The pulp grinding disc, the refining gap, the number of refining stages and the refining concentration are realized. The invention systematically optimizes the refining process conditions, adopts two-stage or three-stage refining, the refining concentration is 20%, and the refining gaps of the first stage and the second stage are respectively 0.4mm and 0.20mm. The present invention analyzes the relationship between the refining process and the performance of tobacco stem fibers through overall research, and summarizes the optimal controllable refining conditions, which ensures that the prepared tobacco stem pulp has the longest fiber length and the highest bulk thickness of the paper. The good quality of the reconstituted tobacco leaves is guaranteed, the performance of the paper base of the tobacco sheet is comprehensively improved, and finally a technical basis is provided for improving the quality of the tobacco sheet and the quality of the cigarette.

Owner:CHINA TOBACCO GUANGDONG IND +1

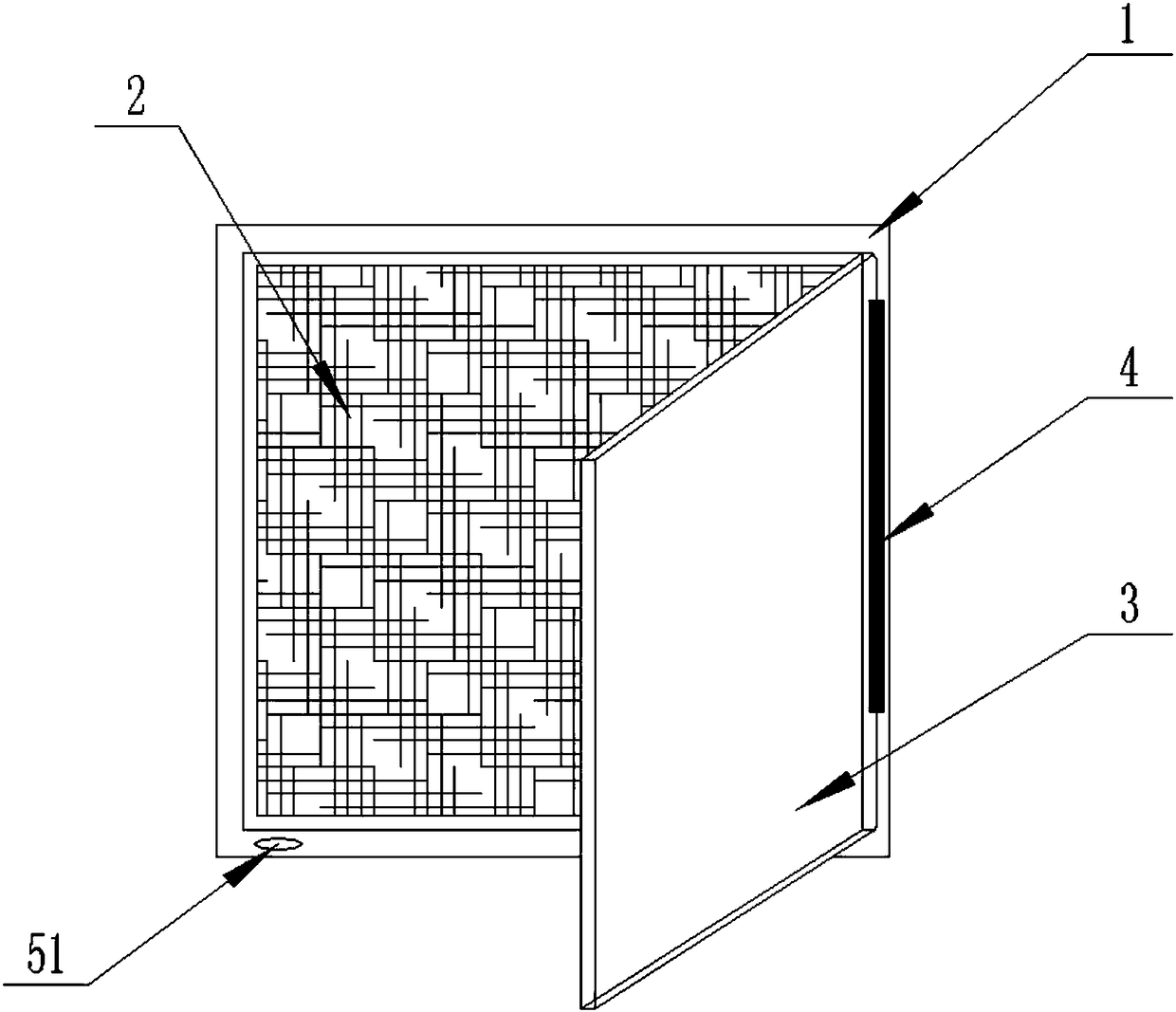

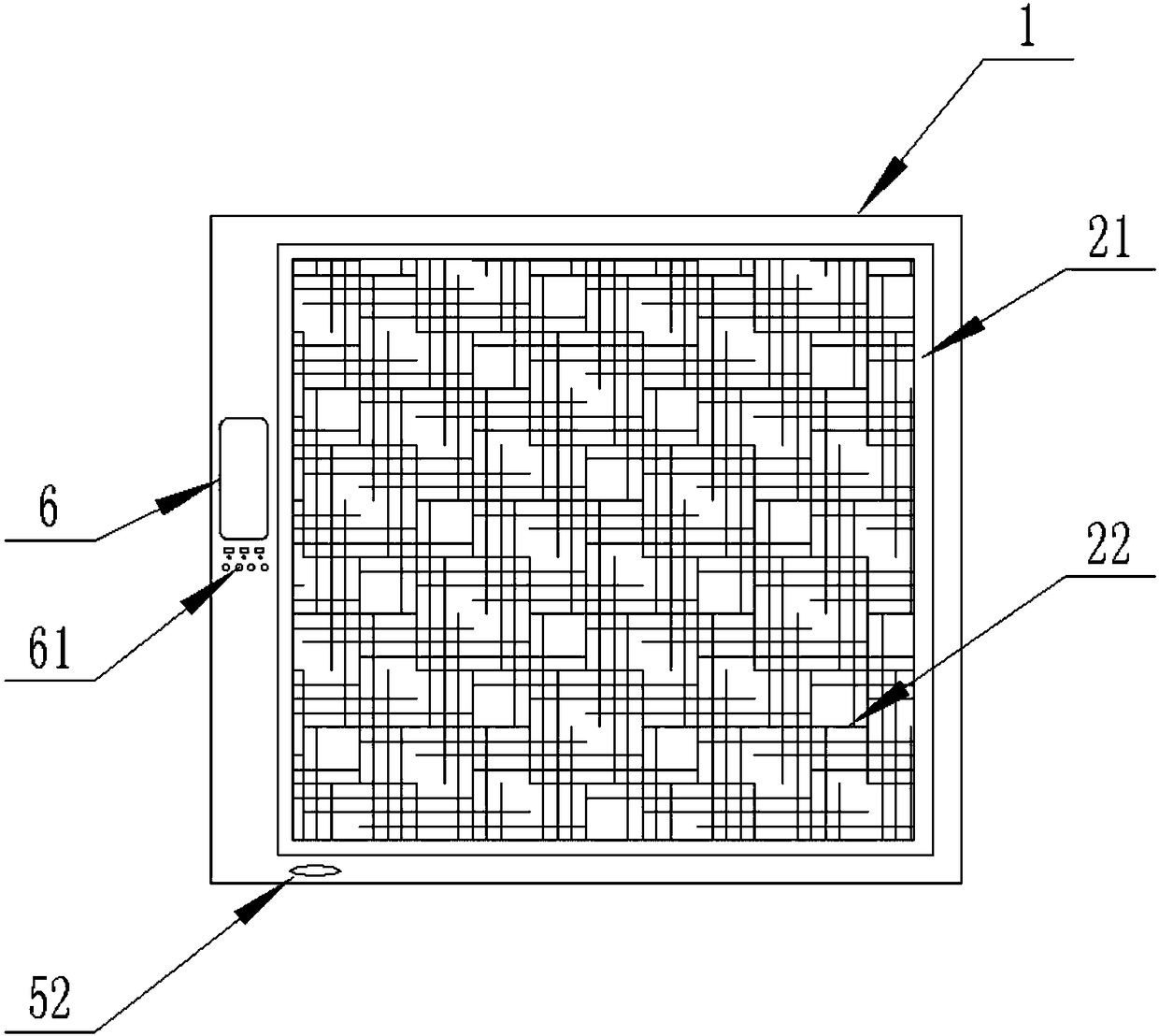

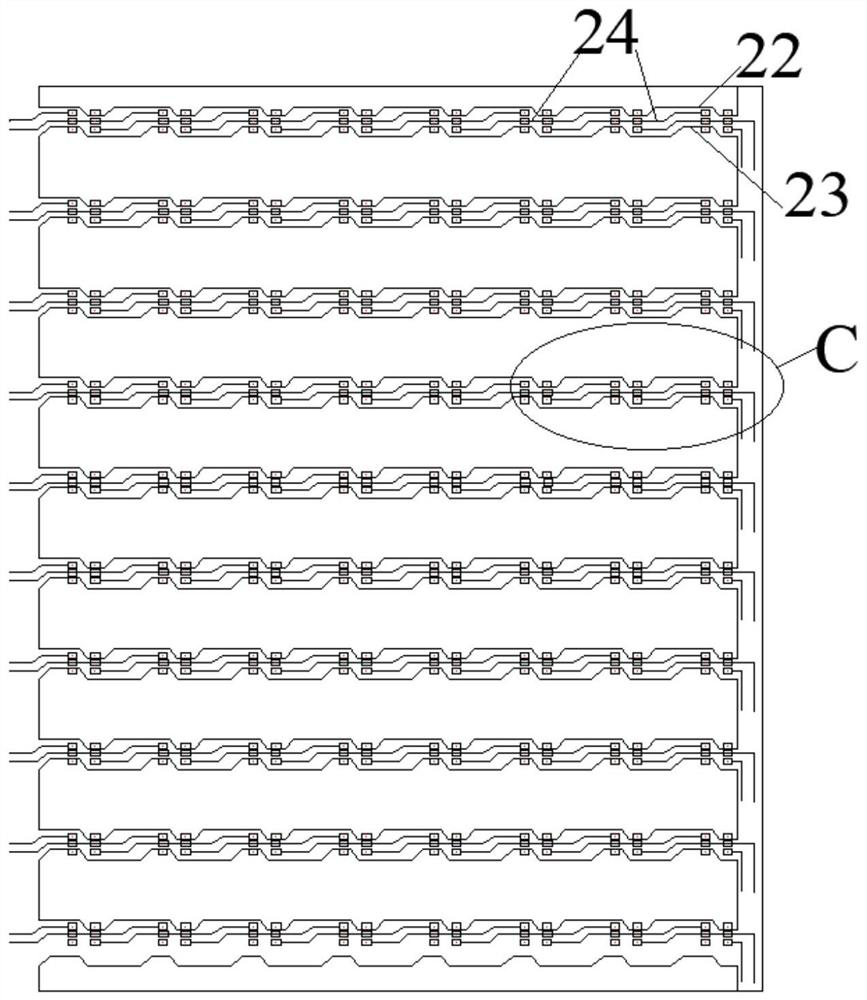

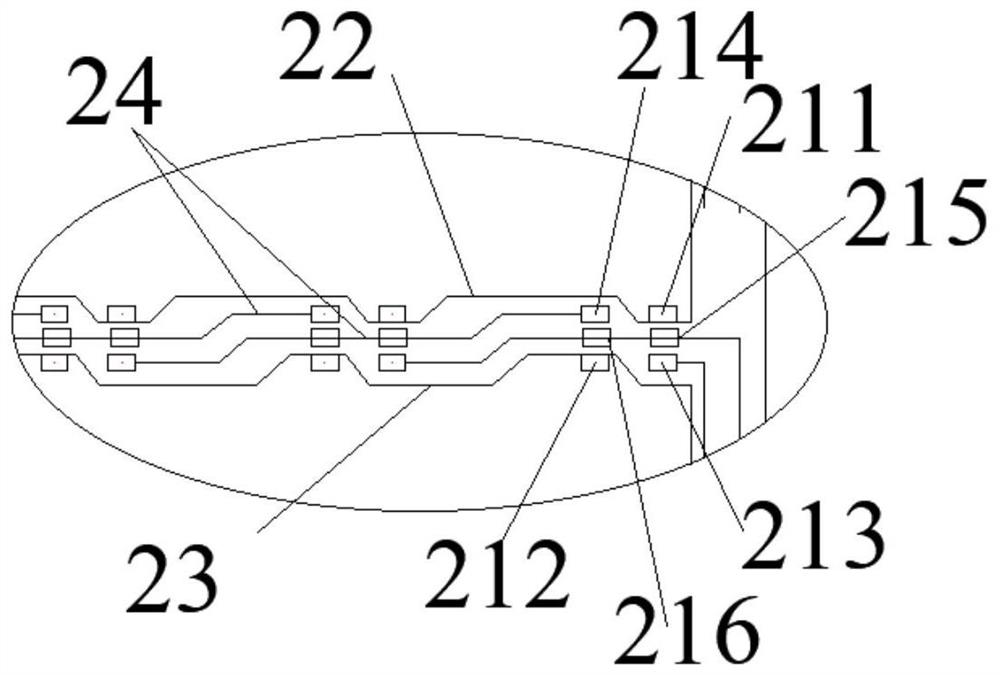

LED transparent display screen

ActiveCN113241015AImprove reliabilityFirmly connectedCasings/cabinets/drawers detailsIdentification meansEngineeringMaterials science

The invention belongs to the technical field of display screens and particularly relates to an LED transparent display screen. The invention discloses a transparent display unit in an LED transparent display screen. The transparent display unit comprises a power supply assembly and at least one LED transparent lamp panel, wherein the LED transparent lamp panel comprises a plurality of lamp strips which are arranged in parallel, each lamp strip comprises a positive electrode end and a negative electrode end which are oppositely arranged, and the positive electrode ends and the negative electrode ends are linearly arranged; a positive electrode end of one lamp strip and a negative electrode end of the other lamp strip in every two adjacent lamp strips are adjacent and arranged at intervals, and a plurality of lamp beads arranged in a row are arranged at the positions of the adjacent positive electrode ends and the adjacent negative electrode ends of every two adjacent lamp strips. Due to the fact that the positive pole end and the negative pole end, connected with the positive pole lamp base and the negative pole lamp base on each lamp strip respectively, of the LED transparent lamp panel are linearly arranged, and the connecting lines on each lamp strip are also linearly arranged, the circuit of the lamp face is simple, the permeability rate of the LED transparent lamp panel is guaranteed, two paths of signals are formed on the lamp strip, and when one path of signals breaks down, the other signal line is used for replacing work, so reliability of the LED transparent display screen is improved.

Owner:浙江德广信电子科技股份有限公司

Separator for battery and preparation method thereof

ActiveCN108807804BHigh rate dischargeImprove cycle performanceCell component detailsElectrical batteryPhysical chemistry

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

A haze isolation window based on static conductive gauze

ActiveCN106014168BEasy to installGuaranteed air permeabilityInsect protectionElectrostatic separation detailsIsolation effectGuide wires

The invention discloses a haze-isolating window based on static-conducting gauze. The haze-isolating window comprises a window frame, wherein the window frame comprises an inner insulating frame and an outer frame; an ordinary metal net and the static-conducting gauze are arranged in the window frame, a tip end discharge structure is arranged on at least one side of the static-conducting gauze, the metal net and the static-conducting gauze are isolated by the inner insulating frame, the metal net is grounded through a guide wire, and the static-conducting gauze is connected with a negative electrostatic bag generation control device. The haze-isolating window is green, safe and energy-saving and has remote intelligent control and good air breathability and haze isolation effect.

Owner:合肥四周建筑装饰有限公司

Anti-residue device for discharging bin of cement grinding equipment

InactiveCN112660851ANo residue dischargeGuaranteed air permeabilityLoading/unloadingGear driveGear wheel

The invention discloses an anti-residue device for a discharging bin of cement grinding equipment in the technical field of cement grinding, comprising a base. A grinding machine is arranged at the top of the base; the right side of the grinding machine communicates with one end of a discharging pipe; the other end of the discharging pipe is connected with a discharging mechanism; and a supporting frame is arranged at the bottom of the discharging mechanism. When a driven gear drives an elastic rod to rotate, an inclined rod at the top of the driven gear drives fan blades to rotate upwards, air can be blown downwards, the blown air can blow off cement falling on the discharging mechanism due to floating, and therefore a motor can work, when the discharging plate is guaranteed to shake off the cement, a driving assembly used for driving the discharging plate to vibrate is guaranteed not to have cement residues, and residue-free discharging of the discharging bin of the cement grinding equipment can be achieved; a filter screen is driven to vibrate through a reset spring, so that the air passing performance of the filter screen is guaranteed; and normal circulation of airflow is guaranteed when blades of a rotating assembly work.

Owner:叶兰芳

An antibacterial and durable cotton yarn with moisture absorption and quick drying function

ActiveCN109910379BWith moisture absorption and quick drying functionImprove ventilation performanceSynthetic resin layered productsWoven fabricsYarnPolymer science

The invention discloses an antibacterial and durable cotton yarn with moisture absorption and quick-drying function, which comprises a first moisture absorption layer, a main thread core, a main moisture absorption cloth and a reinforced moisture absorption cloth, the inner side of the first moisture absorption layer is connected by a first connecting line layer. Base fabric layer, the outside of the main thread core is wrapped with an outer wrapping thread, the main absorbent cloth is provided with a main absorbent cloth warp thread and a main absorbent cloth weft thread, and the main absorbent cloth warp thread and the main absorbent cloth weft thread are provided with a main thread core and an outer wrapping thread. The reinforced hygroscopic cloth is provided with a reinforced hygroscopic cloth warp and a reinforced hygroscopic cloth weft, and the reinforced hygroscopic cloth warp and the reinforced hygroscopic cloth weft are provided with a main thread core and an outer cover wire, and the connection between the main hygroscopic cloth and the reinforced hygroscopic cloth There are intersections and passages. The antibacterial and durable cotton yarn with moisture absorption and quick drying function can effectively ensure the moisture absorption performance of the cotton yarn through the first moisture absorption layer and the second moisture absorption layer, and at the same time, the base fabric layer ensures the ventilation performance, so that the cotton yarn can be dried quickly .

Owner:英麒科技集团有限公司

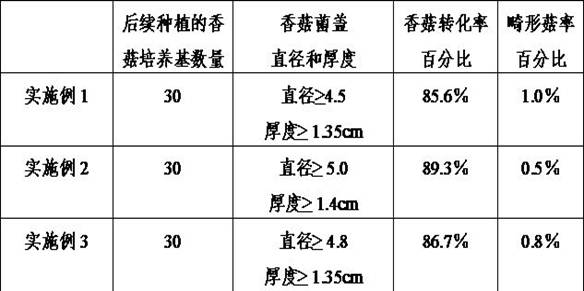

Pollution prevention and control method in shiitake mushroom cultivation process

PendingCN112840944AProduce pollutionGrow fastBioloigcal waste fertilisersCultivating equipmentsBARLEY GRASSHypha

The embodiment of the invention discloses a pollution prevention and control method in a shiitake mushroom cultivation process, and particularly relates to the field of shiitake mushroom cultivation. The pollution prevention and control method comprises the following specific prevention and control steps: S1, preparing a shiitake mushroom culture medium material; S2, shaping a shiitake mushroom culture medium; S3, inoculating the shiitake mushrooms; S4, culturing the shiitake mushrooms; and S5, preparing the culture medium for subsequently planted shiitake mushrooms. According to the pollution prevention and control method in the shiitake mushroom cultivation process, the culture medium is prepared from wood chips, sophora japonica pods, bean coats, corncobs, sweet potato residues, barley grass, bean cake residues and humic acid, the culture medium is borne by a bearing cylinder made of loofah sponge, the bearing cylinder is placed in a dark environment in a bamboo tube to culture hyphae after inoculation, and finally, a bamboo tube is removed, so that the hyphae are transferred into a greenhouse to be cultivated; after subsequent picking, the whole culture medium with shiitake mushroom roots, the culture medium material and the loofah sponge continues to be composted, no waste is generated in the whole culture medium manufacturing process and the shiitake mushroom cultivation process, all the adopted materials are pure natural materials, and no pollution is generated to the environment.

Owner:江苏红叶福茸农业科技有限公司

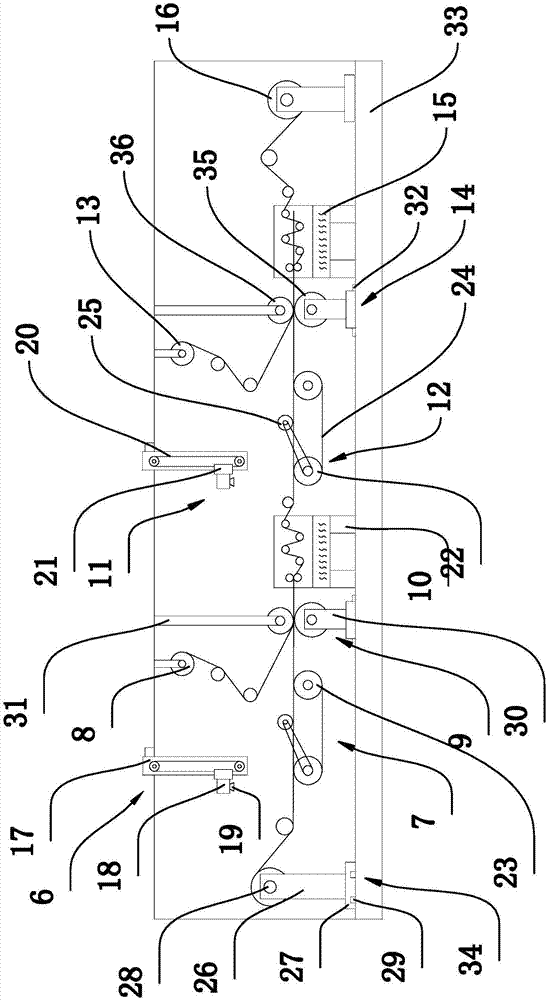

Surface treatment technology of singeing and calendering integrated machine

The invention discloses a surface treatment technology of a singeing and calendering integrated machine. The technology comprises the following steps that a to-be-treated filter material passes a front cloth storage frame and a carding box, enters a calender set through a cloth guiding roller 1, a cloth guiding roller 3 and a connection bridge upper roller, passes a gap between an upper press roller and a thermal roller in the calender set, enters the calender set again through a rear spreading roller, enters a singeing machine set through a front spreading roller, a connecting bridge middle roller and a cloth guiding roller 2 in sequence, and then passes a connecting bridge lower roller, a pulling roller, a cooling roller and a rear cloth storage frame, so that rolling action is completed. Based on the premise of guaranteeing that conventional performance of the thickness, air permeability and the like of the filter material reaches targets, the requirements of a client of coarse appearance quality of the filter material subjected to surface treatment are met, the defects of the prior art are overcome, the market demand is expanded, new application of the singeing and calenderingintegrated machine is developed, the utilization efficiency of the singeing and calendering integrated machine is improved, and not only is the running cost reduced, but also the technology is improved.

Owner:中材科技膜材料(山东)有限公司

A multifunctional anti-haze window based on metal honeycomb mesh

ActiveCN106121497BGuaranteed air permeabilityEnhance the effect of static haze isolationVacuum evaporation coatingInsect protectionPush and pullHoneycomb

The invention discloses a multi-function anti-haze window based on a metal cellular network. The multi-function anti-haze window based on the metal cellular network comprises a window frame, window screen nets, an electrostatic generator and a master control electrical circuit; the window frame is composed of an insulated inner frame body and an outer frame body; the insulated inner frame body is used for unfolding the window screen nets; the outer frame body is used for being combined with a push and pull slide way of a window screen; the window screen nets are composed of three nets, namely an electric conductive screen net with fringes, a static electricity storage screen net and an insulated screen net in sequence; and the electric conductive screen net with fringes is connected with the negative static electrode of the electrostatic generator. The multi-function anti-haze window based on the metal cellular network has the advantages of energy saving, good anti-haze effect, excellent breathability and the like.

Owner:邵 辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com