Circuit board and manufacturing method thereof

A production method and circuit board technology, applied in the directions of printed circuit components, secondary processing of printed circuits, and non-metallic protective layer coating, etc., can solve the problem of poor adhesion of cover films, easy oxidation, and inability to effectively protect circuits, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The manufacturing method of the circuit board provided by the technical solution and the produced circuit board will be further described in detail below in conjunction with the accompanying drawings and embodiments.

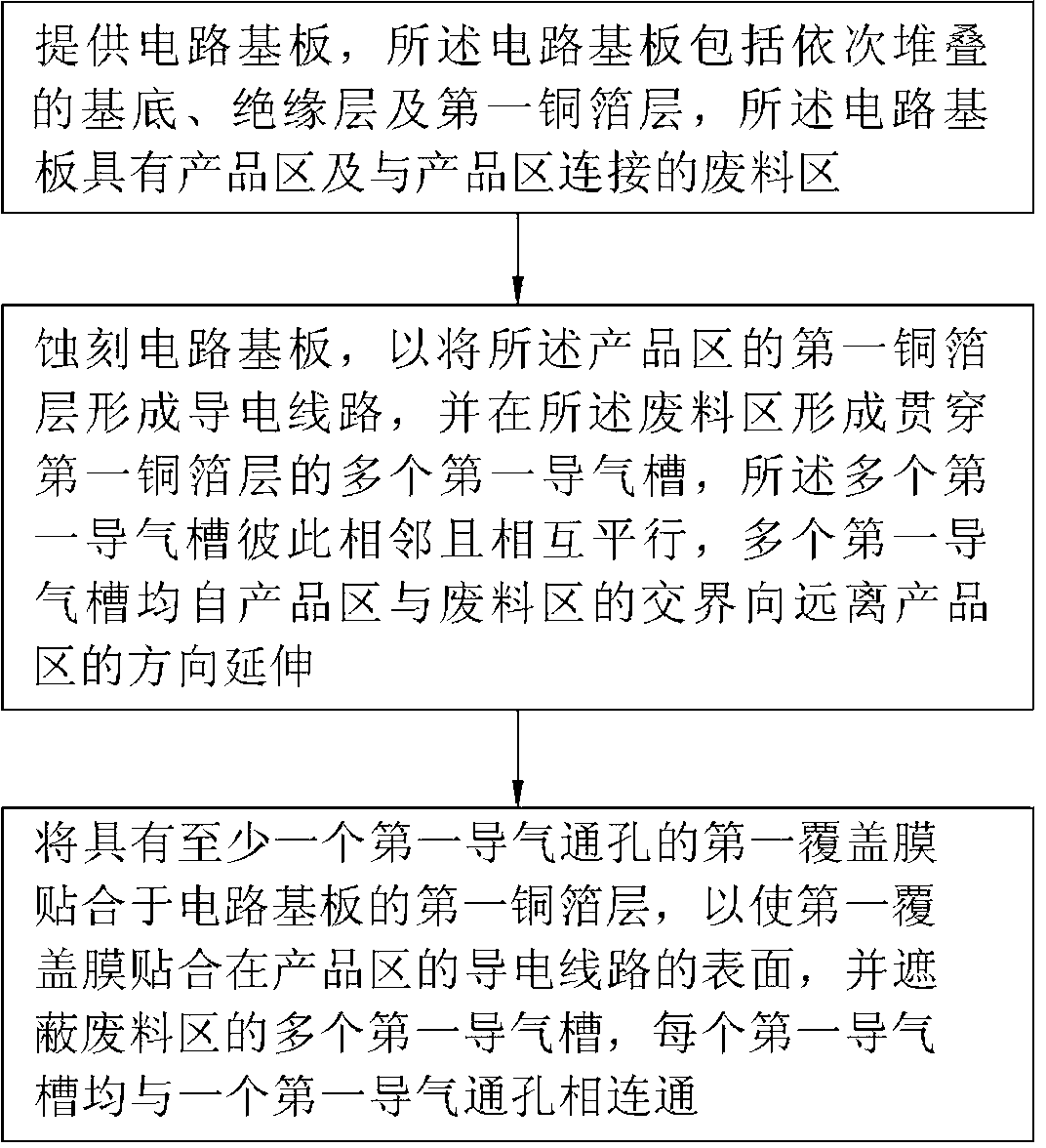

[0032] see figure 1 , the manufacturing method of the circuit board provided by the technical solution, comprising steps:

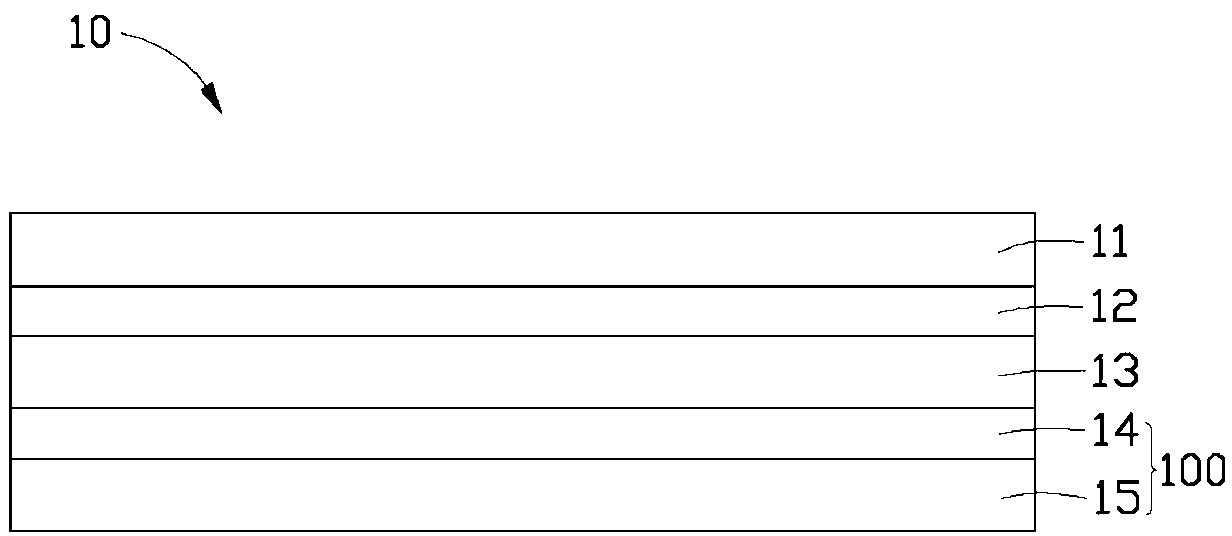

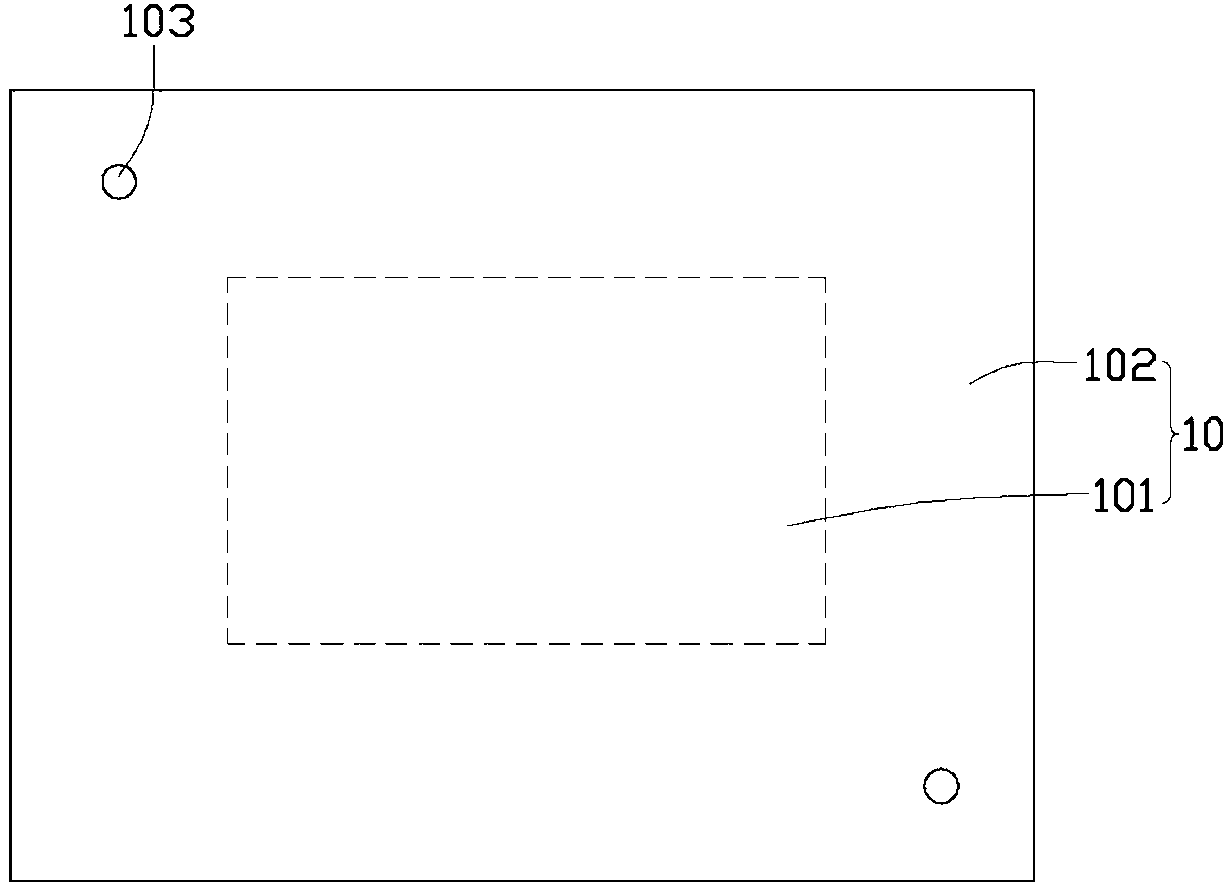

[0033] For a first step, see figure 2 and image 3 , providing a circuit substrate 10 . In this embodiment, the circuit substrate 10 is a double-sided adhesive flexible copper clad laminate, which includes a first copper foil layer 11, a first adhesive layer 12, an insulating layer 13, a second The adhesive layer 14 and the second copper foil layer 15 . The insulating layer 13 plays a supporting role, and its most commonly used material is polyimide (Polyimide, PI), but it can also be polyethylene terephthalate (Polyethylene Terephtalate, PET) or polyethylene naphthalate. Poly(ethylene naphthalate), PEN. The second adhesive la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com